Patents

Literature

137results about How to "Appropriate intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exercise intensity measuring device and exercise quantity measuring device

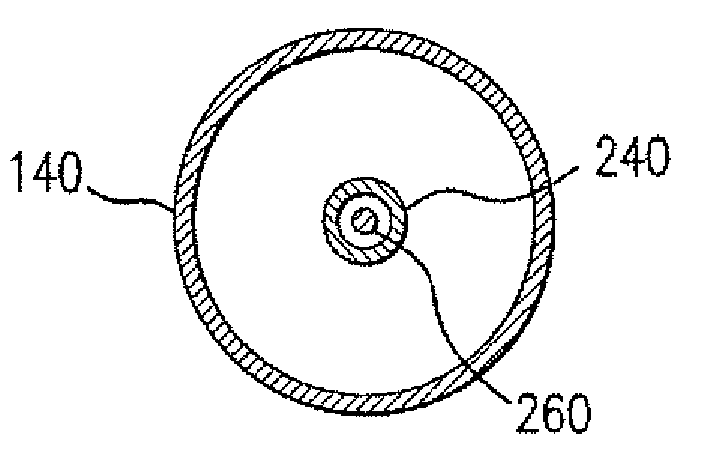

PCT No. PCT / JP97 / 00928 Sec. 371 Date Jan. 23, 1998 Sec. 102(e) Date Jan. 23, 1998 PCT Filed Mar. 21, 1997 PCT Pub. No. WO97 / 35514 PCT Pub. Date Oct. 2, 1997An exercise intensity and exercise quantity measuring device is disclosed, which is capable of measuring the exercise intensity, irrespective of the type, of exercise, and measuring the exercise quantity only when the user is carrying out exercise of suitable intensity. The user first estimates his Vo2max in advance by the conventional direct method, and inputs this value into the device. The device determines upper and lower limit values of pulse rate corresponding to this Vo2max. During the time of exercise when pulse rate is between the upper and lower limit values, CPU 308 increments the accumulated time stored in RAM 309, at intervals based on a clock pulse supplied by oscillation circuit 311 and frequency dividing circuit 312. At the same time, CPU 308 compares the pulse waveform during exercise and the pulse waveform at rest, and estimates the exercise intensity.

Owner:SEIKO EPSON CORP

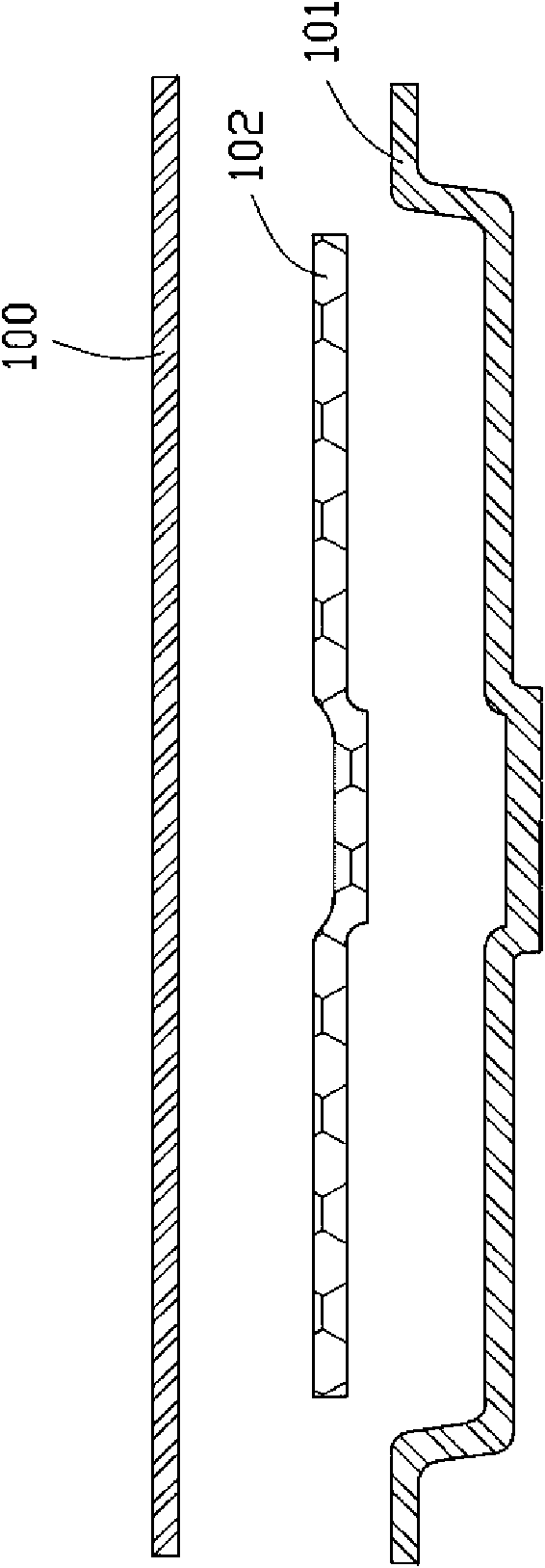

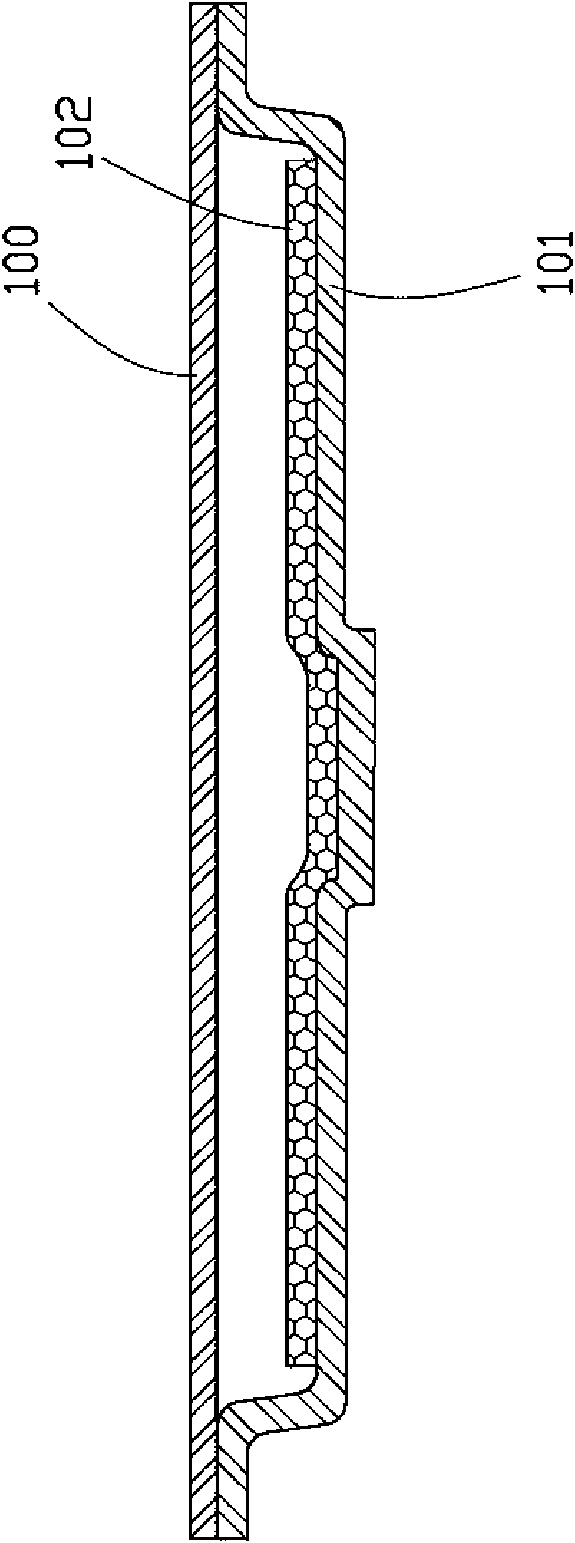

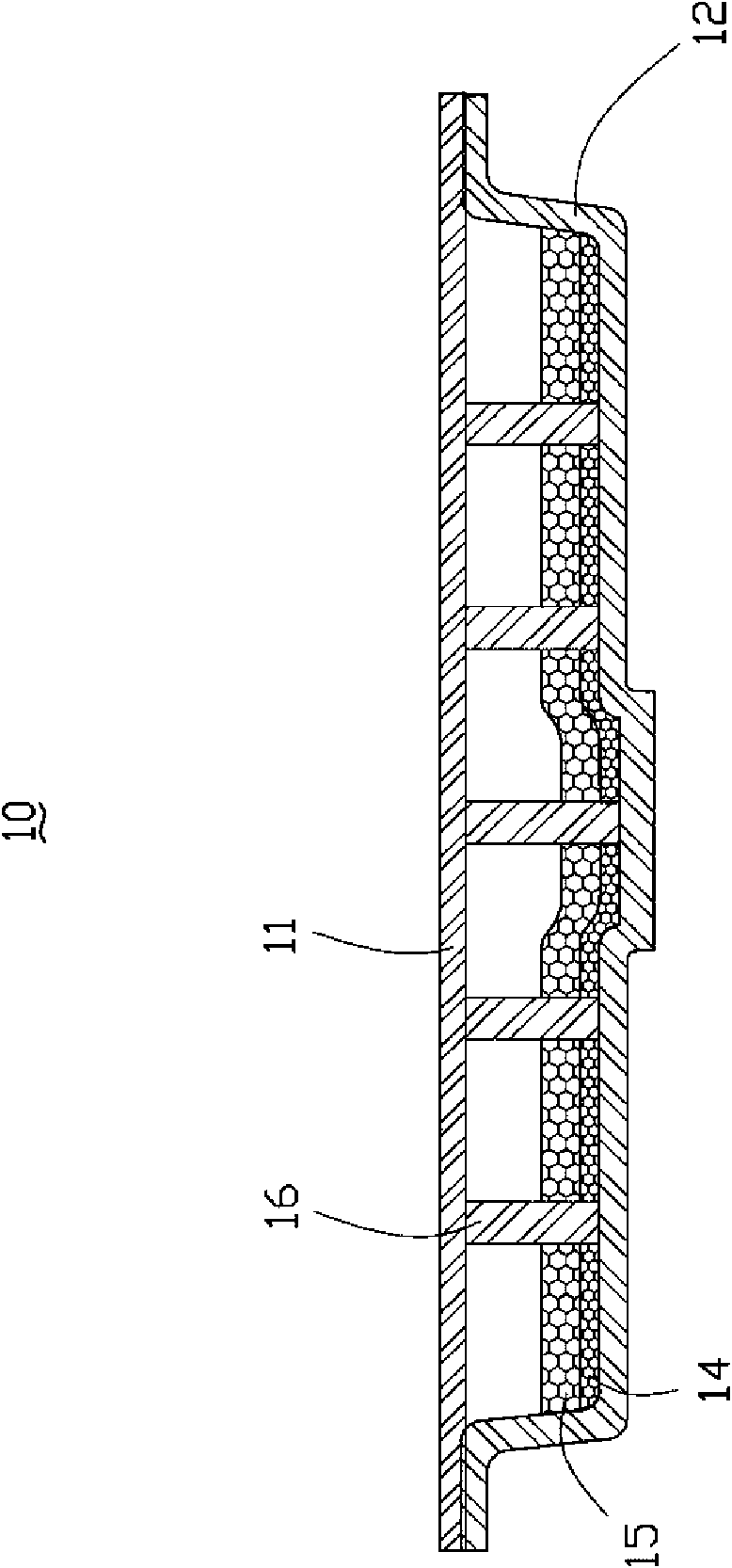

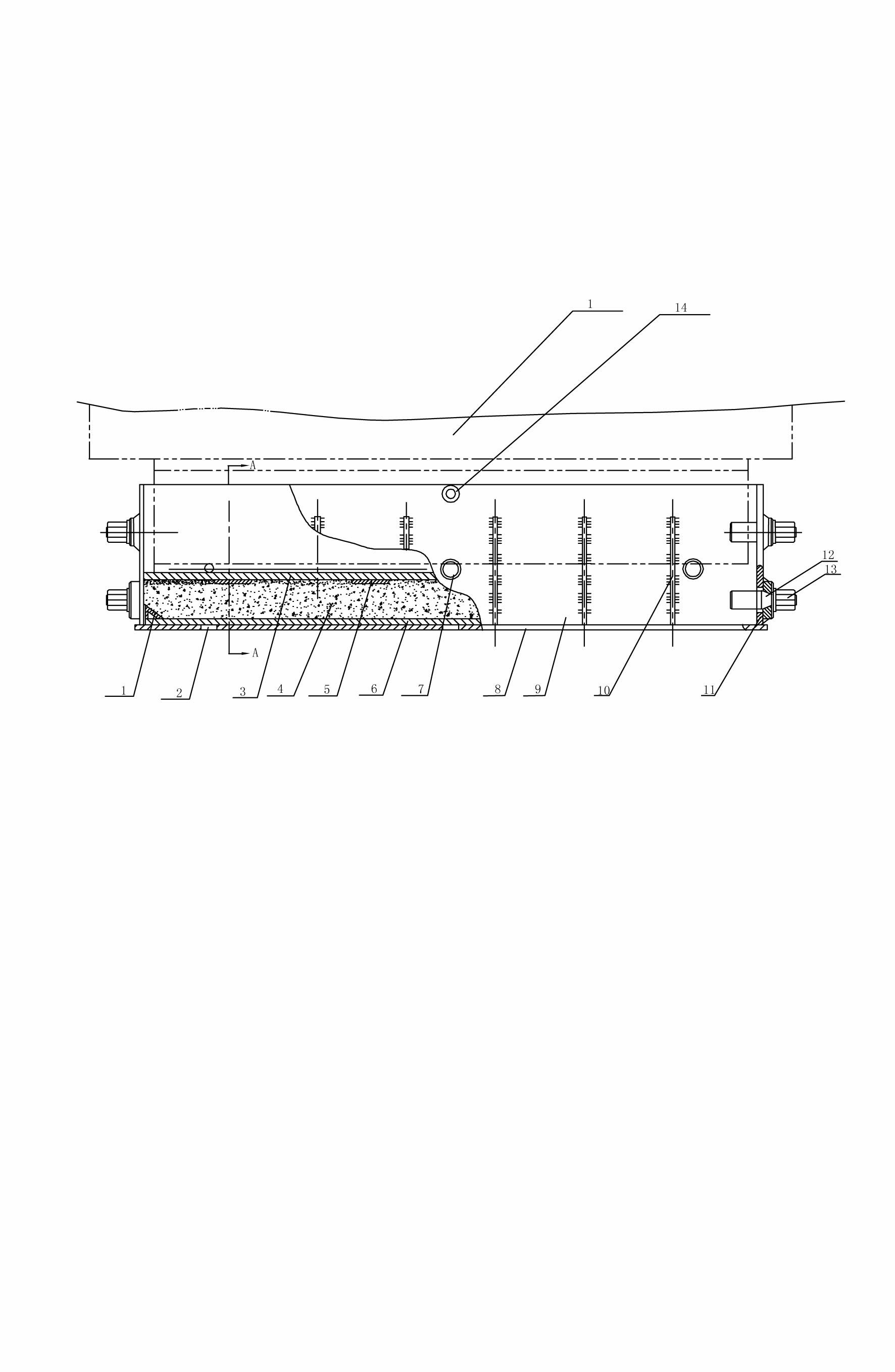

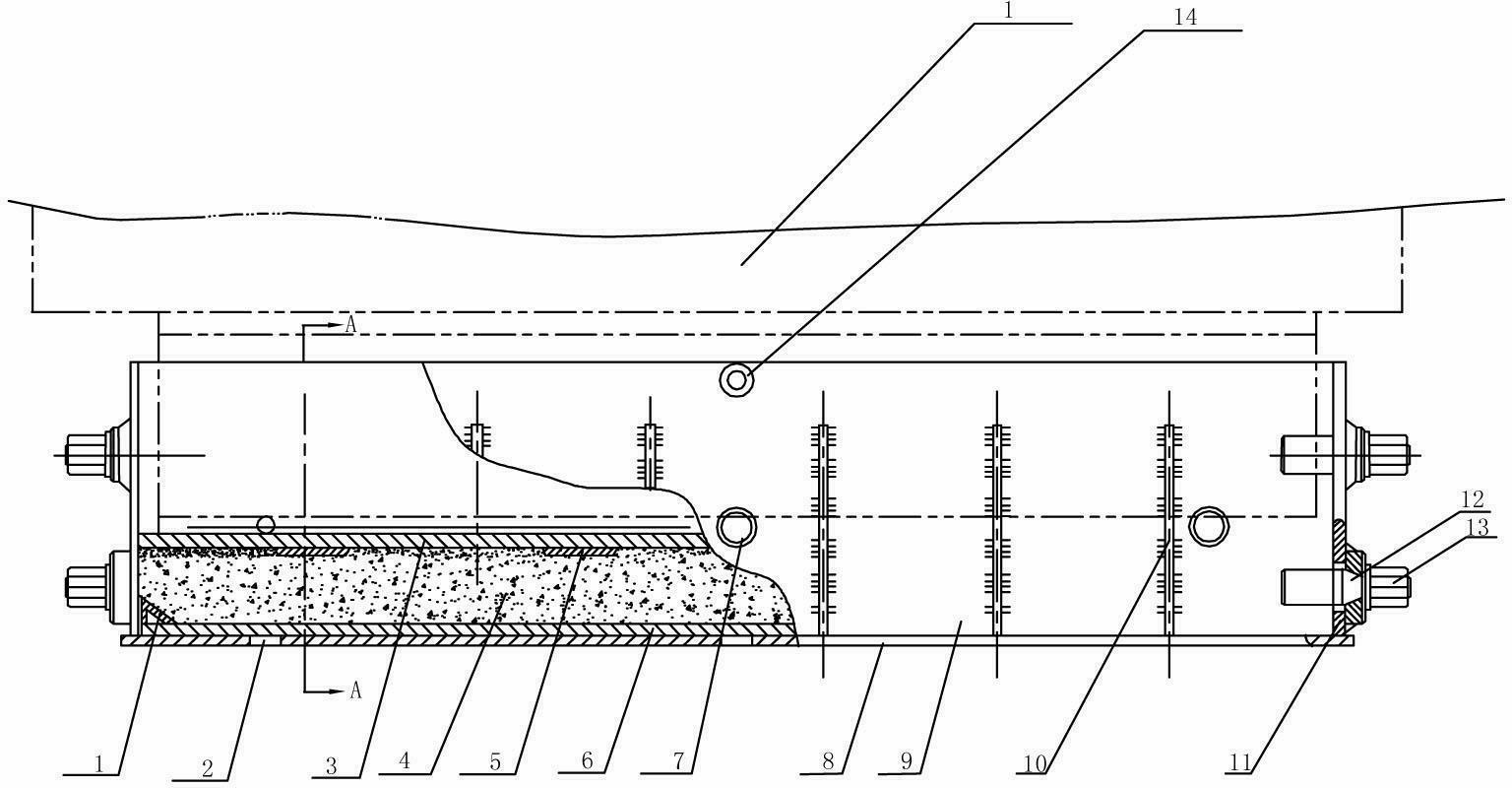

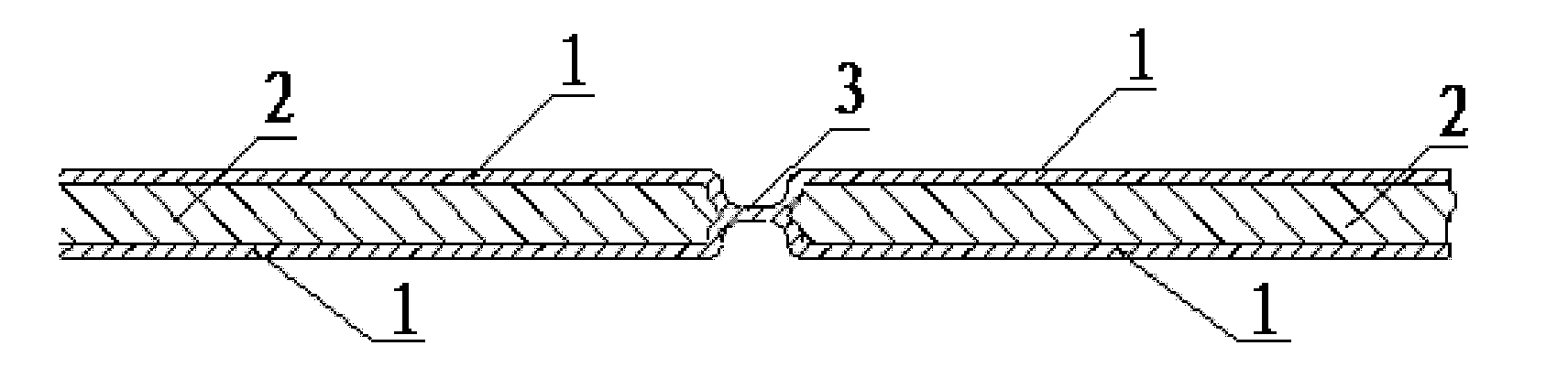

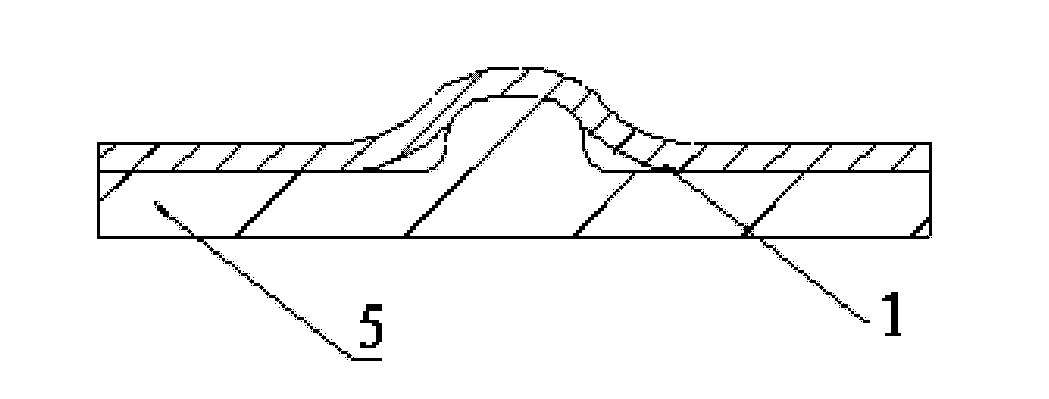

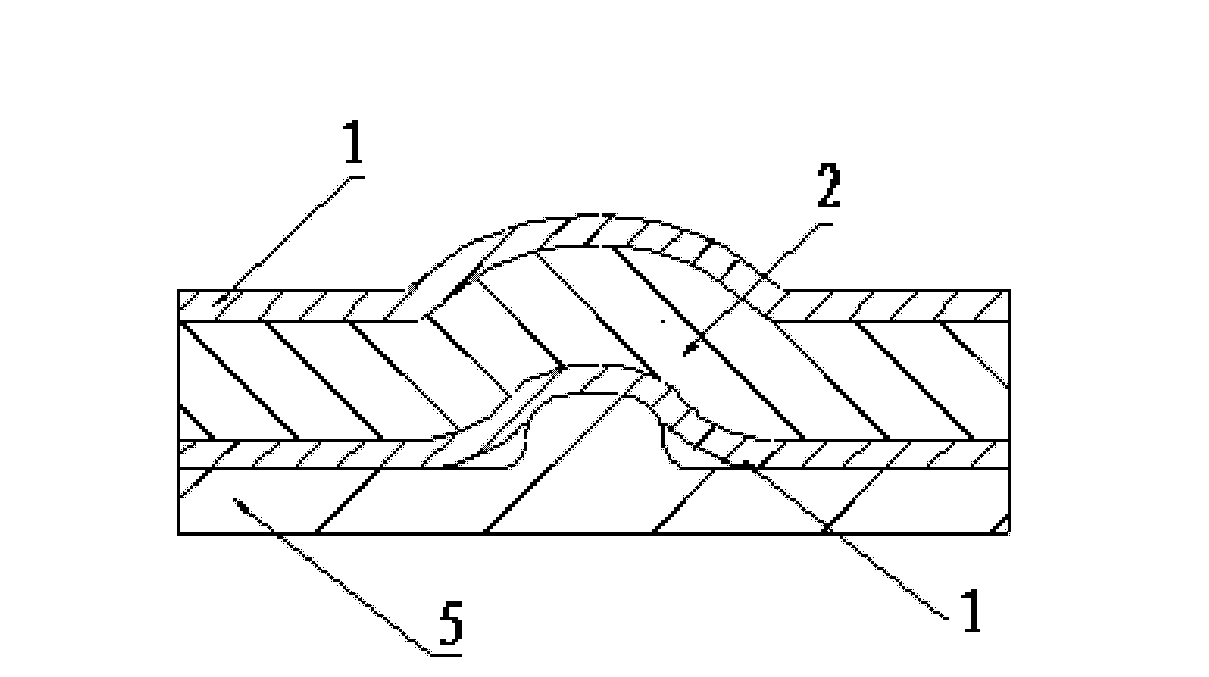

Method for manufacturing flat-plate heat tube

InactiveCN101639331AAppropriate intensityAppearance and shapeIndirect heat exchangersVacuum pumpingWorking fluid

