Patents

Literature

48results about How to "Appropriate softness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

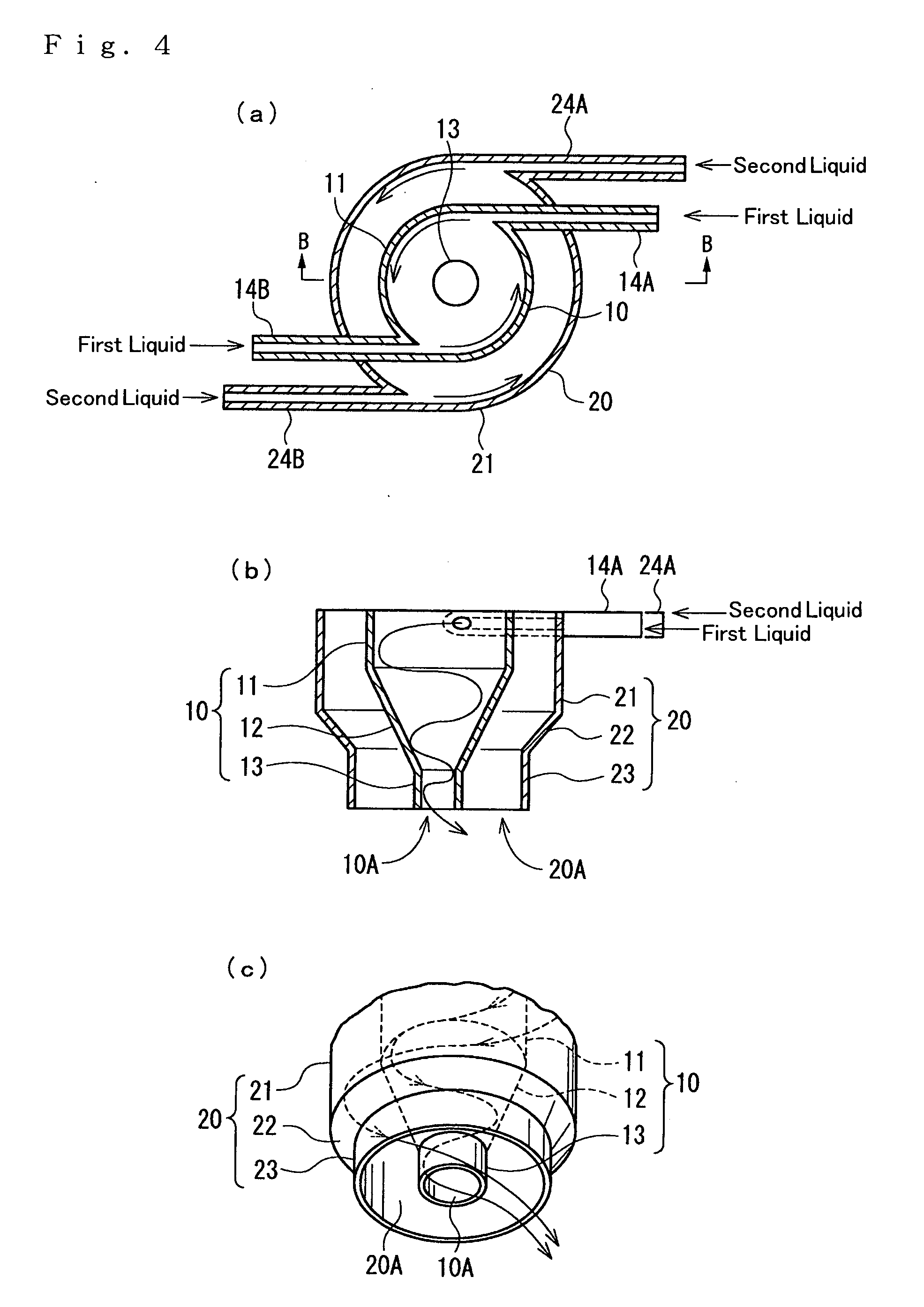

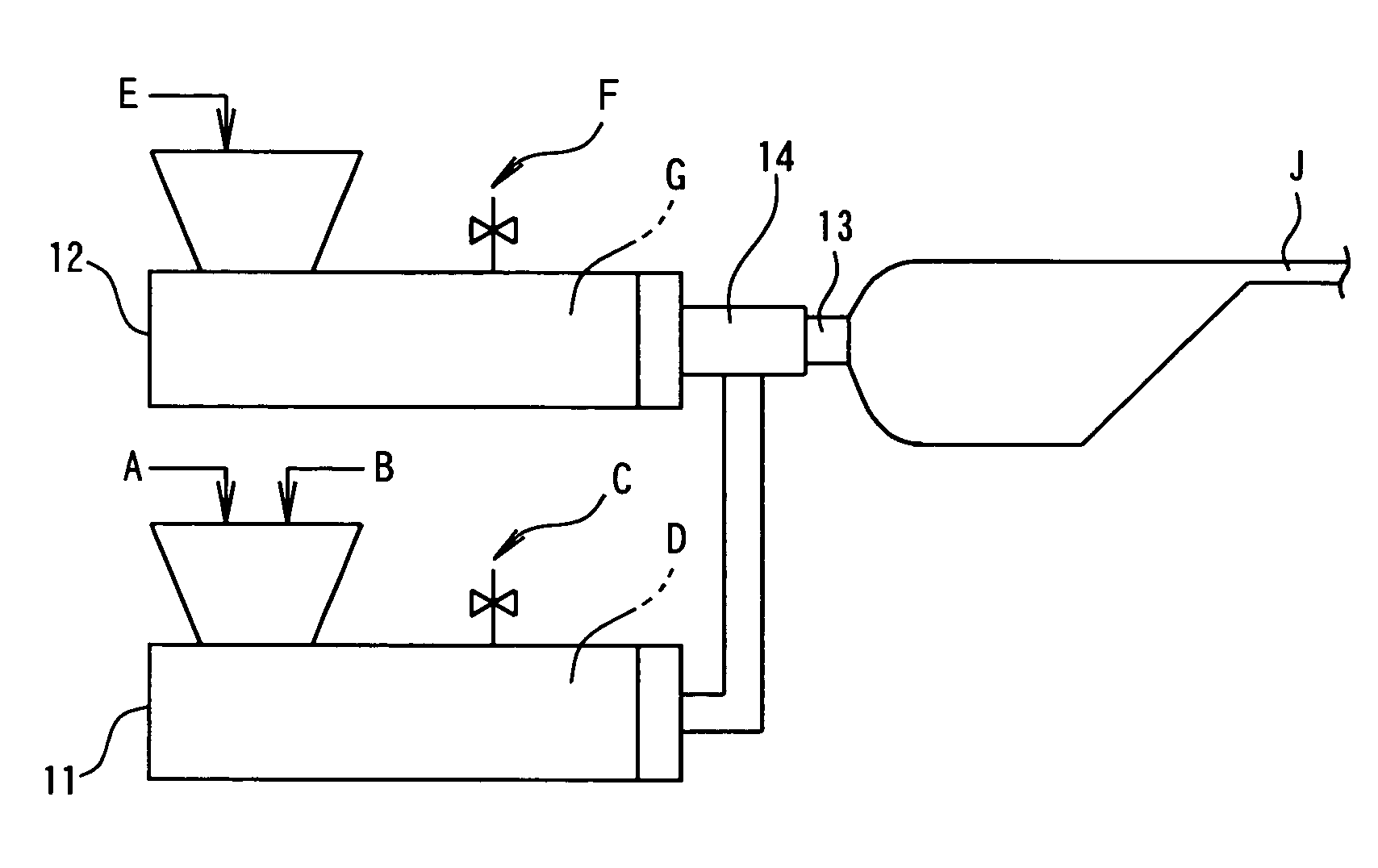

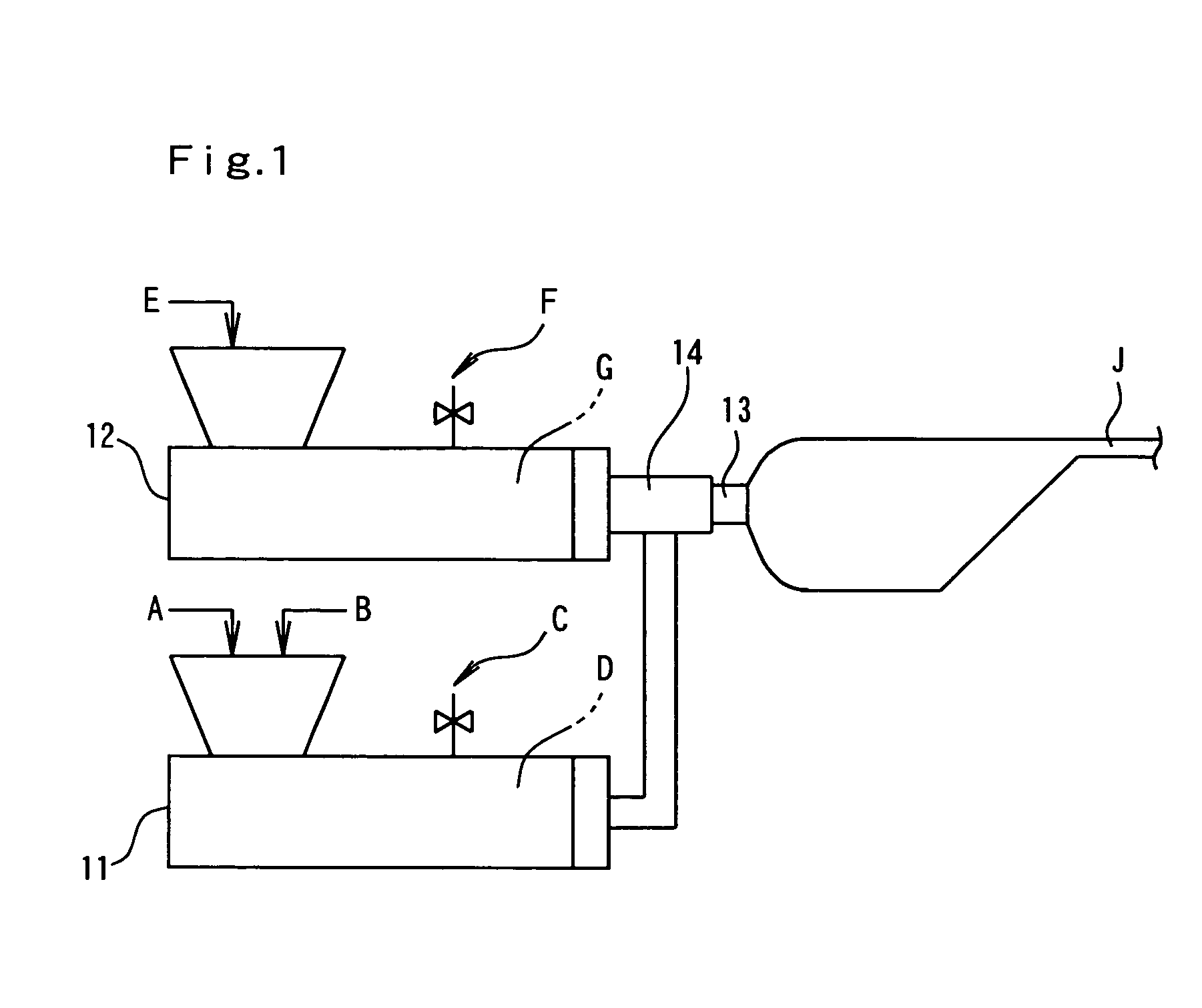

Absorbent composite and method for producing same, asorbent article and nozzle

InactiveUS20090264845A1Big absorptionFast absorptionLiquid surface applicatorsBaby linensParticulatesPolymer science

An absorbent composite comprising a bound particulate absorbent polymer in which two or more nearly spherical absorbent polymer particles are bound to each other and a web-like absorbent polymer, wherein the bound particulate absorbent polymer and the web-like absorbent polymer are bound to a substrate. The composite has a large absorption and a high absorbing speed in which the absorbent polymer is kept uniformly dispersed on the support throughout before and after absorption.

Owner:MITSUBISHI CHEM CORP

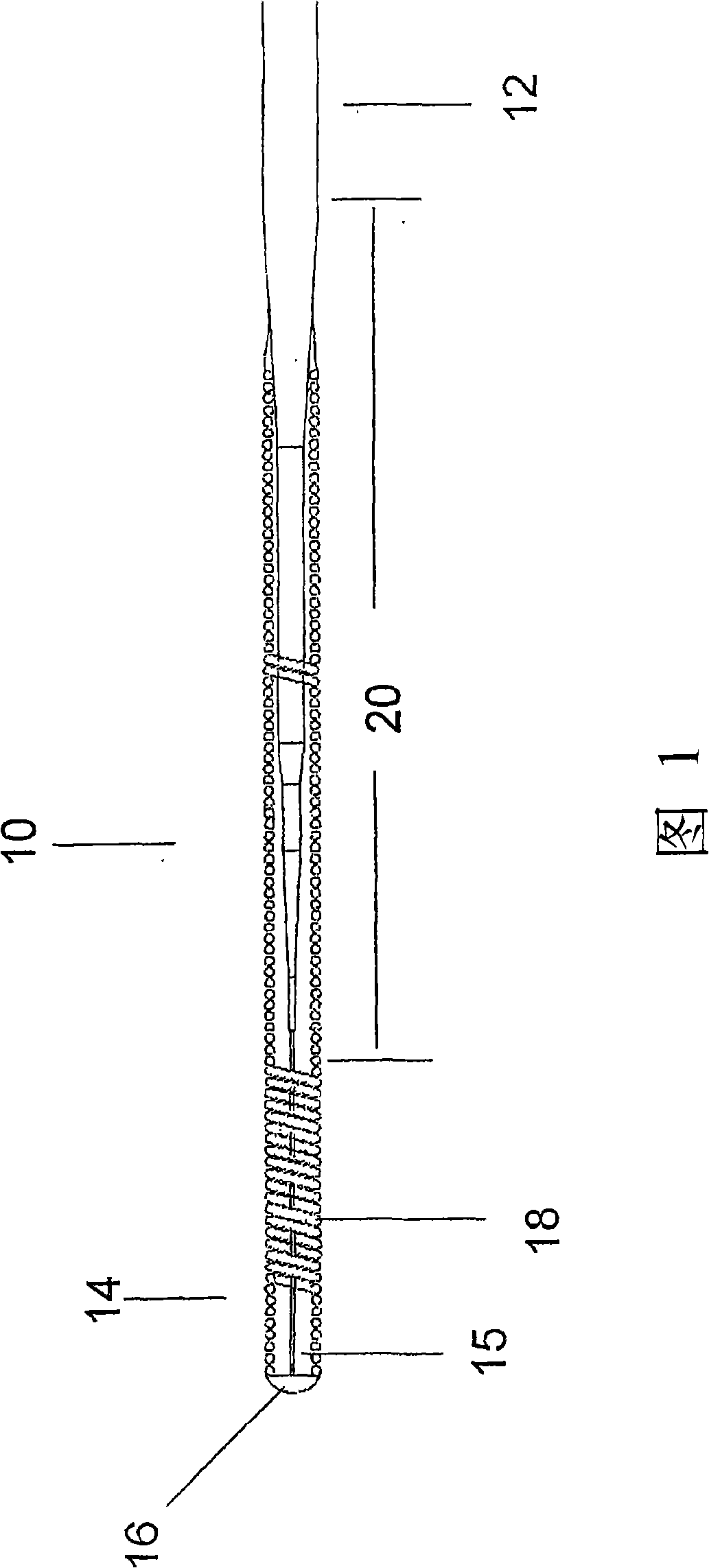

Conductive filament of titanium molybdenum alloy

InactiveCN101360448AAppropriate rigidityThe process is simple and convenientGuide wiresSurgeryTitanium molybdenum alloyTitanium nickelide

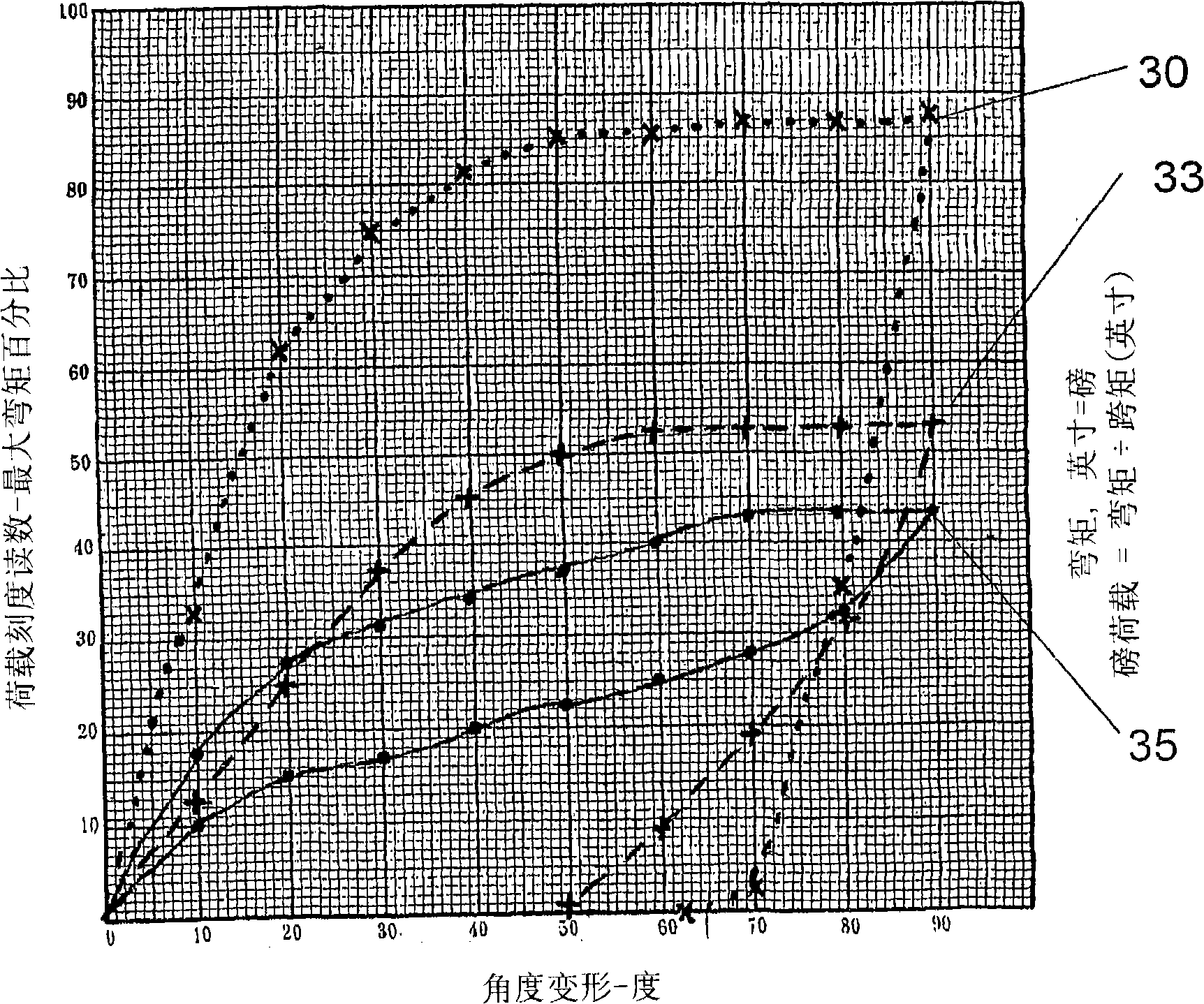

A guidewire for medical use such as in vascular and nonvascular systems. The guidewire made from a titanium molybdenum alloy wire with a composition of approximately 78% titanium 11.5% molybdenum 6% zirconium and 4.5% tin by weight such that it is softer than stainless steel guidewires and stiffer than NiTi alloy guidewires. The distal end of the guidewire is of a smaller diameter and softer than the proximal end and fitted with a coil for springiness such that the distal end will bend when encountering curves in the body passageways. The distal tip may be heat treated for a gradient of softness with the distal tip being the softest. The distal end may also be tapered to provide an additional gradient of softness. A distal tip on the distal end of the guidewire protects the wall of the passageway from being punctured as the guidewire travels through the passageway. The resulting guidewire has properties between those of stainless steel guidewires and NiTi alloy guidewires for better torsion and stiffness characteristics.

Owner:MINNESOTA MEDICAL DEV

Production method of soft and fluffy facial tissue

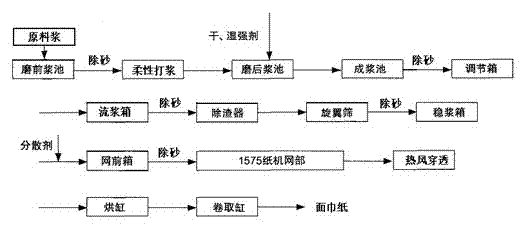

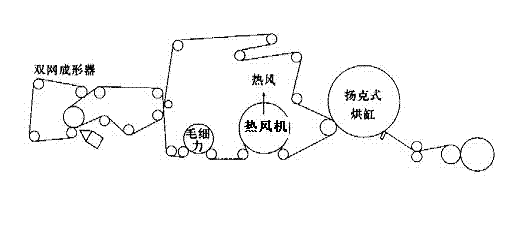

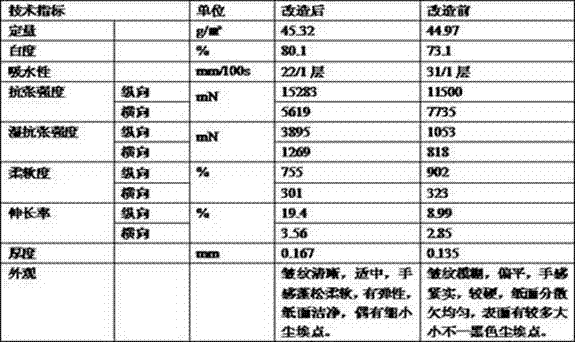

ActiveCN103696318AImprove excessive tightness and insufficient bulkinessHigh speedPulp beating methodsDryer sectionPapermakingToughness

The invention relates to a papermaking method, and particularly relates to a method for producing household paper facial tissue by taking bagasse as a main raw material. The technical scheme is as follows: the bagasse pulp and a small amount of wood pulp at a high ratio are used as main raw materials, wherein the weight ratio of the bagasse pulp to the wood pulp is (65-75):(25-35); five grit removal processes are adopted to adjust the previous and later paper pulp concentration of each piece of equipment; a flexible beating process for fibrillation is adopted; a process of high-speed hot air penetrating through paper sheets is adopted to produce the soft and fluffy facial tissue with high toughness and low cost and meeting the health standard.

Owner:GUANGXI TIANLIFENG ECOLOGICAL MATERIAL

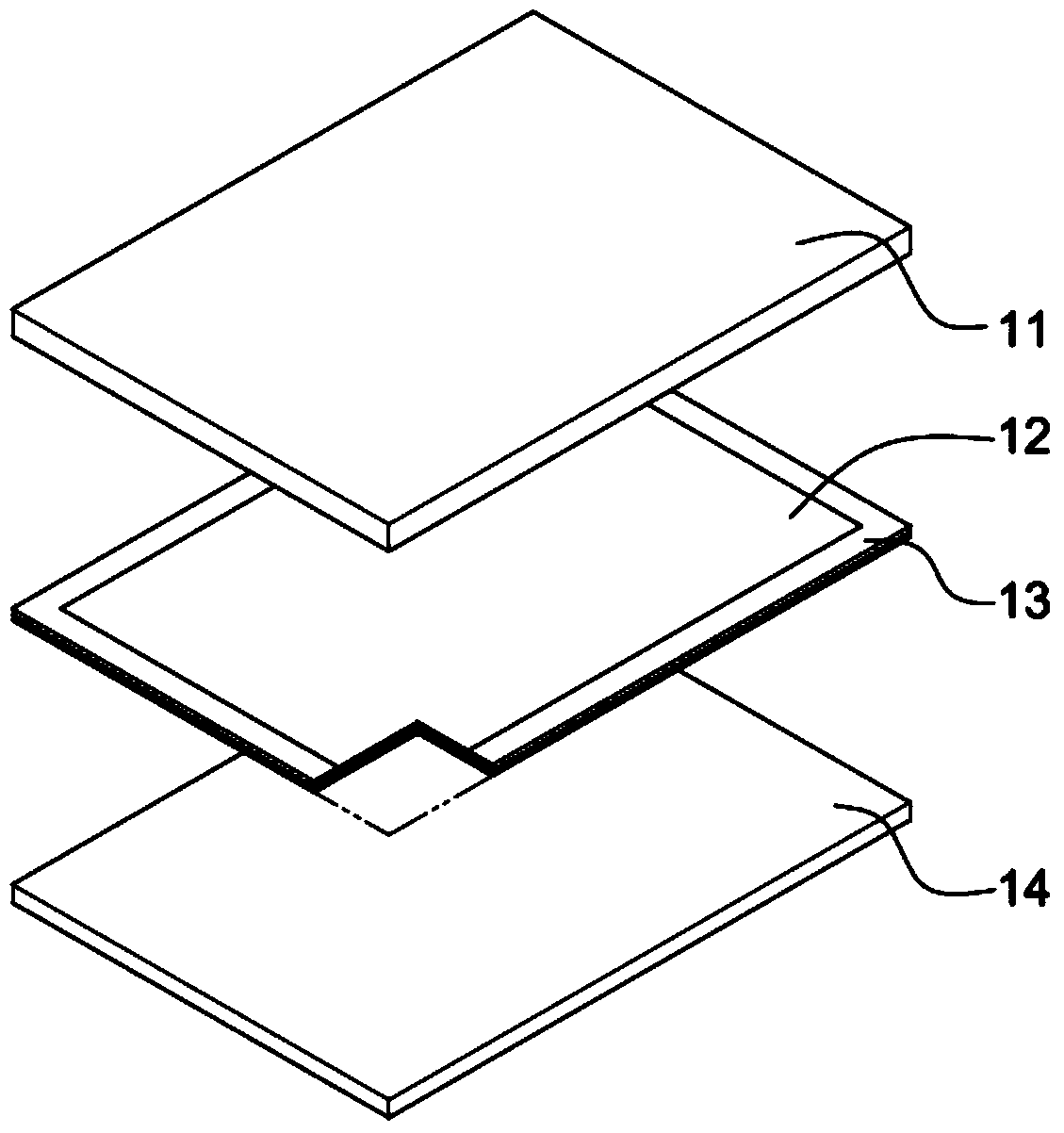

A light curable frame glue material composition

ActiveCN103525354AGood light transmissionHigh refractive indexNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesOligomerPlasticizer

The invention provides a light curable frame glue material composition comprising a) (methyl) acrylics oligomer comprising one or more functional groups, b) light initiator, and c) plasticizer with high refractive index. The viscosity value of the frame glue material composition is not less than 8000 cps. The light curable frame glue material composition has both good transmission of light and high refractive index and appropriate liquidity and softness, is easy to cooperate with liquid optical glue (water glue) in order to be used for coating and pasting correlative touch control panels, and does not generate an interface at the junction of the frame glue and the water glue. The light curable frame glue material composition can be used in optical products and simplifies and improves a conventional procedure.

