In-situ mineralization and water-saving emission-reduction dyeing post-treatment method for polyacrylonitrile fibers and auxiliary agents

A technology of polyacrylonitrile fiber and in-situ mineralization is applied in the field of textile dyeing and finishing, which can solve the problems of large water consumption and large waste water discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

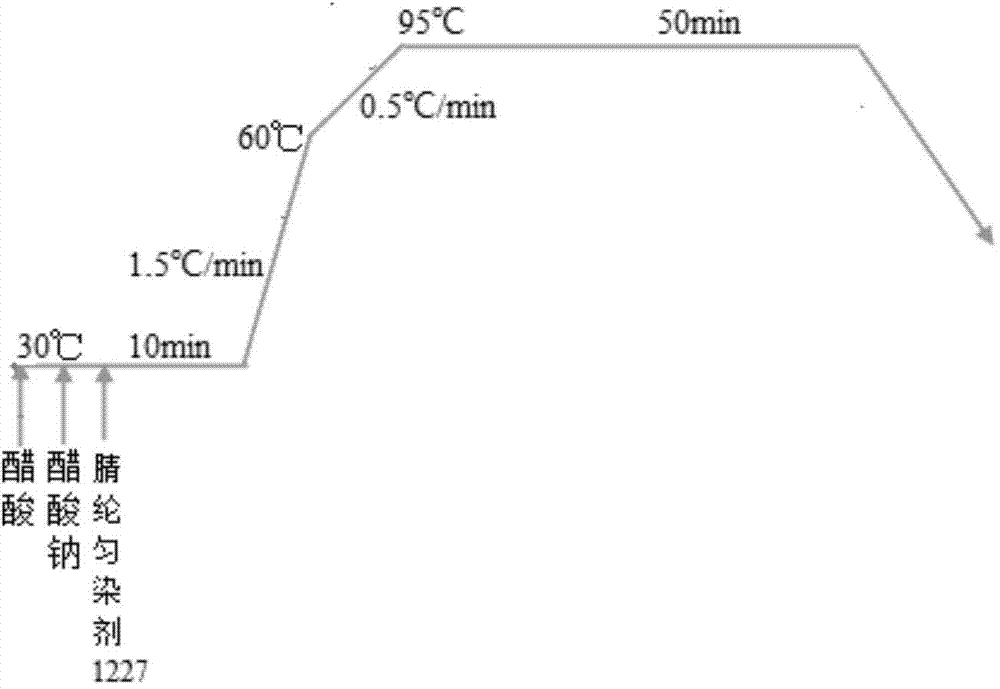

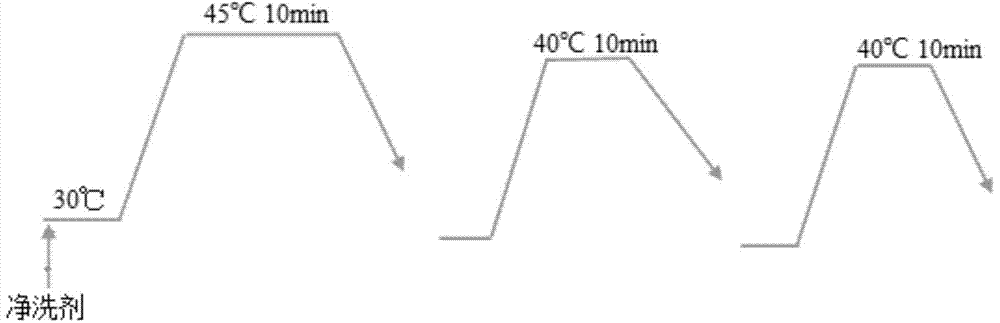

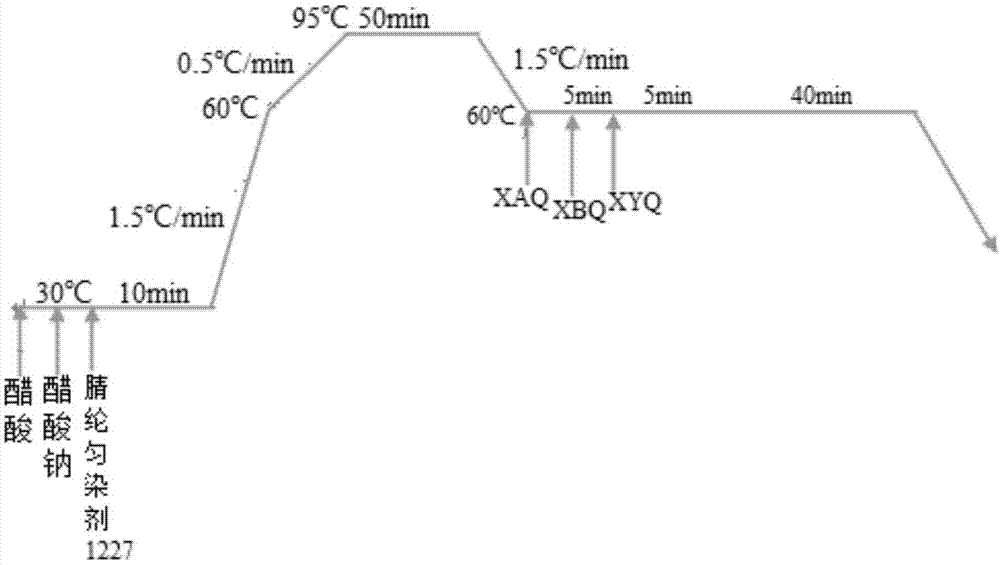

Method used

Image

Examples

Embodiment 1

[0118] Polyacrylonitrile fiber dyeing post-treatment auxiliary XAQ, composed of the following raw materials by mass percentage: polyacrylamide 1%, polyaluminum sulfate 1.5%, dodecyl dimethyl benzyl ammonium chloride 6.0%, dioctadecane Base-methyl benzyl ammonium chloride 0.5%, dioctadecyl dimethyl ammonium chloride 1.0%, Pingpingjiao 15%, purified water 75%, the total content of the above components is 100%;

[0119] The preparation method of XAQ, the post-processing auxiliary agent for polyacrylonitrile fiber dyeing: Weigh the following raw materials according to mass percentage: polyacrylamide 1%, polyaluminum sulfate 1.5%, dodecyl dimethyl benzyl ammonium chloride 6.0%, 0.5% dioctadecyl-methyl benzyl ammonium chloride, 1.0% dioctadecyl dimethyl ammonium chloride, 15% Ping Pinga O, 75% pure water, the total content of the above components is 100%; The weighed polyacrylamide, polyaluminum sulfate, dodecyl dimethyl benzyl ammonium chloride, dioctadecyl-methyl benzyl ammonium c...

Embodiment 2

[0126] Polyacrylonitrile fiber dyeing post-treatment auxiliary XAQ, composed of the following raw materials by mass percentage: polyacrylamide 1.5%, polyaluminum sulfate 2.0%, dodecyl dimethyl benzyl ammonium chloride 5.0%, dioctadecane Base-methyl benzyl ammonium chloride 0.8%, dioctadecyl dimethyl ammonium chloride 1.5%, Pingpingjiao 12%, purified water 77.2%, the total content of the above components is 100%;