The invention relates to a method for manufacturing a flat-plate heat tube. The method comprises the following steps: (1) providing an upper cover plate and a lower cover plate; (2) providing a plurality of first metal powders, and after being sintered, the first metal powders form a plurality of supporting columns; (3) arranging one end of each of the supporting columns on the upper surface of the lower cover plate, and correspondingly, the height of each supporting column is equivalent to the distance between the corresponding positions of the upper cover plate and the lower cover plate; (4)providing a plurality of second and third metal powders, filling the bottom of the lower cover plate with the metal powders, arranging the metal powders in the way of surrounding the supporting columns, and sintering the lower cover plate at a high temperature so as to enable the second metal powders to form a first capillary structure attached to the upper surface of the lower cover plate and toenable the third metal powders to form a second capillary structure attached to the upper surface of the first capillary structure; (5) welding the supporting columns and the lower cover plate on thelower surface of the upper cover plate so as to form a rough blank; and(6) processing the rough blank by vacuum-pumping, working fluid injection, degasification, sealing and surface heat treatment, thereby obtaining the final product of the flat-plate heat tube.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

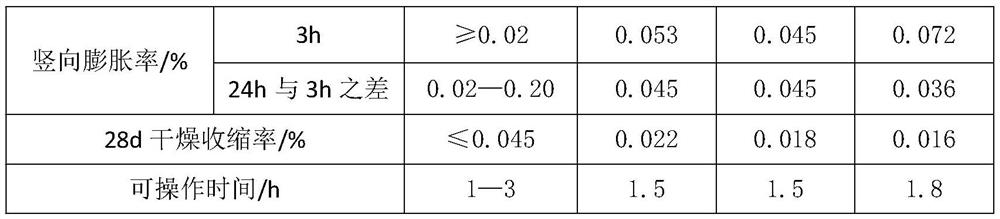

Emulsification asphalt cement mortar for plate-type slag-free orbit and its preparing method and application

ActiveCN101033122AGood temperature adaptability and constructionExcellent durability and anti-vibration fatigue performanceSlagDefoaming Agents

This invention relates to a panel dreg-free emulsified asphalt-cement mortar used in orbits, its manufacturing method and an application including cement, mixed materials, emulsified asphalt, sand, water, polymer latex, defoaming agent, Al powder, an air entrainer and a regulator, which solves the problem of short working time, poor adaptability to temperature, easy separation, hard expansion after 24 hours of injection of the present emulsified asphalt-cement mortar and provides a panel dreg-free emulsified asphalt-cement mortar working long, well suitable to temperature, hard separated, easily expanding, low cost and raw materials are got easily.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

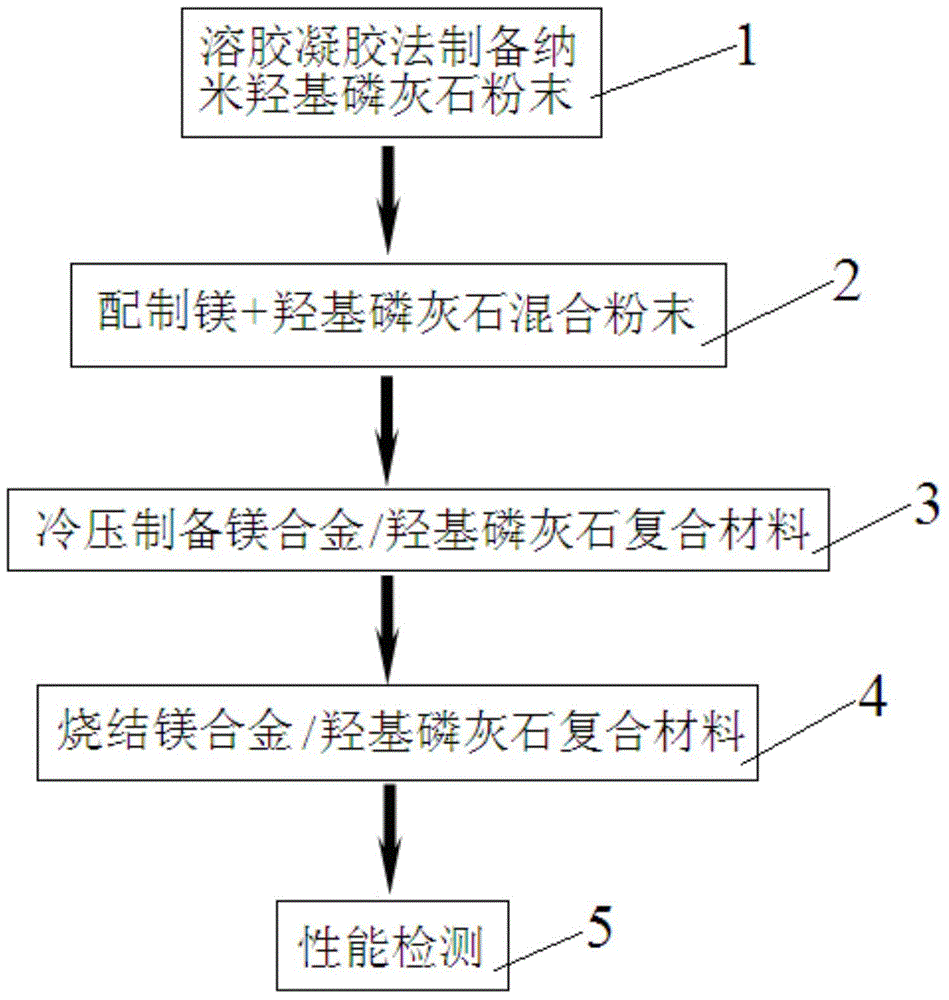

Preparation method of magnesium alloy/hydroxyapatite composite

InactiveCN103599561ADegradability adjustableDegradative regulationSurgical adhesivesProsthesisSolubilityCardiovascular stent

The invention relates to a preparation method of a magnesium alloy / hydroxyapatite composite, which comprises the steps of firstly preparing nano hydroxyapatite powder by a sol-gel process, and then uniformly mixing the magnesium powder with the nano hydroxyapatite powder; putting the mixture into a mould and performing cold pressing; putting the cold-pressing formed sample into a vacuum heat treatment furnace for sintering to obtain the magnesium alloy / hydroxyapatite composite. Compared with the prior art, in the method provided by the invention, the magnesium alloy is used as a metal matrix, the hydroxyapatite with the same chemical composition as the human skeleton and having low solubility in the human body environment is used as a reinforcing body, and the method aims at preparing a magnesium alloy / calcium phosphate composite biomedical material by use of a powder metallurgical process; the material is mainly applied to clinical medicine as a degradable endosteal fixing material, a porous bone repair material, a dental implantation material, an oral repair material, a cardiovascular stent and the like, and has broad prospects in terms of bone tissue defect repair.

