Patents

Literature

43results about How to "Implement the manufacturing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lens, near-infrared ray absorption glass lot and manufacturing method therefore

InactiveCN1939856AWith near-infrared absorption functionImprove imaging effectGlass pressing apparatusInfraredRefractive index

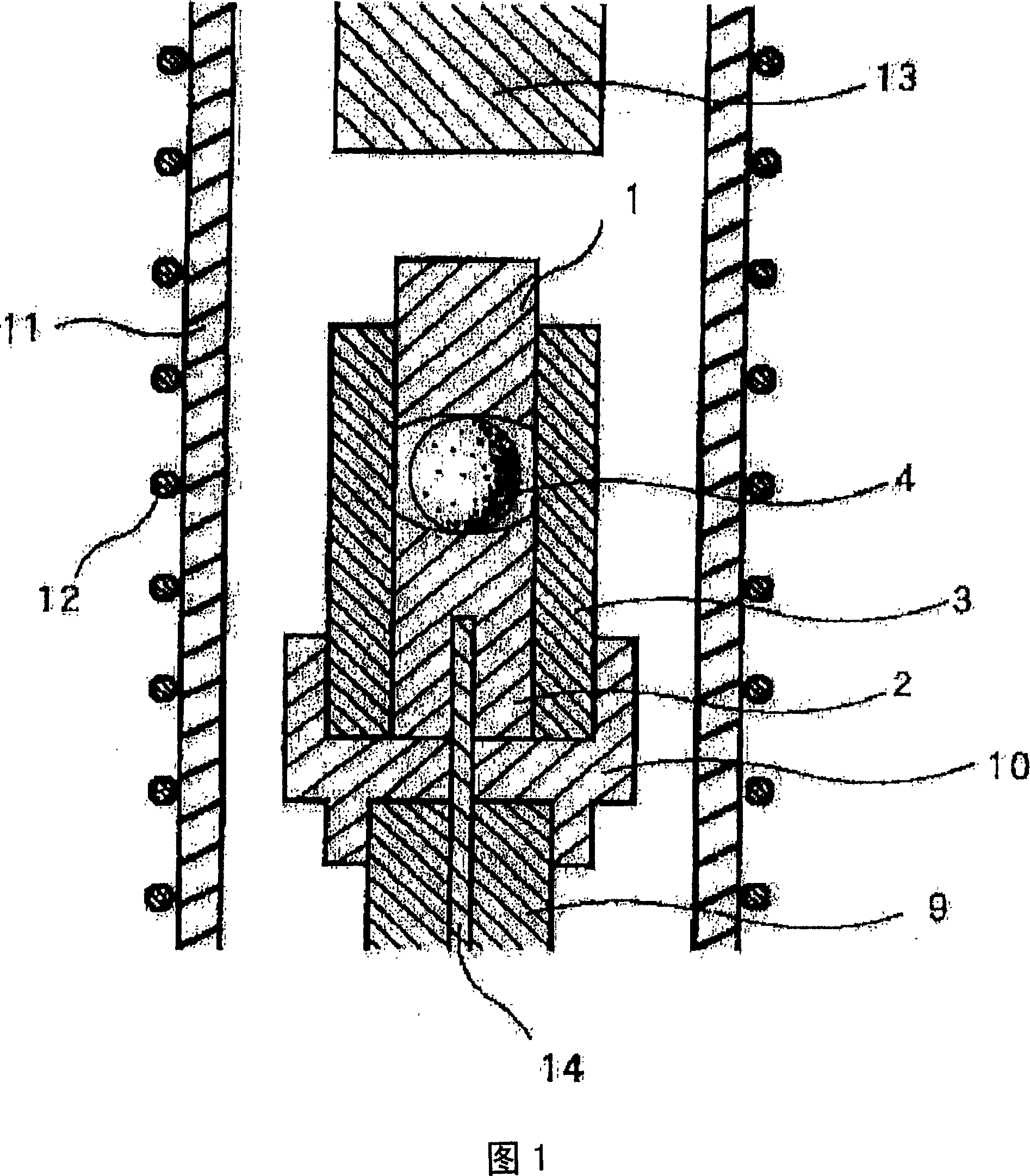

In a near-infrared ray absorption glass lot made of a copper-containing near-infrared ray absorption glass material, a near-infrared ray absorption glass lot is constituted of a glass material of which the tolerance of the refractive index (ne) at a wavelength of 546.07 nm is less than +-0.001.

Owner:HOYA CORP

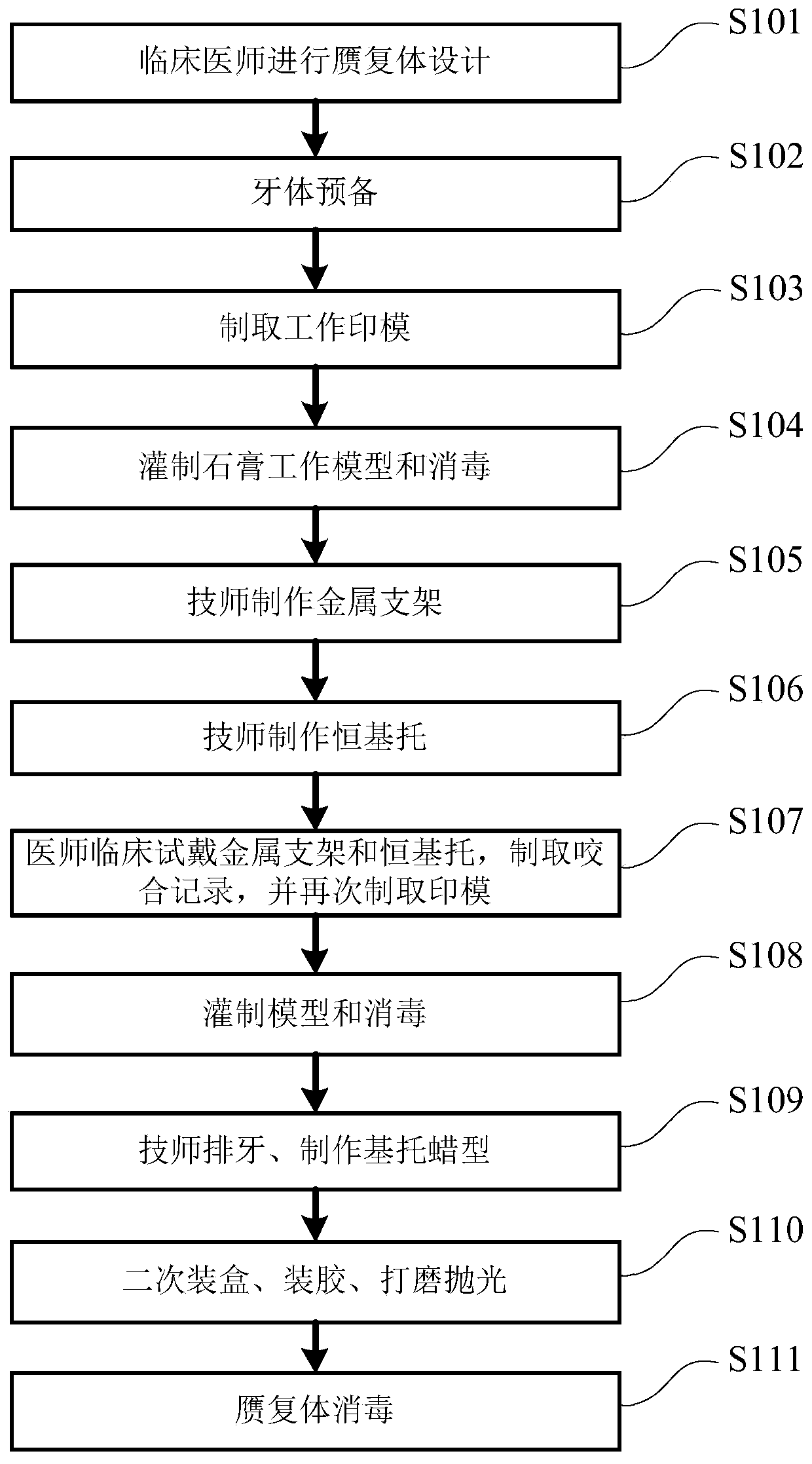

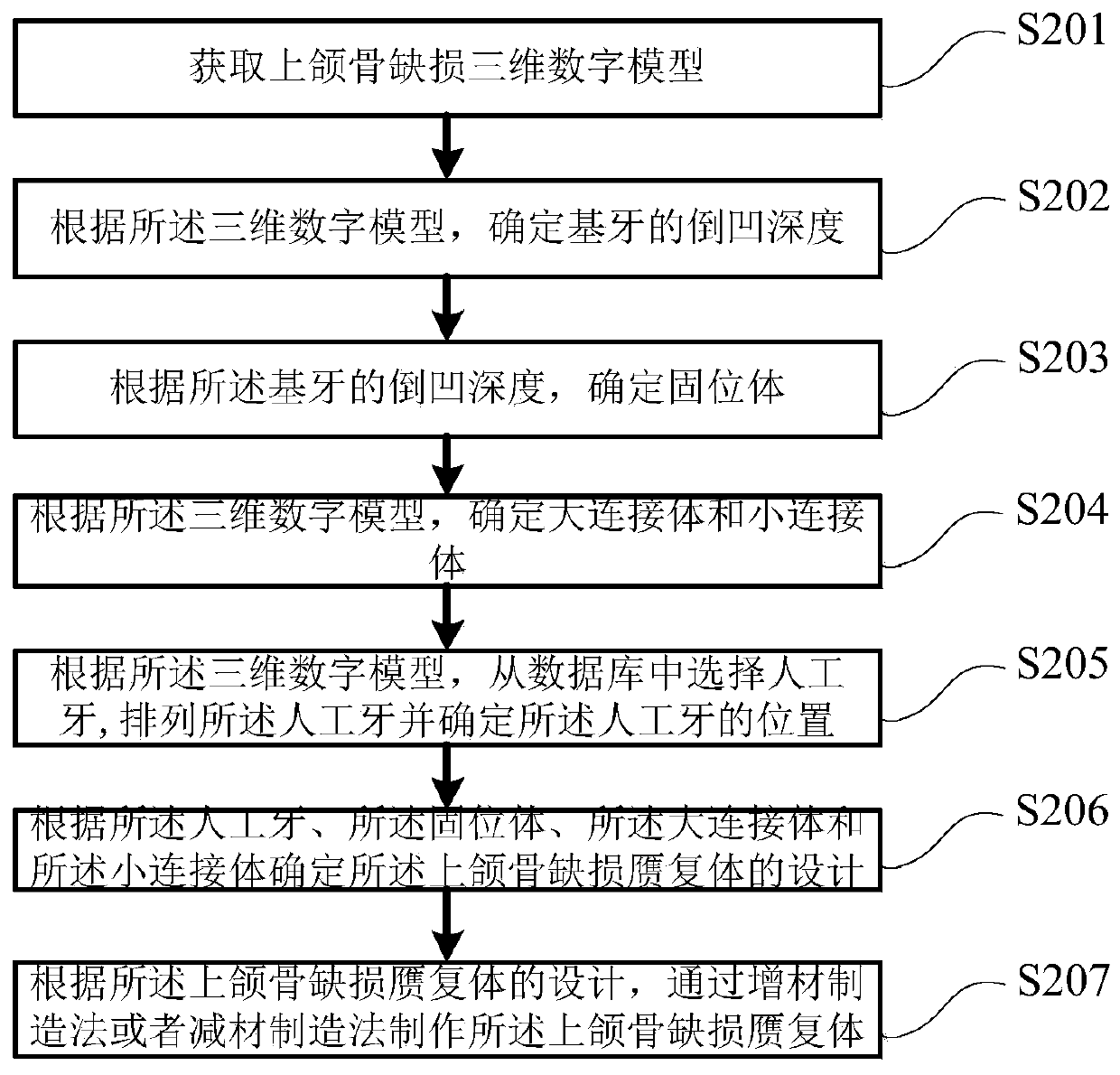

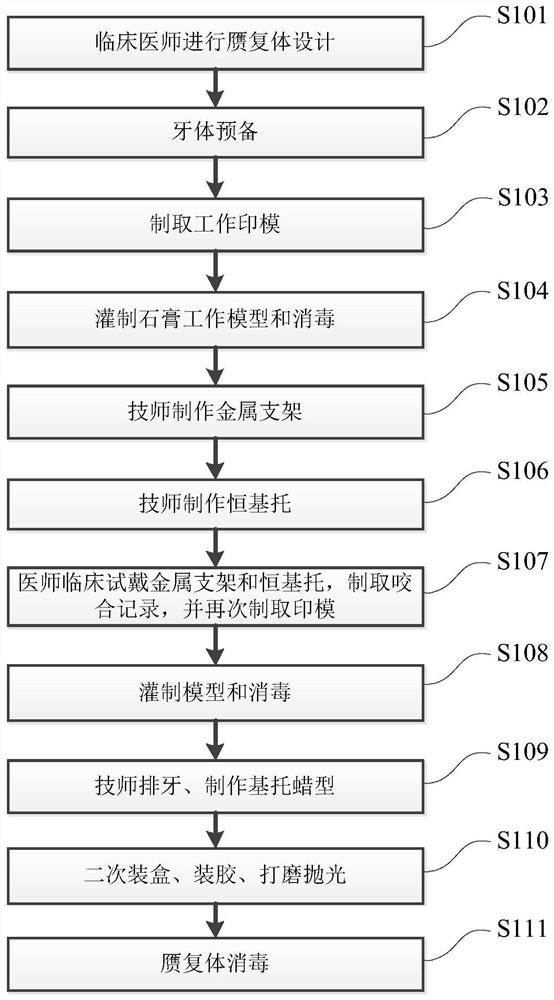

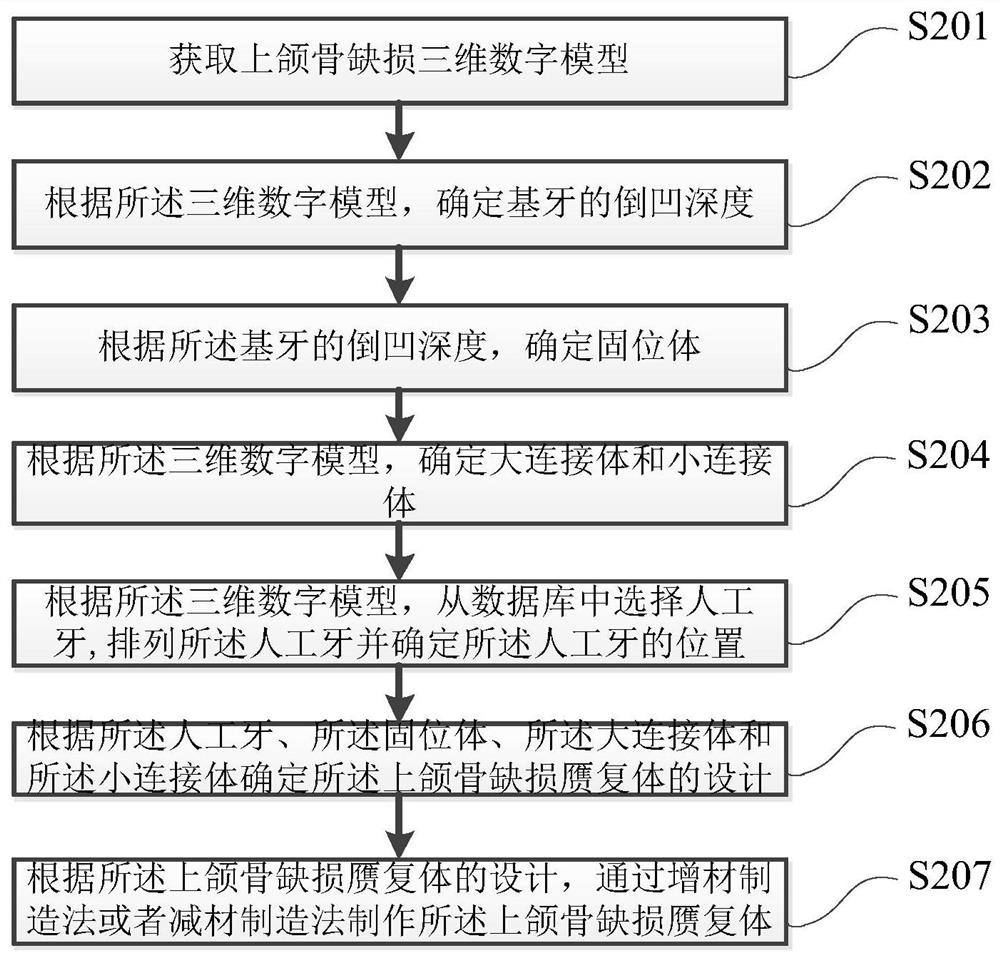

Production method and system of maxillary defect prosthesis

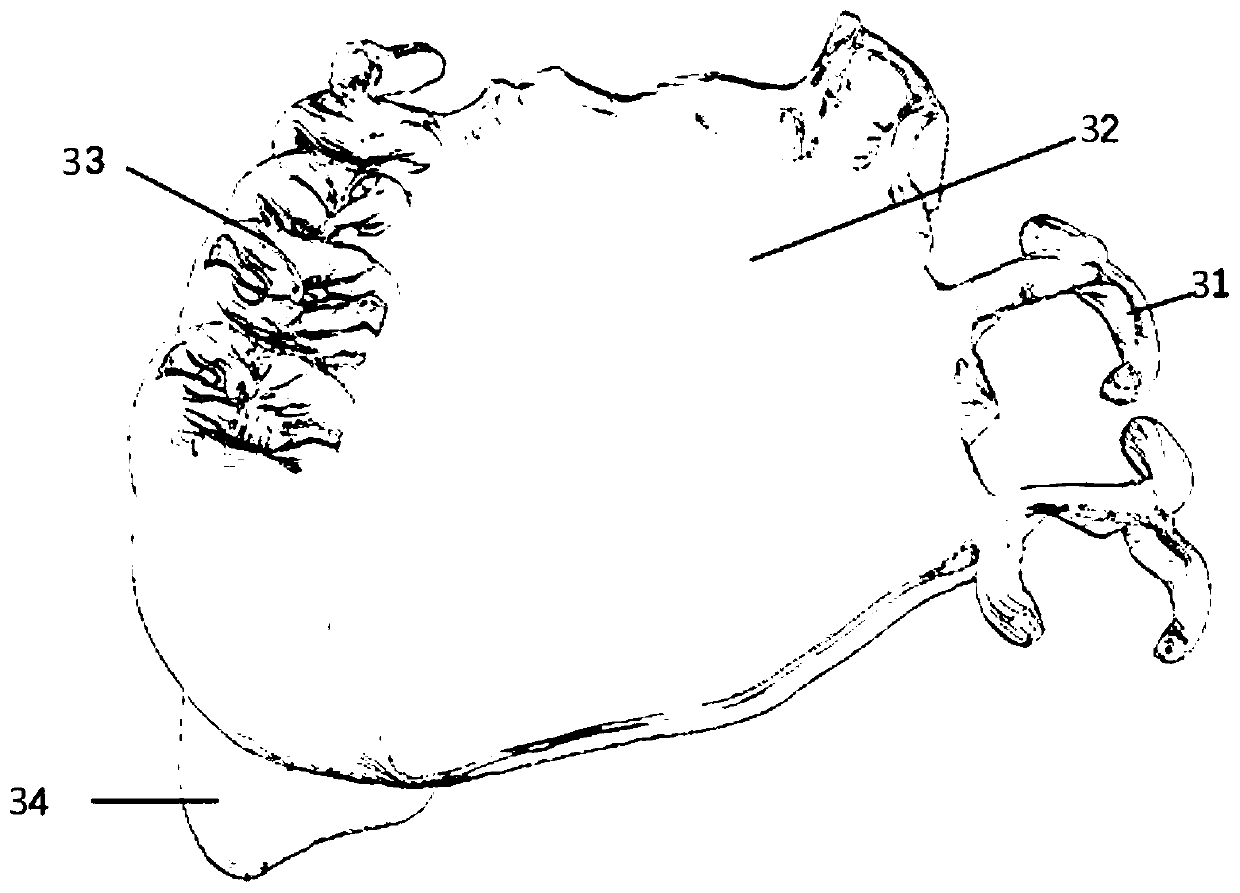

ActiveCN111513881ARealize the whole process of digital designAchieve preparationImpression capsArtificial teethProsthesisRetainer

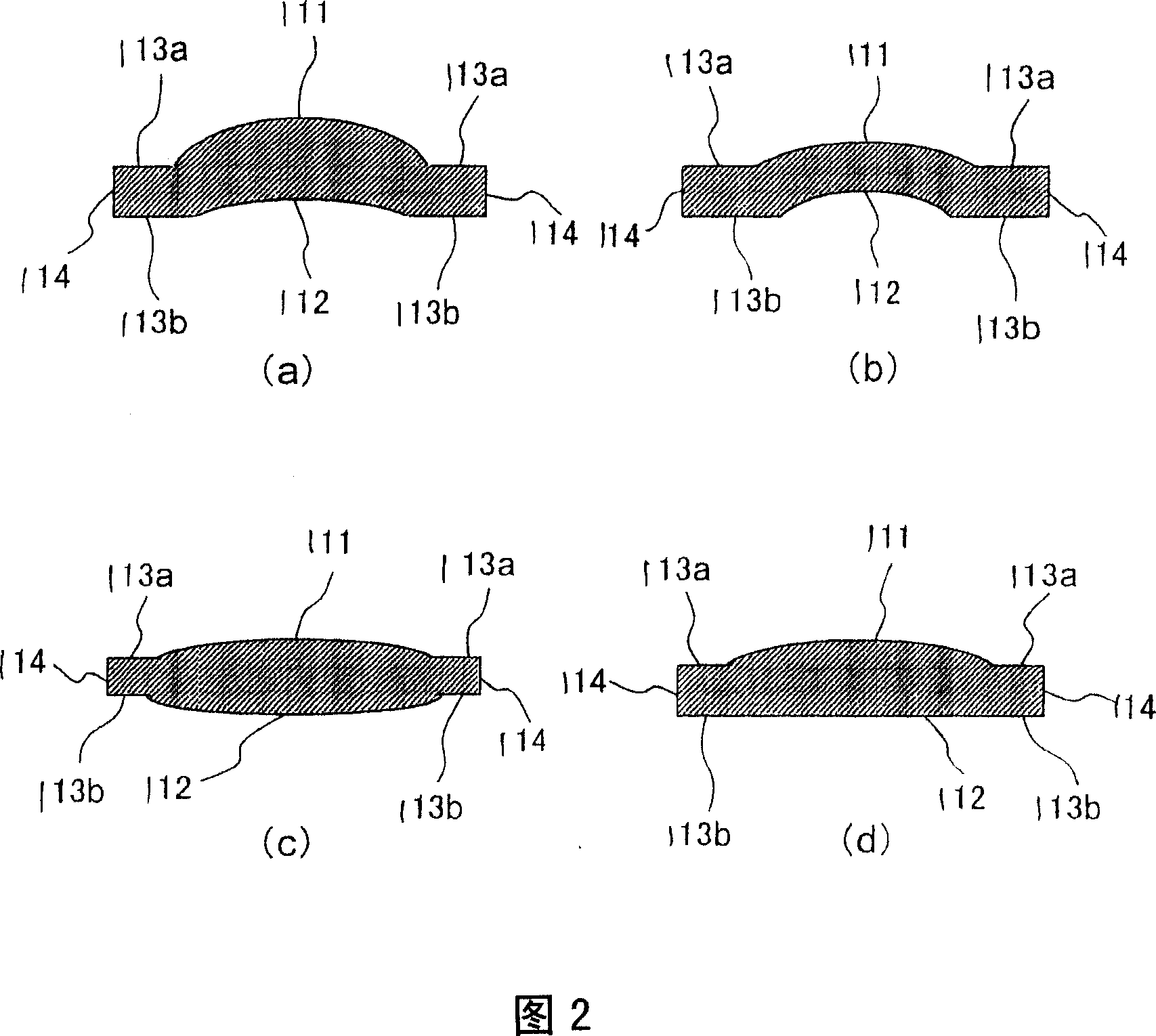

The application discloses a full digital design and a production method and system of a maxillary defect prosthesis in order to improve production accuracy, quality and efficiency and shorten a production period of the prosthesis. The production method comprises the steps of: acquiring a maxillary defect three-dimensional digital model; according to the three-dimensional digital model, carrying out model observation and determining an undercut depth of an abutment tooth; according to the undercut depth of the abutment tooth, determining retainers; according to the three-dimensional digital model, determining a big connector and a small connector; according to the three-dimensional digital model, selecting artificial teeth from a database, arranging the artificial teeth and determining positions of the artificial teeth; according to the artificial teeth, the retainers, the big connector and the small connector, determining the design of the maxillary defect prosthesis; and according tothe design of the maxillary defect prosthesis, producing the maxillary defect prosthesis by an additive manufacturing method or a subtractive manufacturing method. The application further discloses the full digital design and the production system of the maxillary defect prosthesis

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Combined manufacturing method for large-scale integrated metal structure part

