Patents

Literature

264results about How to "Won't fall apart" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

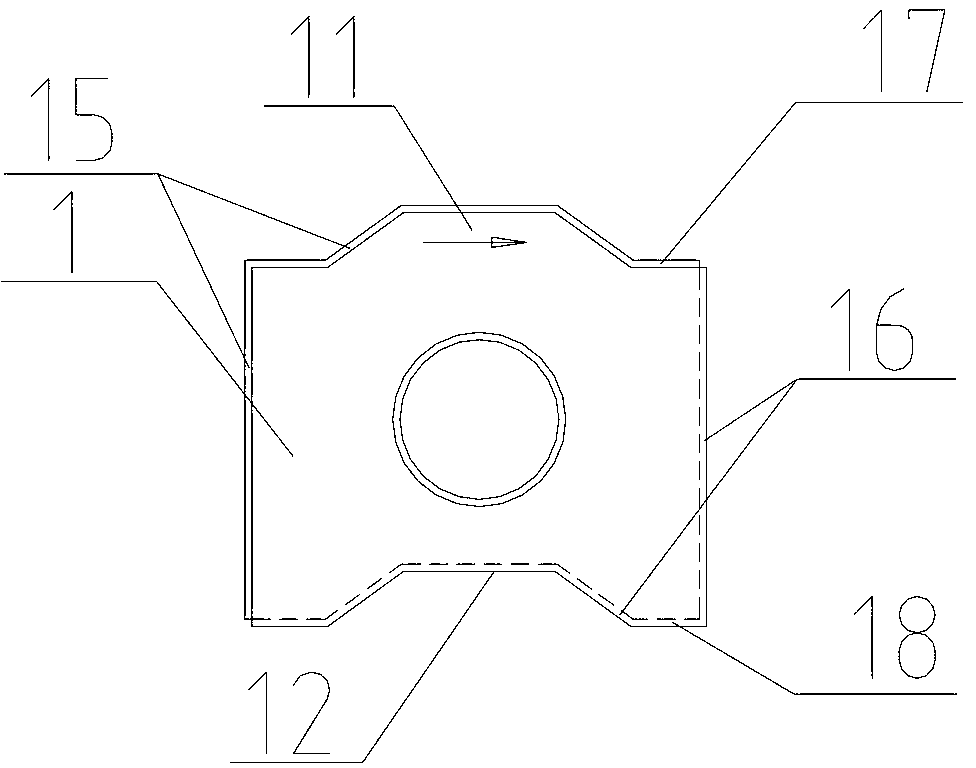

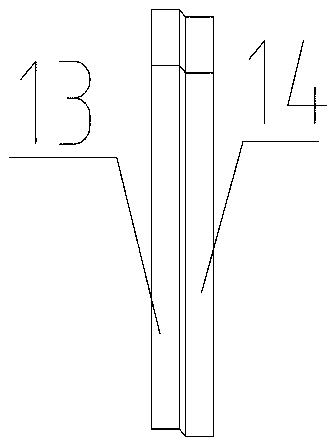

Microgroove cable

InactiveCN104078139ANot easy to escapeNot easy to escape, but easy to take out during constructionInsulated cablesPower cablesStructural engineeringProtection layer

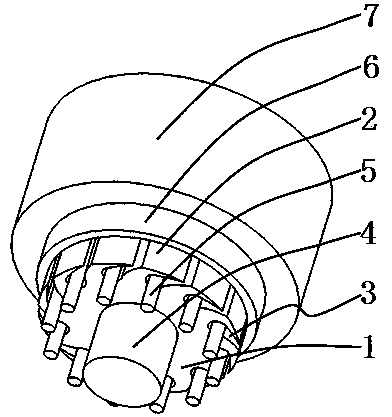

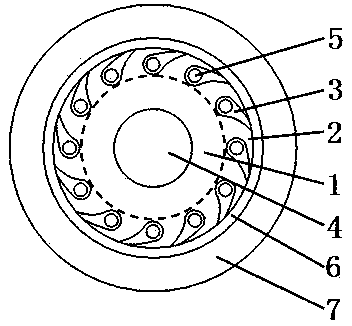

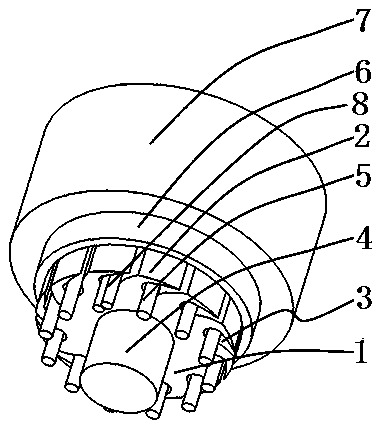

The invention belongs to the technical field of cables and particularly relates to a microgroove cable, which comprises a framework body, a plurality of framework blades, a plurality of framework slots, a reinforcing piece, a plurality of cable cores, a protective layer and a protective sleeve layer, wherein the framework body, the framework blades, and the framework slots are integrally formed; the framework blades are positioned on the edge of the framework body; the reinforcing piece is positioned in the center of the framework body; one framework slot is formed between each two adjacent framework blades; the cable cores are positioned in the framework slots; the framework blades are coated with the protective layer; the protective layer is coated with the protective sleeve layer in an extrusion manner; the microgroove cable is characterized in that the outer edges of the framework blades, and the outer edges of the framework slots are positioned on the side surface of the same cylinder, and at any cross section, the midpoint of the connecting line of the two ends of the opening of each framework slot and the connecting line of the top point of the bottom of each framework slot do not pass through the center of the reinforcing piece; all the framework slots are in the same direction. The microgroove cable has the main benefits as follows: the microgroove cable is easy to produce, higher in qualification rate of finished products, low in production equipment input, less in resource consumption, higher in product density, and more stable in product quality.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

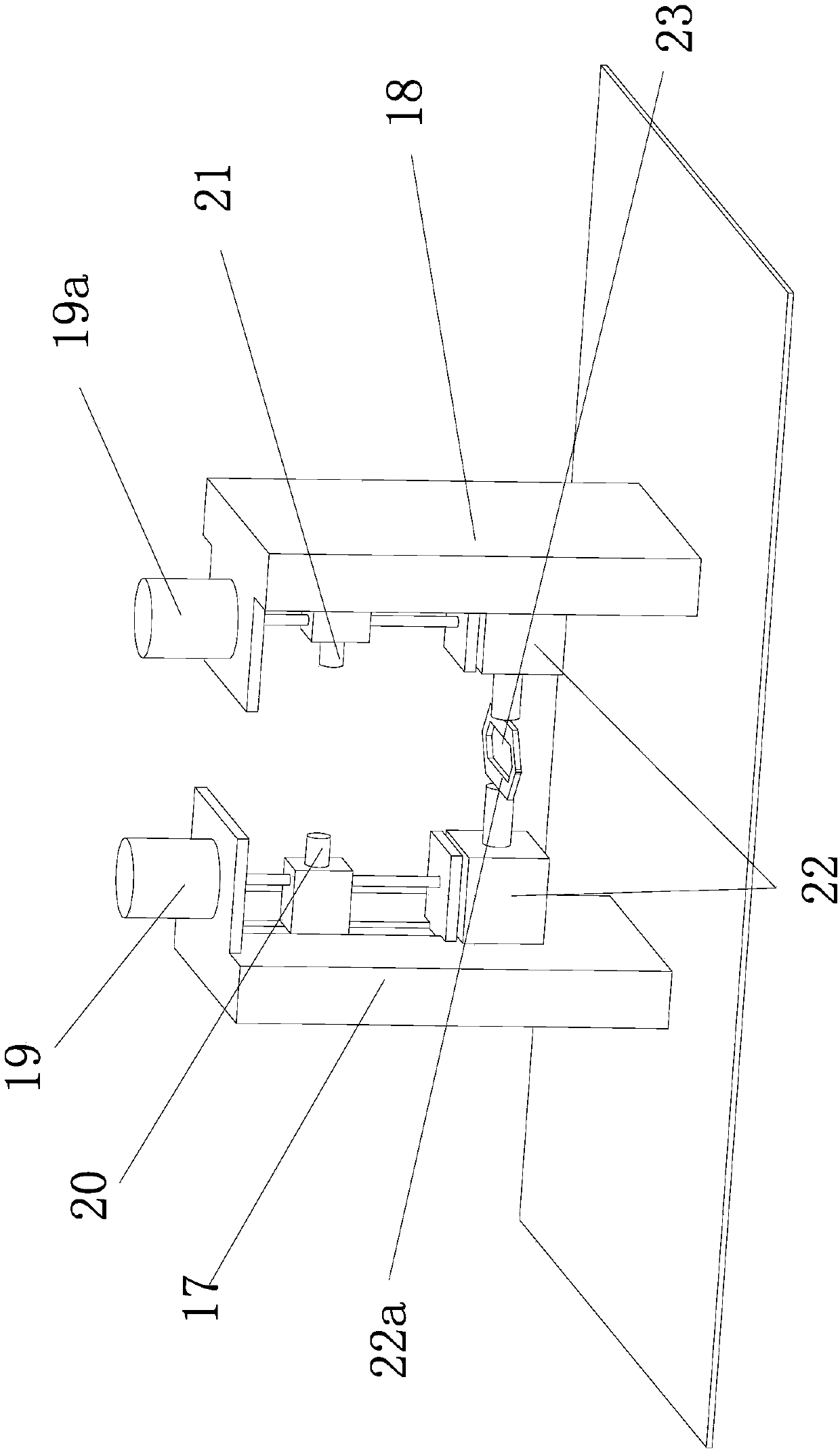

Sock packer

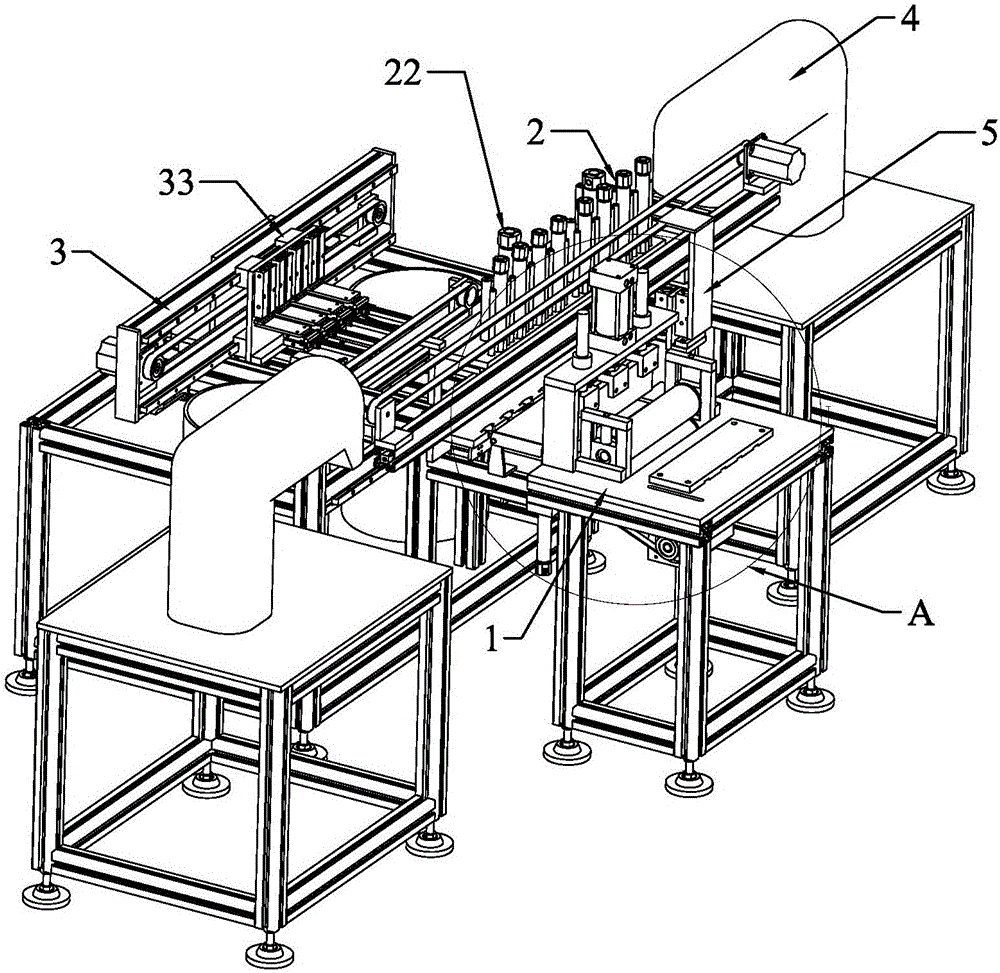

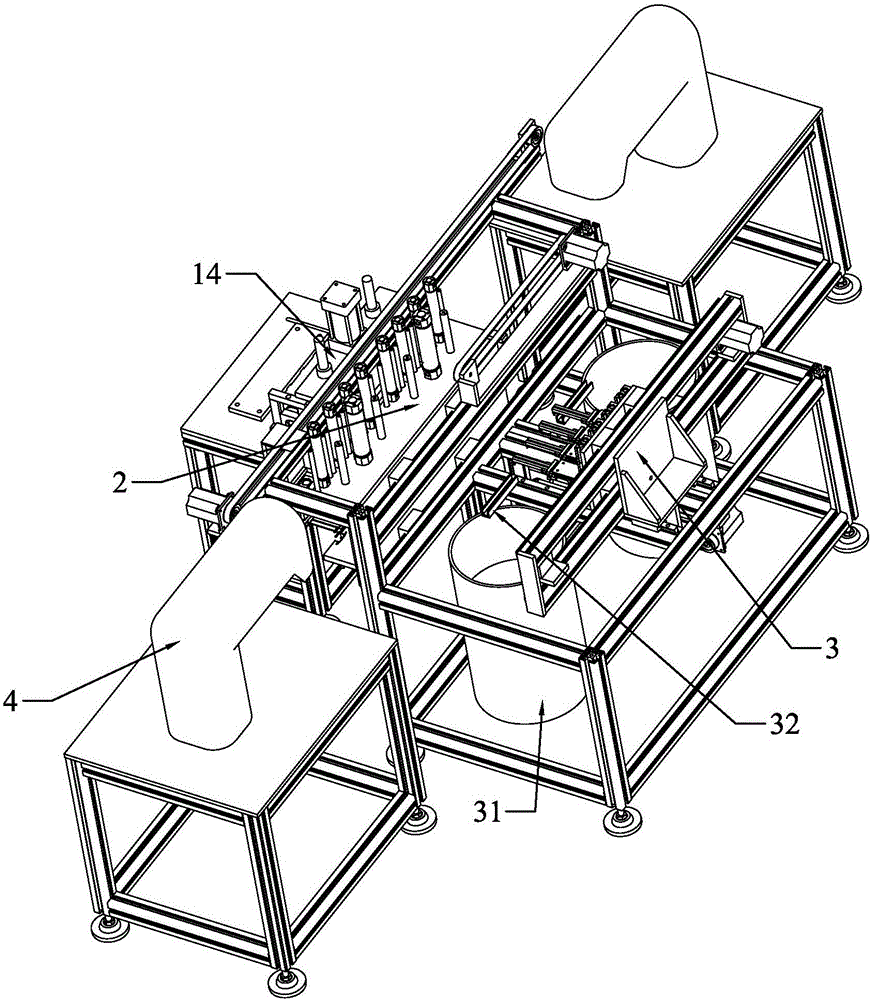

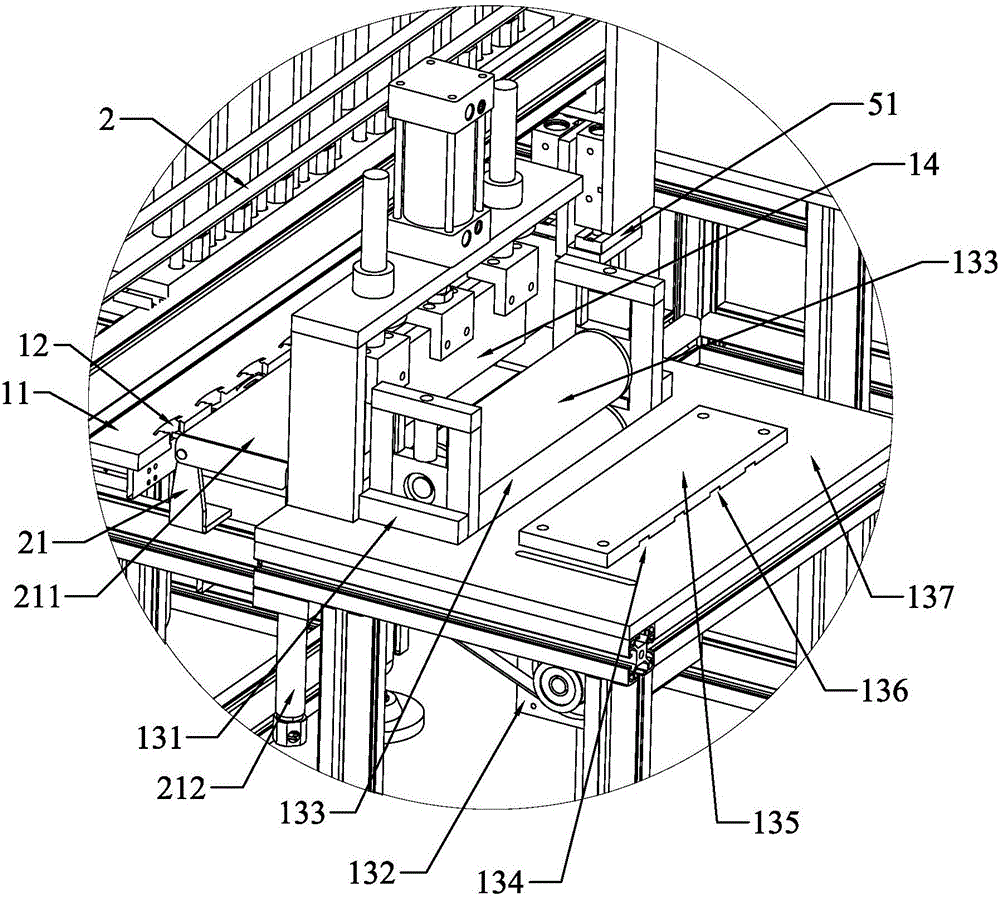

ActiveCN107776944AAvoid violent collisionsSave productivityLabelling deformable materialsSortingSOCKSBiochemical engineering

