Water absorbent resin and method for producing same

A water-absorbent, resin-based technology, applied in absorbent pads, bandages, transportation and packaging, etc., can solve the problems of powder fluidity and particle strength reduction, and achieve high liquid absorption performance, excellent fluidity, and high shape retention properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

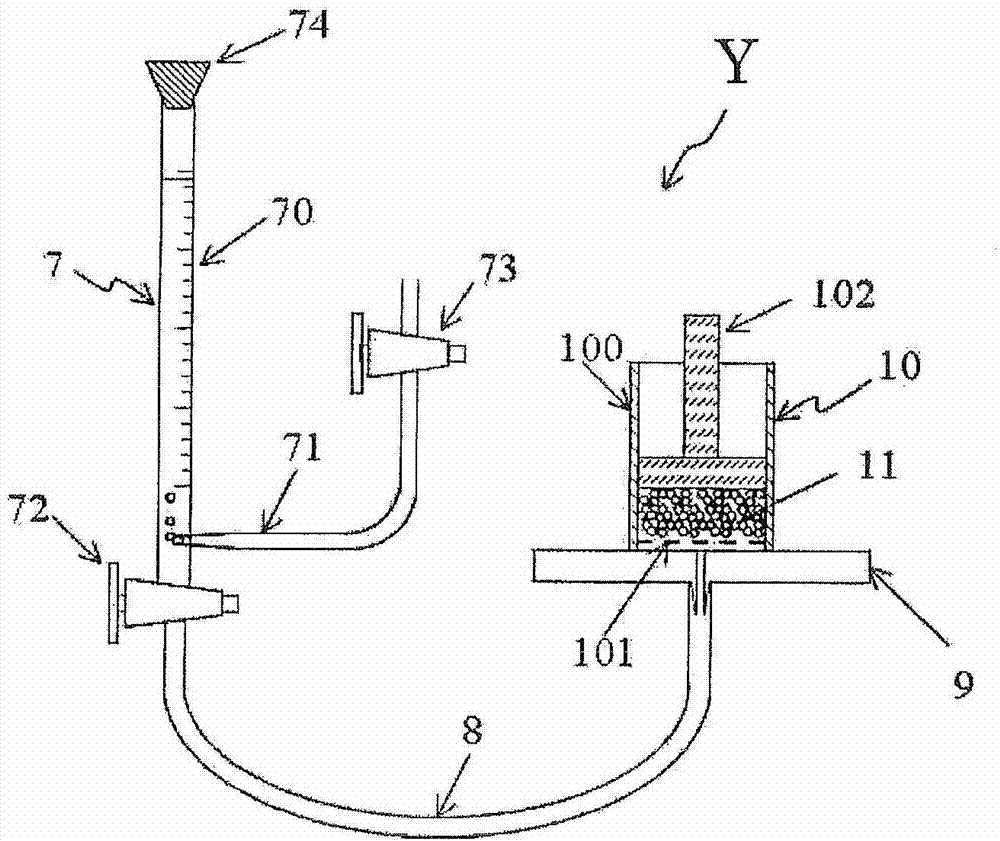

[0137] Provided with an inner diameter of 100mm, equipped with a reflux condenser, a dropping funnel, a nitrogen gas introduction pipe, and a stirring paddle with 2 sets of 4 inclined-blade flat paddles (paddle diameter: 50 mm) as a stirrer, a detachable round bottom cylinder flask. 500 ml of n-heptane was charged in the flask, and 0.92 g of sucrose stearate having an HLB of 3 (manufactured by Mitsubishi-Kagaku Foods Corporation, Ryoto sugar ester S-370) was added thereto and 0.92 g of a maleic anhydride-modified ethylene-propylene copolymer (manufactured by Mitsui Chemicals, Ltd., Hi-wax 1105A). The temperature was raised to 80°C to dissolve the surfactant, and thereafter the solution was cooled to 50°C.

[0138] Separately, 92 g of an aqueous acrylic acid solution (80.5% by mass) was charged in an Erlenmeyer flask (500 ml capacity), and 167.7 g of an aqueous sodium hydroxide solution (18.4% by mass) was added dropwise thereto under external cooling to neutralize 75 mol%. T...