InactiveCN105563014AImplement the manufacturing methodIncrease profitIncreasing energy efficiencyManufacturing technologyRapid prototyping

The invention aims to provide a manufacturing method for a large-scale metal structure part. By adopting the method, the defects of a traditional manufacturing technology are overcome and the shortage of large-size materials and large-tonnage equipment is covered so that the manufacturing problem of the large-scale integrated metal structure of a plane can be solved and meanwhile the design requirements of the plane can be met. According to the method, the step-by-step forging technology and the laser rapid prototyping technology are combined, the advantages of the two technologies can be brought into full play, and hence the manufacturing method of the large-scale metal structure part can be obtained. The method specifically comprises the steps that the integrated metal structure part is divided into two parts manufactured through the step-by-step forging technology and the laser rapid prototyping technology, step-by-step forging is adopted for the body part, the laser rapid prototyping technology is adopted for the other parts, and the integrated structure part meeting the design requirements can be obtained ultimately.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

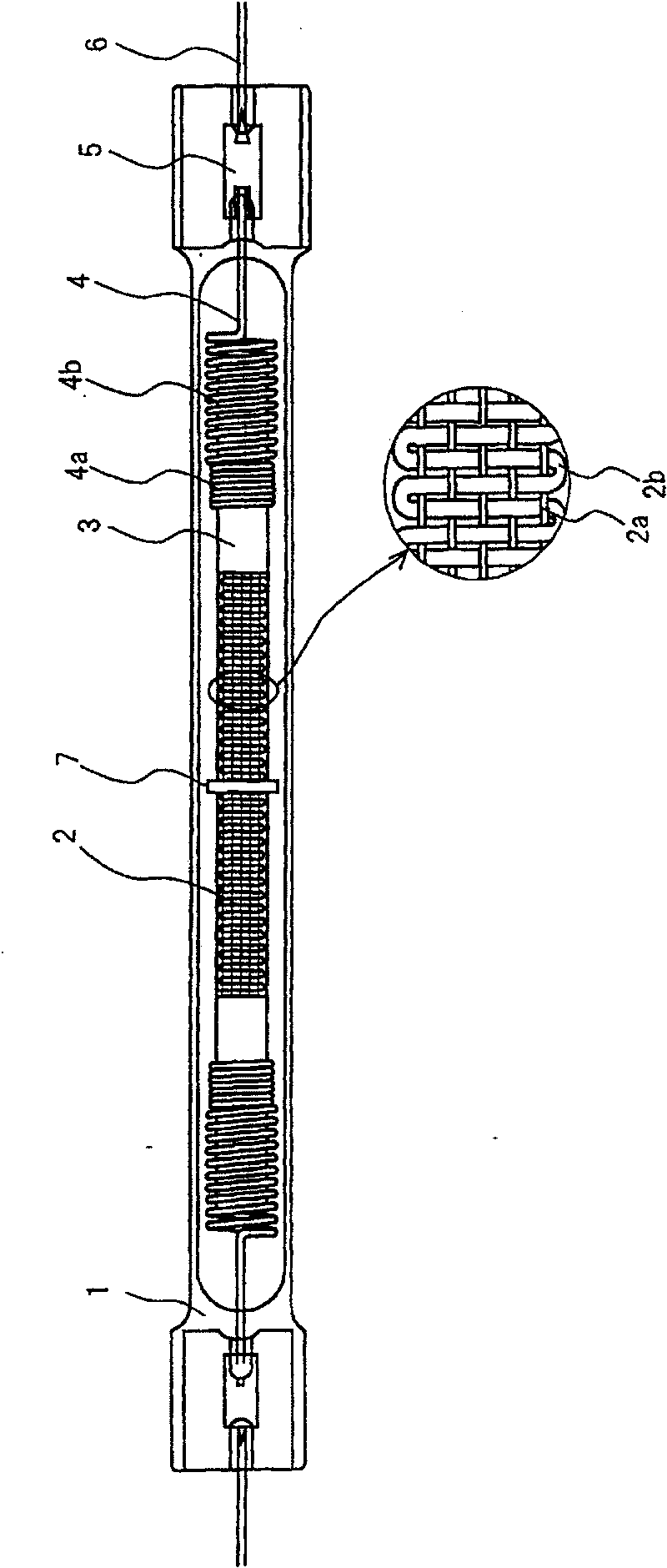

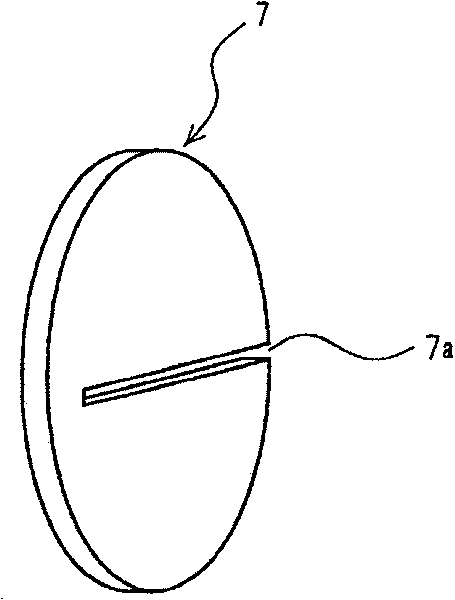

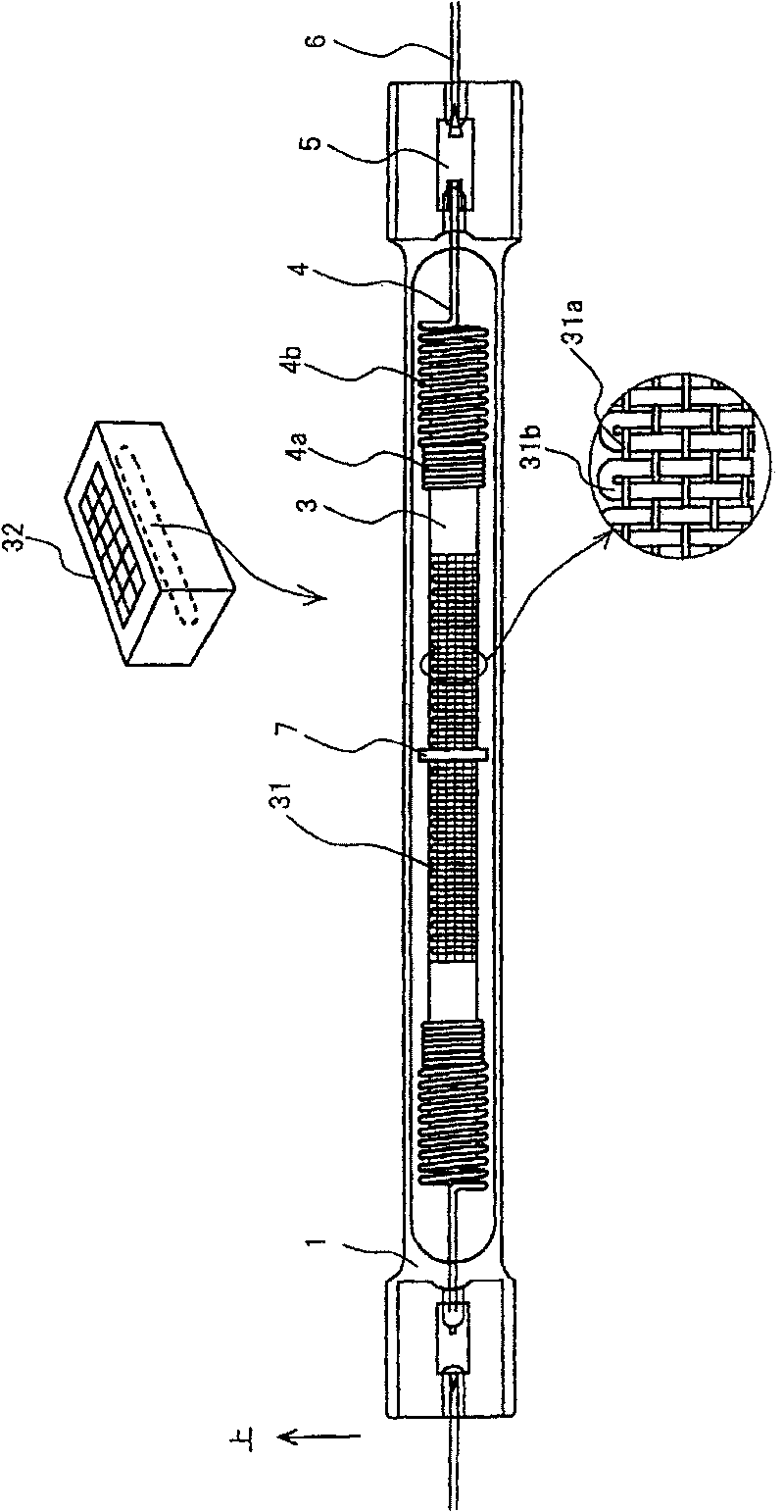

Manufacturing method of carbons heating element, carbons heating elements, heater and heating device

InactiveCN1622695BWon't fall offImplement the manufacturing methodOhmic-resistance heating detailsHeating element shapesFiberCarbon fibers

The invention can provide a carbon heater in which respective carbon fibers do not spread out, even the fibers are thinned for giving predetermined resistance and the fibers can have predetermined strength, a method for manufacturing the carbon-based heater, a heater and a heating device. The heater comprises a glass tube having a carbon-based heater sealed therein, in which the carbon heater is formed by firing a material formed by weaving a plurality of continuous fibers such that at least a weft alternatively passes through above or below each warp, and respective warp alternately passing through above or below each weft.

Owner:PANASONIC CORP

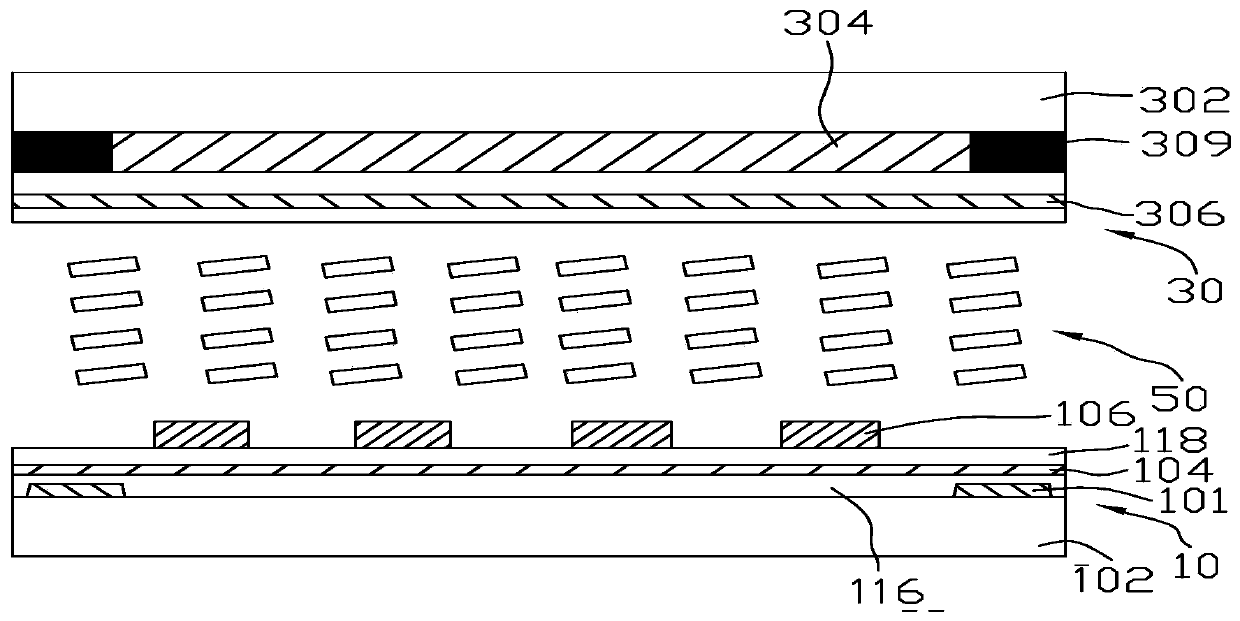

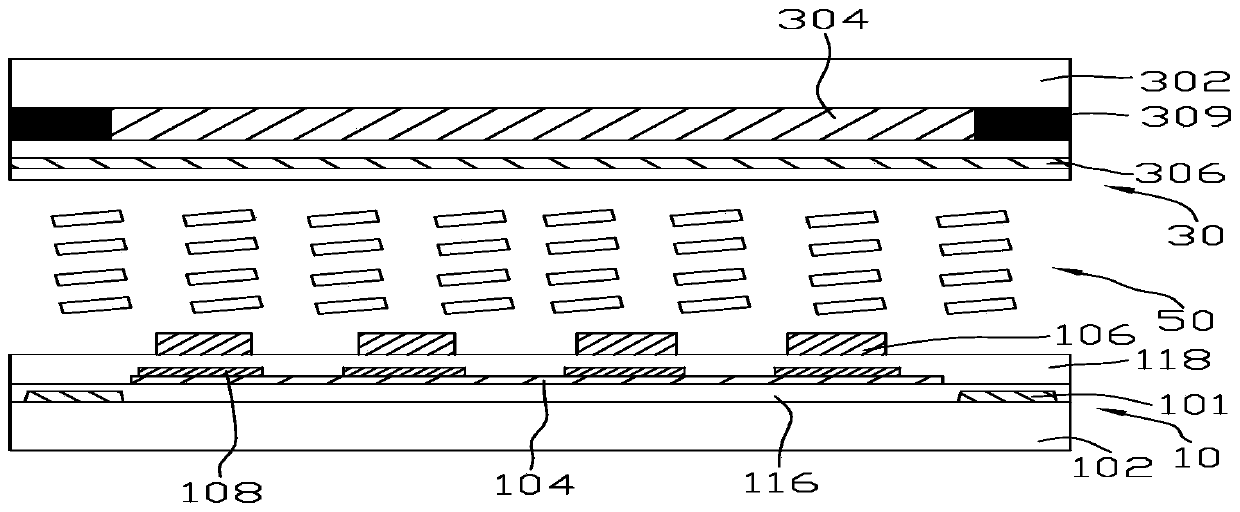

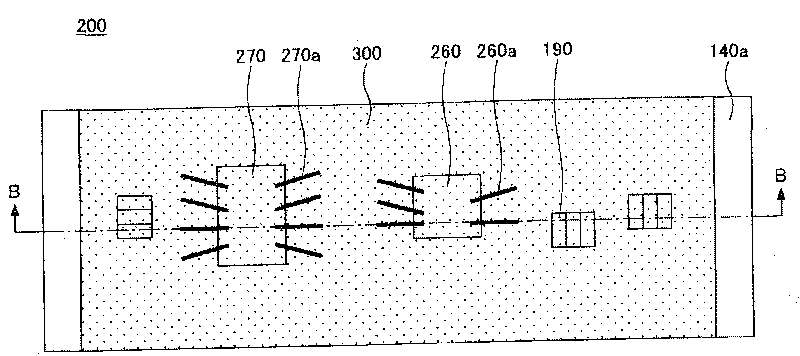

Liquid crystal display device and liquid crystal display device manufacturing method thereof

ActiveCN110780473AImplement the manufacturing methodNon-linear opticsLiquid-crystal displayLiquid crystal

The invention discloses a liquid crystal display device and a liquid crystal display device manufacturing method. The liquid crystal display device comprises an array substrate, a color film substrateand a liquid crystal layer, wherein a plurality of first pixel units and a plurality of second pixel units are formed on the array substrate, the array substrate comprises a shielding layer, and theshielding layer is arranged in an region corresponding to the second pixel units and used for shielding front viewing angle light leakage during full-narrow viewing angle display of the liquid crystaldisplay device; the color film substrate comprises a third conducting layer, and the third conducting layer is a visual angle control electrode. According to the liquid crystal display device manufactured by means of the liquid crystal display device manufacturing method, wide viewing-angle display, full-narrow viewing-angle display and left-right narrow-viewing-angle display can be achieved, left-right peep prevention and up-down peep prevention can be achieved simultaneously in a full-narrow viewing-angle mode, and the peep prevention effect is greatly improved; the shielding layer can shield part of light leakage at a front viewing angle, and can prevent light leakage at the front viewing angle in a full-narrow viewing angle mode, so that large-viewing-angle light leakage is achieved,the front-viewing-angle light leakage is avoided or reduced and the display effect is improved.

Owner:KUSN INFOVISION OPTOELECTRONICS

spark plug

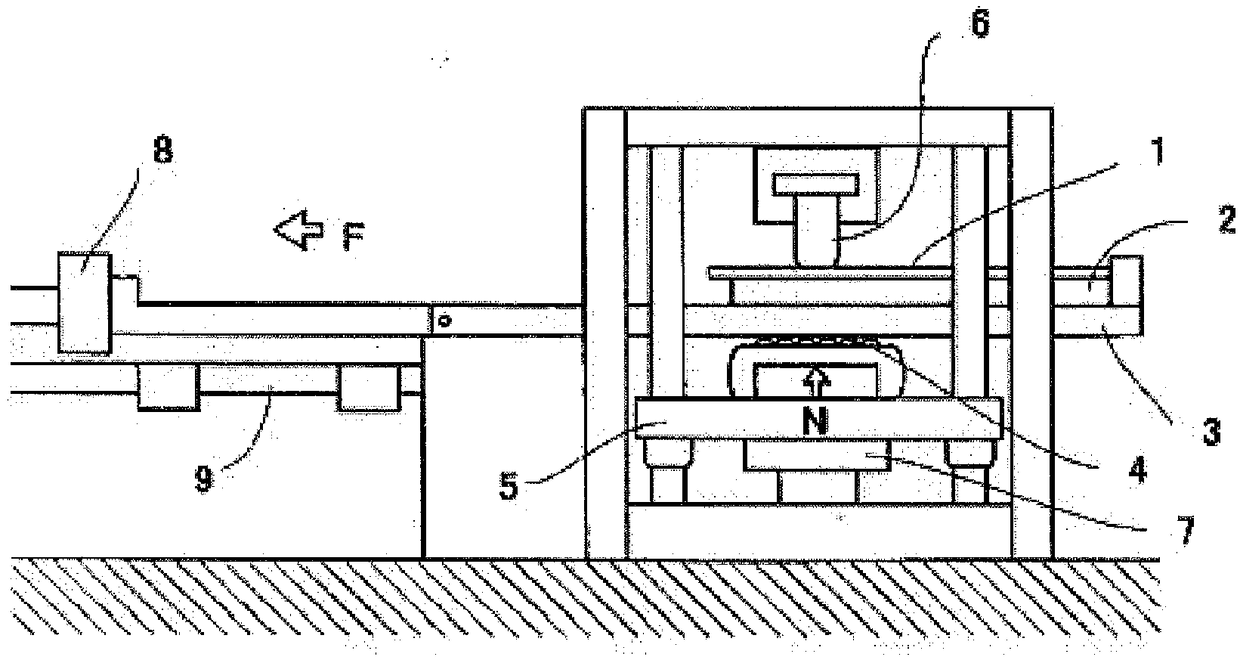

InactiveCN102273032AImplement the manufacturing methodSparking plugsMachines/enginesMaterials scienceSpark plug

The invention provides a spark plug. The spark plug (100) has a center electrode chip (90, 95) at the tip of the electrode. The center electrode chip (90, 95) is: mainly composed of Pd, the content of Pd is more than 40% by weight, and contains at least one element of Ir, Ni, Co, and Fe. When Ir is contained, the content of Ir is 0.5% by weight. % to 20% by weight, and when Ni, Co, and Fe are contained, the content of each element is 0.5% by weight to 40% by weight.

Owner:NITERRA CO LTD

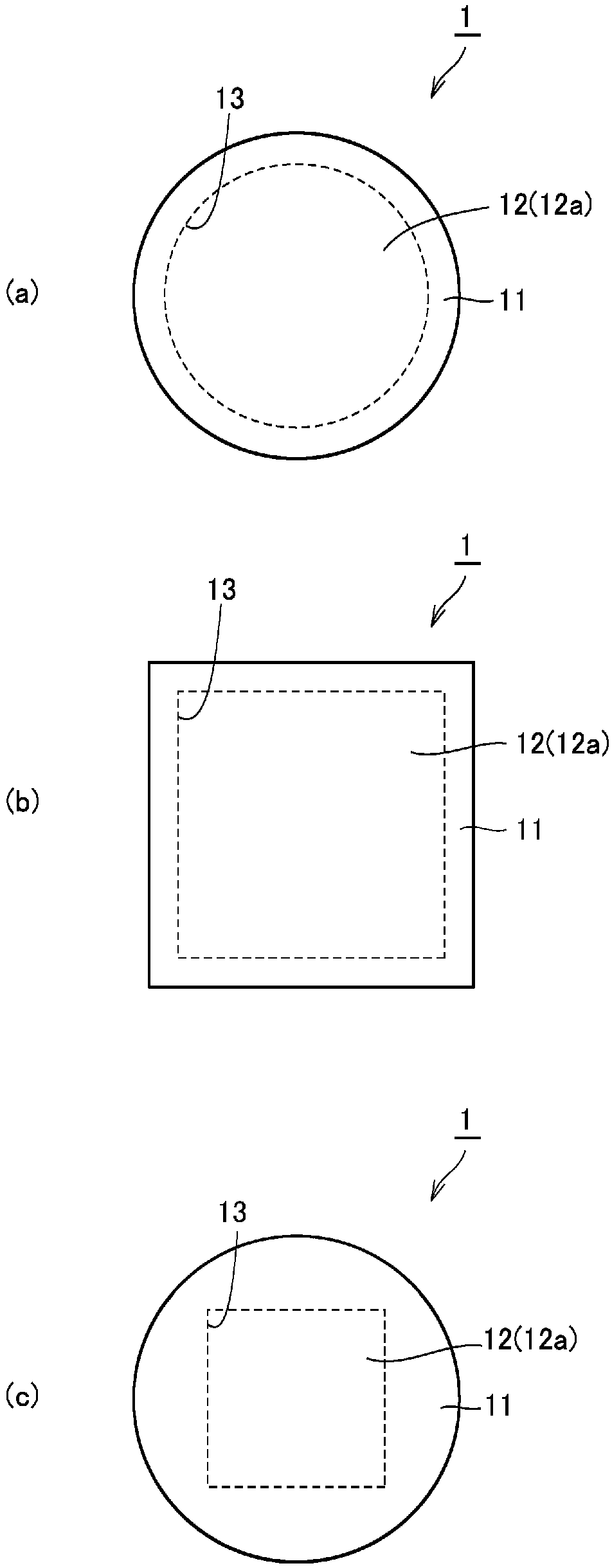

Compound semiconductor substrate, pellicle film, and method for manufacturing compound semiconductor substrate

ActiveCN108699687AImplement the manufacturing methodPolycrystalline material growthAfter-treatment detailsEtchingThin membrane

