Patents

Literature

97results about "Upholstery auxillary devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

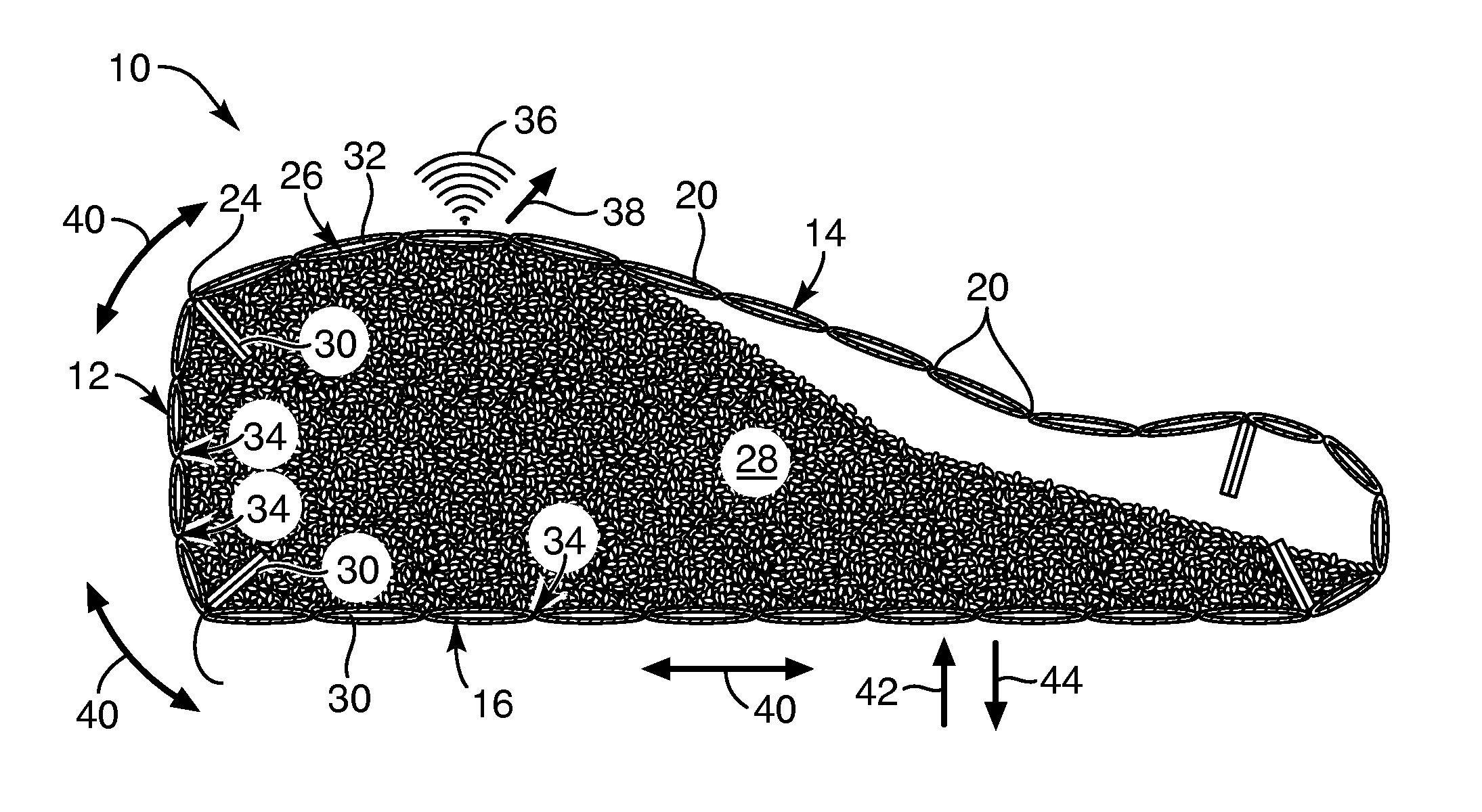

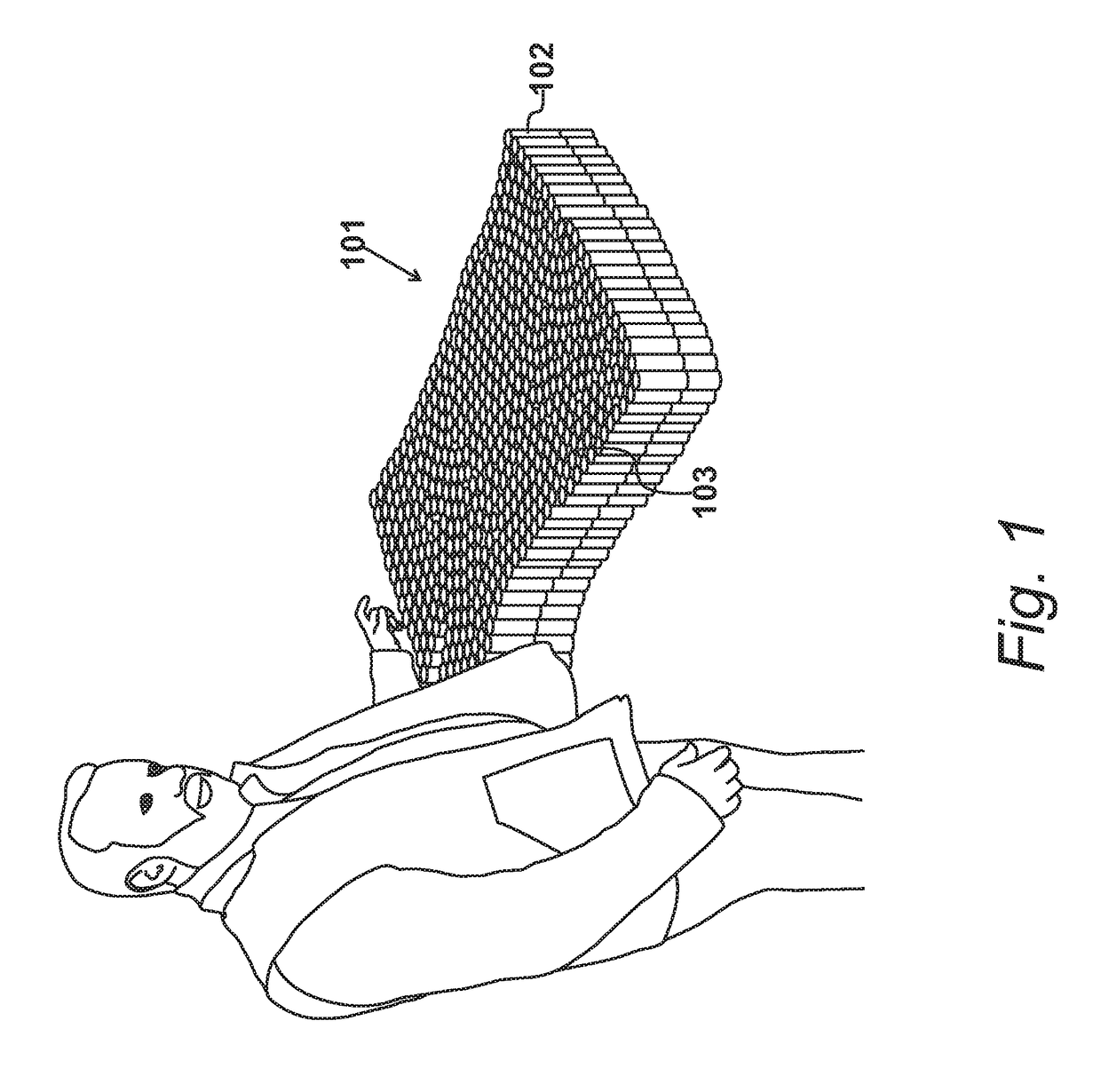

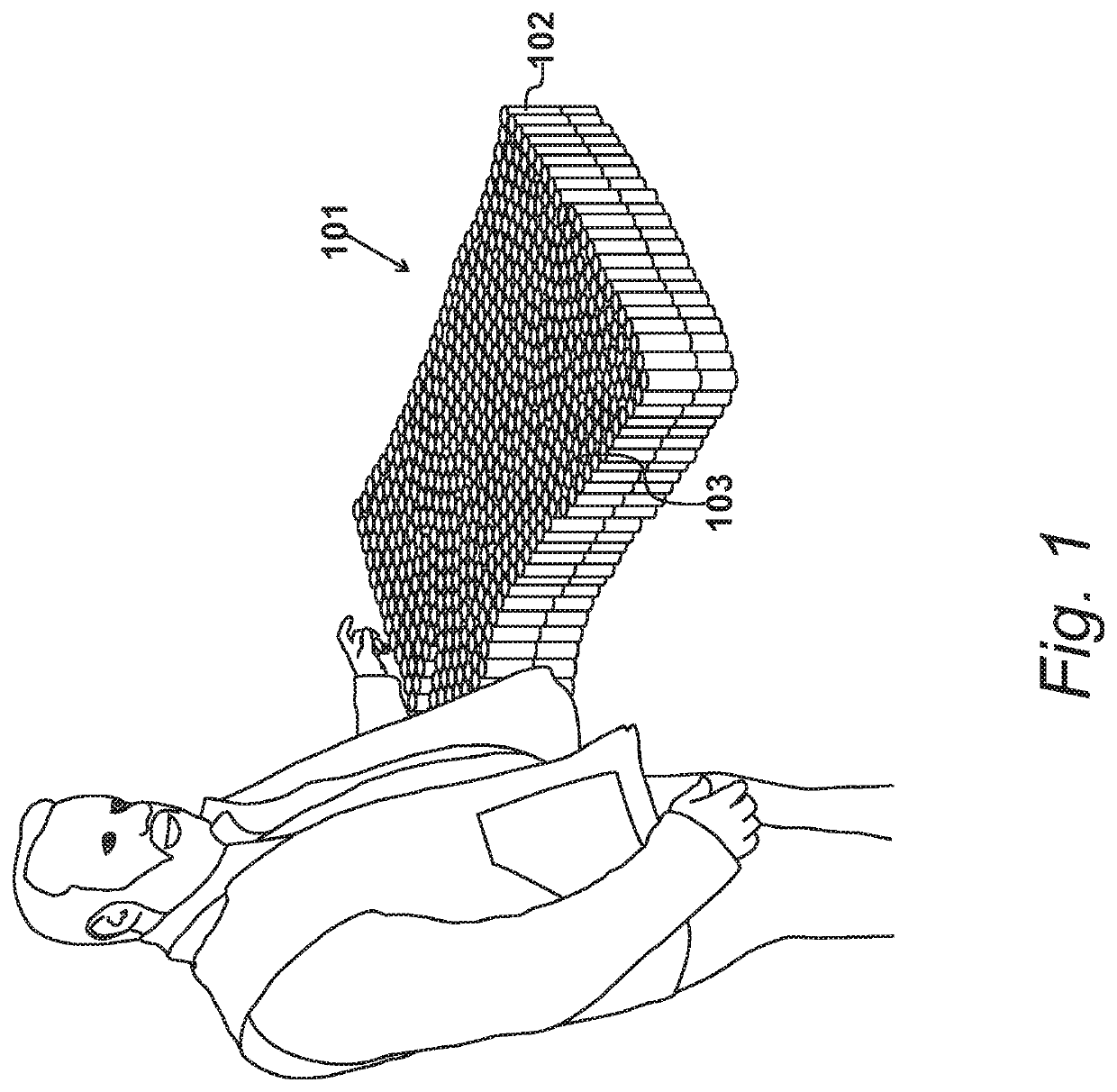

Cpap pillow apparatus and method

Owner:RANDALL BRET

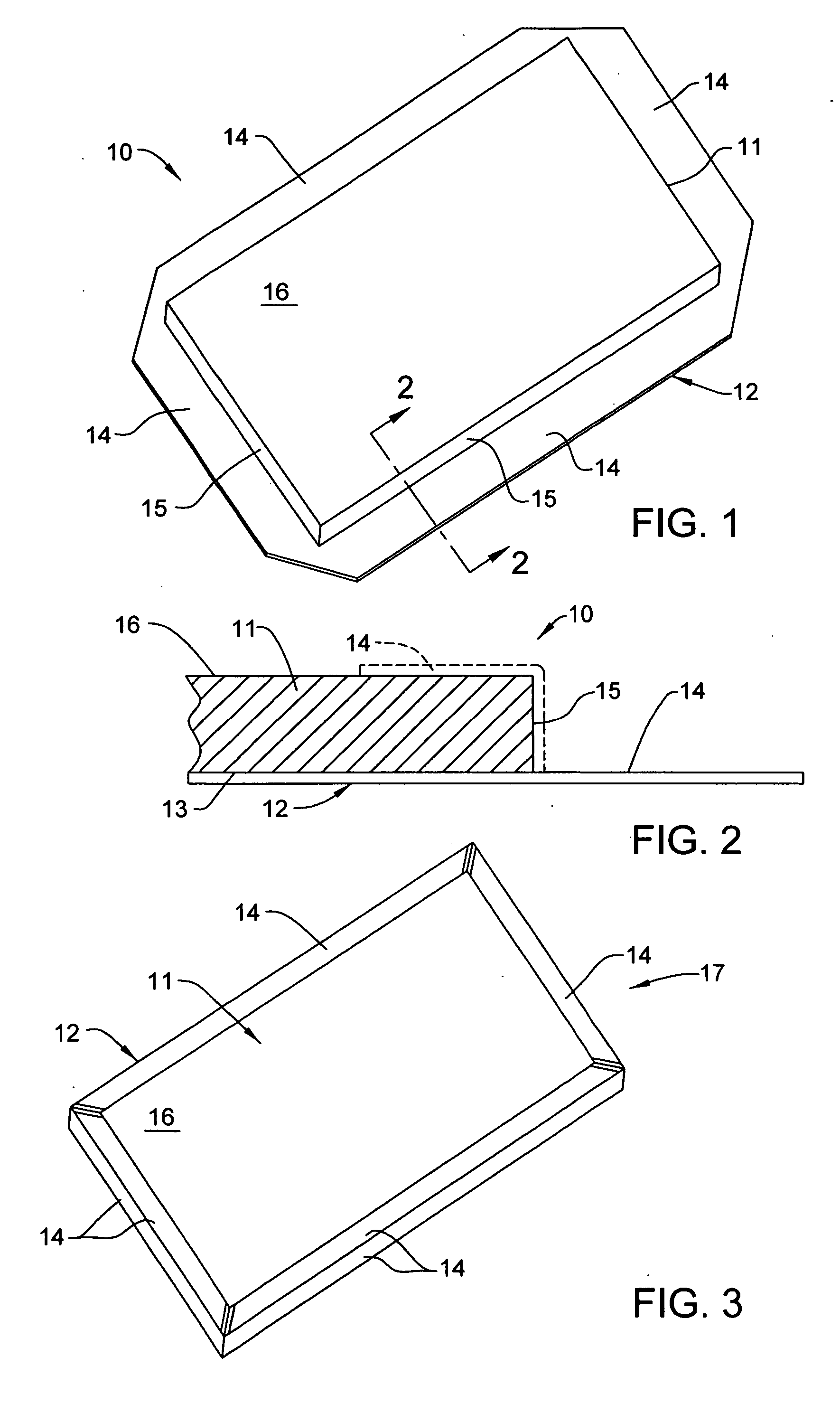

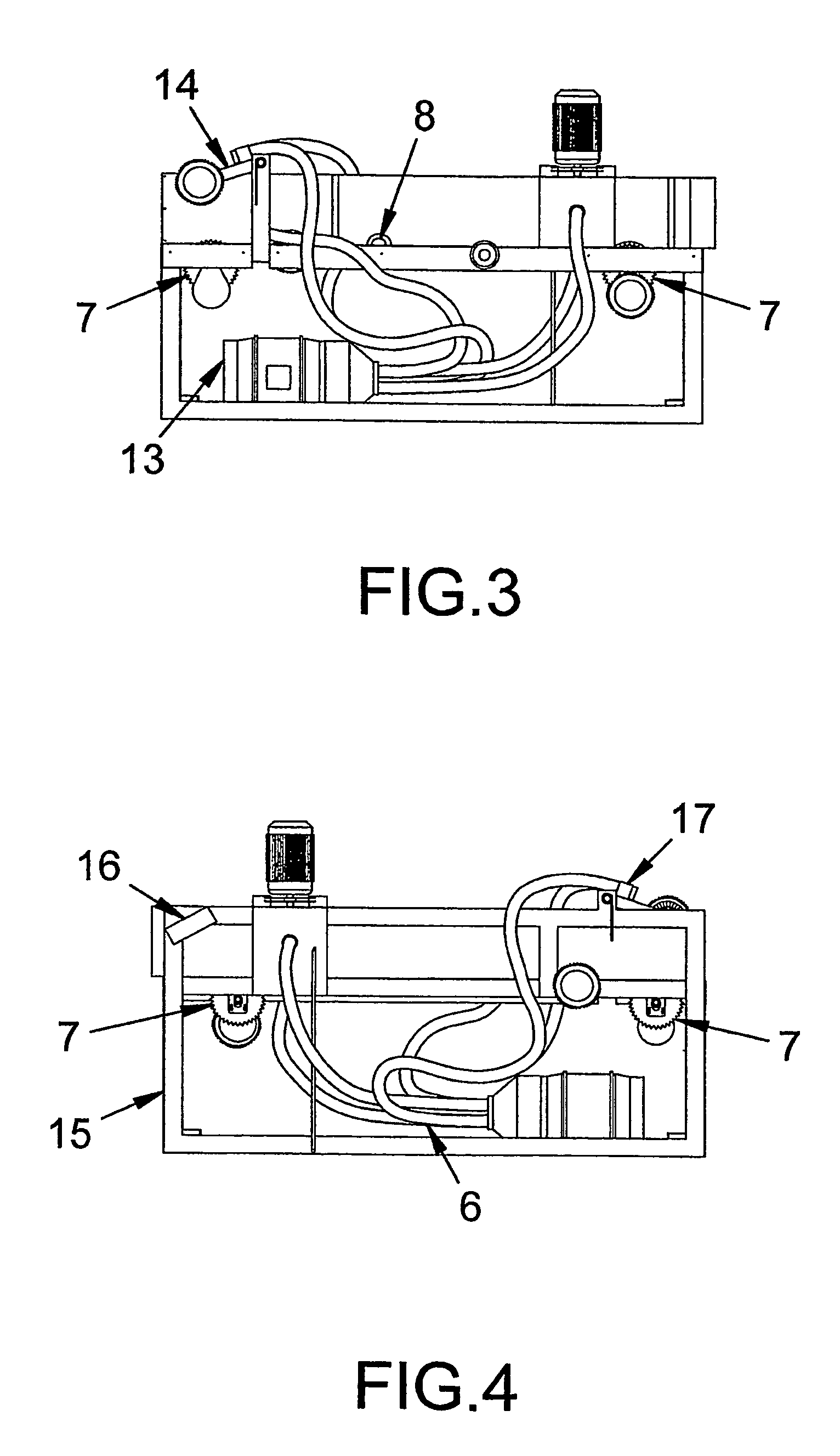

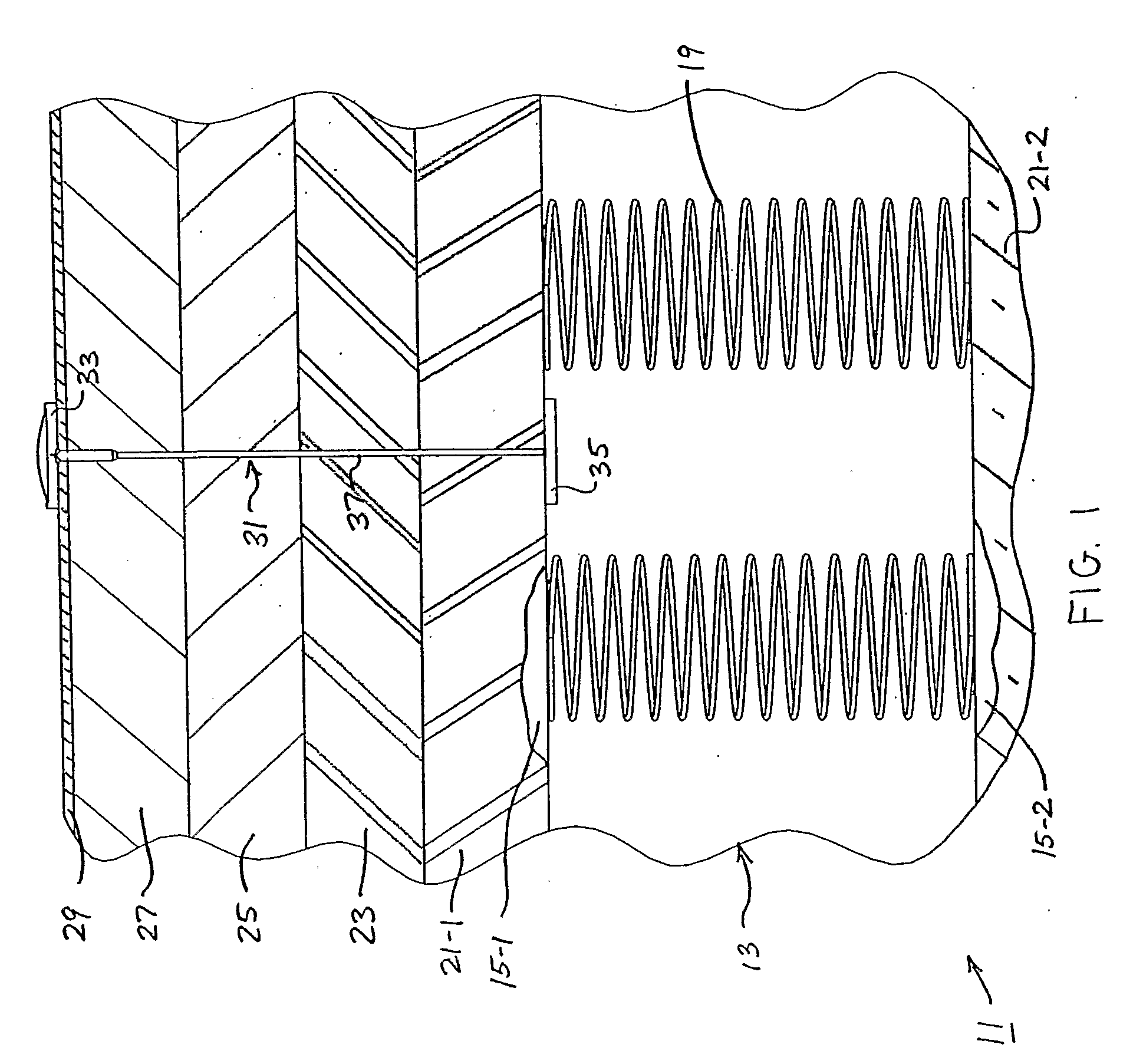

Process and apparatus for edge wrapping upholstered articles

ActiveUS20070214625A1Smooth and uniform transferenceUpholstery manufactureUpholstery auxillary devicesManufactured apparatusEngineering

A manufacturing apparatus and process to effect substantial automatic wrapping of the edges of a covered article, namely, the wrapping of cover sheet flaps around the edges of a substrate and the adhesive securement of the cover sheet flaps to the back side of the substrate, to form an upholstered article such as a pad or panel in a highly automated process which eliminates significant manual manipulations.

Owner:HAWORTH SPA

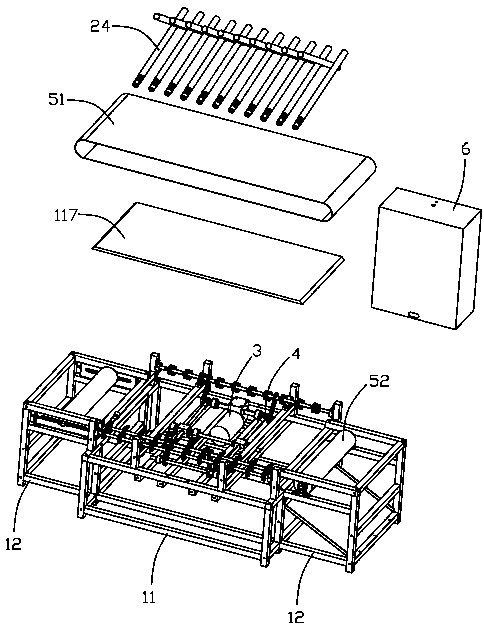

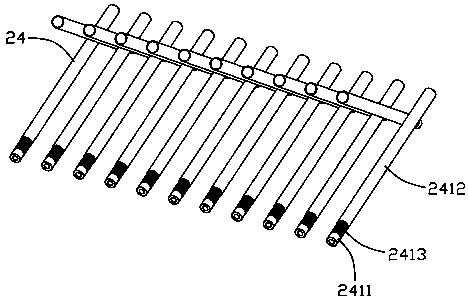

Bagged spring bed core connected with band-shaped material on side surface and manufacturing device and method thereof

InactiveCN108887997AEfficient bondingIncreased durabilityUpholstery manufactureStuffed mattressesMechanical engineeringBunches