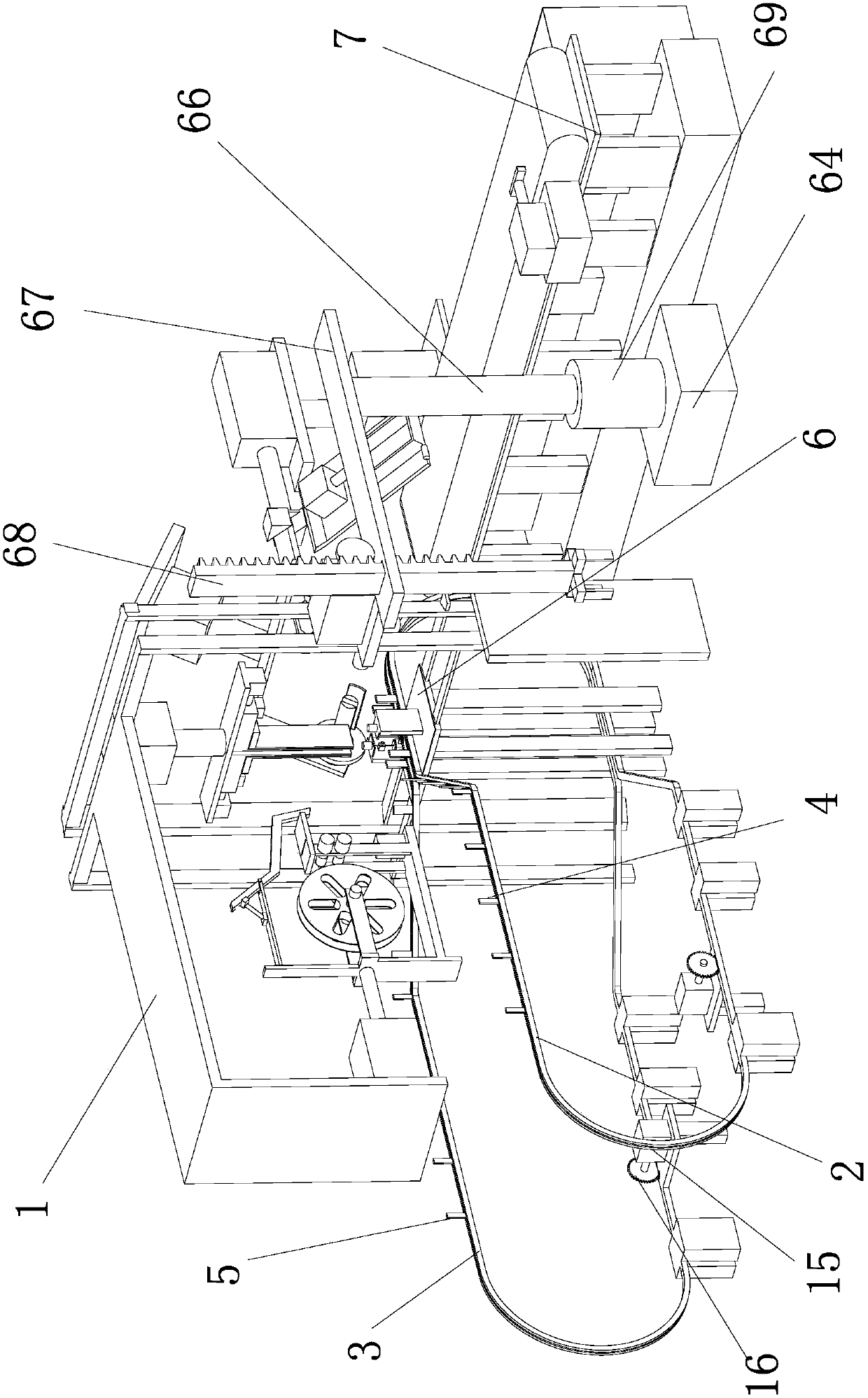

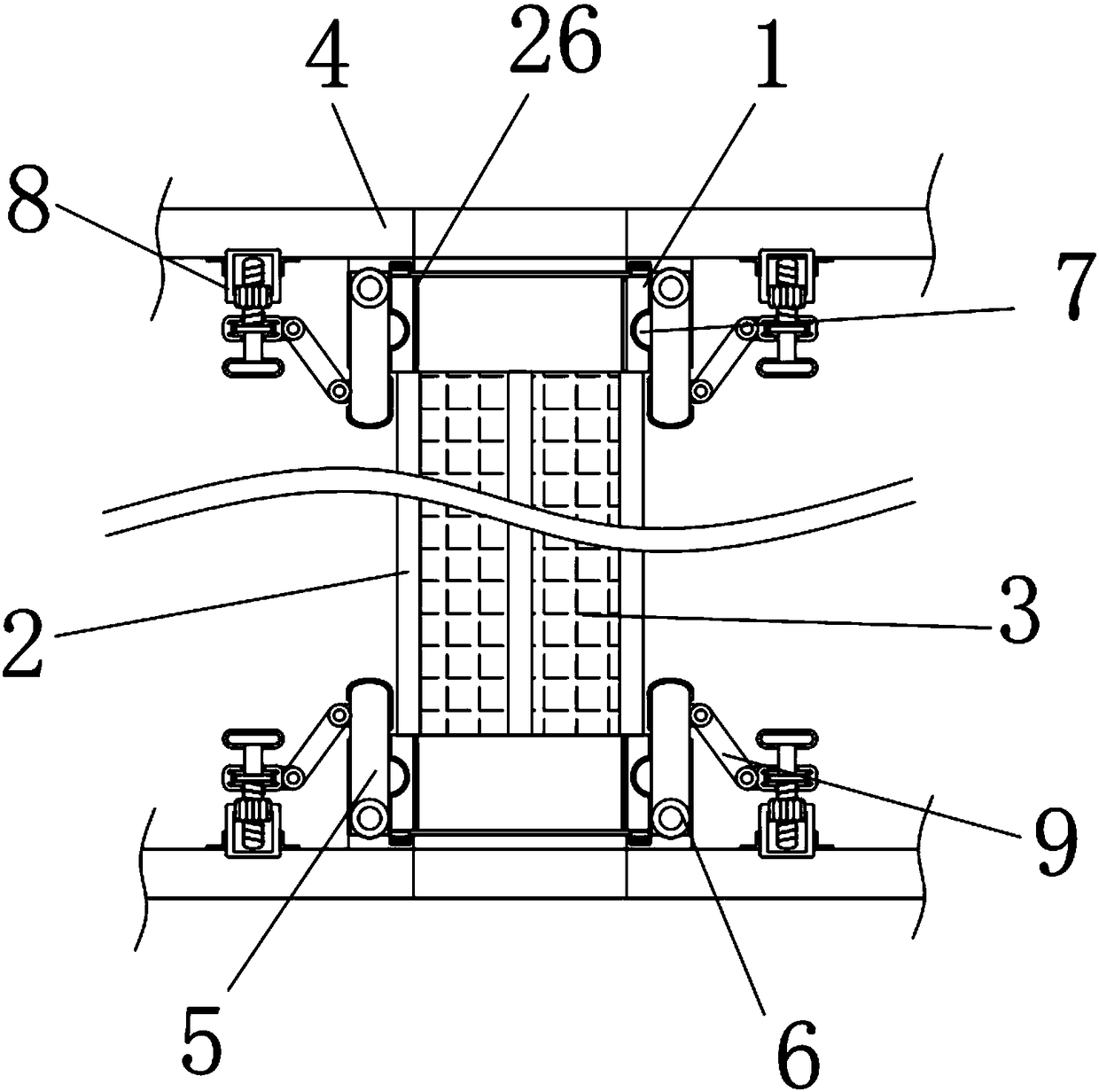

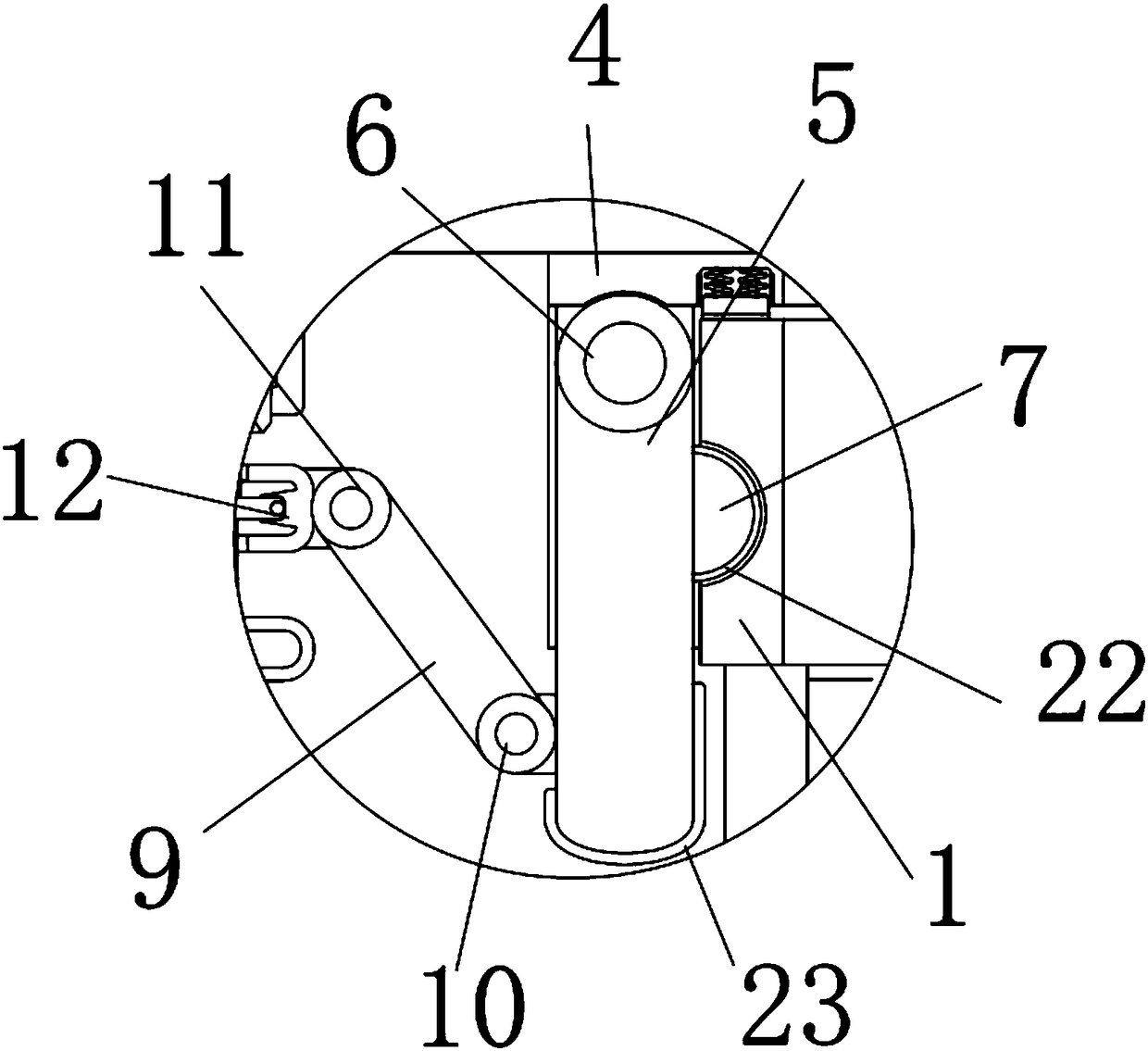

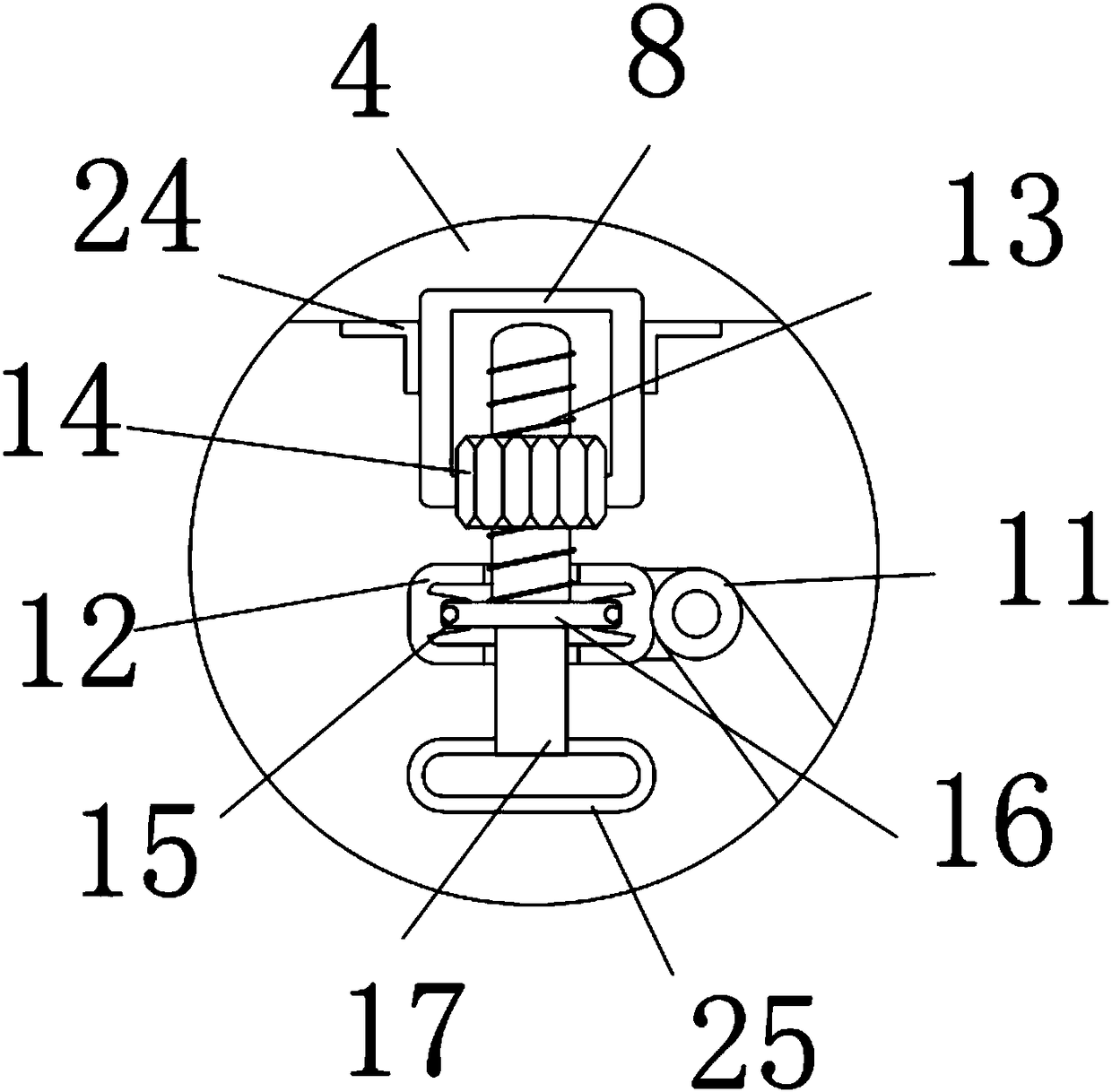

The invention provides a sock packer, belongs to the technical field of machinery and solves the technical problems of low efficiency and the like in prior sock packing. The sock packer comprises a rack and is characterized in that a first rail and a second rail which are in closed circulation are fixed on the rack, a first gap is formed between one end of the first rail and one end of the secondrail, a second gap is formed between the other end of the first rail and the other end of the second rail, and the second gap is smaller than the first gap; a first guide groove is formed in the firstrail, a first through hole communicated with the first guide groove is formed in the lower part of the first rail, a second guide groove is formed in the second rail, and a second through hole communicated with the second guide groove is formed in the lower part of the second rail. The sock packer has the advantage that socks are packed automatically and efficiently.

Owner:全椒县瑞祥工艺品有限公司

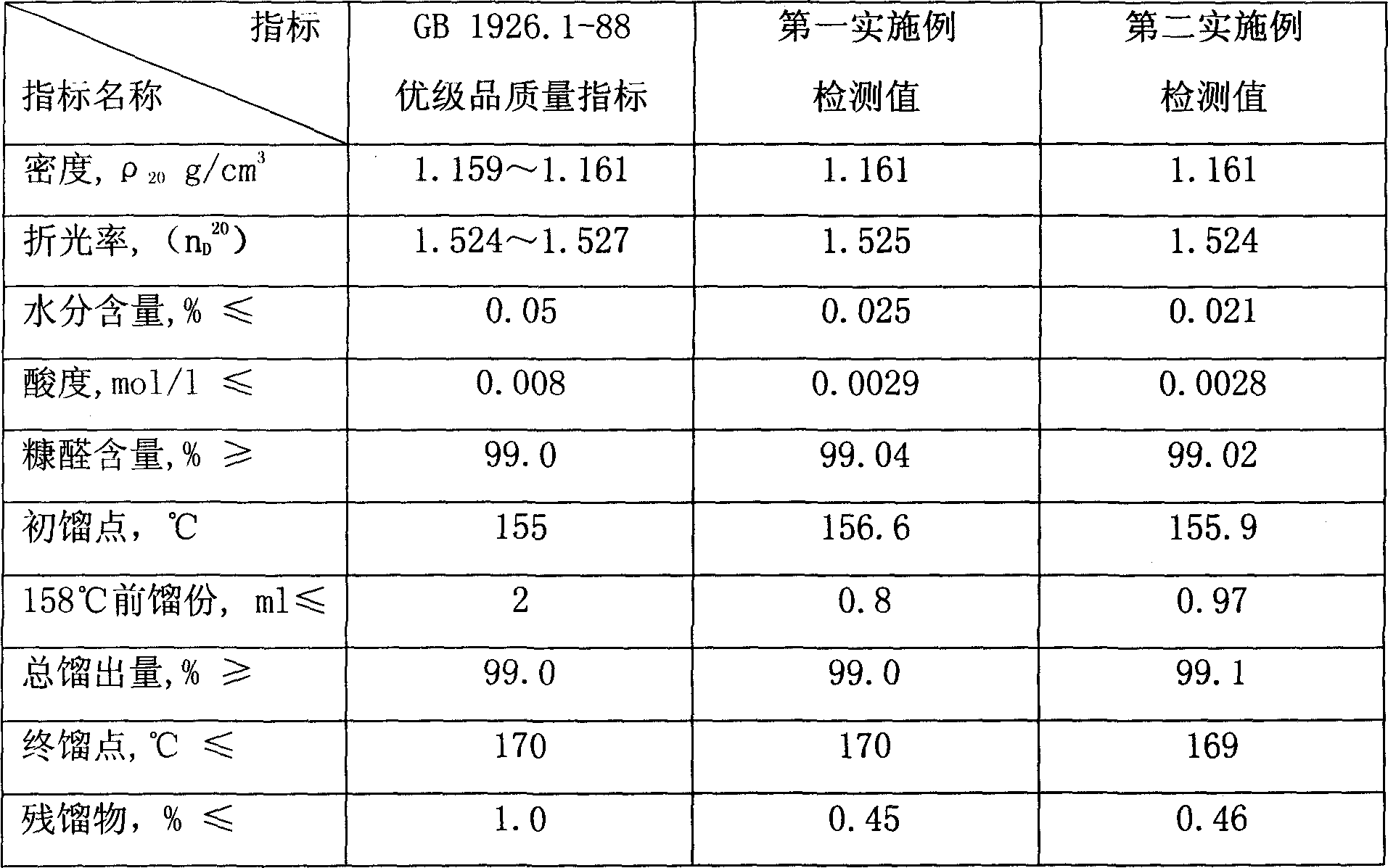

Method for producing furol by plant stalk pelletizing

InactiveCN1858044ASuitable for industrial productionStable and reliable productionOrganic chemistryDistillationPlant stalk

The plant stalk pelletizing process for producing furol belongs to the field of furol preparing technology. The process includes the following steps: cutting plant stalk into 2-4 cm long segments, controlling water content, crushing into powder, pelletizing, mixing with acid, hydrolysis to raw furol liquor, leading the raw furol liquor to the primary distillation tower to obtain raw furol and refining in a furol refining apparatus to obtain furol product. The production process is stable, reliable, low in production cost, high in furol yield and high in furol quality.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Control cable winding device convenient to fix

Owner:JIANGYIN YONGCHANG TRAFFIC MACHINERY PARTS

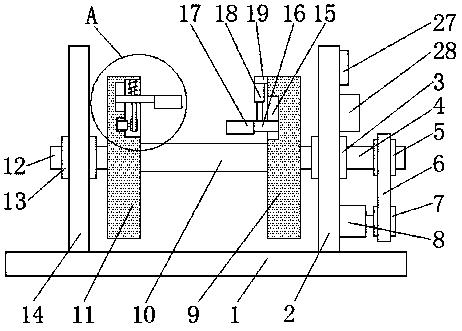

Simple fixture for manual PCB debugging

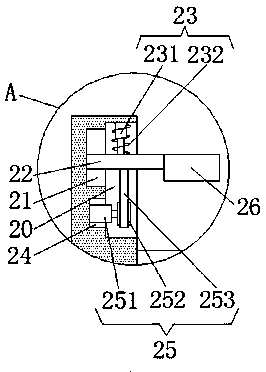

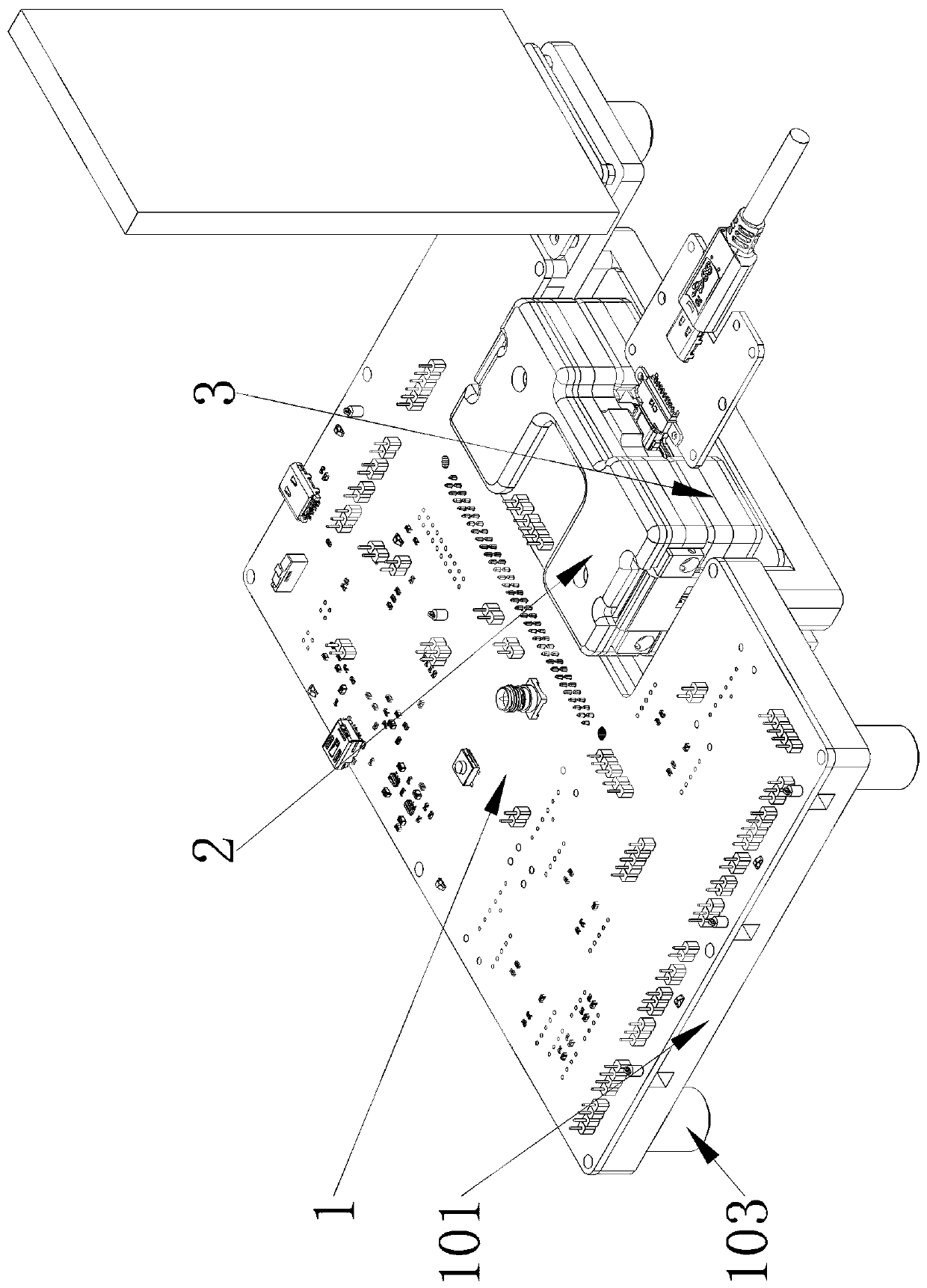

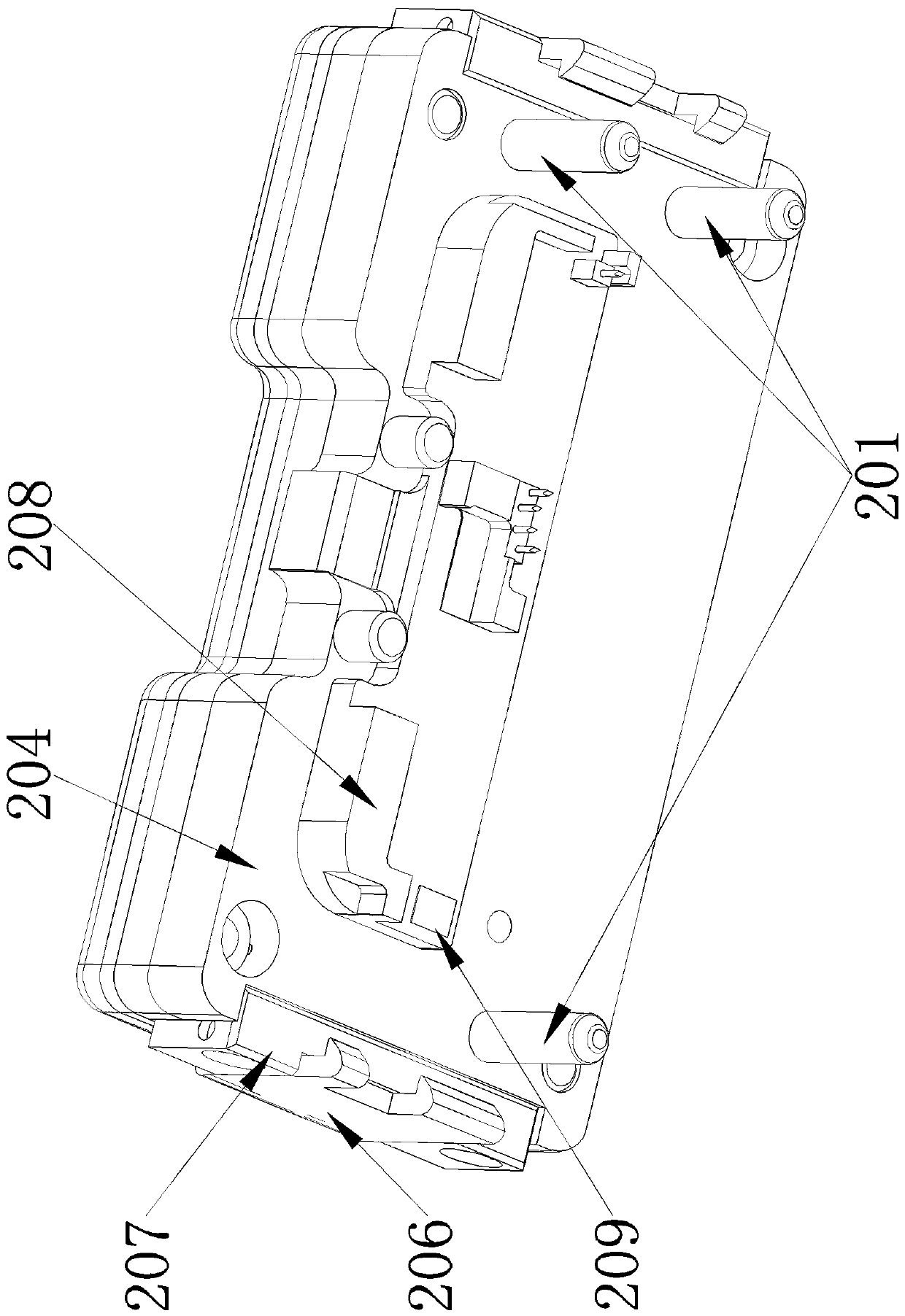

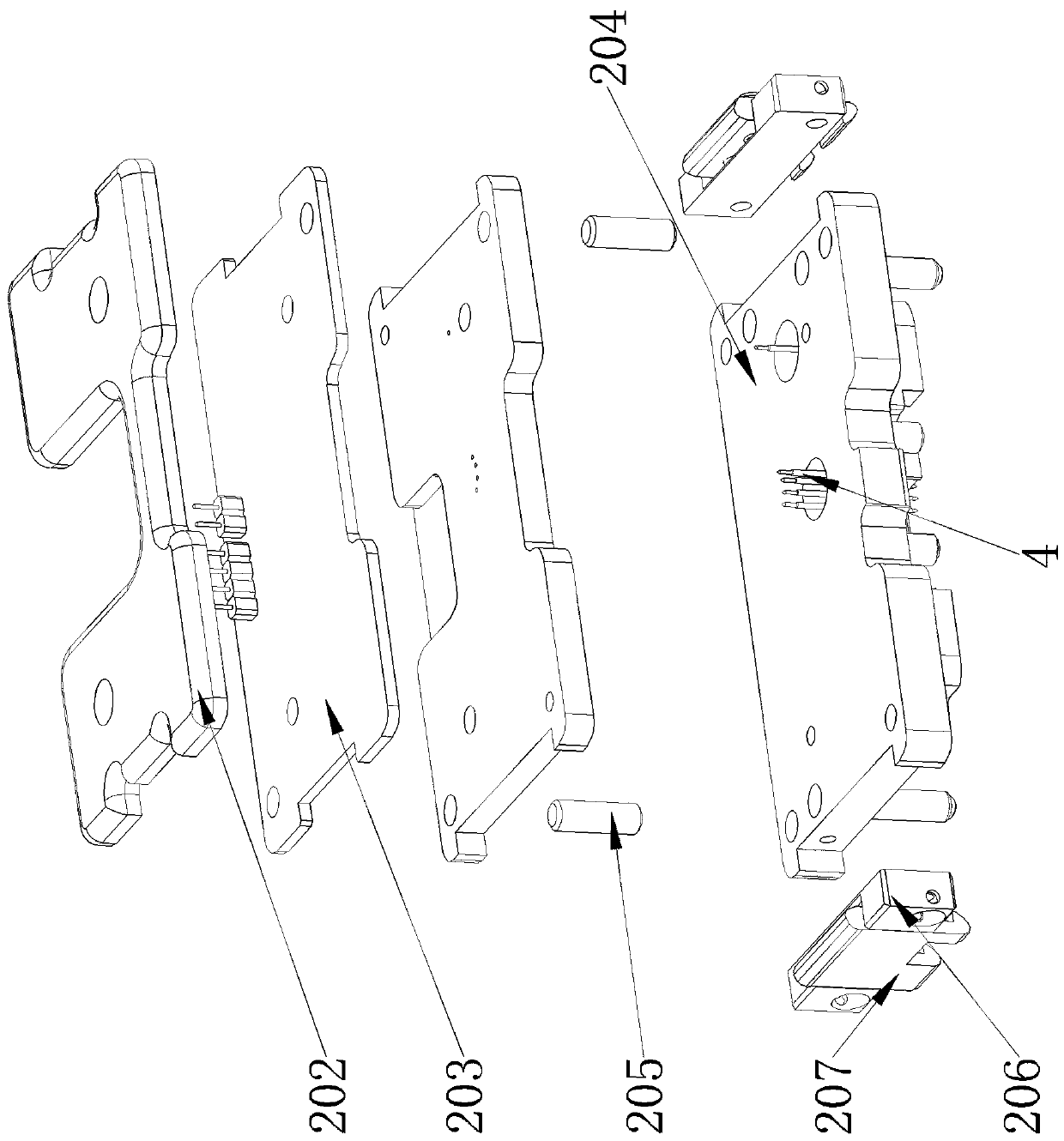

PendingCN109828125AImprove stabilityImpact contact testElectronic circuit testingMeasurement instrument housingDisplay deviceEngineering

The present invention provides a simple fixture for manual PCB debugging. The simple fixture has the advantages of small size and convenience in testing and carrying. The simple fixture of the invention includes a debugging board card, an upper probe board and a lower probe board; the upper probe board and the lower probe board are each provided with a plurality of probes; the probes are in electric signal connection with the debugging board card; the lower probe board is fixedly matched with the debugging board card; a product placement groove is formed in the lower probe board; the upper probe board is in matched connection with the lower probe board through a clamping buckle structure; when the upper probe board is in matched connection with the lower probe board, the probes contact with and are in electric signal connection with a PCB to be tested arranged in the product placement groove; and the debugging board card is provided with a display for displaying test data. The simple fixture of the invention is applied to the technical field of debugging tools.

Owner:珠海市运泰利自动化设备有限公司

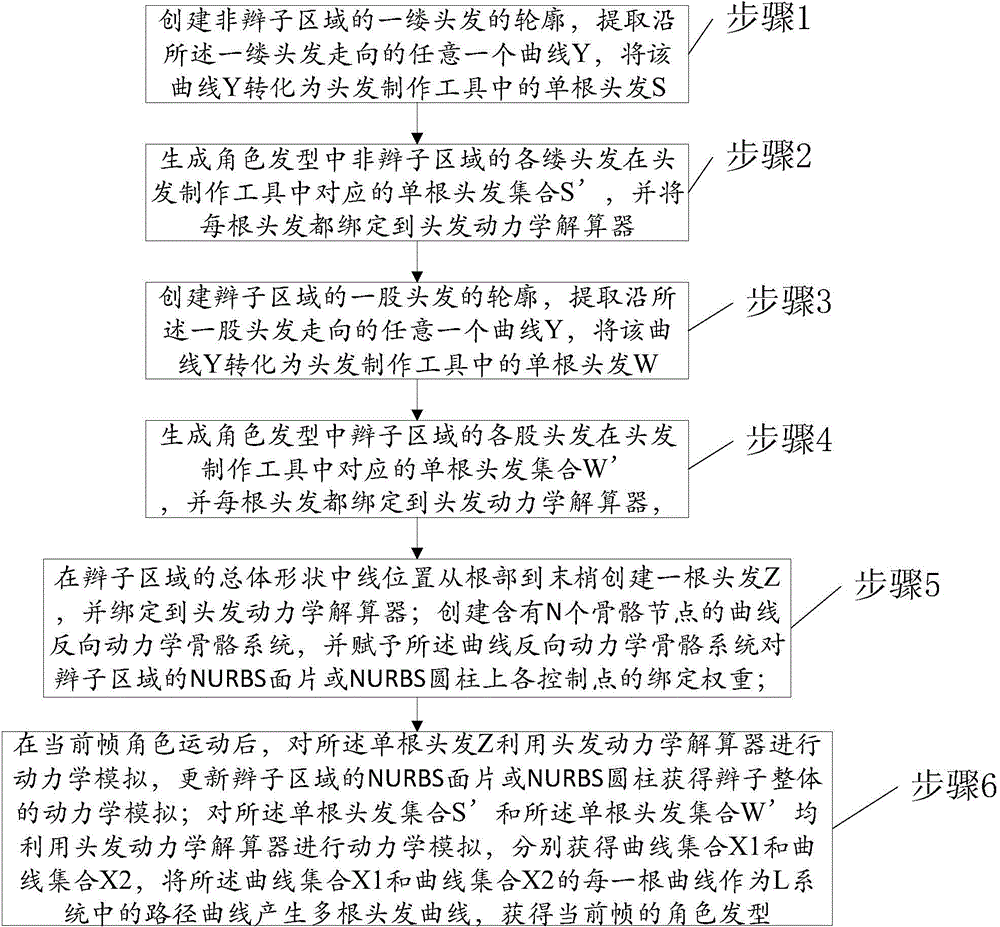

Rapid generation method of role hair style in three-dimensional animation

The invention provides a rapid generation method of a role hair style in a three-dimensional animation. The method comprises the steps that the outline of a strand of hair in a non-braid zone is established, any curve Y on the outline is converted into a single piece of hair S in a hair manufacturing tool, and a set S' of single pieces of hair corresponding to all strands of hair is obtained; in the same way, a set W' of single pieces of hair corresponding to all strands of hair in a braid zone is acquired; a single piece of hair Z is established in the hair manufacturing tool along the center line of a braid, and skeleton nodes are established along a curve Z and provided with binding weights; after role movement of a current frame, dynamic resolving is carried out on the single piece of hair Z, then dynamic resolving is carried out on the set S' and the set W' to obtain a curve set X1 and a curve set X2 respectively, multiple hair curves are generated with all curves in the curve set X1 and the curve set X2 serving as path curves in an L system, and then the role hair style of the current frame is obtained. The hair style dynamic system adopted in the method is high in resolving speed, and the generated braid does not get loose easily.

