Anchor cable for cage-shaped mine and preparation method thereof

A manufacturing method and cage-shaped technology, which can be used in mining equipment, earth-moving drilling, installation of bolts, etc., can solve problems such as insufficient anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention will be further described below with reference to the accompanying drawings.

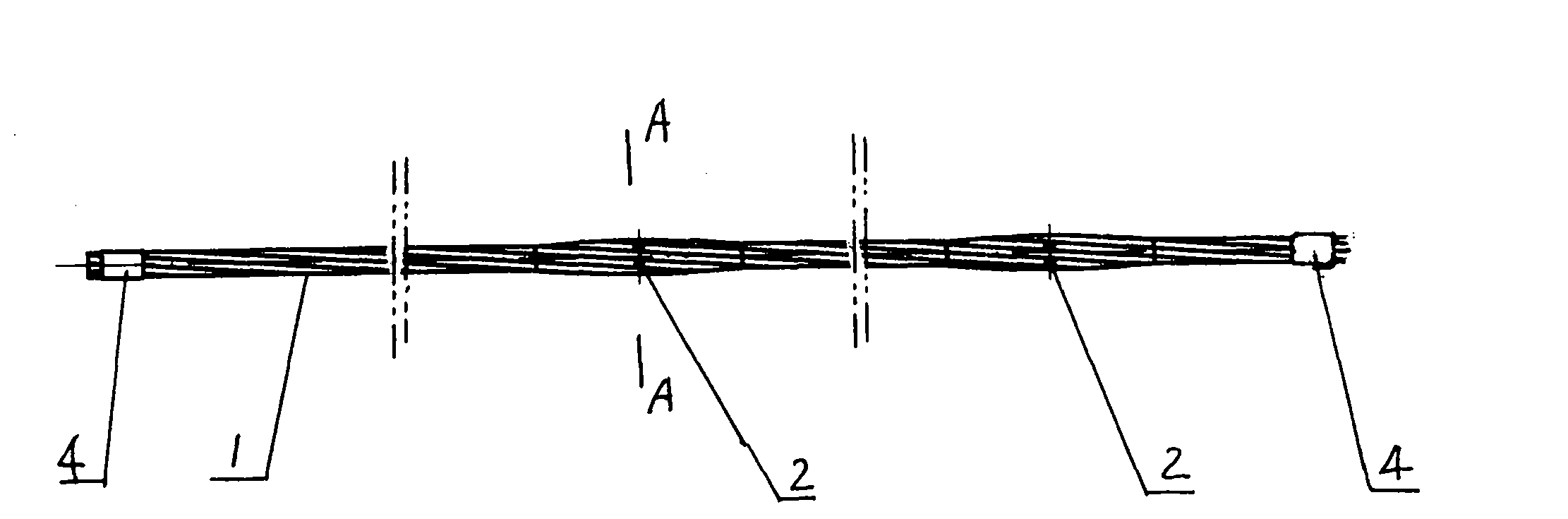

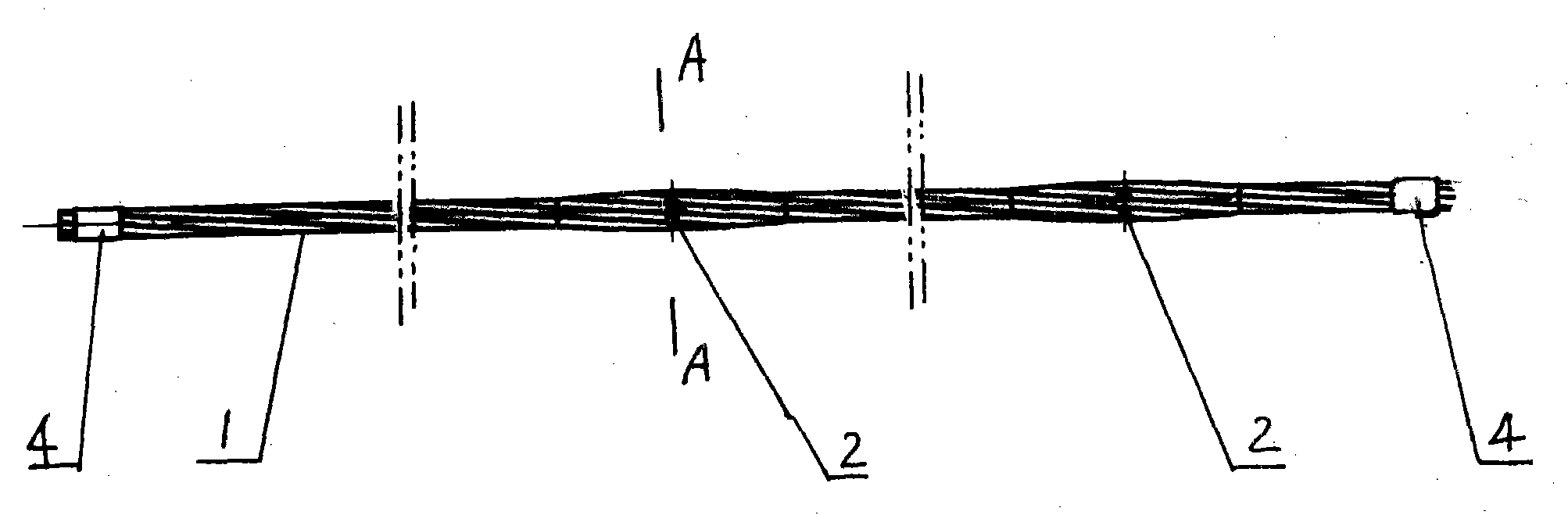

[0011] As shown in the figure, the cage-shaped mining anchor cable of the present invention is processed with a plurality of cage-shaped expansion joints 2 on the existing anchor cable body 1, and the outer diameter of the cage-shaped expansion joints 2 is smaller than the diameter of the anchor borehole.

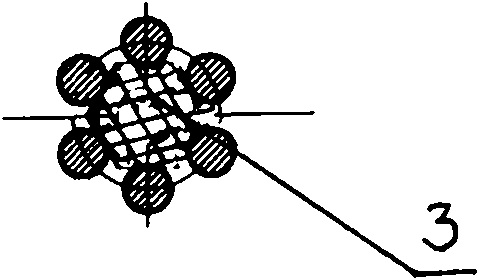

[0012] During production: Clamp the steel strands in the fixture of the workbench, use a special cage braider to reverse the twist direction of the steel strands to break the steel strands, and then fill the broken pieces with filler 3 In the steel strand, the cage braider is used to rotate the twist of the steel wire in the forward direction, so that the steel strand forms a cage-shaped expansion joint 2, and finally the two ends of the steel strand are buckled and clamped 4 to form a cage-shaped mining anchor cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com