Owner:GUANGZHOU LIANROU MACHINERY & EQUIP

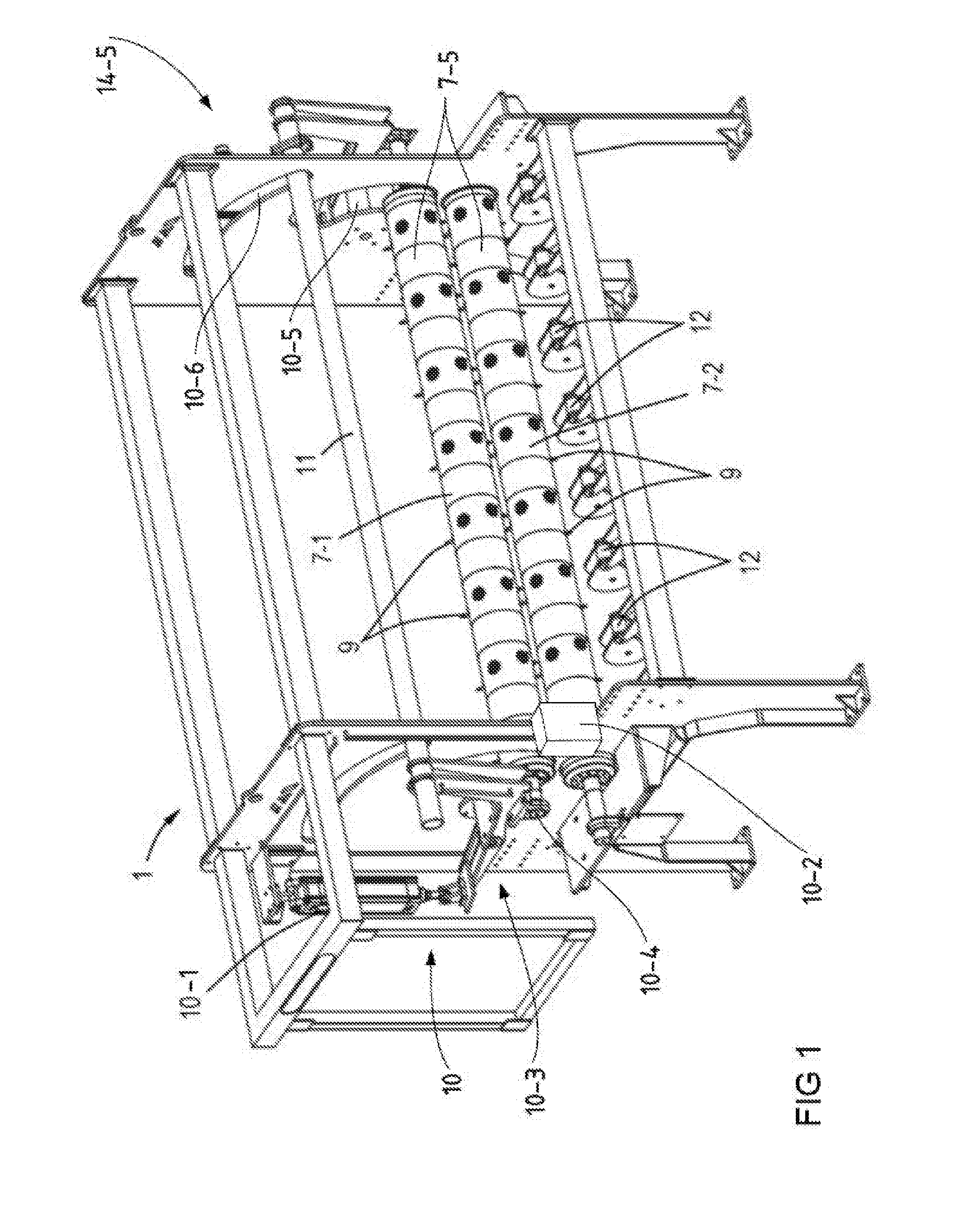

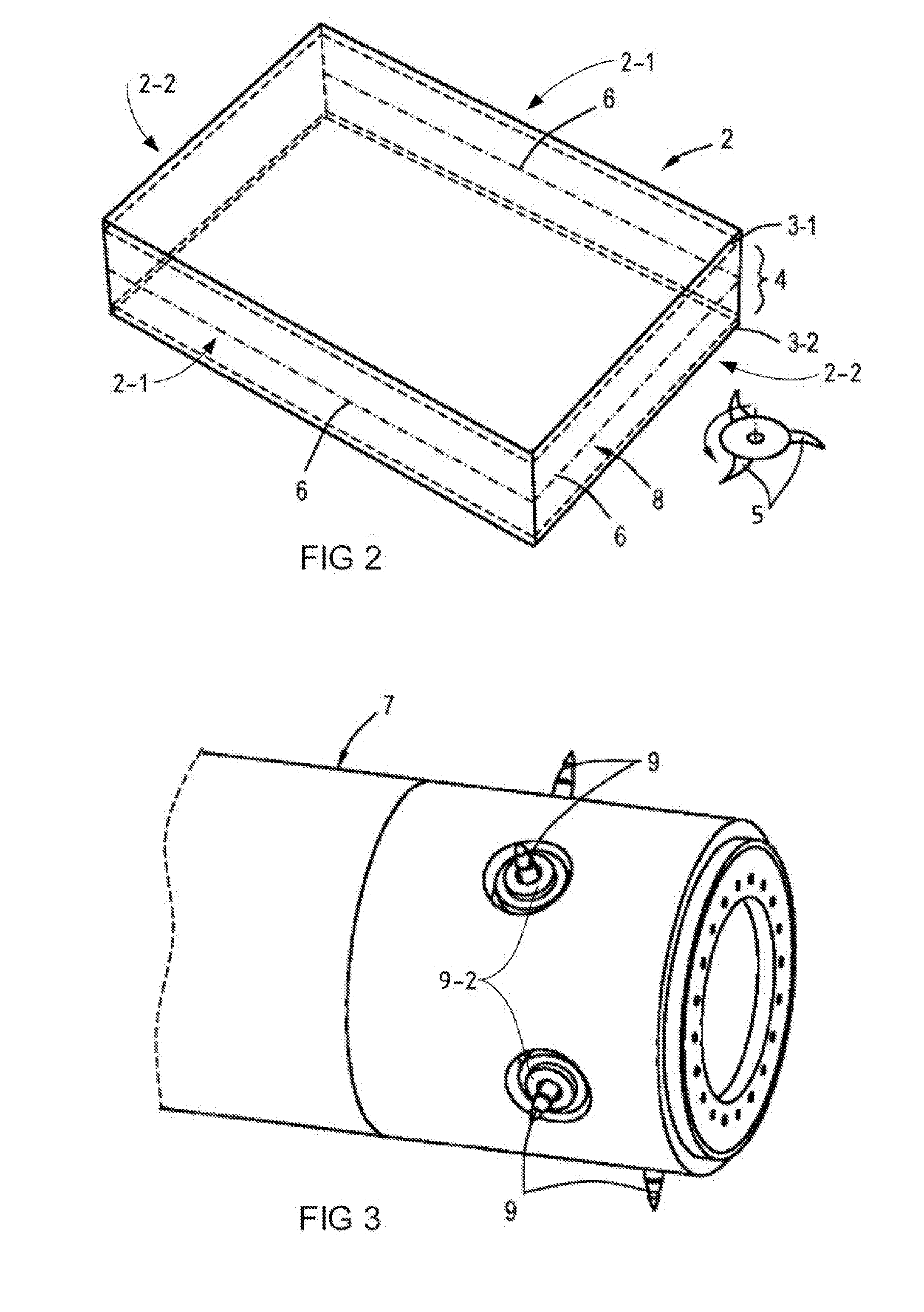

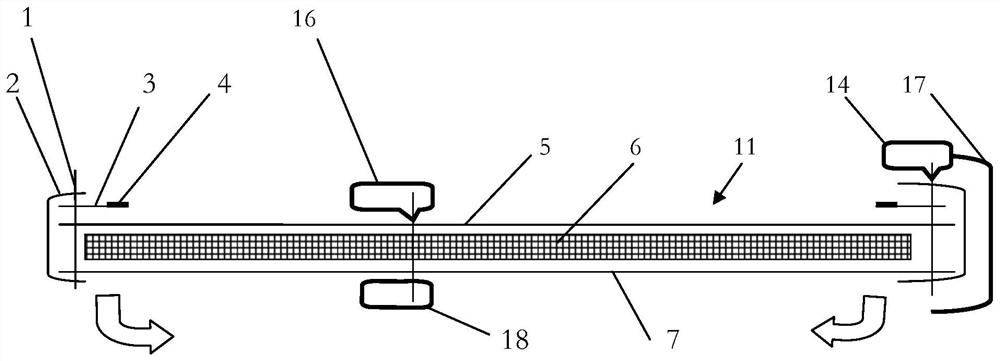

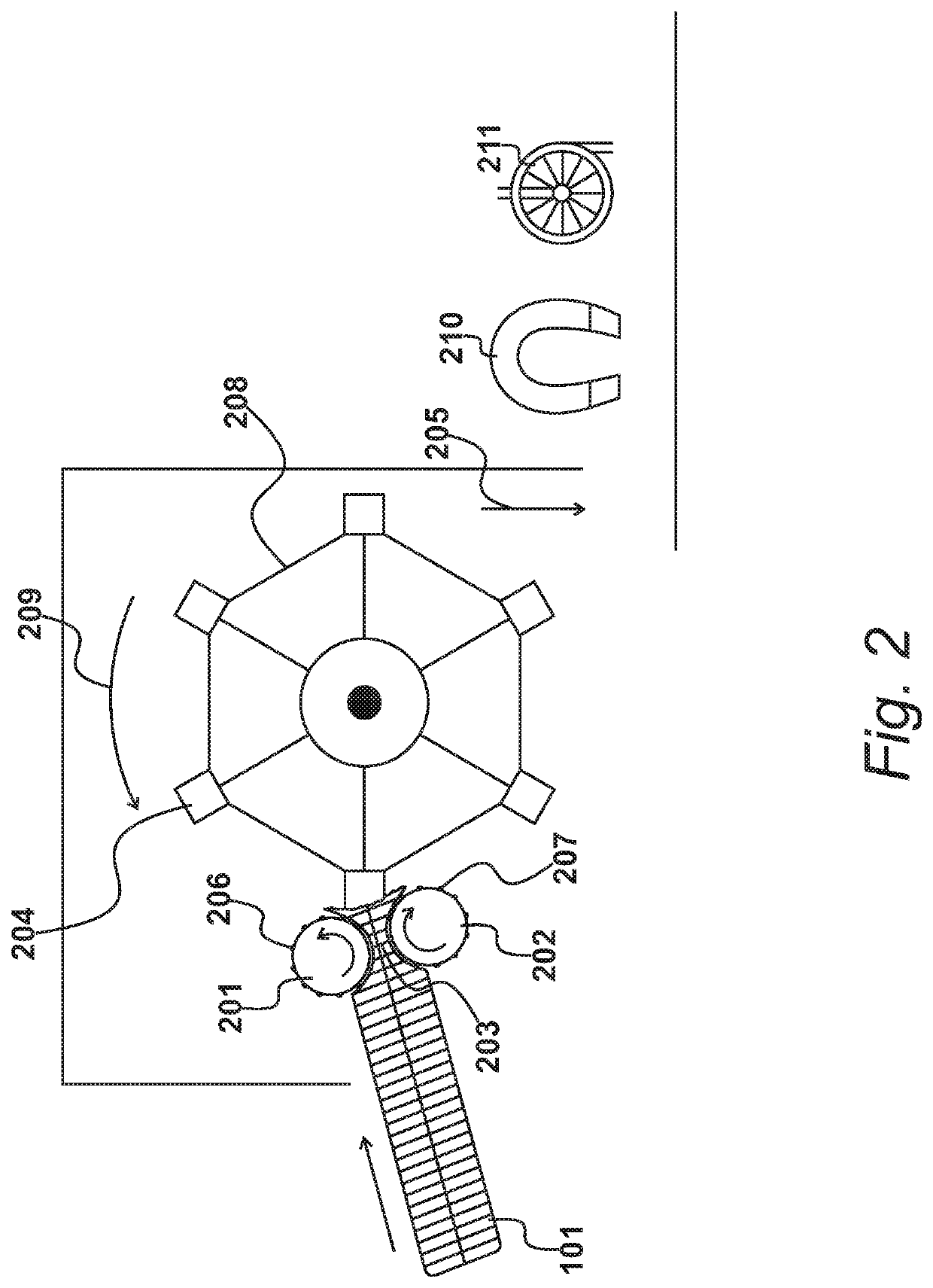

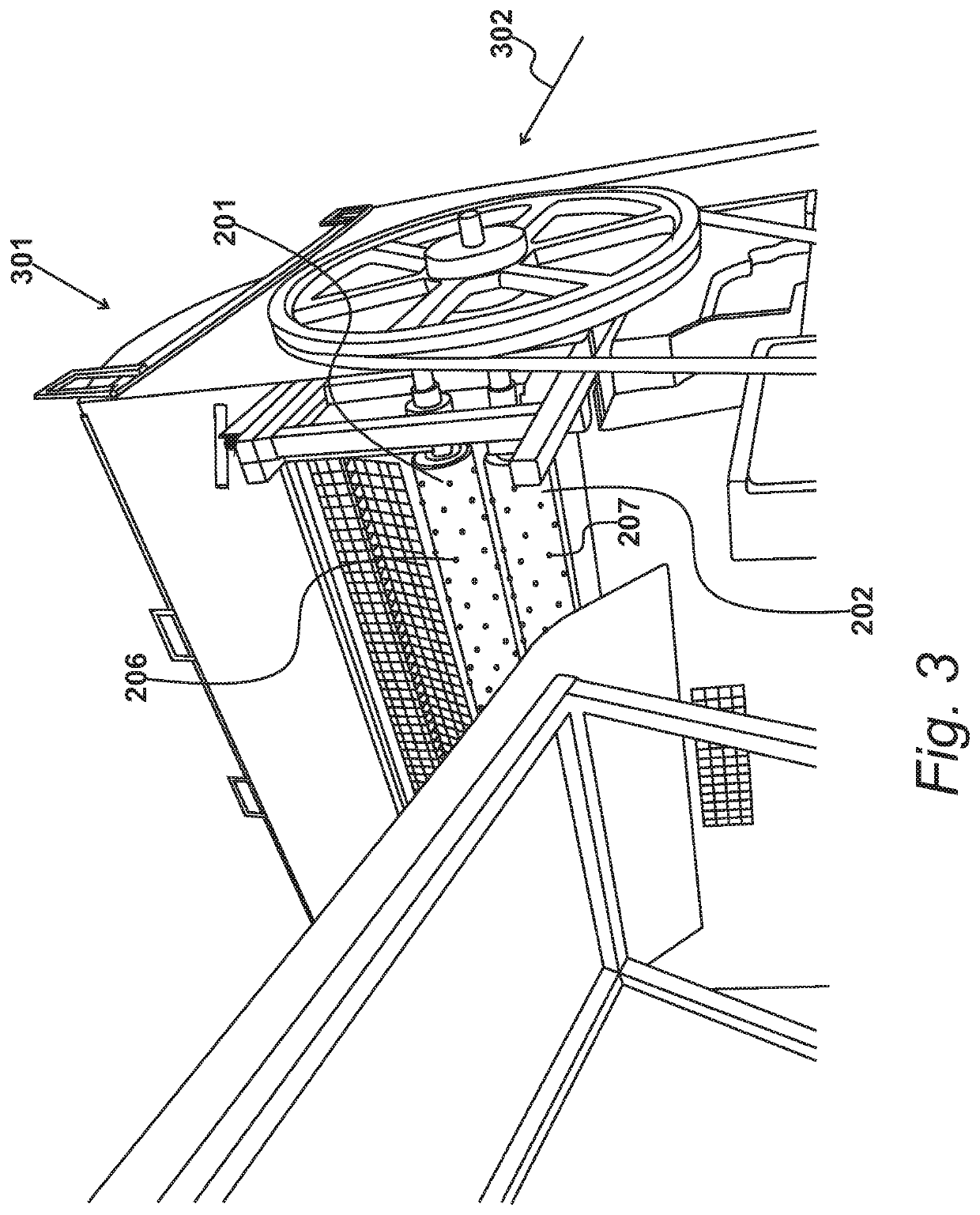

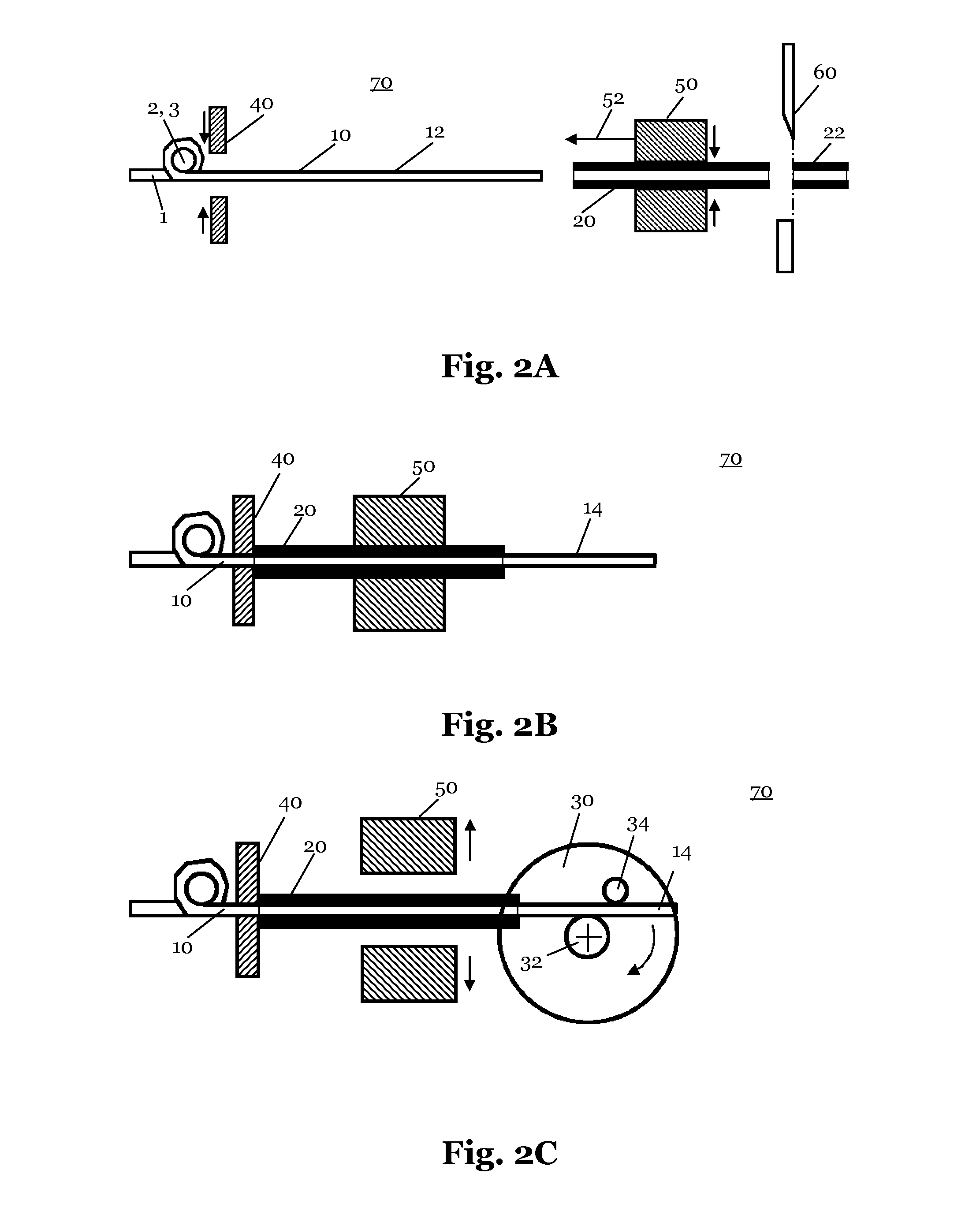

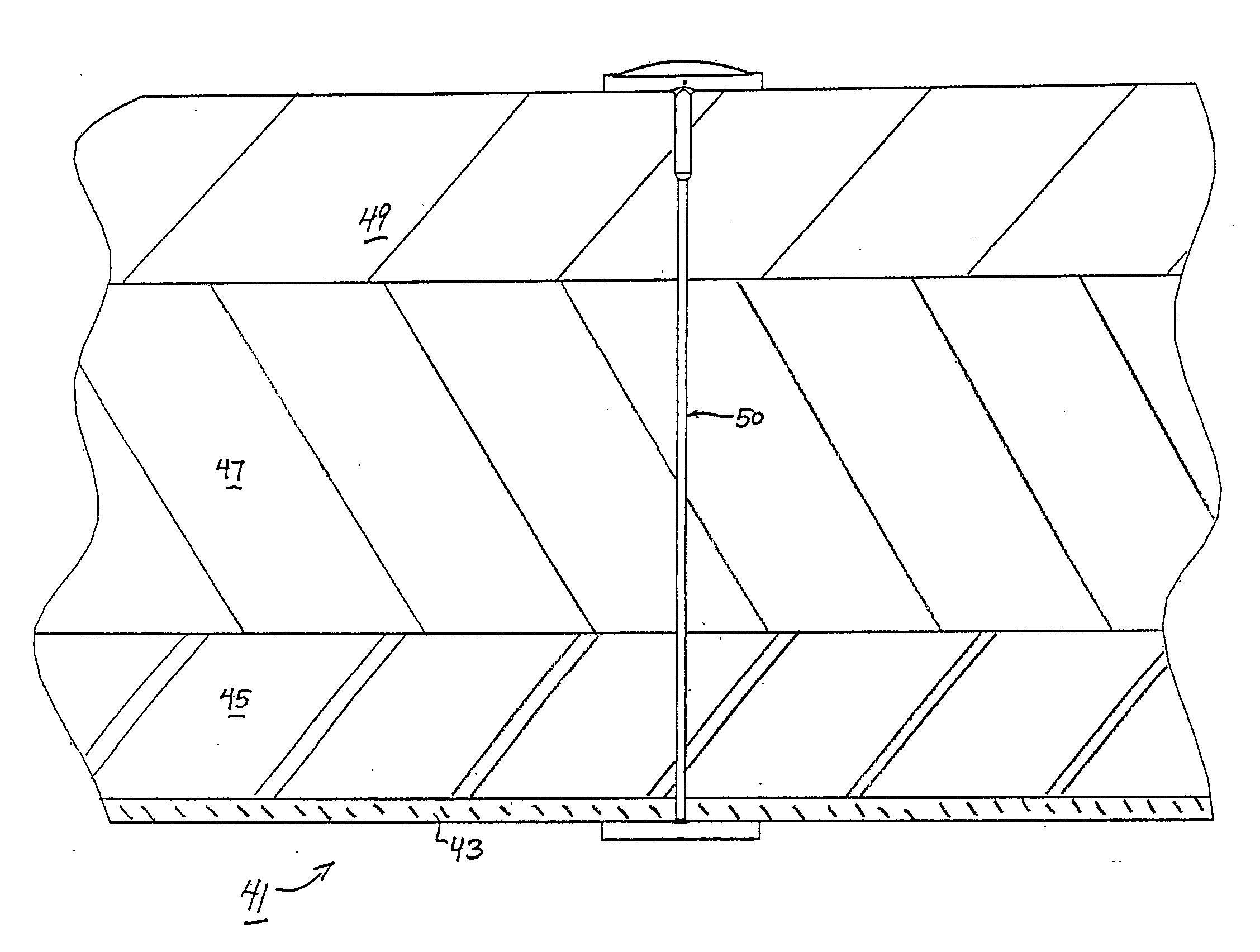

Method and equipment for the disassembly of matresses

InactiveUS20160264397A1Disassemble mattressEasy to disassembleUpholstery auxillary devicesMetal working apparatusMechanical engineeringEngineering

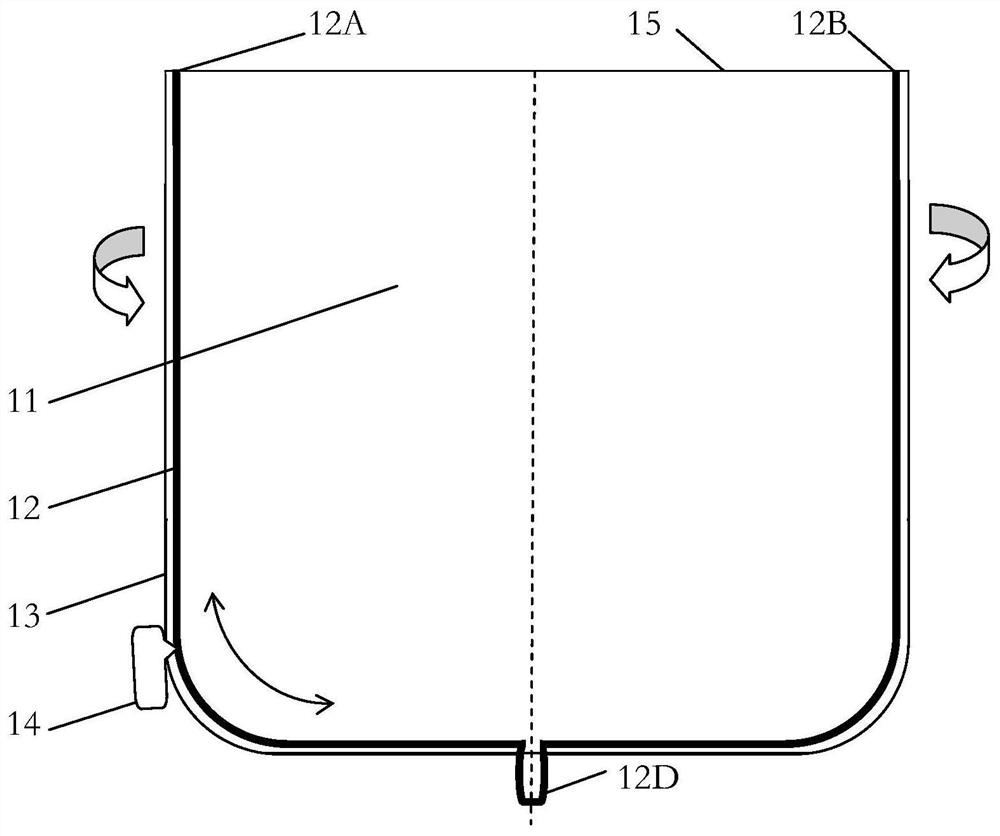

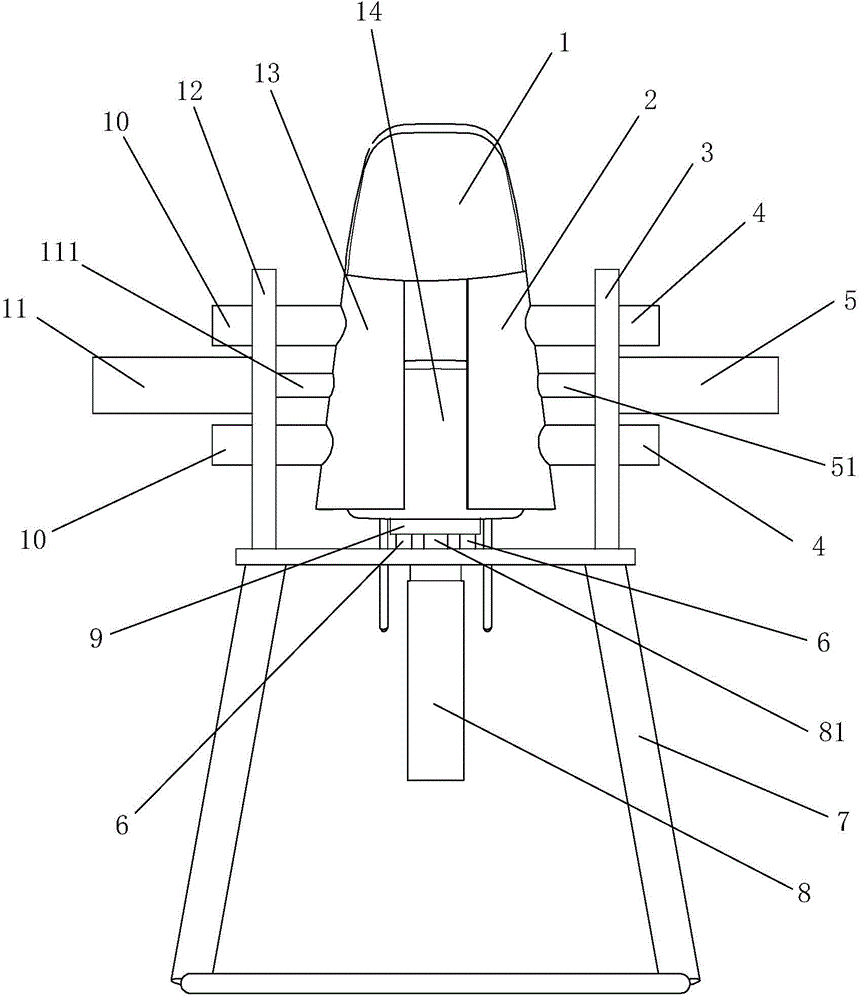

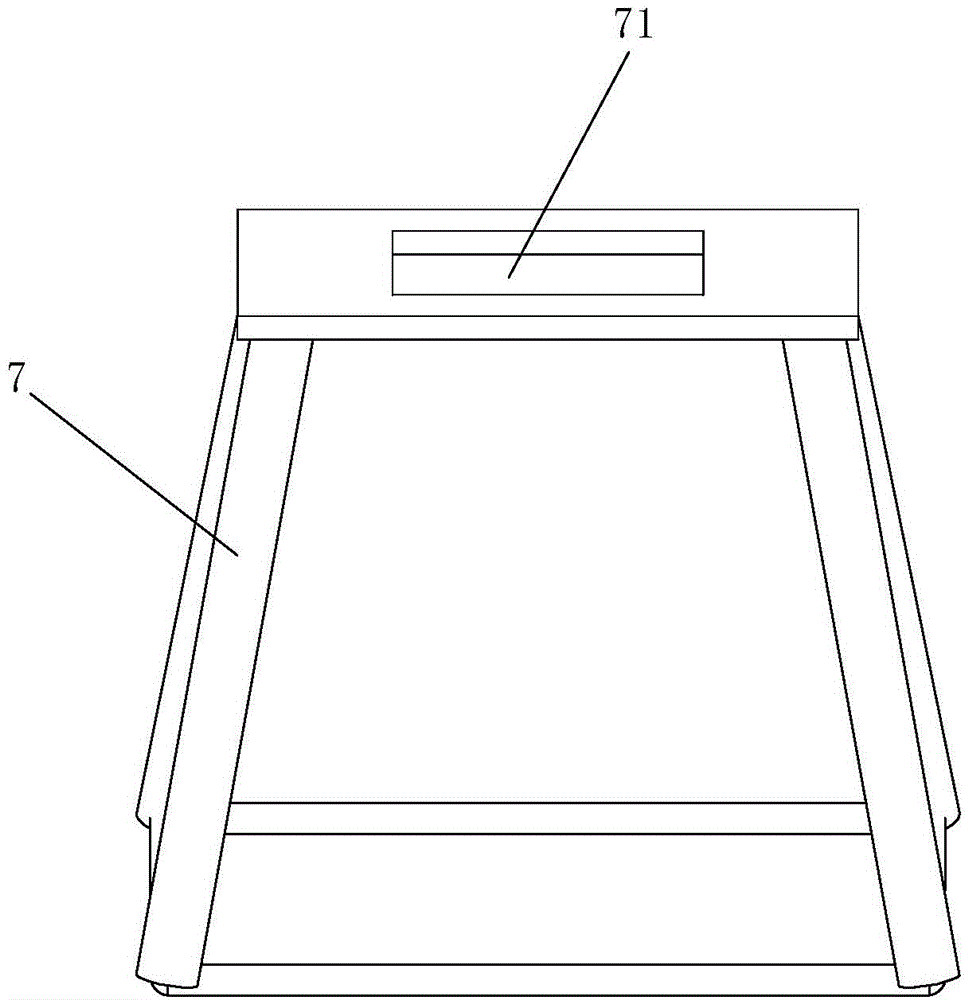

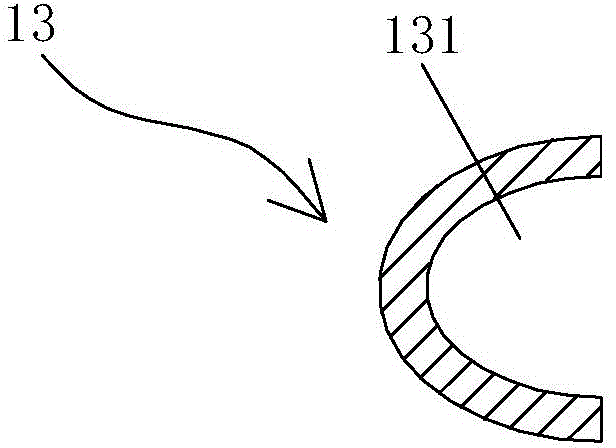

An apparatus to disassemble a mattress, the mattress including a mattress core between a top ticking and a bottom ticking and the mattress having perimeter surfaces comprising a pair of opposing side surfaces extending in a longitudinal direction and a pair of opposing end surfaces extending between the opposing side surfaces, the apparatus including: a cutting arrangement for applying at least one cut along a length of at least one of the perimeter surfaces; and at least one peeling roller having a peeling surface with retractable pins for engaging with the top and / or bottom ticking, the retractable pins being movable between a retracted position and an extended position, wherein the at least one peeling roller is rotatable in a peeling direction for peeling the top and / or bottom ticking from the mattress with the pins in the extended position and wherein the at least one peeling roller is rotatable in a removal direction, opposite to the peeling direction, for removing the peeled ticking from the peeling surface with the pins in the retracted position.