Owner:ETERNAL MATERIALS CO LTD

Polyurethane and manufacturing method therefor, master batch, ink binder, ink composition, thermoplastic polymer composition for molding, molded body, and compound molded body and manufacturing method therefor

The present invention provides a polyurethane which is non-sticky, exhibits superior handling properties and superior moldability, and has superior adhesive properties with silicones even if a surface activation treatment is not carried out beforehand. The polyurethane of the present invention contains polyol units and organic polyisocyanate units. The polyol units contain an alkenyl group-containing organopolysiloxane structure in an amount ranging from 0.01 to 20% by weight with respect to the weight of the aforementioned polyurethane.

Owner:DOW CORNING TORAY CO LTD

Elastic non-woven cloth with high water absorption and air permeability for medical magnetic therapy

InactiveCN108978042AAppropriate intensityAppropriate softnessMonocomponent polyurethanes artificial filamentElectrotherapyFiberBiocompatibility Testing

The invention discloses elastic non-woven cloth with high water absorption and air permeability for medical magnetic therapy. The elastic non-woven cloth is made from, by weight, 20-27 parts of modified polylactic acid fiber, 20-33 parts of modified bamboo fiber, 10-20 parts of hydroxymethyl cellulose, 2-5 parts of casein, 20-30 parts of soybean fiber, 5-10 parts of sodium alginate, 20-35 parts ofstarch, 20-23 parts of magnetic starch, 40-45 parts of modified polyacrylamide fiber and 3-5 parts of a plant extract. The non-woven cloth has bacteriostatic activity, can effectively prevent wound infection, and is suitable for extensive symptoms, remarkable in health effect, safe and reliable in magnetic therapy function and economical and practical; raw materials adopted are biodegradable natural polymer materials and have good biocompatibility, and simpleness in the method is achieved.

Owner:HEFEI SHENGDA GARMENT ACCESSORIES CO LTD

Biological fermentation soft feed and production method thereof

InactiveCN101971915AGood palatabilityGood digestion and absorptionAnimal feeding stuffNutrientChemistry

The invention discloses a biological fermentation soft feed and a production method thereof. The feed is prepared from raw materials in a weight ratio. The production method is characterized by comprising the following steps of: mixing master powder and conventional powder in a ratio of (0.4-0.8):(99.2-99.6); adding water to ensure that the humidity is 40-50 percent; stirring and then carrying out aerobic natural fermentation for 48-72 hours at 25-30 DEG C; and sealing for storing. In the invention, the tastes of protein, starch, fat, and other macromolecule nutrients in conventional feeds are changed through fermentation by utilizing Chinese herbal medicines under proper oxygen, moisture and temperature conditions and the macromolecule nutrients are converted into nutrient substances such as glucose, amino acid, and the like so as to be convenient for livestock to quickly absorb, thus the livestock can quick grow. The feed is particularly suitable for the livestock such as pigs, cows, rabbits, and the like.

Owner:SICHUAN TONGWANG AGRI & LIVESTOCK GROUP

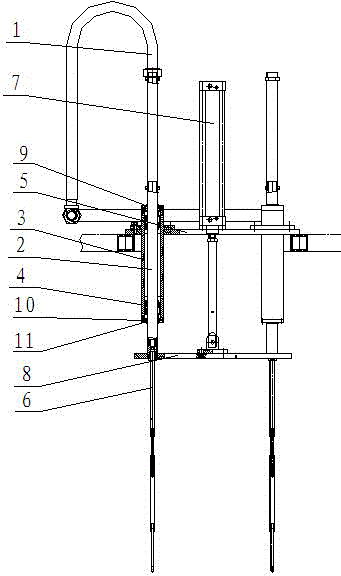

Spraying device for workpiece cleaning

InactiveCN104368565AEasy to cleanGuaranteed cleaning effectCleaning using liquidsEngineeringMechanical engineering

The invention provides a spraying device for workpiece cleaning. The spraying device comprises spraying pieces, an air cylinder and a connecting plate. Each spraying piece comprises a water inlet pipe, a guide post, a guide rod seat, a linear bearing, a base plate used for fixing the guide rod seat and the air cylinder and probes. The water inlet pipe is communicated with each probe through the guide post, each guide post penetrates the corresponding linear bearing fixed in the guide rod seat, the guide rod seats and the air cylinder are fixed on the base plate, the piston end of the air cylinder is connected with the connecting plate, and the guide posts are fixed on the connecting plate. By the arrangement, the problem about automatic lifting of the probes during workpiece cleaning is solved, close-range cleaning of the workpiece is facilitated, and cleaning effect of the workpiece is guaranteed.

Owner:安徽宝辉清洗设备制造有限公司

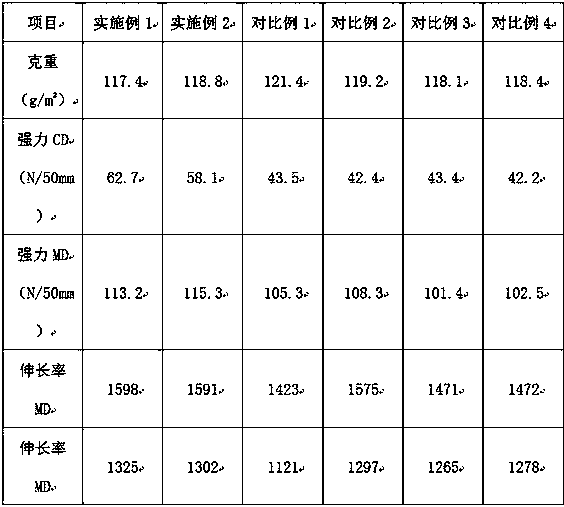

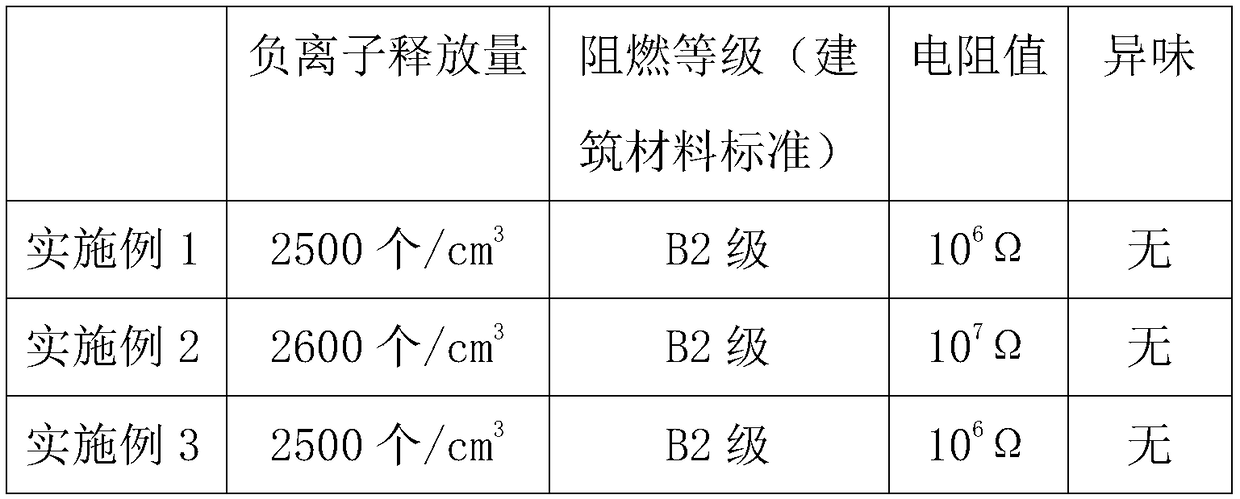

Antistatic wall cloth and production process thereof

ActiveCN109296152ARelatively uniform molecular weightEasy to processCovering/liningsMicroparticleHuman health

The invention discloses the technical field of wall cloths and particularly relates to an antistatic wall cloth and a production process thereof. A material, namely tourmaline powder, included in theantistatic wall cloth is silicate crystals and is powder prepared in the mode that electrical raw ores are subjected to impurity removing, and then smashed and purified, the tourmaline powder can generate electric ions and release negative ions for a long term, the content of the negative ions in the tourmaline powder can reach 80000-100000 per cubic meter, the tourmaline powder enables a face layer to have the effect of releasing the negative ions, and the negative ions can purify air, remove dust, smoke microparticles and bacteria, prevent mould and remove undesirable odors, and is favorableto human health; an antistatic agent has the characteristics of a surfactant and makes combined action with sodium chloride and white carbon black, so that the surface of the face layer of the antistatic wall cloth is combined with moisture to achieve the function of electric conduction and the function of leaking static electricity in time, and through the antistatic agent, the sodium chloride and the white carbon black, the resistance of the face layer of the antistatic wall cloth is kept within the range of 106-107 omega; and the prepared antistatic wall cloth has the good antistatic capability, meanwhile is diverse in function and can meet the requirements of people for indoor wall surface decorating materials.

