Patents

Literature

31results about How to "Save water for dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

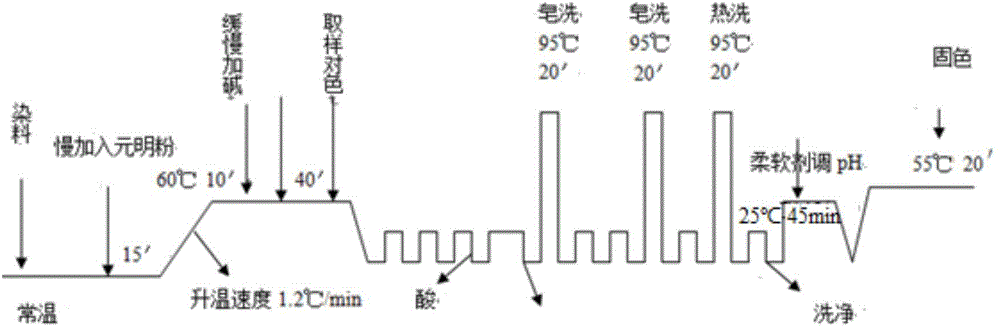

Reactive dye ecological dyeing method of silk fabrics

InactiveCN102767099ASave water for dyeingEasy to operateDyeing processSodium bicarbonateSodium Bicarbonate Solution

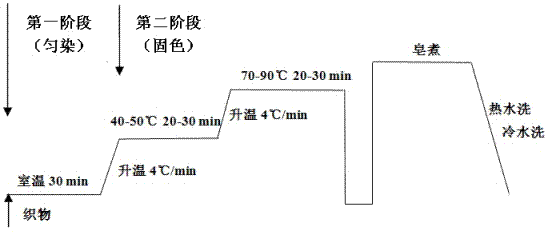

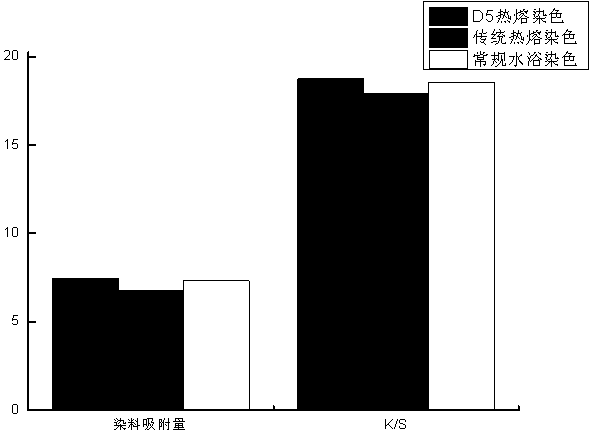

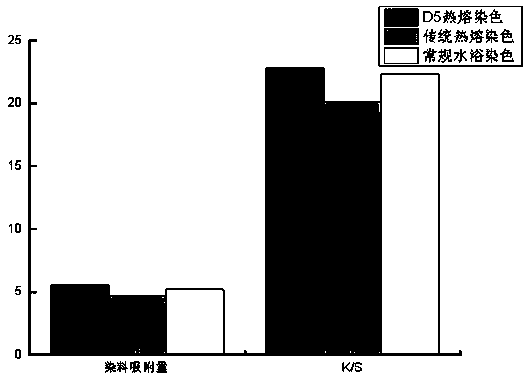

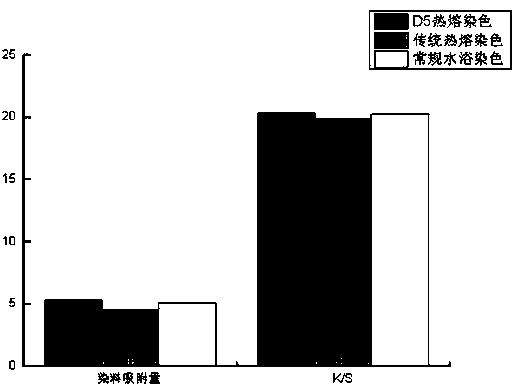

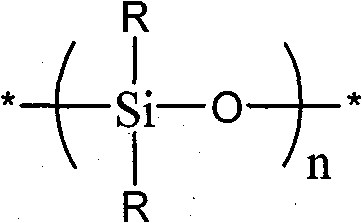

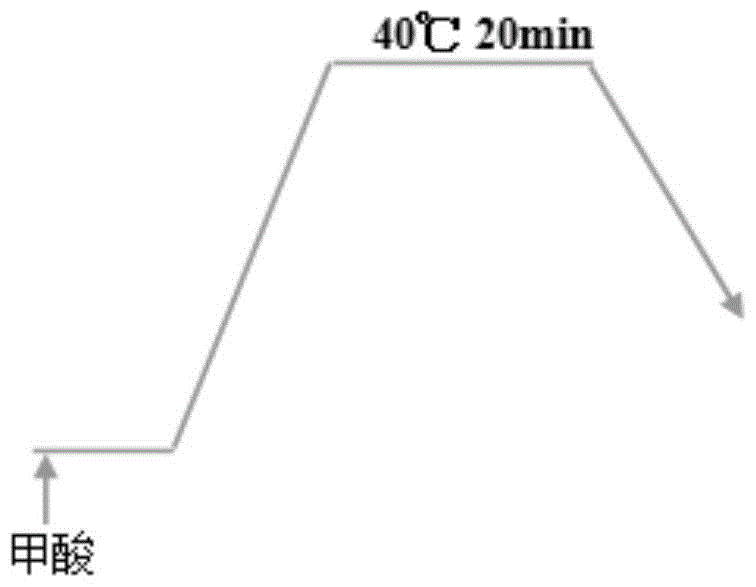

The invention provides a reactive dye ecological dyeing method of silk fabrics, which comprises the following steps of: (1) even dyeing: using reactive dye and decamethyl cyclopenta siloxane (D5) according to the mass ratio of 1:10 to 50 to prepare a reactive dye / D5 suspending dispersed liquid; padding the silk fabrics in 30 to 90 g / l of sodium bicarbonate solution; and dyeing the silk fabrics in the reactive dye / D5 suspending dispersed liquid with the rolling liquid rate of 160 to 200% at room temperature for 25 to 35 minutes, wherein the rolling liquid rate is used for ensuring even dyeing of the silk fabrics; and (2) color fixing: heating a mixture system obtained from the step (1) to 40 to 50 DEG C, and keeping the temperature for 20 to 30 minutes; then heating to 70 to 90 DEG C, and keeping the temperature for 20 to 30 minutes; and taking the silk fabrics out, and performing soap boiling. In the process of dyeing provided by the invention, an electrolyte is not added for dyeing acceleration, the dyeing rate of the dye is close to 100%, the fixing rate is higher than that of traditional bath dyeing, and the fastness of the fabrics is good after dyeing. Because the electrolyte is not needed for dyeing acceleration, the burden of treating dyeing waste water is effectively reduced, and the ecological environment is protected.

Owner:ZHEJIANG SCI-TECH UNIV

Thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as medium

InactiveCN104278576ASave water for dyeingReduce sublimationDyeing processDisperse dyeEcological environment

The invention discloses a disperse dye thermosol dyeing method taking decamethylcyclopentasiloxane (D5) as a medium. The method comprises the following steps: (1) pretreating polyester fabric; (2) adding a certain amount of pure disperse dyes into a dyeing medium D5, controlling the amount of the dyeing medium D5, so that a ratio of the weight of a to-be-dyed fabric to the weight of the medium D5 is 1:10 to 1:30, dyeing in a dyeing machine, heating the system to 90-100 DEG C, preserving the temperature for 5-10 minutes, heating to the temperature of 180-200 DEG C, and performing thermosol fixation, wherein the fixation time is 10-30 minutes; and (3) performing reduction clearing on the dyed fabric according to a GB2394-80 method after dyeing. According to the method, non-aqueous medium dyeing is adopted, lots of water resources are saved, the thermosol temperature can be obtained under normal pressure, the conventional dyeing equipment can be adopted, the operation is simple, pure disperse dyes are adopted for dyeing, lots of dispersing aids are saved, the utilization rate of the dyes is improved, wastewater emission is reduced, and ecological environment protection is facilitated.

Owner:ZHEJIANG SCI-TECH UNIV

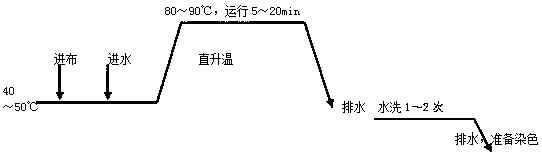

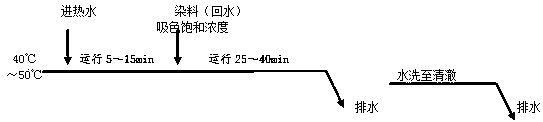

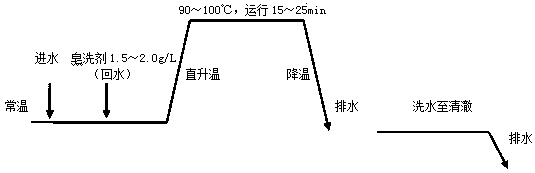

Wash-free dyeing method for silk

ActiveCN101275365AReduce consumptionEmission reductionHeating/cooling textile fabricsDyeing processWater savingSewage

The invention relates to a textiles dyeing method, especially to a silk facing material dyeing method. The object of the invention is to provide an improved method for silk dyeing. The invention has features of waterless or little water dyeing, reduced cost, reduced sewage water discharging and good products color fastness; the products hand feeling maintains the silk facing material special styles; and the invention is water-saving and energy-saving. The invention adopts the technical scheme: executing according to the following steps in sequence: preparing dye liquor, dyeing, pre baking, decatizing, soft liquid slop padding, drying and finishing.

Owner:杭州喜得宝集团有限公司

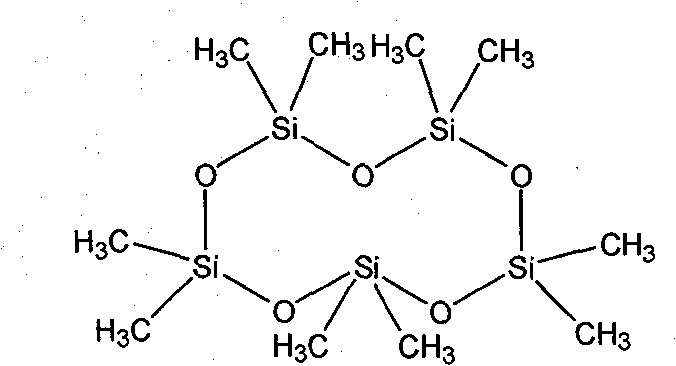

Dyeing method of disperse dyestuff with special methylsiloxane as medium

InactiveCN103074781ASave water for dyeingHarmless to healthDyeing processDisperse dyePulp and paper industry

The invention relates to a waterless dyeing method of a disperse dyestuff for a textile and discloses a dyeing method of a disperse dyestuff with special methylsiloxane as a medium. The method comprises the following steps: (1) refining a terylene fabric; (2) adding a pure disperse dyestuff into a dyeing medium according to dyeing requirements, controlling the usage amount of the dyeing medium to allow a ratio (a bath ratio) of the weight of a to-be-dyed fabric to the total amount of the medium to be 1:5-20, carrying out insulation at a temperature of 60 DEG C for 20 min under stirring, adding the to-be-dyed fabric and a certain amount of water and carrying out dyeing in a dyeing machine; and (3) removing the unfixed dye on the surface of the fabric after dyeing: a step of drying the dyed fabric and carrying out reduction and cleaning according to a method prescribed in GB2394-80. According to the invention, the pure disperse dyestuff is used for dyeing of terylene; a good dyeing effect is obtained, cost is saved, and dyeing procedures and discharge of waste water are reduced.

Owner:ZHEJIANG SCI-TECH UNIV

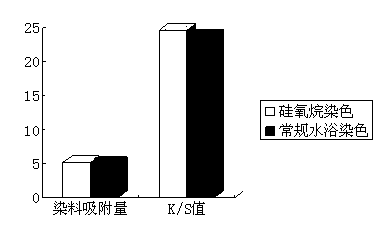

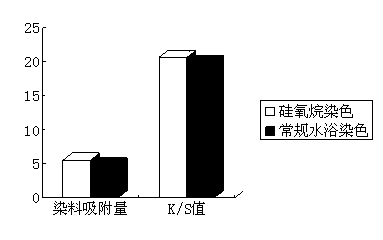

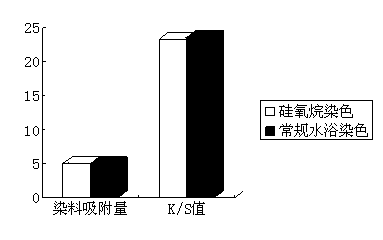

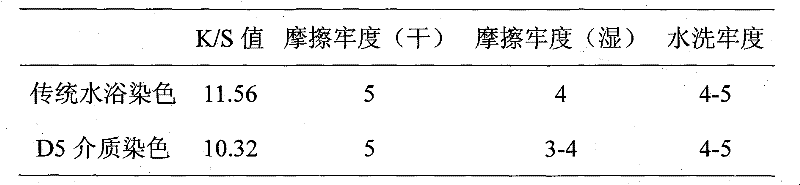

New dyeing method of active dye taking methylsiloxane as medium

The invention discloses a new dyeing method of an active dye taking methylsiloxane as a medium. In the invention, a non-aqueous medium is adopted, which can rapidly close to a fiber surface under the condition of not adding electrolyte for accelerating dye completely, thereby obviously improving adsorption rate and equilibrium adsorption capacity of the active dye, improving fixation rate of the dyeing, completely avoiding the problems of environment and zoology caused by using a large number of inorganic salts, and realizing salt-free dyeing of the active dye in a real meaning. The medium adopted by the invention can be used repeatedly, thereby reducing environmental pollution.