Owner:RTM RECYCLING SYST

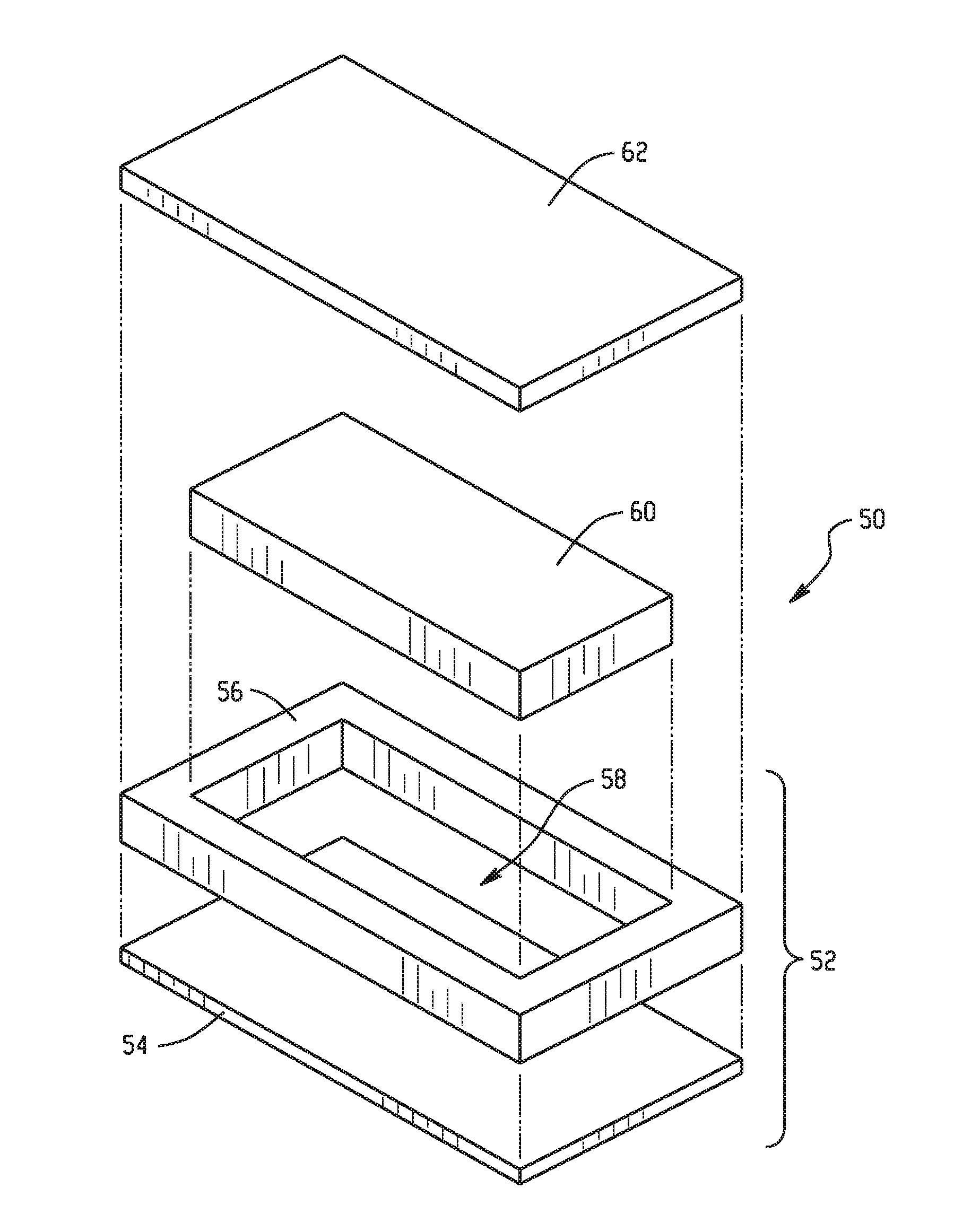

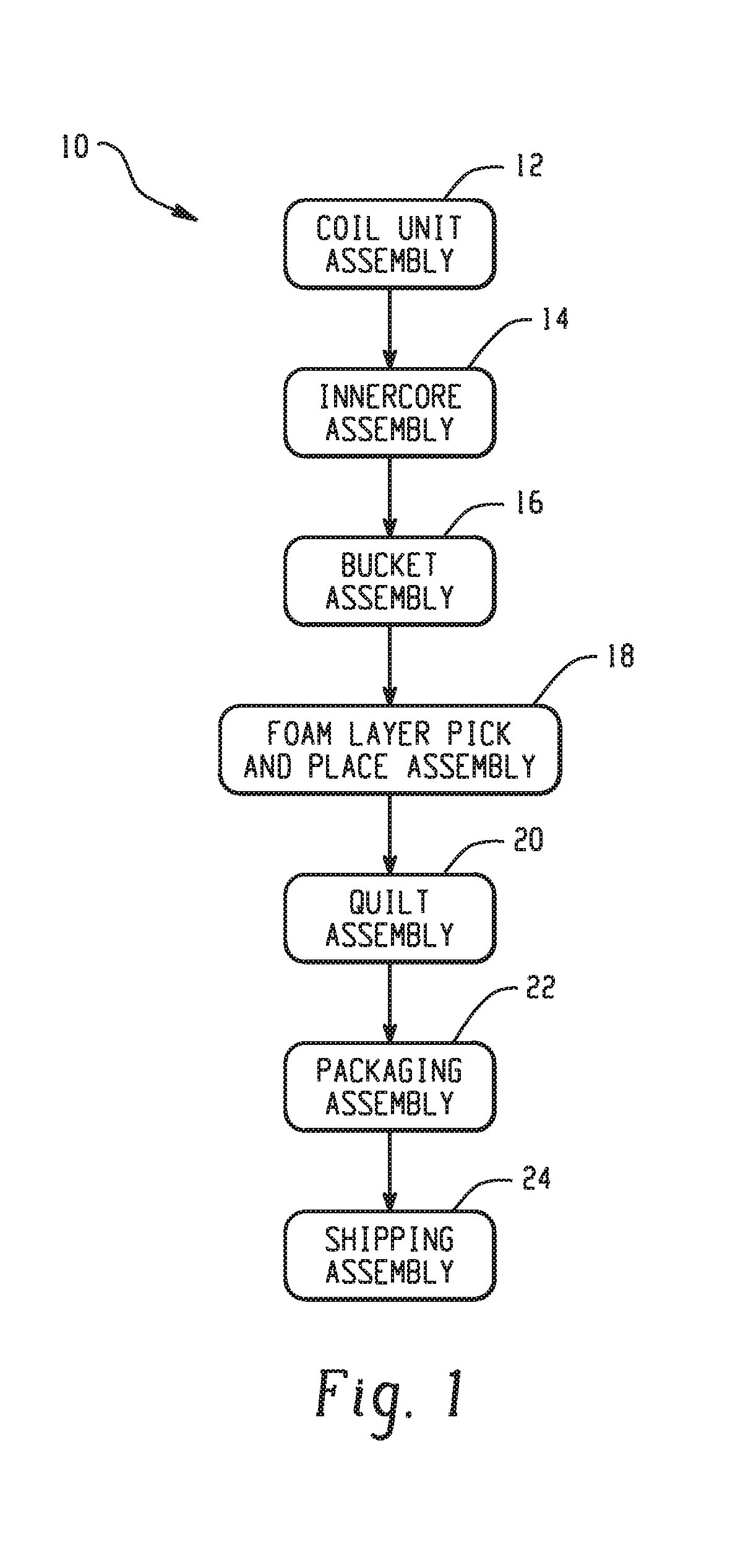

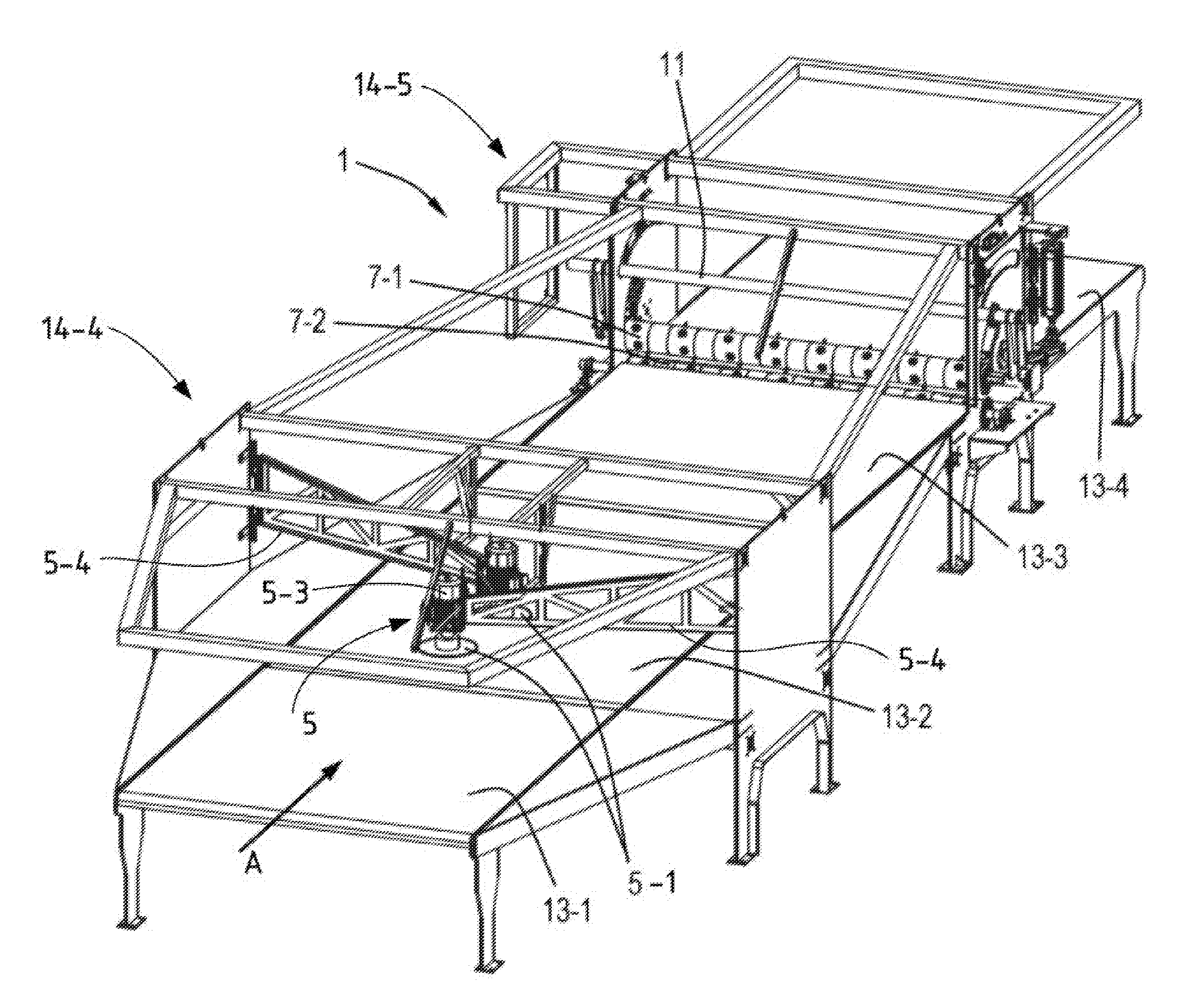

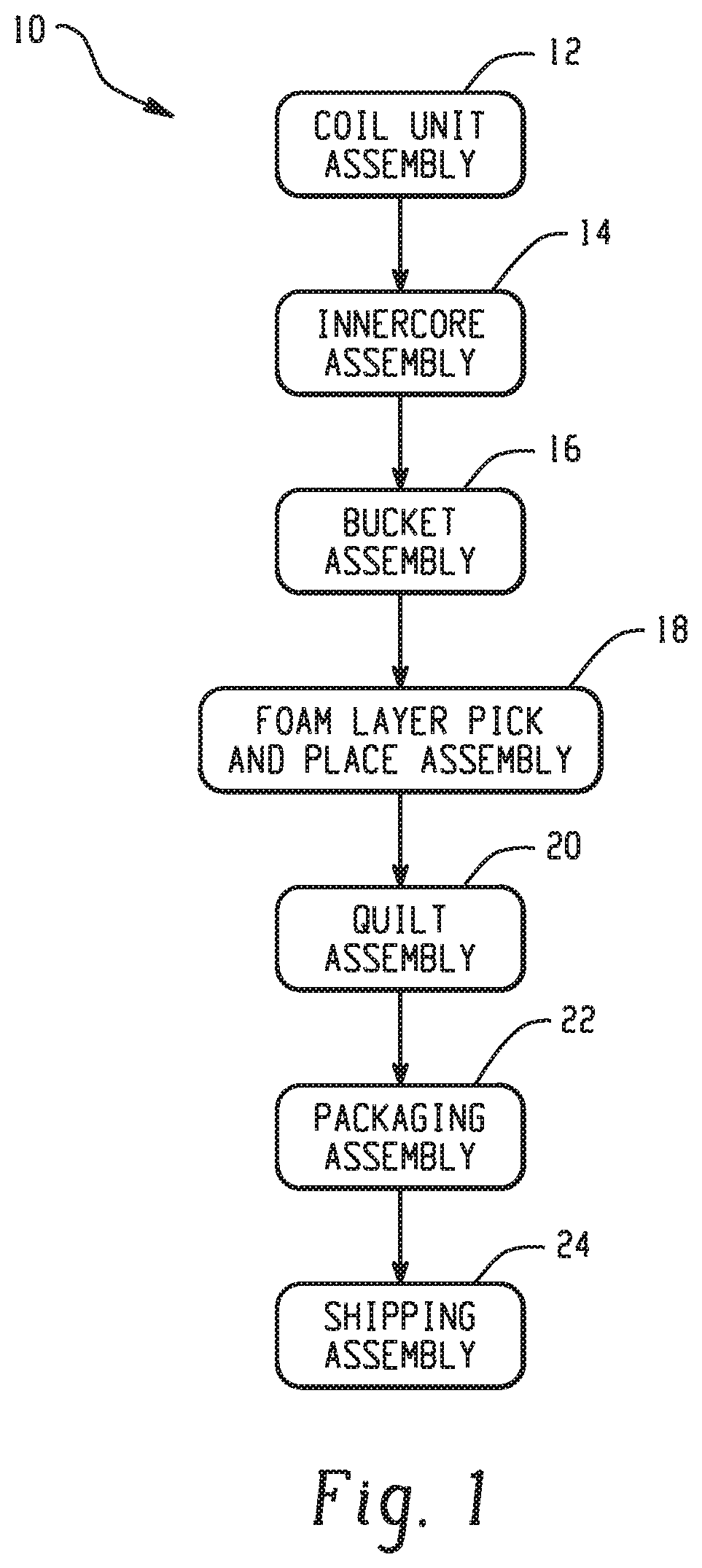

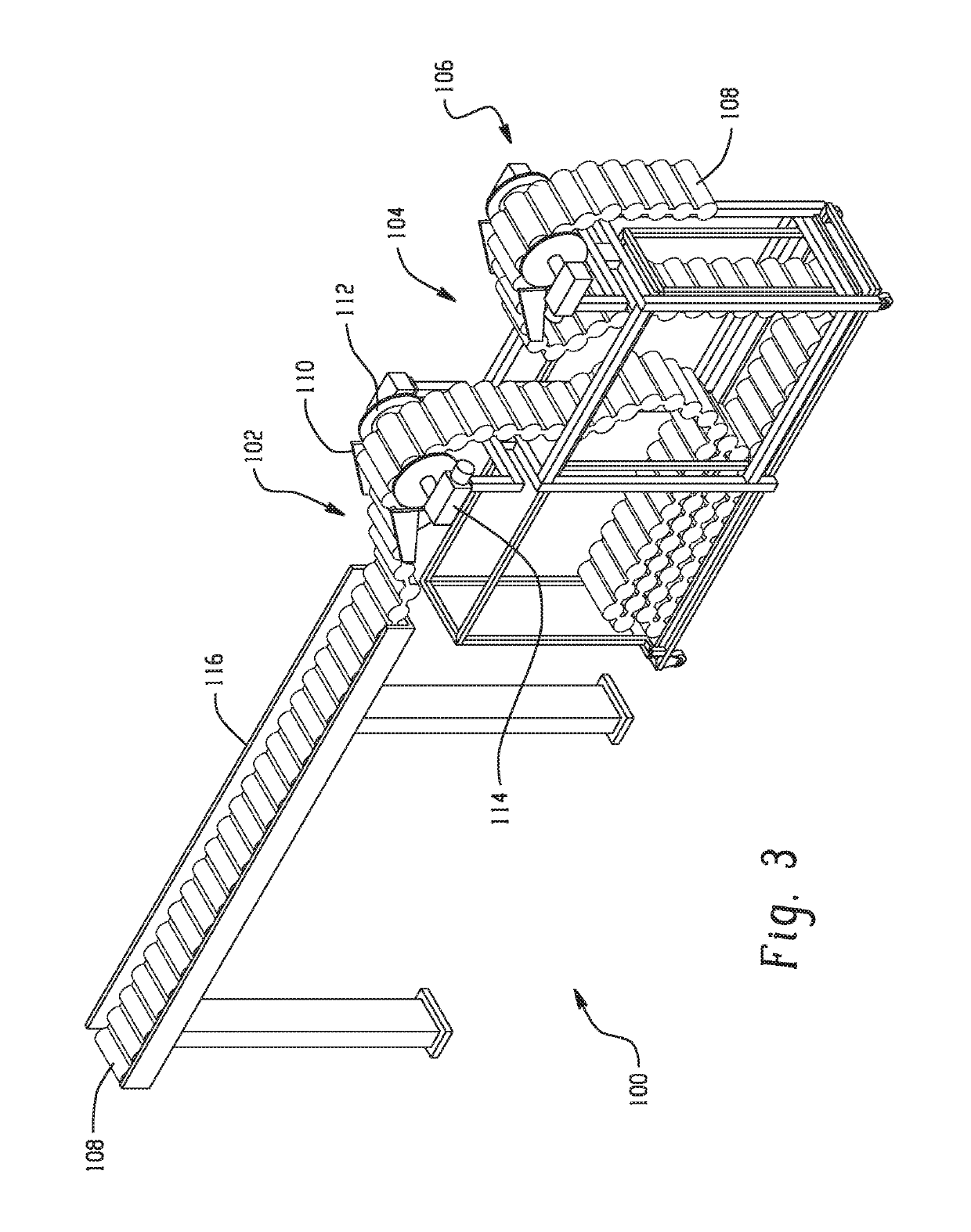

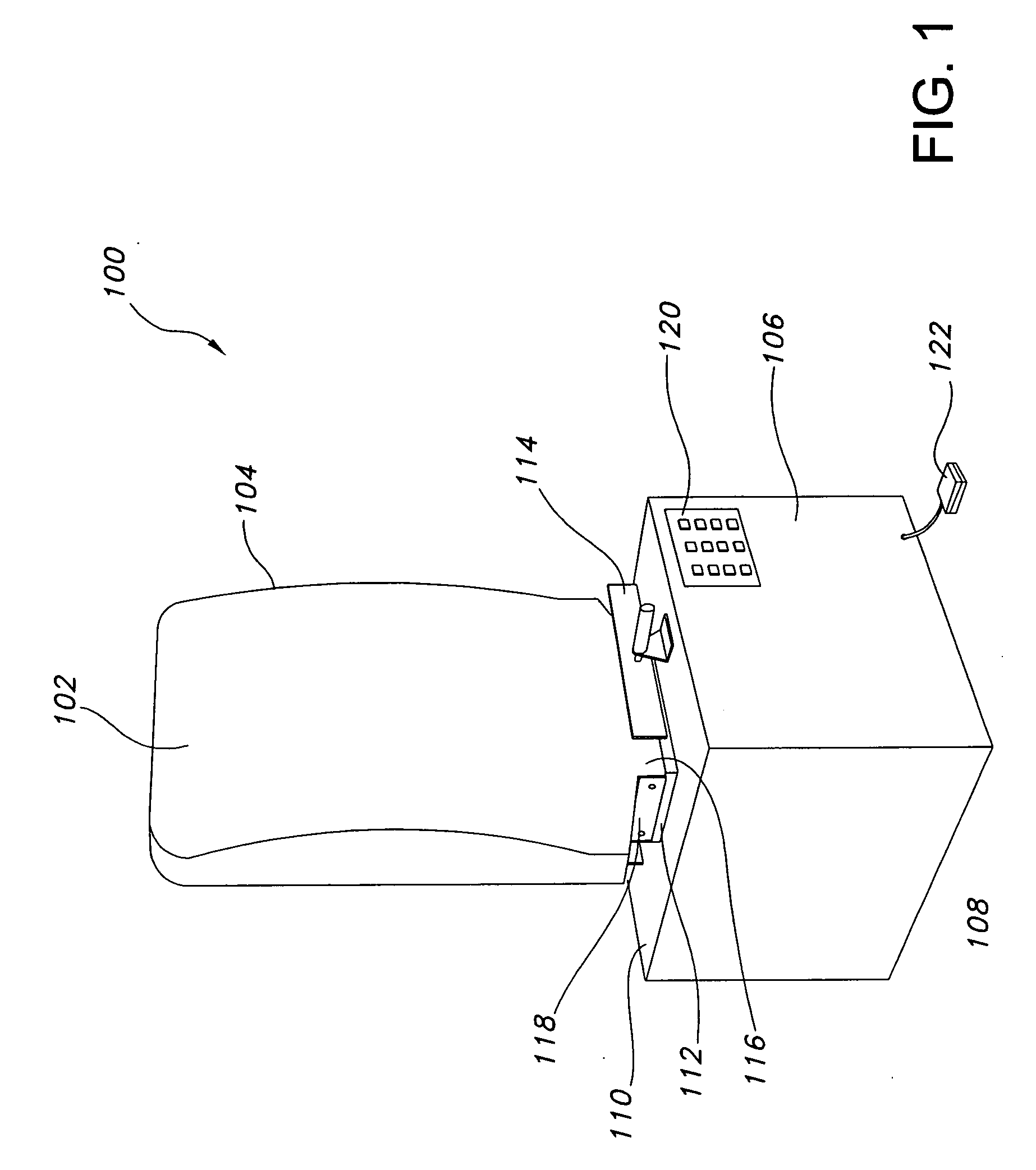

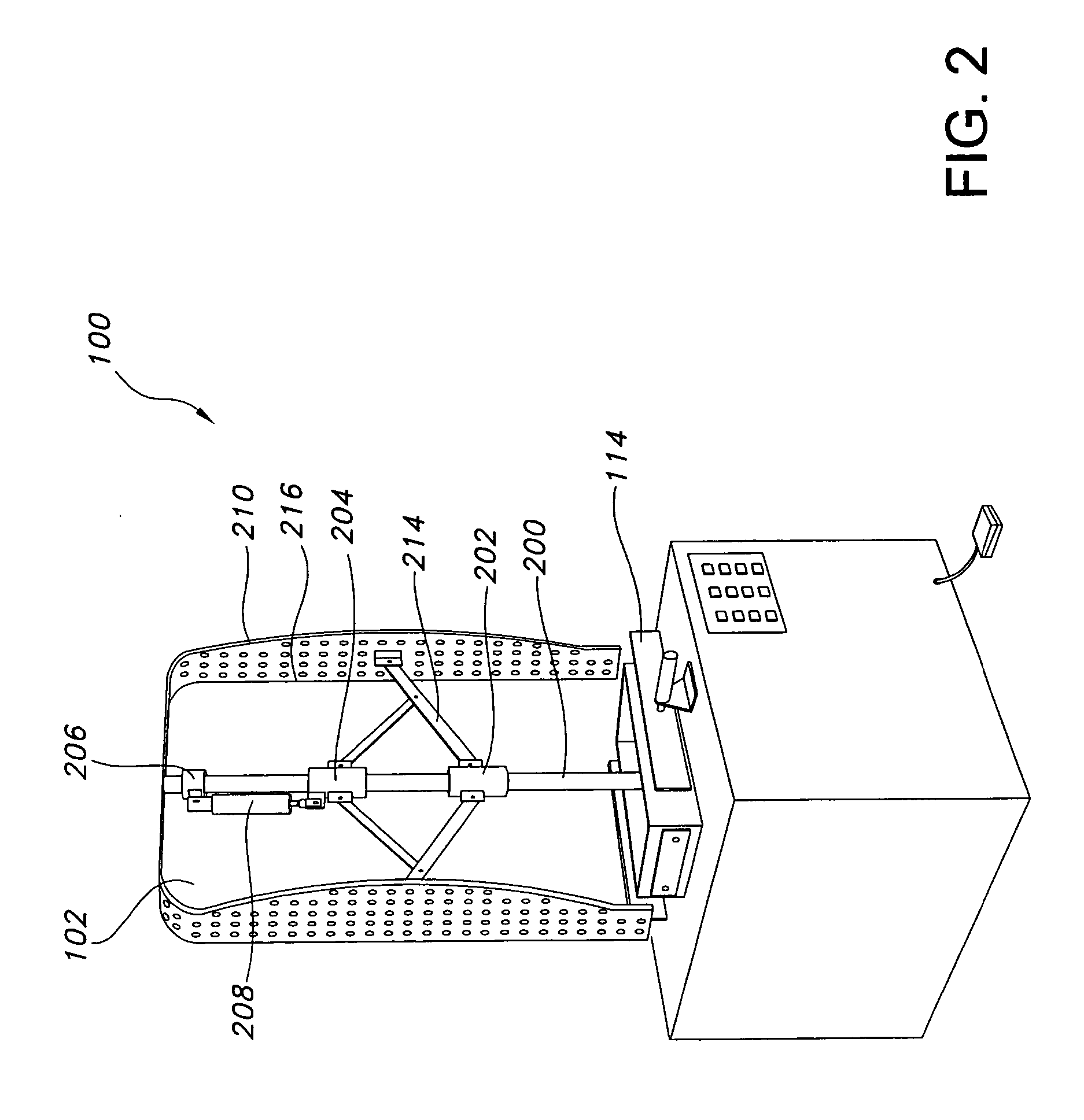

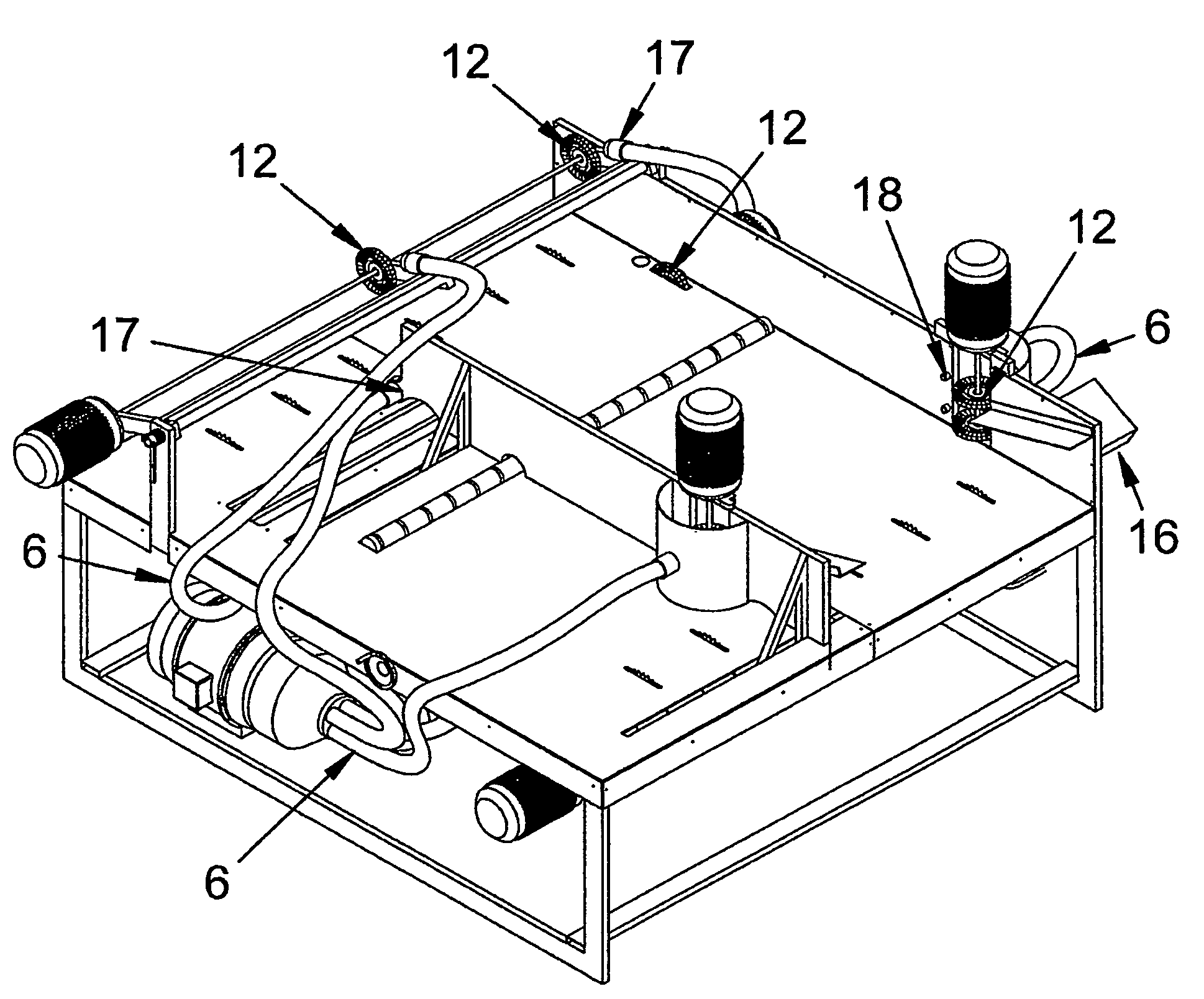

Automated mattress manufacturing process and apparatus

ActiveUS10525557B2Upholstery manufactureStuffed mattressesMechanical engineeringIndustrial engineering

Owner:DREAMWELL

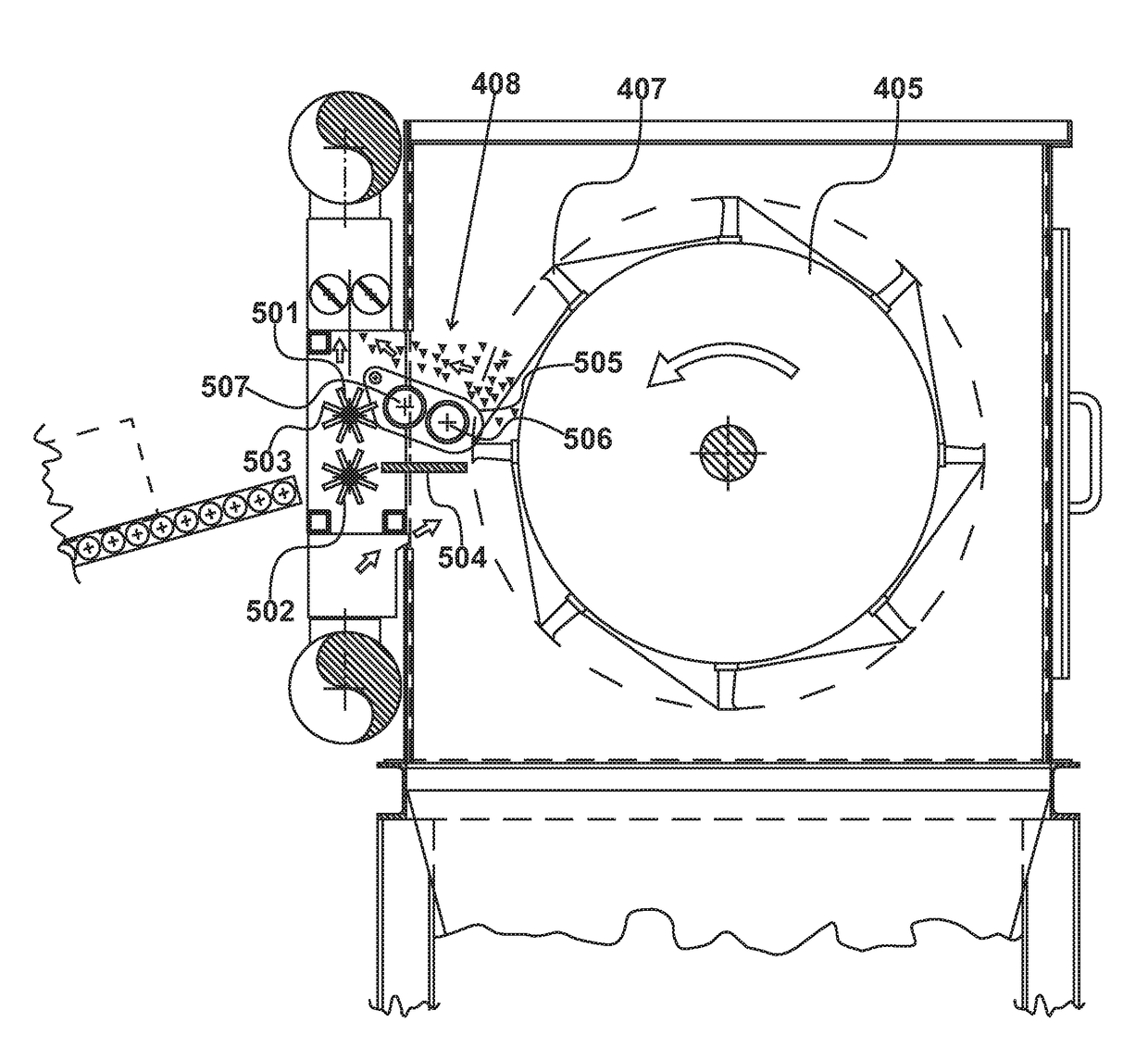

Separating Components of a Pocket Sprung Mattress Sub-Assembly

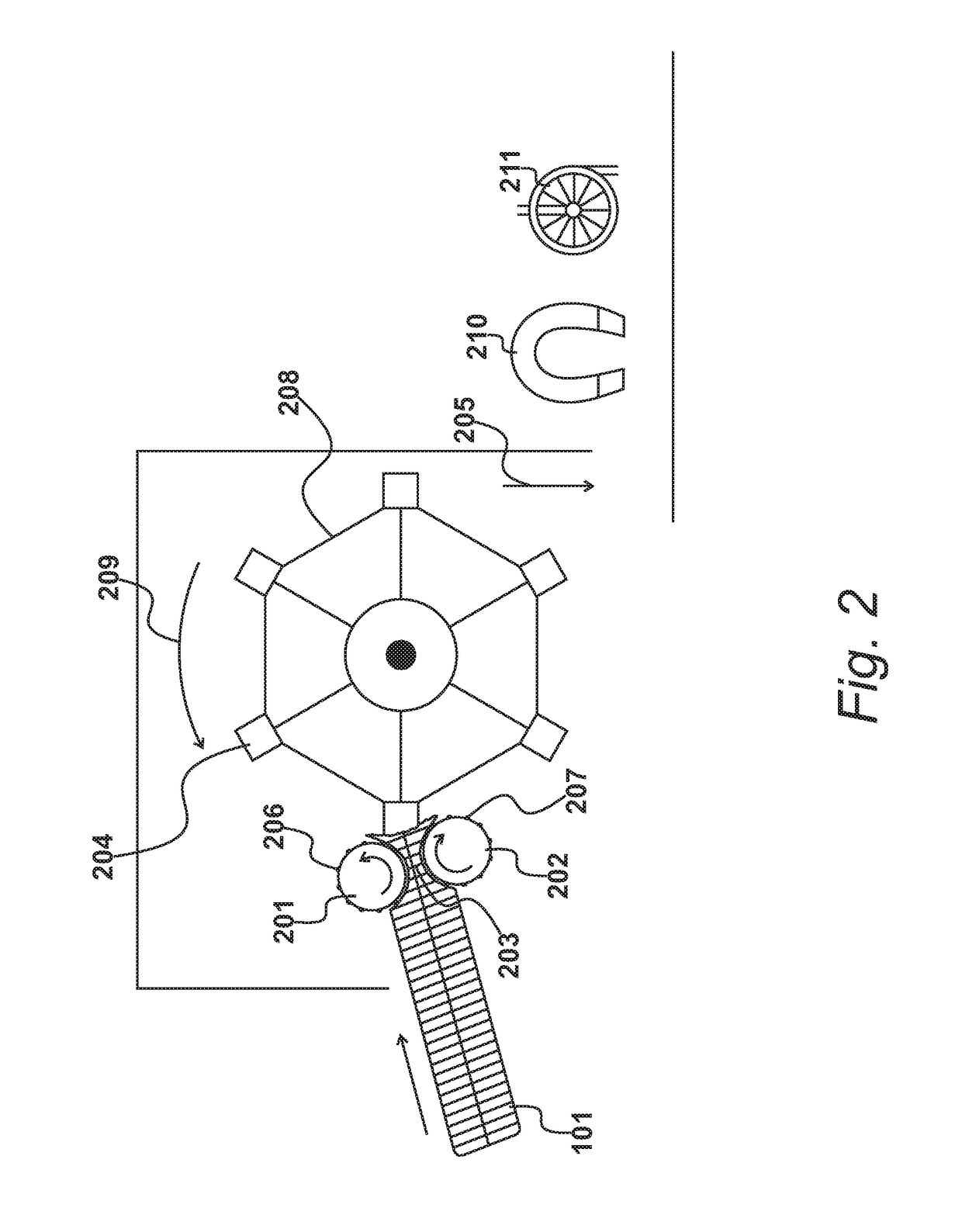

Components of a pocket-sprung-mattress sub-assembly having individual metal springs retained within a matrix of fabric pockets are separated. A rotatable tearing drum 405 is driven by a drive motor 406. Tearing devices 407 are arranged to pull metal springs from a pocket-sprung-mattress sub-assembly during the rotation of the tearing drum 405. A feeding assembly 408 compressors an end portion of the mattress sub-assembly and moves this end portion continually to bring an end of the mattress sub-assembly into contact with the rotating tearing devices 407.