Owner:路联新材料集团股份有限公司

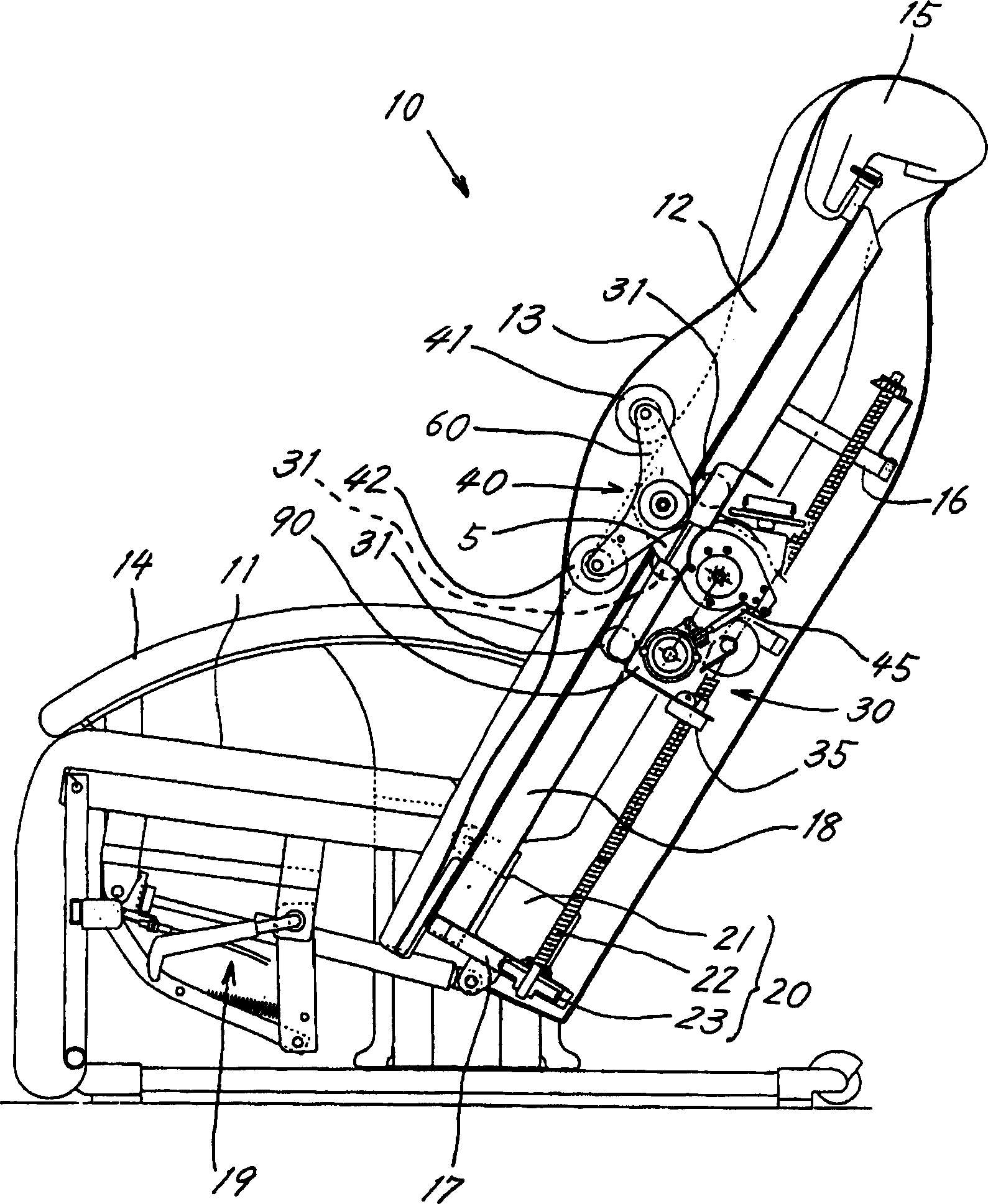

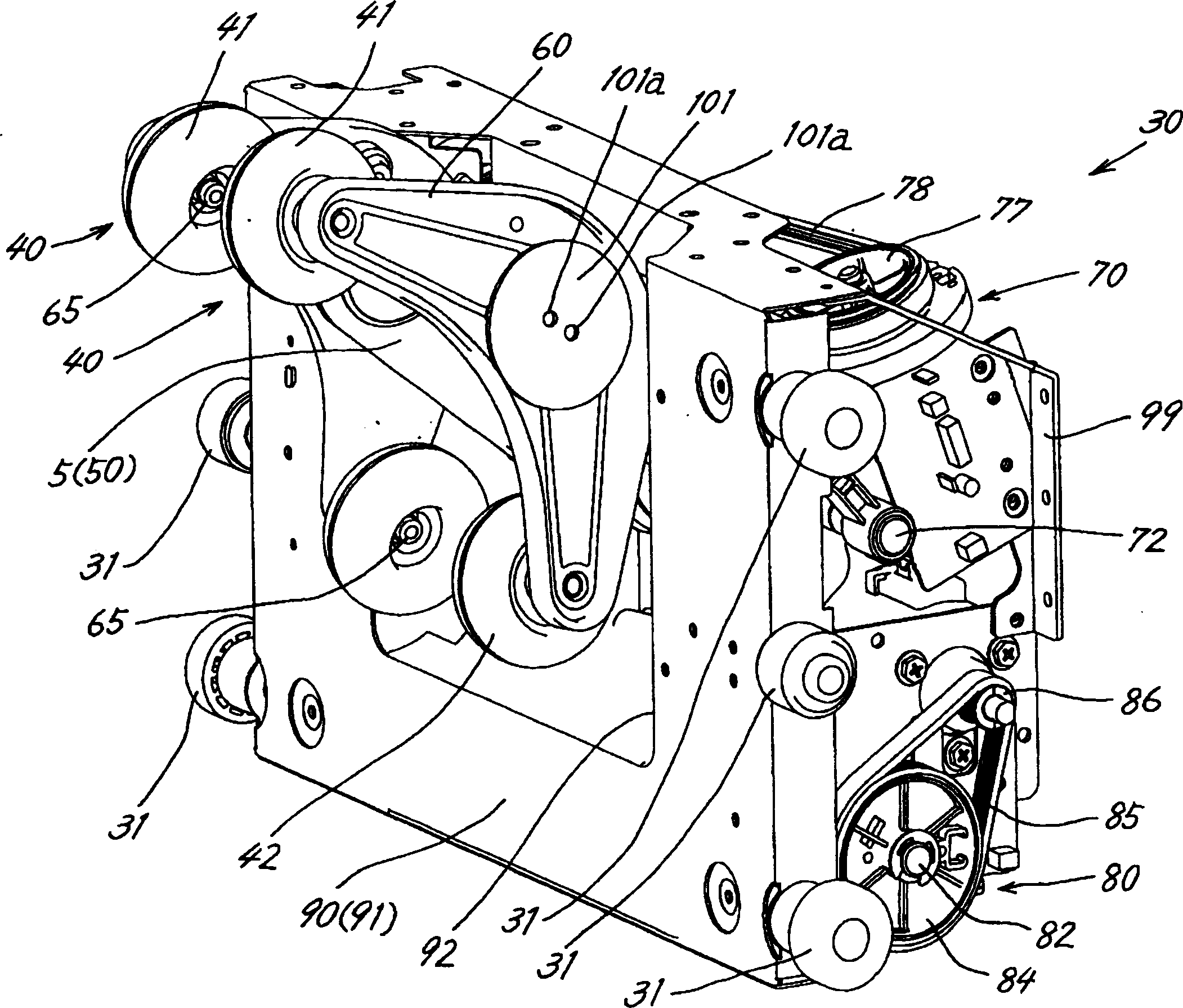

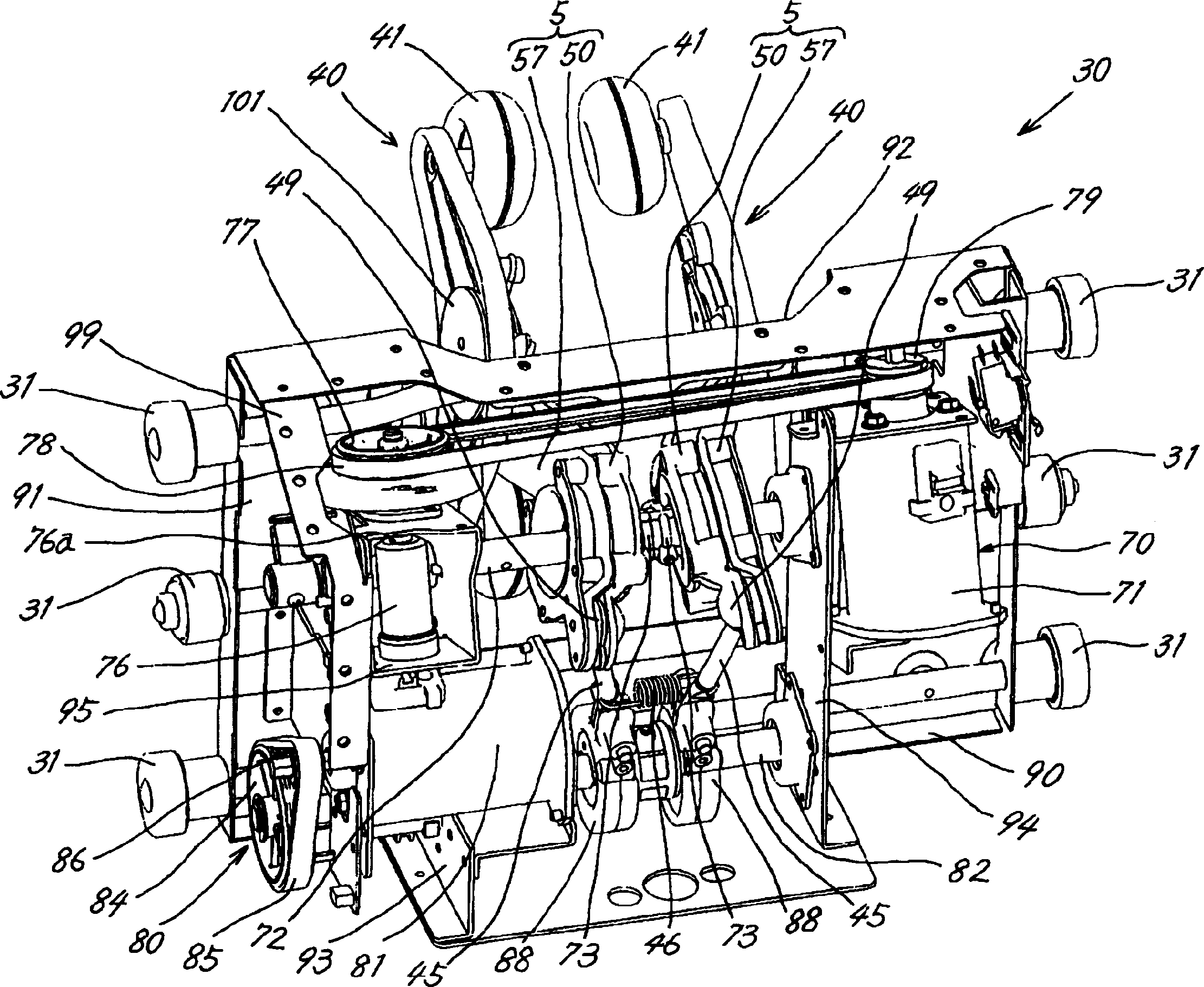

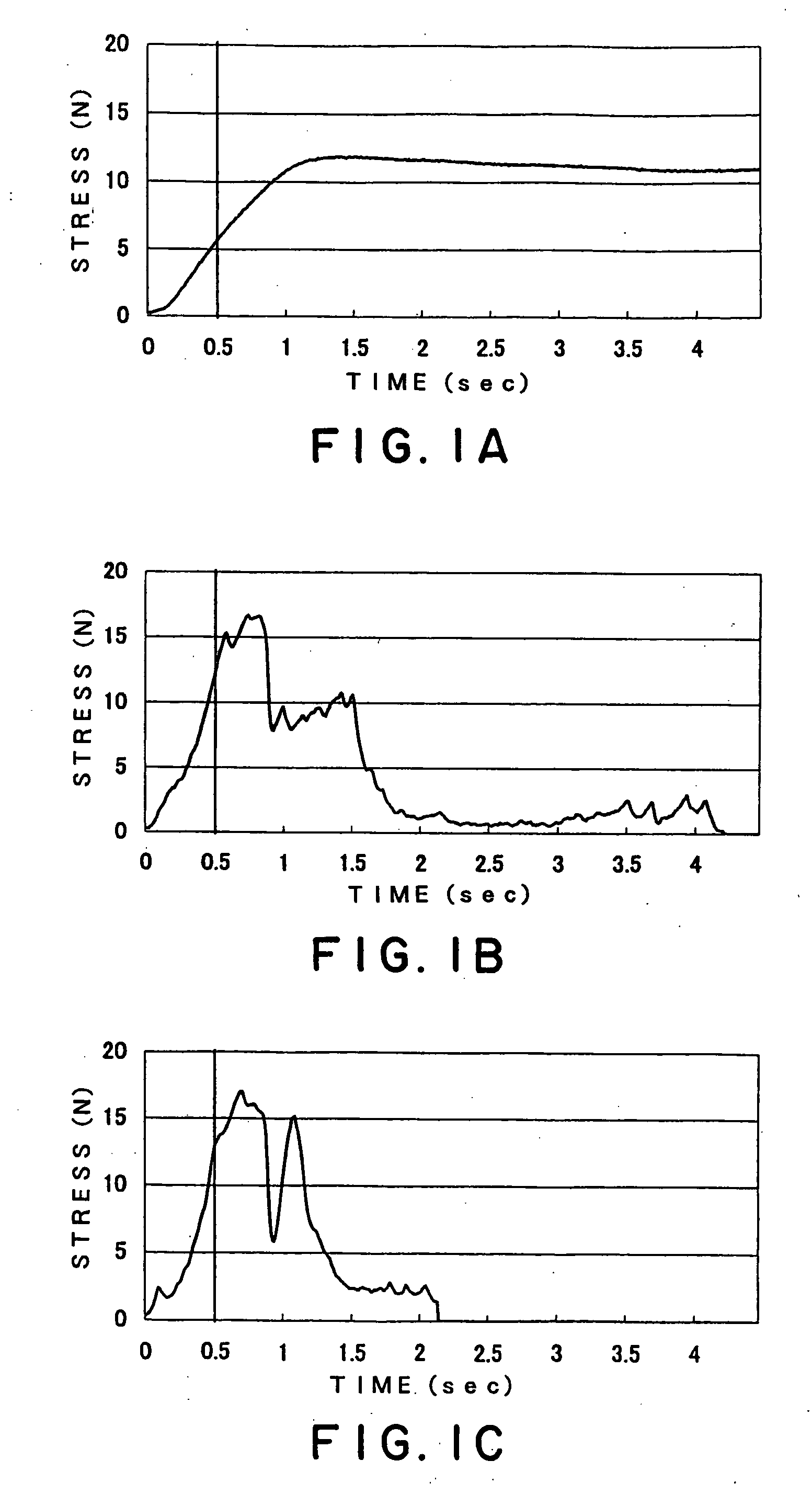

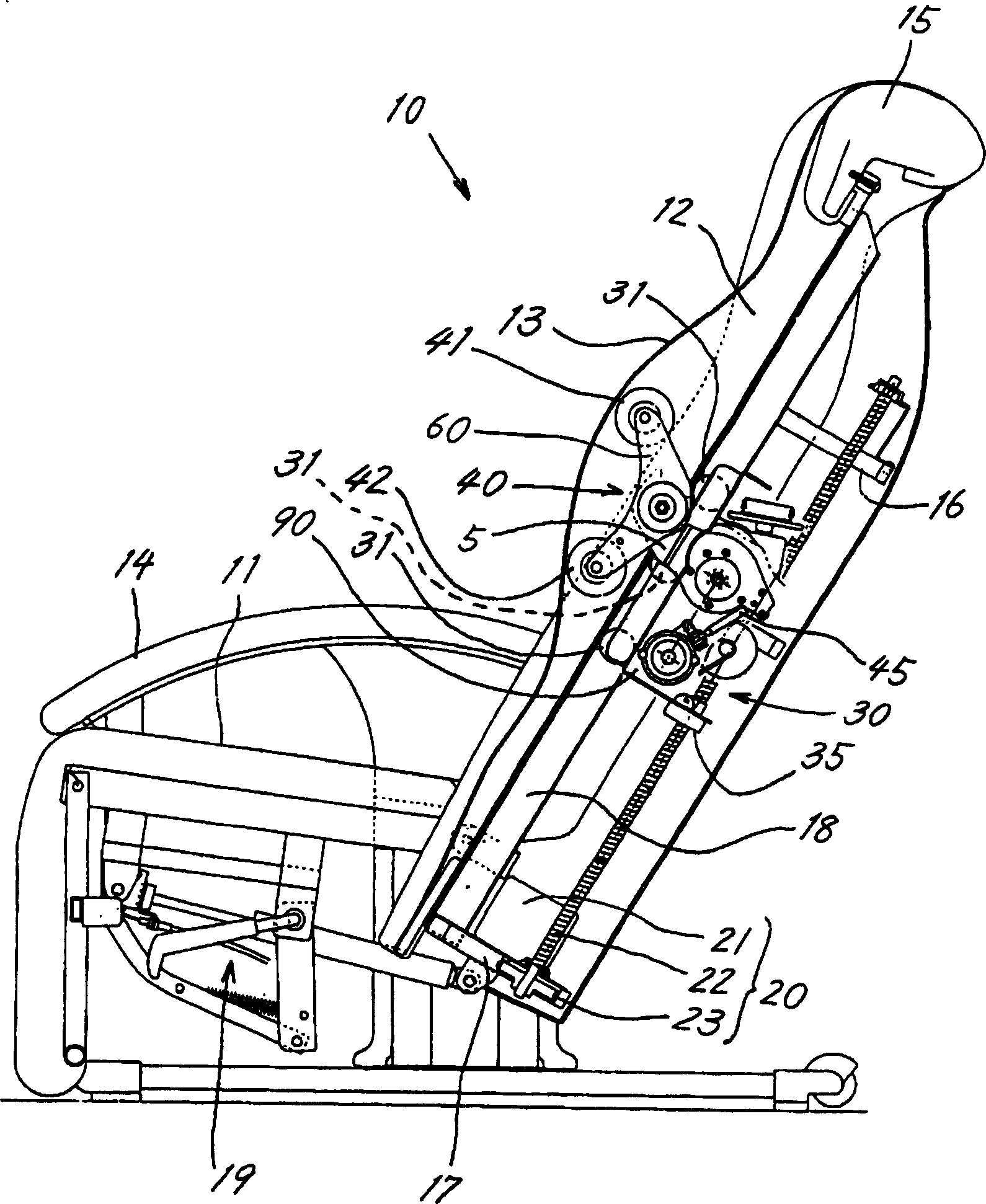

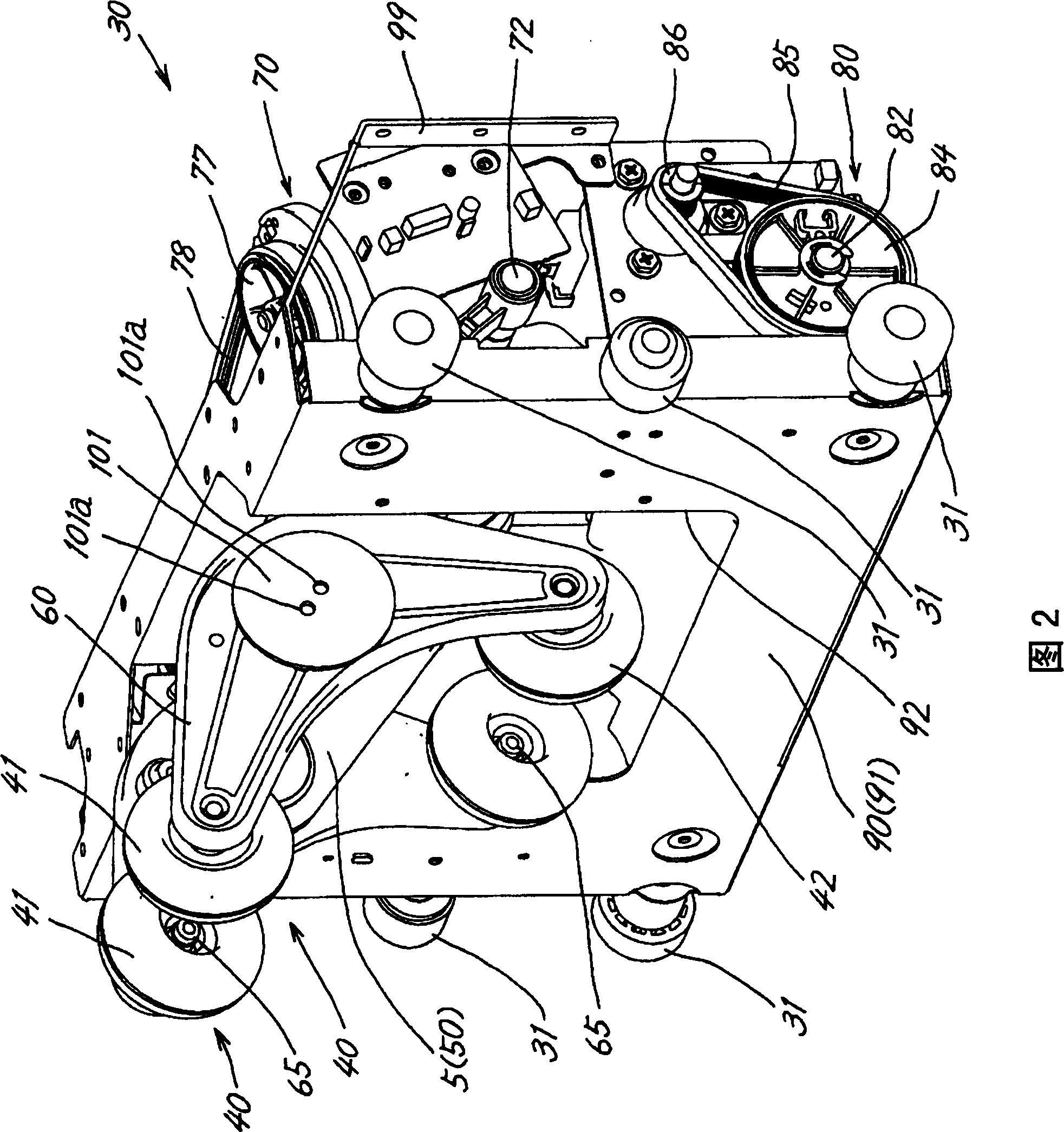

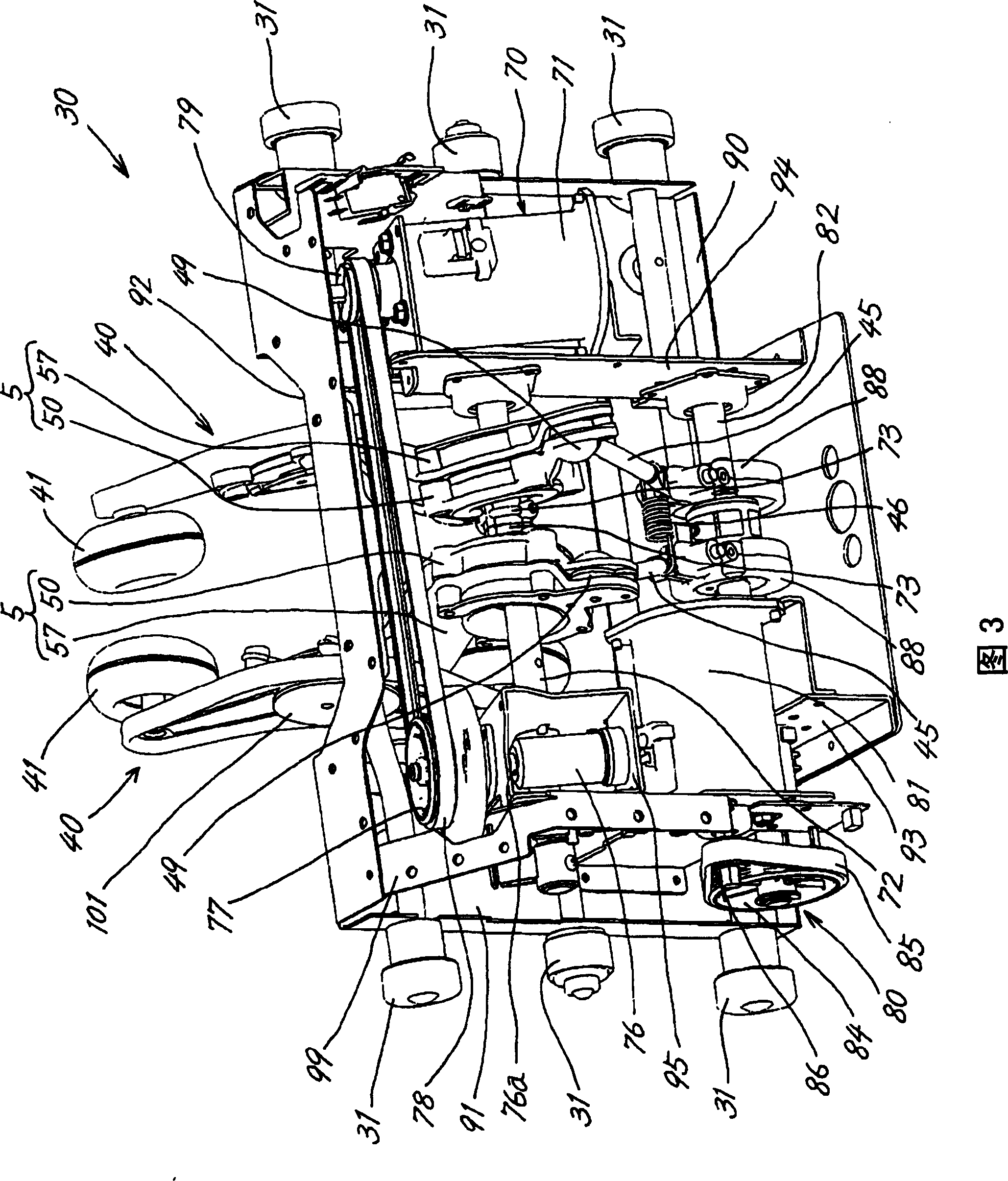

Massaging device

InactiveCN1827074AWon't hurtNo stress concentrationVibration massageSuction-kneading massageMassagePhysical therapy

The invention provides a seat massage appliance, comprising a massage unit (30), equipped with a pair of treating finger tilted assembled on rotating massage axis (72) powered by massage generator (71); said treating finger (40) comprises a massage arm (5) supported by massage axis, supporting bar (60) supported by axle (51) in front of massage arm, and massage ball (41) installed in front of supporting bar. The massage appliance is characterized in that: the supporting bar is forced through spring by massage arm on direction of massage ball forwardly pushed, said spring is torsion spring (47), the coiling part (48) of which is inserted into axle, one end of said torsion spring is fixed on massage arm and the other end (47 b) is fixed on supporting bar.

Owner:SANYO ELECTRIC CO LTD

Protein-Rich Baked Food and Process for Producing the Same

InactiveUS20070264392A1Excellent chewabilityExcellent dissolvabilityDough treatmentBaking mixturesHigh concentrationWhole food

This invention provides a high-protein baked food product, comprising at least: at least 15% by weight (on a dry weight basis), based on the whole food product, of a protein component; an oil and fat component and a saccharide component, wherein the high-protein baked food product is obtainable by finely grinding a first material mixture comprising a protein component, an oil and fat component, and a saccharide component, stirring the mixture to prepare a creamy primary product, mixing the primary product with a secondary material mixture provided separately from the primary product and comprising at least an oil and fat component and a saccharide component, and baking the mixture. This baked food product contains protein in a high concentration, is soft and has good chewability and dissolvability within the mouth.

Owner:BOURBON CORP

Preparation method of slow-rebound polyurethane foam

The invention relates to a preparation method of slow-rebound polyurethane foam. The method is characterized by including the following steps of firstly, heating AA and DEG for esterification polycondensation reaction, and conducting reaction till the acid value is 20-25 mgKOH / g; secondly, adding oxidized carbon black containing carboxyl and hydroxyl functional groups to the product obtained in the first step, conducting vacuumizing, conducting reaction till the acid value is smaller than or equal to 2.0 mgKOH / g, and increasing the vacuum degree and continuing to conduct reaction to obtain DEG polyhydric alcohols modified by oxidized carbon black and terminated with hydroxyl groups, namely modified DEG polyhydric alcohols; thirdly, adding chain extender, catalyst, H2O and polyether triols to the product obtained in the second step to be evenly mixed to prepare a component A for preparing polyurethane foam; fourthly, conducting heating polymerization on diisocyanate and polyether triols to prepare a component B for preparing polyurethane foam, wherein diisocyanate is excessive; fifthly, evenly mixing the component A and the component B for preparing polyurethane foam according to the molar ratio of hydroxyl groups to isocyanate groups being 1.0:1.05, coating a PET film with the mixture according to the thickness of 0.1-0.4 mm, and conducting heating and curing to obtain the slow-rebound polyurethane foam.

Owner:JIAXING ZHONGYI CARBON TECH

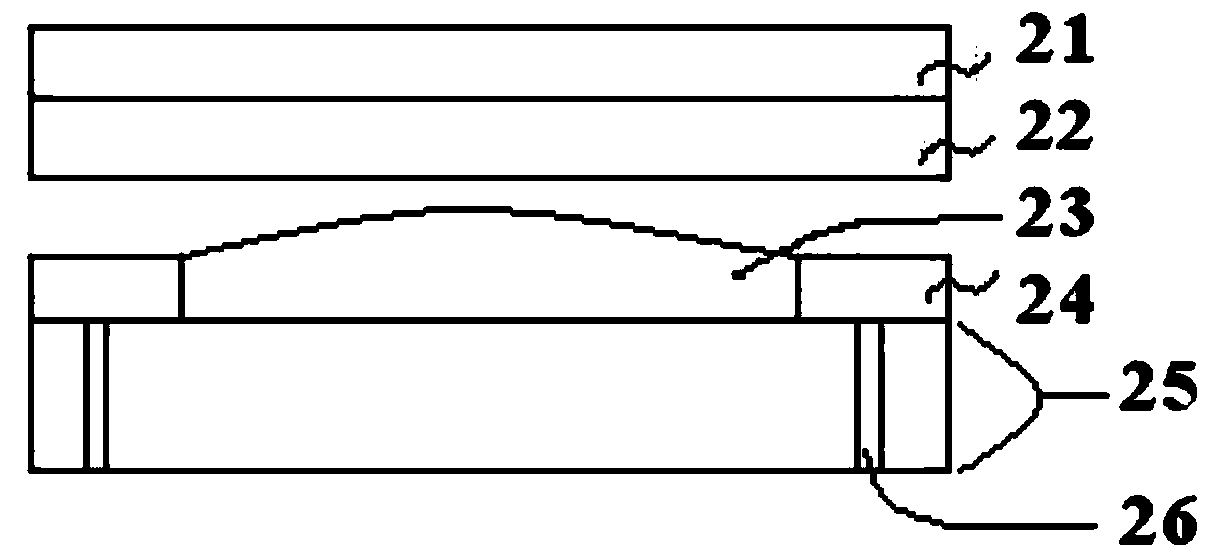

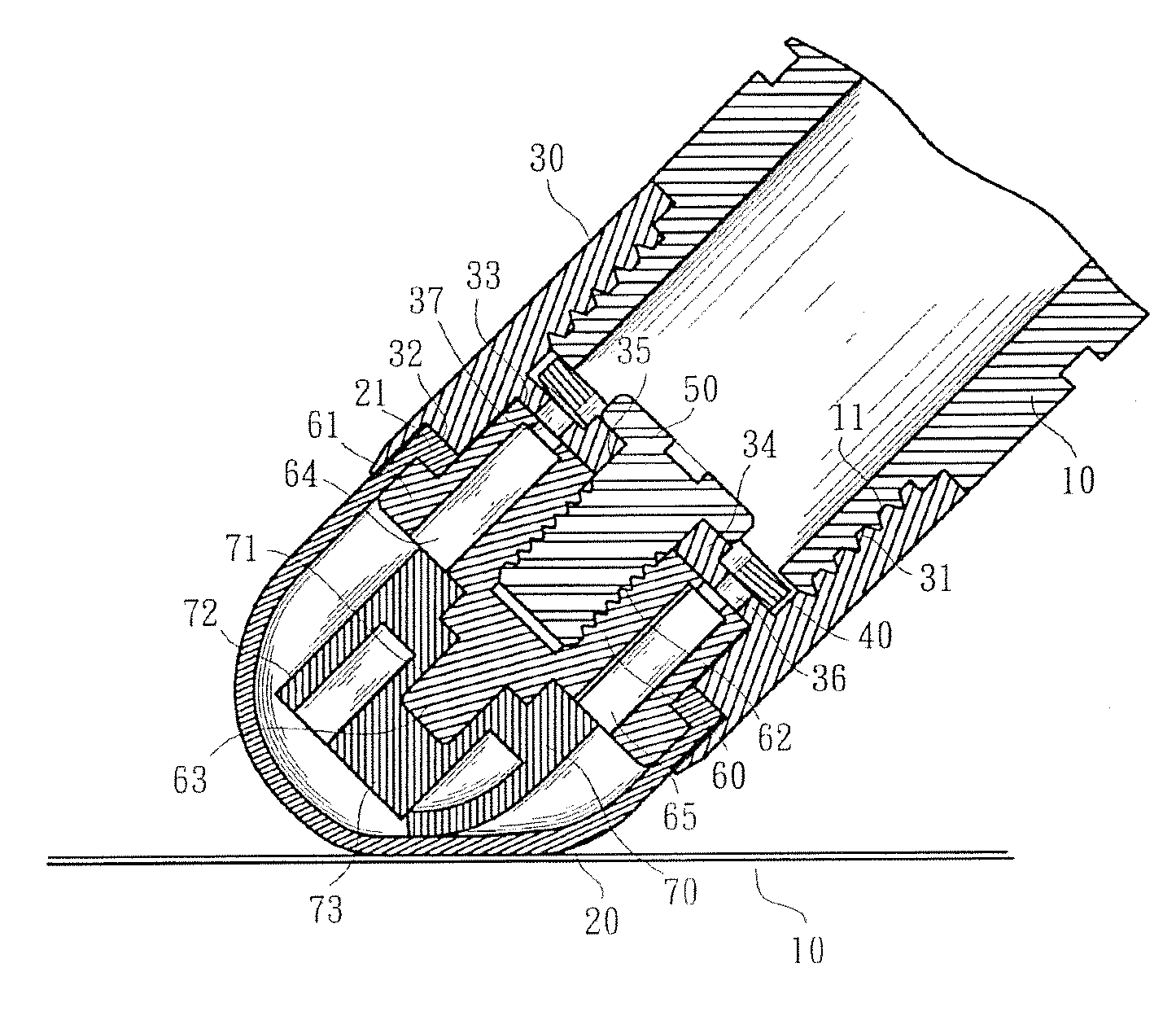

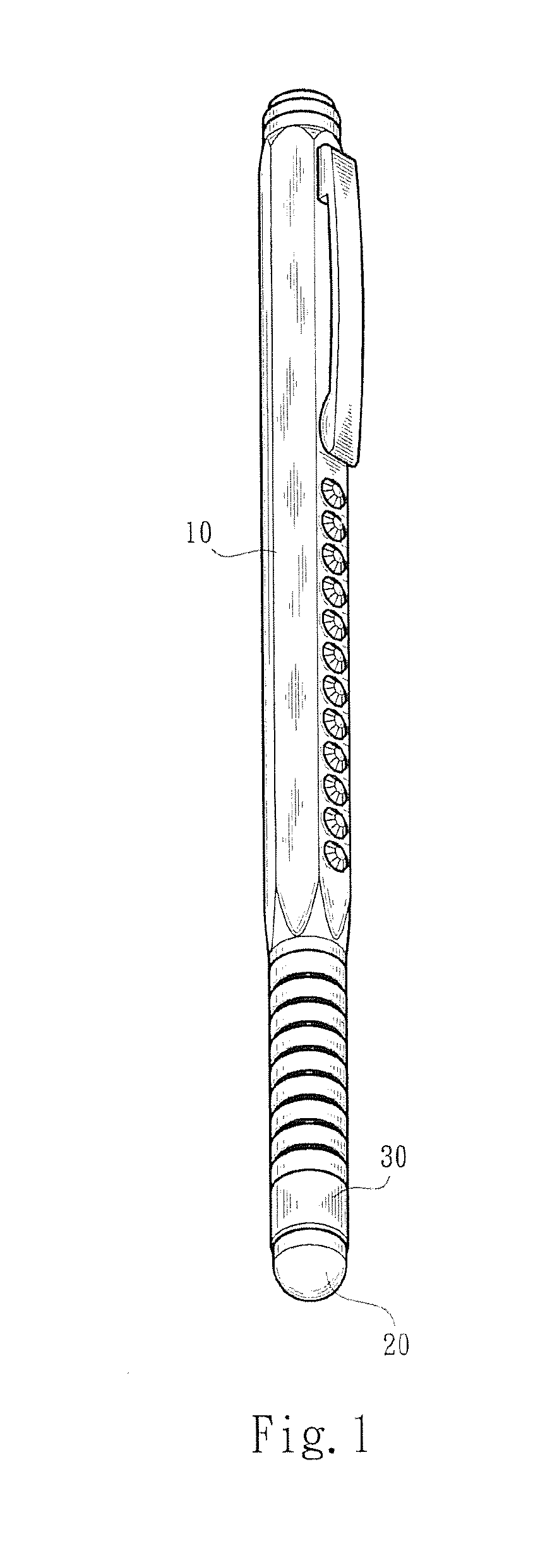

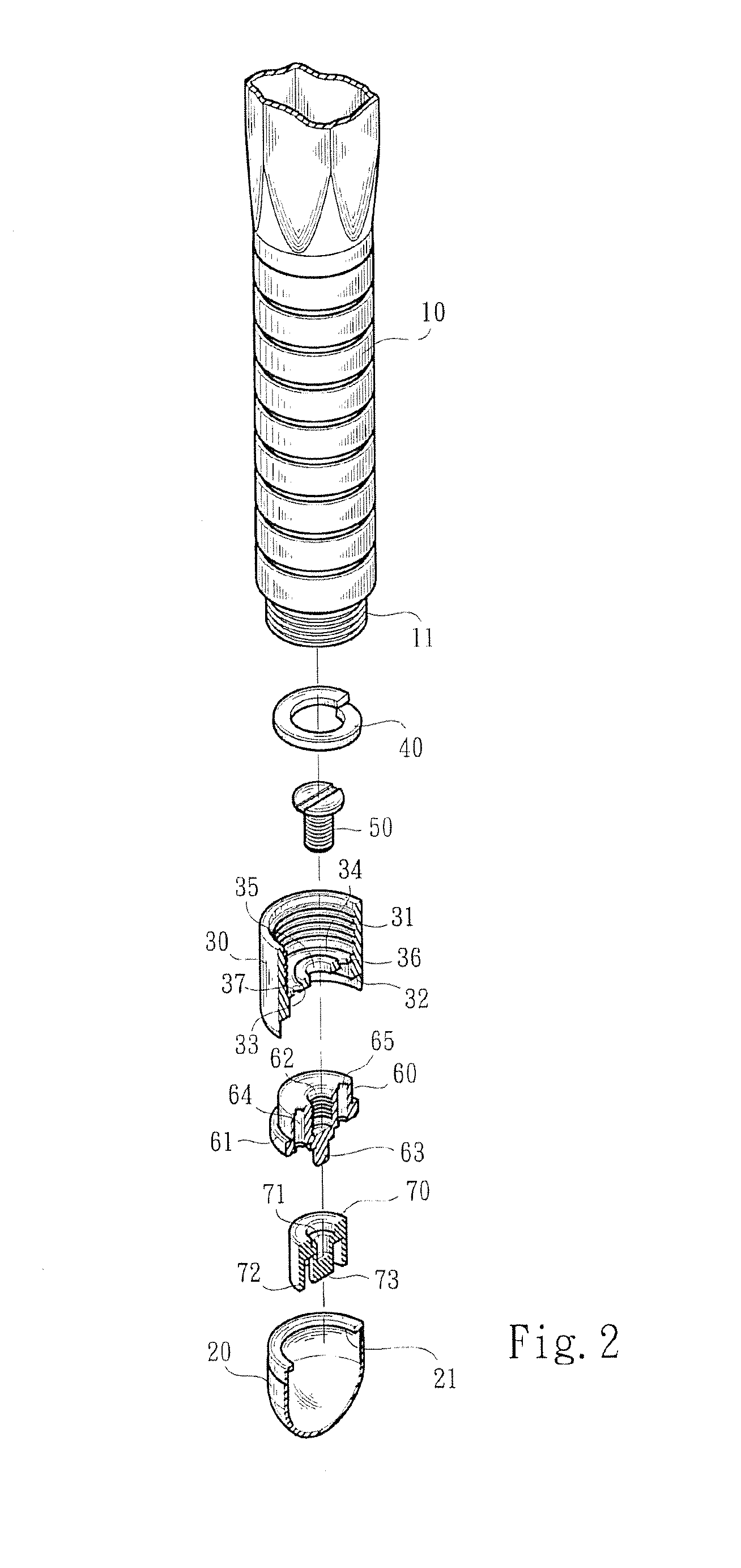

Capacitive stylus

ActiveUS20130300720A1Appropriate softnessReliable contactTransmission systemsGraph readingRubber materialEngineering

A capacitive stylus includes: a hollow stylus stick; a soft touch member made of conductive plastic or rubber in the form of a hollow housing, the soft touch member having a domed touch end; a connection collar assembled with an end section of the stylus stick, the connection collar and the soft touch member together defining an internal space; a support member disposed in the internal space, the support member being made of a rubber material with hardness greater than that of the soft touch member; and a rest seat assembled with the support member, the support member being spaced from the soft touch member by a gap and formed with a multi-support structure facing the soft touch member. In operation, the soft touch member can keep a proper softness without being over-deformed or collapsed.

