Reactive leveling agent and its preparation method and application

A leveling agent, reactive technology, applied in the preparation of the above reactive leveling agents, the field of reactive leveling agents, can solve the problems of difficulty in meeting, reduced dye utilization, poor leveling effect, etc., to improve the overall Leveling effect, improvement of color difference between inner and outer layers, and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

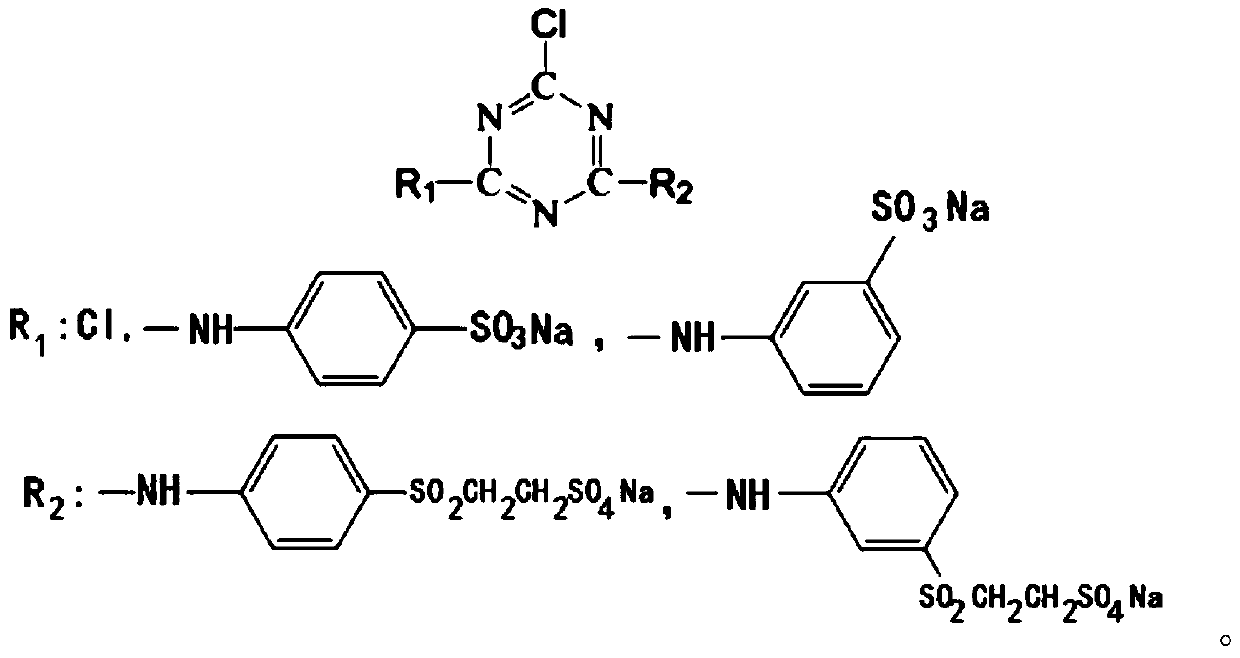

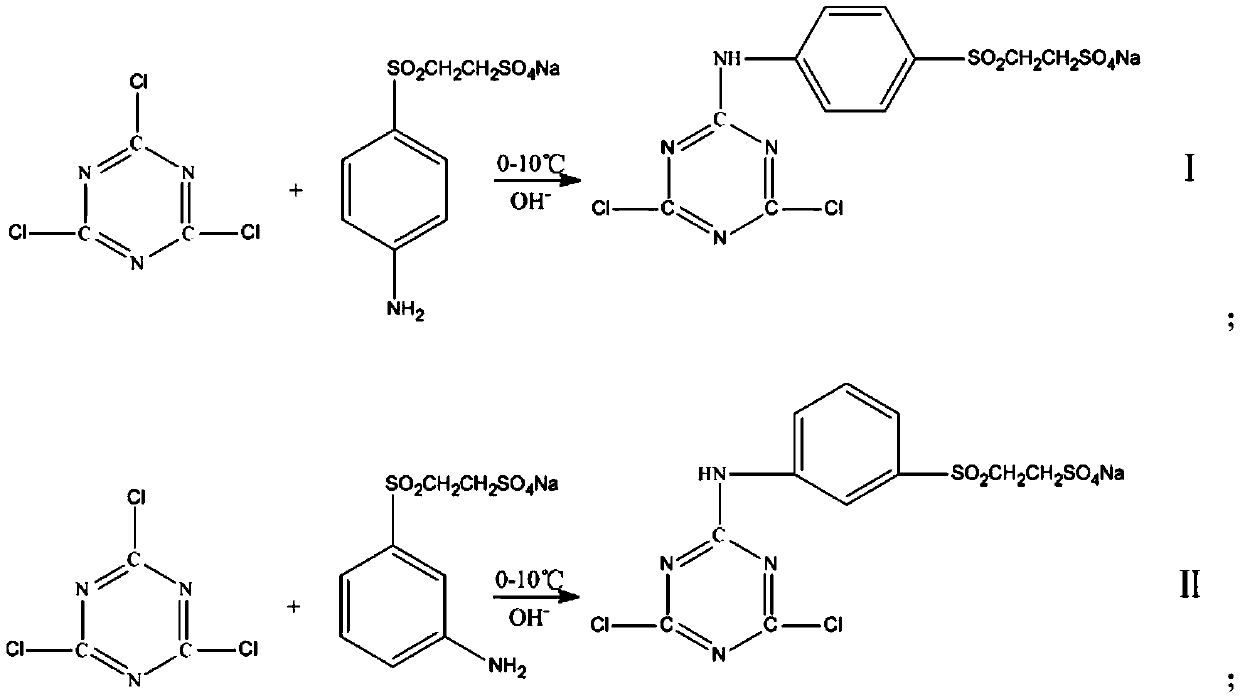

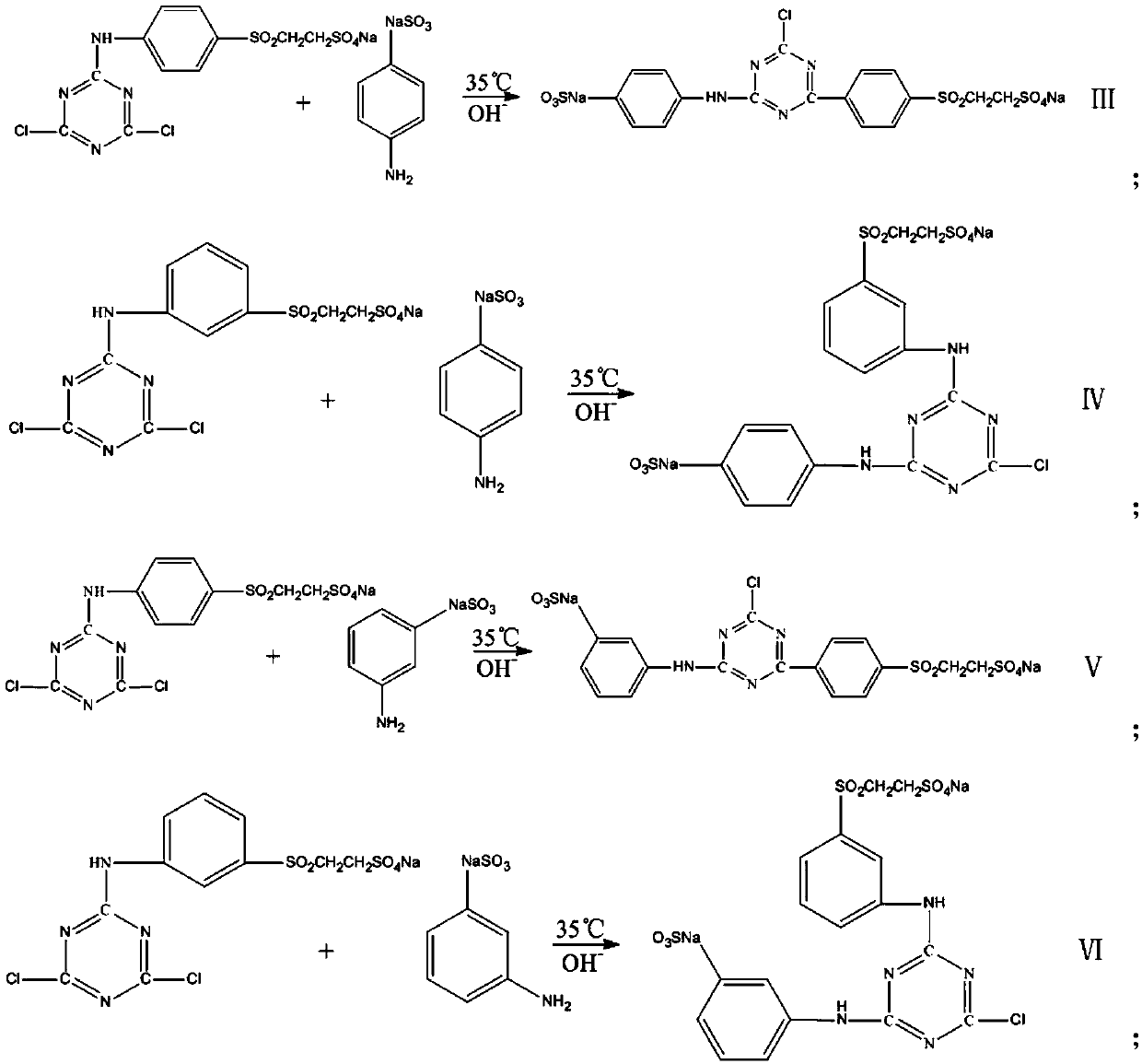

[0061] The preparation method of reactive leveling agent of the present invention specifically implements according to the following steps:

[0062] Step 1, synthesizing multi-active group leveling agent, specifically implement according to the following steps:

[0063] Step 1.1, weigh the following materials respectively by mass percentage:

[0064] Cyanuric chloride 4.0% ~ 8.0%, (β-sulfate ethyl sulfone) aniline 6.0% ~ 12.0%, sodium sulfanilate 0 ~ 8.0%, sodium carbonate 2.2% ~ 8.5%, purified water 15.0% ~ 52.8 %, ice cubes 30.0% to 40.0%, sodium chloride 5.0% to 8.0%, the total content of the above components is 100%;