Owner:北京春天影视科技有限公司

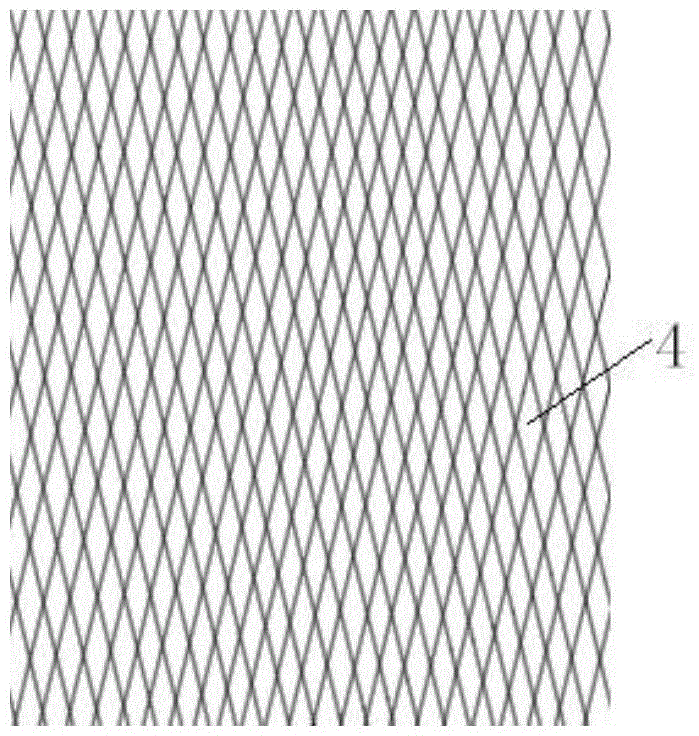

Low-temperature Lycra free-cut double-sided knitting fabric

The invention relates to a low-temperature Lycra free-cut double-sided knitting fabric which is made of blended yarns formed by interweaving low-temperature Lycra yarns and spinning fiber yarns. The fabric is formed by interweaving the blended yarn. The blended yarn is of a rib or double-rib woven structure. The fabric is a double-faced weft-knitting knitted structure, and joints between the blended yarns are mutually soluble bonding points. The low-temperature Lycra free-cut double-sided knitting fabric is advantageous in that the yarn is bonded solidly in a mutually soluble mode, the fabric can be cut freely, edges will not ravel, the manufacturing cost is low, and the overall fabric is flat and beautiful.

Owner:JIANGSU NEW XUEZHU INT FASHION

Manufacture process of warp knitted fringe lace

ActiveCN102978825AWon't fall apartReduce manual disengagement processOrnamental textile articlesWarp knittingTasselPulp and paper industry

The invention discloses a manufacture process of a warp knitted fringe lace. The manufacture process comprises the following steps of S1, forming patterns on a fall plate lace raw material to manufacture the warp knitted fringe lace, wherein during pattern forming, the pattern is circled and is simultaneously evaded; S2, connecting one evaded side of the warp knitted fringe lace with a fabric surface by a water dissolving yarn; and S3, dyeing the warp knitted fringe lace through pretreatment, preshaping, dyeing and shaping, wherein the pretreated warp knitted fringe lace is subjected to dirt removal in water, the water temperature is lower than or equal to the dissolving temperature of the water dissolving yarn, and the dyeing temperature during dyeing is greater than the dissolving temperature of the water dissolving yarn. The manufacture process of the warp knitted fringe lace has the advantages that during dyeing, the water dissolving yarn is dissolved, and then the lace is automatically disengaged from the fabric surface, so the artificial disengagement is not needed, the artificial cost is reduced, and the speeds of production and manufacture are increased; and the variable chaining can be adopted, so the curved fringe lace is realized.

Owner:FUJIAN DONGLONG KNITTING & TEXTILE

Scrap steel strap reeling, bending and recycling device and reeling, bending and recycling method thereof

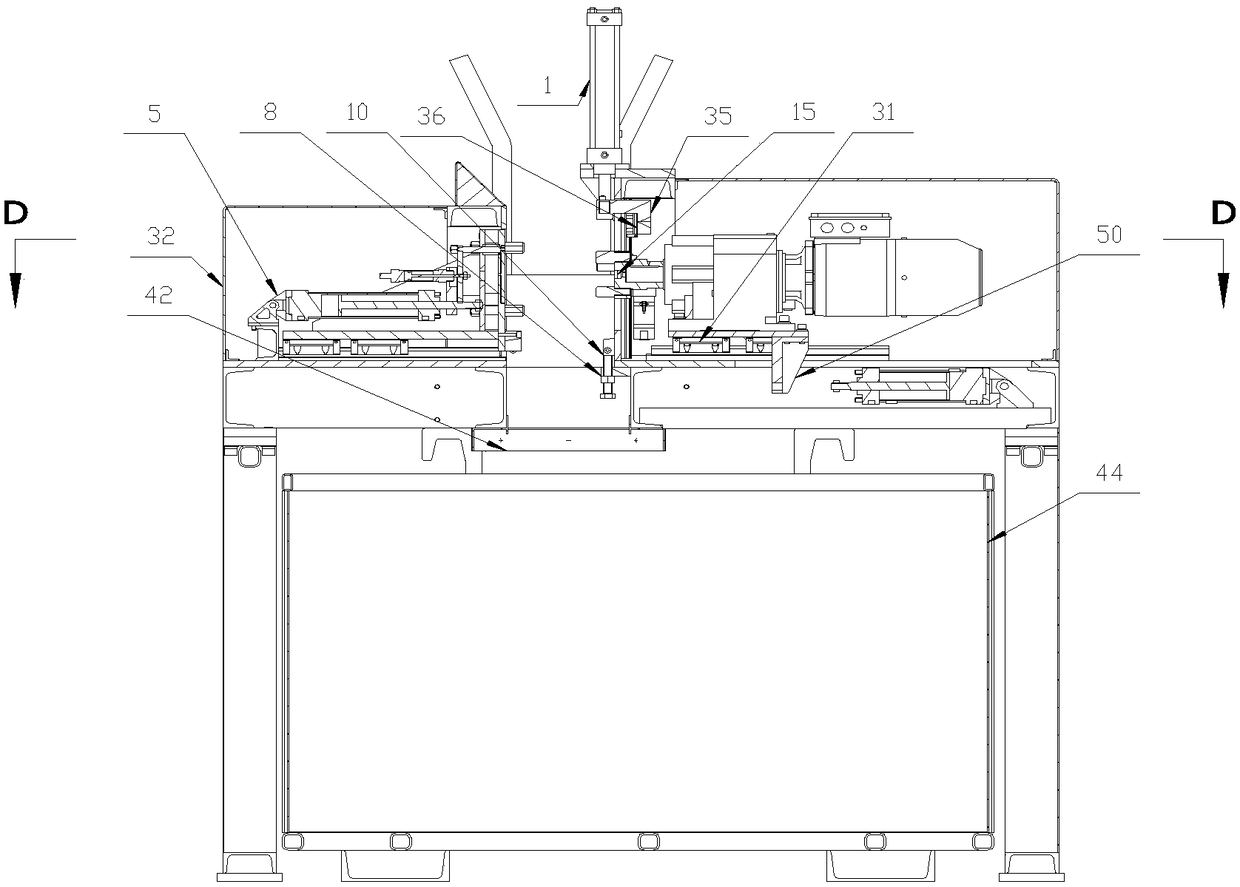

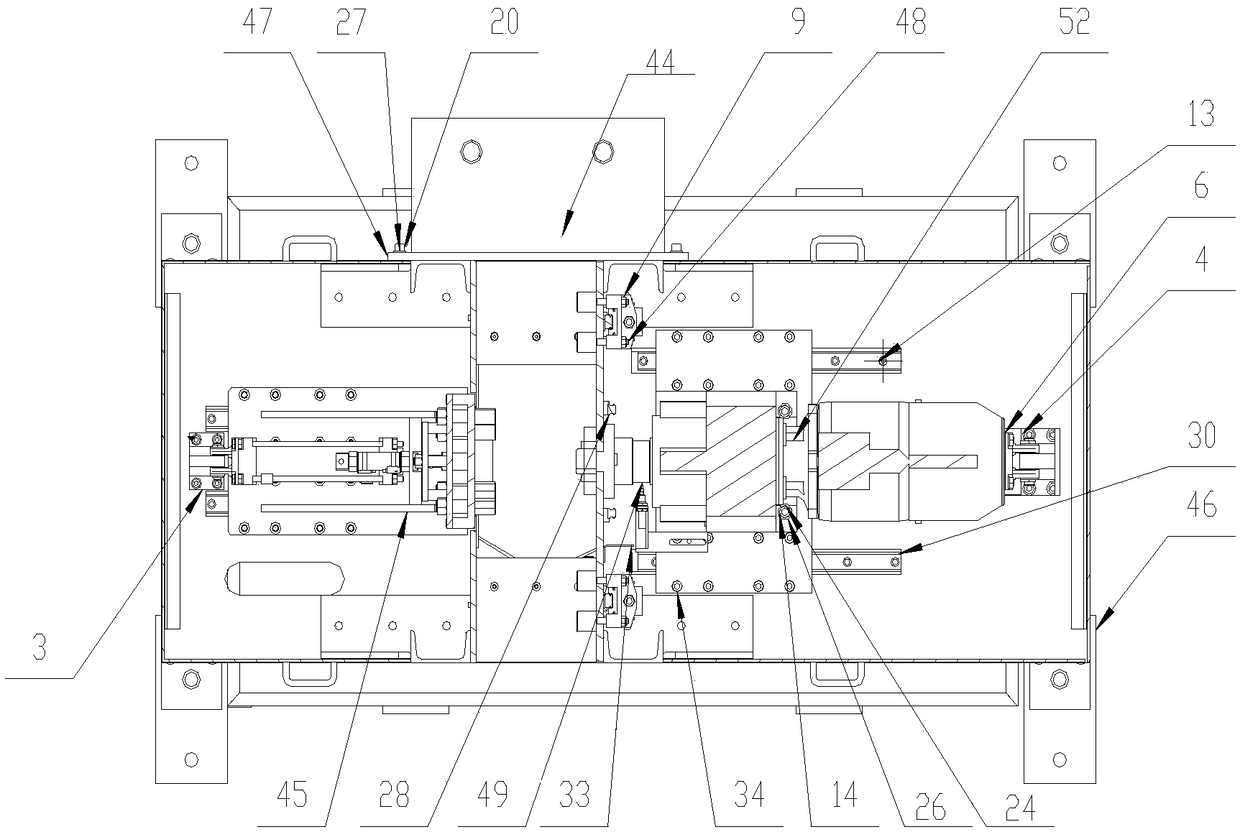

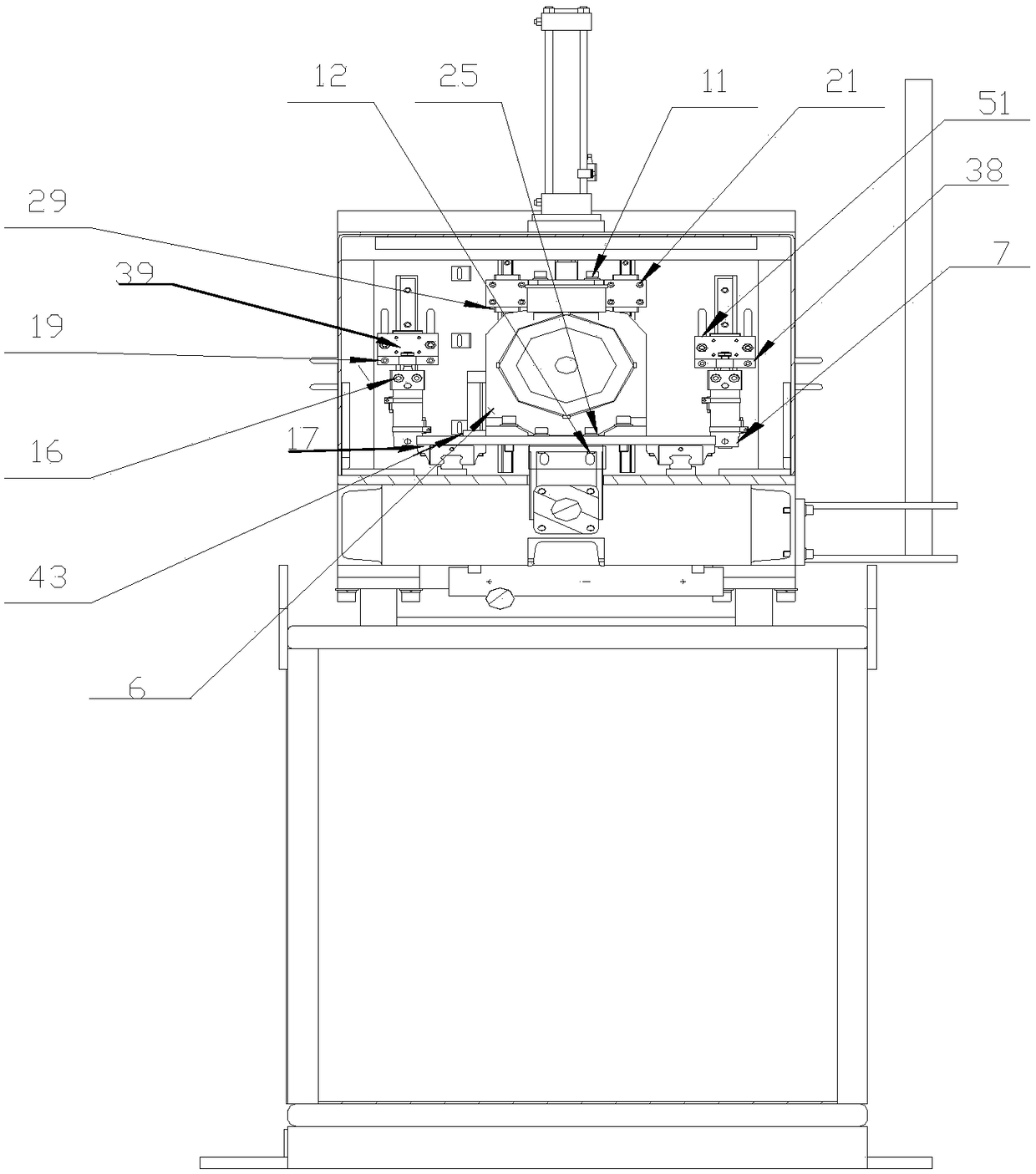

ActiveCN108687100ASolving Recycling ProblemsSolve shipping problemsSolid waste disposalHydraulic cylinderEngineering

The invention discloses a scrap steel strap reeling, bending and recycling device and a reeling, bending and recycling method thereof. The device comprises a rising and falling hydraulic cylinder, a pneumatic three-connection part, a first dual-lug-ring angle base, second dual-lug-ring angle bases, a first air cylinder, a second air cylinder and the like; a strap head waste joint is connected witha base assembly, the base assembly is connected with a waste box assembly, a first bolt and nut set is located above the strap head waste joint, the first bolt and nut set is connected with a third bolt and nut set, the third bolt and nut set is located below a fifth bolt connecting part, the fifth bolt connecting part is located below a second mounting plate, the second mounting plate is connected with a press head, the rising and falling hydraulic cylinder is located above the second mounting plate, a second sliding block is located on the right side of the third bolt and nut set, the second sliding block is connected with an air cylinder connecting support, and a cover shell is connected with the base assembly. Each long steel strap manually or automatically detached from a steel coilcan be reeled and bent automatically, and storage and transportation are facilitated.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

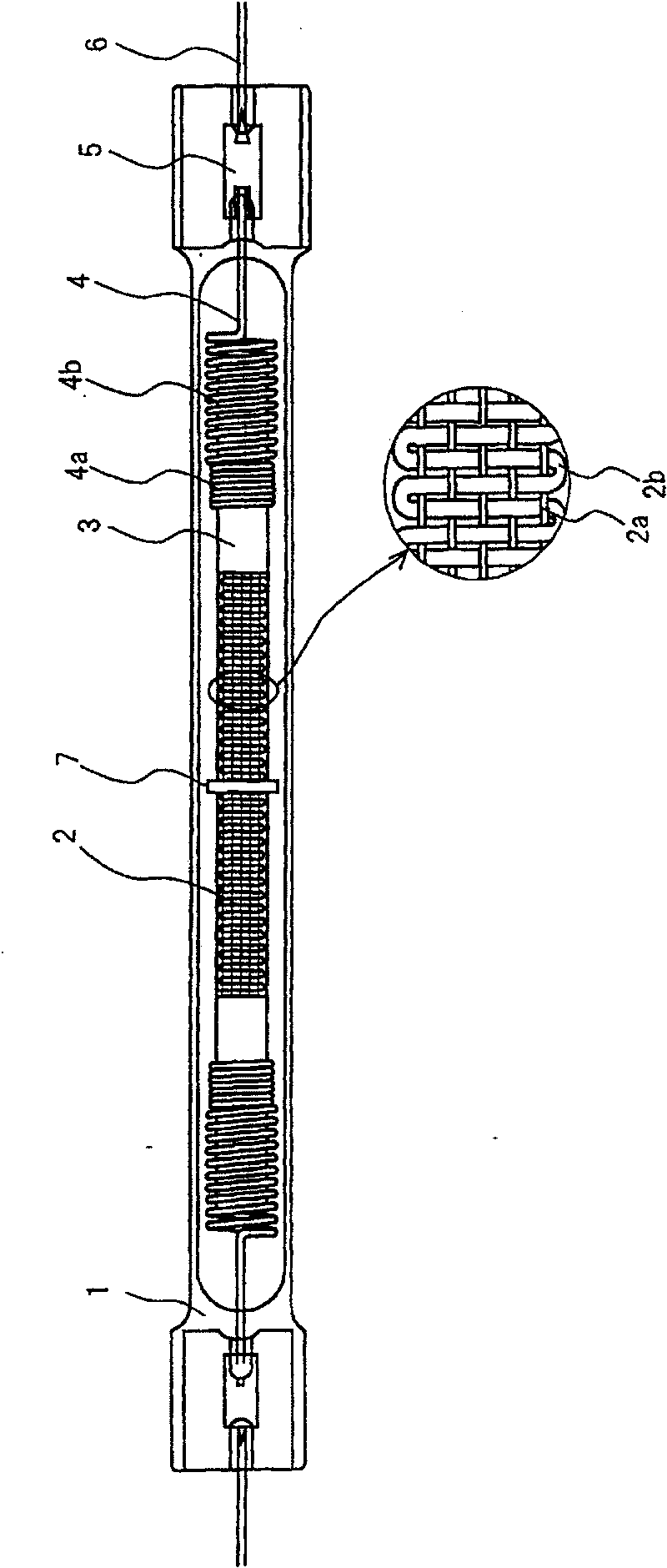

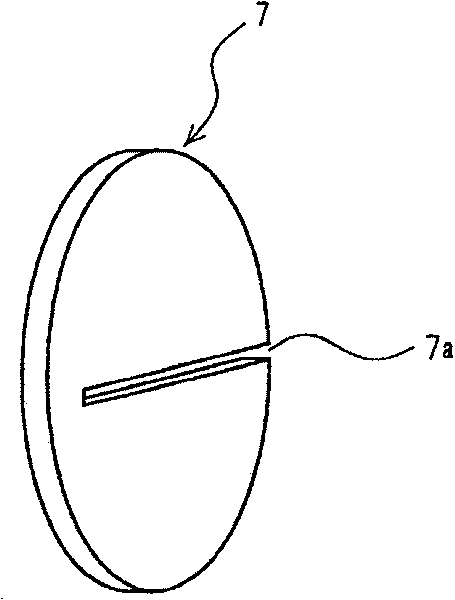

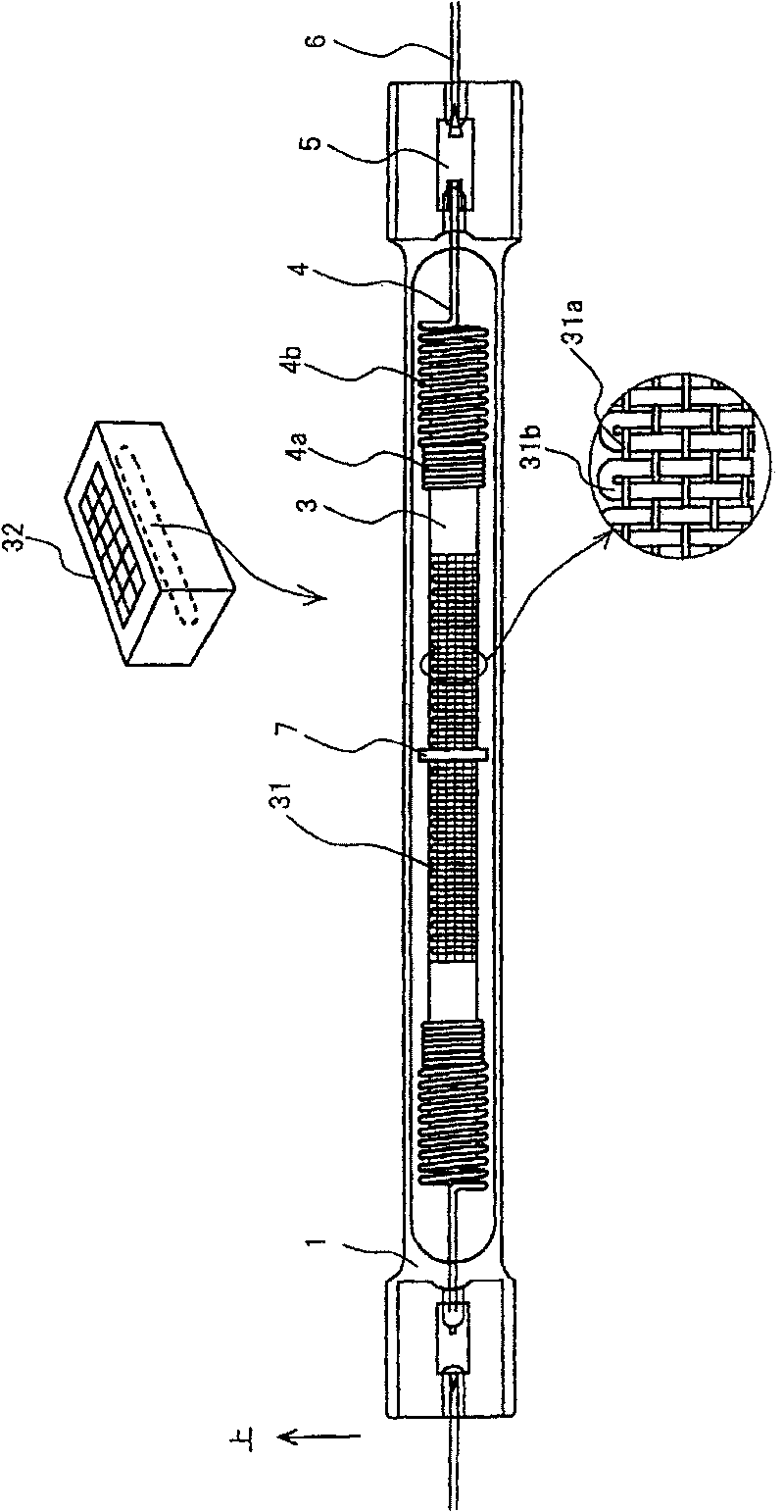

Manufacturing method of carbons heating element, carbons heating elements, heater and heating device

InactiveCN1622695BWon't fall offImplement the manufacturing methodOhmic-resistance heating detailsHeating element shapesFiberCarbon fibers

The invention can provide a carbon heater in which respective carbon fibers do not spread out, even the fibers are thinned for giving predetermined resistance and the fibers can have predetermined strength, a method for manufacturing the carbon-based heater, a heater and a heating device. The heater comprises a glass tube having a carbon-based heater sealed therein, in which the carbon heater is formed by firing a material formed by weaving a plurality of continuous fibers such that at least a weft alternatively passes through above or below each warp, and respective warp alternately passing through above or below each weft.

