Lens, near-infrared ray absorption glass lot and manufacturing method therefore

A near-infrared ray and manufacturing method technology, applied in glass manufacturing equipment, glass pressing, manufacturing tools, etc., can solve the problems of insufficient lens performance and inability to use aspheric lens performance, etc., and achieve excellent imaging performance and color sensitivity correction function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0150] Example 1-1 (manufacturing example of a near-infrared-absorbing glass batch)

[0151] First, using fluoride, metaphosphorus compound, and oxide as glass raw materials, the raw materials were weighed into A and B glasses each having the composition shown in Table 1, and mixed thoroughly. After that, the mixed raw material was charged into a platinum crucible sealed with a lid, and heated and melted in an electric furnace at a temperature ranging from 790 to 850° C. under a dry nitrogen atmosphere under stirring. In the platinum crucible, dry nitrogen gas having a dew point of -30°C or less was always flowed, and the gas kept in the crucible for a constant time or longer was exhausted to continuously replace the atmosphere. The evacuated gas is filtered for purification and discharged to the outside.

[0152] While replacing the atmosphere, the molten glass in this state is clarified and homogenized so that the resulting molten glass flows continuously from a temperature...

Embodiment 1-2

[0168] Example 1-2 (manufacturing example of an optical element)

[0169] Next, the round rod glass obtained in Example 1-1 was vertically cut into a longer direction, ground and polished to prepare spherical lenses or prisms.

[0170] Subsequently, the round rod glass obtained in Example 1-1 was vertically cut into a longer direction, ground and polished to prepare a precision compression molding preform.

[0171]Then, the mold is changed to form sheet glass from the molten glass. Subsequently, the sheet glass is slowly cooled, cut, ground and polished to produce optical elements such as spherical lenses or prisms. In addition, sheet glass is cut, ground, and polished to produce precision compression molded preforms.

