Method for improving drying effect of clothes through speed change of roller and clothes drying machine

A speed change, clothes dryer technology, applied in the field of clothes drying, can solve the problems of poor drying effect, difficult drying, and the rotation speed of the drum without considering the drying weight, so as to achieve the effect of improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

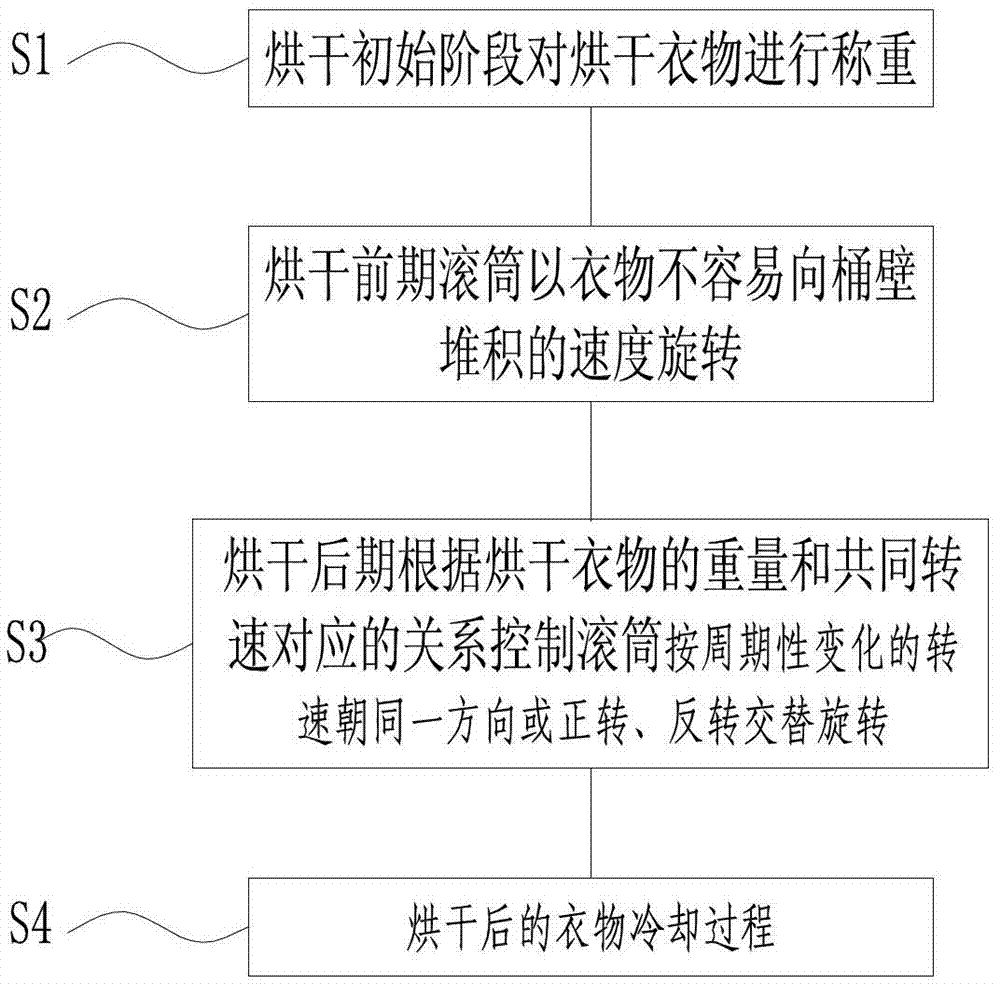

[0036] A method of improving the drying effect of clothes by changing the speed of the drum, such as figure 1 , figure 2 As shown, the method includes the following stages:

[0037] Weighing stage 101: in the initial stage of drying, the weight of the dried clothes is determined;