Owner:PANASONIC CORP

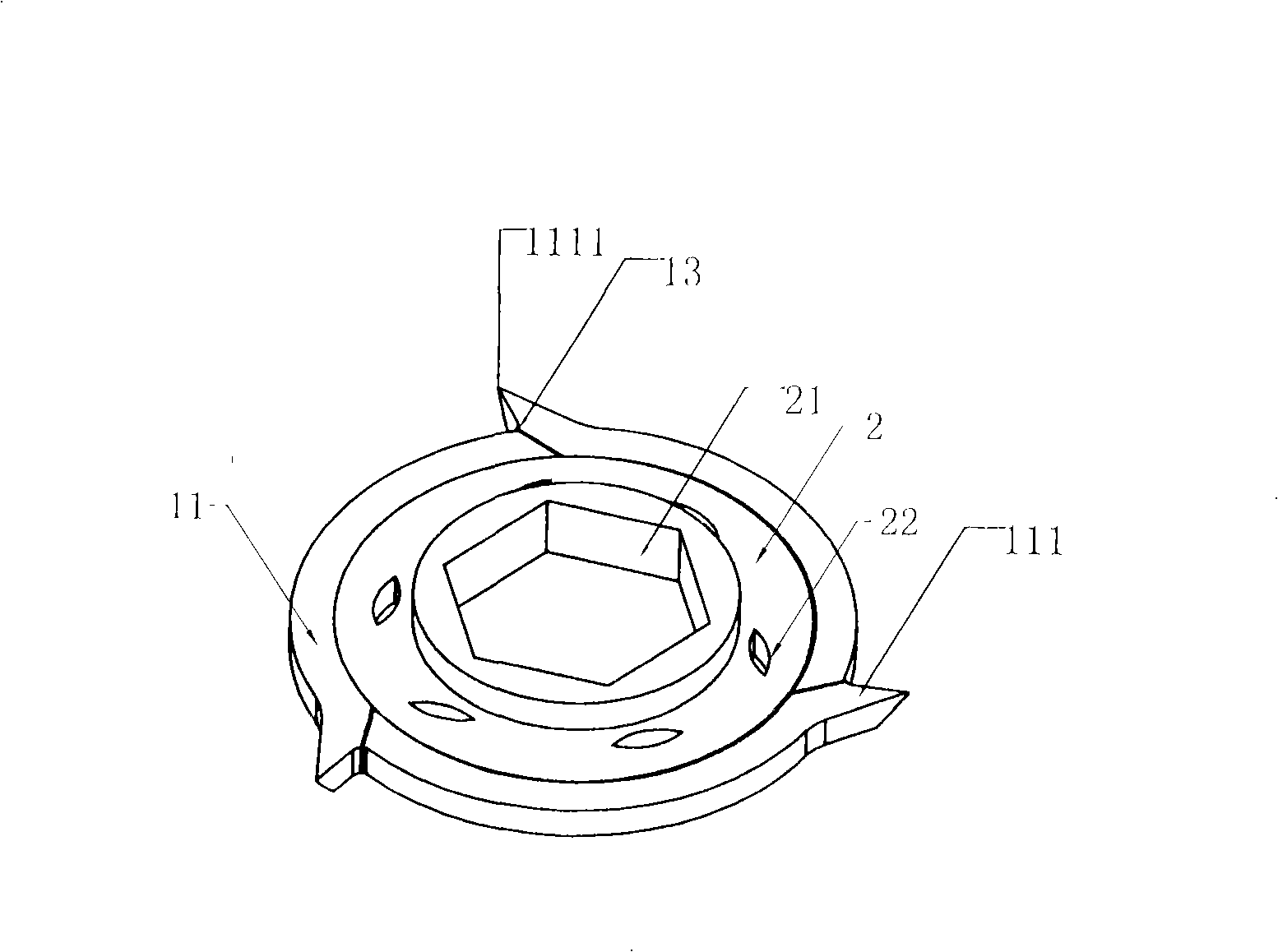

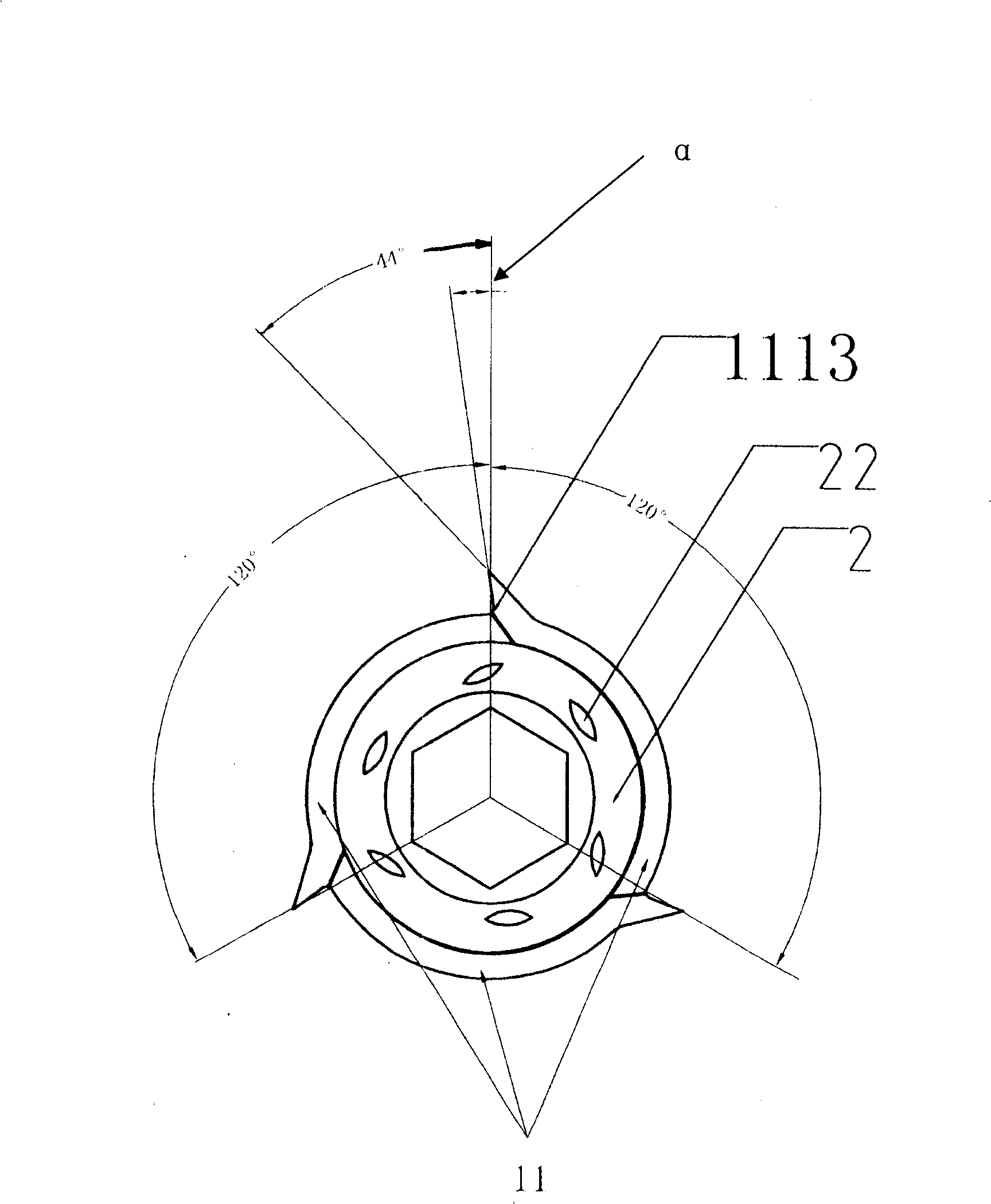

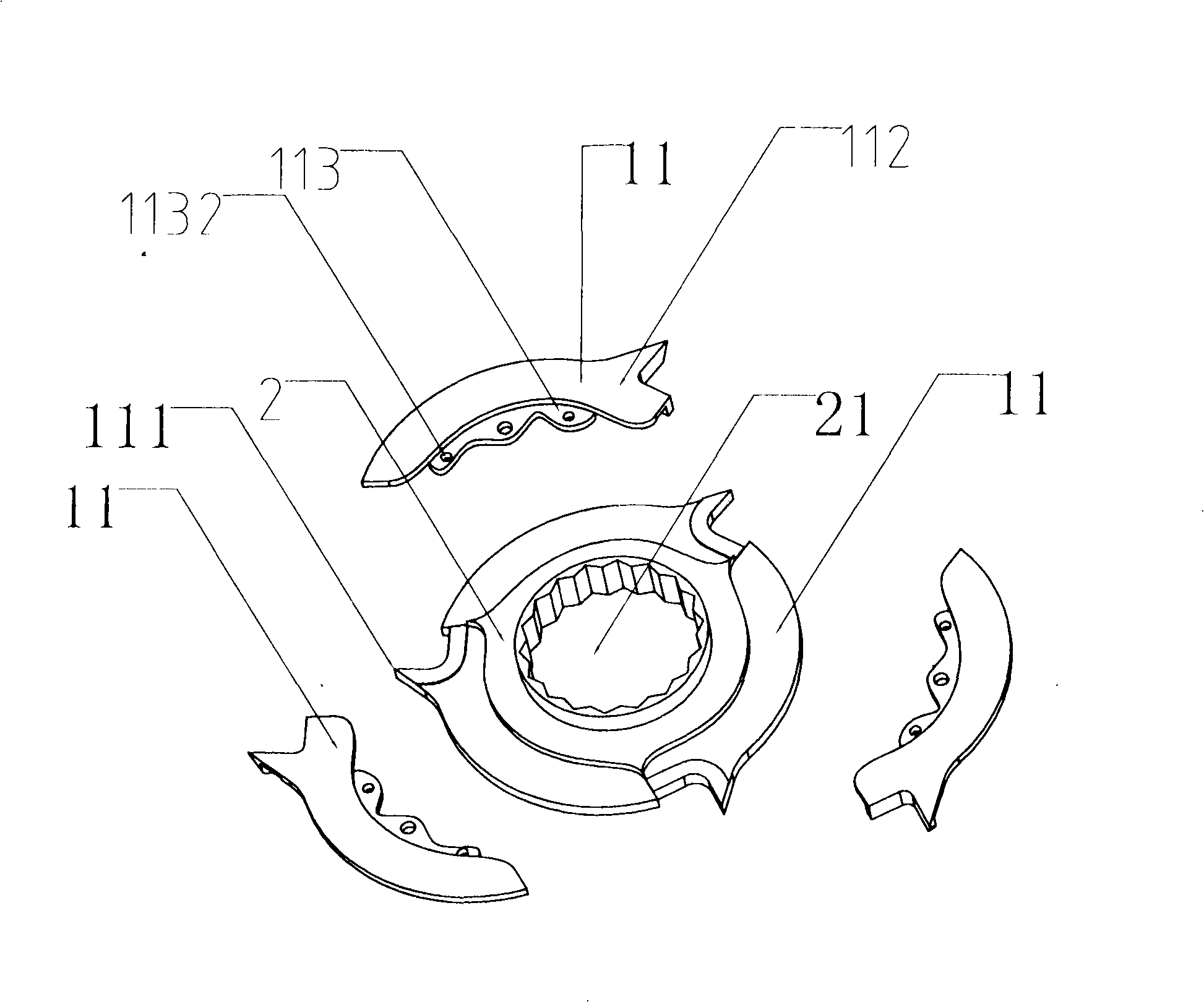

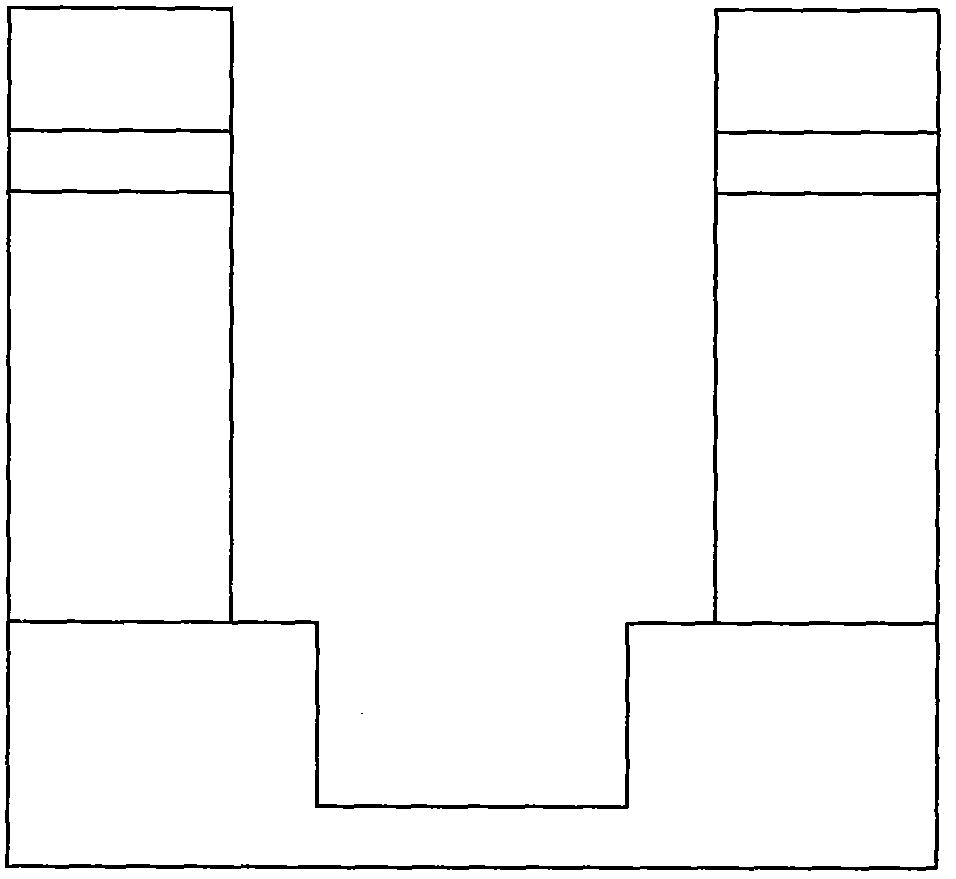

Paper crusher combined structure blade and manufacture method thereof

The invention discloses a combined structure blade of a paper shredder, which particularly relates to a combined structure blade of a paper shredder which is made from two kinds of materials and can reduce the blade cost and the paper shredder cost, and a preparation method thereof. The combined structure blade comprises a blade which is positioned at periphery and has a cutting blade and a base ring positioned inside the combined structure blade, the center of the base ring is an axis hole which can match various shapes of axial rods, wherein, the blade is made from metal material, the base ring is made from high polymer material, the blade and the base ring are integrated by injection molding. The combined structure blade is characterized in that the blade consists of a multi-segment arc blade which can surround a circle of the base ring, the multi-segment arc blade separates a breaking point along the periphery of a complete unbroken original blade, the breaking point is positioned below the tip of the cutting blade and reaches the intersection point between the connecting line of the tip of the cutting blade and the axis and the periphery of the original blade, and the quantity of the multi-segment arc bade is same as that of the cutting blade on the blade.

Owner:白雪惠

Fabric cutting device capable of preventing scattering of weaved watchband and difficult in machining process

The invention discloses a fabric cutting device capable of preventing scattering of a weaved watchband and difficult in machining process. The device structurally comprises a moving case, a moving placing groove, an observation window, a running operation box and an excess outlet end, the excess outlet end penetrates through the inside of one end of the running operation box mutually, and the running operation box comprises a slide rail, a handle, an extruding fixing set, an extruding control box, a main control box, a rotary cutting edge sealing device, cutting hot sealing equipment, a protective shell, a to-be-treated case and a hollow-out case, the hollow-out case is arranged right below the rotary cutting edge sealing device, and the handle penetrates through the inside the protectiveshell. When placed in the device, the watchband can be subjected to edge sealing, in the hole drilling process, a blade of the device rotatably cuts the watchband, the periphery of the watchband is pressed by an auxiliary body, the watchband cannot be influenced by the part subjected to cutting, after cutting is completed, the part after cutting is completed is heated slightly, the inner wall of the watchband can be bonded, and the watchband cannot be scattered.

Owner:绍兴柯桥徐力绣品有限公司

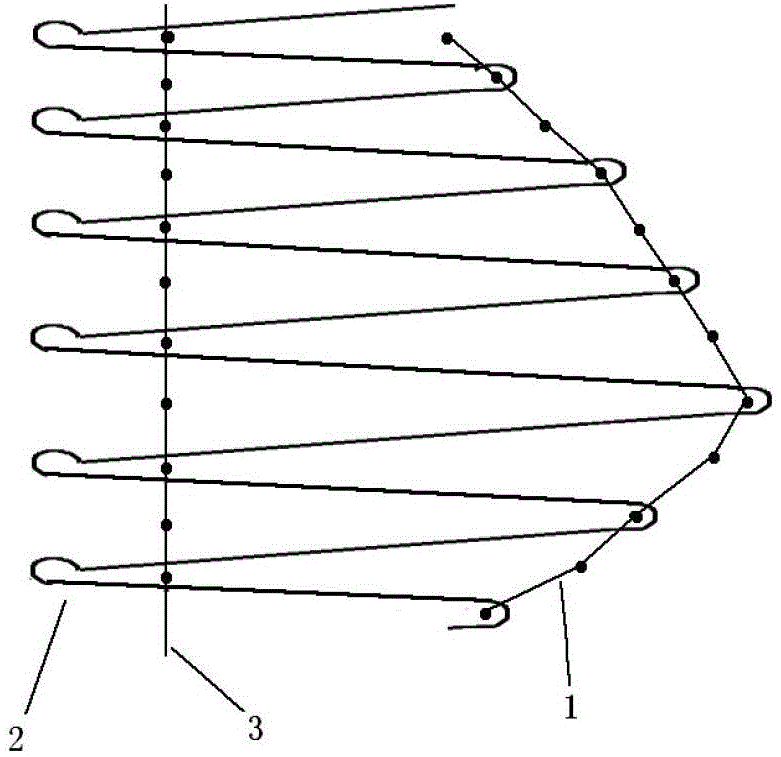

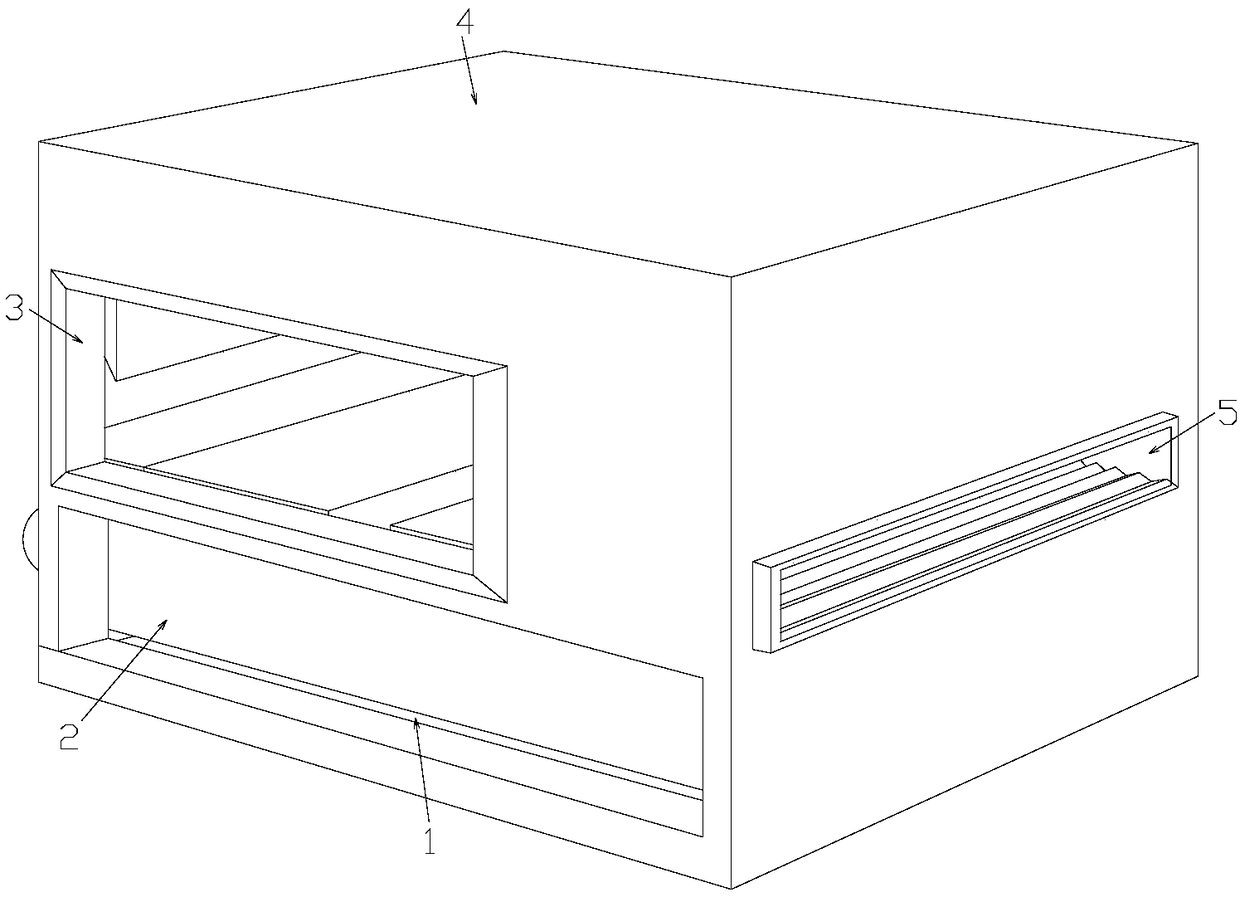

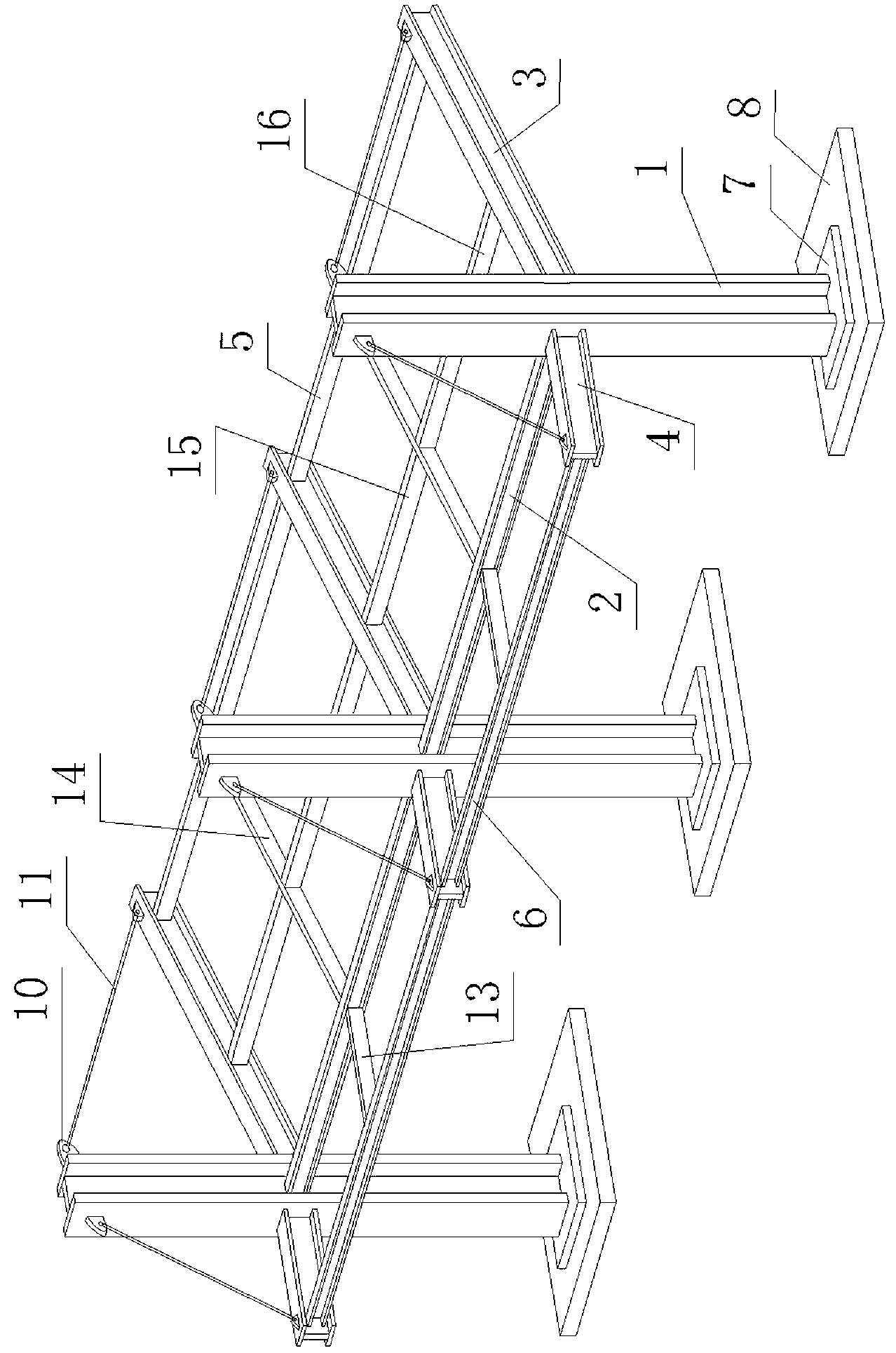

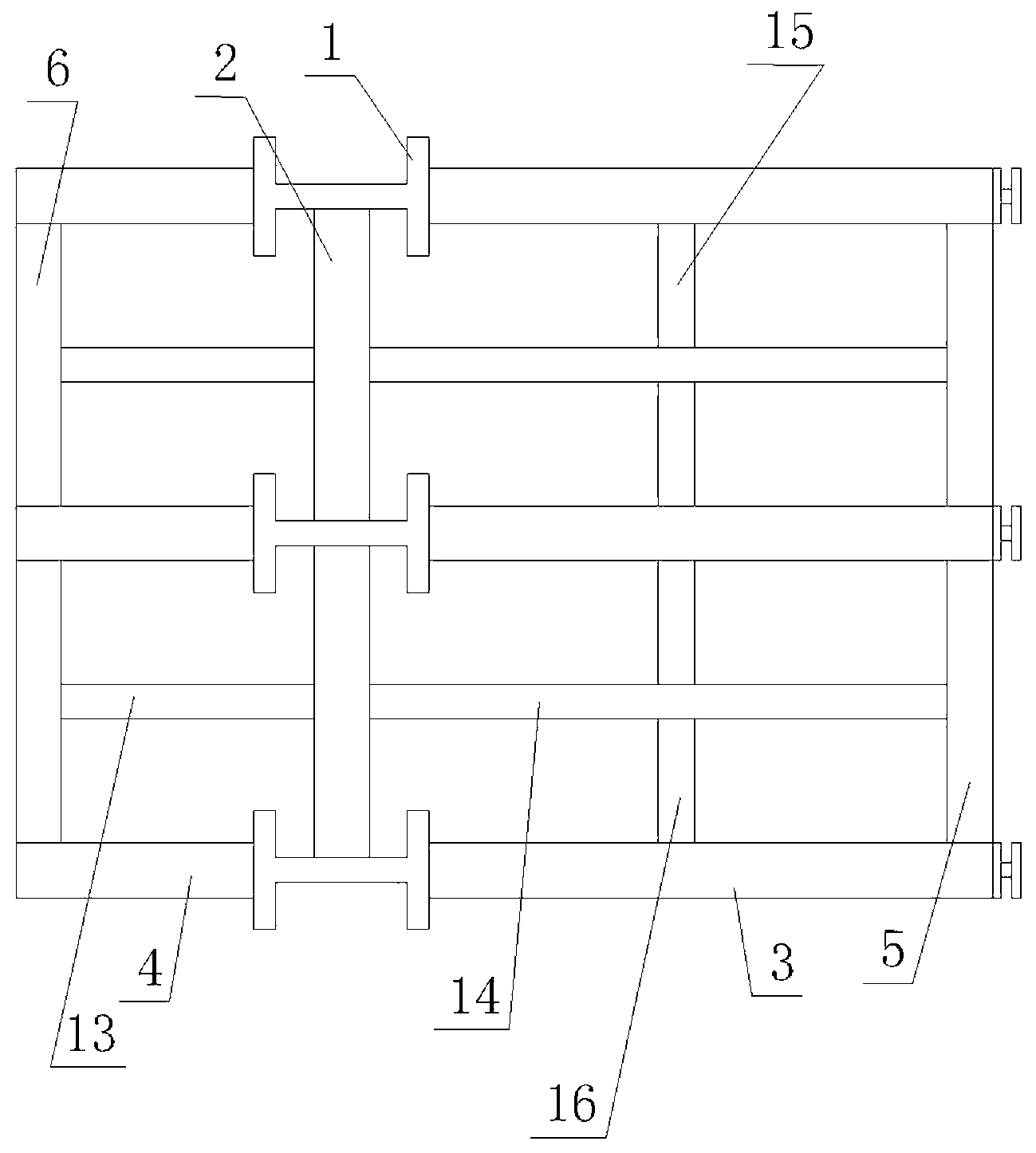

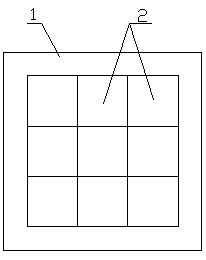

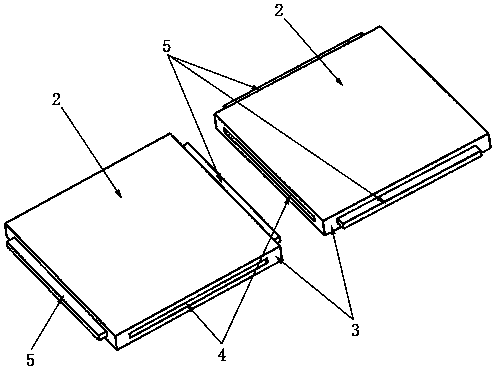

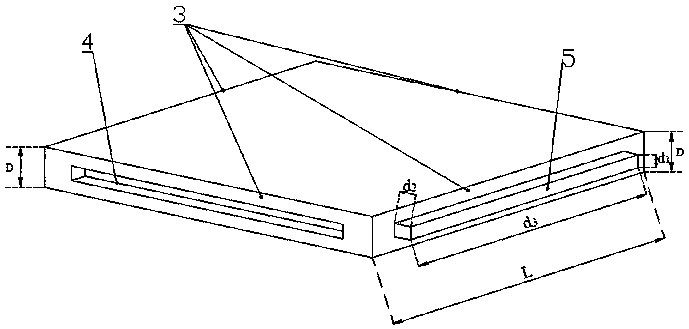

Steel reinforcement processing shed and construction method therefor

InactiveCN102913007AEasy to driveEasy to assembleBuilding material handlingIndustrial buildingsRebarCantilever

The invention discloses a steel reinforcement processing shed and a construction method for the steel reinforcement processing shed. The steel reinforcement processing shed comprises a row of I-shaped steel uprights (1), an I-shaped steel main beam (2) is arranged between the adjacent I-shaped steel uprights (1), cantilever upwarp I-shaped steel beams (3) are arranged in front of the I-shaped steel uprights (1), cantilever horizontal I-shaped steel beams (4) are arranged behind the I-shaped steel uprights (1), a front auxiliary beam (5) is arranged between the adjacent cantilever upwarp I-shaped steel beams (3), and a rear auxiliary beam (6) is arranged between the adjacent cantilever horizontal I-shaped steel beams (4). The construction method for the steel reinforcement processing shed comprises the following steps: the I-shaped steel uprights (1), the I-shaped steel main beams (2), the cantilever upwarp I-shaped steel beams (3), the cantilever horizontal I-shaped steel beams (4), the rear auxiliary beams (6) and the front auxiliary beams (5) are installed in sequence. The steel reinforcement processing shed and the construction method have the characteristics that steel reinforcements can be carried conveniently, the in / out driving for vehicles for transporting the steel reinforcements is convenient, the putting up and the dismantling are convenient and fast, and the steel reinforcement processing shed is good in strength.

