Patents

Literature

88results about How to "Guaranteed color fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

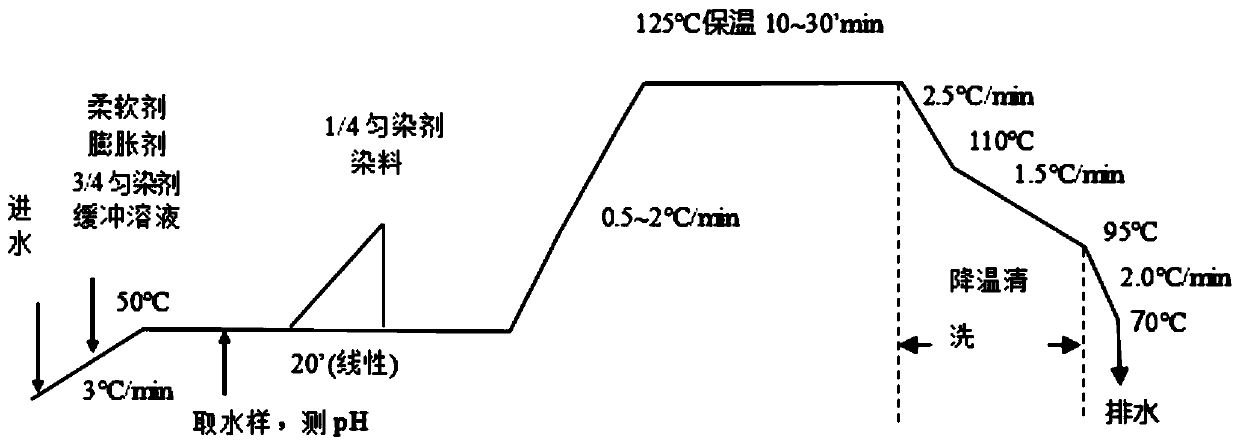

Method for dyeing superfine terylene fabric

ActiveCN104878618AGuaranteed color fastnessImprove dye uptakeDyeing processDisperse dyeColour fastness