Owner:HUNG GEORGE

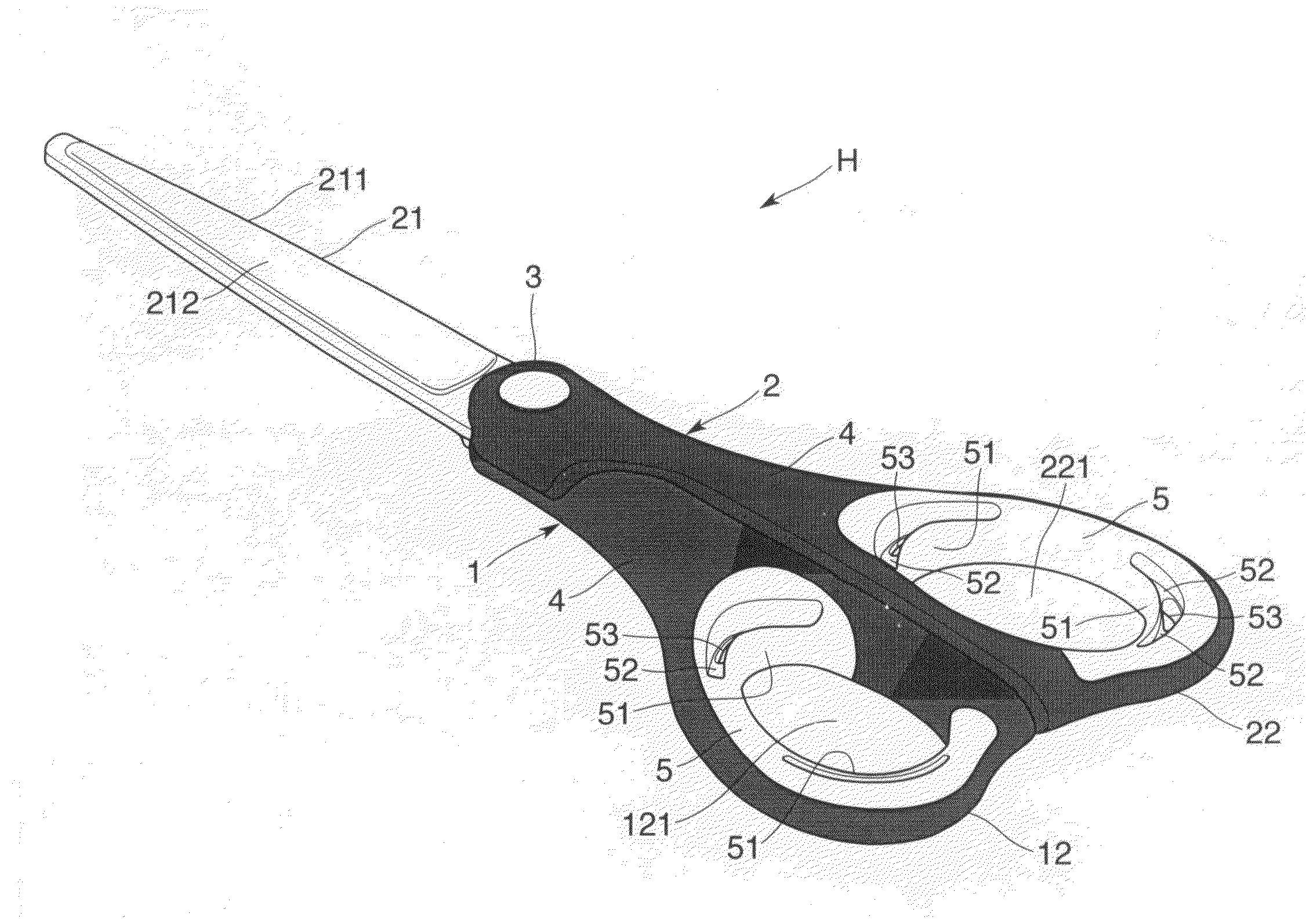

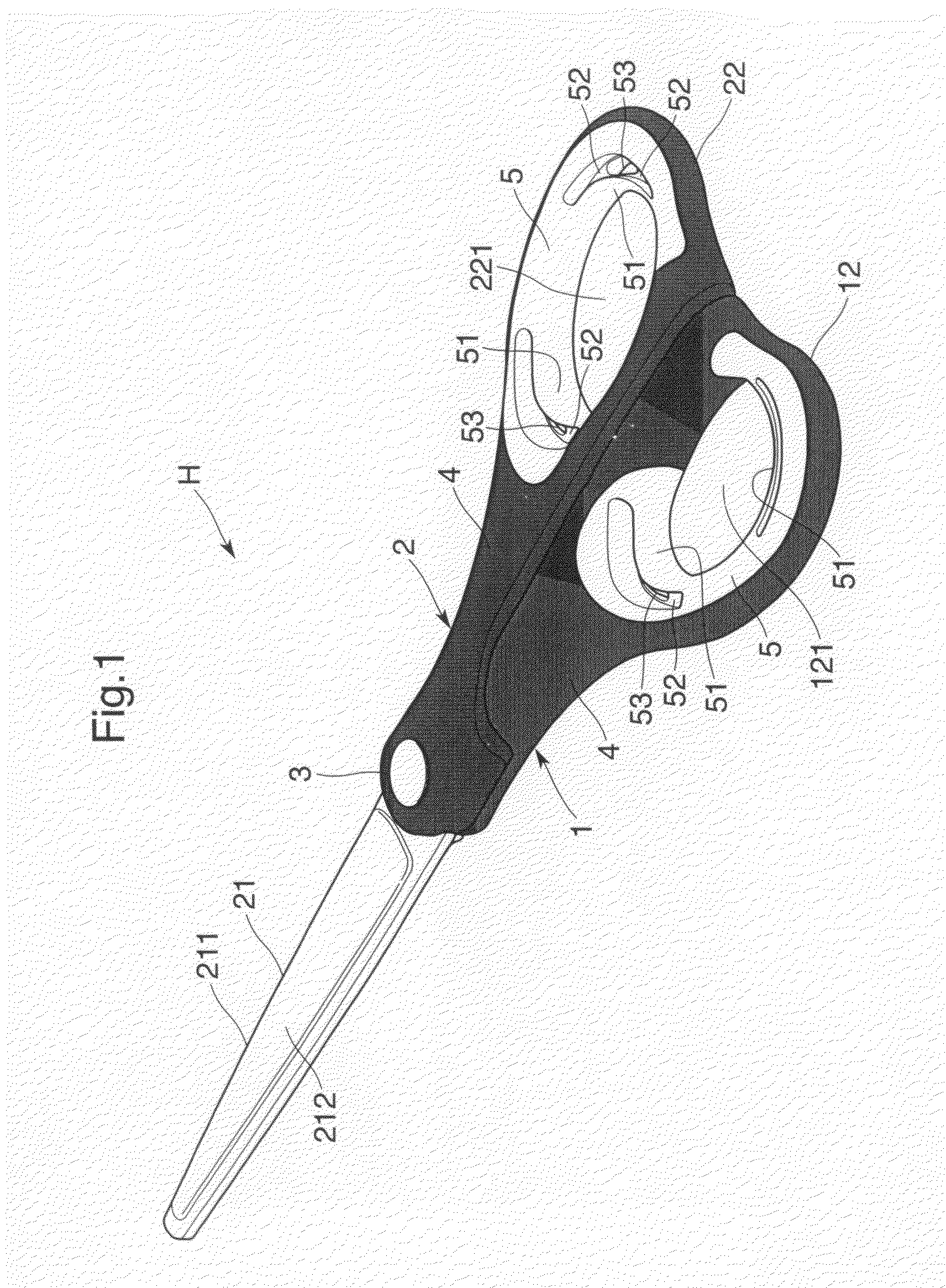

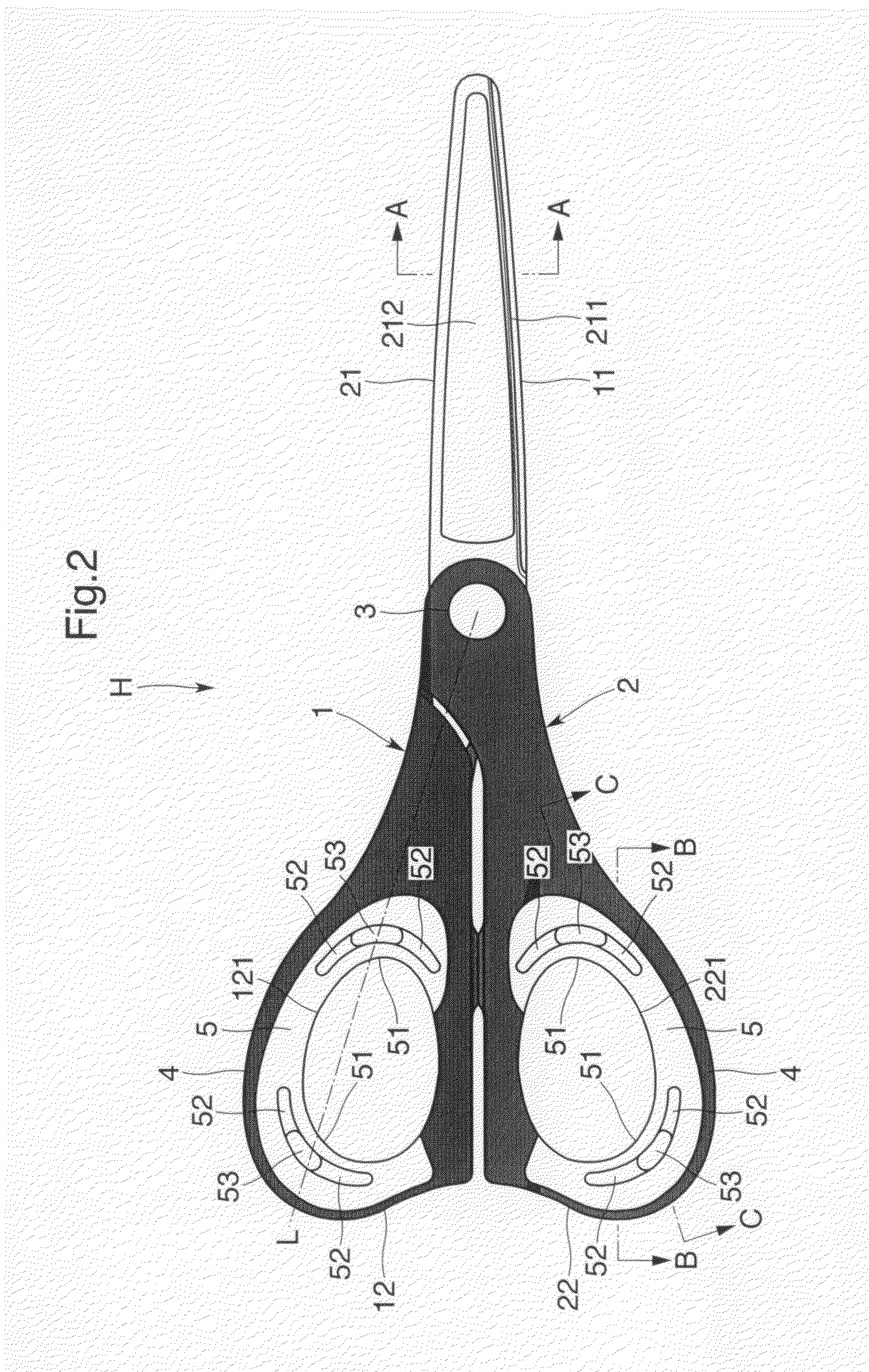

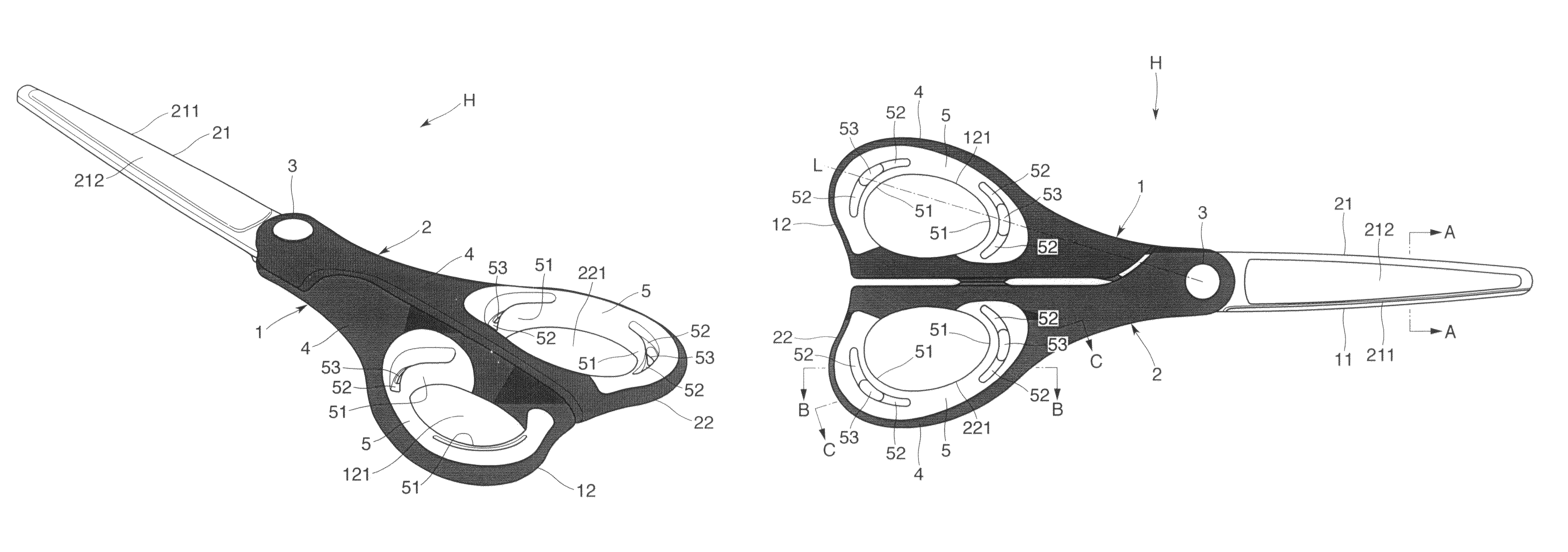

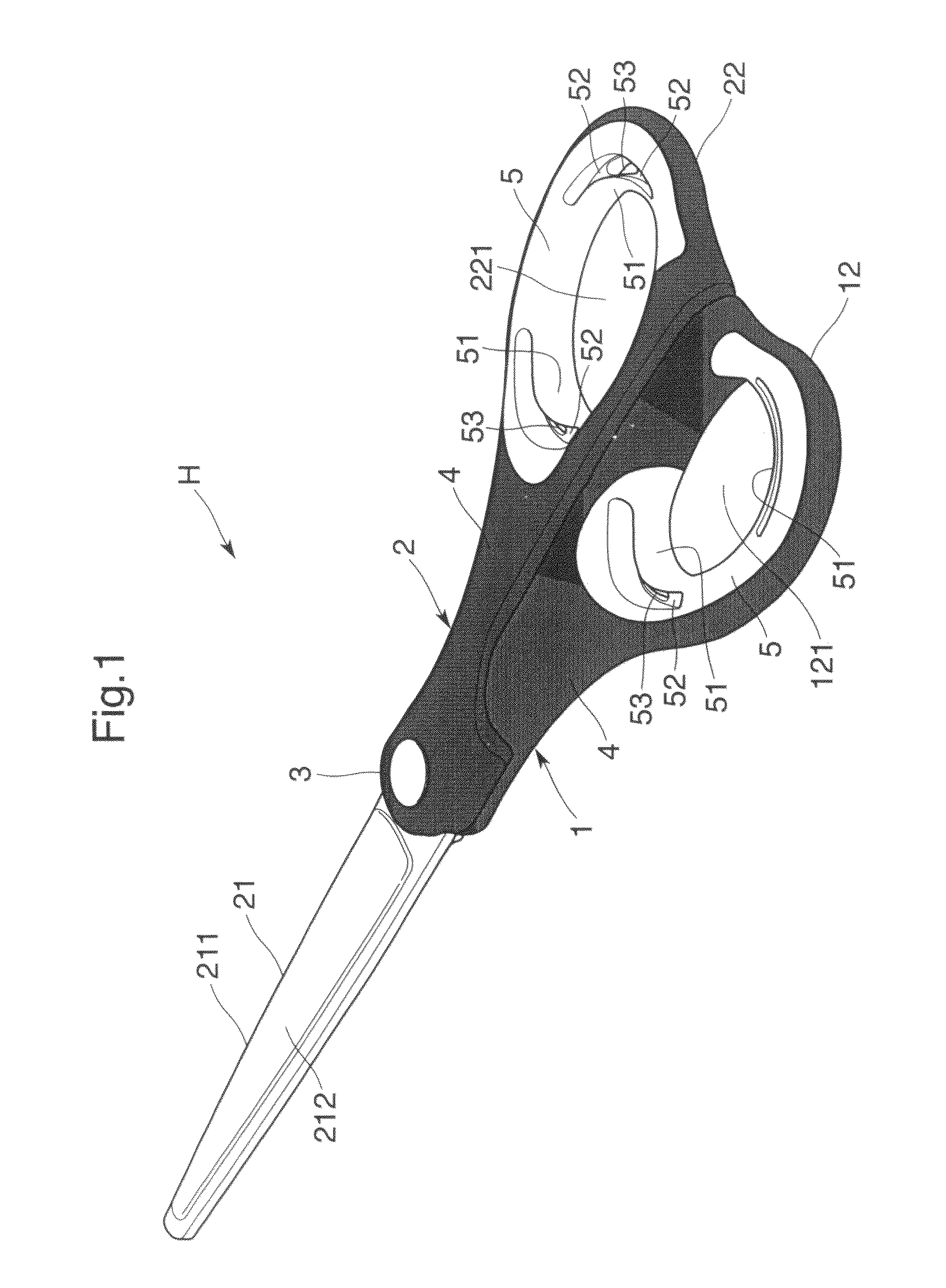

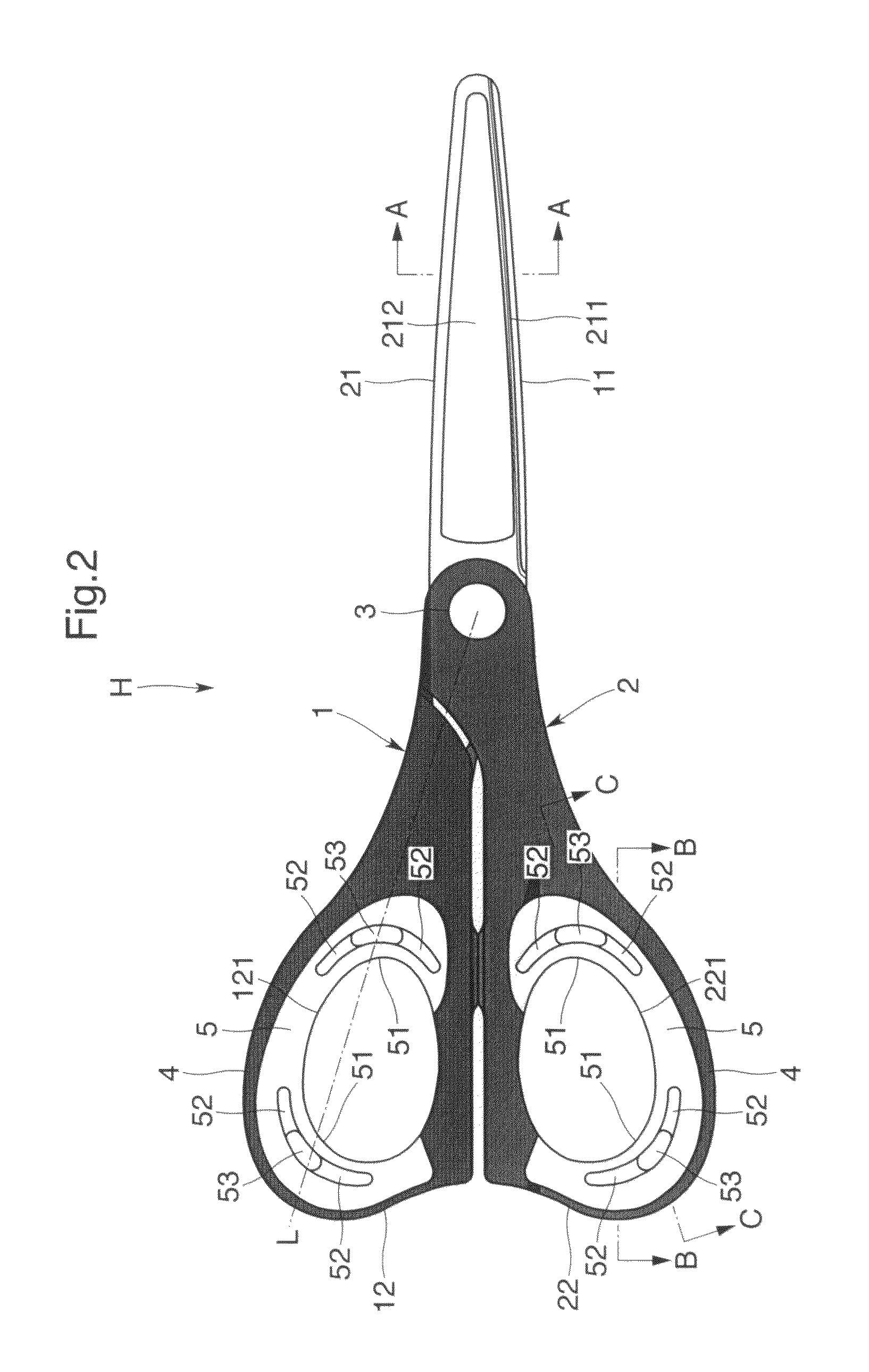

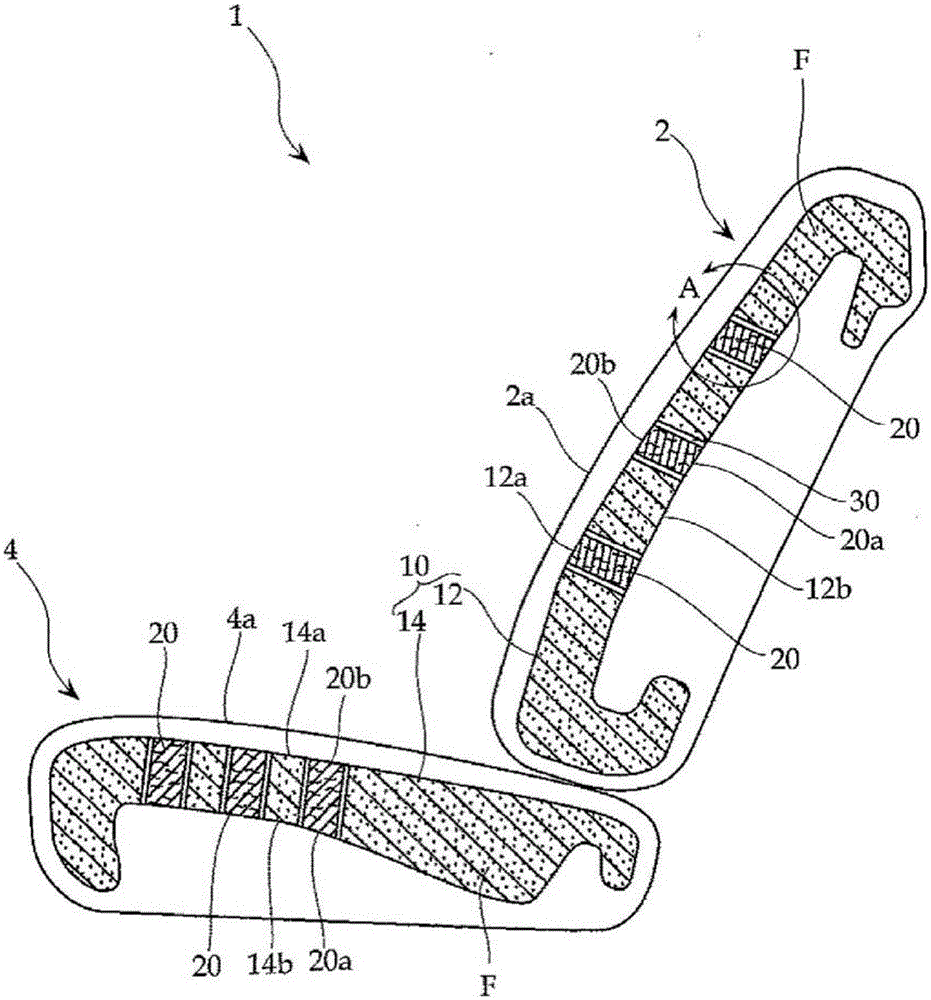

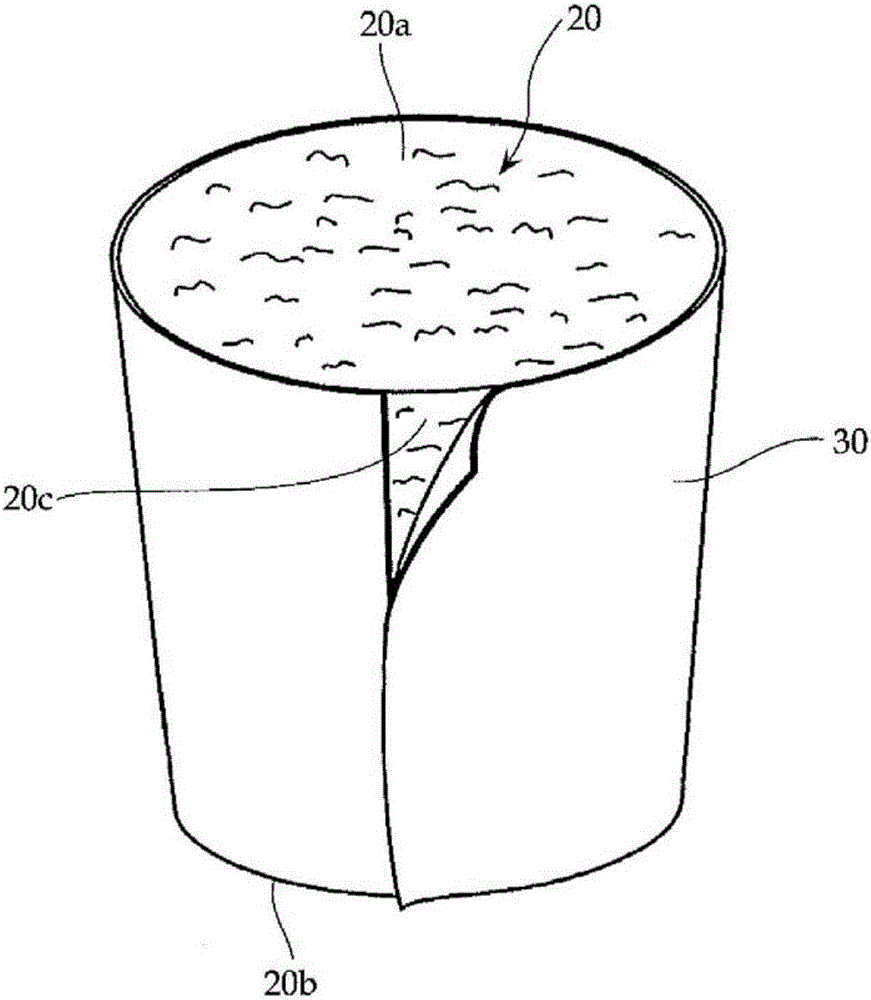

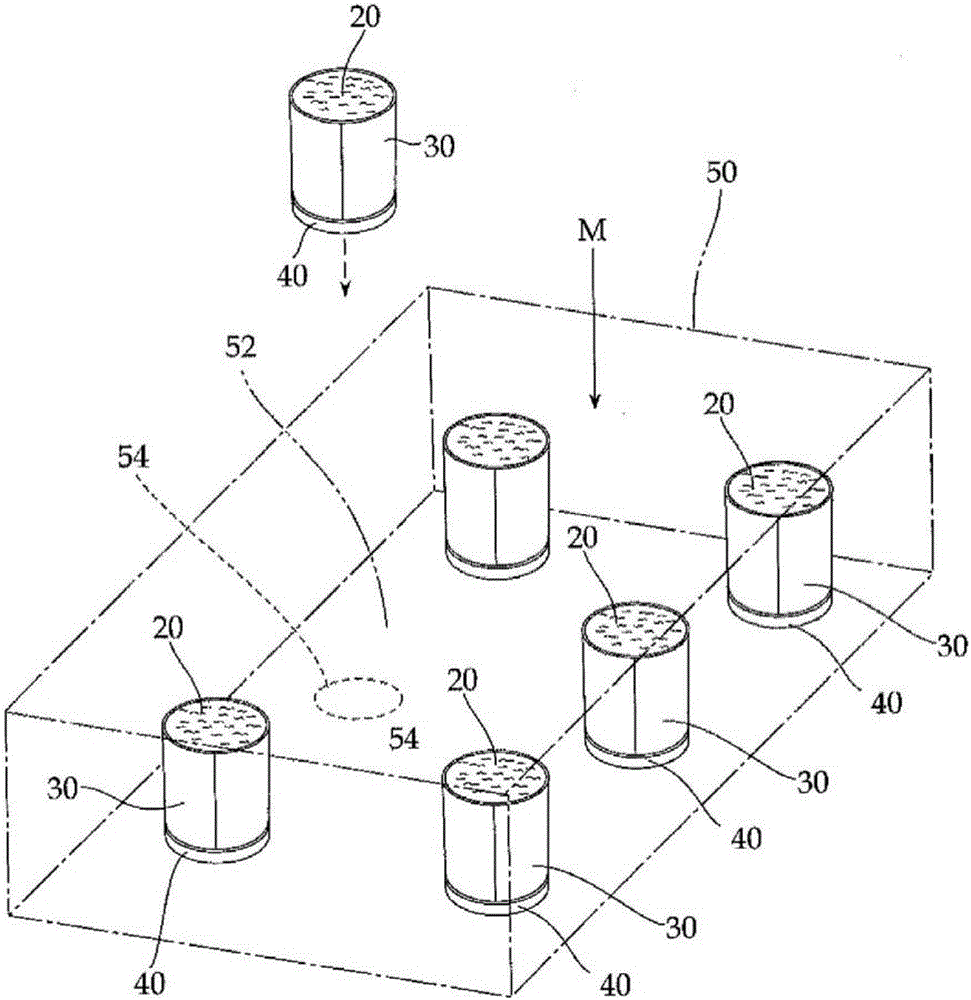

Handle of tool

ActiveUS20100263215A1More usableEasy to handleTravelling carriersHoldersBiomedical engineeringHard core

Each of handles of a pair of scissors includes a hard core member and a soft member softer than the core member and including a contact face portion with which a finger of a user comes in contact, a bottomed recessed hole portion adjacent to the contact face portion and thinner than portions around it, and a through hole portion continuous with the bottomed recessed hole portion. When the user