Owner:浙江省二建建设集团有限公司

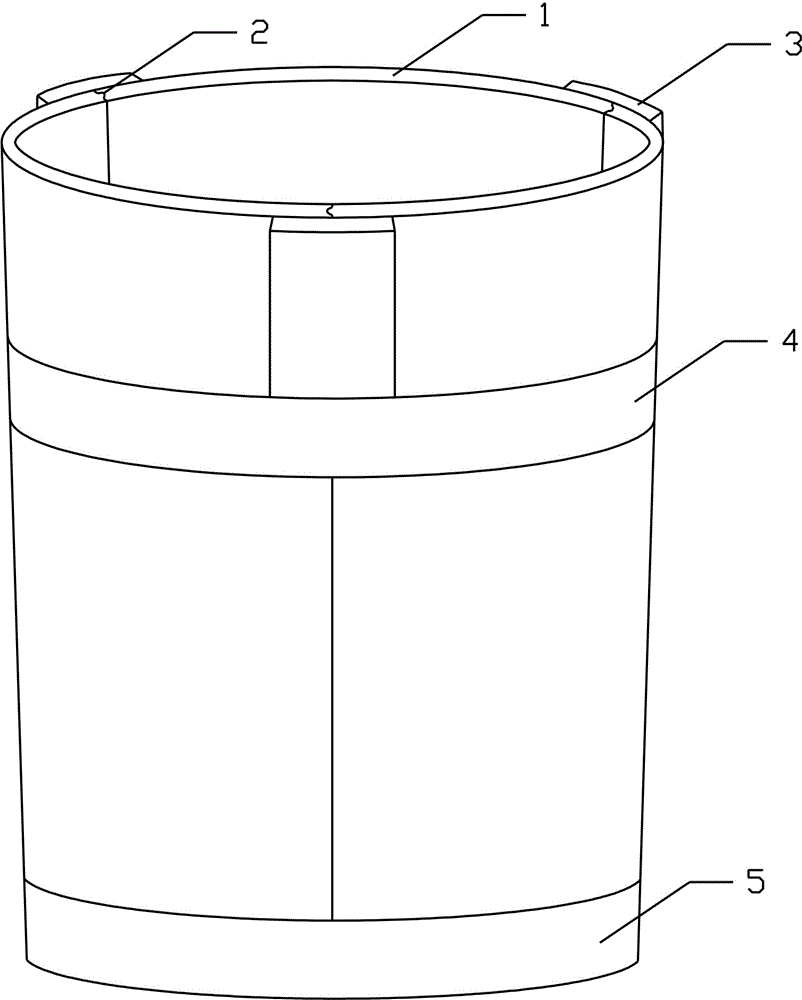

Detachable flowerpot

InactiveCN106605536ASave energyEasy to take outCultivating equipmentsReceptacle cultivationBonsaiEngineering

Owner:侯银堂

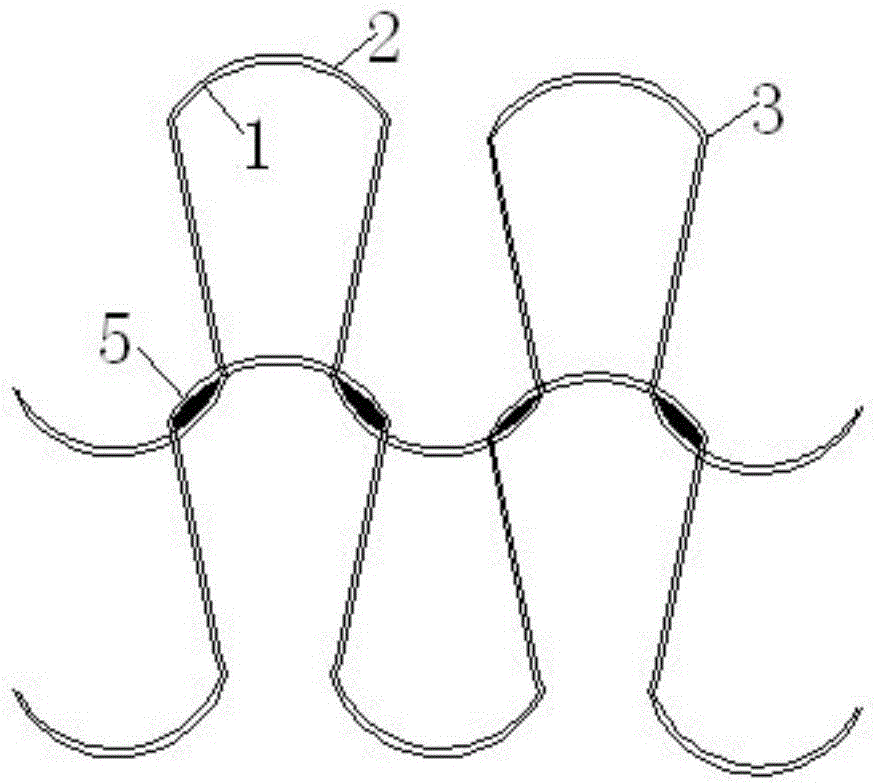

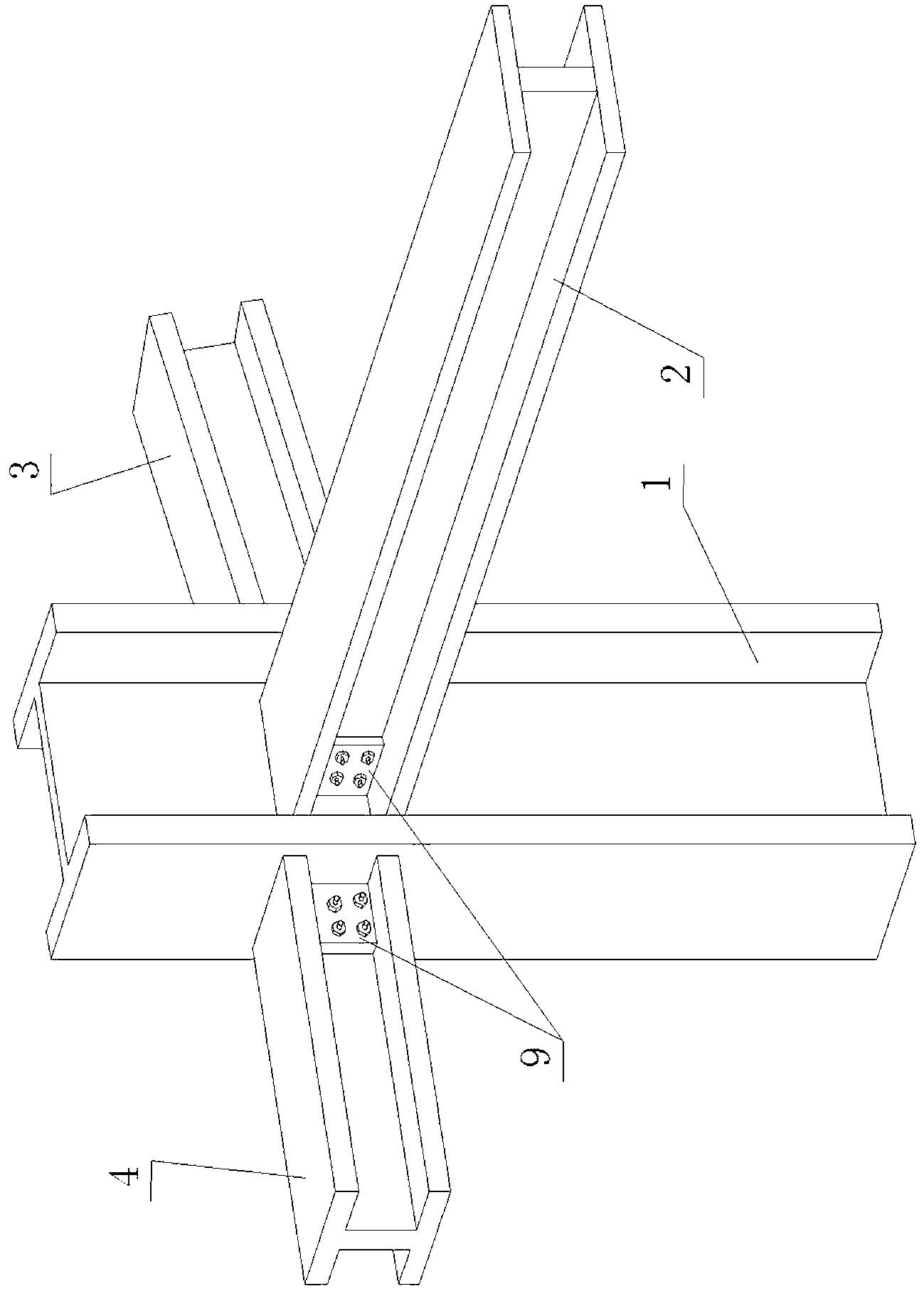

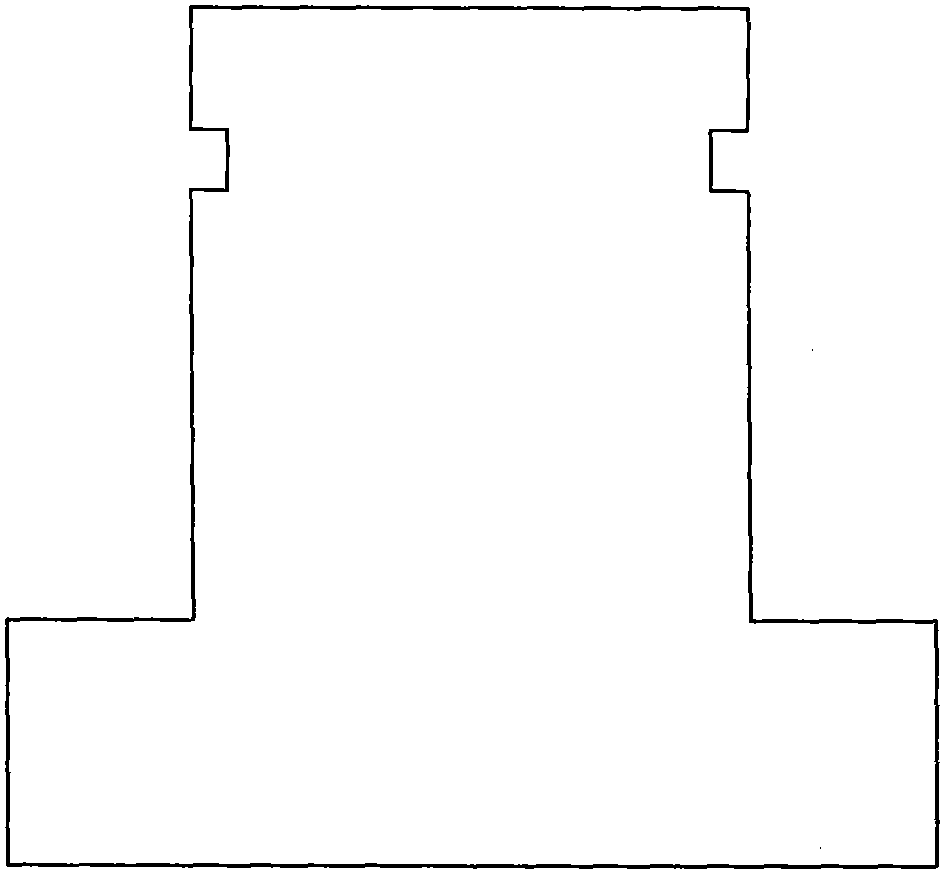

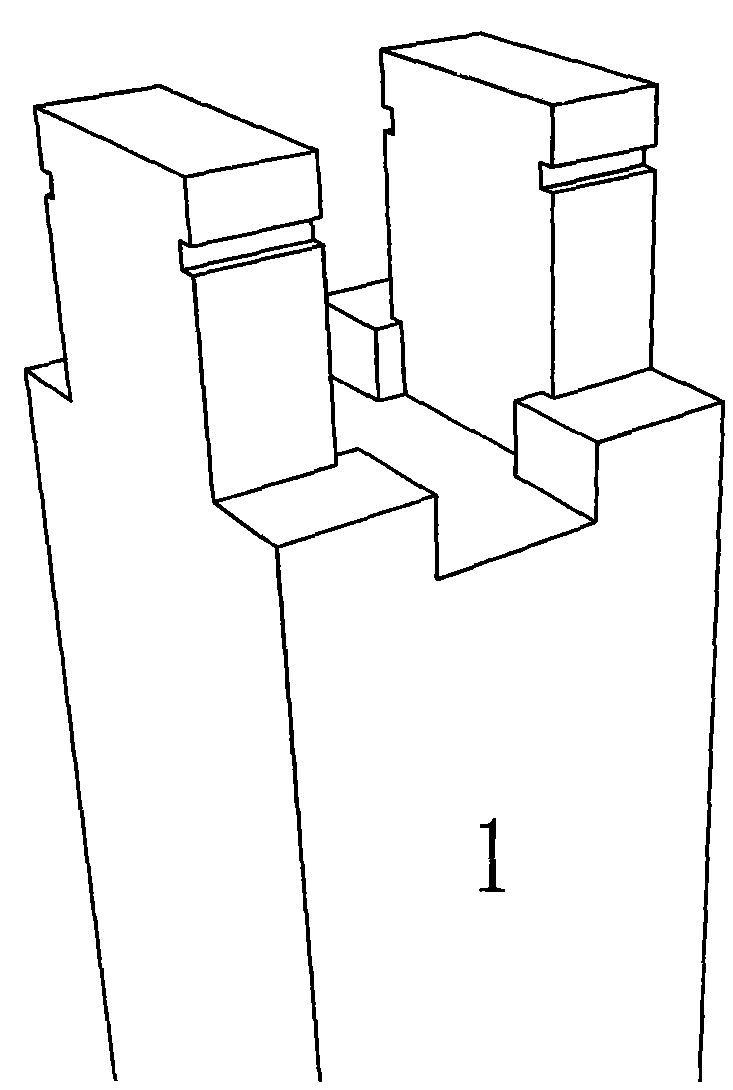

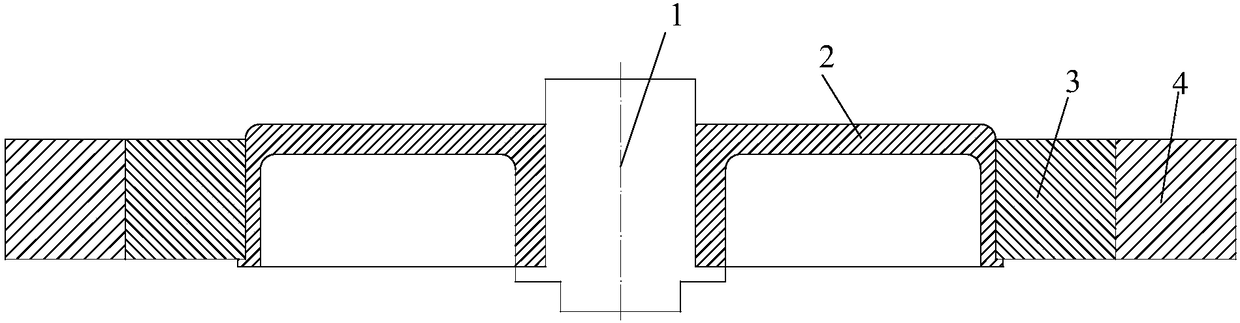

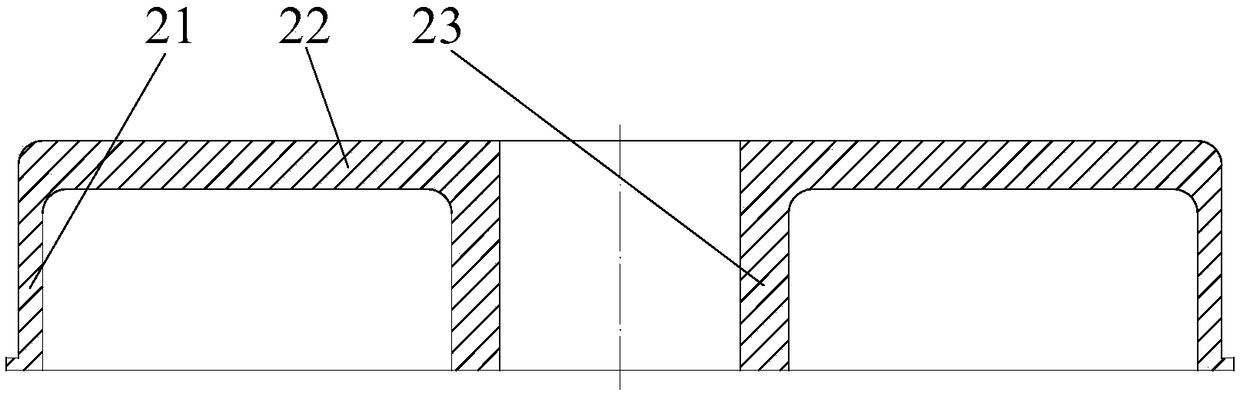

Connecting structure for pitch point

InactiveCN102995751AFlexible and convenient assemblyWon't fall apartBuilding constructionsFurniture joiningMortise and tenonEngineering

The invention discloses a connecting structure for a pitch point. The connecting structure comprises six groups of components which are one group of first components (1), two groups of second components (2), two groups of third components (3) and one group of fourth components (4), wherein the first components (1) are in a shape of a U-shaped T-type tenon; the two groups of second components (2) are symmetrically arranged and are in a shape of a concave L-shaped mortise; the two groups of third components (3) are symmetrically arranged and are in a shape of a hook-shaped I-type tenon; the group of fourth components (4) is in a shape of a concave line-shaped mortise; the first components (1) and the fourth components (4) are vertically-placed components; and the second components (2) and the third components (3) are horizontally-placed components. According to the connecting structure for the pitch point, components can be prefabricated and processed according to different specifications and dimensions and are conveniently and flexibly assembled. Compared with conventional connection under a mortise and tenon structure for fixing through a certain wooden dowels and modern connection under a connecting component which is completely exposed, the connection disclosed by the invention has the advantages that the whole point is fixed by buckling the components with each other in an ingenious way, and the connecting component can be basically hidden by outer components.

Owner:ZHEJIANG FORESTRY UNIVERSITY

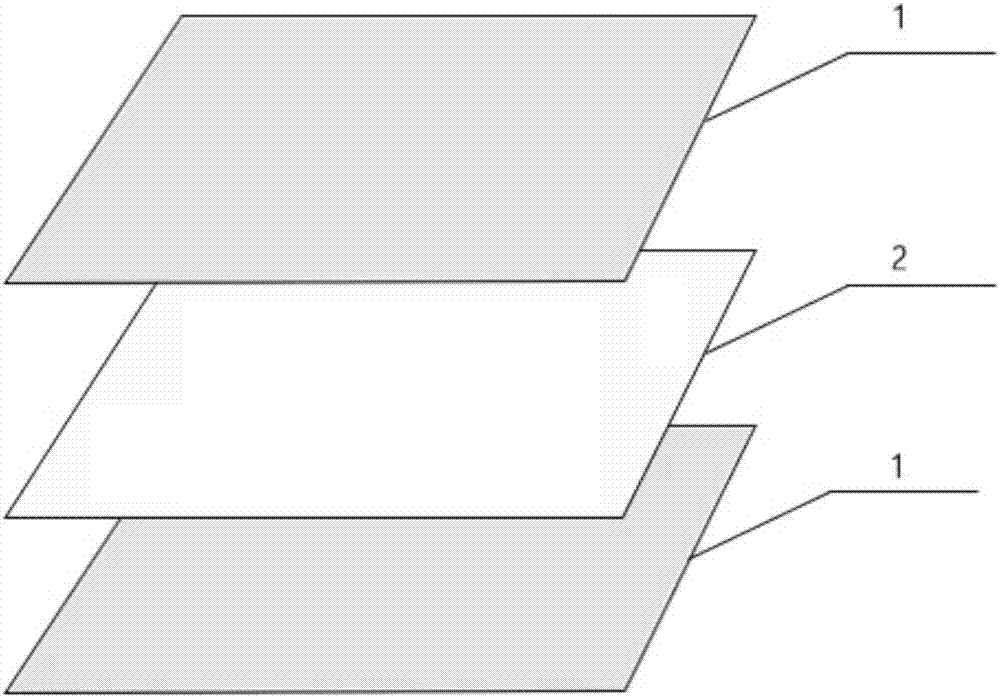

Thin-layer composite tissue repair material with stable mechanical property and preparation method thereof

InactiveCN107213516AProlong degradation timeGrow in quicklyProsthesisMechanical propertyColonization

The invention relates to a thin-layer composite tissue repair material with stable mechanical property and a preparation method thereof. The composite material is formed by compounding a nonwoven material or a porous synthetic membrane as a mechanical stability layer, and three-dimensional network structure diaphragm materials as upper and lower surface layers. The thin-layer composite tissue repair material is capable of significantly improving the mechanical strength of the three-dimensional network structure diaphragm material on the premise of not obviously improving the overall thickness of the composite tissue repair material, has long-term mechanical stability, and is free of a dead space, free of a colonization space for bacteria, good in biosecurity and wide in clinical application prospect.

Owner:EXCELLENCE MEDICAL TECH SUZHOU CO LTD +1

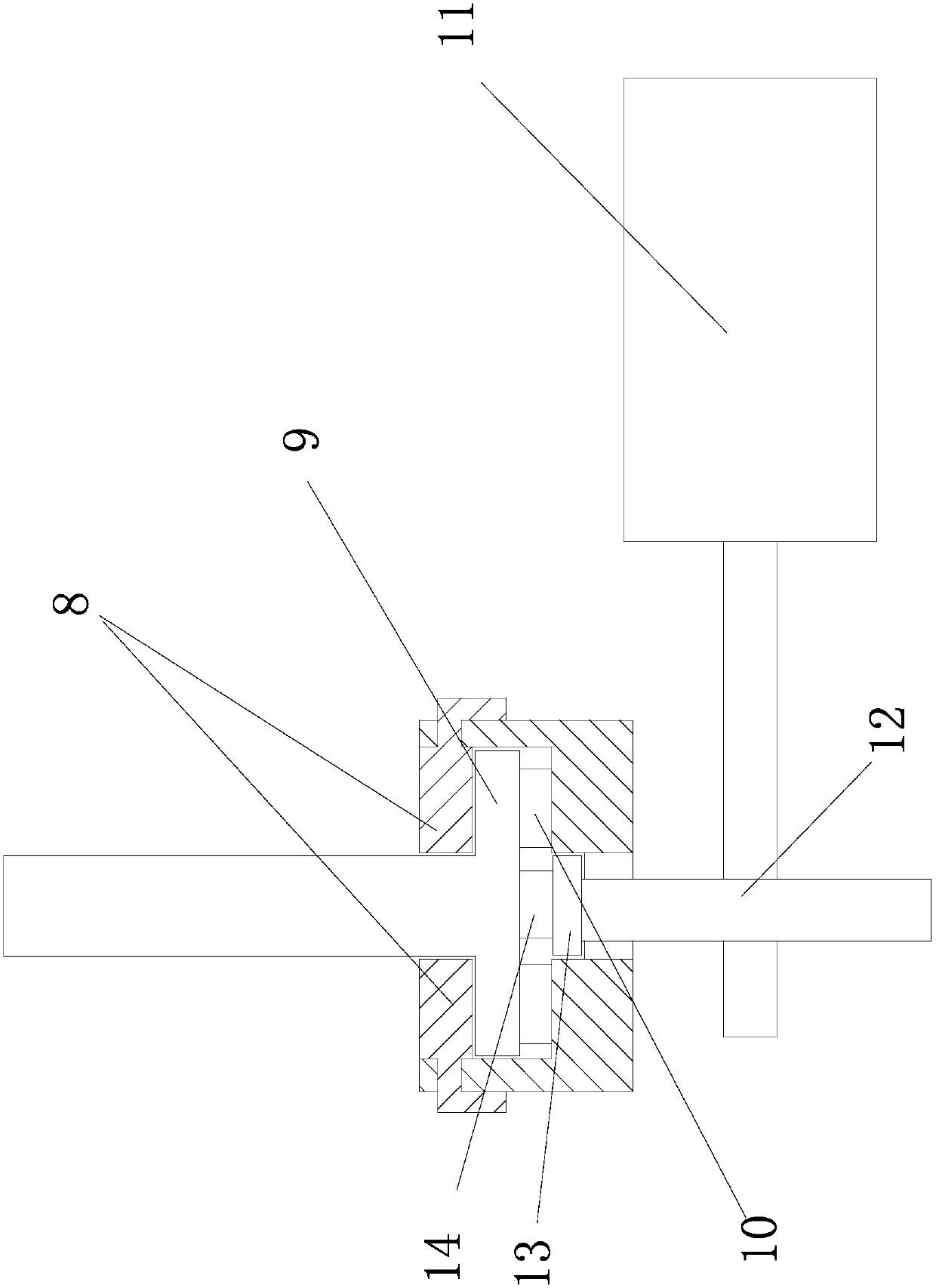

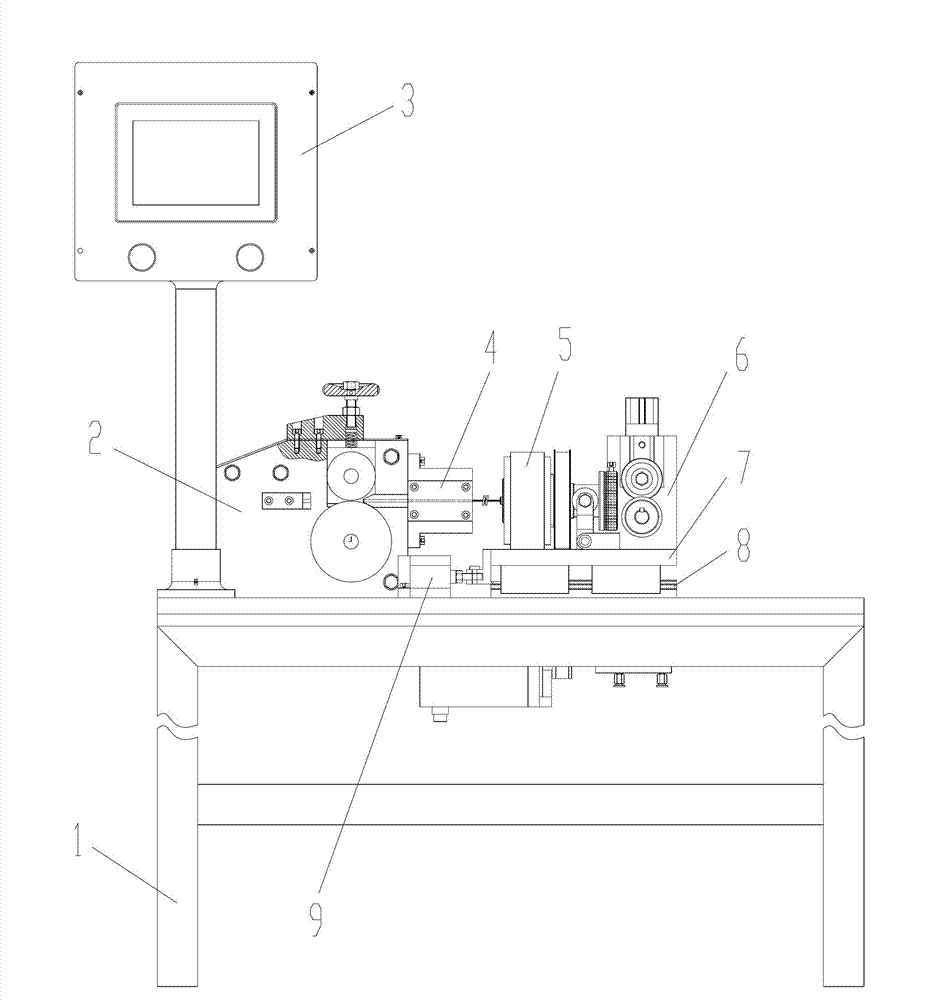

Steel wire fusing machine

The invention discloses a steel wire fusing machine, which relates to the field of disposable lock production equipment. The steel wire fusing machine comprises a rack, wherein a human-computer interface, a steel wire feeding machine, a steel wire clamping mechanism, a high-frequency fusing part, a steel wire twisting-off machine and a discharging part are arranged at the upper end of the rack; the human-computer interface, the steel wire feeding machine, the steel wire clamping mechanism and the high-frequency fusing part are fixed at the upper end of the rack; the steel wire twisting-off machine and the discharging part are fixed at the upper end of a movable plate which is arranged on a guide rail; the guide rail is fixed at the upper end of the rack; and one end of the movable plate is connected with an air cylinder. The steel wire fusing machine has a simple structure, is reasonable in design and high in automation degree, is easy and convenient to use and can automatically work after being set well; and a steel wire is rotated and twisted off after being heated at high frequency, so that the section of the steel wire cannot be separated and can form a tip end which can directly penetrate through a lock core, and the steel wire does not need to be ground again, therefore, the process step is simplified, and the production efficiency is improved.

