Patents

Literature

239results about How to "Improve vacuum efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

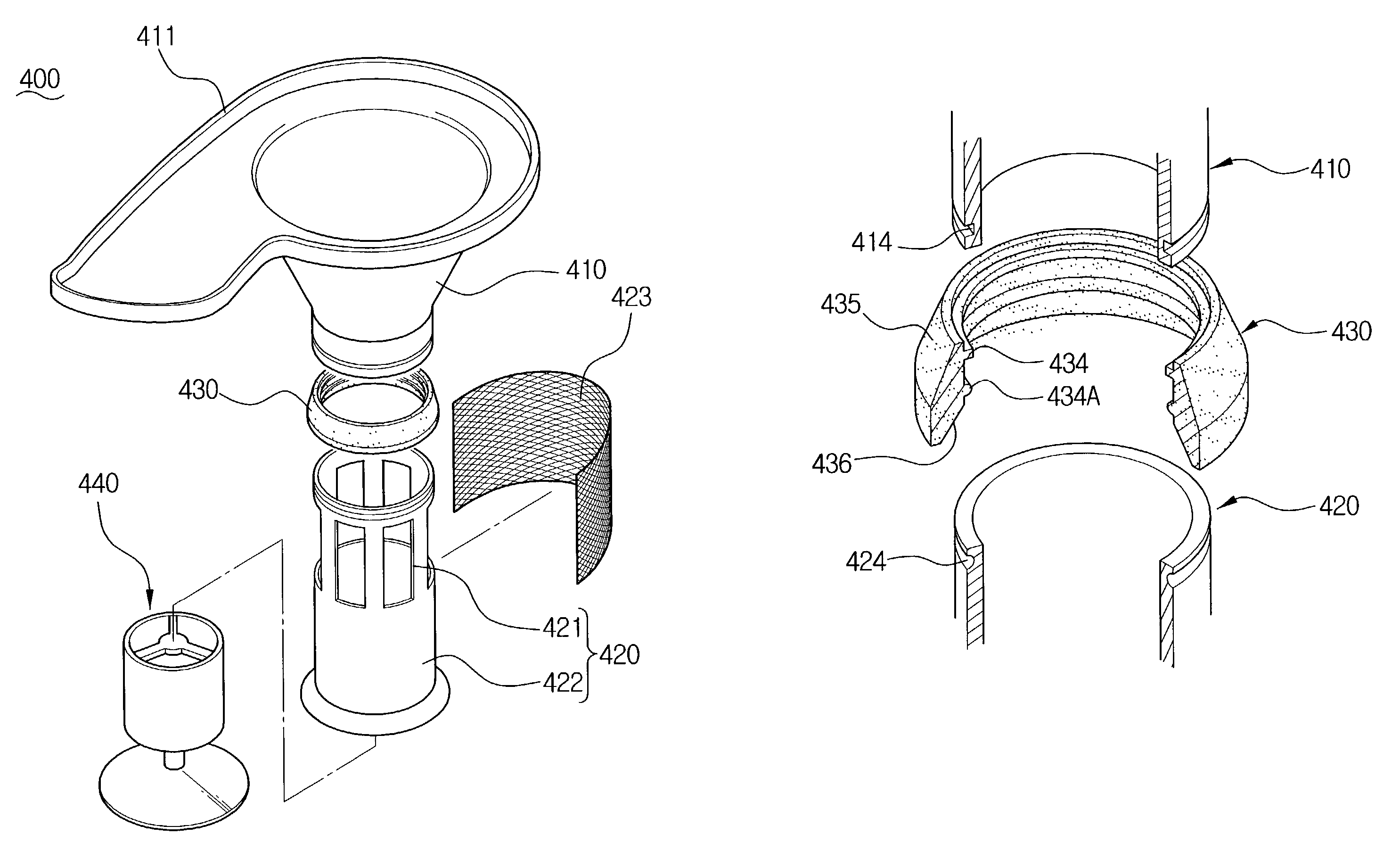

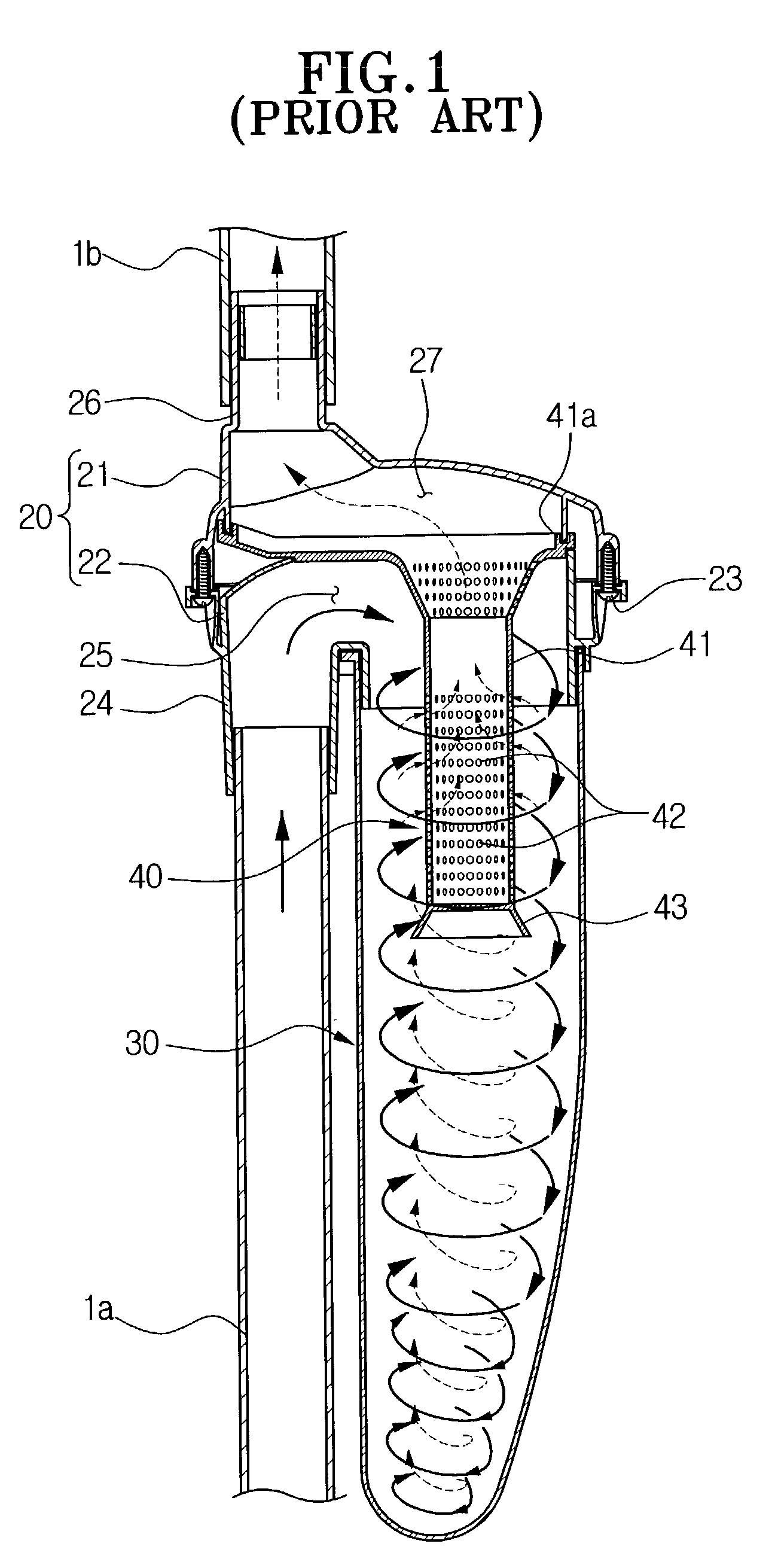

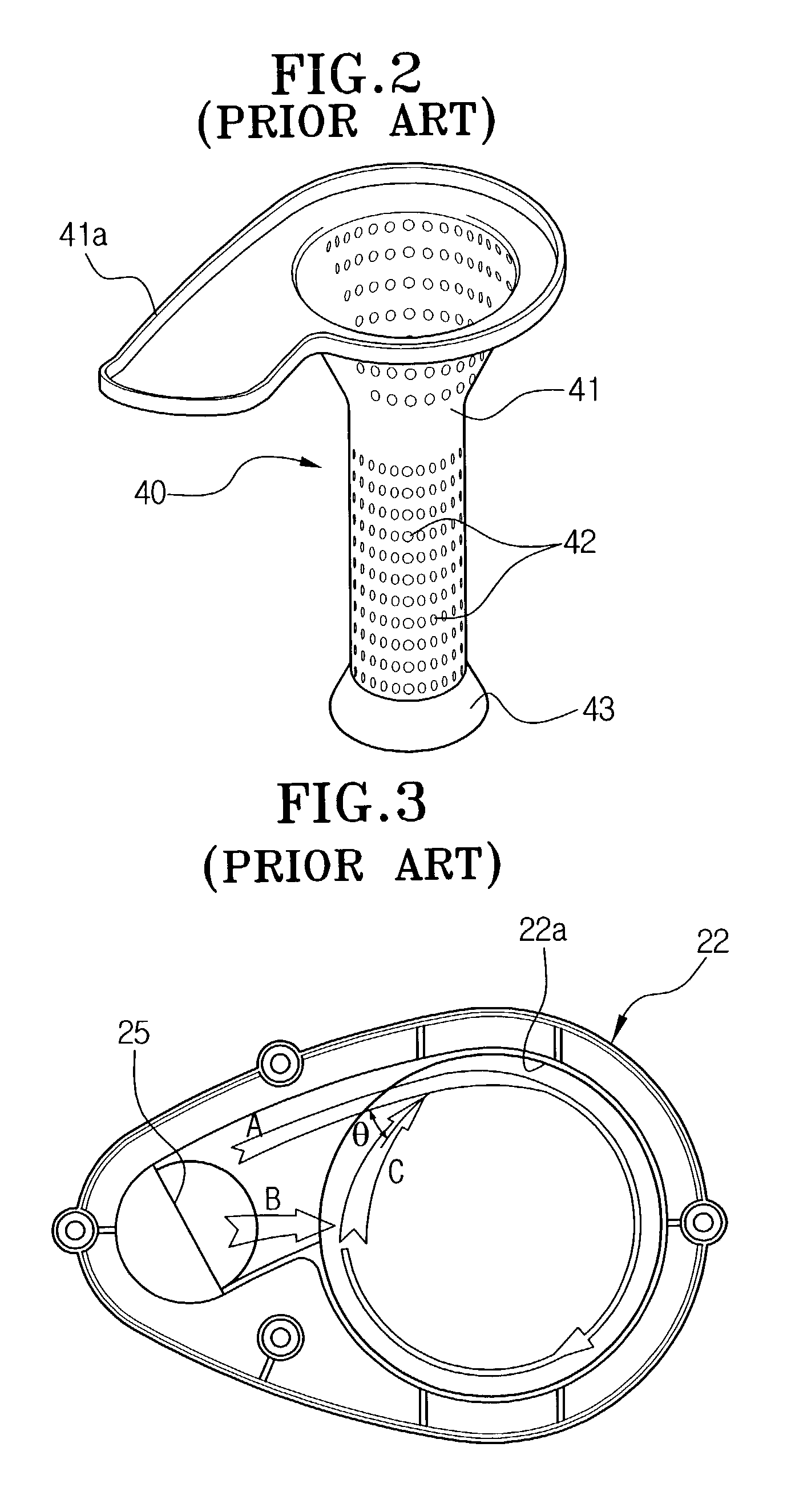

Cyclone-type dust-collecting apparatus for vacuum cleaner

InactiveUS6968596B2Easy maintenanceImproves stability and directionalityCleaning filter meansCombination devicesCycloneEngineering

A cyclone-type dust-collecting apparatus for a vacuum cleaner comprises a conically shaped grill assembly disposed at the air outflow port of a cyclone body. The grill assembly includes a grill portion and prevents reverse flow of dust and dirt from the cyclone body. The grill assembly members are easily separable to allow a user to easily remove the dirt collected in the grill portion by simply separating the second grill member from the connection member and washing the second grill member with water.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

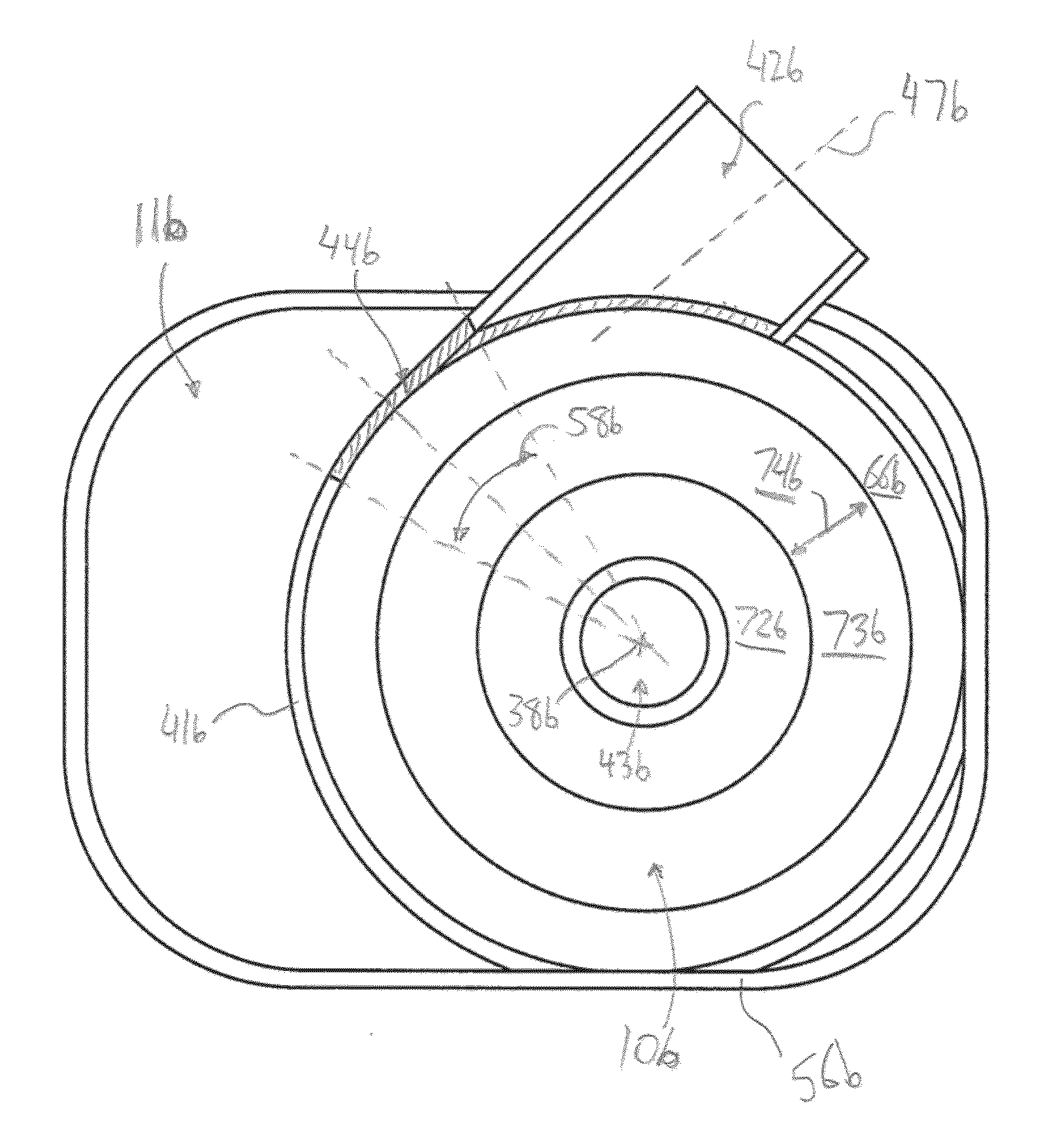

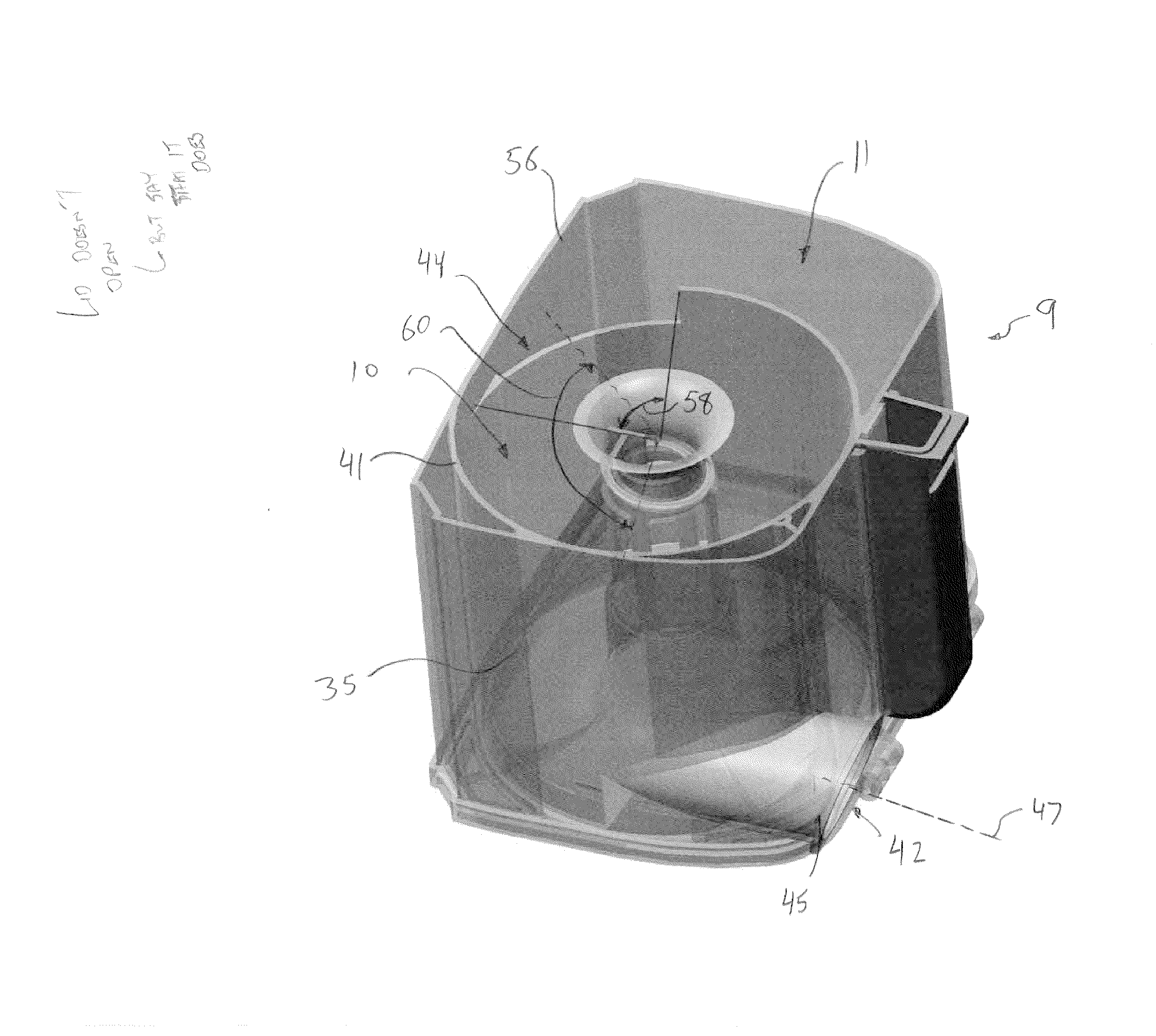

Cyclone such as for use in a surface cleaning apparatus

ActiveUS20140237956A1Reduce the soundReduce noiseCombination devicesSuction filtersCycloneSurface cleaning

A cyclone comprises a cyclone chamber having an air inlet, an air outlet, a first end wall, a second end wall and a sidewall, the air inlet has an inlet end having a shape and a cross sectional area in a plane transverse to a direction of airflow through the air inlet, and the air inlet is provided at a first juncture of the sidewall and the first end wall, wherein the first juncture downstream of the inlet is configured to at least approximate a portion of the shape of the air inlet that is adjacent the first juncture.

Owner:OMACHRON INTPROP

Cyclone such as for use in a surface cleaning apparatus

ActiveUS20140237964A1Reduce the soundReduce noiseGas treatmentSuction filtersCycloneSurface cleaning

A cyclone comprises a cyclone chamber having an air inlet, a vortex finder, a first end wall, a second end wall and a sidewall, the air inlet has an inlet end having a shape and a cross sectional area in a plane transverse to a direction of airflow through the air inlet, and the air inlet is provided at a first juncture of the sidewall and the first end wall, the vortex finder has a wall that meets one of the first and second end walls at a second juncture, wherein the second juncture extends at an angle to both the wall of the vortex finder and the end wall on which the vortex finder is provided.

Owner:OMACHRON INTPROP

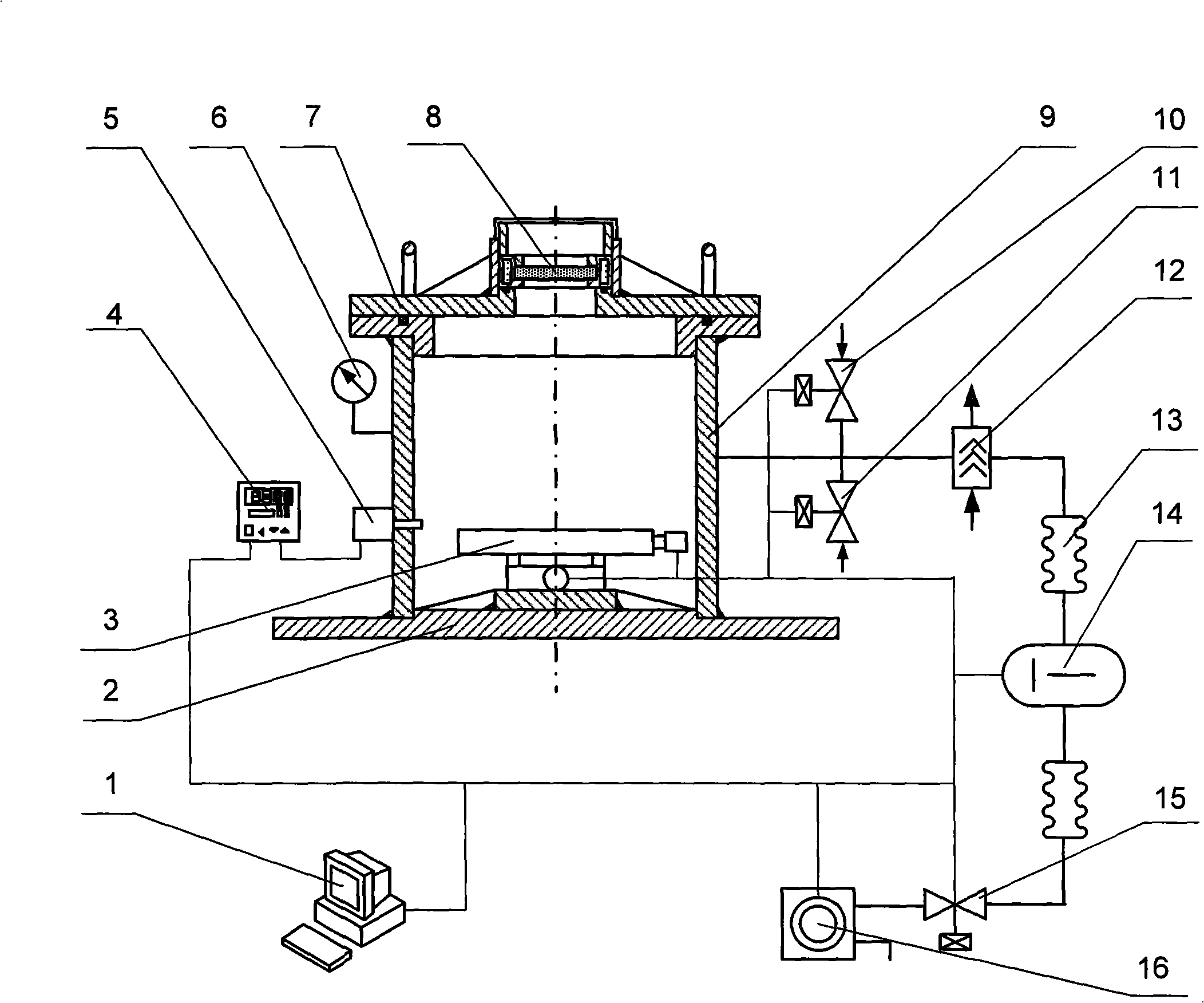

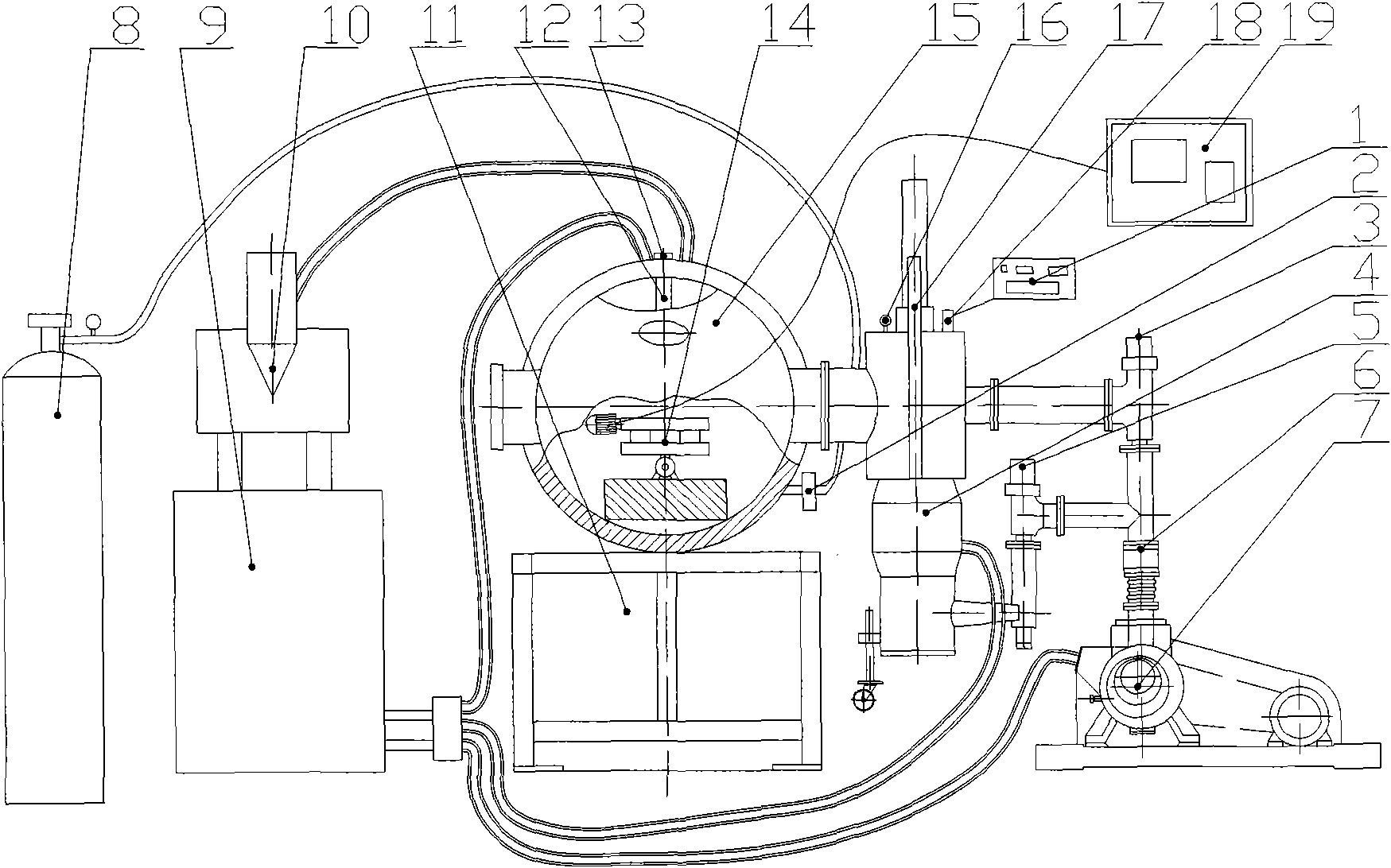

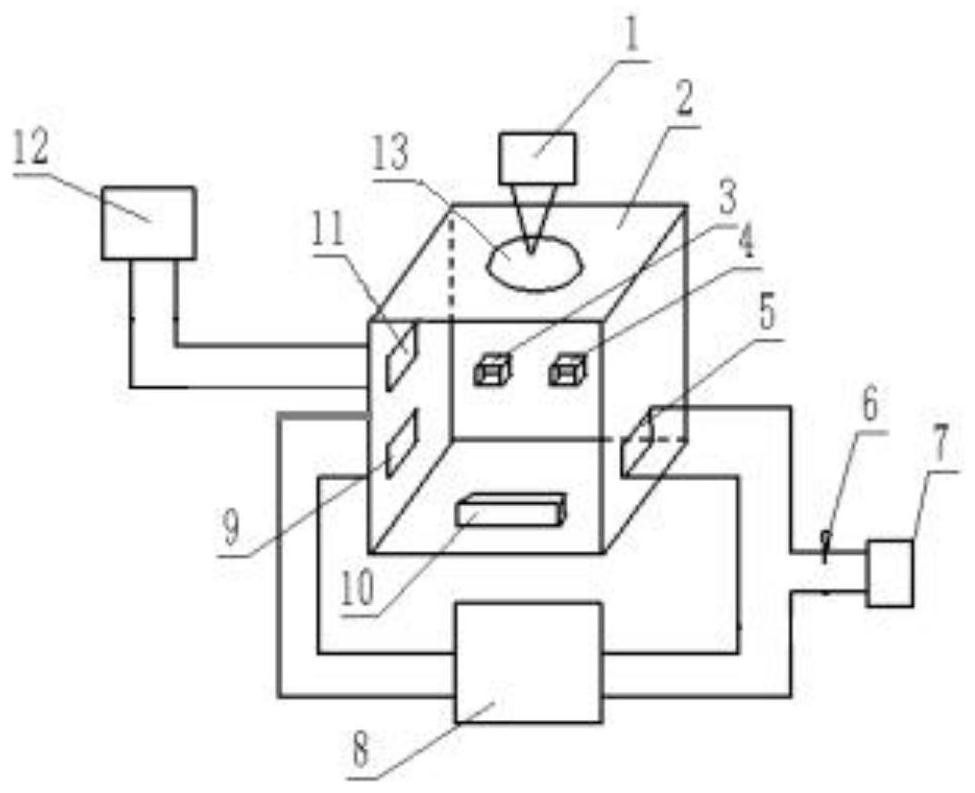

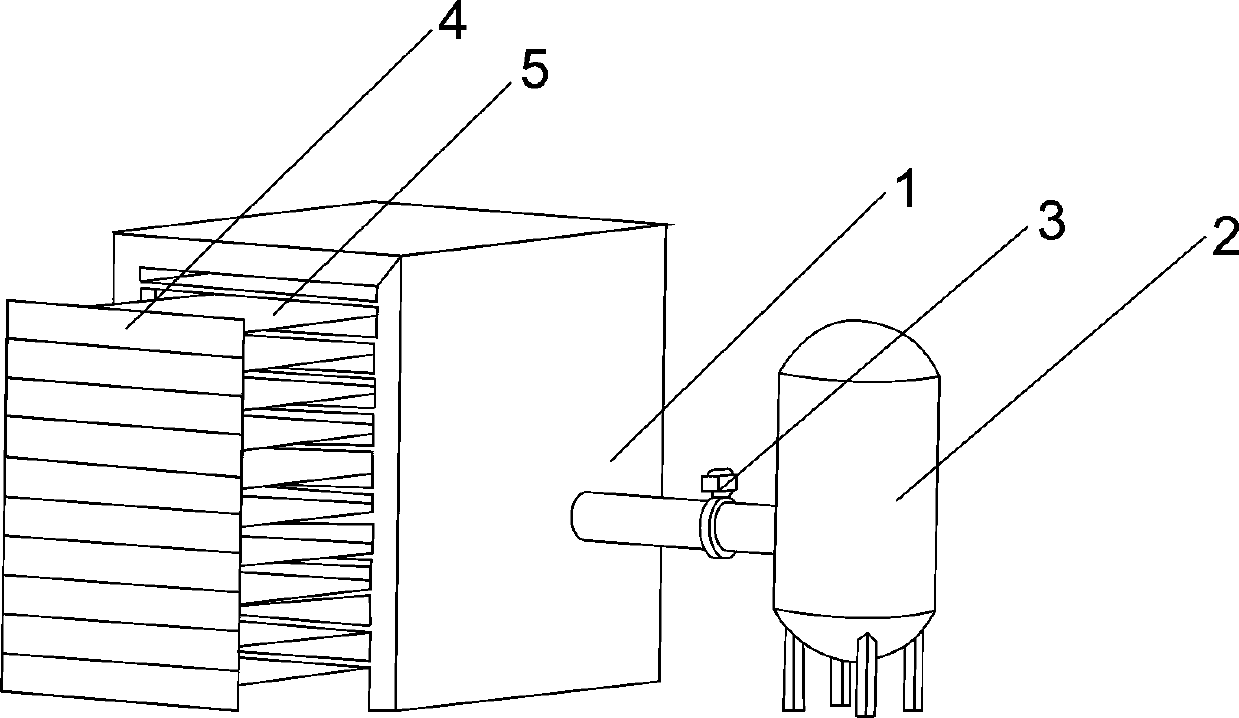

Vacuum system for laser processing

InactiveCN101264554ARealize laser processing operationsLow laser absorptionLaser beam welding apparatusVacuum pumpingLaser processing

The invention discloses a vacuum system for laser processing, aiming to provide a technical proposal for solving the problem that a plurality of metallic materials can not be processed by laser in the unprotected condition: the system mainly comprises a vacuum tank, a vacuum pumping and gas filling component matched with the vacuum tank and a computer control module (1) used for controlling and connecting the vacuum tank and the component. The vacuum system can realize the laser processing operation on two-dimensional surface in vacuum environment or shielding gas condition and has the advantages of low laser absorptivity, best transmissivity and long service life by adopting the laser window with zinc selenide lens, improved efficiency of the vacuum pumping, enhanced efficiency and quality of the laser processing by adopting the Root's vacuum pump and rotary mechanical pump, convenient operation, high reliability and favorable guarantee of laser processing quality by adopting the vacuum sensor and the vacuum manometer to read the vacuum degree of the vacuum tank, convenient operation, friendly interface, enhanced automation degree, performance stability and reliability of laser processing, thus being also convenient for integration and control with the other systems by adopting the computer control management.