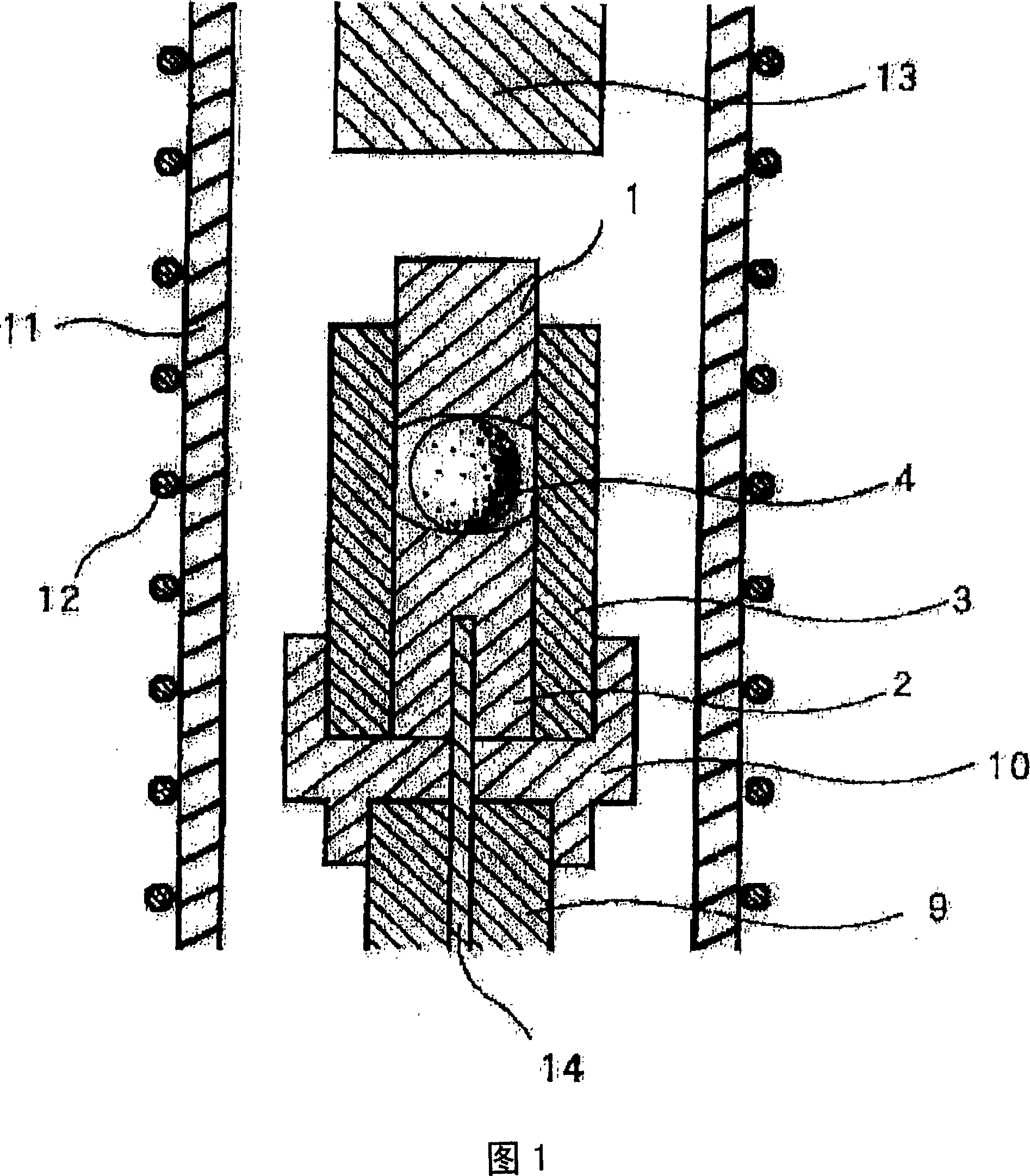

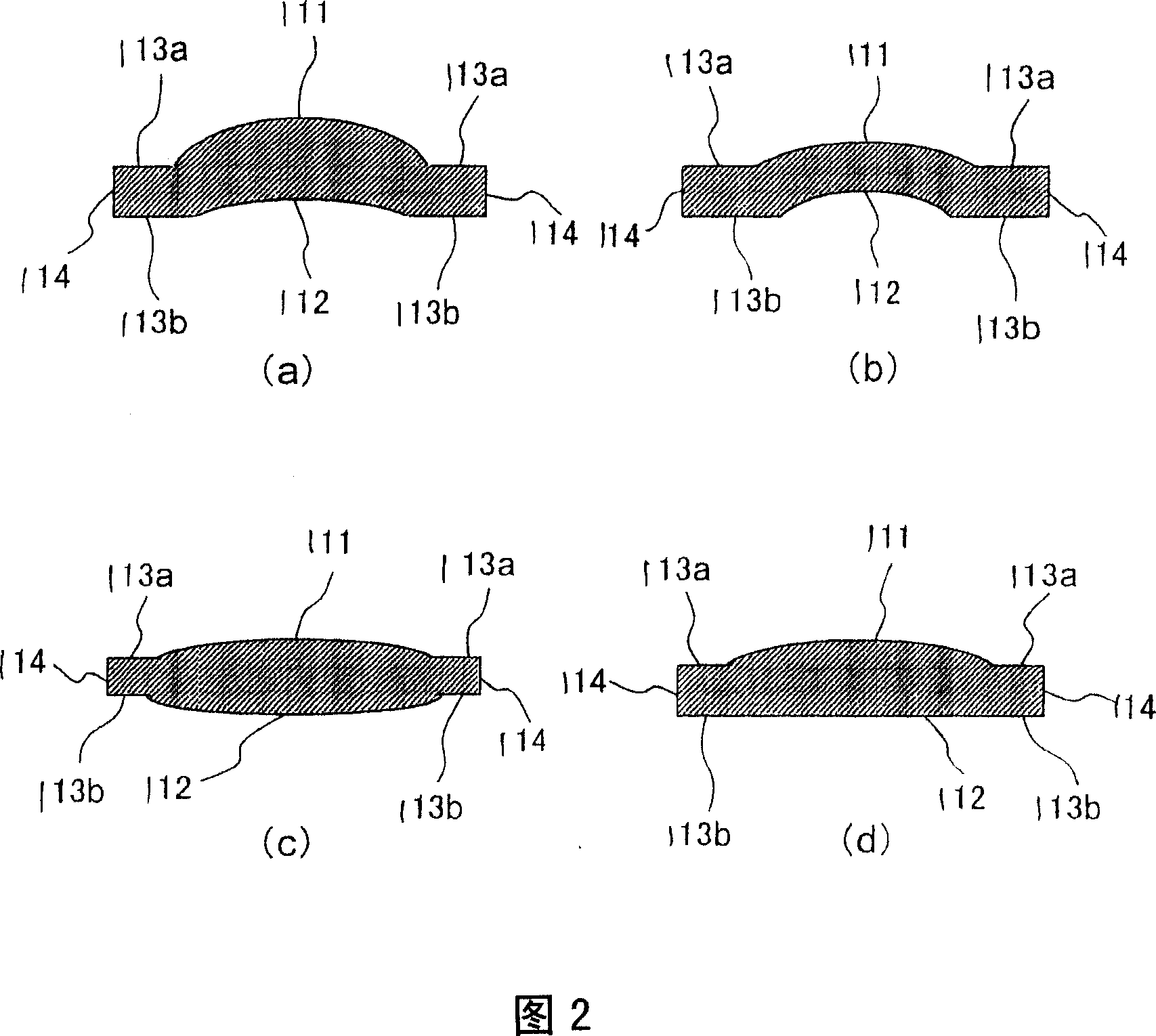

[0172] The preform thus obtained was subjected to precision compression molding using an extruder shown in FIG. 1 to obtain an aspheric lens. Specifically, after the preform 4 is placed between the lower mold 2 and the upper mold 1 of the compression mold fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com