Owner:BENGBU SECURITY SEALS

Insert-buckled bullet-proof ceramic wafer and preparation method thereof

The invention discloses an insert-buckled bullet-proof ceramic wafer and a preparation method thereof. The bullet-proof ceramic wafer is composed of 40-50% of silicon carbide powder, 20-25% of siliconpowder, 18-22% of short carbon fibers and 10-16% of phenolic resin powder, and the bullet-proof ceramic wafer is in butt joint in a concave-convex or top-bottom insert-buckled manner, so that the bonding area and bonding strength of the adhesive in the insert-buckled structure are increased, and the joint strength and rigidity between the ceramic wafers are enhanced. Moreover, the raw materials are subjected to cold-pressing and hot-pressing molding, a sintered composite ceramic material which has high strength, hardness and good wear resistance and is nearly completely dense can be obtained,the service life is long, and the processibility is high.

Owner:LUOYANG INST OF SCI & TECH

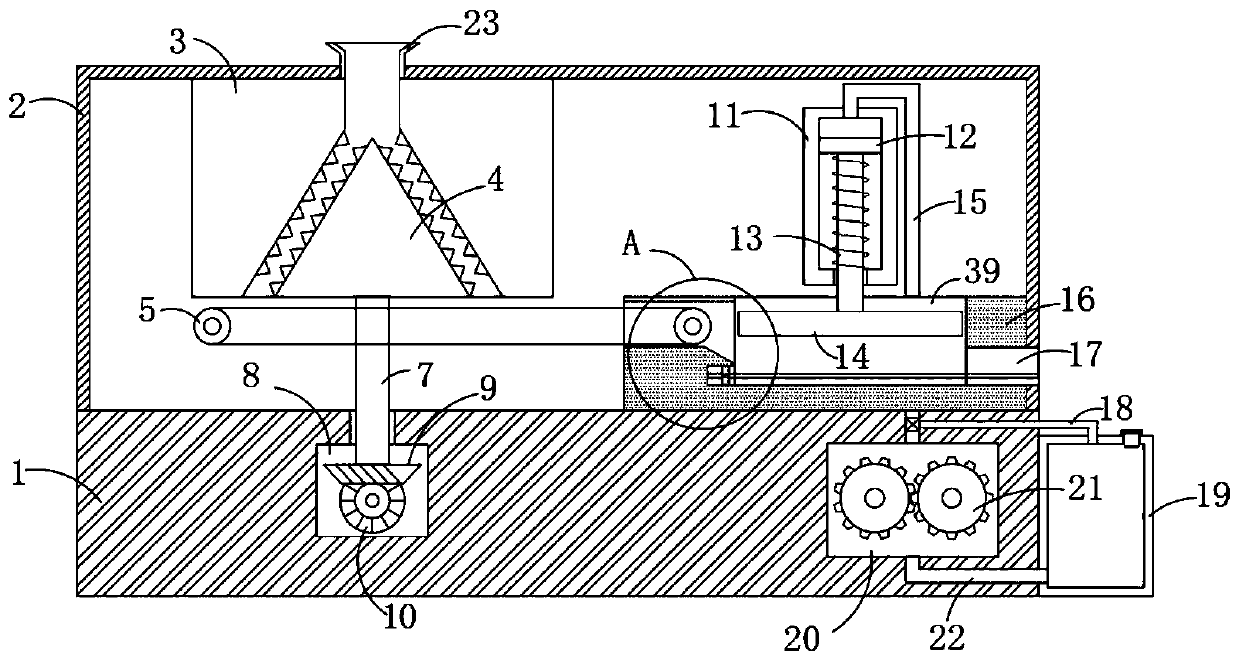

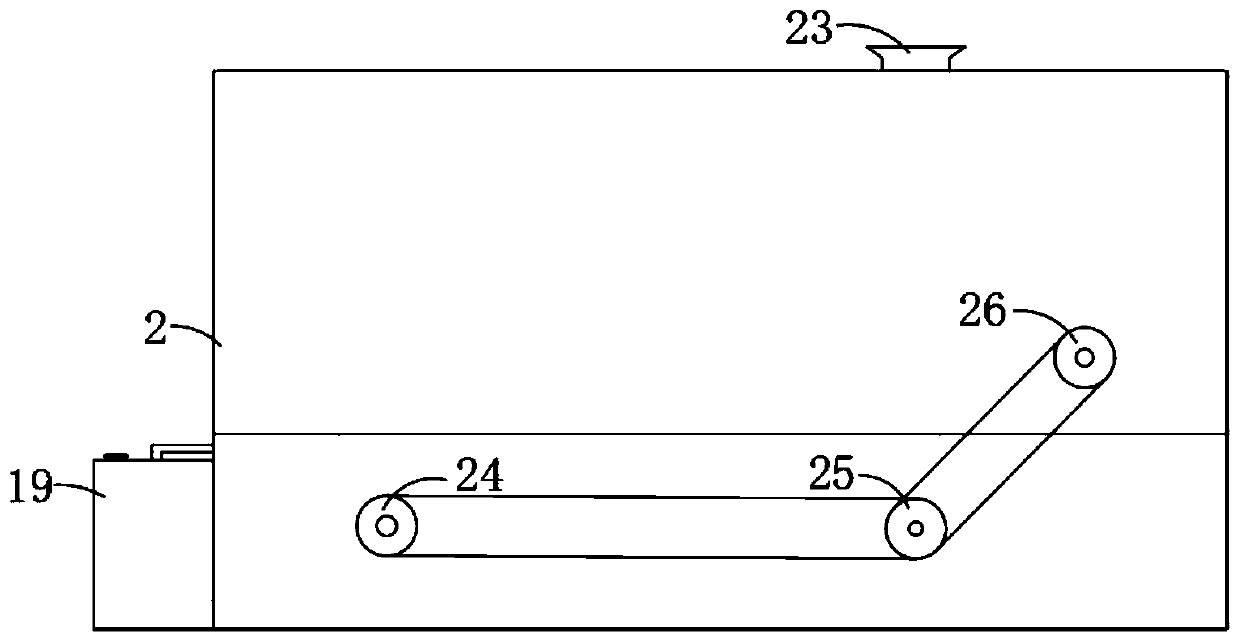

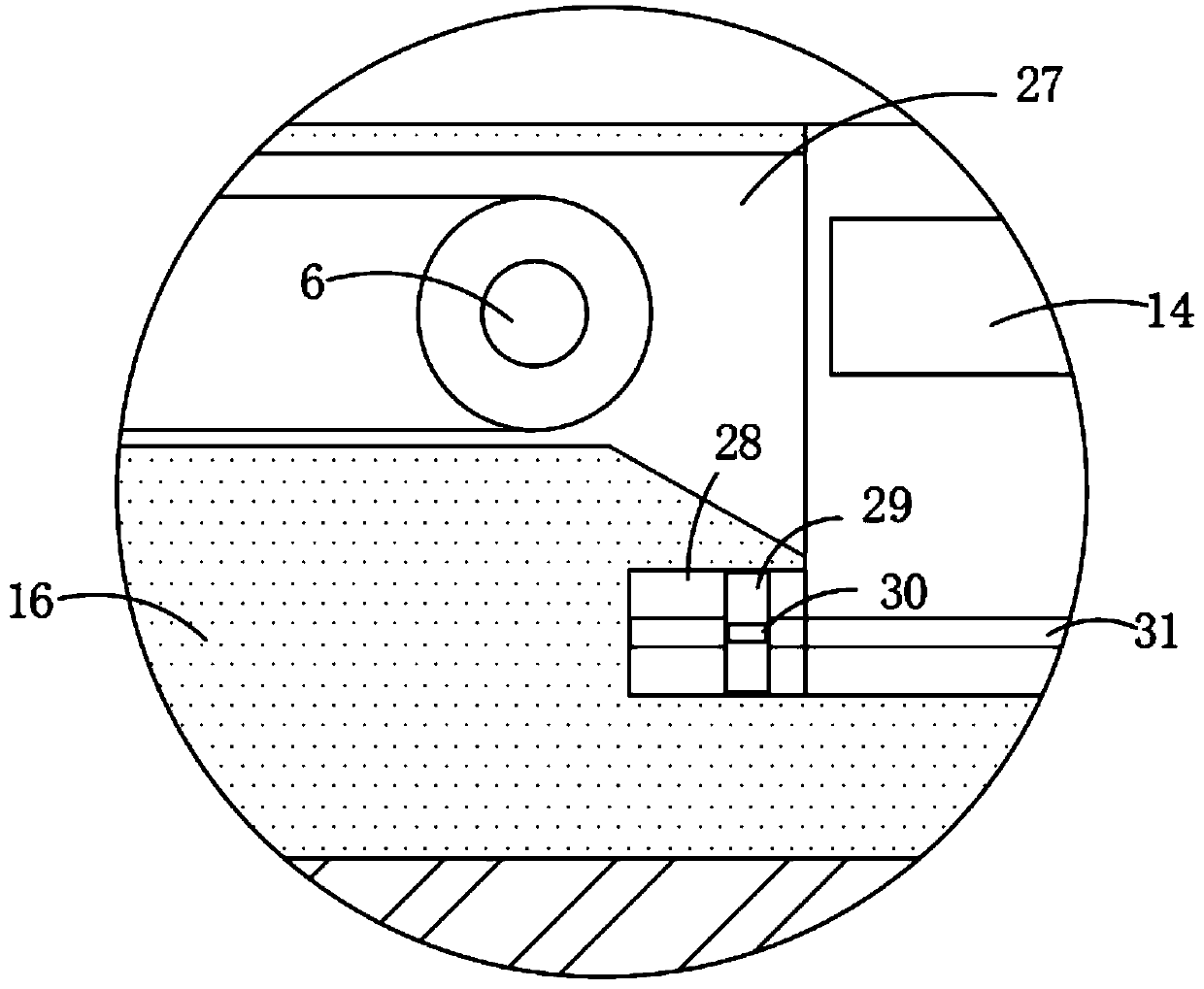

Aluminum profile waste breaking, recycling and lifting device

ActiveCN110014026AWon't fall apartEasy to recycleSolid waste disposalGrain treatmentsAgricultural engineeringUniform size

The invention discloses an aluminum profile waste breaking, recycling and lifting device comprising a base. A device box is fixedly connected to the upper end of the base. Two trapezoidal blocks are fixedly connected to the inner top of the device box. A strut is rotationally connected to the upper end of the base. A cone roller is connected to the strut coaxially and fixedly. A plurality of breaking teeth are fixedly connected to the side wall of the cone roller at equal intervals. A plurality of breaking teeth are fixedly connected to the side wall of the end, close to the cone roller, of each trapezoidal block. A mechanism groove is formed in the base. A first bevel gear is rotationally connected to the inner wall of the mechanism groove. According to the aluminum profile waste breaking, recycling and lifting device, broken aluminum profile waste is conveyed into a square groove by a conveying belt, then a pressing plate is driven to move up and down, the aluminum profile waste in the square groove can be pressed into blocks with uniform size and shape, in this way, recycling is convenient, and the aluminum profile waste is not scattered.

Owner:奋安铝业股份有限公司

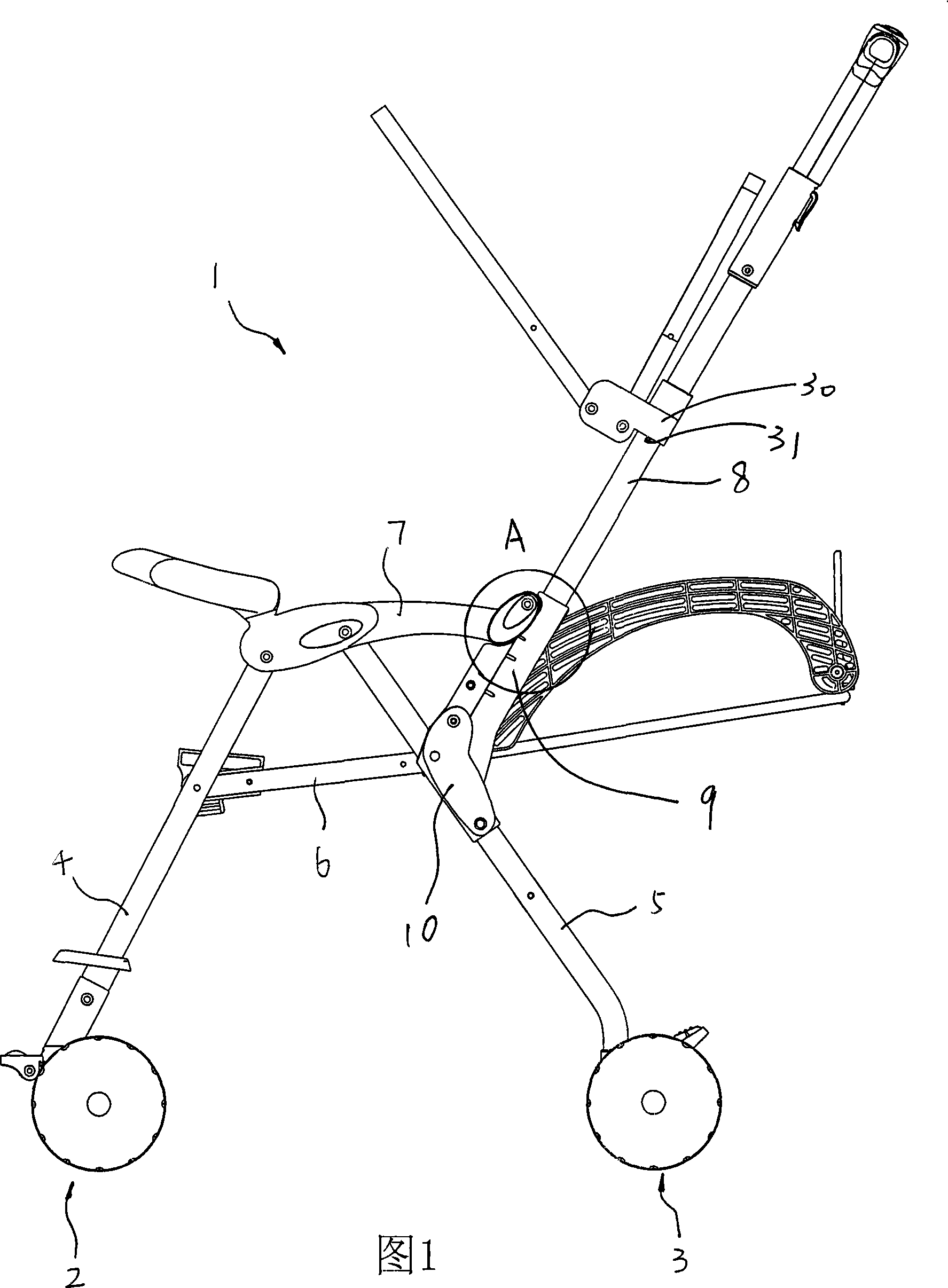

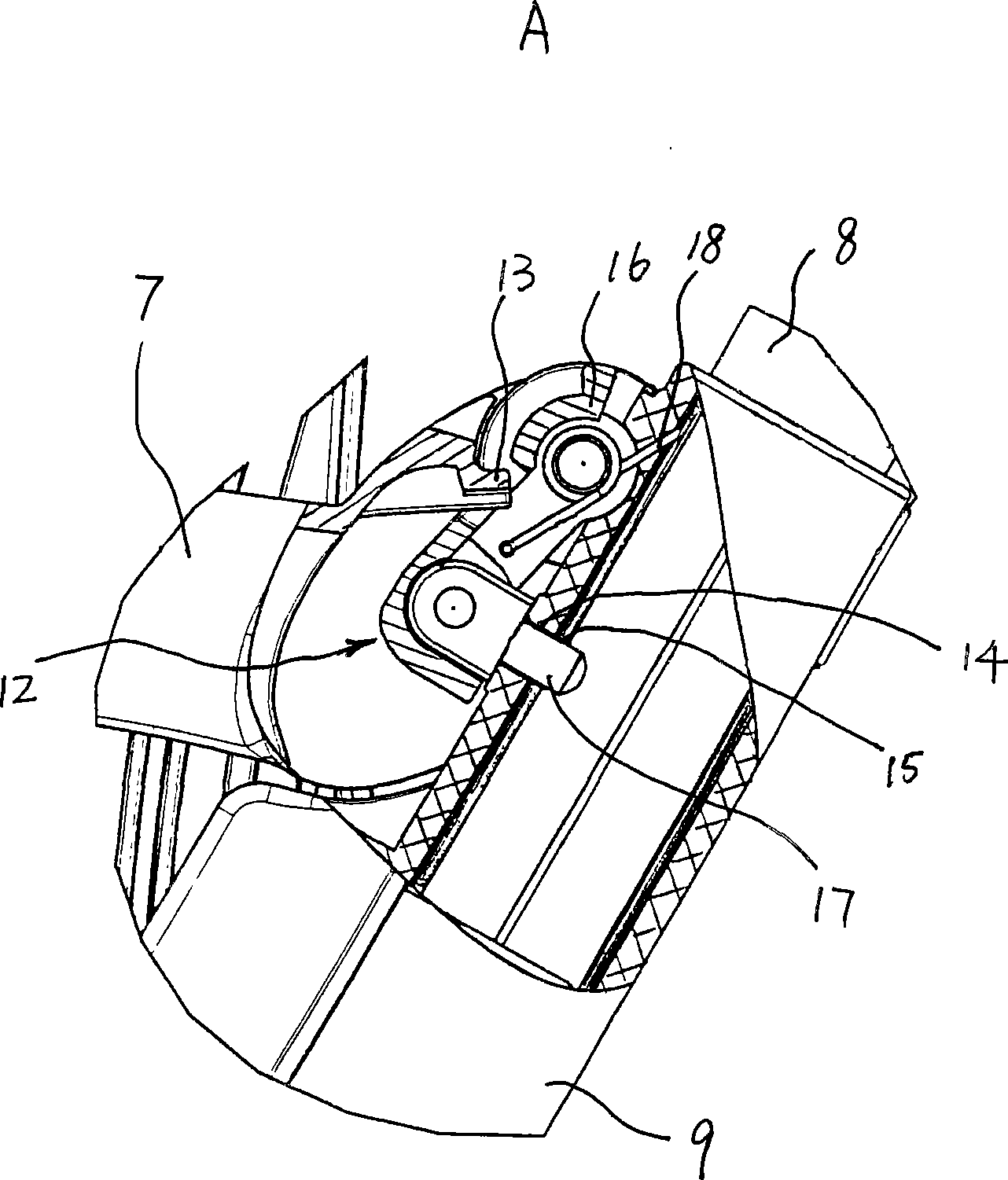

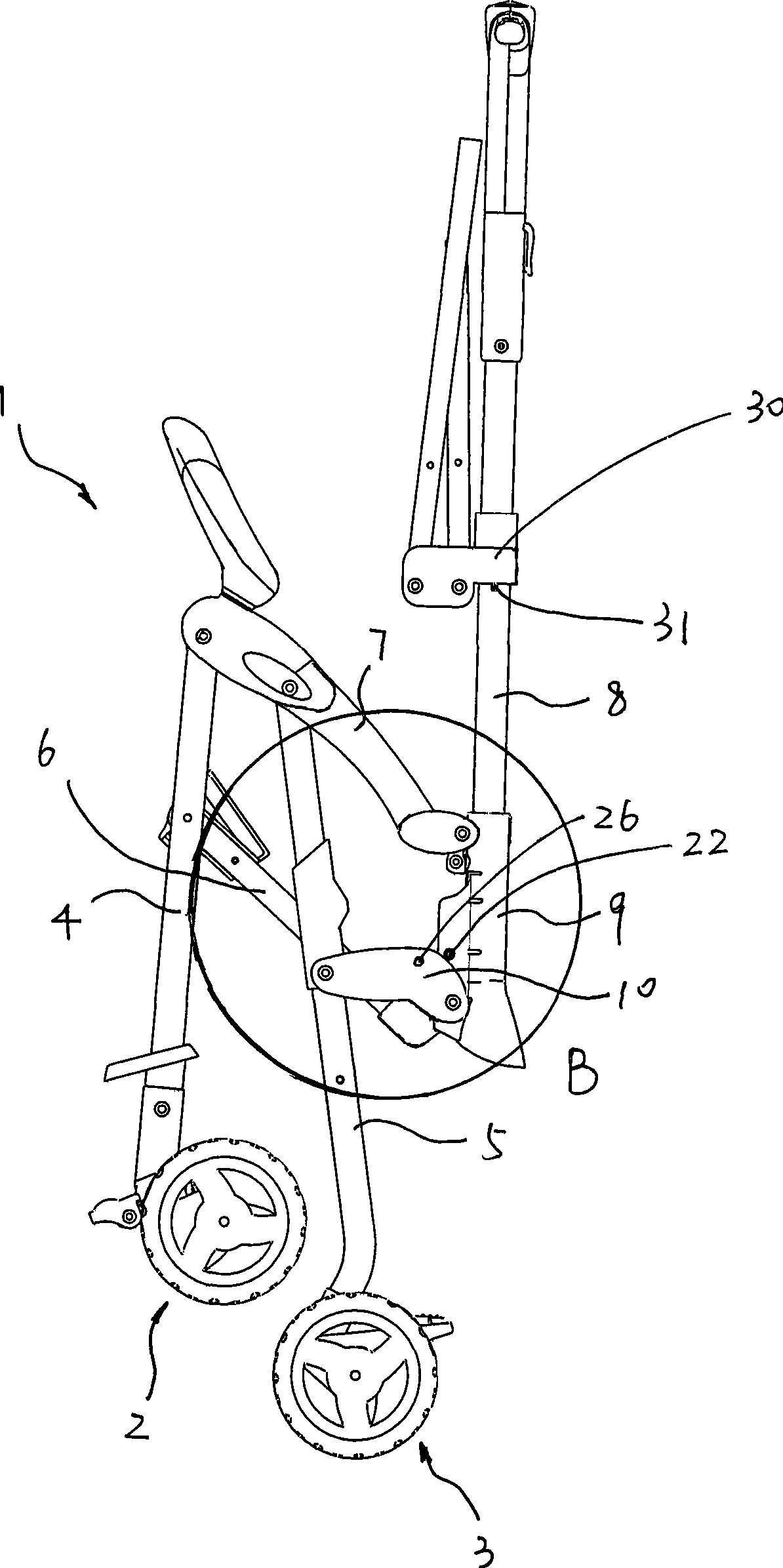

Baby carriage

InactiveCN101376399AReduce volumeReduce shipping costsCarriage/perambulator with multiple axesHandrailVehicle frame

The invention relates to a child stroller, a stroller frame of which comprises a front-wheel support, side arms, a back-wheel support, a saddle connecting bar, a connecting component, a handspike and a folding lock mechanism, wherein the front parts of the side arms are rotationally connected with the upper end part of the front-wheel support; the upper end part of the back-wheel support is rotationally connected with the side arms; the upper end part of the saddle connecting bar is rotationally connected with the front-wheel support; one end part of the connecting component is rotationally connected with the back-wheel support; the folding lock mechanism is used for locking the stroller frame in a folding position; a sliding bush is sleeved on the handspike; the upper part of the sliding bush is rotationally connected with the back parts of the side arms; and the lower part of the sliding bush is rotationally connected with the back-end part of the saddle connecting bar and the other end part of the connecting component. The connecting component slides down to a lower position relative to the sliding bush after the stroller frame is folded, that is, the height of the folded stroller frame is lower, so that the volume of the folded stroller frame is smaller, and the transport cost is reduced.

Owner:GOODBABY CHILD PROD CO LTD

Cured plane-interlocking stereo-stacking engineering block and production method thereof

ActiveCN103321184AEmission reductionReduce burnCoastlines protectionBuilding componentsEngineeringMethods of production

The invention discloses a cured plane-interlocking stereo-stacking engineering block and a production method thereof. The cured plane-interlocking stereo-stacking engineering block comprises left bank convex blocks, left bank concave blocks, right bank convex blocks, right bank concave blocks and liner strips. One left tank concave block is laid above two left tank convex blocks through first extension projections and fourth extension projections; one right bank concave block is laid above two right bank convex blocks through sixth extension projections and seventh extension projections; solid waste accounts for 80wt% of raw materials, and water accounts for 5wt%. The cured plane-interlocking stereo-stacking engineering block and the production method thereof have the advantages that the block has the functions of plane interlocking and stereo stacking; plane interlocking makes sure that the blocks laid on the surface of a block slope protection cannot scatter; the solid waste reaches 80% of the raw materials, production cost is low, production efficiency is high, and energy consumption is low; automatic yield is high, and profit of enterprises is high.