Owner:SHENYANG INST OF AERONAUTICAL ENG

Cyclone such as for use in a surface cleaning apparatus

ActiveUS20140237965A1Reduces suctionReduce back pressureReversed direction vortexDispersed particle separationEngineeringPhencyclone

A cyclone comprises a cyclone chamber having a first end having a first end wall, a second end having a second end wall, a sidewall, an air inlet at the first end, an air outlet and a first central insert member extending away from a center of the second end wall into the cyclone chamber wherein the first central insert member comprises a central member wall extending away from the second end wall and the central member wall and the second end wall meet at a first juncture that extends at an angle to both the central member wall and the second end wall

Owner:OMACHRON INTPROP

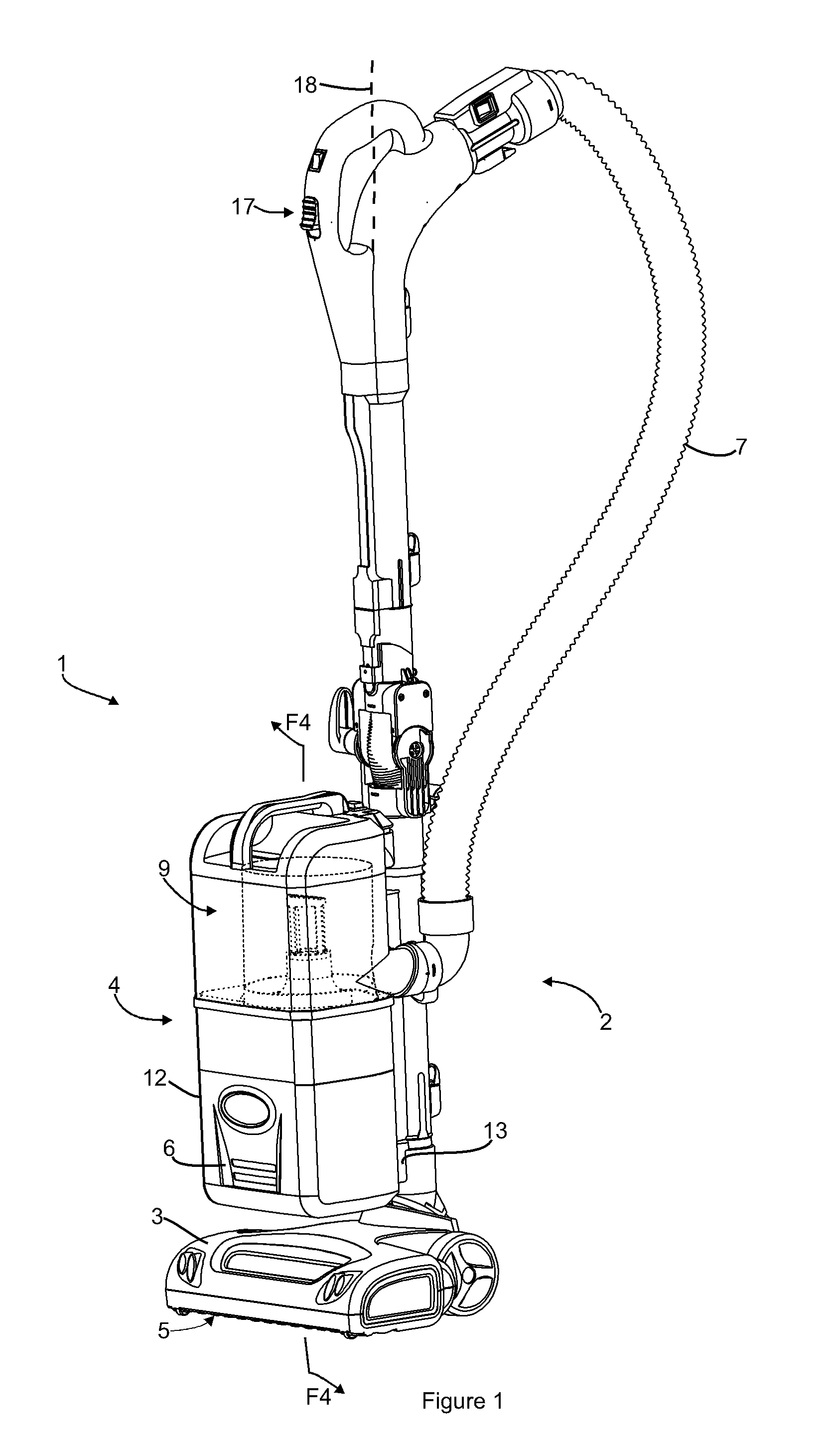

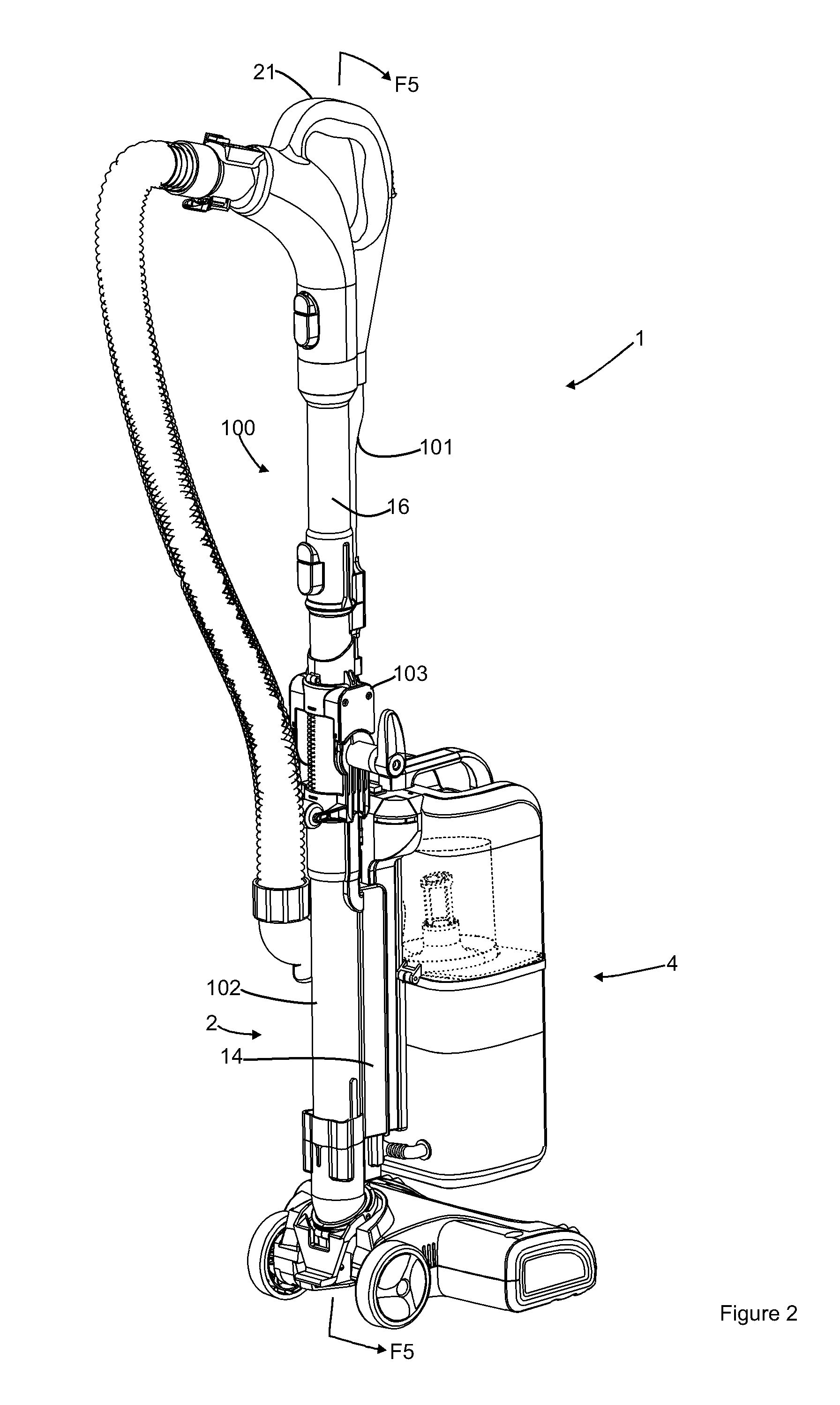

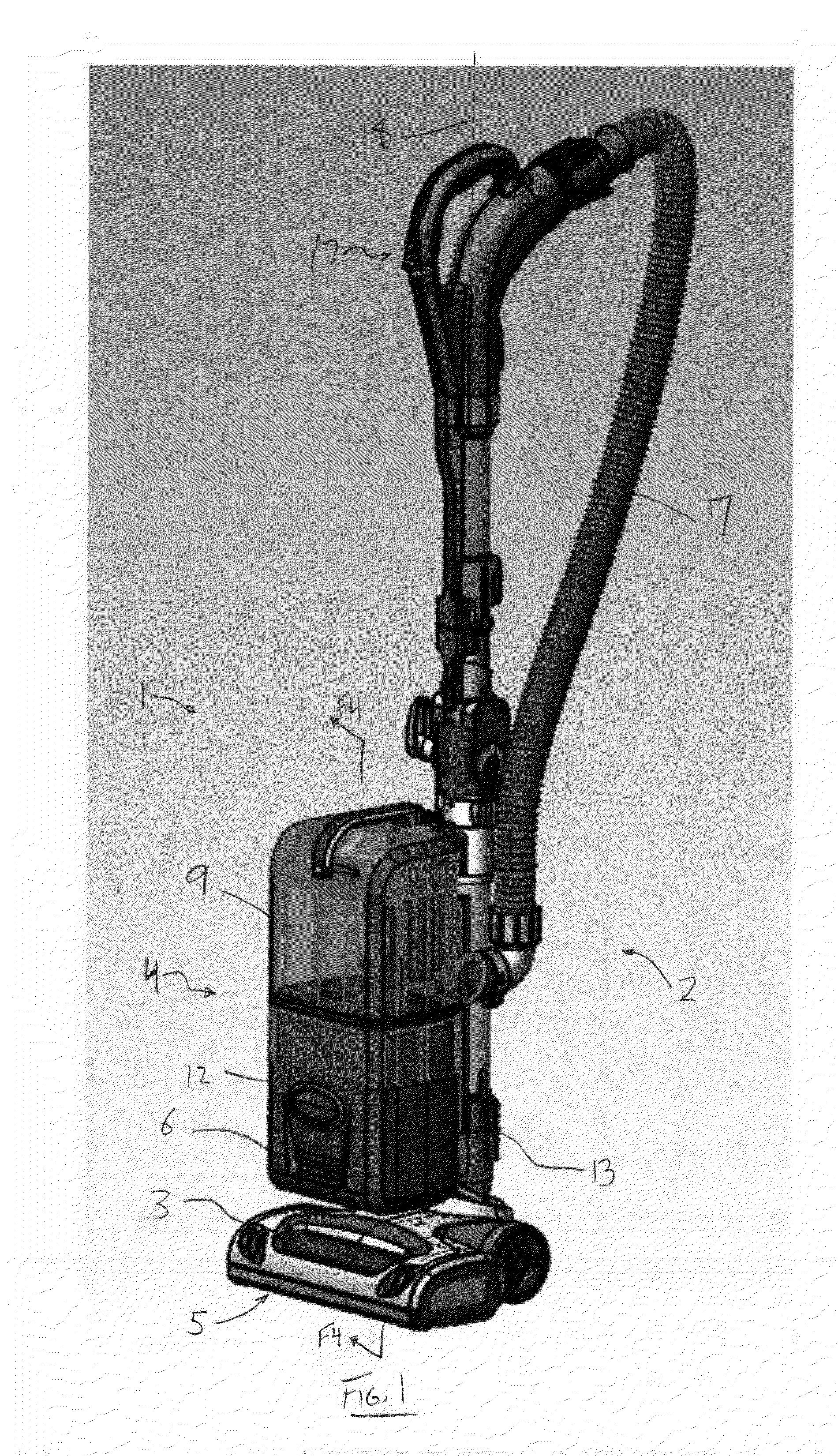

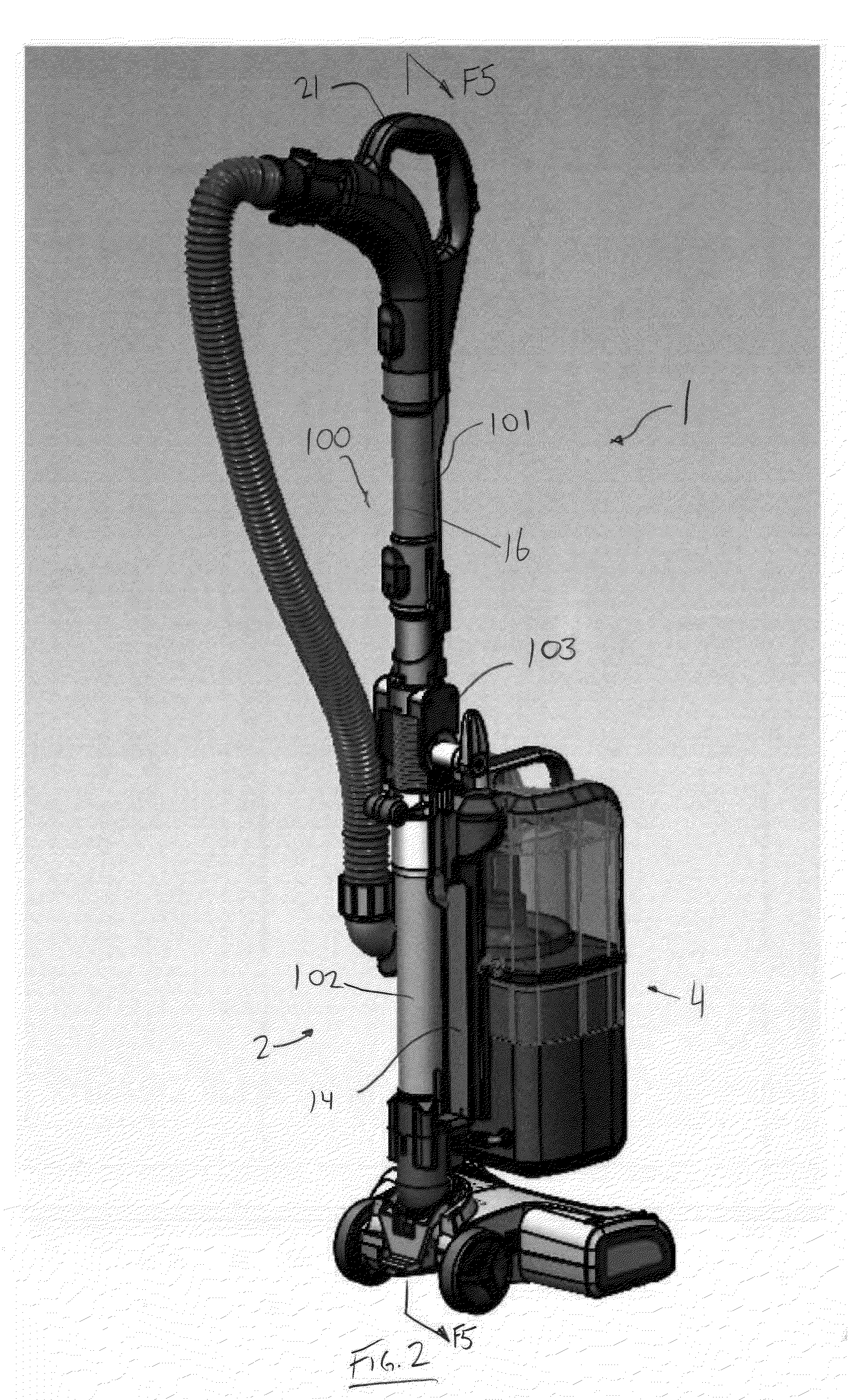

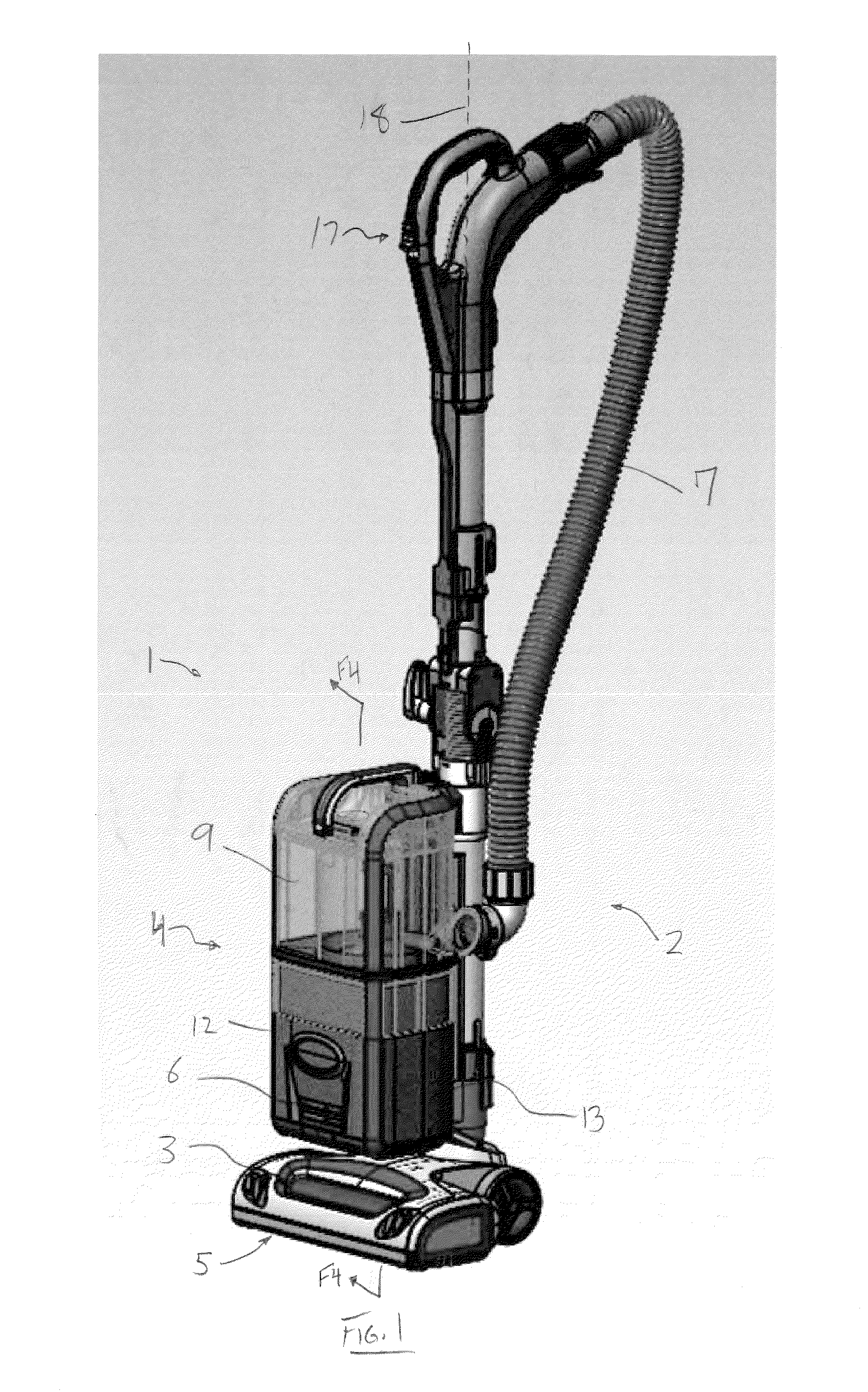

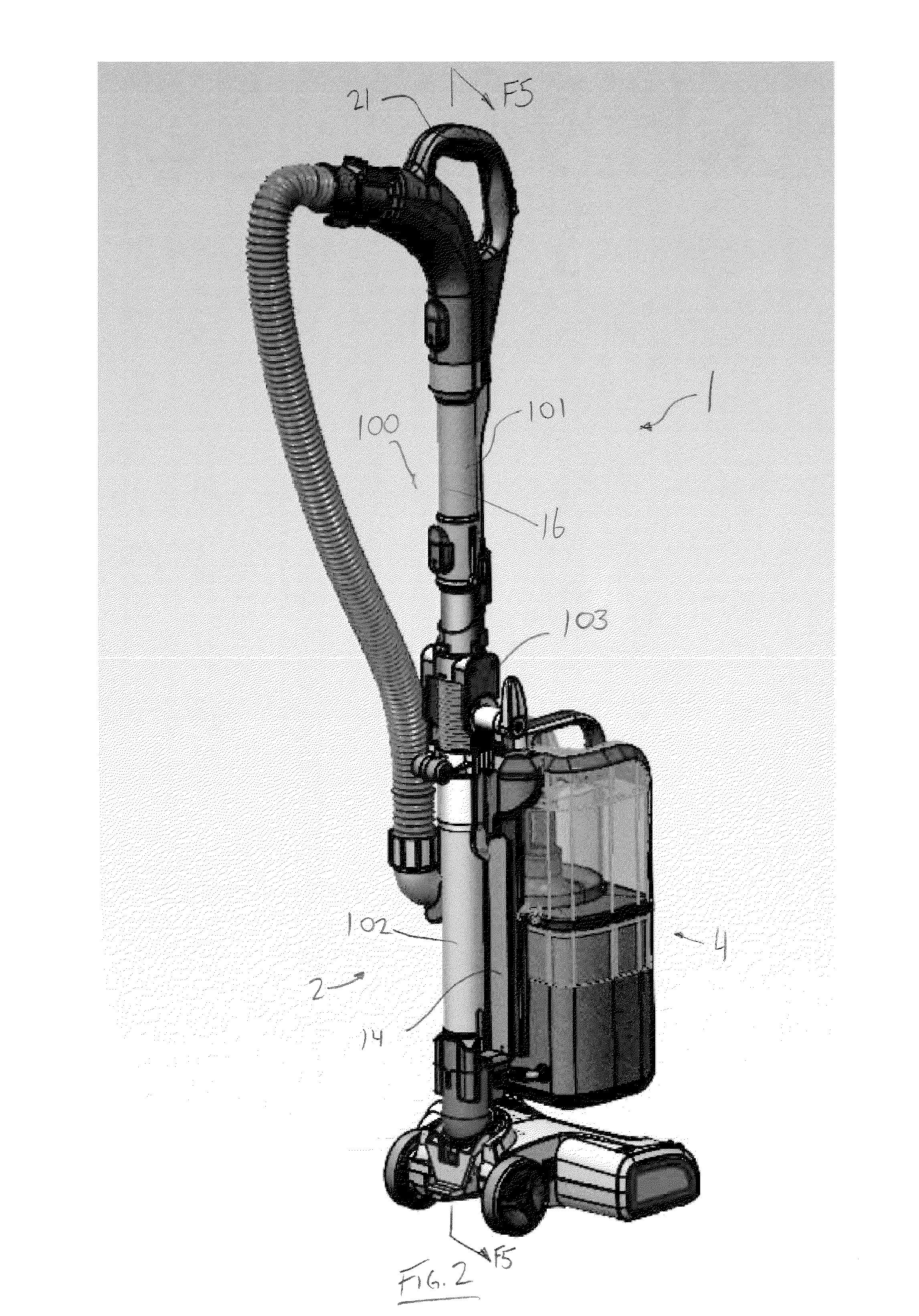

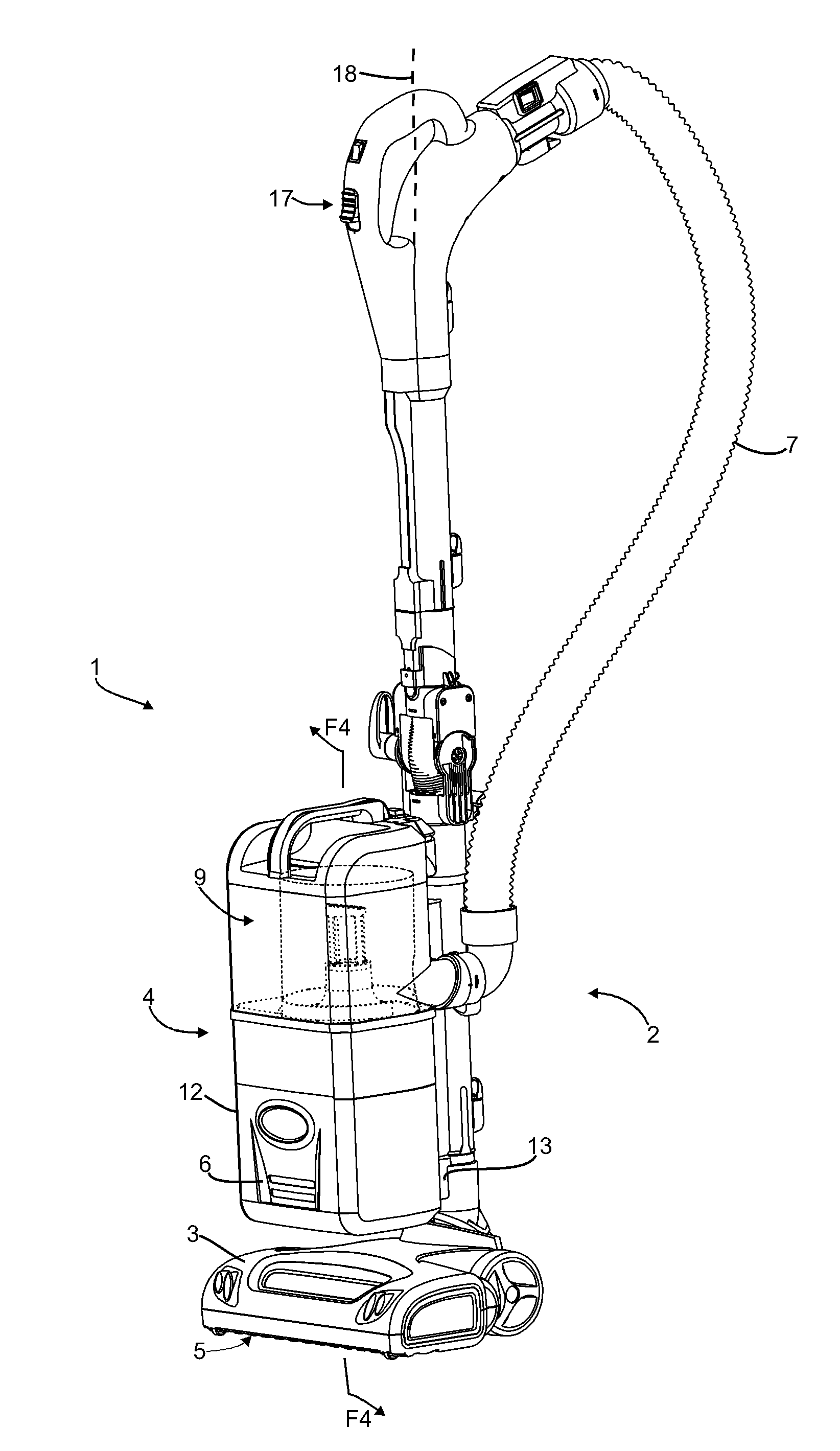

