Edge sealing method for vacuum glass

A vacuum glass and edge sealing technology, which is applied in the field of vacuum glass processing and manufacturing, can solve problems such as poor vacuum degree, many equipment used, complex process, etc., and achieve the effect of reducing the use of equipment, convenient installation and maintenance, and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

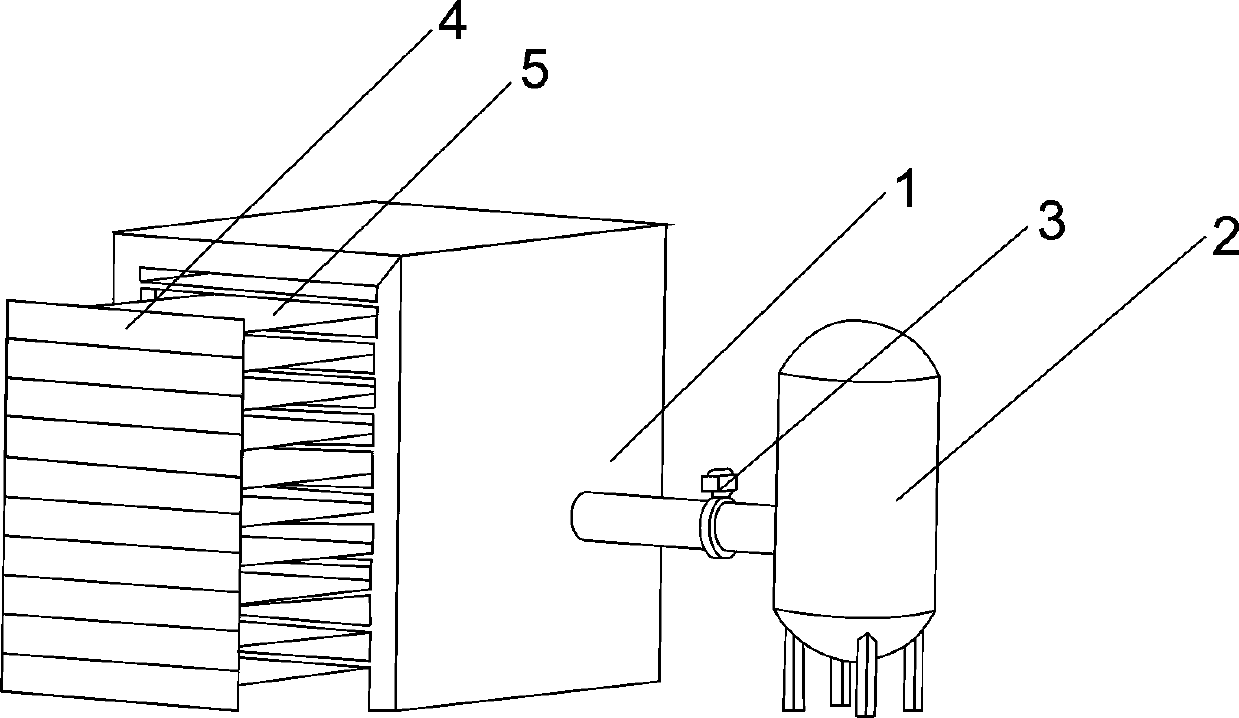

[0024] combined with figure 1 , a method for edge sealing of vacuum glass, the edge sealing method uses a set of edge sealing device, the edge sealing device includes a main chamber 1, a secondary chamber 2, a vacuum valve 3 and several drawers 4, the main chamber 1 is connected to There is a vacuuming device, the vacuuming device is a vacuum pump, an insertion port for inserting the drawer 4 is arranged on one side of the main chamber 1, and a plurality of drawer guide rails are arranged from top to bottom in the main chamber 1, and the plurality of drawers are respectively a A pair of corresponding slides is connected on the drawer guide rail, and after some drawers 4 of the main chamber 1 are all inserted in the main chamber 1, the main chamber 1 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com