inserts and removes his / her fingers into and from finger rings, the contact face portions escape while compressing the through hole portions and the contact face portions tilt by using the bottomed recessed hole portions as fulcrums. Moreover, the bottomed recessed hole portions and the through hole portions continuous with each other are molded, which allows an elastic deformation property and a shape retaining property of the contact face portions to go together and also contributes to durability of the soft members including the contact face portions.

Owner:KOKUYO CO LTD

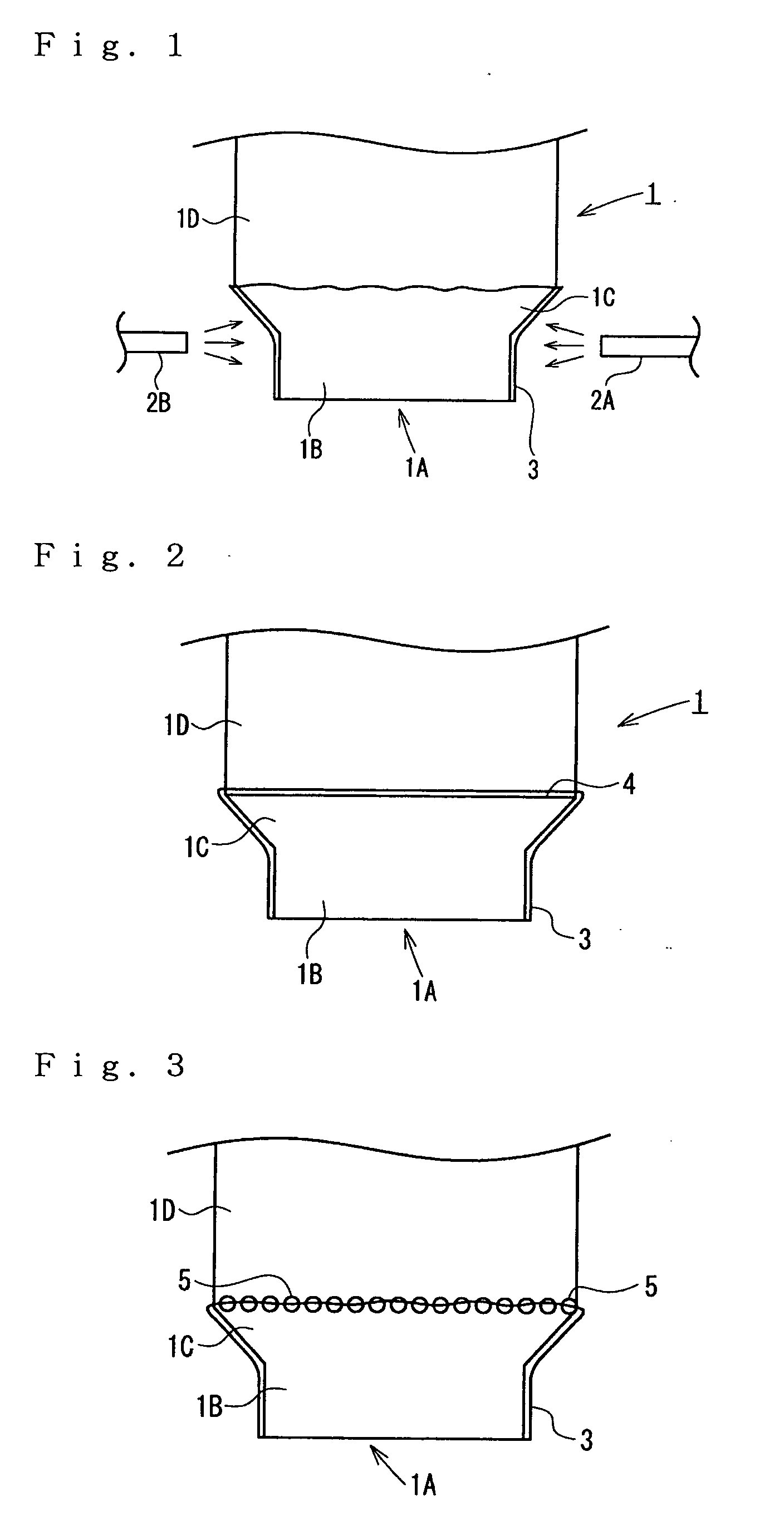

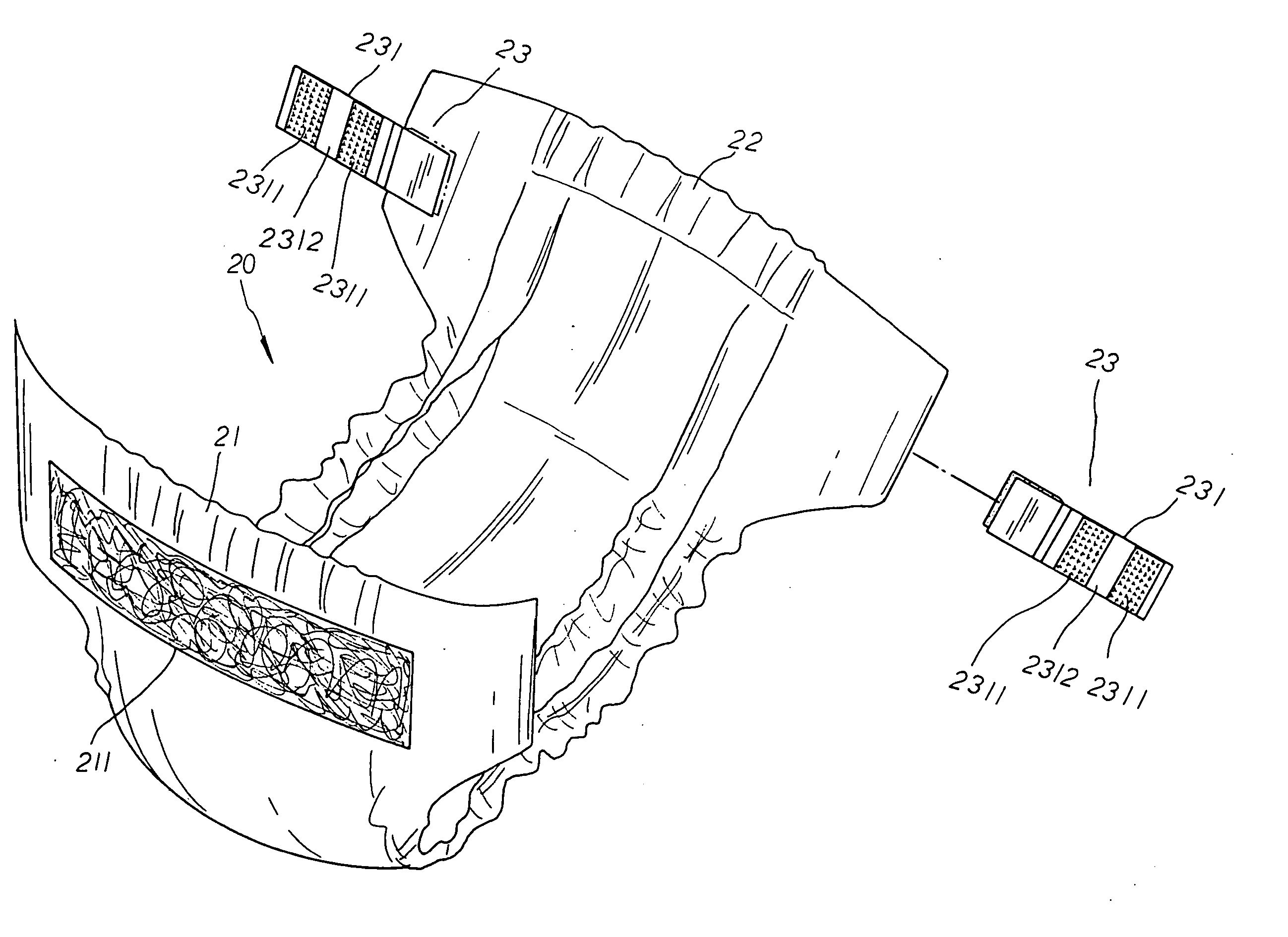

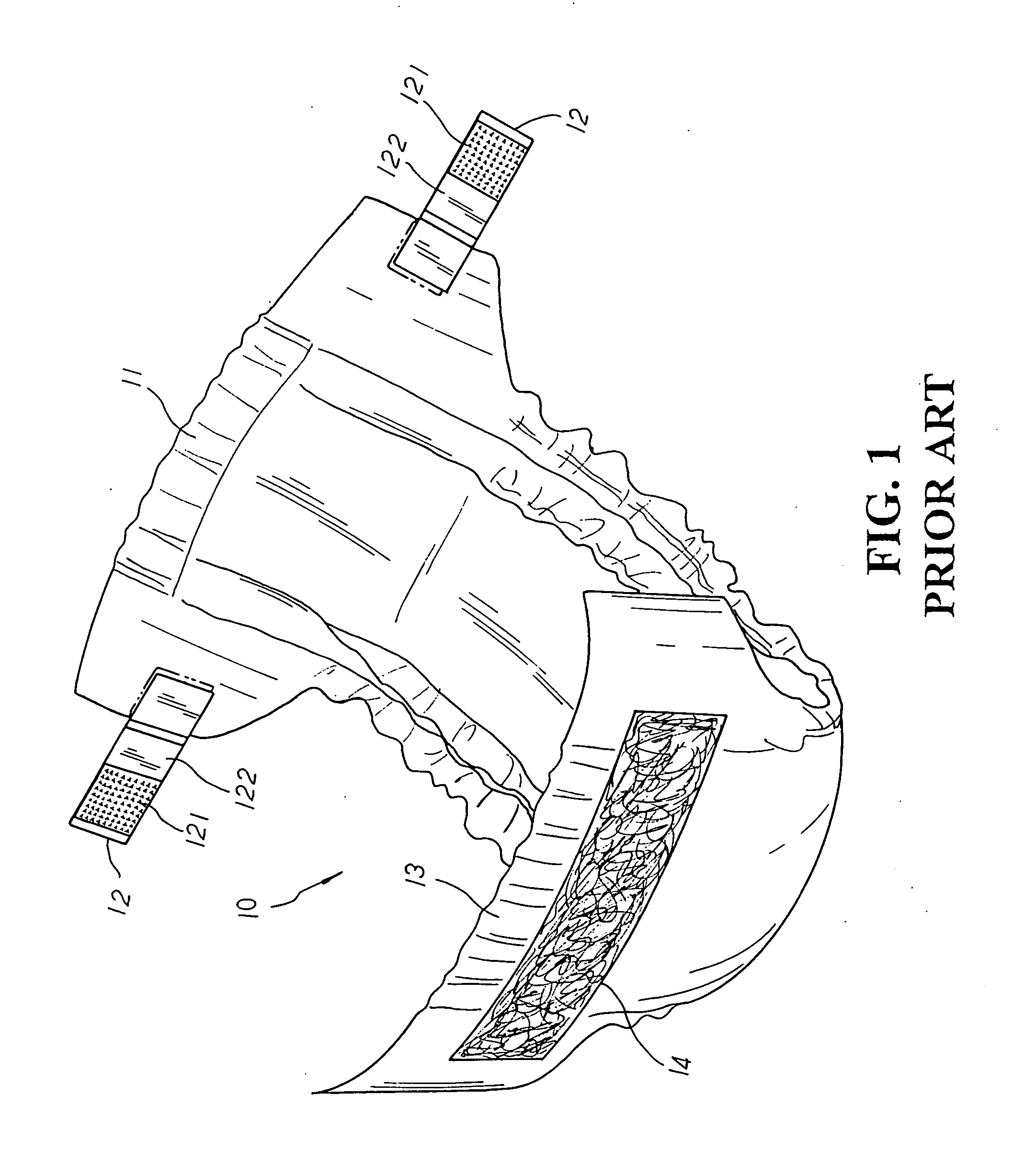

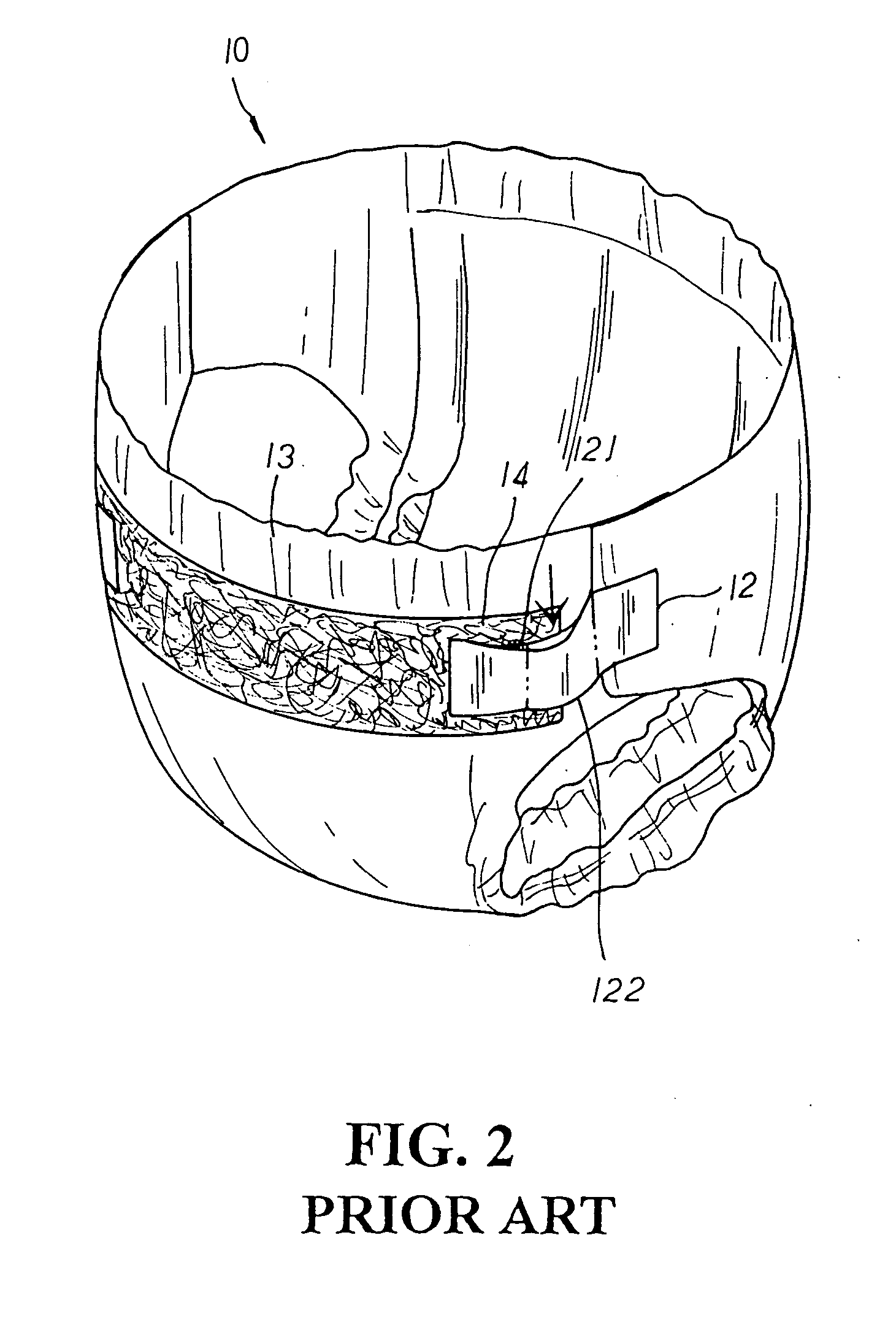

Buckling device for disposable articles

InactiveUS20050197642A1Better engagementAppropriate softnessAbsorbent padsBaby linensEngineeringMechanical engineering