Owner:AIR WATER INC

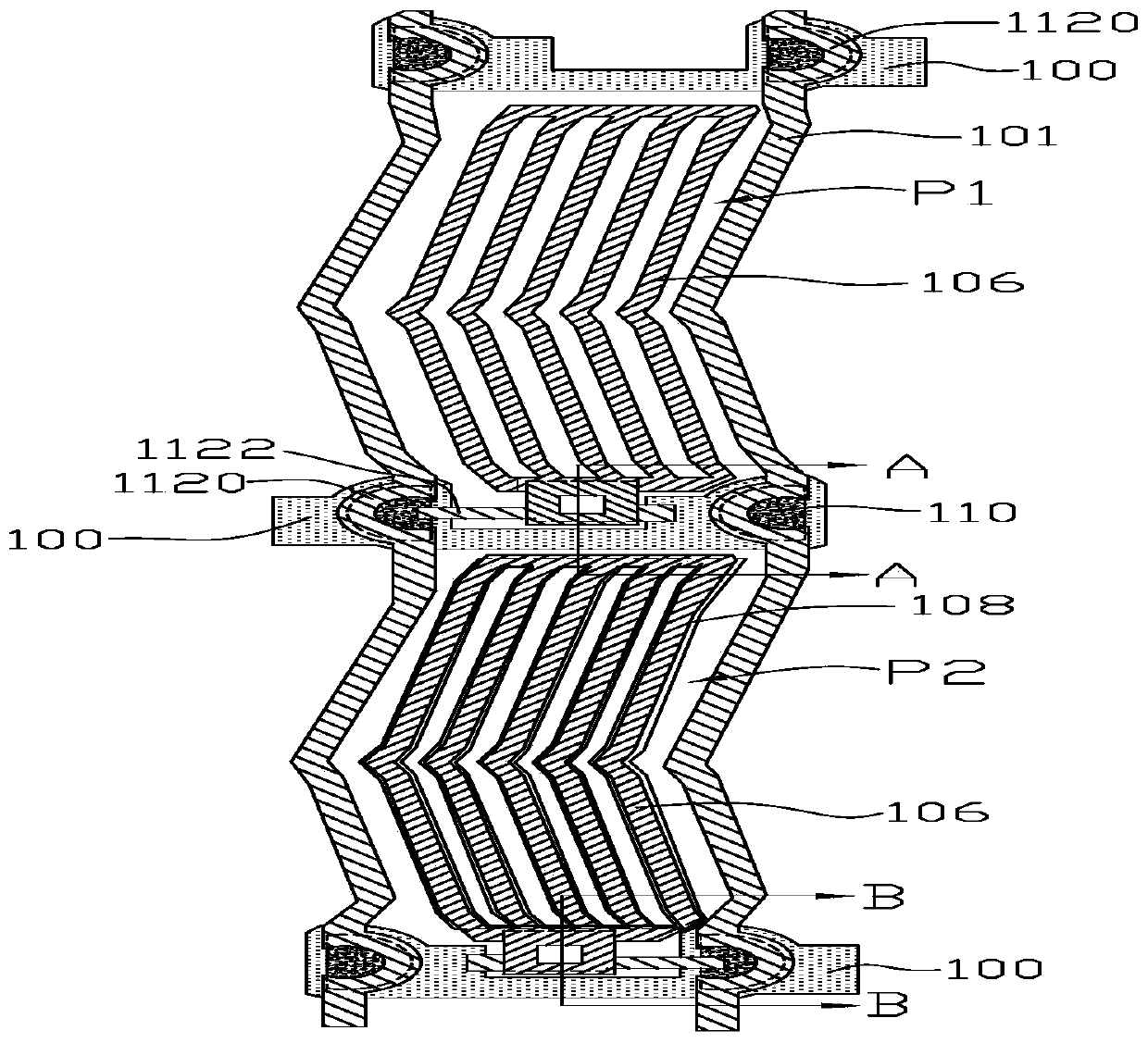

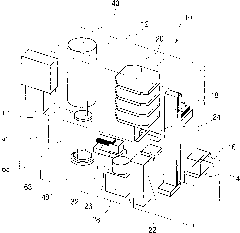

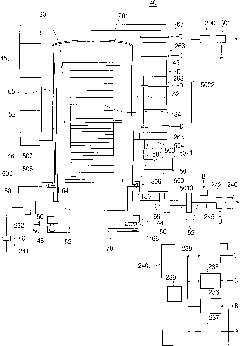

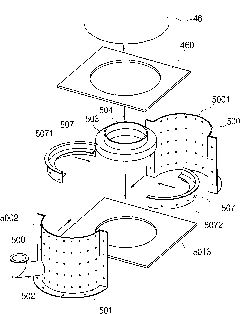

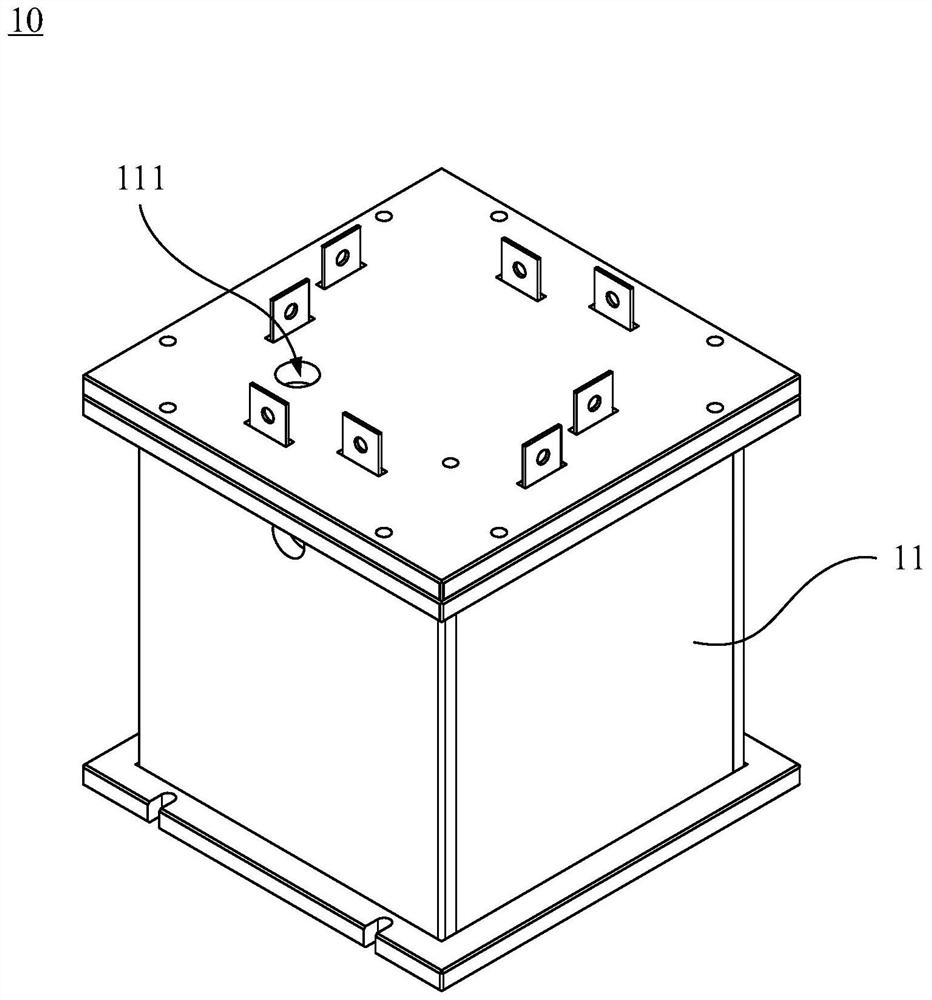

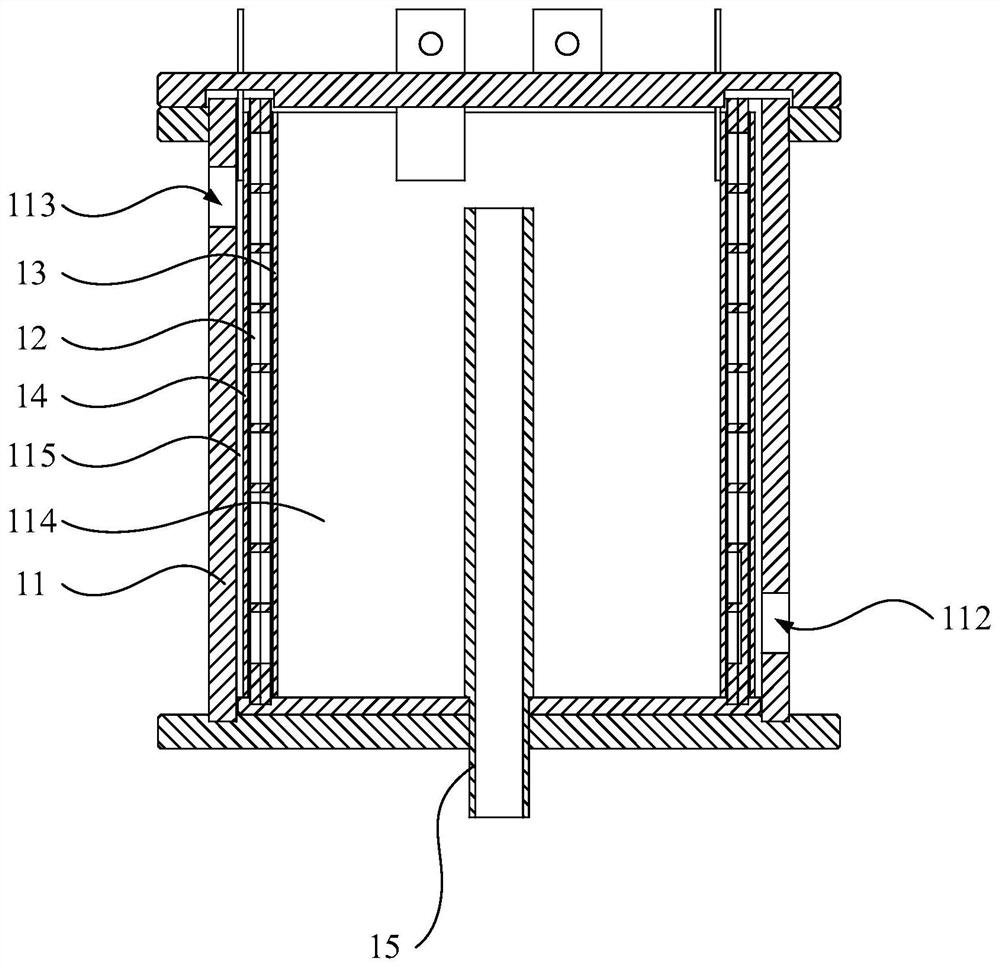

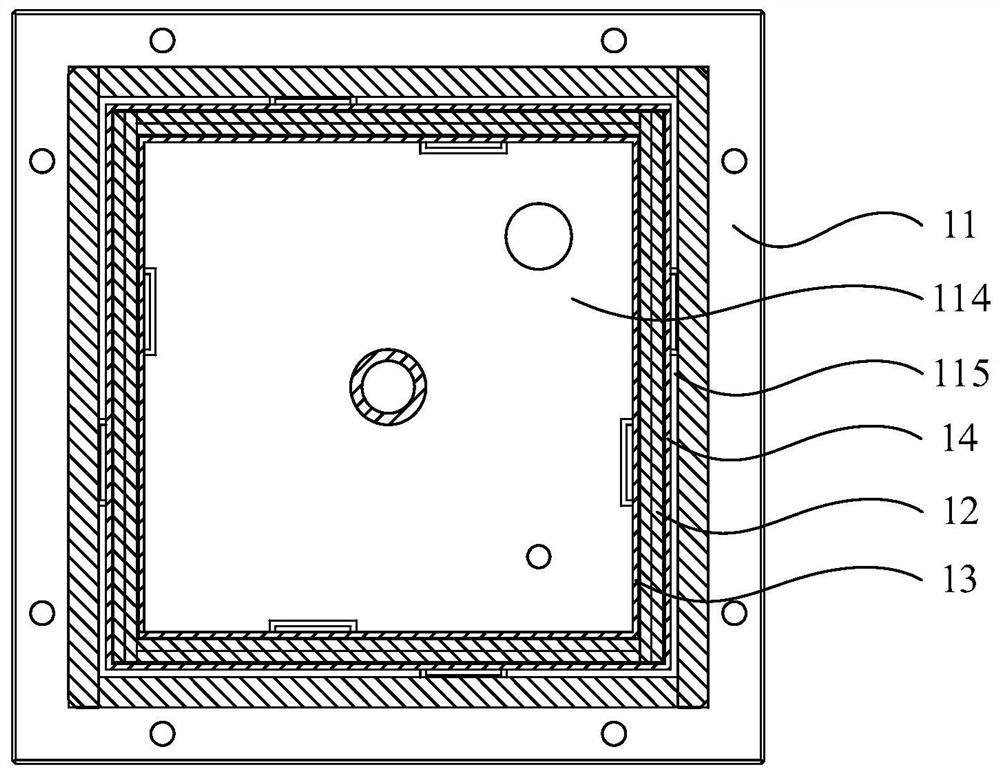

Heat treatment apparatus and method of manufacturing semiconductor device

ActiveCN102194661AImplement the manufacturing methodHigh precisionSemiconductor/solid-state device manufacturingPower semiconductor deviceBiomedical engineering

A heat treatment apparatus capable of achieving high-accuracy processing and high safety and a method of manufacturing a substrate are provided. The heat treatment apparatus 10 includes a reaction tube 42 for processing a substrate, a manifold 44 for supporting the reaction tube 42, a heater 46 installed around the reaction tube 42 to heat an inner part of the reaction tube 42, a circumferential portion 500 installed to surround a side portion of the reaction tube 42 arranged in a lower portion than the heater 46; an exhaust device 301 for forcibly exhausting a gap 506 between the circumferential portion 500 and the reaction tube 42; and a sealing member 150 installed in a contacting portion between the reaction tube 42 and the manifold 44. Here, an inlet port 501 through which the exhaust device inhales an atmosphere outside the circumferential portion 500 to the gap 506 is installed in the circumferential portion 500.