Owner:TONGJI UNIV

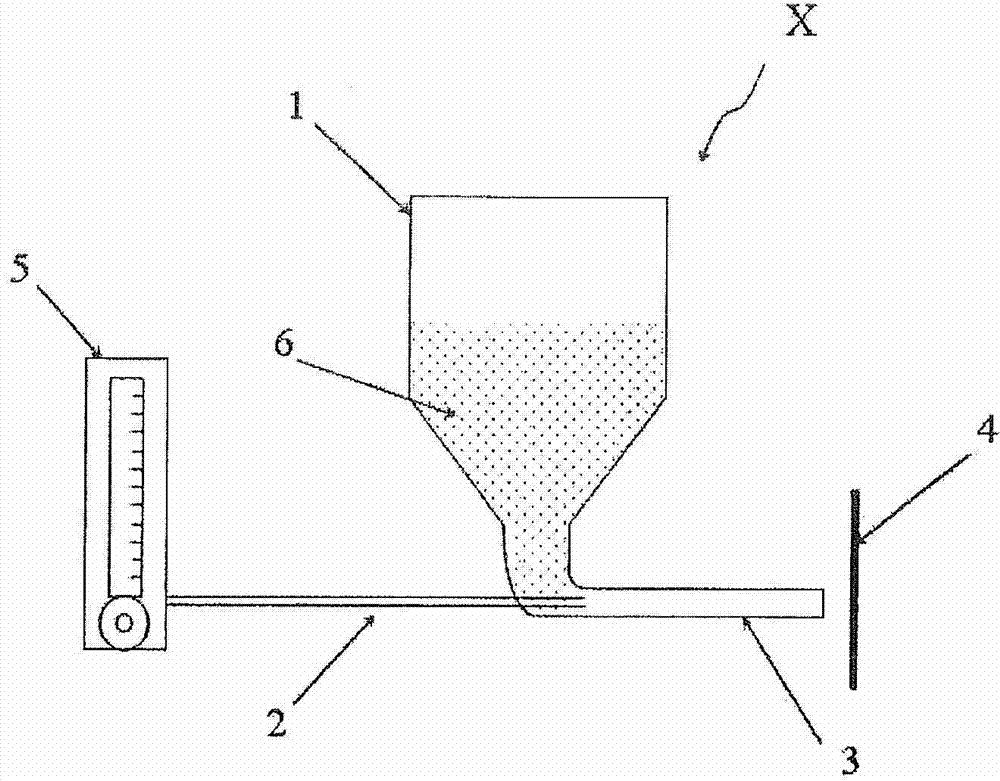

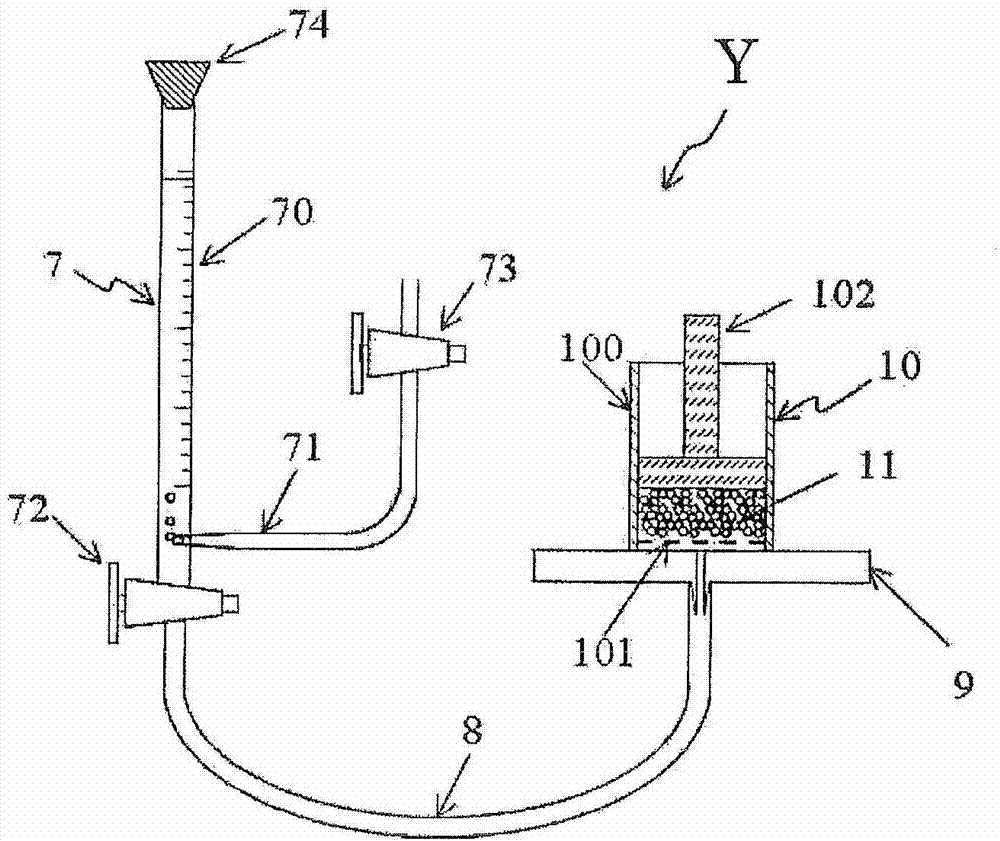

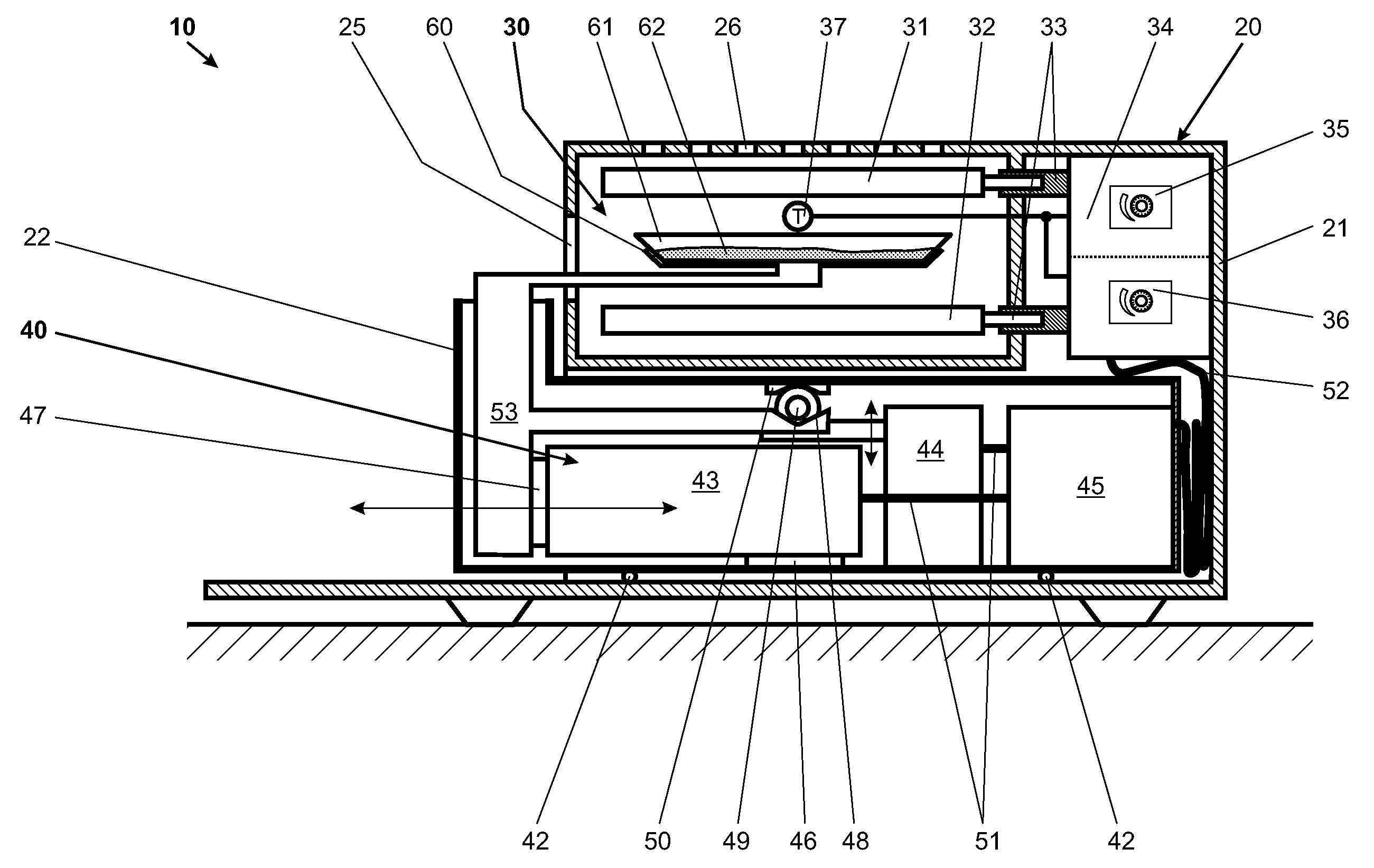

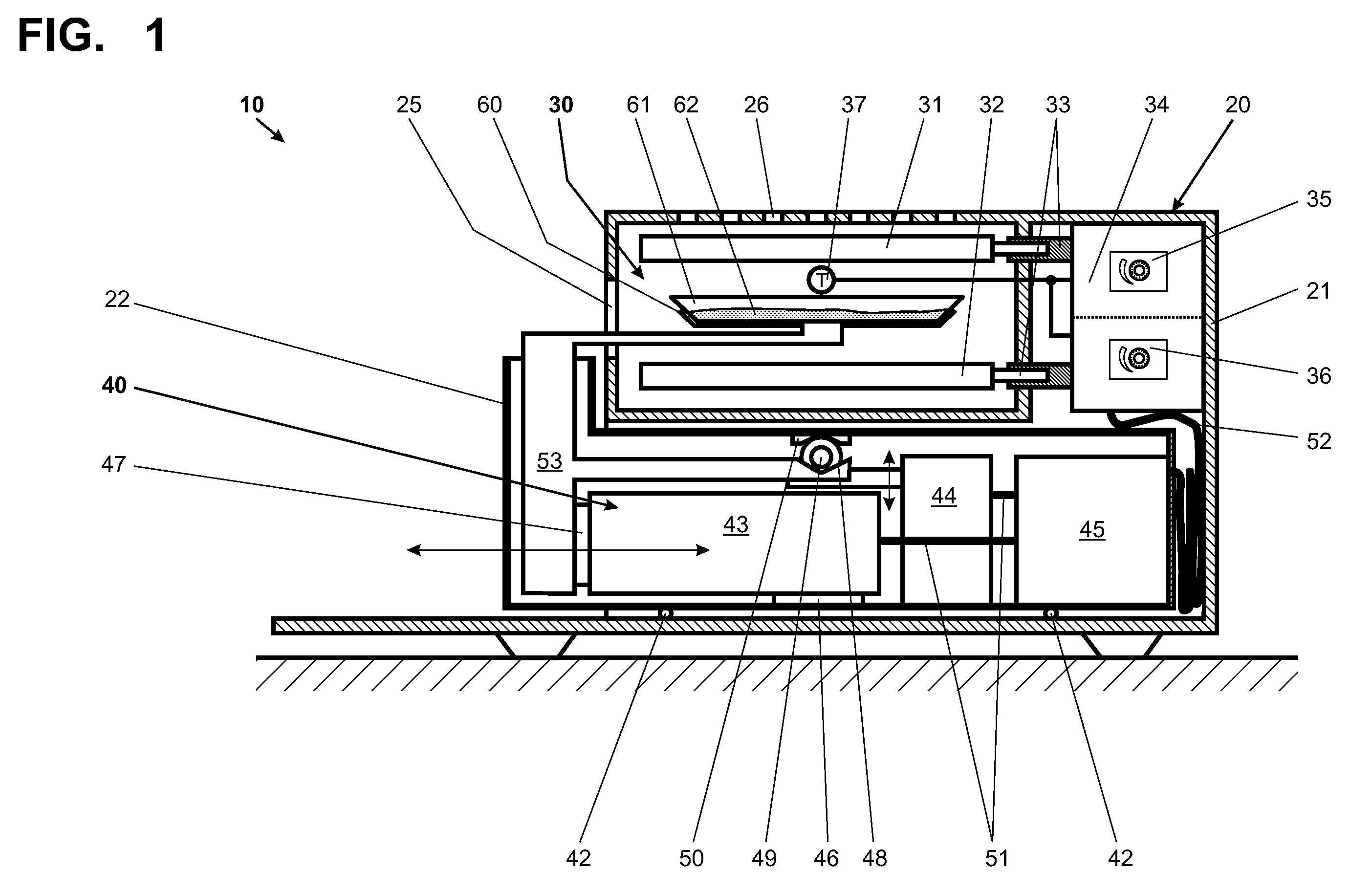

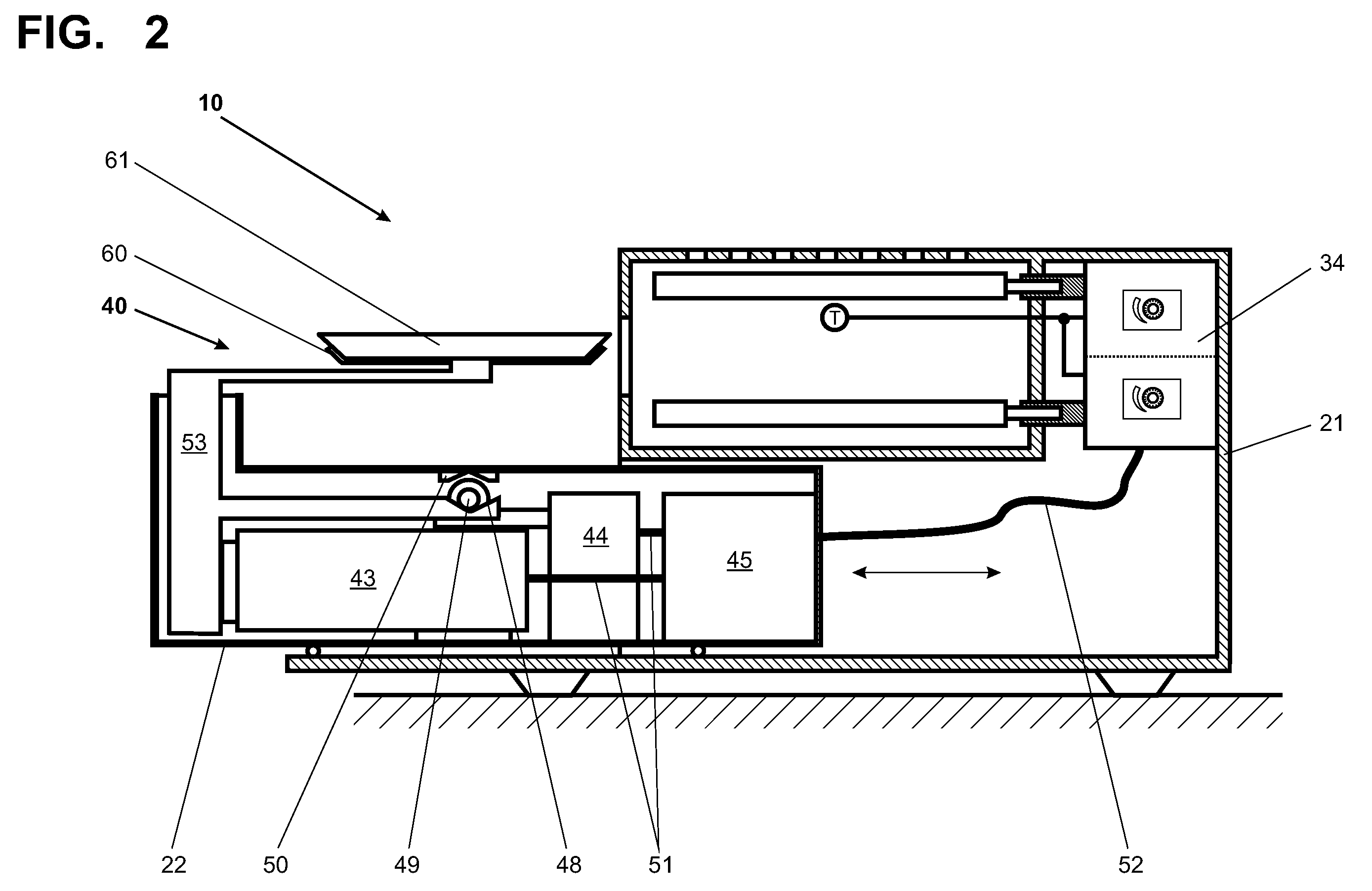

Measuring instrument for gravimetric moisture determination

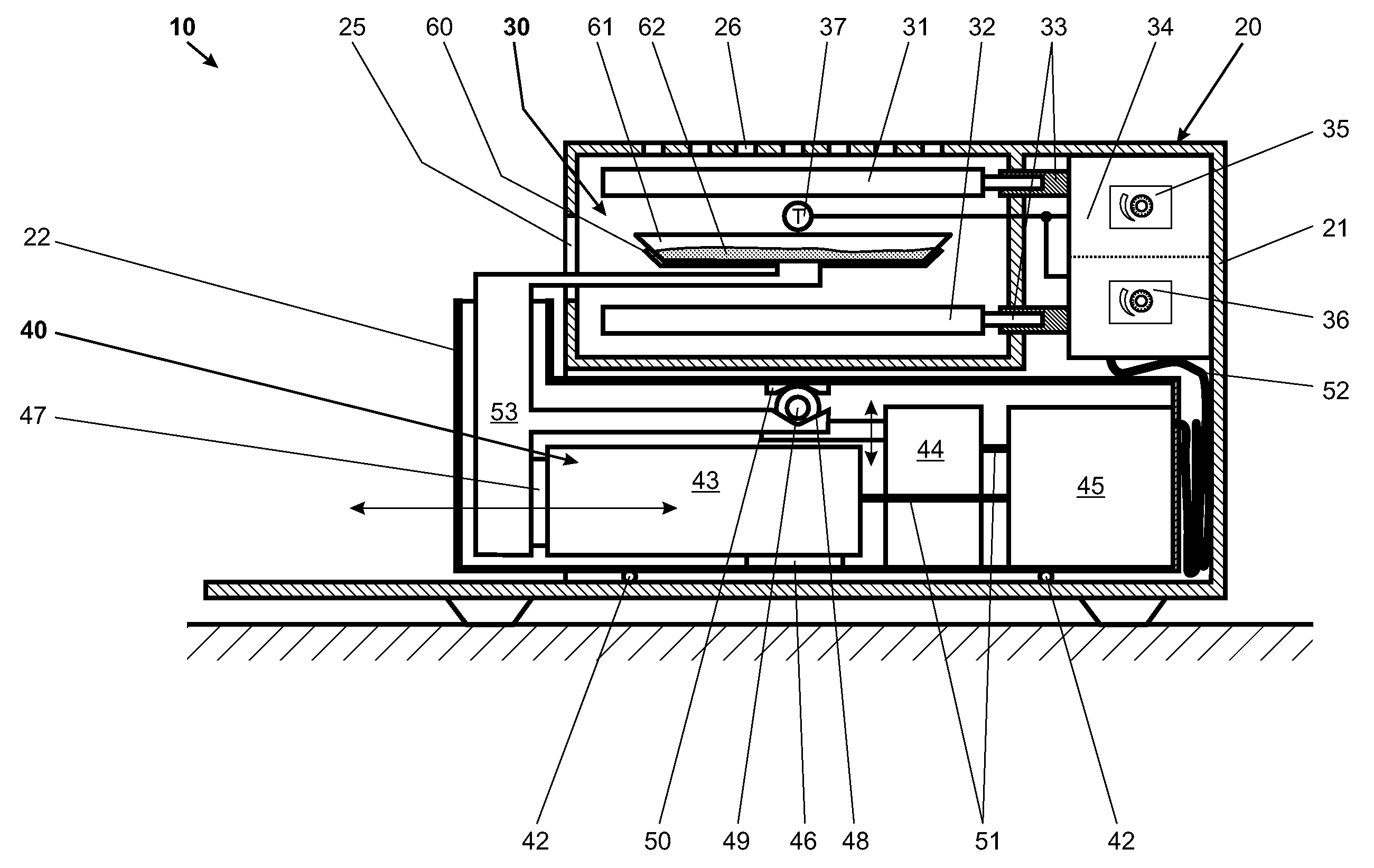

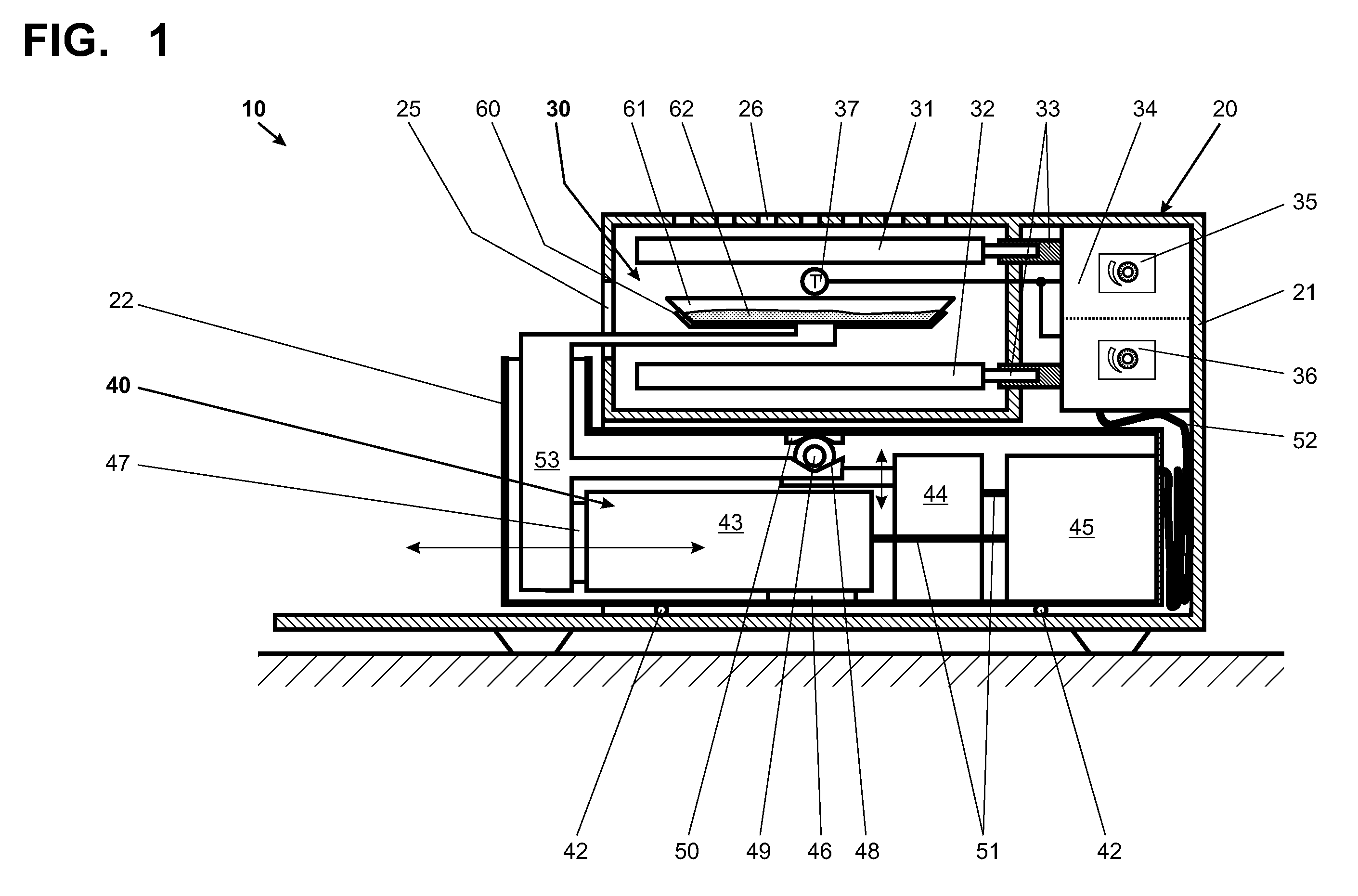

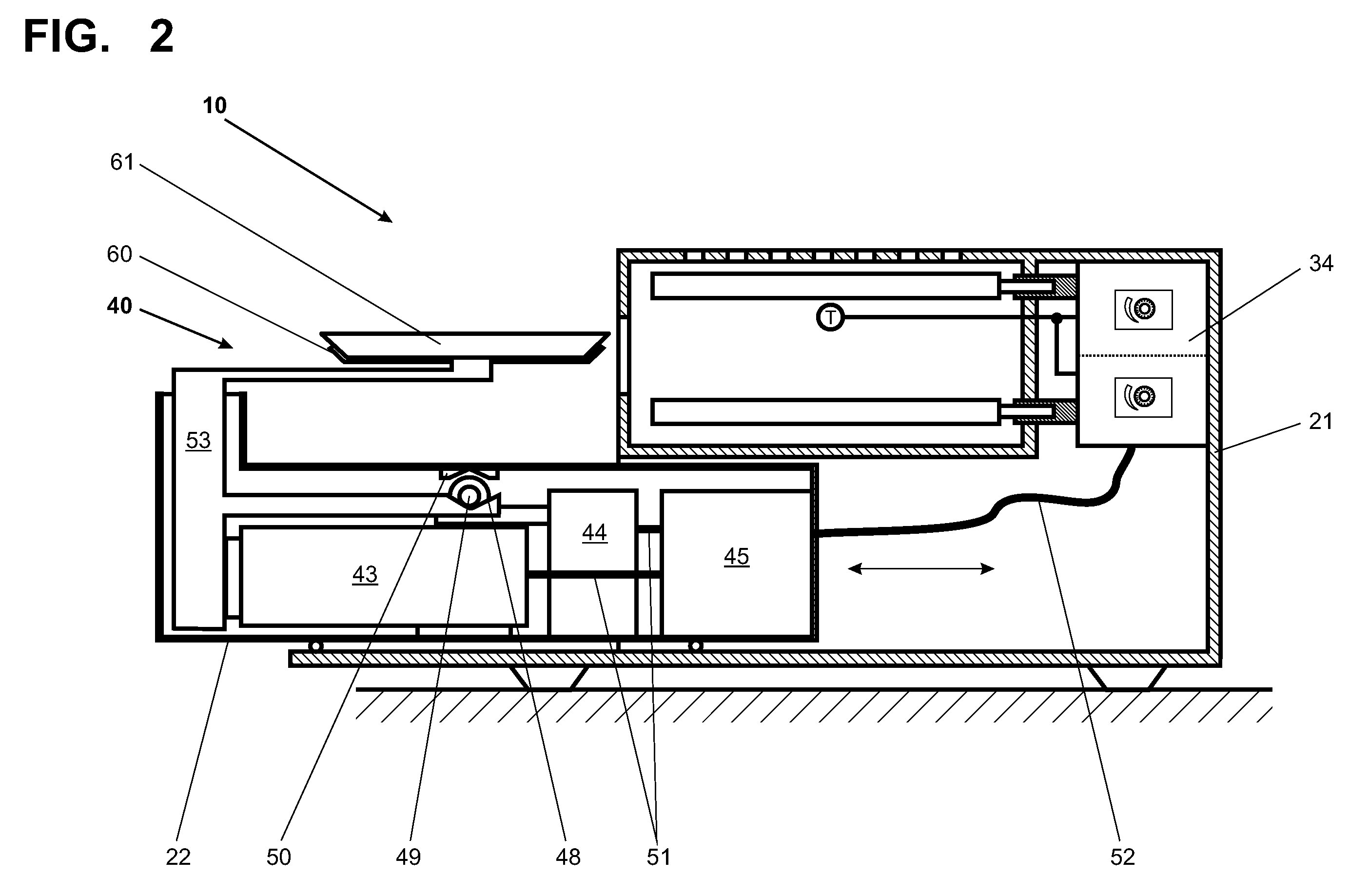

ActiveUS20070245813A1Good reproducibilityLower measured weightDrying solid materials with heatMaterial moisture contentMeasuring instrumentEngineering

An instrument for gravimetrically determining the moisture content of a sample has a housing with a weighing device therein. The weighing device has a load-receiving portion and a sample receiver, the latter designed for connection to the load-receiving portion. The housing also contains a test compartment. When set in position to perform a measurement, the sample receiver is disposed inside the test compartment. One embodiment of a means arranged in the test compartment for heating a sample placed on the sample receiver has first and second radiation sources, with the sample receiver arranged therebetween.

Owner:METTLER TOLEDO GMBH

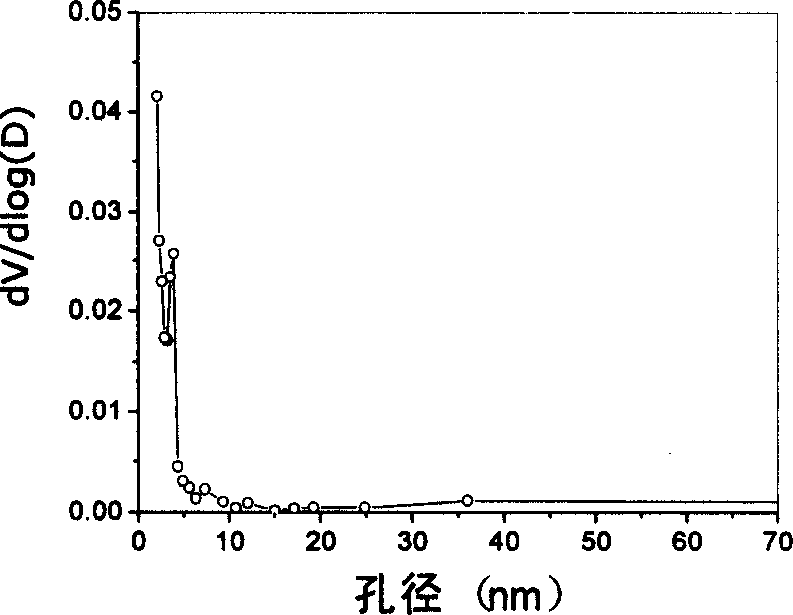

Process for preparing big aperture active carbon fibers

The invention belongs to the field of material preparation and relates to a preparation method of activated carbon fibers with large apertures. In the present invention, the fiber raw material is pretreated by impregnating the catalyst aqueous solution, and then dried, oxidized, carbonized, activated, and washed in sequence to obtain activated carbon fibers with large pores; the feature is that the catalyst is sulfuric acid, phosphoric acid, boric acid or hydrochloric acid Any two or three of potassium salts, sodium salts, ammonium salts, cobalt salts, nickel salts, and iron salts, the amount of the catalyst is 1-10% by weight of the raw materials; the impregnation time of the catalyst aqueous solution is 5-60 minutes. The surface pore diameter of the prepared fiber is greater than 50 nanometers, and the specific surface area reaches 800-1800m2 / g. The material prepared by the method of the present invention is soft and has appropriate strength, and can be used for masks, protective clothing, filter sheets and equipment, etc., and can also be used for virus and chemical protection, as well as industries such as chemical industry, environmental protection, pharmaceuticals, hygiene, and electronics.

Owner:DONGHUA UNIV

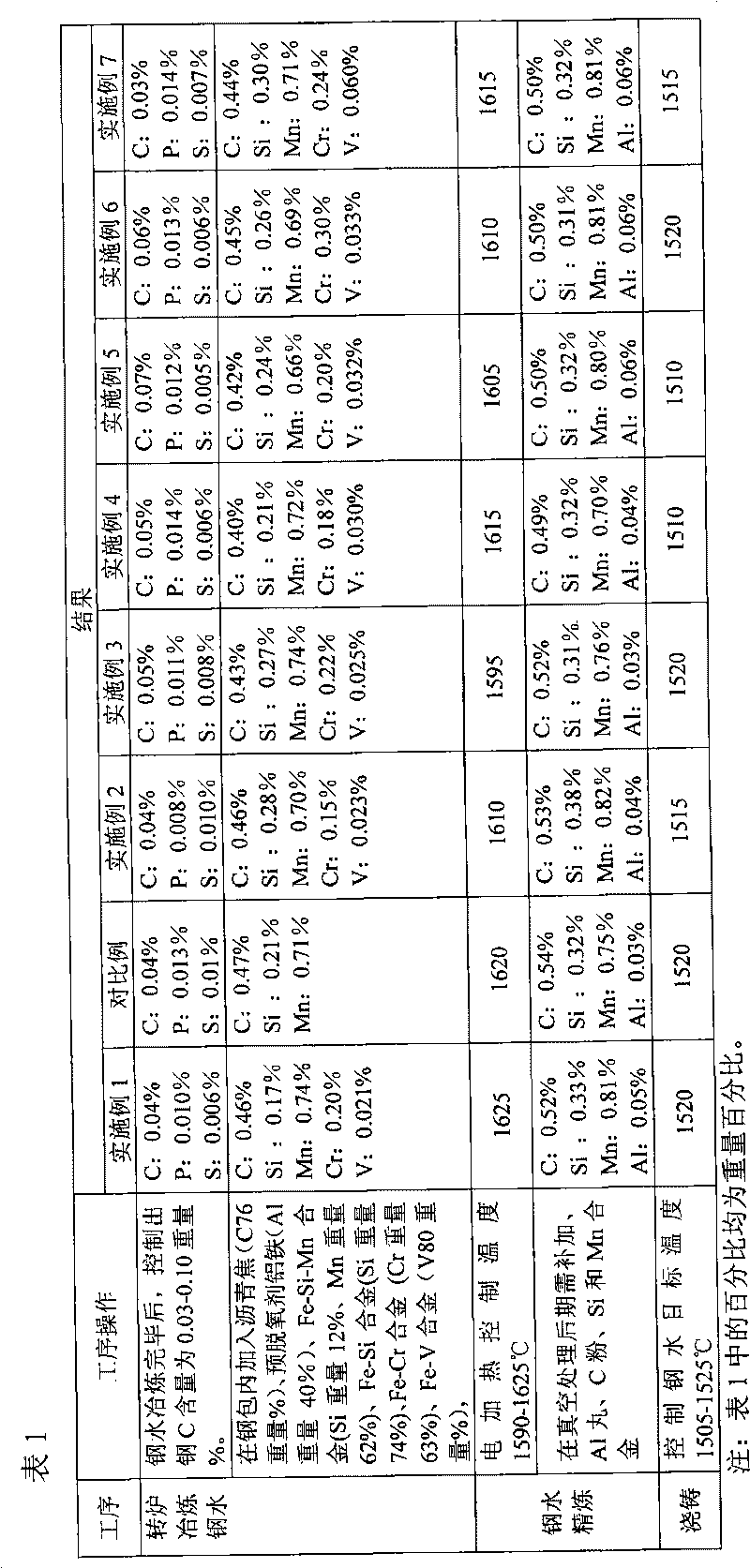

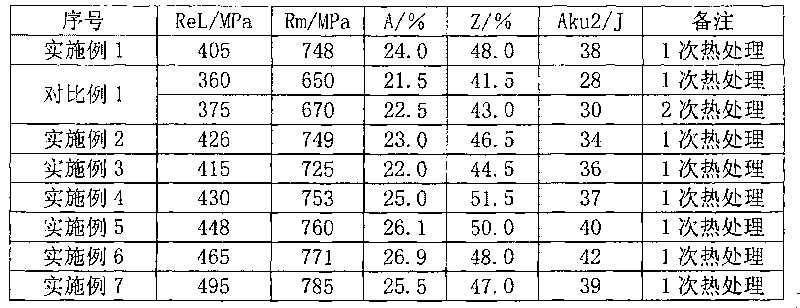

Axle shaft steel and preparation method thereof

ActiveCN101724787AAppropriate intensityAppropriate toughnessMetal rolling arrangementsChemical compositionUltimate tensile strength

The invention provides an axle shaft steel. The axle shaft steel comprises the following chemical components in percentage by weight: 0.47 to 0.54 percent of C, 0.2 to 0.4 percent of Si, 0.7 to 0.9 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.02 percent of S, 0.02 to 0.04 percent of Al, 0.02 to 0.06 percent of V, 0.15 to 0.3 percent of Cr, less than or equal to 0.2 percent of Ni, less than or equal to 0.2 percent of Cu, less than or equal to 0.00025 percent of H, less than or equal to 0.002 percent of O, less than or equal to 0.007 percent of N, and the balance of iron and impurities. The invention also provides a preparation method for the axle shaft steel. The axle shaft steel provided by the invention not only has higher proper strength and toughness,but also ensures the production cost to be lower than that of the axel shaft prepared through repeated thermal treatment in the prior art.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

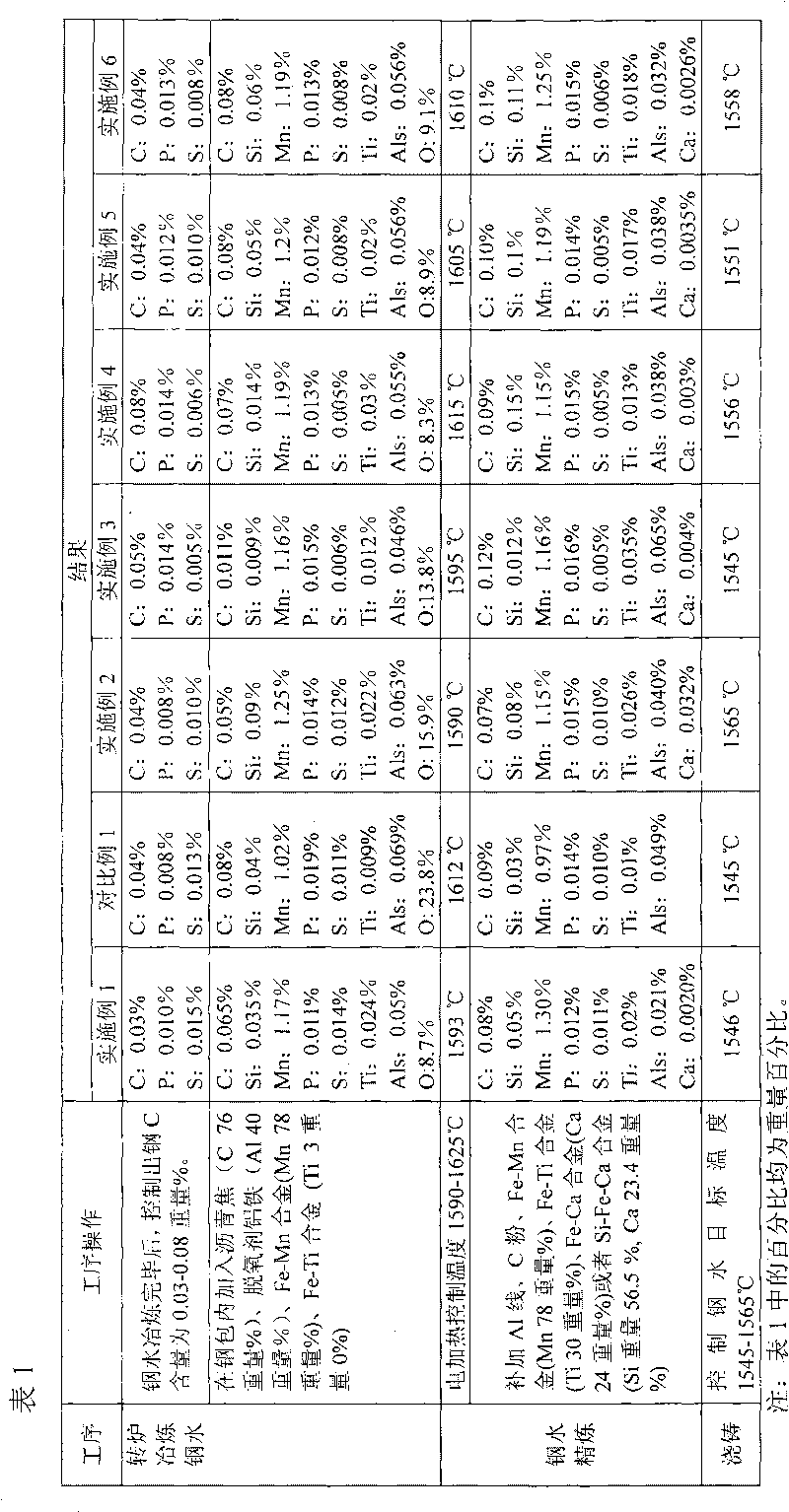

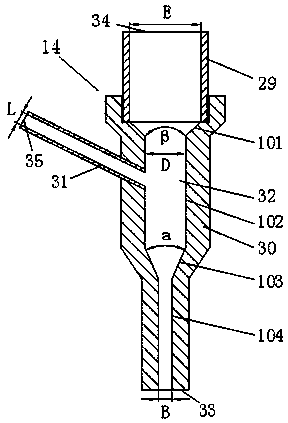

Wheel steel and preparation method as well as wheel thereof

The invention provides a wheel steel which contains the following chemical components measured by simple substances on the basis of the total weight of the wheel steel: 0.07-0.12wt% of C, 0.01-0.15wt% of Si, 1.1-1.3wt% of Mn, 0.01-0.04wt% of Ti, 0.001-0.004wt% of Ca, 0.015-0.065wt% of acid-soluble Al, not larger than 0.025wt% of P, not larger than 0.015wt% of S and 97.31-98.87wt% of Fe. The invention also provides a preparation method of the wheel steel and a wheel, wherein the wheel is made of the wheel steel provided by the invention. The wheel steel provided by the invention has proper higher strength and toughness.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