Owner:ZHEJIANG SCI-TECH UNIV +1

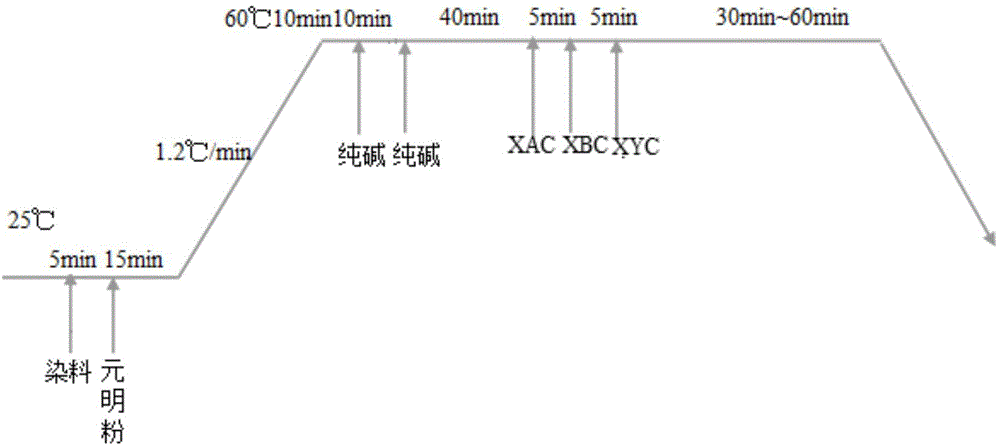

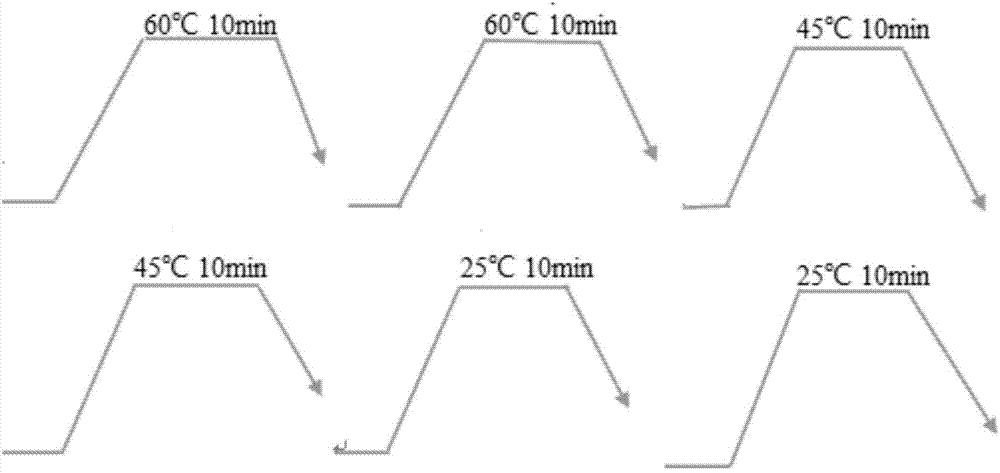

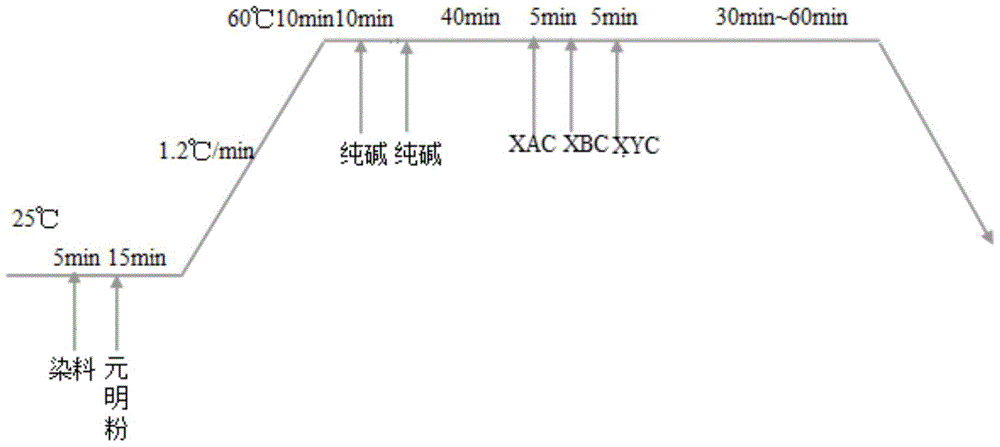

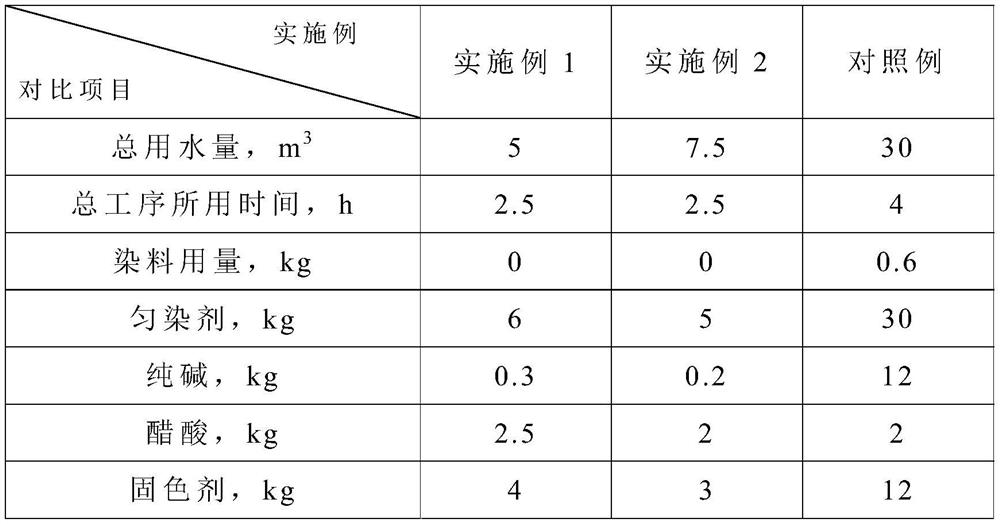

Cellulosic fiber in-situ mineralization deep water-saving and emission reduction dyeing aftertreatment method and additive

The invention discloses a cellulosic fiber in-situ mineralization deep water-saving and emission reduction dyeing aftertreatment method which comprises the following steps: firstly, putting a fabric to be dyed into dyeing equipment, adding dyeing water into the dyeing equipment, and keeping circulation of a dye bath; performing dyeing processing on the fabric to be dyed by using a common deying method for the cellulosic fiber, and after dyeing is completed, retaining the residual dyeing liquid; further simultaneously performing in-situ mineralization treatment on the residual dyeing liquid obtained after cellulosic fiber dyeing processing and the dyed fabric by using cellulosic fiber aftertreatment additives XAC, XBC and XYC; storing the residual dyeing liquid obtained after the mineralization treatment as later dyeing water; dehydrating and drying the dyed fabric, thereby completing dyeing and aftertreatment on the fabric. The invention further discloses the cellulosic fiber dyeing aftertreatment additives XAC, XBC and XYC. By adopting the dyeing aftertreatment method disclosed by the invention, the water consumption problem and the wastewater discharge problem in the cellulosic fiber dyeing processing can be fundamentally solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Viscose color-gorgeous blended blocky gray plus material and preparation method

InactiveCN108385259AQuality improvementImprove operational efficiencyWeft knittingDyeing processYarnTextile manufacturing

The invention discloses a viscose color-gorgeous blended blocky gray plus material and a preparation method, and belongs to the technical field of textile manufacturing. A common viscose fiber and a modified color-quick-absorption viscose fiber (namely a color-gorgeous fiber) are blended into mixed yarn according to a certain proportion; afterwards, the mixed yarn is woven into the blocky gray plus material through a circular knitting machine. The blocky gray plus material is according to the principles that the color-gorgeous fiber can quickly absorb dye in a condition that dyeing auxiliariesof an alkali and a salt, and the like, are not added and dyeing liquor on the common viscose fiber needs to be removed through soaping, so as to form the blocky gray plus material; the principle is reasonable in design; the plus material is gorgeous in color, and is moisture-absorption and sweat-permeable; the process flow and the processing difficulty are greatly shortened and decreased; the useof the alkali and the salt is reduced, and the blocky gray plus material is more environmentally friendly.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