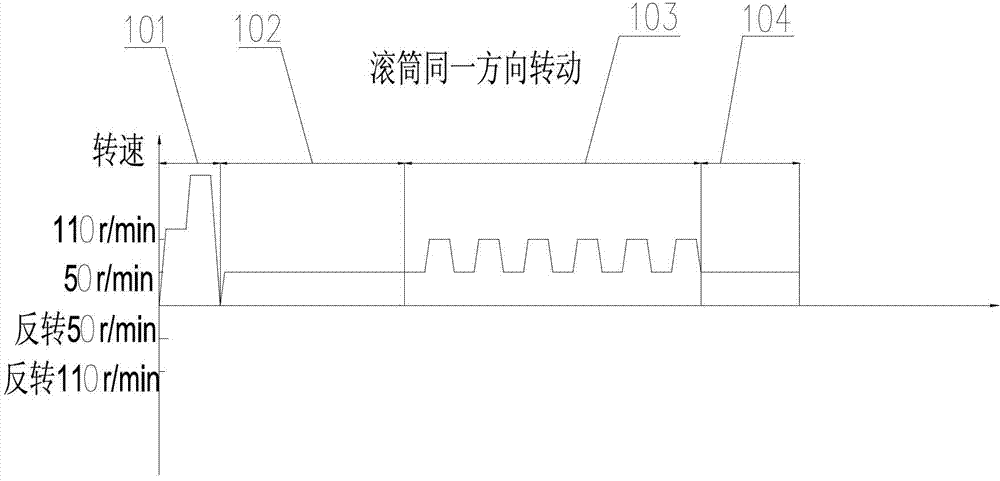

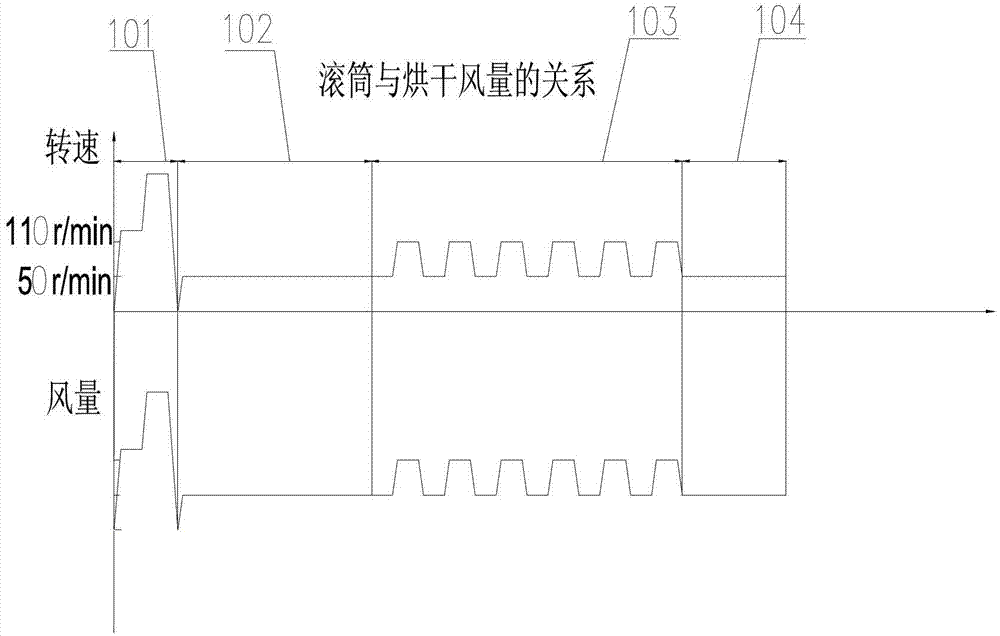

[0038] Drying early stage 102: In the early drying stage, the clothes are relatively damp, and the drum rotates at a speed at which the clothes are not easy to accumulate on the wall of the drum (the speed is 40-60 r / min);

[0039] Post-drying stage 103: In the post-drying stage, according to the unit weight of the clothes measured in step A, the drum is controlled to rotate in the same direction or rotate forward and reverse at a periodically changing speed, and the periodically changing speed includes at least two different Rotating speed;

[0040] Clothes cooling stage 104: a process of cooling clothes after drying.

[0041] In the early stage of drying 102 and the clothes cooling stage 104,...

Embodiment approach 2

[0050] In this embodiment, the drying stage 202, the weighing stage 201, and the clothes cooling stage 204 are the same as the control method for the drum in the first embodiment, for example Figure 4 As shown, the difference from Embodiment 1 is that the method of changing the rotation speed of the drum in the later stage of drying 203 is different. In this embodiment, a change period of the drum's periodically changing rotation speed is: the drum first accelerates to rotate to the first rotation speed , and rotate forward at the first speed for a period of time and then accelerate to the second speed, after rotating forward at the second speed for a period of time, decelerate and rotate in reverse, after the reverse rotation first accelerate to the first speed, and then rotate at the first speed After the rotation speed is reversed for a period of time, it is accelerated to the second rotation speed and reversely rotated for a period of time at the second rotation speed. The...

Embodiment approach 3

[0052] In this embodiment, the drying stage 302, the weighing stage 301, and the clothes cooling stage 304 are the same as the control method for the drum in the first embodiment, as shown in Figure 5 As shown, the difference from Embodiment 1 is that the method of changing the rotation speed of the drum in the post-drying stage 303 is different. In this embodiment, a change cycle of the periodically changing rotation speed of the drum is: the drum first accelerates to rotate to the highest speed , and after rotating at the highest speed for a period of time, decelerate and reverse the rotation, accelerate to rotate to the highest speed after reversing, and rotate at the highest speed for a period of time. In this way of changing the rotation speed of the drum, since the drum rotates in a single way, the control of the drum is relatively simple, but the drying effect on clothes is greatly improved compared with that of the existing clothes dryer.

[0053] The change period of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com