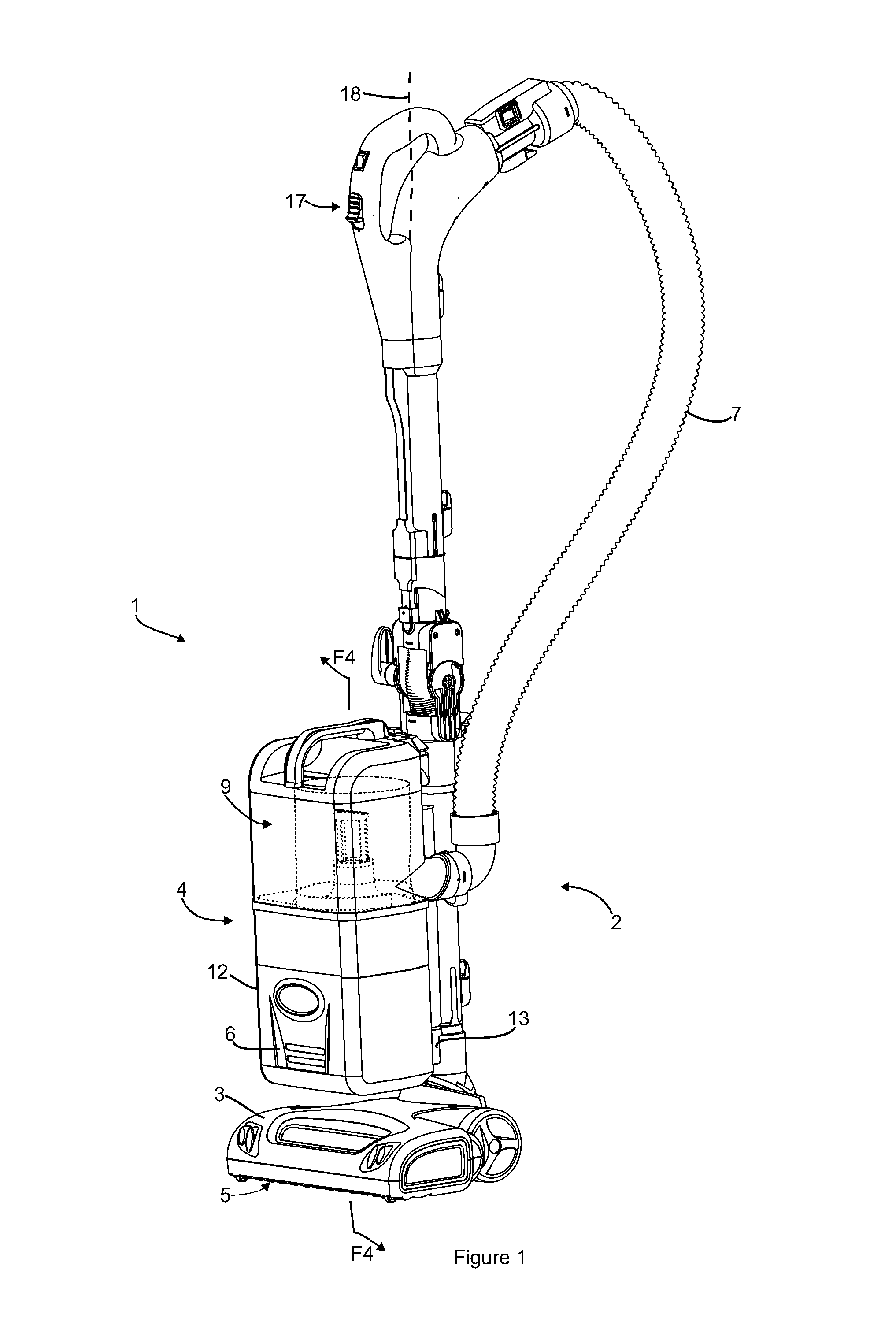

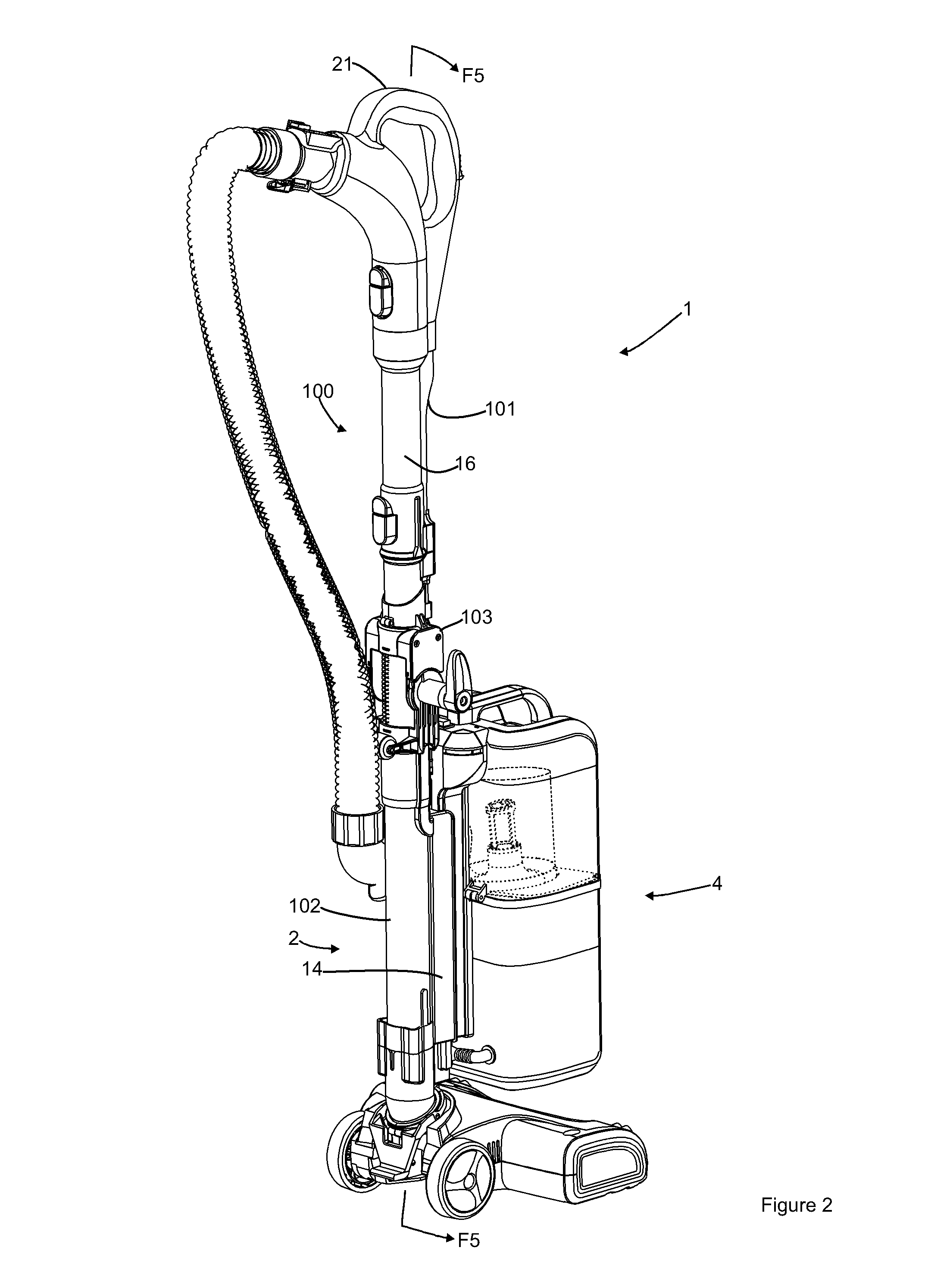

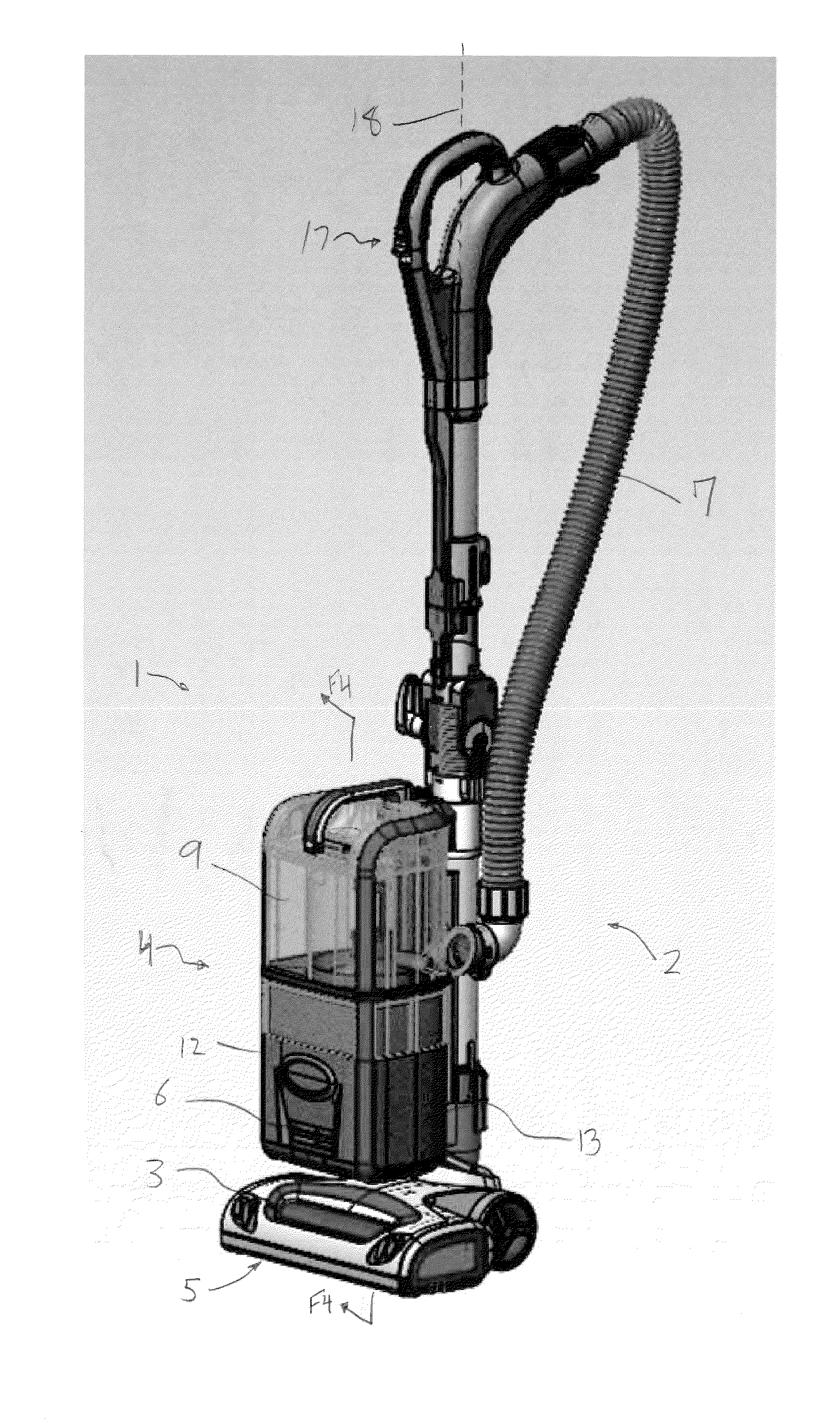

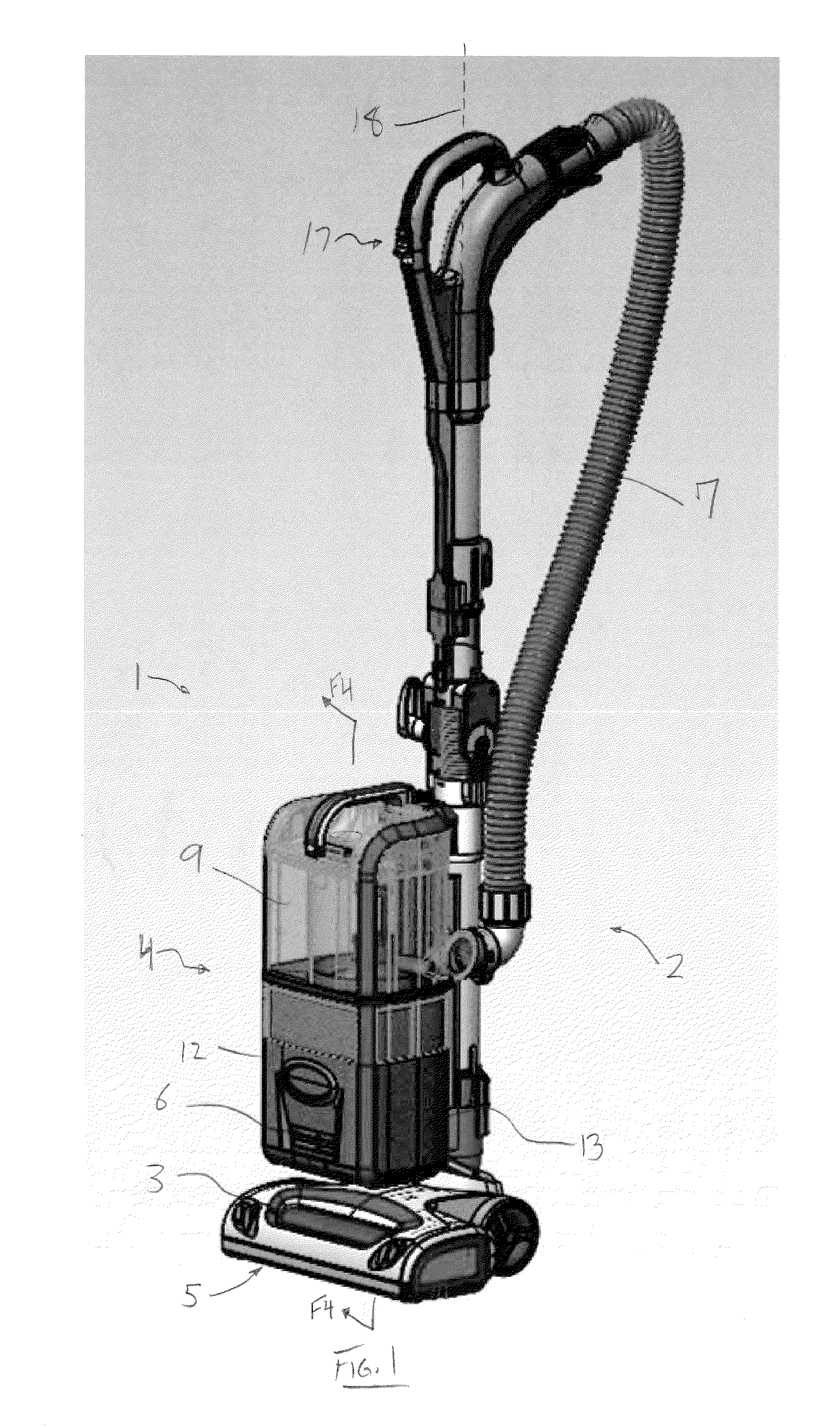

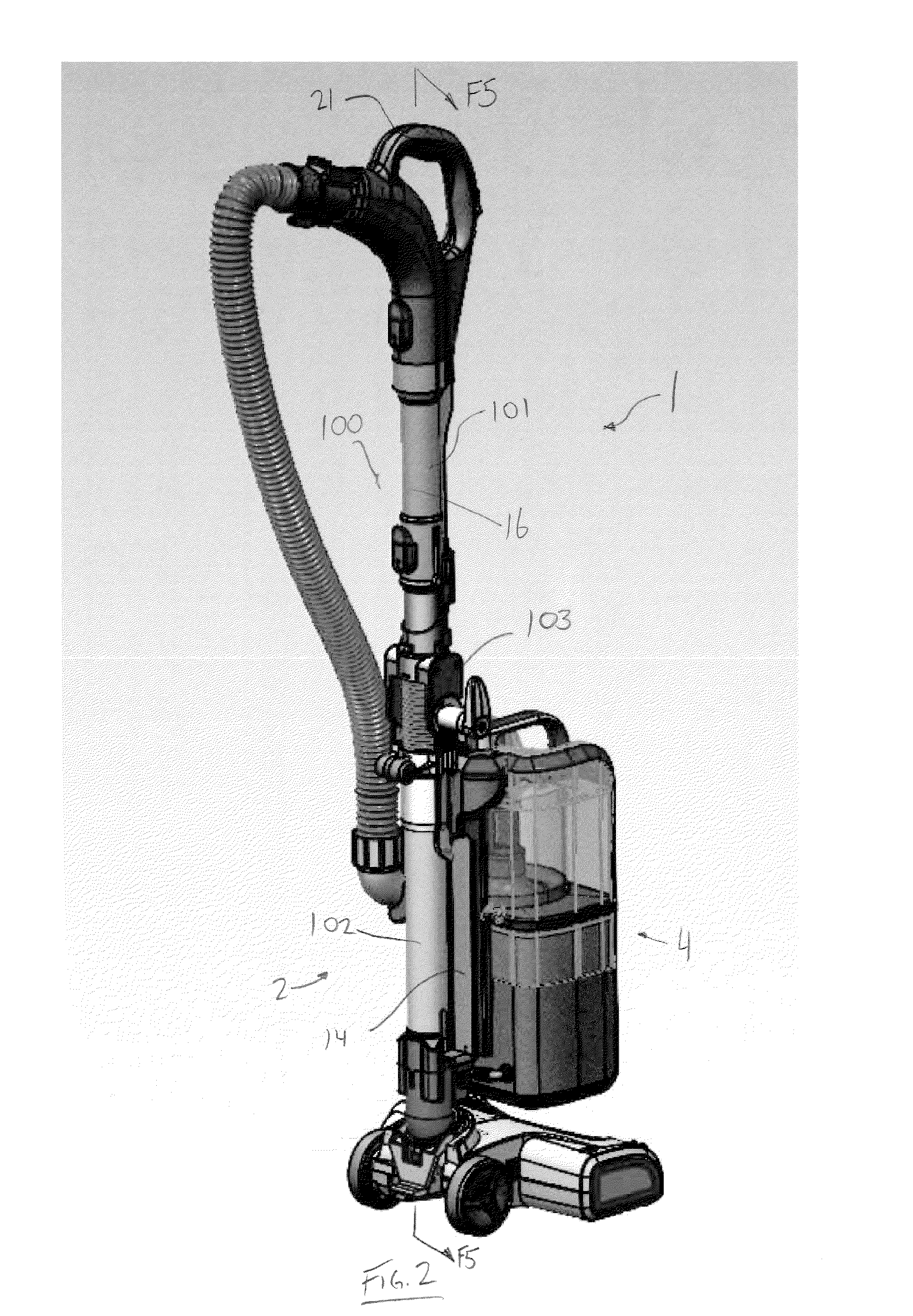

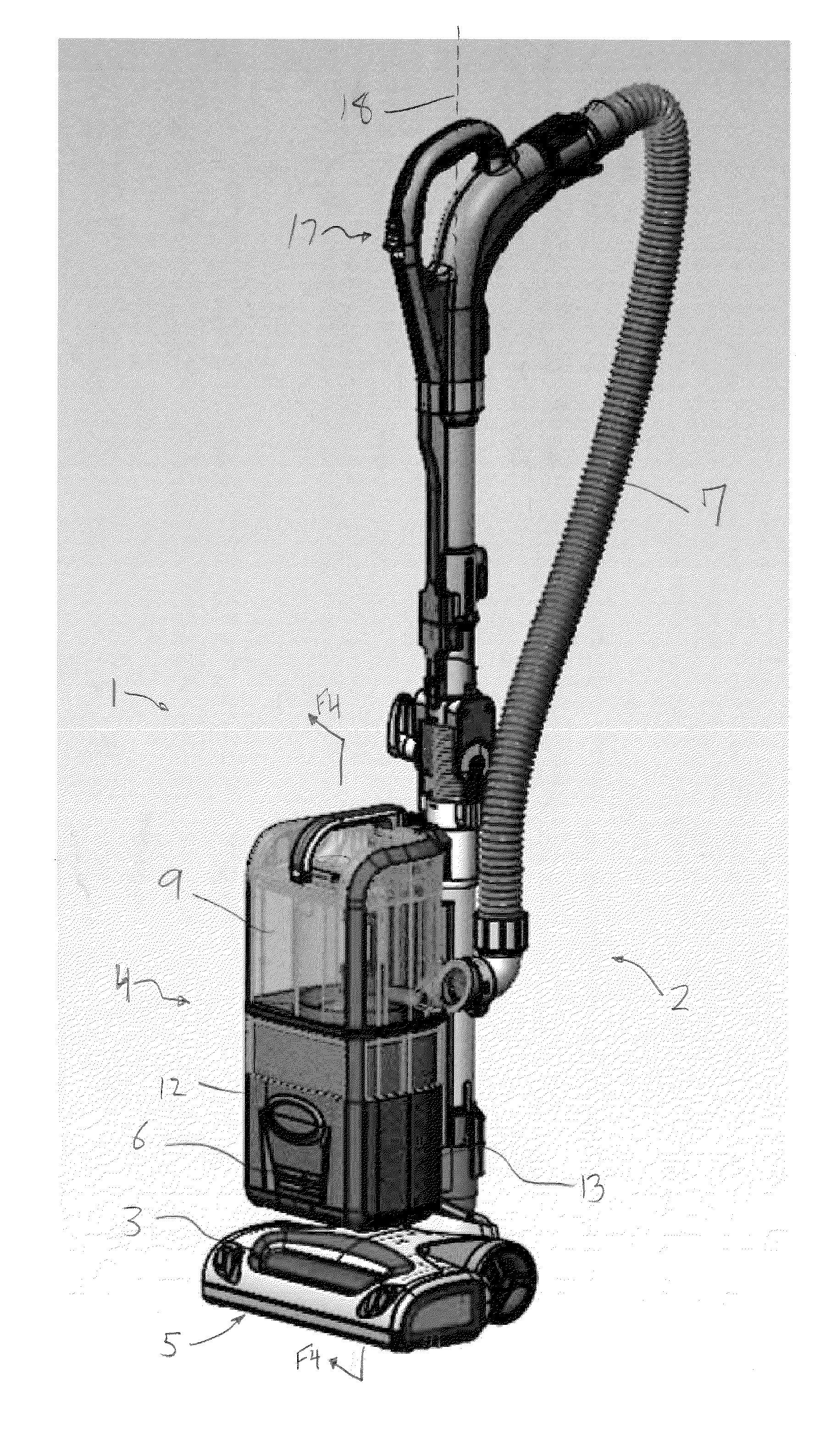

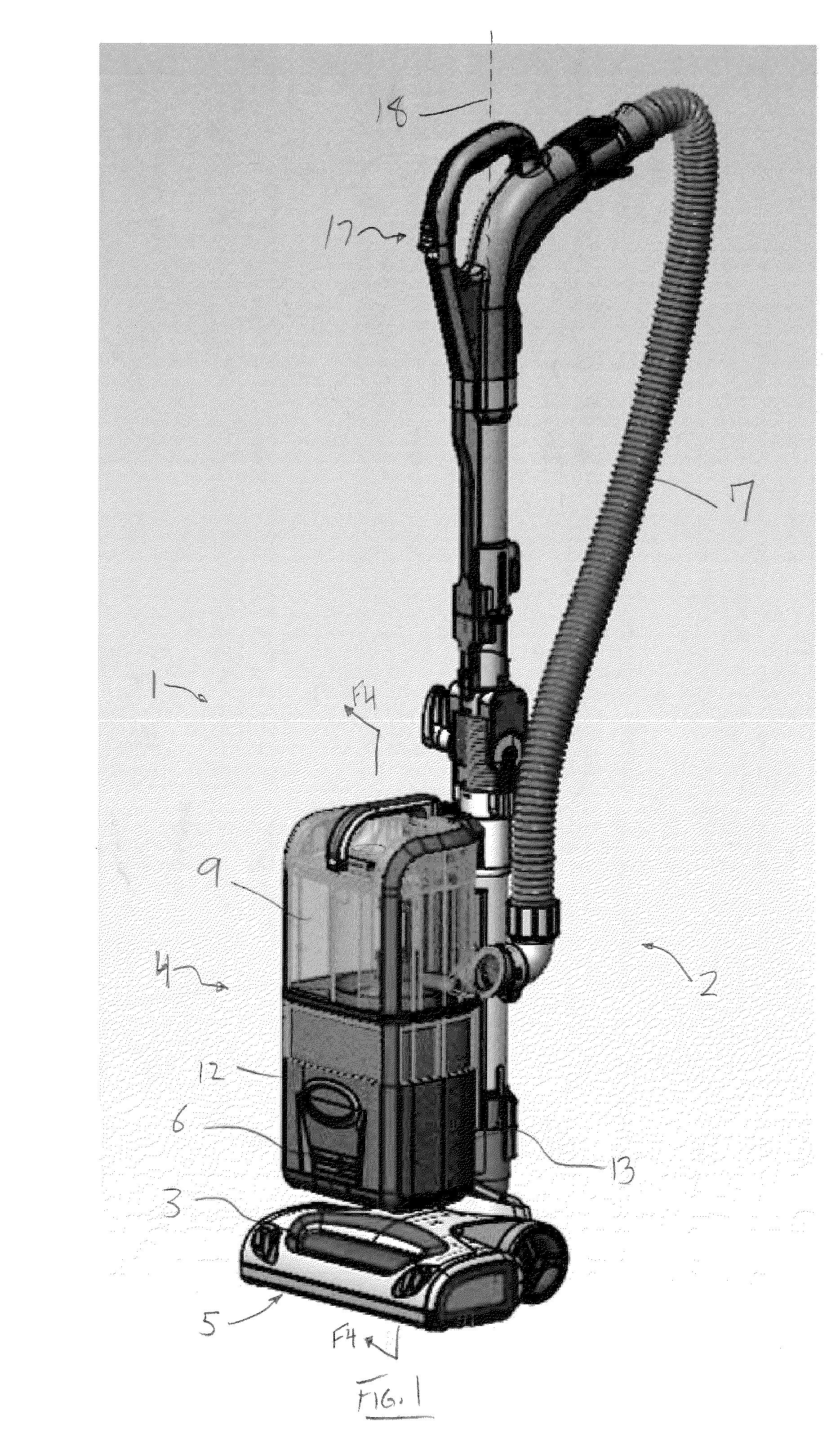

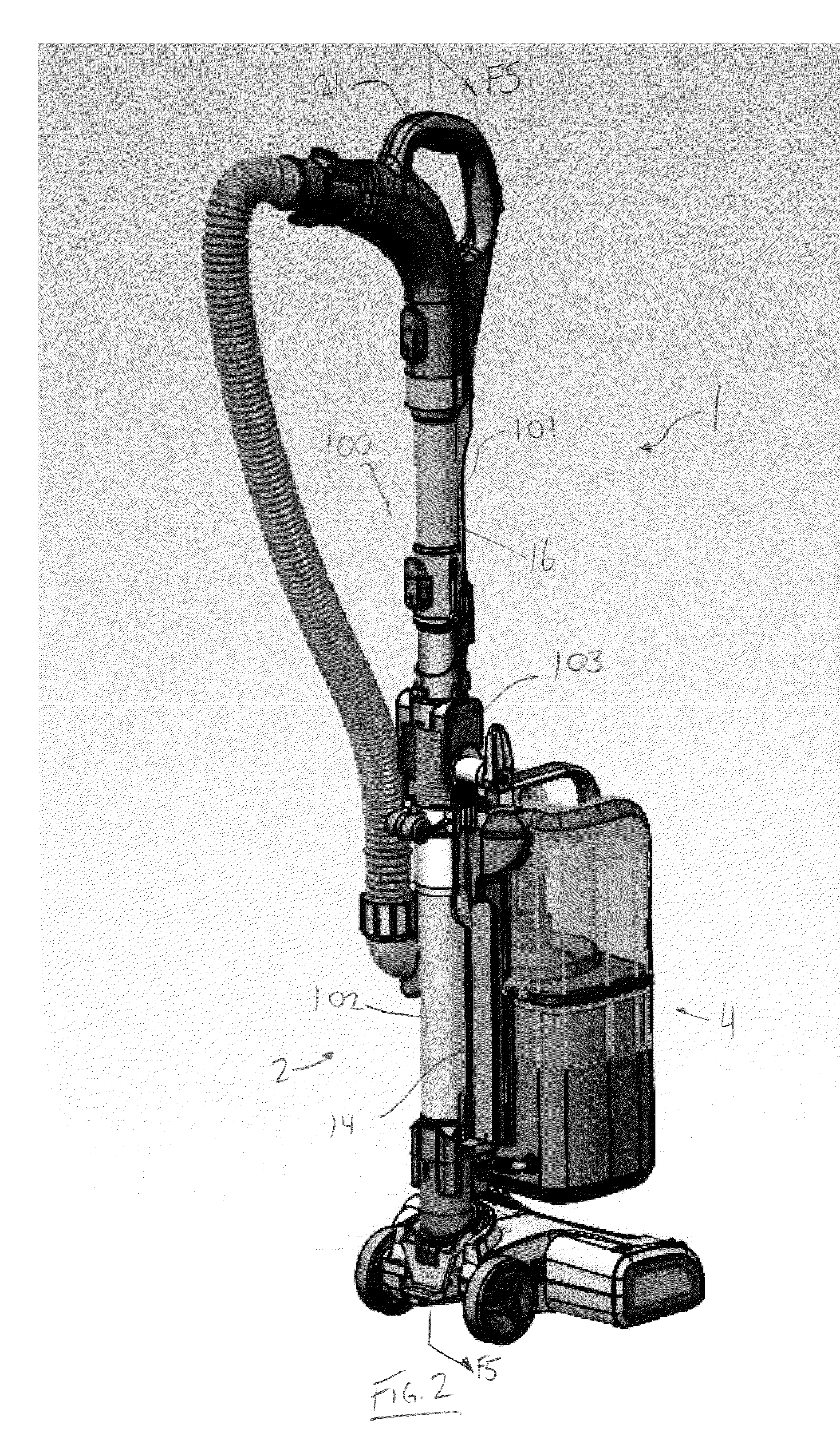

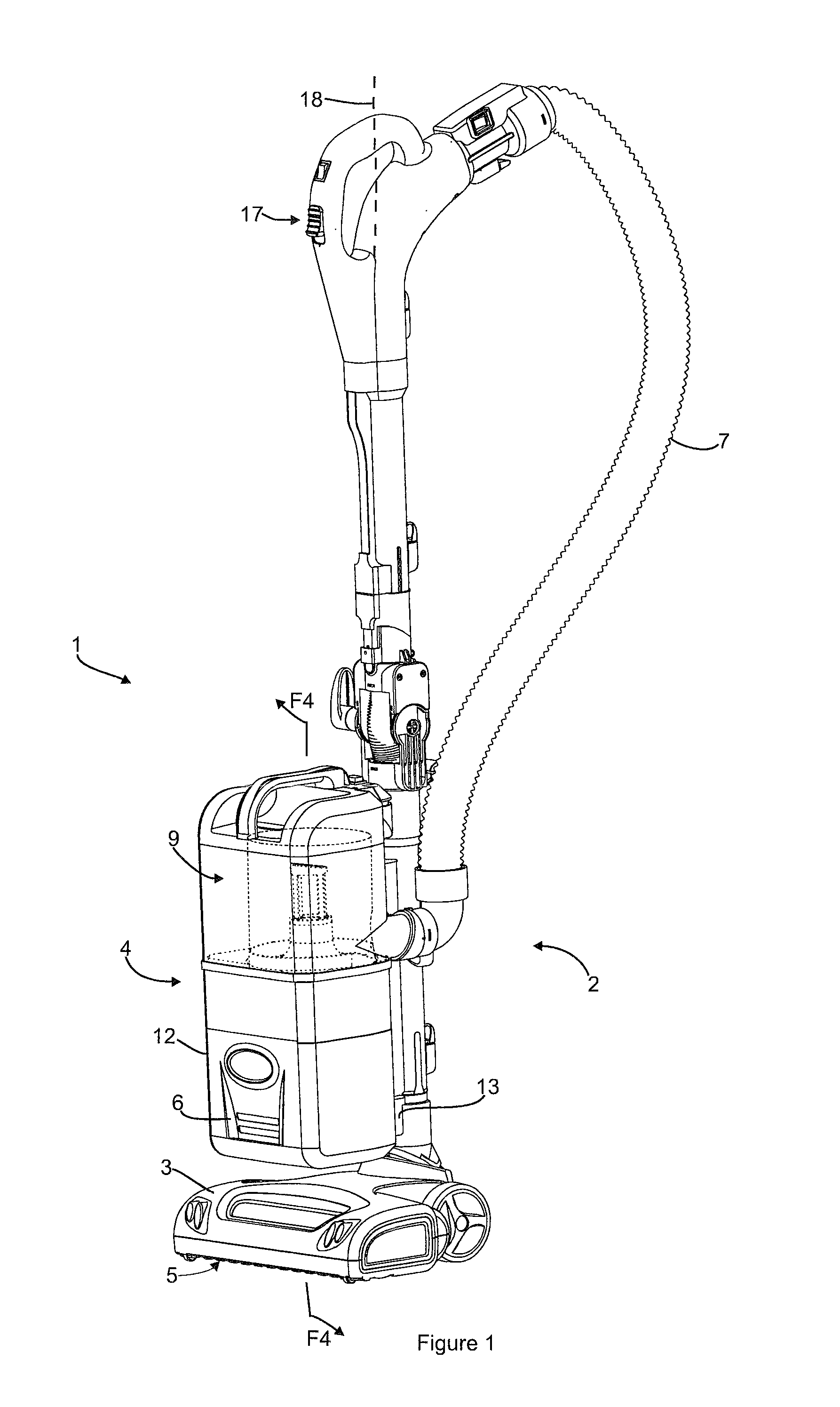

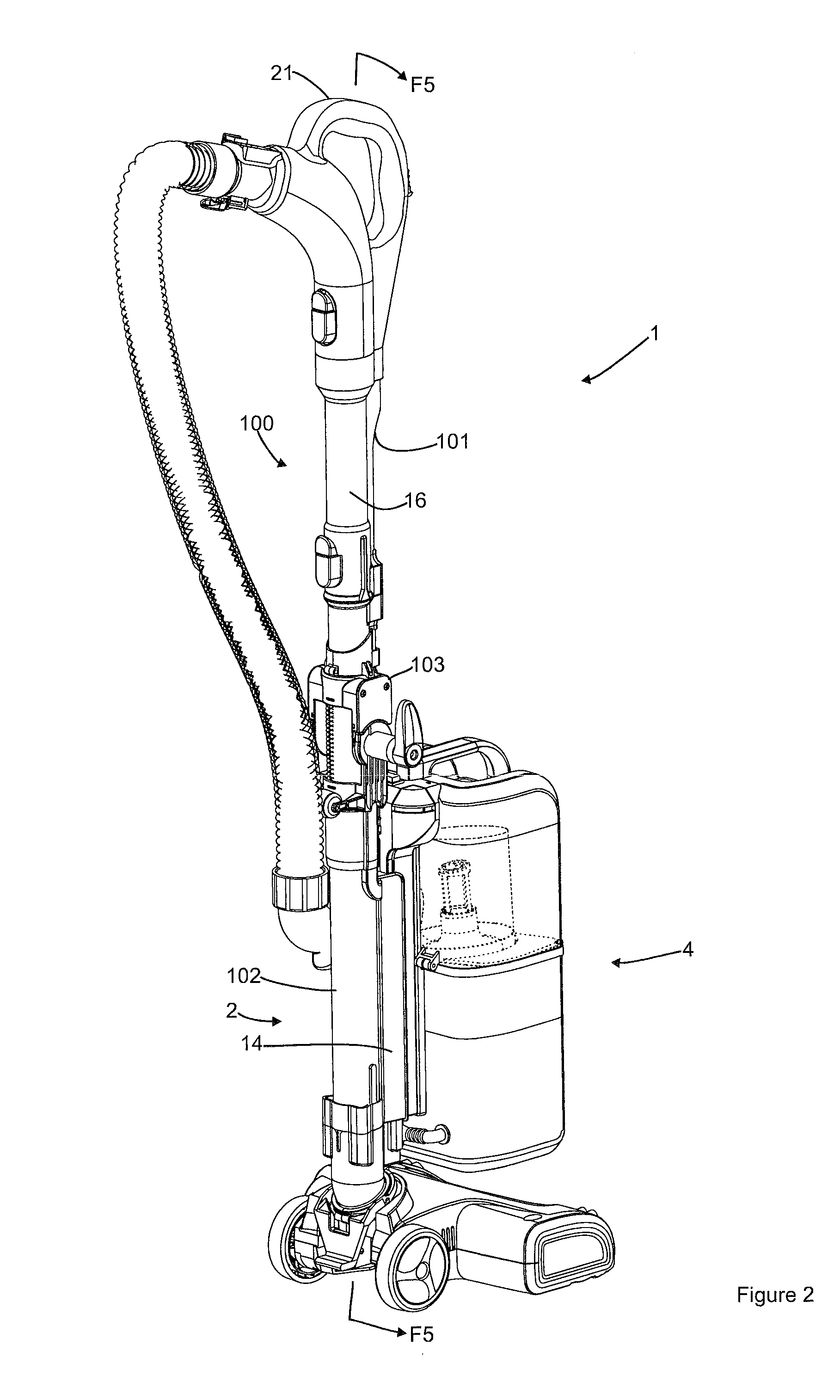

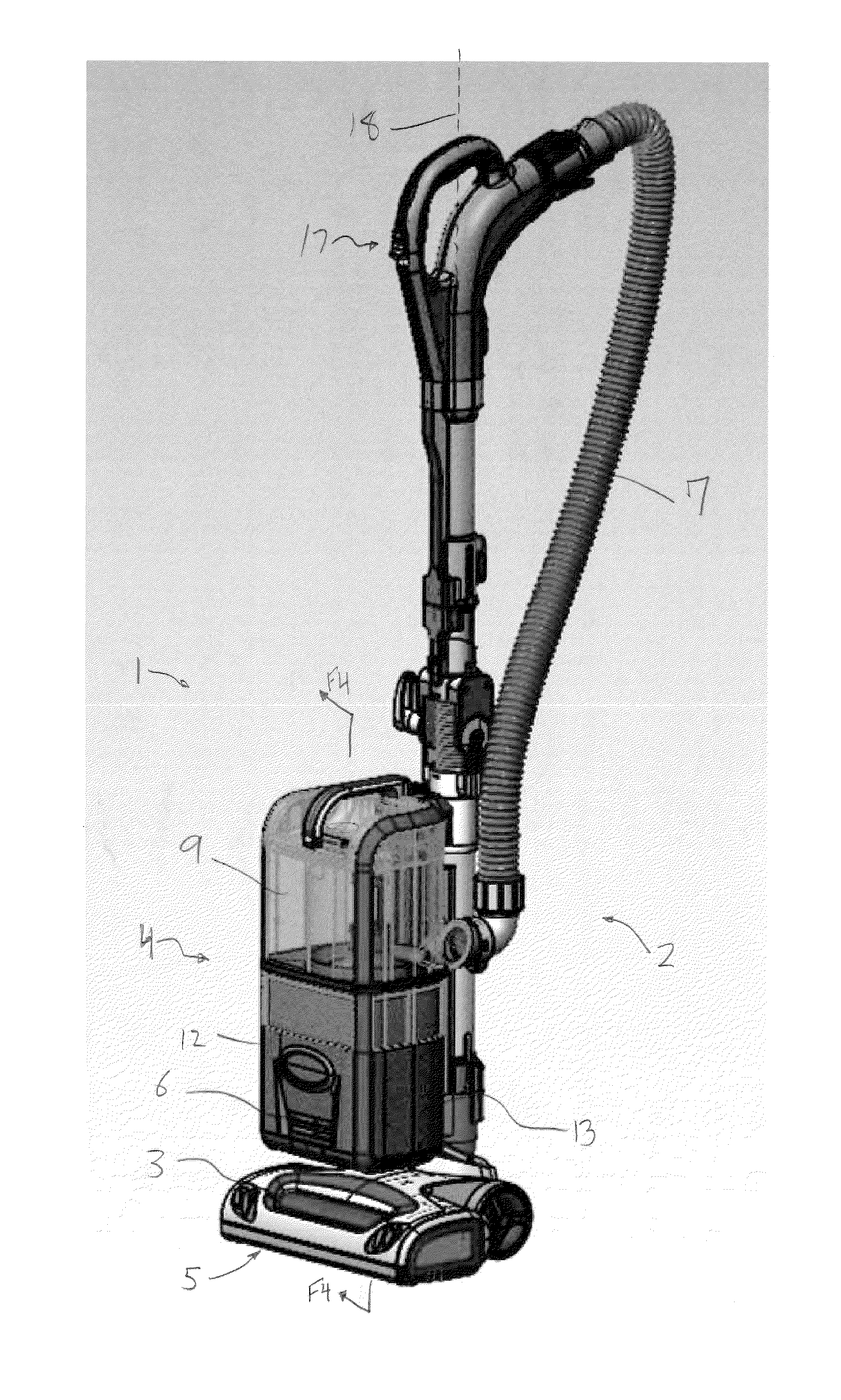

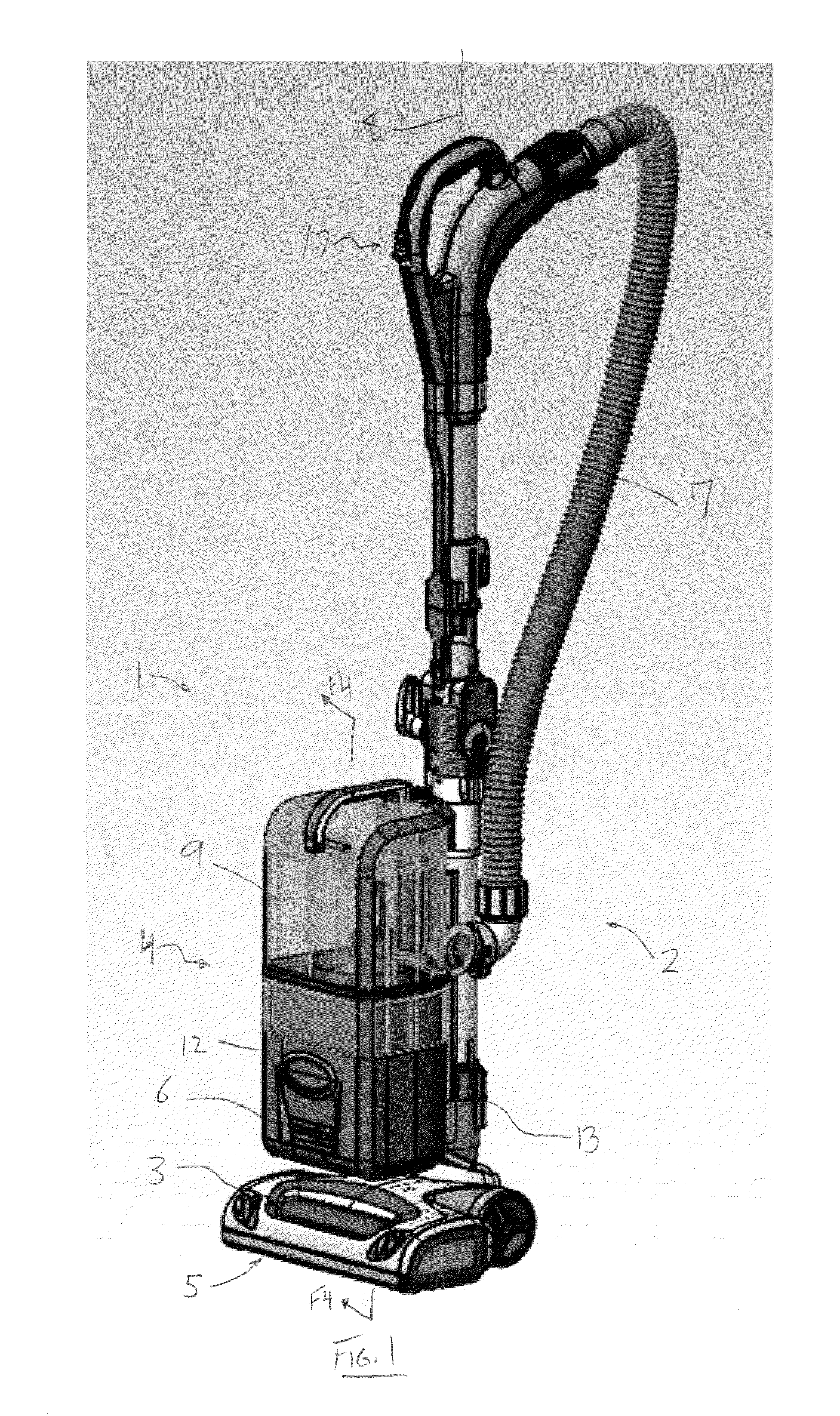

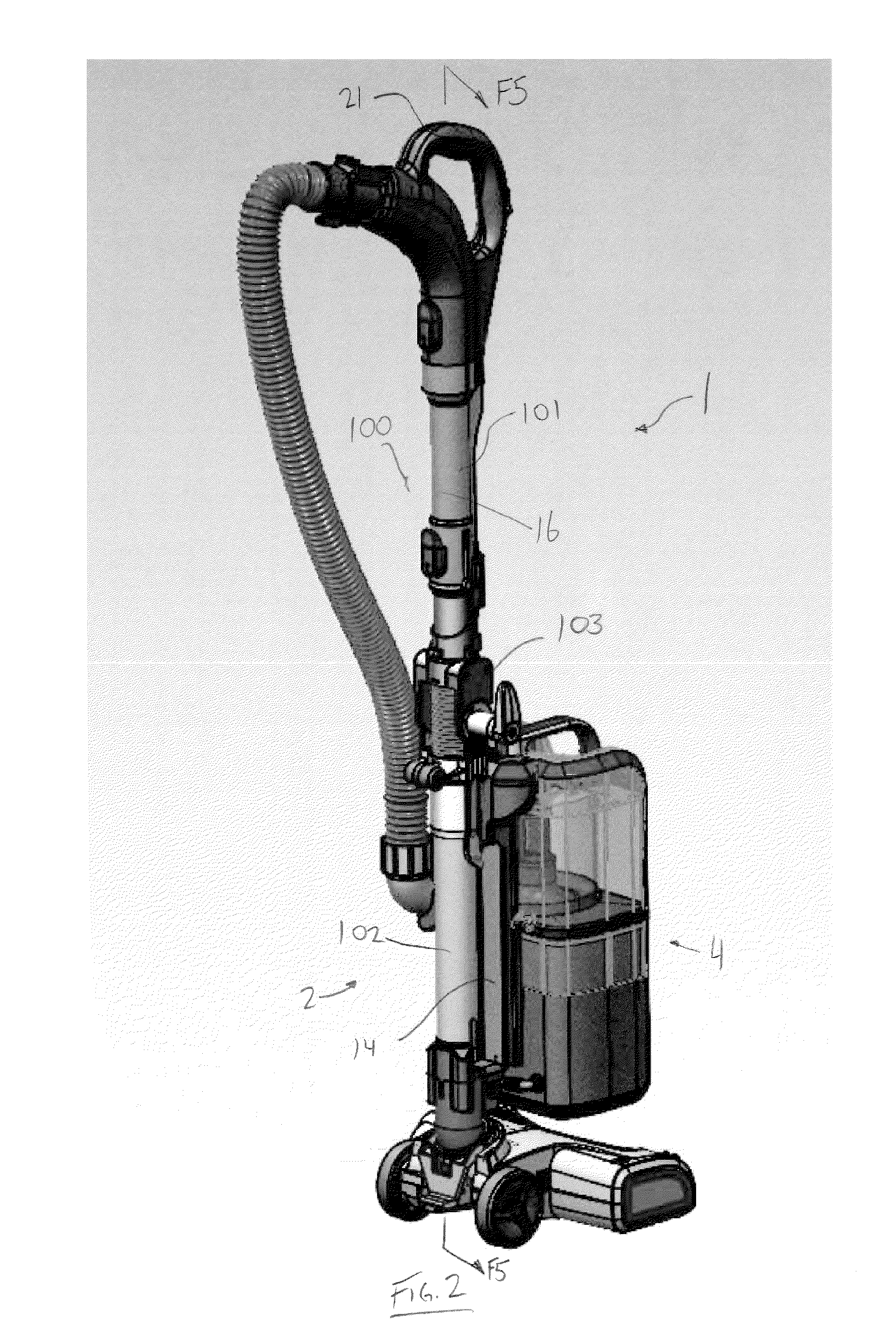

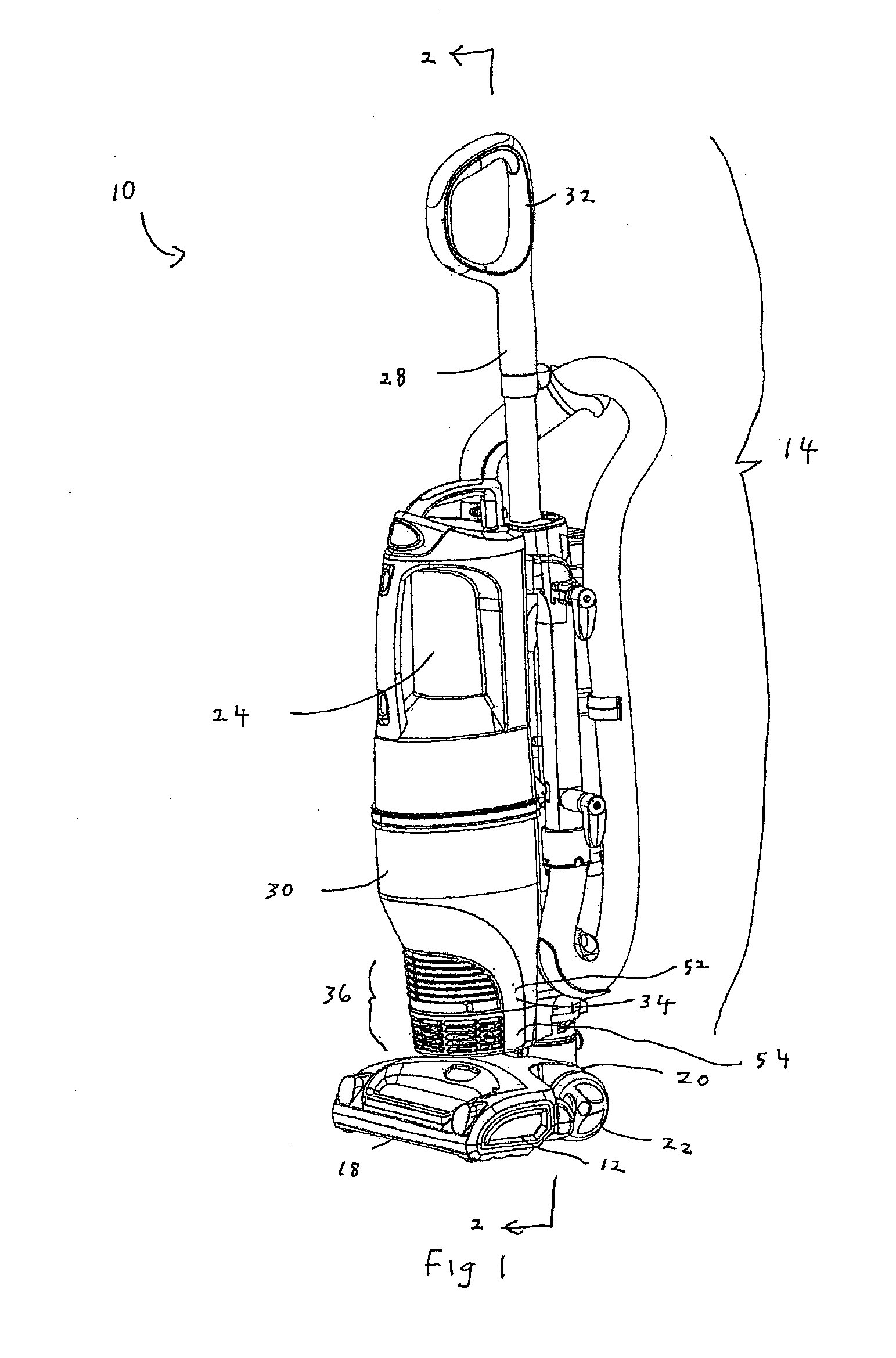

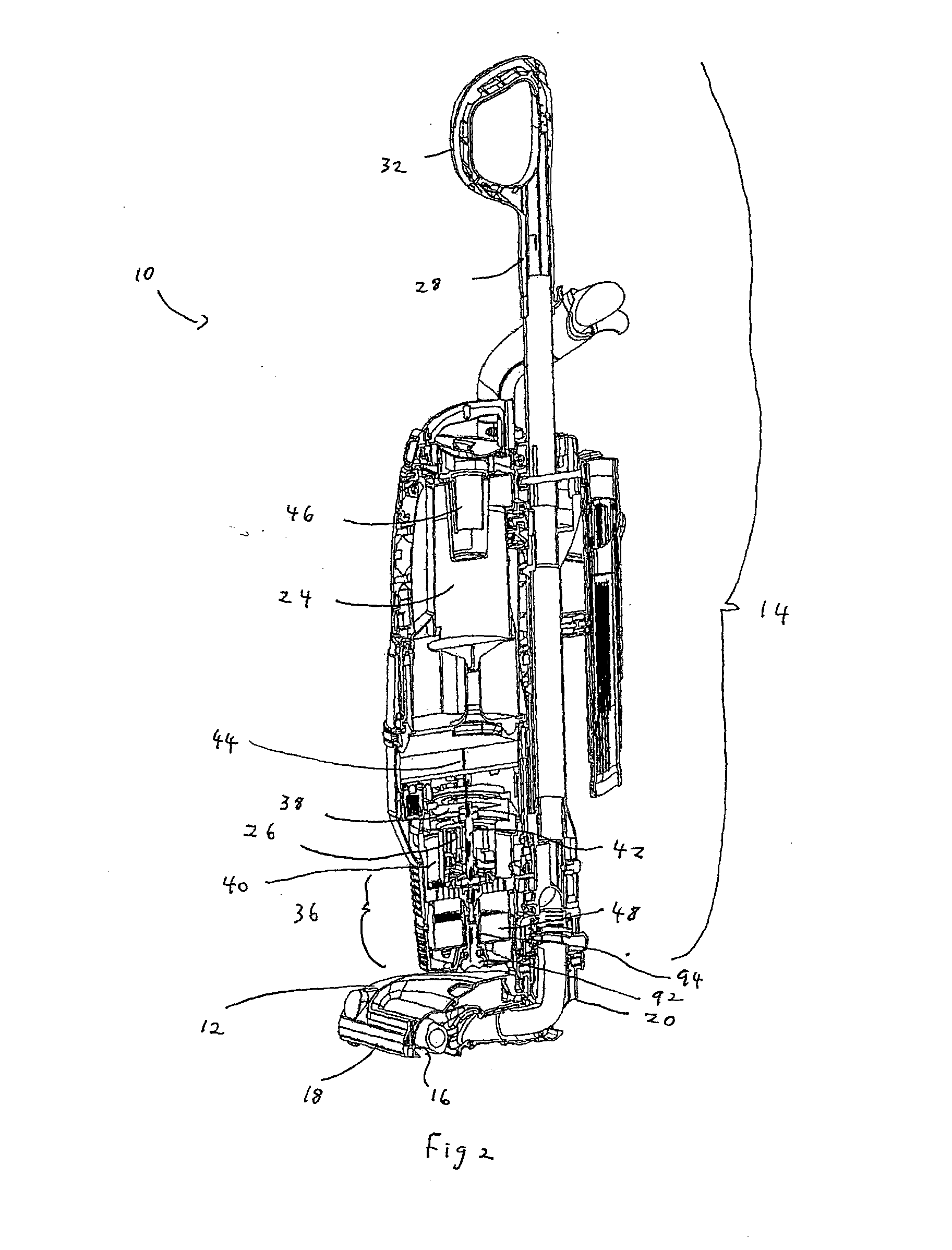

Surface cleaning apparatus

ActiveUS9326652B2Low efficiencySpeed up the air flowSuction filtersSuction hosesCycloneSurface cleaning

A surface cleaning apparatus is provided wherein a uniflow cyclone comprises a cyclone chamber defined by a longitudinal axis, the cyclone chamber having a dirt outlet that has a variable length in the direction of the longitudinal axis. A cyclone chamber having a barrier wall facing the dirt outlet of the cyclone chamber is also provided.