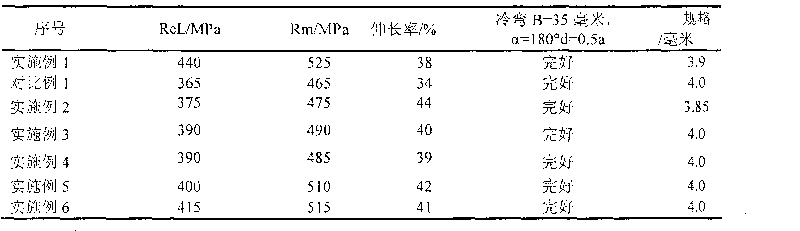

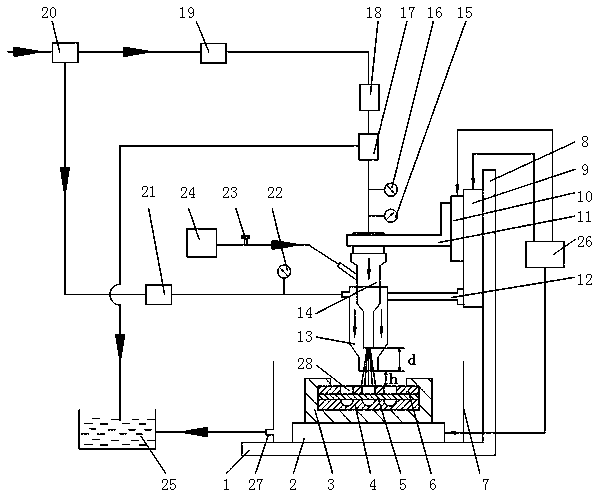

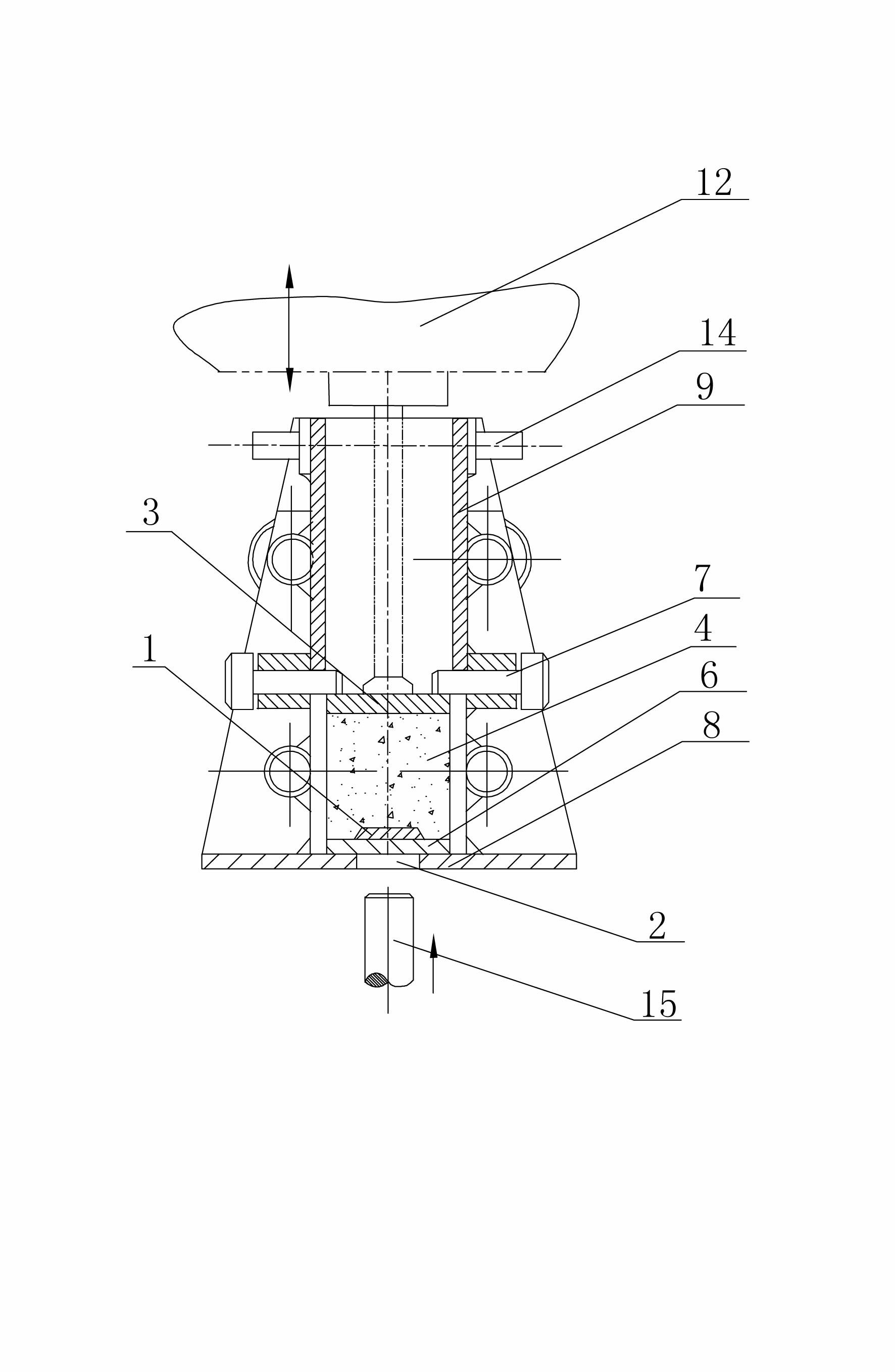

Device and method for plastic formation of micro parts through manual submerging type cavitation jetting

ActiveCN108890541AAppropriate intensityEasy to moveBlast gunsAbrasive feedersWorking fluidCavitation

The invention discloses a device and method for plastic formation of micro parts through manual submerging type cavitation jetting. The method comprises the following steps: enabling a working fluid to flow towards a pressurizing cylinder and a speed-regulating valve through an outlet of a three-way valve, and enabling the working fluid to enter a nozzle after the pressure and flow of the workingfluid are increased; opening a stop valve, spraying nano-scale abrasive particles in a micro-sized abrasive particle tank into the nozzle to be mixed with the fluid, and spraying the fluid out throughan outlet in the lower end of the nozzle; and introducing the residual fluid in the three-way valve to enter a casing pipe from another outlet of the three-way valve through a depressurizing valve. When uniformly mixed nano-scale abrasive particles and the fluid are sprayed out from the outlet of the nozzle and collide with the low-pressure fluid in the casing pipe, strong shear is generated, anda large number of vacuoles are generated and are sprayed to to-be-machined micro parts; and cavitation jetting is combined with the nano-scale abrasive particles, a mutual promotion effect is achieved, the cavitation is promoted, the plastic formation of the micro parts is promoted, the machined positions are not cracked, and the surface polishing and strengthening effects on a formed site of a workpiece are promoted, so that the device can meet the requirements on the strength, fatigue durability and the like of the workpiece.

Owner:JIANGSU UNIV

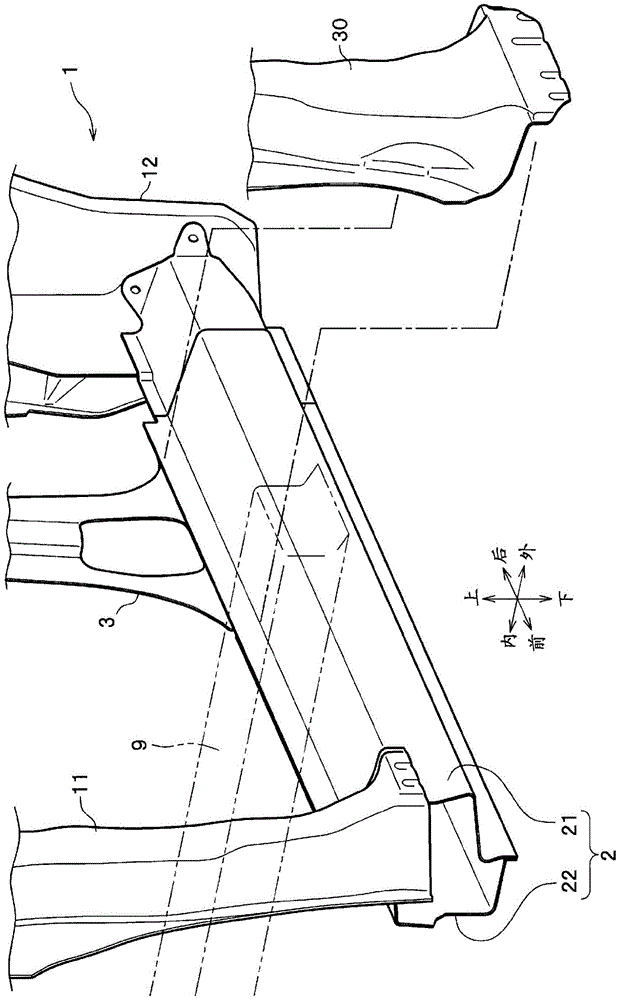

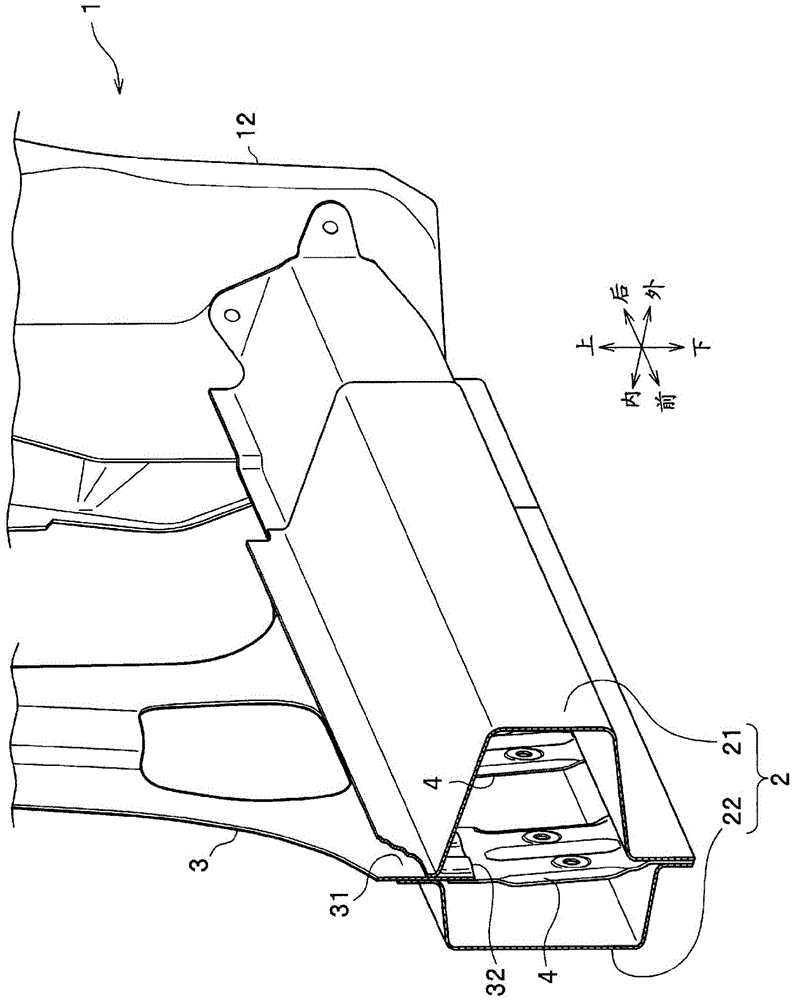

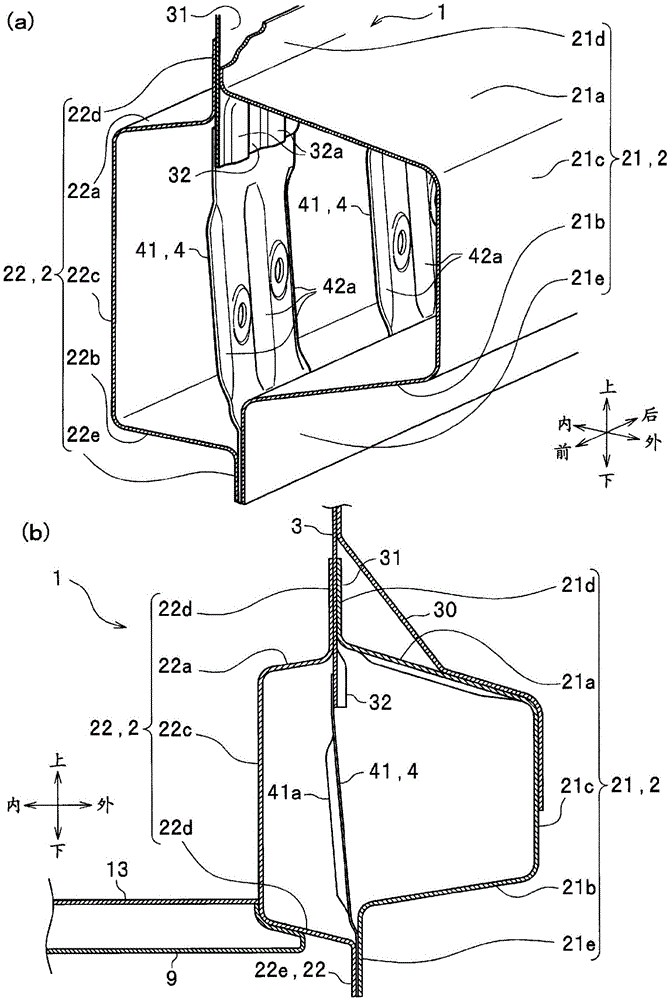

Vehicle body structure

ActiveCN105531180AImprove productivity and yieldIncreased Strength and RigiditySuperstructure subunitsWeight increasingEngineering

A side sill (2) is configured, in a closed section, from a side sill outer element (21) comprising an outer upper wall, outer lower wall, an outer side wall, an outer upper flange and an outer lower flange, and from a side sill inner element (22) comprising an inner upper wall, an inner lower wall, an inner side wall, an inner upper flange and an inner lower flange. On the lower end, a pillar (3) has a joint portion (31) which is held between and joined to the outer upper flange (21d) and the inner upper flange (22d), and a first extension part (32) and a second extension part (33) which extend from the joint portion (31) into the closed section of the side sill, and is provided with an extension (41, 42), the top end of which is joined to the first extension part (32) and / or the second extension part (33) and the bottom end of which is held between and joined to the outer lower flange (21e) and the inner lower flange (22e). By means of this configuration, it is possible to ensure a suitable rigidity through the minimally necessary weight increase, depending on the vehicle specifications.

Owner:HONDA MOTOR CO LTD

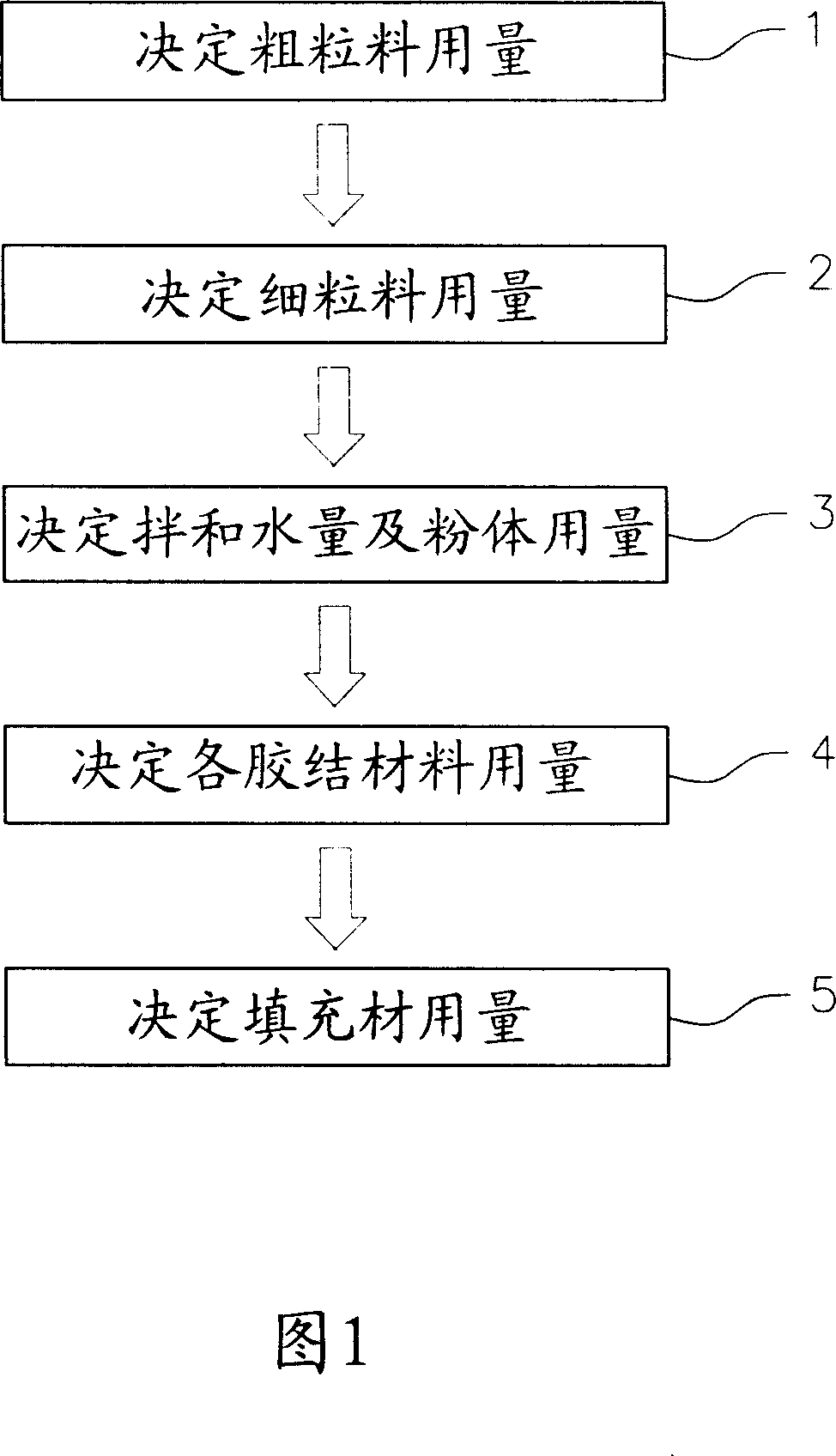

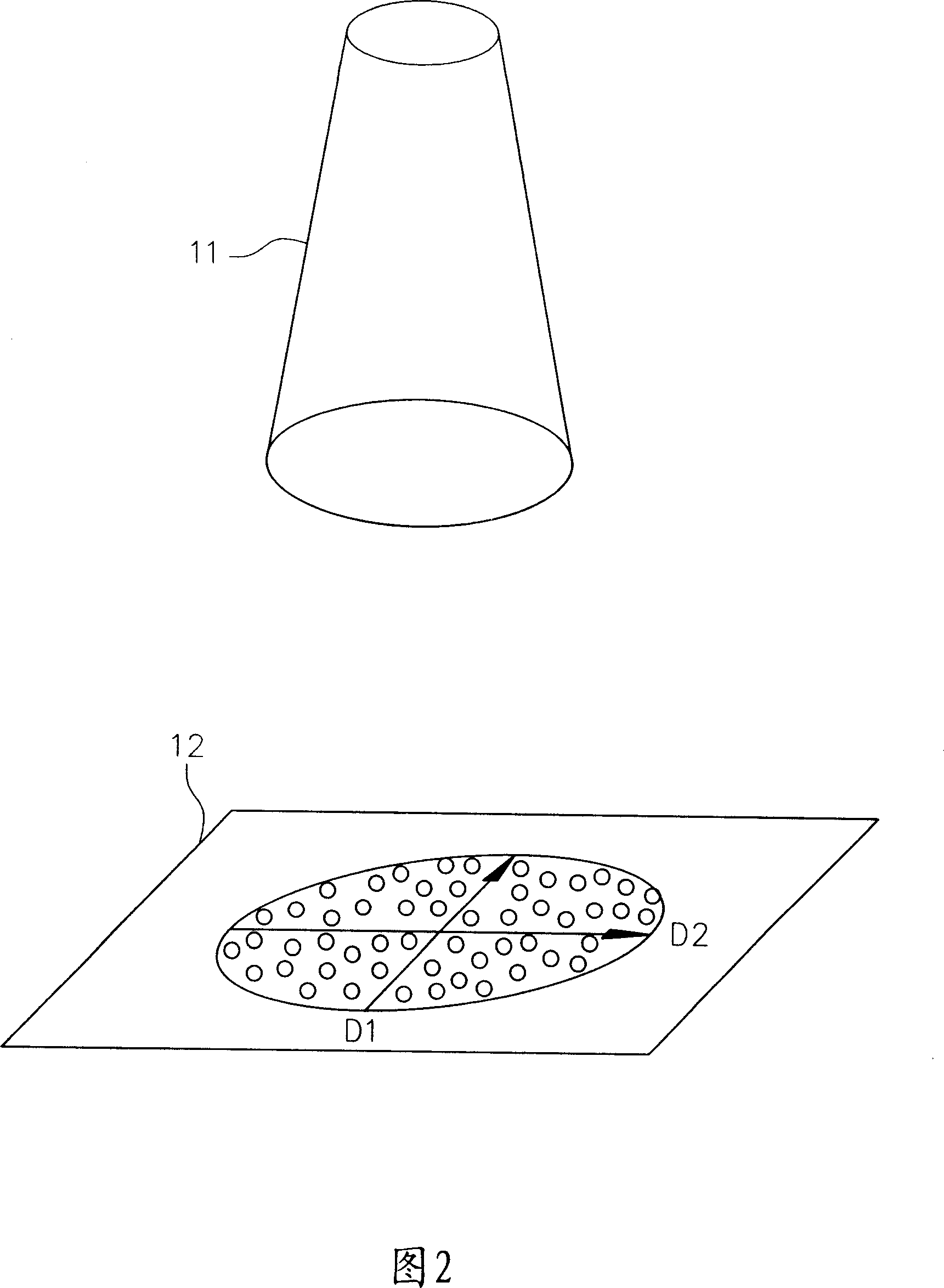

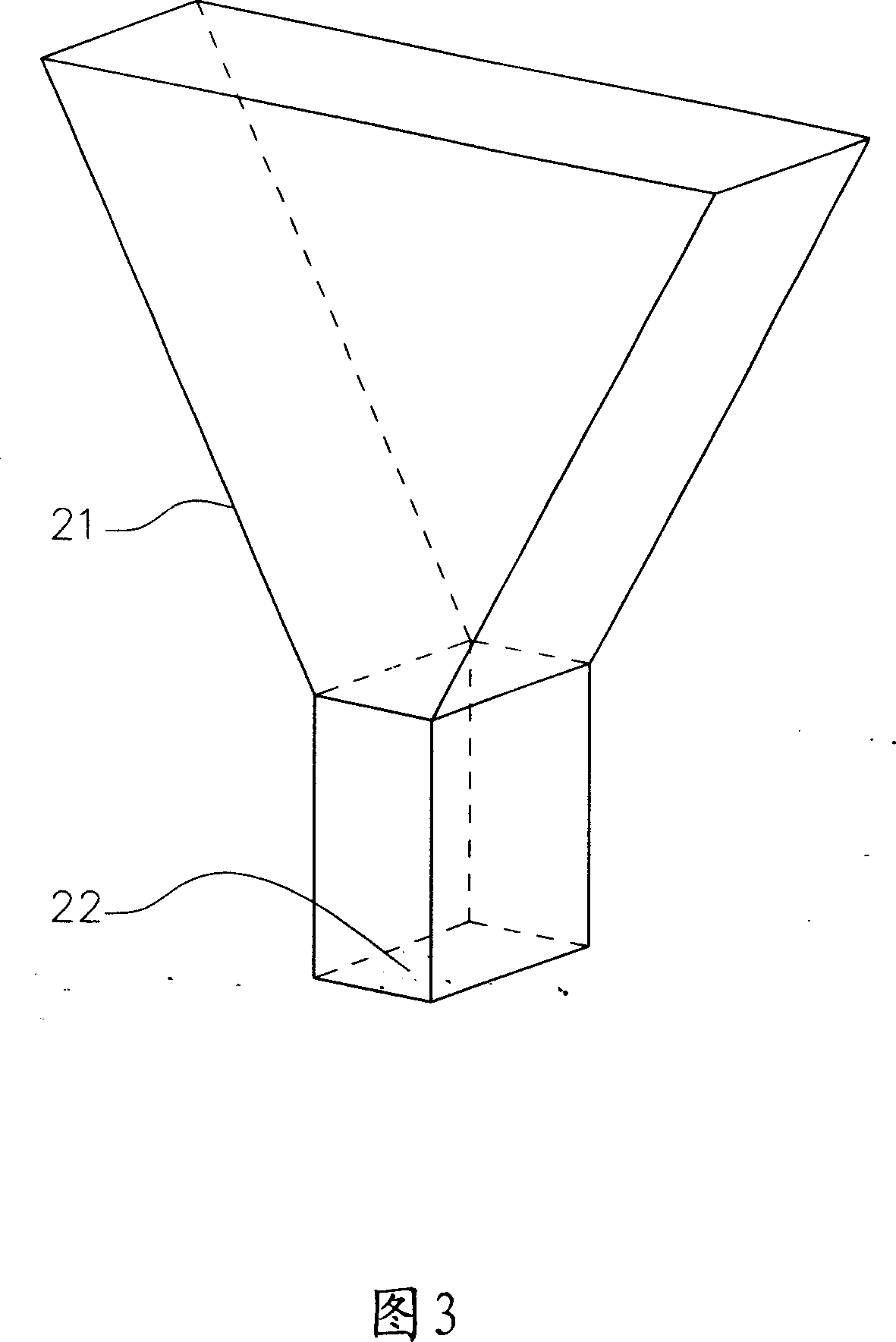

Concrete capable of not dispersing in water

The concrete without dispersion in water is produced with the materials including coarse aggregate; powder of cement and Pozzolan material or inert material without cementing property; water; and cohesion force increasing agent, such as polyacrylamine. One kind of self-filling concrete for water use with even higher performance is also provided, which is compounded with coarse aggregate, fine aggregate, cohesion force increasing agent, and water reducing agent, and may be used in filling reinforcing bar interval, densifying and raising strength. The present invention reveals also the design program and compounding process of the concrete without dispersion in water and the self-filling concrete for water use. The present invention has stable quality and proper strength, and is suitable for use in underwater engineering.

