Water absorbent resin and method for producing same

一种吸水性、树脂的技术,应用在吸收垫、绷带、运输和包装等方向,能够解决粉末流动性和粒子强度减小等问题,达到高液体吸收性能、优异流动性、高形状保持性质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

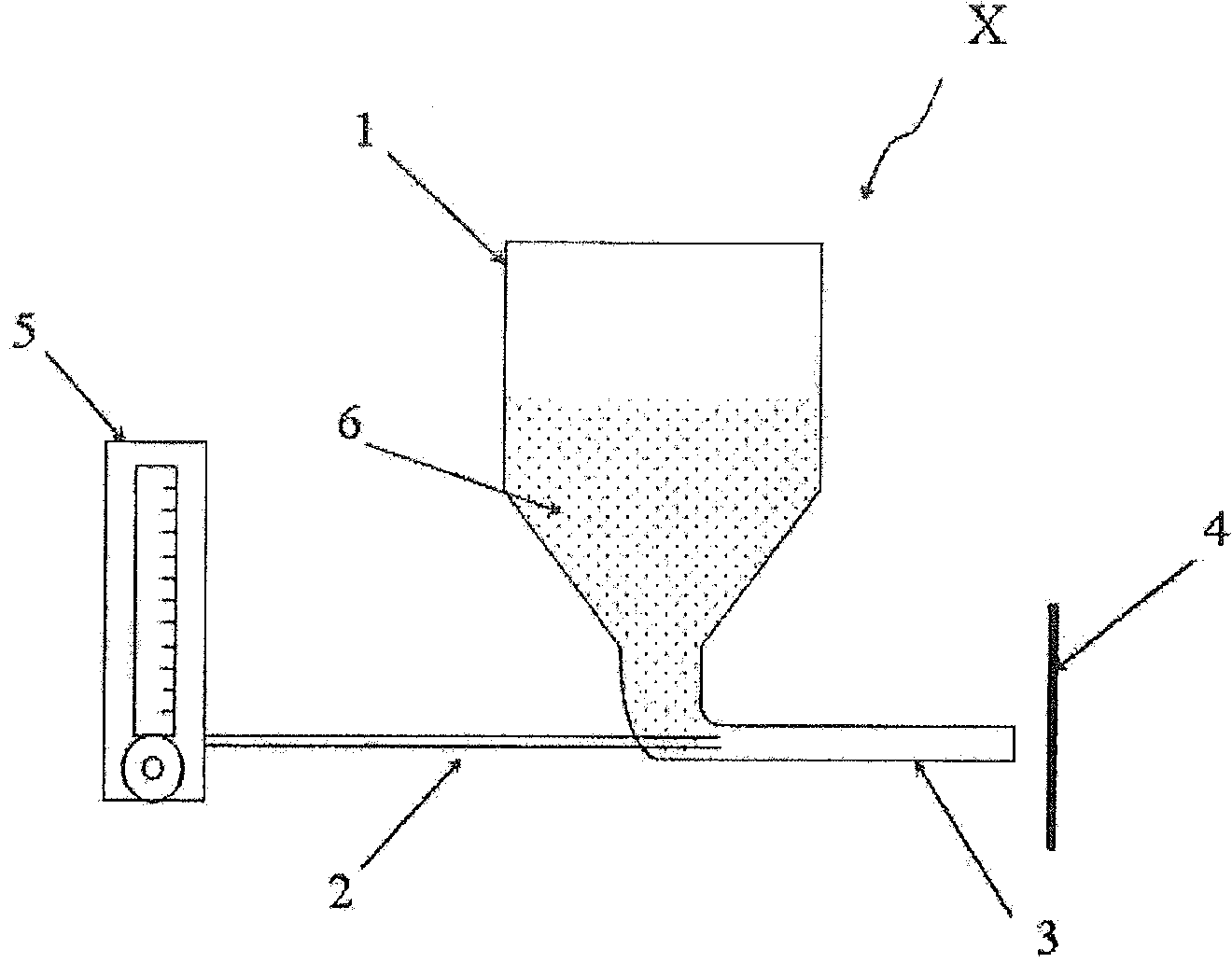

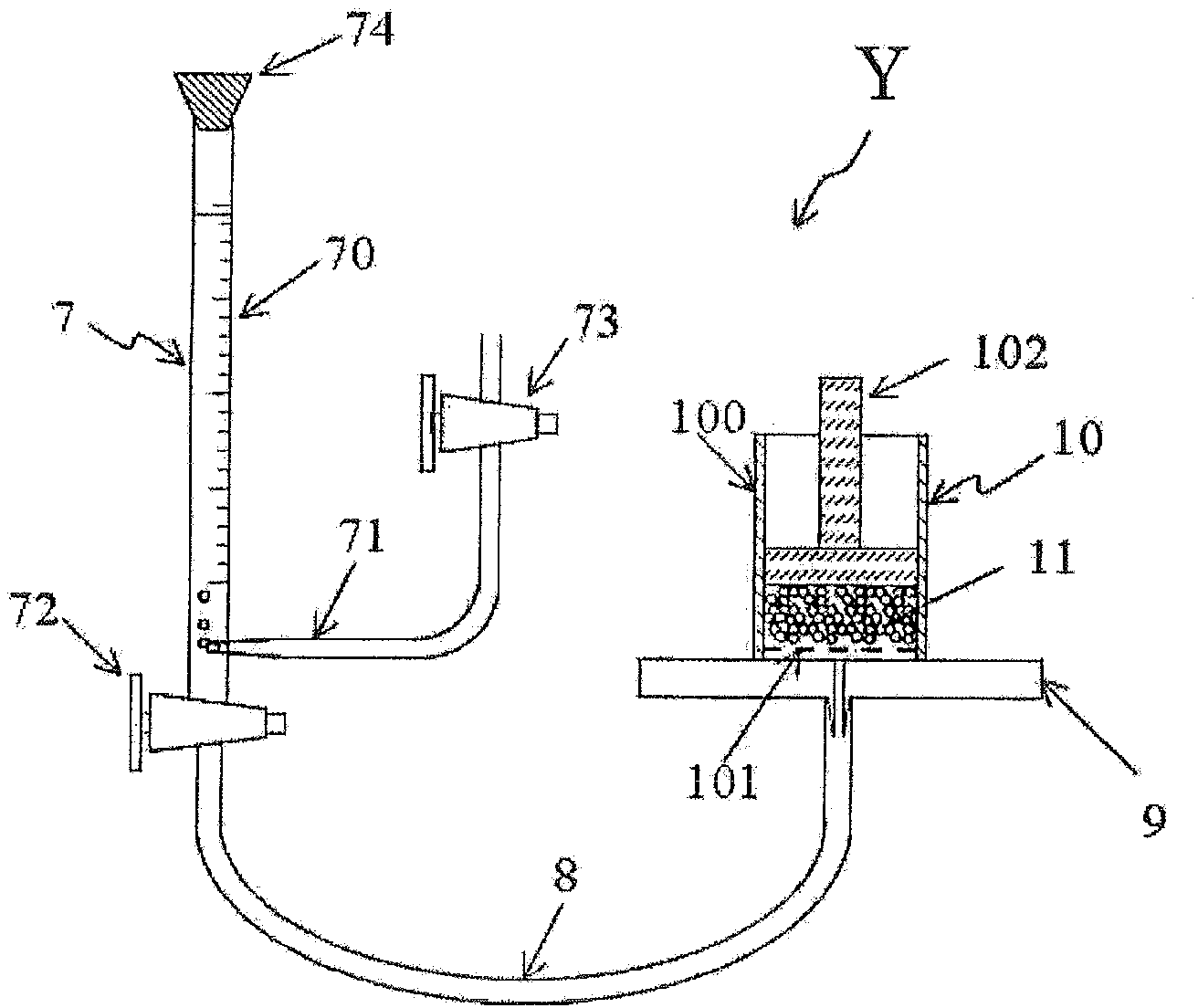

[0137] Provided with an inner diameter of 100mm, equipped with a reflux condenser, a dropping funnel, a nitrogen gas introduction pipe, and a stirring paddle with 2 sets of 4 inclined-blade flat paddles (paddle diameter: 50 mm) as a stirrer, a detachable round bottom cylinder flask. 500 ml of n-heptane was charged in the flask, and 0.92 g of sucrose stearate having an HLB of 3 (manufactured by Mitsubishi-Kagaku Foods Corporation, Ryoto sugar ester S-370) was added thereto and 0.92 g of a maleic anhydride-modified ethylene-propylene copolymer (manufactured by Mitsui Chemicals, Ltd., Hi-wax 1105A). The temperature was raised to 80°C to dissolve the surfactant, and thereafter the solution was cooled to 50°C.

[0138] Separately, 92 g of an aqueous acrylic acid solution (80.5% by mass) was charged in an Erlenmeyer flask (500 ml capacity), and 167.7 g of an aqueous sodium hydroxide solution (18.4% by mass) was added dropwise thereto under external cooling to neutralize 75 mol%. T...