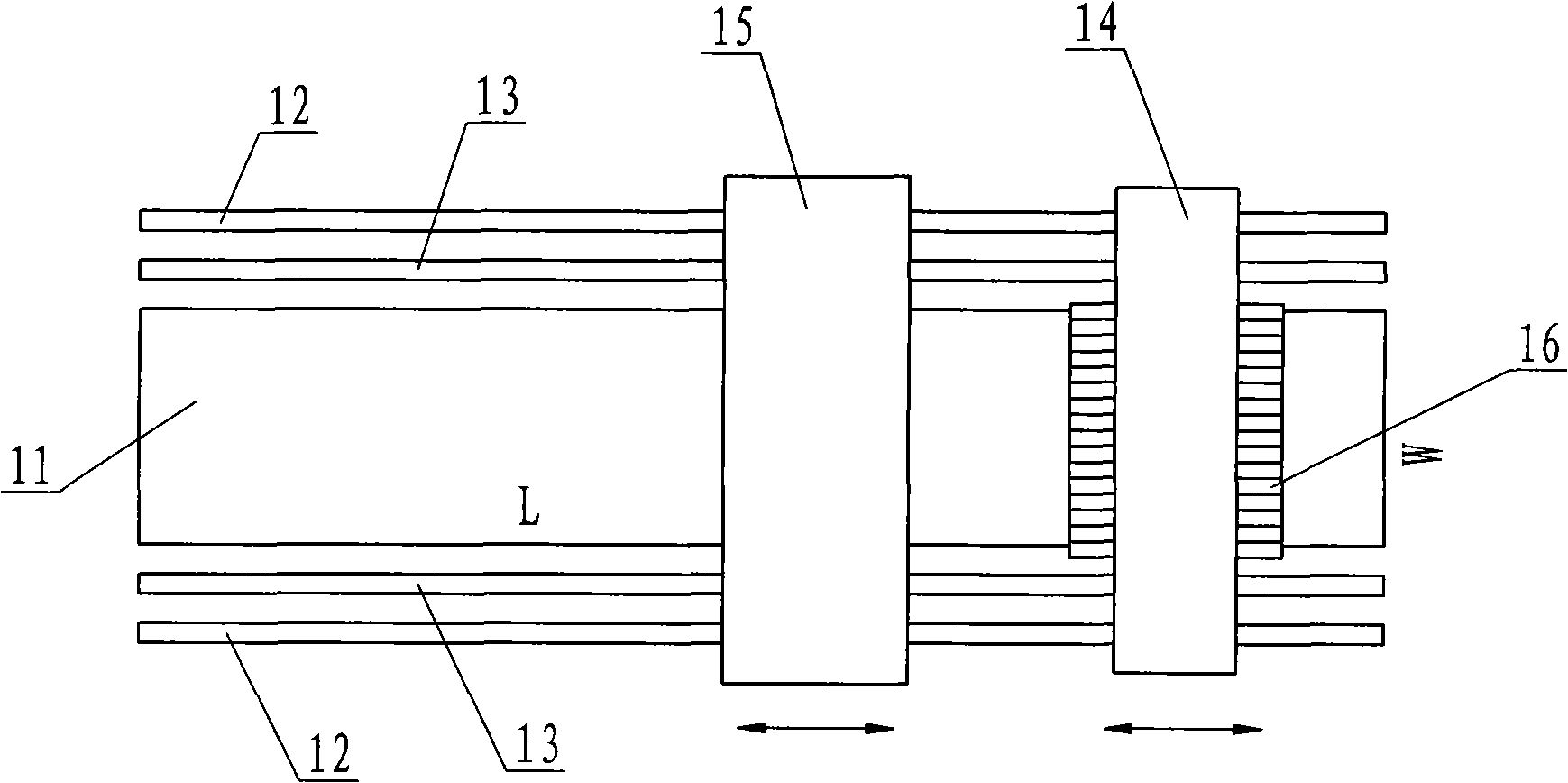

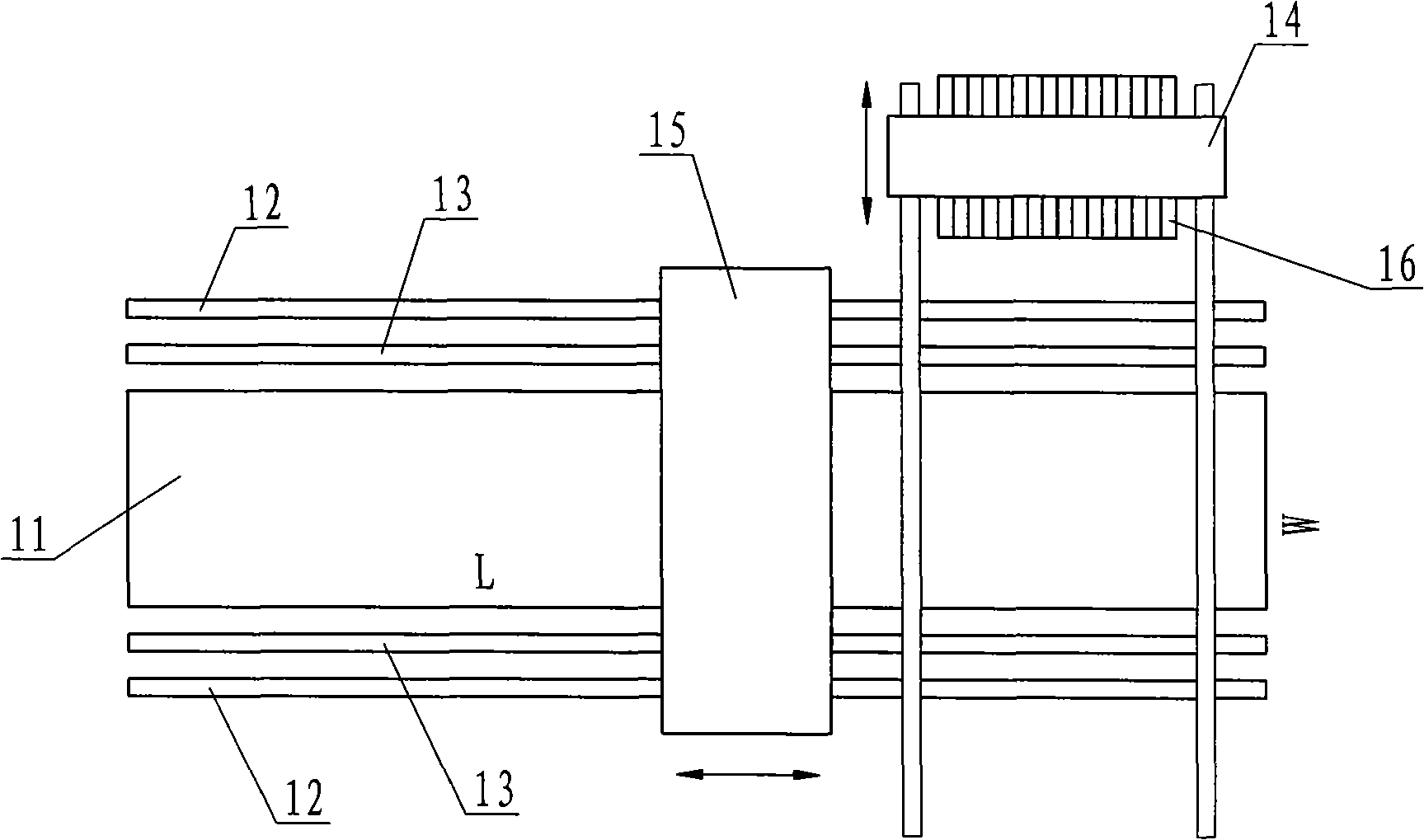

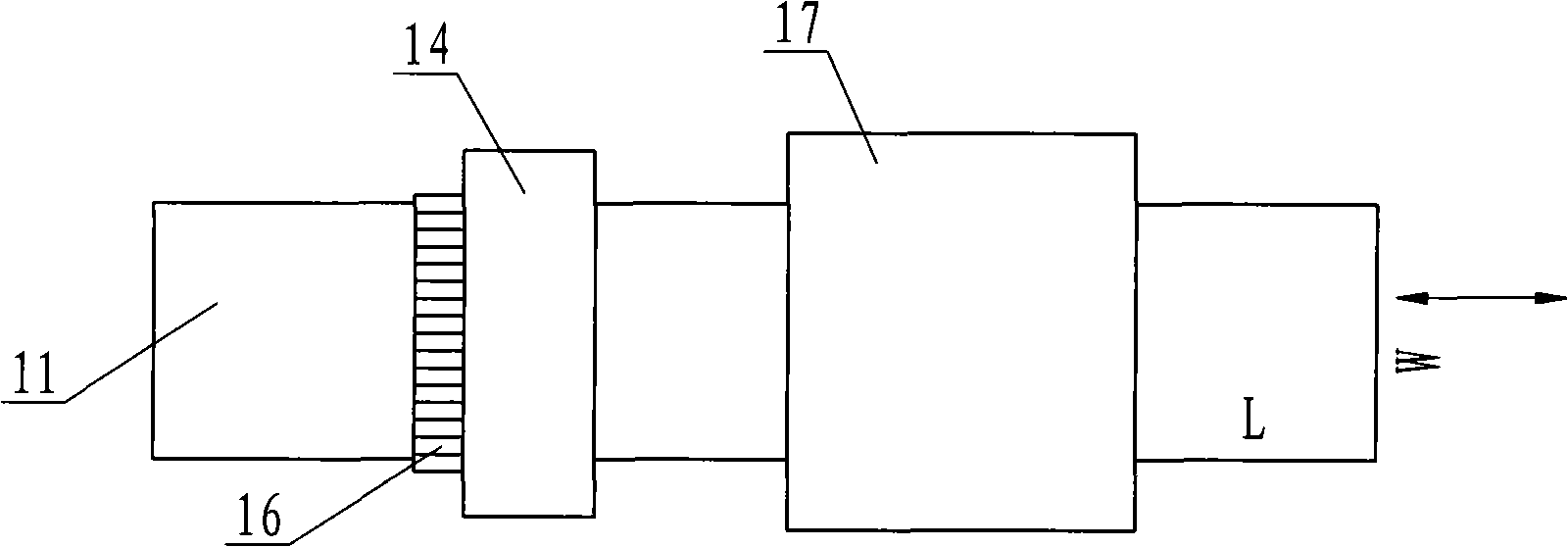

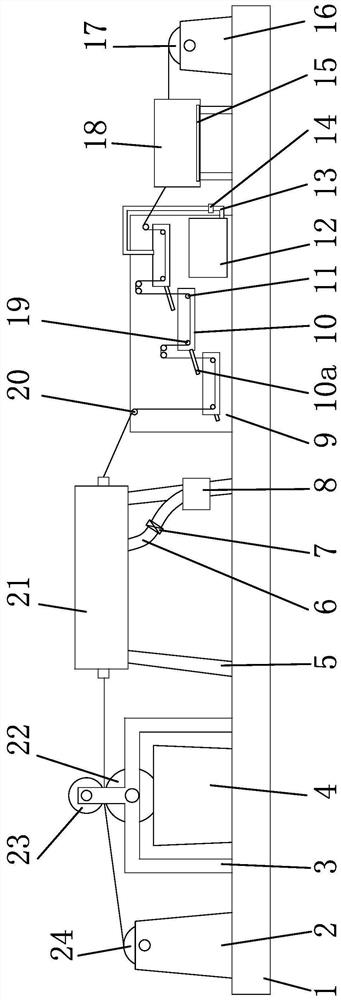

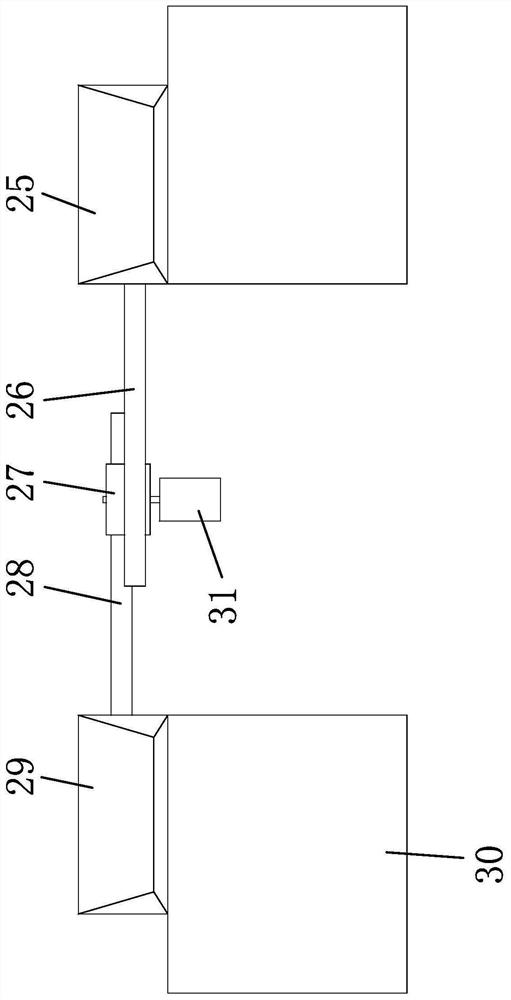

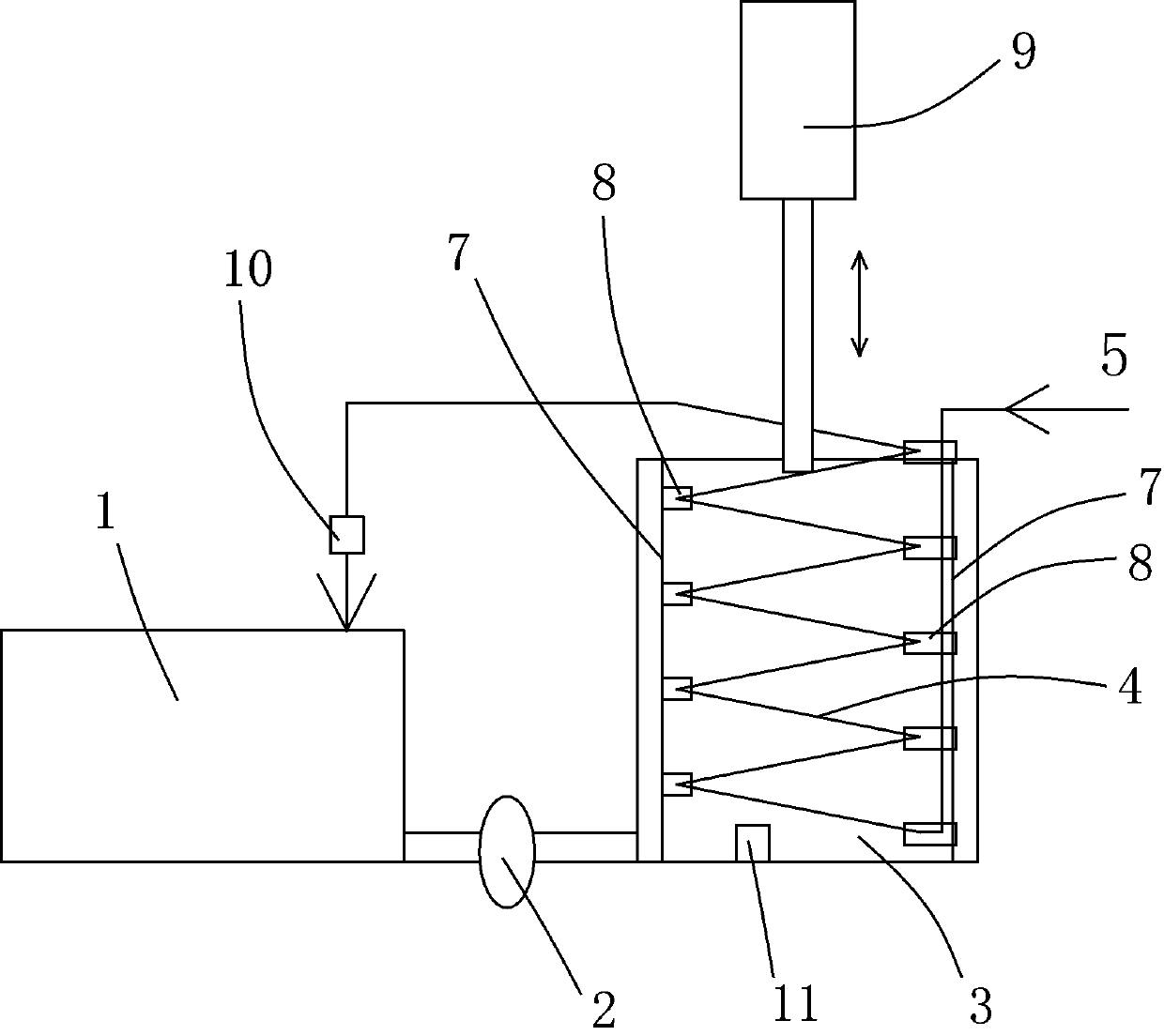

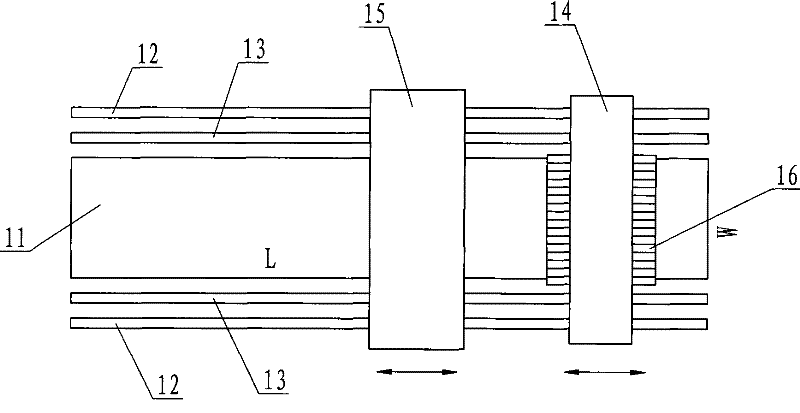

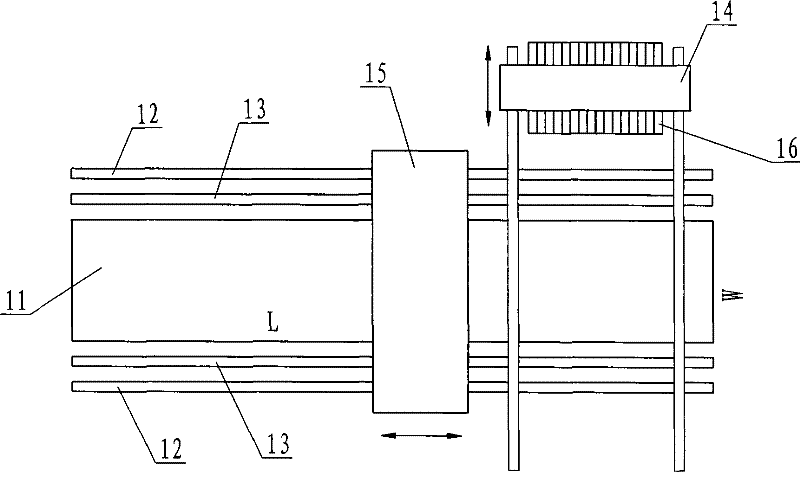

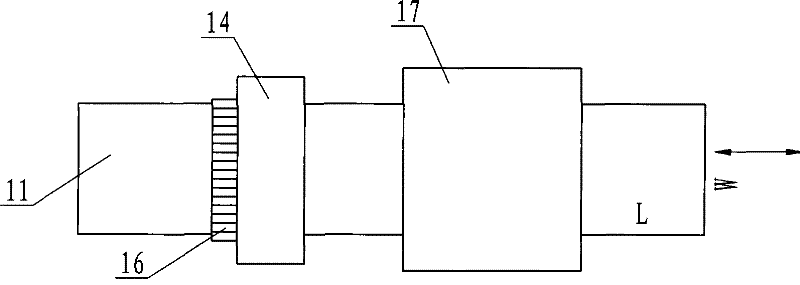

Gradually dyeing novel process for fabric and employed dyeing apparatus

ActiveCN101492866AEmission reductionSave water for dyeingTextile treatment machine partsTextile treatment by spraying/projectingEngineeringDyeing

The invention discloses a fabric gradual color dyeing technique and an employed coloration device thereof. The present gradual color dyeing method can only dye the gradual color of one color at a time and can only dye two colors at utmost, therefore, the yield and the quantity of colors are limited to a certain extent. The invention colors the fabrics by the coloration device, the employed coloration device comprises a plurality of spray coloration apparatuses capable of regulating the concentration of a dyeing liquid, the plurality of spray coloration apparatuses are arrayed in one group or more than two groups, each spray coloration apparatus operates individually to independently regulate the concentration of the dyeing liquid sprayed by each spray coloration apparatus so that the concentration of the dyeing liquid sprayed by each group of the spray coloration apparatuses is regulated to be incremented or decremented in sequence, thus generating, on the fabric, the gradual colors of one or more than two colors at a time.