Owner:THE FURNITURE RECYCLING GRP LTD

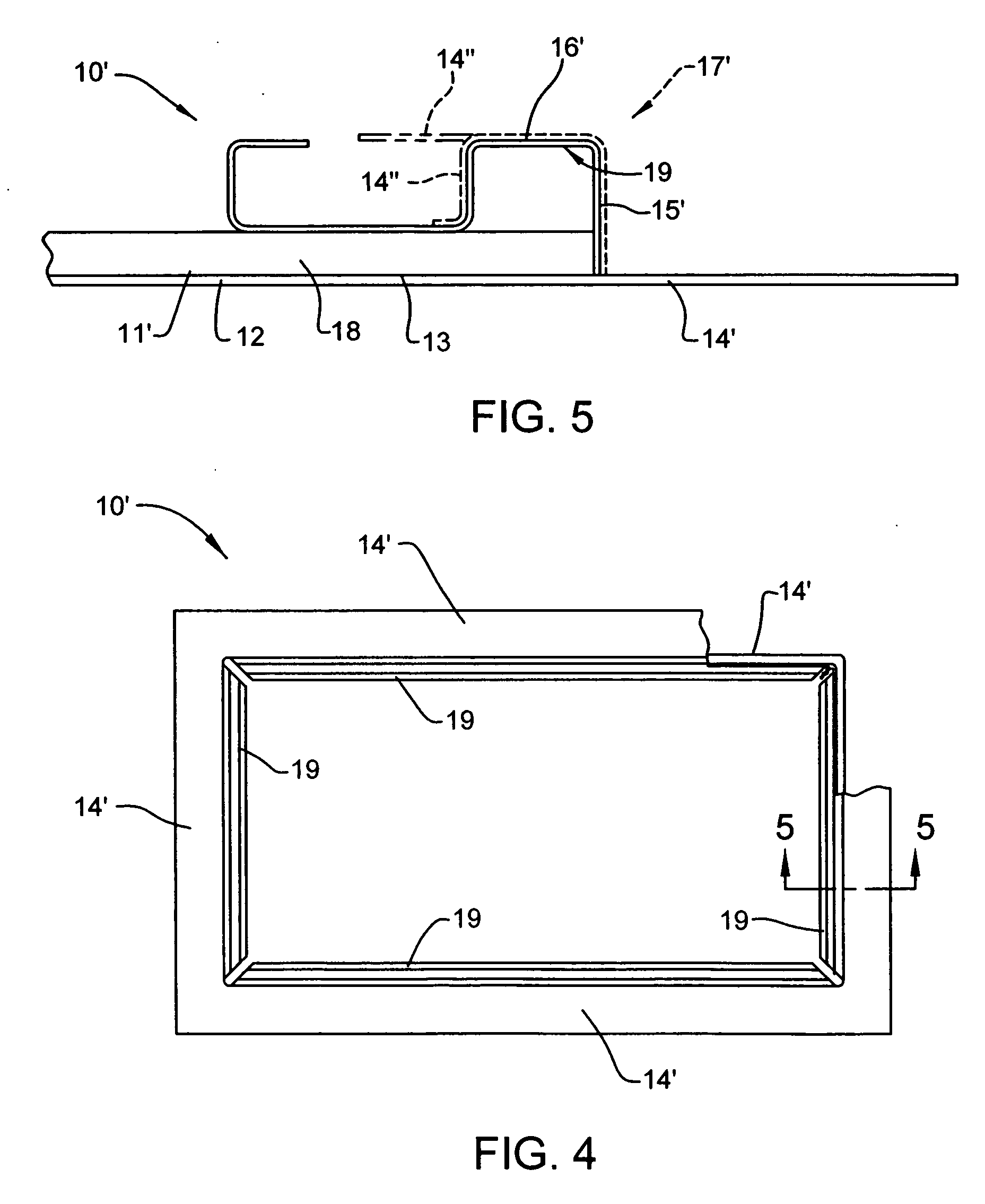

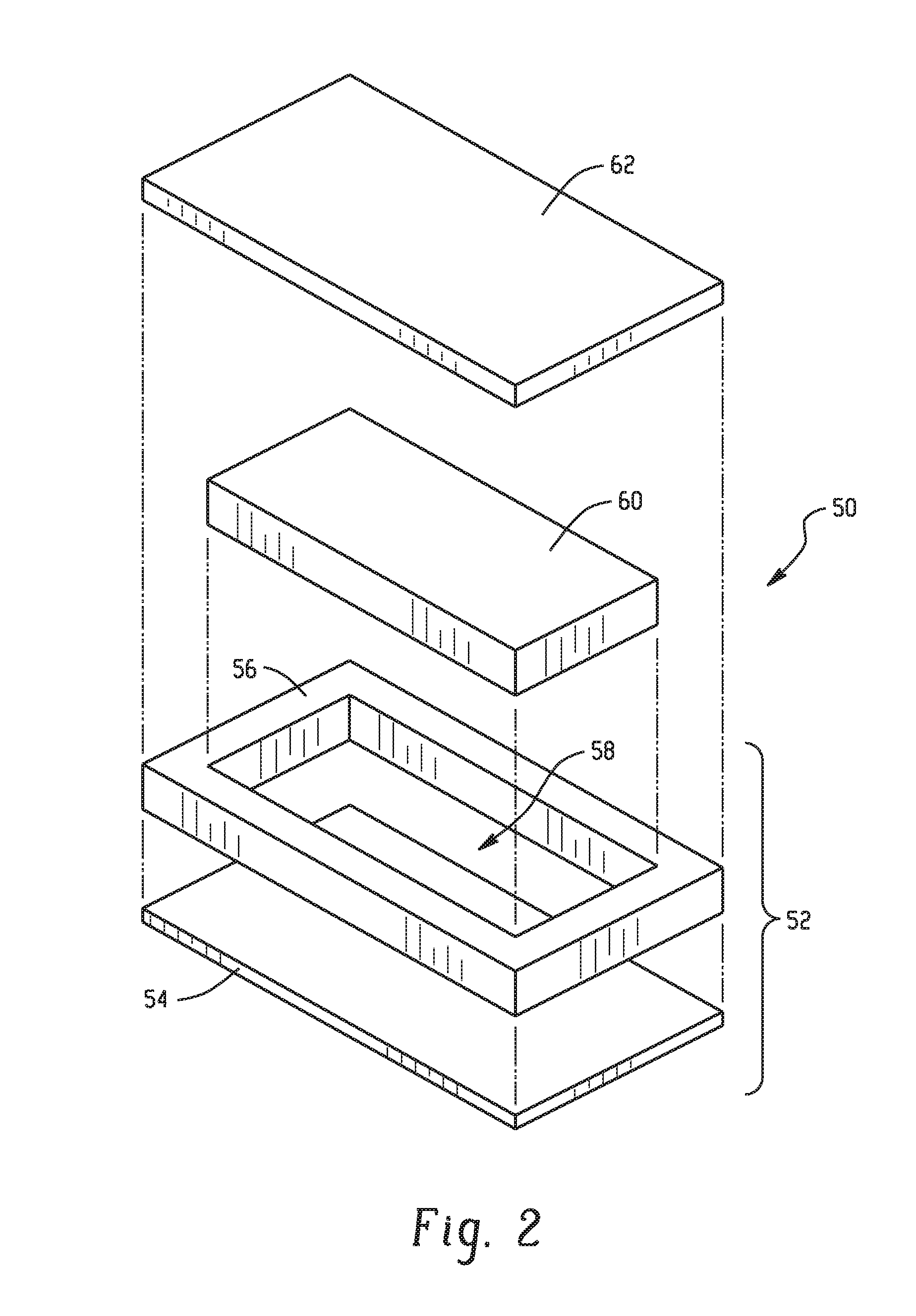

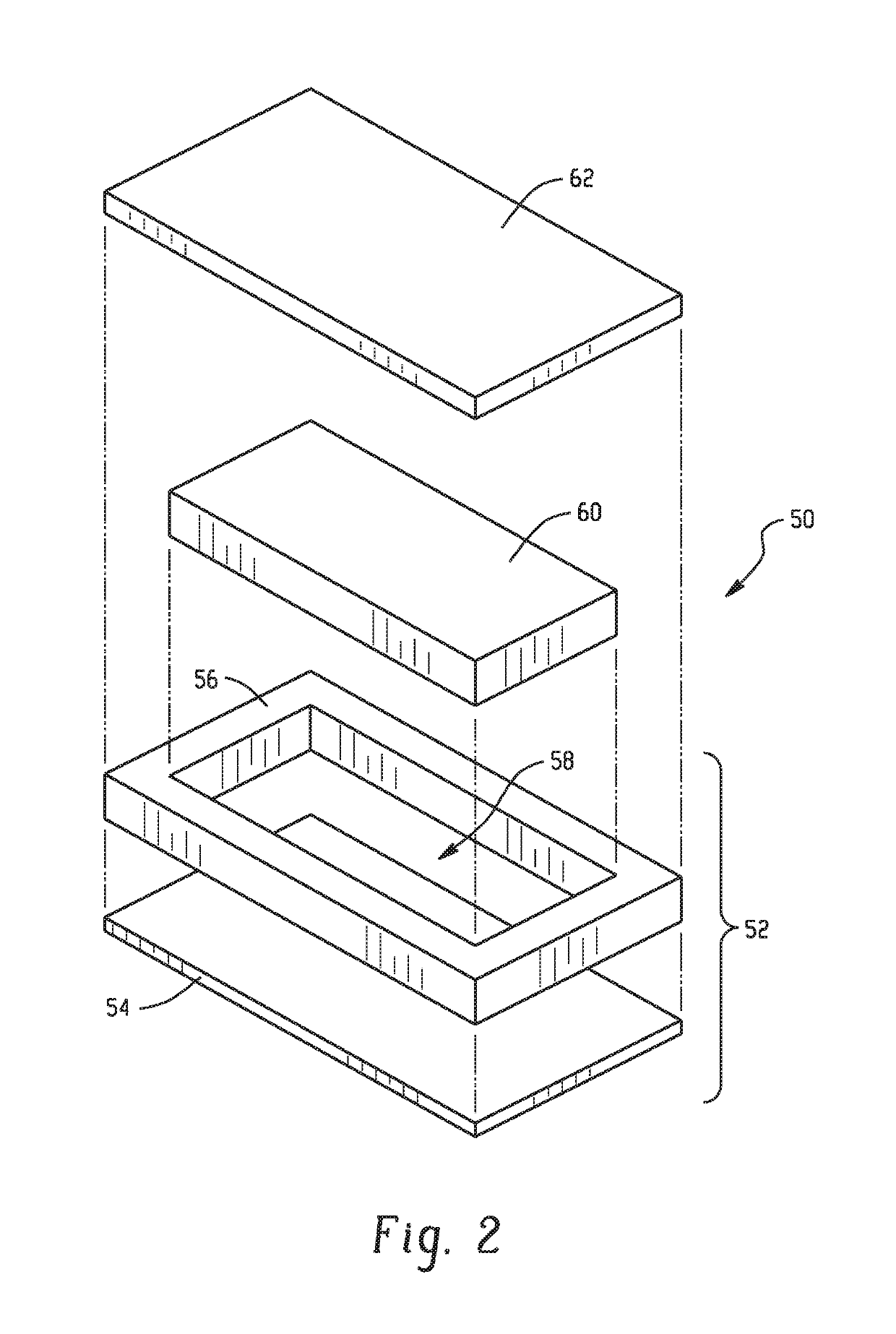

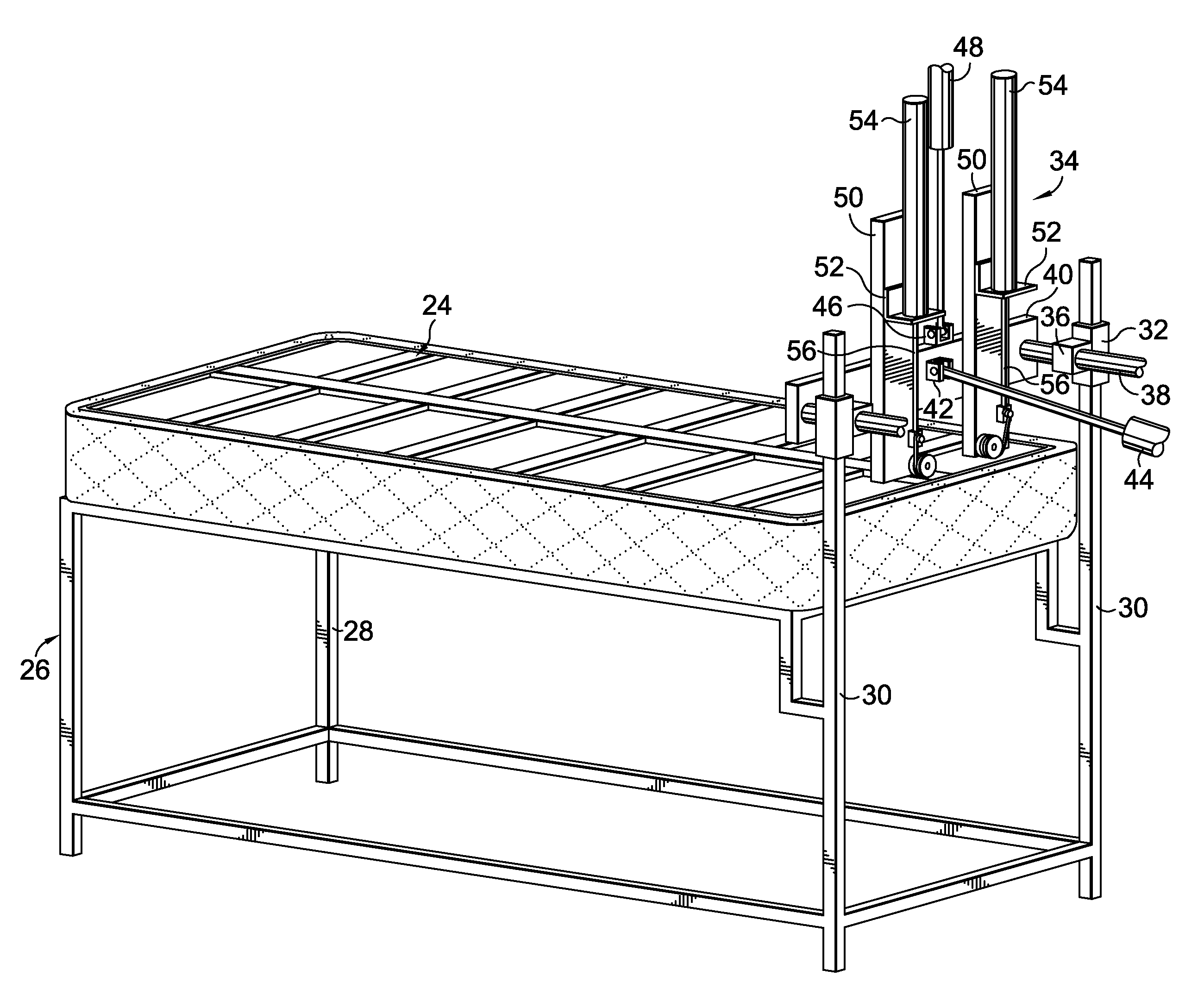

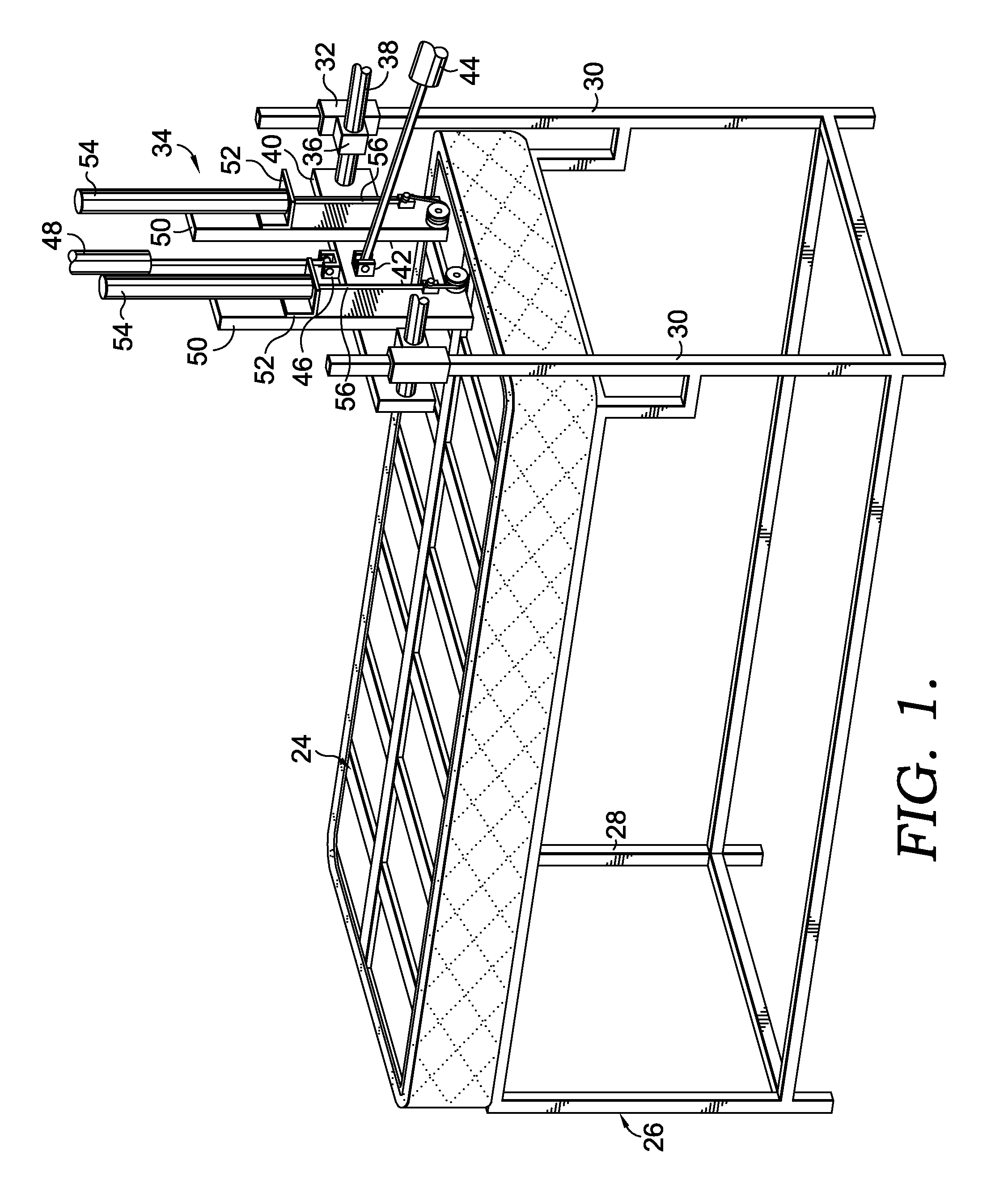

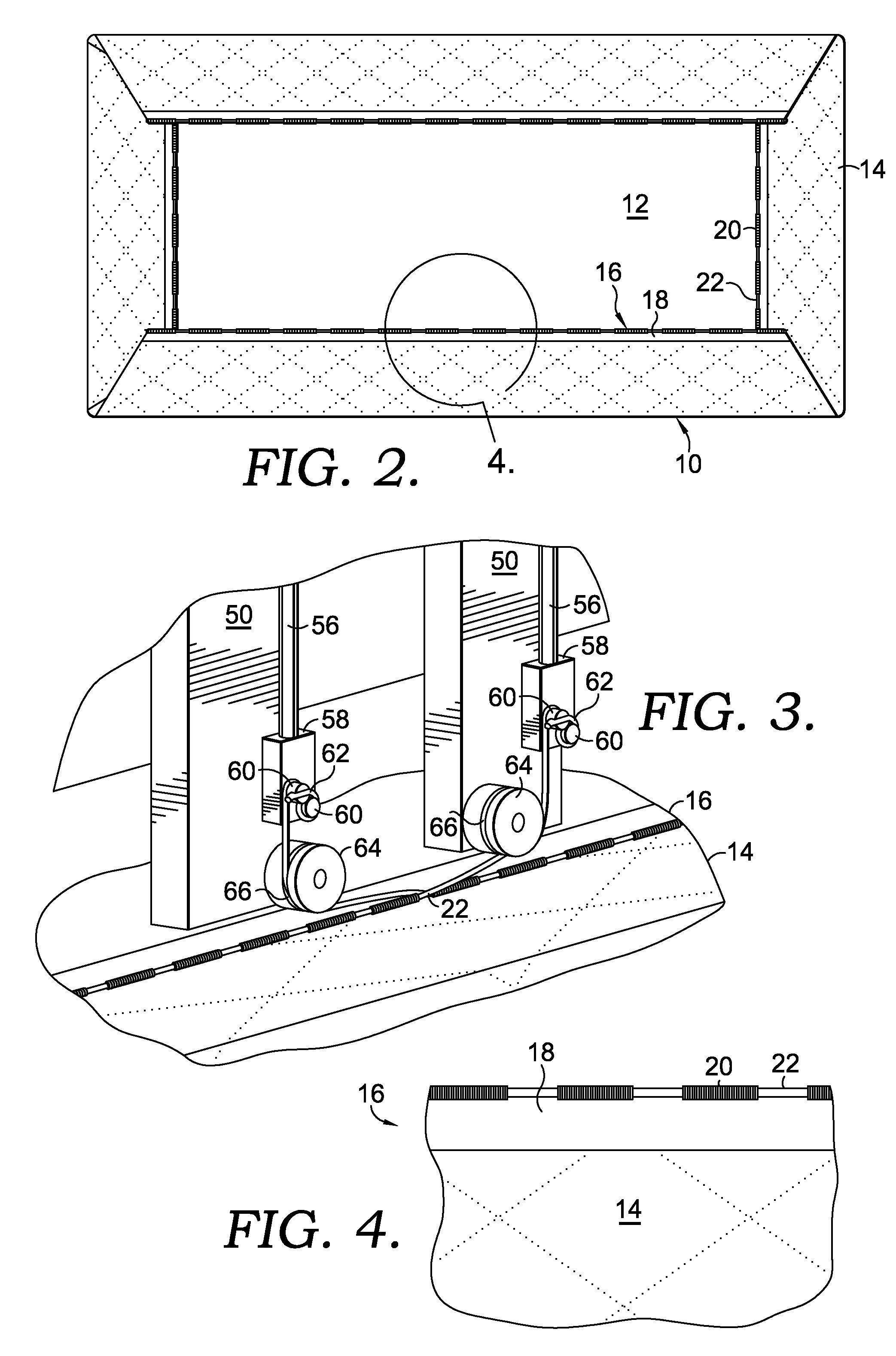

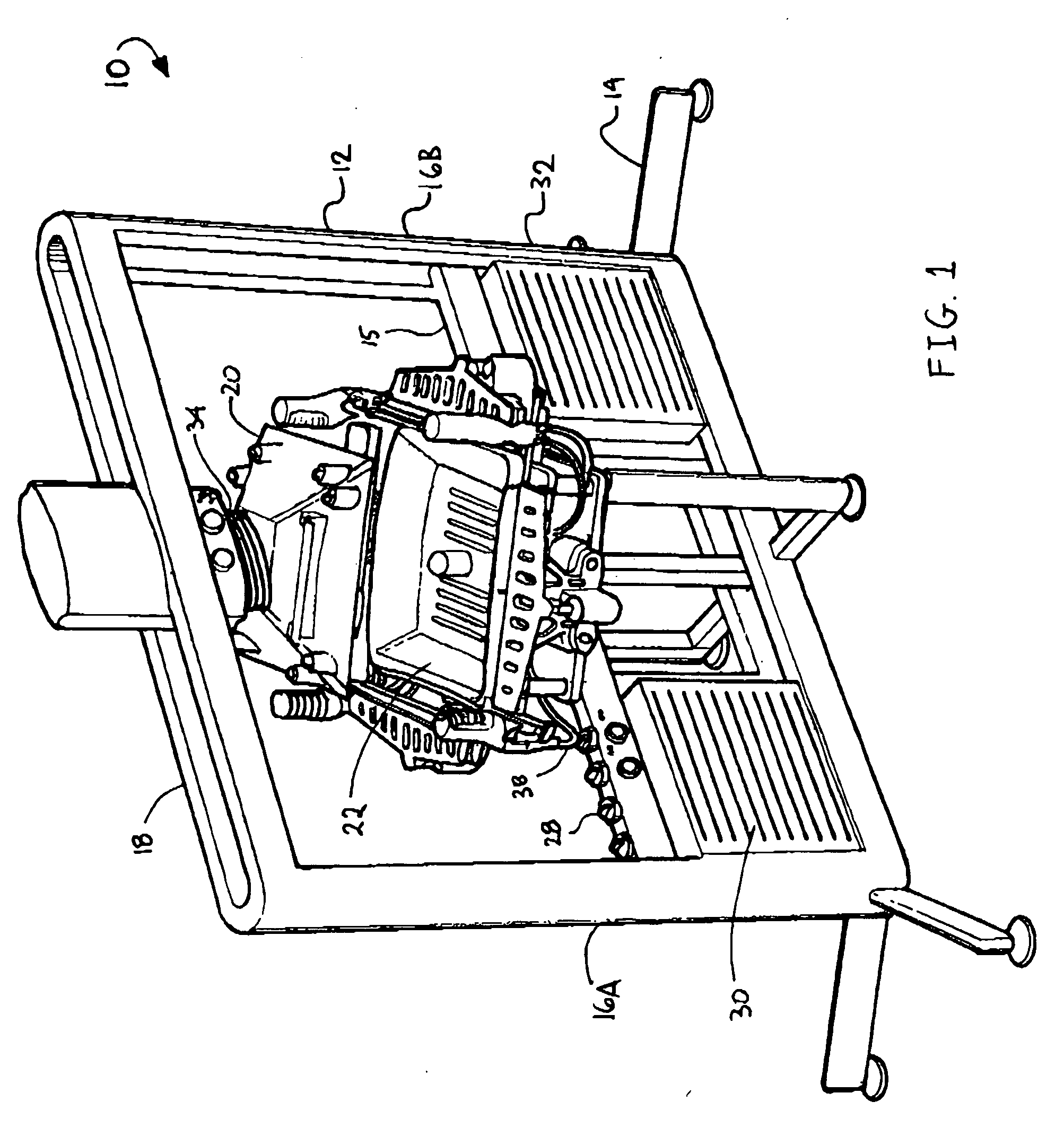

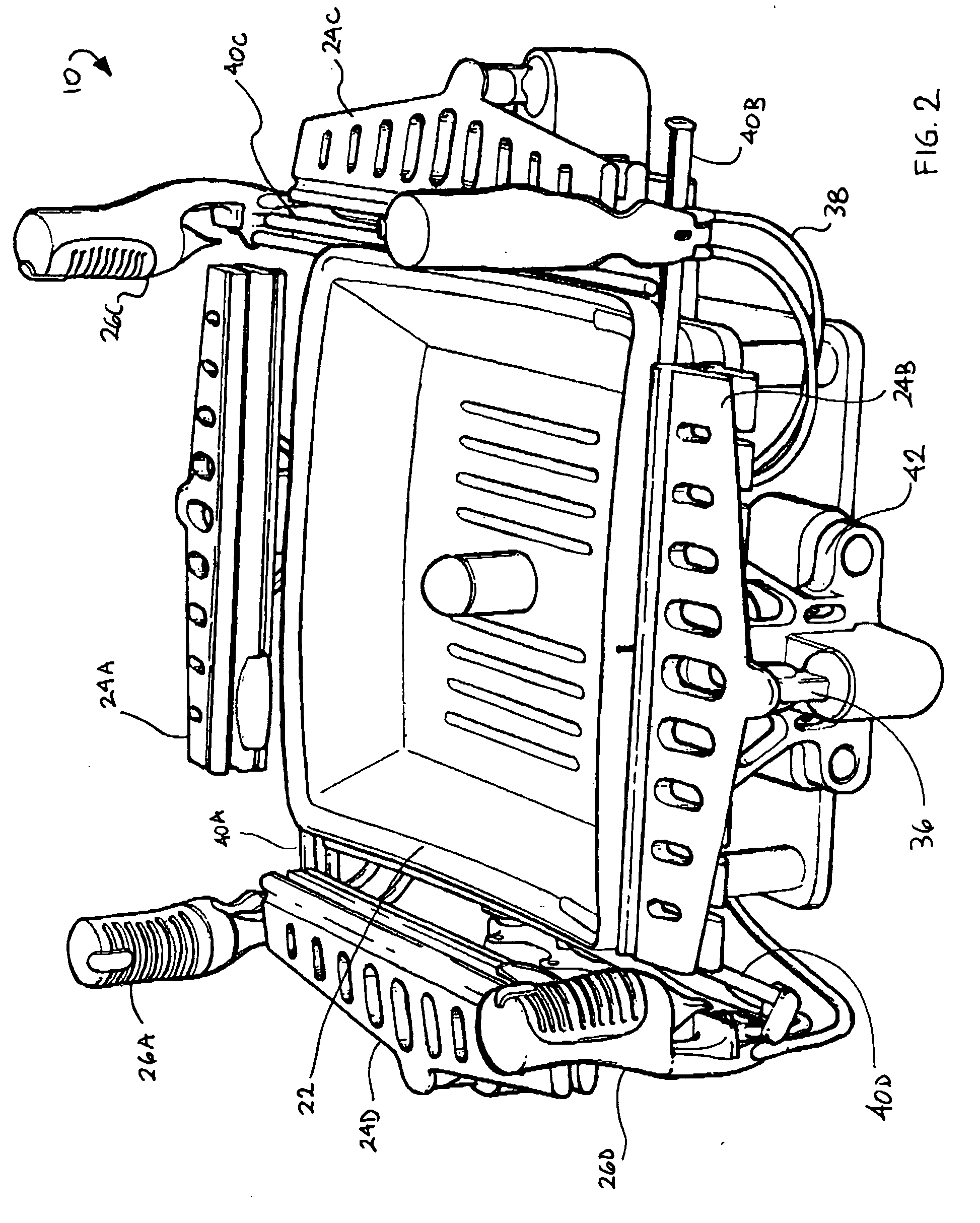

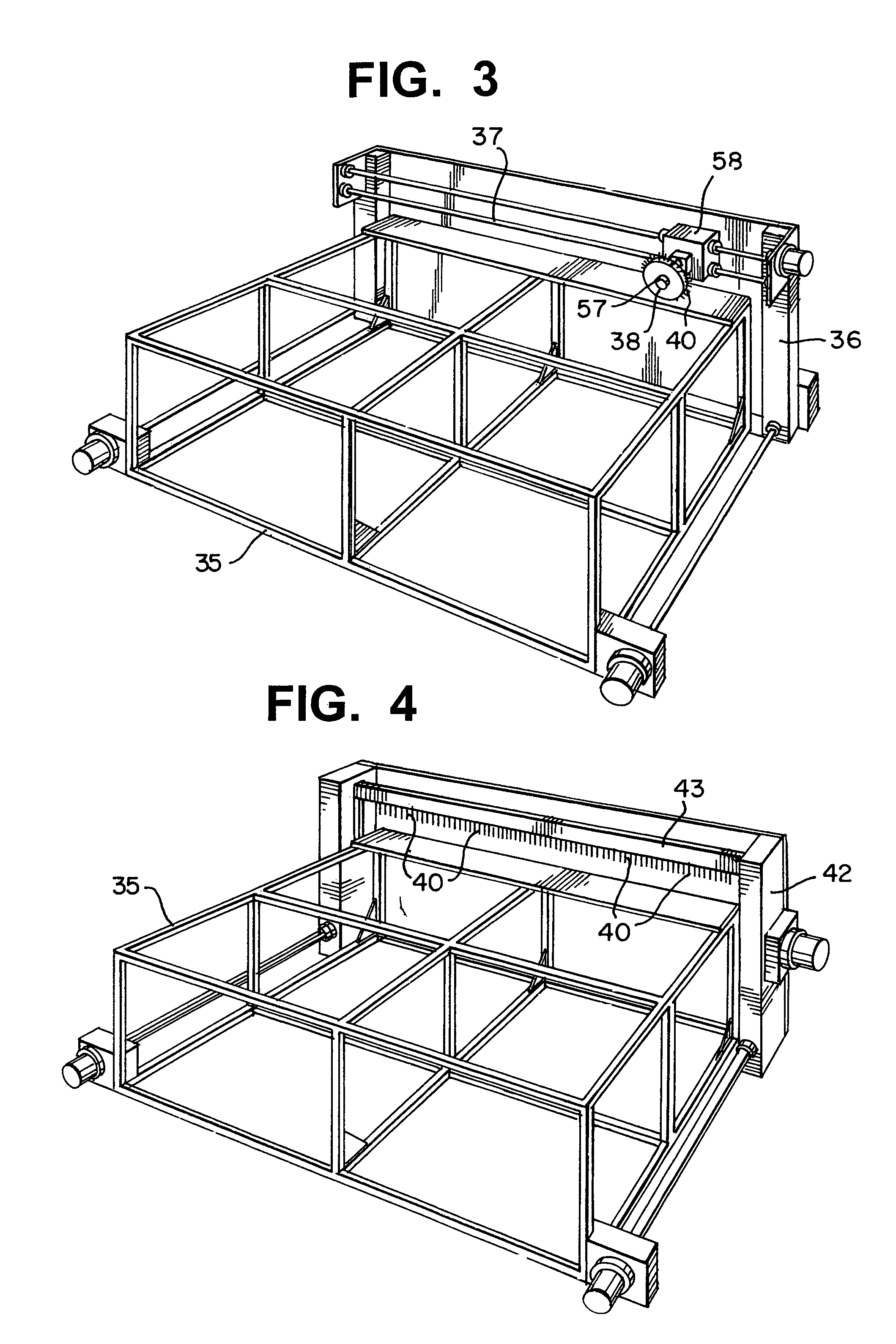

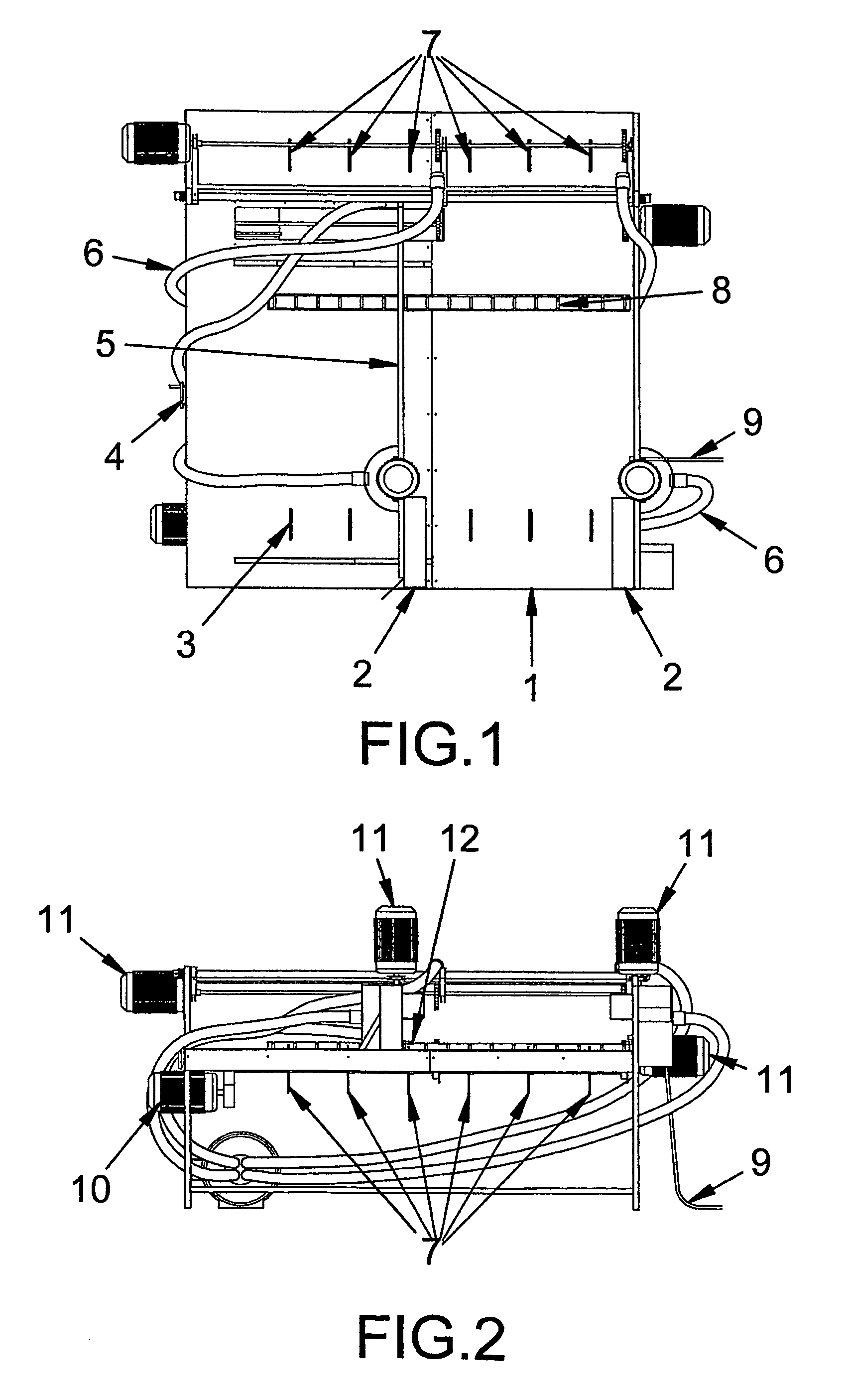

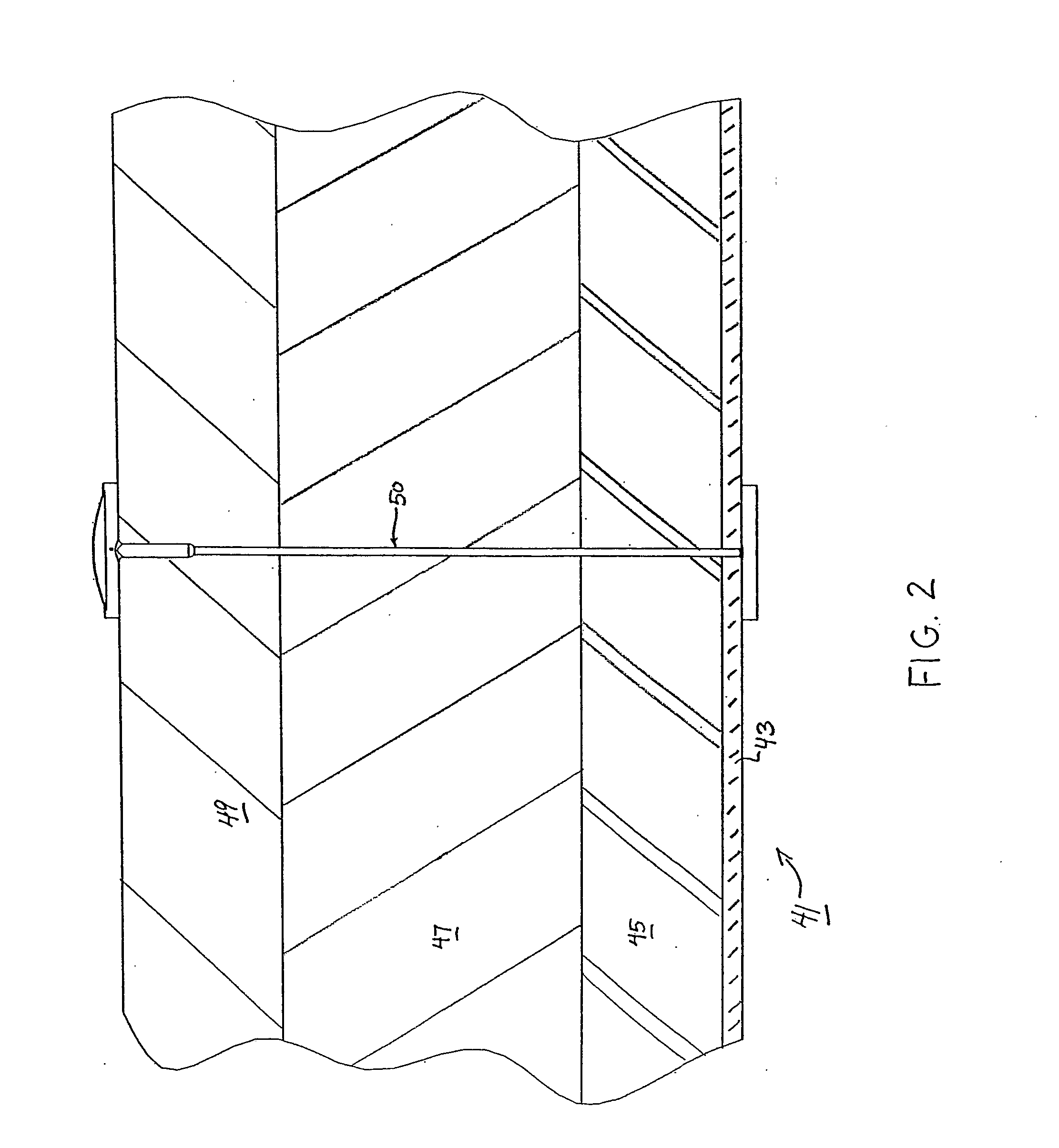

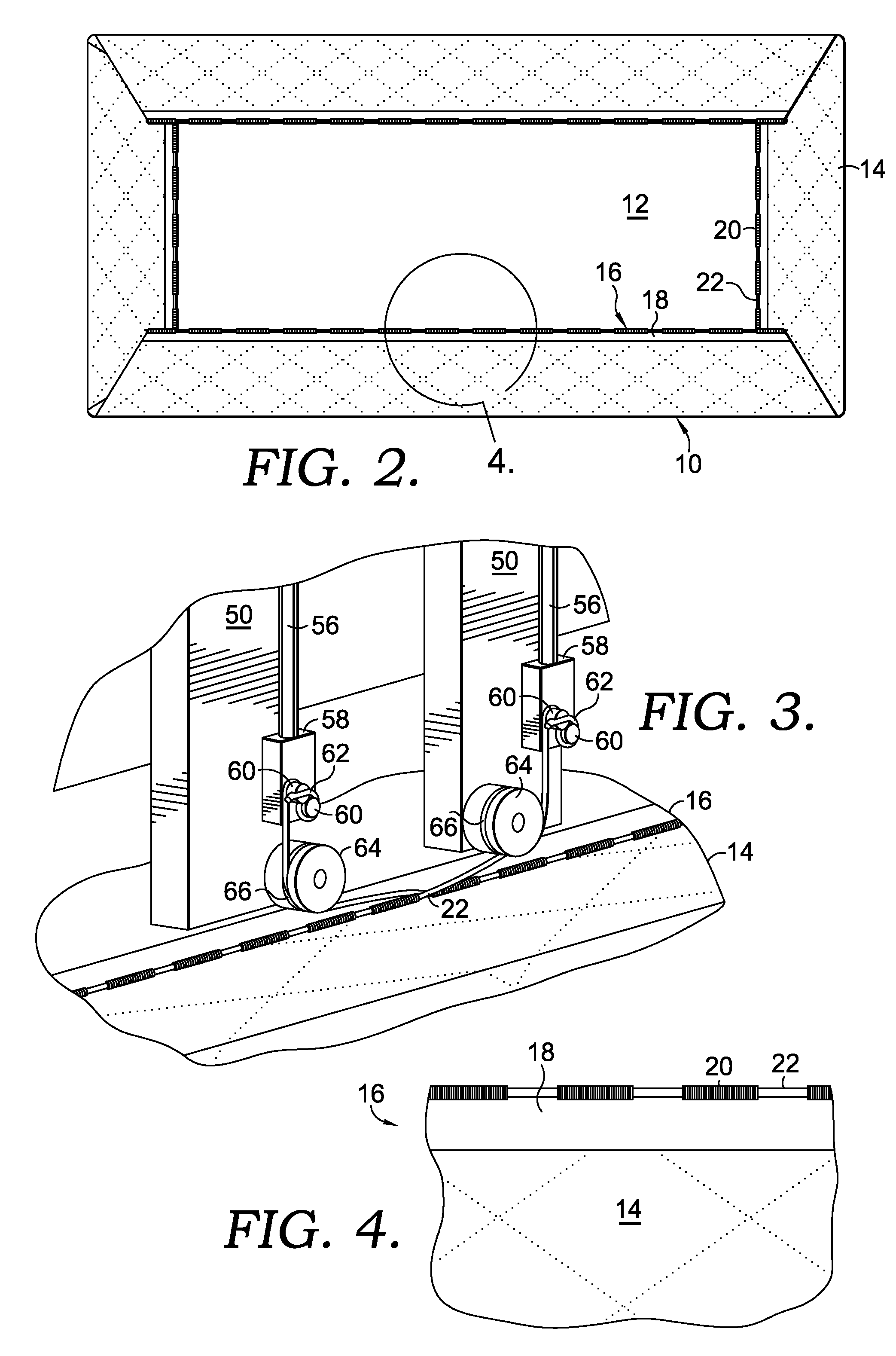

Apparatus and method for upholstering box springs

InactiveUS20100011553A1Upholstery manufactureUpholstery auxillary devicesEngineeringMechanical engineering

The present invention generally relates to an apparatus and a method used to upholster a box-spring frame. A textile tape with a portion encapsulating a draw cord is sewn to the inner perimeter of a border material. The other edge of the border material is sewn to a top cover material. The box-spring frame is placed within this assembly, with the top side of the frame abutting the top cover. This assembly is placed in the attachment apparatus. The attachment apparatus optionally compresses the box-spring frame and is equipped with a pair of tension applicators. Once in place, each of the two draw cord ends are secured to a corresponding tension applicator, and tension is applied to the draw cord. This tension tightens the border assembly edge around the frame. With the proper tension applied, the draw cord is secured to the box-spring frame. The bottom cover is then attached in the conventional manner with a series of staples.