Owner:KOKUSAI DENKI KK

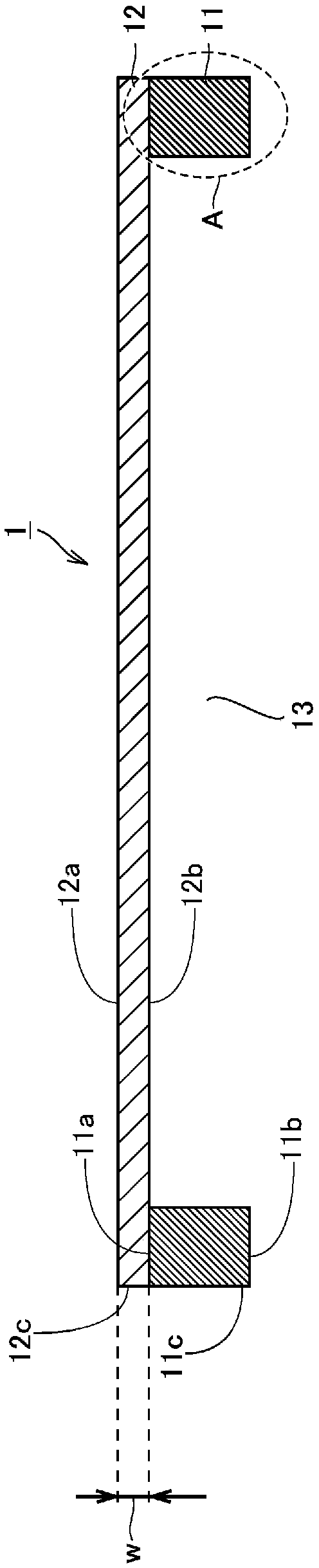

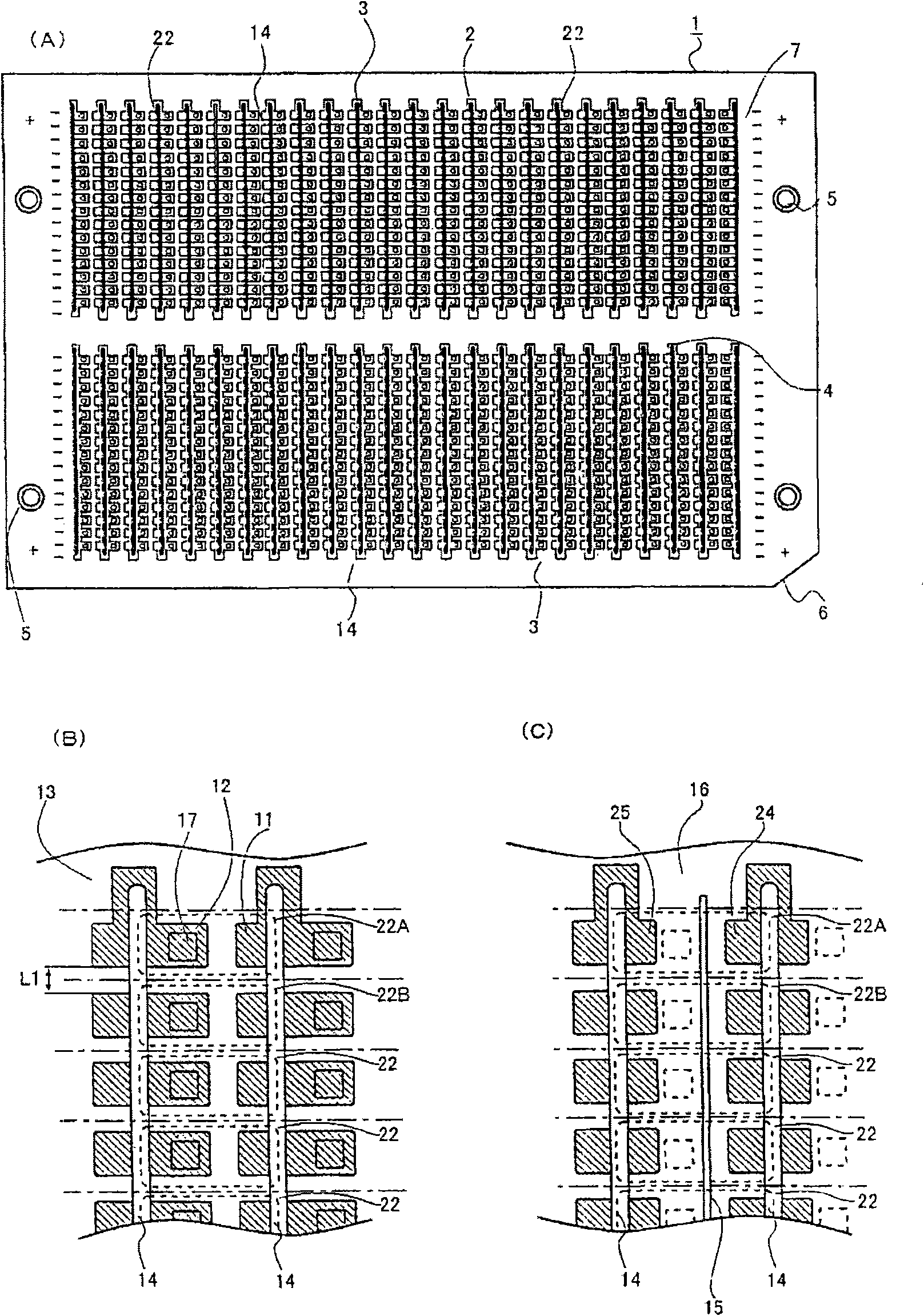

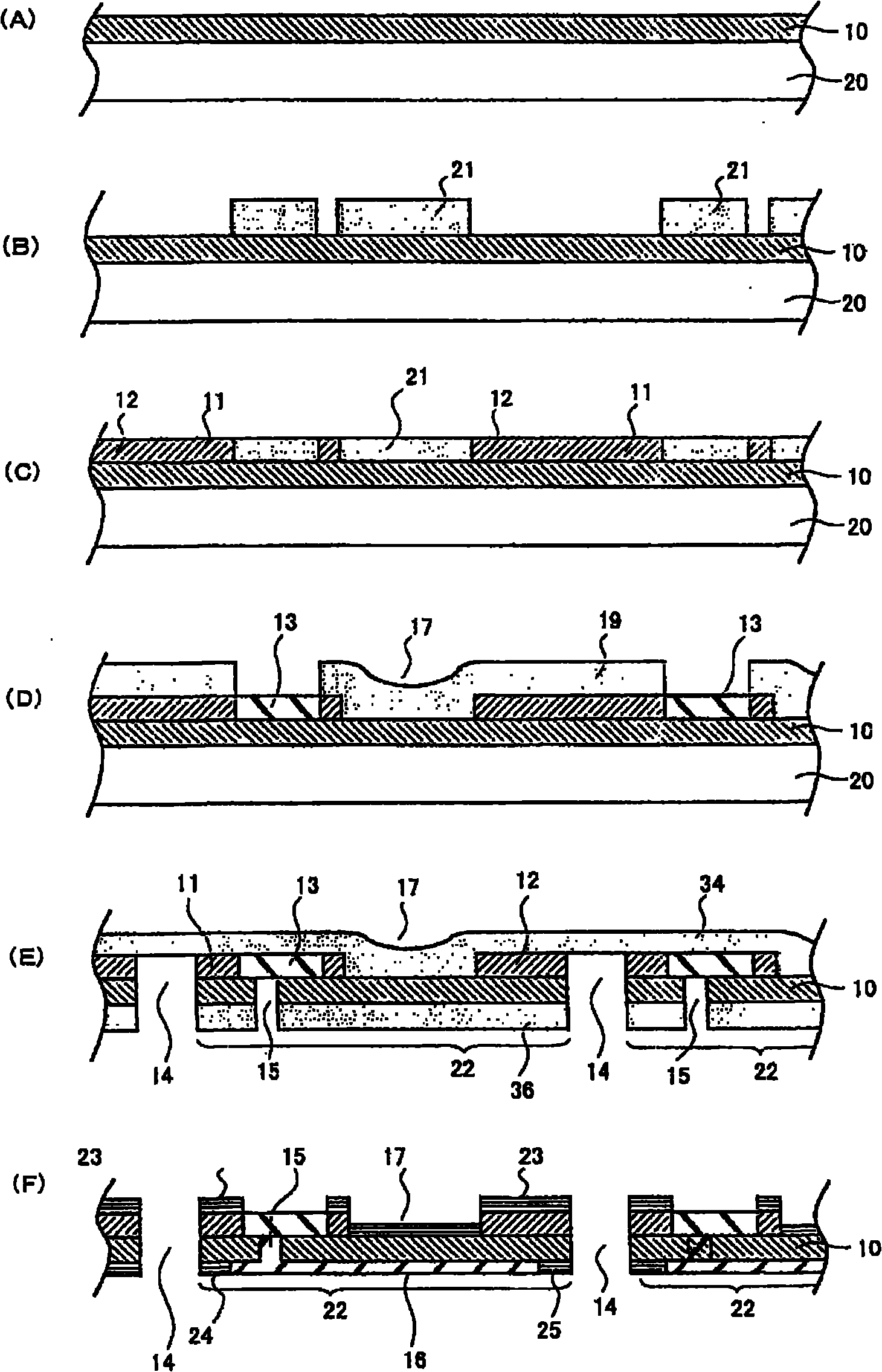

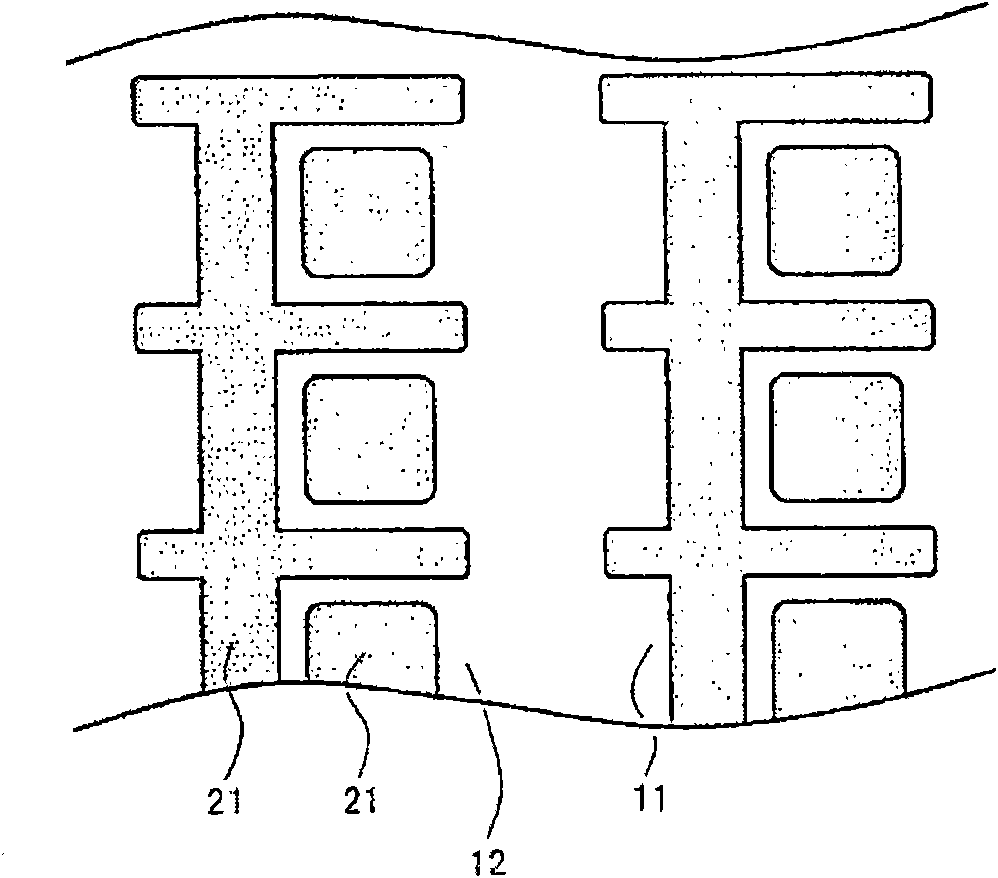

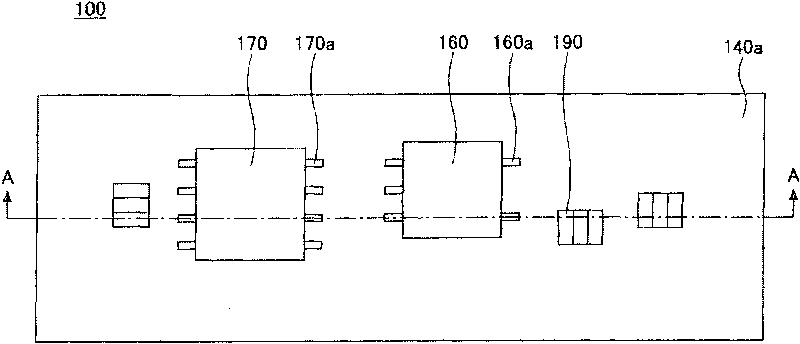

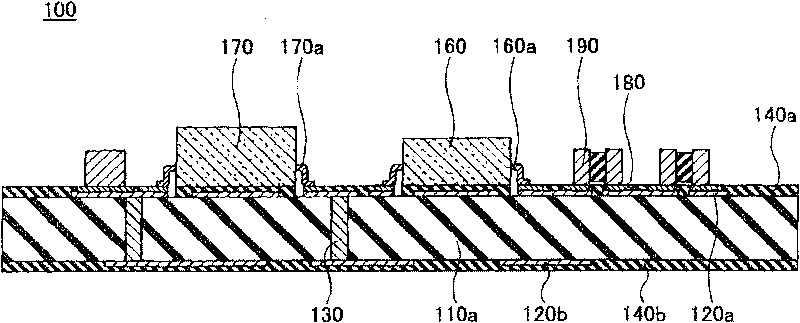

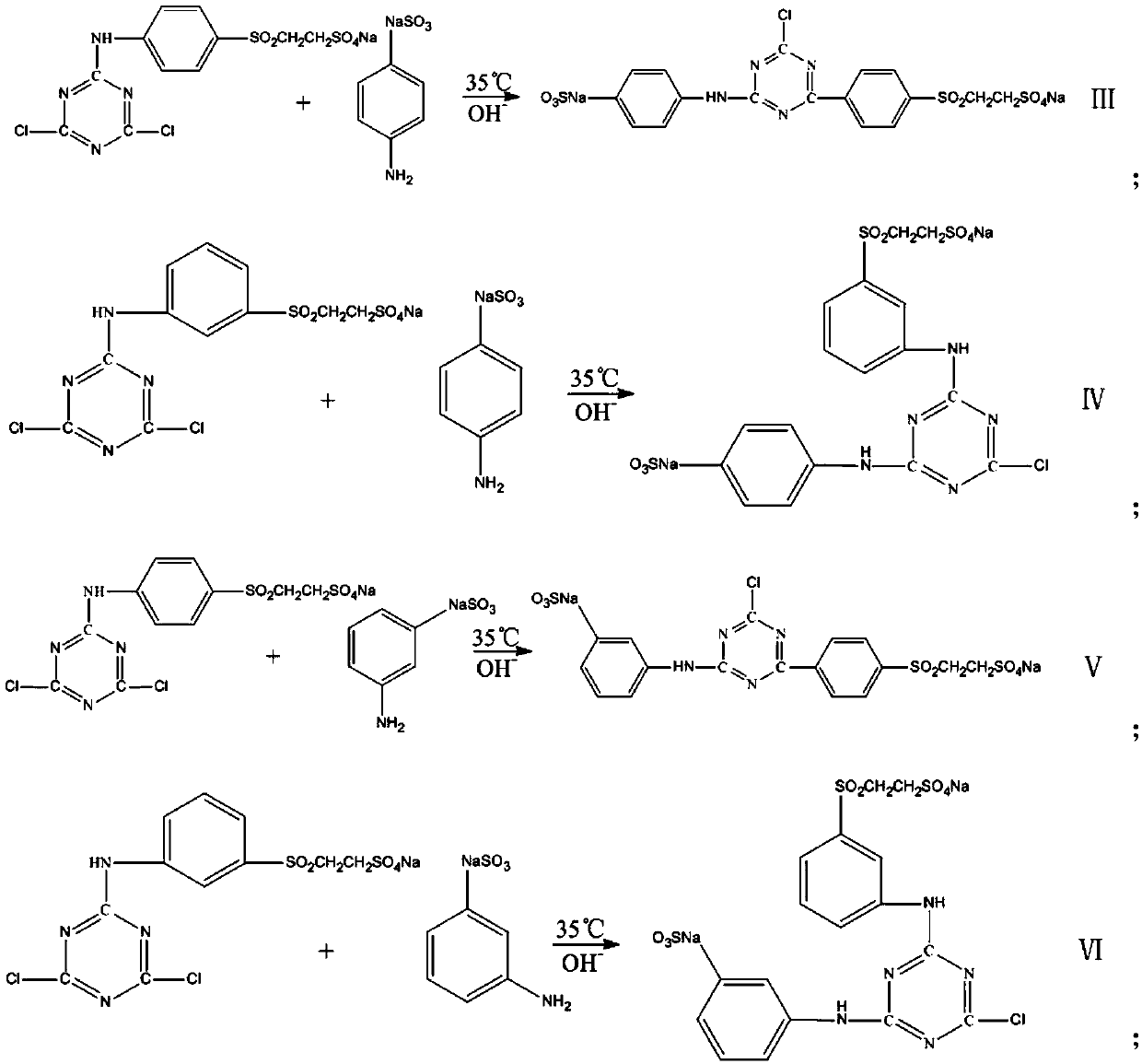

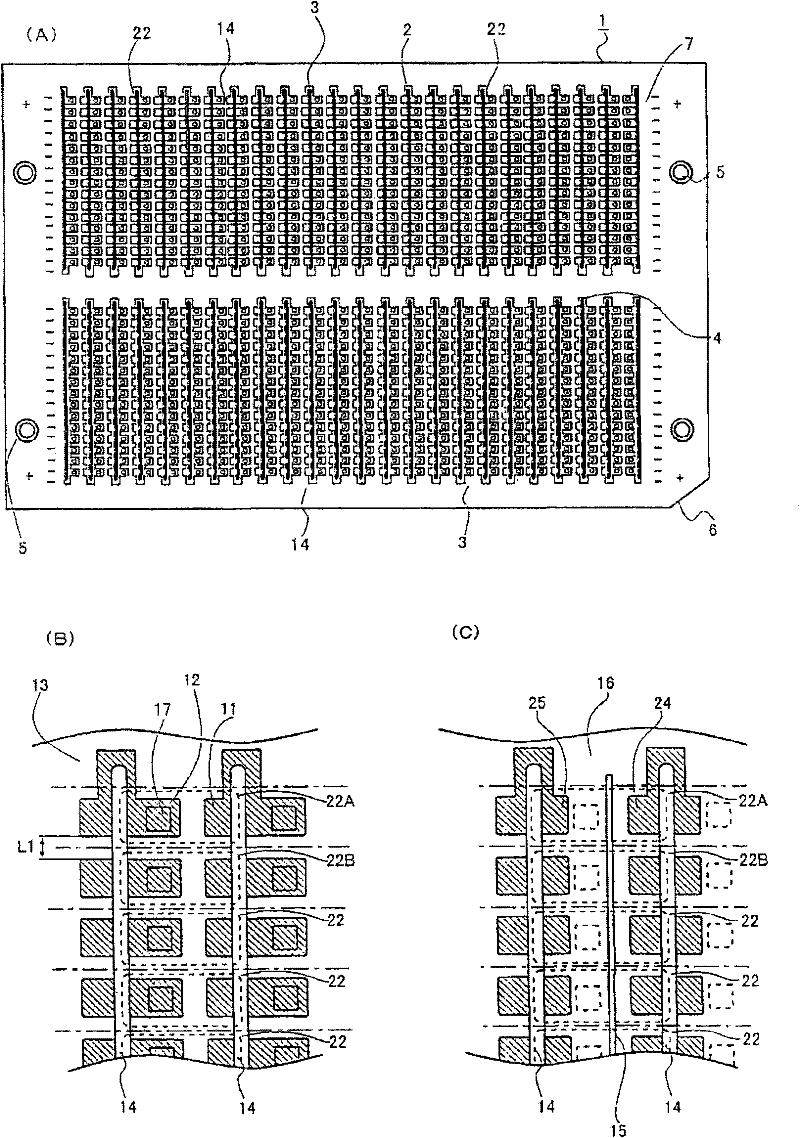

Mounting substrate, and method for manufacturing thin light-emitting device using same

InactiveCN101930964AHigh speed separation processEasy to handleSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsEngineering

The invention provides a mounting substrate and a method for manufacturing thin light-emitting device using same, which is capable of inhibiting generation of burrs and realizing mass production of light-emitting device. In the mounting substrate of the invention, a conductive foil is removed at the edge of a unit. In particular, on the upper surface of the mounting substrate, a unit formed of a first electrode part and a second electrode part encircling a mounting part is formed, a plurality of units are arranged in columns. Furthermore, on the lower surface of the mounting substrate, a first external take-out electrode part connected with the first electrode is provided, and a second external take-out electrode part connected with the second electrode is provided. Besides, resin material for forming the mounting substrate, without the existence of conductive foil and other metal materials, is provided among the units. Therefore, in the manufacture of the light-emitting device, even if the mounting substrate between the units is cut off, the burr is not generated as the metal material is not cut off.

Owner:ELEMENT DENSHI

Manufacturing method of circuit module

InactiveCN101728281ASuppress manufacturing costImplement the manufacturing methodSemiconductor/solid-state device detailsSolid-state devicesThinningEngineering

The aim of the invention is to provide a manufacturing method which suppresses the increase of manufacturing cost and can realize further thinning. According to the manufacturing method of a circuit module according to the invention, the circuit module carries a semiconductor device on a substrate which is provided with a wiring pattern in a preset area, and furthermore the semiconductor component is sealed by sealing agent. The manufacturing method of the circuit is characterized by comprising the following steps: a first step of equipping the semiconductor component on the substrate; a second step of electrically connecting the semiconductor component with the wiring patter; a third step of sealing the semiconductor component with the sealing agent; and a fourth step of equipping electronic components on the area which is on the substrate and is not sealed by the sealing agent.

Owner:MITSUMI ELECTRIC CO LTD

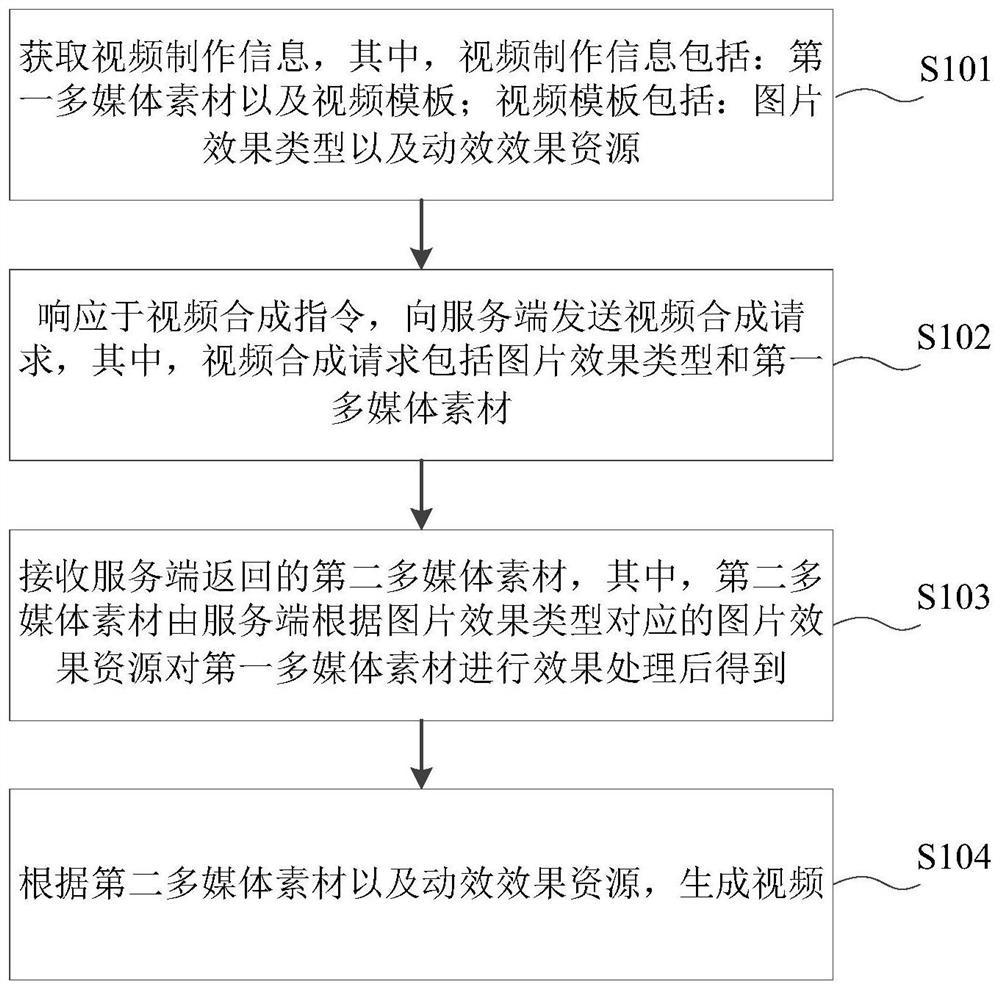

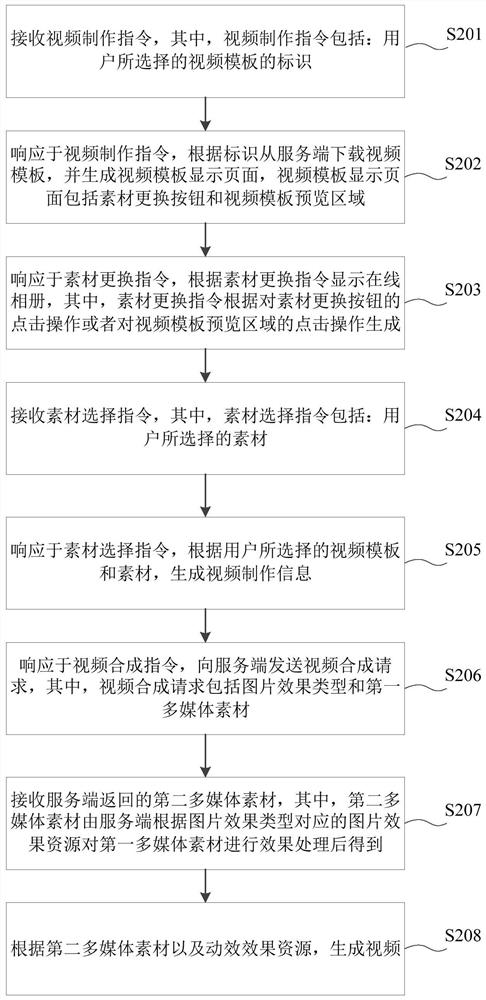

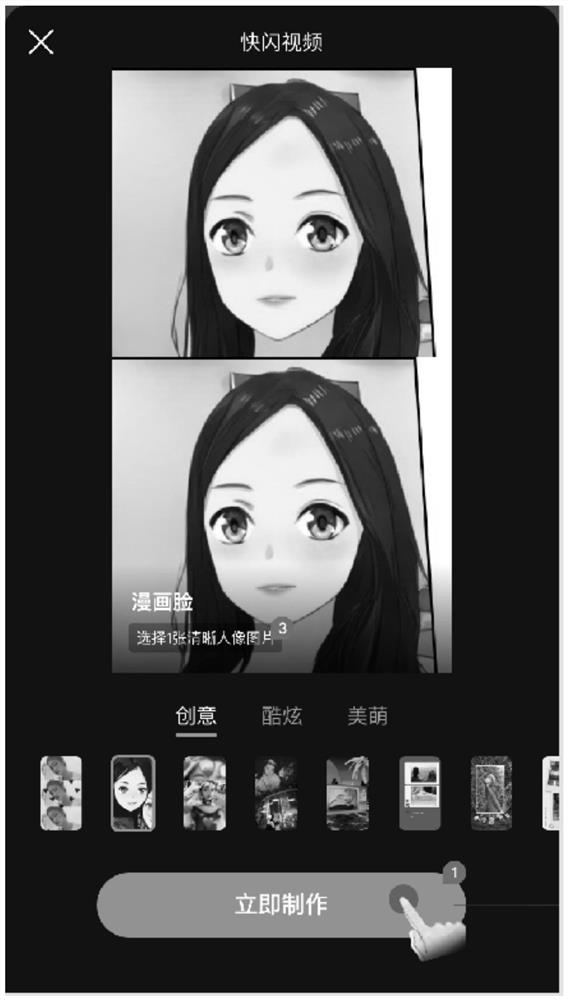

Video production method and device, electronic equipment and storage medium

PendingCN112532896AImplement the manufacturing methodTelevision system detailsColor television detailsProcess engineeringVideo production

The invention relates to a video production method and device, electronic equipment and a storage medium, and relates to the technical field of terminals. The video production method comprises the steps that: after a client obtains video production information, the client can carry a first multimedia material and a picture effect type in the video production information in a video synthesis request in response to a video synthesis instruction, and sends the video synthesis request to the server, so as to obtain a second multimedia material obtained after the server performs effect processing on the first multimedia material according to a picture effect resource corresponding to the picture effect type; and a video is generated according to the second multimedia material and dynamic effectresources. Therefore, part of complex processing of the first multimedia material can be processed by the server, the calculation amount of the client is reduced, the performance requirement for theclient is reduced, and the video synthesis efficiency is improved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

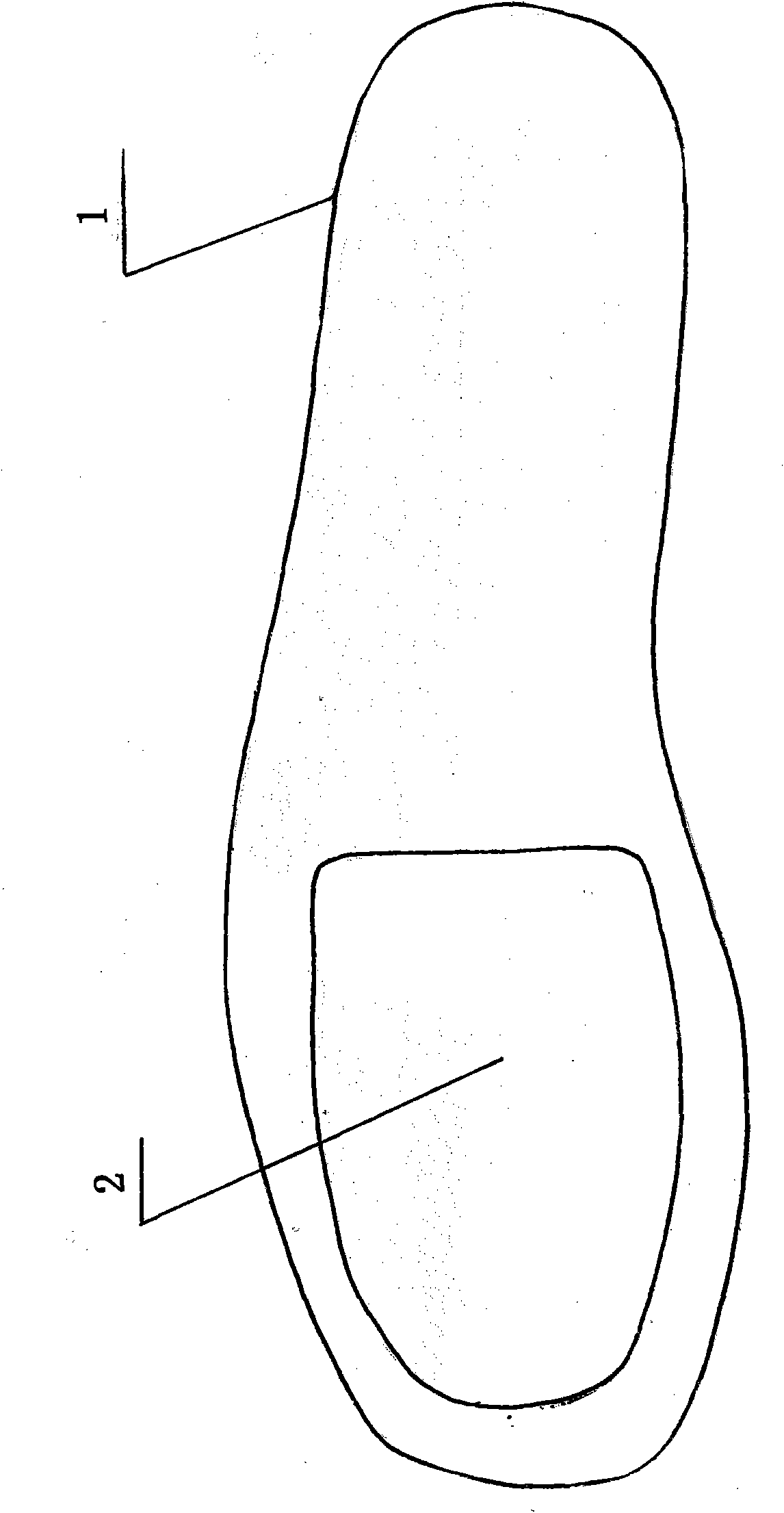

Making method of charging heating shoes

The invention relates to a making method of a pair of charging heating shoes, characterized in that infrared electric heating films are arranged on the middle shoe soles and the front half parts of the soles. Each infrared electric heating film is an electric-heating infrared radiator, which is made of metal and sealed by an upper layer and a lower layer of plastic films with high insulation strength and resistances to aging and high temperature, so that the radiator is not in contact with air. After being connected with a power supply, the shoes can radiate infrared rays with physiotherapy action on human bodies; meanwhile, an external special charger is adopted for connecting an external power supply; after the shoes are fully charged once, the inside temperature of the shoes is controlled to range from 25 DEG C to 28 DEG C and can be kept for about 8 h so that a person can be in a warm state for a long time and the person need is met, and thus, the making method of the charging heating shoes is realized.