Owner:赵文成

Manufacturing method and special forming mold for synthetic sole timber

InactiveCN102490241AShorten the timeReduce the process of subsequent sawingWood working apparatusFlat articlesPre embeddingMaterials science

The invention relates to a manufacturing method and a special forming mold for a synthetic sole timber. The technological process of the manufacturing method is as follows: drying a powder lot or flaky material of imitation wood; adding a binding agent; stirring so as to prepare a synthetic sole timber raw material; extruding the raw material in the mold; performing compression moulding; heating; and demoulding and molding. The special mold comprises a fixed mould, a moving mould and an extrusion apparatus, wherein the fixed mould is composed of a mould bottom plate and two side plates which are fixedly connected with the mould bottom plate; the moving mould is composed of a press mold bottom plate with a longitudinal boss and a press mold upper plate with at least one transverse boss, and the end faces of the two side plates of the fixed mould are provided with moving end plates; and each moving end plate is provided with a pre-embedded positioning sleeve and a lock bolt, and the mould bottom plate is provided with at least one moving mould ejecting port. The manufacturing method and special forming mold provided by the invention have the advantages that the process of follow-up sawing is reduced due to once compression moulding of the synthetic sole timber manufactured by the process and the special mold, the time of a blank on a briquetting machine is reduced, and the production efficiency is improved.

Owner:董久红

One-component flexible polymer waterproof mortar material and method for preparing waterproof mortar by using one-component flexible polymer waterproof mortar material

The invention relates to a one-component flexible polymer waterproof mortar material and a method for preparing waterproof mortar by using the one-component flexible polymer waterproof mortar material. The waterproof mortar material comprises the following powder: cement, sand, rubber powder, cellulose, fiber, silica fume, a defoaming agent, a water reducing agent, a waterproof agent and the balance of a silicon-aluminum material. According to the selected value ranges, the specific powder is selected, matched and added into a stirring device for sufficiently stirring, and a finished product of the one-component flexible polymer waterproof mortar material can be obtained after evenly mixing. The method for preparing waterproof mortar comprises the steps of burdening, adding water and mixing, and treating. The one-component flexible polymer waterproof mortar material and the method have the advantages that the flexible polymer waterproof mortar obtained after evenly mixing the waterproof mortar material and the water has the durability of mortar and certain flexibility so as to prevent cracking and water seepage, and meanwhile the flexible polymer waterproof mortar is ultra-thin, high in anti-permeability, high in wear resistance, good in anti-permeability and waterproof performance, proper in strength, and good in flexibility, impact resistance and cohesive property. The preparation method of the waterproof mortar is easy to grasp and high in efficiency, and can be used for guaranteeing the product quality.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

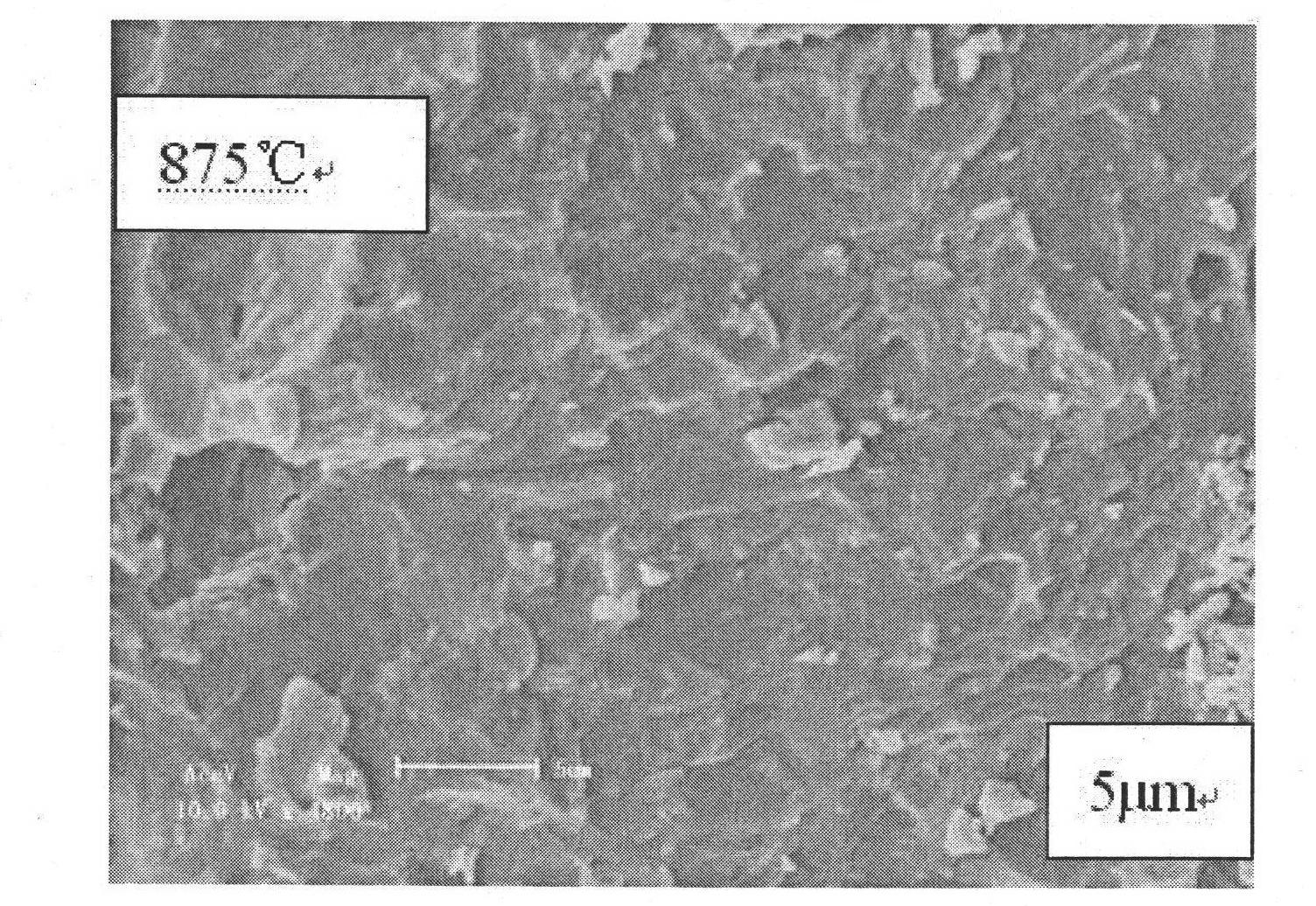

A kind of preparation method of easy-to-remove ceramic core

ActiveCN102266906AHigh strengthAppropriate intensityFoundry mouldsFoundry coresPorosityTurbine blade

The invention relates to a preparation method of an easy-to-remove ceramic mold core. The easy-to-remove ceramic mold core is characterized in specific preparation method requirements that: the effective reaction area of the ceramic mold core is increased through the addition of carbon nano-tubes which takes 0.01% to 0.1% of the mass of the powder material; pores in the mold core are connected byspatial channels formed by sintered carbon nano-tubes, such that chemical liquid can be quickly delivered into the pores of the ceramic mold core, the speed of the reaction between the ceramic mold core and the chemical substances can be greatly improved, and the ceramic mold core can be quickly removed. Compared to prior arts, the ceramic mold core provided by the present invention is suitable for the producuction of high pressure hollow turbine blades with complicated inner chamber structures; the ceramic mold core material can be used for preparing ceramic mold cores with tiny and complicated structures. The prepared ceramic mold cores have relatively high strength and density. Also, certain porosity is maintained while a proper strength is maintained. Therefore, practical production requirements are ensured.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

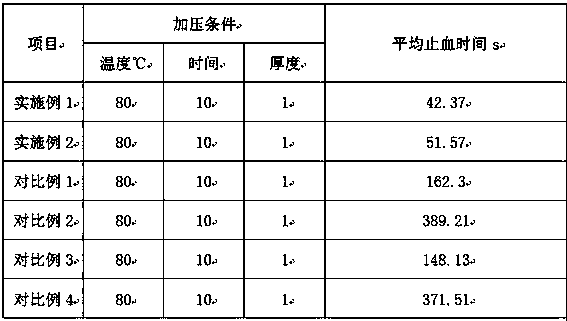

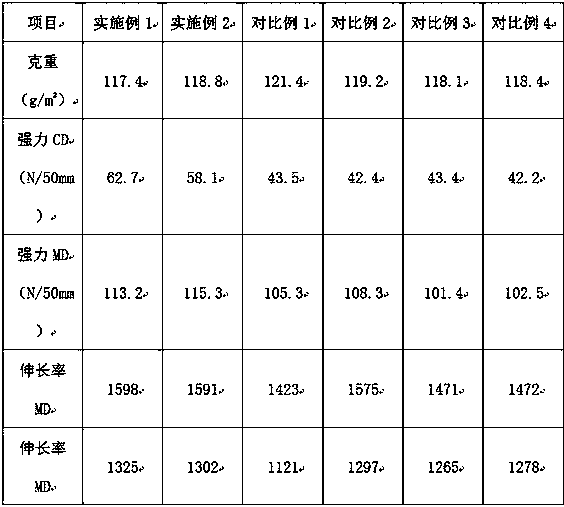

Elastic non-woven cloth with high water absorption and air permeability for medical magnetic therapy

InactiveCN108978042AAppropriate intensityAppropriate softnessMonocomponent polyurethanes artificial filamentElectrotherapyFiberBiocompatibility Testing

The invention discloses elastic non-woven cloth with high water absorption and air permeability for medical magnetic therapy. The elastic non-woven cloth is made from, by weight, 20-27 parts of modified polylactic acid fiber, 20-33 parts of modified bamboo fiber, 10-20 parts of hydroxymethyl cellulose, 2-5 parts of casein, 20-30 parts of soybean fiber, 5-10 parts of sodium alginate, 20-35 parts ofstarch, 20-23 parts of magnetic starch, 40-45 parts of modified polyacrylamide fiber and 3-5 parts of a plant extract. The non-woven cloth has bacteriostatic activity, can effectively prevent wound infection, and is suitable for extensive symptoms, remarkable in health effect, safe and reliable in magnetic therapy function and economical and practical; raw materials adopted are biodegradable natural polymer materials and have good biocompatibility, and simpleness in the method is achieved.

Owner:HEFEI SHENGDA GARMENT ACCESSORIES CO LTD

Dry method paper cigarette filter candle and preparation method thereof

InactiveCN1669491AThe production process is simpleFeel fullTobacco smoke filtersPaper sheetCigarette filter

The invention discloses a dry method paper cigarette filter candle and preparation method, wherein the filter candle comprises filtering element base material and forming paper, the filtering element base material is prepared paper made through dried bulking process. During the filter candle manufacturing procedure, the dry method paper meeting the index point is arranged onto the feed arrangement of the conventional filter candle forming machine, wherein filter candles are formed on the forming machine through bundled modeling. Since no cellosolve or modeling adhesive are needed, the preparation process can be simplified. The filtering ratio of the obtained cigarette filter tip is over 40%.

Owner:梅建华

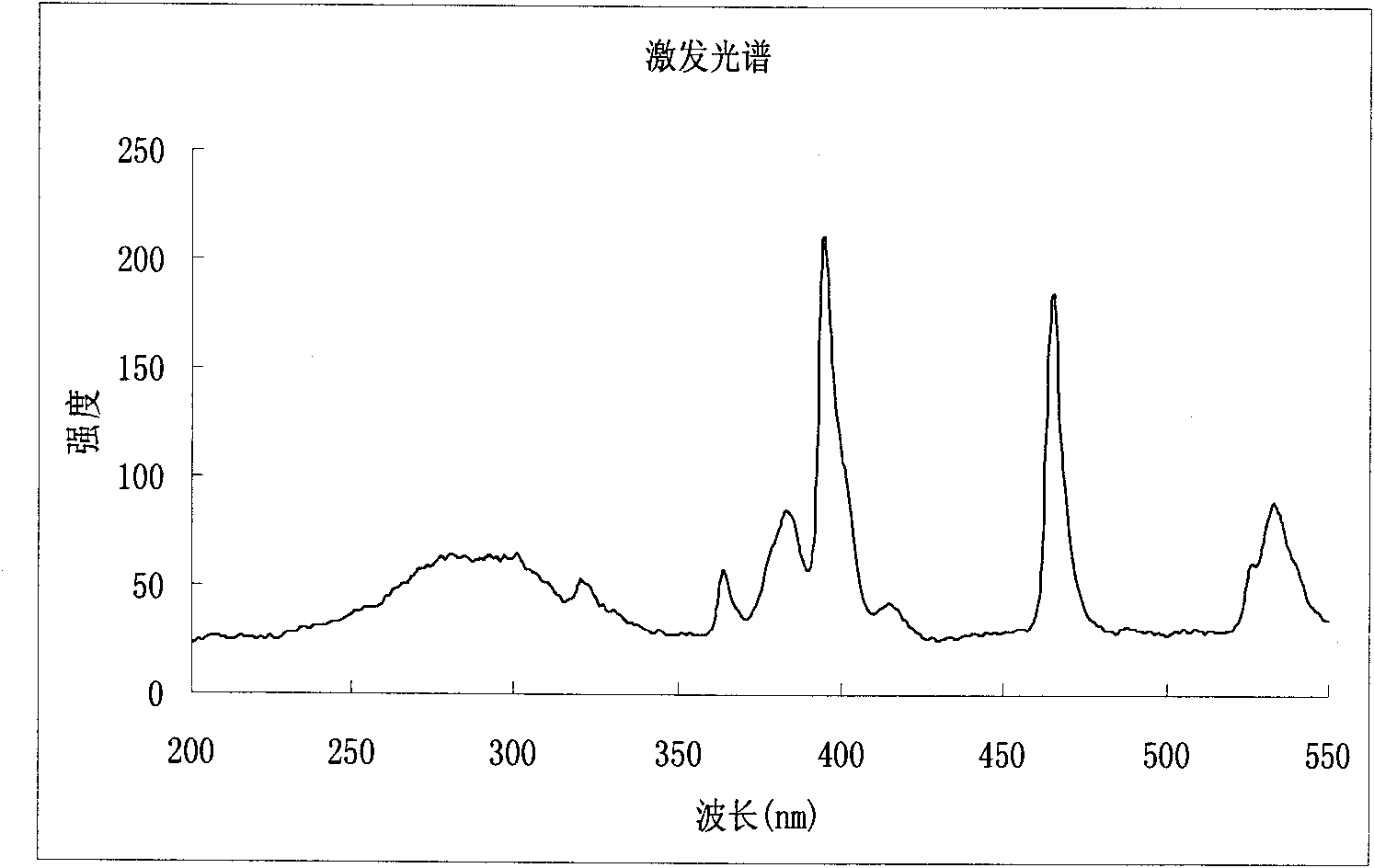

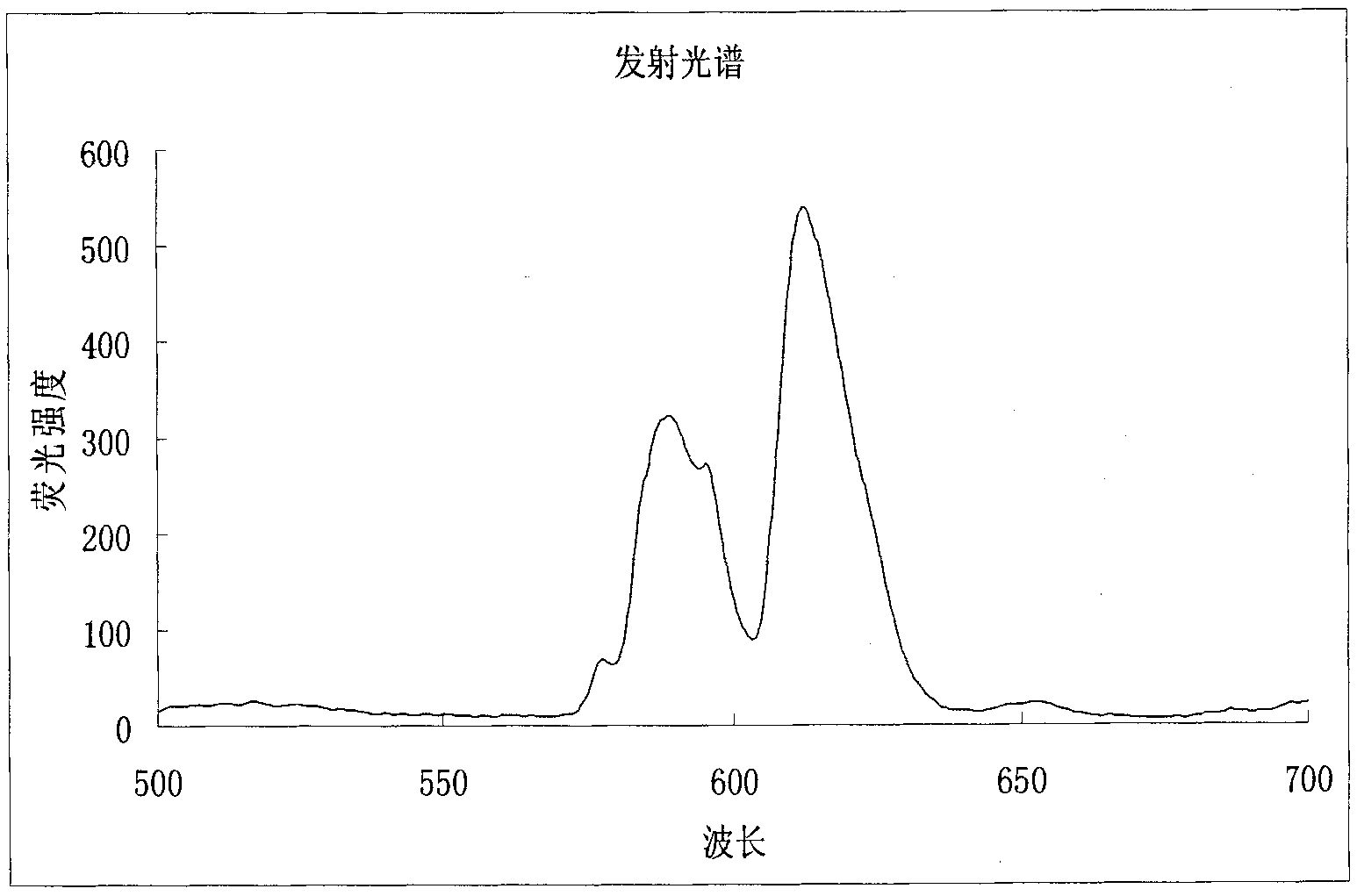

Light-emitting low-temperature co-fired ceramic powder, preparation method thereof and light-emitting low-temperature co-fired ceramic

The invention provides a light-emitting low-temperature co-fired ceramic powder, a preparation method thereof and a light-emitting low-temperature co-fired ceramic prepared from the light-emitting low-temperature co-fired ceramic powder. The light-emitting low-temperature co-fired ceramic powder is prepared from 15-20mol% of CaCO3, 60-70mol% of Si(OC2H5)4, 10-25mol% of B2O3, 3-11mol% of photoactivating agent, 0.9-3.2mol% of sensitizing agent and charge compensation agent gel equivalent to the total content of the photoactivating agent and the sensitizing agent by calcination. The low-temperature co-fired ceramic powder has the advantages of low sintering temperature, small dielectric loss, high mechanical strength and high light intensity, and can be used in the fields of ceramic base plates, electronic devices such as resonators and the like, other micro electronic potting materials and white light LED potting materials.