Owner:L & P PROPERTY MANAGEMENT CO

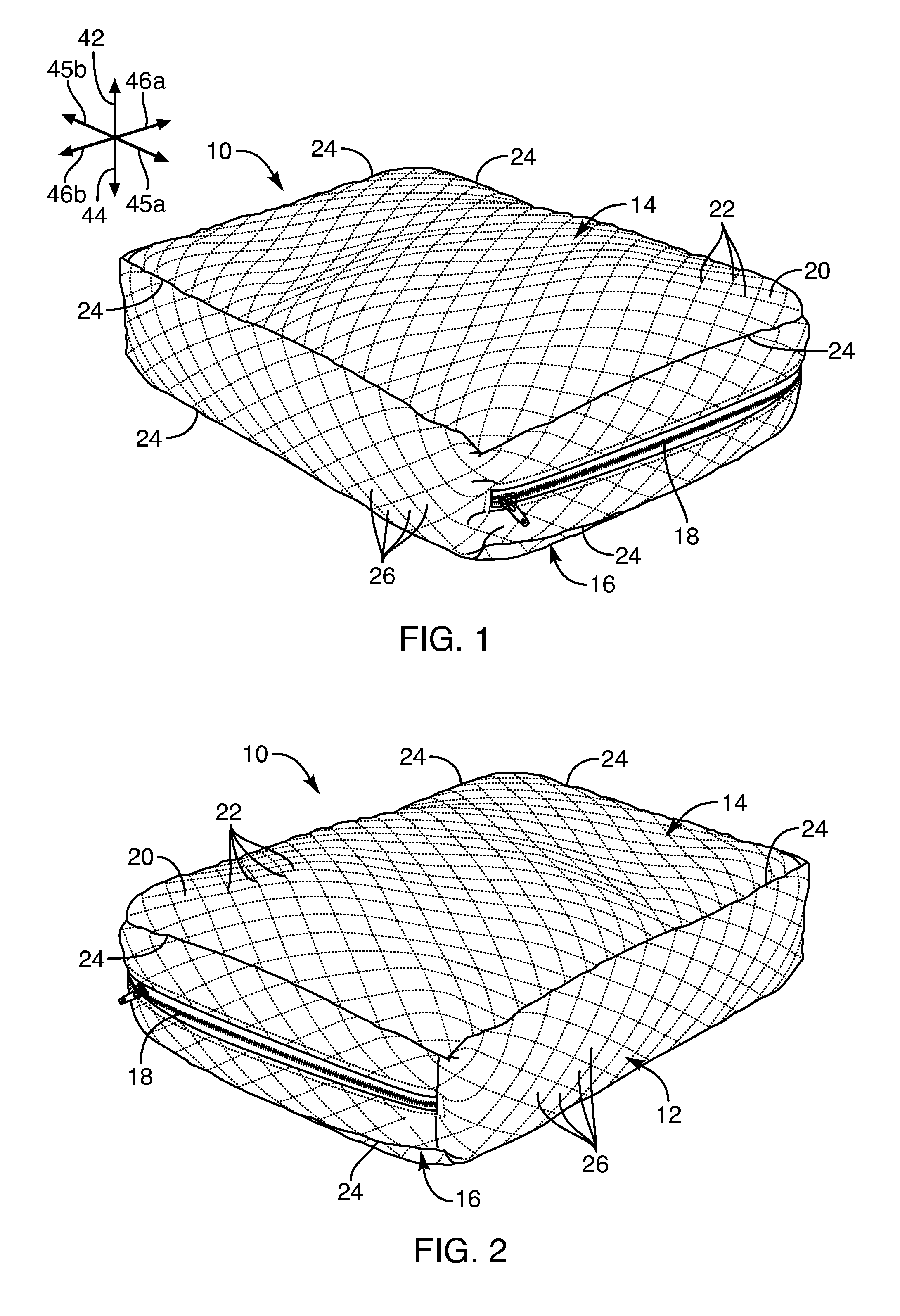

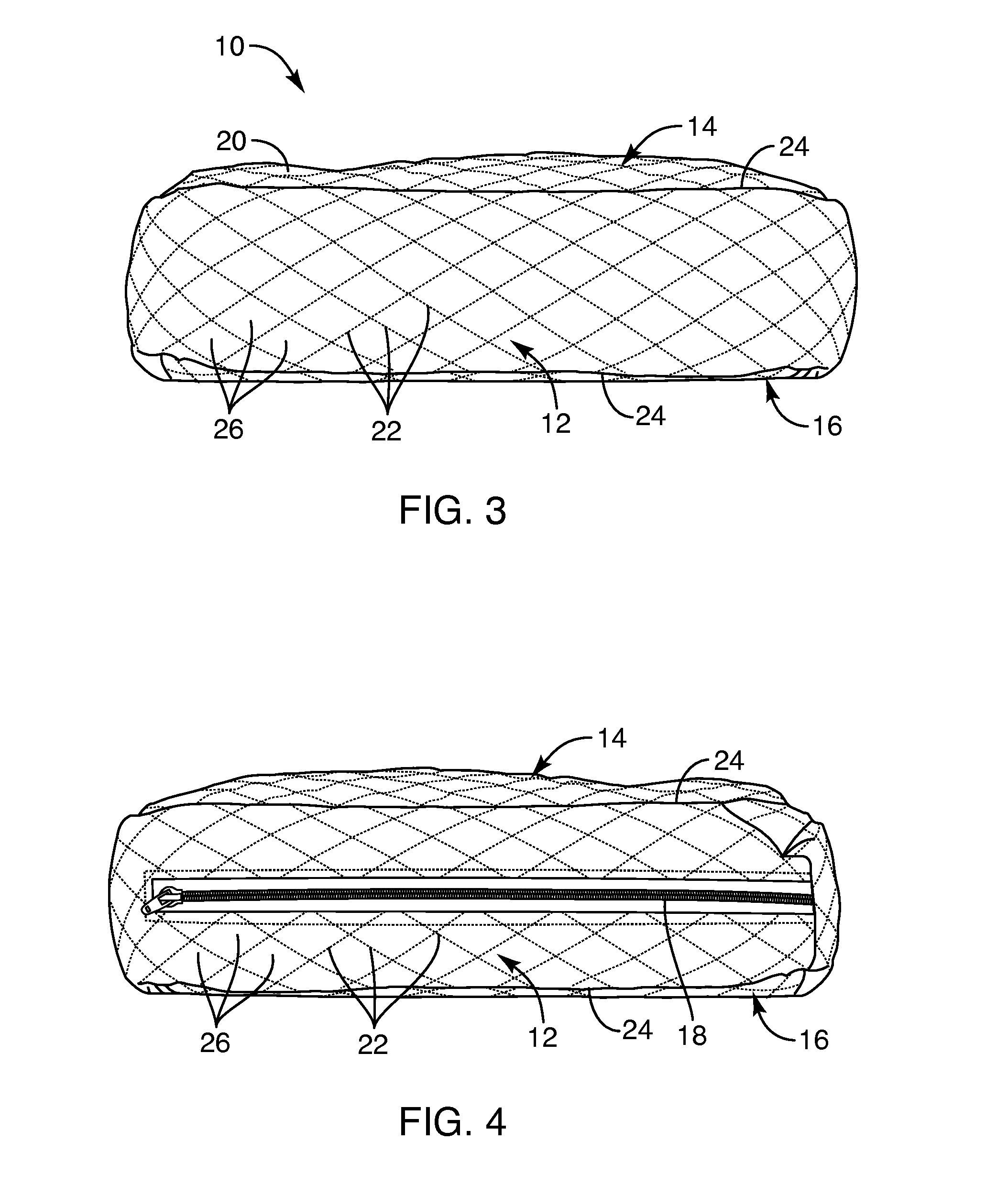

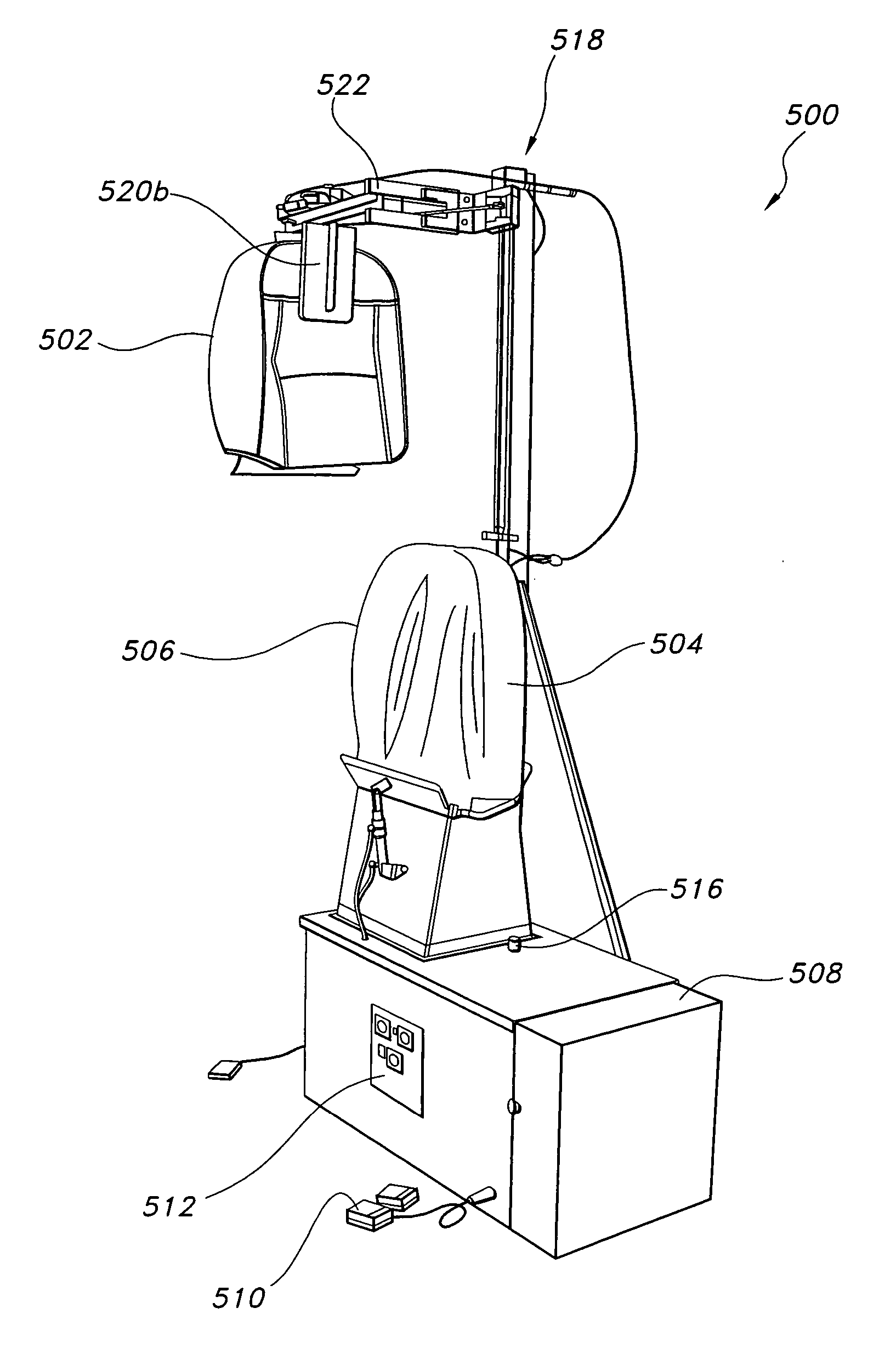

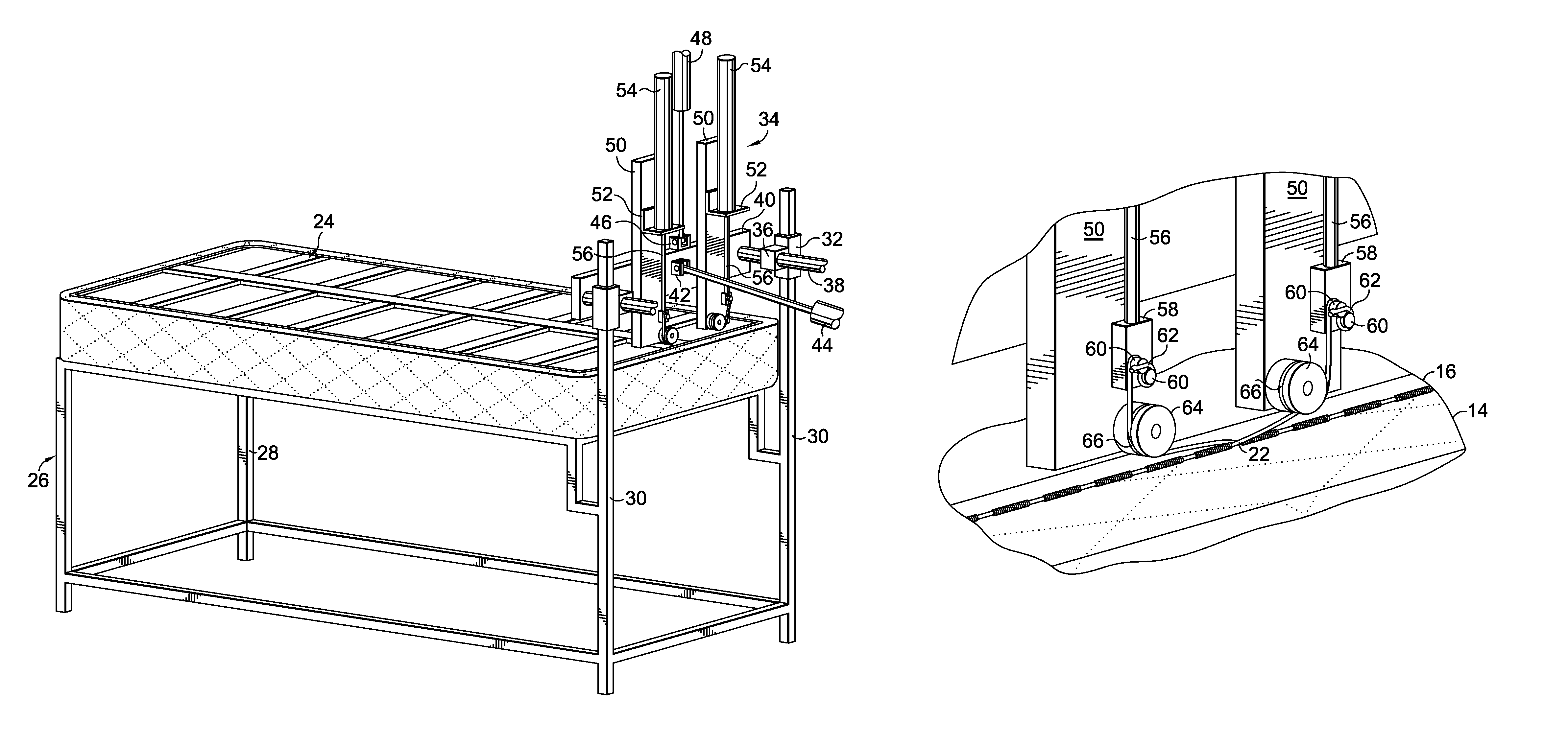

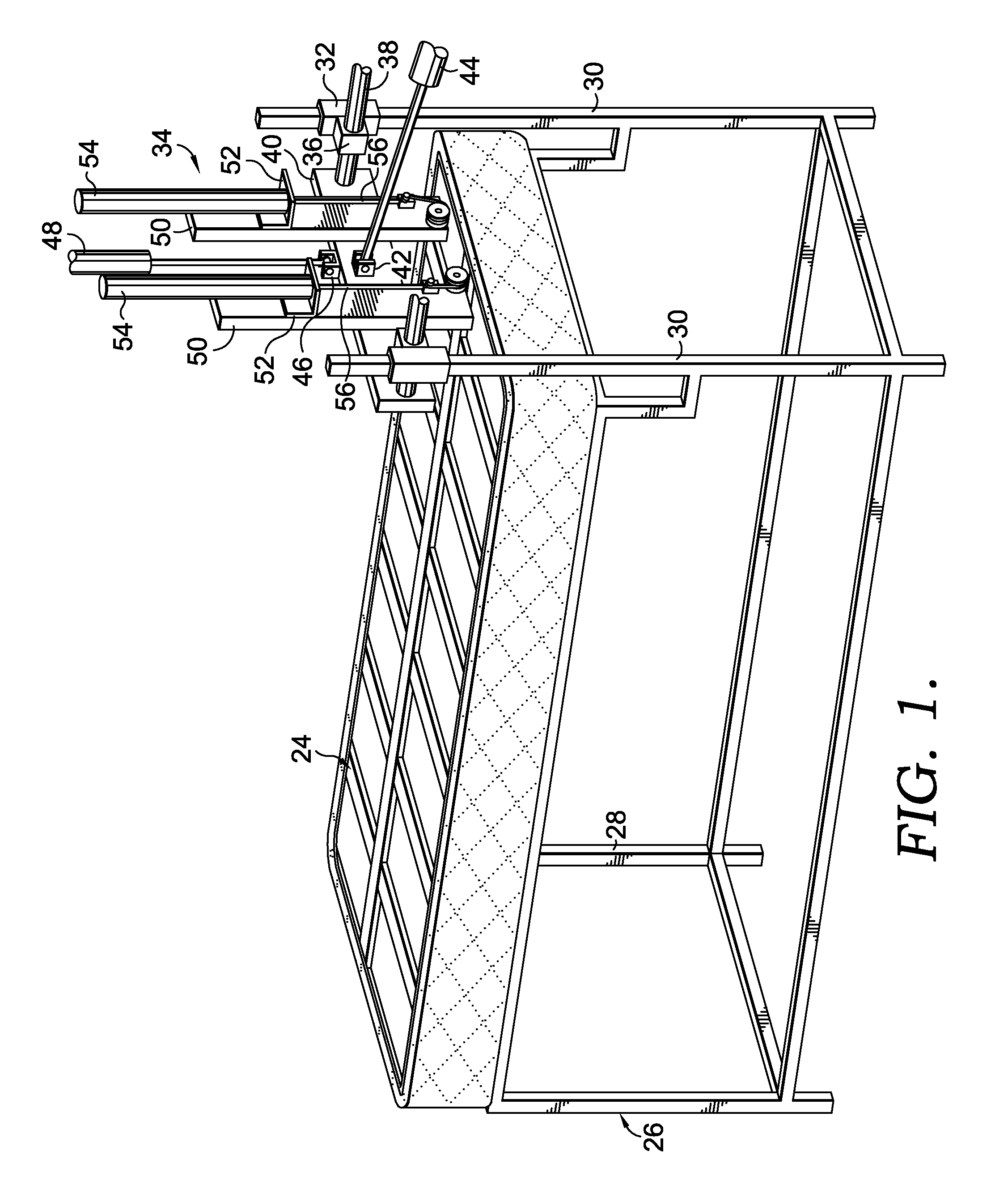

Methods, systems, and apparatus for finishing a vehicle seat component

InactiveUS20070137014A1Quality improvementUpholstery manufactureVehicle seatsEngineeringMechanical engineering

The present invention relates to methods, systems, and apparatus for finishing an upholstered component, such as a vehicle seat component. A finishing process is provided wherein undesirable features in the material of the seat component, such as wrinkles, creases, sewing pucker, marks, and the like, can be removed. Embodiments of the present invention can include an inflatable bag capable of receiving a seat component, a form area capable of receiving the inflatable bag, an air or gas system capable of inflating the inflatable bag, a tensioning system capable of providing a force on the form area, and a steam supply system capable of providing steam to the seat component mounted to a portion of the inflatable bag. A seat component removal system may be provided that can remove the seat component after the finishing process is complete.

Owner:VEIT BRISAY AMERICA

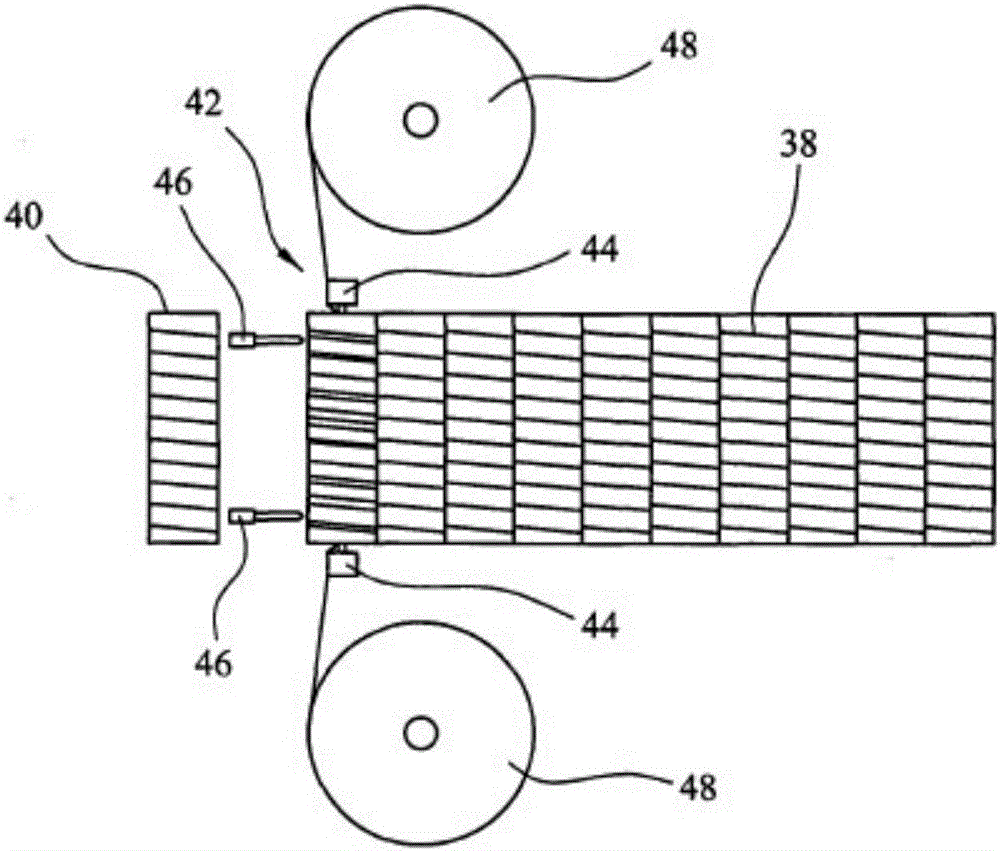

Elastomeric material application systems and methods

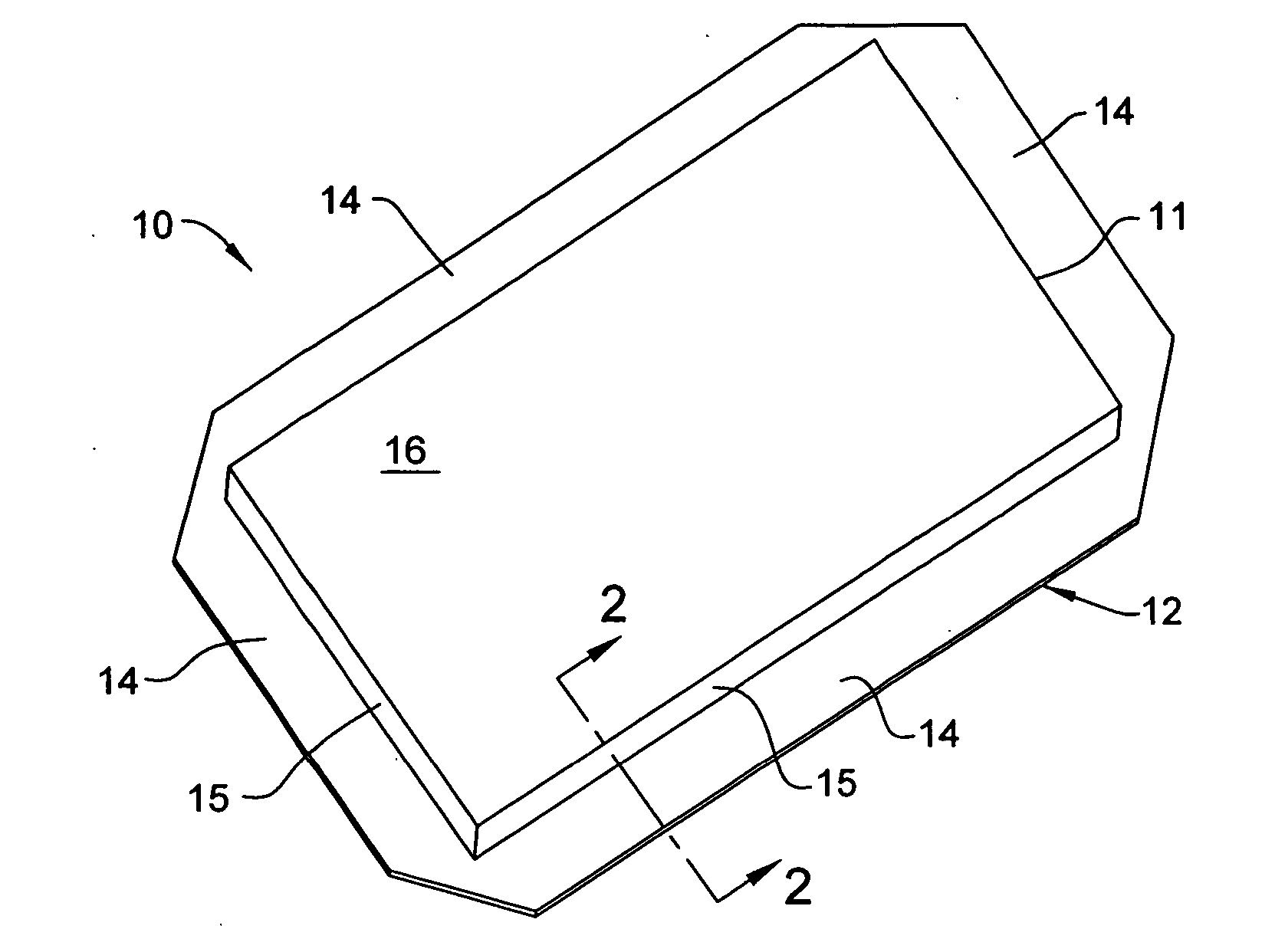

ActiveUS20050044678A1Efficient and effectiveApplied to materialUpholstery manufactureStuffed mattressesMechanical engineeringEngineering

A material application system for applying a panel of material to a framework with a shoe for retaining the framework, a nest, opposed mechanisms for retaining opposite portions of the panel of material traversing between the shoe and the nest, an arrangement for selectively moving the shoe and the nest into and out of an engaged position wherein the panel of material is sandwiched between the shoe and the nest and a disengaged position, and an arrangement for inducing an attachment of the panel of material to the framework. The opposed mechanisms can be clamping mechanisms, which can be segmented and individually moveable to enable variable pretensioning. A contoured deflection control member can alternatively produce variable pretensioning. A pressing arrangement with a tooth member can press a locking spline into a groove in the framework to secure the material.

Owner:CVEK SAVA

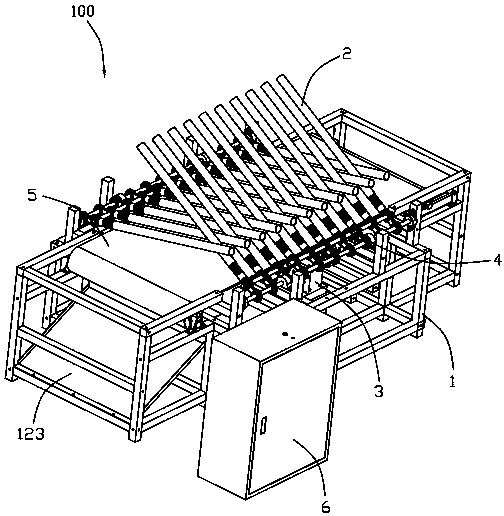

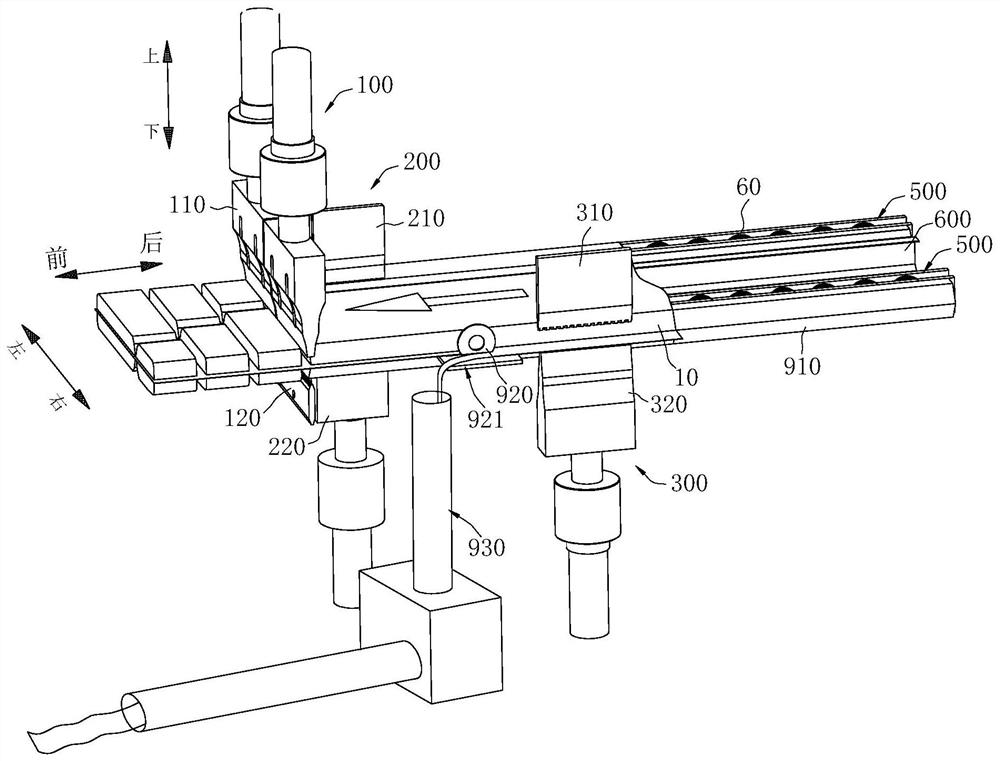

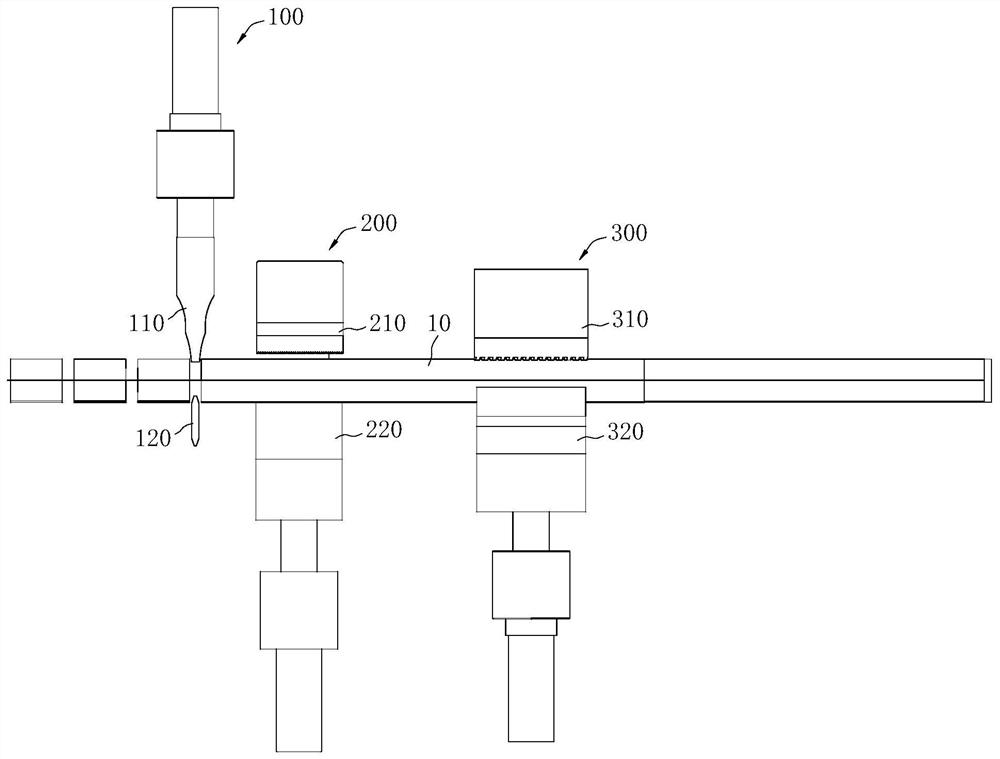

Sewing technology of sewn products, processing equipment and sewn products processed by processing equipment

PendingCN113089189AWon't spread outWon't fall apartUpholstery manufactureSleeping rugProcess equipmentProcess engineering

The invention discloses a sewing technology of sewn products, processing equipment and a sleeping bag, a bag or a garment processed by the processing equipment. The sewing technology and the processing equipment realize integrated operation of a plurality of procedures of cutting, alignment, quilting / compounding, edge sealing and the like, realize automatic, mechanical, batched, continuous, uninterrupted, low-cost, efficient, high-controllability and high-consistency flow line production, solve the problems that a large number of skilled sewing workers are needed for production of sleeping bags, bags or garments, manual operation is low in production efficiency and the like, and have a good application prospect and a wide application range.

Owner:宁波甬畅国际贸易有限公司

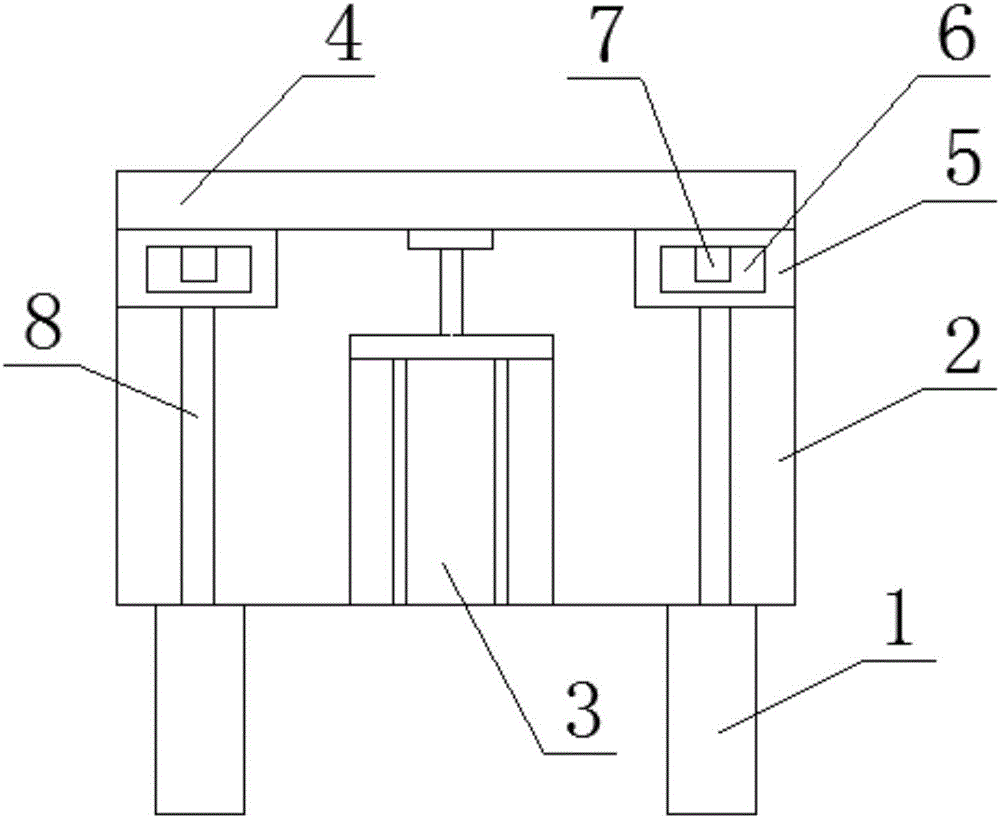

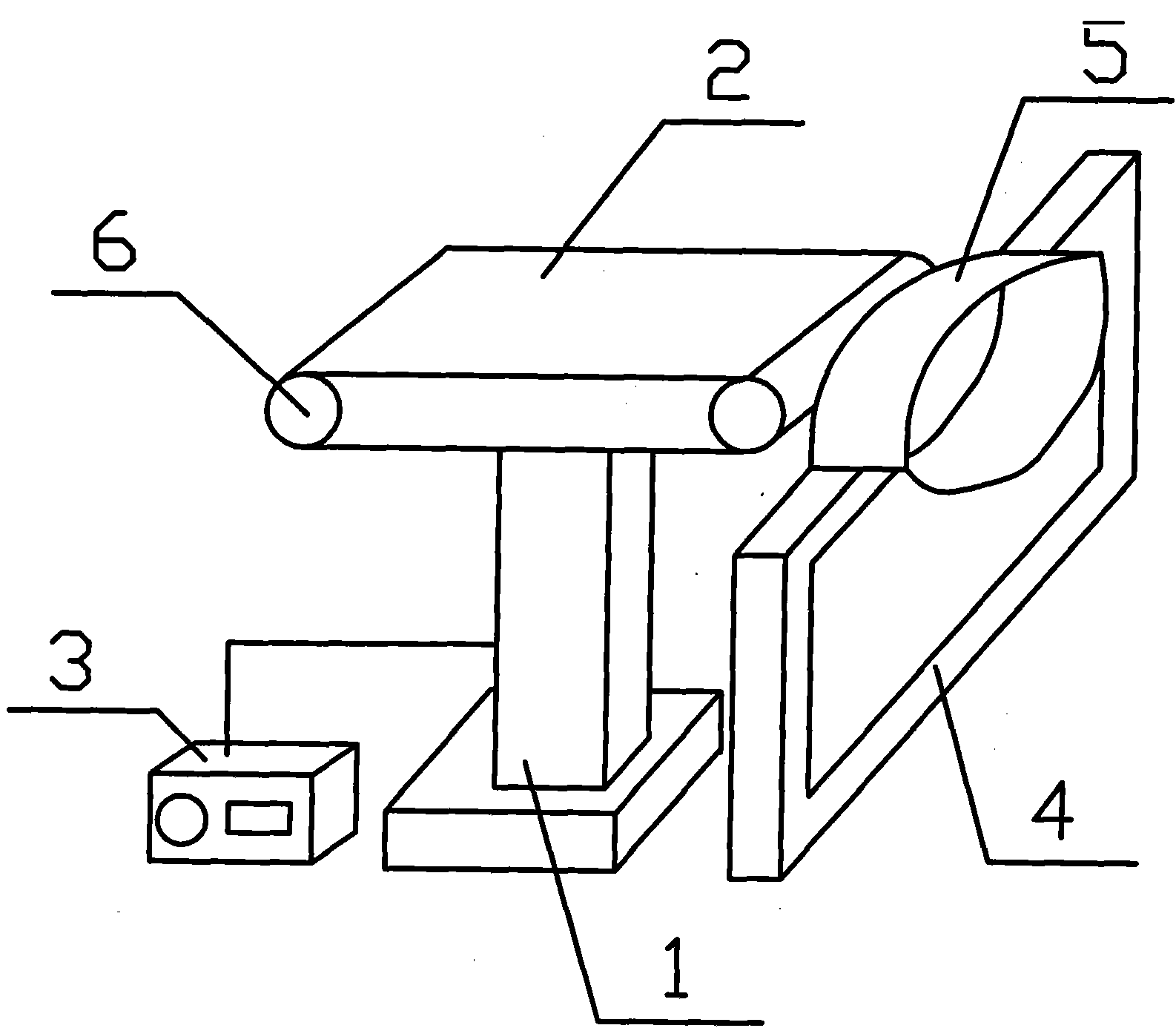

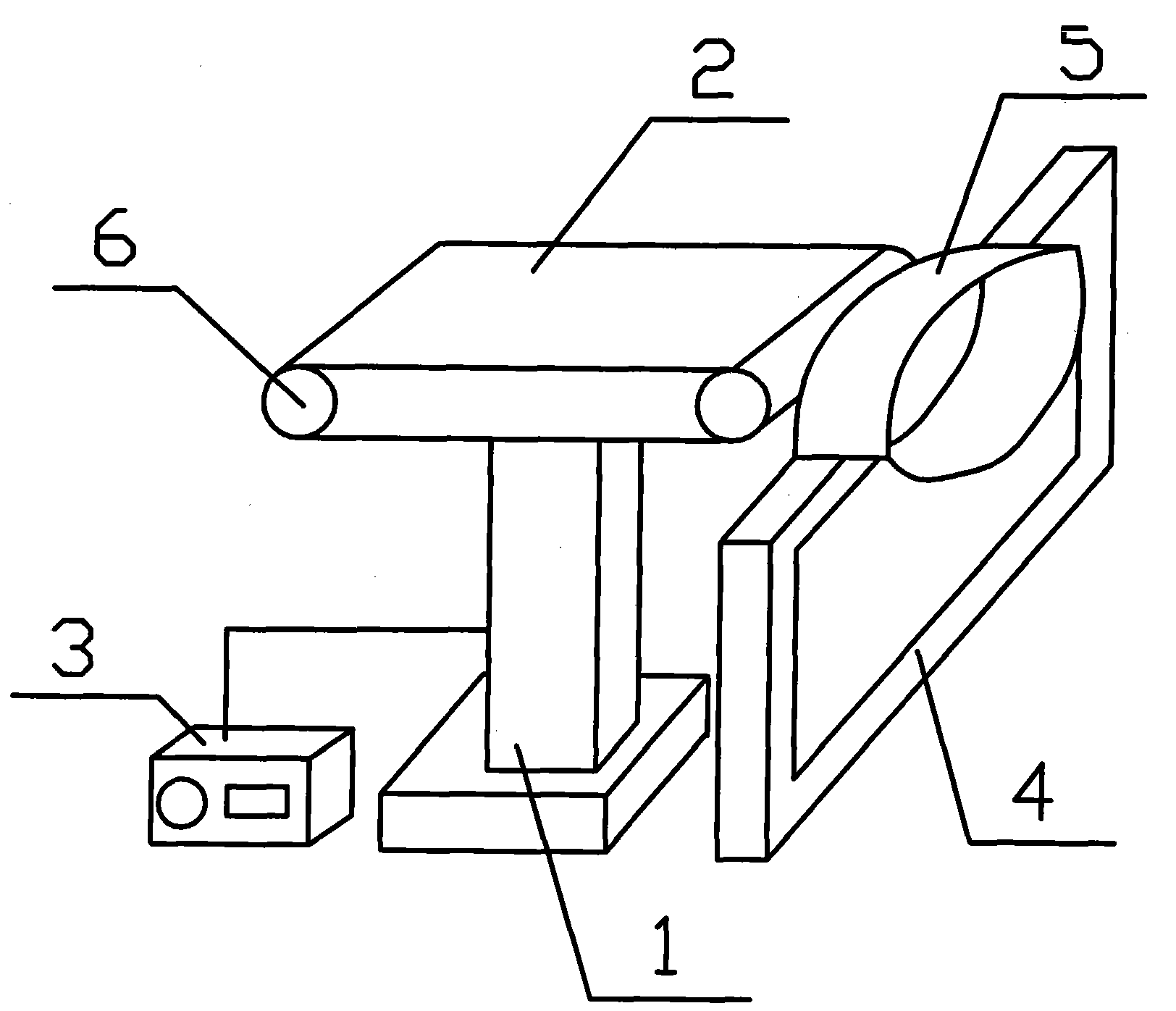

Device for quickly filling headrest cover with headrest foam

InactiveCN104692316ANo damageReduce work intensityUpholstery manufactureUpholstery auxillary devicesHeadrest coverEngineering

The invention discloses a device for quickly filling a headrest cover with headrest foam and relates to a device for filling of a headrest cover on an automobile seat. The device comprises a worktable, a left cylinder, a right cylinder, a left side fixing plate, a right side fixing plate, a left headrest foam pressing plate, a right headrest foam pressing plate, a lower pushing cylinder and a lower pushing plate, wherein the left side fixing plate and the right side fixing plate are arranged on the worktable and are positioned on two opposite sides of a through hole; the left cylinder and the right cylinder are arranged on the left side fixing plate and the right side fixing plate respectively; a lower pushing rod is connected to the lower pushing plate; a left pushing rod is connected to the left headrest foam pressing plate; a right pushing rod is connected to the right headrest foam pressing plate; left guide posts are arranged on two sides of the left cylinder; right guide posts are arranged on two sides of the right cylinder; lower guide posts are arranged on two sides of the lower pushing cylinder. Through the adoption of mechanical action and pneumatic control, the damage to the foam is avoided; the pollution to the cover is avoided; the working efficiency is improved; the working strength of workers is reduced; the manpower resources are saved; the headrest cover is relatively high in consistence of appearance and shape.

Owner:广西双英集团股份有限公司

Separating components of a pocket sprung mattress sub-assembly

Components of a pocket-sprung-mattress sub-assembly having individual metal springs retained within a matrix of fabric pockets are separated. A rotatable tearing drum 405 is driven by a drive motor 406. Tearing devices 407 are arranged to pull metal springs from a pocket-sprung-mattress sub-assembly during the rotation of the tearing drum 405. A feeding assembly 408 compressors an end portion of the mattress sub-assembly and moves this end portion continually to bring an end of the mattress sub-assembly into contact with the rotating tearing devices 407.

