Expansion anchor rod

A technology of expanding bolts and bolts, which is applied in the installation of bolts, construction, excavation, etc., can solve the problem of soft rock and large deformation roadway support, and the limitation of the strength and creep resistance of the bolt body , single anchoring force of the anchor rod, etc., to achieve the effect of wide selection of structures and materials, wide range of structures and materials, and large anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

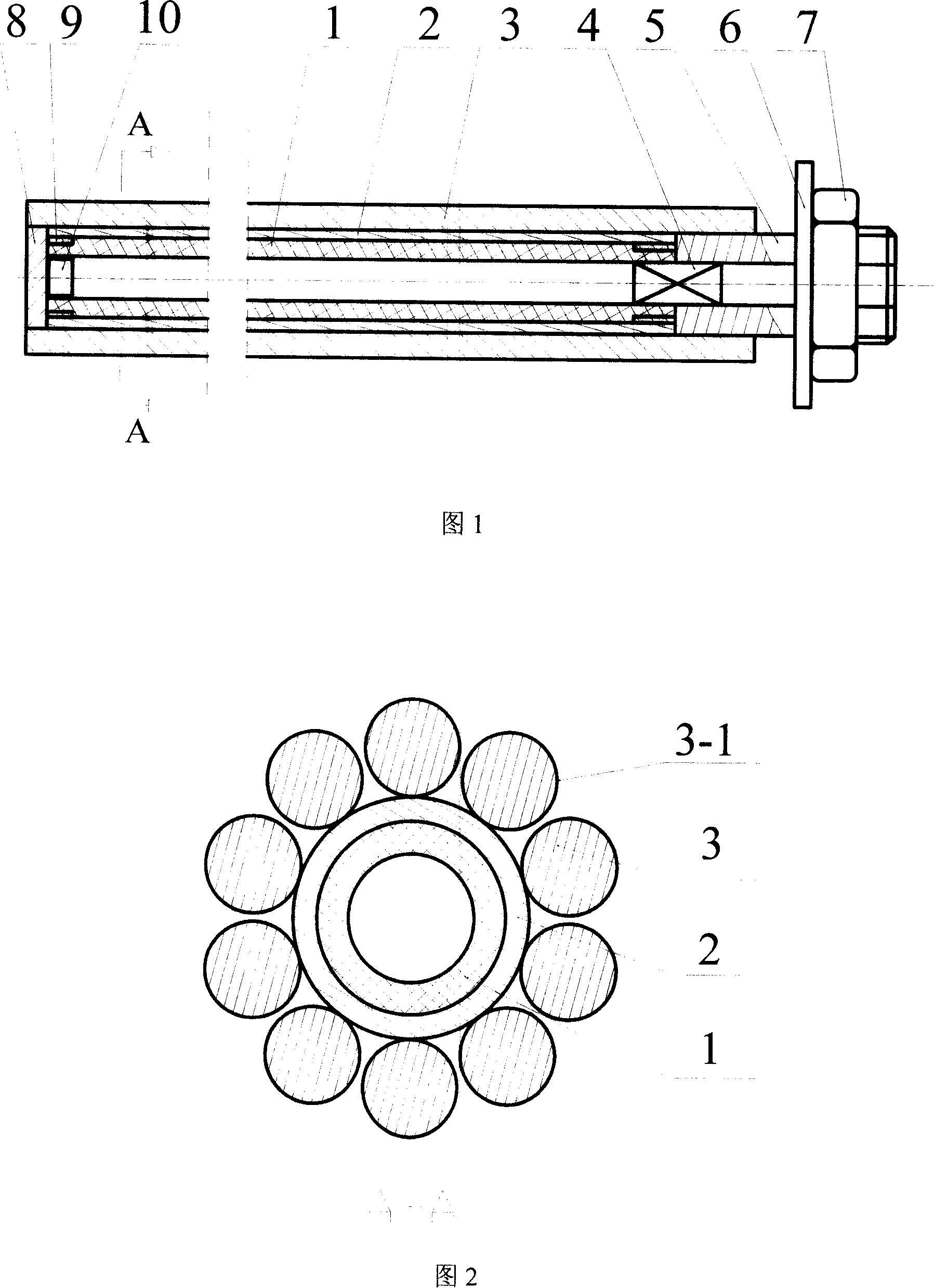

[0024] 1. Embodiment 1: Anchors with circular cross-sections and expansion bolts

[0025] Coal mines usually use a drill bit with a diameter of 28mm to drill the anchor hole to place the anchor rod. In order to facilitate the installation of the "expansion anchor rod", the diameter of the anchor rod body is slightly smaller than the diameter of the drill bit, which is determined to be 27mm, and the length of the anchor rod is 2 meters. As shown in Figure 1 and Figure 2, the expansion body 1 is a straight cylindrical rubber bladder made of rubber with an outer diameter of 15mm and a thickness of 2mm; the expansion force transmission layer 2 is a circumferential fracture rolled with a 0.3mm thin metal plate, And overlap the cylinder for a week; the circular cross-section anchor 3-1 of the anchor layer 3 is a round steel bar or round threaded steel bar with a diameter of 5mm; the injection valve 4 is a valve core for an aviation tire; the pipe hole anchor head 5 is a Threaded ste...