Owner:ZHEJIANG SILK TECH

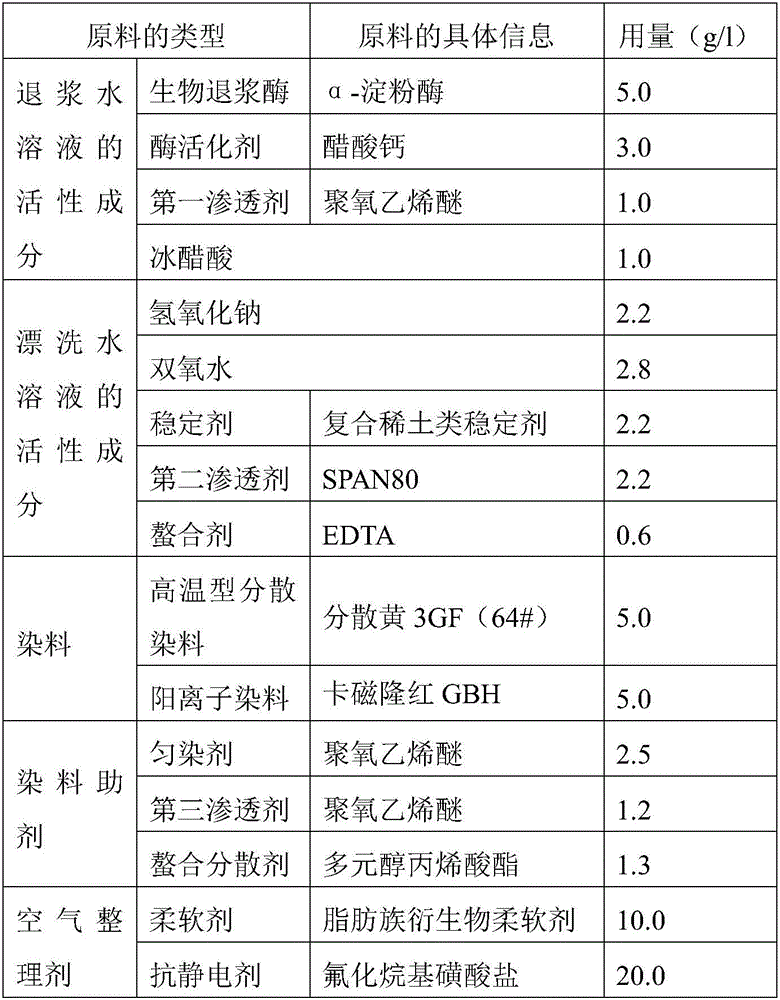

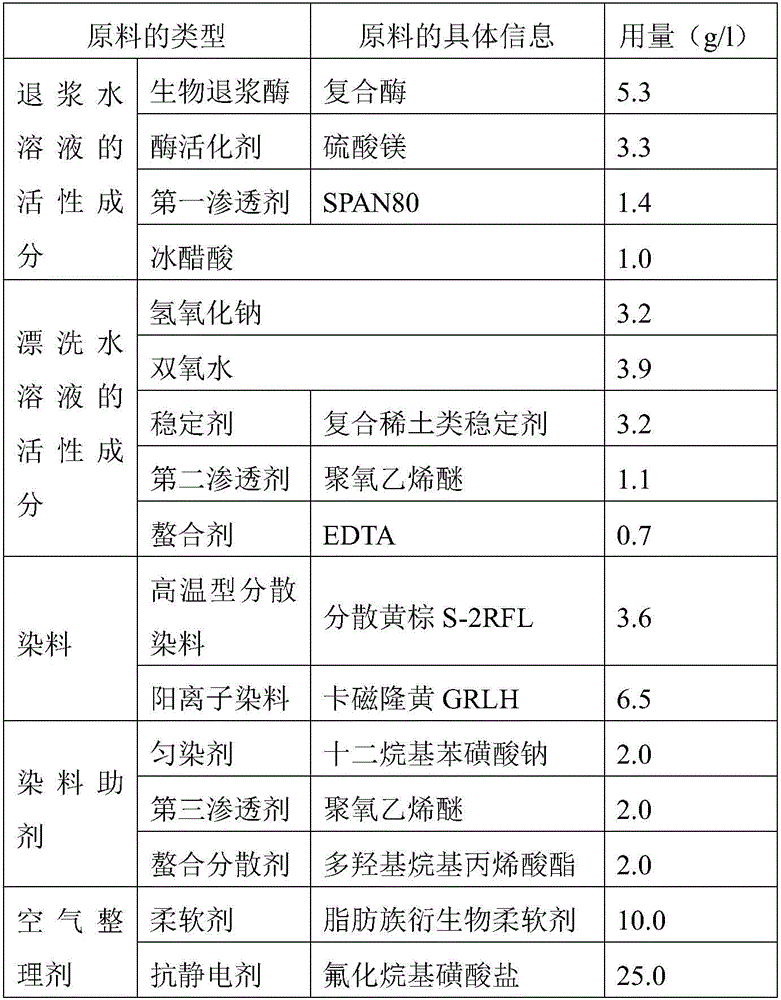

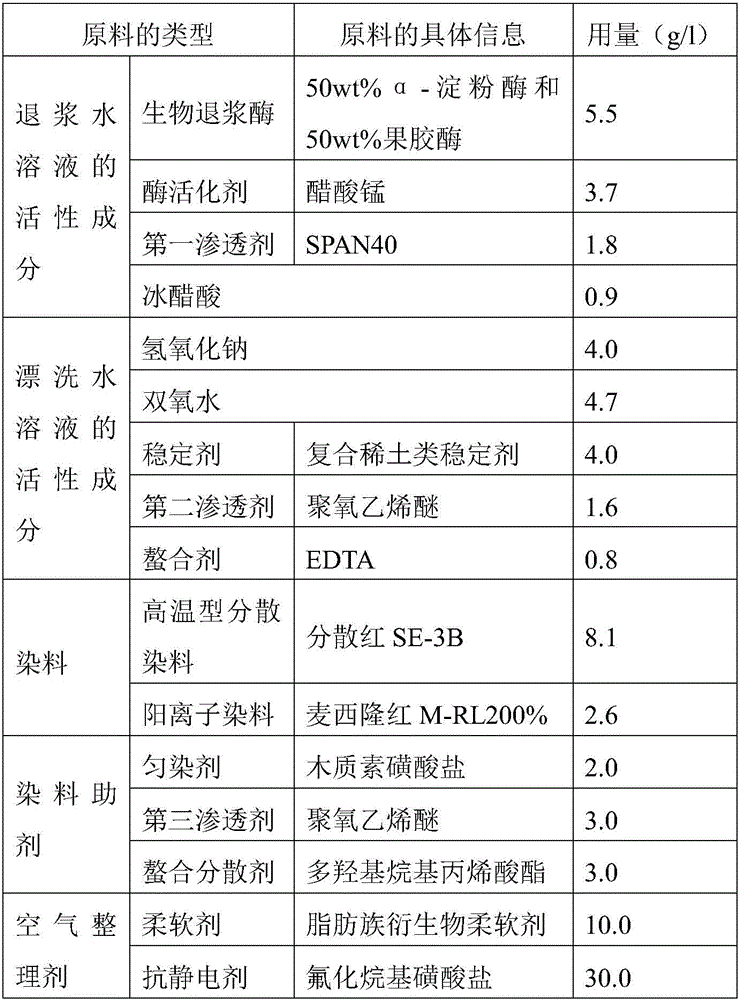

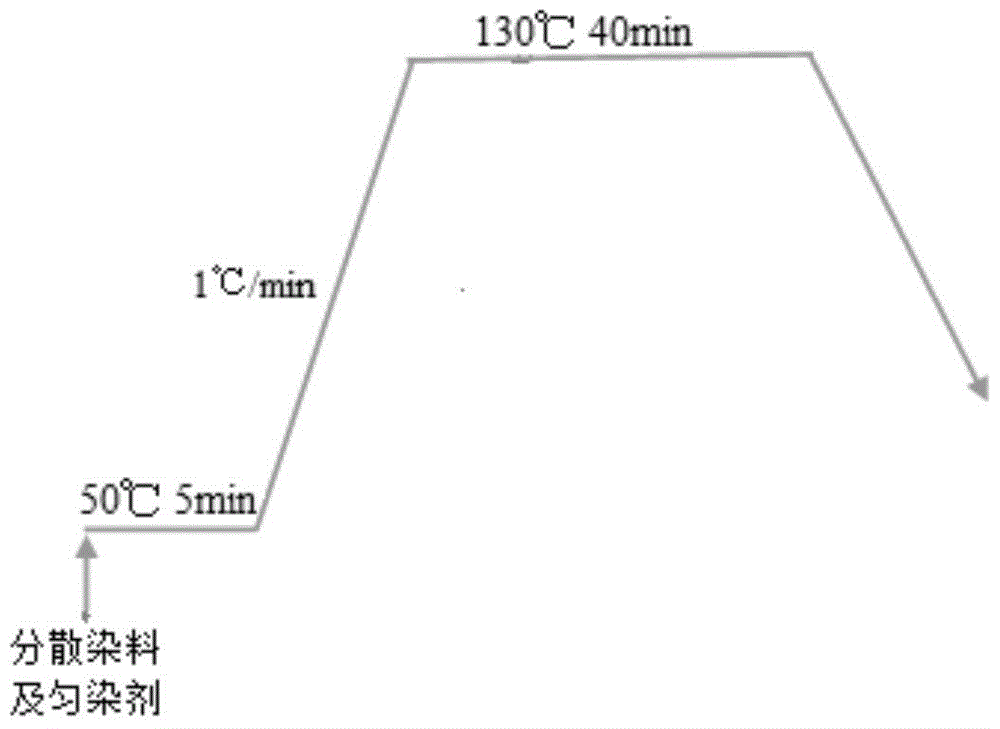

Dyeing process of fire retardant fibers

ActiveCN105714575AImprove parallelismGreat production valueHeat resistant fibresDry-cleaning apparatus for textilesFiberWater baths

The invention aims at providing a dyeing process of fire retardant fibers. The dyeing process comprises the following steps: step 1, desizing: adding the fire retardant fibers into a desizing eater solution at 50-60 DEG C, keeping the heat and washing with water; step 2, rinsing: adding the fire retardant fibers subjected to the desizing into a rising water solution at 95-100 DEG C, keeping the heat and washing with the water; step 3, dehairing: taking the rinsed fire retardant fibers and removing hairs on the surfaces of the fire retardant fibers; step 4, dyeing: taking the unhaired fire retardant fibers and adding the unhaired fire retardant fibers into water at 15-35 DEG C; gradually heating a water bath to 100-102 DEG C; adding dyestuff when the water bath is 68-71 DEG C and adding a dyestuff auxiliary agent when the water bath is 95-100 DEG C; keeping the heat at 100-102 DEG C for 0.5-1 hour; gradually heating the water bath to 130-135 DEG C and keeping the heat at 130-135 DEG C for 0.5-1 hour; gradually cooling the water bath to 75-80 DEG C; taking out the fire retardant fibers and soaping at 75-80 DEG C for 0.1-0.5 hour; and step 5, finishing: taking the dyed fire retardant fibers and sequentially carrying out air finishing and full decatizing finishing on the dyed fire retardant fibers. The dyeing process has the advantage that the dyeing effect is improved.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

Dyeing method using waste cooking oil as dyeing solvent

The invention discloses a dyeing method using waste cooking oil as a dyeing solvent. The method comprises the following steps that (1) a fabric is put into pretreatment liquid so that the fabric is fully swelled; then, the mangle expression of the fabric is controlled through a padder; (2) the fabric after the padding is soaked into the waste cooking oil dispersed with dye accounting for 1 to 15 percent of the weight of the fabric; adsorption and color fixation are completed under the condition of 10 to 100 DEG C; (3) through padding, the excessive waste cooking oil on the fabric is removed; waste cooking oil collected in a padding groove and waste cooking oil in a dyeing bath are cyclically used; the fabric after the padding is washed by water to obtain a dyed fabric. The dyeing method has the advantages that the utilization rate of dye is high; the adsorption rate is about 100 percent; the color fixation rate is 20 to 40 percent higher than that of the traditional dyeing. The dyeingprocess is based on the principle that similar substances dissolve in each other; the characteristic that the dye can be used to easily get rid of oil and enter the water is utilized, so that completesalt-free dyeing is realized.

Owner:JIANGNAN UNIV

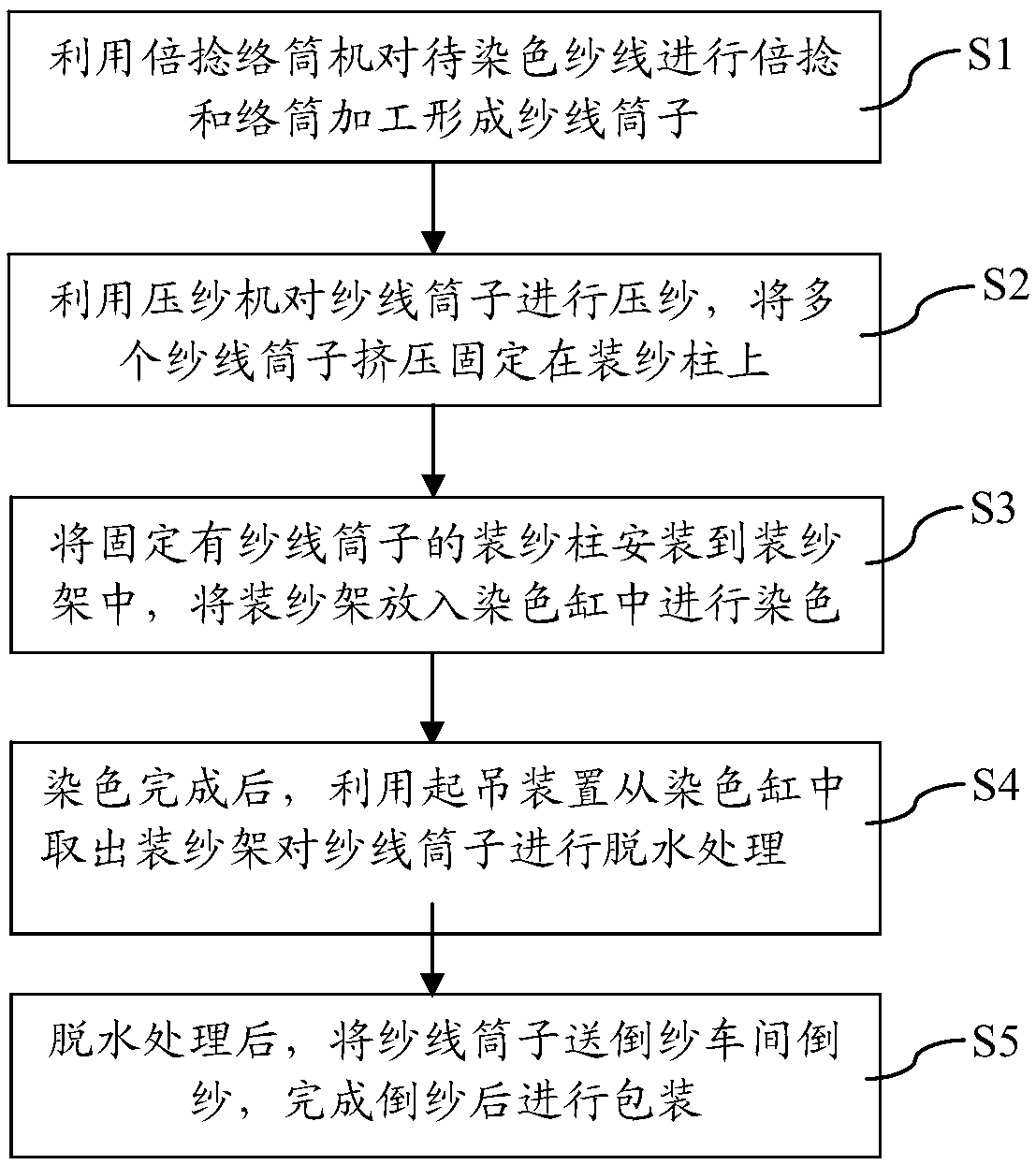

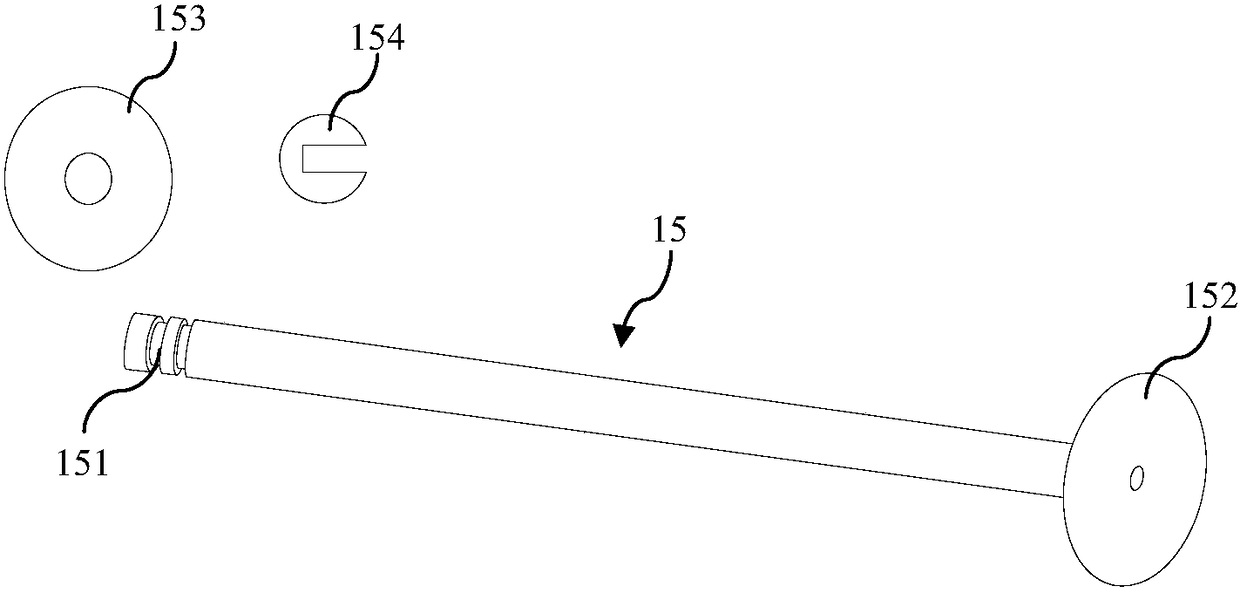

Polyester dyeing method

InactiveCN108411512AEvenly distributedSave water for dyeingLiquid/gas/vapor removal by centrifugal forceDyeing processPolyesterYarn

The invention discloses a polyester dyeing method. The method comprises the following steps of step one, utilizing a double twisting machine to perform double twisting and spooling processing to formyarn bobbins; step two, utilizing a yarn pressing machine to perform yarn pressing on the yarn bobbins, and pressing and fixing a plurality of yarn bobbins on a yarn loading column; step three, mounting the yarn loading column to which the yarn bobbins in a yarn loading frame, and placing the yarn loading frame into a dyeing cylinder for dyeing by using a lifting device; step four, after the dyeing is completed, taking out the yarn loading frame from the dyeing cylinder by using the lifting device, and dehydrating the yarn bobbins. The polyester dyeing method fixes a plurality of yarn bobbinson the yarn loading column through pressing, the yarn loading column is installed in the yarn load frame for centralized dyeing, the yarn bobbins are evenly distributed, more yarns are stored per volume, thereby saving the amount of dyeing water and saving energy, and the yarn pressing machine is used for improving the degree of automation and mechanization of the dyeing, thereby greatly improvingthe production efficiency.

Owner:福建益明纺织有限公司

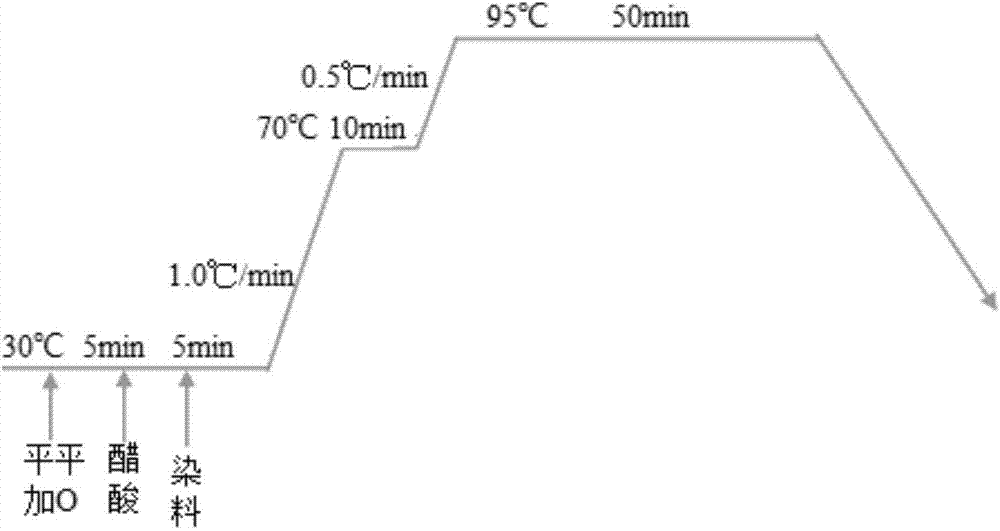

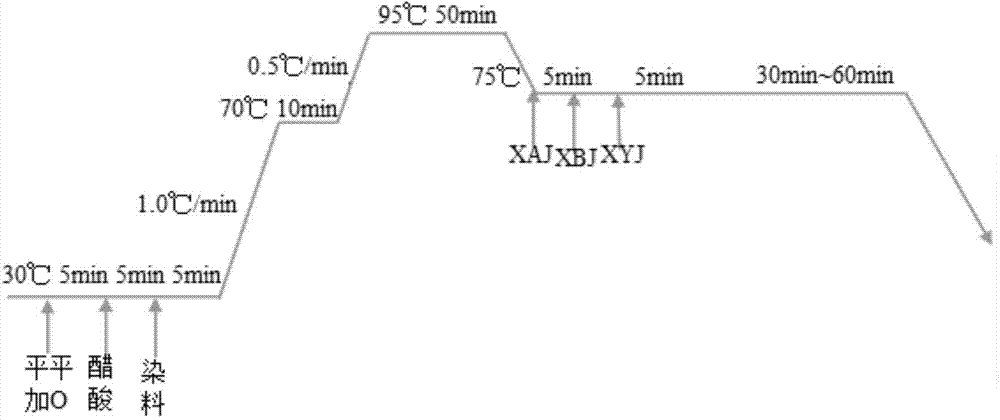

Method and auxiliary agents for polyamide fiber in-situ mineralization deep water-saving and emission-reducing dyeing after-treatment

