Manufacturing method of carbons heating element, carbons heating elements, heater and heating device

A manufacturing method and technology of a heating device, which are applied in the directions of heating element material, heating element shape, ohmic resistance heating parts, etc., can solve the problems of broken wires and scattered fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, an embodiment specifically showing the best mode for carrying out the present invention will be described with reference to the drawings.

[0065] (Embodiment 1)

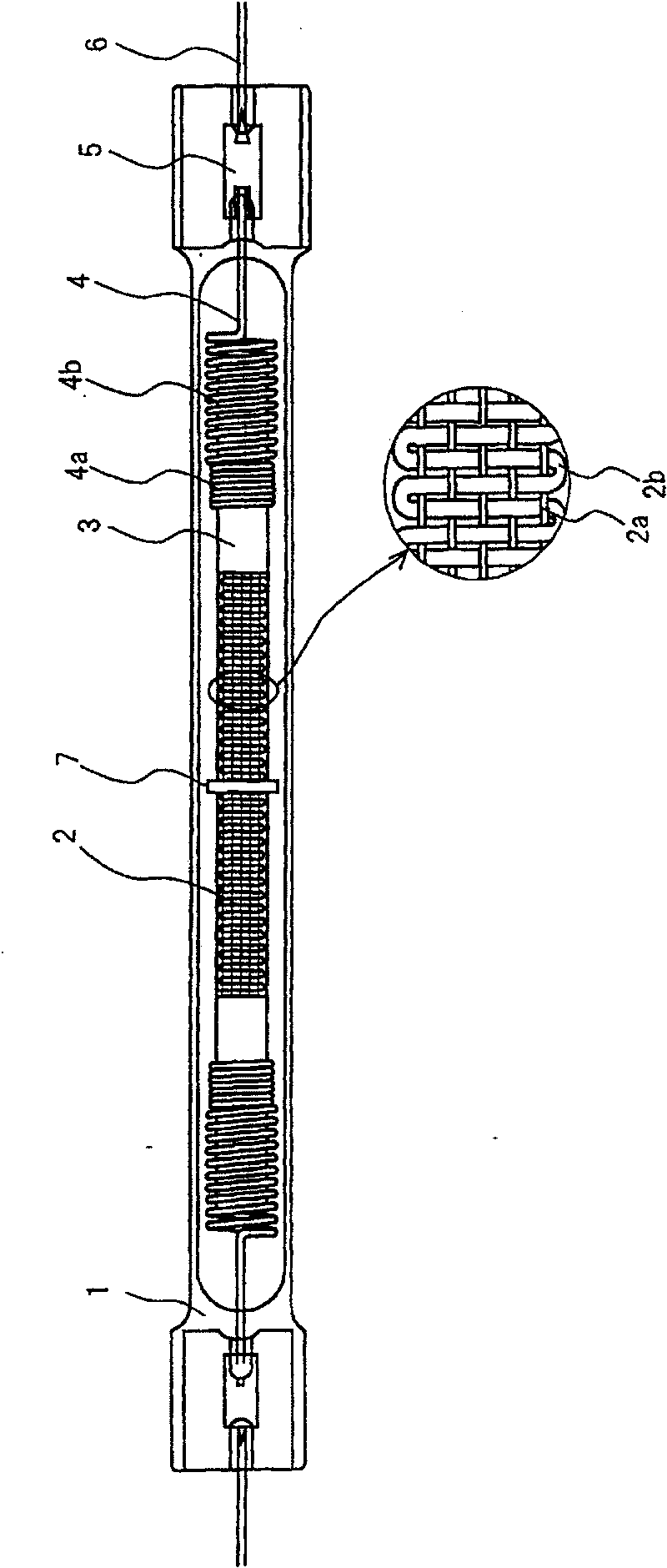

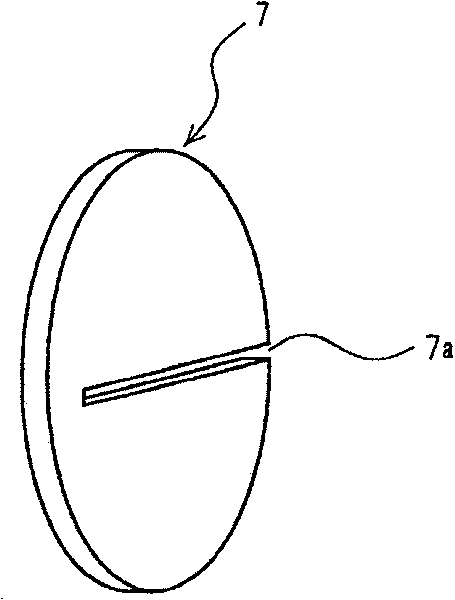

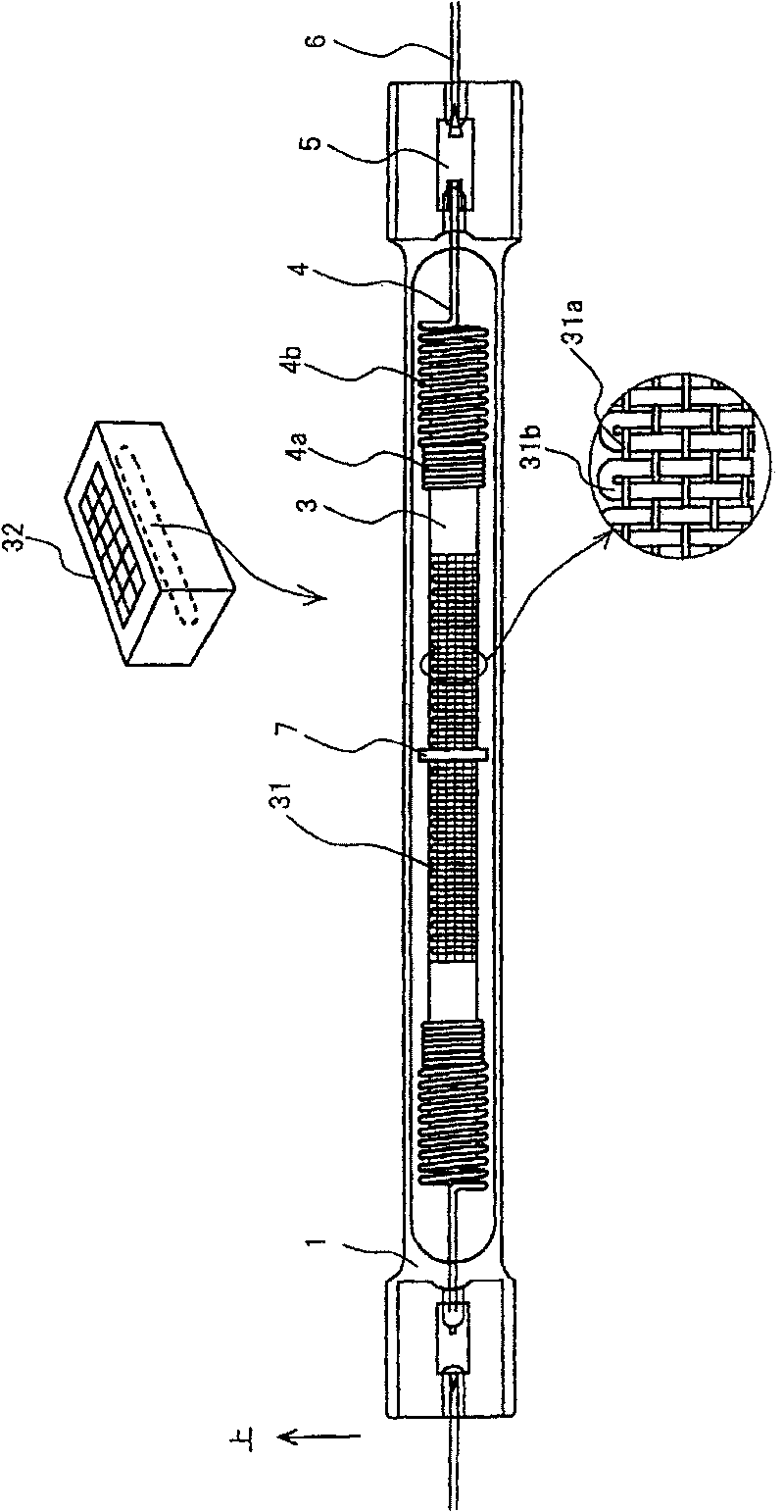

[0066] use figure 1 and figure 2 A method for producing a carbon-based heating element, a carbon-based heating element, a heater, and a heating device according to Embodiment 1 of the present invention will be described. figure 1 It is a figure showing the structure of the heater of Embodiment 1 of this invention. The heater is formed by encapsulating the heating element 2 , the cooling block 3 and the internal wire 4 into the glass tube 1 .

[0067] The glass tube 1 is amorphous glass such as transparent quartz glass (for example, #214 produced by GE or borosilicate heat-resistant glass (product number #7190) produced by Dow Corning Co.). The diameter of the glass tube is made such that it does not collide with the heating element 2 even if it vibrates. In Embodiment 1, the size of the gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com