Embodiment approach 2

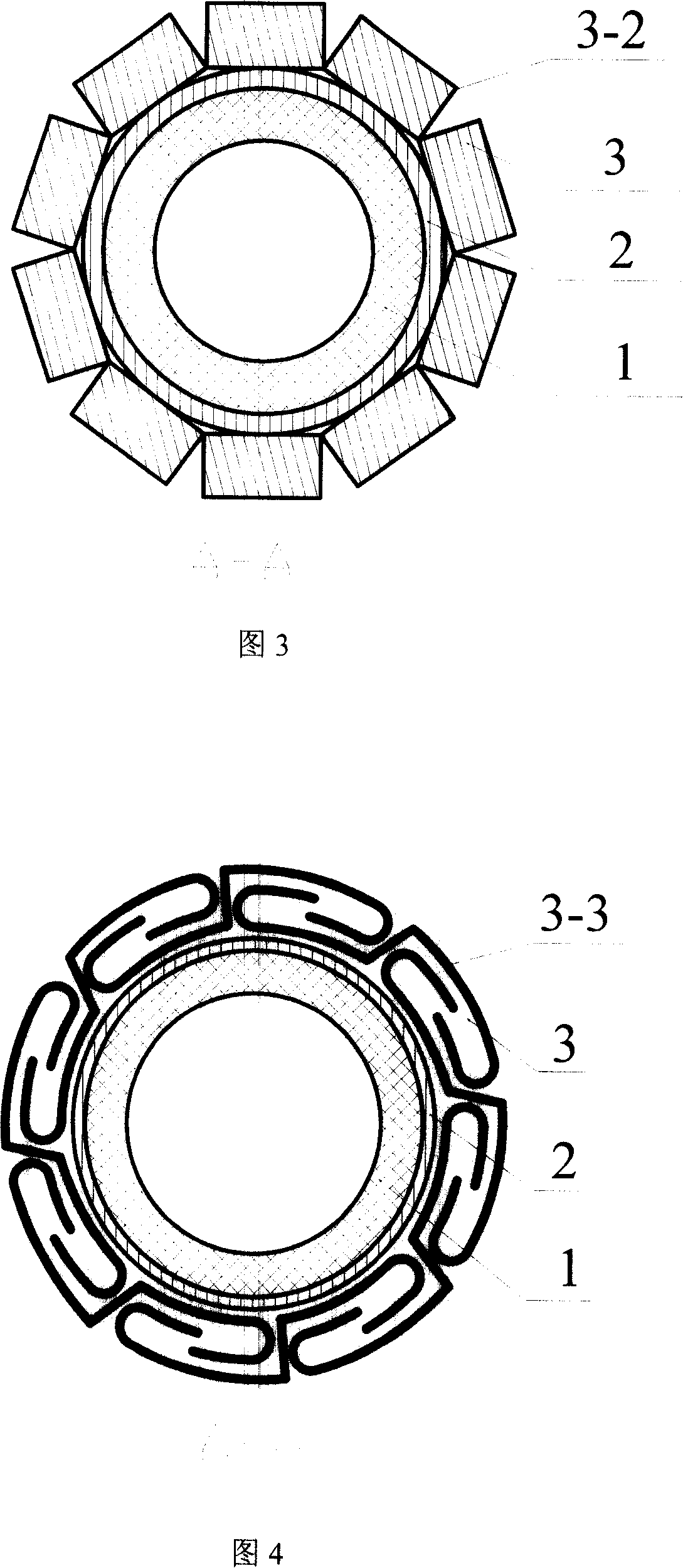

[0028] 2. Embodiment 2: Anchors with rectangular cross-section expand the anchor rod

[0029] As shown in Figure 3, a rectangular anchor 3-2 with a cross-sectional size of 8×5 mm is selected to form an expansion anchor rod, and the others are the same as in the first embodiment.

[0030] Compared with Embodiment 1, the difference of this structure is only on the anchoring layer 3, the circular anchoring piece is replaced by the rectangular anchoring piece, which greatly increases the contact area between the anchoring layer 3 and the surrounding rock mass, and improves the anchoring force. According to the different grades of steel used in the anchor, the anchor rod can provide a maximum anchoring force of 120-340kN.