Owner:OMACHRON INTPROP

Cyclone such as for use in a surface cleaning apparatus

InactiveUS20140237764A1Reduce the soundReduce noiseCleaning filter meansCombination devicesCycloneSurface cleaning

A cyclone comprises a cyclone chamber having an air inlet, an air outlet, a screen upstream of the air outlet, a longitudinal axis, a first end wall, a second end wall and a sidewall, the air inlet having a cross sectional area in a plane transverse to a direction of airflow through the air inlet and the screen having an inner end spaced longitudinally inwardly from the air outlet and having a cross-sectional area transverse to the cyclone axis that is less than the cross sectional area of the air inlet.

Owner:OMACHRON INTPROP

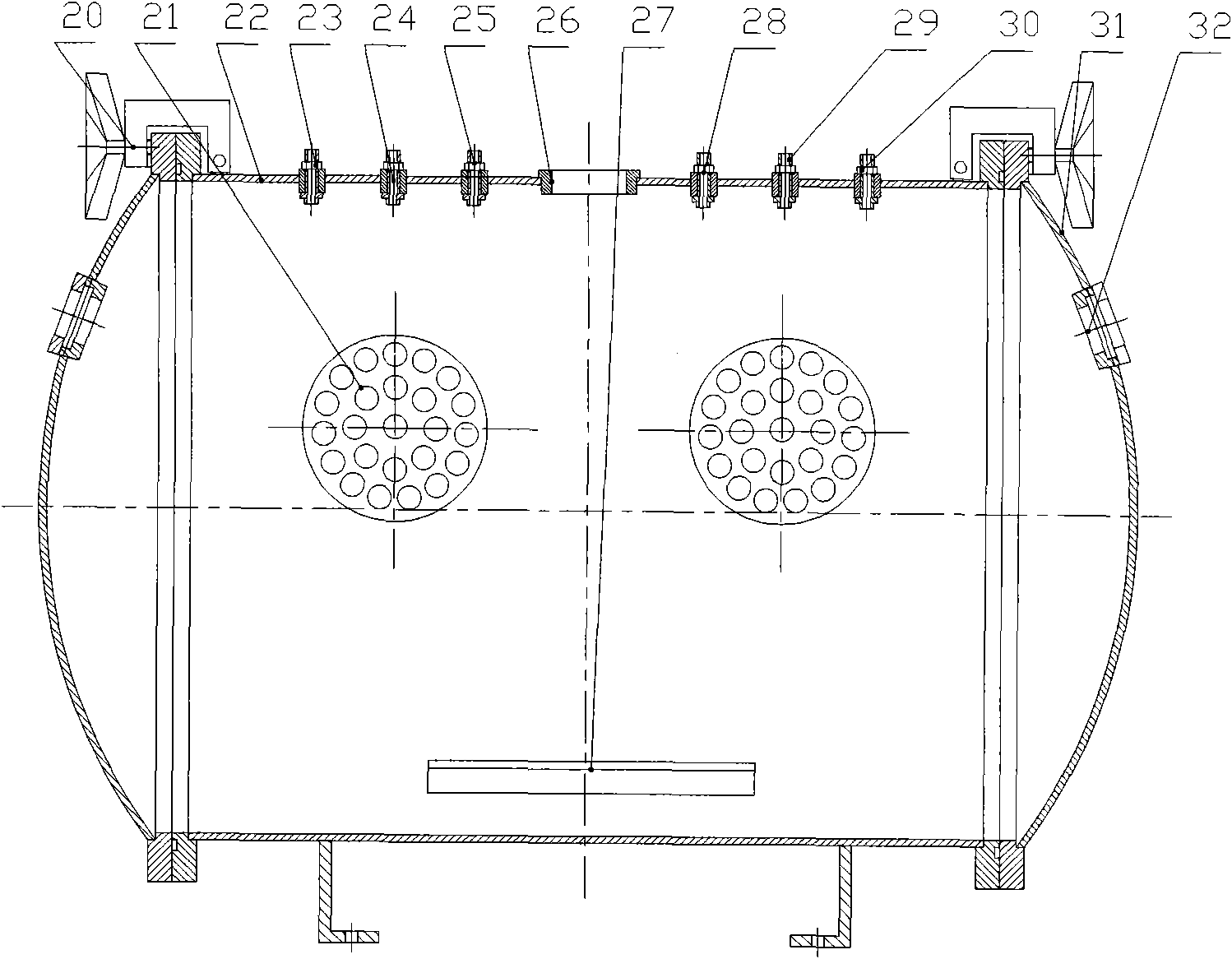

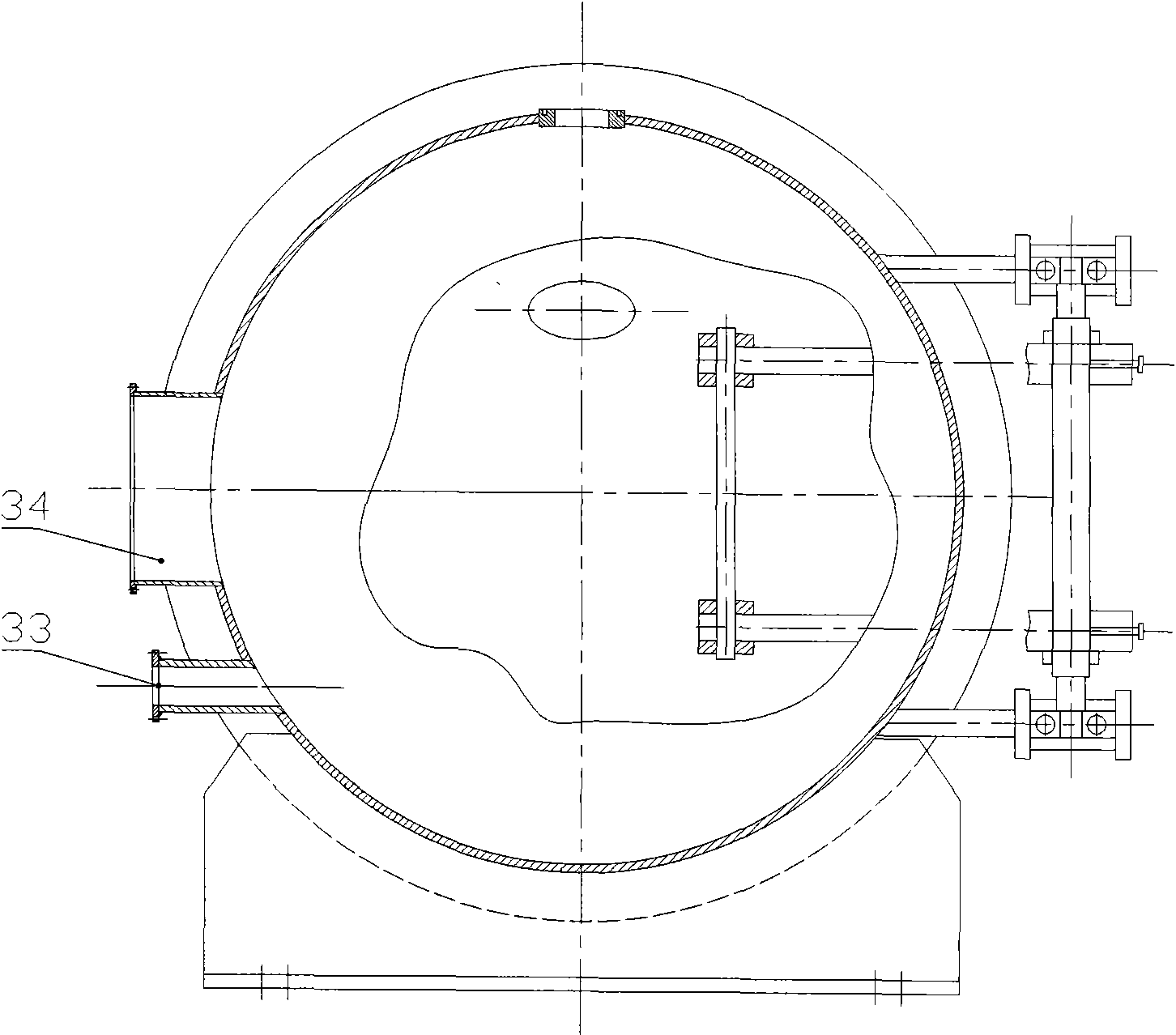

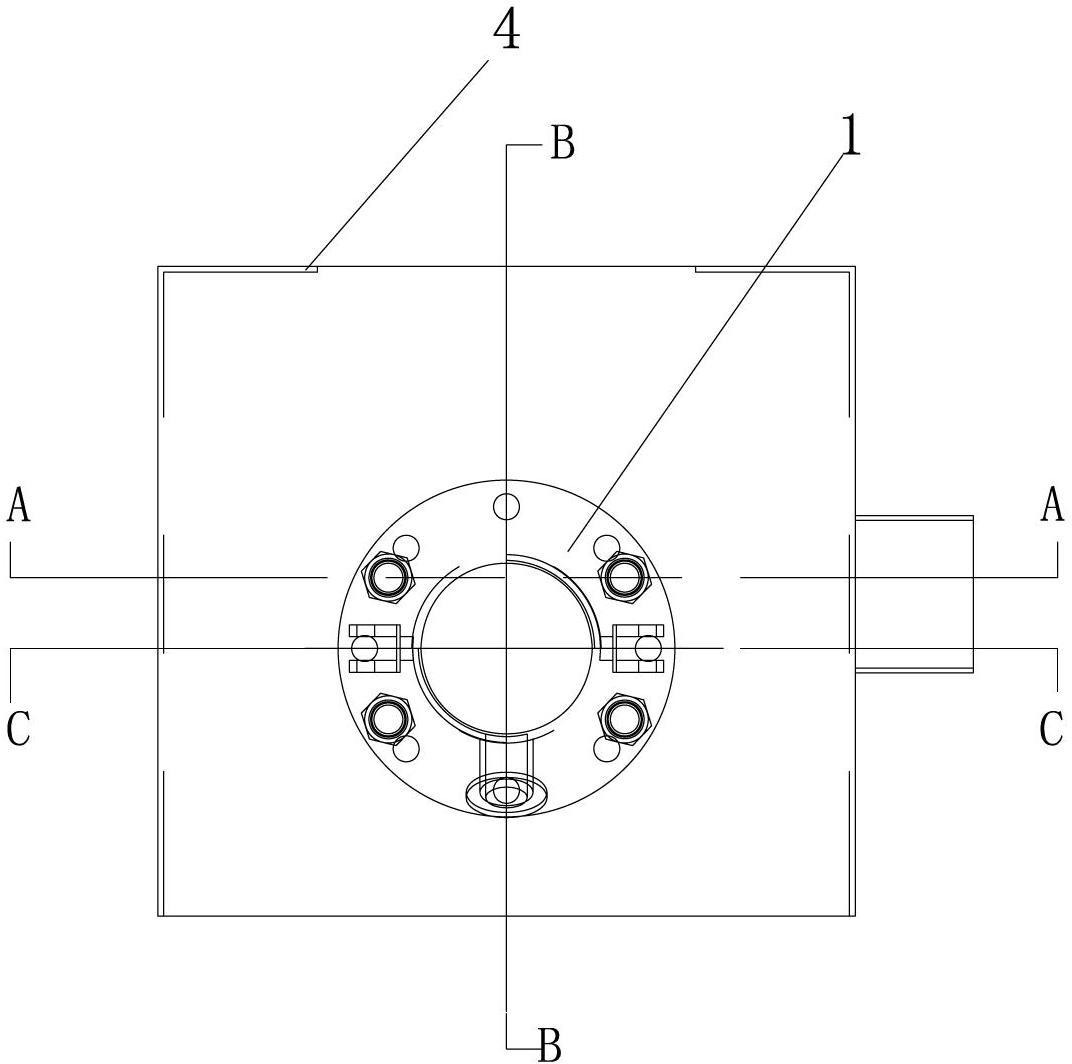

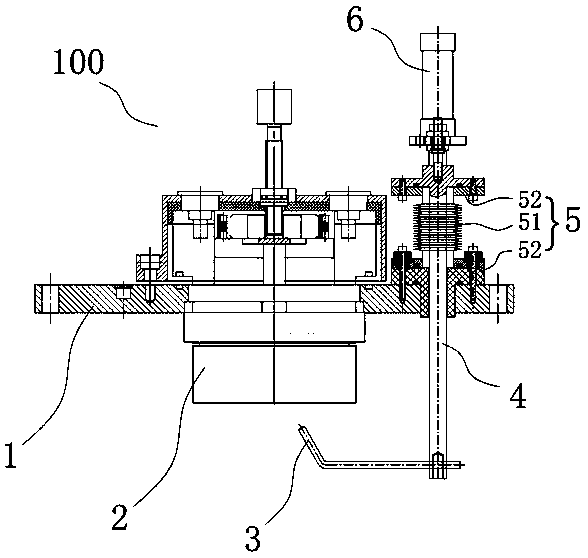

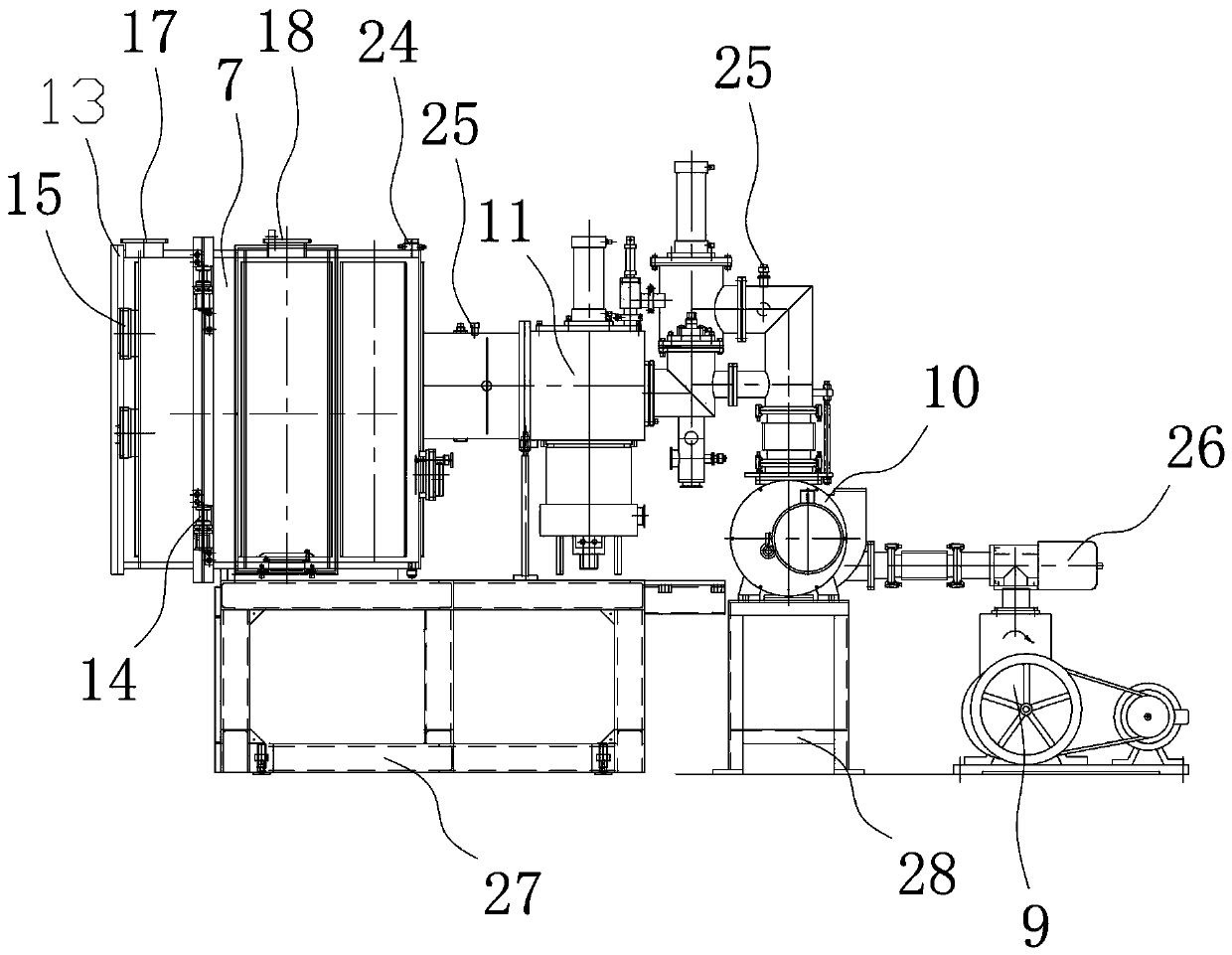

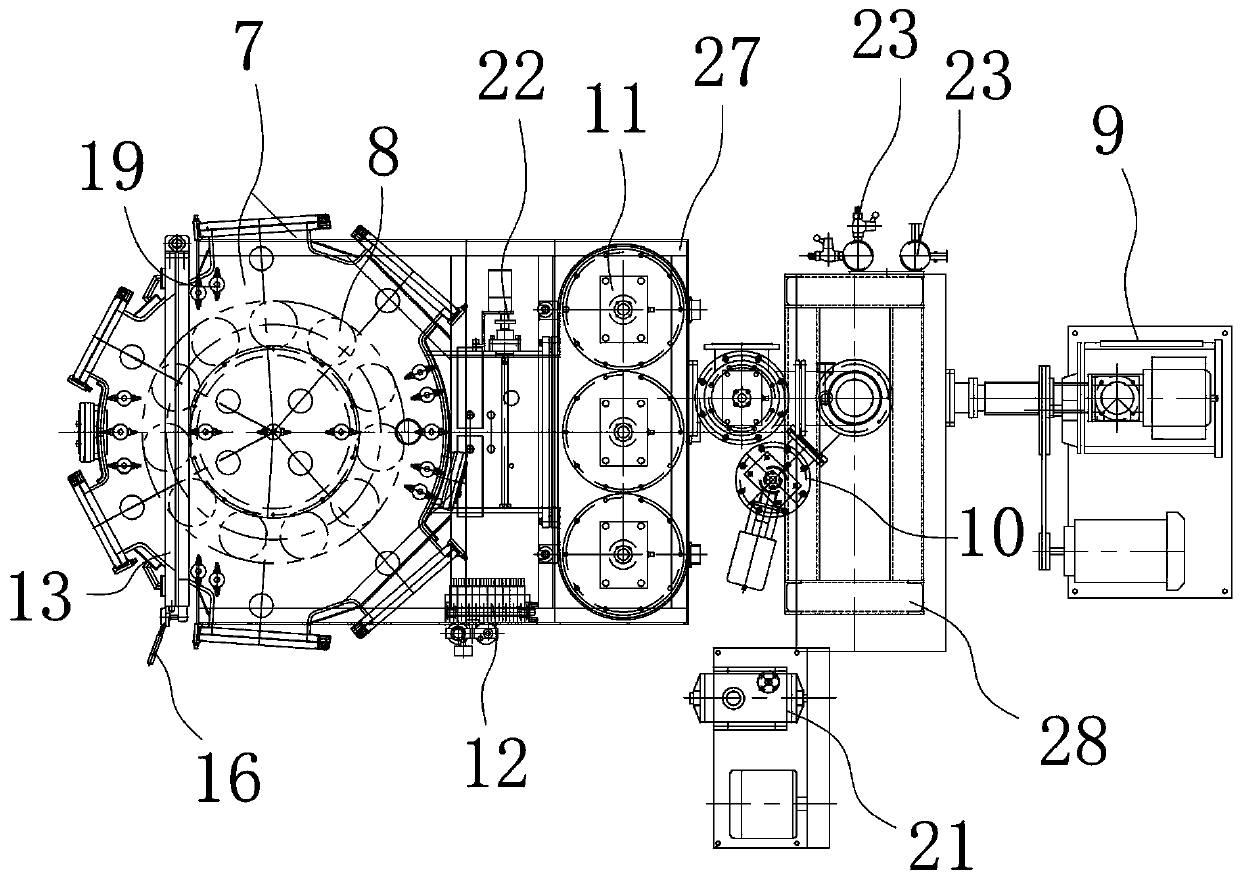

Vacuum box system for laser processing

InactiveCN101549438ARealize laser processing operationsLow laser absorptionLaser beam welding apparatusComputer control systemLaser processing

A vacuum box system for laser processing mainly comprises a shielding gas system, a vacuum chamber, a vacuum obtaining system, a cooling system, a three-dimensional worktable, a powder delivering system, a computer control system and an electronic control system. The three-dimensional worktable is fixed in the vacuum cavity; the shielding gas system, the powder delivering system and the vacuum obtaining system are connected with the vacuum chamber through tubes; the cooling system is in system connection with the vacuum chamber and the vacuum through tubes; and the computer system and the electronic control system are connected with the vacuum chamber, the powder delivering system and the vacuum obtaining system through electric wires. The vacuum box system adopts manual manner to control processes of vacuumizing and charging shielding gas; the operation process is simple, safe and reliable; and the vacuum box system can realize laser processing in three-dimensional space under vacuum environment or shielding gas environment.

Owner:SHENYANG INST OF AERONAUTICAL ENG

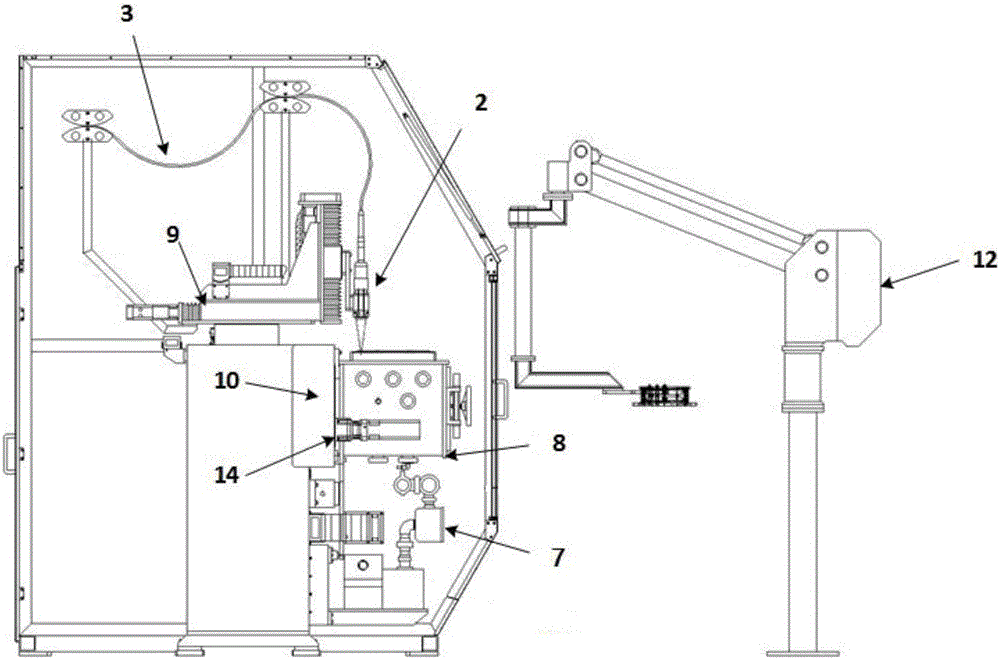

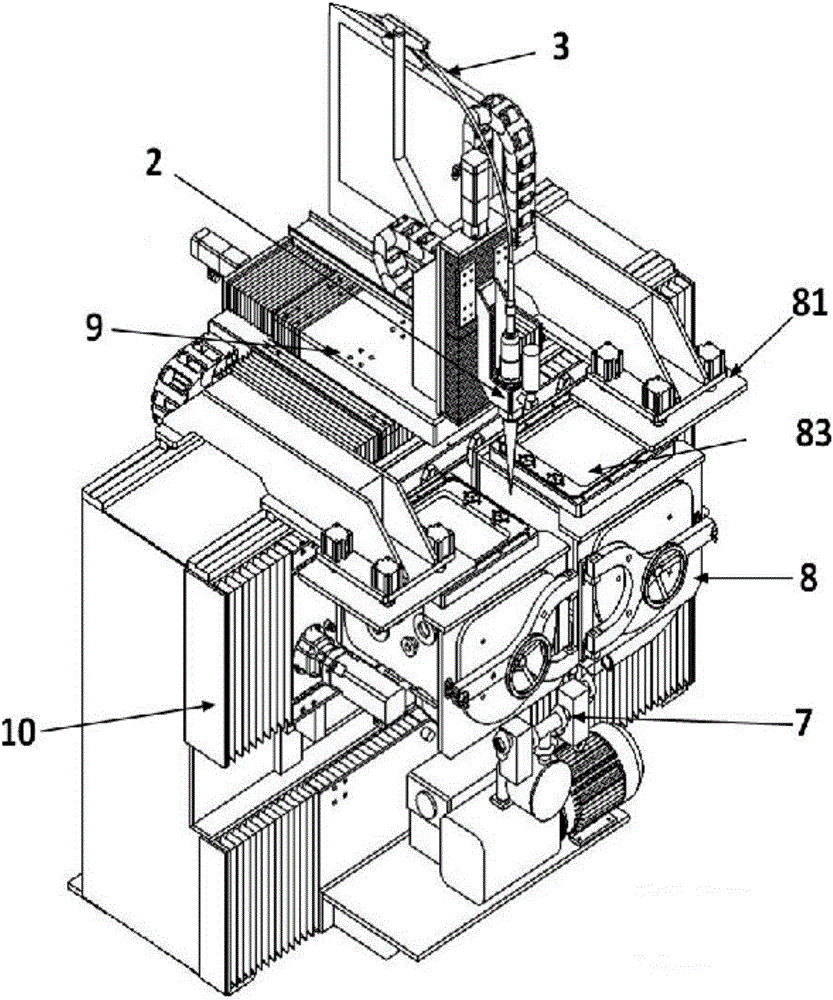

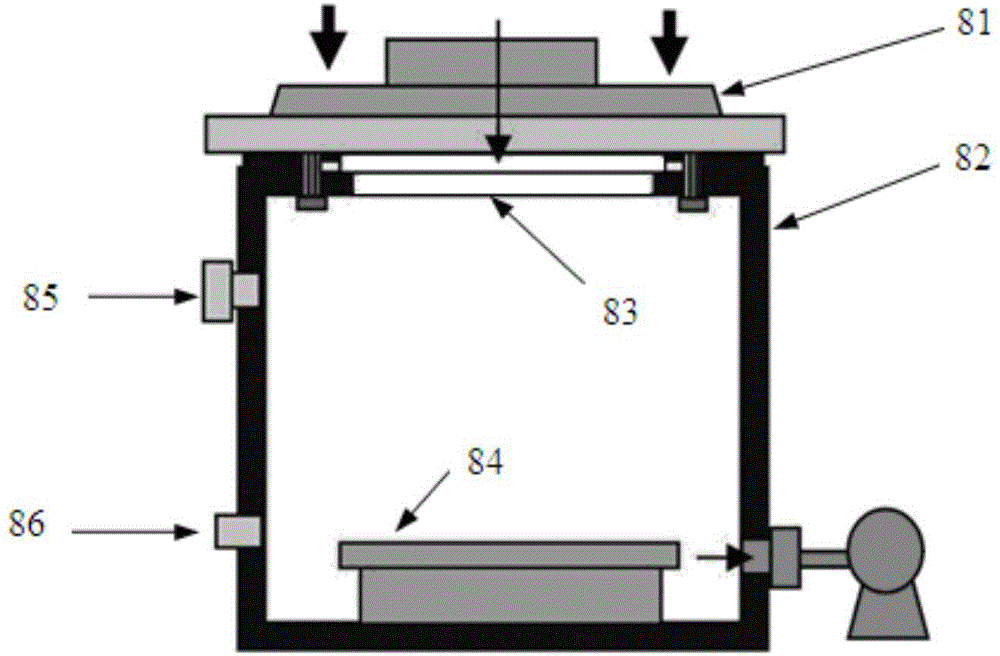

Vacuum laser welding system for grillwork

ActiveCN105710533AImprove flexibilityGood pointing stabilityLaser beam welding apparatusTransmittanceEngineering

The invention discloses a vacuum laser welding system for a grillwork and belongs to the technical field of laser welding. The vacuum laser welding system meets the requirements for the welding environment of the zirconium alloy grillwork and high precision. A laser welding head of the vacuum laser welding system is fixed to a three-dimensional movement mechanism. The three-dimensional movement mechanism drives the laser welding head to move. A laser signal input port of the laser welding head is connected with a laser signal output port of a laser device through an optical cable. A vacuum room is arranged under the laser welding head. The vacuum room is an airtight rectangular box body. Light-transmittance glass is arranged on the upper side wall of the box body. A worktable is arranged under the light-transmittance glass. The worktable is arranged on the bottom face of the vacuum room. A servo system drives the worktable to rotate and overturn through a workpiece position-changing mechanism. An argon charging opening and an exhaust opening are formed in the left side wall of the vacuum room. The vacuum laser welding system is suitable for welding the grillwork.