Owner:安培

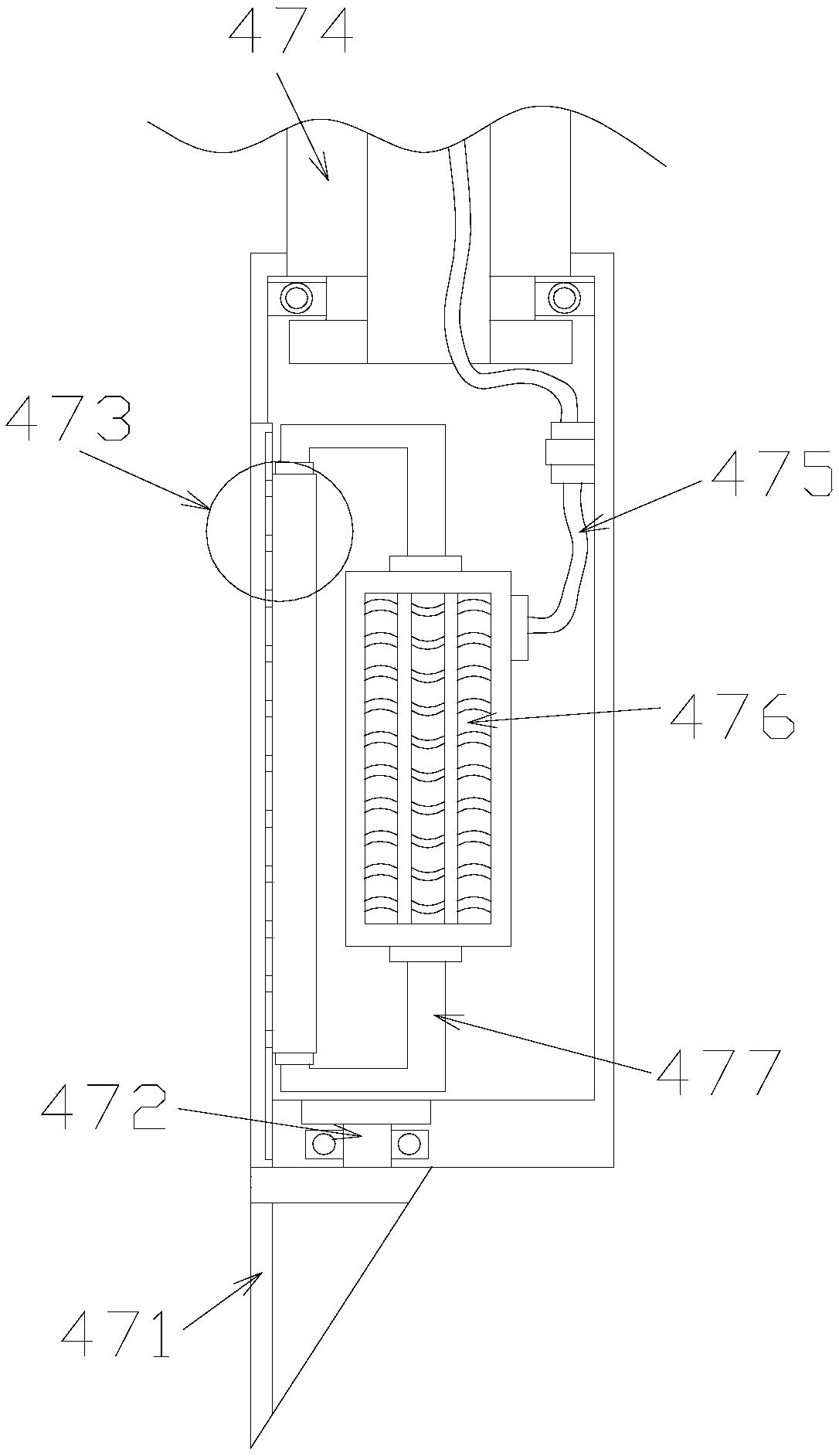

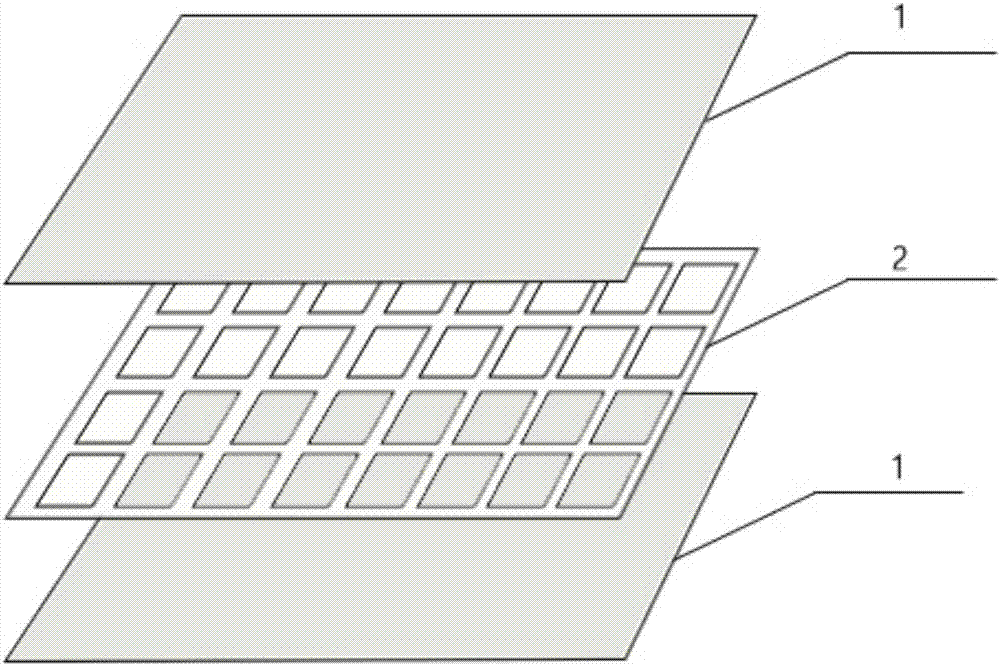

Household air filter element placement structure

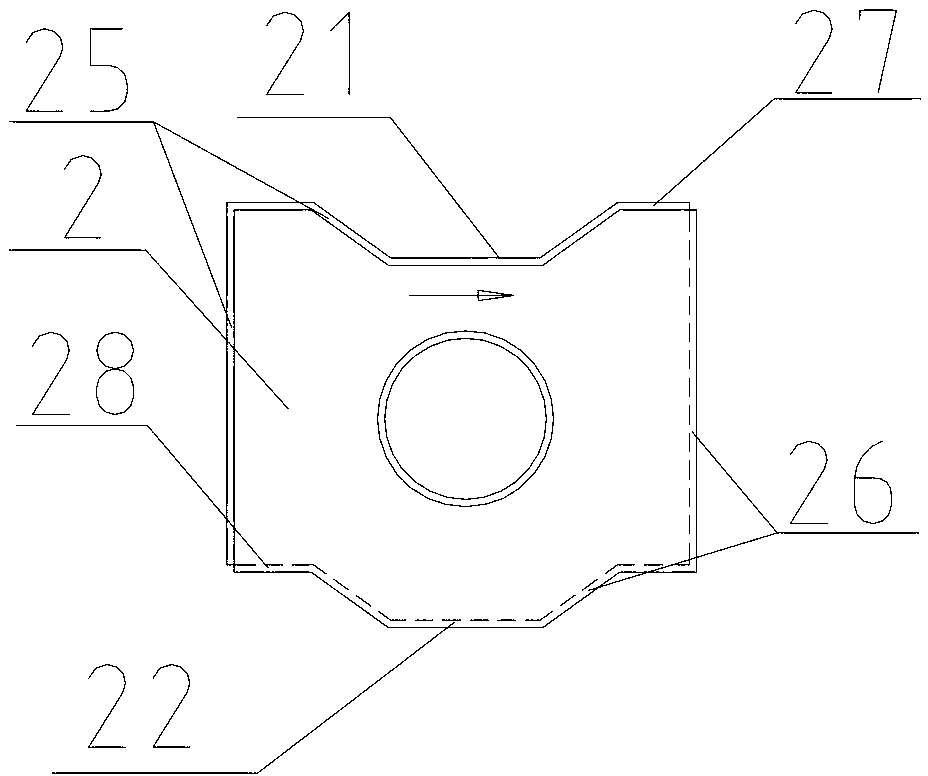

PendingCN108114544AWon't fall apartGuaranteed to proceed normallyGas treatmentDispersed particle filtrationAir filterEngineering

The invention discloses a household air filter element placement structure. The household air filter element placement structure comprises a connecting pipe and connecting rods, wherein the connectingrods are mounted on four corners of the bottom of the connecting pipe, a bolt sequentially penetrates through a second channel steel and a nut, and a first channel steel is mounted on the outer wallof the nut and is connected with a base. According to the household air filter element placement structure, the connecting rods, the connecting pipe and a filter net are combined into a filter element, so that the filter net can be used for filtering and is not scattered; the filter element can be placed on the base and can be clamped on the base through a baffle; the baffle and the connecting pipe can be mutually clamped through a clamping block and cannot be easily separated, and the connecting pipe is fixed on the baffle; and the baffle is stabilized and unlikely to shake by virtue of the connecting rods, so that the filter element is fixed on the base, and the filter element can be taken down from the base by wrenching the baffle and can be conveniently cleaned.

Owner:湖州南浔兴科纺织品原料厂

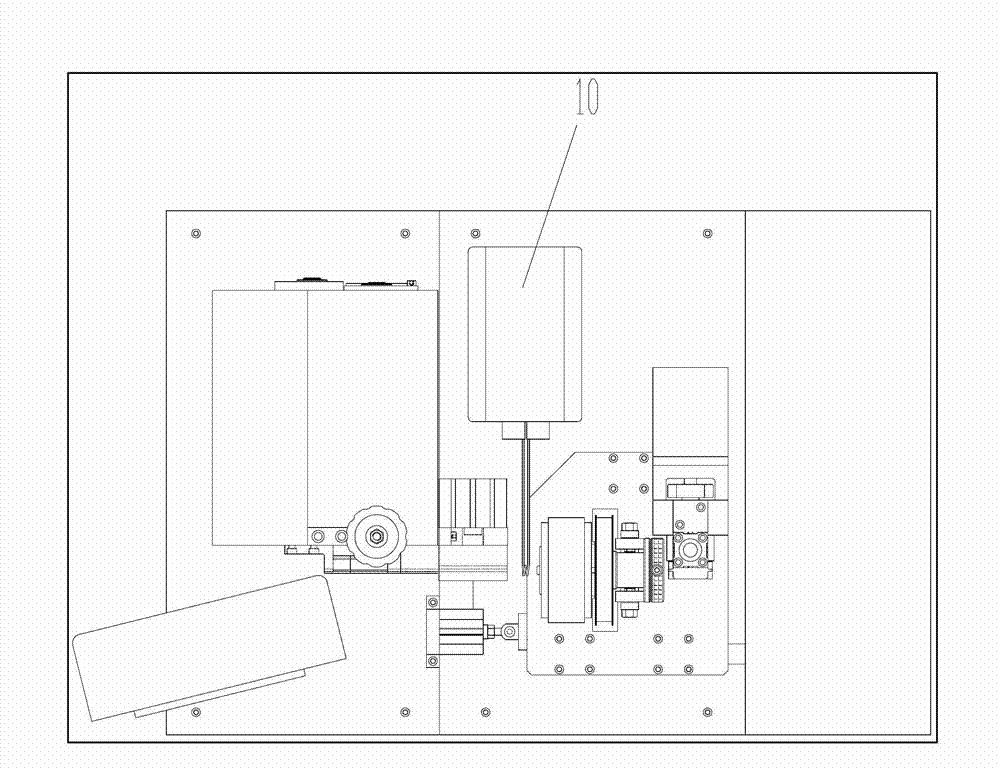

Automatic buckle-belt-passing machine

The invention relates to an automatic buckle-belt-passing machine, comprising a belt passing apparatus and a transfer apparatus; the belt passing apparatus comprises a buckle fixing mechanism, a belt conveying mechanism and a belt cutting mechanism, the buckle fixing mechanism is provided with buckle fixing positions, the belt conveying mechanism is provided with a belt conveying driver and belt passages, the belt conveying driver drives belts to move along the belt passages, the buckle fixing positions correspond to the belt passages so that holes of buckles fixed to the buckle fixing positions are aligned with the belt passages, the belts are driven by the belt conveying driver out of the belt passages and then passed through the holes of the buckles fixed to the corresponding buckle fixing positions, the belt cutting mechanism cuts off the belts after the belts are passed through the holes of the buckles, the transfer apparatus comprises a belt turning mechanism and a gripping mechanism, the belt turning mechanism is arranged at the front ends of the buckle fixing positions, and the belt turning mechanism turns the belts passed through the holes so that the gripping mechanism performs gripping after the belts are cut off; the manual buckle belt passing manner is changed, automatic buckle belt passing is achieved, and production efficiency is improved.

Owner:罗数基础(天津)机器人技术有限公司

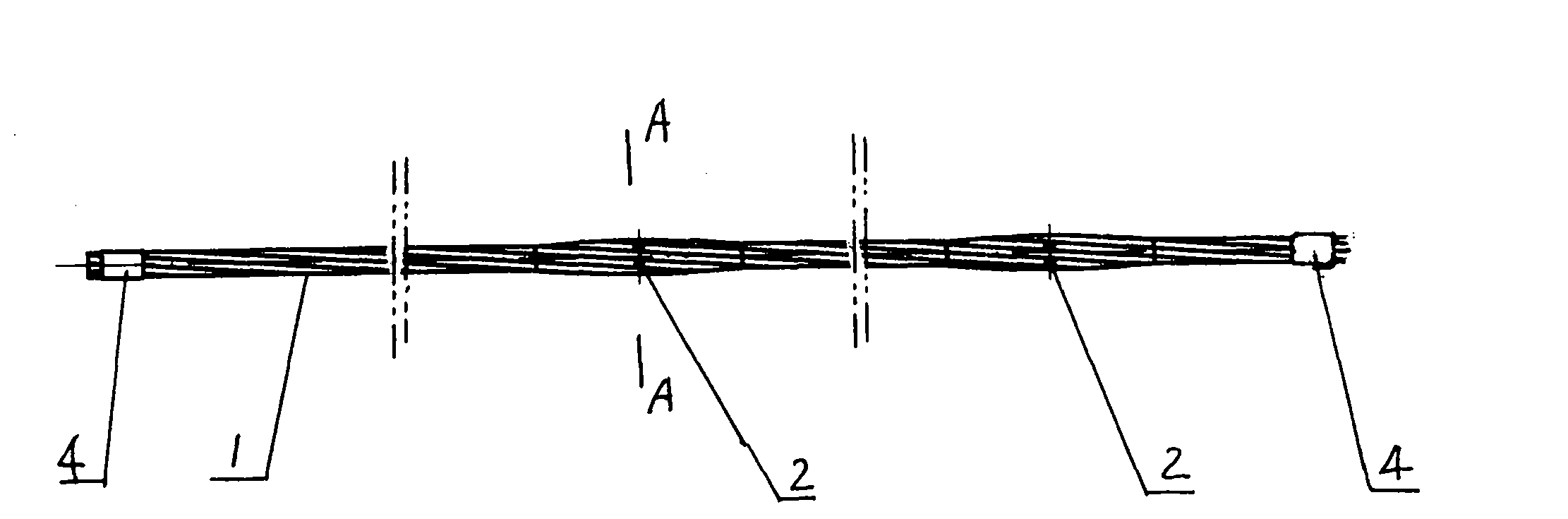

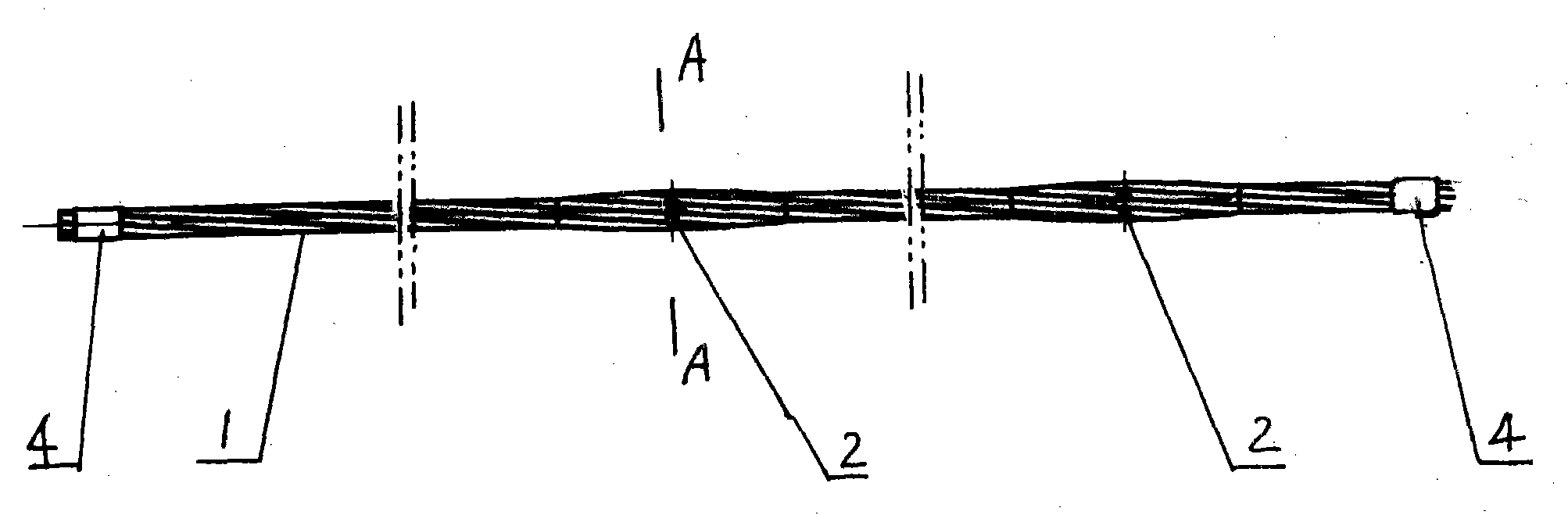

Anchor cable for cage-shaped mine and preparation method thereof

The invention discloses an anchor cable for a cage-shaped mine and a preparation method thereof. The method comprises the following steps: clamping a steel stranded wire in the jig of a workbench, using a special cage weaving machine to rotate the steel stranded wire in the reverse direction of twist to scatter the steel stranded wire, then filling filler in the scattered steel stranded wire, using the cage weaving machine to rotate the steel stranded wire in the direction of twist to form a cage-shaped expansion joint on the steel stranded wire, and finally pressing and binding the two ends of the steel stranded wire to form the anchor cable for the cage-shaped mine. Under the action of the expansion joint of the invention, the resin anchoring agent can be fully and evenly stirred and combined with the bore wall firmly, the anchoring force is increased by 20% compared with that of the common anchor cable for the mine; by using the anchor cable for the cage-shaped mine, the anchor cable can be centered and straightened in a bore and not incline to the bore wall, thus increasing the anchoring force of the anchor cable; and the end of the cementing segment of the anchor cable for the cage-shaped mine is fixed by a snap ring, thus the end of the anchor cable can not be scattered.