[0065] In the above formula: (β-sulfate ethyl sulfone) aniline is p-(β-sulfate ethyl sulfone) aniline (referred to as p-ester) or m-(β-sulfate ethyl sulfone) aniline (abbreviated as m-ester) ); sodium sulfanil is sodium p-aminobenzenesulfonate or sodium m-aminobenzenesulfonate;

[0066] Step 1.2, first divide the ice cubes weighed in step 1.1 into two equ...

Embodiment 1

[0111] (1) Reactive leveling agent, composed of the following raw materials by mass percentage: multi-active group leveling agent 20.0%, water 20.0%, sodium dihydrogen phosphate 5.0%, disodium hydrogen phosphate 5.0%, sodium chloride 50.0%, The total content of the above components is 100%;

[0112] (2) The preparation method of reactive leveling agent is as follows:

[0113] (a) Synthesis of multi-active group leveling agent: take the following raw materials respectively by mass percentage: 4.0% cyanuric chloride, 6.0% to (beta-sulfuric acid ester ethyl sulfone) aniline, 0.5% sodium p-aminobenzenesulfonate , sodium carbonate 3.0%, purified water 51.5%, ice cubes 30.0%, sodium chloride 5.0%, the total content of the above components is 100%;

[0114] First divide the weighed ice cubes into two parts, then pour the weighed cyanuric chloride, purified water and a part of ice cubes into the stirring device for mixing. The stirring time is 8 minutes to obtain the mixed material A...

Embodiment 2

[0125] (1) Reactive leveling agent, made up of the following raw materials by mass percentage: 30.0% of multi-active group leveling agent, 30.0% of water, 8.0% of potassium dihydrogen phosphate, 7.0% of dipotassium hydrogen phosphate, 25.0% of sodium chloride, The total content of the above components is 100%;

[0126] (2) The preparation method of reactive leveling agent is as follows:

[0127] (a) Synthesis of multi-active group leveling agent: take the following raw materials respectively by mass percentage: 7.0% cyanuric chloride, 9.6% m-(β-sulfuric acid ester ethyl sulfone) aniline, 3% sodium p-aminobenzenesulfonate , sodium carbonate 5.0%, purified water 33.4%, ice cubes 35.0%, sodium chloride 7.0%, the total content of the above components is 100%;

[0128] First divide the weighed ice cubes into two equal parts, then pour the weighed cyanuric chloride, purified water and a part of ice cubes into the stirring device for mixing. The stirring time is 9 minutes to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com