Owner:THE FURNITURE RECYCLING GRP LTD

Pat-scattering machine

The invention provides a pat-scattering machine which is provided with a support, a pat mechanism movably fixed on the support, a driving motor for driving the pat mechanism to work and a transmission mechanism arranged between the driving motor and the pat mechanism. The driving motor drives the pat mechanism to pat down and feather filled products, down and feather arranged in the down and feather filled products are pat to be scattered, each cutting part of the down and feather filled products is evenly filled with the down and feather, and the comfort degree of the down and feather filled products is improved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

Method for manufacturing enhanced foam thermoplastic products

By providing a unique product enhancing step which enables any desired section, portion, or element of a product being produced to be treated in a manner to provide desired enhanced physical, structural, and / or aesthetics characteristics, a new, fully integrated enhanced foam manufacturing system is attained which is capable of producing virtually any desired foam product, with each product incorporating any desired area or zone being formed with a particular physical, structural, and / or aesthetic property, characteristic, or enhancement. In addition, in accordance with the teaching of the present invention, any desired cross-sectional shape or configuration is capable of being manufactured in fully automated, high volume, rapid production conditions, with virtual ease and simplicity, with a specific physical, structural, or aesthetic property incorporated therein.

Owner:NOMACO

Spreading machine

InactiveCN106629569ARetraction speed adjustmentStretching saves time and effortUpholstery auxillary devicesData displayEngineering

The invention relates to a spreading machine which comprises a bracket, a mounting seat, a cylinder and a moving rod, wherein the mounting seat is fixedly arranged at the upper end of the bracket; the cylinder is arranged on the mounting seat and vertically attached to the end face of the mounting seat; the moving rod is arranged at the edge of the upper end of the mounting seat; an output shaft of the cylinder is fixedly connected with the moving rod; the output shaft of the cylinder stretches to drive the moving rod to be attached to the end face of the mounting seat so as to vertically move; slide blocks are arranged on the lower sides of two ends of the moving rod; clamps used for clamping cloth are arranged on the two slide blocks; tension sensors used for detecting cloth tension are arranged on the two clamps and used for performing data display on the detected tension. Compared with the prior art, the spreading machine disclosed by the invention has the advantages that the spreading efficiency can be improved, the operating difficulty is reduced, and the spreading quality is guaranteed.

Owner:柳州市代代福针织服装有限公司

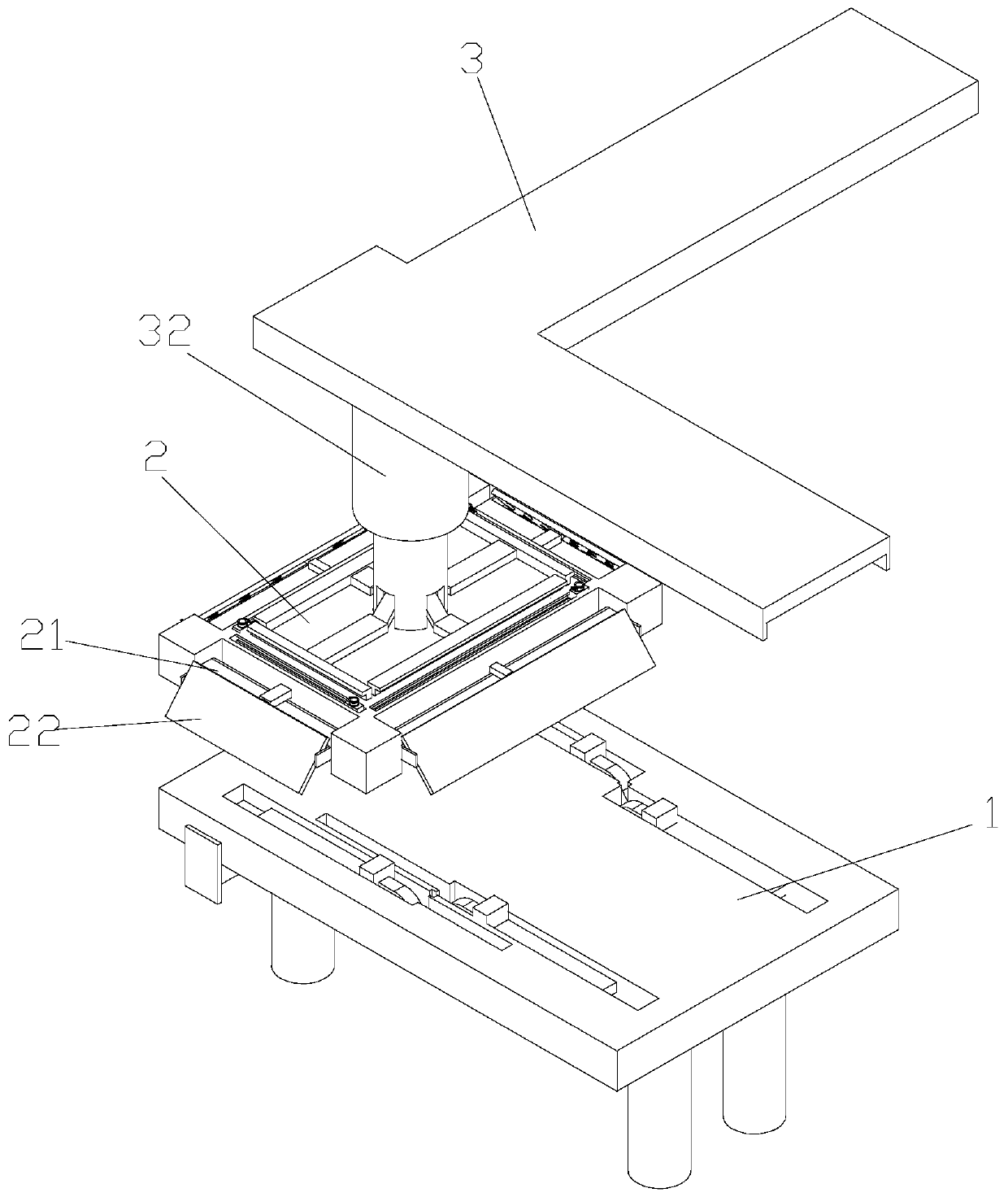

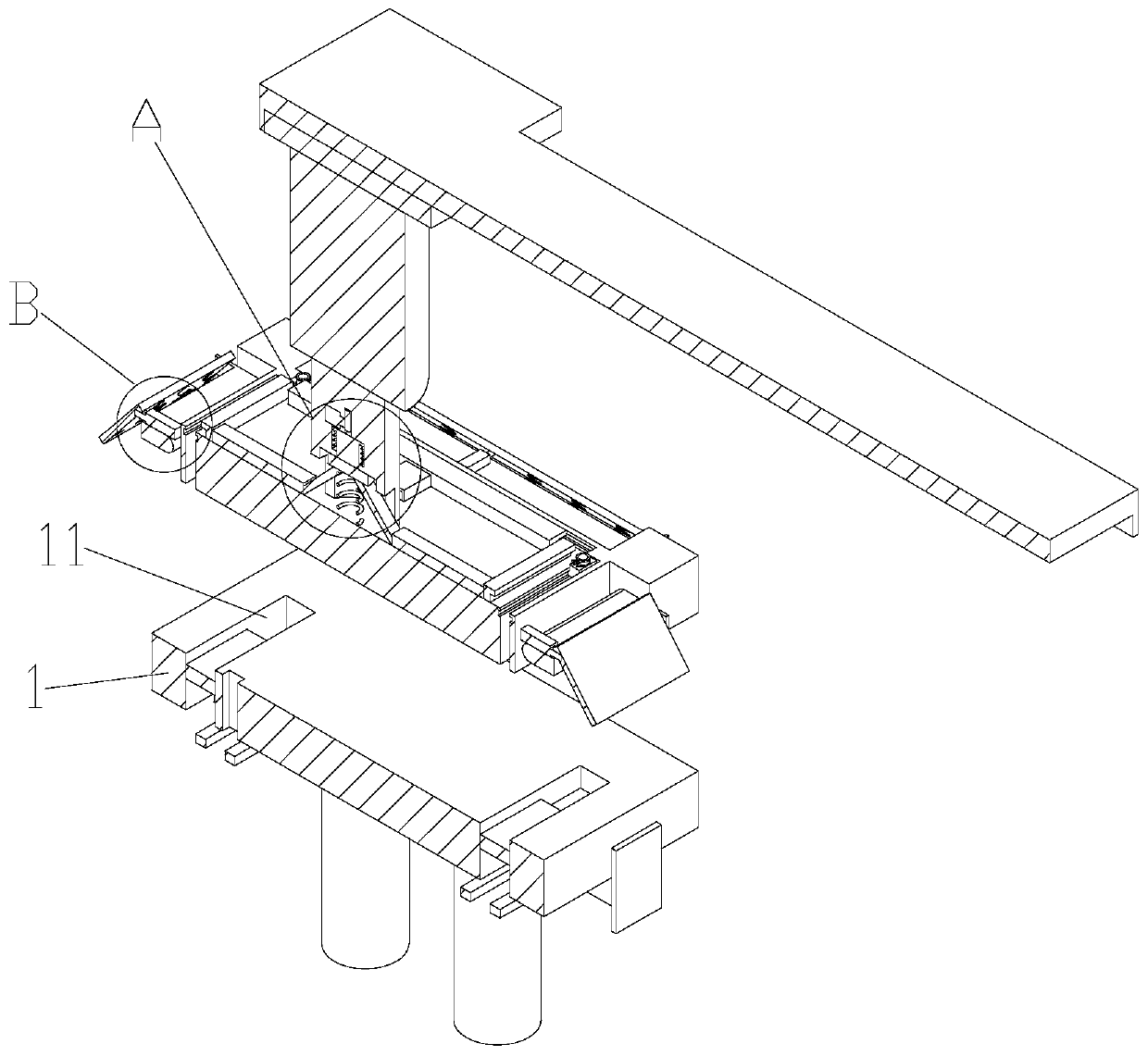

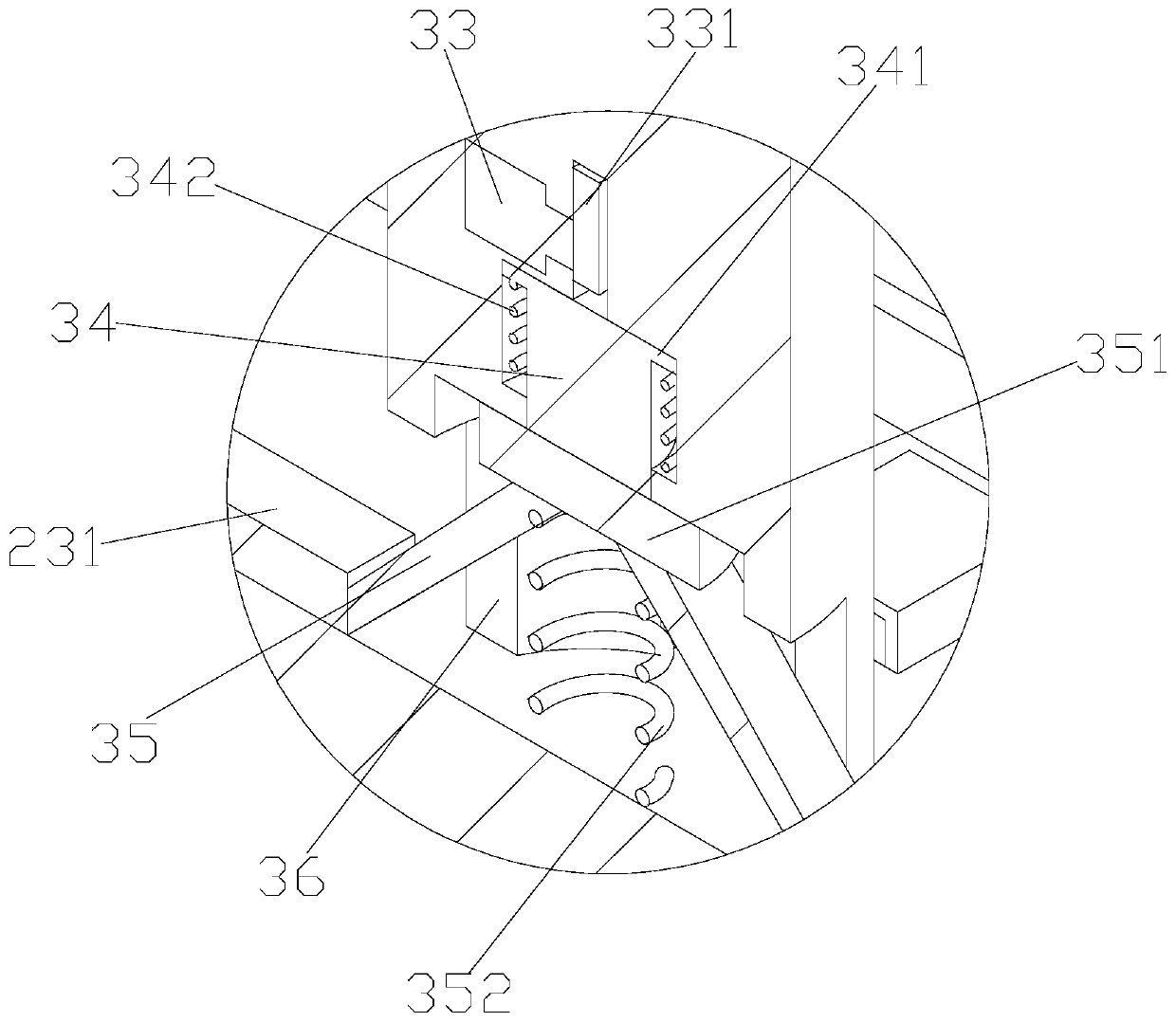

Multi-layer bagged spring string welding device, manufacturing method and bagged spring cushion manufacturing equipment

ActiveCN112674545AAvoid swingingStuffed mattressesUpholstery auxillary devicesMechanical engineeringIndustrial engineering

The invention discloses a multi-layer bagged spring string welding device, a manufacturing method and bagged spring pad manufacturing equipment, and the multi-layer bagged spring string welding device comprises a second welding module, at least one first welding module, at least one first driving mechanism and at least two spring conveying mechanisms arranged at intervals, cloth is folded and wrapped on the spring conveying mechanism to move, the first welding module is driven by the first driving mechanism to move gradually in the length direction of the containing cavity, the position of the first welding module is adjusted, the first welding module welds the cloth to form a separation joint, and the containing cavity is divided into at least two layers of first cavities. Cloth is welded through the second welding module, so that the cloth forms spaced containing cavities, the positions of the separation joints are gradually changed along with movement of the cloth, and therefore manufacturing of the multilayer bagged spring string with the intervals continuously and gradually changed is achieved, and the method is used for the technical field of bagged spring cushion production and manufacturing.

Owner:GUANGZHOU LIANROU MACHINERY & EQUIP

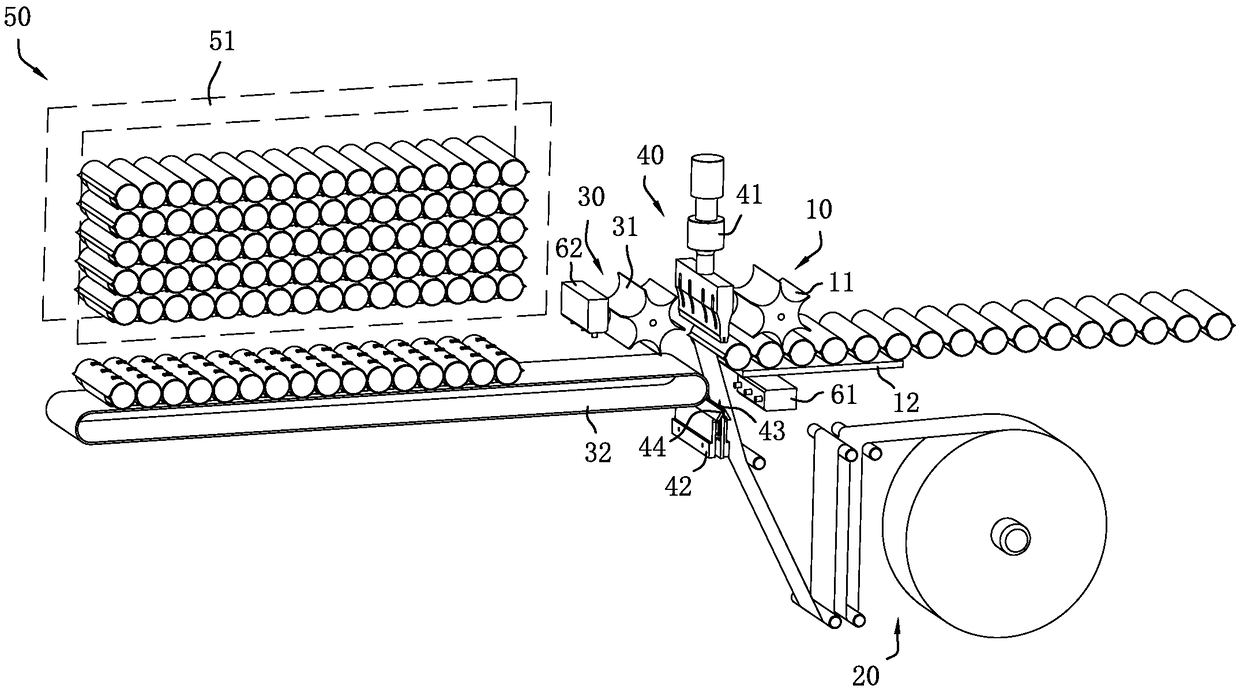

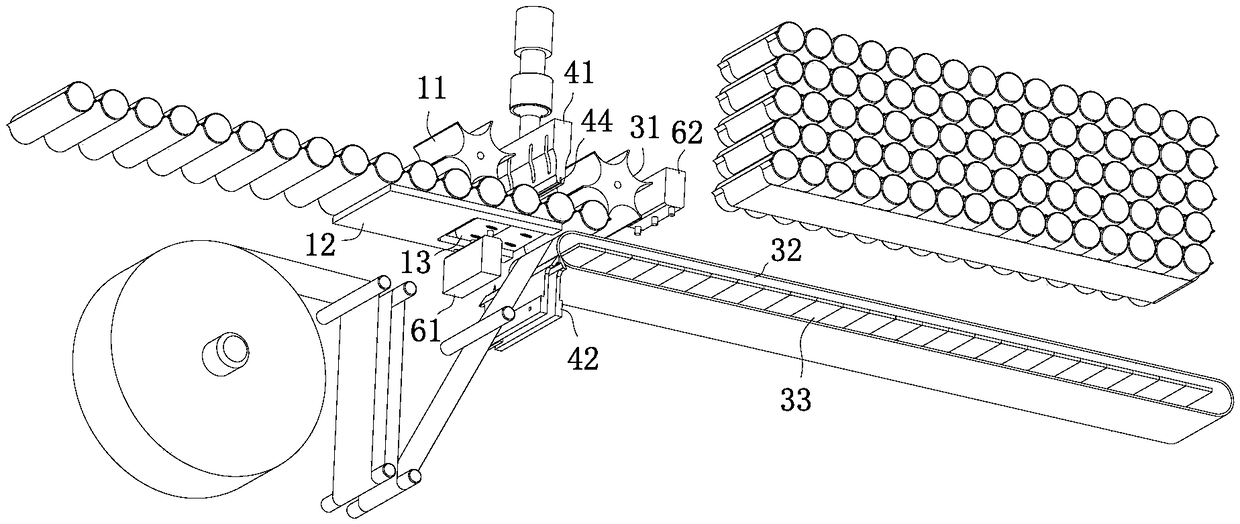

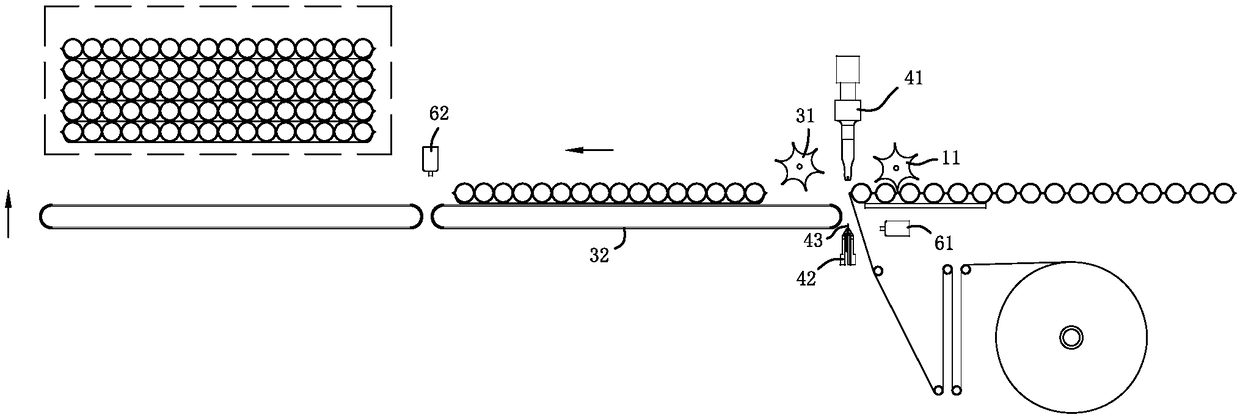

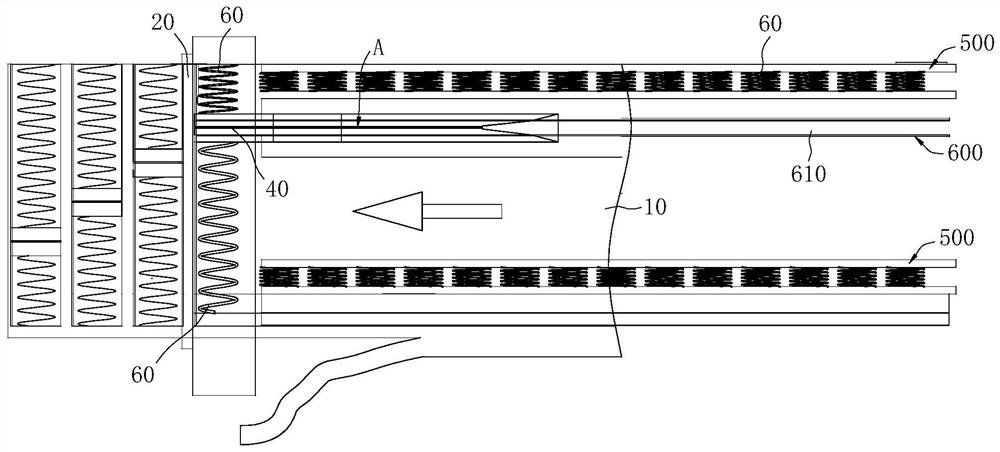

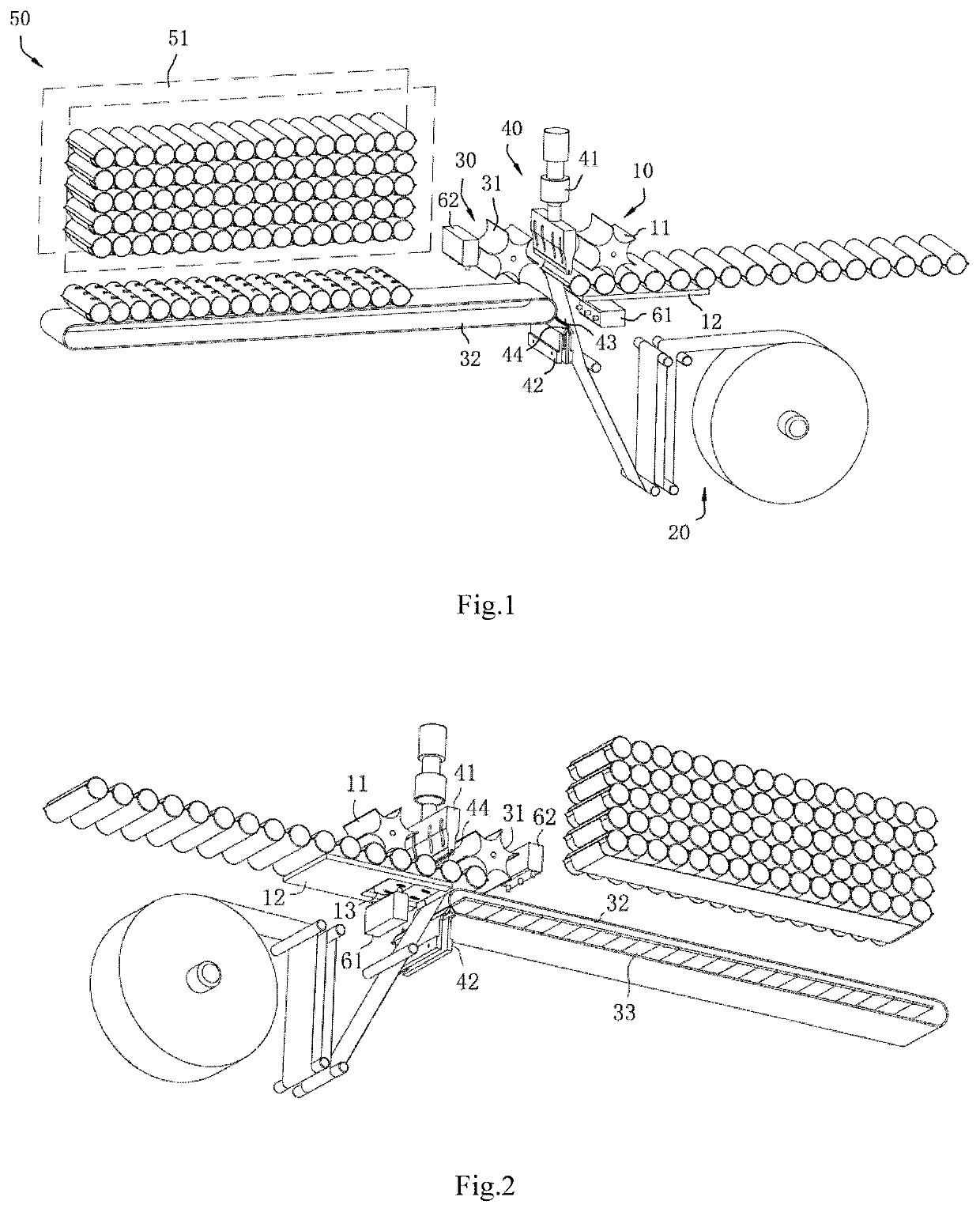

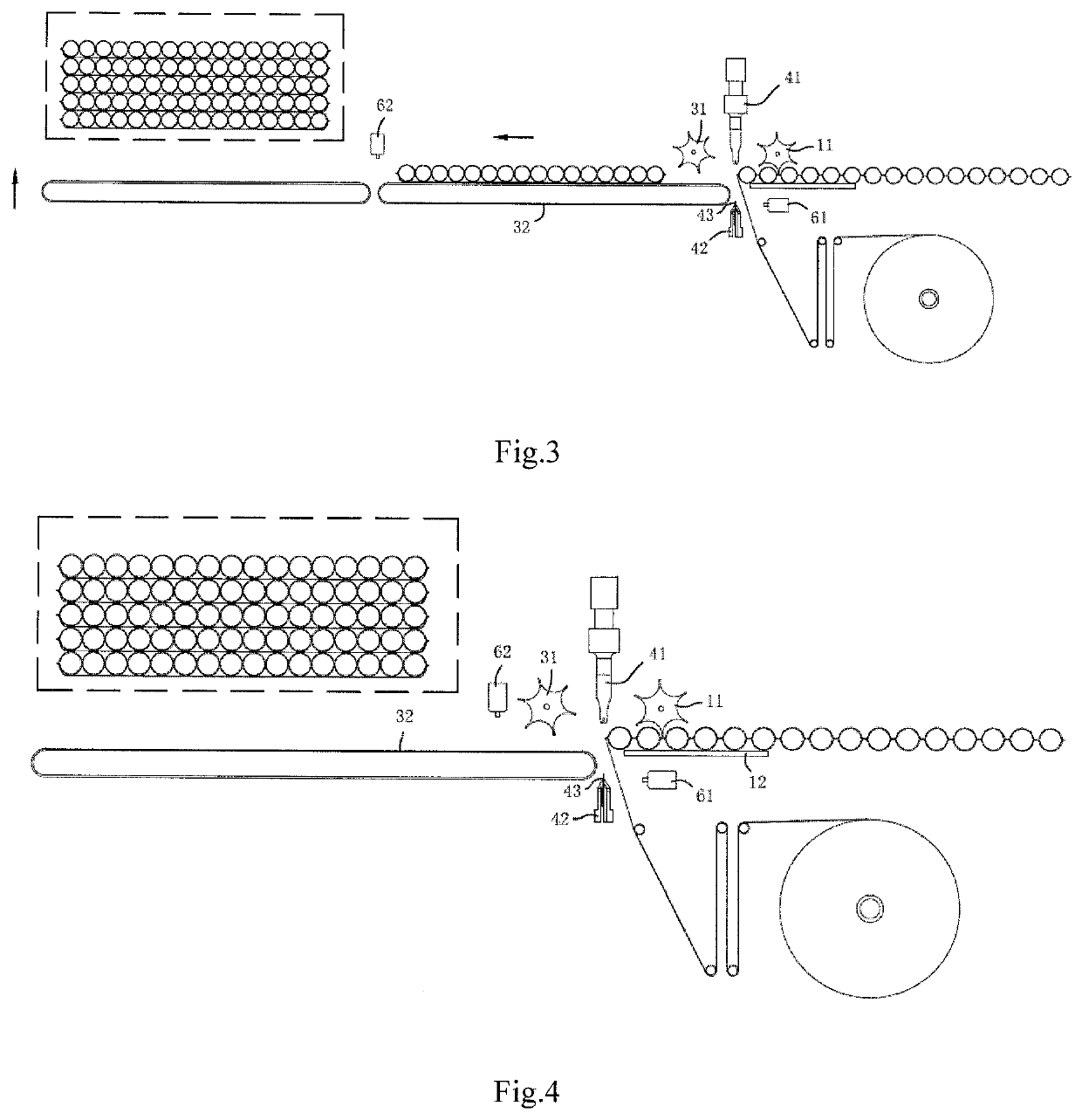

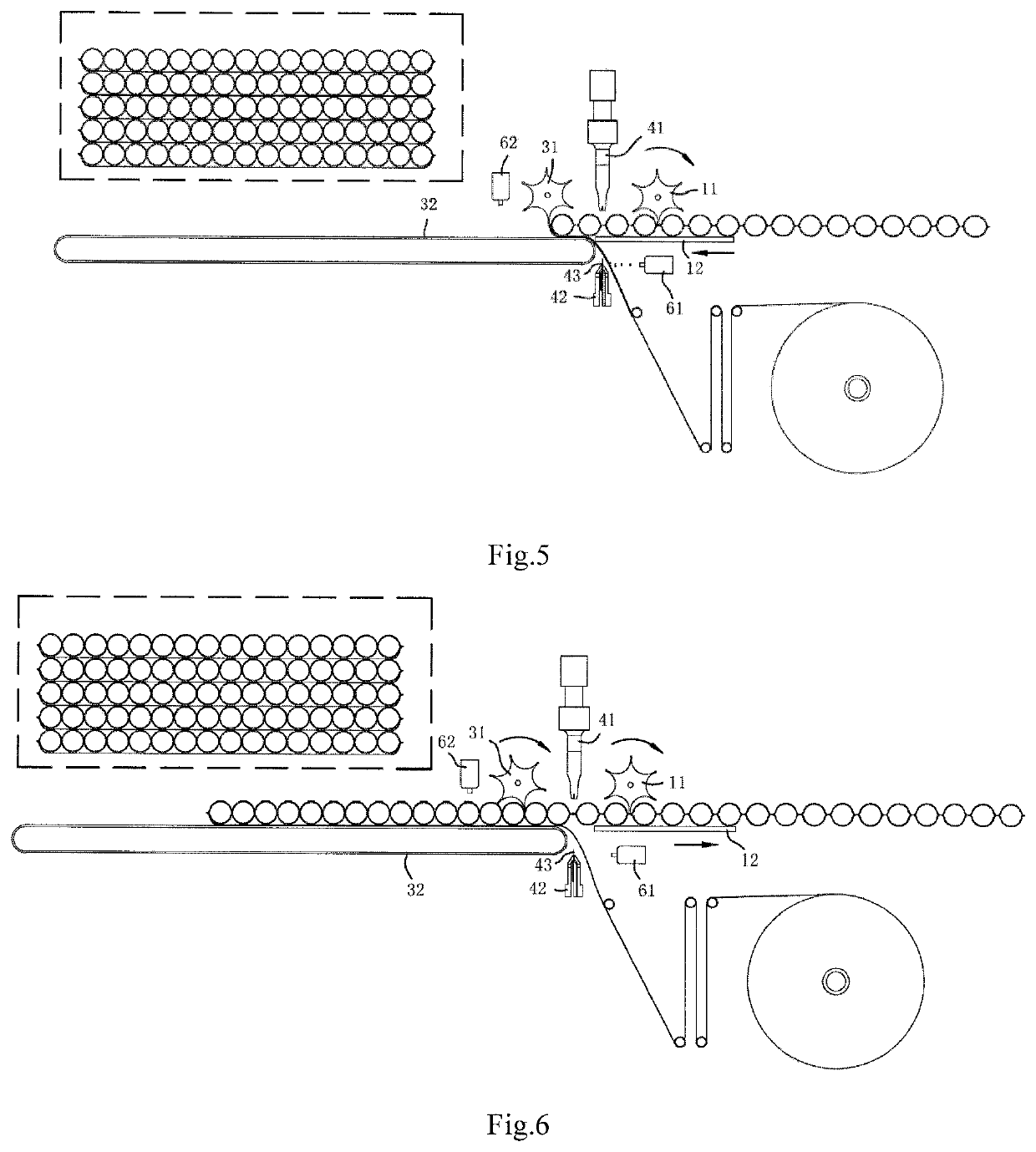

Bagged spring bed core with side connected to strip-shaped material and manufacturing device and method thereof

InactiveUS20200198961A1Good dimensional stabilityIncreased durabilityUpholstery manufactureStuffed mattressesStructural engineeringMechanical engineering

Disclosed are a bagged spring bed core with a side connected to a strip-shaped material and a manufacturing device and method thereof. The bed core is formed by arranging and bonding bagged spring strings connected to a strip-shaped material. The device includes a string feeding mechanism, a feeding mechanism, a tidying mechanism, and a sealing and cutting mechanism. The sealing and cutting mechanism cuts off the bagged spring string and the strip-shaped material to form bagged springs connected to the strip-shaped material. By bonding the strip-shaped material, the bagged spring string is no longer easily elongated or shortened by the action of an external force, so that the finally formed bagged spring bed core has good dimensional stability and can be compressed and coiled for packaging. Moreover, the strip-shaped material is provided between adjacent bagged spring strings in the bed core, so that the bed core has better durability.