Owner:QINGDAO HENGDA CO LTD +1

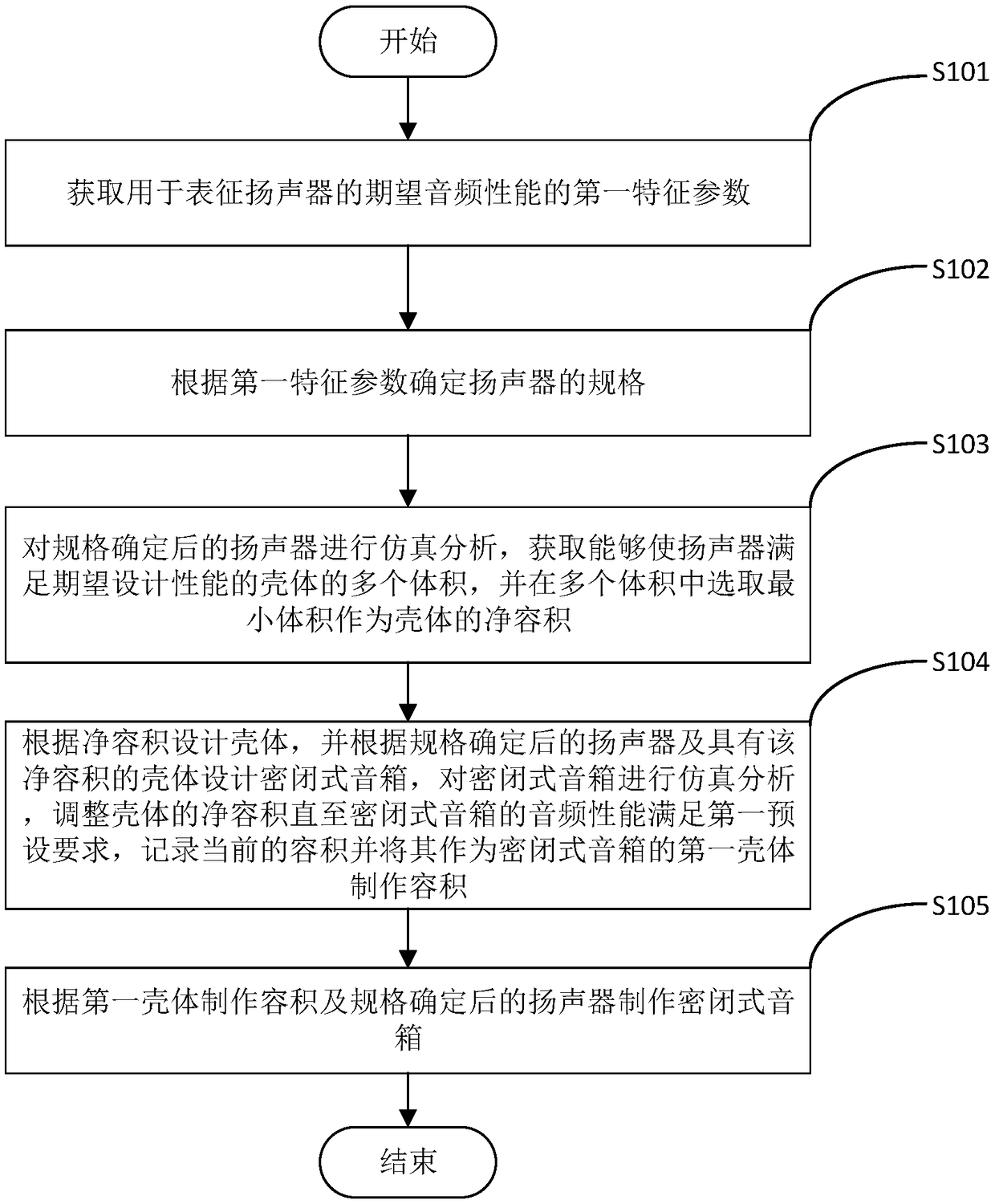

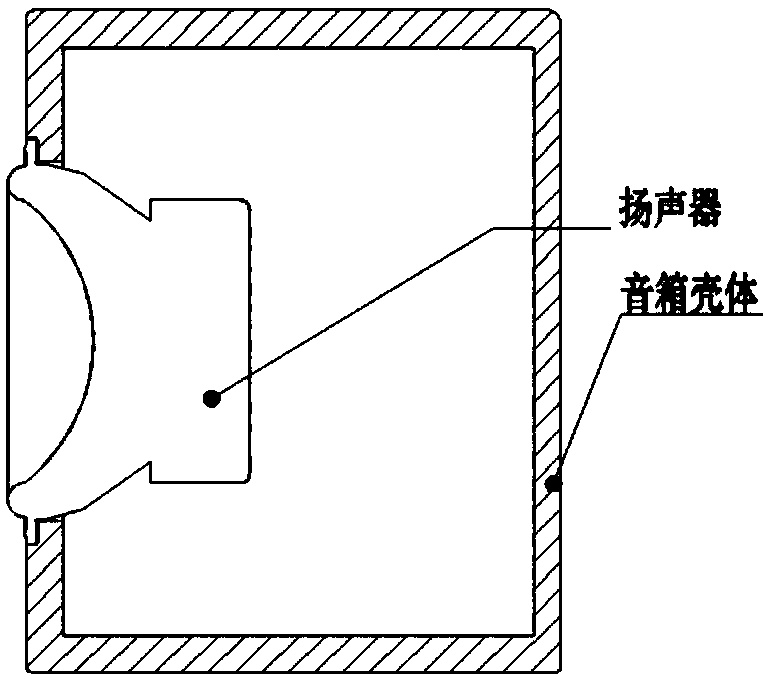

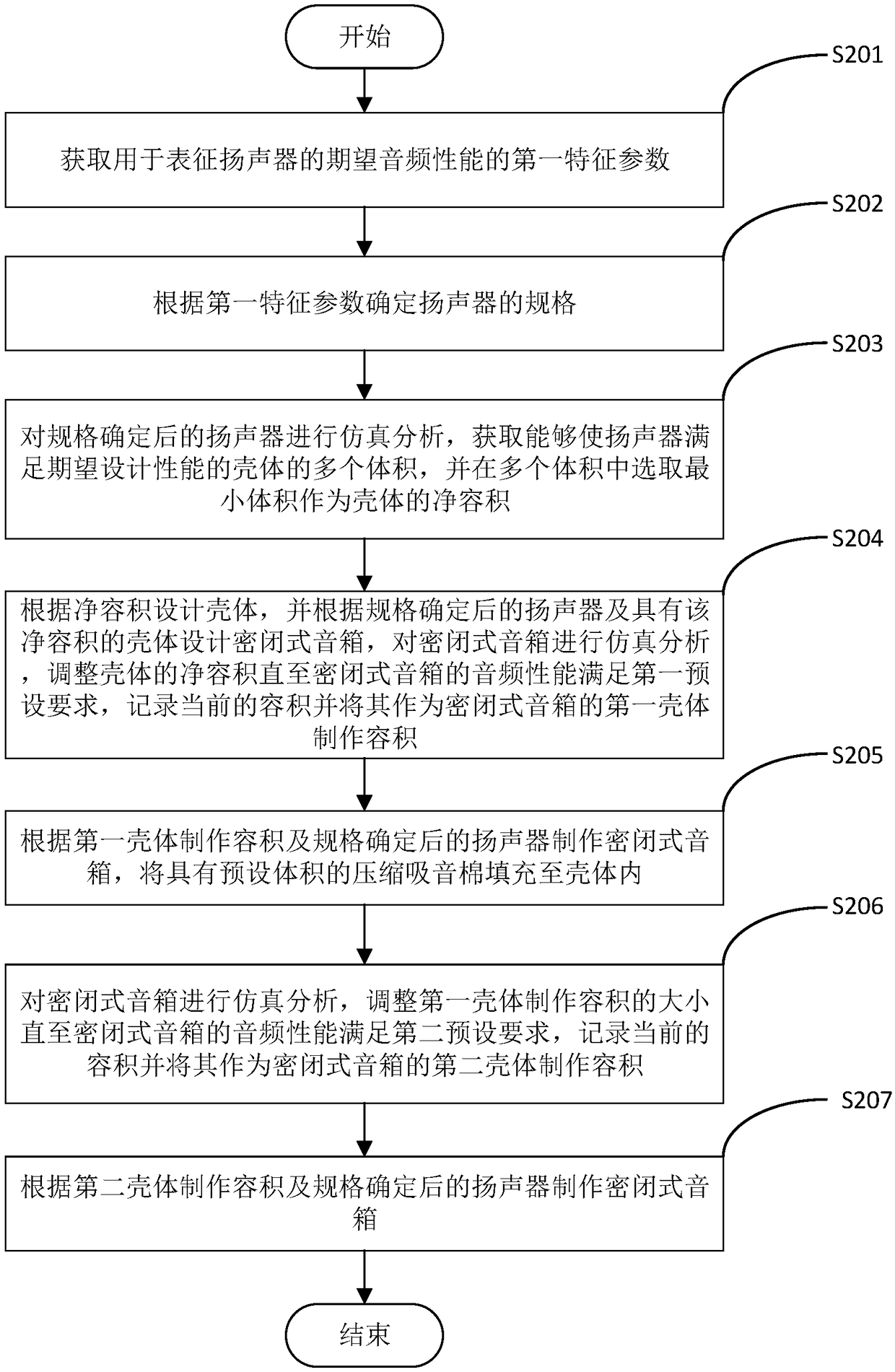

Manufacturing method and device of enclosed sound box and computer readable storage medium

InactiveCN109379669AMeet low frequency performanceReduce volumeFrequency/directions obtaining arrangementsLoudspeakerLow frequency

The embodiment of the invention relates to the technical field of sound equipment, and discloses a manufacturing method and device of an enclosed sound box and a computer readable storage medium. Themanufacturing method of the enclosed sound box comprises the following steps: acquiring a first feature parameter for representing the expected audio performance of a loudspeaker; determining the specification of the loudspeaker according to the first feature parameter; performing emulation analysis on the loudspeaker to obtain a plurality of sizes of a shell which can enable the loudspeaker to meet expected design performance, and selecting a minimum size from the plurality of sizes to serve as the net volume of the shell; designing the shell according to the net volume, performing emulationanalysis on the enclosed sound box, adjusting the net volume of the shell till the audio performance of the enclosed sound box meets a first preset requirement, and recording the current volume as a first shell manufacturing volume; and manufacturing the enclosed sound box according to the loudspeaker of which the first shell manufacturing volume and the specification are determined. Through adoption of the manufacturing method and device of the enclosed sound box and the storage medium provided by the invention, the size of the sound box is small while the low-frequency performance of the sound box is met.

Owner:GUANGZHOU KUGOU TECH

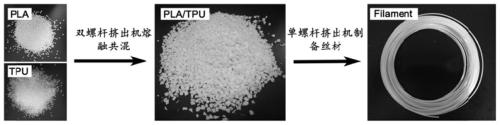

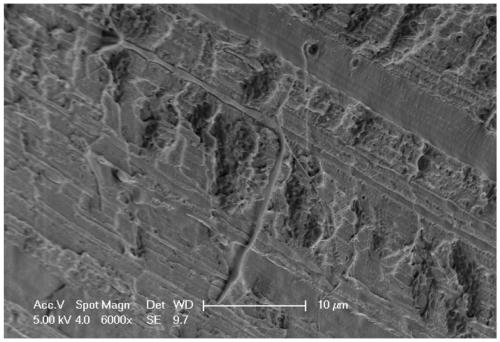

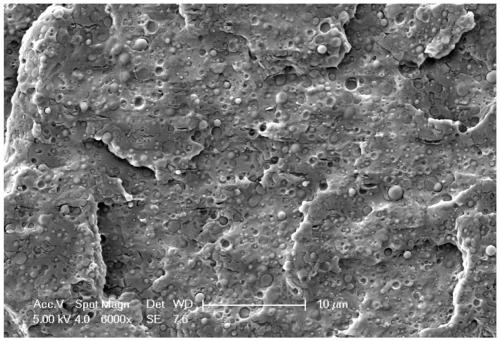

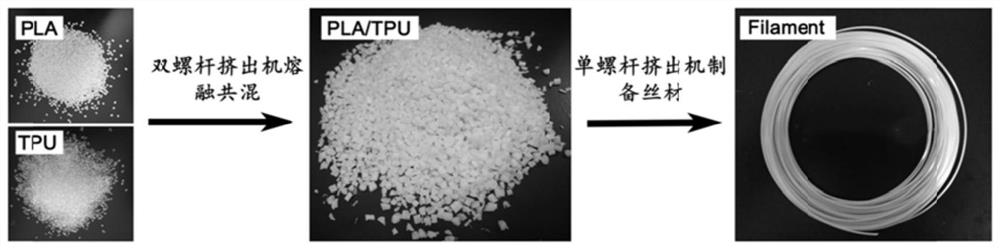

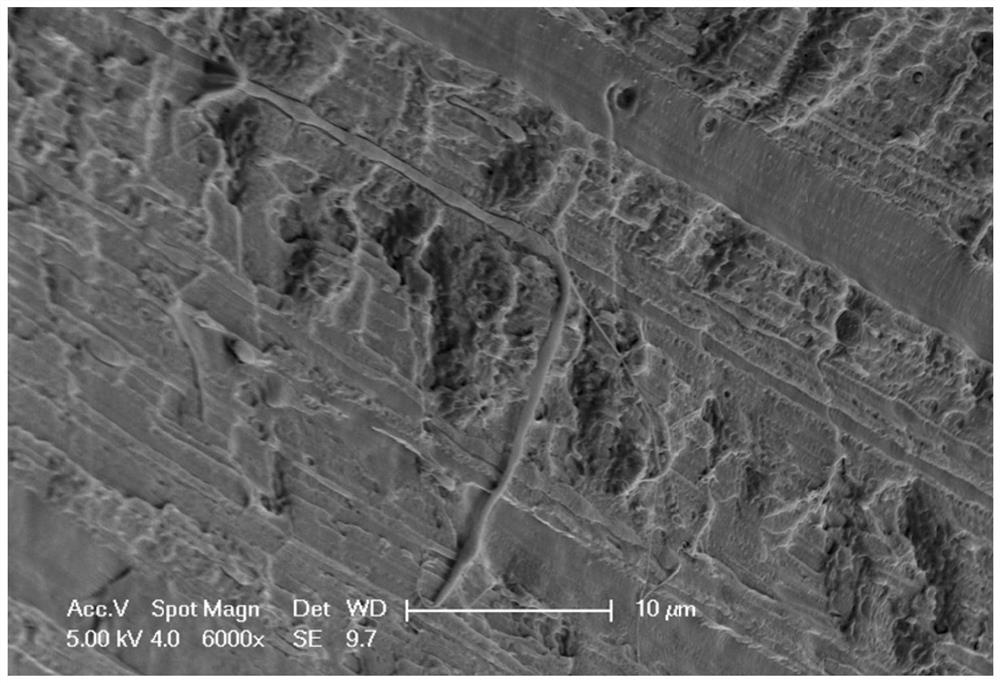

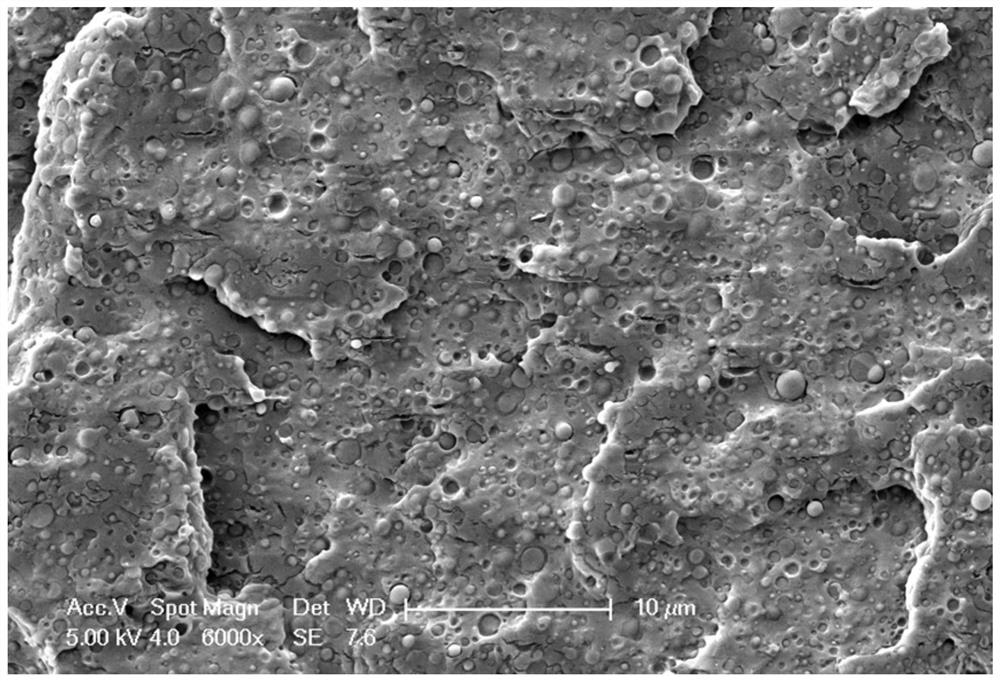

Elastomer short fiber toughened crystalline polymer product and preparation method thereof

ActiveCN110054878AAchieve short fiber distributionImplement the manufacturing methodAdditive manufacturing apparatusConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention discloses an elastomer short fiber toughened crystalline polymer product and a preparation method thereof. The preparation method includes: mixing thermoplastic elastomers and a crystalline resin raw material according to the mass percentage ratio of (10-30%):(70-90%), using a double-screw extruder to perform melt blending granulation, and drying to obtain blended granules, wherein the difference between the melting temperature of the thermoplastic elastomers and the melting temperature of the crystalline resin raw material is 10-20 DEG C; adding the obtained blended granules into a single-screw extruder to perform melt extrusion, and the extruded material is subjected to primary stretching and three-stage water tank cooling treatment to obtain 3D printing wires; placing the3D printing wires in a fused deposition modeling 3D printer, subjecting the melt to secondary stretching and tertiary stretching during printing, stacking on a forming platform to form a three-dimensional structure, and cooling to obtain the elastomer short fiber toughened crystalline polymer product. The preparation method is simple in equipment, easy in processing process control, capable of forming complex geometrical structures and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Electrolytic bath, device and method for preparing EOW without metal ions

PendingCN113149145AAchieve preparationEasy to prepareWater treatment parameter controlWater/sewage treatment apparatusElectrolytic agentChemical physics

The invention relates to the technical field of EOW preparation, in particular to an electrolytic bath, a device and a preparation method for preparing EOW without metal ions. The device for preparing the EOW free of the metal ions comprises theelectrolytic bath, the electrolytic bath comprises a bath body, an anionic membrane assembly, a cathode and an anode, a cavity is formed in the bath body, a liquid injection opening used for injecting electrolyte, a water inlet used for feeding pure water and a water outlet used for discharging the EOW are further formed in the bath body, and the anionic membrane assembly is located in the cavity. The cavity is divided into a cathode cavity and an anode cavity, the liquid injection opening is communicated with the cathode cavity, the water inlet and the water outlet are both communicated with the anode cavity, the cathode is located in the cathode cavity, and the anode is located in the anode cavity. According to the present invention, the anion membrane assembly only allows the passing of the negatively charged ions and restricts the passing of the positively charged ions, such that the metal cations in the cathode cavity cannot enter the anode cavity through the anion membrane assembly, the EOW generated in the anode cavity does not contain the metal cations, and the good sterilization effect of the prepared EOW is ensured.

Owner:HUNAN MANYUANHONG WATER TECH CO LTD

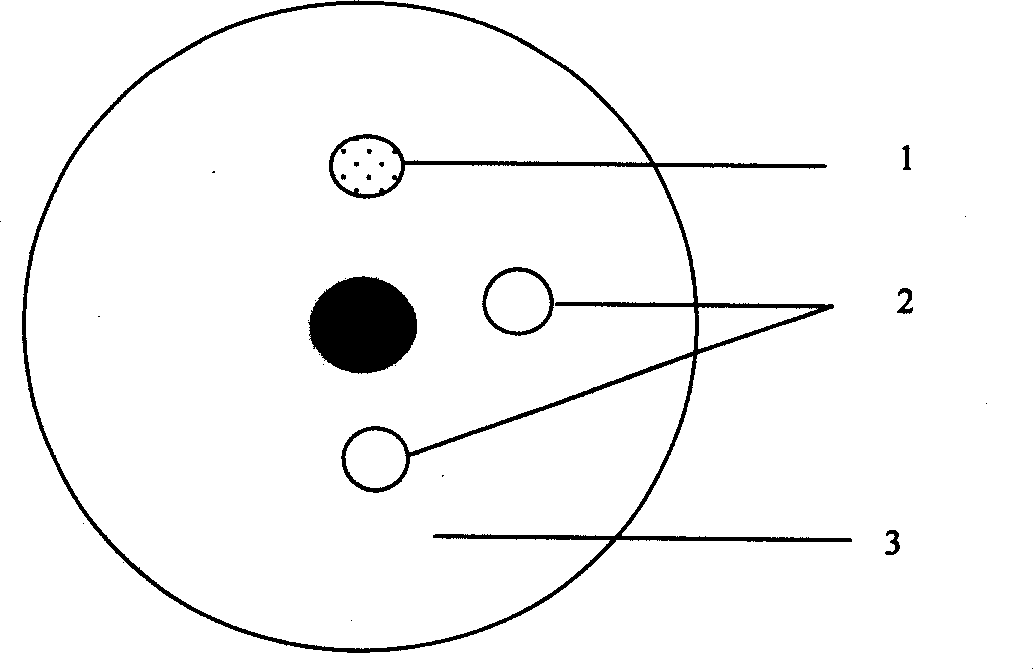

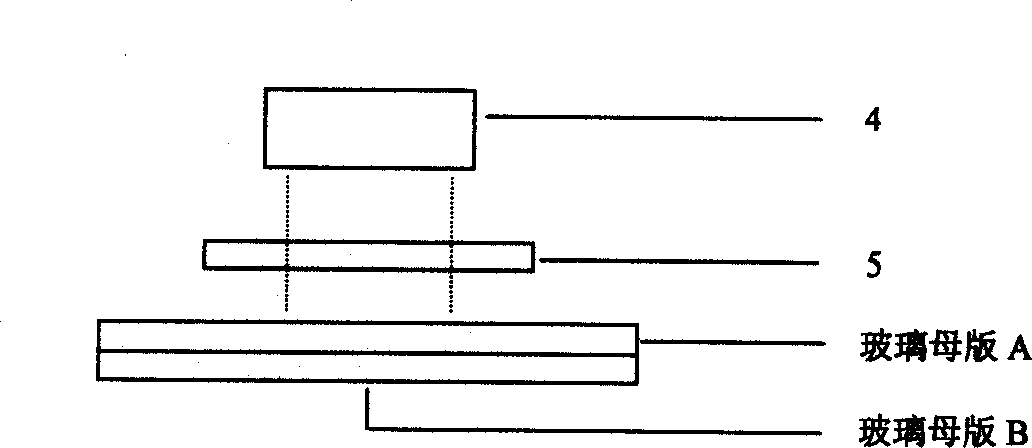

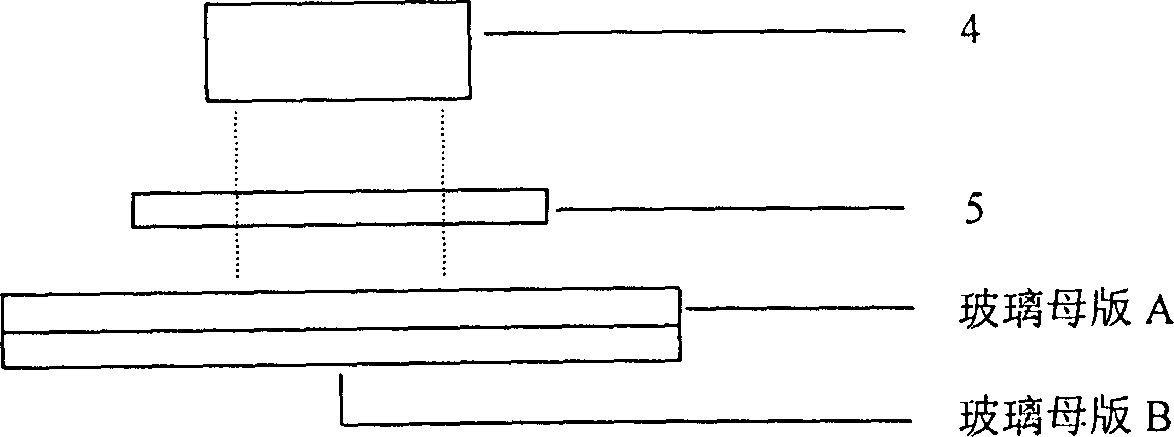

Nanometer track CD-enciphering method and CD based on the method

InactiveCN1350287AImplement the manufacturing methodOptical re-recordingRecord information storageHeavy particleFourier transform on finite groups

The present invention relates to a method for enciphering optical disk by using nano track and antipiracy optical disk made by using said method. The basic principle of said invention lies in that itutilizes bombardment of heavy particle and mementary deposition on the mother plate of optical disk to form random information with identical nano track on the contact surface of two optical disk mother plates, then utilizes the Fourier transform method to process said information and make secondary encryption of said information, finally makes it and applied software data form on optical disk together. Said invention can effectively prevent optical disk from pirating.

Owner:马振东

Method for producing galvanized steel plate

ActiveCN108713071AExcellent compression formabilityLow sliding resistanceHot-dipping/immersion processesMolten spray coatingAlkaline waterAqueous solution

Provided is a method for producing a galvanized steel plate having exceptional press moldability. This method is provided with: an oxide layer formation step in which a galvanized steel plate is heldfor 1-60 seconds after being brought into contact with an acidic solution, then washed with water; and a neutralization step in which the surface of the zinc oxide layer formed in the oxide layer formation step is held for 0.5 second or longer in a state of contact with an alkaline aqueous solution, then washed with water and dried. The acidic solution contains a total of 0.10-5.0 g / L inclusive ofHF2Na and / or HF2K.

Owner:JFE STEEL CORP

Method for producing stir-fried luffa with fried dough stick

InactiveCN104336602AImplement the manufacturing methodHeat-clearing and detoxifyingFood preparationMonosodium glutamateGram

The invention relates to a method for producing stir-fried luffa with fried dough stick. The stir-fried luffa with fried dough stick comprises one mercury-free fried dough stick, one luffa, one green capsicum, half eggplant, 20 grams of pork, three star aniseeds, one large slice of ginger, one dried tangerine peel, three tablespoons of cooking oil, one tablespoon of peanut oil, one tablespoon of Weijixian soy sauce, one tablespoon of dark soy sauce, a bit of minced scallion, salt, monosodium glutamate and ground pepper. The luffa and the eggplant are peeled, the handle of the green capsicum is removed, the green capsicum and the fried dough sticks are cut into fine blocks, the pork is chopped into pork paste, the peanut oil is added into a wok, the star aniseeds, the ginger and the tangerine peel are stirred and fried in the peanut oil and removed from the wok, the minced scallion is stirred and fried in the wok, and then the pork paste is added into the wok, the fine blocks are added into the wok when the pork paste is cooked, the cooking wine is poured into the wok and the mixtures are stirred for 10 minutes, the salt, the monosodium glutamate and the ground pepper are added into the wok and then the mixtures are continuously stirred for 10 minutes, the Weijixian soy sauce and the dark soy sauce are added into the wok, and finally the mixtures are uniformly stirred and the stir-fried luffa with fried dough stick is produced. The method solves the defects of the existing traditional method that the fried dough stick is stirred and fried mainly by using the frying method of oil and food stuffs, but the fried dough stick tastes ordinary, is greasy and impairs the stomach, without nutrition value. The method is suitable for food production.