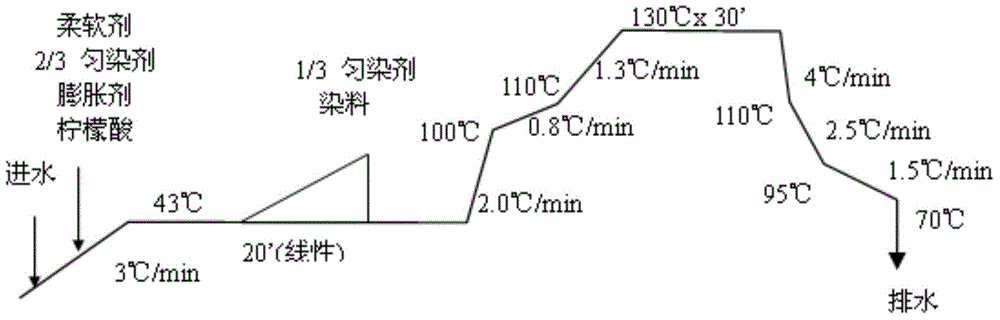

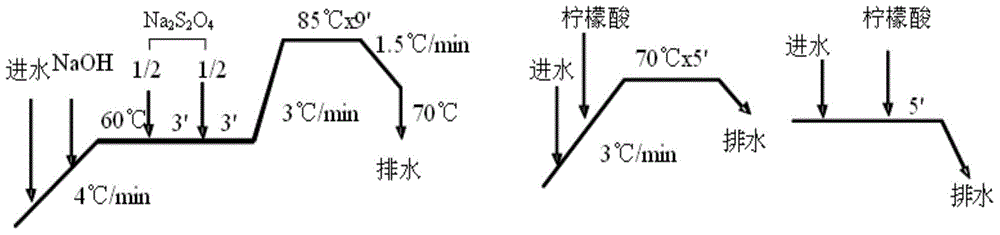

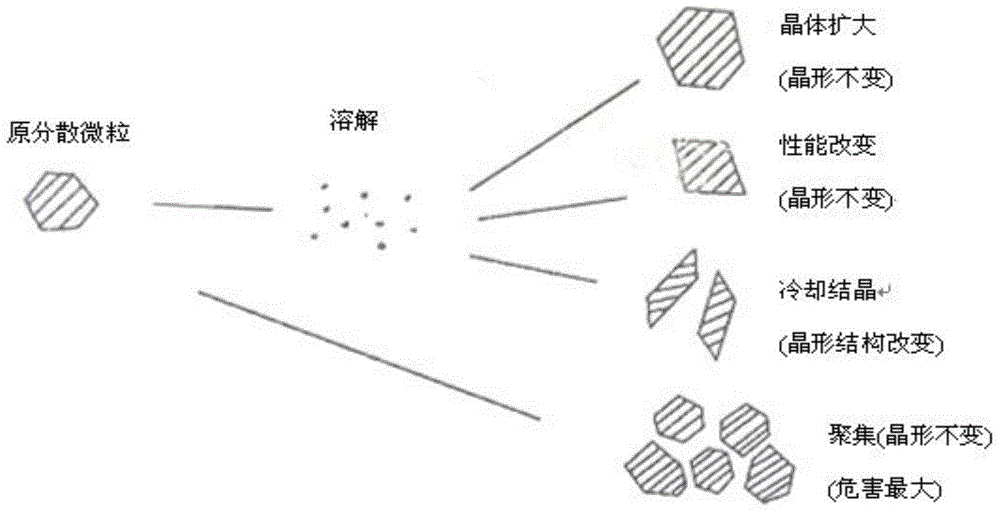

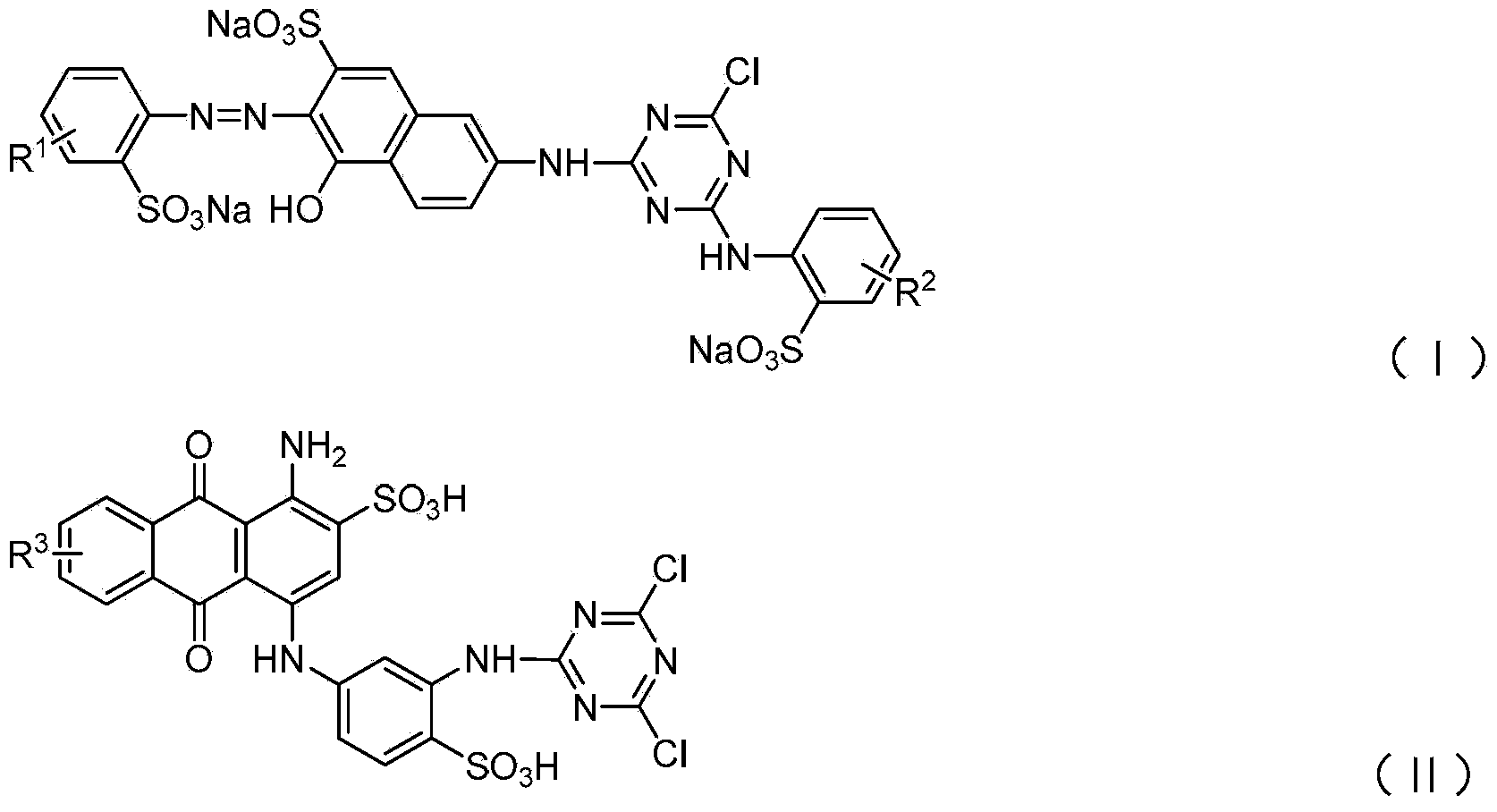

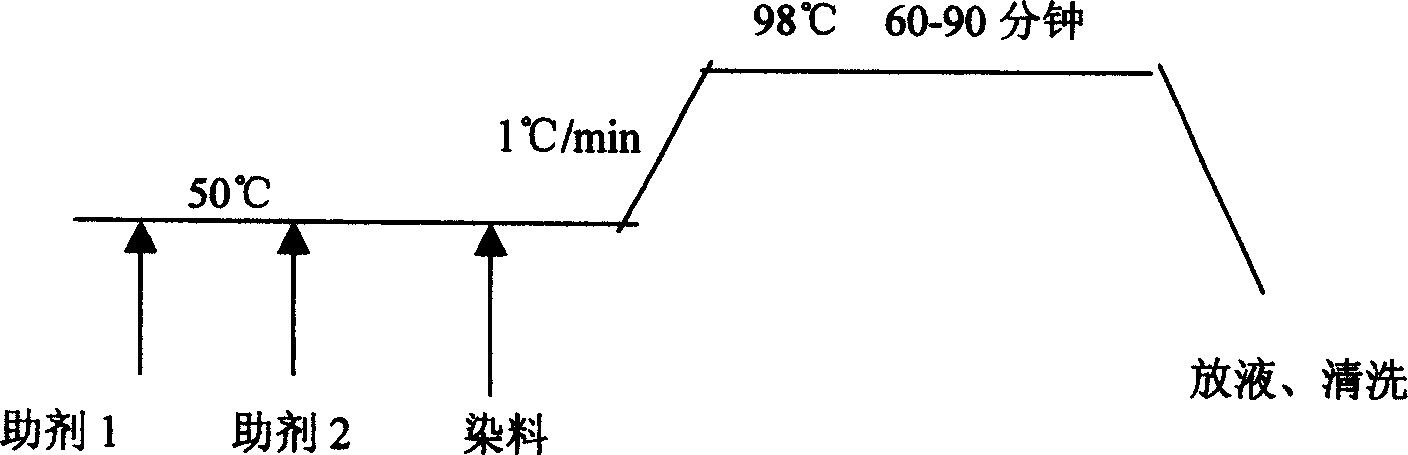

The invention discloses a method for dyeing a superfine terylene fabric. The method comprises the following dyeing steps: adding a softening agent, part of a leveling agent, and an expansive agent into the soppy superfine terylene fabric to prepare a working solution; adding a pH regulator to regulate the pH value of the working solution to 3.5-4.0; heating the working solution with the adjusted pH value to 43 DEG C, and adding disperse dye and the residual leveling agent to prepare a dye liquor; carrying out heating and dyeing. The method aims at dyeing of a brightly colored superfine terylene fabric, and has the advantages the softening agent, the leveling agent and the expansive agent are added simultaneously, and the pH value of the dye liquor is regulated to 3.5-4.0, so that poor leveling property, uneven dyeing and other quality problems existing in a low-bath-ratio dyeing process can be solved; moreover, the dye-uptake rate of the disperse dye can be improved, secondary aggregation of the disperse dye in a high-temperature descending process is prevented, all color fastness indices of the superfine terylene fabric exceed 4-level, the dyeing property is improved, and the dyeing effect is ideal; the method further has the advantages of being environment-friendly and low in energy consumption.