Owner:GUANGZHOU LIANROU MACHINERY & EQUIP

Method for manufacturing a suspension mat

Owner:FICO CABLES LDA (PT)

Mattress material removal device

ActiveUS8286337B2Easy to disassembleUpholstery manufactureAutomatic control devicesMaterial removalEngineering

Owner:MILLS LUKE

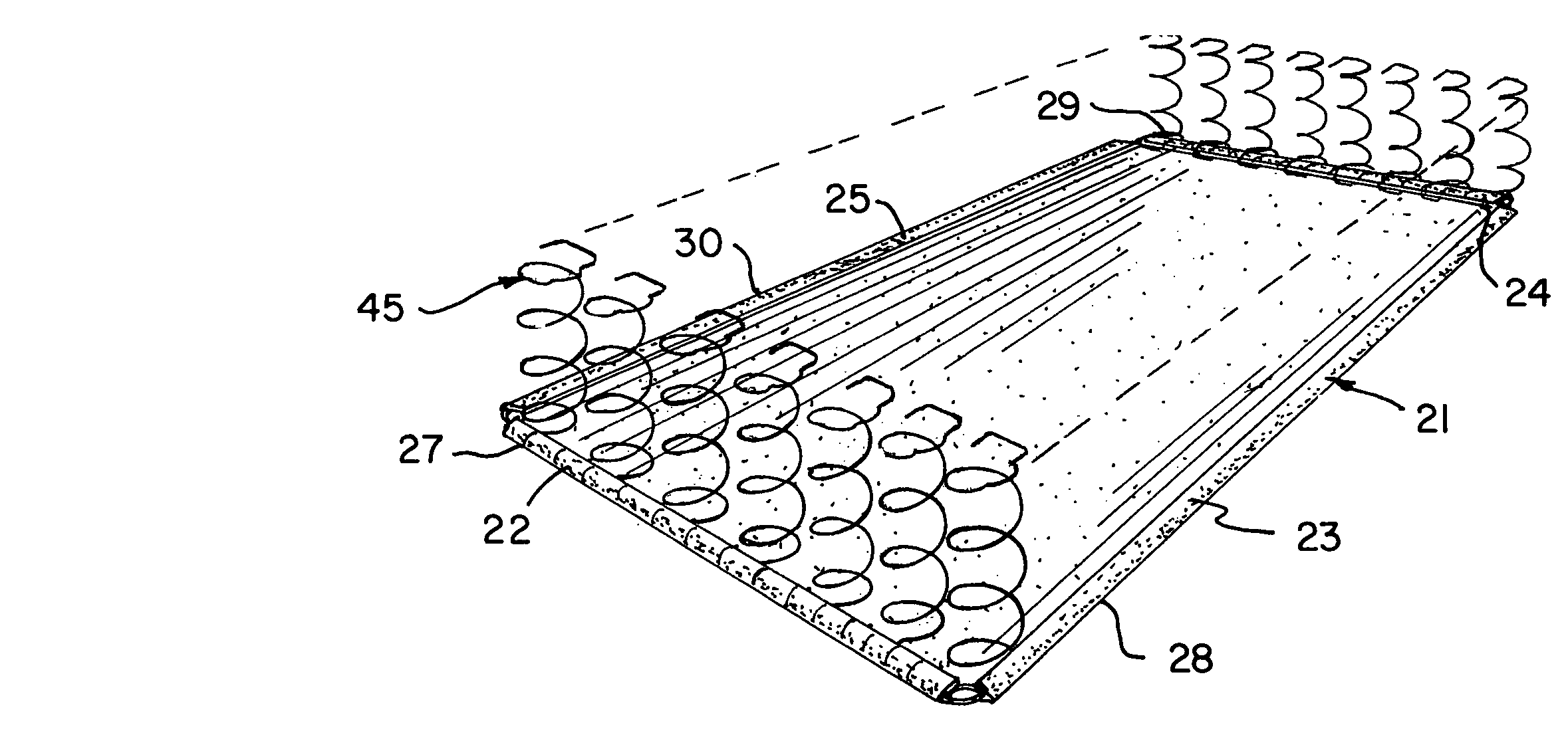

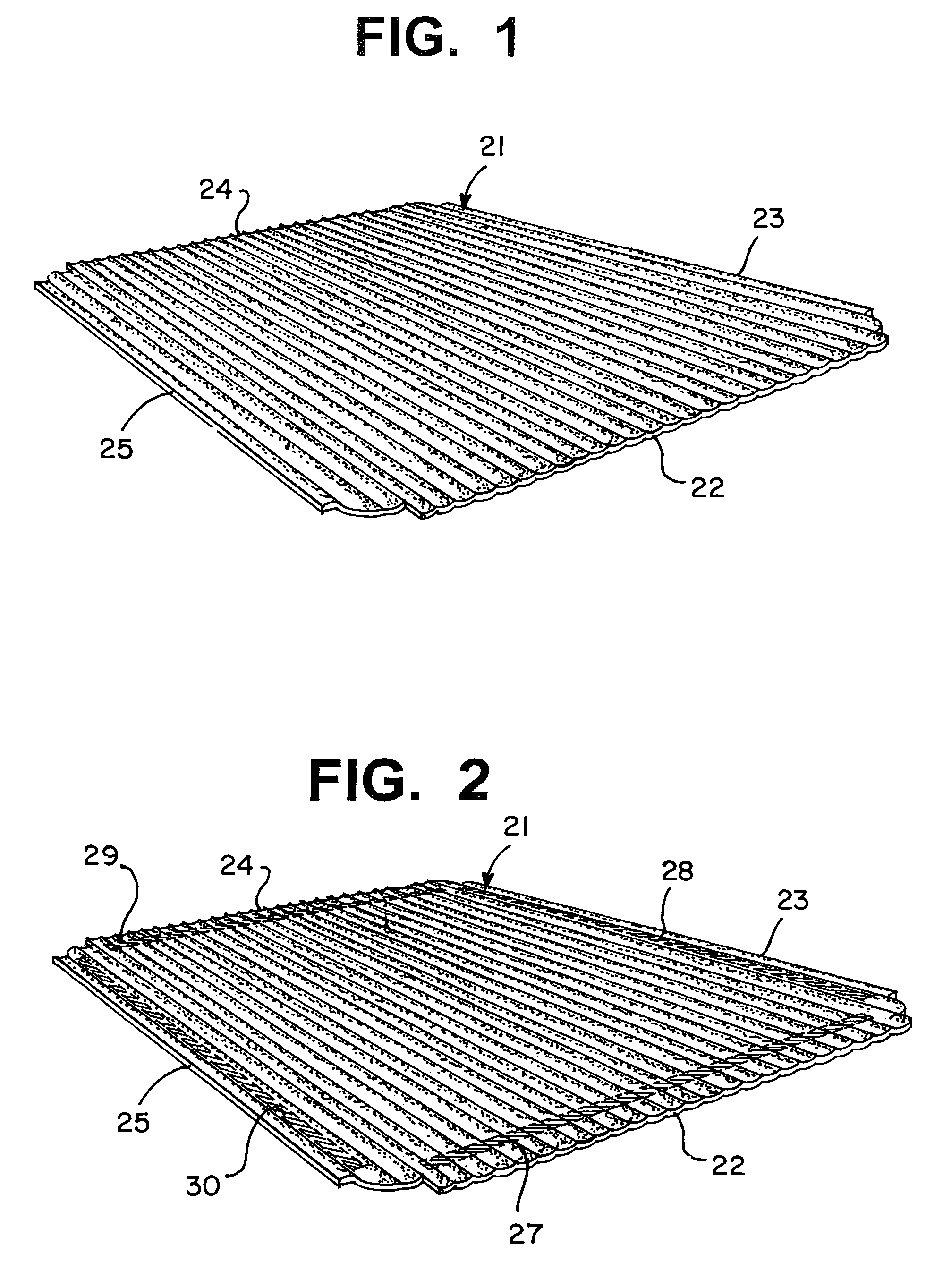

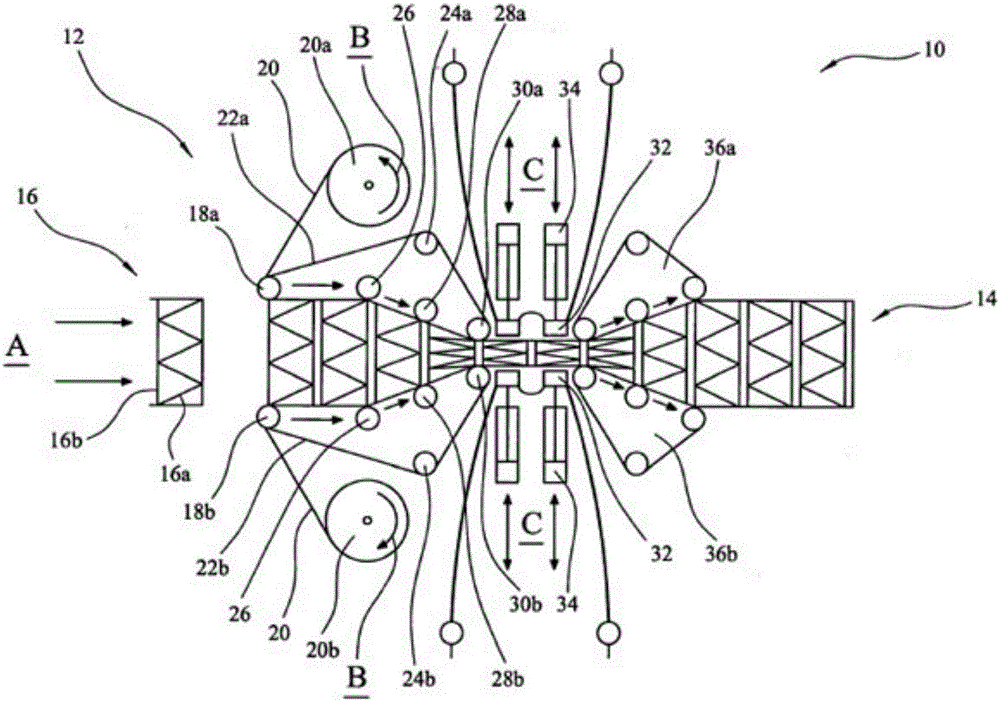

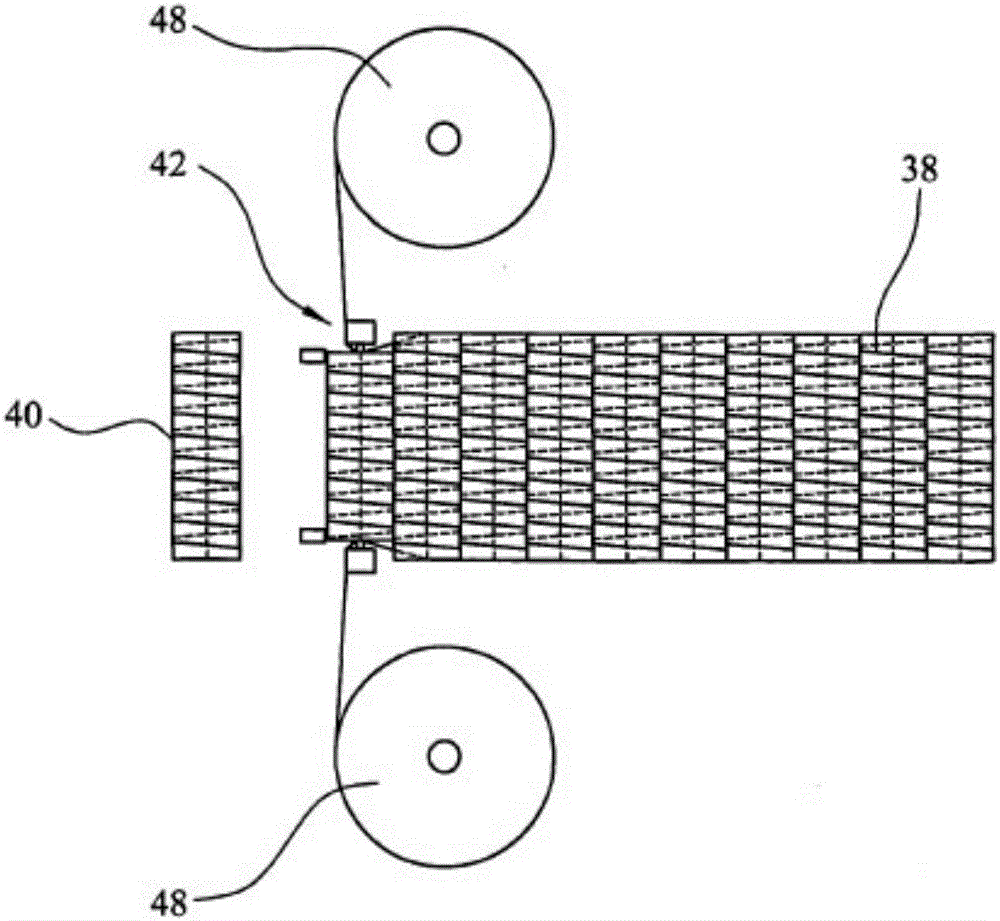

Pocketed spring unit and method and apparatus for forming the same

A method of forming a pocketed spring unit (38) for an upholstered article comprises taking successive strings (16) of pocketed springs and welding at least one sheet of material (20) to at least a first end of the pocketed springs. Anvils (46) are moved from a non- operative position to an operative position, in which they are located between adjacent pockets at upper and lower ends of the springs. This embodiment makes use of the surplus material that is formed at the ends of the pockets in the form of flaps (50) or "ears" of material. These flaps (50) protrude upwardly initially, and then become folded flat as the spring unit advances between the rolls (48) of material. The external anvils (44) are then made to apply heat and pressure to the material flaps (50) trapped between them and the internal anvils (46) at the sides of the pockets, between the springs to weld them to the material from the rolls (48).

Owner:HARRISON SPINKS COMPONENTS

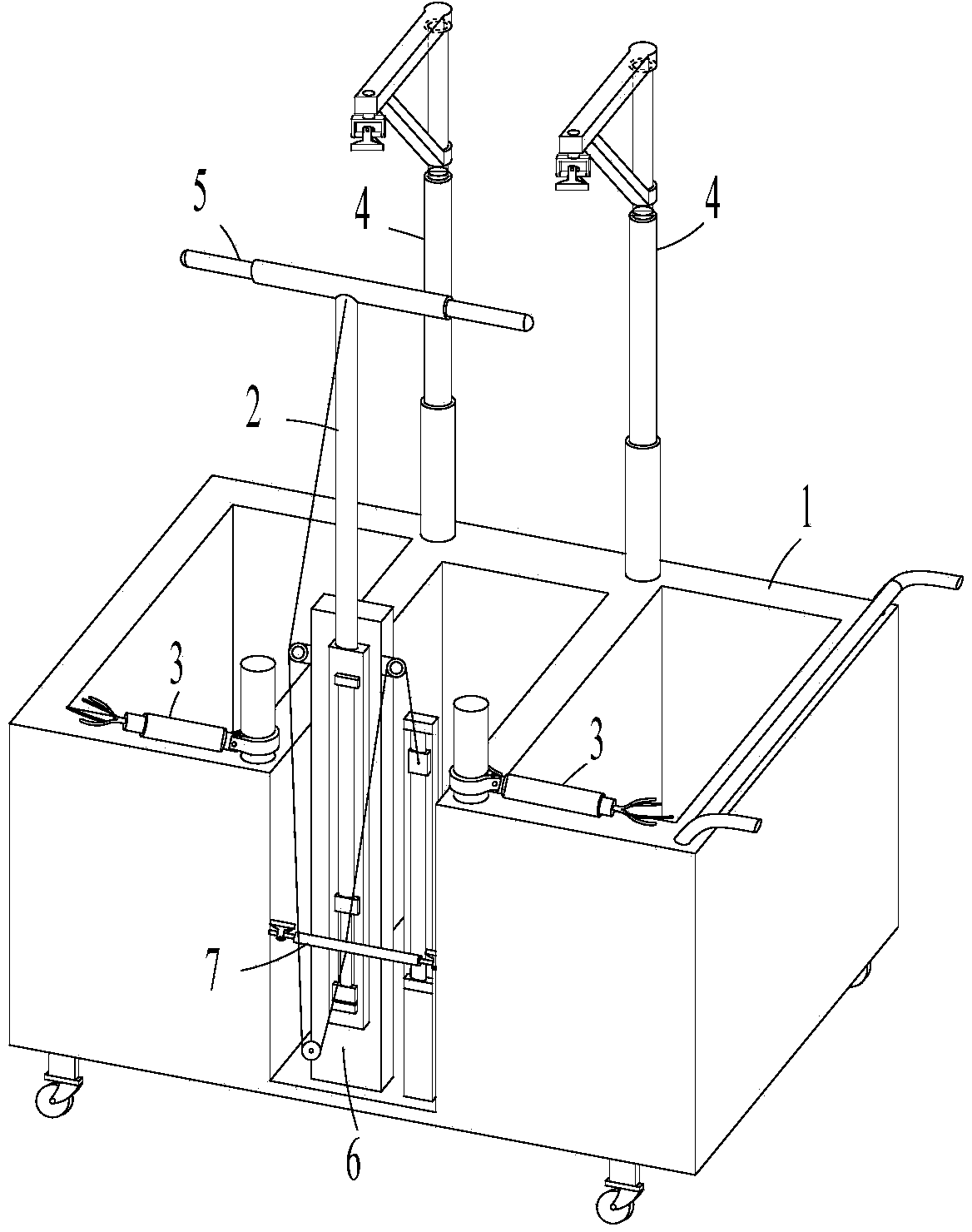

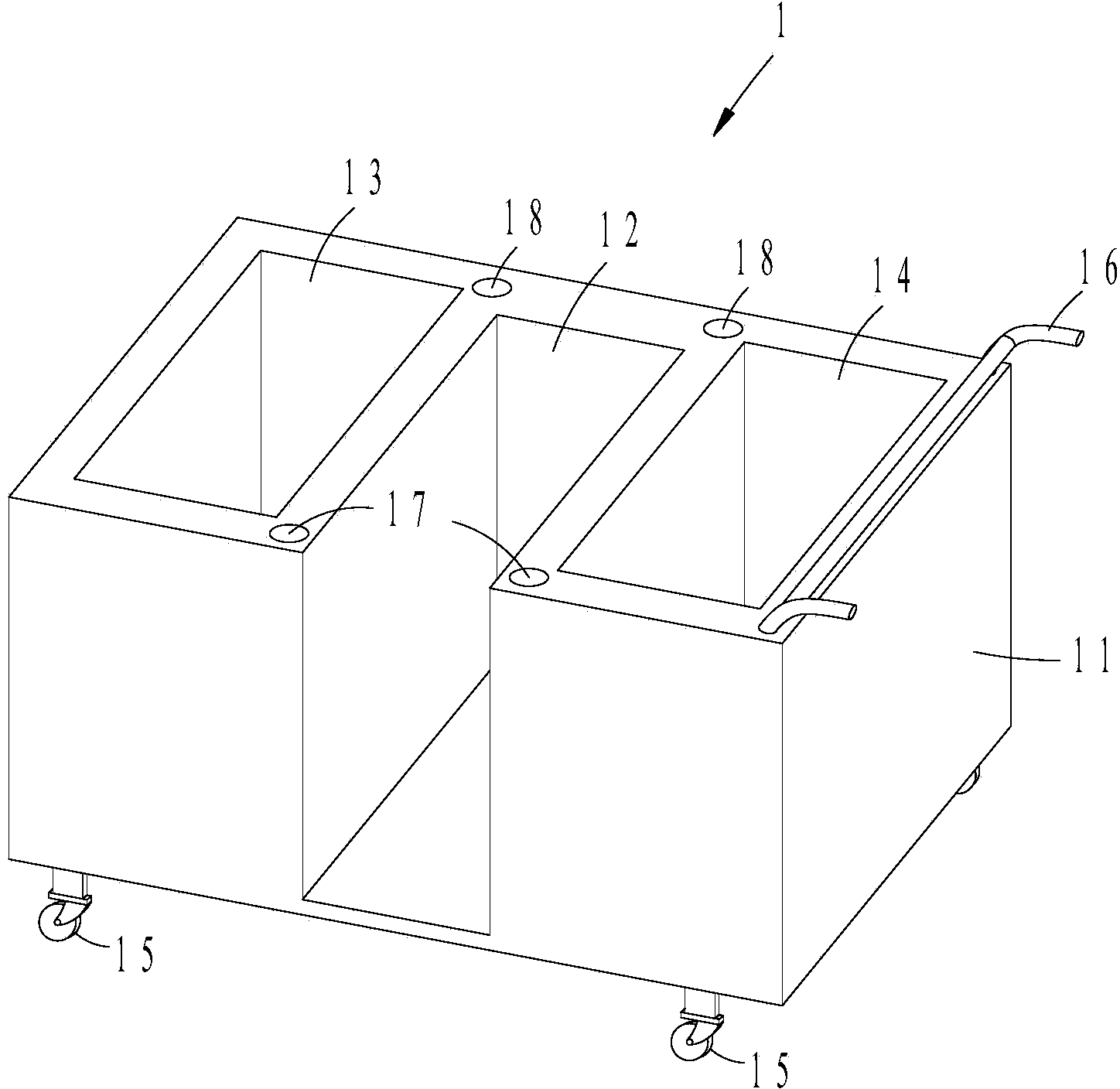

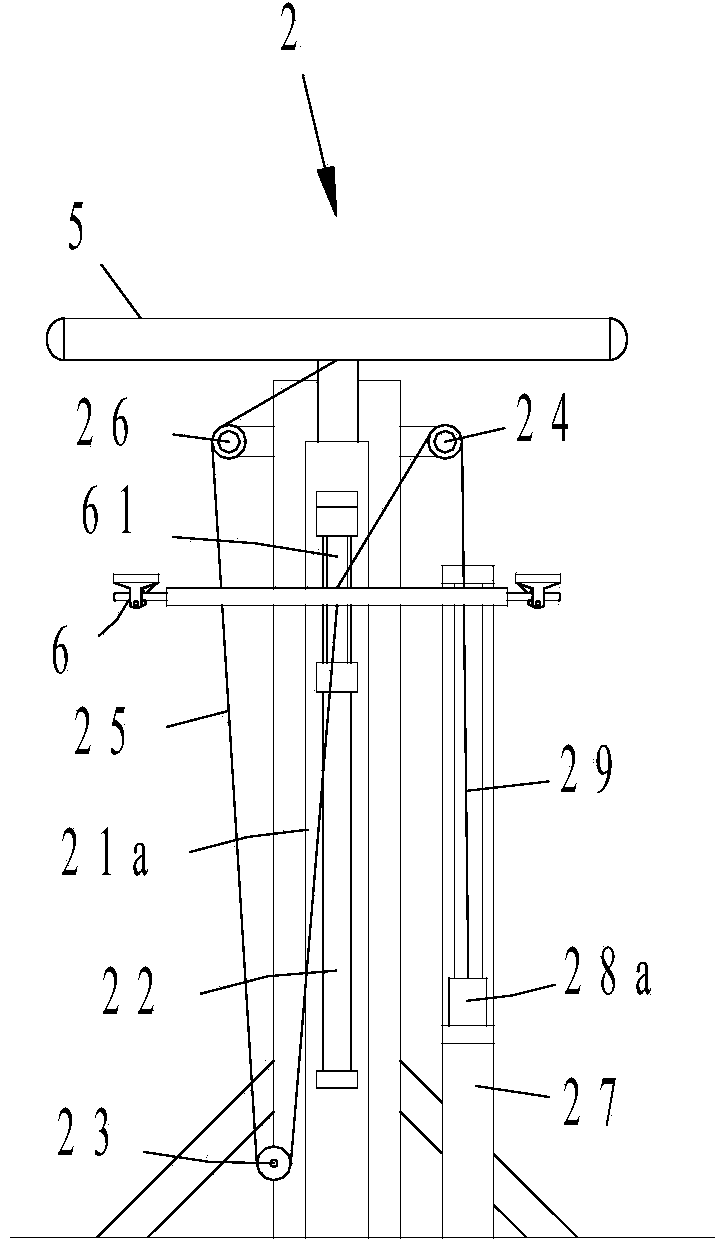

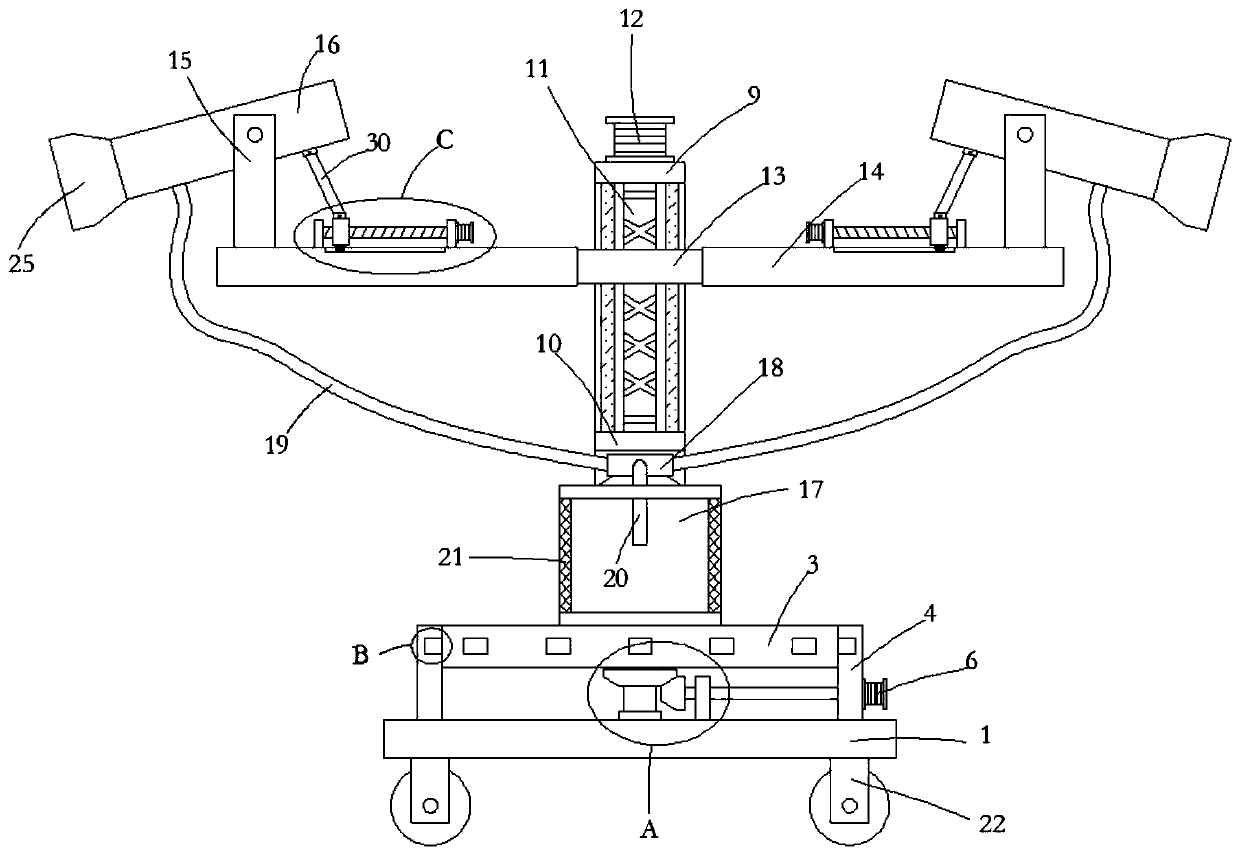

Pulley combination ascending and descending type quilt cover replacing machine

The invention relates to a pulley combination ascending and descending type quilt cover replacing machine, which comprises a machine frame, wherein a telescopic component, a quilt clamping component and two quilt take-off components are arranged on the machine frame, each quilt take-off component is provided with a quilt take-off support rod, the end parts of each quilt take-off component are provided with two clamps capable of clamping an old quilt cover, a clamping component comprises two liftable clamps capable of lamping a quilt core or a new quilt cover, the telescopic component comprises an air rod, an air rod piston rod is connected with a support rod in a horizontal direction, an air rod sleeve is provided with a clamp rod slide rail in the vertical direction, a clamp rod can be glidingly connected in the clamp rod slide rail through a clamp rod slide block, a first fixed pulley and a second fixed pulley are respectively arranged under and above the clamp rod slide block, a first typing rope passing through the first fixed pulley is connected between the support rod and the clamp rod, a second tying rope passes through the second fixed pulley, one end of the second tying rope is connected with the clamp rod, and the other end of the second typing rope is connected with an object block. The quilt cover replacing machine has the advantages that the new quilt cover can be automatically unfolded, the quilt core loading into the quilt cover can be realized during the separation of the old quilt cover and the quilt core, the structure is simple, the operation is convenient, and the quilt cover replacing efficiency is greatly improved.

Owner:郑永强

Automatic sleeving machine

InactiveCN102030300ASave human effortImprove work efficiencyUpholstery auxillary devicesBed-coversEngineeringMechanical engineering

The invention discloses an automatic sleeving machine. The machine comprises a bracket and a workbench which are connected with each other, wherein the workbench is arranged on the bracket; the bracket is connected with a motor; a fixing seat is arranged at a position close to any end of the workbench and is provided with a sleeve; and the workbench is made of stainless steel or plastic. The automatic sleeving machine has the advantages of saving manpower and improving work efficiency.

Owner:南通金宝罗家用纺织品有限公司

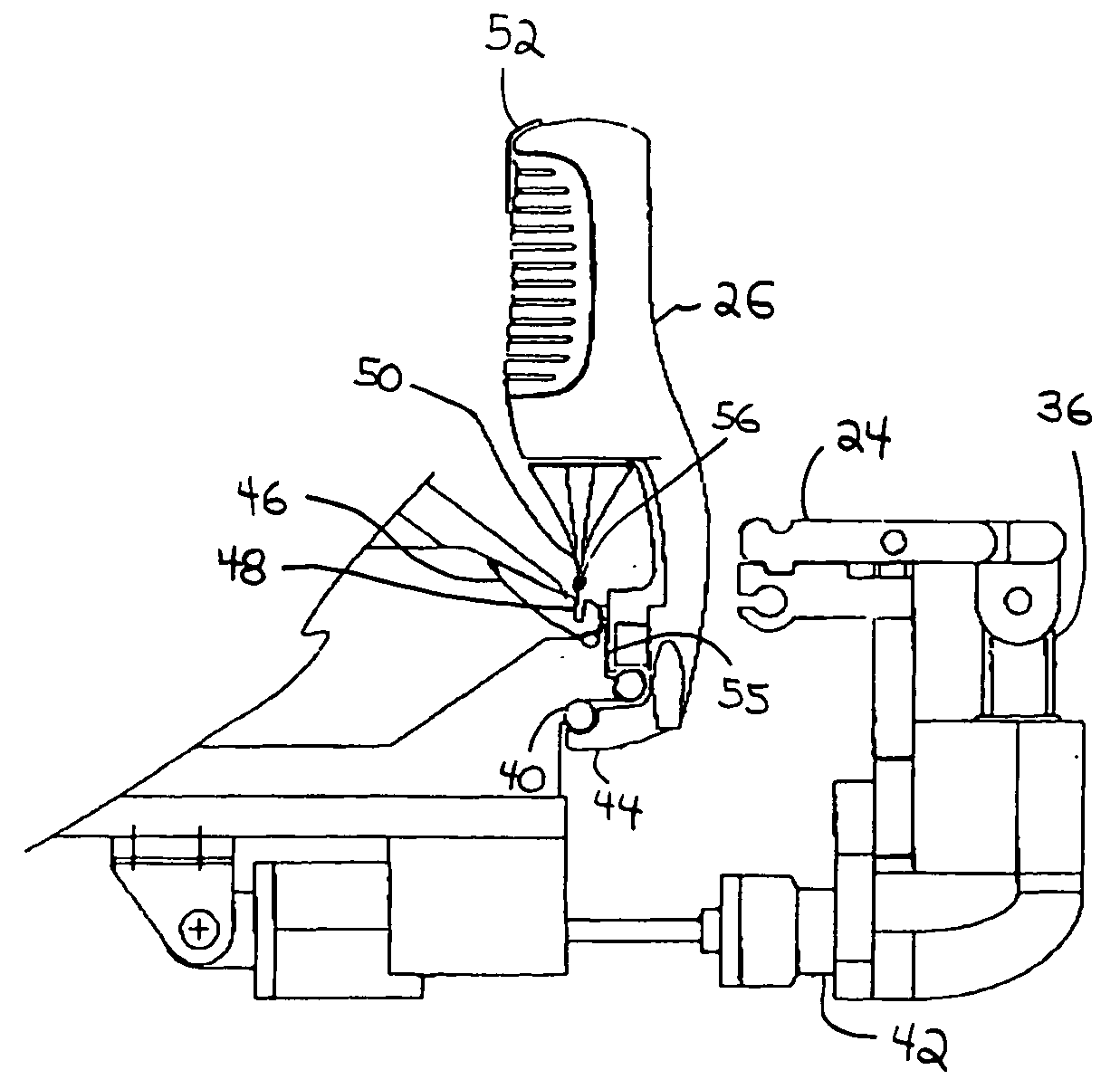

Tool for Securing Together Two or More Layers of a Mattress Using a Plastic Fastener

A method for coupling together at least two layers of a mattress includes the steps of aligning each layer in its proper position in relation to the other layers of the mattress and, after the alignment step, inserting a plastic fastener through the layers. A fastener dispensing tool is provided for inserting plastic fasteners through the layers of the mattress. In one embodiment, the fastener dispensing tool includes a housing, a hollow sharpened needle fixedly coupled to the housing, an ejection mechanism for advancing a cross-bar of the plastic fastener through the hollow needle, a needle guard slidably coupled to the housing over a portion of the sharpened needle, and a needle guard stop slidably coupled to the housing in such a manner so that it can be releasably fixed place in either of two or more set positions. In use, the needle guard is adapted for slidable displacement between an extended position in which the sharpened tip of the needle is substantially protected by the needle guard and a retracted position in which a portion of the sharpened needle is exposed. When in its retracted position, the needle guard contacts the needle guard stop so as to limit further retraction of the needle guard. In this capacity, the position selected for the needle guard stop determines the portion of the hollow needle that is available for insertion through the layers of the mattress.

Owner:AVERY DENNISON CORP

Method for upholstering box springs

InactiveUS8453306B2Upholstery manufactureUpholstery auxillary devicesEngineeringMechanical engineering