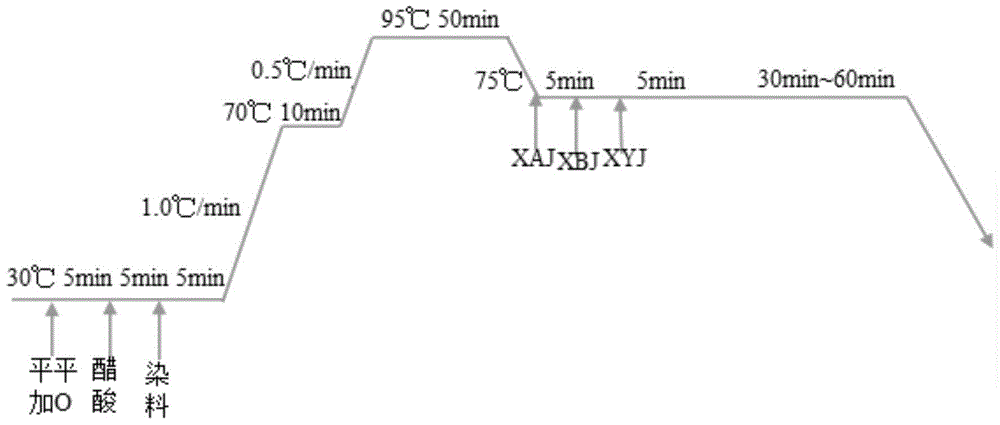

The invention discloses a method for polyamide fiber in-situ mineralization deep water-saving and emission-reducing dyeing after-treatment. The method comprises the following steps: putting a to-be-dyed textile into dyeing equipment, adding dyeing water, and keeping dye-bath cycling to perform preparation before dyeing; performing dyeing processing on the to-be-dyed textile according to a general dyeing method of polyamide fibers; synchronously performing in-situ mineralization treatment on a dyeing residual bath and the dyed textile by using polyamide fiber dyeing after-treatment auxiliary agents XAJ, XBJ and XYJ; storing the dyeing residual bath subjected to the mineralization treatment to serve as water for subsequent dyeing; and dehydrating and drying the dyed textile to finish the whole dyeing after-treatment processing. The invention also discloses the polyamide fiber dyeing after-treatment auxiliary agents XAJ, XBJ and XYJ. By adopting the method for the polyamide fiber in-situ mineralization deep water-saving and emission-reducing dyeing after-treatment, the problems of water consumption and wastewater discharge during dyeing processing of the polyamide fibers are fundamentally solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

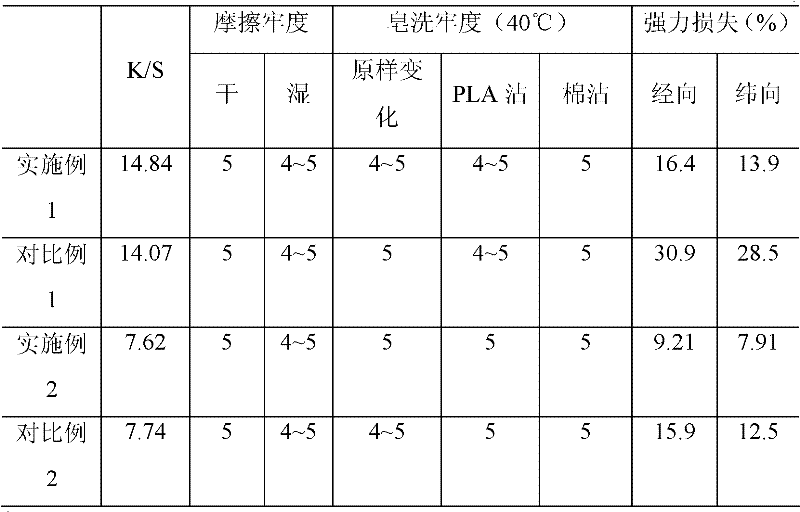

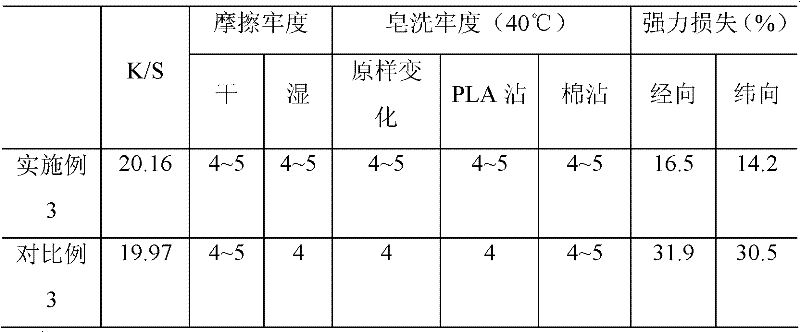

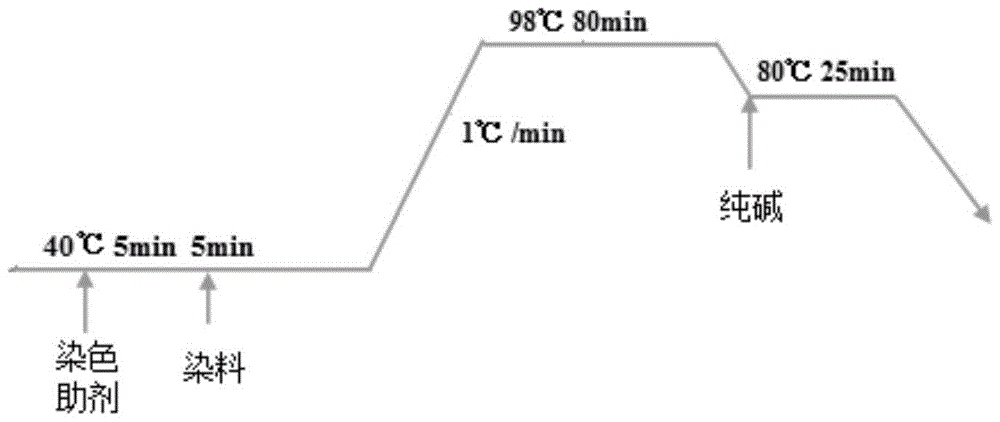

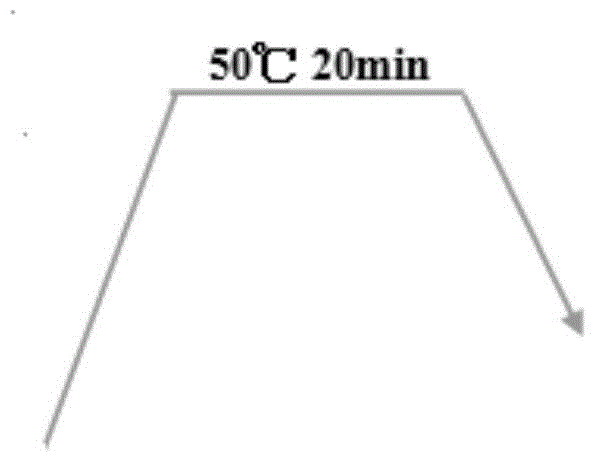

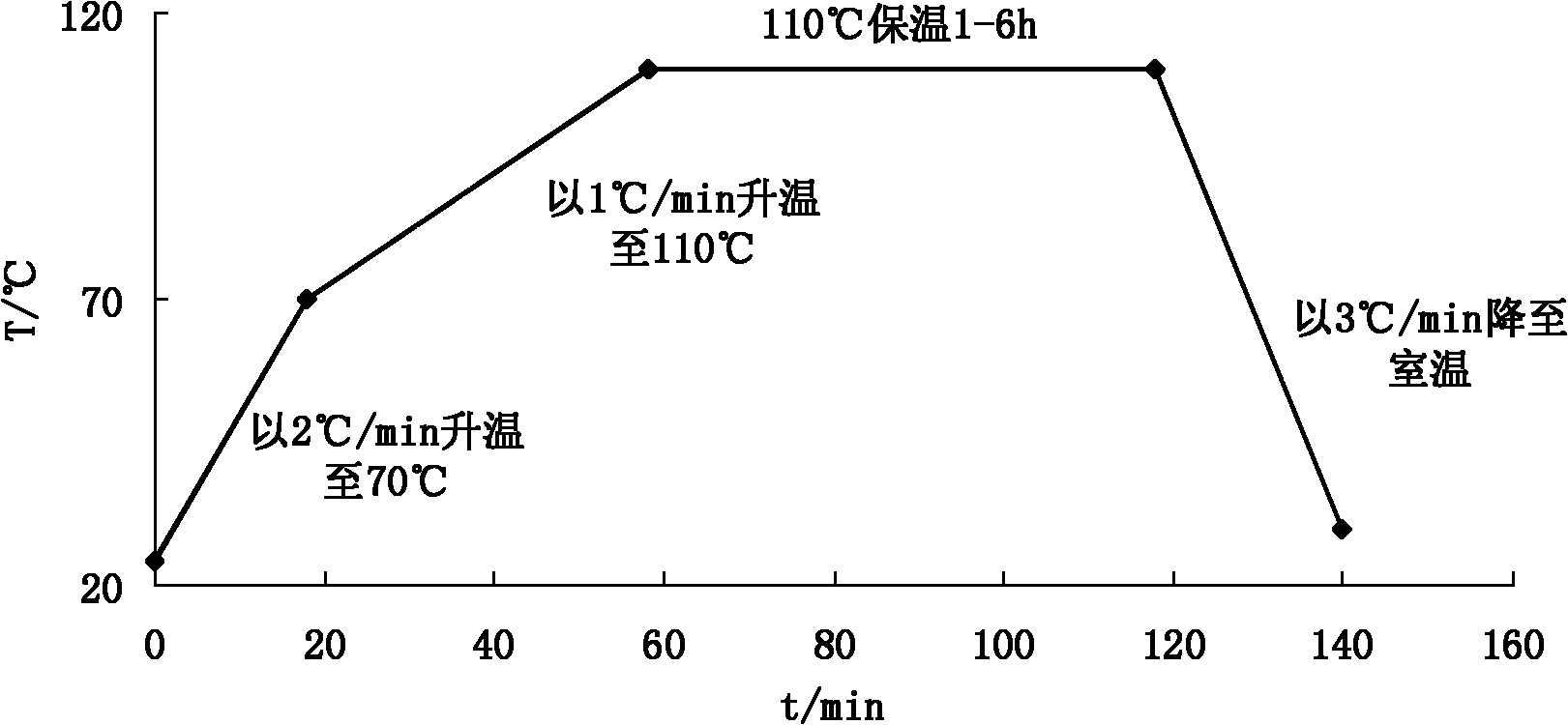

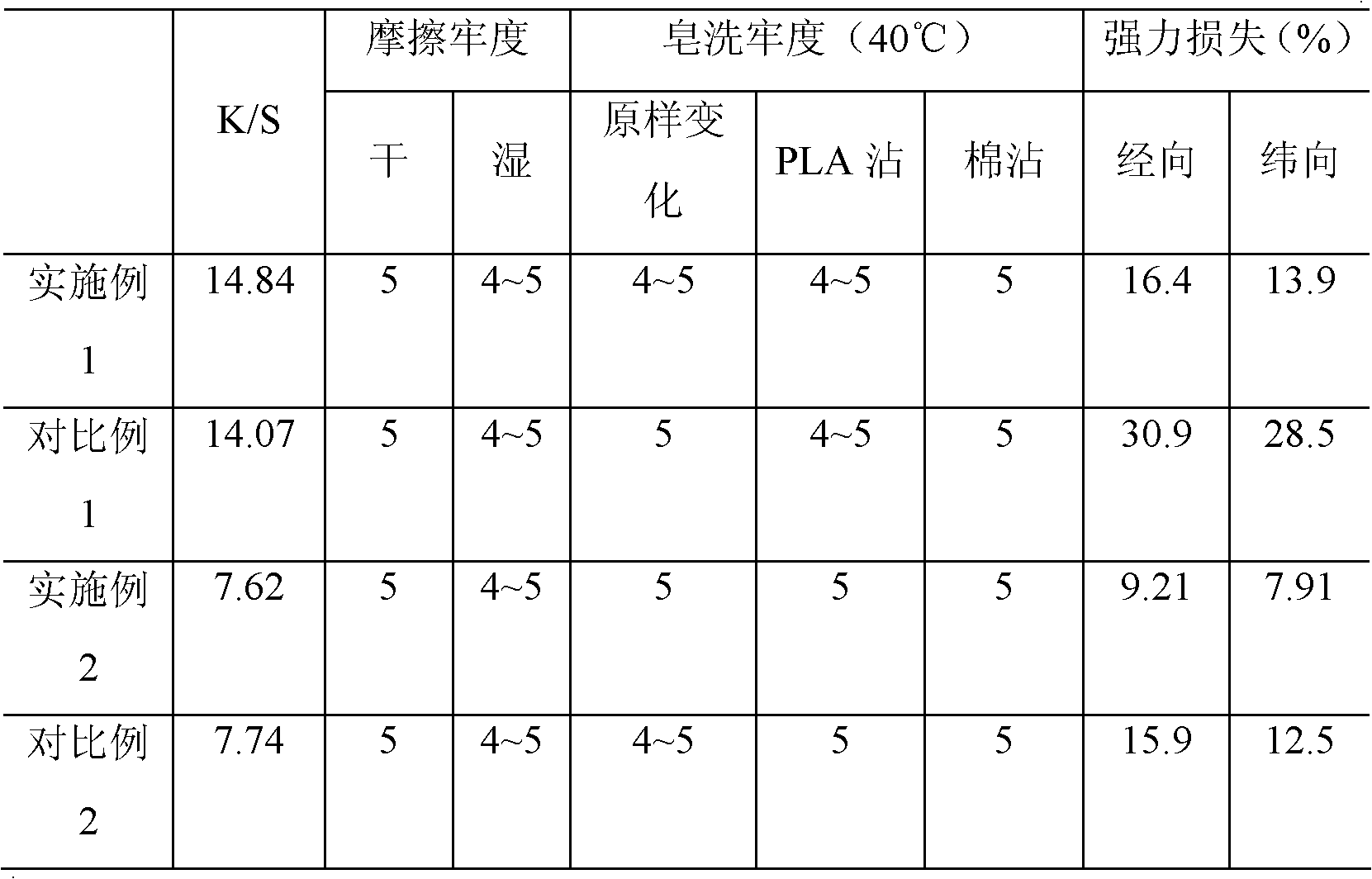

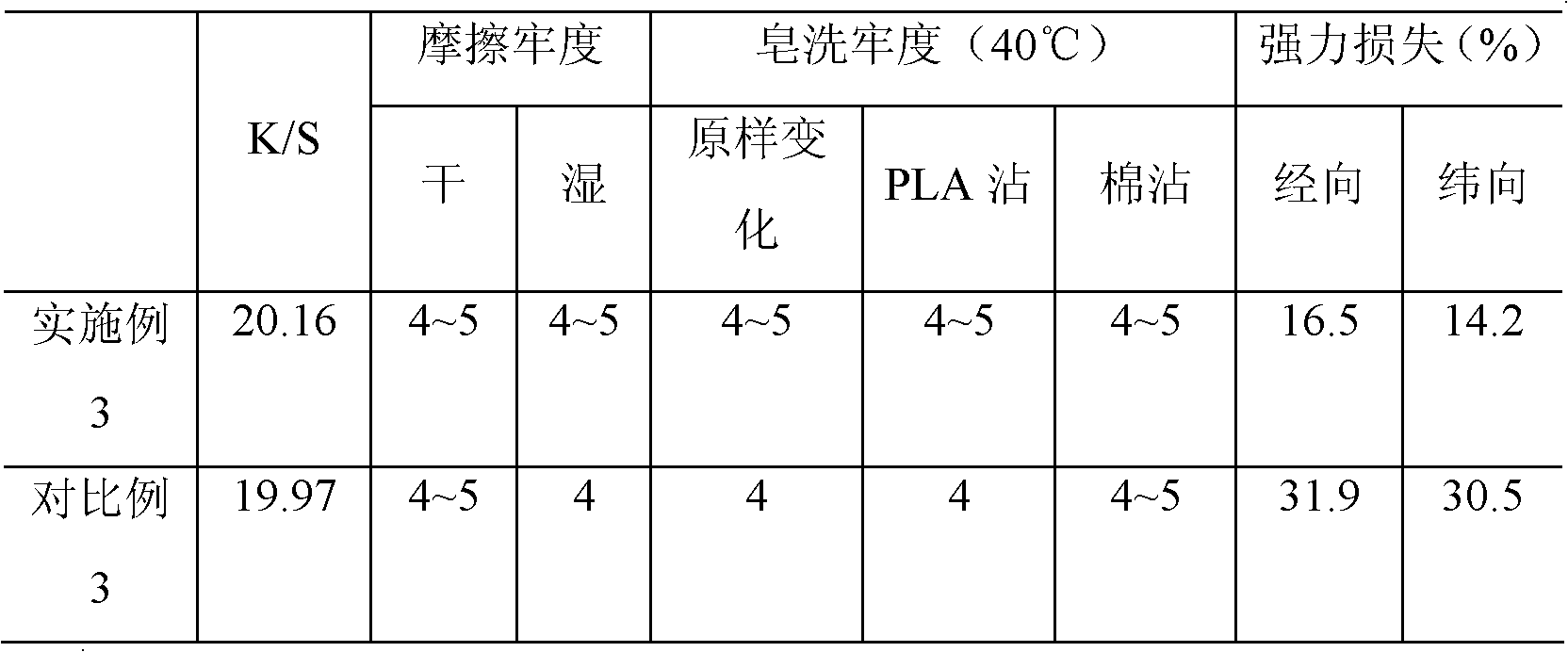

Microcapsule dyeing method of poly lactic acid fibers and/or poly lactic acid fiber product