Embodiment 2

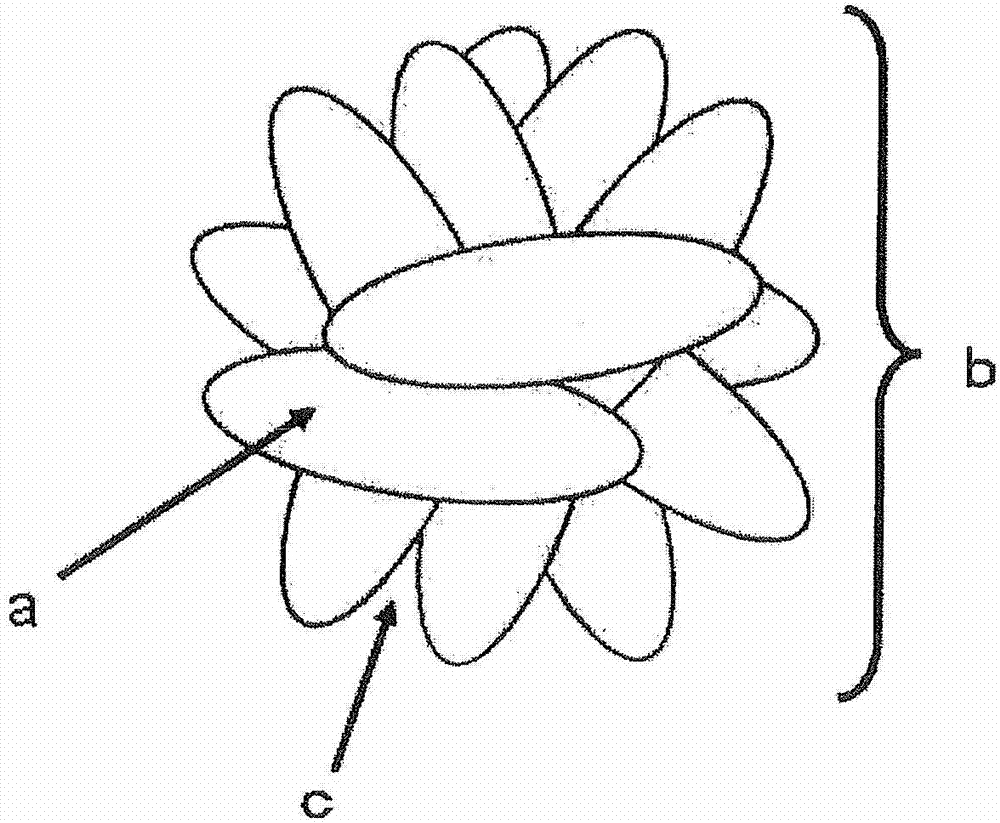

[0144] The same procedure as in Example 1 was repeated, except that the stirring speed for the first-stage polymerization was changed to 400 rpm, and 2% of the ethylene glycol diglycidyl ether added after azeotropic dehydration was The amount of the aqueous solution was changed to 11.13 g, thereby obtaining 213.1 g of a water-absorbent resin having a form of secondary particles in which ellipsoidal primary particles were aggregated (it should be noted that when an oil bath at 120° C. When azeotropic distillation of water and n-heptane was performed to distill only water out of the system and then dried by n-heptane evaporation, the resulting ellipsoidal primary particles had a median particle size of 280 μm and an aspect ratio of 1.4). The obtained water-absorbent resin had a median particle size of 720 μm and a water content of 7%. Table 1 shows the measurement results of each property.

Embodiment 3

[0146] The same procedure as in Example 1 was repeated, except that the stirring speed for the first-stage polymerization was changed to 700 rpm, and 2% of the ethylene glycol diglycidyl ether added after azeotropic dehydration was The amount of the aqueous solution was changed to 6.07 g, thereby obtaining 214.0 g of a water-absorbent resin having a form of secondary particles in which ellipsoidal primary particles were aggregated (it should be noted that when an oil bath at 120° C. When azeotropic distillation of water and n-heptane was performed to distill only water out of the system and then dried by n-heptane evaporation, the resulting ellipsoidal primary particles had a median particle size of 110 μm and an aspect ratio of 1.6). The obtained water-absorbent resin had a median particle size of 470 μm and a water content of 7%. Table 1 shows the measurement results of each property.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water sorption capacity | aaaaa | aaaaa |

| water sorption capacity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com