Owner:L & P PROPERTY MANAGEMENT CO

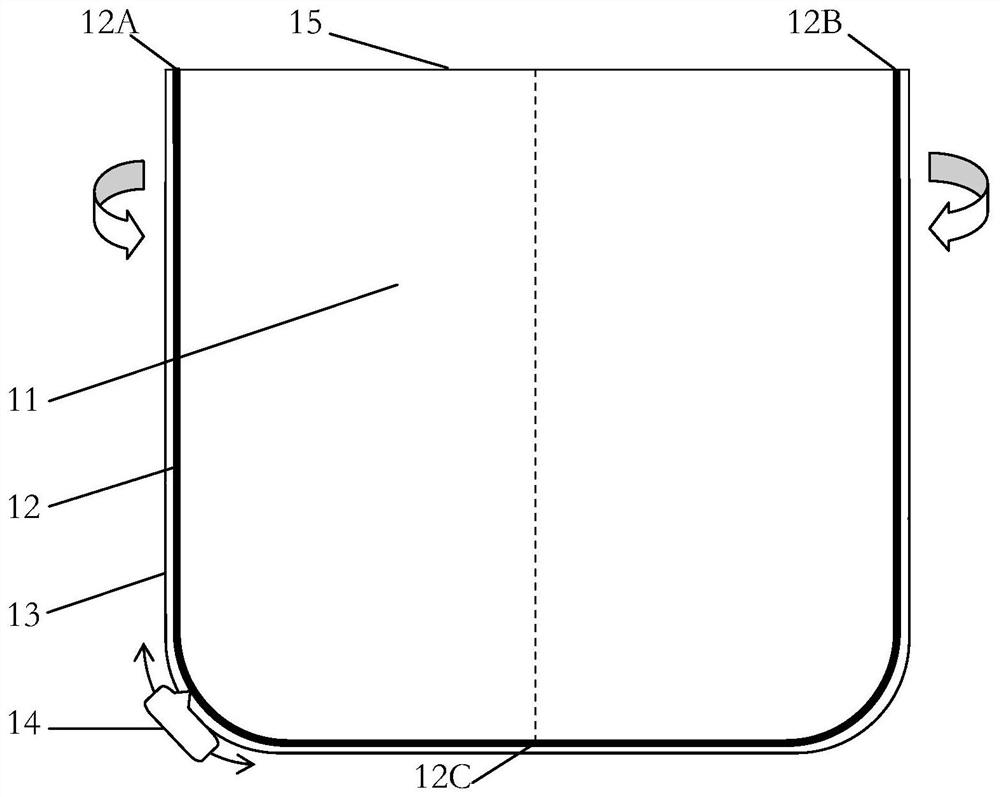

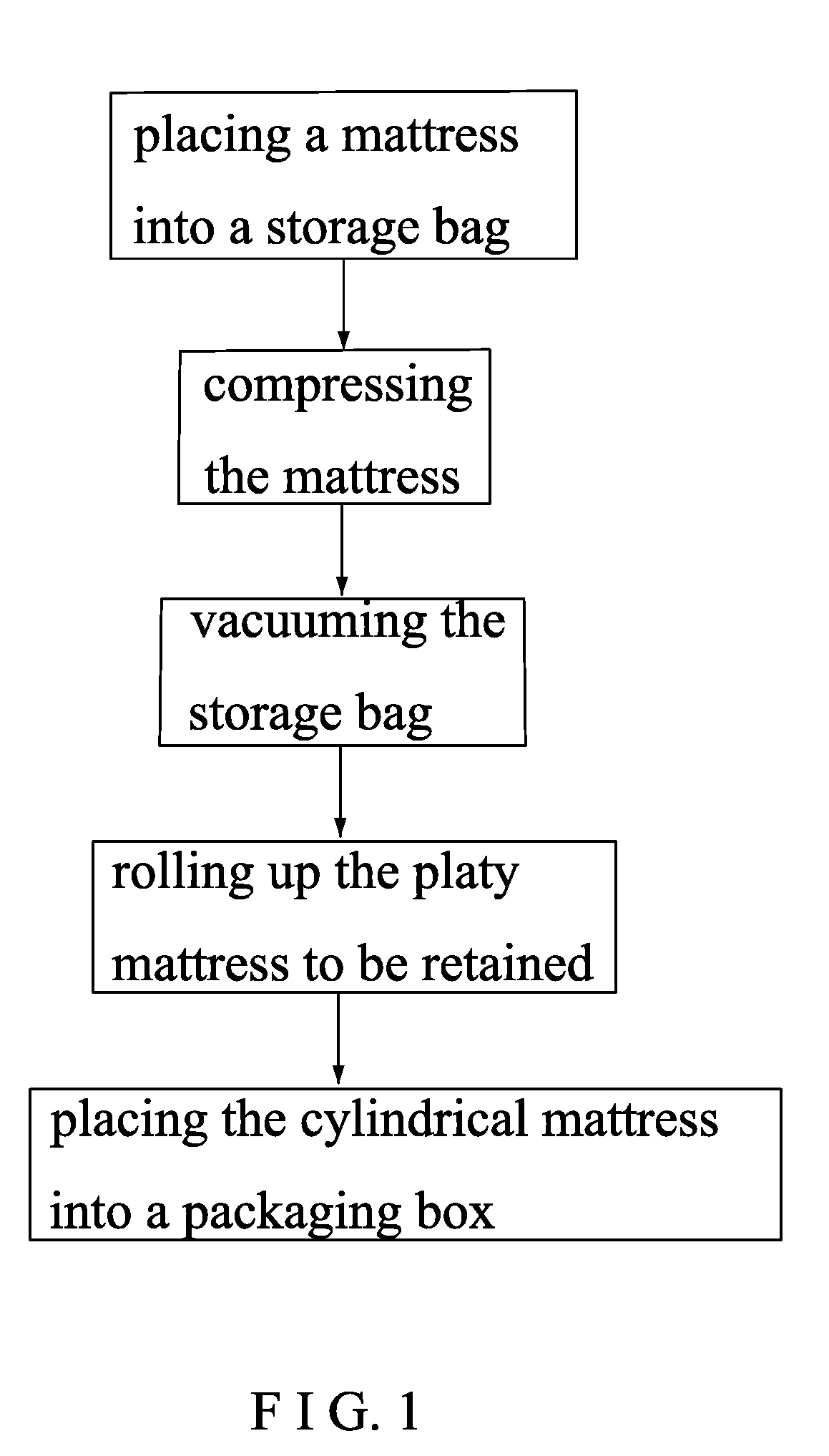

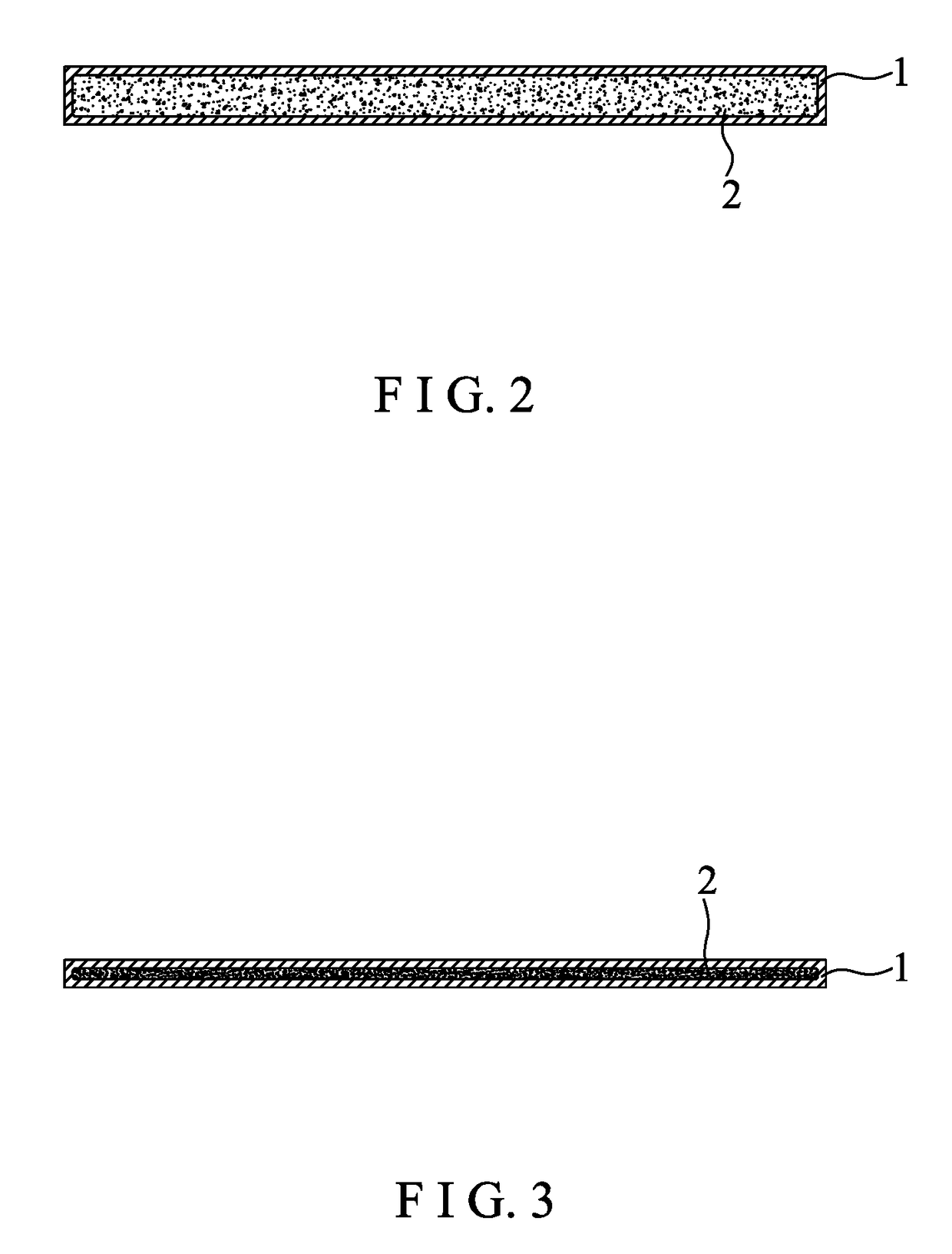

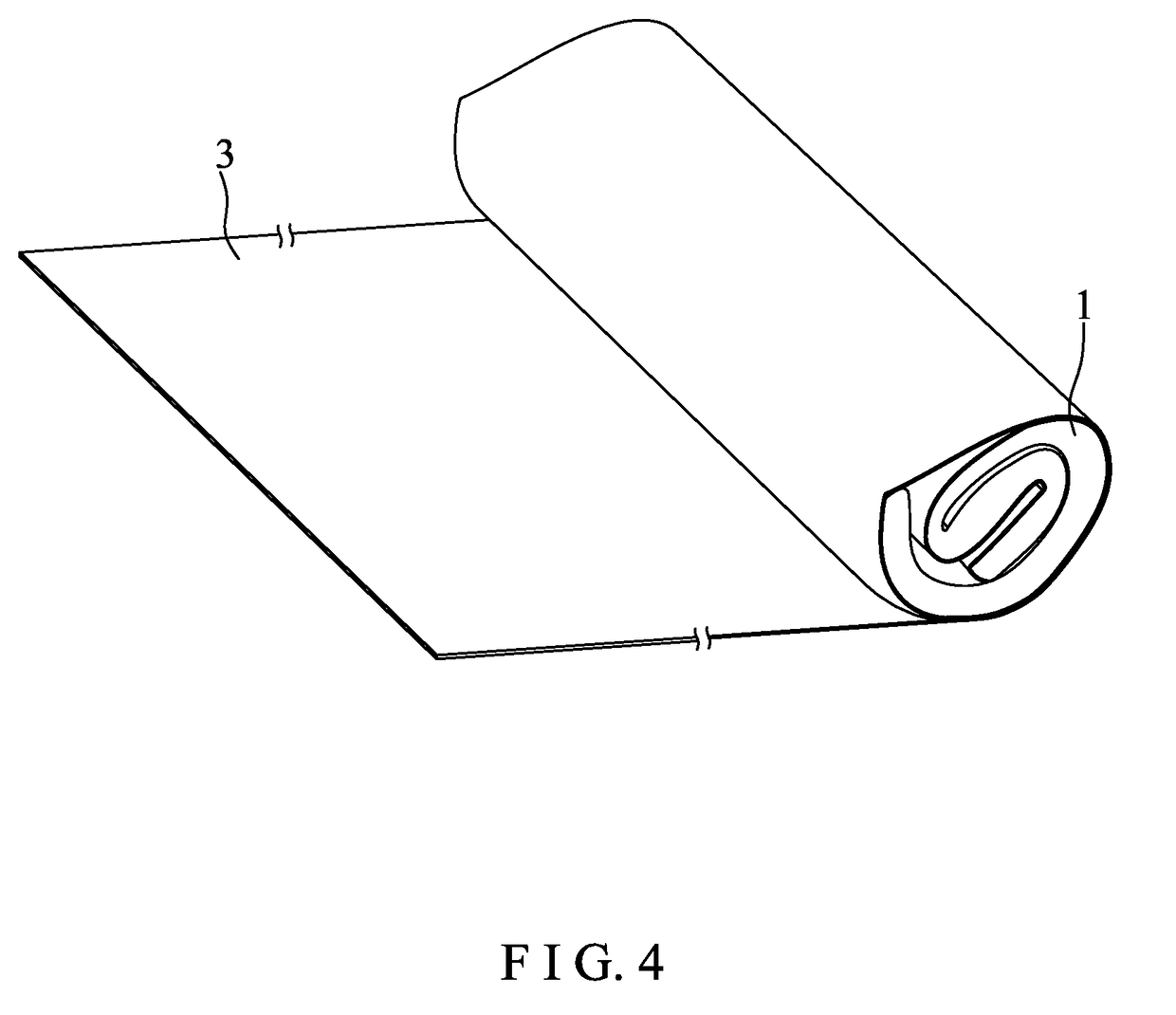

Method of packaging mattress

InactiveUS20190023440A1Ensure integrityLarge frictional forceUpholstery auxillary devicesWrappingEngineeringMechanical engineering

Owner:GRANTEC (XIAMEN) CO LTD

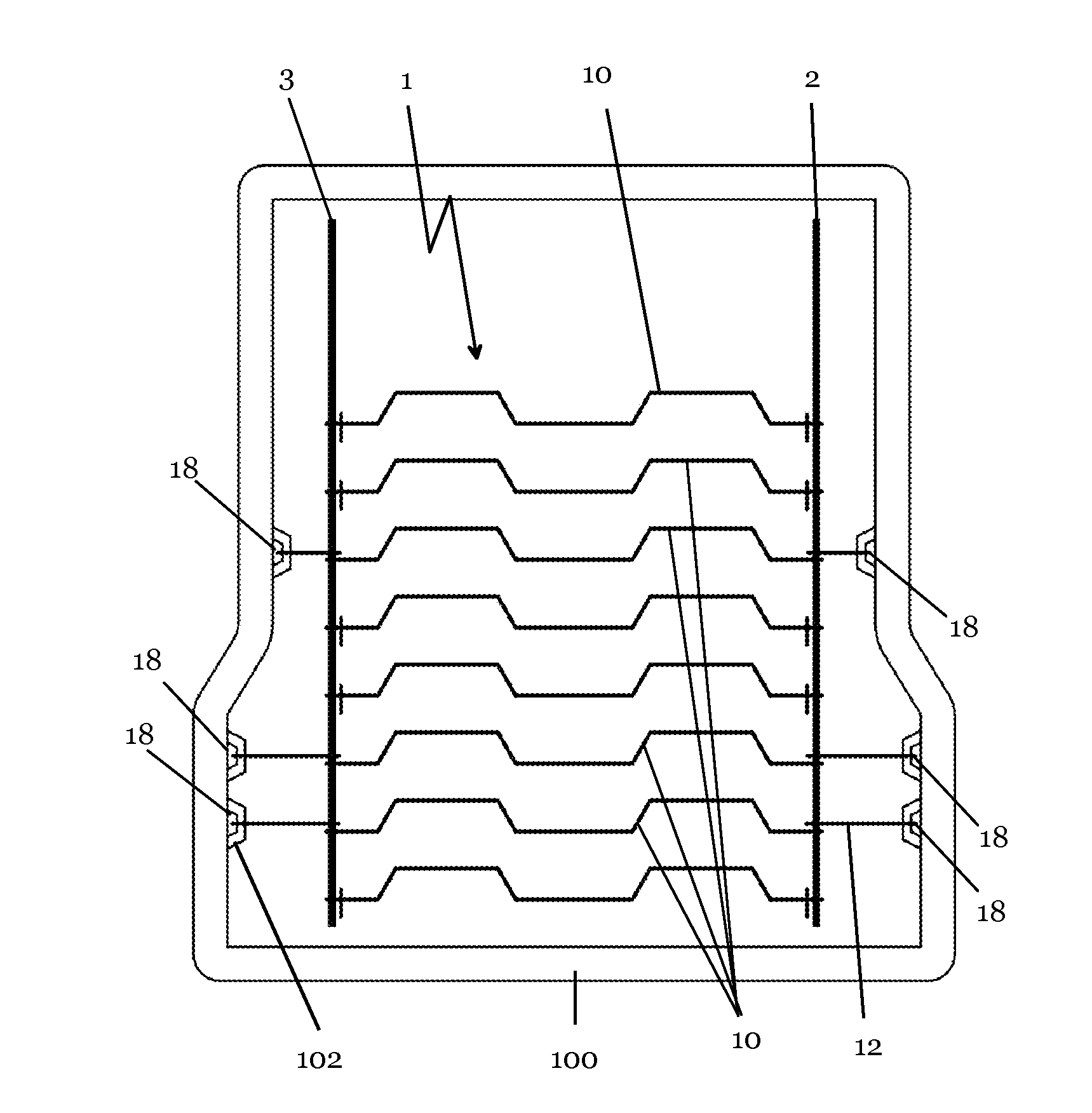

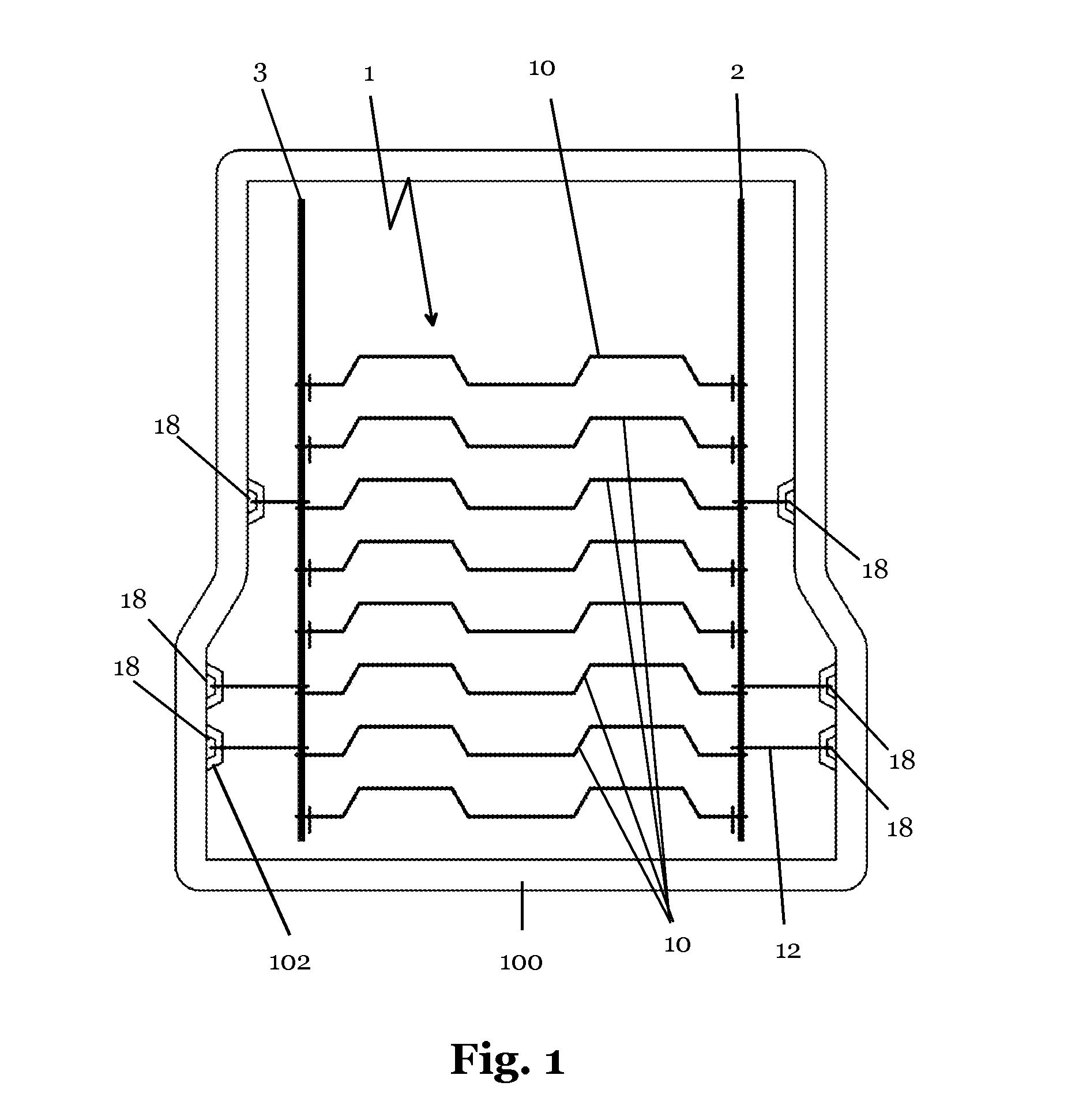

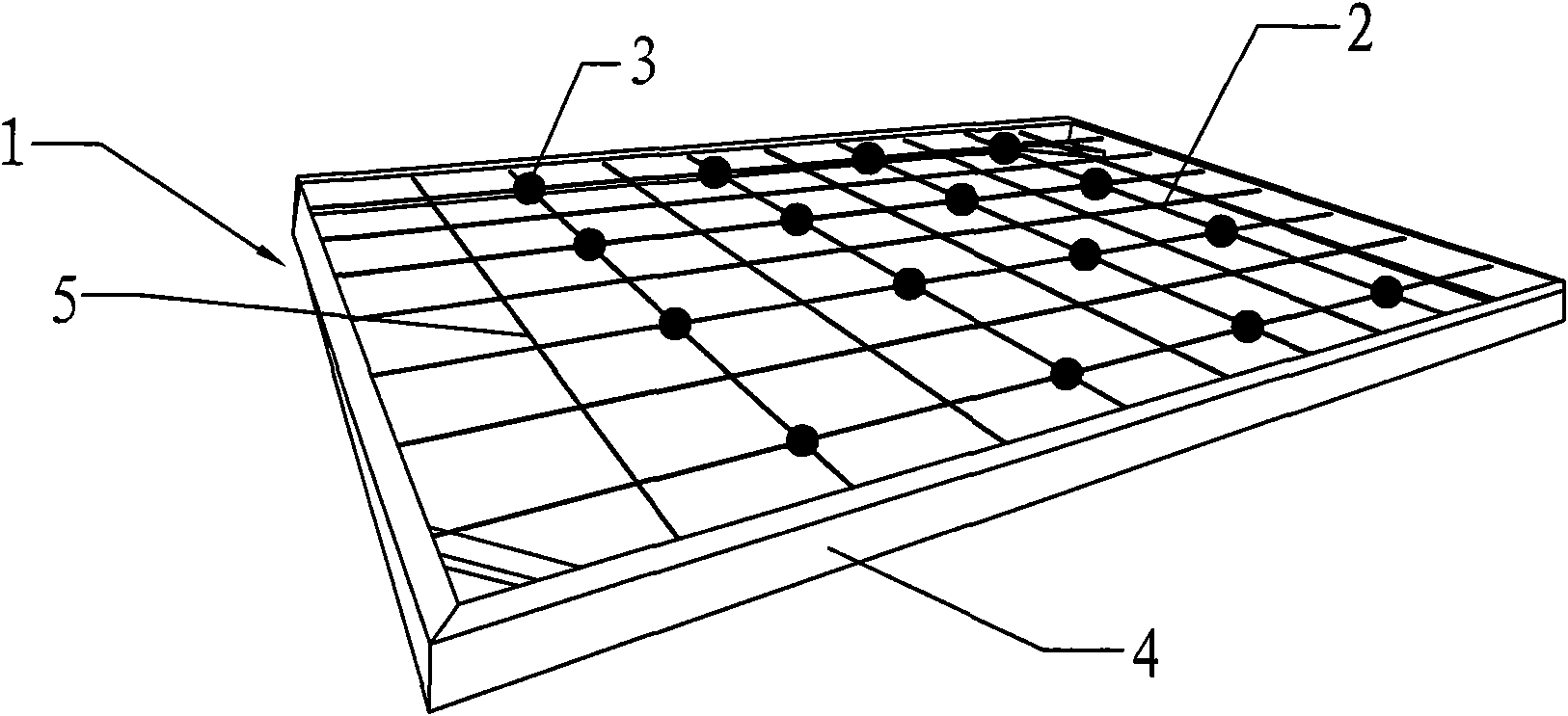

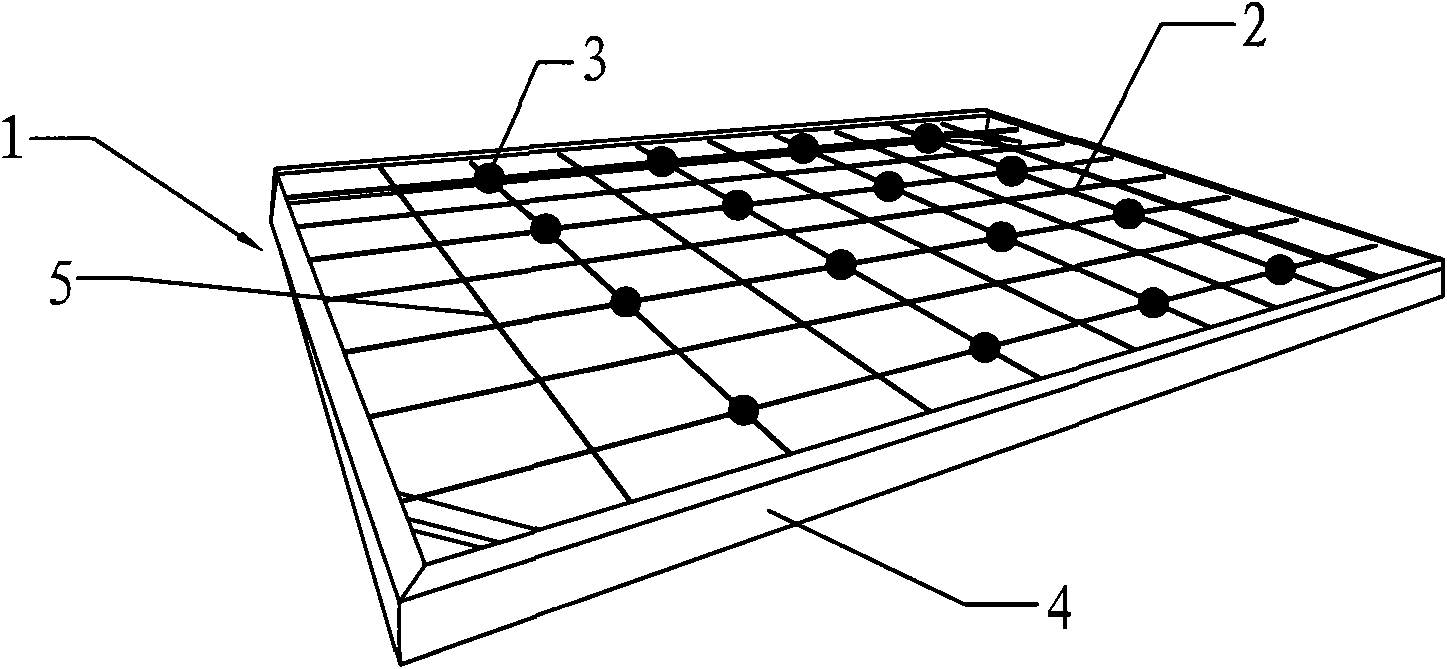

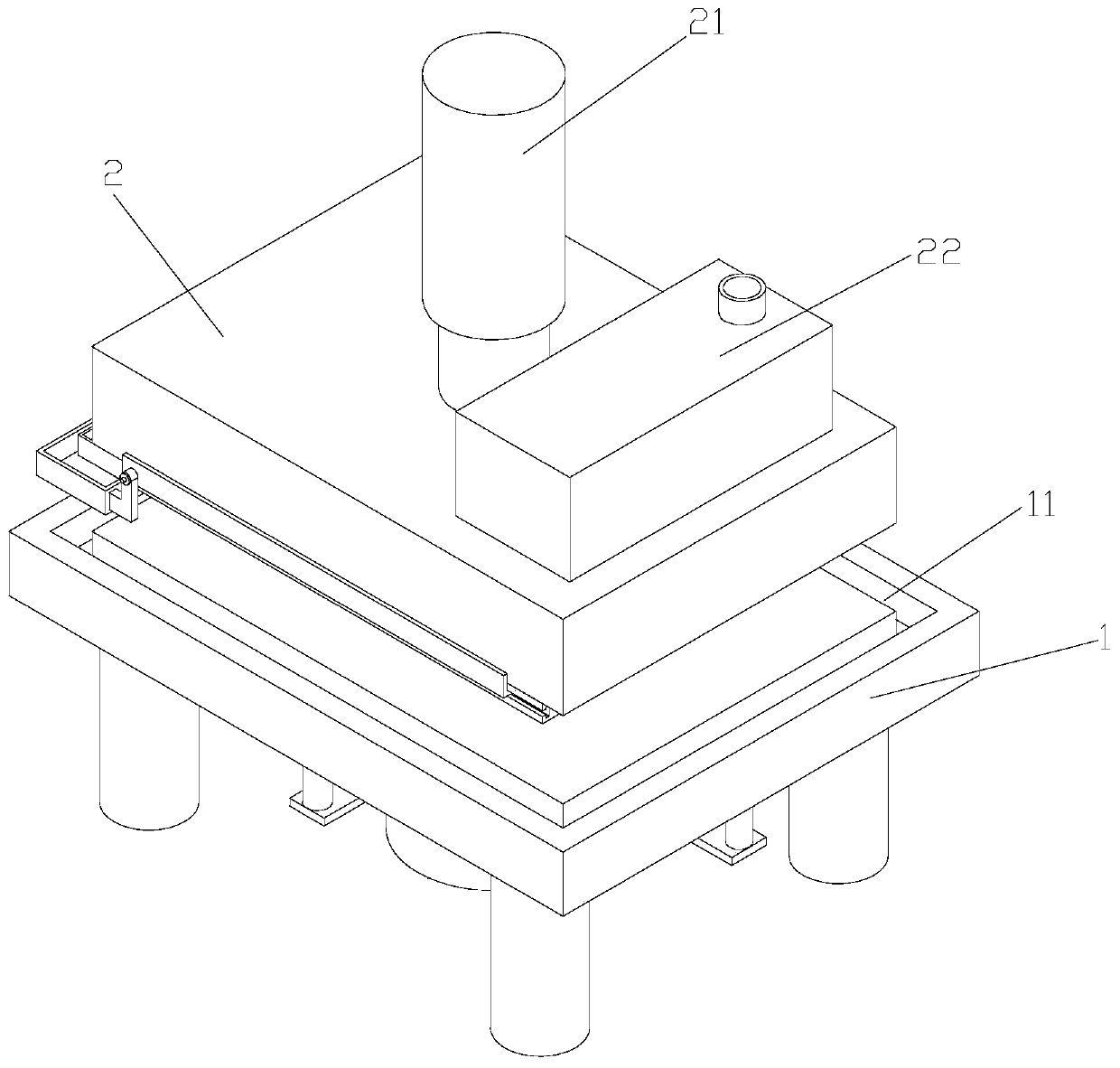

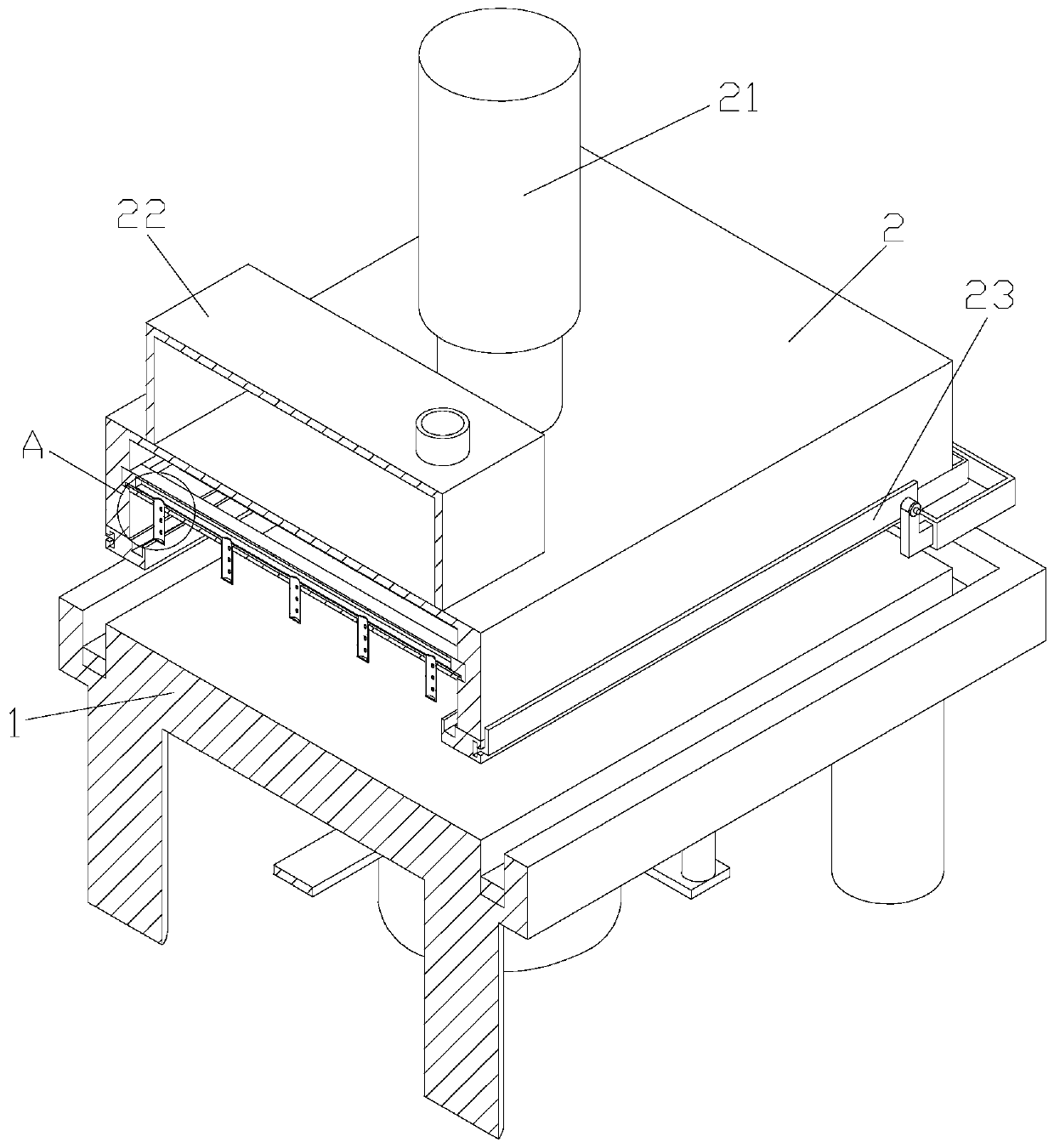

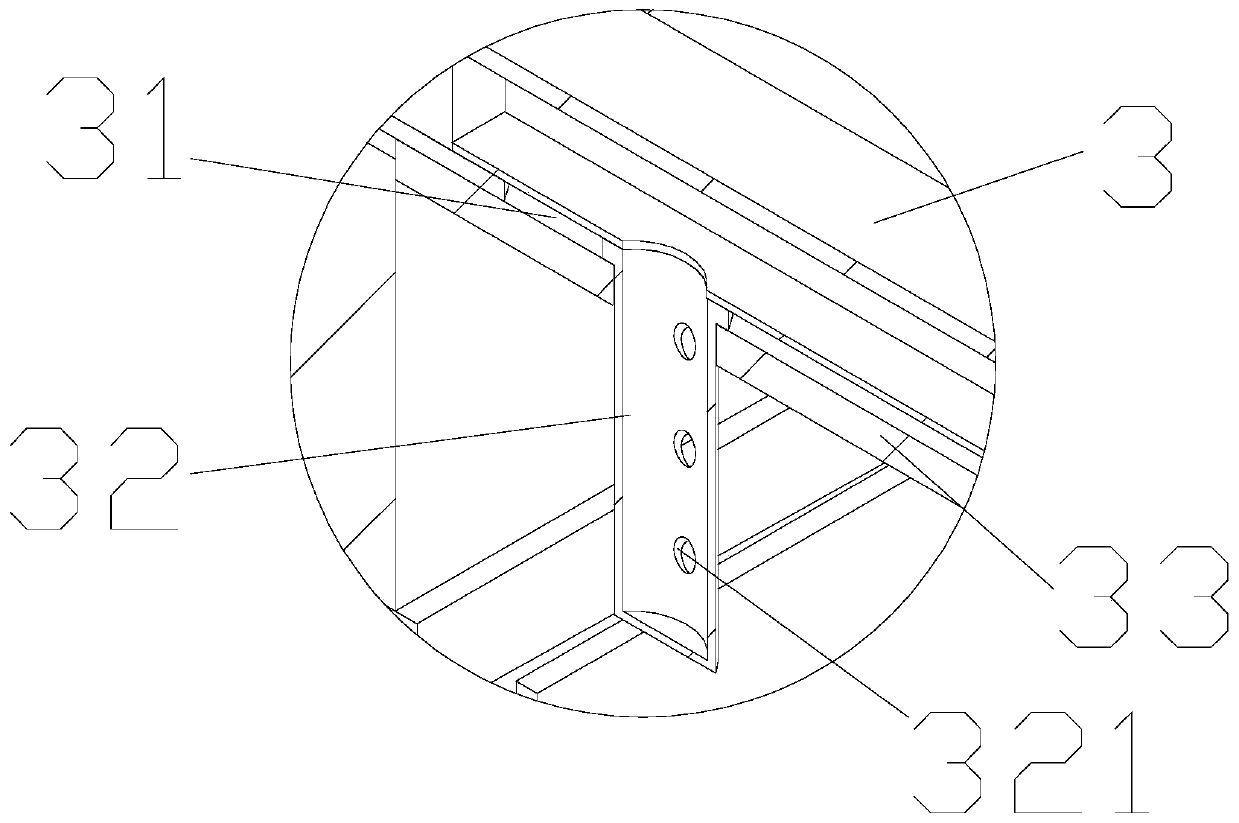

Quilting platform

InactiveCN102001612ANeat appearanceImprove efficiencyUpholstery auxillary devicesEngineeringCross point

The invention discloses a quilting platform. The quilting platform mainly comprises a surrounding frame, a plurality of transverse tension ropes and a plurality of longitudinal tension ropes, wherein the surrounding frame consists of four beams and is used for fixing and supporting objects; the two ends of each transverse tension rope are connected to the surrounding frame; the two ends of each longitudinal tension rope are connected to the surrounding frame; and the transverse tension ropes and the longitudinal tension ropes are provided with positioning bumps at least at a part of crossing points. A quilt sewn with the assistance of the quilting platform has neat appearance, and sewing efficiency is improved.

Owner:WUJIANG CITY JILI SILK PROD

Mattress production and processing technology

ActiveCN110217752AImprove processing efficiencyHigh degree of automationUpholstery auxillary devicesEngineeringBlanket

The invention discloses a mattress production and processing technology. The mattress production and processing technology includes the steps that a, spring making is conducted; b, net stringing is conducted; c, edge iron mounting is conducted, specifically, edge iron sleeves a bed net, spring forks are fixed to the periphery of the bed net, bed net clamps are mounted at the periphery of the bed net by a mattress gun, and an iron frame around the bed net is fixed; d, bottoming is conducted, specifically, a blanket is laid on the bed net, brown blanket nails are nailed along the four edges of the bed net by a brown blanket gun, and lines are stringed in the middle of the bed net, so that the blanket is firmly positioned; e, cloth buckling is conducted, specifically, a bottomed mattress is placed on cloth buckling equipment, and padding is pasted to the front face and the back face of the mattress, so that the padding is fixed to the bed net; f, edge surrounding is conducted, specifically, side cloths sleeve the peripheral edges of the mattress, four air-permeable holes are formed in openings in the two sides of the mattress, and a foam strip is taken to surround the edges along withan edge surrounding machine; and g, packaging is conducted, specifically, dust on a table surface is cleaned by blowing by an air gun, trademarks and quality inspection tapes are pasted to the middleof the tail end of the mattress, the mattress is packaged by PVC, four wrap corners and a guarantee are placed, and the periphery of the mattress is sealed by adhesive paper.

Owner:佛山市布麻凡纺织科技有限公司

Mattress production and processing technology

ActiveCN110143562AEasy to fixHigh degree of automationStuffed mattressesUpholstery auxillary devicesEngineeringOperating table

The invention discloses a mattress production and processing technology which comprises the following steps that a, springs are produced, specifically, a steel wire sleeves a sitting shaft, the steelwire at one end is pulled out and loaded into a spring producing machine, and a link spring with required parameters is produced; b, net stringing is carried out, specifically, the steel wire sleevesthe sitting shaft, the steel wire at one end is pulled out and loaded into a net stringing machine, and a net stringing worker steps on the net stringing machine to produce a standard wavy snake wire,and the snake wire strings the springs in rows to form a bed net; c, trimming is carried out; d, bottoming is carried out, specifically, the bed net is placed on an operating table, cotton felt is transported to the upper side of the bed net through a material conveying plate, then the cotton felt is covered on the bed net, the cotton felt is fixed on the bed net, and then threads are stringed inthe middle of the bed net to firmly position the cotton felt; e, cloth covering is carried out; f, hemming is carried out, specifically, mattressses are placed on a conveyor belt, the mattressses aremoved to a material conveying device along the conveyor belt, the mattresses on the material conveying device is conveyed to a processing table one by one, and the cloth on the two sides of the mattresses and the cloth around the mattresses are sewed through a hemming machine; and g, packaging is carried out.

Owner:阜阳皖春家俬有限公司

Auxiliary device for automatic cotton filling machine

InactiveCN111547674AEasy to useUniform azimuth adjustmentUpholstery manufactureUpholstery auxillary devicesRotary stageBall bearing

The invention relates to the technical field of cotton filling machines. The invention further discloses an auxiliary device for the automatic cotton filling machine. The device includes a base, and the center of the upper end of the base is rotationally connected with a rotating shaft through a ball bearing. The upper end of the rotating shaft is fixedly connected with a rotating table; the upperend of the base is further fixedly connected with a fixing cylinder clamped on the outer side of the rotary table in a sleeving mode. T shaft wall of the rotating shaft is fixedly sleeved with a driven bevel gear, the barrel wall of the fixing cylinder is fixedly connected with a rotating motor, the output shaft of the rotating motor is fixedly connected with a rotating rod, and one end of the rotating rod is fixedly connected with a driving bevel gear engaged with the driven bevel gear. The auxiliary device for the automatic cotton filling machine has the advantages that omnibearing positionadjustment of the suction cylinder can be achieved, the cotton adsorption efficiency is greatly improved, and the cotton filling machine can be conveniently and practically operated to be used.

Owner:JIANGSU SHANGCHENG FASHION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com