Mattress production and processing technology

A processing technology and mattress technology, applied to mattresses, spring mattresses, stuffed mattresses, etc., can solve the problems of heavy workload of workers and affect the production efficiency of mattresses, so as to improve the degree of automation, reduce the labor load of workers, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

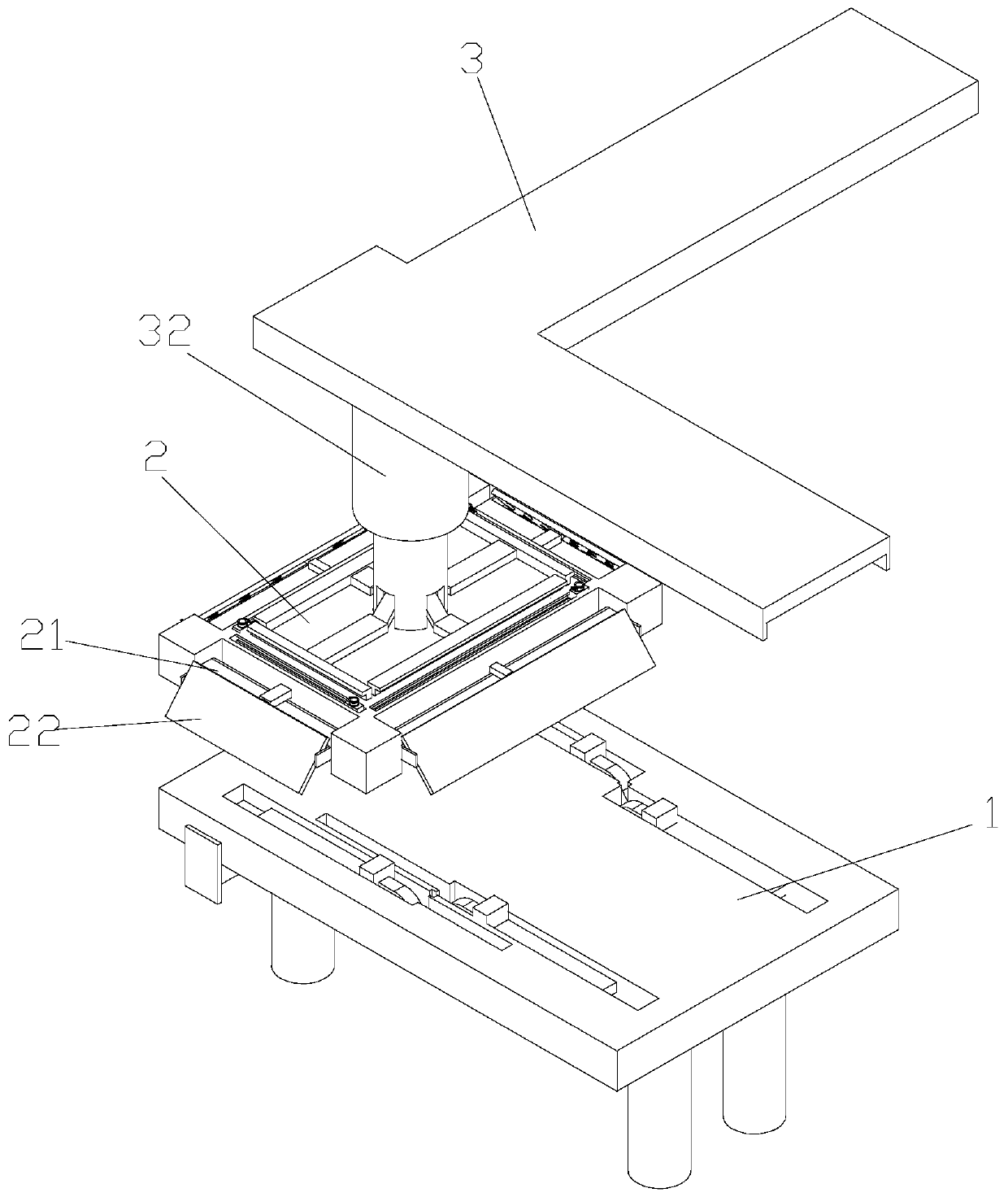

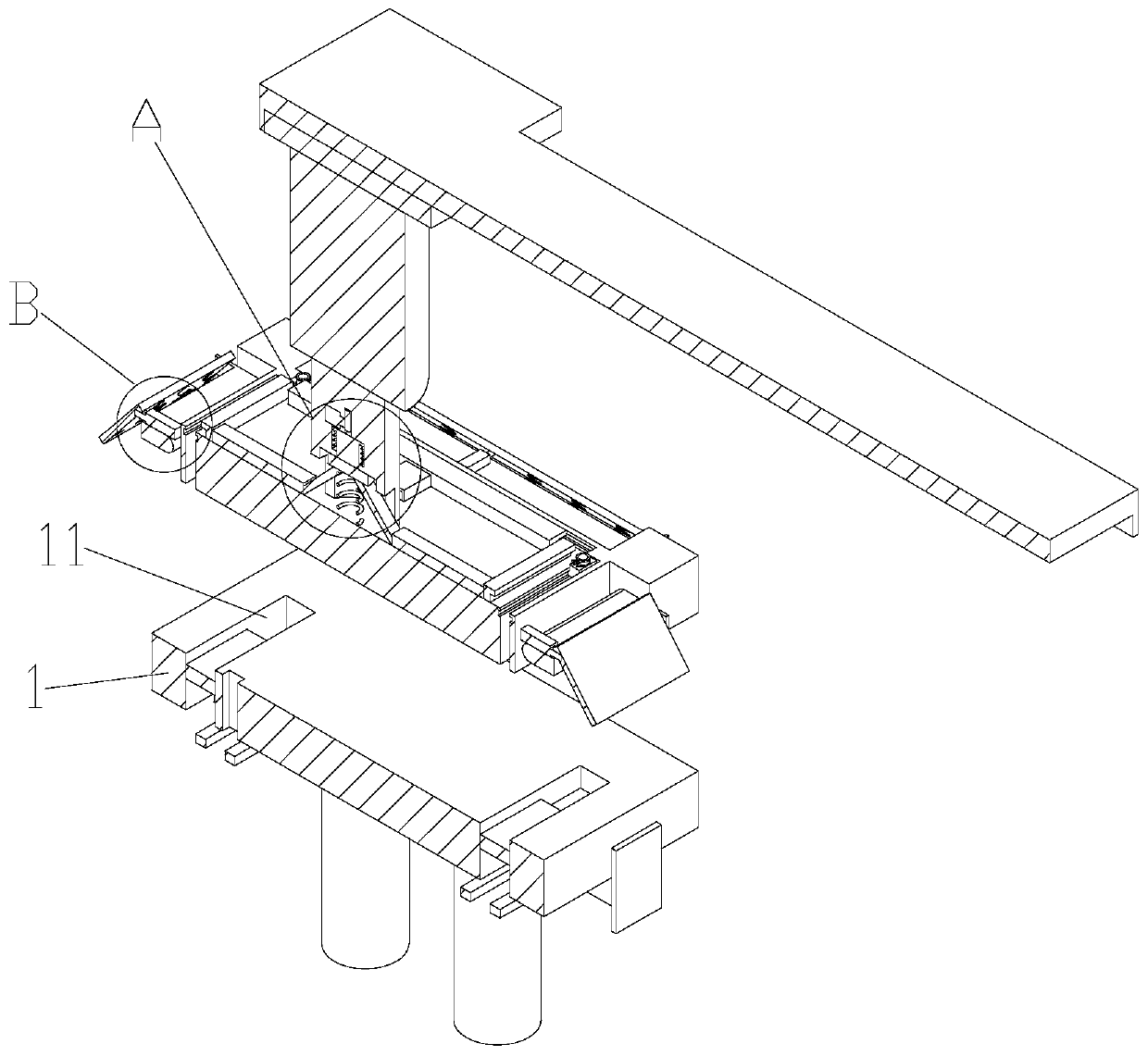

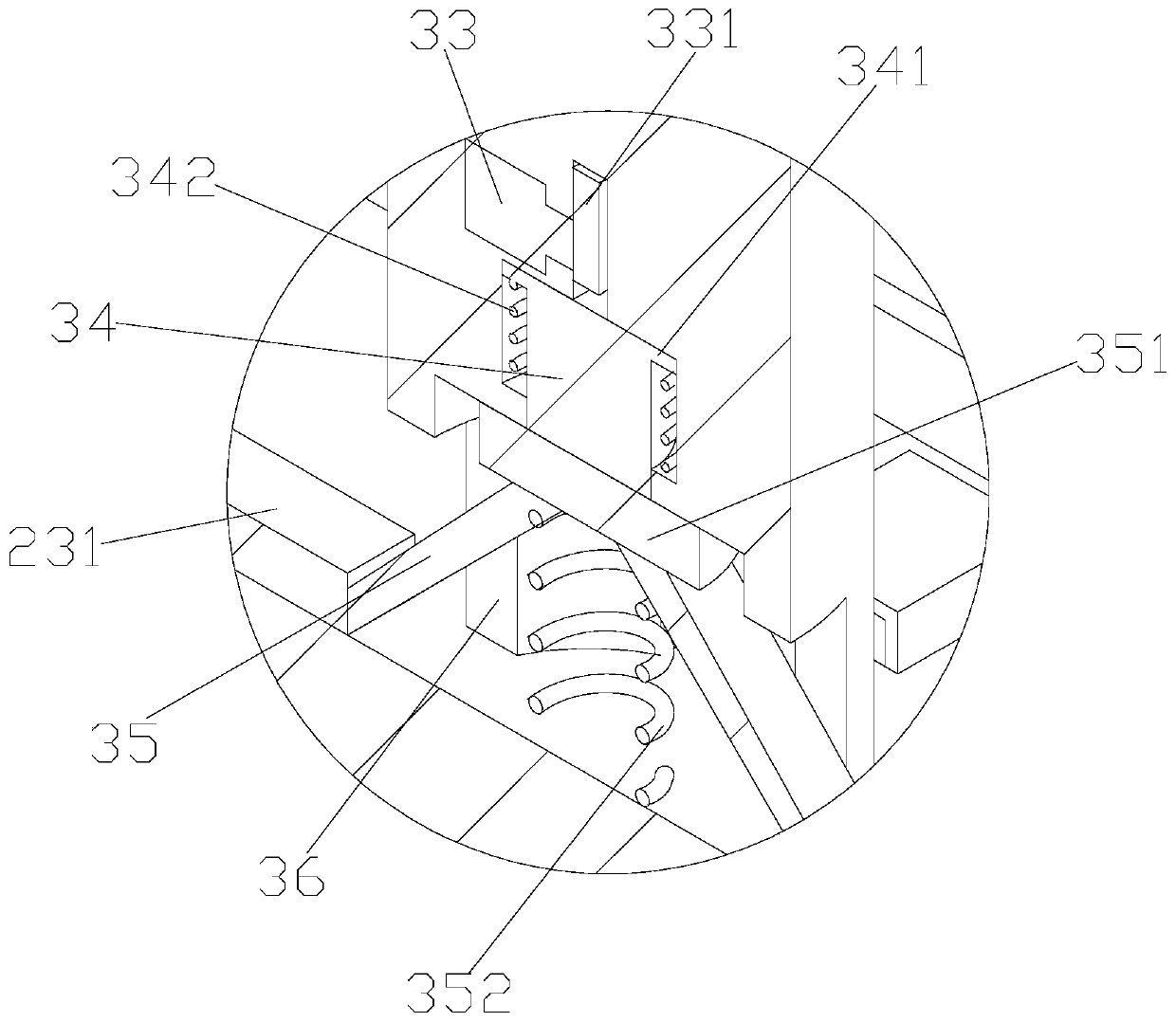

Embodiment 1

[0034] A mattress production and processing process, including: a. springing: put the steel wire on the seat shaft, pull out a steel wire at one end and put it into the spring machine, and punch out the desired parameter link spring; b. stringing the net: put the The steel wire is set on the seat shaft, and a steel wire at one end is pulled out and put into the net stringing machine. The net stringing worker steps on the net stringing machine to produce a standard wave-shaped snake line, and the snake line strings the springs in each row. Open to form the bed net; c, beating: put the side irons on the bed net, fix the spring forks around the bed net