Downhole bypass valve

a bypass valve and downhole technology, applied in the field of downhole tools, can solve problems such as tool “dormant”, and achieve the effect of facilitating fluid actuation of the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

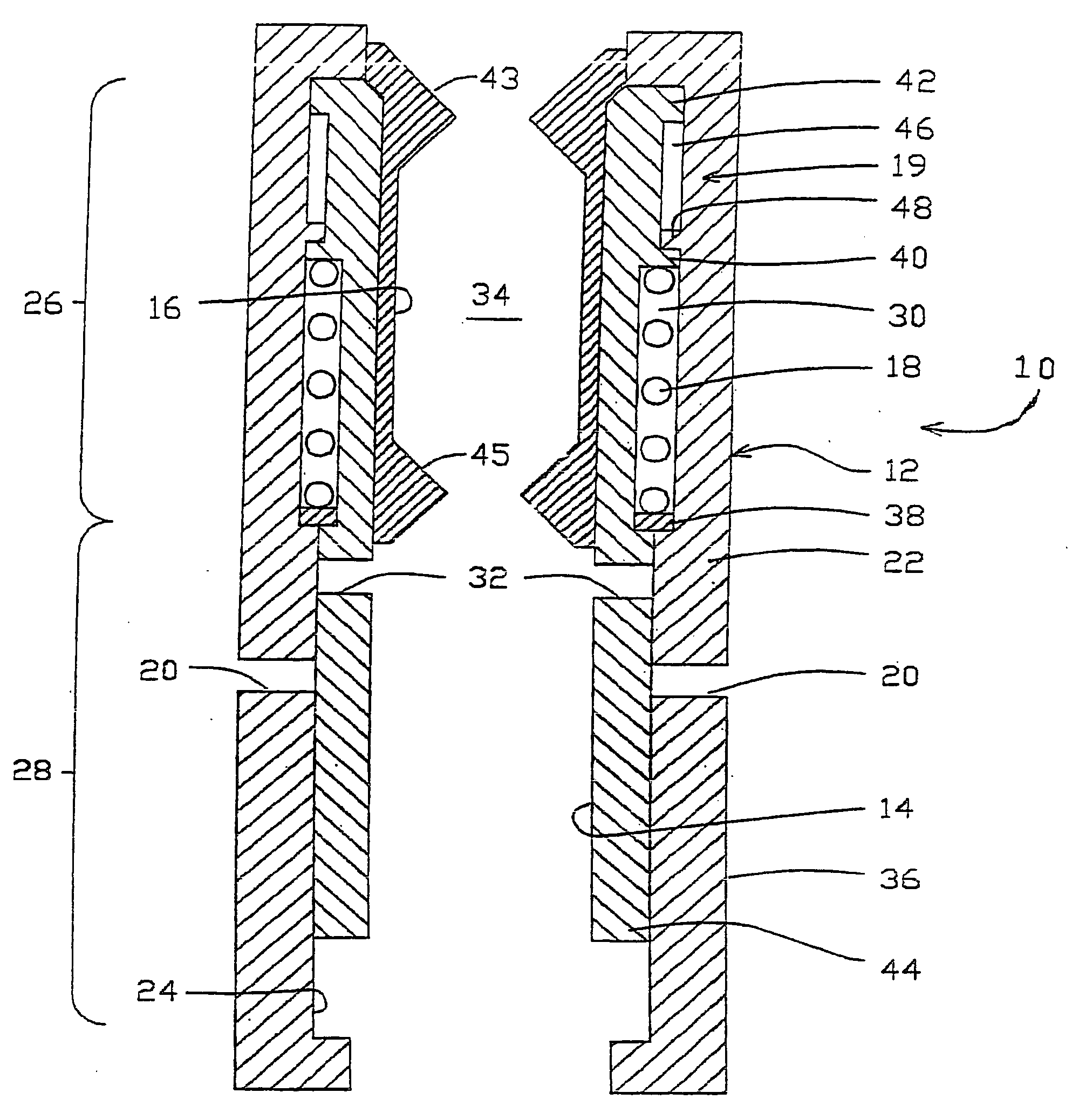

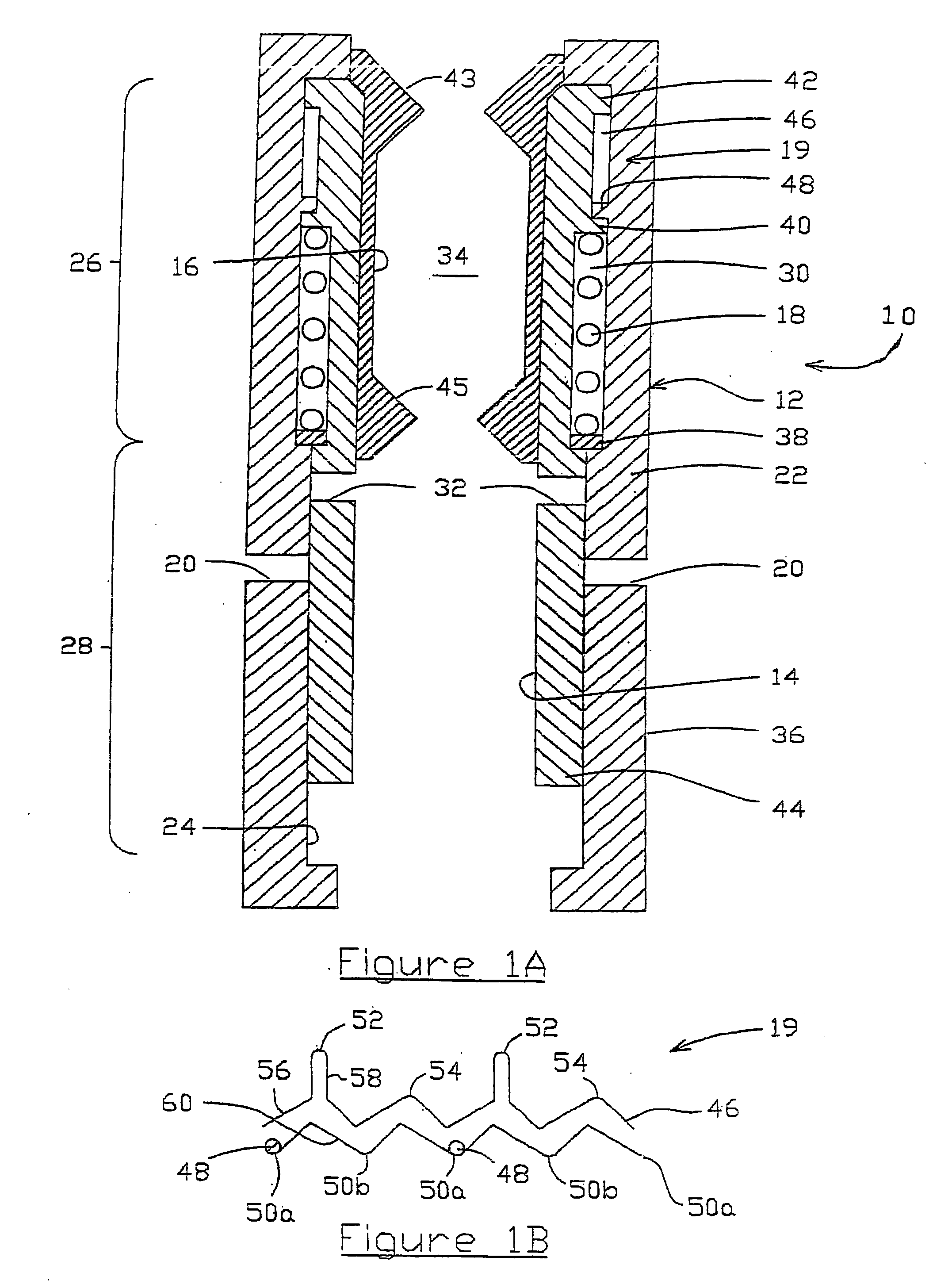

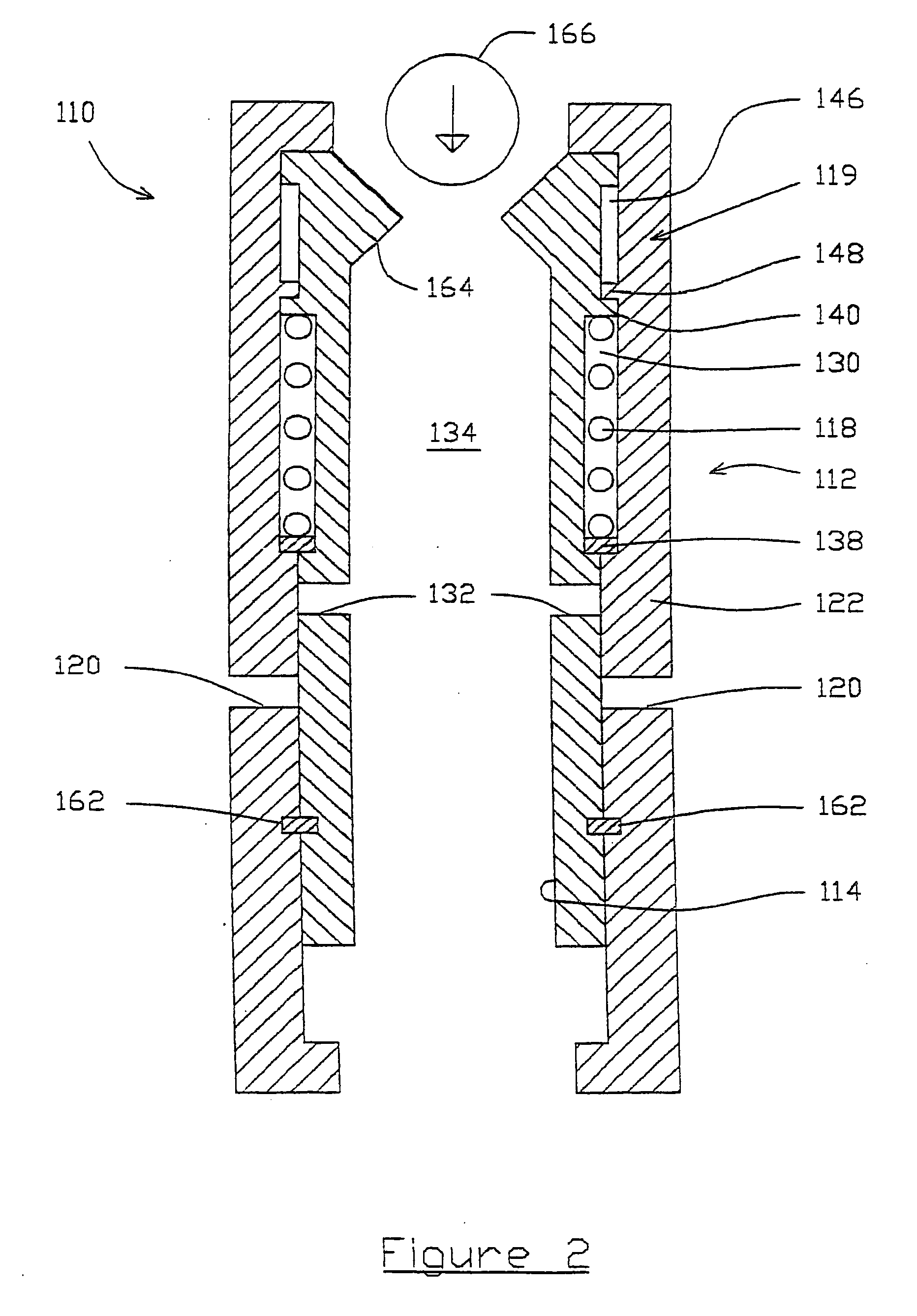

[0060] Referring firstly to FIG. 1, there is shown a longitudinal cross-sectional view of a downhole tool in accordance with an embodiment of the present invention, the downhole tool indicated generally by reference numeral 10. The downhole tool 10 forms part of a drill string (not shown) run into a borehole (not shown) of an oil well, and is coupled at its upper and lower ends to sequential sections of drill string tubing via threaded joints, in a fashion known in the art.

[0061] The downhole tool 10 shown in FIG. 1A is a bypass tool comprising a tubular outer housing 12, a tubular bypass sleeve 14, a tubular flow restriction insert 16, a bypass sleeve spring 18 and a pin and groove assembly indicated generally by reference numeral 19.

[0062] Those of skill in the art will understand that the tool 10 will be provided with a variety of appropriate seals, however in the interest of brevity the individual seals will not be identified and described.

[0063] The tubular outer housing12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com