Owner:赵 瑞

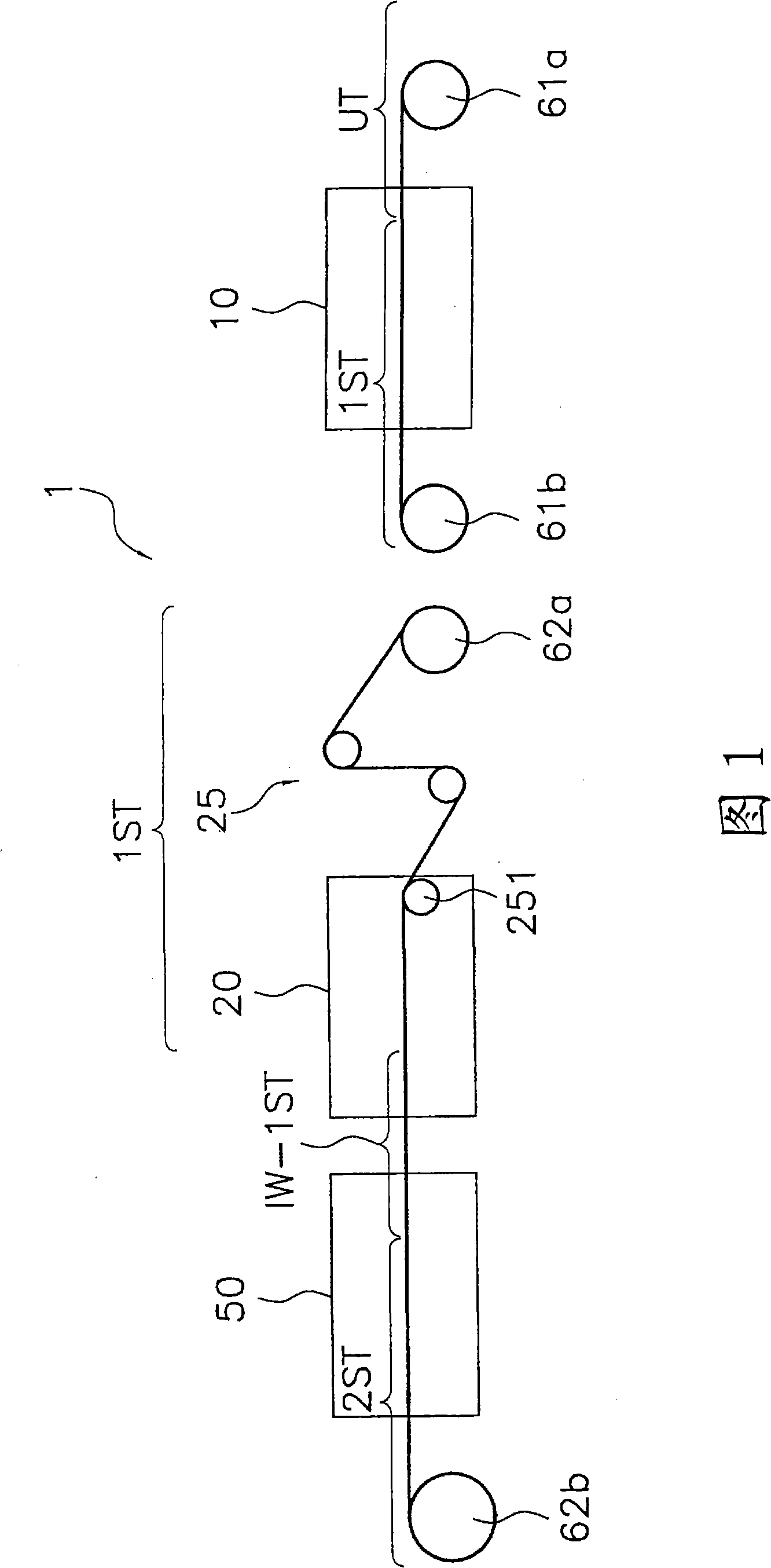

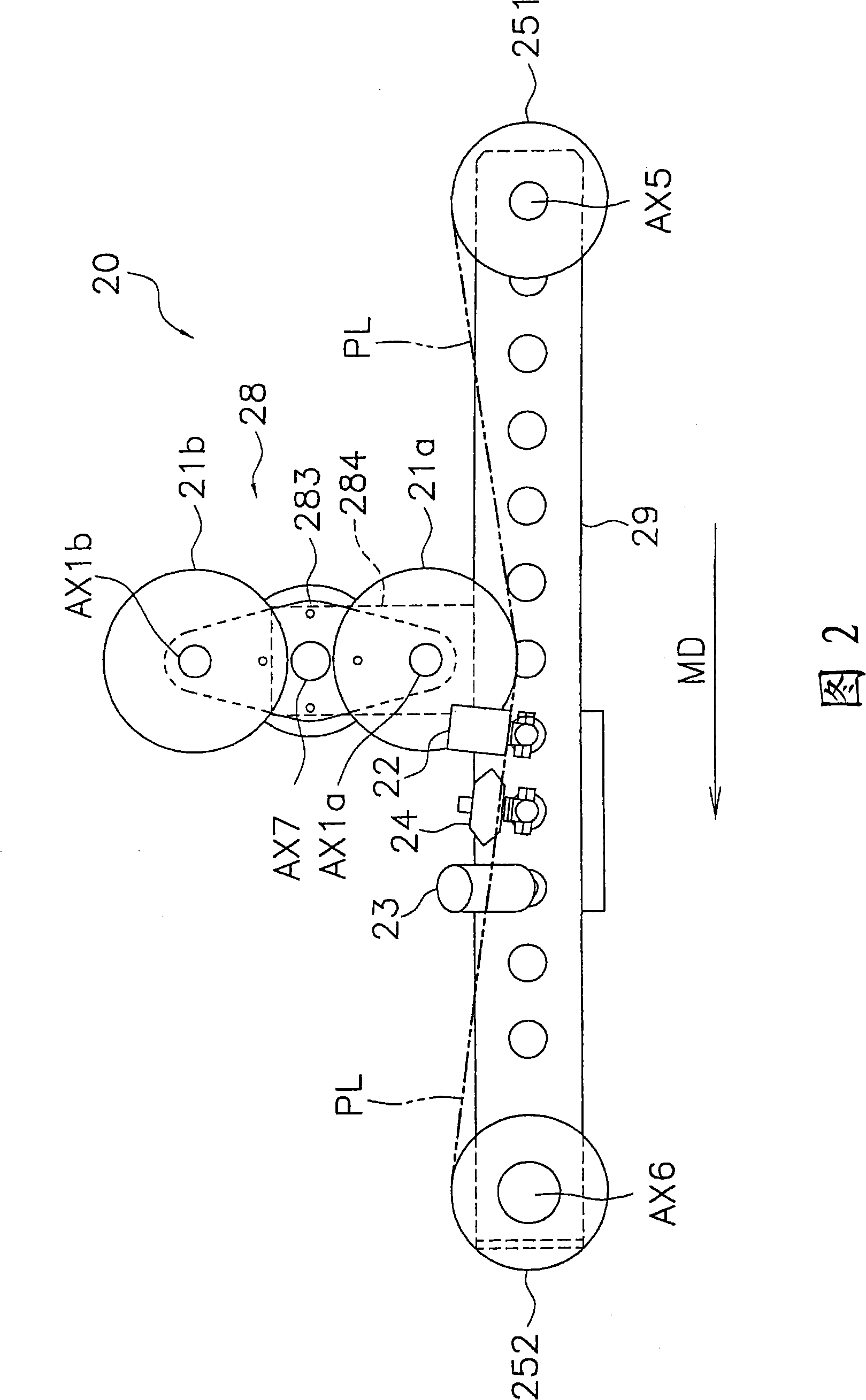

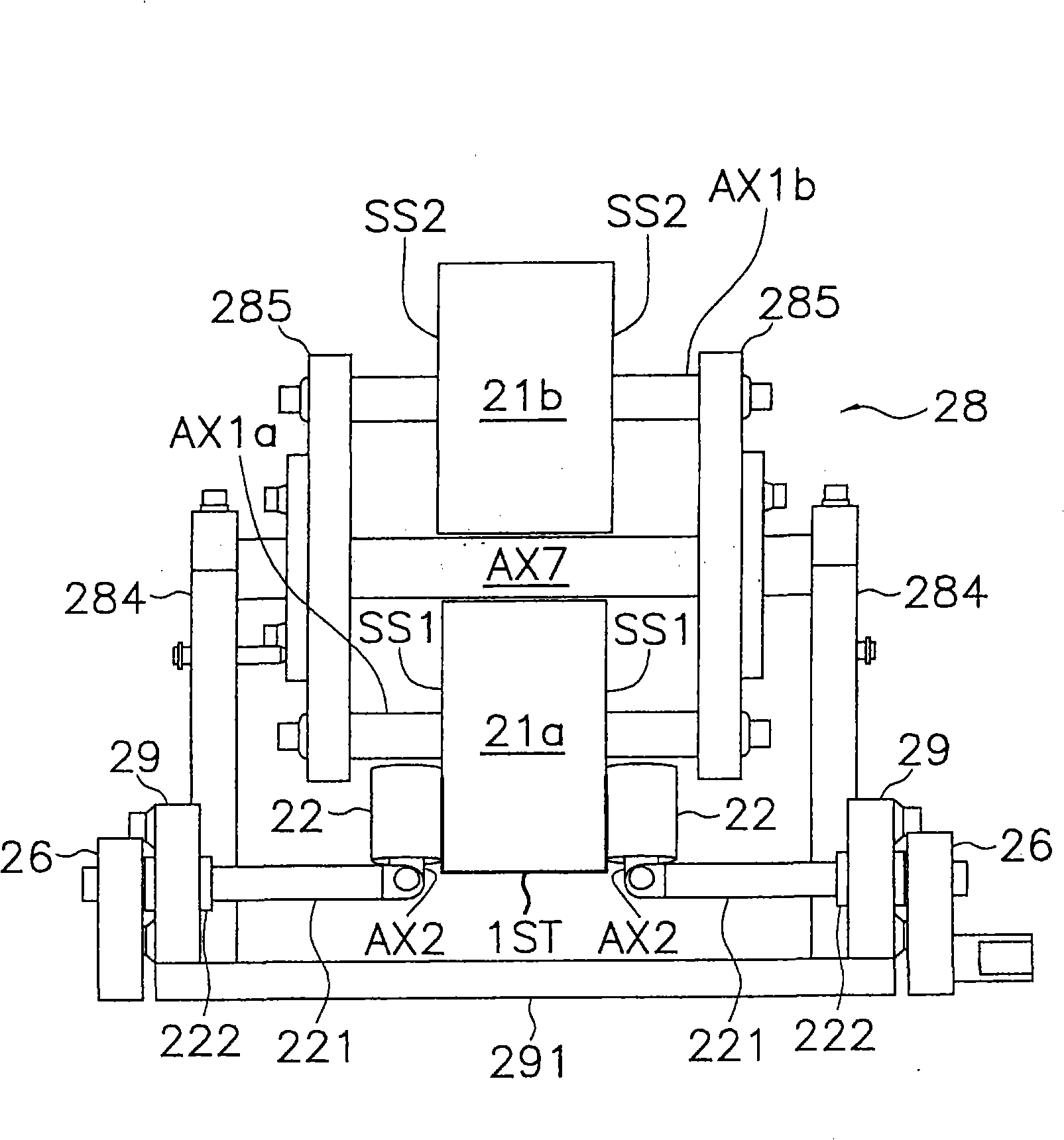

Method and device for manufacturing biaxial extending ribbon and device for bending ribbon

ActiveCN101407110AQuality improvementImplement the manufacturing methodFolding thin materialsEngineeringMagnification

The invention provides a biaxial extension strip-like article manufacturing method, manufacturing device and strip-like article retracting device. The inventive biaxial extension strip-like article manufacturing method is not needed to reset the controlling parameters and the like of a calendaring forming apparatus and a longitudinal extension apparatus and the like, even if the mode of enlarging the extension magnification of the transverse extension apparatus changes. In a first extension process of the manufacturing method, a first extension strip-like article is produced by extending the non extension strip-like article in its length direction. In a retracting process, an end or two ends at the width directional of the first extension strip-like article retracts one time or multiple times, to produce a first extension strip-like article with scheduled width, namely a first extension strip-like article with variable width. In a second extension process, part or whole of the retracting part of the first extension strip-like article with variable width is held, the first extension strip-like article with variable width is made to extend in the width direction for producing a second extension strip-like article.

Owner:DAIKIN IND LTD

A method and system for making a prosthesis for a maxillary defect

ActiveCN111513881BImplement the manufacturing methodAchieve preparationImpression capsArtificial teethProsthesisRetainer

This application discloses a fully digital design and production method and system for a maxillary defect prosthesis, which is used to improve the production accuracy, quality and efficiency, and shorten the production cycle of the prosthesis, including: obtaining a three-dimensional digital model of the maxillary defect; According to the three-dimensional digital model, perform model observation and determine the undercut depth of the abutment; determine the retainer according to the undercut depth of the abutment; determine the large connector and the small connector according to the three-dimensional digital model; According to the three-dimensional digital model, select artificial teeth from the database, arrange the artificial teeth and determine the position of the artificial teeth; Determine the design of the maxillary defect prosthesis; according to the design of the maxillary defect prosthesis, manufacture the maxillary defect prosthesis by additive manufacturing or subtractive manufacturing. The application also discloses a fully digital design and production system for a maxillary defect prosthesis.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

A kind of elastic short fiber toughened crystalline polymer product and preparation method thereof

ActiveCN110054878BAchieve short fiber distributionImplement the manufacturing methodAdditive manufacturing apparatusConjugated synthetic polymer artificial filamentsElastomerFiber

The invention discloses an elastomer short fiber toughened crystalline polymer product and a preparation method thereof, comprising: mixing thermoplastic elastomer and crystalline resin raw materials according to mass percentages of 10%-30%:70%-90%, Melt, blend and granulate through a twin-screw extruder, and obtain blended pellets after drying; the melting temperature of the thermoplastic elastomer and the melting temperature of the crystalline resin raw material are 10-20°C different; the obtained blended pellets are fed into a single screw The extruder performs melt extrusion, and the extruded material is stretched for the first time and cooled in a three-stage water tank to obtain a 3D printing filament; the obtained 3D printing filament is placed in a fused deposition modeling 3D printer, and the melt is printed During the process, after the second stretching and the third stretching, and superimposed on the forming platform to form a three-dimensional structure, the elastomeric short fiber toughened crystalline polymer product is obtained after cooling. The invention has the characteristics of simple equipment, easy control of the processing technology, and the ability to form complex geometric structures.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

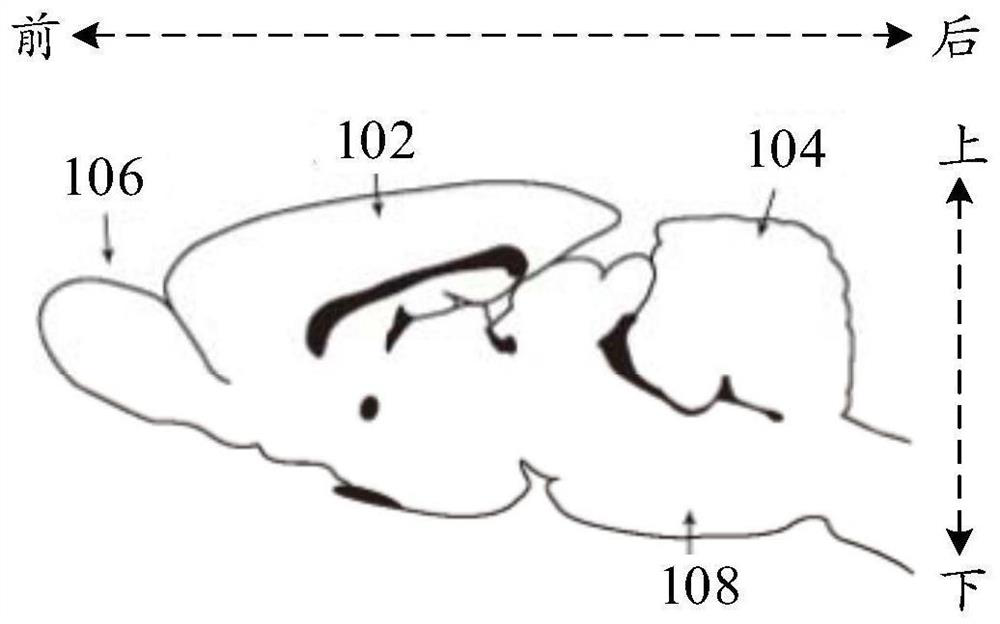

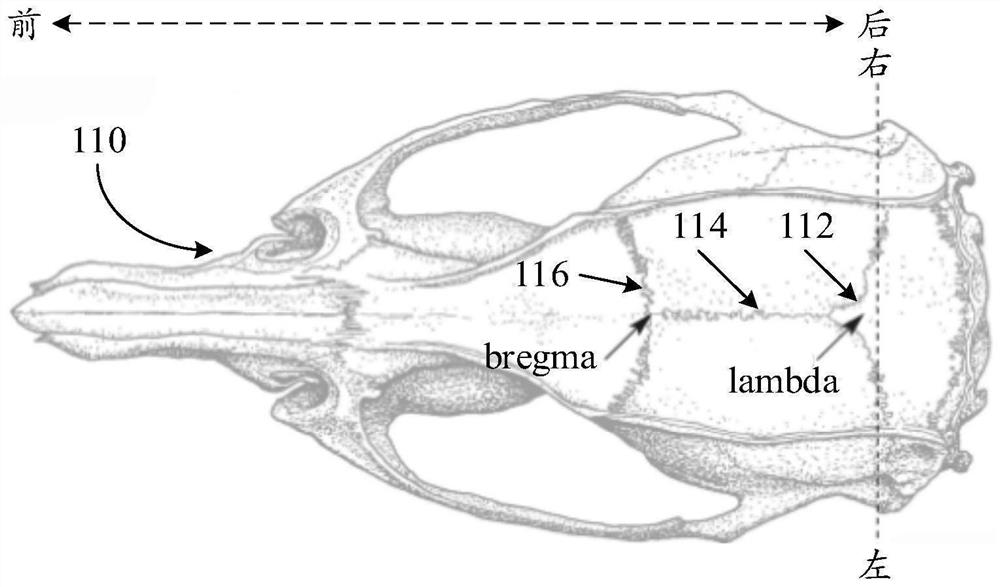

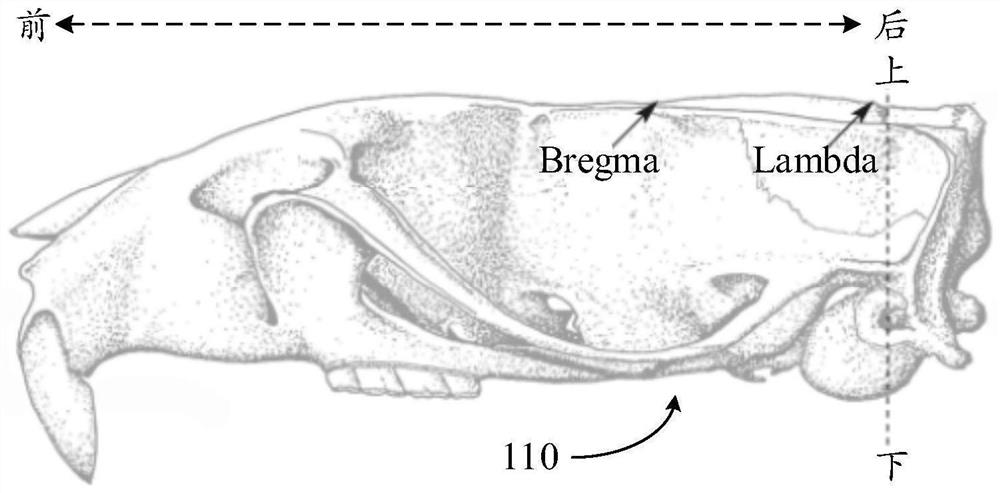

Brain slice mold manufacturing method, device, electronic equipment and storage medium

ActiveCN112238602BImplement the manufacturing methodFit tightlyAdditive manufacturing apparatusManufacturing data aquisition/processingAnatomical landmarkEngineering

The disclosure provides a method for making a brain slice mold, a device, an electronic device and a storage medium, and relates to the field of life science devices. The method includes: receiving the complete shape data of the skull determined by optical scanning technology, and determining the anatomical landmarks of the skull; aligning the complete shape data with the coordinate system of a preset three-dimensional coordinate space through the anatomical landmarks of the skull, so as to obtain the alignment coordinate system the first shape data; receive the second shape data determined by optical scanning technology, import the second shape data into the three-dimensional coordinate space and align with the first shape data, so as to obtain the imported third shape data; according to the third shape A brain slice mold is generated from the data; a cutter groove is formed on the brain slice mold according to a preset slice position; 3D printing is performed on the brain slice mold formed with the cutter groove. Through the disclosed scheme, the groove of the brain slice mold fits the brain tissue more closely, makes the slice direction consistent with the standard brain atlas slice direction, and improves the slice quality.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

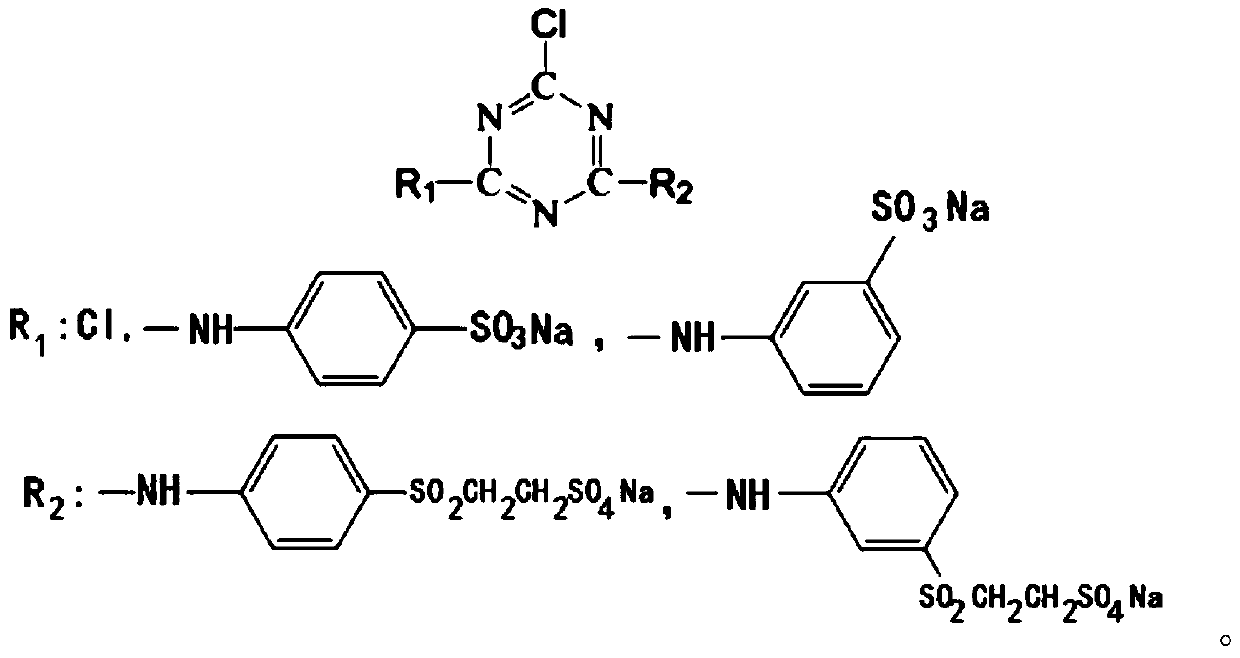

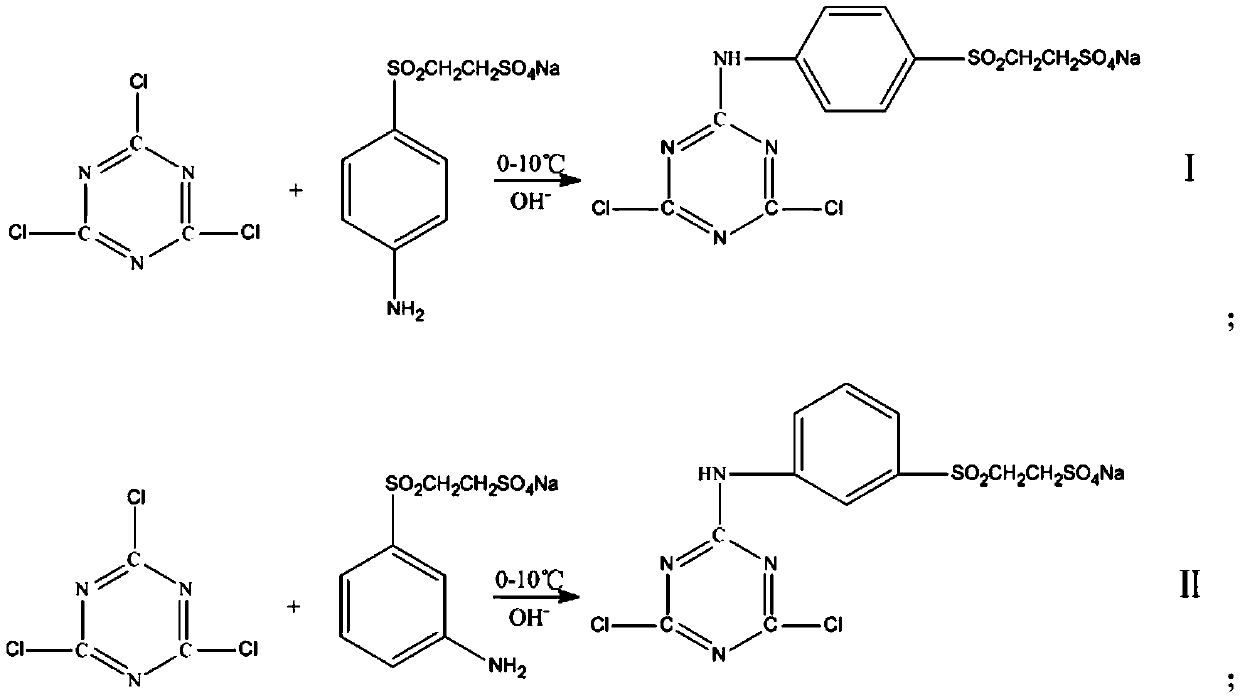

Reactive leveling agent and its preparation method and application

ActiveCN107142753BGood level dyeingImprove color difference between inner and outer layersDyeing processYarnInorganic salts

The invention discloses a reactive dye leveler which comprises, in weight percent, 20.0%-40.0% of multi-active dye levelers, 20.0%-40.0% of water, 5.0%-10.0% of dihydric phosphate, 5.0%-10.0% of perlate salt and 0%-50.0% of inorganic salt. The total content of the components is 100%. The invention further discloses a preparation method and an application of the reactive dye leveler. The reactive dye leveler is mainly used for cellulose fibers and protein fibers, dyeing uniformity is obviously improved by competitive dyeing of the reactive dye leveler and dyes, occupation of specific sites for dyeing through fiber reaction and the buffer function for dye bath pH (potential of hydrogen) values, good uniform dyeing effects can be achieved particularly for light color and sensitive color dyeing, the reactive dye leveler is applied to dyeing of loose fibers and cone yarns, the color difference between an inner layer and an outer layer can be obviously improved, and overall uniform dyeing effects are improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Mounting substrate, and method for manufacturing thin light-emitting device using same

InactiveCN101930964BAchieve installationImplement the manufacturing methodSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsEngineering

The invention provides a mounting substrate and a method for manufacturing thin light-emitting device using same, which is capable of inhibiting generation of burrs and realizing mass production of light-emitting device. In the mounting substrate of the invention, a conductive foil is removed at the edge of a unit. In particular, on the upper surface of the mounting substrate, a unit formed of a first electrode part and a second electrode part encircling a mounting part is formed, a plurality of units are arranged in columns. Furthermore, on the lower surface of the mounting substrate, a first external take-out electrode part connected with the first electrode is provided, and a second external take-out electrode part connected with the second electrode is provided. Besides, resin material for forming the mounting substrate, without the existence of conductive foil and other metal materials, is provided among the units. Therefore, in the manufacture of the light-emitting device, even if the mounting substrate between the units is cut off, the burr is not generated as the metal material is not cut off.