Embodiment approach 3

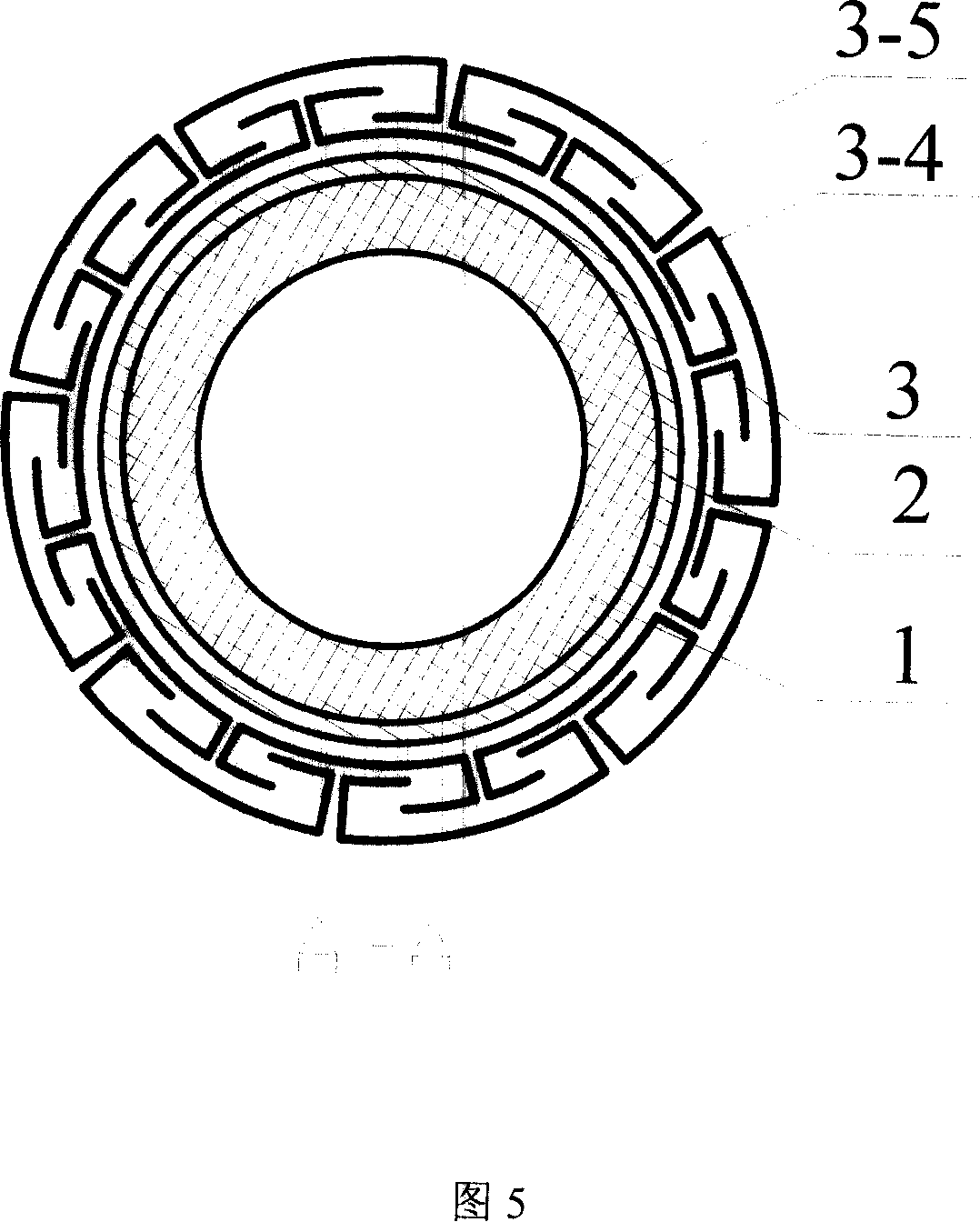

[0031] 3. Implementation plan three: S-shaped cross-section anchor expansion anchor rod

[0032]As shown in Figure 4, the expansion force transmission layer 2 is a circular closed cylinder braided with high-strength and high-elastic fibers, which is set on the expansion body; steel strips with a thickness of 1.5 mm are used to make S-shaped anchors 3-3 The anchoring layers are interlocked and linked one by one to form a circularly stretchable cylindrical structure, and are fitted on the outer edge of the expansion force transmission layer to form an expansion anchor rod, and the others are the same as in the first embodiment.

[0033] Compared with Embodiment 1, the difference of this structure is that the anchoring layer 3 is replaced by a circular anchoring piece by an S-shaped anchoring piece, which increases the contact area between the anchoring layer 3 and the surrounding rock mass and improves the anchoring force. At the same time, the anchoring layer 3 It has the abili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com