Owner:TSINGHUA UNIV

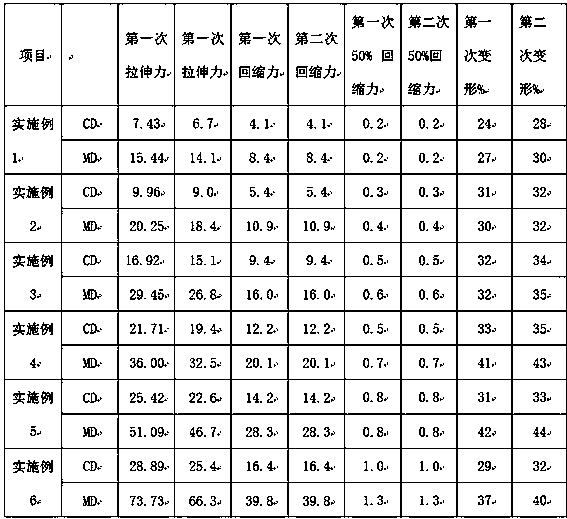

Water absorbent resin and method for producing same

ActiveCN103080139AAppropriate granularityAppropriate intensityAbsorbent padsThin material handlingFiberUltimate tensile strength

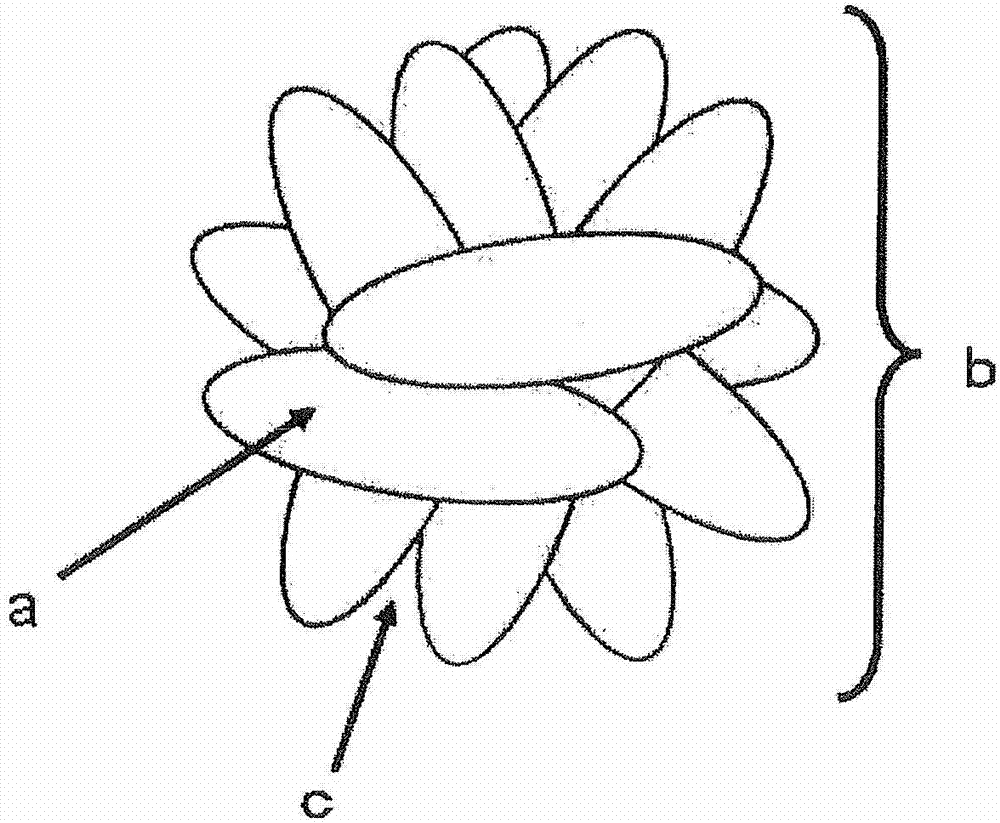

The main objective of the present invention is to provide: a water absorbent resin having excellent general absorption performance as a water absorbent resin, an adequate particle size and a high particle strength as well as having excellent fiber tenacity and high fluidity as a powder, as properties suitable for a water absorbent for use in a hygienic material; and a method for producing the same. The objective of the present invention is also to provide an absorber and an absorbent article using the water absorbent resin. The water absorbent resin is in a form with an aspect ratio of 1.0 to 3.0 and a median particle size (D) of 100 to 2,000 [mu]m, in which first particles with an aspect ratio of 1.1 to 200 and a median particle size (d) of 50 to 600[mu]m are aggregated.

Owner:SUMITOMO SEIKA CHEM CO LTD

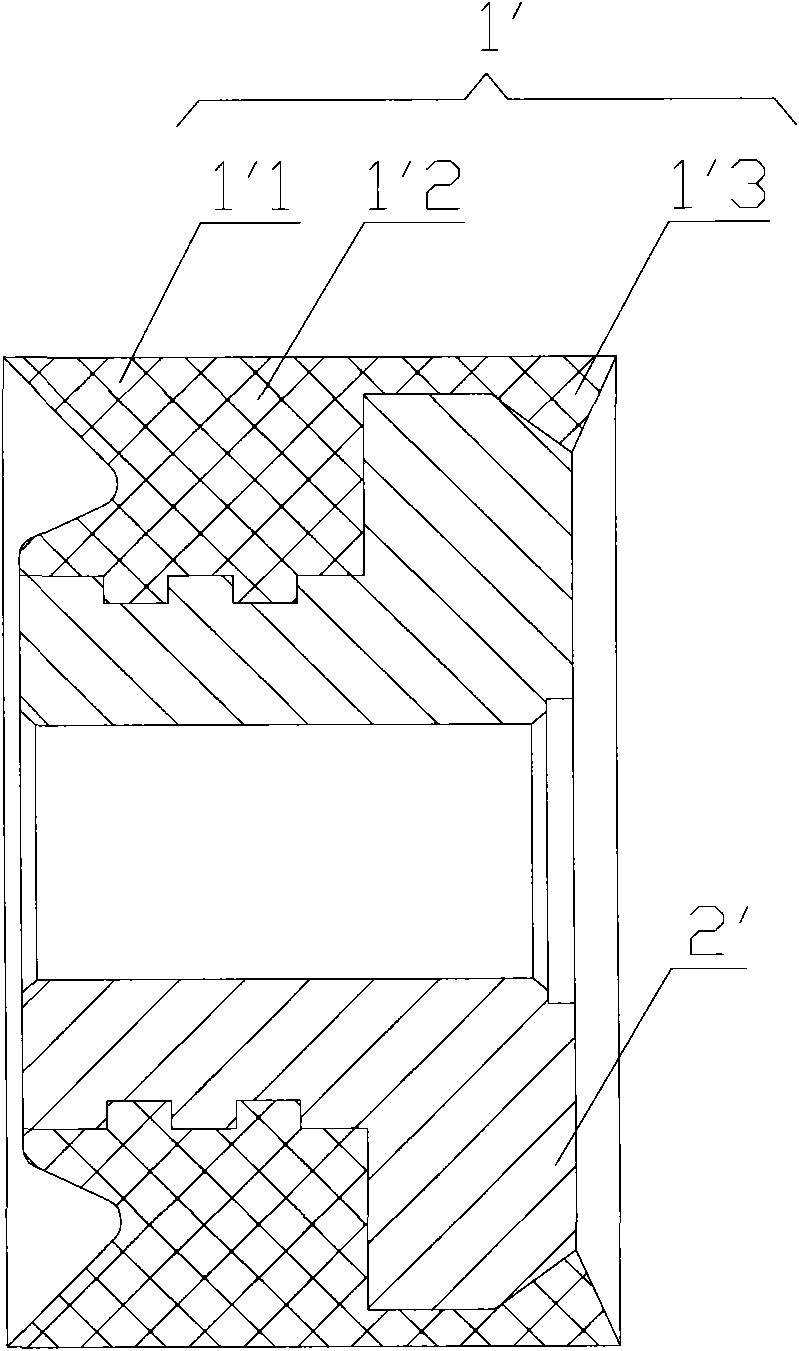

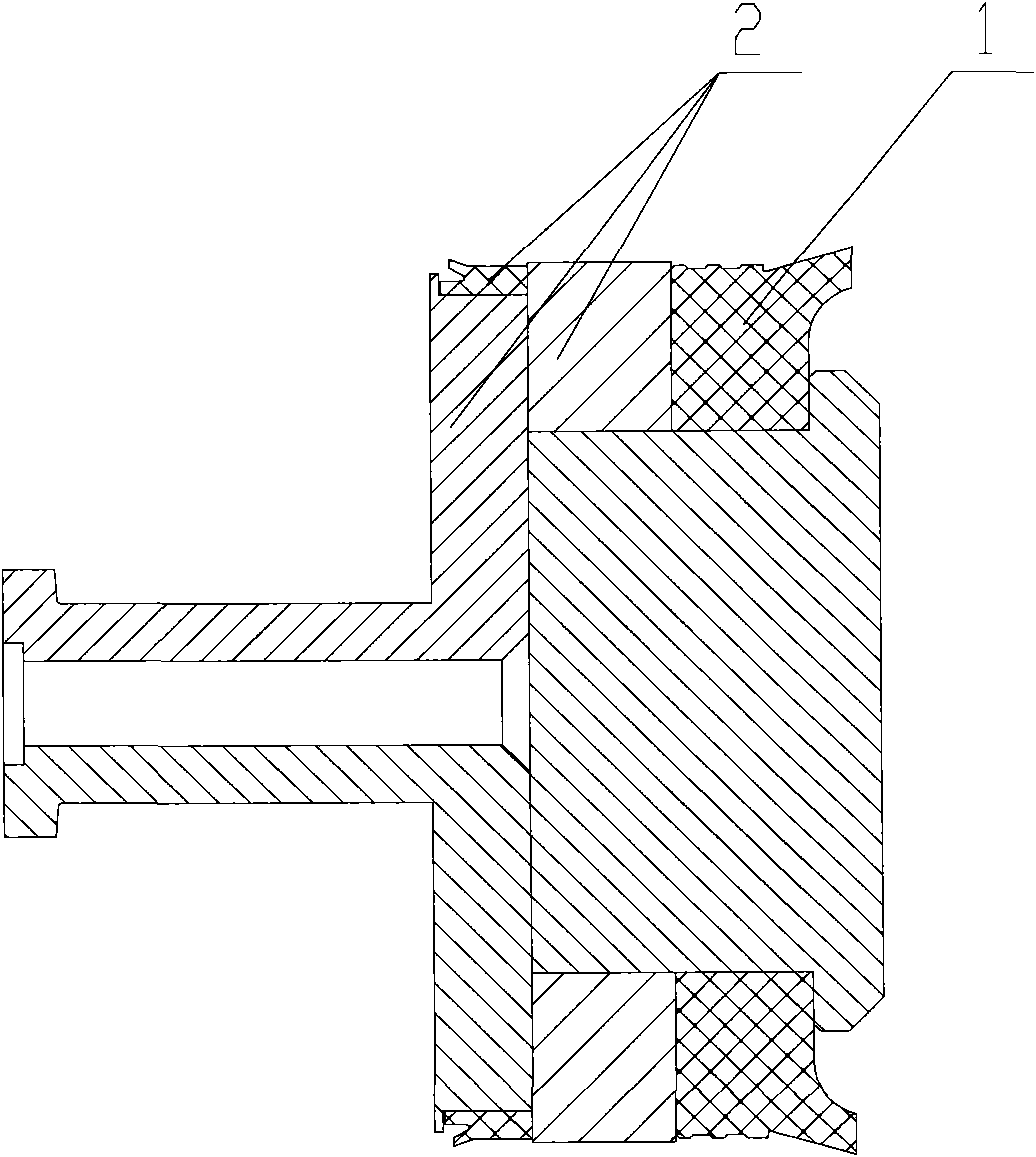

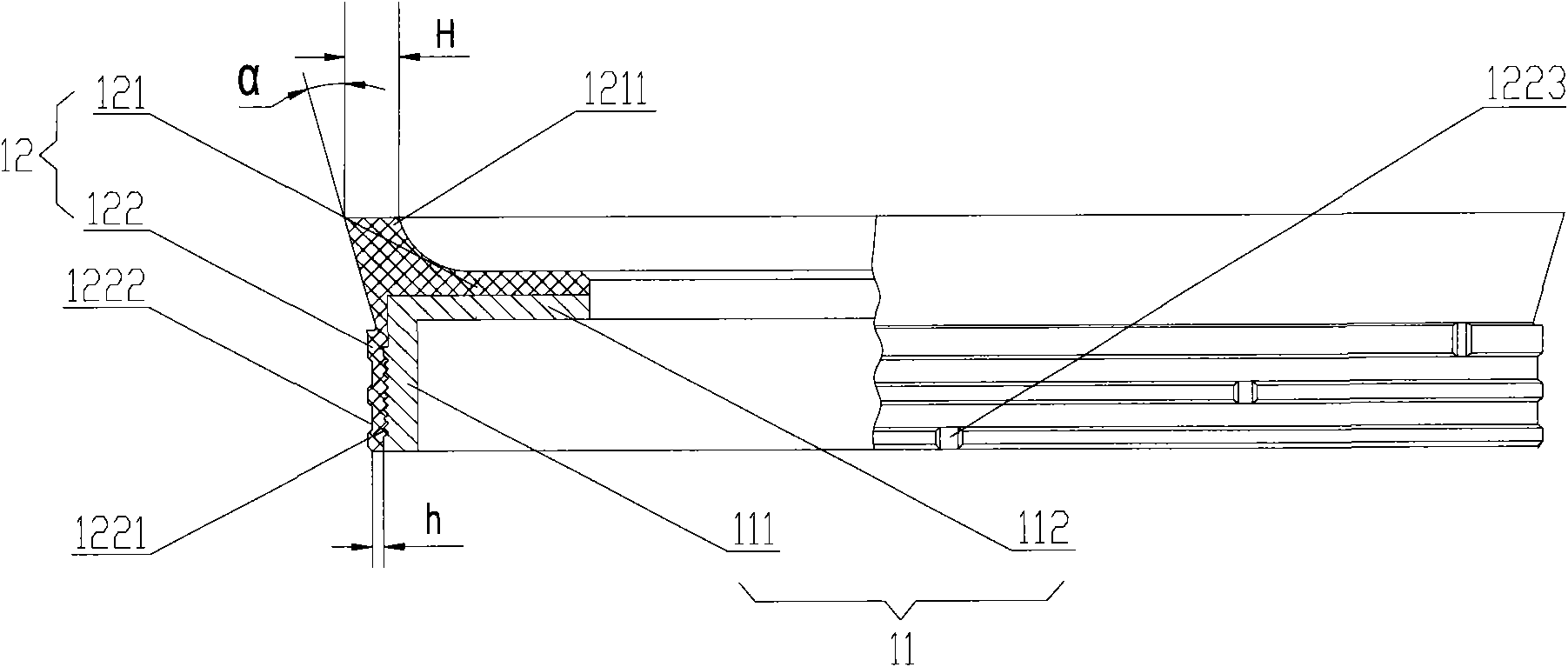

Concrete pumping equipment and piston body thereof

ActiveCN101608616AImprove mechanical propertiesUniform mechanical propertiesPositive displacement pump componentsPumpsEngineeringMechanical engineering

The invention discloses a piston body used for concrete pumping equipment. The piston body includes a main body part (2) connected with a piston rod of the concrete pumping equipment and a sealing component (1) arranged at the front end of the main body part (2) detachably and provided with a sealing lip (1211). The sealing component (1) includes a framework part (11) with proper strength and a cladding part (12) with proper hardness. The arrangement of the framework part (11) improves the mechanical property of the sealing component (1), leads to uniform abrasion of the sealing lip (1211) and reduces the heat energy accumulated due to the deformation of the sealing lip (1211), thus further relieving the temperature rise of the sealing component (1) caused by the heat energy, avoiding the problem of early failure caused by the situation that the working temperature of the sealing component (1) exceeds the normal use temperature, prolonging the service life of the sealing component of the piston body and enhancing the economical efficiency of the piston body in use process.

Owner:SANY AUTOMOBILE MFG CO LTD

Measuring instrument for gravimetric moisture determination

ActiveUS7617717B2Easy to controlLess timeDrying solid materials with heatMaterial moisture contentMeasuring instrumentEngineering

An instrument for gravimetrically determining the moisture content of a sample has a housing with a weighing device therein. The weighing device has a load-receiving portion and a sample receiver, the latter designed for connection to the load-receiving portion. The housing also contains a test compartment. When set in position to perform a measurement, the sample receiver is disposed inside the test compartment. One embodiment of a means arranged in the test compartment for heating a sample placed on the sample receiver has first and second radiation sources, with the sample receiver arranged therebetween.

Owner:METTLER TOLEDO GMBH

Asphalt cement mortar

ActiveCN101186477AMeet the needs of constructionGood weather resistanceWeather resistanceCement mortar

The invention discloses an asphalt cement mortar, which is a compound synthesized by dry materials, emulsified asphalt, water-reducing agent, defoaming agent and water pro rata. Each component in the mixture is calculated in portions by weight: 70-80 portions of the dry materials, 10-20 portions of the emulsified asphalt, 0.1-0.4 portion of the water-reducing agent, 0.005-0.01 portion of the defoaming agent and 8-15 portions of the water. The dry materials consist of cement, aggregate and expansion agent. Each component in the dry materials is calculated in portions by weight: 35-42 portions of the cement, 58-65 portions of the aggregate and 0.0015-0.0025 portion of the expansion agent. The component proportion of the asphalt cement mortar of the invention is proved by a great number of experiments and can lead each component to be fully used and generate synergistic effect. The invention has appropriate intensity and elasticity, good weather resistance and construction ability and can completely meet the need of plate-typed unballasted track construction in railways or in cities. Furthermore, the raw materials of the components of the invention are all produced in domestic, thus greatly saving cost.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

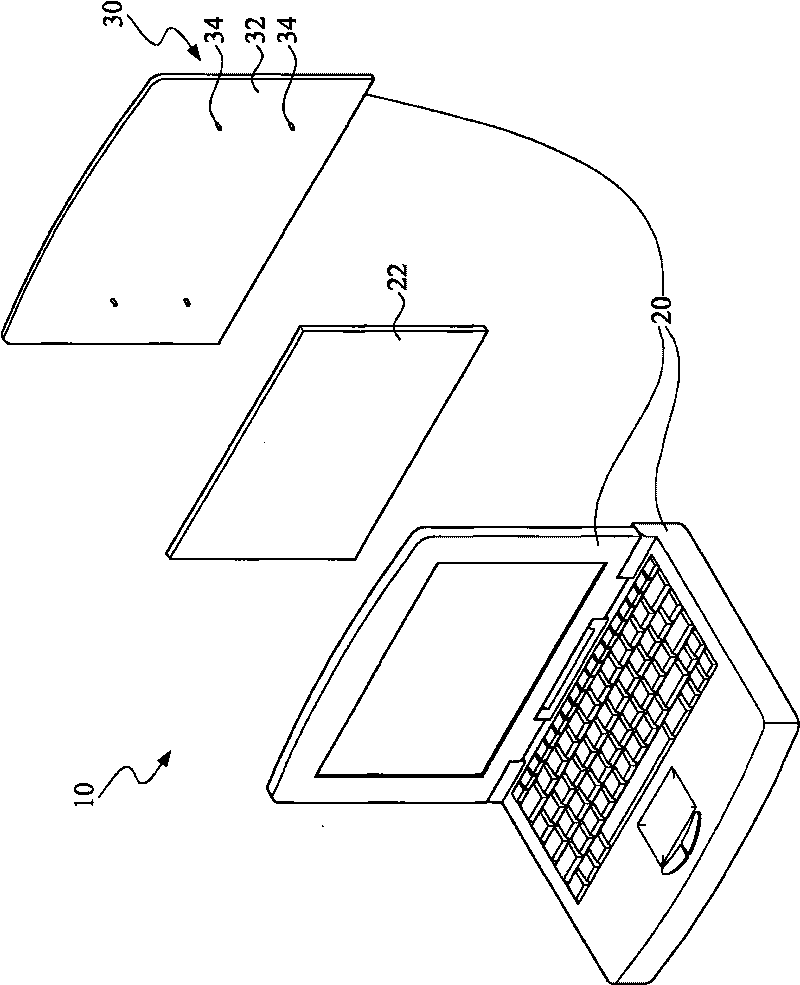

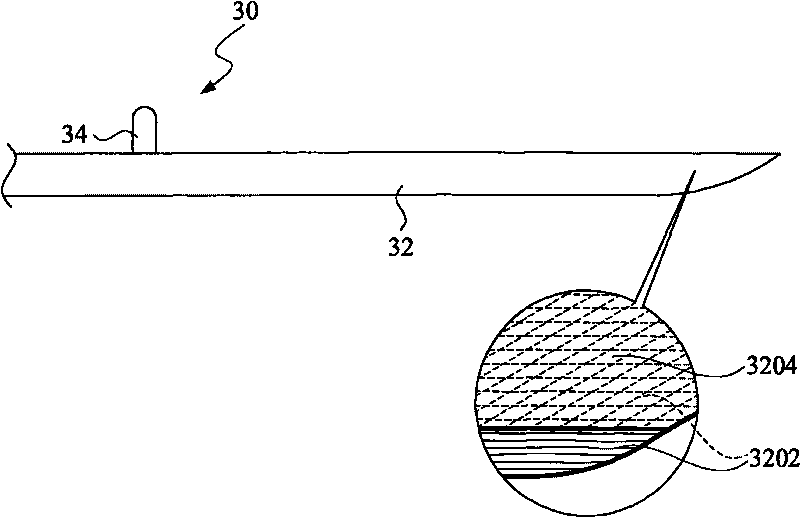

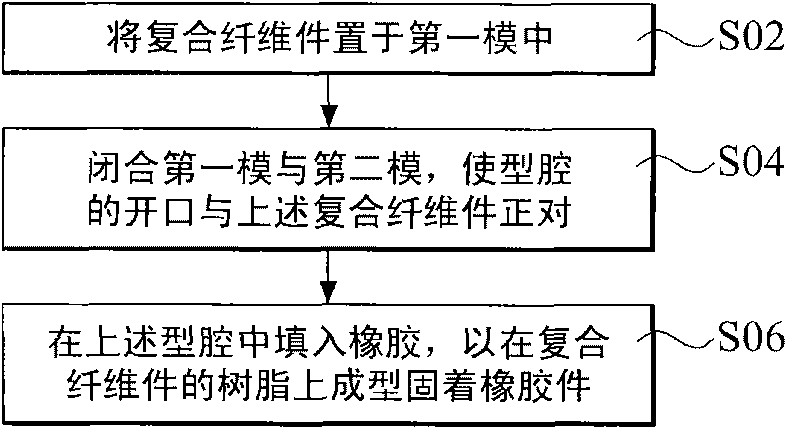

Compound material object and fabrication method thereof

InactiveCN101722663AImprove tensile strengthLight weightElectrical apparatus casings/cabinets/drawersPolymer scienceUltimate tensile strength

The invention relates to compound material object which is fabricated by combing rubber and compound fiber material and provided with rubber articles and compound fiber articles and a fabrication method thereof. The fabrication method has the following steps: placing hot-set compound fiber object or compound fiber object not yet hot-set in a first module of a die, wherein the compound finer object is a structure coated by at least a fiber layer with resin; then, closing the first module and a second module of the die, so that the opening of a cavity of the second module exactly aligns with the compound fiber object; finally filling the cavity with rubber and providing different molding environments according to the hot-set or not yet hot-set conditions so as to mold and fix the rubber object on the resin of the compound fiber object. The compound material object of the invention is provided with a surface with special touch, good shearing resistance and tension stress and the design suitable for slim trend of products. With the fabrication method of the invention adopted, combination of the rubber and the compound fiber object can be provided with moderate strength and reliability, the combination processes can be simplified and consumption of auxiliary raw materials can be reduced.