Owner:ELEMENT DENSHI

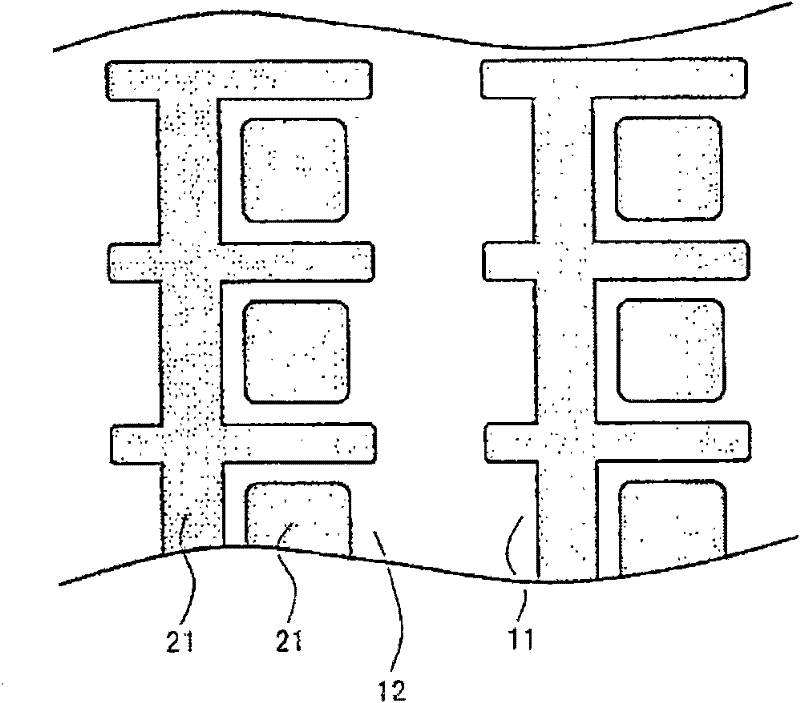

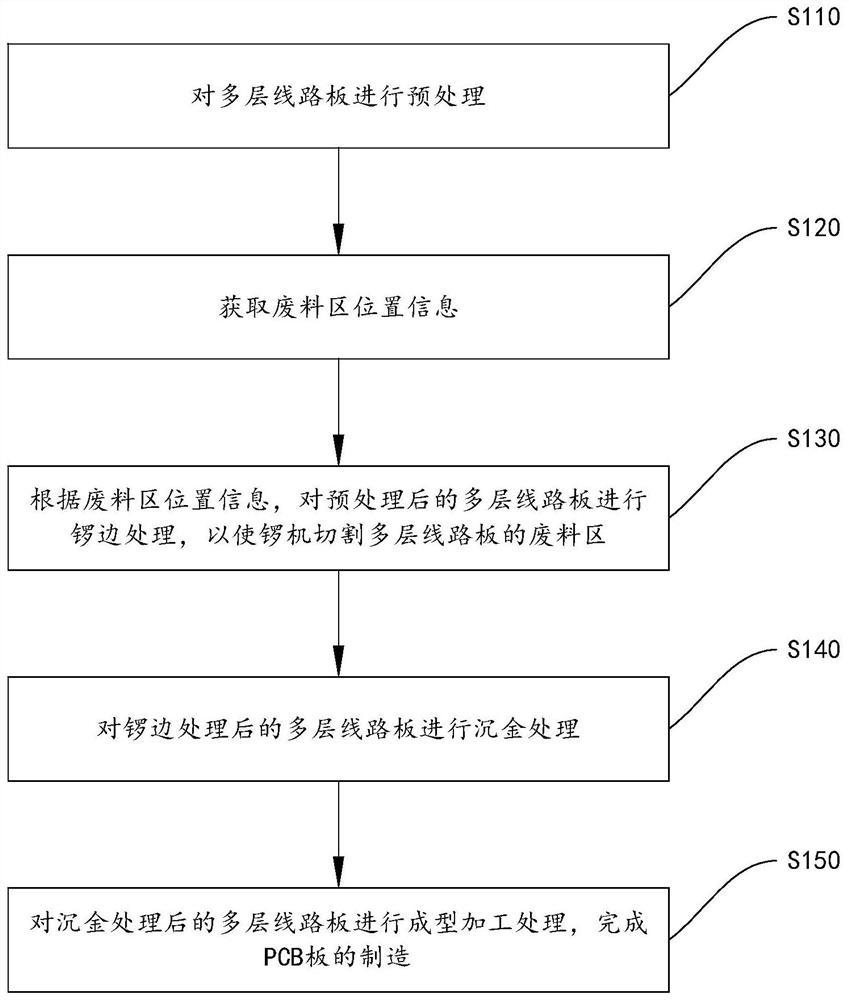

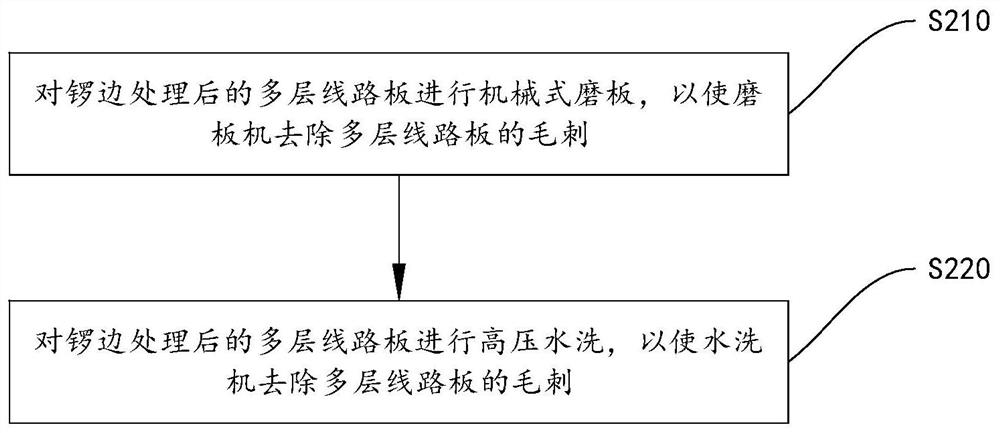

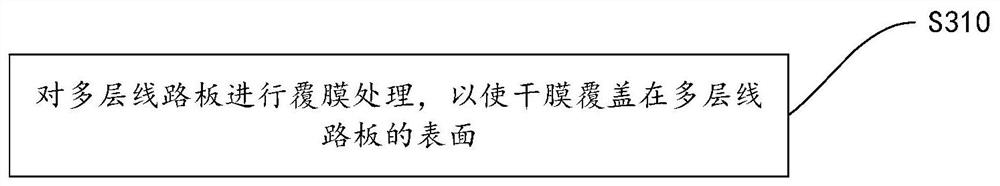

PCB manufacturing method and PCB

PendingCN113923897AImplement the manufacturing methodAvoid pollutionMultilayer circuit manufactureAdhesive beltProcess engineering

The invention discloses a PCB (Printed Circuit Board) manufacturing method and a PCB. The method comprises the following steps of: pre-processing a multi-layer circuit board; acquiring waste material area position information; according to the waste material area position information, carrying out edge milling treatment on the preprocessed multilayer circuit board so that a milling machine can cut the waste material area of the multi-layer circuit board; performing gold immersion treatment on the multilayer circuit board after the edge milling treatment; and carrying out forming processing on the multilayer circuit board after gold immersion treatment to complete manufacturing of the PCB. According to the scheme provided by the embodiment of the invention, the position information of the waste area can be obtained, and the waste area of the multilayer circuit board is cut through the milling machine, so that the multilayer circuit board without the edge of the waste area is subjected to gold immersion treatment, the PCB manufacturing method without adhesive tape coating is realized, the production efficiency is effectively improved, and the environment pollution is avoided.