The present invention relates to a microcapsule dyeing method of poly lactic acid fibers and / or a poly lactic acid fiber product. The method comprises: (1) weighing disperse dye microcapsules according to 0.1-10% (o.w.f.), adopting a HAc aqueous solution as a dyeing solution, weighing and taking the dyeing solution according to a bath ratio of 15-60:1, and carrying out dyeing for the poly lactic acid fibers and / or the poly lactic acid fiber product; (2) carrying out acid washing for the dyed poly lactic acid fibers and / or the poly lactic acid fiber product, then washing by clear water, and drying to obtain the product; or filtering the resulting waste water from the step (1) to obtain the microcapsule-free dyeing bath, soaking the dyed poly lactic acid fibers and / or the poly lactic acid fiber product into the resulting microcapsule-free dyeing bath, carrying out a thermal insulation treatment for 10-20 minutes at a temperature of 70-110 DEG C, then washing by clear water, and drying to obtain the product. The method of the present invention has the following advantages that: the dyeing process is simple; the dyeing time is short; the reductive cleaning treatment is saved; the dyeing solution cleaning is easy to treat; the purposes of environmental protection and cost saving are achieved; the damage on the PLA fibers is low, the tint is dark after dyeing, and the color fastnessis high.

Owner:DONGHUA UNIV

Preparation method and dyeing method of polyester fabric disperse dyestuff less-water dyeing color paste

ActiveCN111235924ARealization of less water dyeingGood dispersionDyeing processDisperse dyePolymer science

The invention discloses a preparation method and dyeing method of disperse dyestuff less-water dyeing color paste. According to the preparation method, disperse dyestuff is dissolved in an organic solvent, then a dispersing agent and an emulsifying agent are utilized to obtain the stable disperse dyestuff less-water dyeing color paste under an ultrasonic agitation condition. In the ultrasonic agitation process, the disperse dyestuff dissolved in the organic solvent is uniformly dispersed in an aqueous solution in the form of particles to form stable dispersion liquid, and meanwhile a long-timegrinding process in a traditional color paste preparation process is omitted. Through the method, less-water dyeing of a polyester fabric through the disperse dyestuff is realized, the cost of waterfor dyeing is lowered, and all fastness of the dyed fabric is consistent with that of conventional disperse dyestuff hot-melting dyeing.

Owner:湖南鼎诺新材料科技有限公司

Natural protein fiber in-situ mineralization water-saving emission reduction dyeing post-treatment method and auxiliaries

The invention discloses an in-situ mineralization and water-saving emission-reduction dyeing post-treatment method for natural protein fibers. The method comprises the following steps: putting a to-be-dyed textile into dyeing equipment, adding dyeing water, keeping dye bath recycling, and making preparations before dyeing; performing dyeing processing on the to-be-dyed textile with a general natural protein fiber dyeing method, and not discharging dyeing residual liquid after finishing dyeing; simultaneously performing in-situ mineralization treatment on the residual dyeing bath and the dyed textile by utilizing natural protein fiber dyeing post-treatment auxiliary agents XAM, XBM and XYM; storing the residual dyeing bath subjected to mineralization treatment as subsequent dyeing water; performing dehydration and drying on the dyed textile, and finishing the whole dyeing post-treatment process. The invention further relates to the natural protein fiber dyeing post-treatment auxiliary agents XAM, XBM and XYM used in the dyeing post-treatment method. The dyeing post-treatment method solves problems of water consumption and wastewater discharge in a natural protein fiber dyeing processing process.

Owner:XI'AN POLYTECHNIC UNIVERSITY

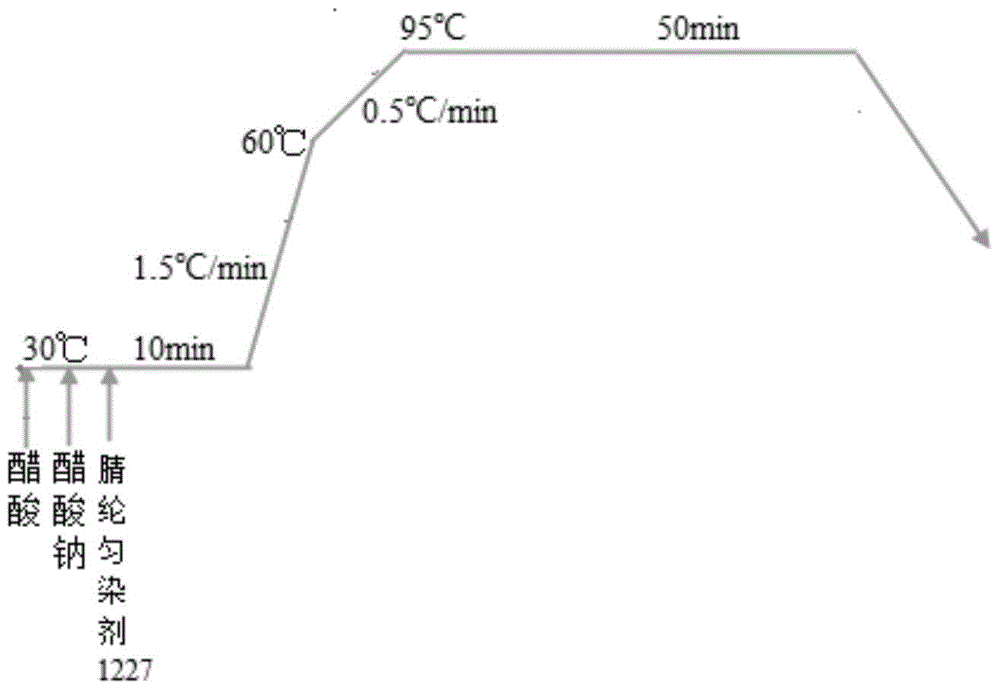

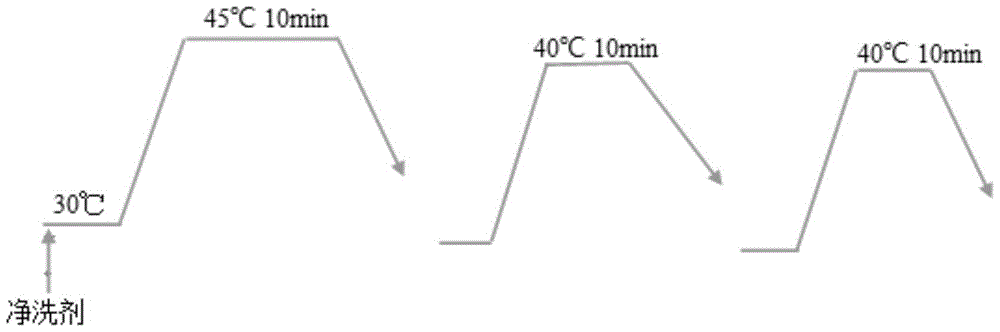

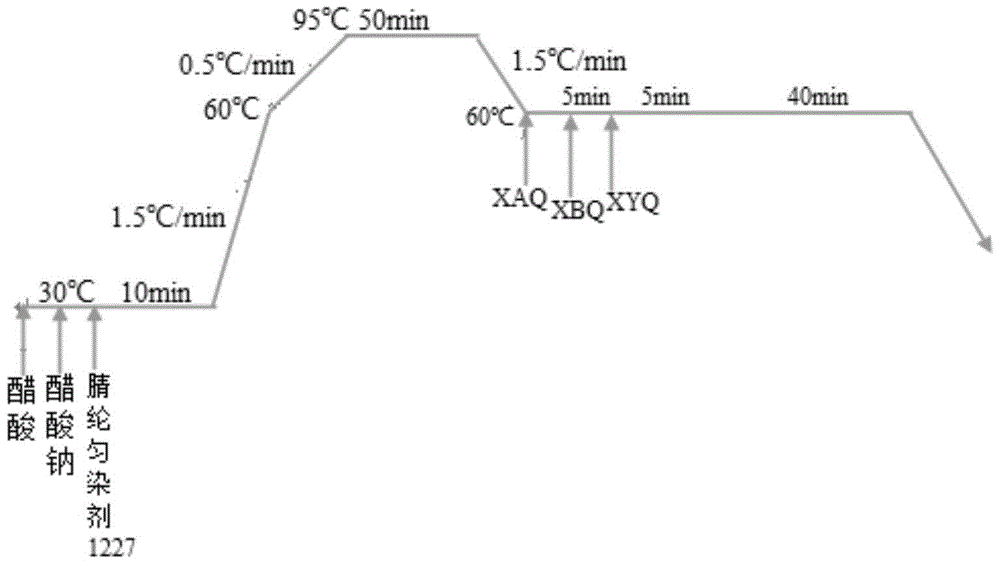

In-situ mineralization and water-saving emission-reduction dyeing post-treatment method for polyacrylonitrile fibers and auxiliary agents

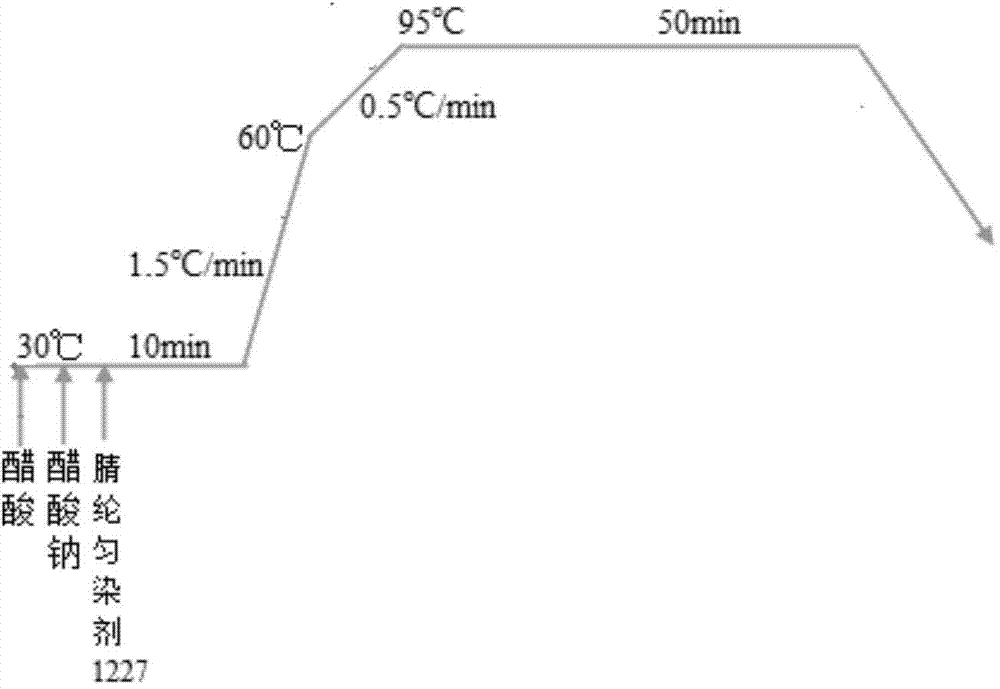

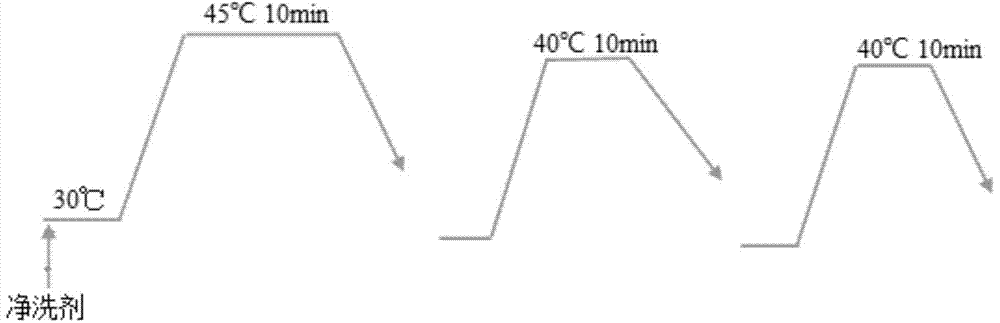

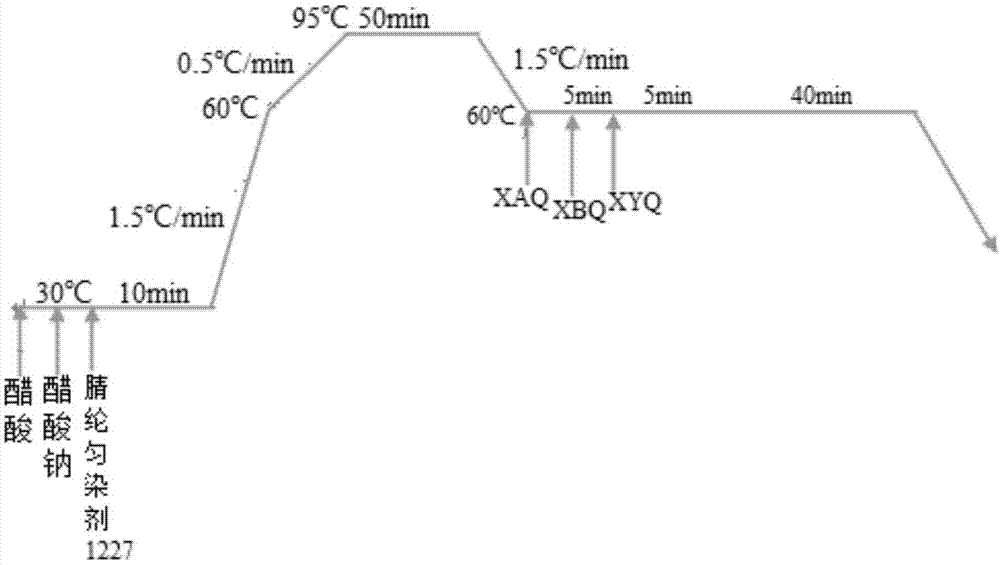

The invention discloses an in-situ mineralization and water-saving emission-reduction dyeing post-treatment method for polyacrylonitrile fibers. The method comprises the following steps: putting a to-be-dyed textile into dyeing equipment, adding dyeing water, keeping dye bath recycling, and making preparations before dyeing; performing dyeing processing on the to-be-dyed textile with a general polyacrylonitrile fiber dyeing method, and not discharging dyeing residual liquid after finishing dyeing; performing mineralization treatment on the dyed textile by utilizing polyacrylonitrile fiber dyeing post-treatment auxiliary agents XAQ, XBQ and XYQ; performing treatment on the obtained residual dyeing bath and the dyed textile, and finishing the whole dyeing post-treatment process. The invention further relates to respective formulae and preparation methods of the polyacrylonitrile fiber dyeing post-treatment auxiliary agents XAQ, XBQ and XYQ. The in-situ mineralization and deep water-saving emission-reduction dyeing post-treatment method for the polyacrylonitrile fibers and the auxiliary agents solve problems of high water consumption and high wastewater discharge amount in a polyacrylonitrile fiber dyeing processing process.