Owner:PACIFIC (PANYU) TEXTILES LTD

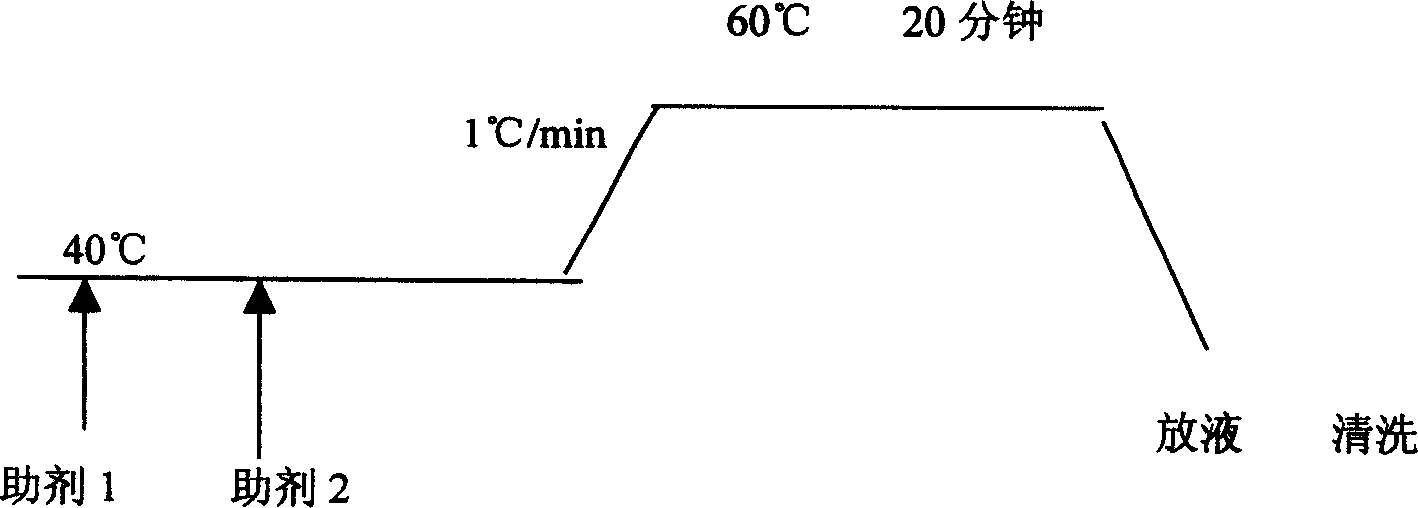

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

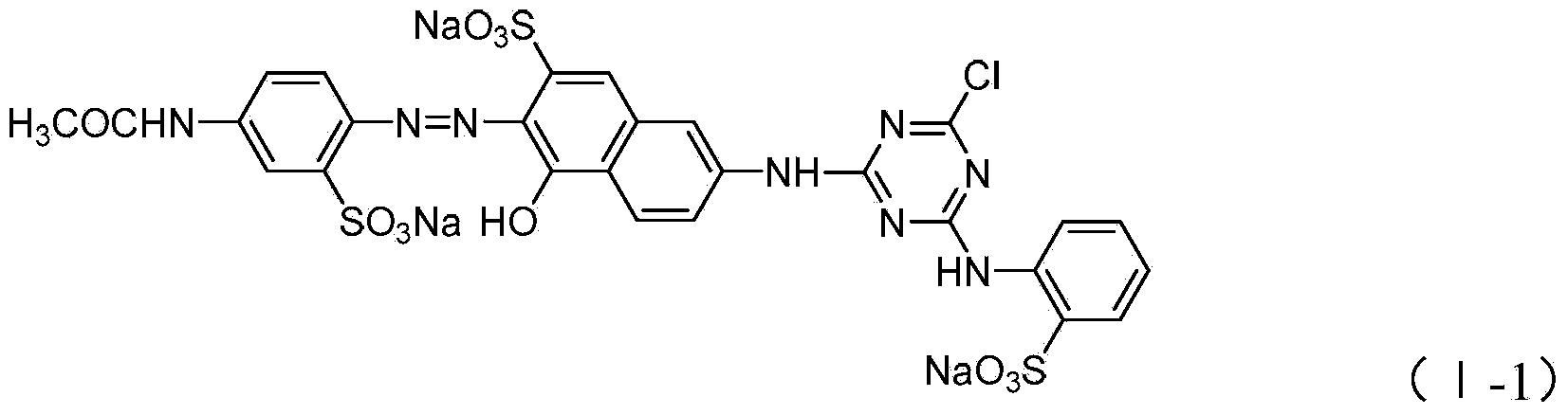

Staining method for aramid fiber

ActiveCN104695239AReduce pollutionAvoid damageBiochemical fibre treatmentFibre typesColour fastnessAramid