Owner:TAIWAN PAIHO LTD

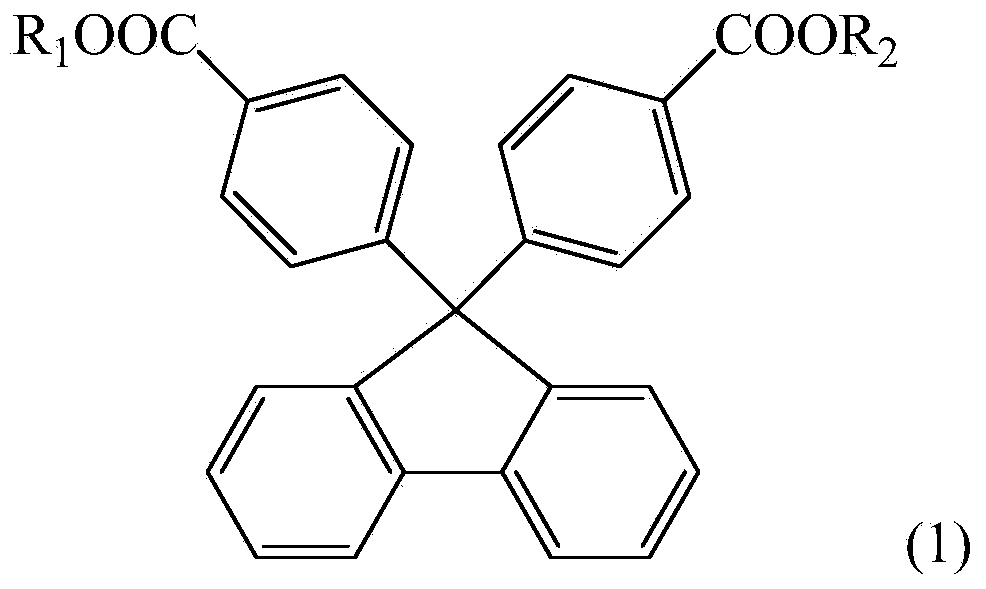

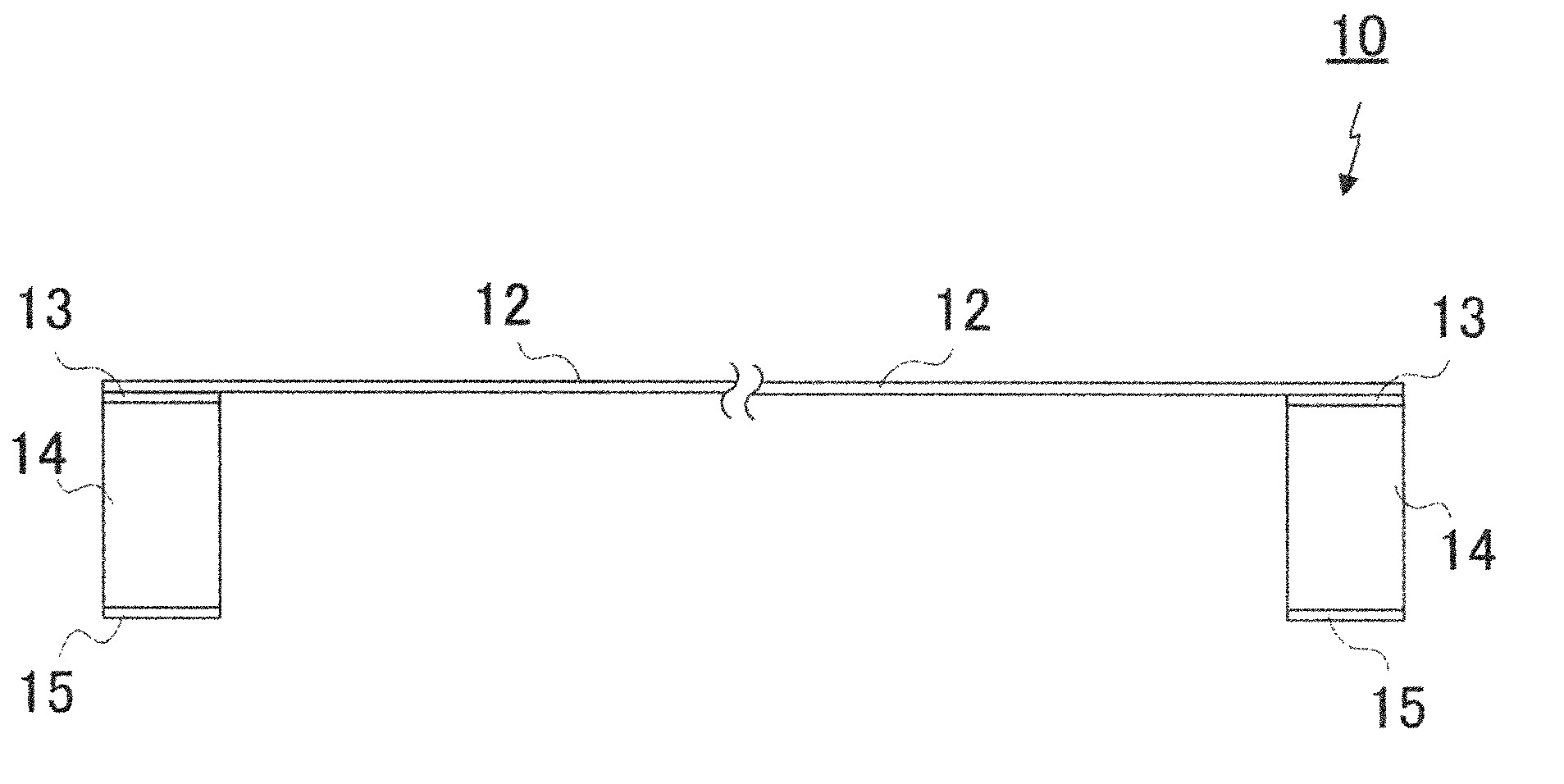

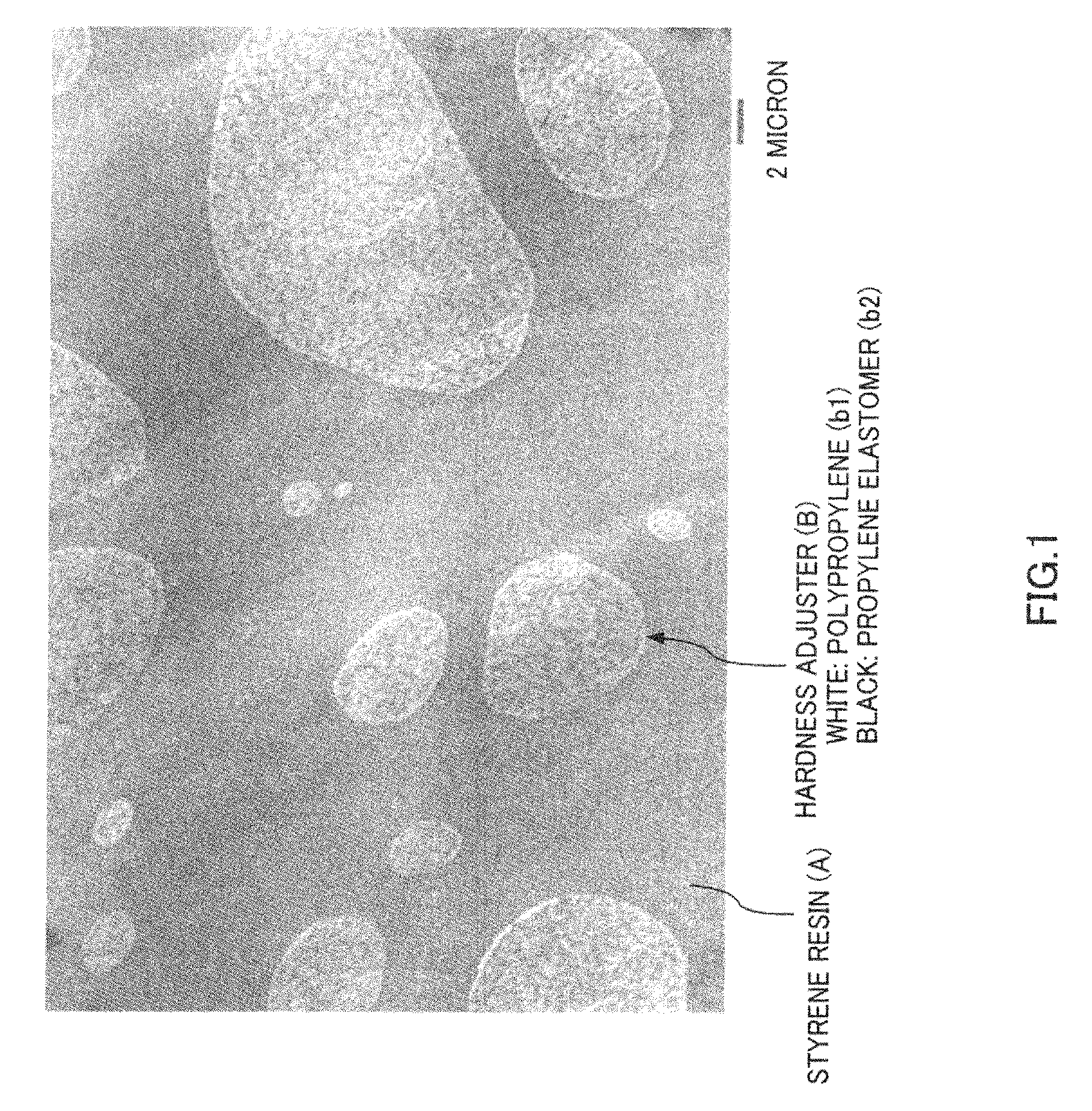

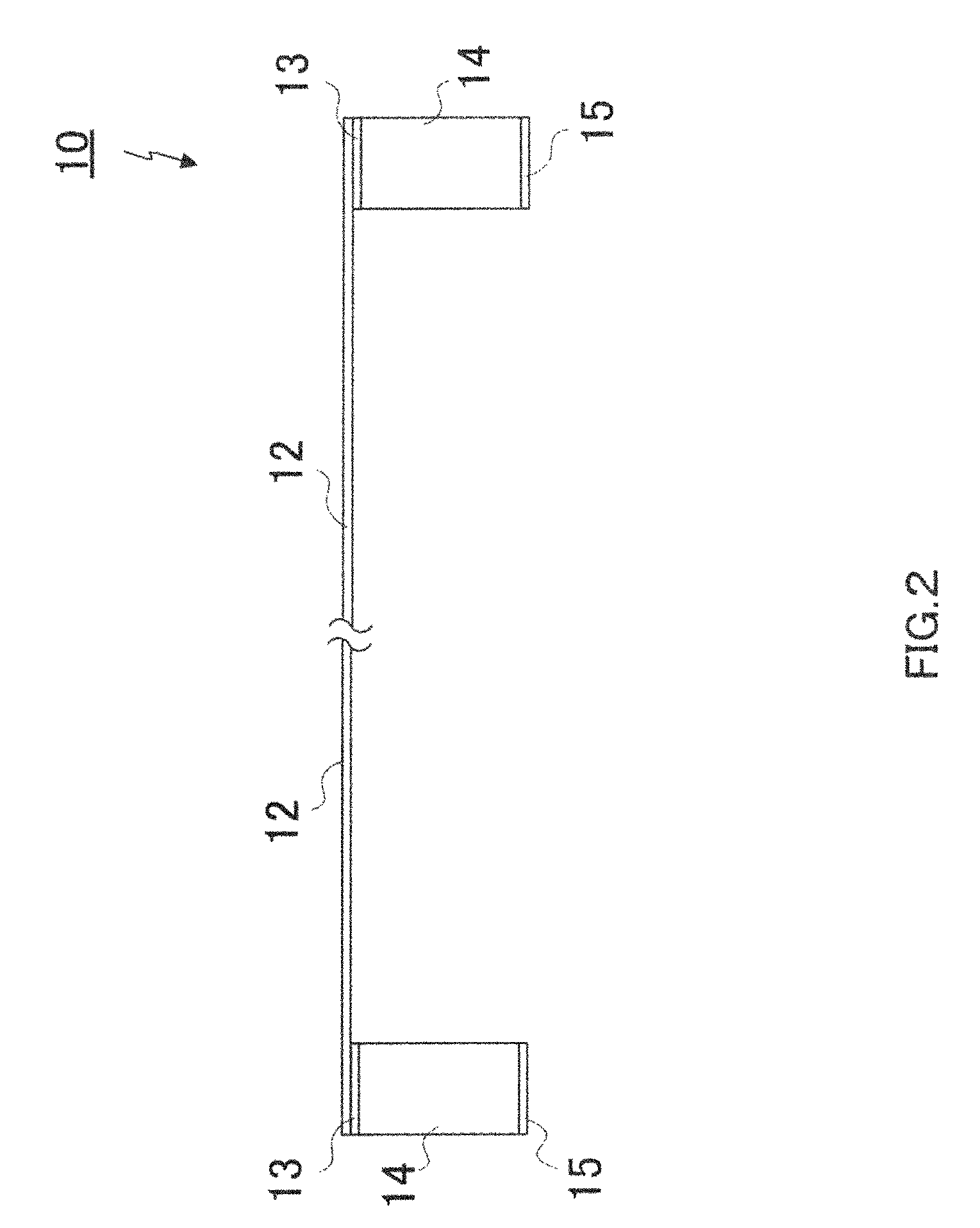

Pellicle and mask adhesive therefor

ActiveUS8685598B2Appropriate softnessNot can be deformed and distortedMixingOriginals for photomechanical treatmentElastomerAdhesive cement

Disclosed is a pellicle having a mask adhesive layer having appropriate softness, having a small adhesive residue after being peeled off from a mask, and having good handling characteristics; and a pellicle for preventing position deviation of patterns, in particular in double patterning. The pellicle of the present invention includes a pellicle frame, a pellicle membrane disposed on one end surface of the pellicle frame, and a mask adhesive layer disposed on other end surface of the pellicle frame; wherein the mask adhesive layer includes 35 to 170 weight parts of a hardness adjuster (B) containing a polypropylene (b1) and a propylene based elastomer (b2) per 100 weight parts of a styrene resin (A); and in an electron microscopic photograph of the mask adhesive layer, a phase-separated structure of a continuous phase of the styrene resin (A) and a discontinuous phase of the hardness adjuster (B) is observed.

Owner:MITSUI CHEM INC

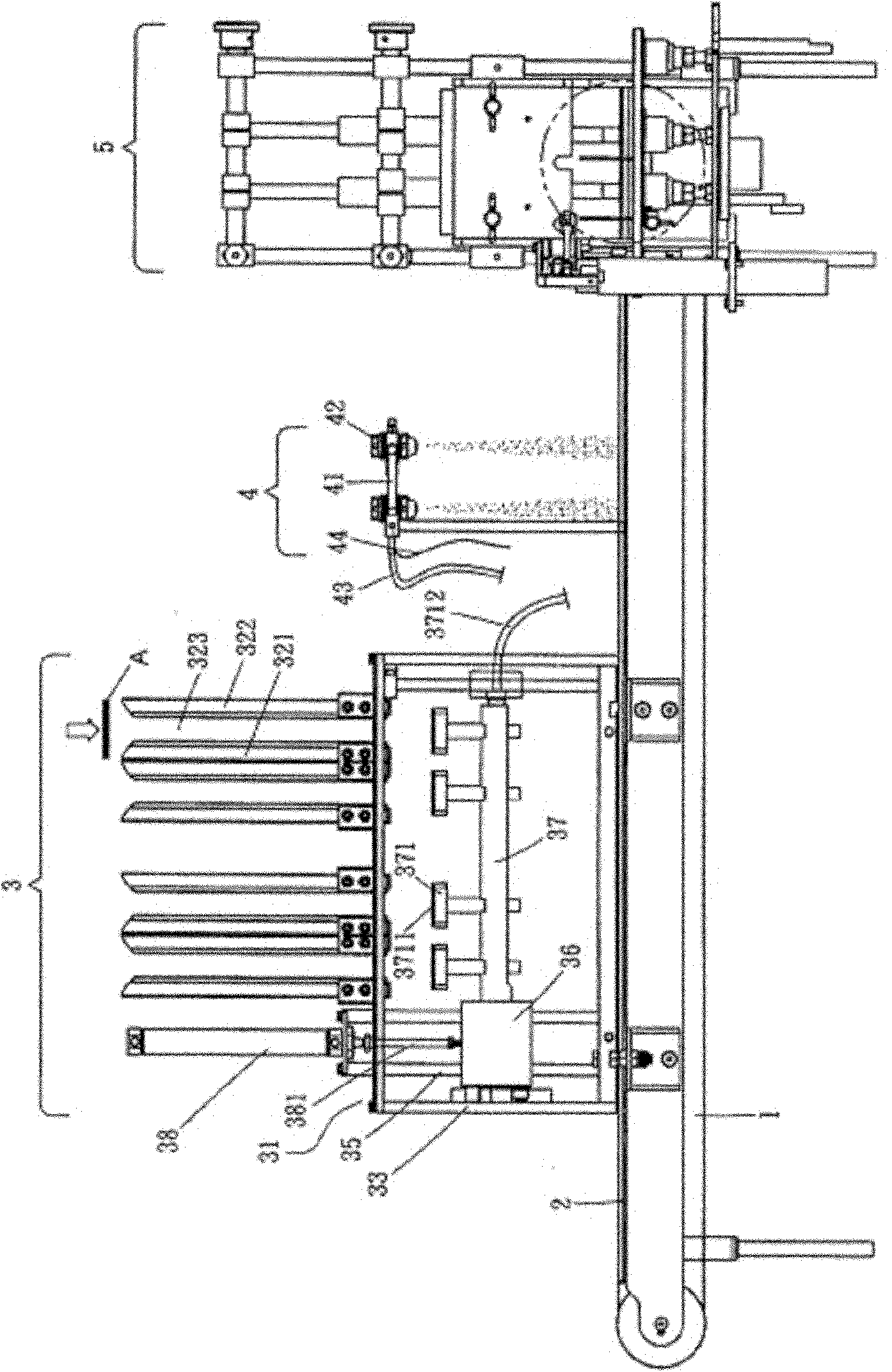

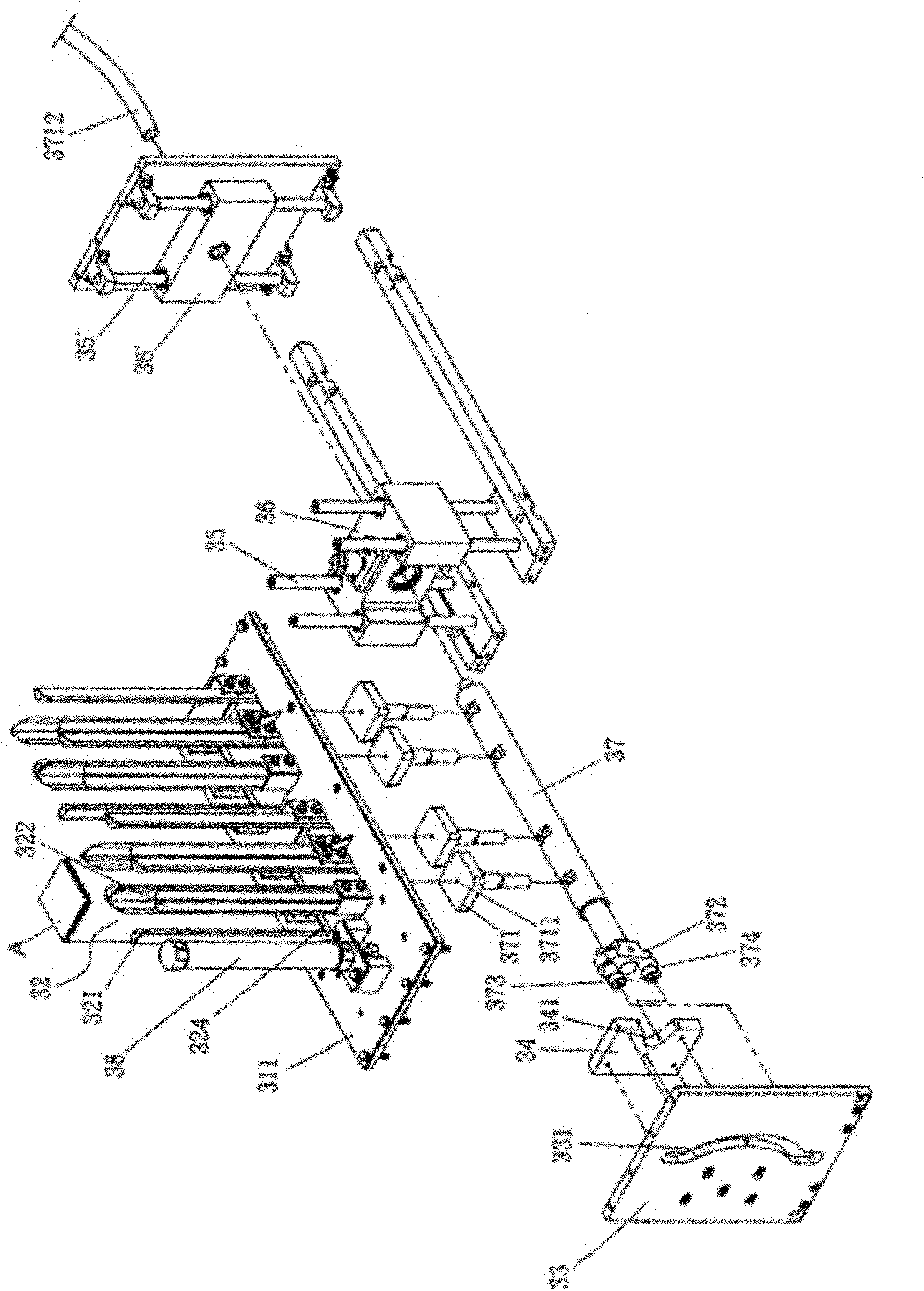

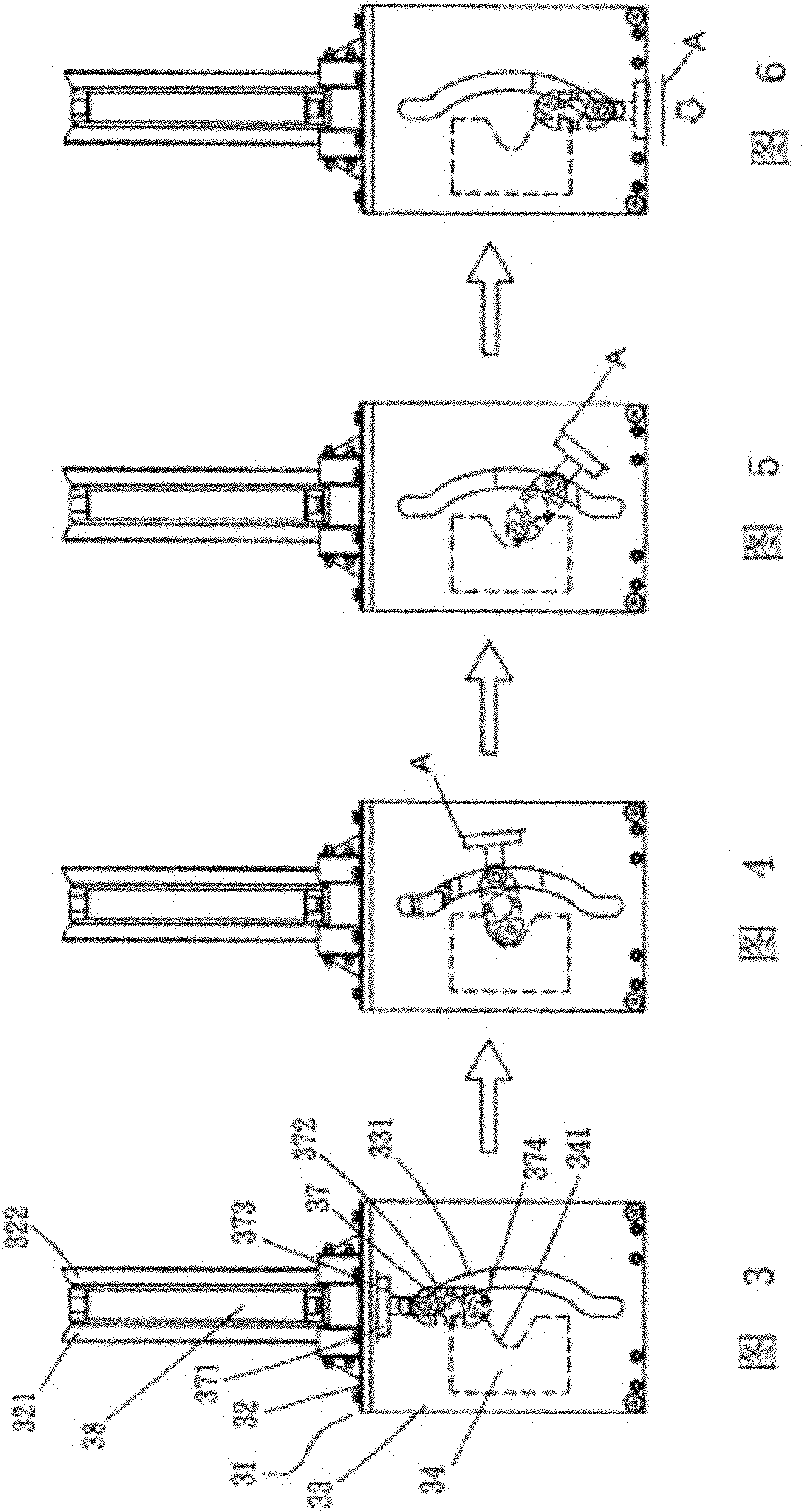

Device for supplying wrapping base materials for preparing Shaomai food

The invention discloses a device for supplying wrapping base materials for preparing Shaomai food. The device comprises a bench and a conveying belt arranged on the bench, wherein a shumai wrapping base material continuous supply unit is arranged above the conveying belt; and a wet sprayer for wet-spraying the shumai wrapping base materials is arranged at the rear end of the shumai wrapping base material continuous supply unit above the convey belt of the bench. The device has the following beneficial effects: through the design, seaweed pieces, tofu skin pieces and spring roll skin pieces with the characteristics of crispness and dryness are automatically and continuously adsorbed on the conveying belt in sequence, then the wet sprayer wet-sprays all the pieces in sequence to soften all the pieces to ensure that all the pieces temporarily have proper softness, the stuffing is filled in the shumai wrapping base materials with a stuffing filler in the later sequence and the shumai wrapping base materials with the stuffing are formed into the shumai food with crisp taste with a mould through extrusion.