Embodiment 2

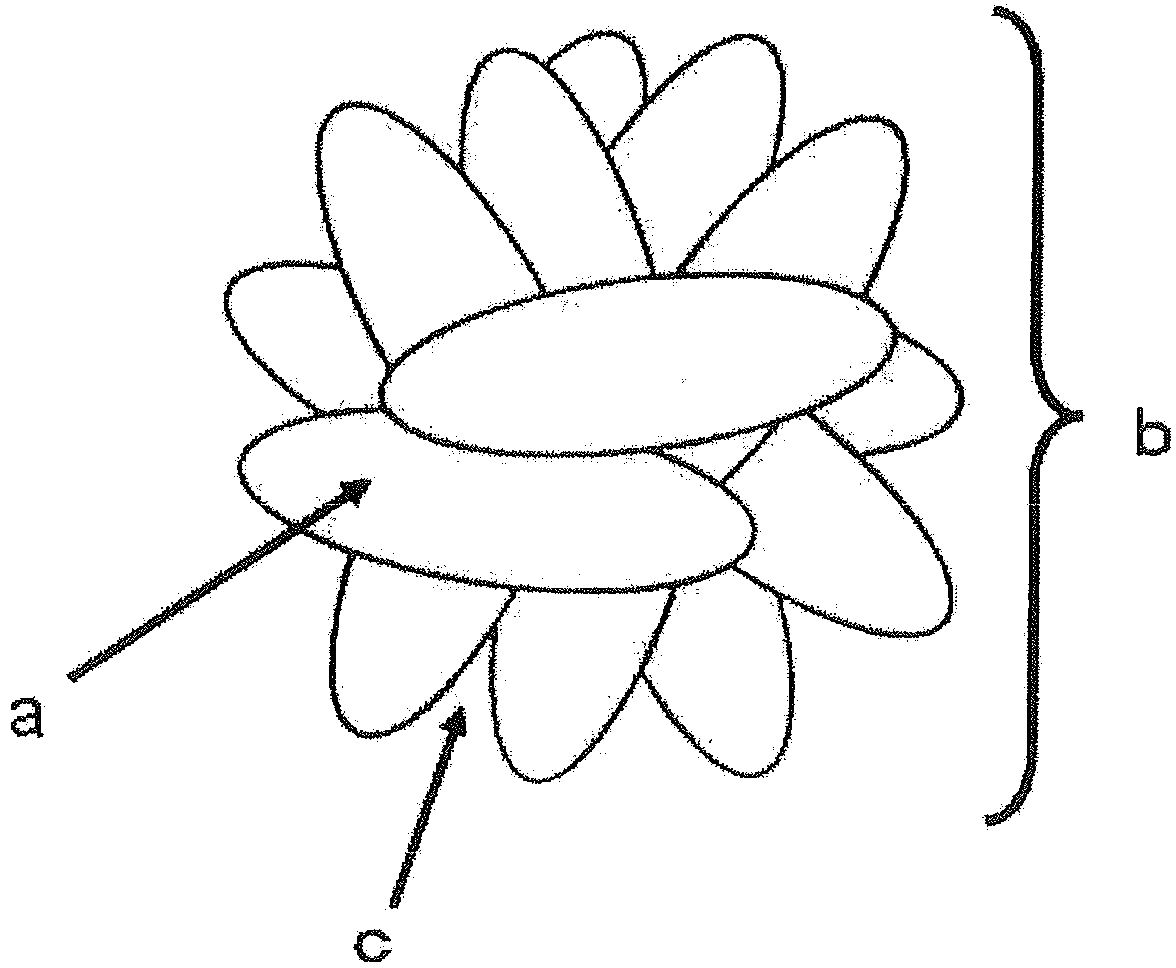

[0144] The same procedure as in Example 1 was repeated, except that the stirring speed for the first-stage polymerization was changed to 400 rpm, and 2% of the ethylene glycol diglycidyl ether added after azeotropic dehydration was The amount of the aqueous solution was changed to 11.13 g, thereby obtaining 213.1 g of a water-absorbent resin having a form of secondary particles in which ellipsoidal primary particles were aggregated (it should be noted that when an oil bath at 120° C. When azeotropic distillation of water and n-heptane was performed to distill only water out of the system and then dried by n-heptane evaporation, the resulting ellipsoidal primary particles had a median particle size of 280 μm and an aspect ratio of 1.4). The obtained water-absorbent resin had a median particle size of 720 μm and a water content of 7%. Table 1 shows the measurement results of each property.

Embodiment 3

[0146] The same procedure as in Example 1 was repeated, except that the stirring speed for the first-stage polymerization was changed to 700 rpm, and 2% of the ethylene glycol diglycidyl ether added after azeotropic dehydration was The amount of the aqueous solution was changed to 6.07 g, thereby obtaining 214.0 g of a water-absorbent resin having a form of secondary particles in which ellipsoidal primary particles were aggregated (it should be noted that when an oil bath at 120° C. When azeotropic distillation of water and n-heptane was performed to distill only water out of the system and then dried by n-heptane evaporation, the resulting ellipsoidal primary particles had a median particle size of 110 μm and an aspect ratio of 1.6). The obtained water-absorbent resin had a median particle size of 470 μm and a water content of 7%. Table 1 shows the measurement results of each property.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com