Owner:PEGATRON

Stethoscope heart sound signal processing method and stethoscope device

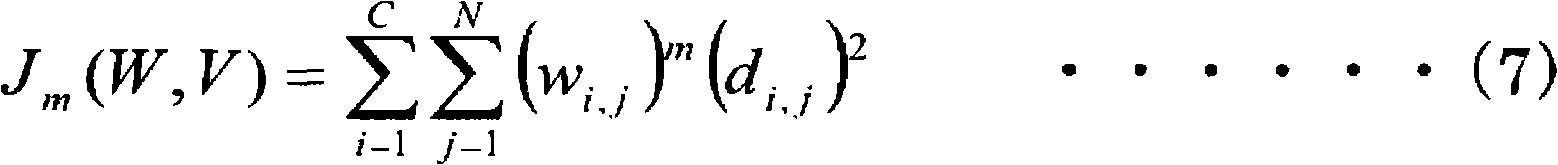

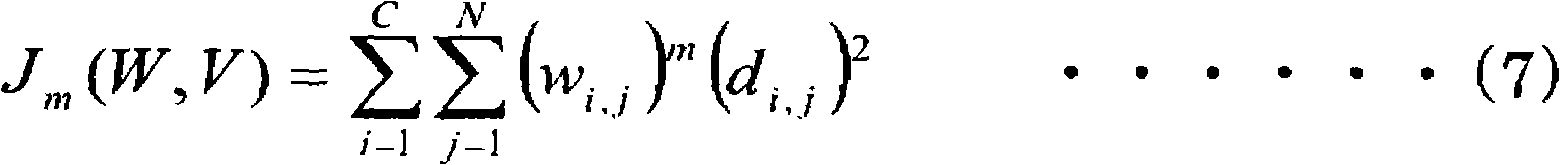

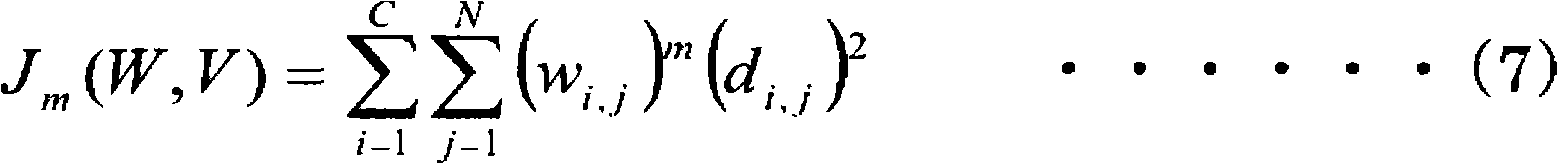

The detected heart sound signal is adjusted to an adequate volume and quantitavely analyzed with high accuracy, and a processing to improve the sound quality of the heart sound signal to make the heart sound signal easy to listen to. In analyzing a heart sound, an evaluation index of a heart sound feature value waveform generated by using heart sound data and a vibration model is determined, the center of a data set is so determined that the evaluation function expressing the dispersion of the evaluation index takes on a minimum value, and the evaluation index for a threshold and the distribution of the center of the data set are determined. To improve the quality of the heart sound, after substantially eliminating the phase difference and multiply the heart sound signal and the heart sound feature value waveform, the product is used as output heart sound data. In adjusting the volume of the heart sound signal, the up gain is determined using a reference table according to the average intensity for a time Ta of the detected heart sound signal, and the heart sound signal for a time Tb after the time Ta is amplified and recorded.

Owner:YAMAGUCHI UNIV

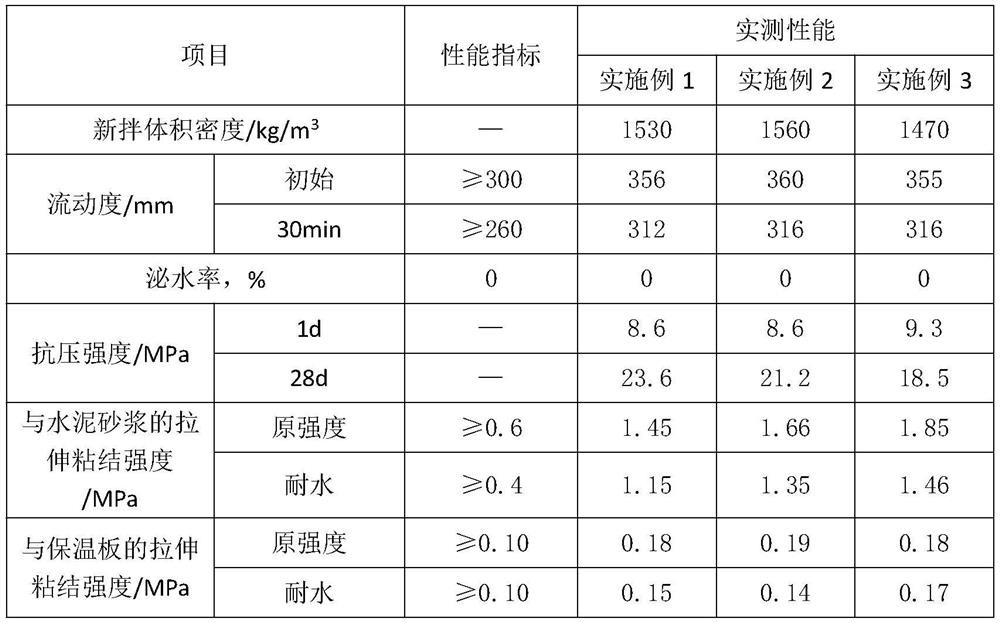

Lightweight grouting material for repairing hollowing of wall thermal insulation system and preparation method

InactiveCN112341124AImprove volume stabilityGood empty drum repair and compact effectAluminateCellulose

The invention belongs to the technical field of building materials, and provides a lightweight grouting material for repairing hollowing of a wall insulation system and a preparation method. The lightweight grouting material comprises a ternary cementing material, an auxiliary cementing material, latex powder, cellulose ether, a water reducing agent, an air entraining agent, an antifoaming agent,a water repellent, an expanding agent, lightweight aggregate and quartz sand, wherein the ternary cementing material is formed by mixing Portland cement, sulphoaluminate cement and gypsum, and the auxiliary cementing material is a mixture of titanium slag micro-powder and fly ash. The lightweight grouting material is simple to prepare and convenient to use, and has the advantages of easiness in grouting, good hollowing repairing effect, controllable setting time and operable time, small volume density, no segregation or layering, quicker early strength development, higher strength, high bonding strength with a matrix, no shrinkage cracking problem and the like; the grouting material is suitable for hollowing repair projects of various wall exterior and wall interior thermal insulation systems, and other grouting repair projects with low requirements on compressive strength and high requirements on adhesive properties.

Owner:TONGJI UNIV

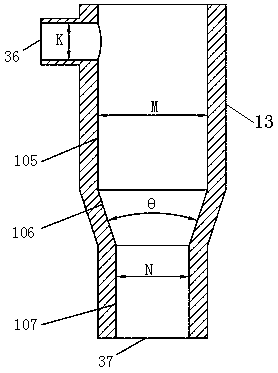

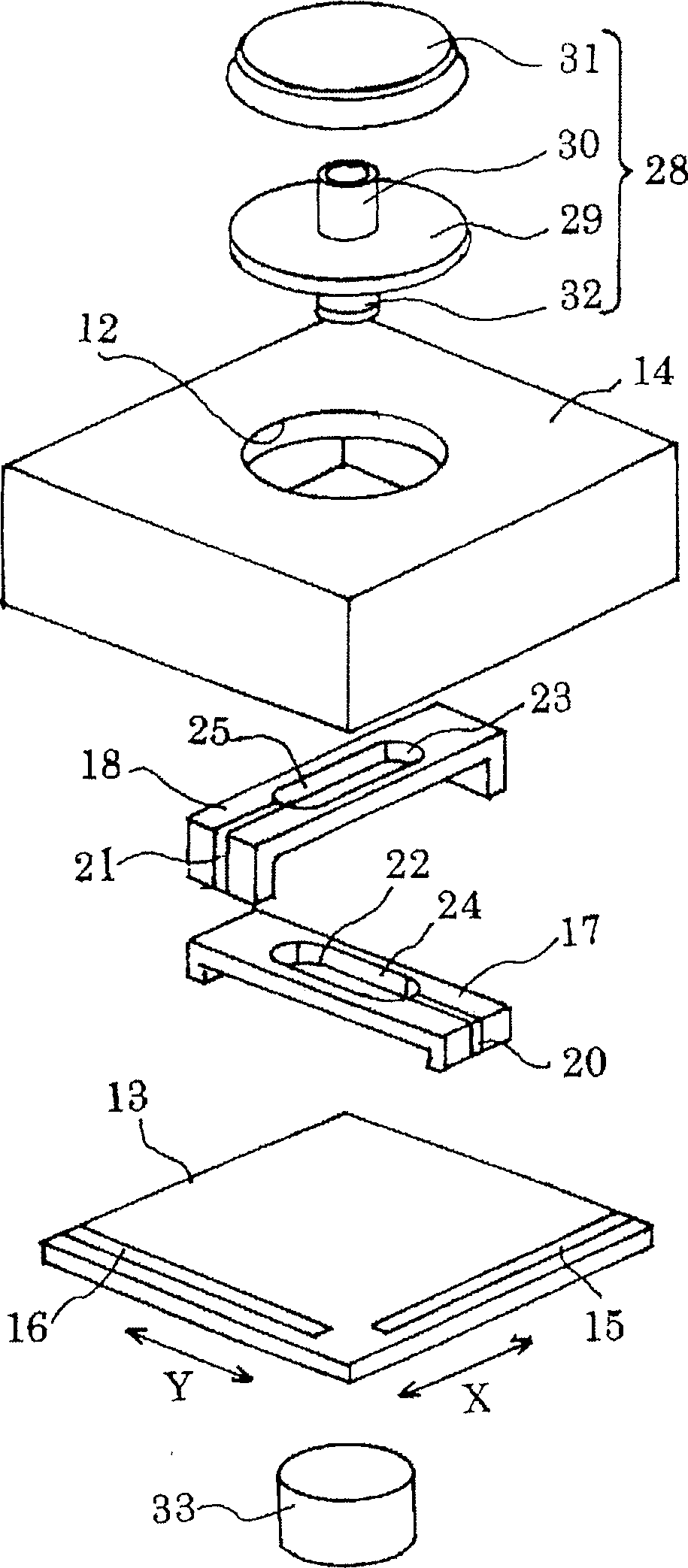

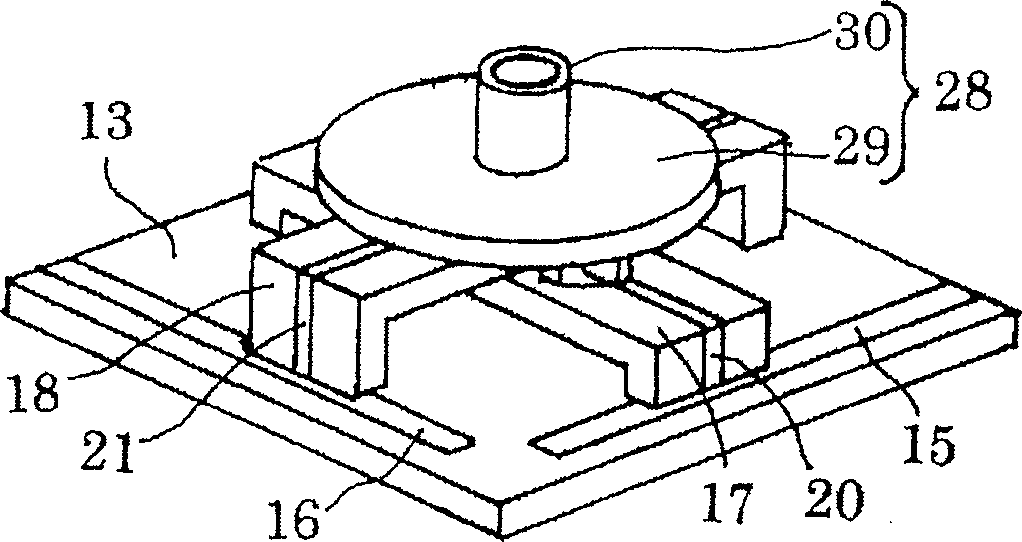

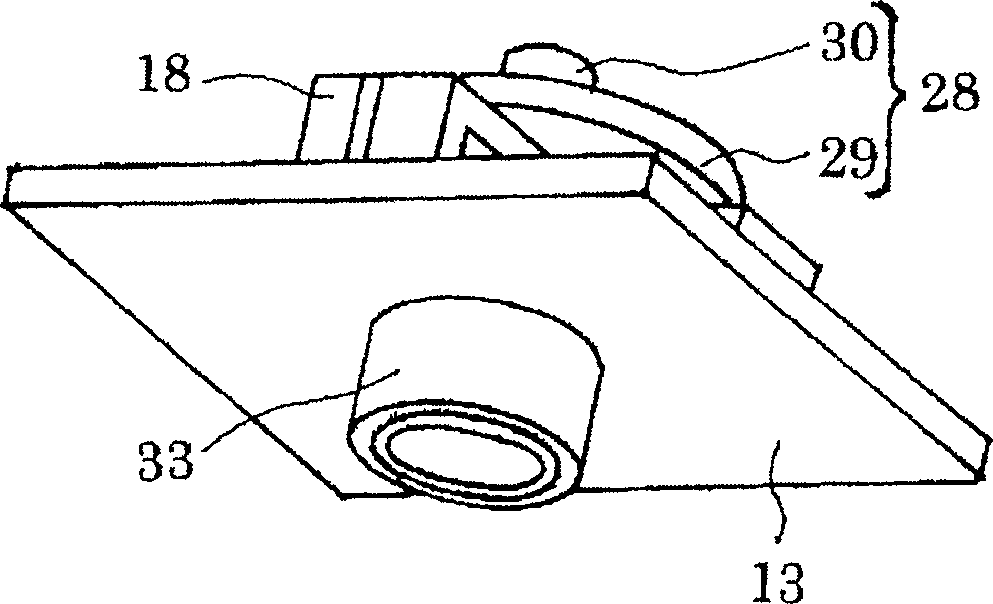

Joy stick controller

InactiveCN1892952AUniform sense of operationImprove operational stabilityManual control with multiple controlled membersLimiting/preventing/returning movement of partsNeutral positionMagnet

The invention provides a joy stick device capable of improving silence while obtaining fixed stick operating feeling. The device is provided with cranks 17 and 18 provided on a substrate 13 freely movably in X and Y directions, and an operating stick 28 having a shaft part 30 penetrating through the center parts of the both cranks 17 and 18, and a lower end part of the shaft part 30 is formed of a magnet 32. A magnet 33 being a magnet member for position return is fixed onto the bottom surface of the substrate 13 corresponding to the neutral position in the X and Y directions. After a stick operation, the magnet 32 at the shaft side is moved right above the magnet 33 by magnetic force to thereby make the operating stick 28 automatically immediately return to the midpoint position.

Owner:MITSUMI ELECTRIC CO LTD

High-water-resistance polyurethane material for coal mine downhole gas sealing and preparation method thereof

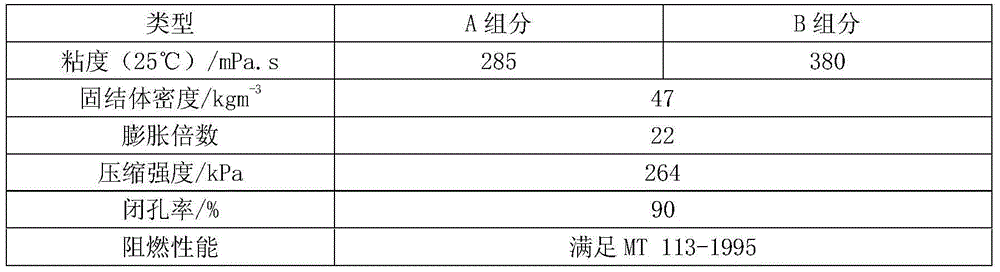

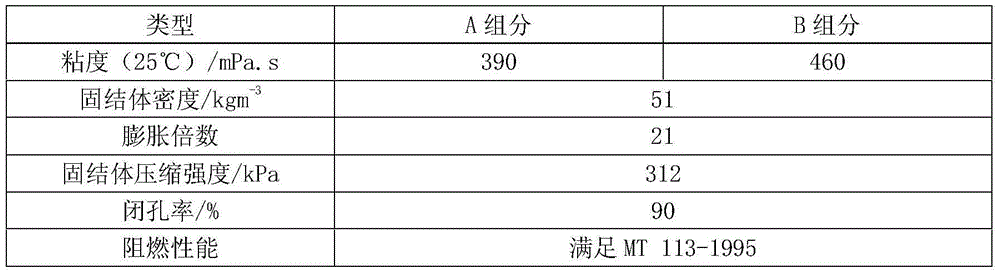

The invention relates to a high-water-resistance polyurethane material for coal mine downhole gas sealing, which is composed of a component A and a component B in a weight ratio of 1:1. The component A comprises the following raw materials in parts by weight: 50-75 parts of polyether glycol 1, 10-20 parts of polyether glycol 2, 1.0-2.0 parts of surfactant, 0.1-2.0 parts of catalyst, 5-15 parts of flame retardant and 10-15 parts of foaming agent. The component B comprises the following raw materials in parts by weight: 40-70 parts of polyisocyanate, 25-50 parts of prepolymer and 5-10 parts of diluter. The polyether glycol 1 in the component A is polyoxypropylene polyalcohol, of which the functionality is 3-5 and the molecular weight is 300-800; and the polyether glycol 2 is polyoxypropylene polyalcohol, of which the functionality is 2-3 and the molecular weight is 150-2000.