Owner:XI'AN POLYTECHNIC UNIVERSITY

In-situ mineralization of polyacrylonitrile fiber, water-saving and emission-reduction dyeing post-treatment method and auxiliaries

ActiveCN104711877BReduced dichromate indexGuaranteed color fastnessDyeing processWater savingPolymer science

The invention discloses an in-situ mineralization and water-saving emission-reduction dyeing post-treatment method for polyacrylonitrile fibers. The method comprises the following steps: putting a to-be-dyed textile into dyeing equipment, adding dyeing water, keeping dye bath recycling, and making preparations before dyeing; performing dyeing processing on the to-be-dyed textile with a general polyacrylonitrile fiber dyeing method, and not discharging dyeing residual liquid after finishing dyeing; performing mineralization treatment on the dyed textile by utilizing polyacrylonitrile fiber dyeing post-treatment auxiliary agents XAQ, XBQ and XYQ; performing treatment on the obtained residual dyeing bath and the dyed textile, and finishing the whole dyeing post-treatment process. The invention further relates to respective formulae and preparation methods of the polyacrylonitrile fiber dyeing post-treatment auxiliary agents XAQ, XBQ and XYQ. The in-situ mineralization and deep water-saving emission-reduction dyeing post-treatment method for the polyacrylonitrile fibers and the auxiliary agents solve problems of high water consumption and high wastewater discharge amount in a polyacrylonitrile fiber dyeing processing process.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Environment-friendly dyeing process of regenerated nylon yarns

ActiveCN112647318AAdvantages of environmental dyeing processEasy to useTextile treatment machine arrangementsTextile/flexible product manufactureYarnPolymer science

The invention provides an environment-friendly dyeing process of regenerated nylon yarns. The environment-friendly dyeing process comprises the following steps: treating cheese yarns through a padding type yarn treating machine, and specifically comprises the following steps: loading a shaft, padding a working solution, oxidizing and curing, washing with water, drying and unloading a bobbin from the shaft.

Owner:ZHEJIANG YINGSHANHONG TEXTILE TECH CO LTD

Wash-free dyeing method for silk

ActiveCN100575595CReduce consumptionEmission reductionHeating/cooling textile fabricsDyeing processColour fastnessWater saving

The invention relates to a textiles dyeing method, especially to a silk facing material dyeing method. The object of the invention is to provide an improved method for silk dyeing. The invention has features of waterless or little water dyeing, reduced cost, reduced sewage water discharging and good products color fastness; the products hand feeling maintains the silk facing material special styles; and the invention is water-saving and energy-saving. The invention adopts the technical scheme: executing according to the following steps in sequence: preparing dye liquor, dyeing, pre baking, decatizing, soft liquid slop padding, drying and finishing.

Owner:杭州喜得宝集团有限公司

Anhydrous acid dye liquor preparation method based on acid eutectic solvent

The invention discloses a preparation method of anhydrous acid dye liquor based on an acid eutectic solvent and application of the anhydrous acid dye liquor in wool fabric dyeing, and belongs to the field of wool fabric dyeing and finishing. According to the method, carboxylic acid and quaternary ammonium salt are used as raw materials, and the quaternary ammonium salt carboxylic acid acidic eutectic solvent anhydrous dyeing medium is prepared through a one-step method. The dyeing medium not only provides a dyeing solvent, but also contains positive ions and acid radicals, so that the generation of dyeing wastewater is avoided, and the addition of acid, alkali, surfactants and other auxiliaries in the dyeing process is also avoided. When the acid dye is used in the dyeing process of the wool fabric, the problems of high water consumption and large energy consumption are solved while the excellent dyeing effect is ensured.

Owner:JIANGNAN UNIV

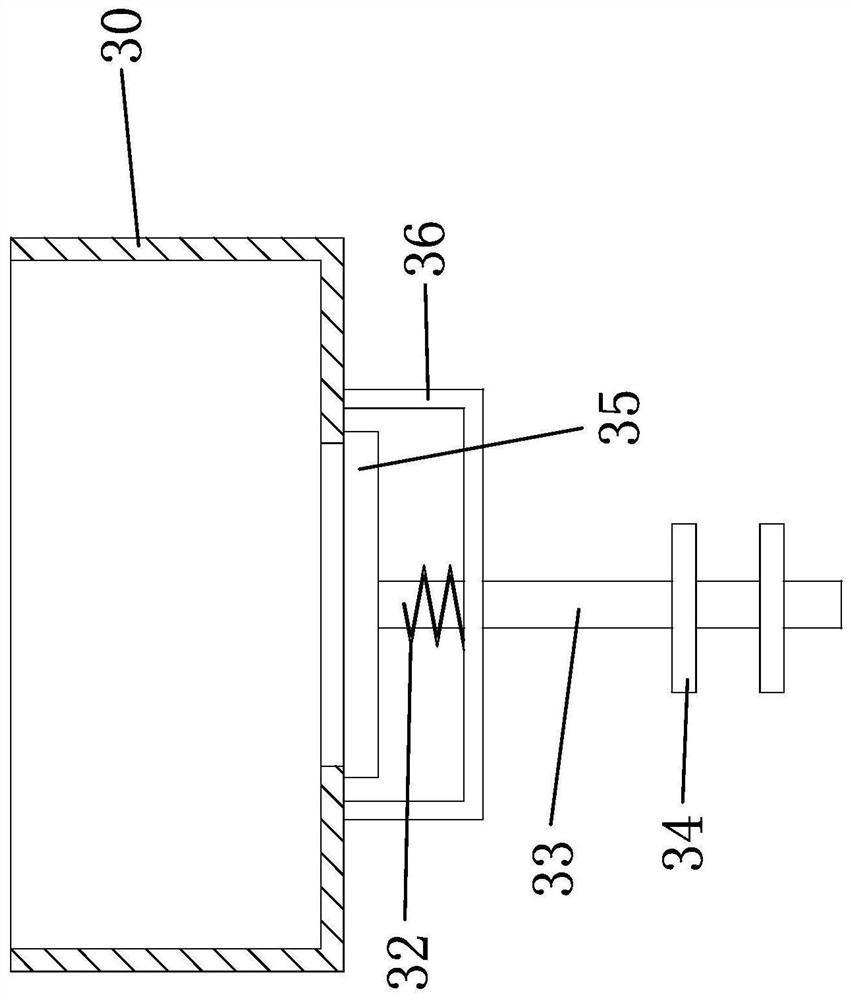

Device and method for recovering acid dye residue and heat energy

ActiveCN107218824BEmission reductionReduce dosageStationary tubular conduit assembliesHeat exchange apparatusLinear motorPhotochemistry

Owner:贵州鼎盛服饰有限公司

Dyeing method using waste edible oil as dyeing solvent

ActiveCN109403067BHigh color fixing rateIncrease concentrationDyeing processPulp and paper industryCooking oil

The invention discloses a dyeing method using waste cooking oil as a dyeing solvent. The method comprises the following steps that (1) a fabric is put into pretreatment liquid so that the fabric is fully swelled; then, the mangle expression of the fabric is controlled through a padder; (2) the fabric after the padding is soaked into the waste cooking oil dispersed with dye accounting for 1 to 15 percent of the weight of the fabric; adsorption and color fixation are completed under the condition of 10 to 100 DEG C; (3) through padding, the excessive waste cooking oil on the fabric is removed; waste cooking oil collected in a padding groove and waste cooking oil in a dyeing bath are cyclically used; the fabric after the padding is washed by water to obtain a dyed fabric. The dyeing method has the advantages that the utilization rate of dye is high; the adsorption rate is about 100 percent; the color fixation rate is 20 to 40 percent higher than that of the traditional dyeing. The dyeingprocess is based on the principle that similar substances dissolve in each other; the characteristic that the dye can be used to easily get rid of oil and enter the water is utilized, so that completesalt-free dyeing is realized.

Owner:JIANGNAN UNIV

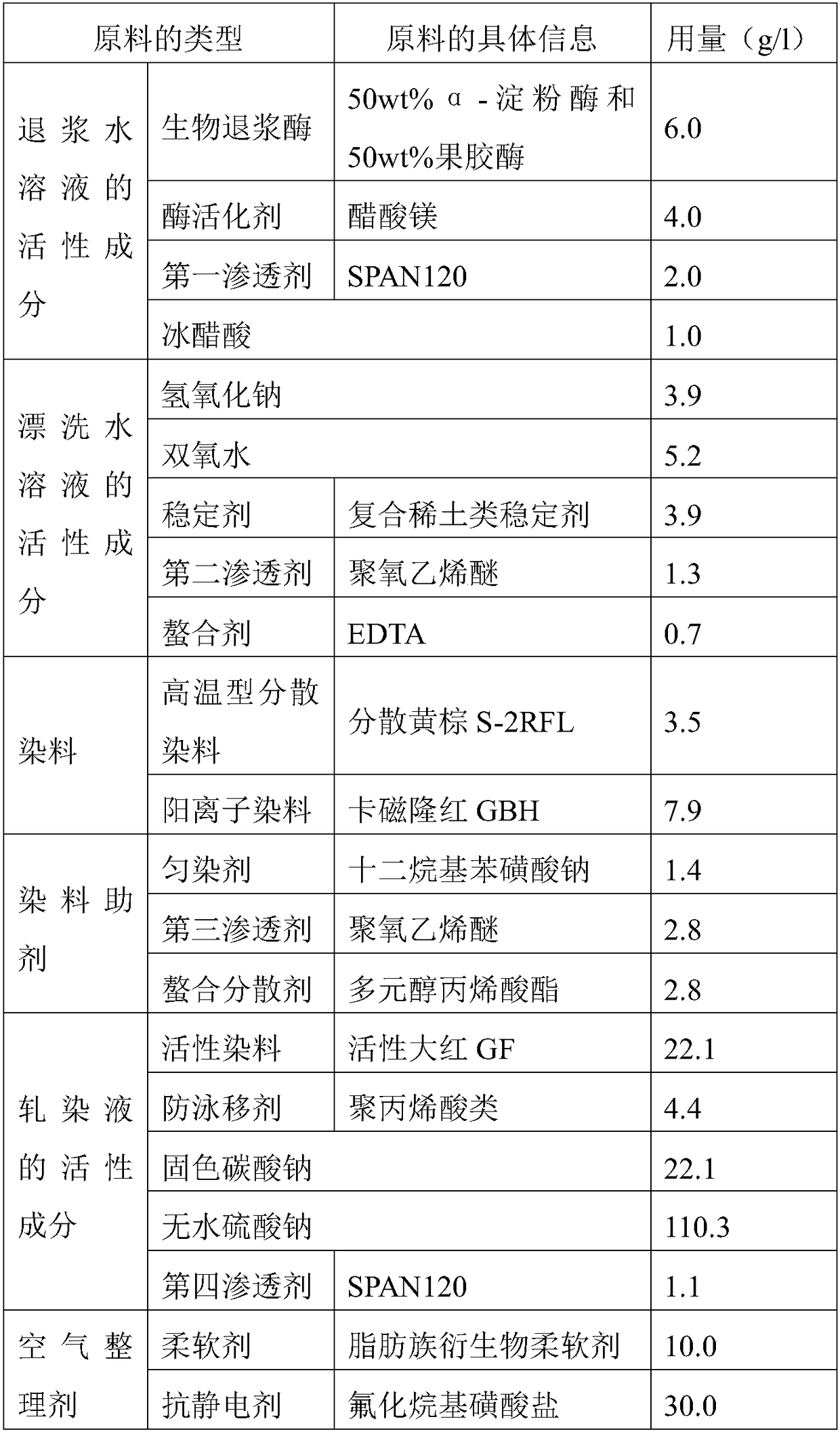

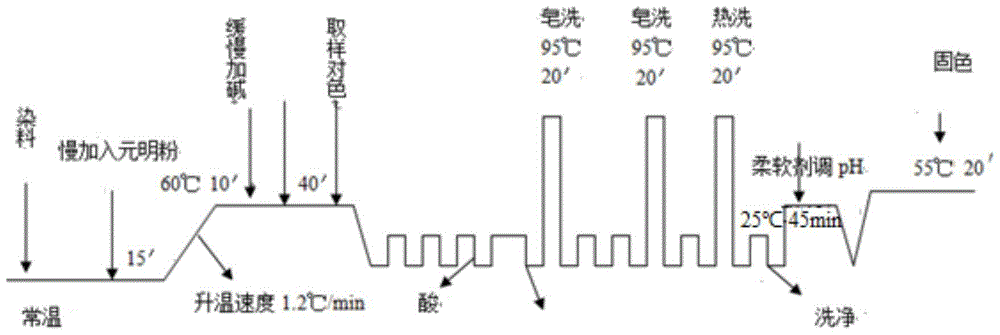

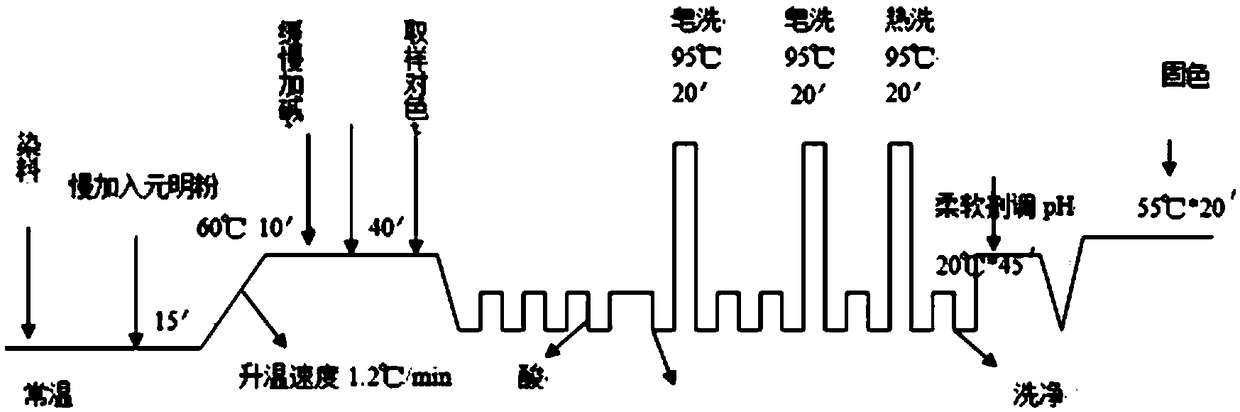

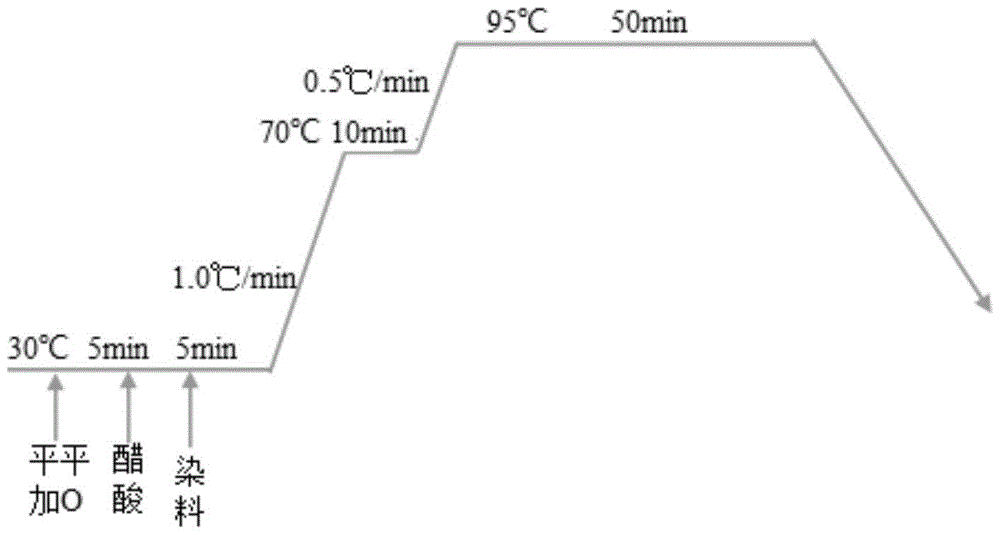

A dyeing process of flame-retardant blended fiber

ActiveCN105908527BIncrease profitPromote infectionDry-cleaning apparatus for textilesDyeing processAcetic acidFiber

