Inorganic composite microporous membrane serving as lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and inorganic composite technology, applied in battery components, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problem of inability to effectively guarantee battery safety performance, battery diaphragm isolation battery Negative electrode, affecting the stability of battery performance and other issues, to achieve good high temperature resistance, prevent direct contact, and improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

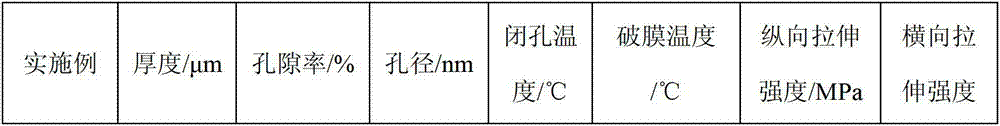

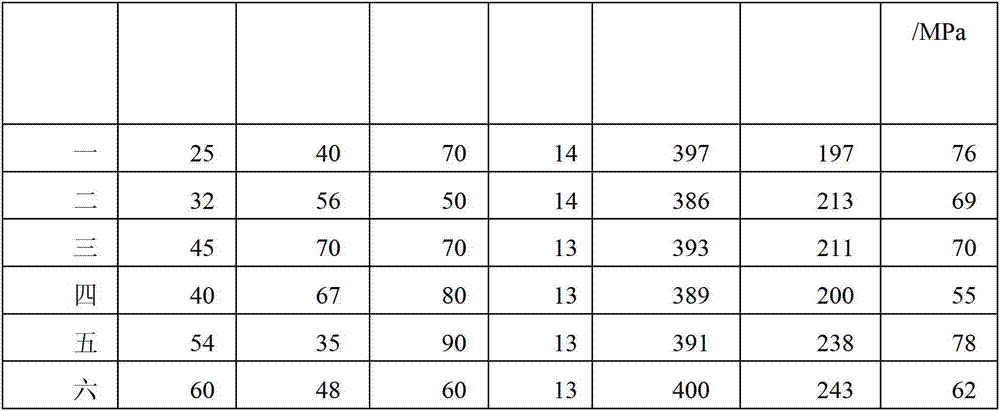

Examples

preparation example Construction

[0037] A preparation method for an inorganic composite microporous membrane used as a lithium-ion battery diaphragm, comprising the following steps:

[0038] Step 1. Co-extrude the inorganic composite polyolefin multilayer precursor through the multilayer die of the extrusion device, and cool the inorganic composite polyolefin multilayer precursor to obtain a sheet, wherein the sheet includes an intermediate layer and two outer layers, and the two outer layers are respectively located on both sides of the middle layer, wherein the middle layer is mainly composed of polyethylene, or a copolymer of ethylene and other olefins or a mixture of polyethylene and other polyolefins The two outer layers are mainly made of a mixture of polypropylene and nano-inorganic particles, and the nano-inorganic particles are at least one of aluminum oxide, magnesium oxide, calcium oxide and silicon oxide;

[0039] Step 2, biaxially stretching the sheet obtained in step 1 to obtain a film;

[0040...

Embodiment 1

[0043] The middle layer is made of polyethylene, which is a mixture of high-density polyethylene and low-density polyethylene, and the molecular weight of high-density polyethylene is 5×10 4 , the melting point is 130°C, and the molecular weight of low-density polyethylene is 3×10 3 , the melting point is 126°C, and the mass percentage of low-density polyethylene is 10%.

[0044] The outer layer solution includes polypropylene, nano inorganic particles and dispersant. Wherein, the nano-inorganic particles are aluminum oxide with a particle diameter of 500nm, the mass percentage of the nano-inorganic particles in the outer layer solution is 40%, and the mass percentage of polypropylene in the outer layer is 59%. The dispersant is polyethylene glycol, and the addition ratio is 1% of the total mass of the outer layer solution.

[0045] The middle layer solution and the outer layer solution are co-extruded through a three-layer die in the extrusion device, and the extruded precu...

Embodiment 2

[0048] The middle layer is made of polyethylene, which is a mixture of high-density polyethylene and low-density polyethylene, and the molecular weight of high-density polyethylene is 5×10 5 , the melting point is 135°C, and the molecular weight of low-density polyethylene is 1×10 4 , the melting point is 130°C, and the mass percentage of low-density polyethylene is 30%.

[0049] The outer layer solution includes polypropylene, nano inorganic particles and dispersant. Wherein, the nano-inorganic particles are magnesium oxide with a particle diameter of 40nm, the mass percentage of the nano-inorganic particles in the outer layer solution is 65%, and the mass percentage of polypropylene in the outer layer is 30%. The dispersant is polyvinyl alcohol, and the addition ratio is 5% of the total mass of the outer layer solution.

[0050] The middle layer solution and the outer layer solution are co-extruded through a three-layer die in the extrusion device, and the extruded precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com