Mounting substrate, and method for manufacturing thin light-emitting device using same

A technology for mounting substrates and manufacturing methods, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as hindering stability, burrs, short circuits, etc., and achieve the effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

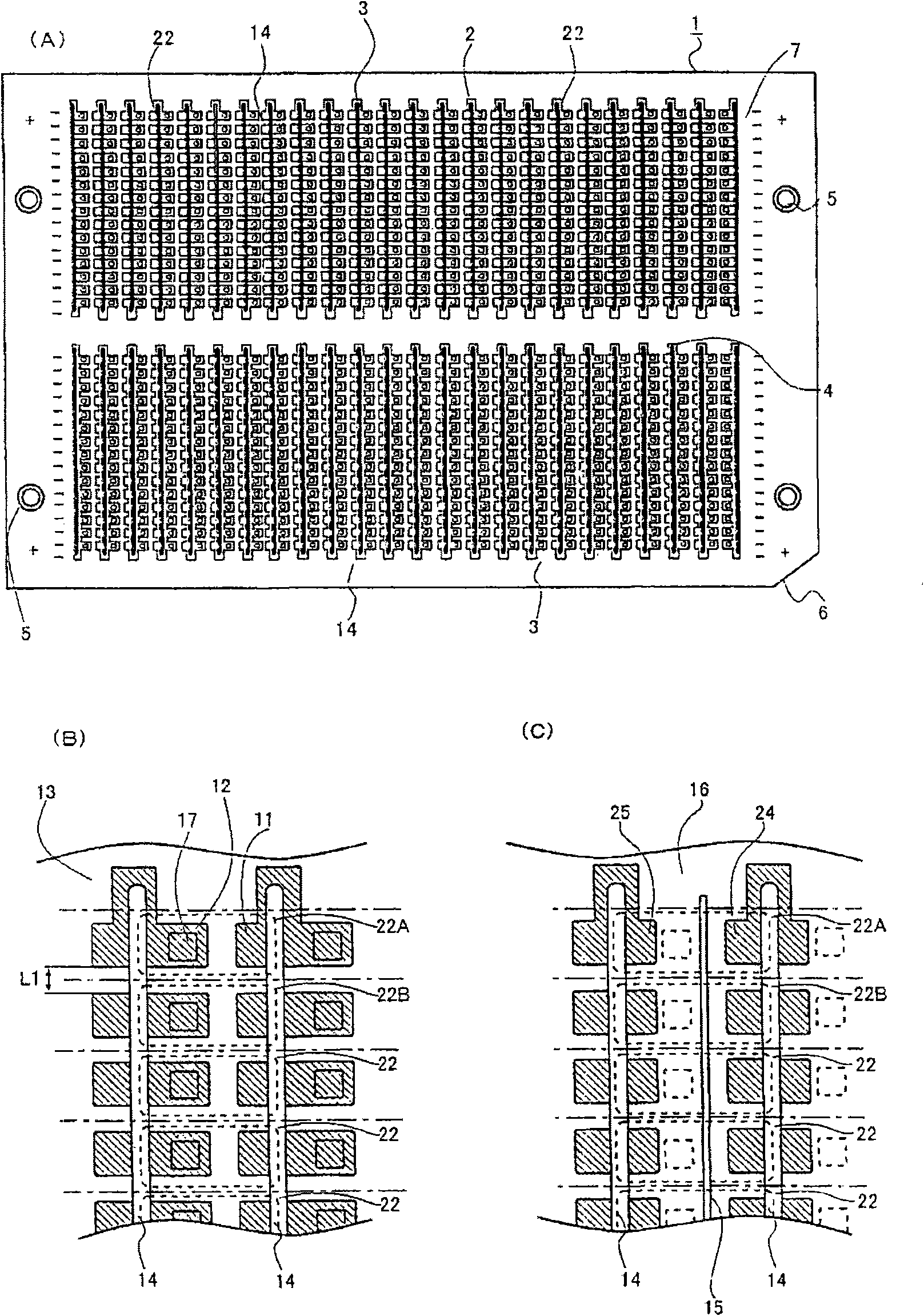

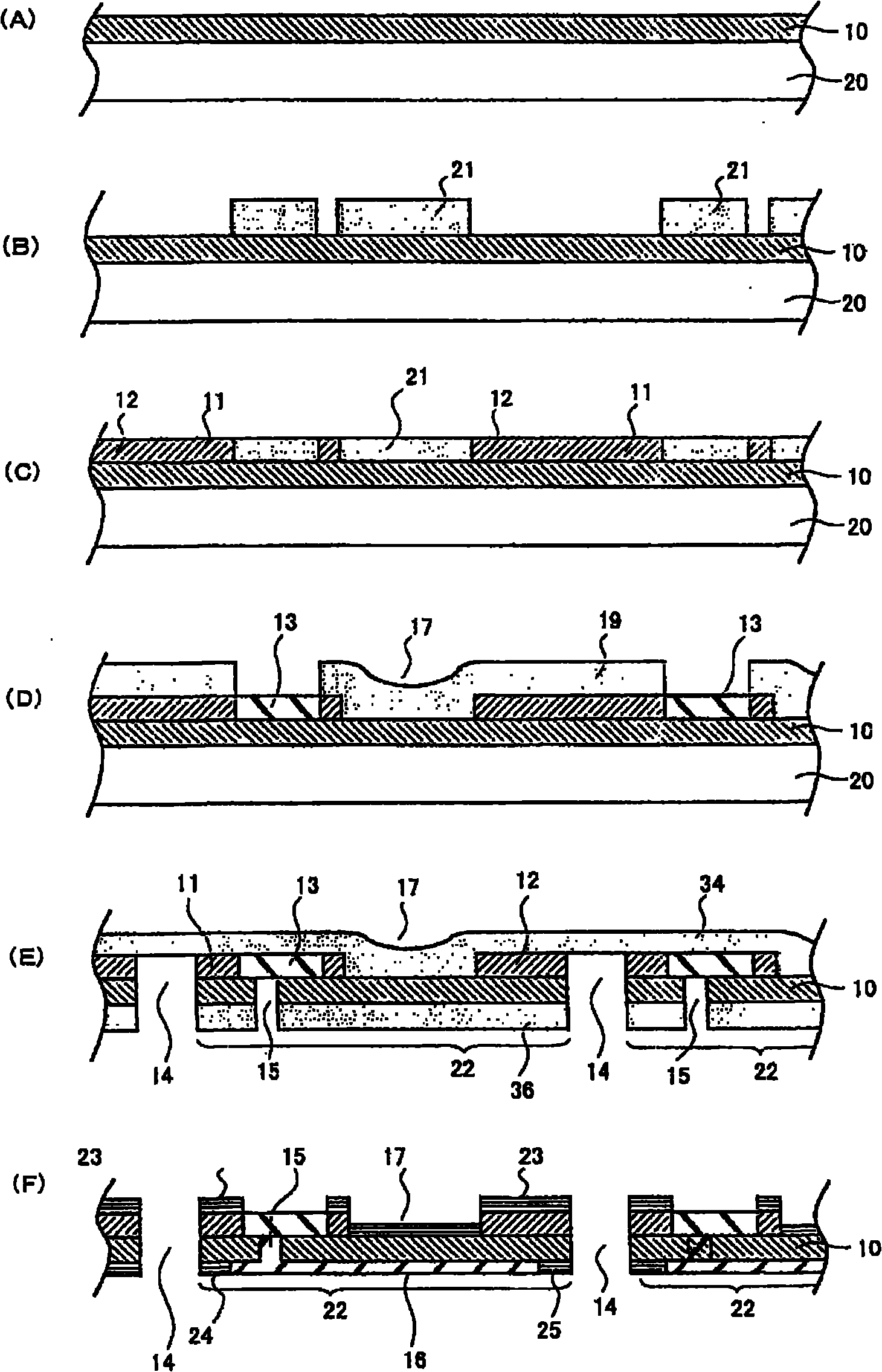

[0040] Below, refer to Figure 1 to Figure 6 Embodiments of the present invention will be described.