Owner:哈尔滨工大焊接科技有限公司

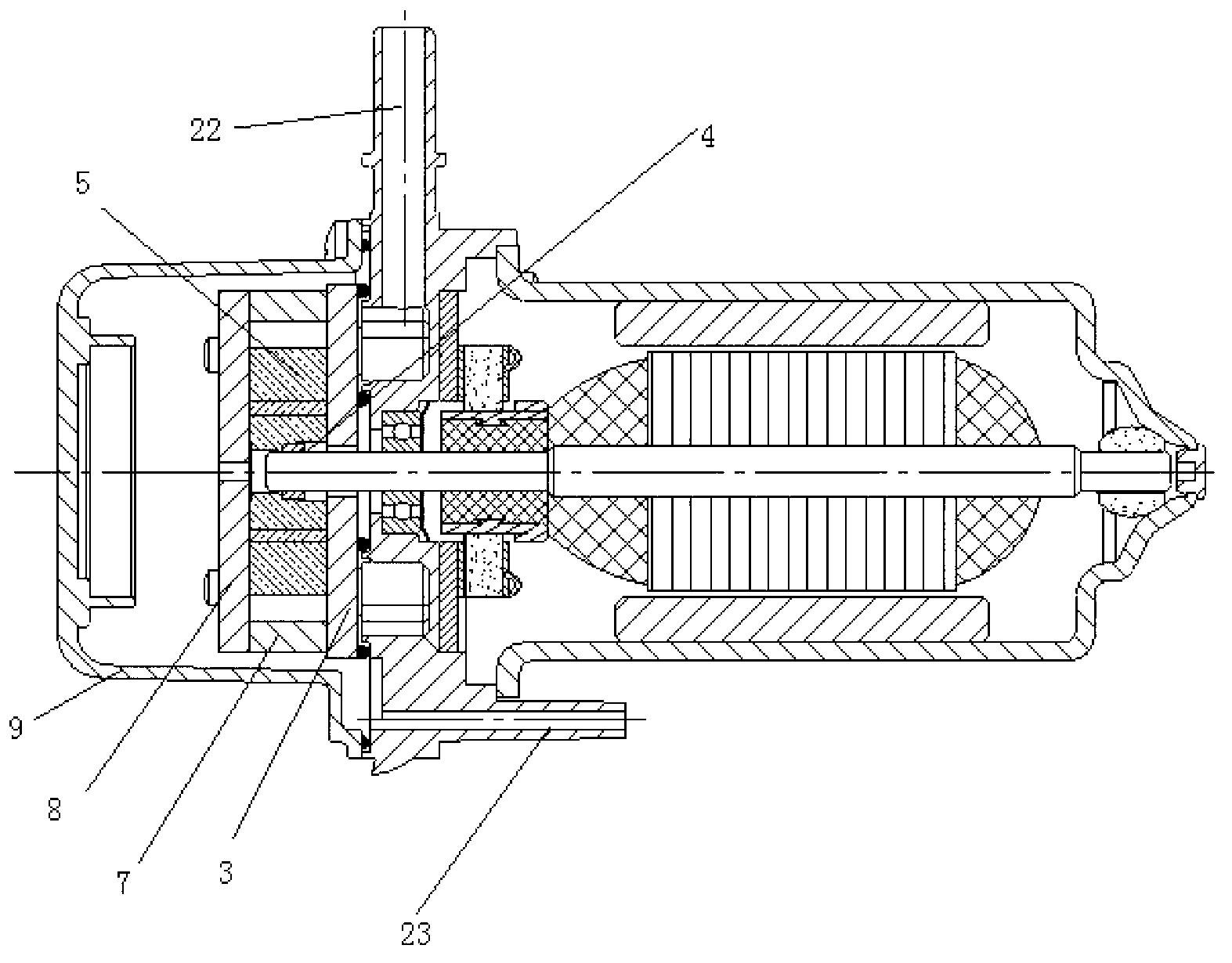

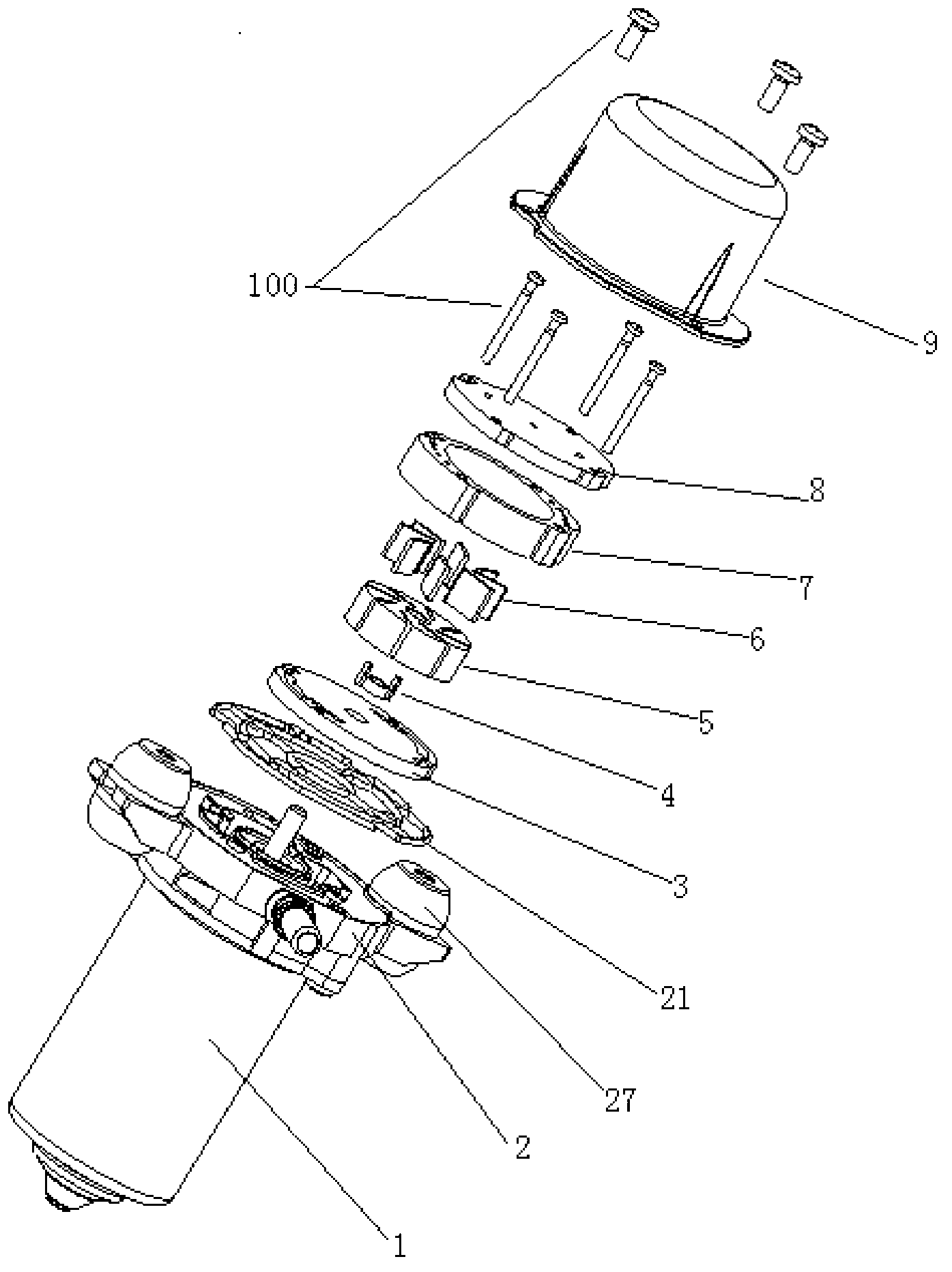

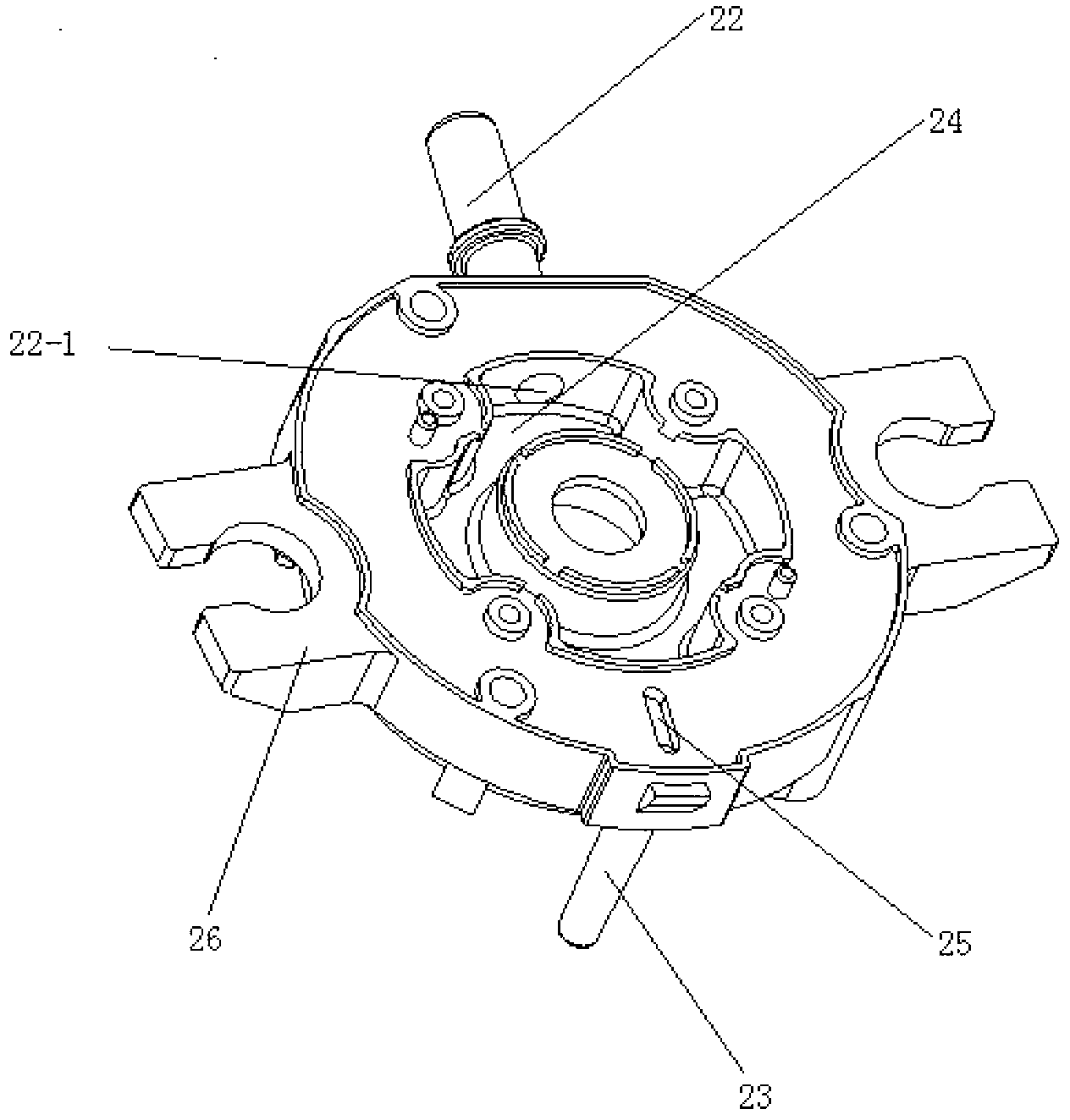

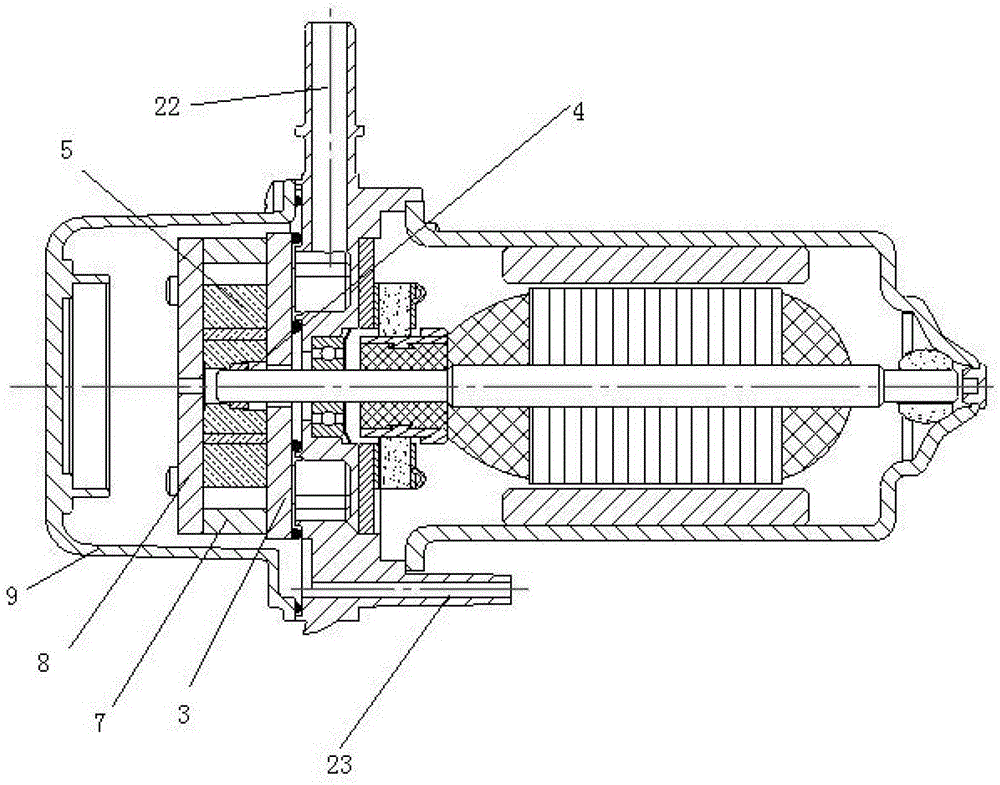

Electronic vacuum pump for new energy vehicle brake vacuum booster

ActiveCN103306979AImprove vacuum efficiencyIncrease air intakeMachines/enginesPumpsVacuum pumpEnergy consumption

The invention discloses an electronic vacuum pump for a new energy vehicle brake vacuum booster. The electronic vacuum pump comprises a motor assembly, a supporting base, a pump chamber lower cover, a driving sleeve, a pump rotor, blades, a pump chamber, a pump chamber upper cover, a pump body cover and fixing pins, wherein a left side air feeding slot of the pump chamber lower cover, a left side air feeding through hole of the pump chamber and a left side air feeding slot of the pump chamber upper cover are communicated with one another to form an air passageway; a right side air feeding slot of the pump chamber lower cover, a right side air feeding through hole of the pump chamber and a right side air feeding slot of the pump chamber upper cover are communicated with one another to form an air passageway; a flow guide slot of the pump chamber lower cover is communicated with an inner cavity of the pump chamber; an air discharging slot of the pump chamber upper cover is communicated with the inner cavity of the pump chamber; the flow guide slot of the pump chamber lower cover and the air discharging slot of the pump chamber upper cover are symmetric. When the vacuum pump works, an air path with four air inlets and two air outlets is formed; therefore, the air feeding resistance is greatly reduced, and the air feeding amount of the pump chamber is increased; under the equal energy consumption, the vacuumizing efficiency of the vacuum pump provided by the invention is higher.

Owner:常州市东南电器电机有限公司

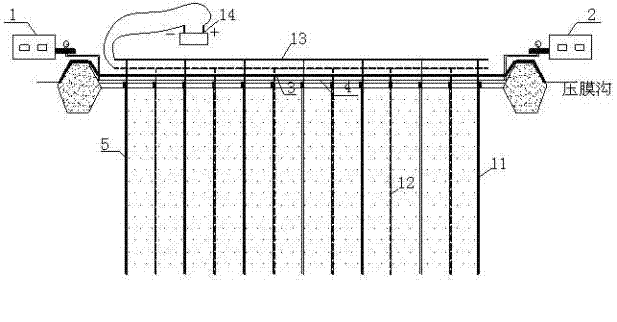

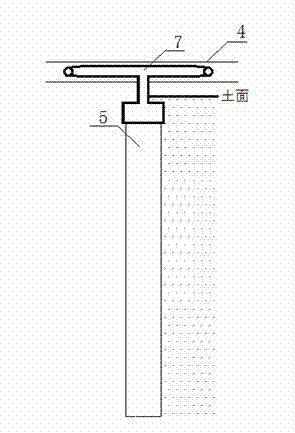

Processing method for reinforcing soft clay ground through vacuum preloading in combination with electro-osmosis method

The invention discloses a processing method for reinforcing a soft clay ground through vacuum preloading in combination with electro osmosis. According to the method, solid airtight separate vacuum preloading in combination with electric osmosis in which reinforcing steel bars are taken as the electro osmosis electrodes are adopted for reinforcing the ground. During the arrangement of vacuum preloading systems, by using a separate seal joint, a sealed water pipe, a sealed main pipe and a vacuumizing device, plastic water drainage plates which are inserted into the soil and plastic water drainage plates which are paved on the surface of the soil form two sets of separate airtight vacuum systems which can be separately controlled to turn on or off, and the vacuum degrees of the two vacuum systems can be separately regulated. After the vacuum systems are arranged, rebar electrodes are inserted in rows in the gaps between the plastic water drainage plates inserted in the soil, and then the perforations between the rebar electrodes and the vacuum preloading airtight systems are sealed. With the processing method, the vacuum transfer and utilization efficiency is improved, the water drainage effect of deep-layer soil is improved, the soil processing uniformity is remarkably improved, the overall soil reinforcing effect is improved, and fast, efficient and energy-saving hybrid reinforcement construction is realized.

Owner:SHANGHAI UNIV

Surface cleaning apparatus

ActiveUS20140237765A1Low efficiencySpeed up the air flowCleaning filter meansSuction filtersSurface cleaningWaste management

A surface cleaning apparatus is provided wherein at least one of an upstream air plenum that is positioned upstream of the pre-motor filter, and a downstream air plenum that is positioned downstream of the pre-motor filter comprises an end wall spaced from the pre-motor filter and comprises a first portion having an air flow port and a second portion proximate the outer perimeter of the pre-motor filter, wherein the first portion and the second portion meet at a first juncture that extends at an angle to the first portion and the second portion.

Owner:OMACHRON INTPROP

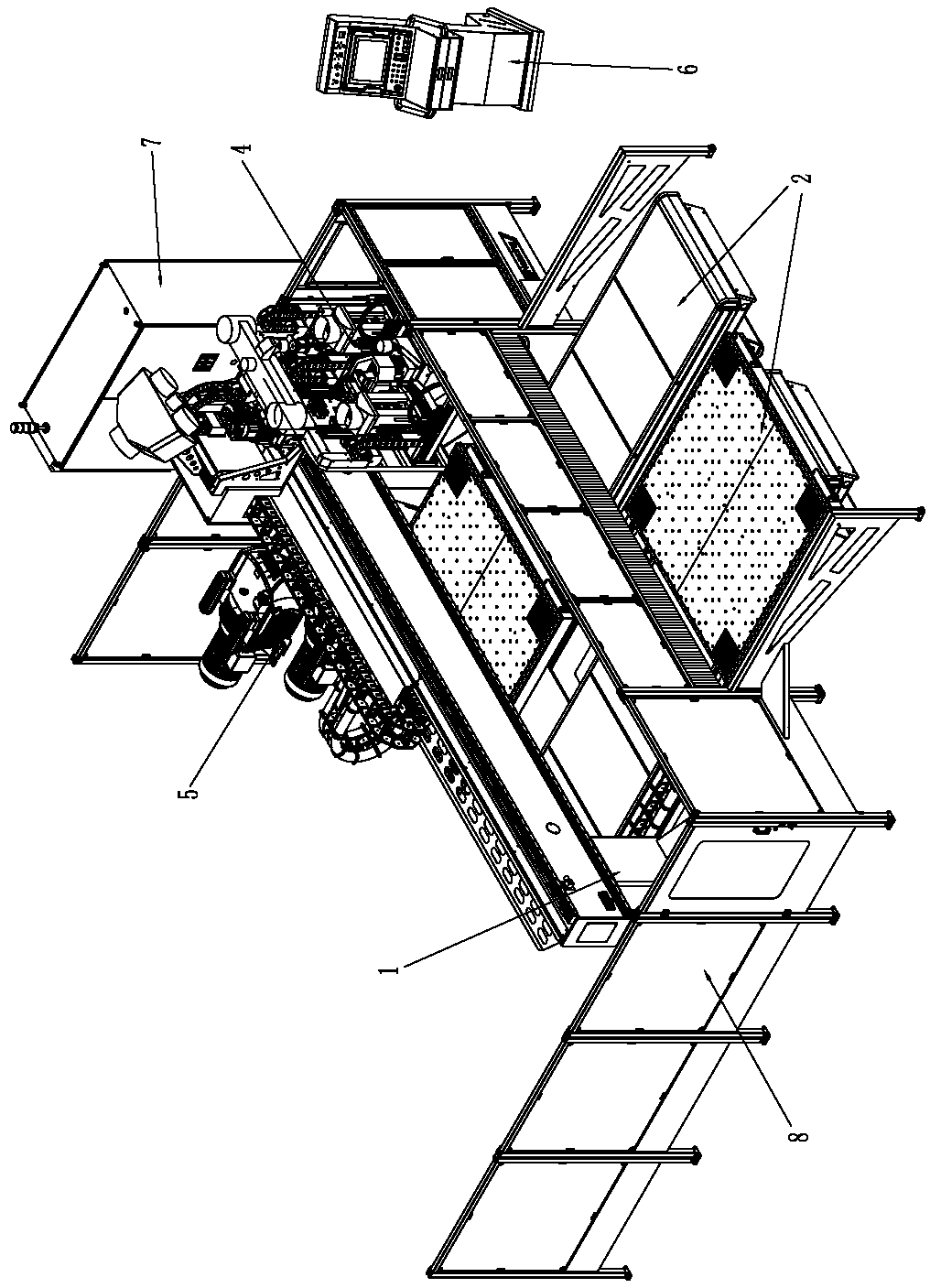

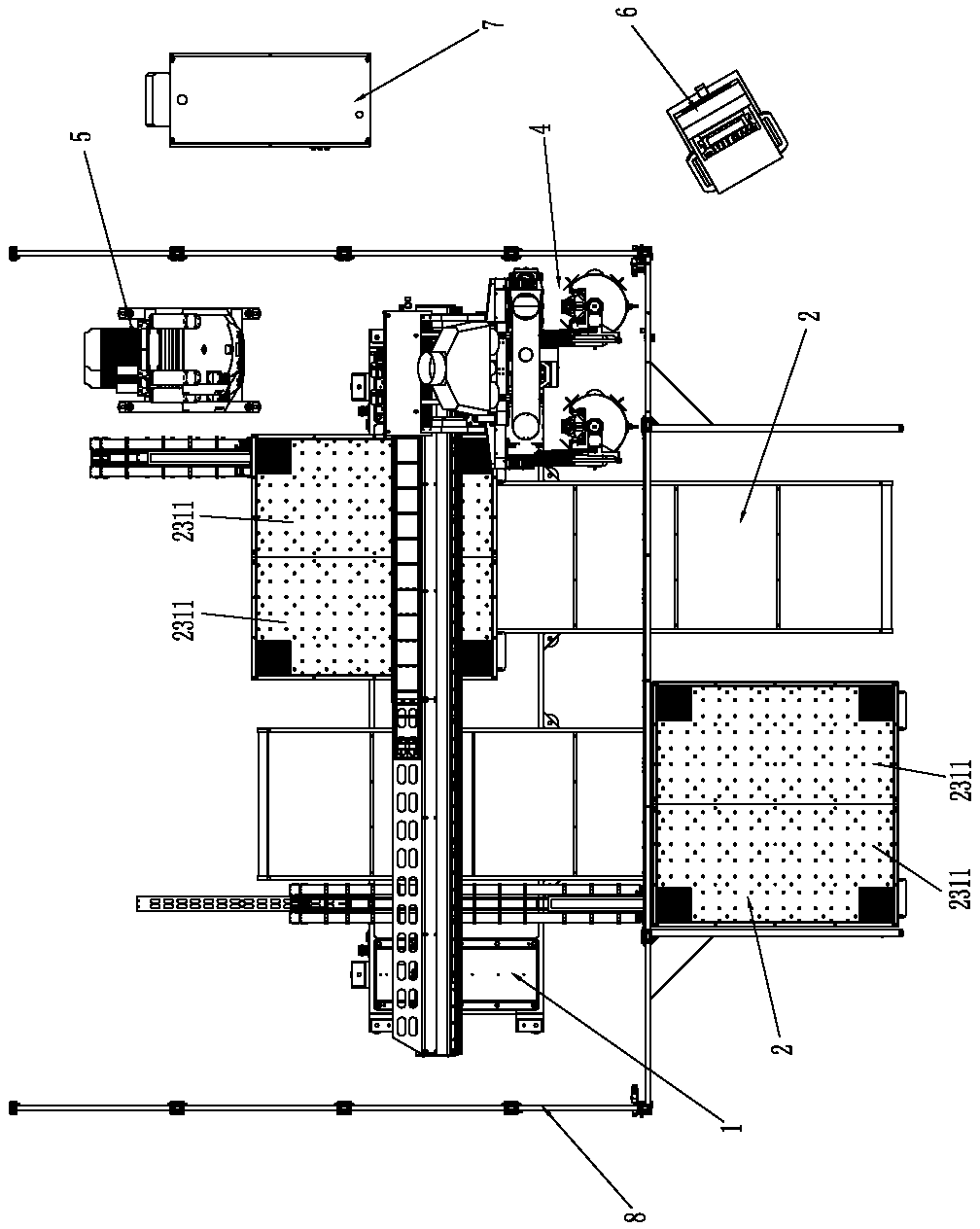

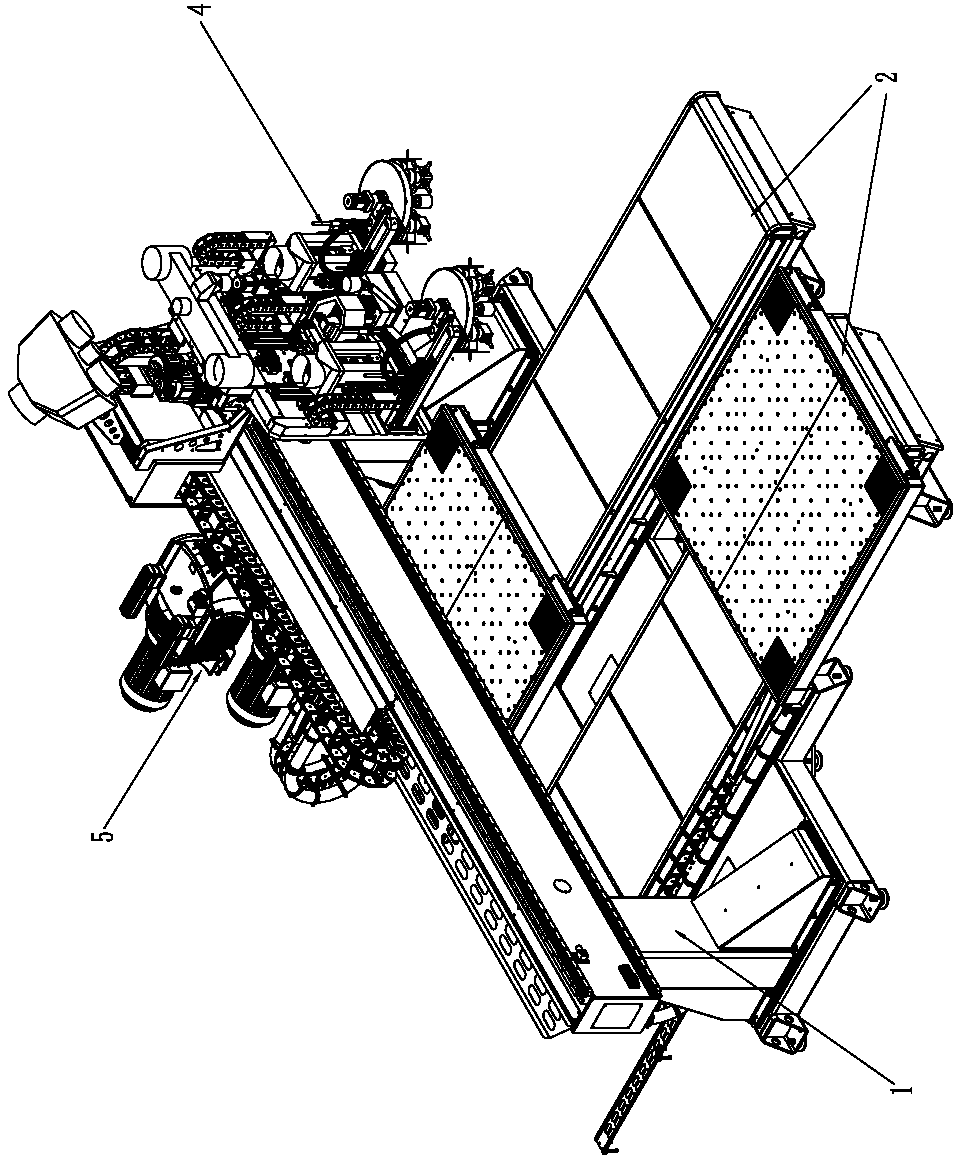

Double-main-shaft double-working-table gantry type heavy wood composite processing center

ActiveCN104369232ASimple processing and assemblyHigh vacuum efficiencyMulti-purpose machinesElectricityEngineering

The invention discloses a double-main-shaft double-working-table gantry type heavy wood composite processing center comprising a bed body, double working tables, an X-Z-shaft sliding table, a double-main-shaft machine head, a vacuum pump component, a control cabinet and an electricity box, wherein the bed body comprises a base, a vertical column and a cross beam, the double working tables are arranged on a Y-shaft guide rail of the base side by side, each working table respectively comprises a sliding base, a hood cover, a working table panel component and a connecting side frame, a Y-axial sliding block is arranged at the bottom of the sliding base and is adapted to the Y-shaft guide rail, and the Y-axial sliding block and the Y-shaft guide rail are both hidden in the hood cover; and the double-main-shaft machine head is adapted to the X-Z-shaft sliding table in a sliding manner by virtue of a Z-shaft sliding plate, the X-Z-shaft sliding table is adapted to the X-shaft guide rail of the cross beam, and the double-main-shaft machine head comprises a gang drill component, two main shaft components and two tool magazine components. Therefore, processes of cutting and sawing, engraving and milling, slotting, vertical drilling and horizontal drilling of two parts can be completed by virtue of one-time clamping and continuous compounding, and moreover, the parts can be respectively processed and clamped on the two working tables synchronously, so that the manufacturing time can be saved, and the production efficiency can be improved.

Owner:NANXING MACHINERY CO LTD

Cyclone such as for use in a surface cleaning apparatus

ActiveUS20140237955A1Low efficiencySpeed up the air flowCombination devicesSuction filtersCycloneSurface cleaning

A cyclone comprises a cyclone chamber having an air inlet, an air outlet, a first end wall, a second end wall and a sidewall, the air inlet has an inlet end having a shape and a cross sectional area in a plane transverse to a direction of airflow through the air inlet, and the air inlet is provided at a first juncture of the sidewall and the first end wall, the first end wall has a vortex finder having a wall that meets the first end wall at a second juncture, wherein the inlet is spaced from the vortex finder

Owner:OMACHRON INTPROP

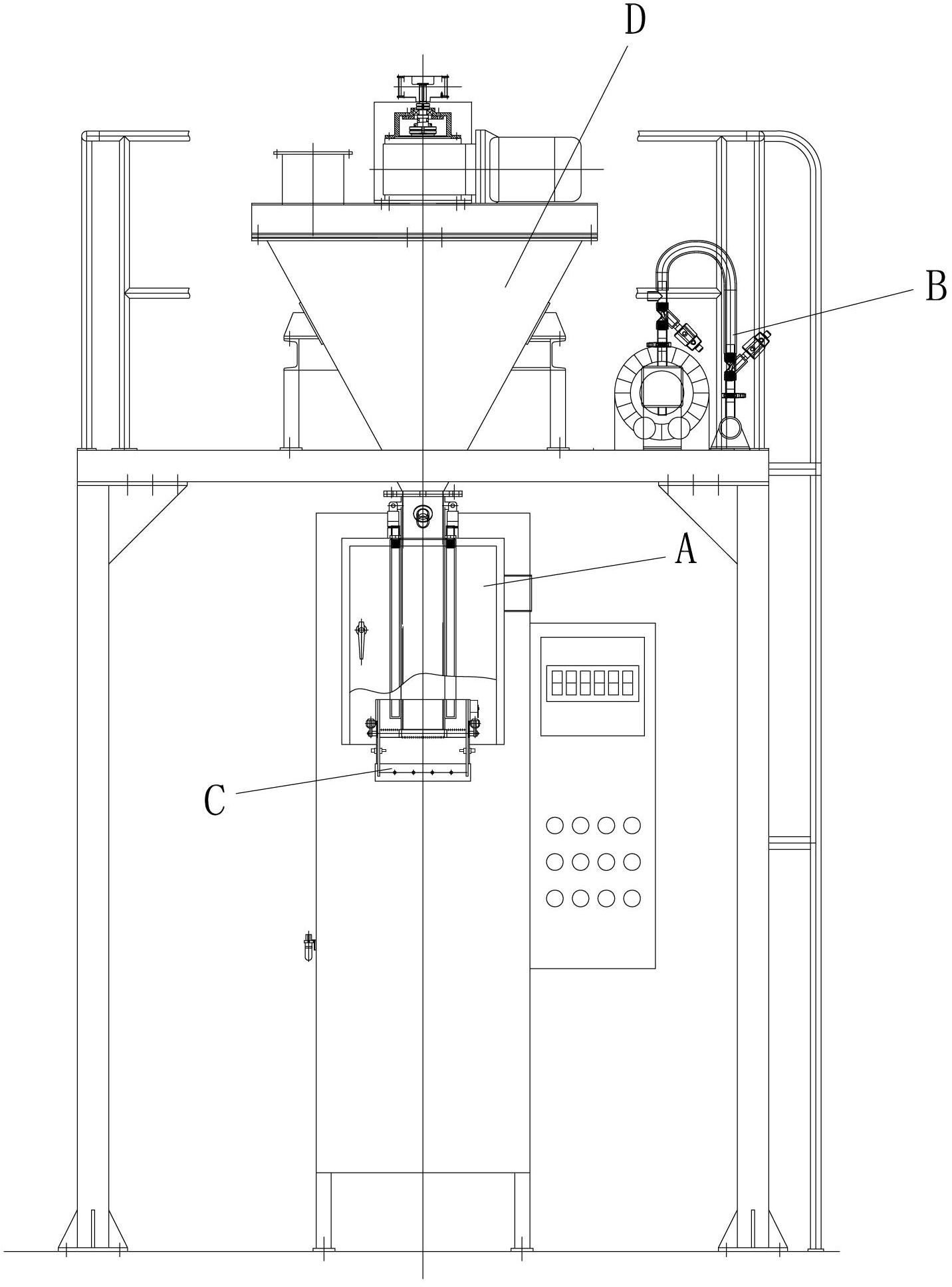

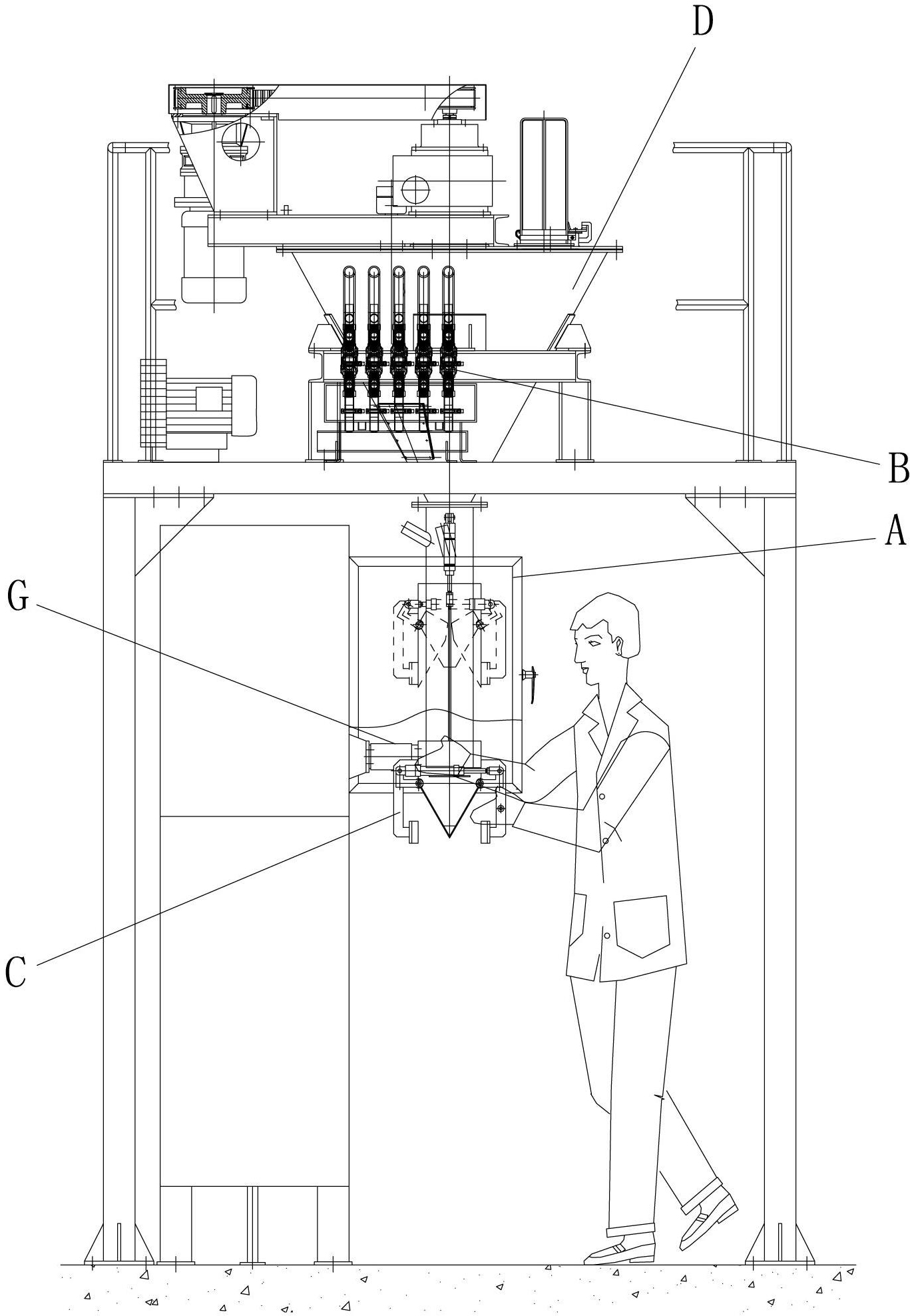

Operating method of powder material packing scale

The invention relates to an operating method of a powder material packing scale, which is suitable to solve the problems that the packaging bag is unable to be vertically placed and the rated quantity of materials are difficultly put into the bag within a normal time when powder materials with high gas contents enter a packaging bag; and the dust is easy to fly everywhere, after the packaging equipment is used, a better effect is obtained, and the efficiency is improved. The packaging scale comprises a degassing blanking device which is arranged on an outlet at the bottom of a hopper, an air suction blowing combination valve group and a vacuum pump which are used for degassing, blowing and blockage removing and are connected with the degassing blanking device, and a pneumatic bag-clamping lifting mechanism which is arranged at the bottom of the degassing blanking device; and the degassing blanking device comprises a blanking barrel, integrated microporous filter elements are arranged at both the inner wall and the outer wall of the blanking barrel, and the pore diameters of the filter elements can be set according to the sizes of material particles, and can range between 50 mum and 1mum. Ports which are communicated with a clearance between the inner wall of the blanking barrel and the inner filter elements are arranged in the outer wall of the blanking barrel; and the ports are connected with air suction blowing combination valves.

Owner:CHANGZHOU CHANGHENG DEYU POWDER INTEGRATIVE SYST

Surface cleaning apparatus

ActiveUS20140237766A1Reduce the soundReduce noiseCleaning filter meansSuction filtersCycloneSurface cleaning

A surface cleaning apparatus is provided wherein a uniflow cyclone comprises a cyclone chamber defined by a longitudinal axis, the cyclone chamber having a dirt outlet that has a variable length in the direction of the longitudinal axis. A cyclone chamber having a barrier wall facing the dirt outlet of the cyclone chamber is also provided.