Owner:ELEC & ELTEK GUANGZHOU ELECTRONICS

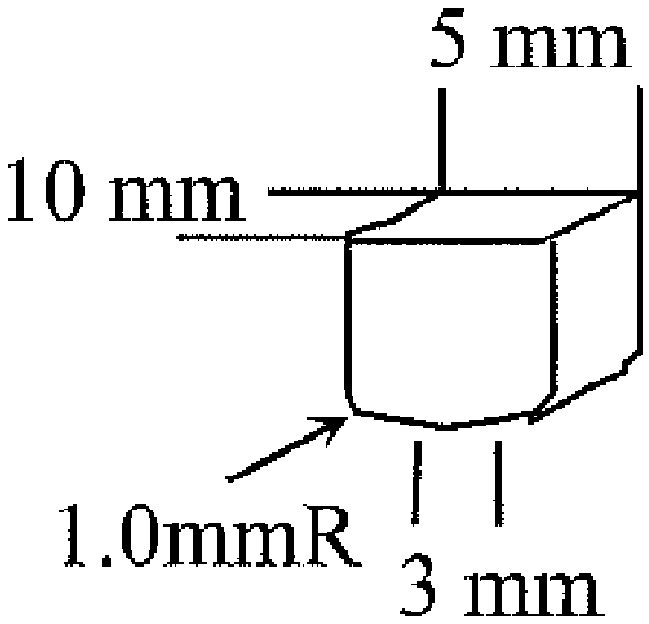

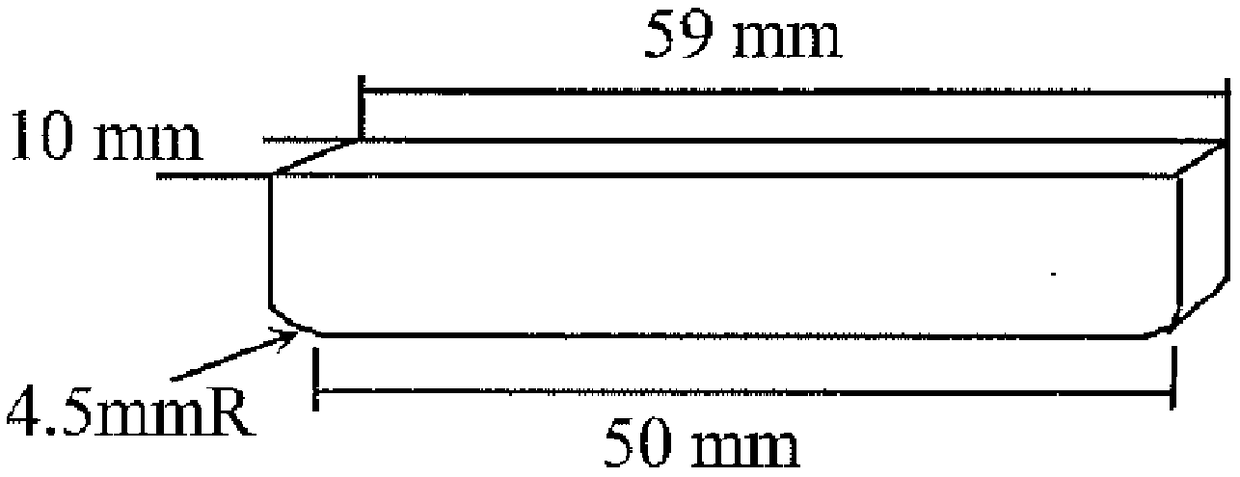

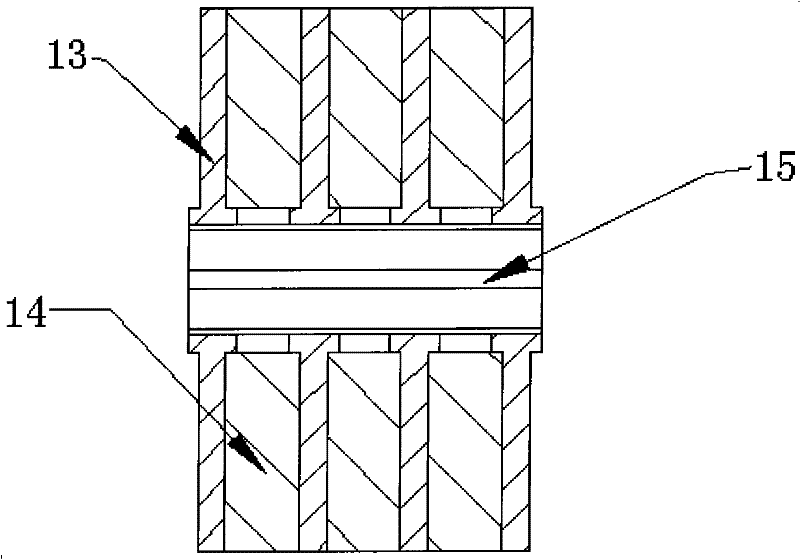

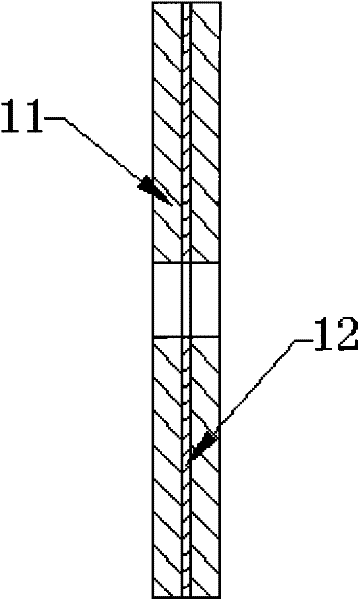

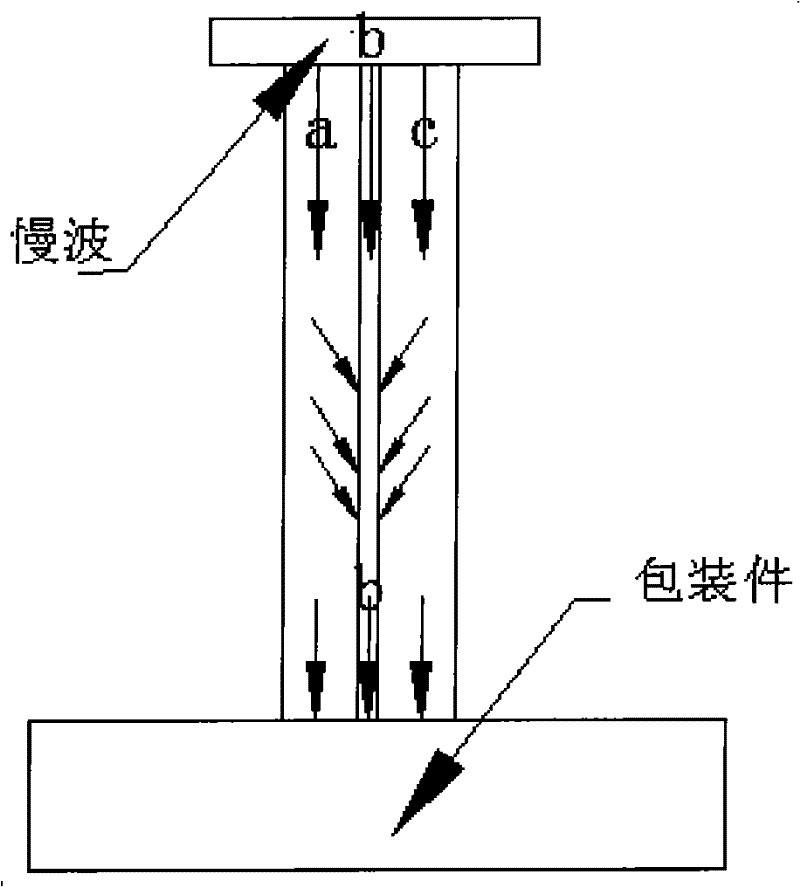

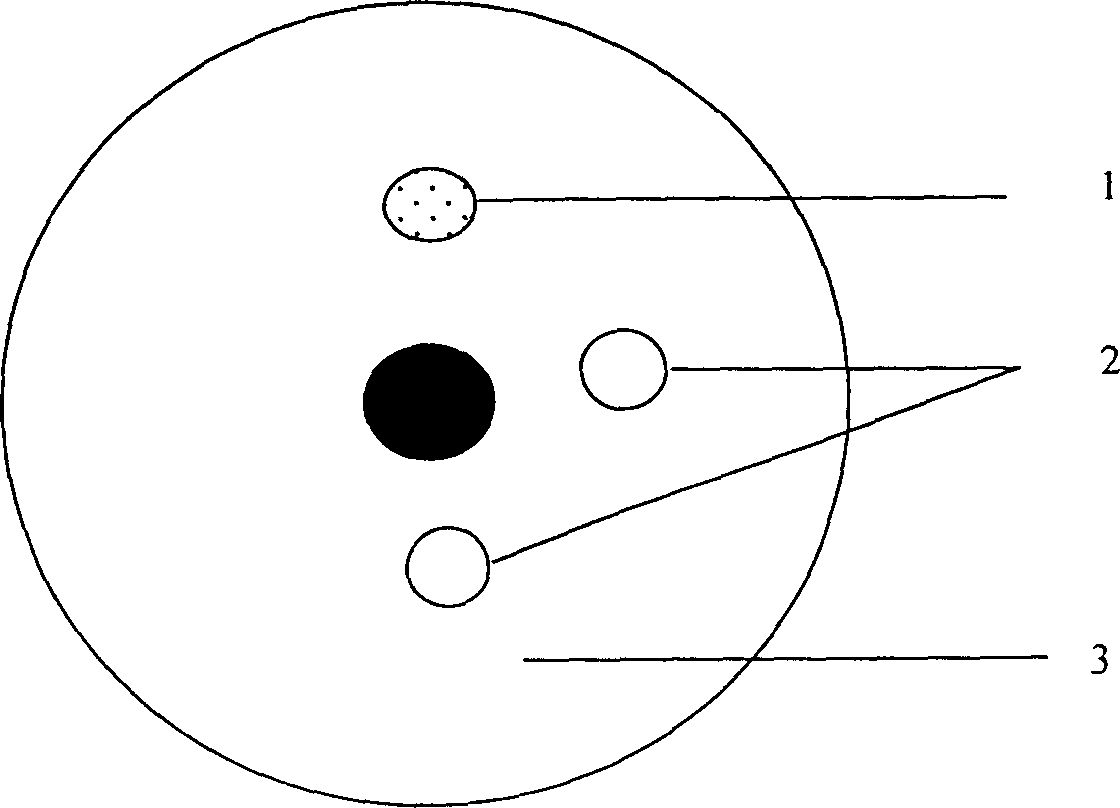

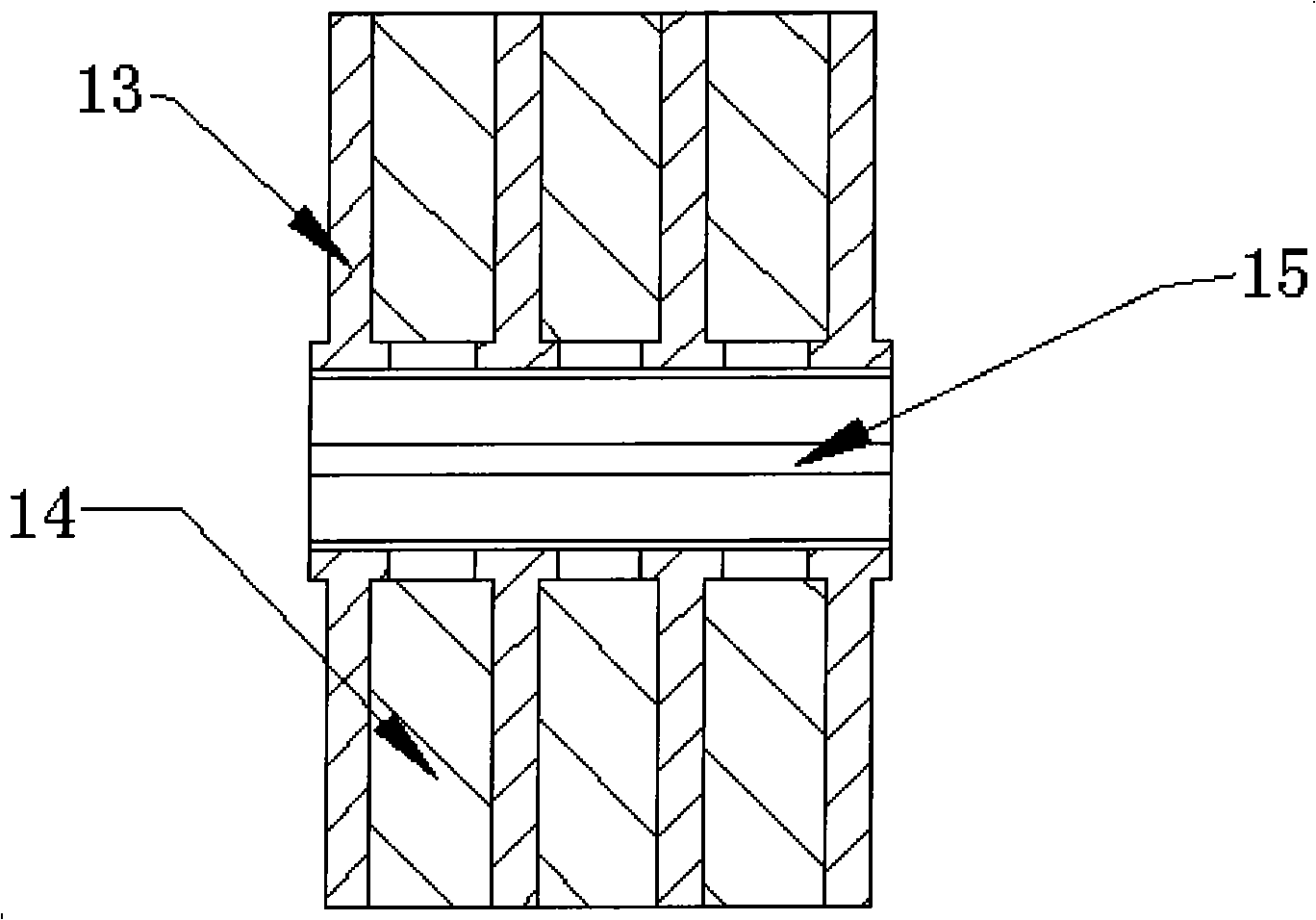

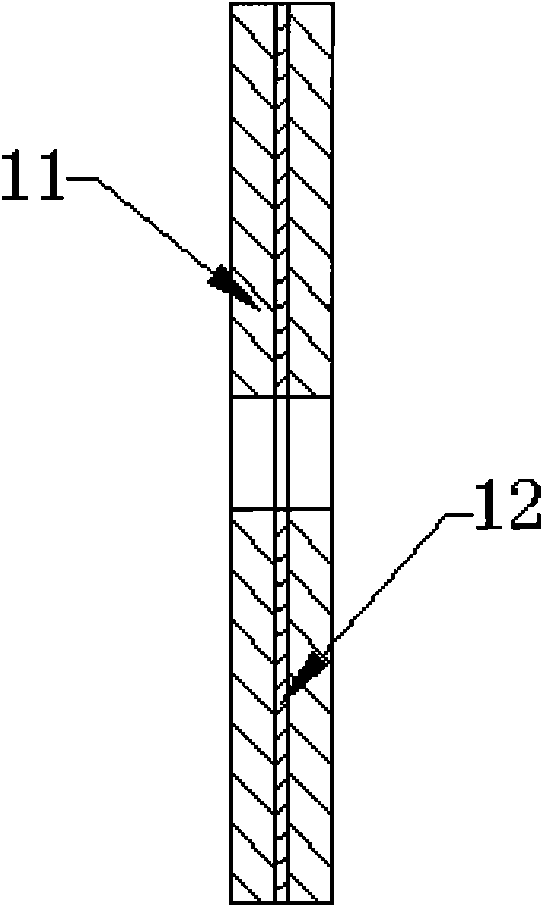

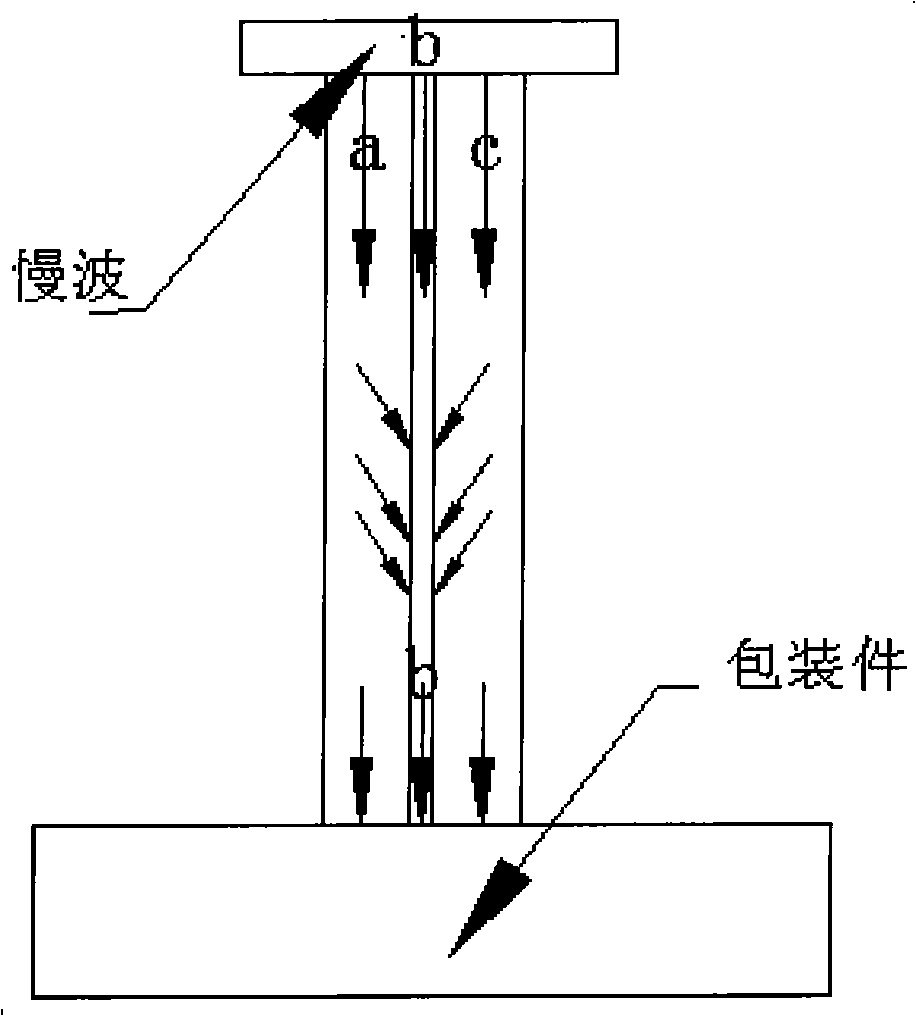

Pole shoe used for slow-wave heat dissipation of millimeter traveling wave tube and production method thereof

InactiveCN101789351BSolve the problem of slow wave heat dissipationImprove thermal conductivityTransit-tube circuit elementsCold cathode manufactureWave tubeDiffusion welding

The invention discloses a pole shoe used for slow-wave heat dissipation of a millimeter traveling wave tube. The pole shoe comprises pole shoe walls arranged at the two sides and made of DT8 magnetic material, wherein a heat conduction layer made of oxygen-free copper material is clamped between the pole shoe walls; and the mass of the oxygen-free copper is not more than 10% of the mass of the total mass of the pole shoe. In the invention, the pole shoe walls and the heat conduction layer are placed in a vacuum furnace and then welded into one by diffusion welding by adopting a diffusion welding tool. The pole shoe used for the slow-wave heat dissipation of the millimeter traveling wave tube in the invention has simple structure, the production method can be easily realized, and the problem of the slow-wave heat dissipation of the traveling wave tube in the traditional technology can be effectively solved. After the heat conduction layer made of oxygen-free copper material is added between the pole shoe walls, the heat conduction capacity of the pole shoe is improved by more than three times, thereby completely meeting the requirement of the slow-wave heat dissipation of the traveling wave tube, greatly prolonging the service life of the traveling wave tube and improving the working accuracy of the traveling wave tube.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Nanometer track CD-enciphering method and CD made using said method

InactiveCN1114194CImplement the manufacturing methodOptical re-recordingRecord information storageHeavy particleFourier transform on finite groups

The present invention relates to a method for enciphering optical disk by using nano track and antipiracy optical disk made by using said method. The basic principle of said invention lies in that it utilizes bombardment of heavy particle and mementary deposition on the mother plate of optical disk to form random information with identical nano track on the contact surface of two optical disk mother plates, then utilizes the Fourier transform method to process said information and make secondary encryption of said information, finally makes it and applied software data form on optical disk together. Said invention can effectively prevent optical disk from pirating.

Owner:马振东

Pole shoe used for slow-wave heat dissipation of millimeter traveling wave tube and production method thereof

InactiveCN101789351ASolve the problem of slow wave heat dissipationImprove thermal conductivityTransit-tube circuit elementsCold cathode manufactureEngineeringWave tube

The invention discloses a pole shoe used for slow-wave heat dissipation of a millimeter traveling wave tube. The pole shoe comprises pole shoe walls arranged at the two sides and made of DT8 magnetic material, wherein a heat conduction layer made of oxygen-free copper material is clamped between the pole shoe walls; and the mass of the oxygen-free copper is not more than 10% of the mass of the total mass of the pole shoe. In the invention, the pole shoe walls and the heat conduction layer are placed in a vacuum furnace and then welded into one by diffusion welding by adopting a diffusion welding tool. The pole shoe used for the slow-wave heat dissipation of the millimeter traveling wave tube in the invention has simple structure, the production method can be easily realized, and the problem of the slow-wave heat dissipation of the traveling wave tube in the traditional technology can be effectively solved. After the heat conduction layer made of oxygen-free copper material is added between the pole shoe walls, the heat conduction capacity of the pole shoe is improved by more than three times, thereby completely meeting the requirement of the slow-wave heat dissipation of the traveling wave tube, greatly prolonging the service life of the traveling wave tube and improving the working accuracy of the traveling wave tube.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

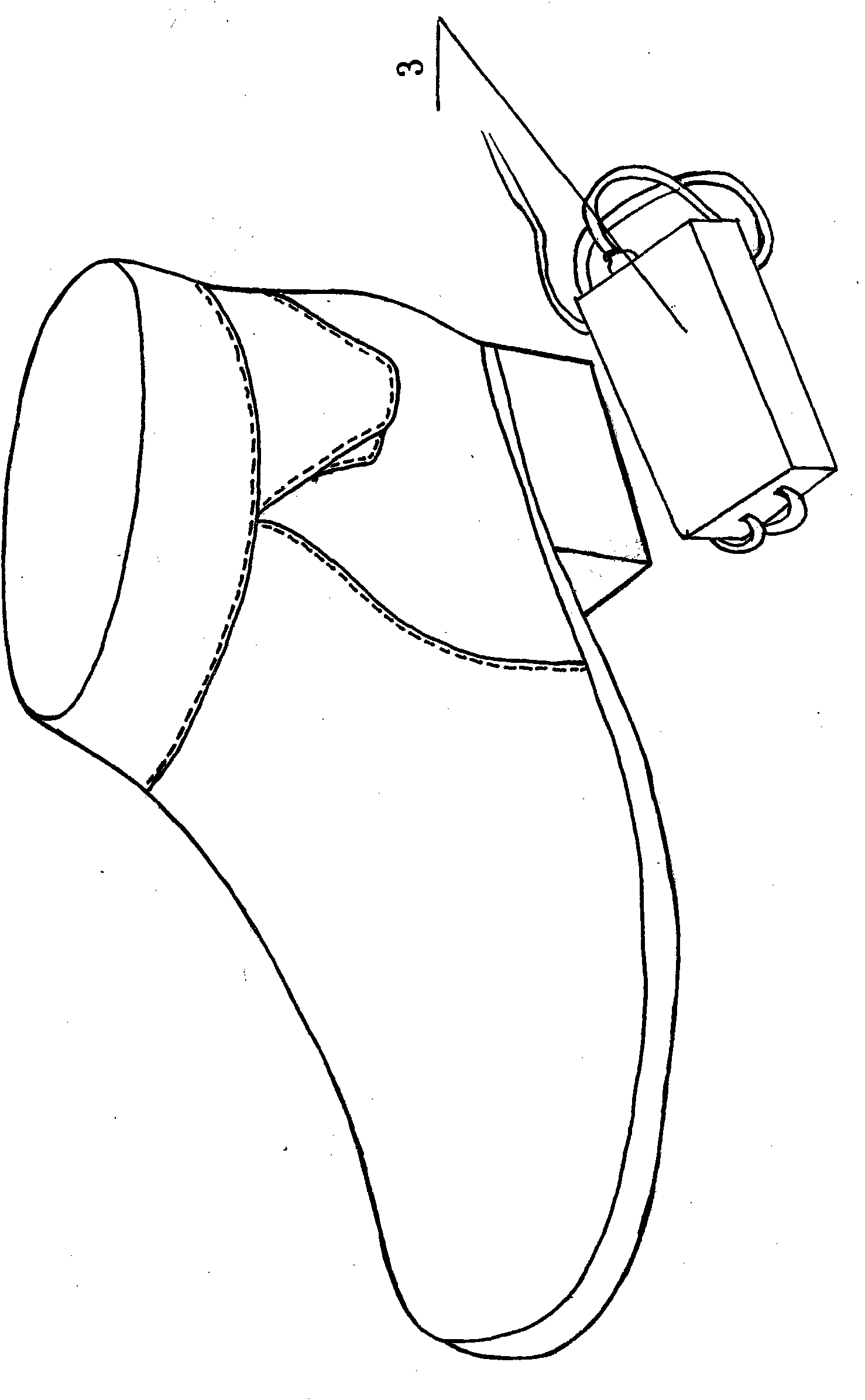

Method for manufacturing elastic hook-and-loop shoes

The invention discloses a method for manufacturing elastic hook-and-loop shoes. The method is characterized in that shoe upper surfaces are made of elastic Lycra cloth, and a plurality of slim Lycra fibers similar to rubber bands are woven to form the elastic Lycra cloth. The method includes a technique for manufacturing shoe uppers and a technology for processing materials of the Lycra cloth. The technique for manufacturing the shoe uppers includes compounding the double-layer elastic Lycra cloth with sponges, to be more specific, uniformly coating hot-melt adhesive onto the Lycra cloth and the sponges by the aid of a point hot-melt adhesive dry type compounding technique, enabling the drying temperatures to range from 80 DEG C to 100 DEG C under the control by the aid of compounding machines, enabling the pressures of scrapers to range from 200kpa to 400kpa under the control, and integrally laminating the elastic Lycra cloth and the sponges after the adhesive is dried. The size of each sponge ranges from 0.1mm to 0.3mm. The double-layer elastic Lycra cloth and the sponges are compounded with one another, accordingly, the upper sides and the lower sides of the shoe uppers can be instantly expanded by 35%-55%, and the left sides and the right sides of the shoe uppers can be enlarged by 25%-45% according to the foot types of wearers. The technology for processing the materials of the Lycra cloth includes carrying out pressing processing on press stubble positions of the Lycra cloth by the aid of a pneumatic pressing technique, to be more specific, brushing adhesive at certain positions of the Lycra cloth at first, regulating the temperatures by the aid of pneumatic pressing machines to enable the temperatures to range from 120 DEG C to 140 DEG C, and performing pressing processing on the certain positions of the Lycra cloth for 5-10 seconds. The distances from the certain positions of the Lycra cloth to the edges of the press stubble positions of the Lycra cloth range from 3mm to 5mm. The method has the advantages that the edges of the press stubble positions are flat and compact and are not loose, and the component adhesion firmness can be guaranteed.

Owner:QINGDAO HENGDA CO LTD +2

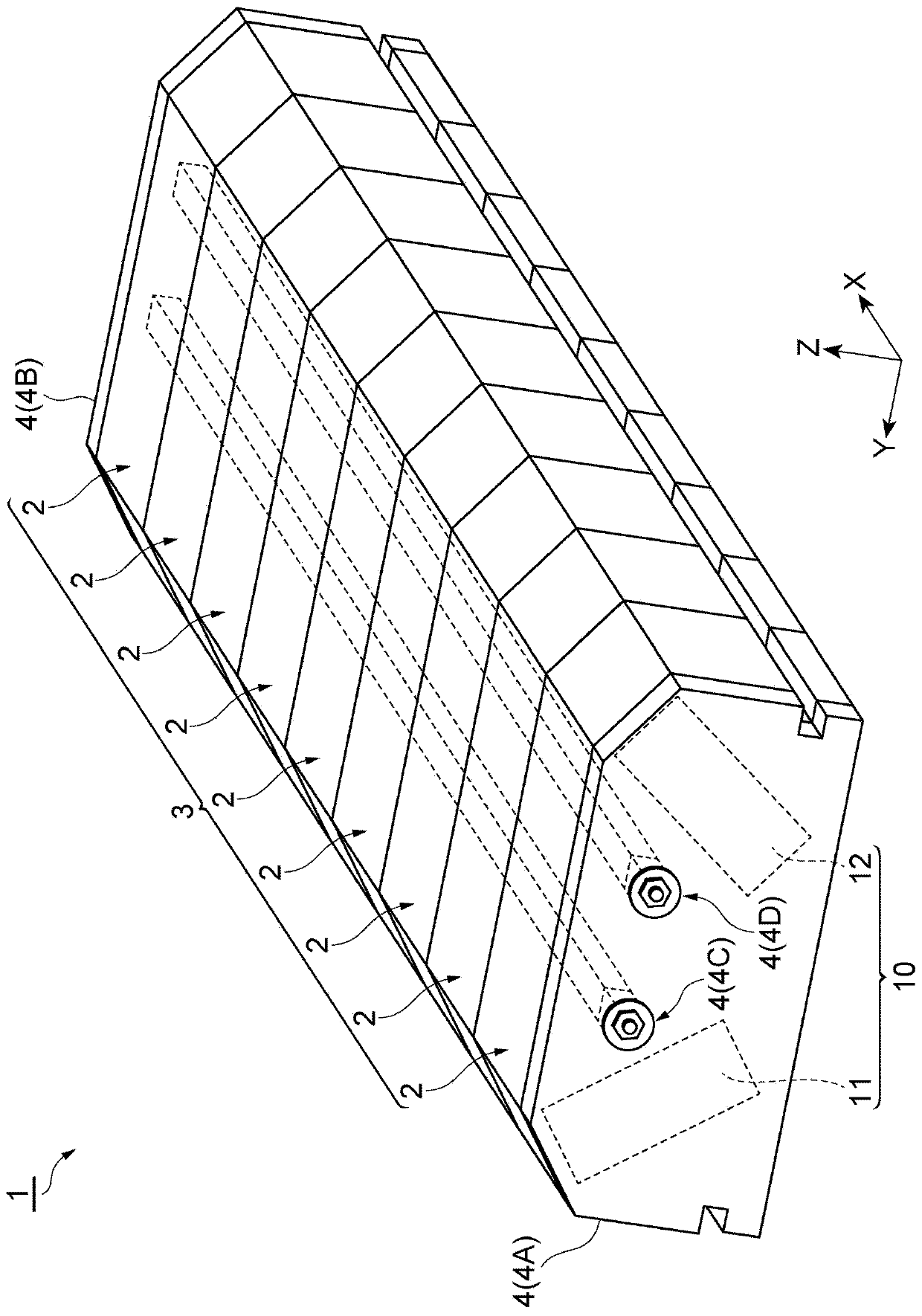

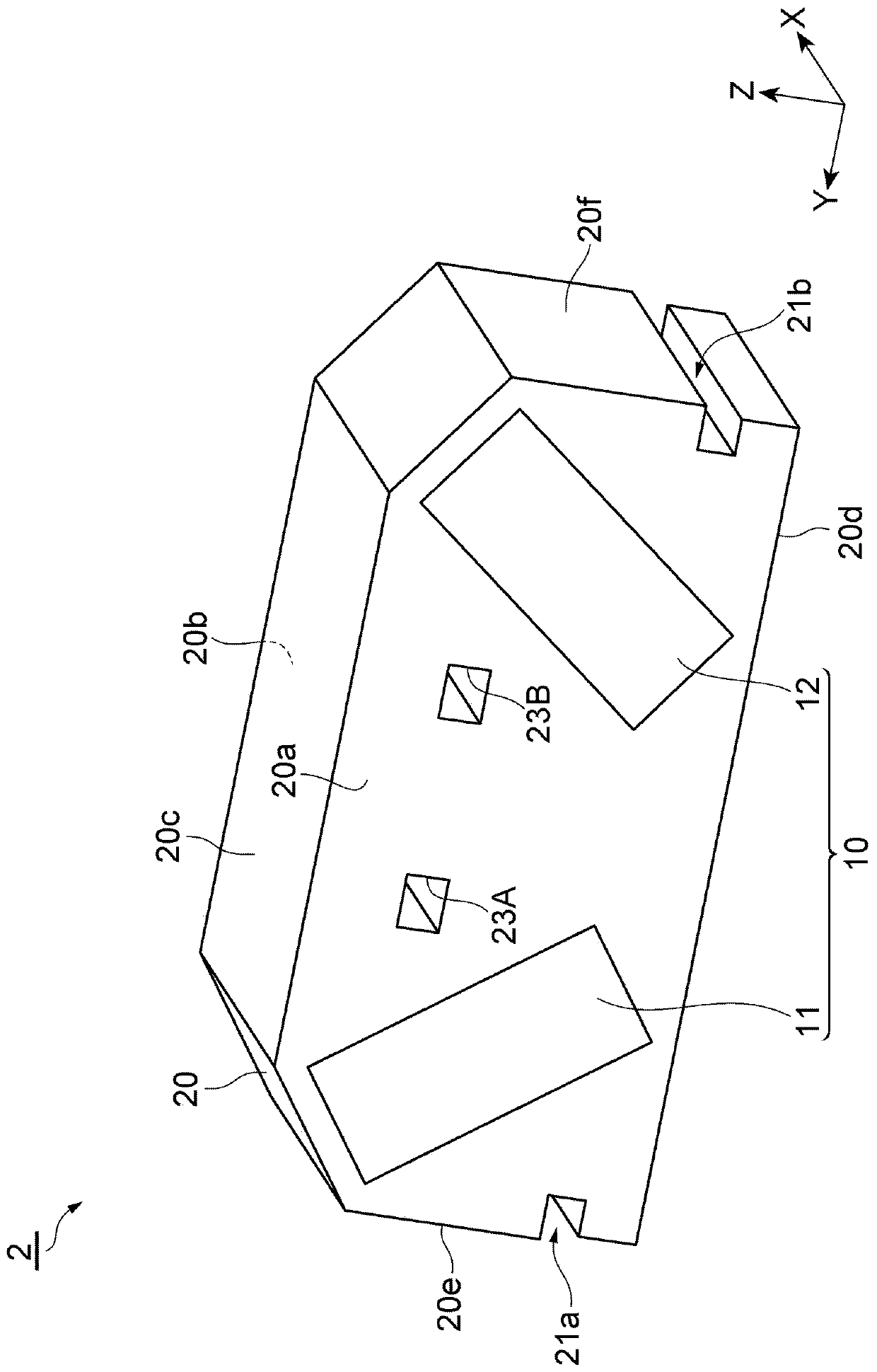

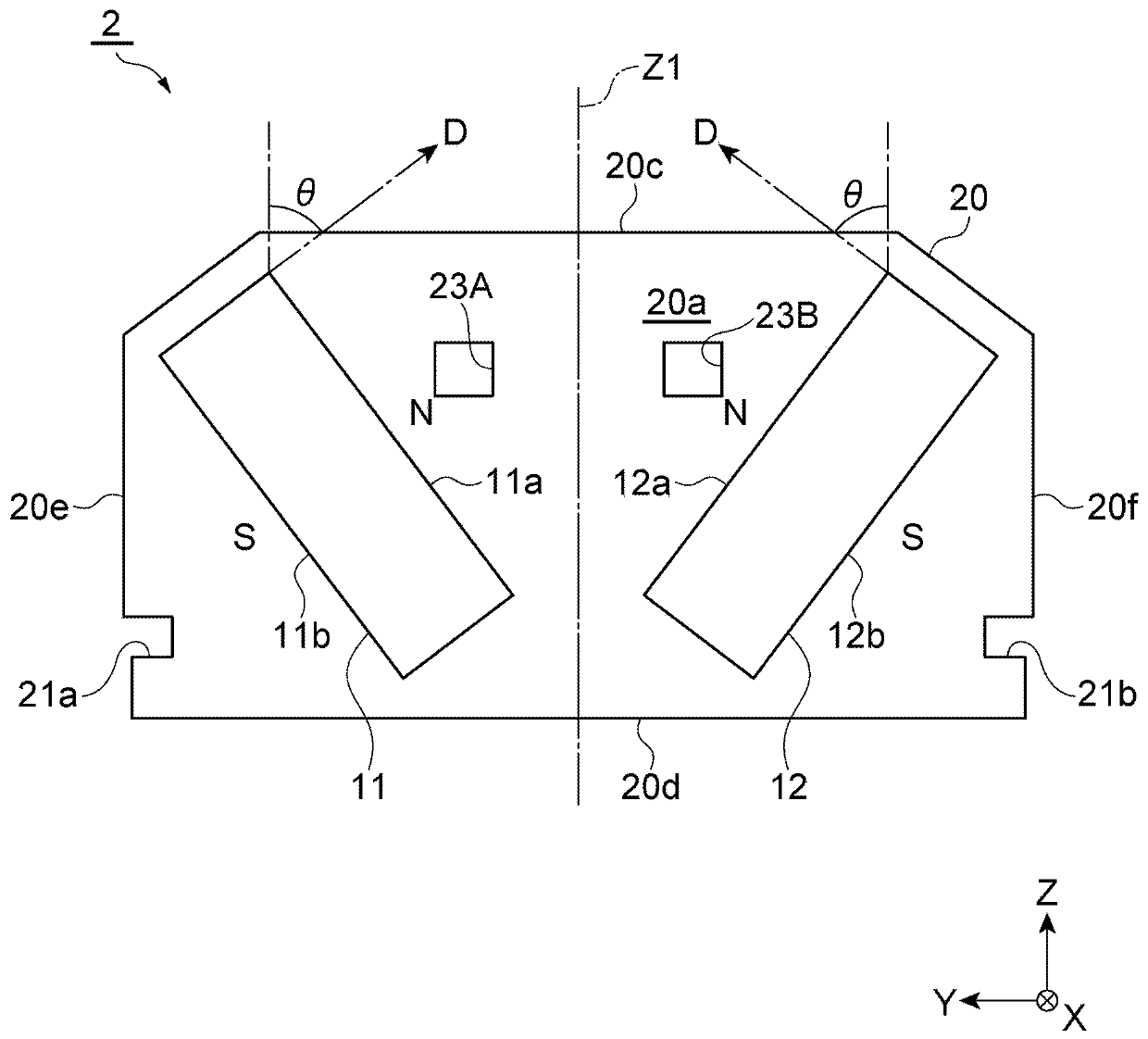

Magnet structure, method for manufacturing magnet structure, and method for manufacturing rotating electrical machine

InactiveCN110829758AAchieve magnetizationImplement the manufacturing methodMagnetic bodiesManufacturing stator/rotor bodiesElectric machineryMagnet

The invention provides a magnet structure which is easy to magnetize, a method for manufacturing the magnet structure, and a method for manufacturing a rotating electrical machine. In the magnet structure and the manufacturing method thereof according to the present disclosure, the magnet structure has a structure provided with a plurality of magnet structure members, and the plurality of stackedmagnet structure members are restrained by a restraint. In this magnet structure, a plurality of magnet structure members can be magnetized by a magnetization step. In the magnetization step, the object to be magnetized is a magnet structure member that is smaller than the entire magnet structure. Therefore, a magnetizing device that is smaller than a magnetizing device that magnetizes the entiremagnet structure can be used, and the magnetization of the magnet structure can be performed more easily.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com