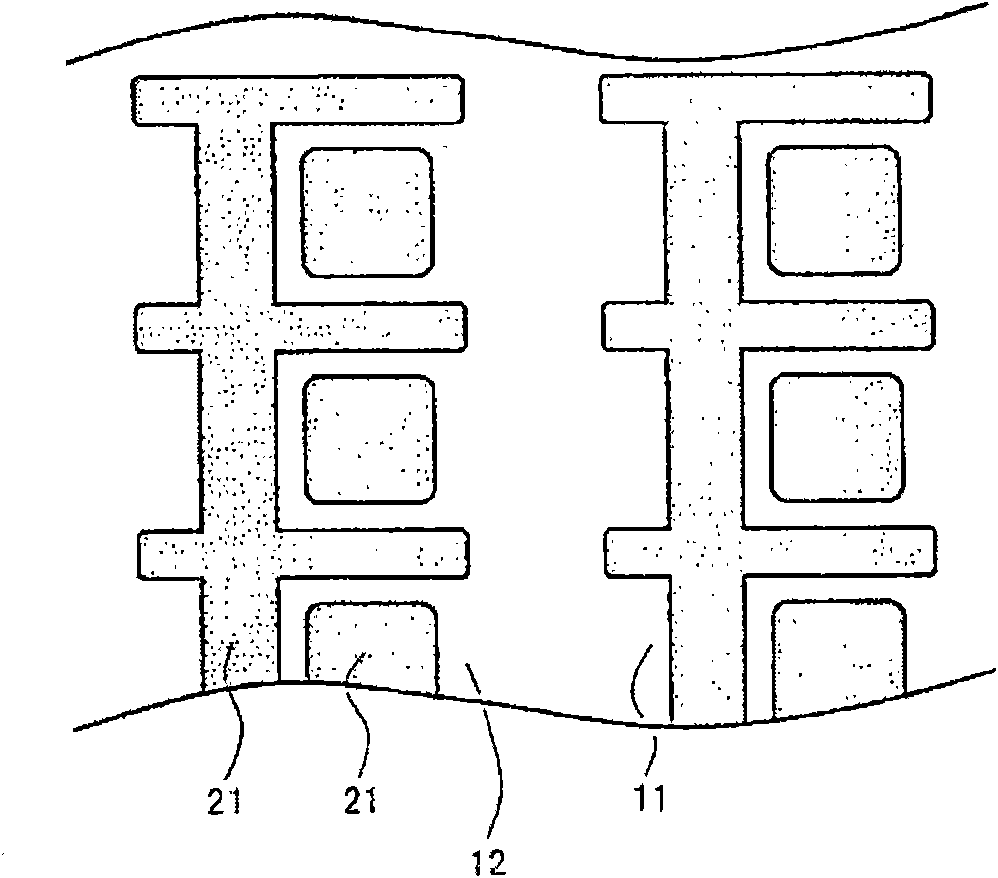

[0041] first, figure 1 Shows the mounting substrate of the present invention. figure 1 (A) is a plan view, figure 1 (B) is an enlarged view of the surface, figure 1 (C) is an enlarged view of the back side.

[0042] The mounting substrate 1 of this embodiment is composed of a conductive foil 10 , a first electrode portion 11 , a second electrode portion 12 , a liquid resin 13 , a separation slit 14 , an insulation slit 15 , and a solder resist layer 16 .

[0043] As the conductive foil 10 , a metal that can be etched and electrolytically plated is selected. In this embodiment, metal foil made of copper is used. Copper foils with extremely thin thicknesses such as 9 μm, 12 μm, 18 μm, and 35 μm are selected. This is because copper foils constitute the mounting substrate of thin light-emitting devices, so it is better to choose copper foils as thin as possible. If the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com