Owner:洛阳贝隆实业有限公司 +1

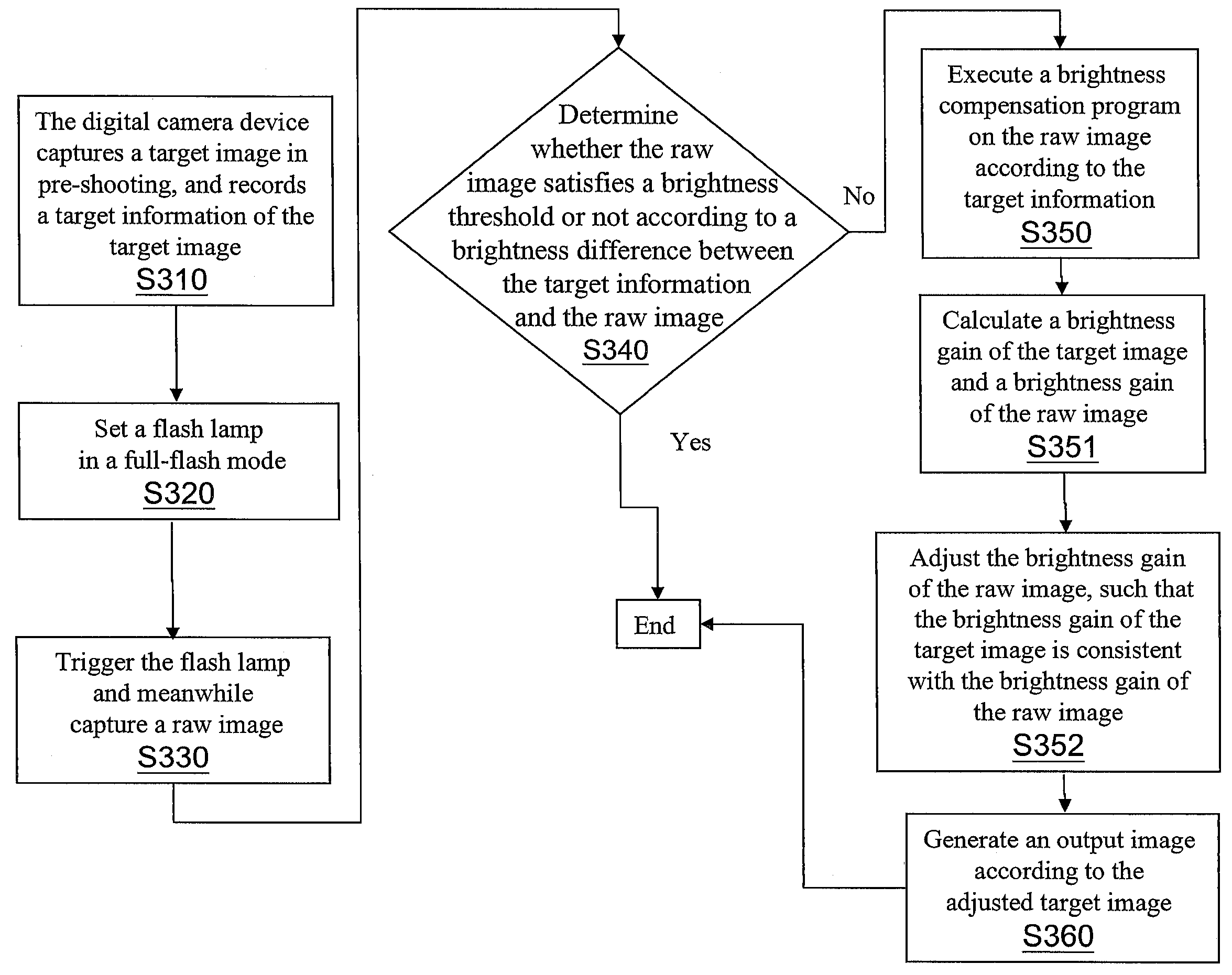

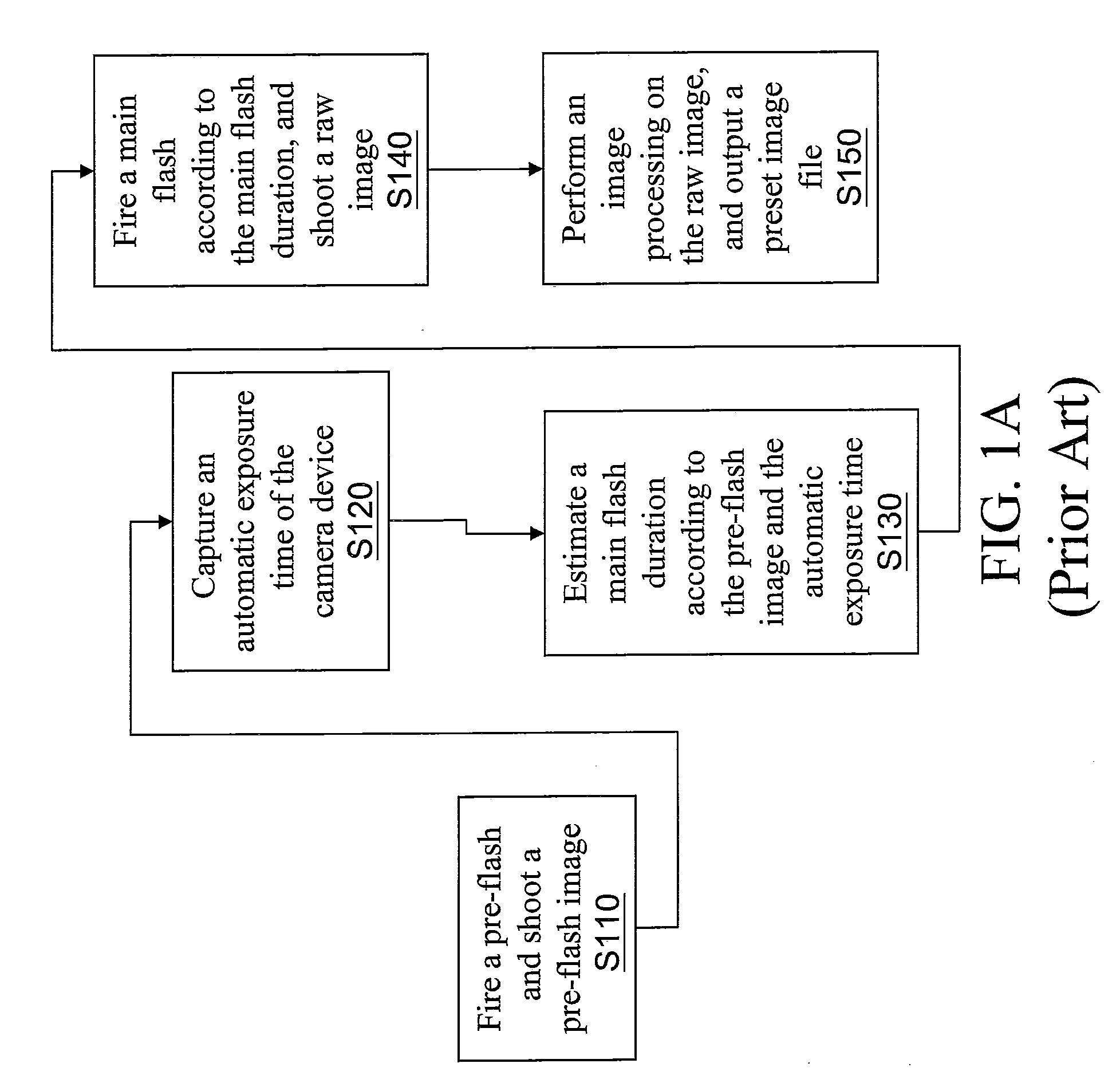

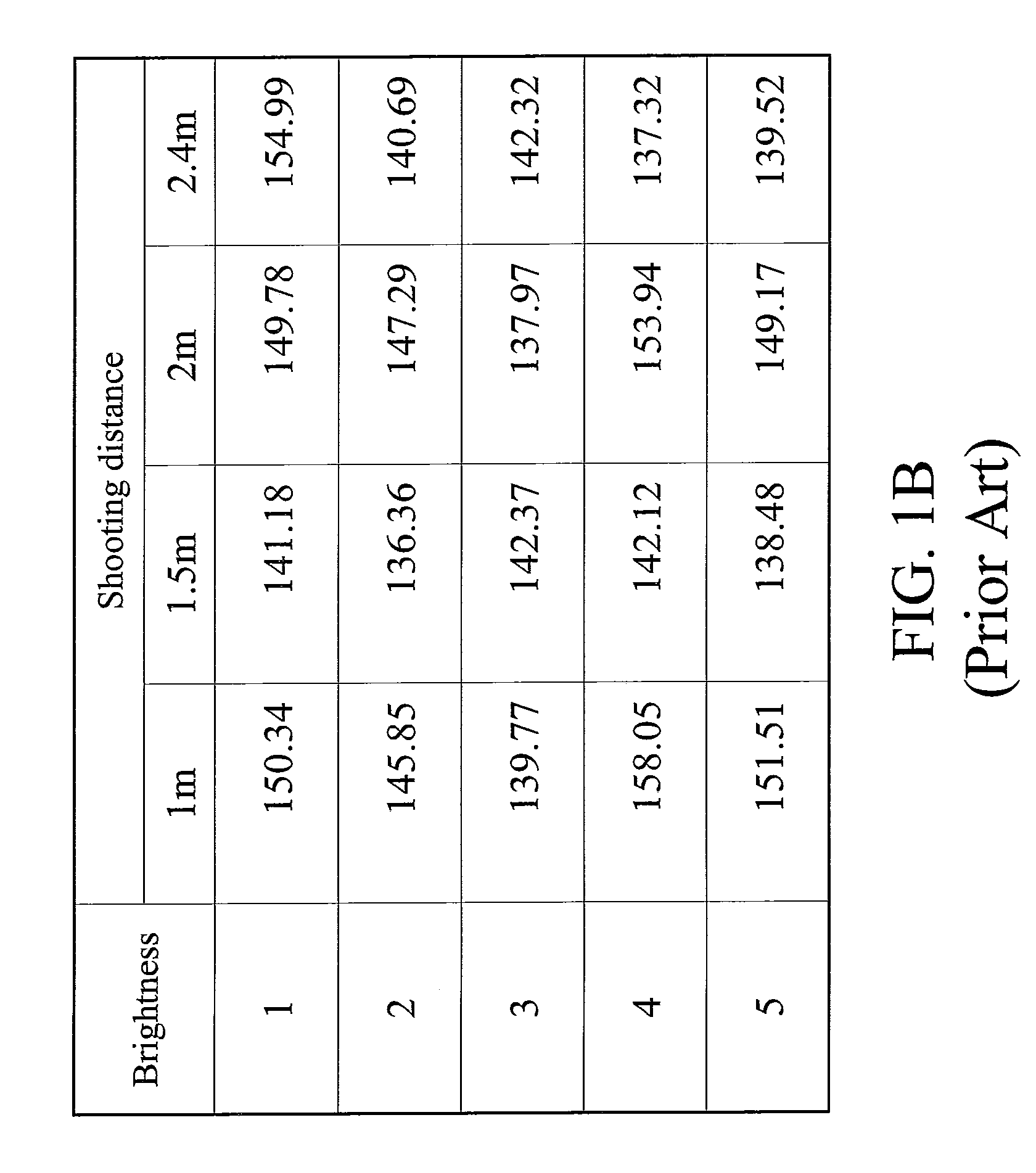

Image brightness compensation method and digital camera device with image brightness compensation function

InactiveUS20100073520A1Appropriate intensityTelevision system detailsColor signal processing circuitsDigital imageBrightness perception

An image brightness compensation method and a digital camera device with an image brightness compensation function are suitable for adjusting a brightness of a digital image shot by a digital camera device, especially when the shot object is located outside a maximum output range of a flash lamp. The method includes the steps of pre-capturing a target image, and recording target information; triggering a flash lamp, and meanwhile capturing a raw image; determining whether the raw image satisfies a brightness threshold or not according to a brightness difference between the target information and the raw image; if the raw image fails to satisfy the brightness threshold, executing a brightness compensation program on the raw image according to the target information; and finally, generating an output image.

Owner:ALTEK CORP

Automobile clothes tree folding structure and manufacturing method thereof

InactiveCN102501805AWith folding functionImprove practicalityLaminationLamination apparatusCompound aEngineering

The invention discloses an automobile clothes tree folding structure and a manufacturing method thereof. The plate of a clothes tree is formed by compounding a body base material and surface fabrics coated on the two sides of the body base material, and a folding line which is formed by adhering the two layers of surface fabrics only is formed between the two parts to be folded of the plate; and in the processing procedure, the automobile clothes tree folding structure is formed through extrusion at one time by using a press. Due to the folding structure, proper strength can be maintained at the position of the folding line of the clothes tree while the clothes tree has a folding function, so that the practicability and the durability of the clothes tree are improved.

Owner:芜湖尚唯汽车饰件有限公司

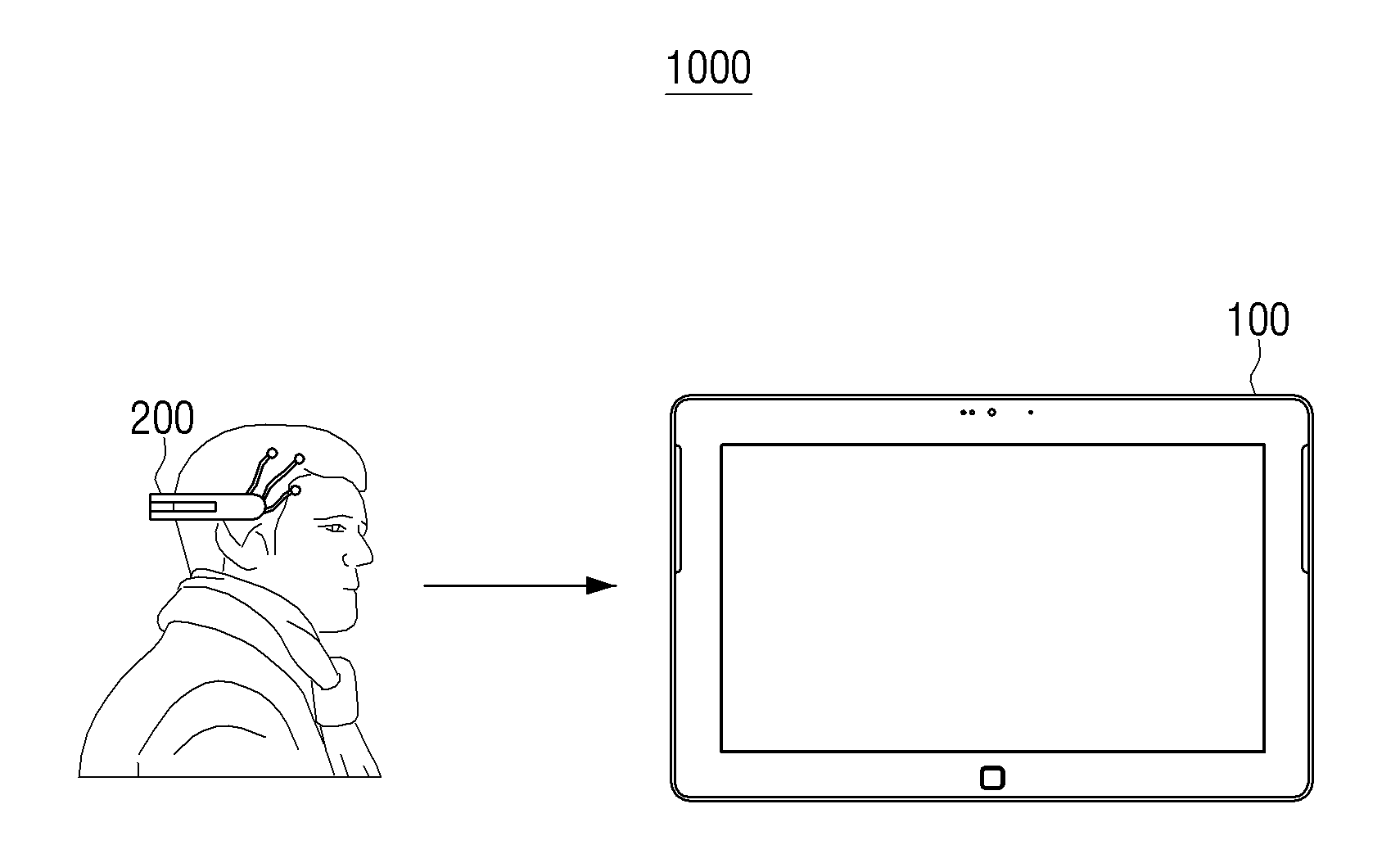

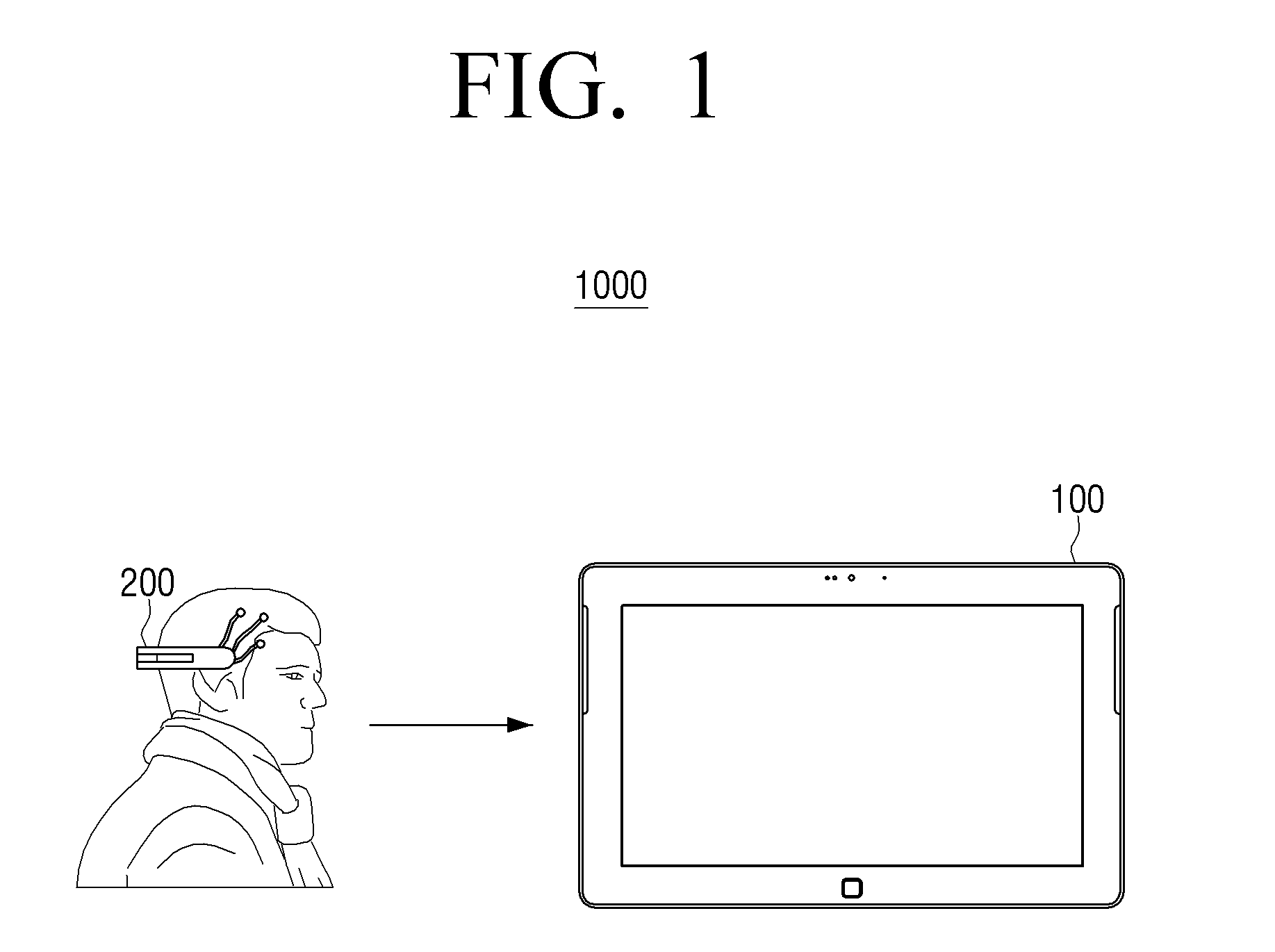

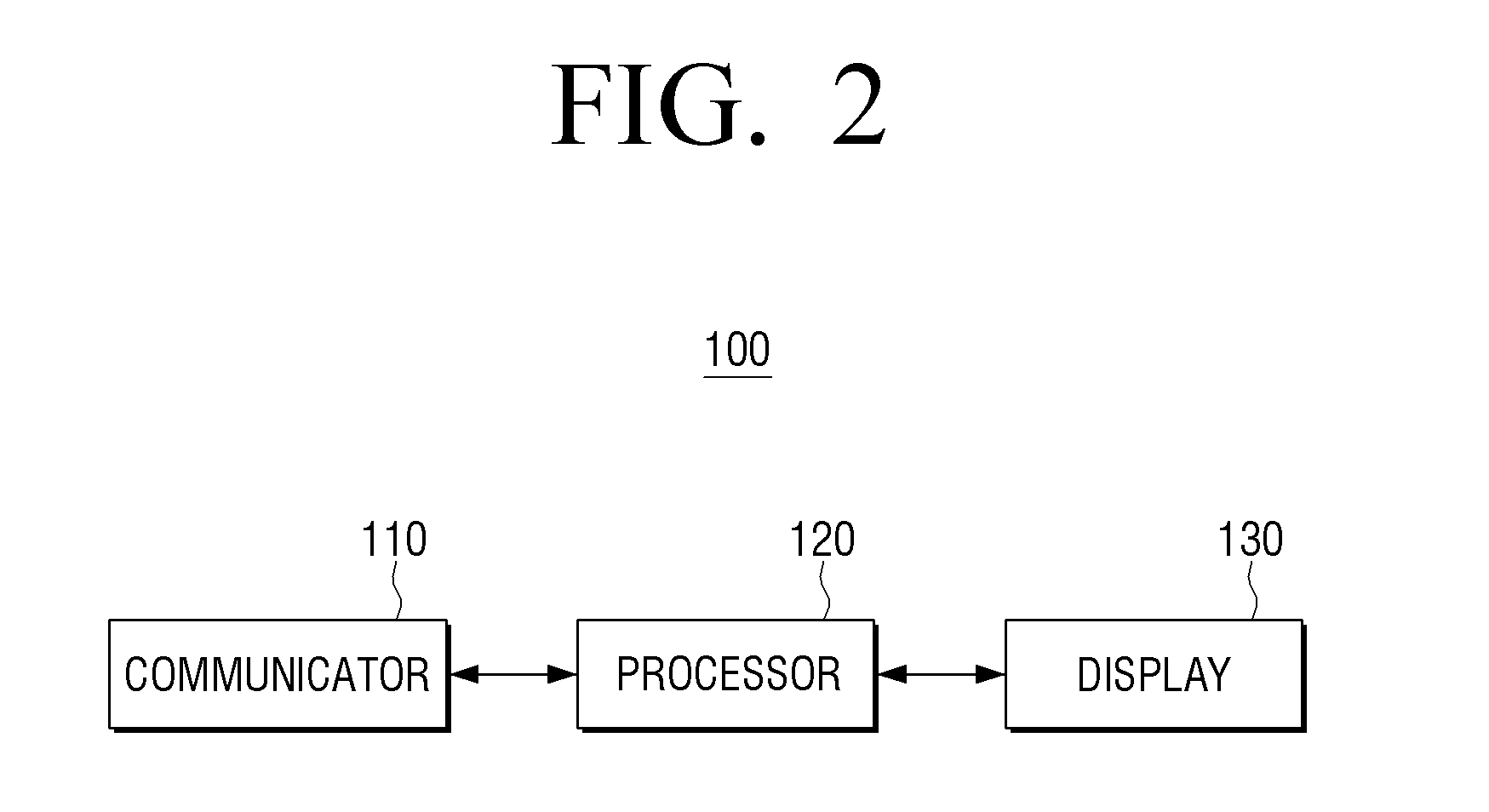

Smart tablet-based neurofeedback device combined with cognitive training, method and computer-readable medium thereof

InactiveUS20160240098A1Maximize training effectAppropriate intensityElectroencephalographySensorsAttention trainingComputer science

A smart tablet-based neurofeedback device combined with cognitive training, a method and a computer readable medium thereof are provided. The neurofeedback combined with cognitive training method includes: receiving a measured beta wave; executing an application for attention training set to a first level; performing a predetermined operation associated with an accomplishment condition of the first level when a value of the received beta wave is larger than a predetermined reference value; and executing a second level including an added accomplishment condition for attention training when the accomplishment condition of the first level is satisfied.

Owner:SEOUL NAT UNIV R&DB FOUND

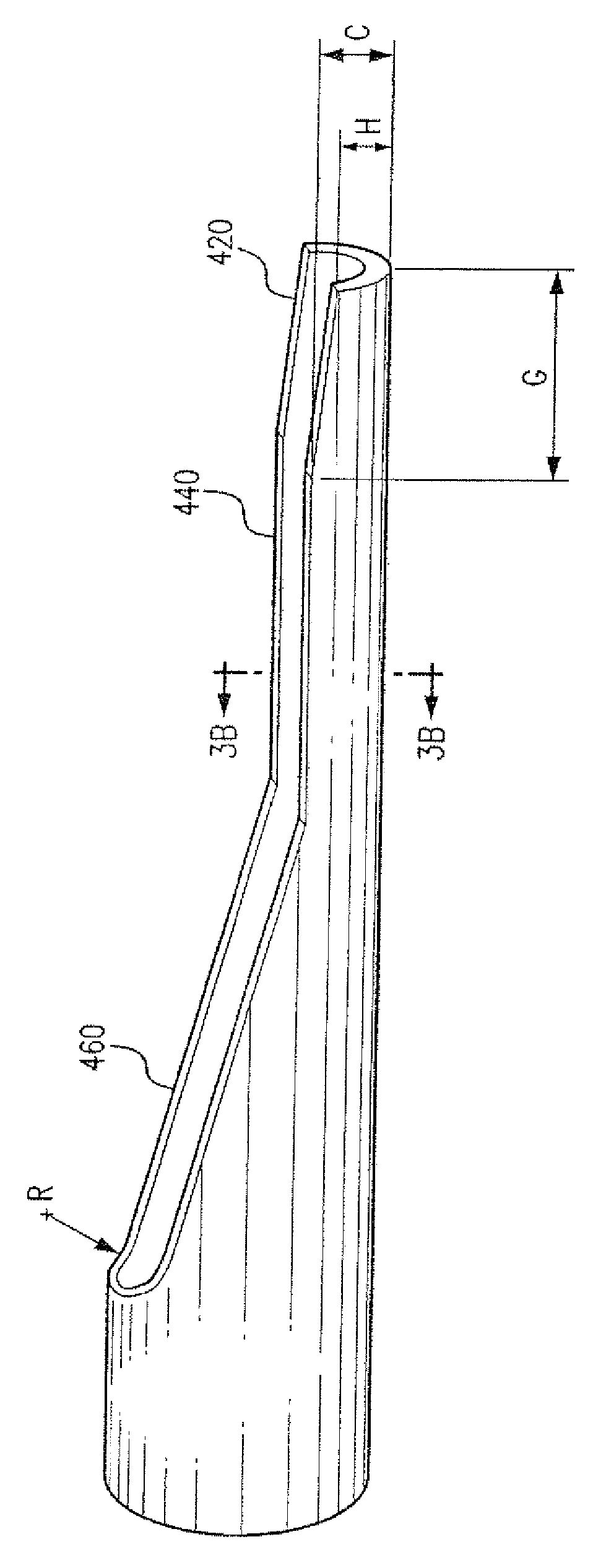

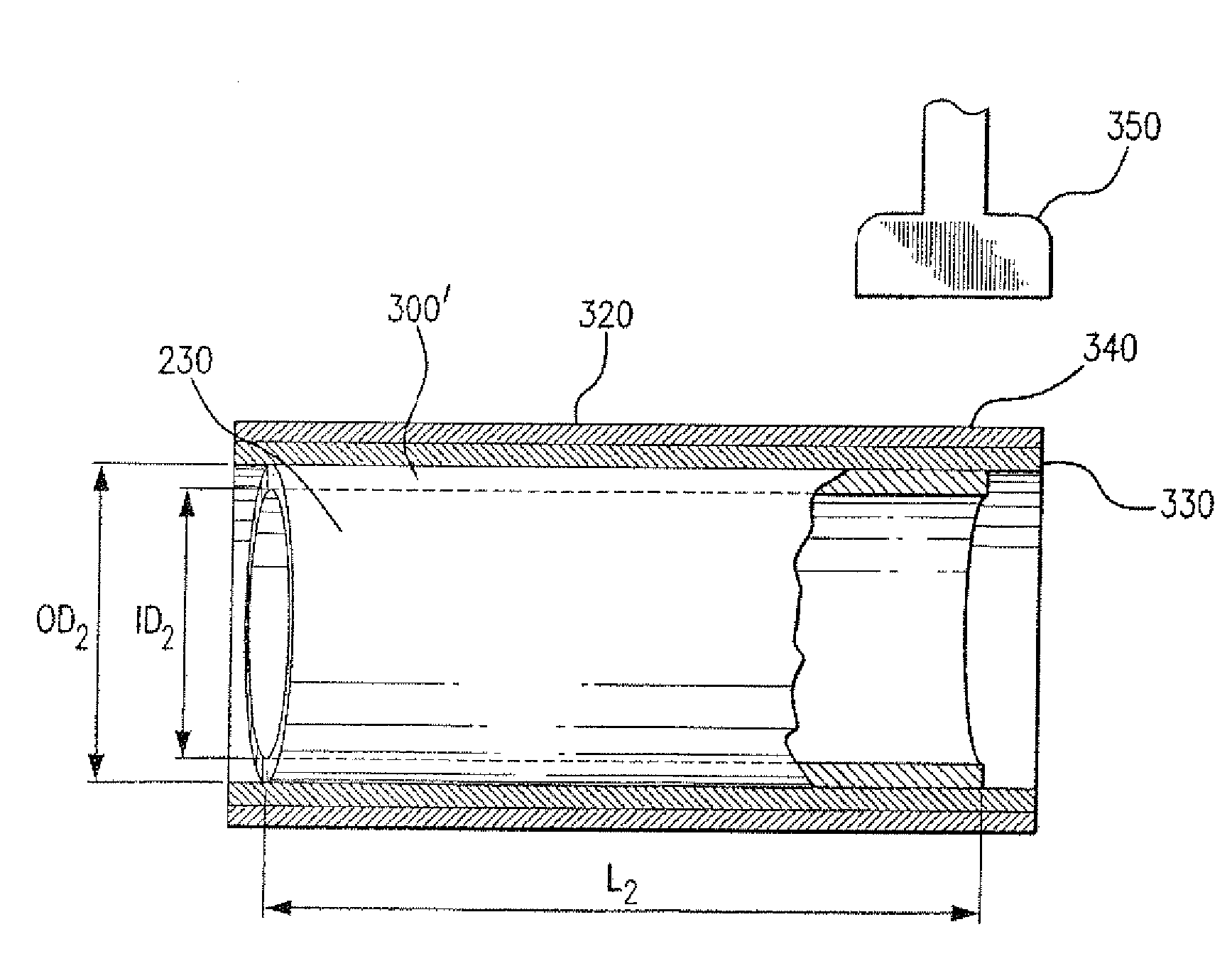

Catheter with stepped skived hypotube

ActiveCN103796707AImprove traceabilityAppropriate intensityBalloon catheterMulti-lumen catheterSurgery

Owner:ABBOTT CARDIOVASCULAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com