Owner:新汶矿业集团物资供销有限责任公司

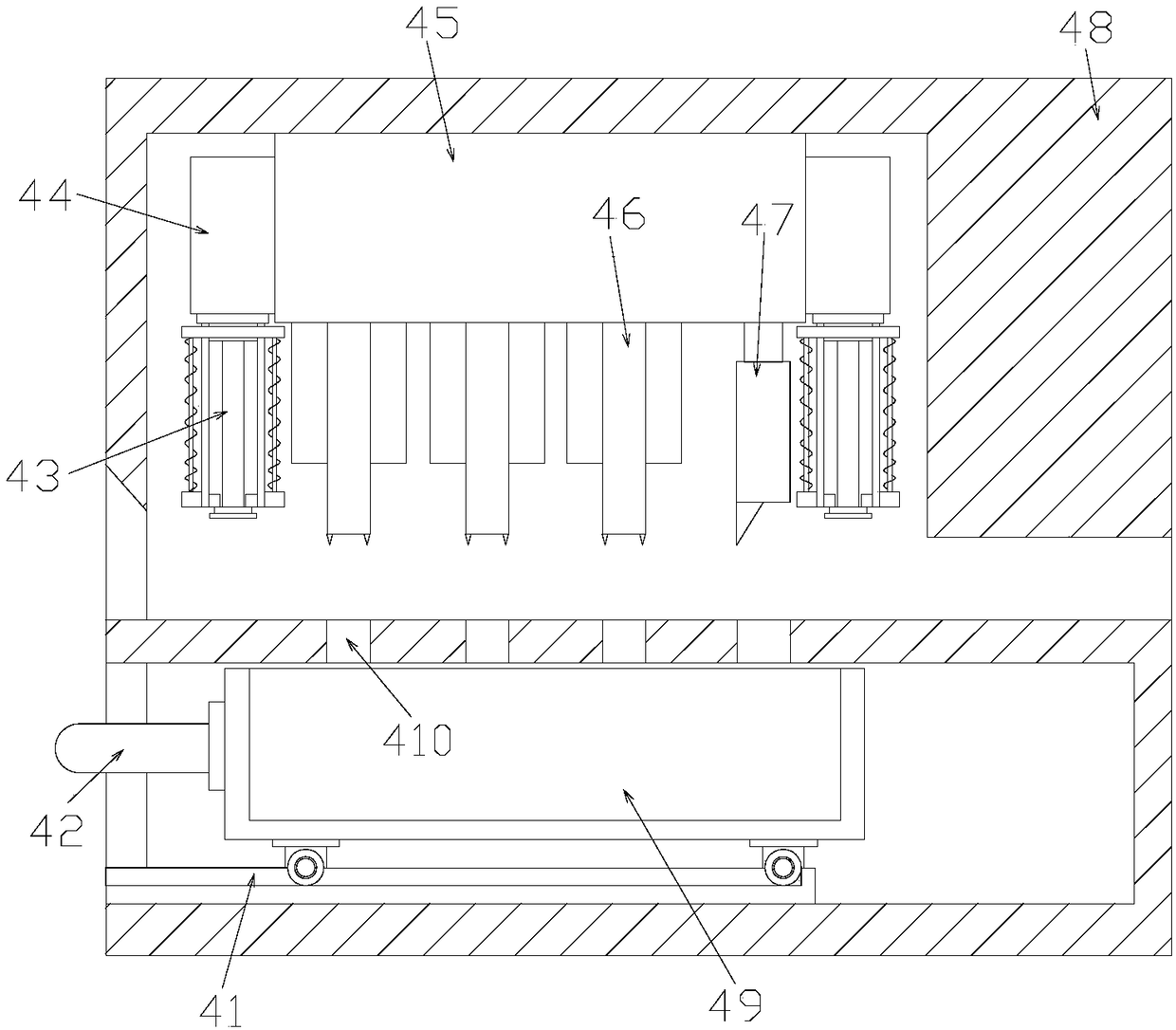

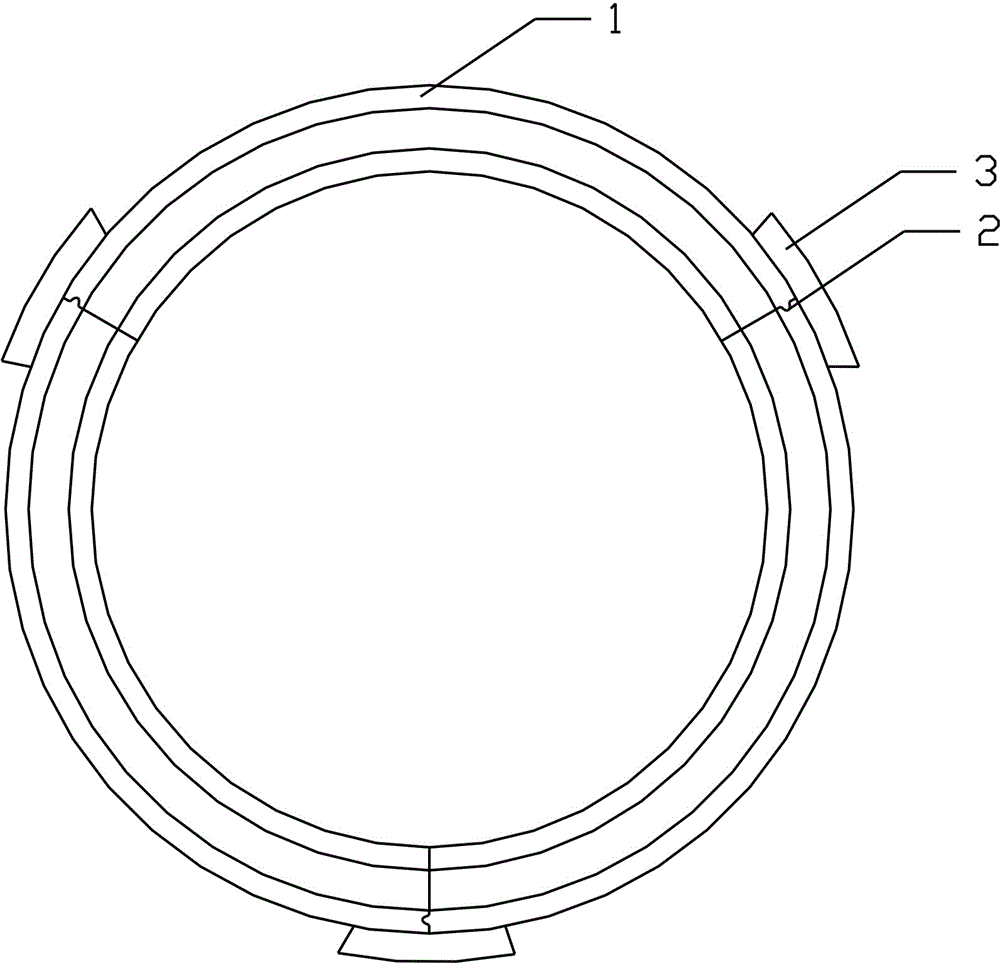

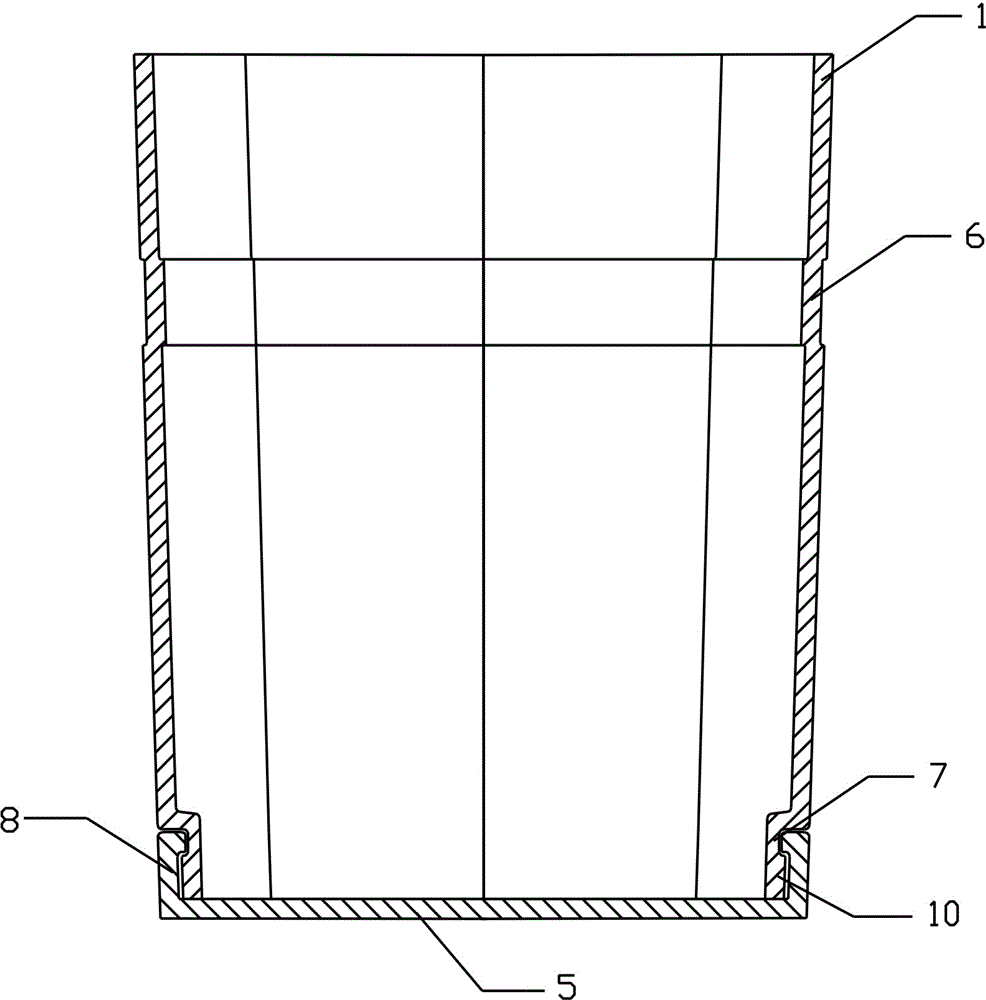

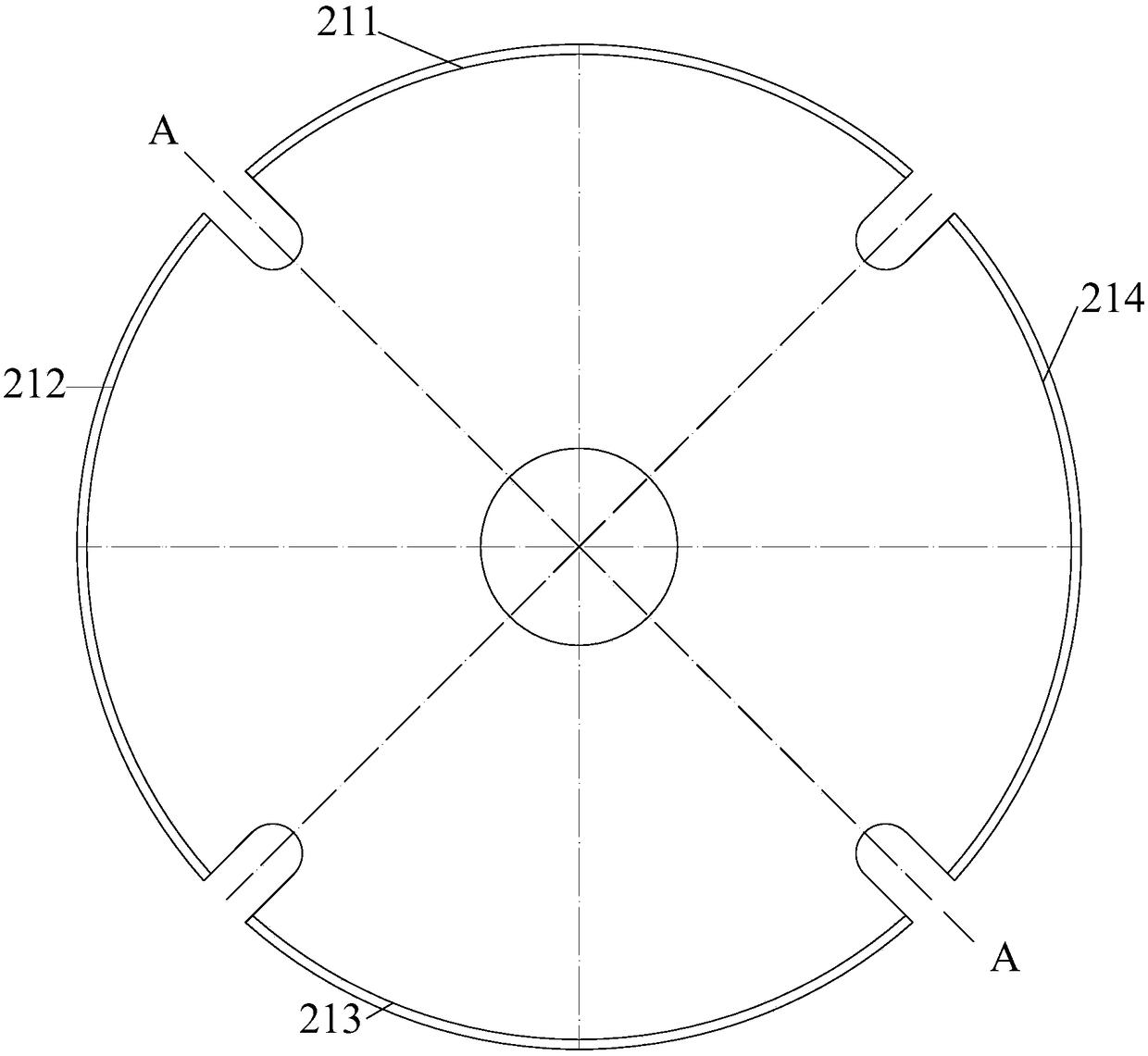

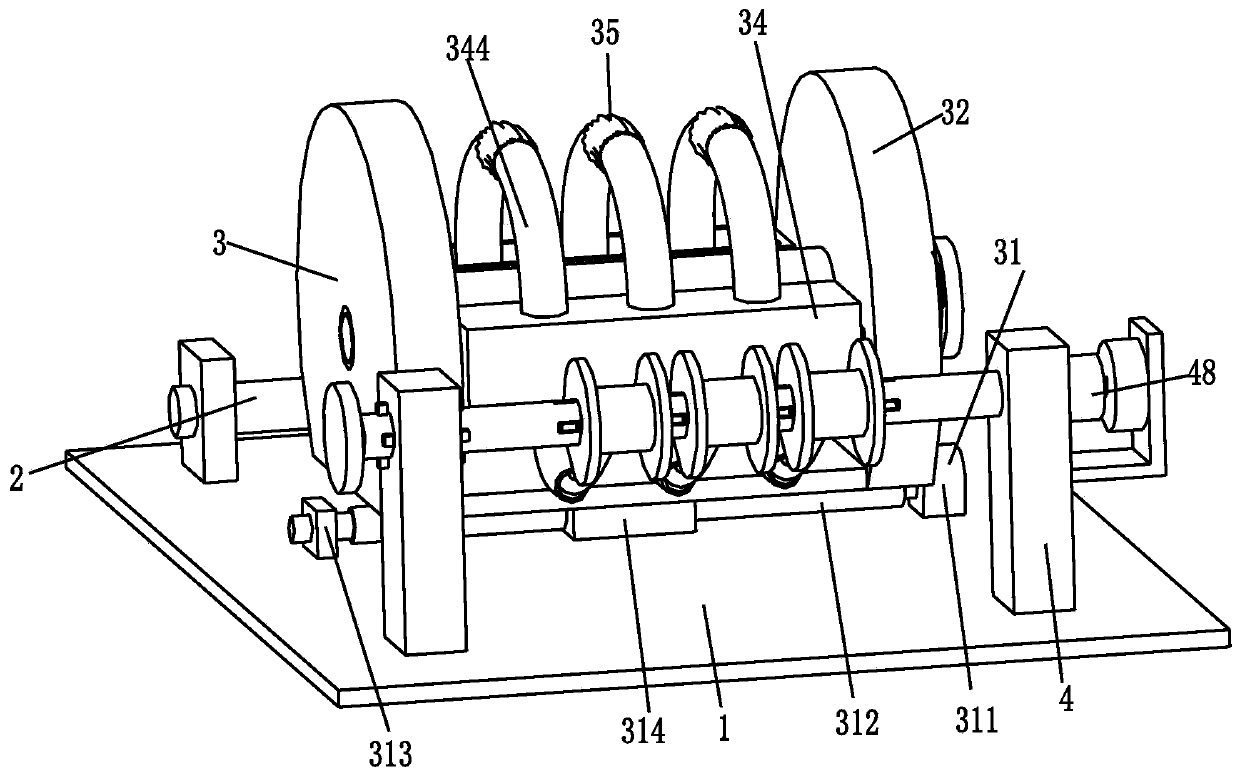

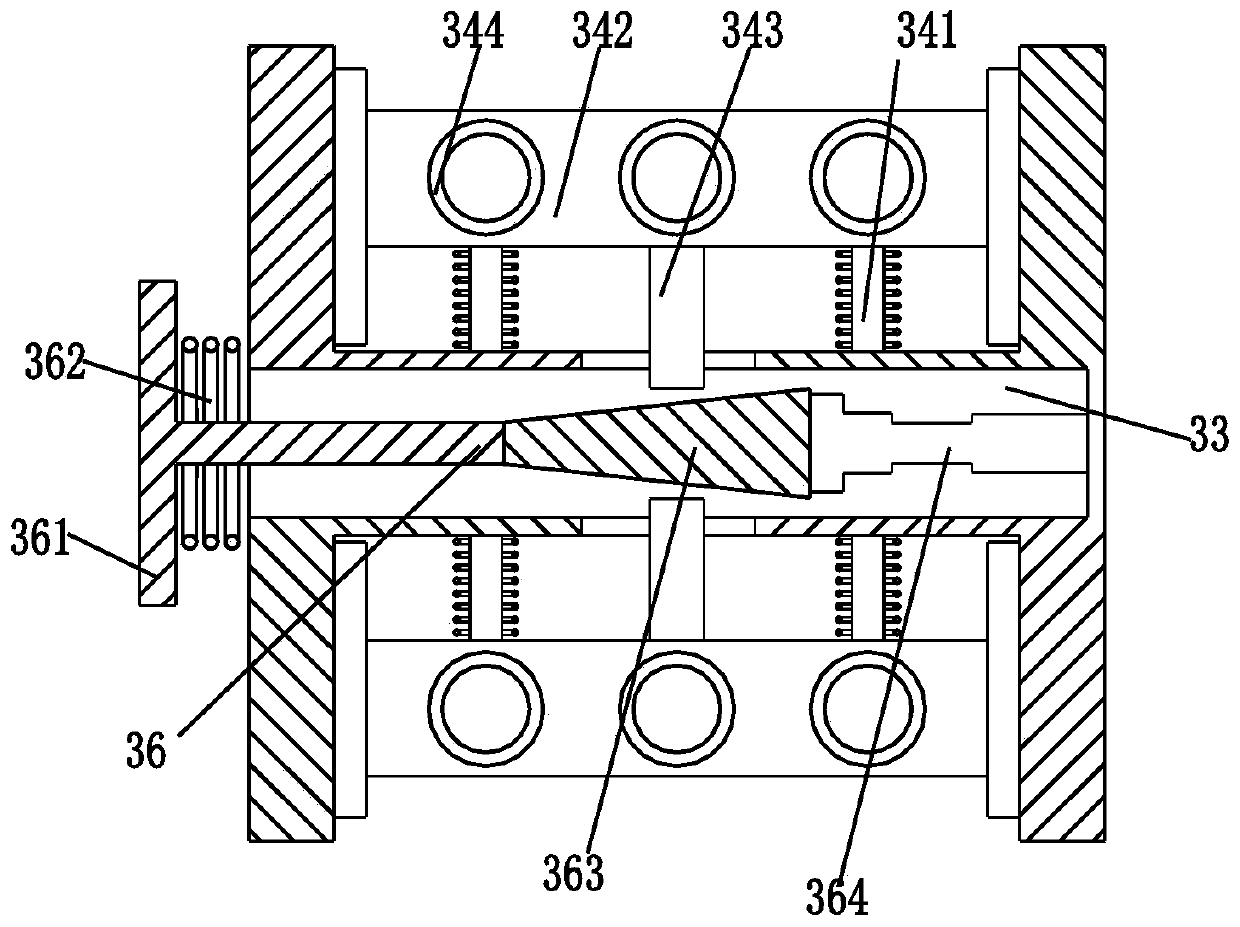

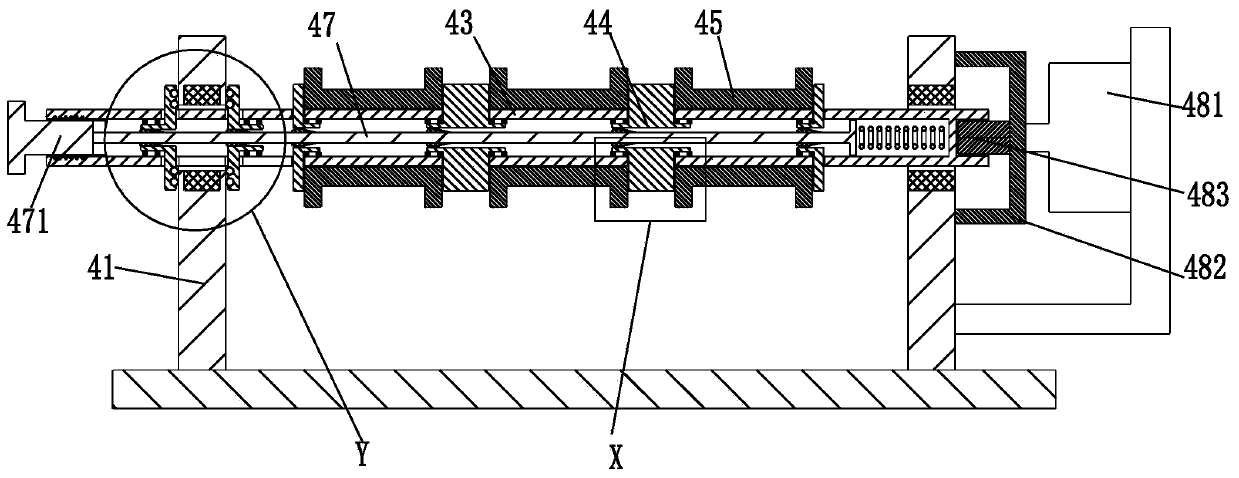

Sectioning circular ring casing and alloy wheel hub combined energy storage flywheel

PendingCN108321977AClose coordinationAchieving Large Deformation CoordinationMechanical energy handlingAlloyEngineering

The invention provides a sectioning circular ring casing and alloy wheel hub combined energy storage flywheel. The flywheel comprises a mandrel, a wheel hub and a wheel rim which are arranged coaxially from inside to outside; the wheel hub comprises a sectioning circular ring casing, a circular ring plate and a cylindrical casing; the circular ring plate is fixedly connected with the cylindrical casing via a hole, corresponding to the cylindrical casing, arranged in the center of the circular ring plate; the circular ring plate is fixedly connected with the sectioning circular ring casing viaan edge, corresponding to the sectioning circular ring casing, formed by segmentation in the periphery of the circular ring plate; and the sectioning circular ring casing is an incomplete circular ring casing formed by segmenting a hollow cylinder concretely. The sectioning circular ring casing matches the circular ring plate in the wheel hub, so that during rotation of the combined energy storageflywheel, the sectioning circular ring casing can be opened outwardly automatically and clings to the inner side of the wheel rim due to that the circular ring casing is the incomplete casing by segmentation, the wheel hub and the wheel edge are cooperated tightly and do not separate from each other during high-speed rotation, gross distortion coordination of the wheel hub and the wheel rim is realized, and the intensity safety under gross distortion coordination is ensured.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Environment protecting bioceramics and its making process

The environment protecting bioceramics is used in the cultivation of plant and the purification of water, has pores and water absorption greater than 18%, and contains: SiO2 65-70- wt%, Al2O3 10-20 wt%, Fe2O3 and FeO 1.5-3 wt%, CaCo3 3-10 wt% and small amount of C. It is produced with the material including common red clay 10-25 wt%, low-viscosity soil 15-30 wt%, dolomite 5-15 wt%, carbon powder 5-30 wt% and viscous soil 18-24 wt%. Its production process includes successive six steps of preparing material, ball milling, sieving slurry, squeezing to dewater, forming and roasting. The present invention has the functions of maintaining tidy environment, eliminating bad smell, purifying water, etc. and the product has easily controlled color and high water absorption.

Owner:厦门益珈华艺术陶瓷有限公司

Yarn winding device and yarn winding process

The invention relates to a yarn winding device and a yarn winding process. The yarn winding device comprises a bottom plate. A winding roller, a tensioning device and a winding device are sequentiallyarranged on the bottom plate from back to front. The yarn winding device and the yarn winding process can solve the following problems in an existing yarn winding operation: a, by means of a traditional yarn winding mode, the tensioning force in the yarn winding operation cannot be guaranteed, the fluffy interiors of the wound yarns are caused easily, the stability of the yarns wound into rolls is influenced, the yarns are easily scattered, and the degree of precision of the yarn winding operation is reduced; and b, in the traditional operation of winding the yarns into the rolls, multiple yarn rolls cannot be wound at the same time, replacement of the yarn rolls and fixed processes are tedious, and the processing efficiency of the yarns is influenced.

Owner:尹梦雅

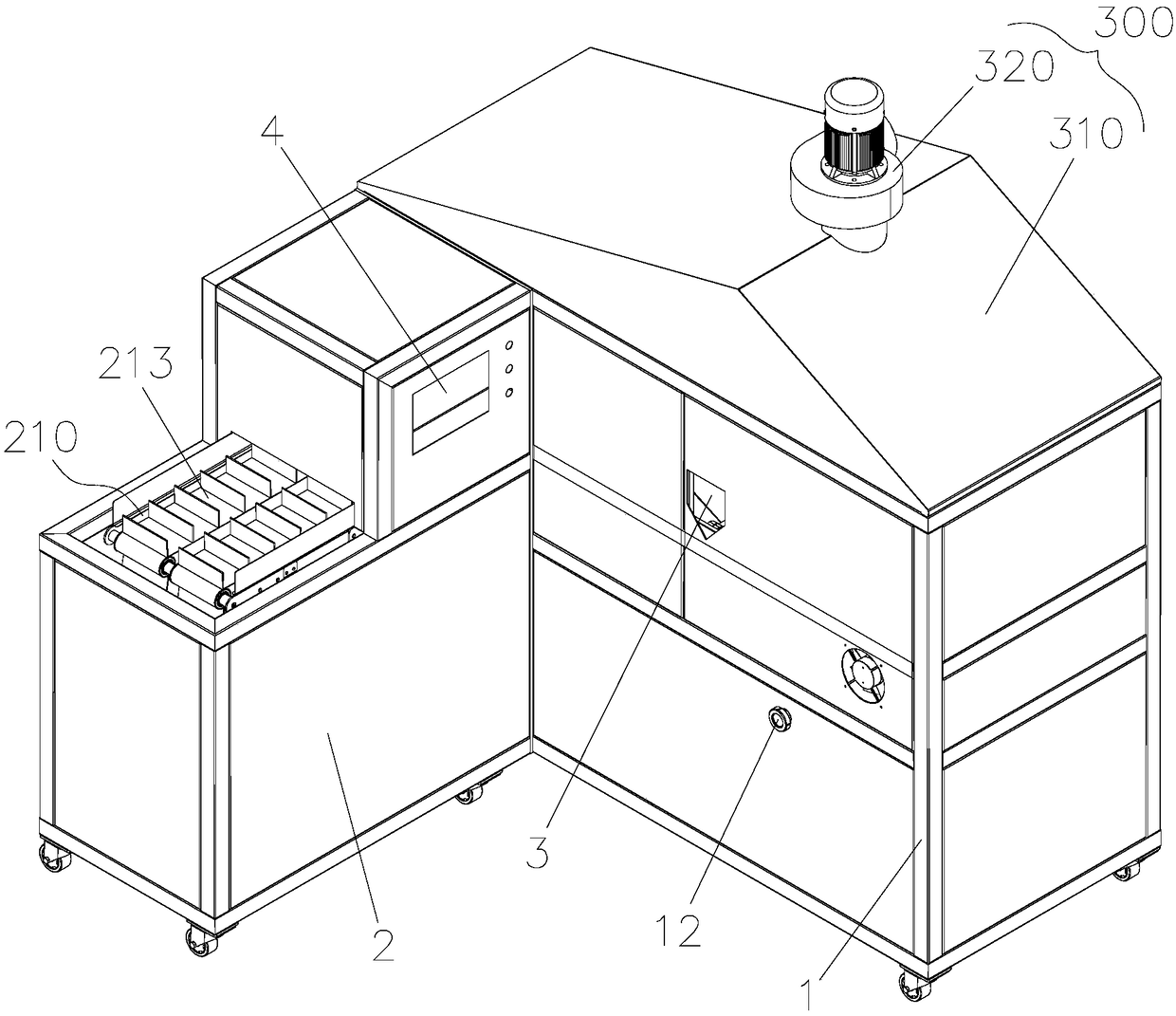

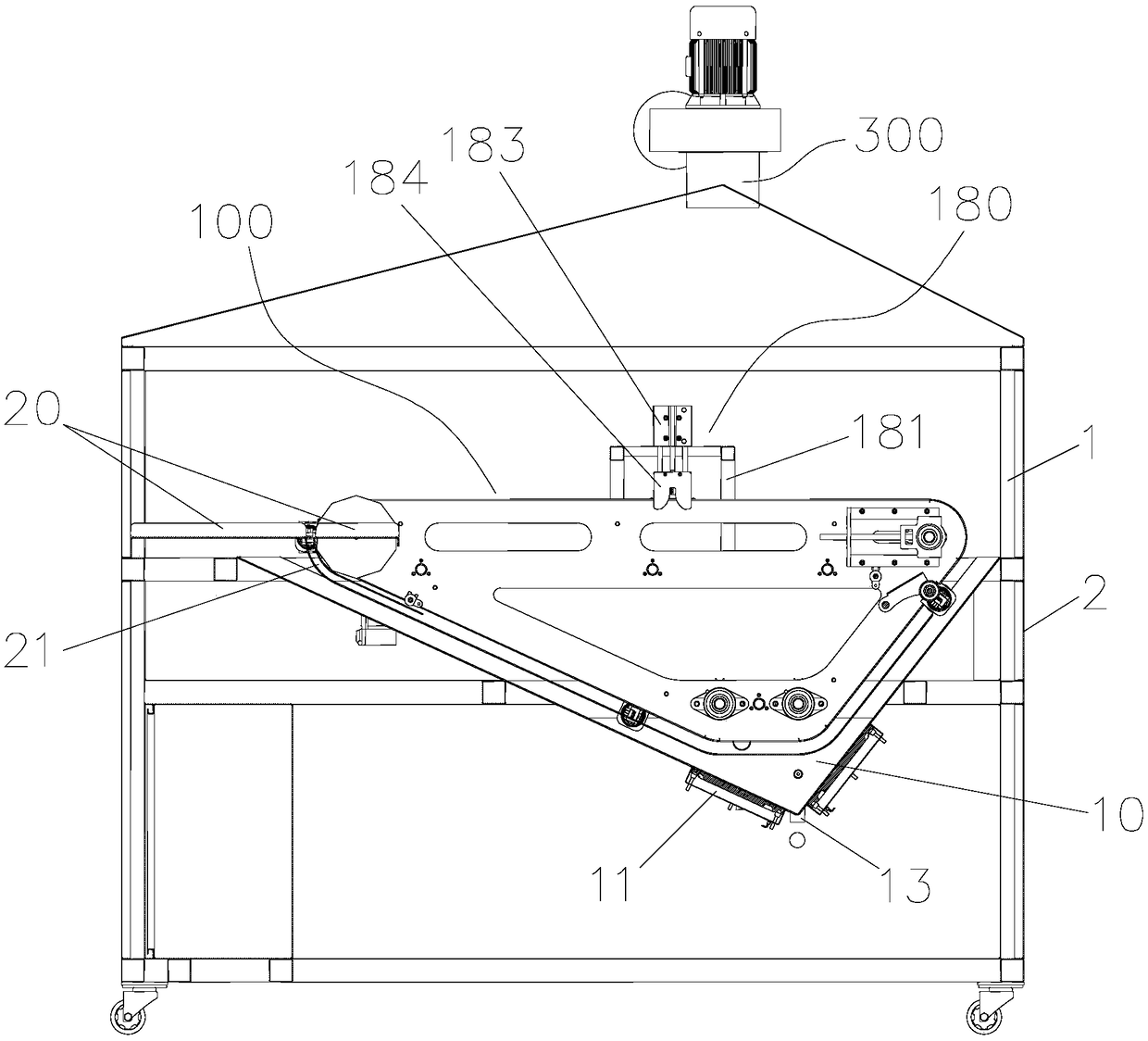

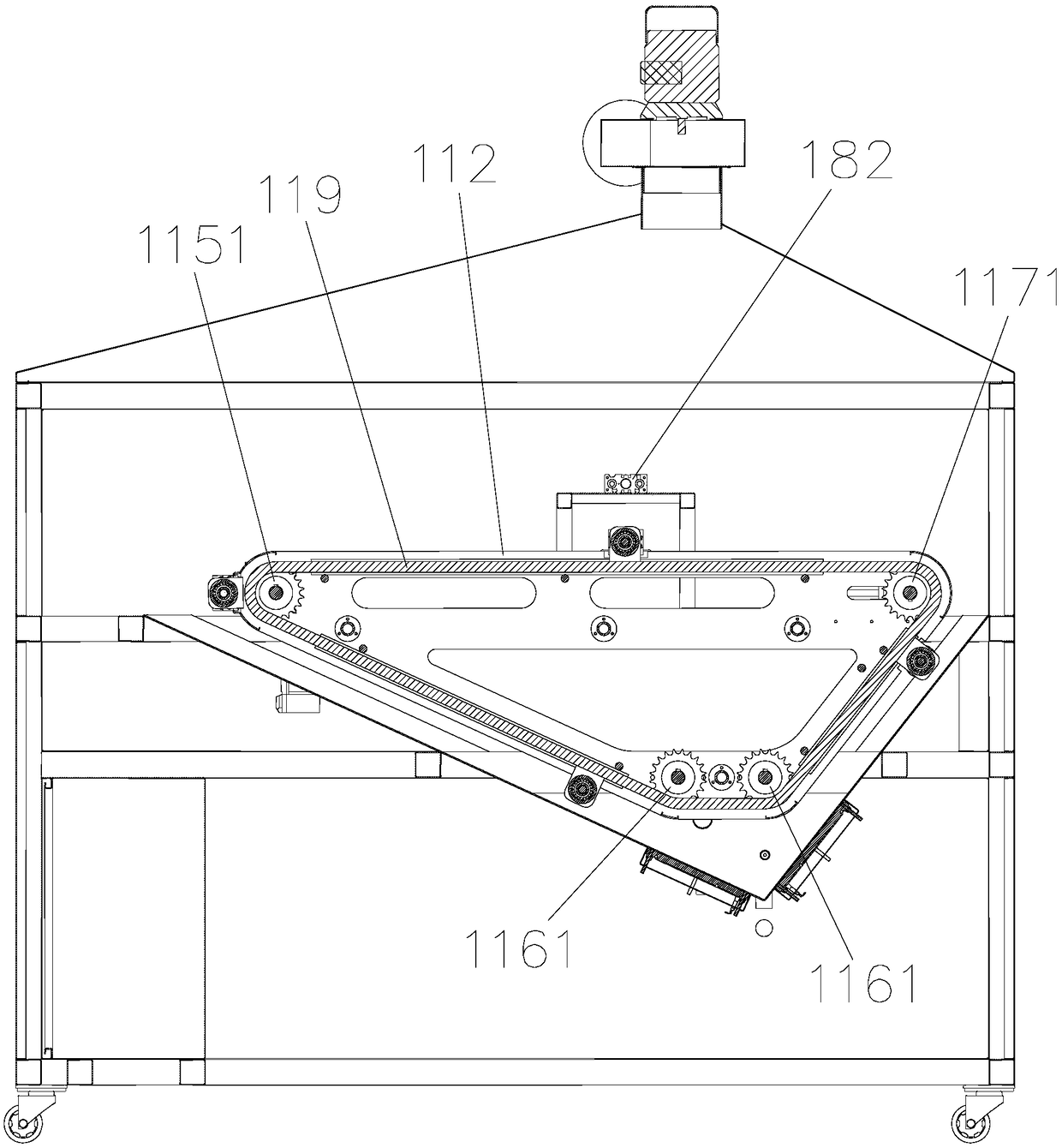

Full-automatic frying and tofu skin coiling all-in-one machine

ActiveCN109275672ARealize automatic windingEasy to take offOil/fat bakingBaking plantsPulp and paper industryManipulator

The invention discloses a full-automatic frying and tofu skin coiling all-in-one machine. The full-automatic frying and tofu skin coiling all-in-one machine comprises a rack, wherein the rack is provided with a frying groove body and a frying device located in the frying groove body, the frying device comprises a first belt type conveying mechanism, a tofu skin clamping air cylinder, a tofu skin coiling motor, a tofu skin coiling pressing wheel and a demoulding air cylinder, the first belt type conveying mechanism comprises a first conveying bracket and a first conveying belt, the outer surface of the first conveying belt is provided with multiple manipulators distributed at intervals, a feeding platform is arranged above a feeding end of the frying groove body, the feeding platform is provided with a channel allowing execution ends of the manipulators to penetrate through, the tofu skin clamping air cylinder is arranged at a feeding end of the first conveying bracket, the tofu skin coiling motor and the tofu skin coiling pressing wheel are arranged at a discharging end of the first conveying bracket respectively, the demoulding air cylinder is arranged in the middle of the top ofthe first conveying bracket, and execution ends of the tofu skin clamping air cylinder, tofu skin coiling motor and demoulding air cylinder cooperate with driving ends of the corresponding manipulators respectively. The full-automatic frying and tofu skin coiling all-in-one machine can conduct automated and standardized frying and coiling on tofu skin, so that the production efficiency is high.

Owner:QUANZHOU TIANFA FOOD MACHINERY

Processing technology for seamlessly and freely tailoring clothes

InactiveCN105686185AWell-formed and stableImprove flatnessWeft knittingLiquid/gas/vapor article treatmentYarnPulp and paper industry

The invention discloses a processing technology for seamlessly and freely tailoring clothes. The processing technology comprises the following steps that firstly, a fabric is woven through a seamless knitted underwear machine, multipath yarn inlet is adopted in the seamless knitted underwear machine, two pieces of yarn enter each path, the two pieces of yarn entering each path are surface yarn and bottom yarn, the bottom yarn is low-temperature meltable spandex, and the two pieces of yarn of each path are fed and woven at the same time; secondly, preshaping of the fabric is conducted through a vacuumization steam pre-shrinking machine, the vacuum degree is 500 Mpa or above, the steam temperature is 100 DEG C or above, and time is 10 minutes or above; thirdly, fabric dyeing is conducted; fourthly, post-shaping of the fabric is conducted; fifthly, clothes manufacturing is conducted, and the fabric is tailored according to a clothes template. By means of the processing technology, waste of materials and labor can be reduced, cost is reduced, no additional auxiliary material or sewing thread track is left on the tailored edge, and the wearing comfort level of the clothes is improved.

Owner:ZHEJIANG LUONA FASHION

Cicada pupa sauce preparation method

The invention discloses a cicada pupa sauce preparation method and relates to the technical field of sauce preparation. The cicada pupa sauce preparation method comprises material preparation, material stir-frying: 1, mixing 30 parts by weight of chopped capsicum, 10 parts by weight of chopped Chinese prickly ash and table salt for seasoning and pouring boiled oil to fry the mixture, 2, stir-frying 25 parts by weight of chopped cicada pupa and 20 parts by weight of chopped ginger in a pot and adding table salt, monosodium glutamate and white sugar into the materials for seasoning, 3, adding water into the ginger juice, fully mixing the ginger juice and starch, putting the materials obtained by the steps 1 and 2 into the starch pulp, and carrying out full stirring to obtain the chopped cicada pupa coated with the starch pulp with the flavoring materials, 4, putting the chopped cicada pupa obtained by the step 3 into gelatin, and carrying out full stirring so that the outer parts of the chopped cicada pupa are coated with gelatin films and 5, heating to cook 40 parts by weight of colleseed oil, stopping heating, carrying out cooling to a temperature 70% of an oil boiling point, adding 15 parts by weight of sesame and broken peanut into the chopped cicada pupa obtained by the step 4 and carrying out repeating stir-frying for 10min, and package. The cicada pupa sauce preparation method has a lasting flavoring fragrance, a good taste and flavor and a high cicada pupa nutrition value.

Owner:ANHUI WINS ONE MEAT FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com