Seat pad

A technology for seat cushions and ventilation components, which is applied to mattresses, vehicle seats, spring mattresses, etc., can solve the problems of blocked ventilation parts and inability to provide riding comfort, and achieve the effects of good softness and good riding comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

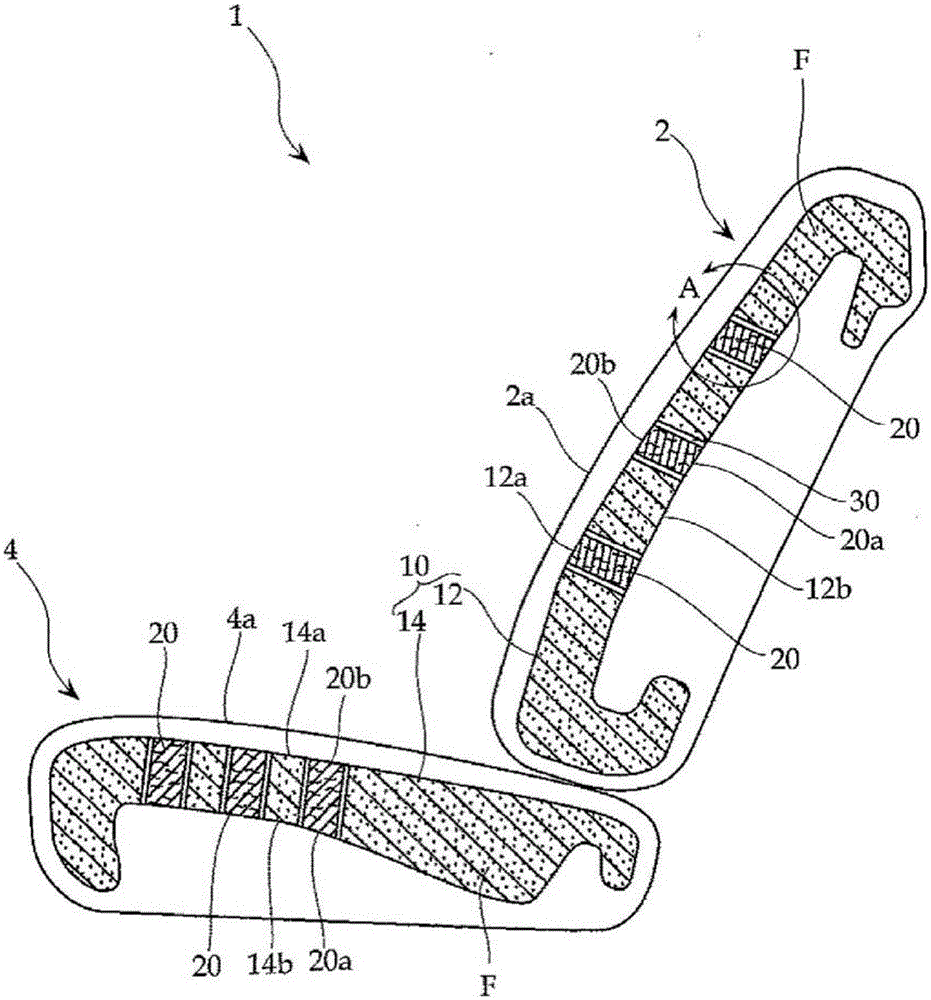

[0037] Next will refer to Figure 1 to Figure 6 Embodiments of the present invention will be described. This embodiment will be described by taking the seat cushion as an example for a vehicle seat.

[0038] figure 1 A diagram for explaining an outline of a seat pad according to the present embodiment used for a seat. As shown in the figure, the seat 1 includes a seat back 2 that supports the back of an occupant and a seat cushion 4 that supports the buttocks of the occupant.