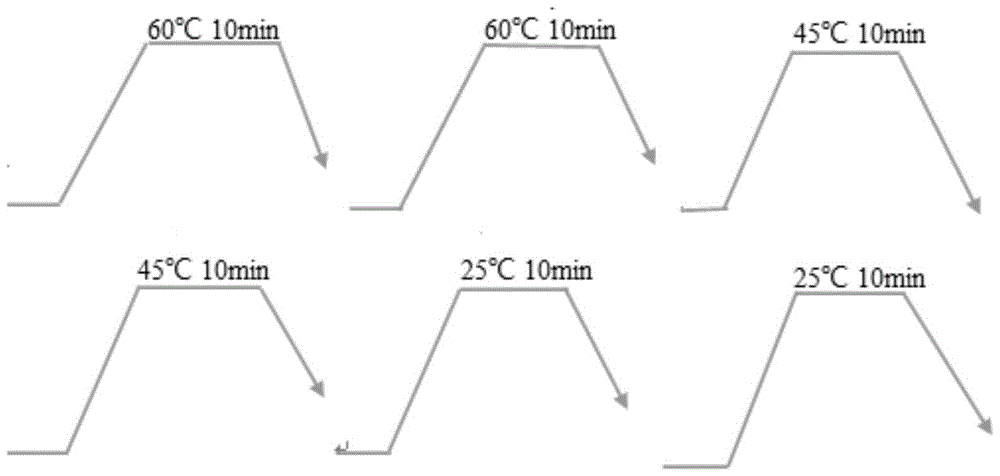

The invention aims to provide a dyeing process of flame-retardant mixed fiber. The dyeing process includes following steps: adding the flame-retardant mixed fiber into a desizing water solution of 50-60 DEG C, holding the temperature, and washing with water at 50-70 DEG C; adding the flame-retardant mixed fiber that is desized into a rinsing water solution of 95-100 DEG C, holding the temperature, and washing with water at 50-70 DEG C; unhairing; adding the flame-retardant mixed fiber that is unhaired into water of 15-35 DEG C, rising the temperature to 100-102 DEG C, adding dye at 68-71 DEG C, adding a dye auxiliary at 95-100 DEG C, and holding the temperature at 100-102 DEG C; rising the temperature to 130-135 DEG C, and holding the temperature at 130-135 DEG C; lowering the temperature to 75-80 DEG C; taking out the flame-retardant mixed fiber, and soaping the flame-retardant mixed fiber at 75-80 DEG C; taking the flame-retardant mixed fiber dyed for the first time, padding the flame-retardant mixed fiber in dye liquid, and air-drying at high temperature; padding the flame-retardant mixed fiber in color fixing liquid, and performing saturated steaming at high temperature; subjecting the flame-retardant mixed fiber after saturated steaming to water washing at 10-15 DEG C, acetic acid neutralizing, soaping at 85-90 DEG C and water washing at 15-35 DEG C sequentially; taking the flame-retardant mixed fiber after being dyed, and subjecting the flame-retardant mixed fiber to air finishing and full decatizing sequentially. The dyeing process has the advantage that dyeing effect is improved.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

Cellulose fiber in-situ mineralization deep water-saving emission reduction dyeing post-treatment method and auxiliaries

Owner:XI'AN POLYTECHNIC UNIVERSITY

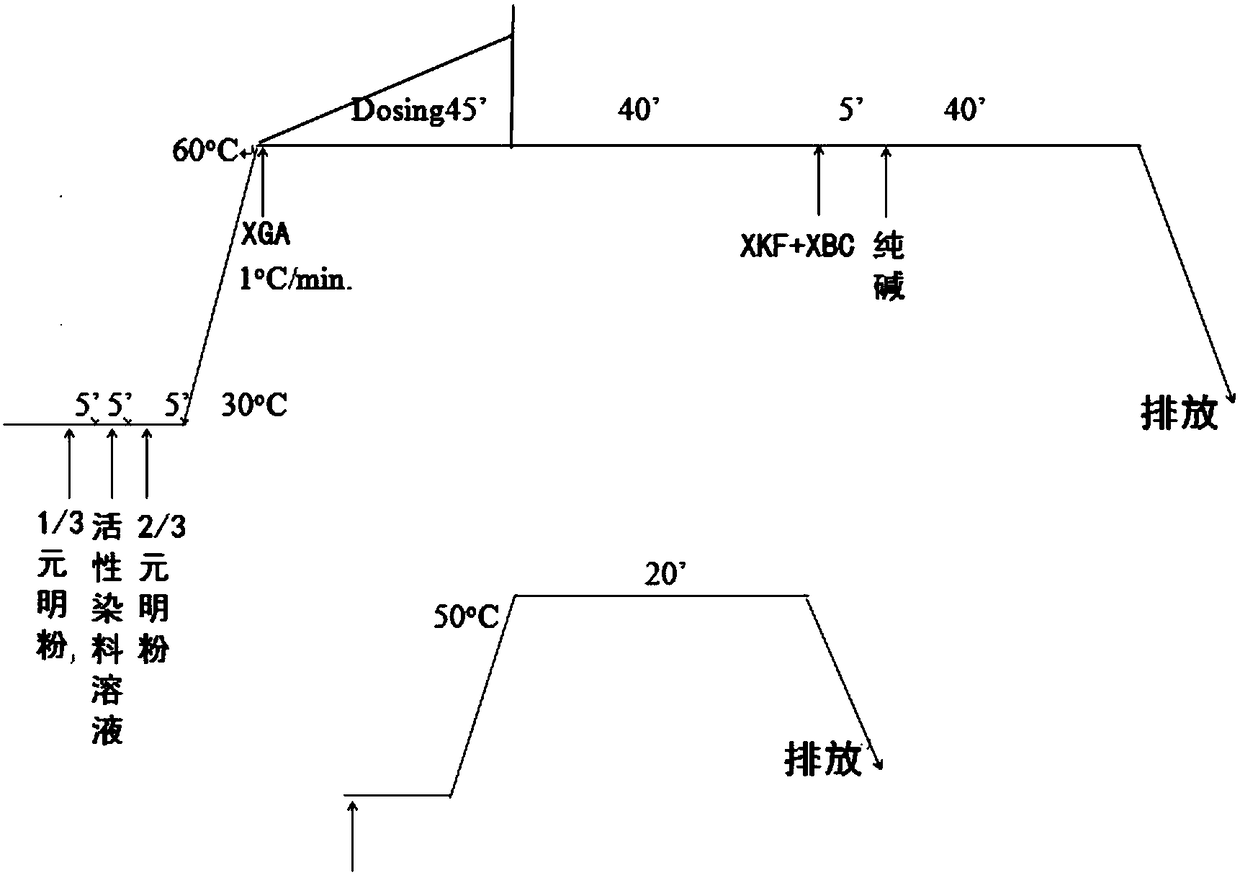

In-situ mineralization dyeing method of cellulose fiber based on color-fixing alkali agent and mineralizing acid agent

ActiveCN106702778BFull color fixationImprove mineralization efficiencyDyeing processCellulose fiberChemistry

The invention discloses a cellulose fiber in-situ mineralization dyeing method based on a fixation alkali agent and a mineralization acid agent, and is a supplement and innovation based on dyeing post-processing methods and additives of cellulose fiber in-situ mineralization deep water saving and emission reduction in the invention patent. The cellulose fiber in-situ mineralization dyeing method based on the fixation alkali agent and mineralization acid agent comprises the following steps that the developed fixation alkali agent XGA and the mineralization acid agent XKH are used, so that reactive dye can normally fix the color of cellulose fibers, and the efficiency of an in-situ mineralization link after dyeing further can be improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Microcapsule dyeing method of poly lactic acid fibers and/or poly lactic acid fiber product

The present invention relates to a microcapsule dyeing method of poly lactic acid fibers and / or a poly lactic acid fiber product. The method comprises: (1) weighing disperse dye microcapsules according to 0.1-10% (o.w.f.), adopting a HAc aqueous solution as a dyeing solution, weighing and taking the dyeing solution according to a bath ratio of 15-60:1, and carrying out dyeing for the poly lactic acid fibers and / or the poly lactic acid fiber product; (2) carrying out acid washing for the dyed poly lactic acid fibers and / or the poly lactic acid fiber product, then washing by clear water, and drying to obtain the product; or filtering the resulting waste water from the step (1) to obtain the microcapsule-free dyeing bath, soaking the dyed poly lactic acid fibers and / or the poly lactic acid fiber product into the resulting microcapsule-free dyeing bath, carrying out a thermal insulation treatment for 10-20 minutes at a temperature of 70-110 DEG C, then washing by clear water, and drying to obtain the product. The method of the present invention has the following advantages that: the dyeing process is simple; the dyeing time is short; the reductive cleaning treatment is saved; the dyeing solution cleaning is easy to treat; the purposes of environmental protection and cost saving are achieved; the damage on the PLA fibers is low, the tint is dark after dyeing, and the color fastness is high.

Owner:DONGHUA UNIV

Gradually dyeing novel process for fabric and employed dyeing apparatus

ActiveCN101492866BEmission reductionSave water for dyeingTextile treatment machine partsTextile treatment by spraying/projectingPolymer scienceEngineering

The invention discloses a fabric gradual color dyeing technique and an employed coloration device thereof. The present gradual color dyeing method can only dye the gradual color of one color at a time and can only dye two colors at utmost, therefore, the yield and the quantity of colors are limited to a certain extent. The invention colors the fabrics by the coloration device, the employed coloration device comprises a plurality of spray coloration apparatuses capable of regulating the concentration of a dyeing liquid, the plurality of spray coloration apparatuses are arrayed in one group or more than two groups, each spray coloration apparatus operates individually to independently regulate the concentration of the dyeing liquid sprayed by each spray coloration apparatus so that the concentration of the dyeing liquid sprayed by each group of the spray coloration apparatuses is regulated to be incremented or decremented in sequence, thus generating, on the fabric, the gradual colors of one or more than two colors at a time.

Owner:ZHEJIANG SILK TECH

Polyamide fiber in-situ mineralization deep water-saving emission reduction dyeing post-treatment method and auxiliaries

The invention discloses a method for polyamide fiber in-situ mineralization deep water-saving and emission-reducing dyeing after-treatment. The method comprises the following steps: putting a to-be-dyed textile into dyeing equipment, adding dyeing water, and keeping dye-bath cycling to perform preparation before dyeing; performing dyeing processing on the to-be-dyed textile according to a general dyeing method of polyamide fibers; synchronously performing in-situ mineralization treatment on a dyeing residual bath and the dyed textile by using polyamide fiber dyeing after-treatment auxiliary agents XAJ, XBJ and XYJ; storing the dyeing residual bath subjected to the mineralization treatment to serve as water for subsequent dyeing; and dehydrating and drying the dyed textile to finish the whole dyeing after-treatment processing. The invention also discloses the polyamide fiber dyeing after-treatment auxiliary agents XAJ, XBJ and XYJ. By adopting the method for the polyamide fiber in-situ mineralization deep water-saving and emission-reducing dyeing after-treatment, the problems of water consumption and wastewater discharge during dyeing processing of the polyamide fibers are fundamentally solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

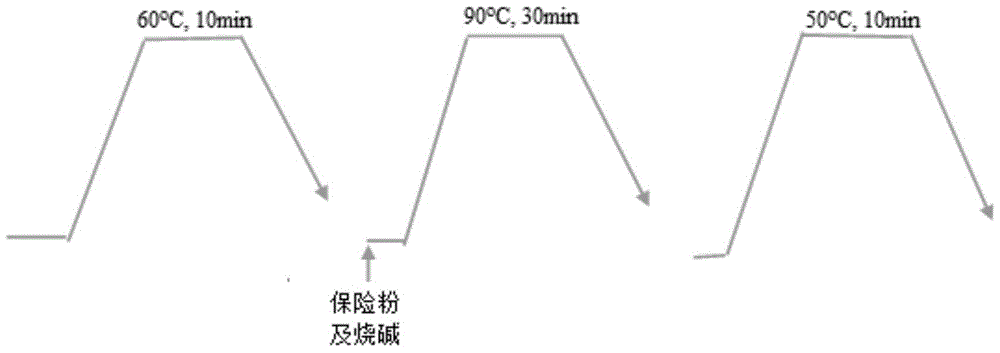

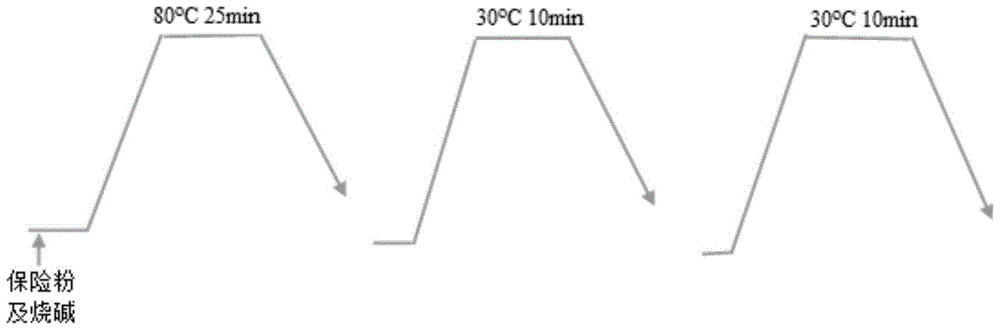

Repairing method of abnormal stains and stains of nylon cloth

ActiveCN107299546BReduce quality impactSave water for dyeingLiquid/gas/vapor removalHeating/cooling textile fabricsBiotechnologyMedicine

The invention relates to a method for repairing abnormal color spots and color patterns of nylon cloth, and belongs to the technical field of nylon cloth dyeing. The method comprises the following steps: unreeling abnormal nylon grey cloth, repairing color, fixing the color, dewatering, drying, performing in-process inspection, and shaping. Compared with the conventional color repairing technology, the method provided by the invention has the advantages as follows: under the condition that fading is not required, color repairing can be completed only by once dipping treatment, so that a lot of dyeing water is saved and influence on the quality of the cloth is relatively small; the secondary bleaching and dyeing process after fading is omitted, so that the color repairing time is greatly shortened, the using amounts and the types of dye, auxiliary agents and other chemical reagents are reduced, and the sewage discharge amount is reduced; the process of repairing the color spots and the color patterns of the conventional nylon cloth are effectively shortened and the production cost is significantly reduced; therefore, the method can be popularized and applied in the field.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

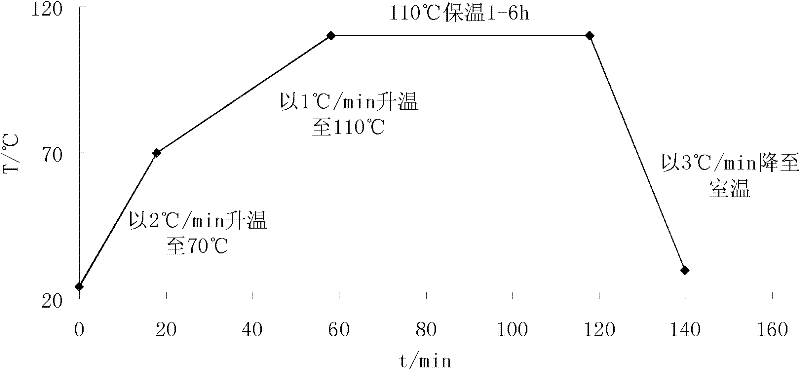

In-situ mineralization of disperse dyes, deep water saving and emission reduction dyeing post-treatment method and auxiliaries

ActiveCN104695238BReduced dichromate indexGuaranteed color fastnessDyeing processDisperse dyePollutant emissions

The invention discloses a dispersed dye in-situ mineralization and deep water conservation emission reduction dyeing aftertreatment method which comprises the following steps: firstly, putting a fabric to be dyed into dyeing equipment, adding dyeing water into the dyeing equipment, and keeping circulation of a dye bath; performing conventional dyeing processing on the fabric to be dyed in the dyeing equipment by using dispersed dye and using a high-temperature high-pressure dyeing method, and after dyeing is completed, retaining the residual dyeing bath; further simultaneously performing in-situ mineralization treatment on the residual dyeing bath and the dyed fabric; finally storing the residual dyeing bath obtained after the treatment as later dyeing water, and dehydrating and drying the dyed fabric, thereby completing the whole aftertreatment process. The invention further discloses three additives used in the dyeing aftertreatment method. By adopting the aftertreatment method disclosed by the invention, later reduction washing and water washing after dyeing can be avoided, the residual dyeing liquid after the in-situ mineralization treatment can be further reused in later dyeing treatment, and thus the water consumption and the pollutant discharge amount of the whole dyeing treatment can be greatly reduced.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com