respectively, use a horse gun to put bed net clamps around the bed net, and fix the iron frame around the bed net; d , Primer: place the bed net on the operating table, transport the cotton felt to the top of the bed net through the feeding board, then spread the cotton felt on the bed net, fix the cotton felt on the bed net, and th...

Embodiment 2

[0048] A mattress production and processing process, including: a. springing: put the steel wire on the seat shaft, pull out a steel wire at one end and put it into the spring machine, and punch out the desired parameter link spring; b. stringing the net: put the The steel wire is set on the seat shaft, and a steel wire at one end is pulled out and put into the net stringing machine. The net stringing worker steps on the net stringing machine to produce a standard wave-shaped snake line, and the snake line strings the springs in each row. Open to form the bed net; c, beating: put the side irons on the bed net, fix the spring forks around the bed net respectively, use a horse gun to put bed net clamps around the bed net, and fix the iron frame around the bed net; d , Primer: place the bed net on the operating table, transport the cotton felt to the top of the bed net through the feeding board, then spread the cotton felt on the bed net, fix the cotton felt on the bed net, and th...

Embodiment 3

[0050] A mattress production and processing process, including: a. springing: put the steel wire on the seat shaft, pull out a steel wire at one end and put it into the spring machine, and punch out the desired parameter link spring; b. stringing the net: put the The steel wire is set on the seat shaft, and a steel wire at one end is pulled out and put into the net stringing machine. The net stringing worker steps on the net stringing machine to produce a standard wave-shaped snake line, and the snake line strings the springs in each row. Open to form the bed net; c, beating: put the side irons on the bed net, fix the spring forks around the bed net respectively, use a horse gun to put bed net clamps around the bed net, and fix the iron frame around the bed net; d , Primer: place the bed net on the operating table, transport the cotton felt to the top of the bed net through the feeding board, then spread the cotton felt on the bed net, fix the cotton felt on the bed net, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com