Owner:欧阳禹

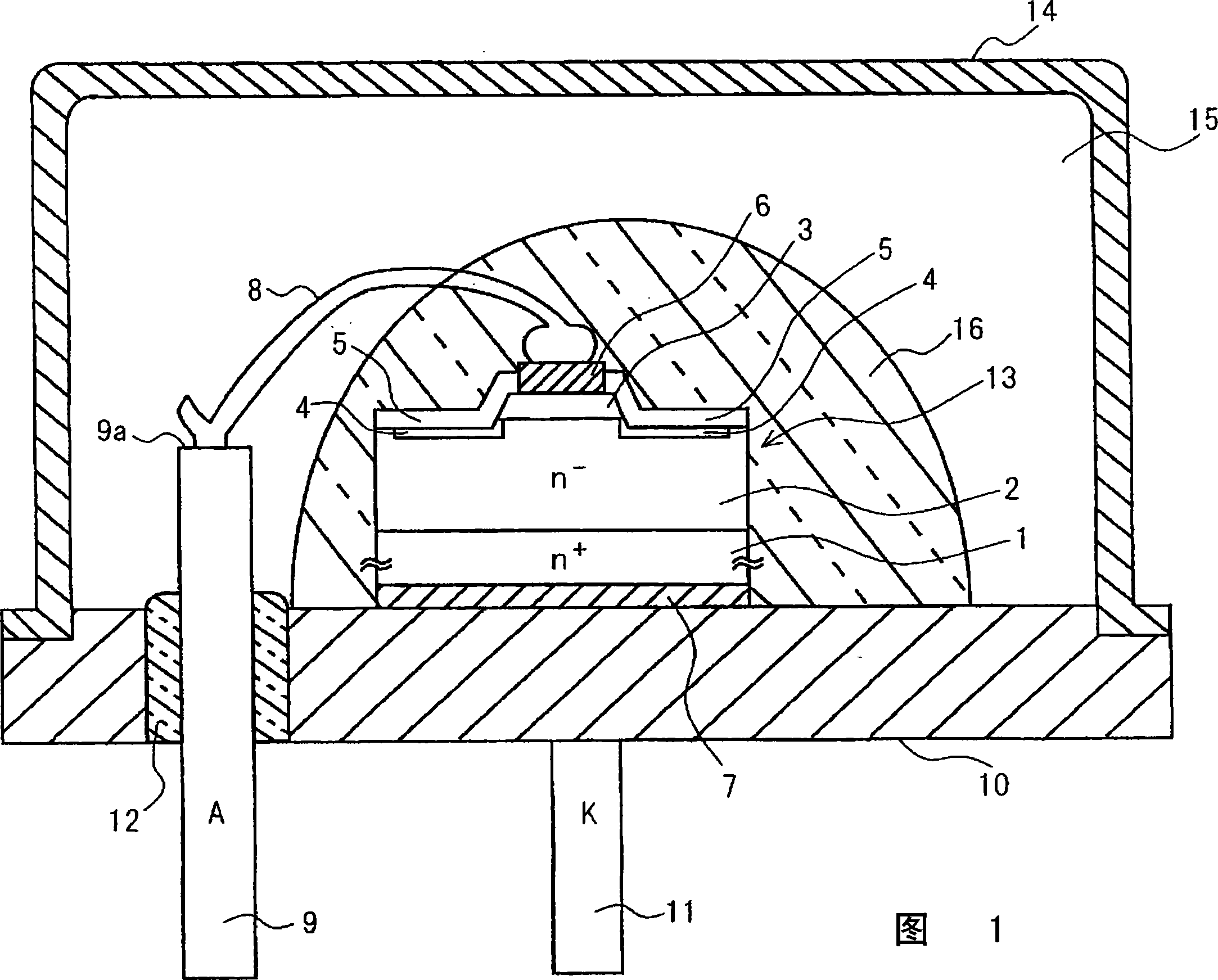

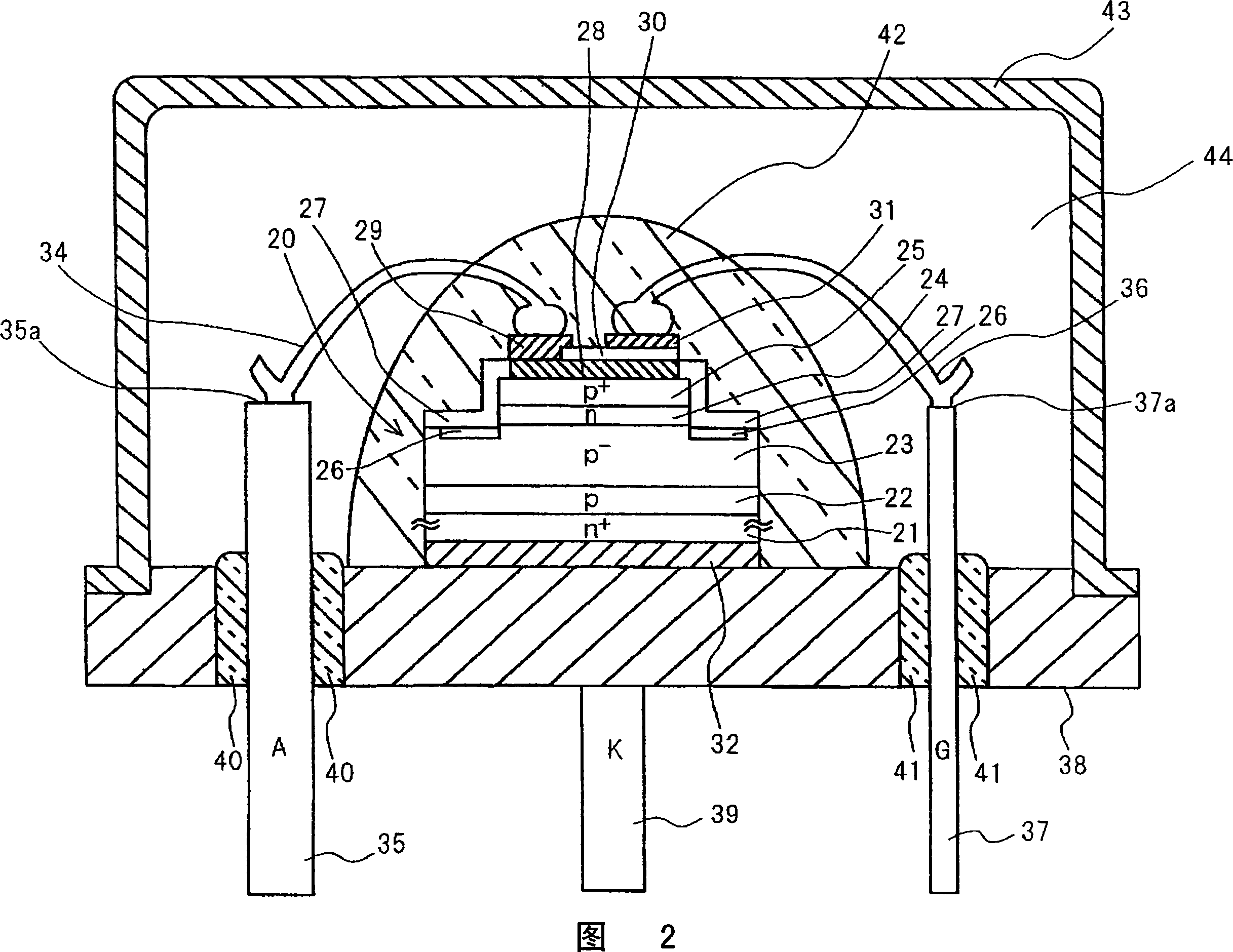

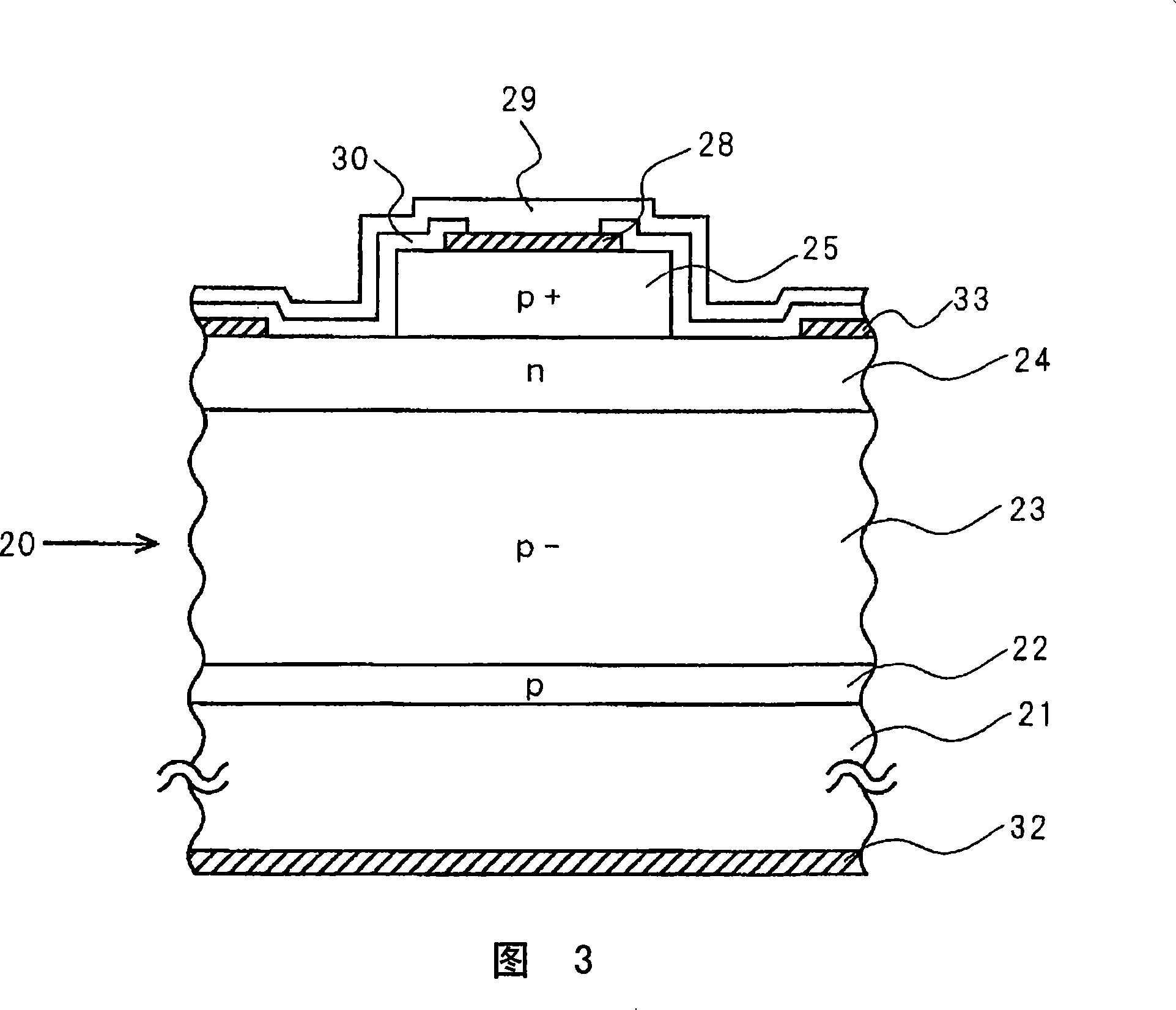

Highly heat-resistant synthetic polymer compound and high withstand voltage semiconductor device

InactiveCN101107293AImprove heat resistanceFast heat conductionSemiconductor/solid-state device detailsSolid-state devicesMicroparticleSynthetic Polymeric Macromolecules

The outer surface of a wide-gap semiconductor device is covered with a synthetic polymer compound. The synthetic polymer compound is formed by linking a plurality of third organosilicon polymers through covalent bonding which is formed by addition reaction, and has a three-dimensional steric structure. The third organosilicon polymers are obtained by linking one or more kinds of first organosilicon polymers having a bridge structure formed by siloxane bonds (Si-O-Si bonds) with one or more kinds of second organosilicon polymers having a linear structure formed by siloxane bonds. Insulating ceramic fine particles having high heat conductivity are preferably mixed with the synthetic polymer compound.

Owner:THE KANSAI ELECTRIC POWER CO +1

Massaging device

InactiveCN1827074BAppropriate softnessHigh strengthVibration massageSuction-kneading massagePhysical medicine and rehabilitationElectric machinery

Owner:SANYO ELECTRIC CO LTD

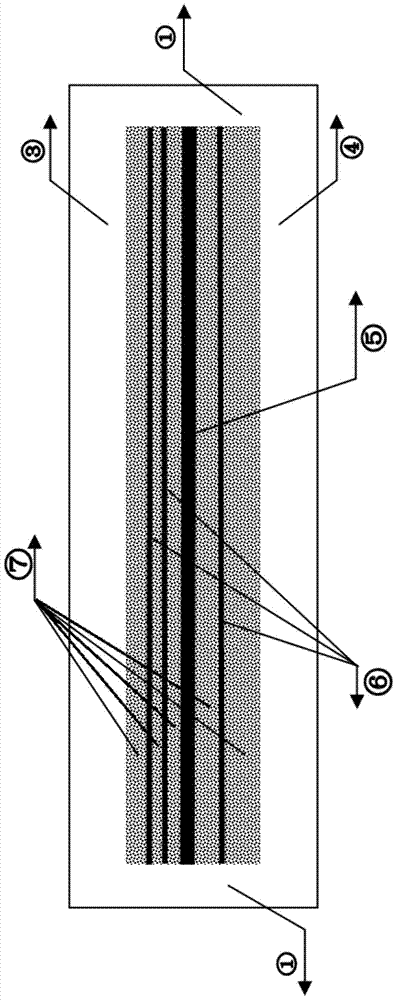

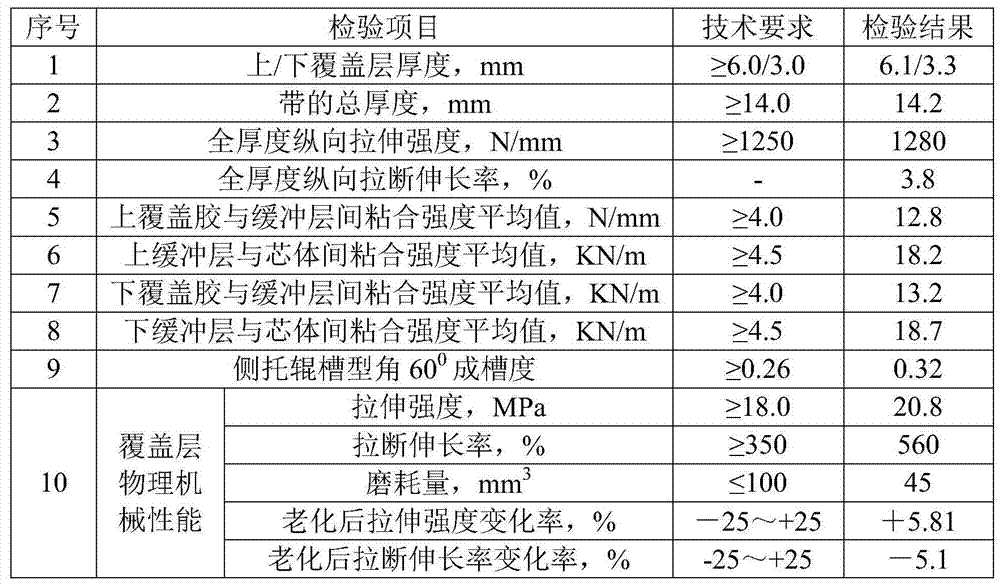

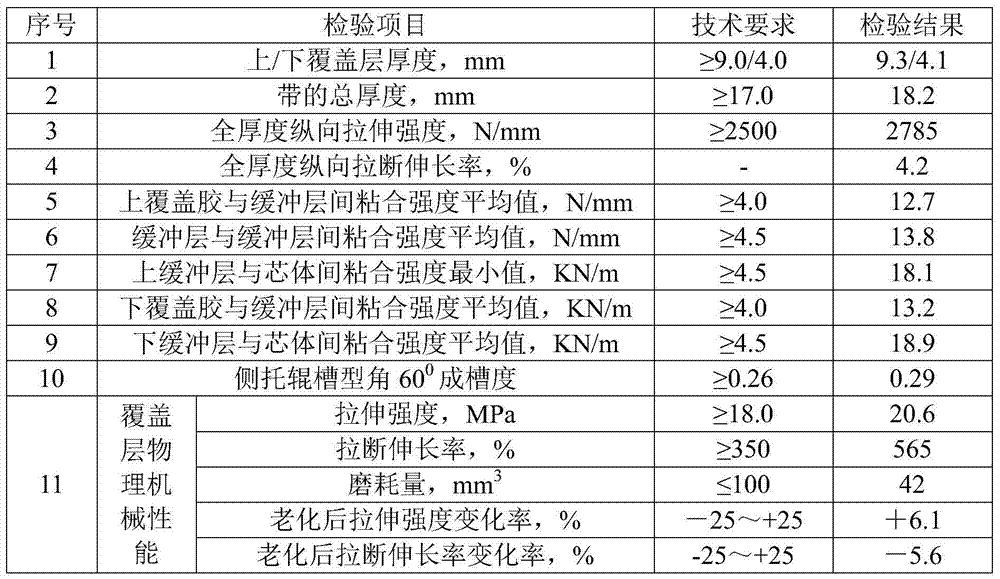

High wear-resistant and impact-resistant aramid fiber core conveyor belt and its production process

ActiveCN105600280BIncrease elasticityImprove impact performanceConveyorsSynthetic resin layered productsYarnNylon 66

The invention relates to a conveying belt, in particular to a high-abrasion-resistance anti-impacting aramid fiber core conveying belt and a production technology thereof. The conveying belt is formed by an aramid fiber canvas skeleton layer, anti-impacting and anti-tearing buffering layers, an upper covering rubber layer, a lower covering rubber layer and a side rubber layer; the anti-impacting and anti-tearing buffering layers are arranged at the upper side and the lower side of the aramid fiber canvas skeleton layer, and the aramid fiber canvas skeleton layer and the anti-impacting anti-tearing buffering layers, the adjacent anti-impacting anti-tearing buffering layers as well as the anti-impacting anti-tearing buffering layers, the upper and lower covering rubber layers and the side rubber layer are bonded through bonding glue and vulcanized into a whole; aramid fiber canvas is of a straight warp and straight weft structure, and warp-wise stress threads are composite thread ropes formed by doubling and twisting straight aramid fiber, nylon 66 composite thread ropes, aramid fiber plied yarn and nylon 66 plied yarn after twisting. A belt body of the high-abrasion-resistance anti-impacting aramid fiber core conveying belt has proper softness, and the anti-impacting capacity is enhanced. The anti-impacting anti-tearing buffering layers are additionally arranged, and the requirement for anti-impacting performance of an application environment with different impact types is met.

Owner:ANHUI OUNAI RUBBER & PLASTIC IND

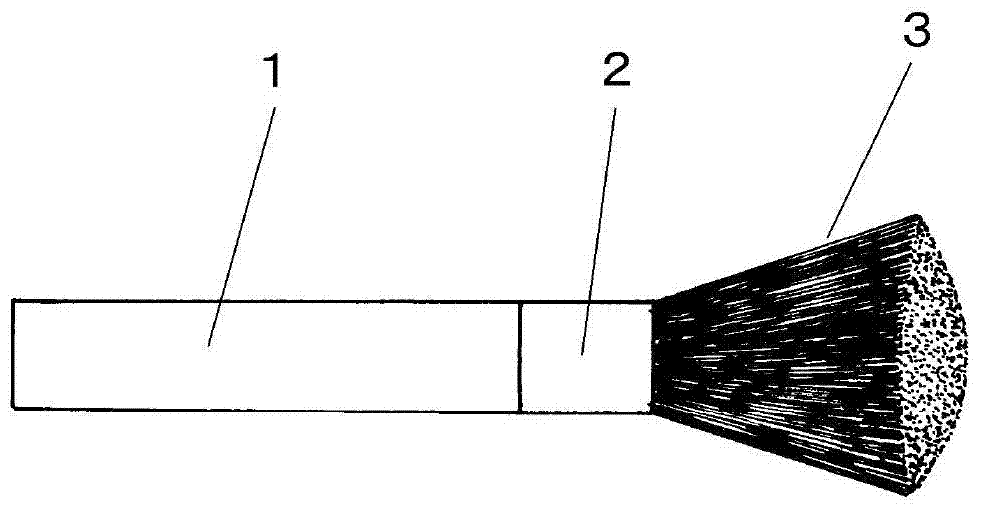

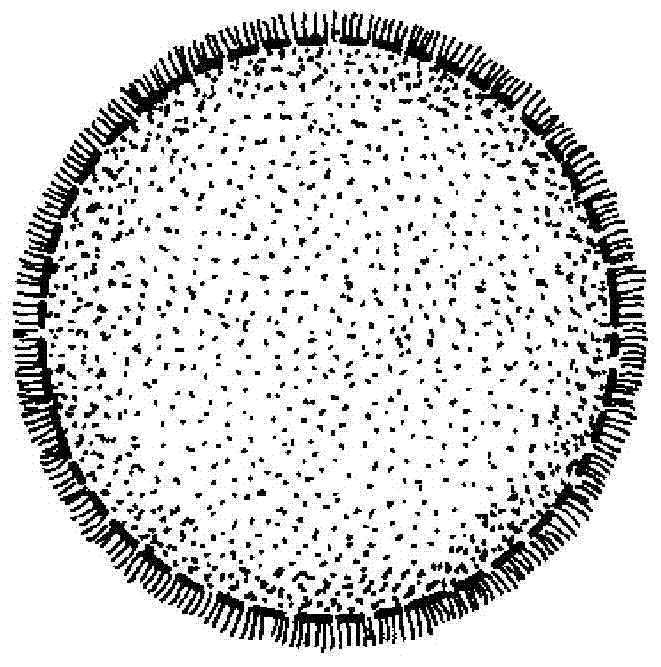

Powder cosmetic material brush

ActiveCN103369987AAppropriate softnessAppropriate toughnessBristlePackaging toiletriesBristleFace powder

Provided is a powder cosmetic material brush provided with S-twist and Z-twist synthetic fiber bristle members at a brush-tip section, the pitch of the S-twist and Z-twist of the brush-tip section of the brush being 10 mm to 30mm, and the brush is able to evenly collect at brush bristles a powder such as powder foundation, face powder, or blush across nearly the entire surface of the bristle member tips when the powder cosmetic material is collected by means of bending the brush-tip section of the brush, causing the powder to be contained in the brush-tip section.

Owner:中村宪司 +1

Handle of tool

ActiveUS8555512B2Facilitates displacement and deformationAppropriate softnessMetal working apparatusMetal-working hand toolsEngineeringBiomedical engineering

Each of handles of a pair of scissors includes a hard core member and a soft member softer than the core member and including a contact face portion with which a finger of a user comes in contact, a bottomed recessed hole portion adjacent to the contact face portion and thinner than portions around it, and a through hole portion continuous with the bottomed recessed hole portion. When the user inserts and removes his / her fingers into and from finger rings, the contact face portions escape while compressing the through hole portions and the contact face portions tilt by using the bottomed recessed hole portions as fulcrums. Moreover, the bottomed recessed hole portions and the through hole portions continuous with each other are molded, which allows an elastic deformation property and a shape retaining property of the contact face portions to go together and also contributes to durability of the soft members including the contact face portions.