Owner:OMACHRON INTPROP

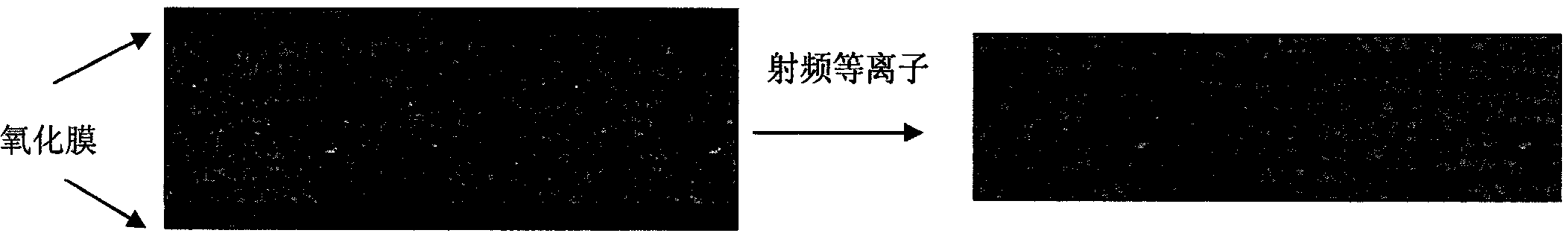

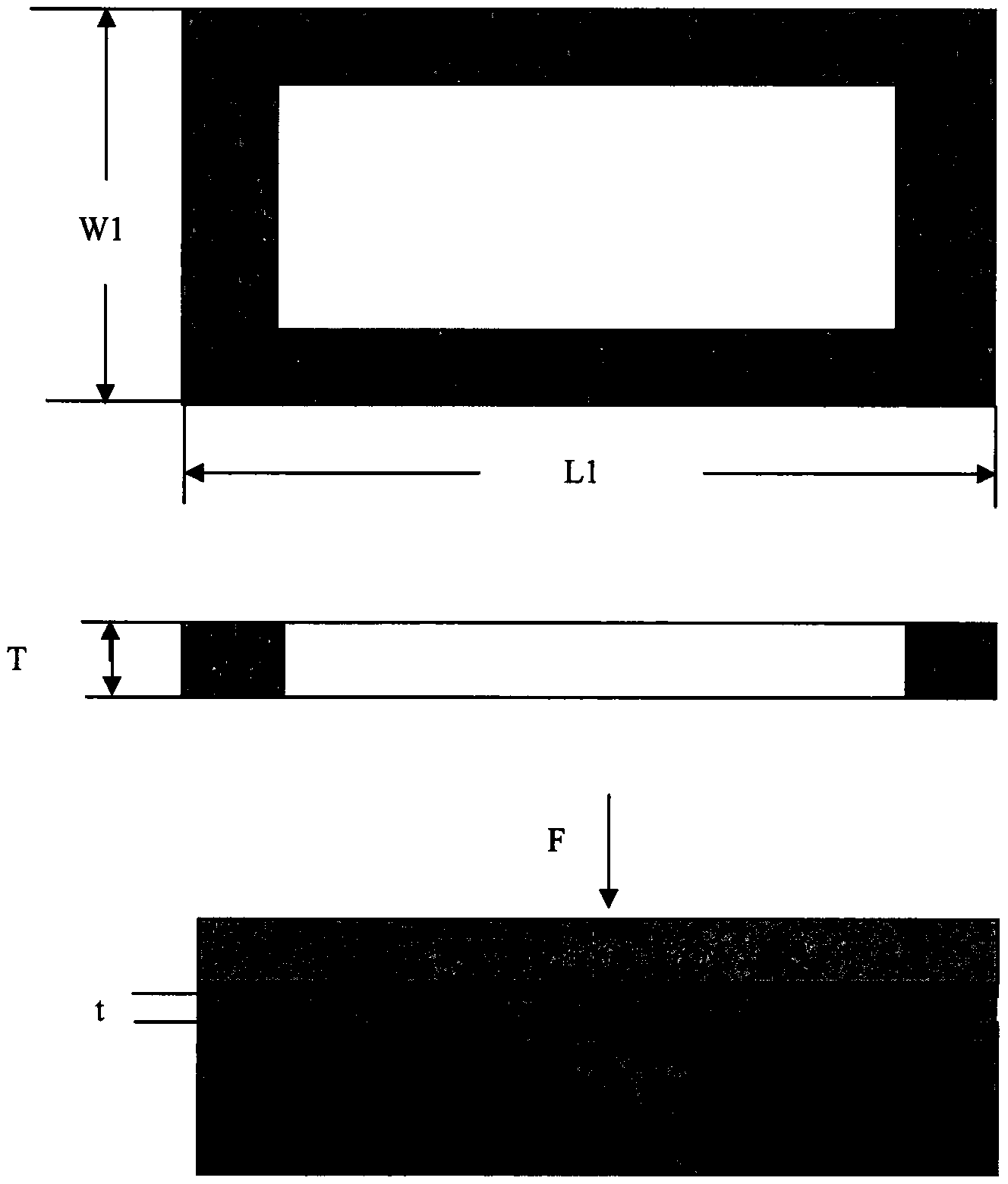

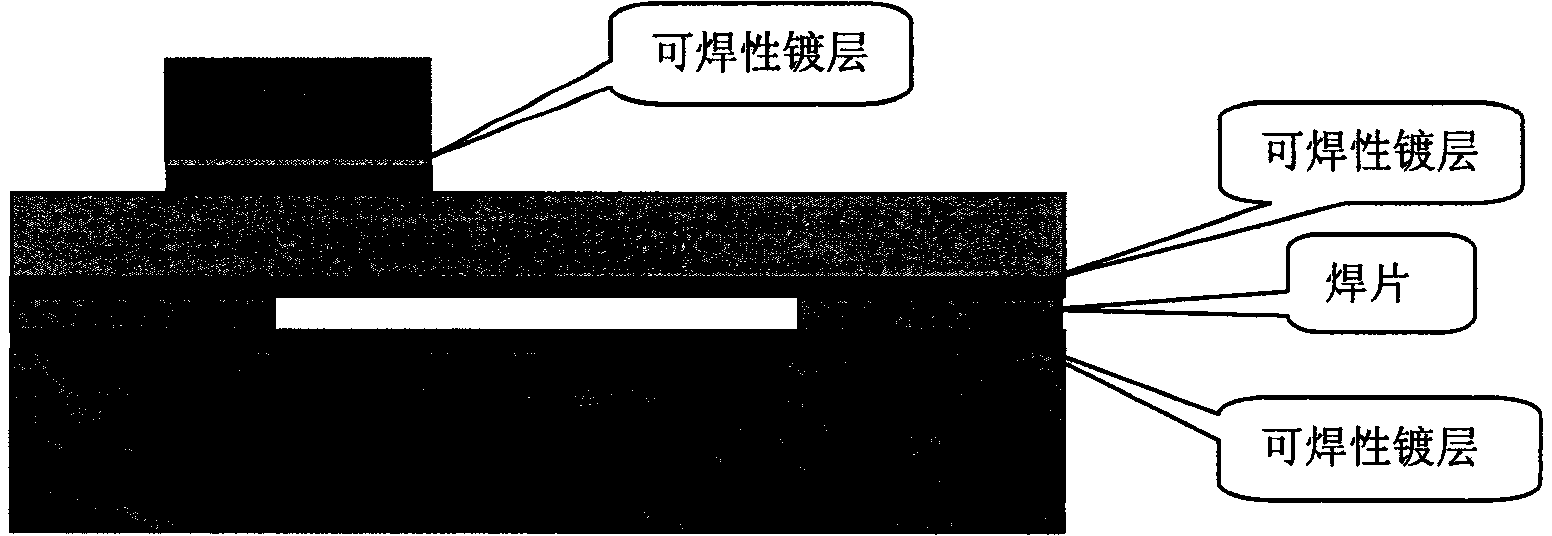

A high brazing rate vacuum welding method based on plasma cleaning

ActiveCN106134330BFast heat conductionEfficient removalWelding/cutting media/materialsSoldering mediaRoom temperatureSoldering

A high brazing rate vacuum welding method based on plasma cleaning, the steps are as follows: (1) plasma cleaning the solder sheet; The shape of the parts is the same, and the middle is hollowed out to form a gasket shape; (3) The welded workpiece, the solder piece, and the carrier are superimposed together in sequence, and a certain weight of tooling is added to exert pressure on the welded workpiece; (4) The superimposed good The workpiece is placed on the heating platform at room temperature, and the heating platform is placed in the vacuum furnace cavity, and the vacuum is started until the vacuum degree is less than 100Pa. At this time, the temperature of the solder piece is at room temperature; (5) The heating platform preheats the workpiece, and keep warm; (6) continue heating until the melting point of the solder sheet is 30-40°C above, and keep warm; (7) backfill the vacuum furnace cavity with the atmosphere, so that the air pressure in the cavity where the workpiece is located returns to atmospheric pressure; (8) cool down until the solder Below the melting point of the sheet, the welding is completed.

Owner:BEIJING SATELLITE MFG FACTORY

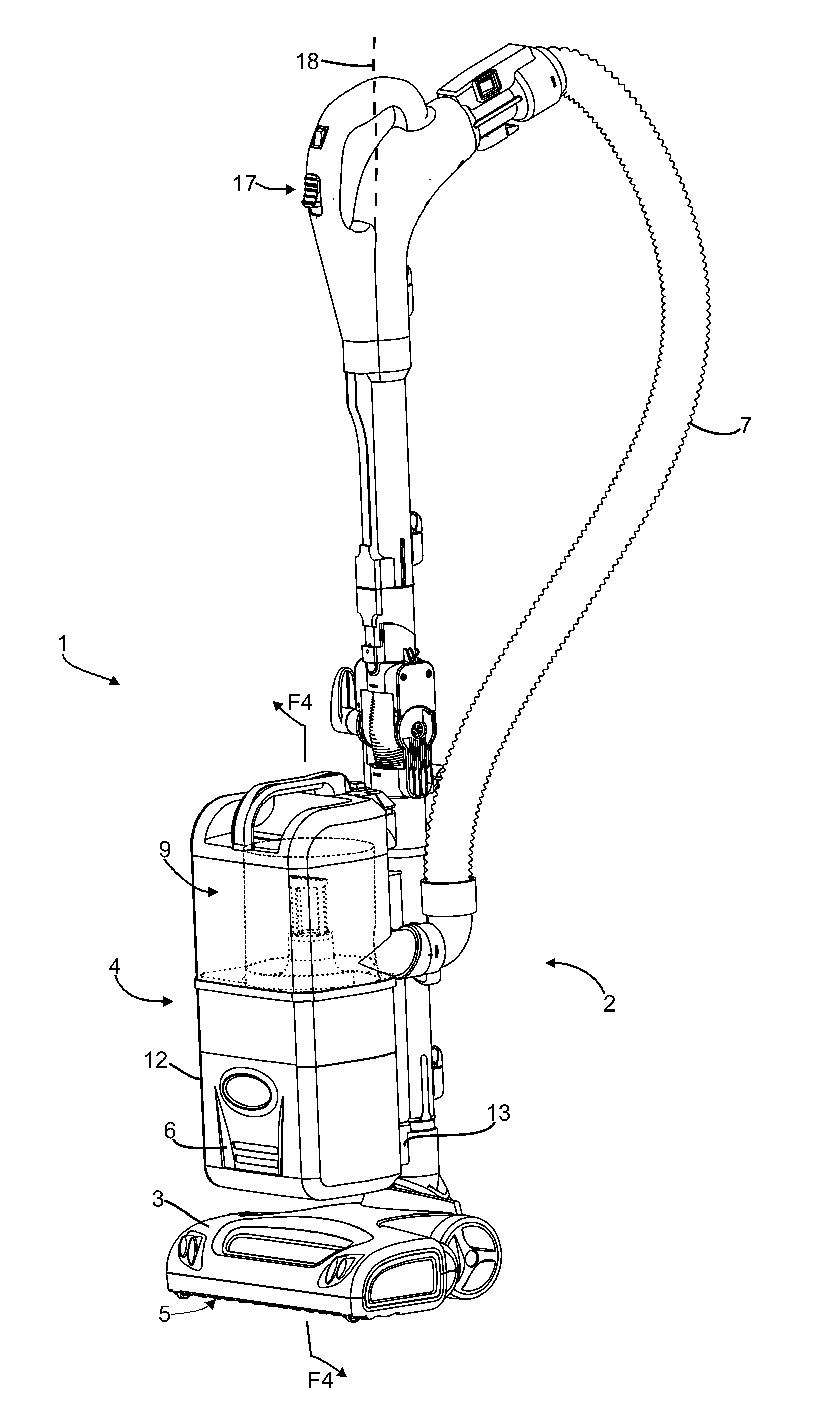

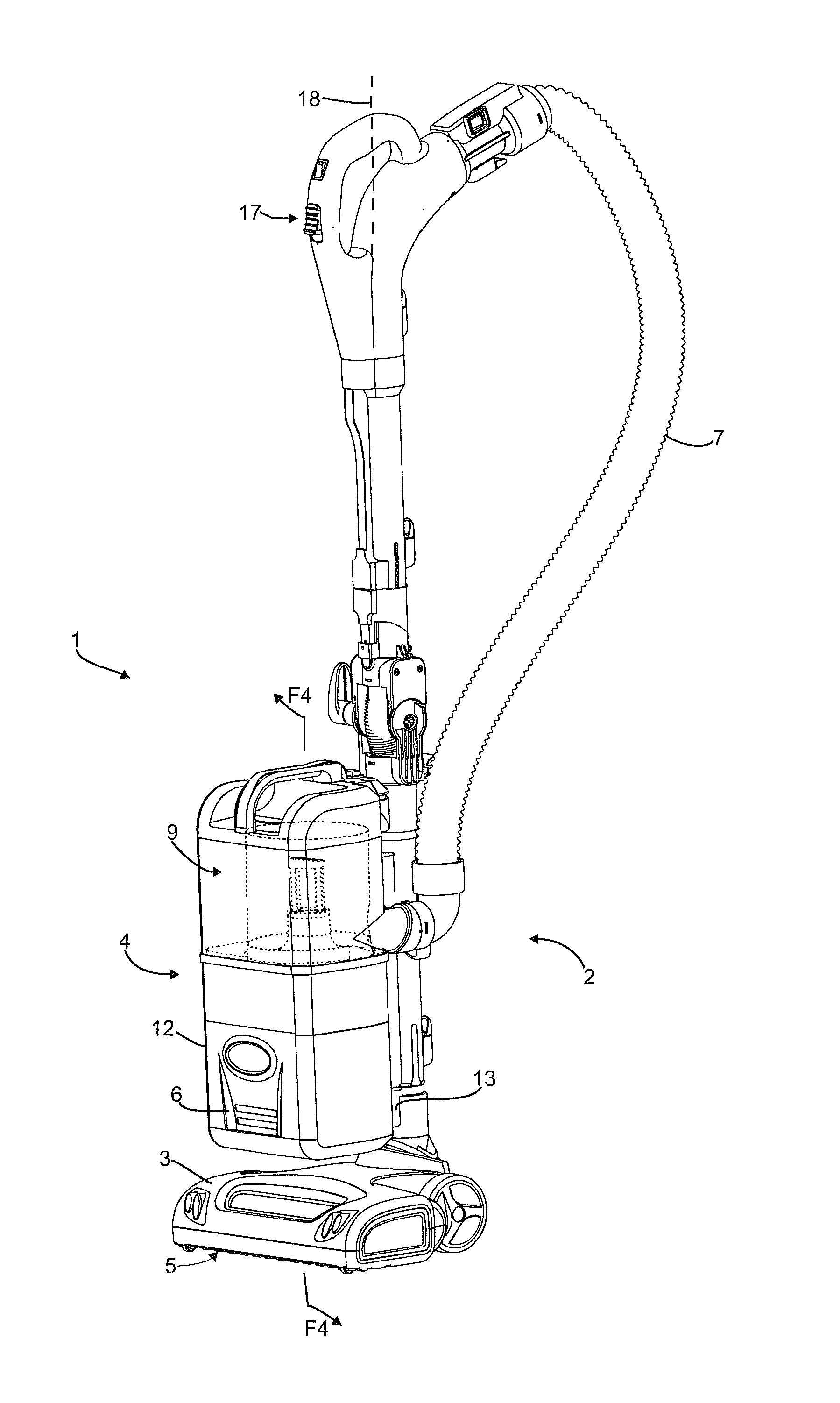

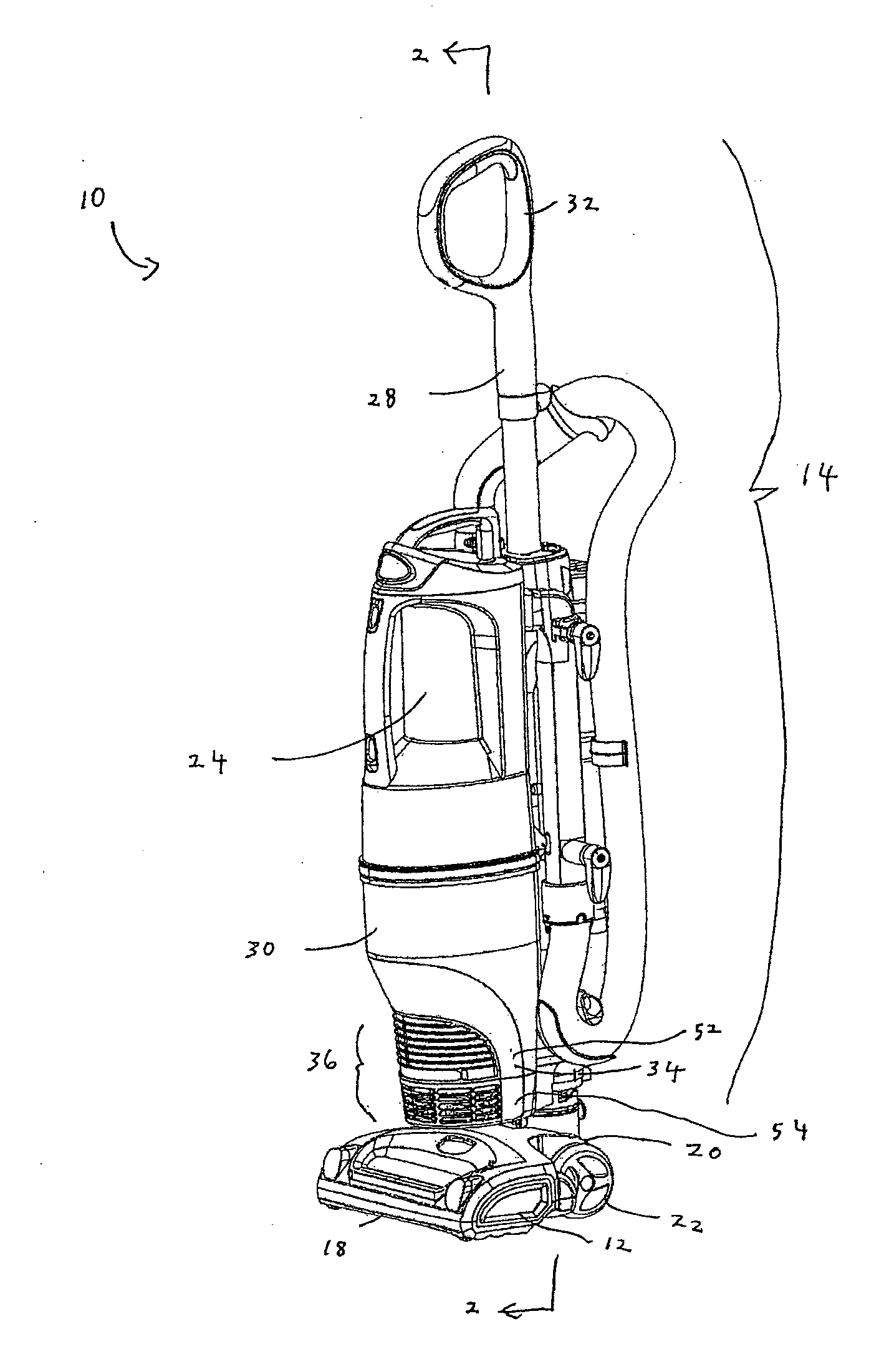

Surface cleaning apparatus with openable filter compartment

ActiveUS20150026915A1Reduce air velocityReduce performance of vacuumCleaning filter meansSuction filtersSurface cleaningEngineering

An upright surface cleaning apparatus is provided wherein the upper section is provided with an openable post motor filter housing. The post motor filter may be axially removable and may be positioned below the suction motor.

Owner:OMACHRON INTPROP

Drying method and drying device for supercapacitor

InactiveCN103745840AImprove drying efficiencyService life is not affectedDrying/impregnating machinesSupercapacitorNitrogen

The invention relates to the capacitor manufacture field, and is to provide a drying method and drying device for a supercapacitor. The drying method for the supercapacitor comprises the following steps: (1) putting the supercapacitor to a drying chamber arranged in a drying furnace; (2) extracting the air in the drying chamber until the vacuum degree is lower than 1 pa; (3) filling nitrogen to the drying chamber; (4) heating the drying furnace for 2-5 hours until the temperature reaches 120-200 DEG; (5) extracting the nitrogen in the drying chamber until the vacuum degree is lower than 1 pa; (6) keeping the vacuum degree in the drying chamber to be lower than 1 pa, and meanwhile, holding the temperature of the drying furnace to be 120-200 DEG for 5-10 hours and performing drying; and (7) filling the nitrogen into the drying chamber, opening the drying furnace and the drying chamber, and taking out the supercapacitor which has been dried. The drying efficiency of the drying method for the supercapacitor is high; the drying effect is good without influencing the service life; and the drying device of the drying method for the supercapacitor is simple in structure and is capable of satisfying the drying requirements.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

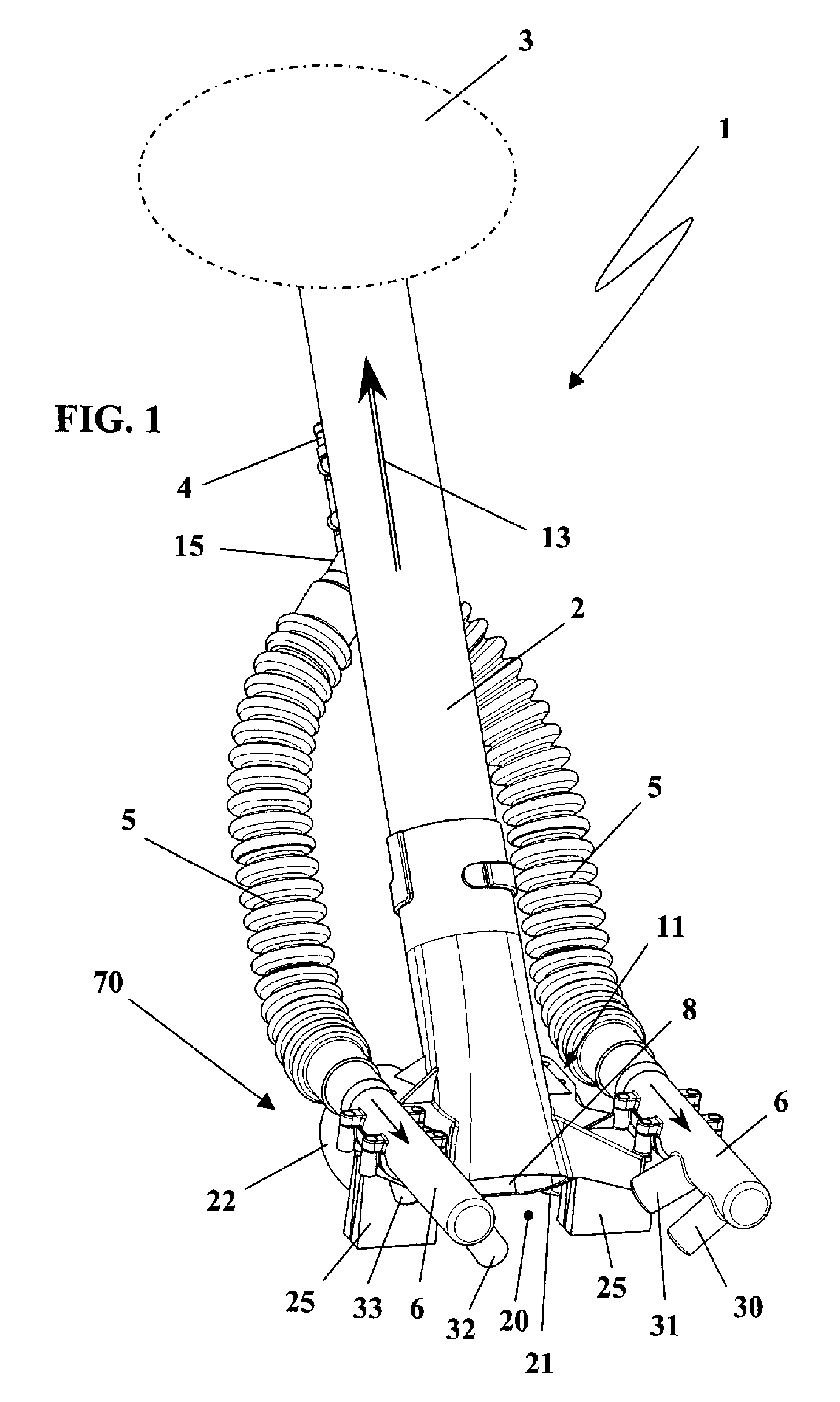

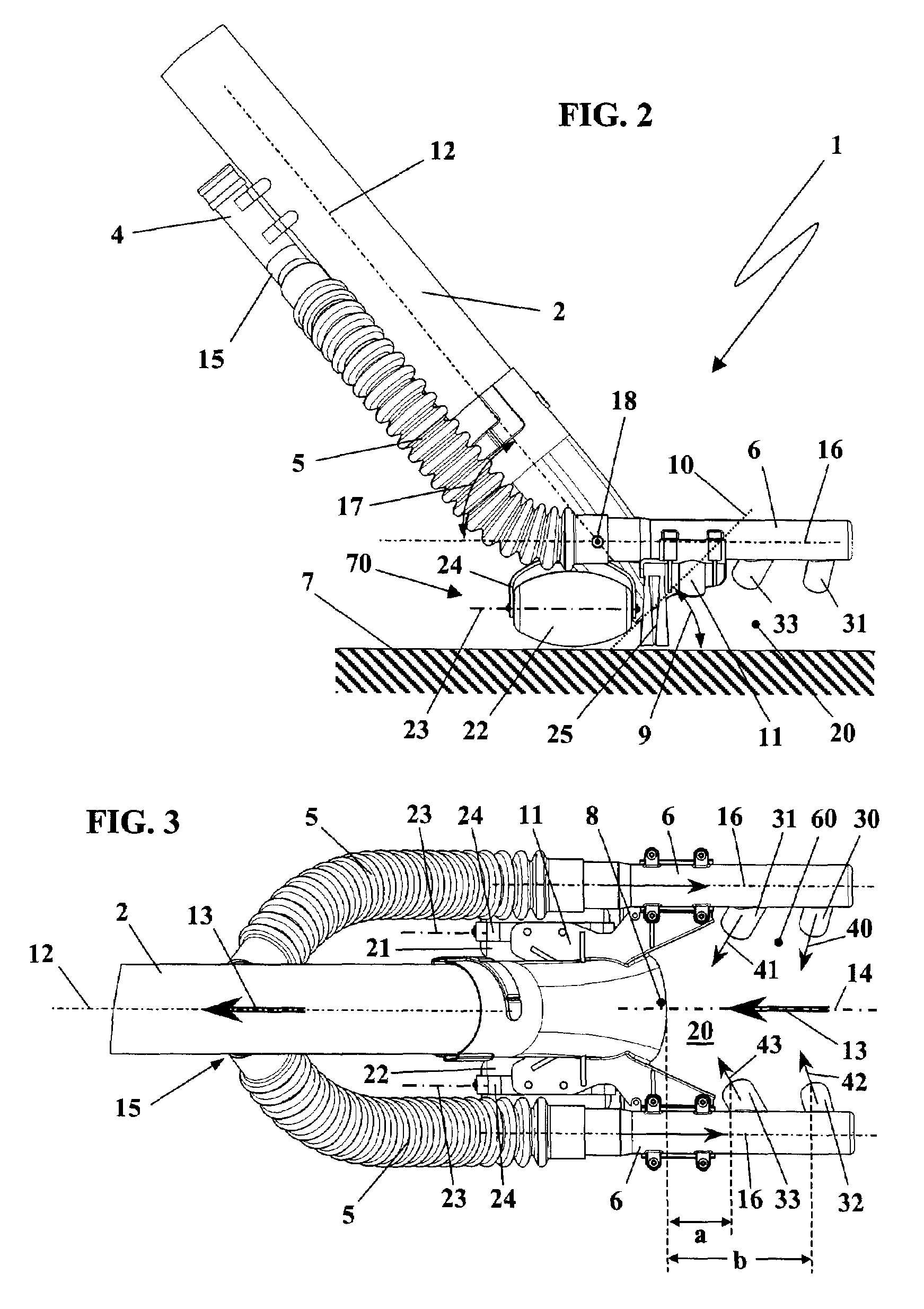

Vacuum arrangement for a ground area

InactiveUS7441304B2Easy to fillImprove vacuum efficiencySuction cleanersHarvestersEngineeringVacuum tube

A vacuum arrangement has a vacuum pipe having a vacuum opening facing a ground surface and adapted to pick up from the ground surface a material to be collected. The vacuum pipe conveys the material to be collected into a collecting container connected to the vacuum pipe. The vacuum pipe has a working area located within the area of the vacuum opening. At least one blower nozzle having a blower air exit is arranged such that a blower air flow exiting from the blower air exit is directed onto the ground surface into the working area. The blower air exit and the vacuum opening are positioned at a spacing relative to one another.

Owner:ANDREAS STIHL AG & CO KG

Electronic vacuum pump for brake vacuum booster of new energy vehicles

ActiveCN103306979BImprove vacuum efficiencyIncrease air intakeMachines/enginesPumpsNew energyPump chamber

The invention discloses an electronic vacuum pump for a new energy vehicle brake vacuum booster. The electronic vacuum pump comprises a motor assembly, a supporting base, a pump chamber lower cover, a driving sleeve, a pump rotor, blades, a pump chamber, a pump chamber upper cover, a pump body cover and fixing pins, wherein a left side air feeding slot of the pump chamber lower cover, a left side air feeding through hole of the pump chamber and a left side air feeding slot of the pump chamber upper cover are communicated with one another to form an air passageway; a right side air feeding slot of the pump chamber lower cover, a right side air feeding through hole of the pump chamber and a right side air feeding slot of the pump chamber upper cover are communicated with one another to form an air passageway; a flow guide slot of the pump chamber lower cover is communicated with an inner cavity of the pump chamber; an air discharging slot of the pump chamber upper cover is communicated with the inner cavity of the pump chamber; the flow guide slot of the pump chamber lower cover and the air discharging slot of the pump chamber upper cover are symmetric. When the vacuum pump works, an air path with four air inlets and two air outlets is formed; therefore, the air feeding resistance is greatly reduced, and the air feeding amount of the pump chamber is increased; under the equal energy consumption, the vacuumizing efficiency of the vacuum pump provided by the invention is higher.

