Steel reinforcement processing shed and construction method therefor

A technology for processing sheds and steel bars, which is applied in industrial buildings, buildings, building structures, etc., can solve the problems of inconvenient vehicle transportation and driving, slow construction and dismantling speed, and easy blowing down of steel structures, so as to achieve fast and convenient disassembly, It is convenient to carry steel bars and has ideal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

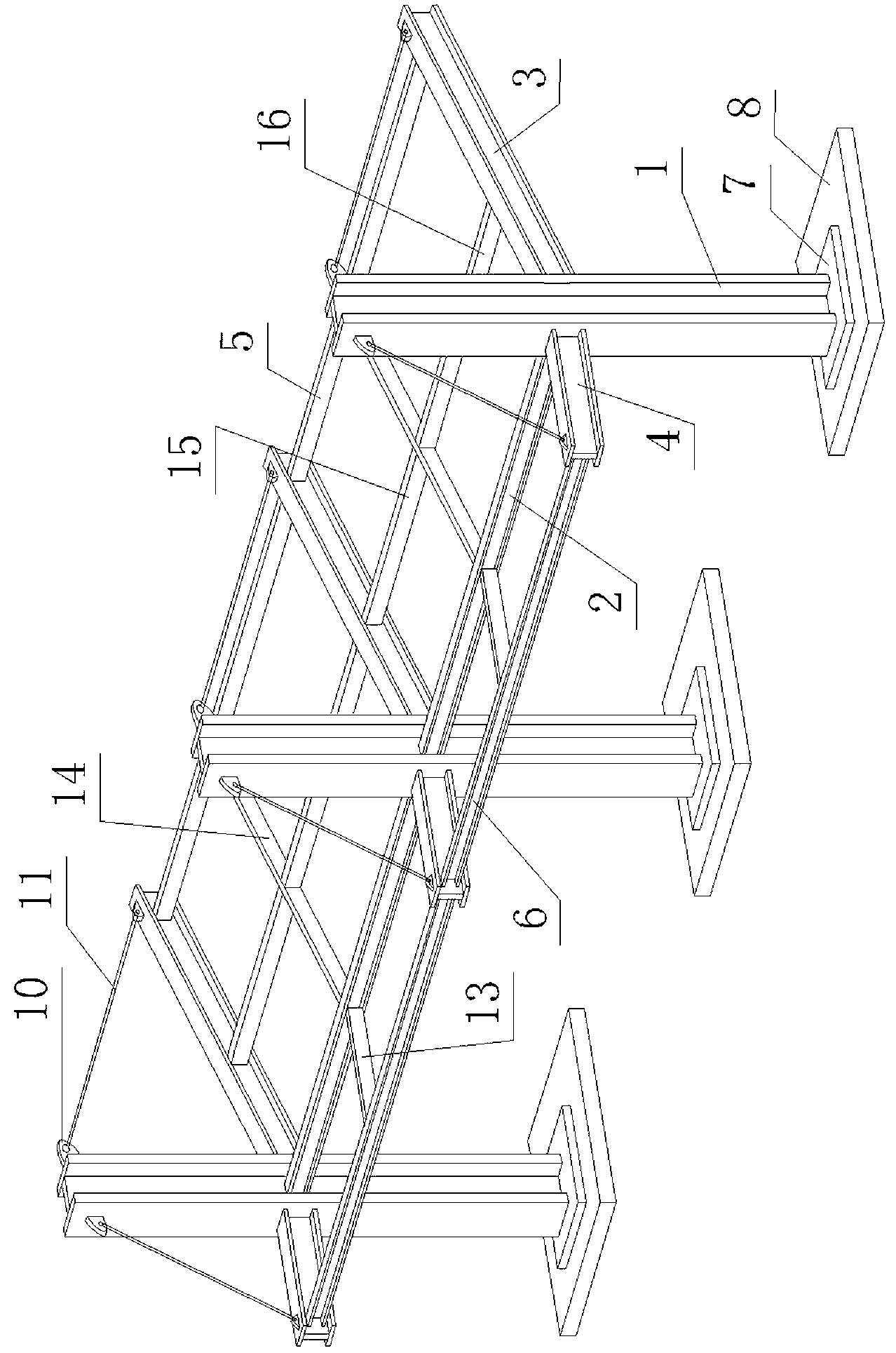

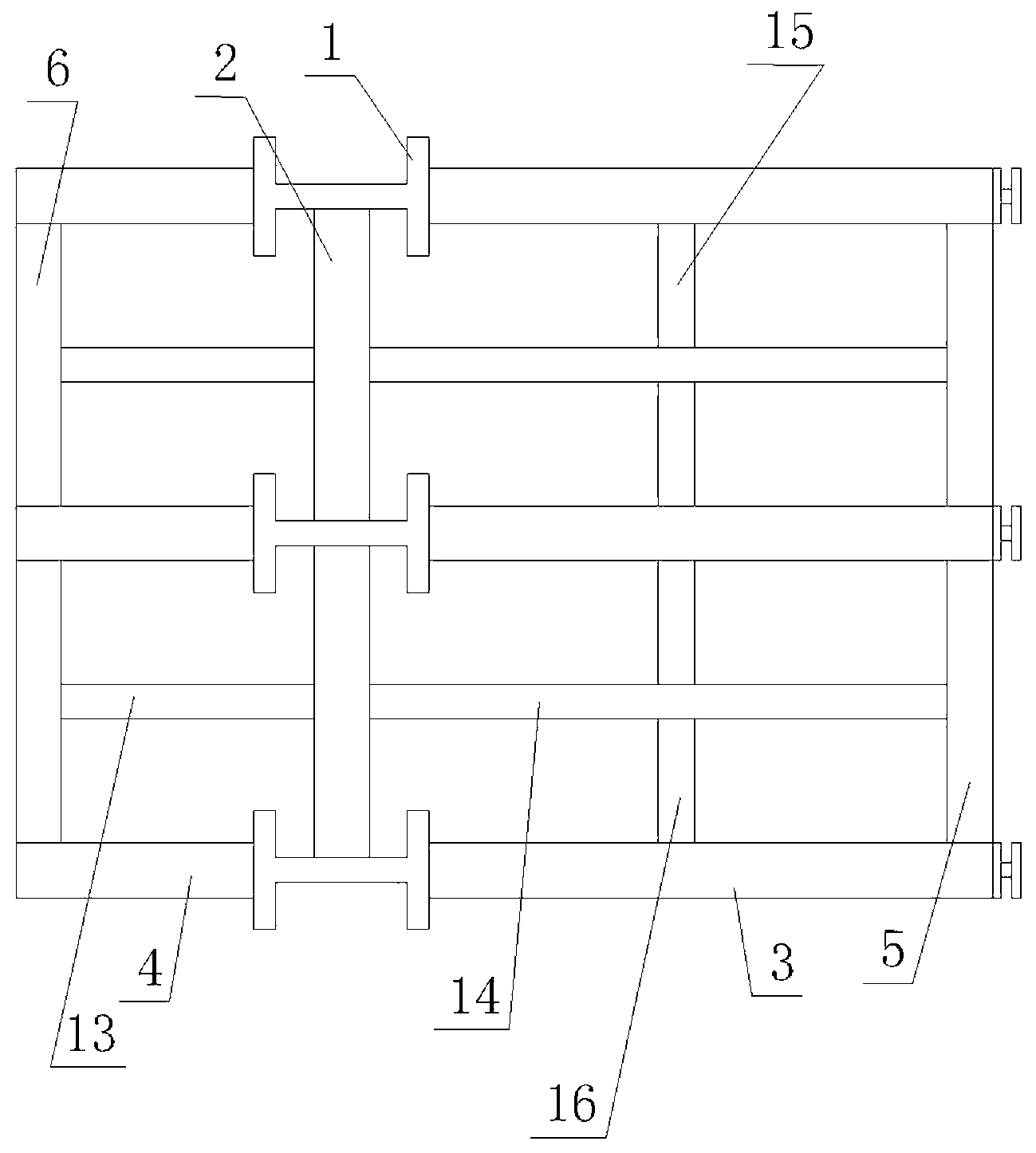

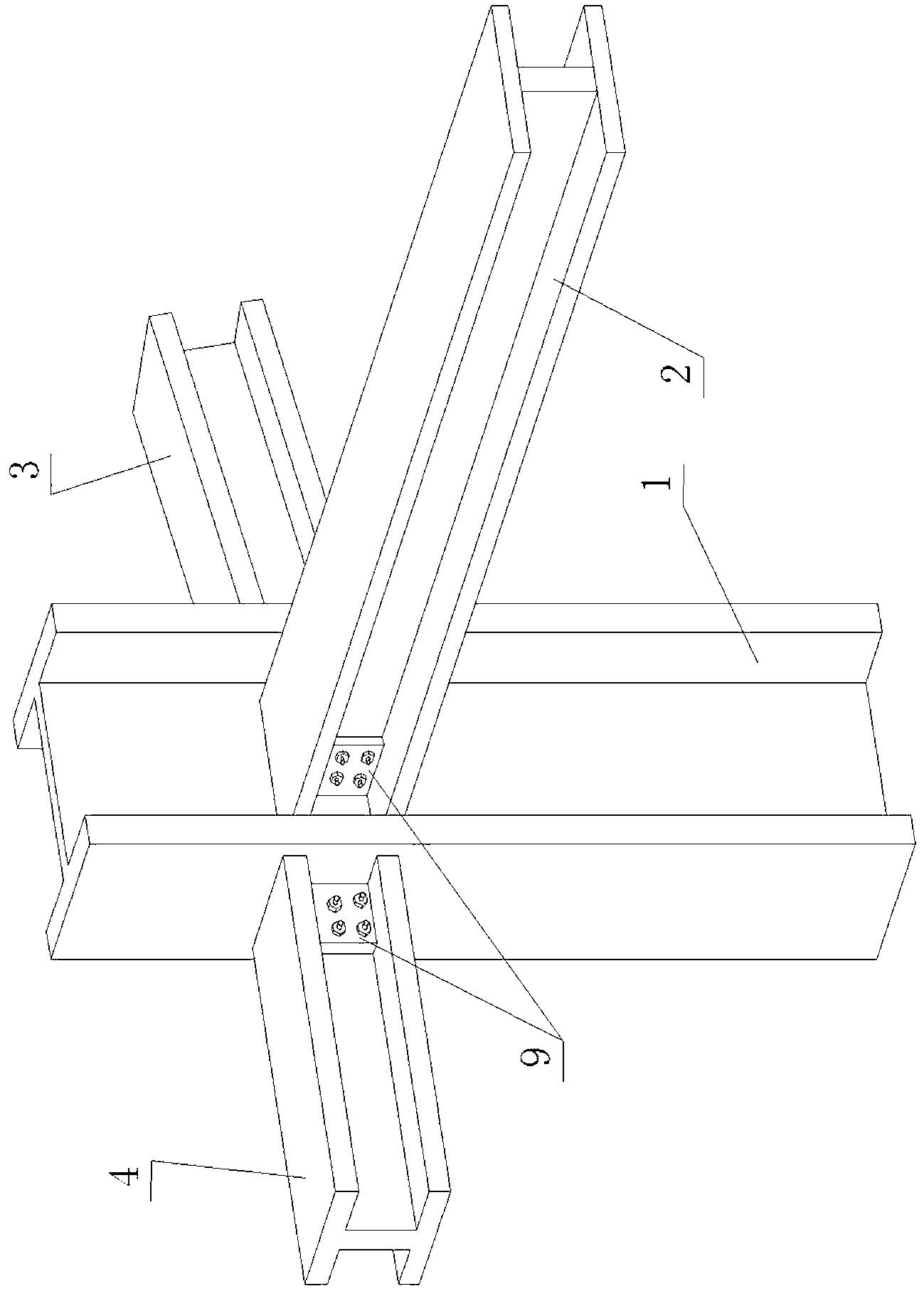

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the steel bar processing shed of the present invention includes an integral steel structure, a top-pressed steel plate and an anti-fall protection railing fixed above the integral steel structure. The overall steel structure includes a row of at least three I-steel columns 1 detachably connected to the ground, and an I-steel main beam 2 is arranged between every two adjacent I-steel columns 1, specifically, each The lower end of the I-beam column 1 is welded with a bottom plate 7 with holes, and the ground below each bottom plate 7 is poured with a reinforced concrete cap 8, and high-strength bolts are pre-embedded in the reinforced concrete cap 8, and the bottom plate 7 passes through the high-strength bolt through the hole. The bolts are screwed to the reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com