Owner:KOKUYO CO LTD

Seat pad

InactiveCN106163340AGood flexibilityGood ride comfortUpholstery manufactureSeat heating/ventillating devicesMechanical engineeringBreathing

Owner:BRIDGESTONE CORP +1

Method of producing composite sheet having polyolefin foam layer

ActiveUS7390445B2Improve antistatic performanceAvoid fireSynthetic resin layered productsLaminationAntistatic agentPolyolefin

A method of producing a composite sheet having a foam layer of a first polyolefin-based resin and a surface layer of a second polyolefin-based resin provided on at least one side of the foam layer and containing a polymeric antistatic agent. The method includes coextruding through die a first melt containing the first polyolefin-based resin and a physical blowing agent and a second melt containing the second polyolefin-based resin, the polymeric antistatic agent and a volatile plasticizer to obtain the composite sheet. The amount of the polymeric antistatic agent is 4 to 100 parts by weight per 100 parts by weight of the second polyolefin-based resin and the amount of the volatile plasticizer is 5 to 50 parts by weight per 100 parts by weight of a total amount of the second polyolefin-based resin and the polymeric antistatic agent. The second polyolefin-based resin has a crystallization temperature of Ta [° C.] and a melt viscosity of Ma [Pa·s], while the polymeric antistatic agent has a crystallization temperature of Tb [° C.] and a melt viscosity of Mb [Pa·s], wherein Ta, Tb, Ma and Mb satisfy the following conditions:Tb<(Ta+30° C.)Mb<Ma.

Owner:JSP CORP

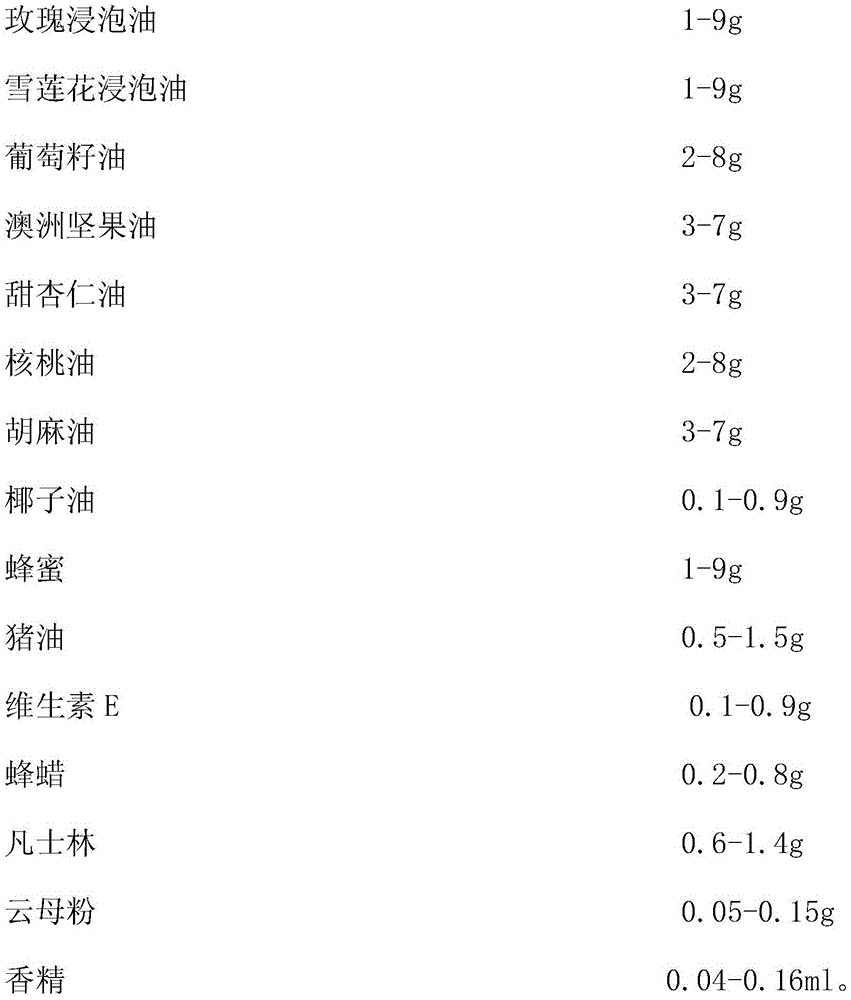

Moisturizing, brightening and repairing lip gloss and preparation method thereof

InactiveCN103989611BLight textureLong lasting full colorCosmetic preparationsMake-upSkin colorMoisture

The invention discloses a moist and bright repair lip gloss and a preparation method thereof. The lip gloss comprises the following substances: walnut oil, linseed oil, rose infused oil, snow lotus herb infused oil, grape seed oil, macadamia nut oil, sweet almond oil, honey, vitamin E, lard oil, coconut oil, beewax, vaseline, mica powder and essence. Compared with the prior art, the suncrack symptom of the lip is nursed by using a plant essence, safe mica powder is adopted, and the lip is fuller, displays different colors, is applicable to different colors of lips and skins, and has fragrance smell, mild property, good moisture effect, high safety and nursing effect. The lip which is not maintained at ordinary times is repaired while beauty is enjoyed, and the lip is fuller.

Owner:广州莱倩化妆品有限公司

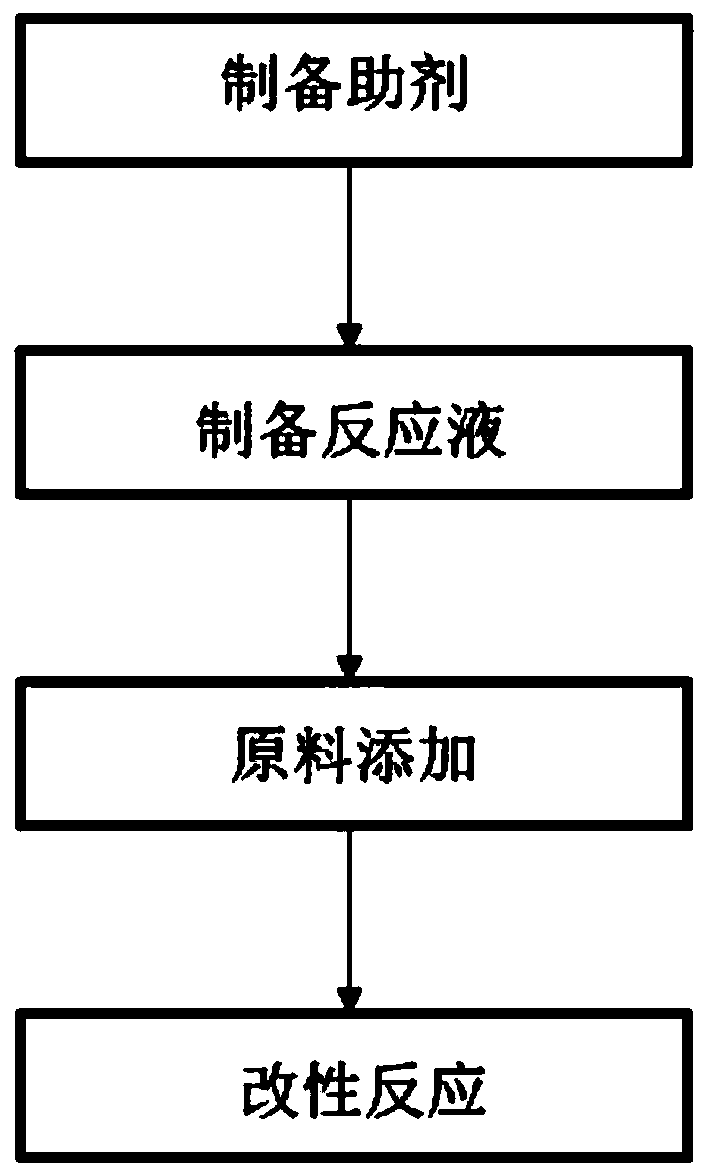

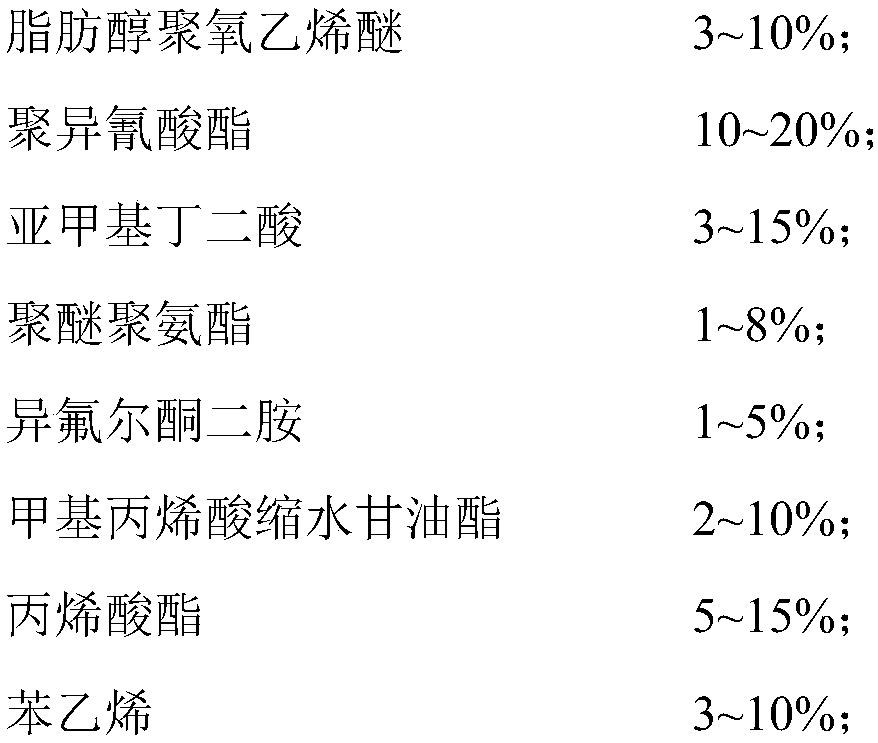

Waterborne aromatic polyisocyanate cross-linking agent and preparation method thereof

InactiveCN108587112AEnvironmental protection is goodImprove reaction efficiencyCross-linkGlycidyl methacrylate

The invention discloses a waterborne aromatic polyisocyanate cross-linking agent. The waterborne aromatic polyisocyanate cross-linking agent comprises the following components in percentages by mass:3 to 10% of fatty alcohol-polyoxyethylene ether, 10 to 20% of polyisocyanate, 3 to 15% of methylene succinic acid, 1 to 8% of polyether urethane, 1 to 5% of isophorone diamine, 2 to 10% of glycidyl methacrylate, 5 to 15% of acrylate, 3 to 10% of styrene, 0 to 8% of isopropanol and 1 to 5% of an auxiliary agent, with the balance being deionized water. The invention also discloses a preparation method for the above-mentioned waterborne aromatic polyisocyanate cross-linking agent. Compared with the prior art, the preparation method provided by the invention has the following advantages: the synthetic process is simple and standardized; the production process and production flow are easy to control; meanwhile, a product prepared by using the preparation method provided by the invention has reliable performance and good stability; production experience can be conveniently summarized and accumulated; production raw materials have good environmental protection performance; meanwhile, the waterborne aromatic polyisocyanate cross-linking agent provided by the invention effectively improves reaction efficiency of the raw materials and controlling and adjusting abilities to the reaction process, and has the characteristics of strong adhesion force, high peel strength, proper softness, good water resistance and scrubbing resistance and low film-forming temperature.

Owner:上海浩登材料股份有限公司 +2

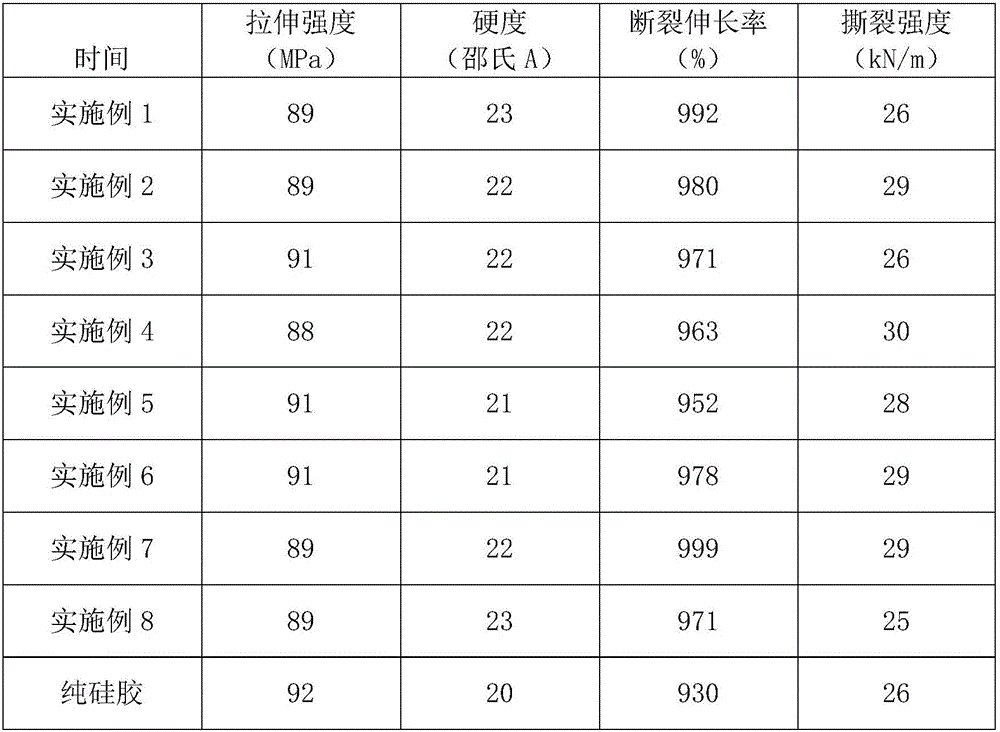

Female breast simulated polyethylene composite material

InactiveCN106432891AImprove wear resistanceImprove antistatic performancePolymer scienceTear resistance

The invention discloses a female breast simulated polyethylene composite material. The material is prepared from, by weight, 100-150 parts of polyethylene, 12-17 parts of polypropylene, 8-15 parts of guar gum, 7-10 parts of ferric chloride aqueous solution, 0.6-1.2 parts of 3,3'-oxoindole and 0.1-0.4 part of 2,4-difluorobenzoic acid. The invention further discloses a method for preparing the female breast simulated polyethylene composite material and application of the female breast simulated polyethylene composite material to materials of infantile pacifiers or teats. The composite material is high in female breast texture simulation degree, excellent in tear resistance, stretch resistance and rebound resilience and appropriate in softness and is a great substitute for silicon rubber or rubber and high in market promotion potential.

Owner:佛山慧创正元新材料科技有限公司

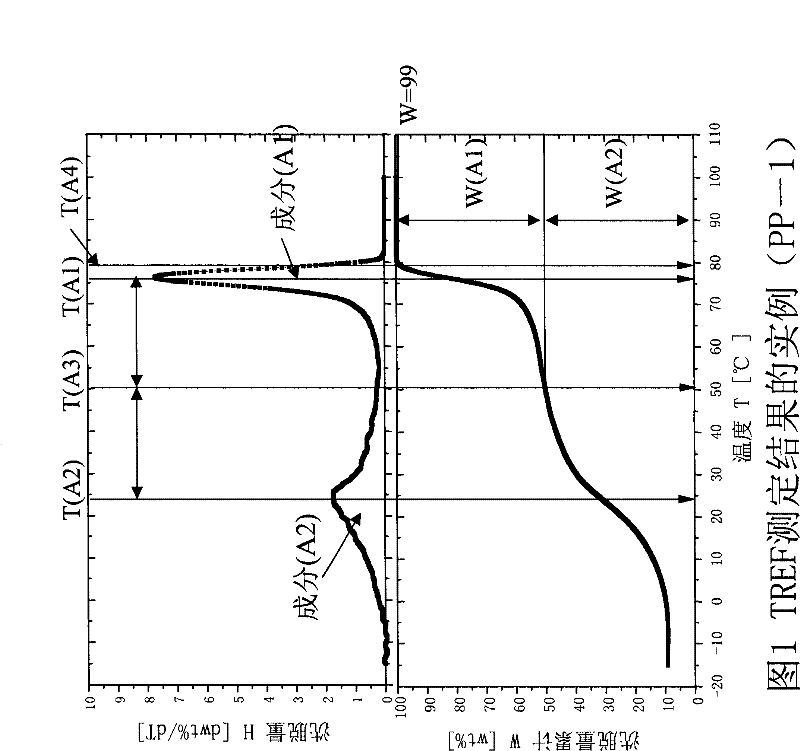

Infusion bag

ActiveCN1853599BHigh transparencyLow transparencyPharmaceutical containersMedical packagingPolymer sciencePolypropylene

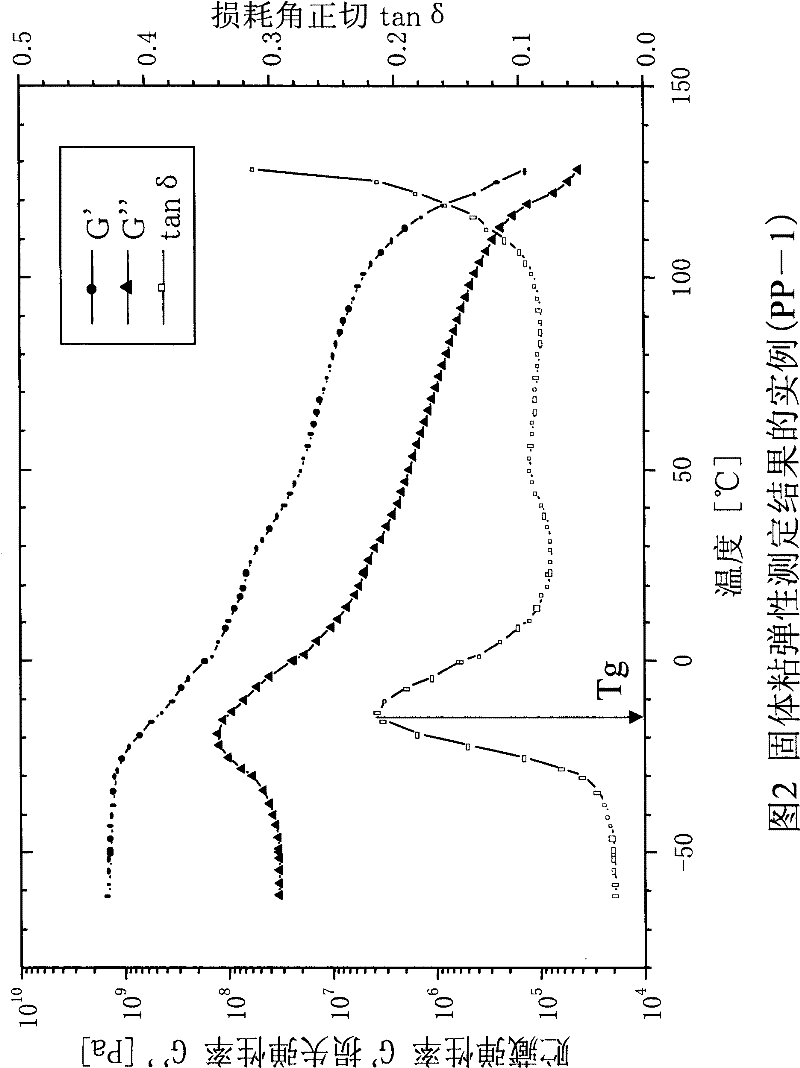

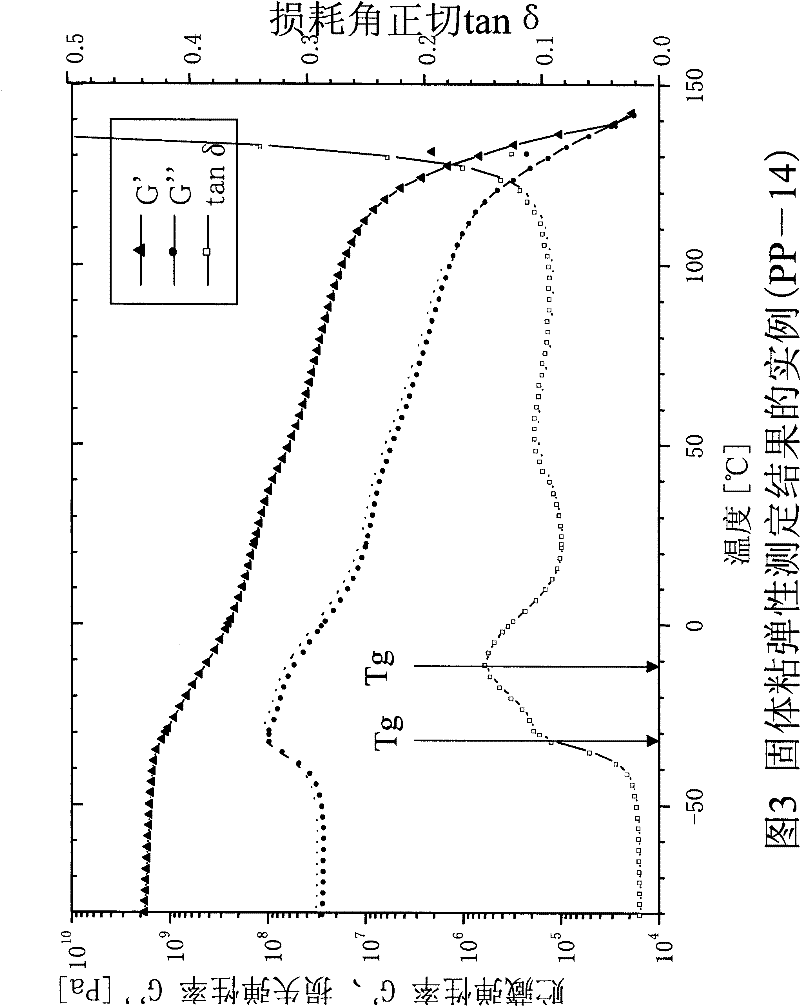

The invention discloses a transfusion bag, which is moulded by polypropylene film of random propylene-ethylene block copolymer (A), wherein the (A) preparing method comprises the following steps through metallocene catalyst: obtaining 30-95% random propylene-ethylene block copolymer (A1) with only 7% propylene or ethylene; producing 70-5% random propylene-ethylene block copolymer (A2) with more ethylene weight than (A1) by 3-20%. (A) Flux fluid rate is 1-20g / 10 min, which displays single peak within not more than 0 deg.c in the temperature-consumption angle tangent curve to obtain DMA.

Owner:JAPAN POLYPROPYLENE CORP

Ultrathin aramid paper flame-retardant adhesive tape and manufacturing method thereof

InactiveCN113372837AImprove heat resistanceImprove adhesionFilm/foil adhesivesHeat resistant fibresGlass fiberAluminium hydroxide

The invention discloses an ultrathin aramid paper flame-retardant adhesive tape, which comprises aramid paper, an adhesive layer, a flame-retardant layer, an insulating layer and a high-temperature-resistant glue which are sequentially stacked from top to bottom, wherein the flame-retardant layer comprises the following components in parts by weight: 18-20 parts of magnesium hydroxide, 18-20 parts of acrylate, 1-2 parts of a dispersing agent, 3-5 parts of ceramic fibers, 14-17 parts of aramid fibers and 3-5 parts of glass fibers, and the insulating layer comprises the following components in parts by weight: 50-60 parts of silicone rubber, 10-20 parts of glass fibers, 8-10 parts of aluminum hydroxide and 4-6 parts of hydroxyl silicone oil. According to the invention, the adhesive tape with a good flame-retardant effect is formed.

Owner:江苏伊诺尔新材料科技有限公司

Soft polyethylene foamed plastic

InactiveCN107652508AAppropriate softnessOverall light weightLow-density polyethyleneBenzoyl peroxide

The invention relates to a foam plastic, concretely relates a soft polyethylene foamed plastic, and belongs to the technical field of foamed plastics. The soft polyethylene foamed plastic comprises, by weight, 40-90 parts of low-density polyethylene resin, 2-14 parts of stannous octoate, 3-9 parts of dichloromethane, 1-8 parts of benzoyl peroxide, 10-16 parts of trimethylolpropane trimethacrylate,8-14 parts of acrylonitrile, 1-6 parts of an organic peroxide cross-linking agent, 2-7 parts of polysulfone resin, 3-9 parts of pentaerythritol, 2-10 parts of a plant powder filler and 4-10 parts ofisopentane. The plastic product has the advantages of suitable softness, light weight, high resilience, and good flame retardation property; and the foamed plastic has a light color, so the productionof color products through adding pigments is facilitated.

Owner:句容市武杭传动机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com