[0127] The preparation method of XAQ, the post-processing auxiliary agent for polyacrylonitrile fiber dyeing: Weigh the following raw materials according to mass percentage: polyacrylamide 1.5%, polyaluminum sulfate 2.0%, dodecyl dimethyl benzyl ammonium chloride 5.0%, 0.8% dioctadecyl-methylbenzyl ammonium chloride, 1.5% dioctadecyldimethyl ammonium chloride, 12% Ping Pinga O, 77.2% pure water, the total content of the above components is 100%; The weighed polyacrylamide, polyaluminum sulfate, dodecyl dimethyl benzyl ammonium chloride, dioctadecyl-methyl benzyl ammo...

Embodiment 3

[0134] Polyacrylonitrile fiber dyeing post-treatment auxiliary XAQ, composed of the following raw materials by mass percentage: polyacrylamide 1.0%, polyaluminum sulfate 1.3%, dodecyl dimethyl benzyl ammonium chloride 3.0%, dioctadecane Base-methyl benzyl ammonium chloride 1.0%, dioctadecyl dimethyl ammonium chloride 1.2%, Pingpingjiao 10%, purified water 82.5%, the total content of the above components is 100%;

[0135] The preparation method of polyacrylonitrile fiber dyeing post-treatment auxiliary agent XAQ: Weigh the following raw materials according to mass percentage: polyacrylamide 1.0%, polyaluminum sulfate 1.3%, dodecyl dimethyl benzyl ammonium chloride 3.0%, 1.0% dioctadecyl-methylbenzyl ammonium chloride, 1.2% dioctadecyldimethyl ammonium chloride, 10% Ping Pinga O, 82.5% purified water, the total content of the above components is 100%; The weighed polyacrylamide, polyaluminum sulfate, dodecyl dimethyl benzyl ammonium chloride, dioctadecyl-methyl benzyl ammonium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com