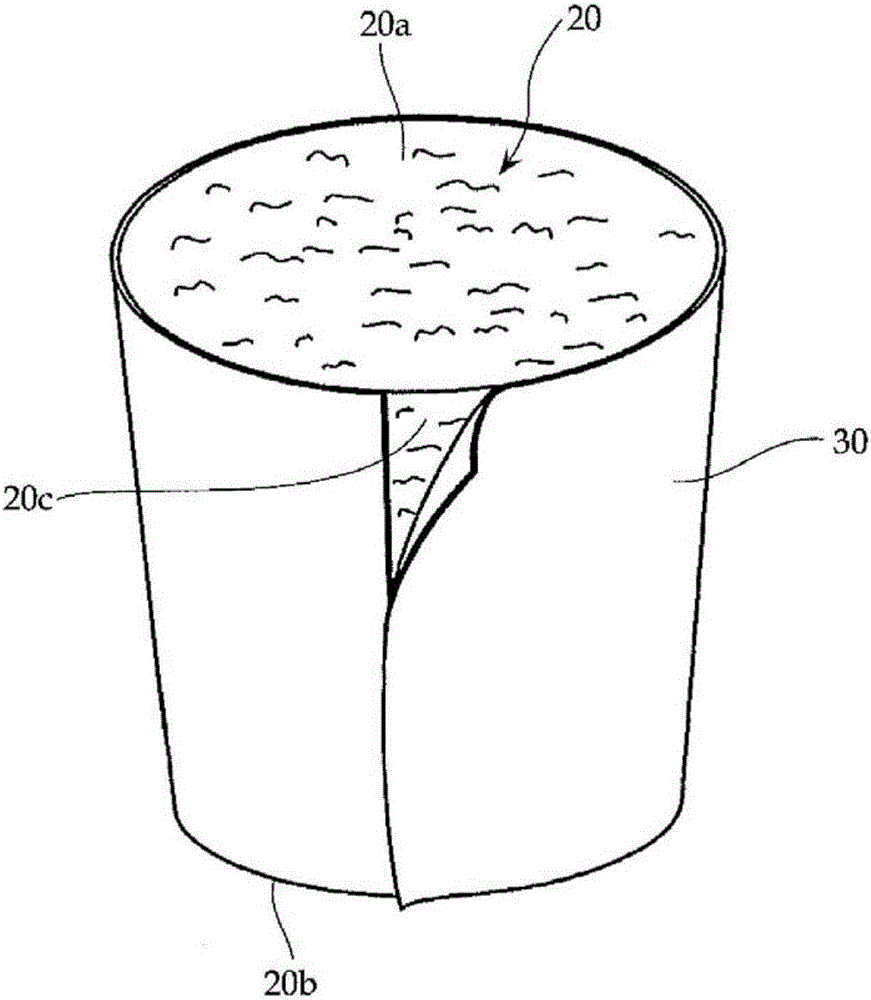

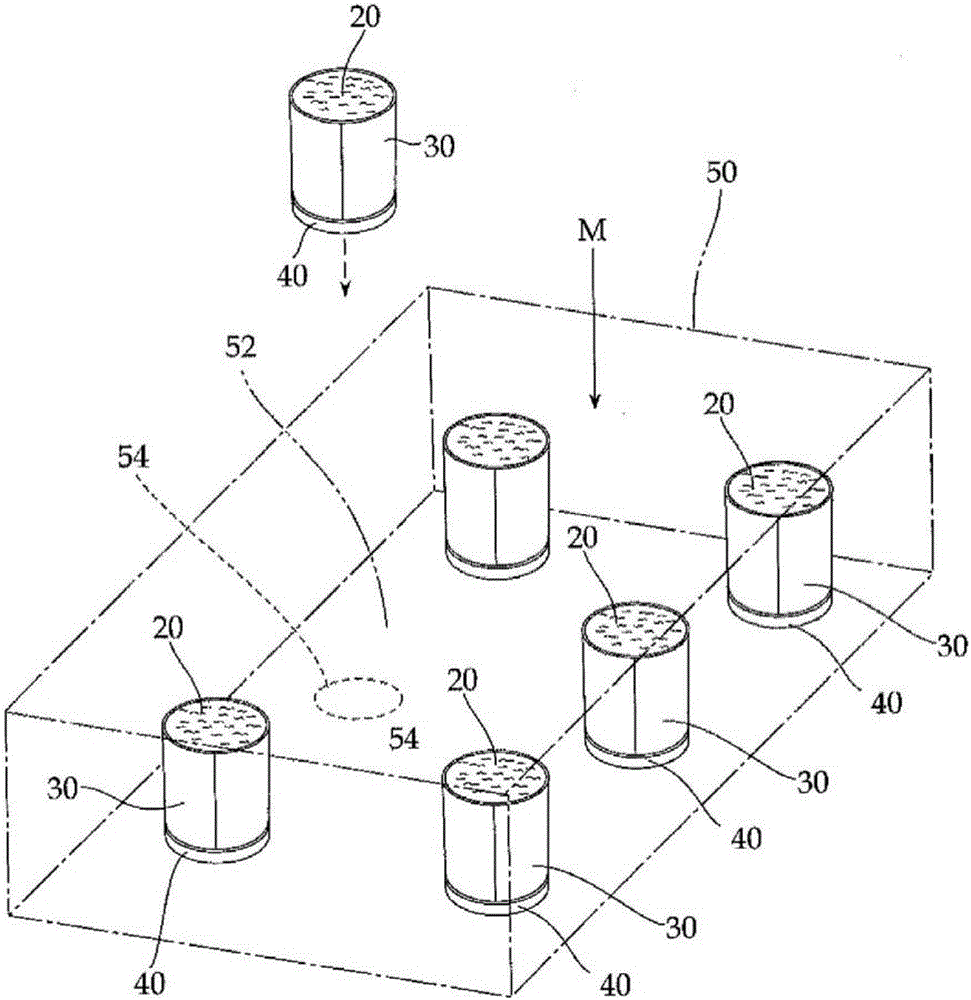

[0039] The seat pad 10 according to the present embodiment is a type of seat pad for such a seat 1, and includes, as a main component, a foamed resin foam F produced by foaming of a foamed resin material.

[0040] The seat cushion 10 includes a back pad 12 and a cushion pad 14, the back pad 12 is covered with a skin 2a providing good air permeability such as a woven or knitted fabric to form the seat back 2, the cushion pad 14 The seat cushion 4 is formed as a result of being covered with a skin 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com