Owner:常州市东南电器电机有限公司

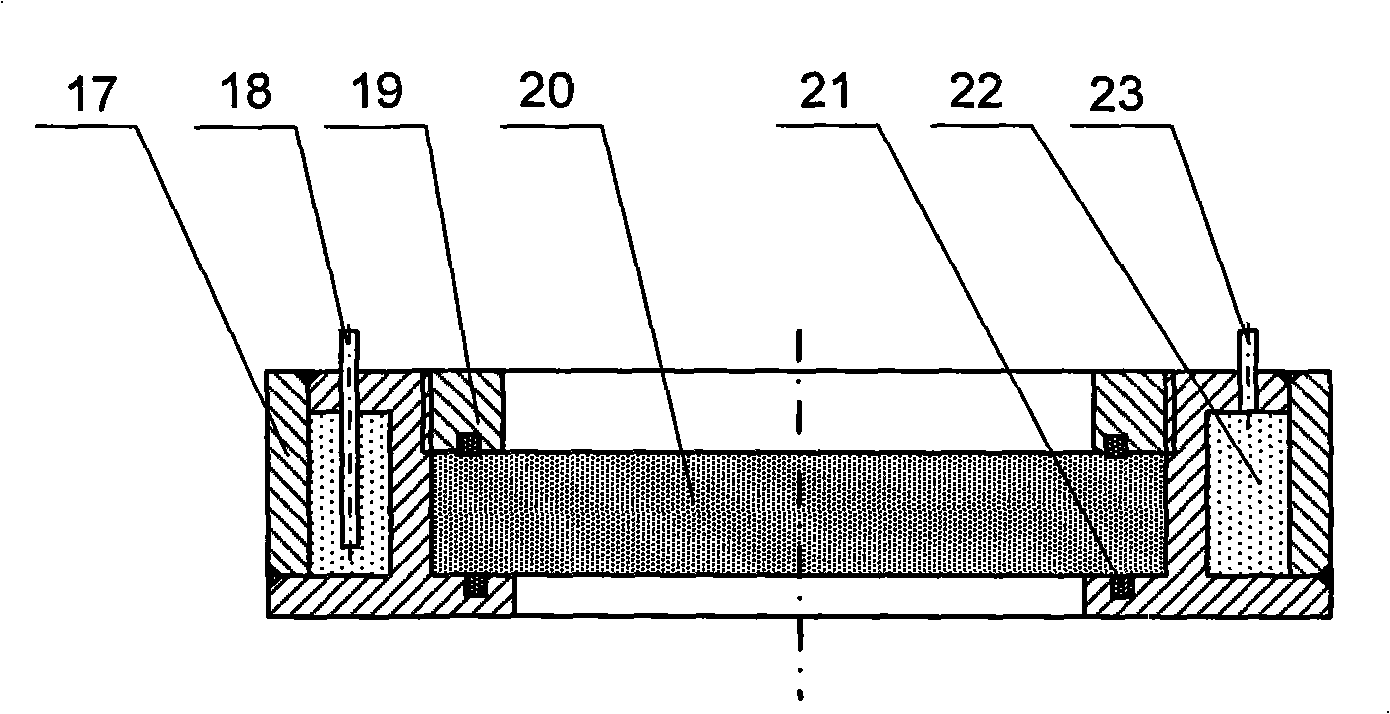

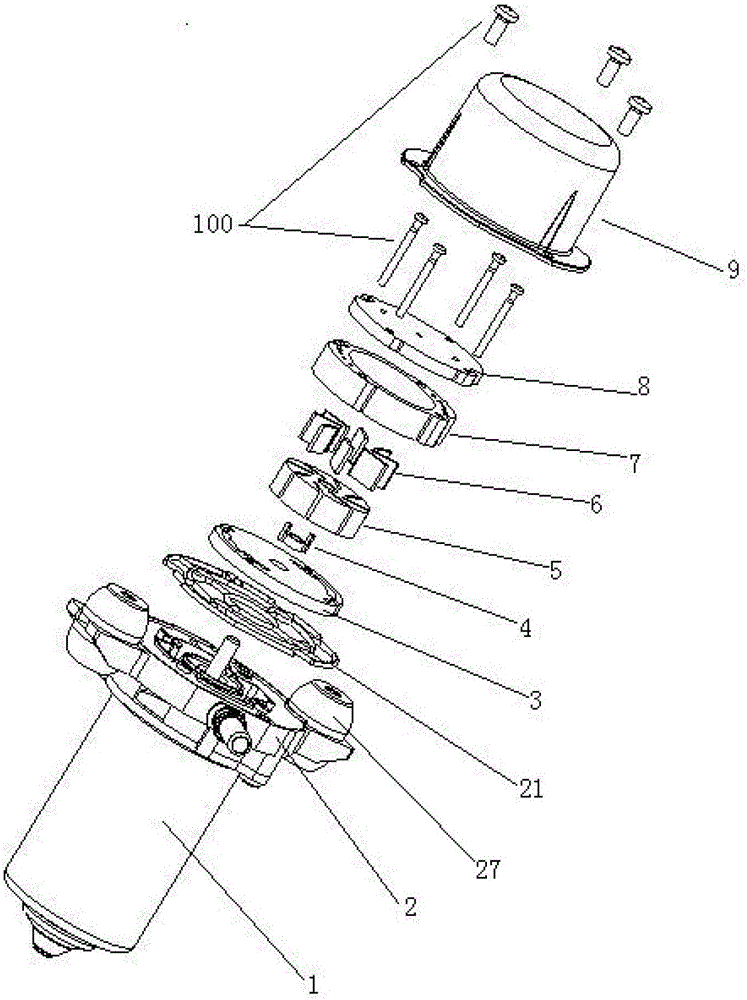

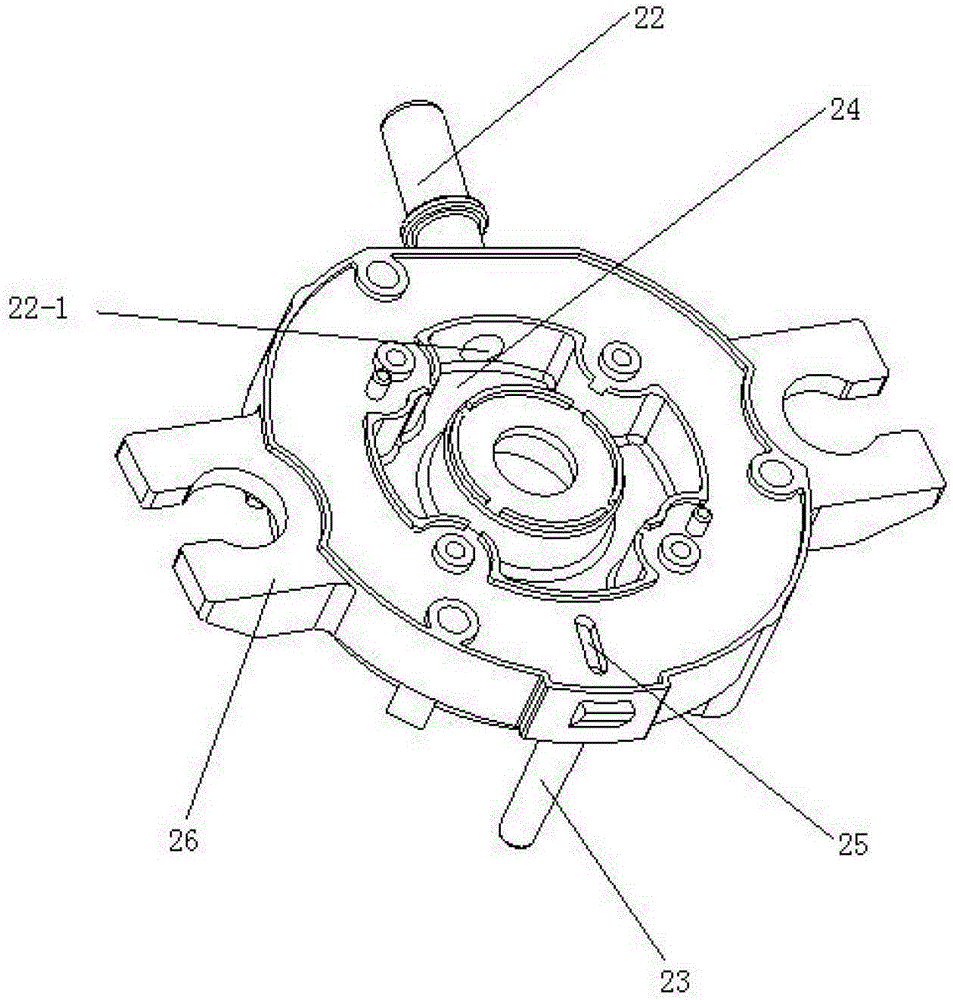

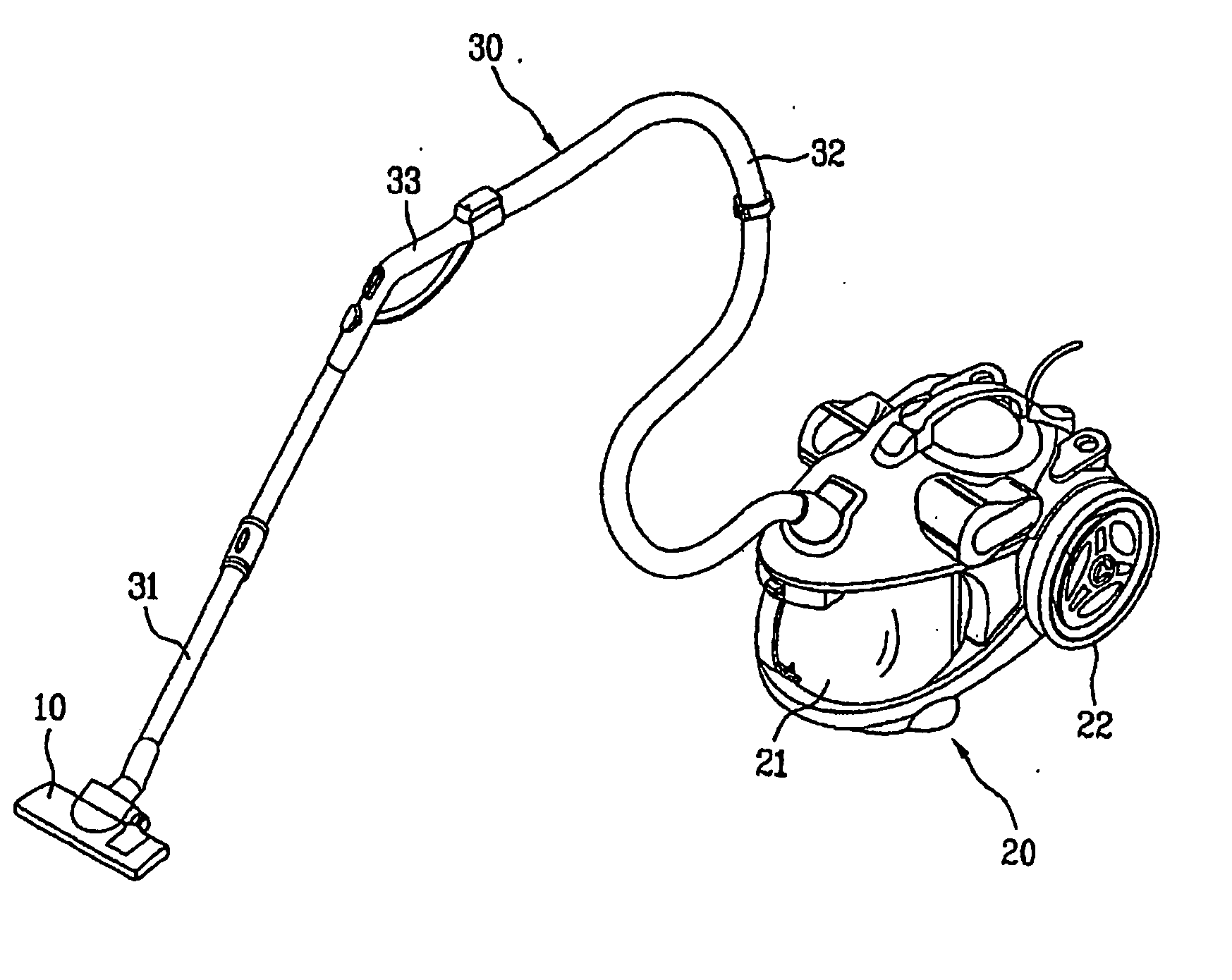

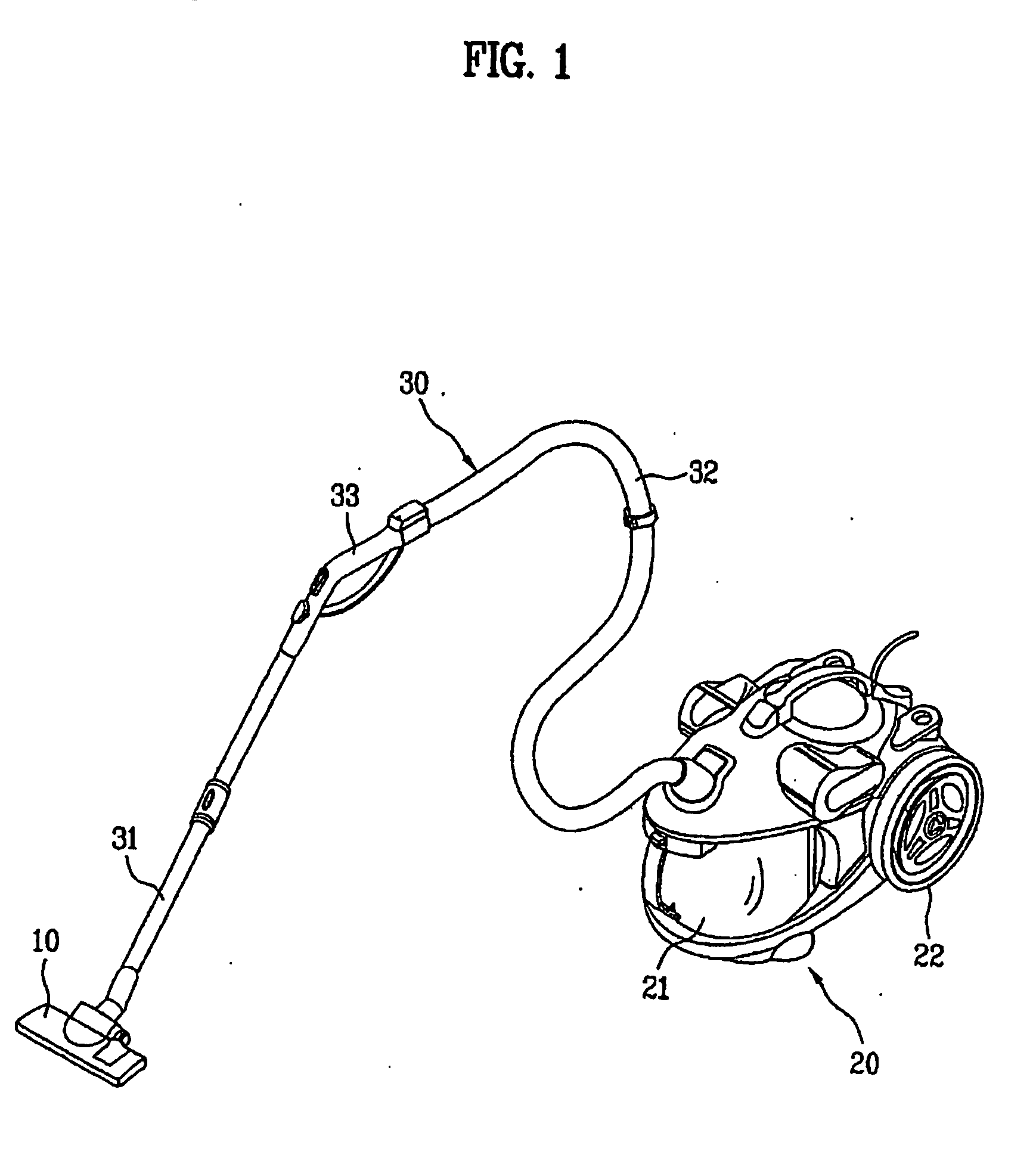

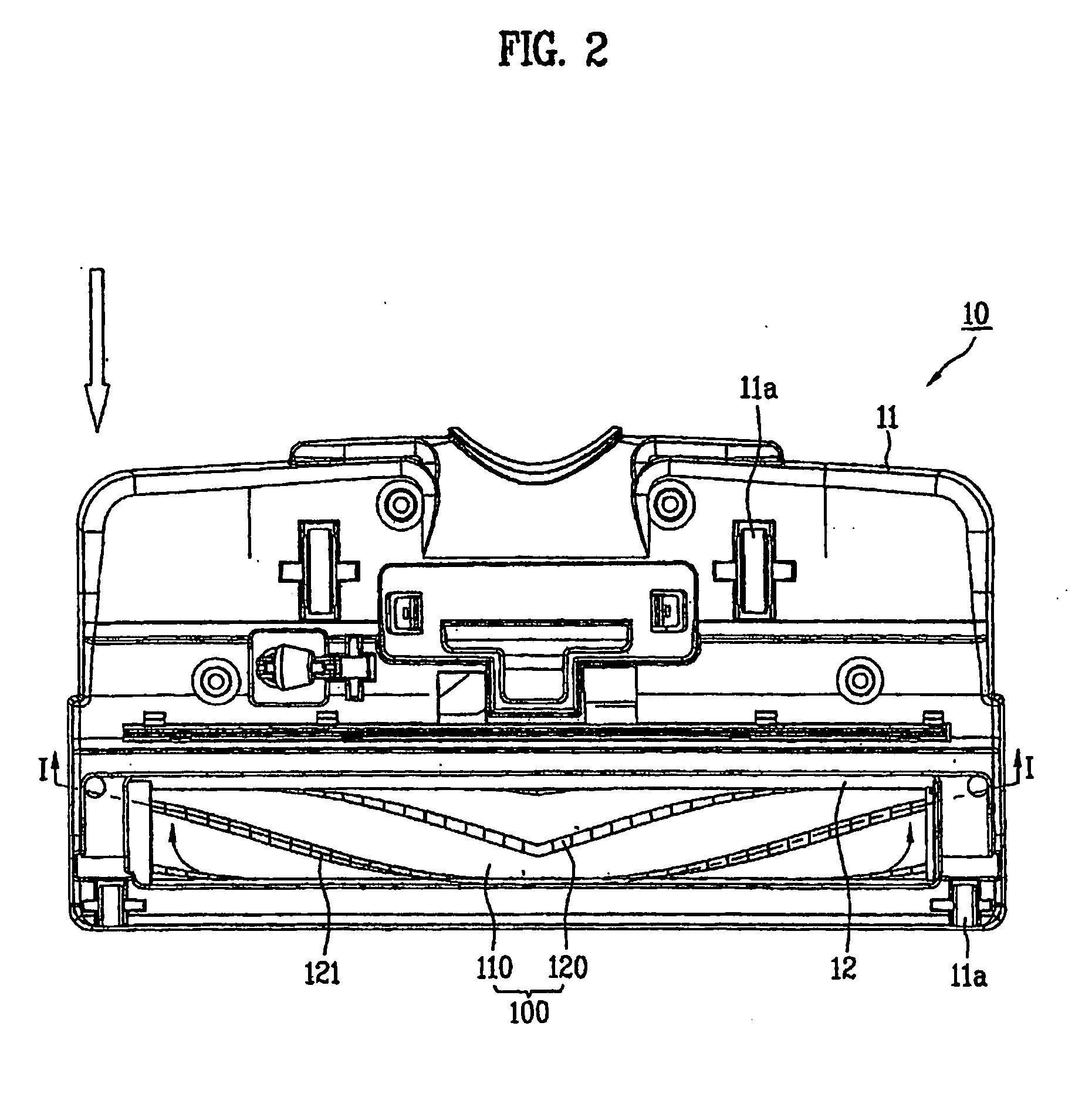

Agitator For Suction Nozzle In Vacuum Cleaner

InactiveUS20080086837A1Effectively in and surfaceImprove vacuum efficiencyBrush bodiesSuction nozzlesKnife bladesVacuum cleaner

An agitator (100) for a suction nozzle (10) in a vacuum cleaner is disclosed for largely improving efficiency of the vacuum cleaner, the agitator (100) including a body rotatably provided at an inlet (12) of the suction nozzle (10), and at least one blade assembly (120) including a plurality of blades (121) configured to come in contact with a surface to be cleaned, and mounted at the body (110) along a length direction thereof.

Owner:LG ELECTRONICS INC

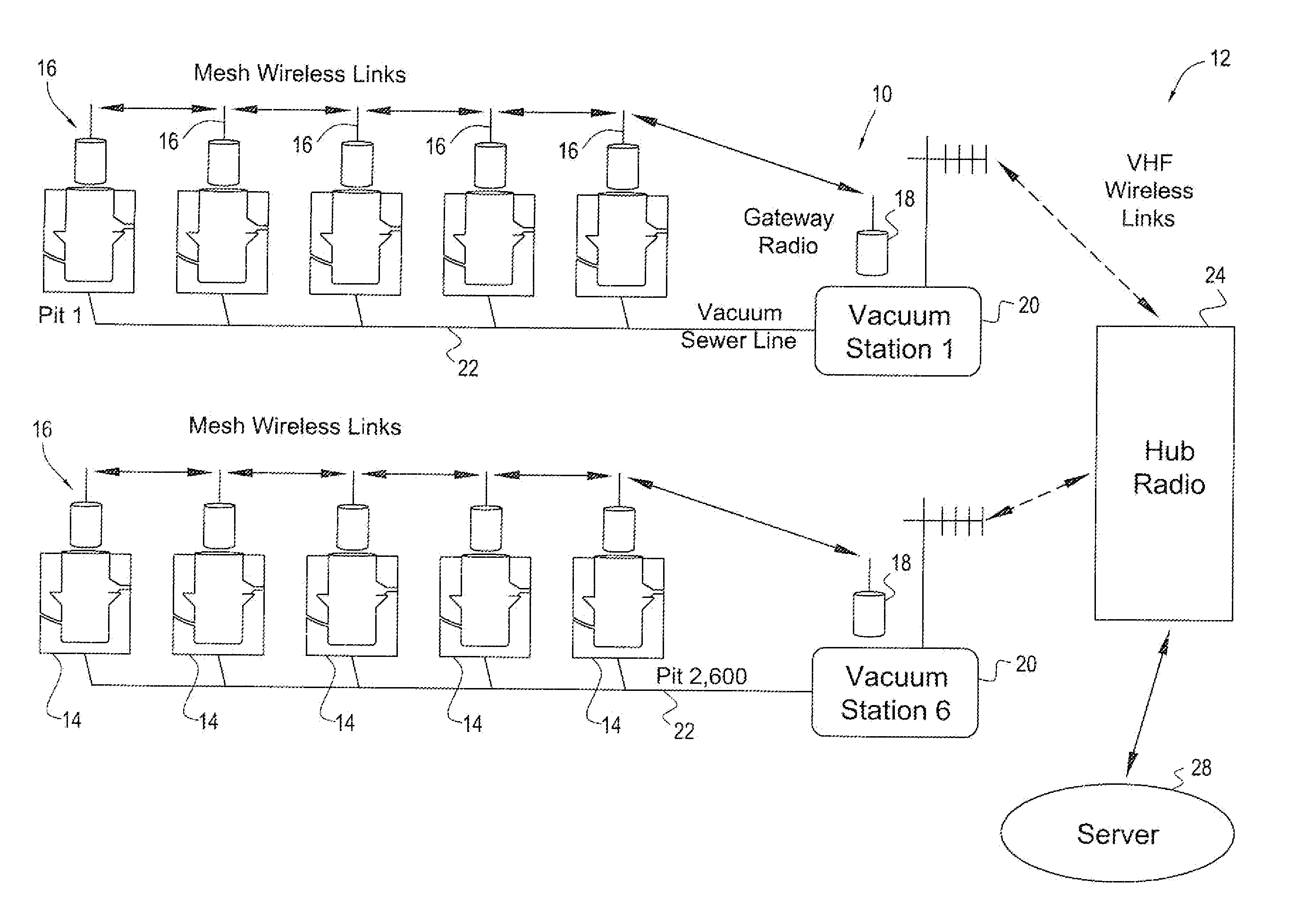

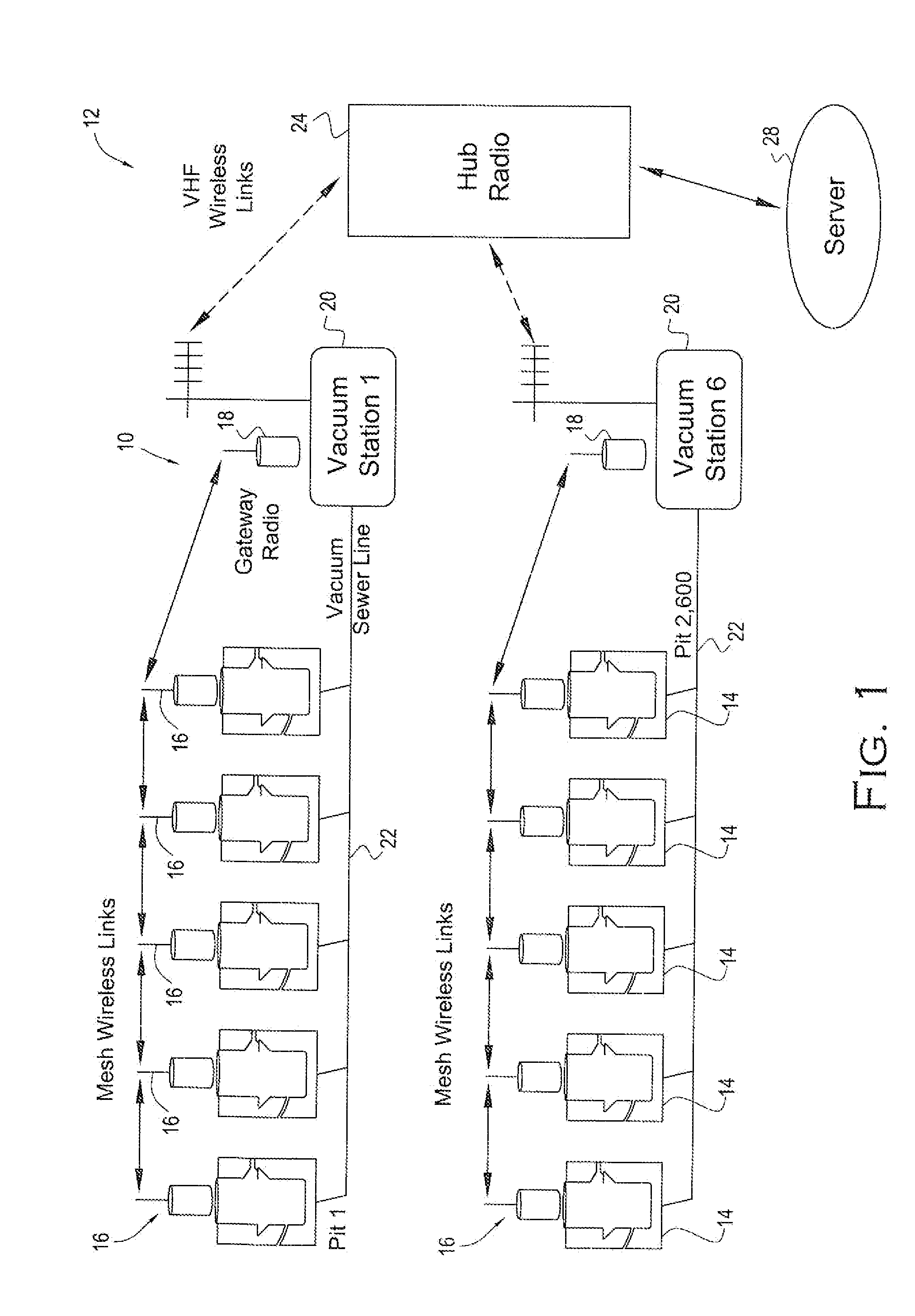

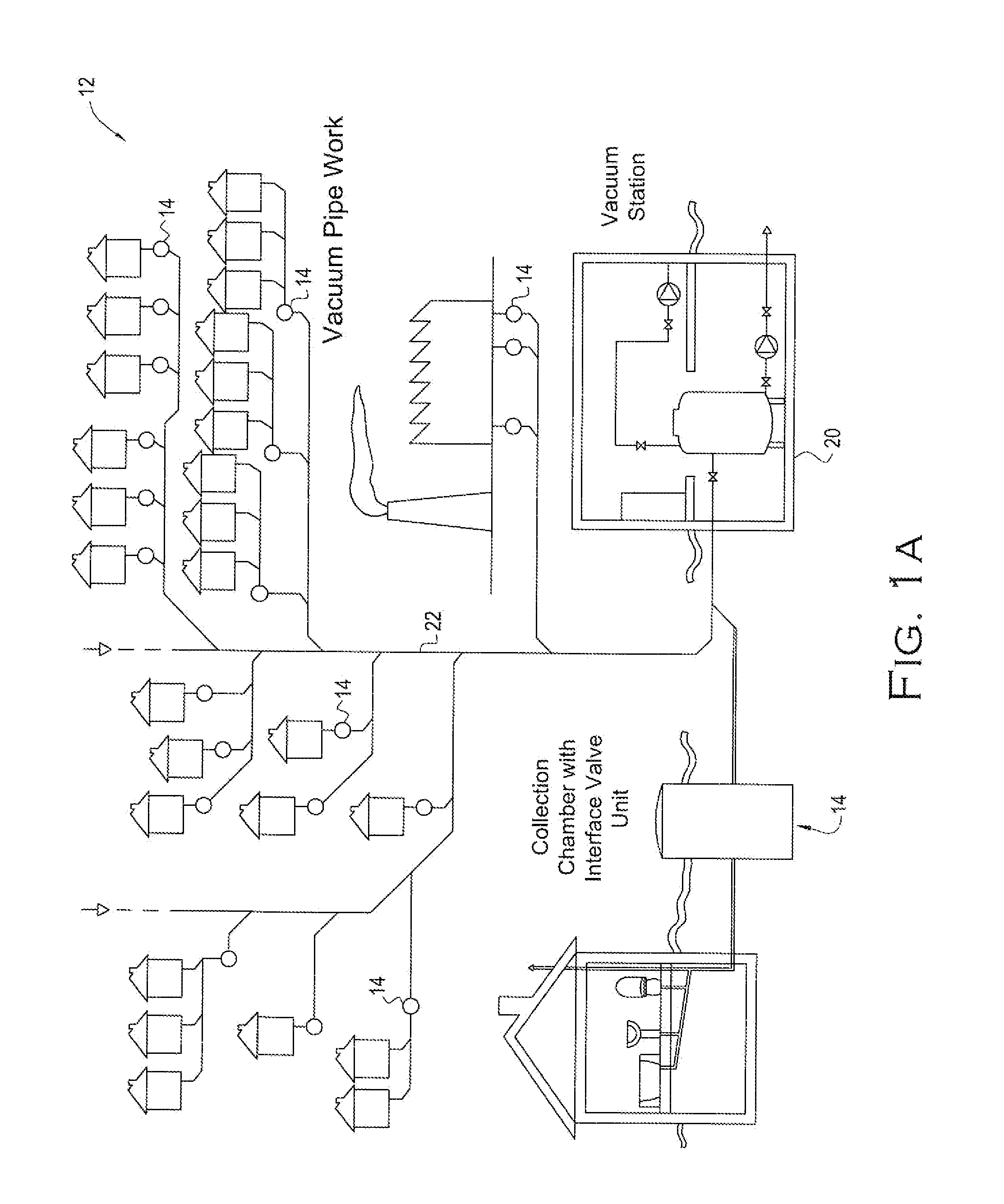

Valve malfunctioning detection system for a vacuum sewer and associated methods

ActiveUS20110205055A1Decreased maintenance costReadily identifyProgramme controlValve arrangementsVacuum sewerRadio unit

A valve malfunctioning detection system for use in a vacuum sewer system including a vacuum pit in fluid communication with a vacuum station is provided. The vacuum pit includes a vacuum sewer valve that is moveable between an opened position and a closed position. The valve malfunctioning detection system may include a radio unit adapted to be carried by the vacuum pit, a gateway radio in communication with the radio unit, a hub radio in communication with the gateway radio to receive a signal transmitted by the gateway radio, and a server in communication with the hub radio. The signal transmitted by the radio unit may include an indication of a status of the vacuum sewer valve.

Owner:DATA FLOW SYST

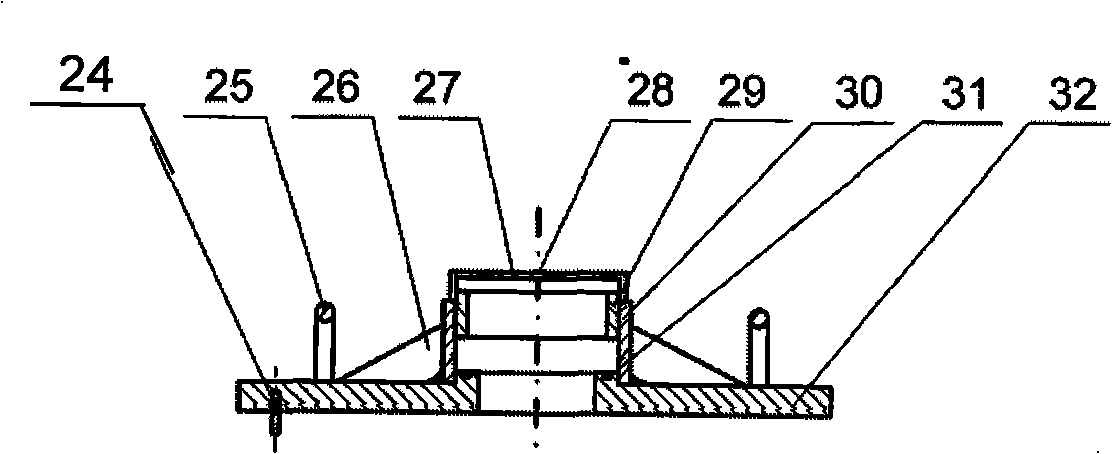

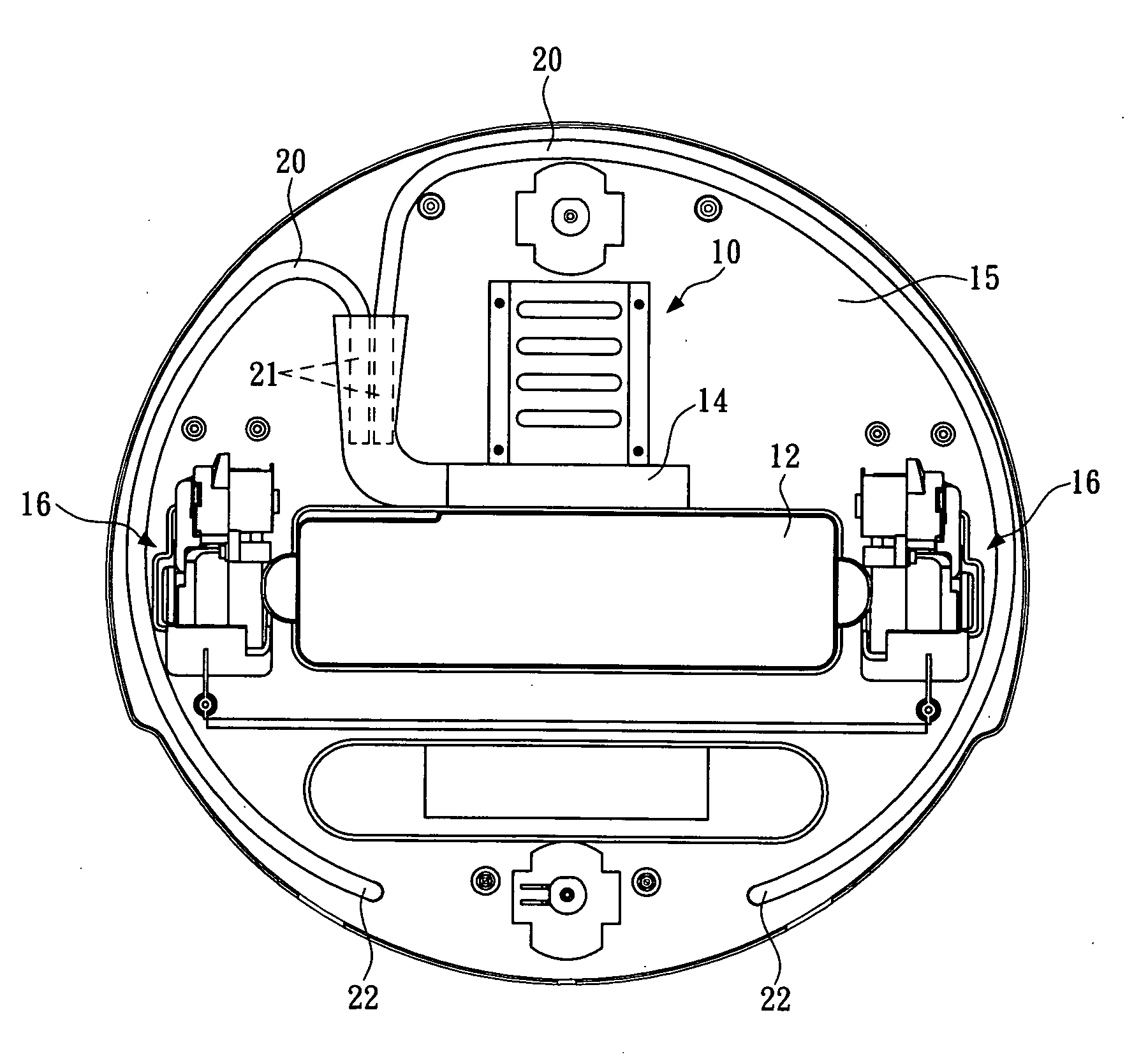

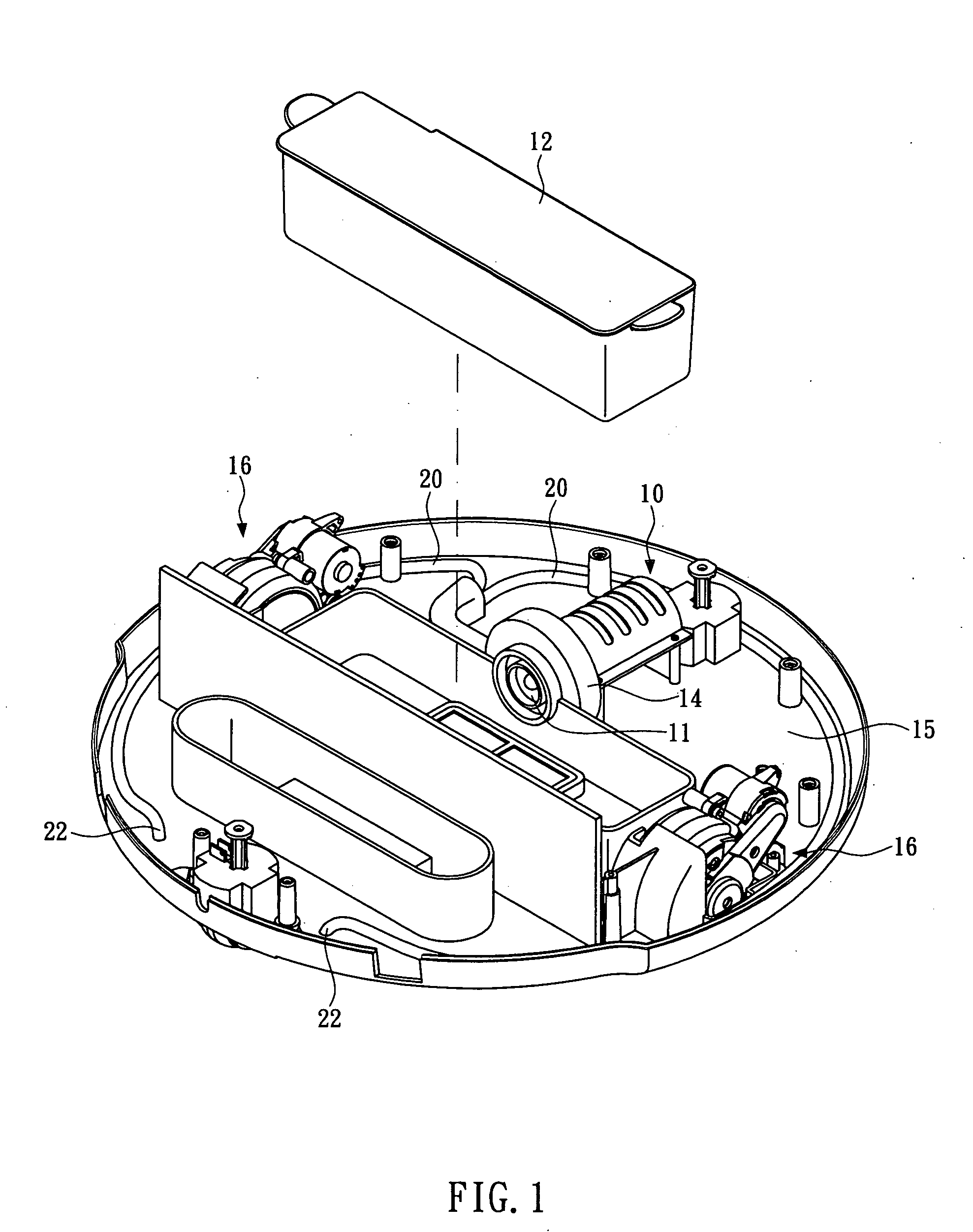

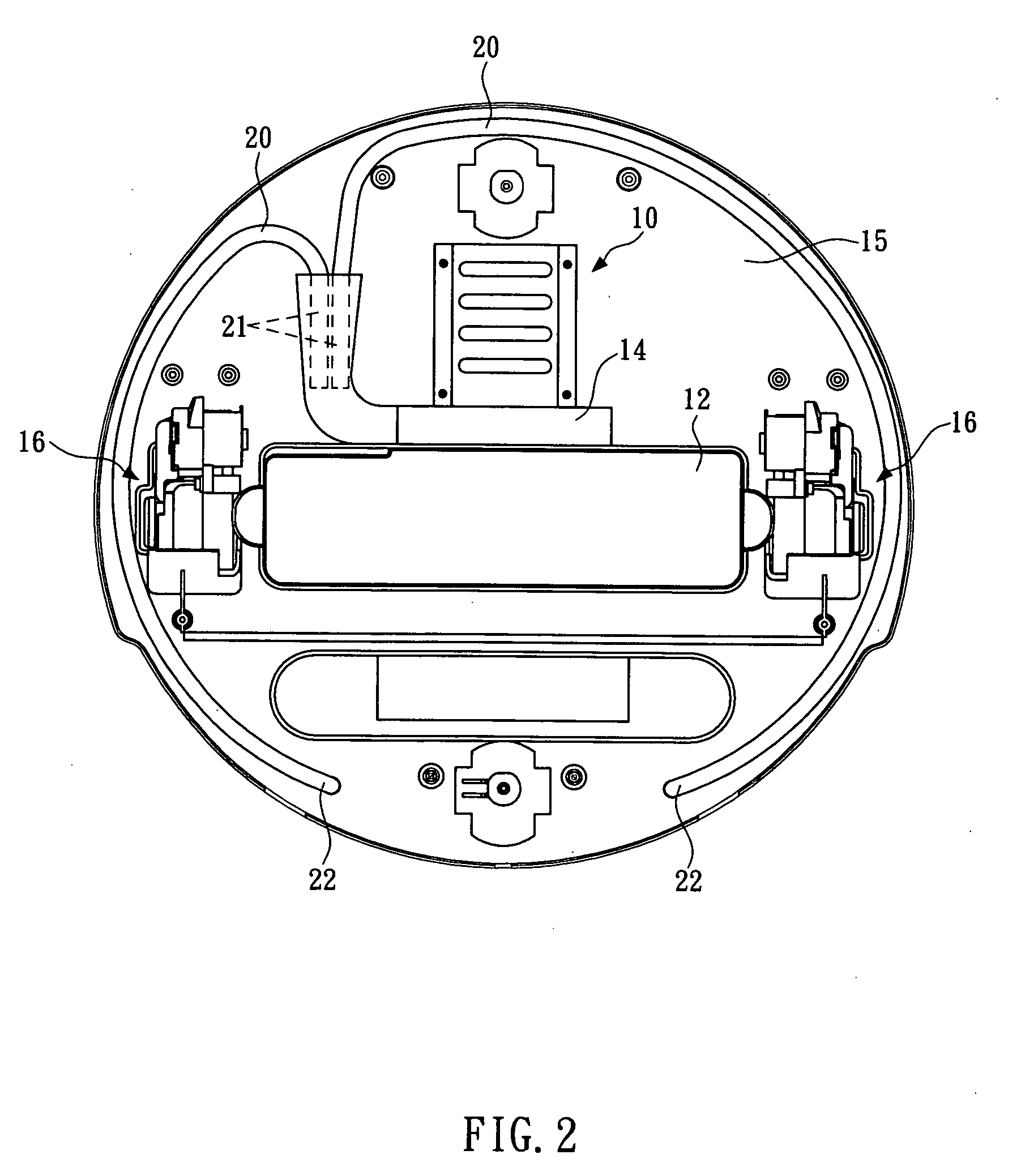

Dust-collecting auxiliary device for vacuum cleaner

InactiveUS20080092324A1Increase areaImprove vacuum efficiencySuction nozzlesCleaning equipmentAerospace engineeringVacuum cleaner

A dust-collecting auxiliary device is equipped on a vacuum cleaner that comprises at least a motor, a fan, a dust-collecting chamber, a suction inlet, and a driving device. Said dust-collecting auxiliary device includes at least one air pipe of which an air inlet at one end is fixed in a fan container of said fan and an air outlet is placed at the lower surface of the bottom cover of the vacuum cleaner in to the neighboring-front the suction inlet, at least two wings wherein each wing with one end fixed at the one side of the suction inlet, while the other end thereof extended forward and outward to give an increasing distance from another wing.

Owner:GUTEN ELECTRONICS INDAL

Weak-atmosphere environment laser welding device and method

PendingCN111633328AReduce vacuum timeImprove welding efficiencyLaser beam welding apparatusShielding gasDust control

The invention discloses a weak-atmosphere environment laser welding device and method. The method comprises the following steps that S1, a to-be-welded workpiece is placed into a working cabin, a gasstorage device and an exhaust device are protected, and the atmosphere environment inside the working cabin forms the protective gas atmosphere under low vacuum; S2, a gas circulation device is turnedon, a welding head emits laser and penetrates through a light transmitting lens arranged on the surface of the working cabin, the to-be-welded workpiece is welded, and after welding, the workpiece istaken out. Within a short period of time, the weak-atmosphere environment applicable to laser welding is achieved, the traditional mode of achieving laser welding environment through vacuumizing is changed, the vacuumizing time is shortened, and the welding efficiency is improved. Gas circular purification under the weak atmosphere environment is achieved, dust removal and purification are performed on smoke and dust inside the working cabin in time, and long-time operation and high-quality welding in the laser welding process are ensured.

Owner:武汉光谷航天三江激光产业技术研究院有限公司

Cathode arc target device and vacuum multi-arc ion plating machine

PendingCN107557735AEasy maintenanceSolution to short lifeVacuum evaporation coatingSputtering coatingEngineeringIon plating

The invention discloses a cathode arc target device and a vacuum multi-arc ion plating machine. The cathode arc target device comprises an arc target body, a target material, an arc striking system, asliding rod, a sliding sealing mechanism and a sliding cylinder, wherein the target material is installed on one side of the arc target body, the sliding rod is installed at one end of the arc targetbody in a sliding manner, the sliding cylinder is connected with the sliding rod, and the arc striking system is driven to be close to or far away from the target material through the sliding rod; and the sliding sealing mechanism is arranged outside the sliding rod and used for conducting vacuum sealing on the sliding rod, the sliding sealing mechanism comprises a bellows and a bellows frame body which is installed on the arc target body, and the two ends of the bellows are welded to the bellows frame body. The cathode arc target device is good in sealing performance, not prone to being subjected to vacuum leakage, easy to maintain, long in service life, simple in structure, reliable and practical.

Owner:东莞市典雅五金制品有限公司

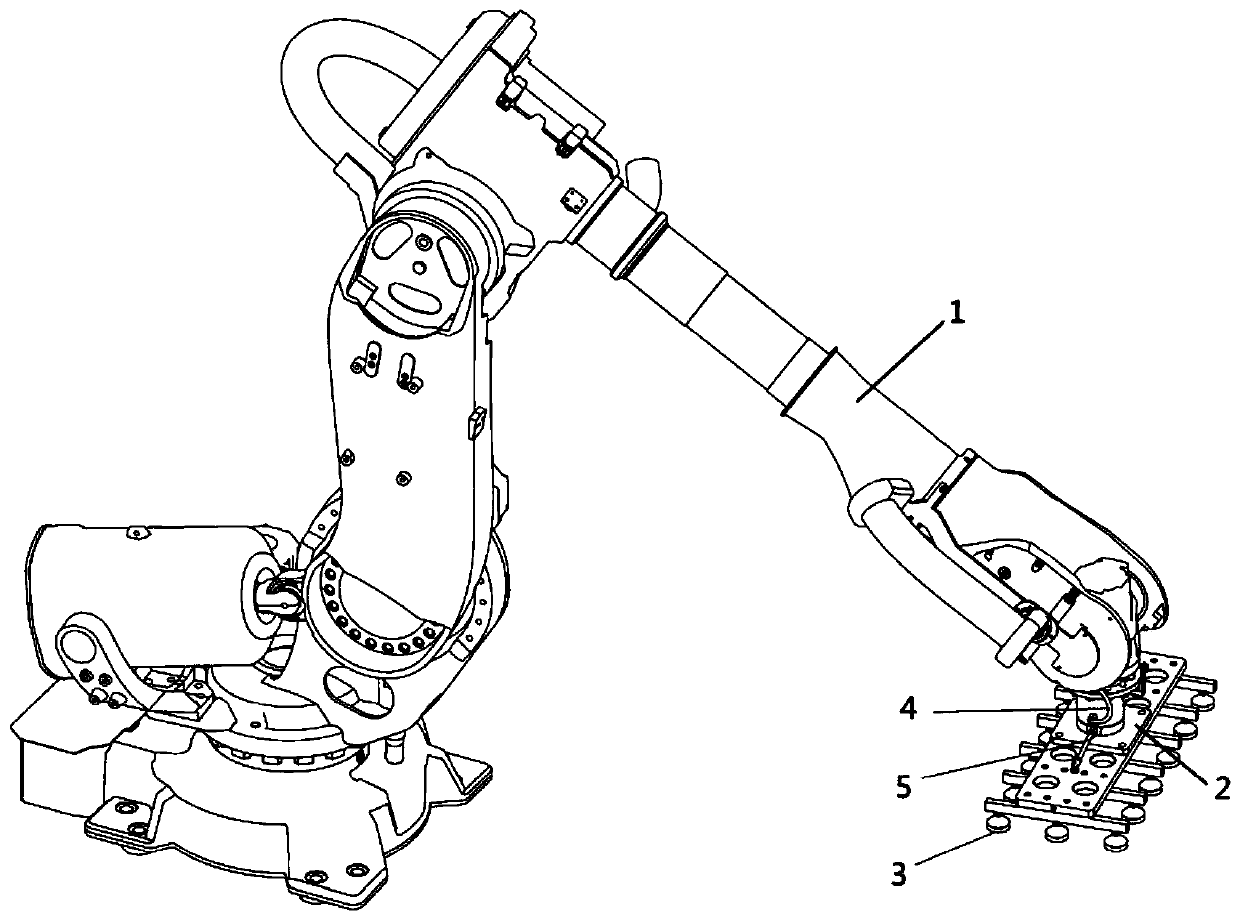

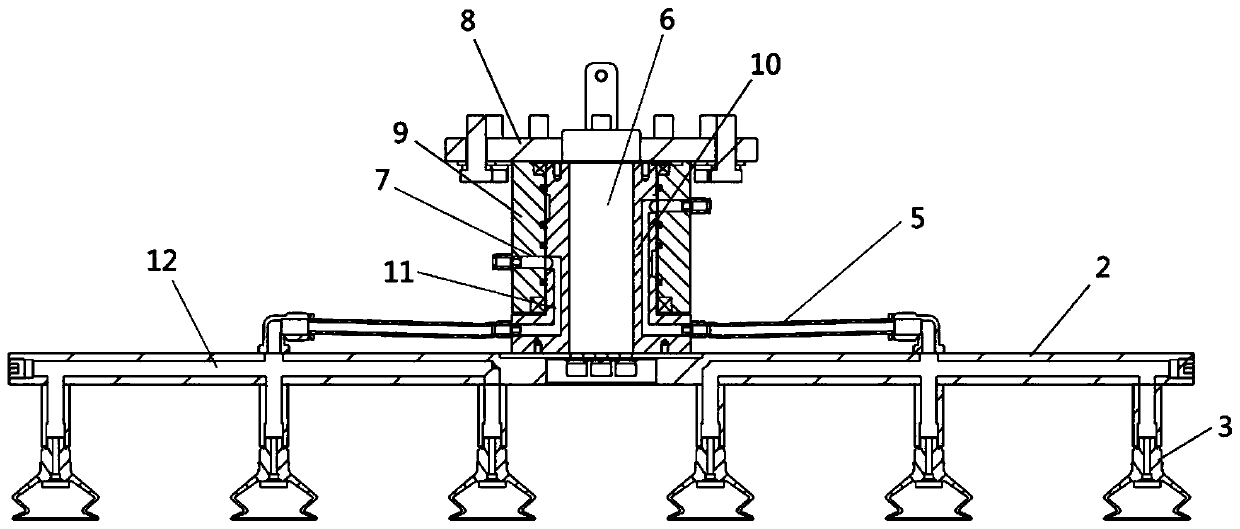

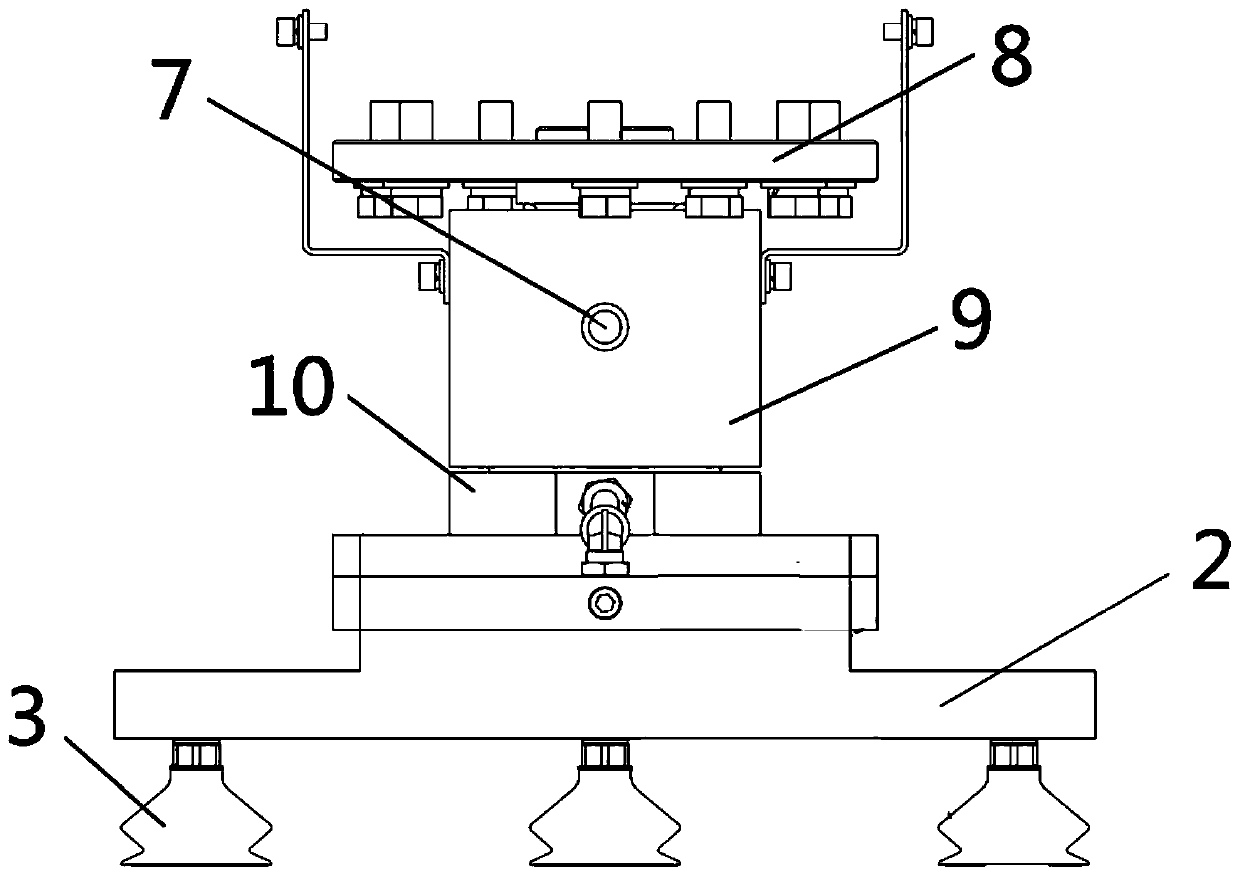

Mechanical arm rotating sucker conveying device

The invention relates to the technical field of conveying devices, in particular to a mechanical arm rotating sucker conveying device. The mechanical arm rotating sucker conveying device comprises a mechanical arm main body, a sucker assembly, an air pipeline assembly and a first air pipe, wherein the sucker assembly comprises a fixed component fixedly connected with the mechanical arm main body, a rotating component which is connected with the mechanical arm main body and rotates relative to the fixed component and a plurality of suckers which are connected with the rotating component and synchronously rotate with the rotating component; the air pipeline assembly comprises a plurality of first air pipeline structures arranged on the fixed component and a plurality of second air pipeline structures arranged on the rotating component, and the second air pipeline structures separately communicate with the suckers and an air path formed by the first air pipeline structures; and the first air pipe is connected with the first air pipeline structures of the fixed component. The service life of the mechanical arm rotating sucker conveying device is longer, economical losses can be reduced, and the production efficiency is increased.

Owner:CHINA TOBACCO GUANGXI IND

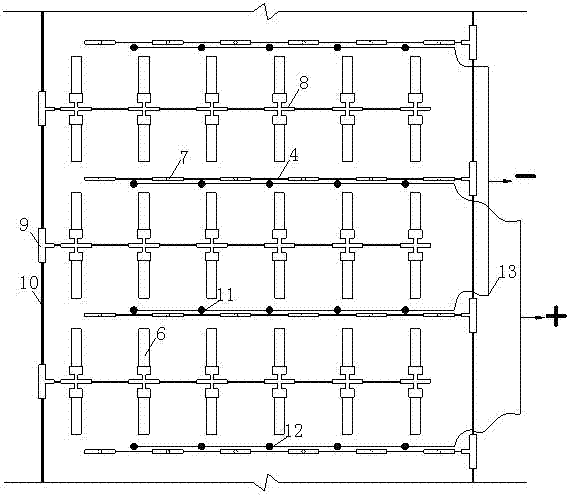

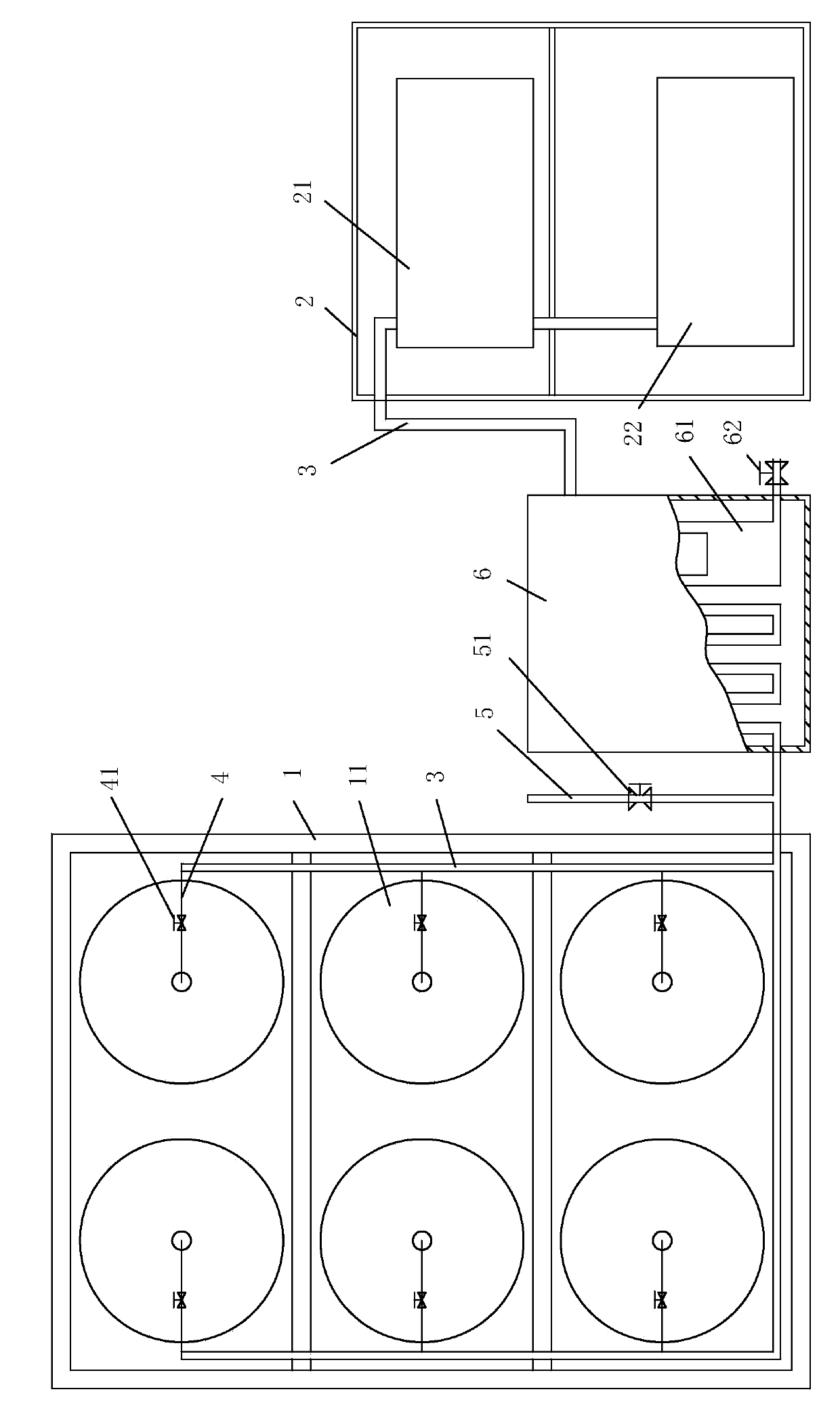

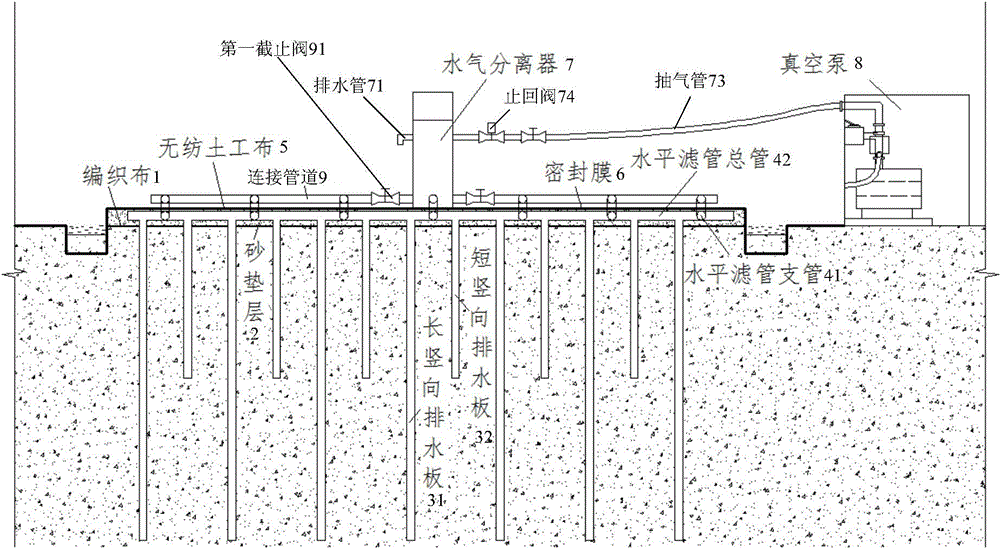

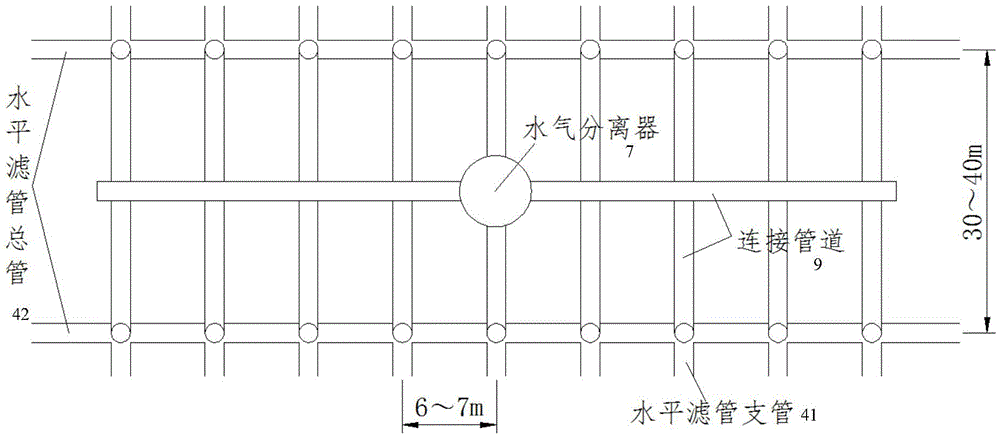

Structure and method for processing consolidation of water pumping and air exhausting soft foundation

The invention discloses a structure and a method for processing consolidation of a water pumping and air exhausting soft foundation. The structure comprises weaving cloth, a sand cushion layer, multiple long vertical water discharging plates, multiple horizontal filter pipe branch pipes, multiple horizontal filter pipe main pipes, non-woven geotextile, a sealing film, water-air separators and a vacuum pump, wherein the weaving cloth and the sand cushion layer are sequentially arranged in a soft foundation processing area, the long vertical water discharging plates are inserted into the soft foundation processing area by penetrating through the sand cushion layer and the weaving cloth, the horizontal filter pipe branch pipes and the horizontal filter pipe main pipes which are arranged in parallel are embedded into the sand cushion layer, the non-woven geotextile and the sealing film are sequentially paved on the sand cushion layer, the water-air separators are arranged by diving the soft foundation processing area into pieces, one water-air separator is arranged in each area, multiple areas are equipped with one vacuum pump, water-air inlets of the water-air separators are connected with the horizontal filter pipe main pipes through connecting pipelines, water outlets of the water-air separators are connected with water discharging pipes, and air pumping openings of the water-air separators are connected with the vacuum pump through air pumping pipes. The structure and the method for processing the consolidation of the water pumping and air exhausting soft foundation, disclosed by the invention, have the advantages that consolidation processing of the water pumping and air exhausting soft foundation is realized by utilizing the vacuum pump and the water-air separators, the cost can be reduced, and the consolidation efficiency can be effectively increased.

Owner:宁波高新区围海工程技术开发有限公司

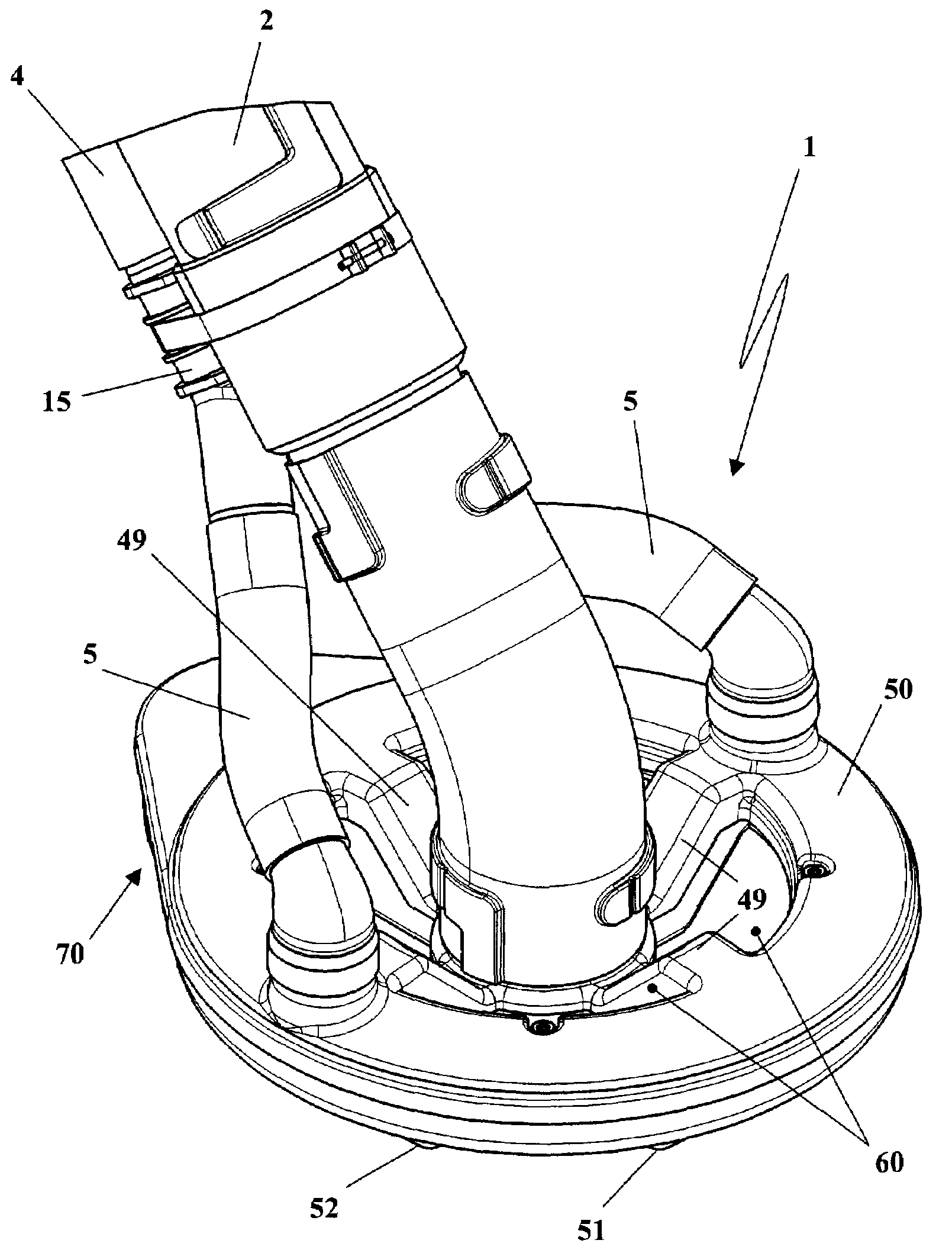

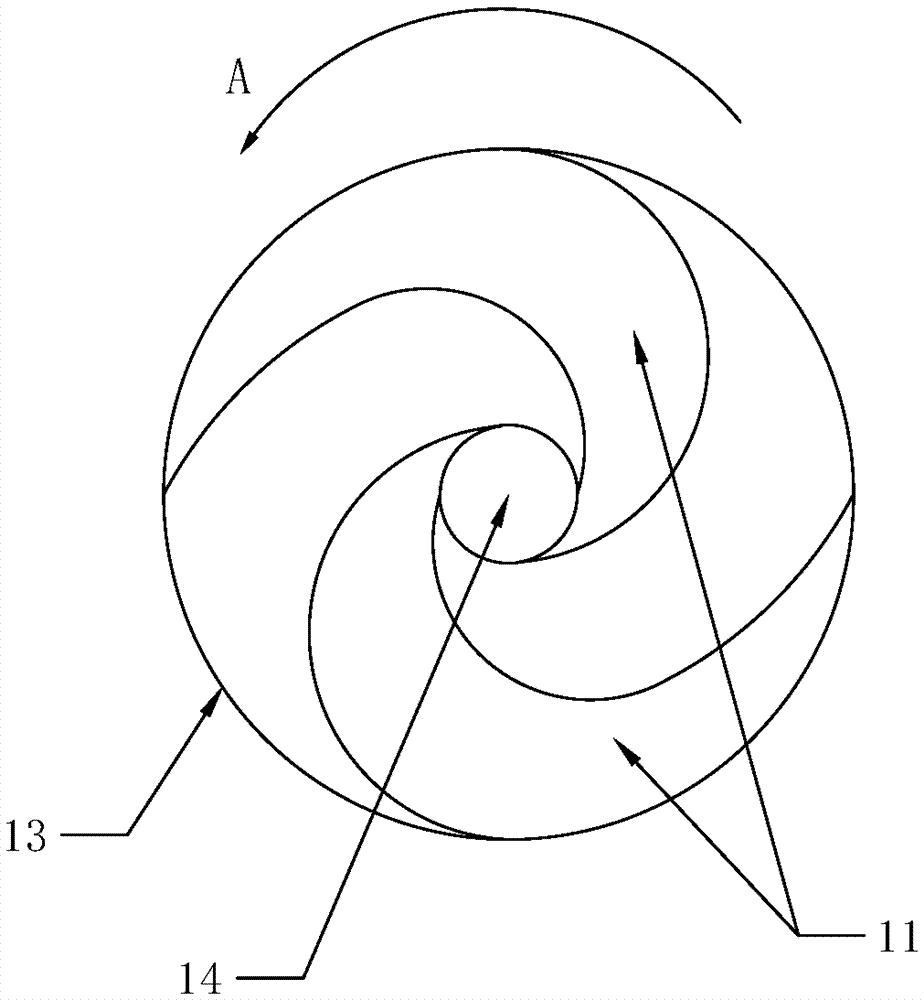

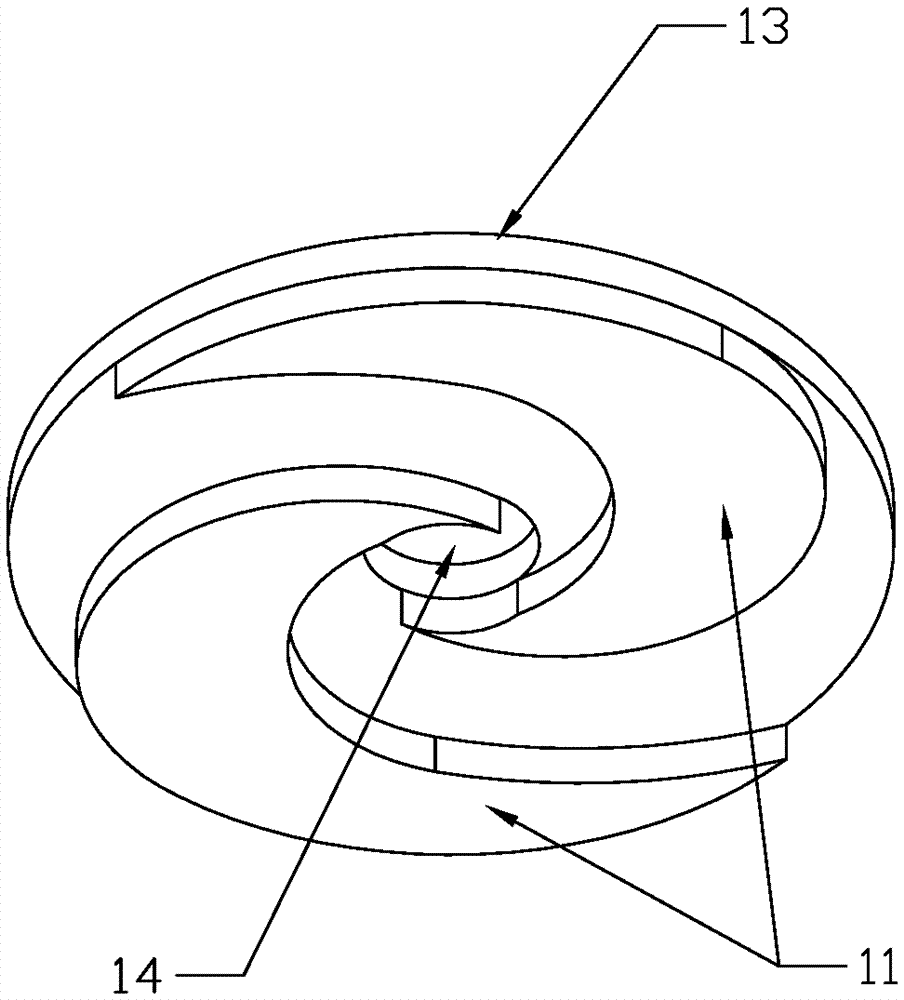

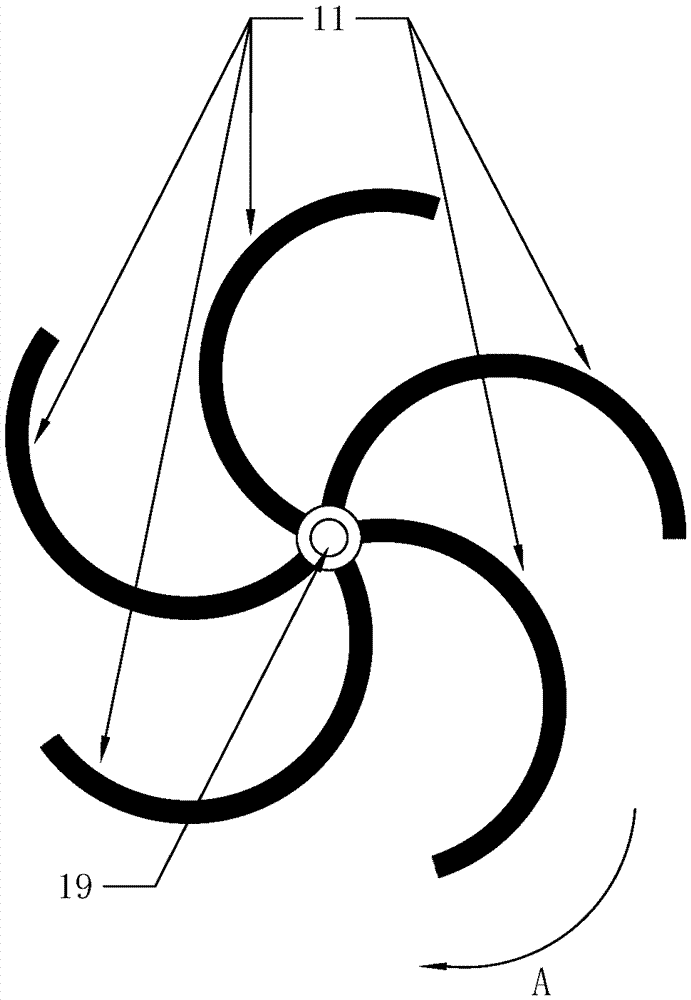

Cleaning head and cleaning tool using cleaning head

InactiveCN106913288APrevent throwing awayOvercome the disadvantages of poor cleaning effectCarpet cleanersFloor cleanersImpellerEngineering

The invention discloses a cleaning head for a rotary cleaning tool. The cleaning head is of an impeller structure and comprises multiple cleaning blades which are distributed in the peripheral direction and used for cleaning a surface to be cleaned, wherein the cleaning blades are bent towards the rotating direction of the cleaning head during working; and channels allowing dirt to move therein are formed between every two adjacent cleaning blades, the cleaning blades bent towards the rotating direction enable dirt to make centred motion along the rotating side of the cleaning blades when the cleaning head rotates, and a dirt gathering function is realized. By the adoption of the cleaning head, the defect of ordinary rotary cleaning tools that dirt can not be gathered and is thrown away easily can be overcome effectively, so that cleaning efficiency is improved. The cleaning head can be applied to cleaning tools like a sweeper, a floor mopping machine, an electric rotary mop, a sweeping robot and an electric window cleaner.

Owner:阳珉

Edge sealing method for vacuum glass

PendingCN109665726AReduce secondary sealingReduce secondary sealing processVacuum pumpingEngineering

The invention discloses an edge sealing method for vacuum glass. The edge sealing method uses a set of edge sealing devices, wherein the edge sealing devices comprise a main cavity chamber, a secondary cavity chamber, a vacuum valve and a plurality of drawers, wherein an insertion opening for inserting the drawers is formed in one side surface of the main cavity chamber; a plurality of guide railsof the drawers are formed in the main cavity chamber from top to bottom; a plurality of the drawers are respectively and correspondingly connected to the guide rails of the drawers one by one in a sliding manner; the main cavity chamber is sealed after a plurality of the drawers of the main cavity chamber are inserted into the main cavity chamber; and a plurality of drawers divide the inner spaceof the main cavity chamber into a plurality of layers, and a heating mechanism is arranged on the side wall of the main cavity chamber of each layer, the main cavity chamber is communicated with thesecondary cavity chamber through a pipeline, and the vacuum valve is arranged on the pipeline. The integral main cavity chamber is evacuated before the toughened glass is sealed, so that the defects of too small vacuum pumping opening and unclean degassing are avoided, and meanwhile, the secondary sealing process is reduced.

Owner:洛阳八佳电气科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com