The invention provides a staining method for aramid fiber. The staining method comprises the steps of preprocessing, preshaping, staining, reduction clearing, color fixing, soft processing, drying, shaping, calendaring and rolling. According to the staining method, DEET is added in to serve as a dye carrier, and the staining effect and efficiency are improved; meanwhile, substitute alkali is adopted to replace a conventional soda substance, and not only is the usage amount decreased, but also the color fixing effect is enhanced to enable the washability of the aramid fiber is further enhanced; the reduction clearing and color fixing processes are added, and therefore the staining fastness is good; green and environmental-friendly non-formaldehyde TCD-R is adopted in the color fixing process, the fiber is dried step by step after color fixing, and therefore the firmness of the fiber is greatly improved; the soft processing process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and therefore the fabric is fluffy and rich in elasticity.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

Salt-free dyeing process for natural silk fabric

InactiveCN104746365AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsFiberInorganic salts

The invention provides a salt-free dyeing process for natural silk fabric. The salt-free dyeing process comprises the following steps: pre-treatment, pre-setting, modified treatment, dyeing, soaping, fixation, after-treatment, drying, setting, calendaring and rolling. The fabric is subjected to modified treatment with a cationic modifying agent, so that the dyeing rate of the fabric is increased; and the difficulty in the subsequent dyeing step is reduced. In the dyeing procedure, inorganic salts such as anhydrous sodium sulphate or table salt are not used, so that the pollution is reduced. Due to the addition of the soaping and fixation processes, the dyeing fastness is good. Green environment-friendly aldehyde-free TCD-R is adopted in the fixation process; and the fiber is gradually dried after fixation, so that the fastness of the fiber is greatly improved. Due to the addition of the after-treatment process, the color fastness and the softness of the fabric are improved; the roughness sense of the fabric is relieved; and the fabric is fluffy and elastic.

Owner:太仓市宝明化纤有限公司

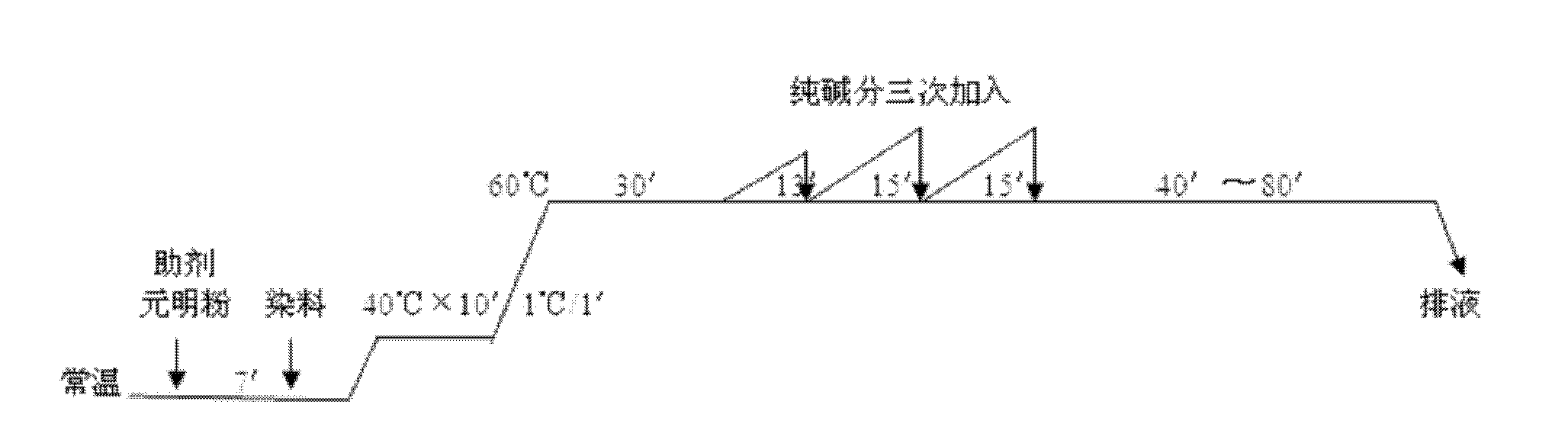

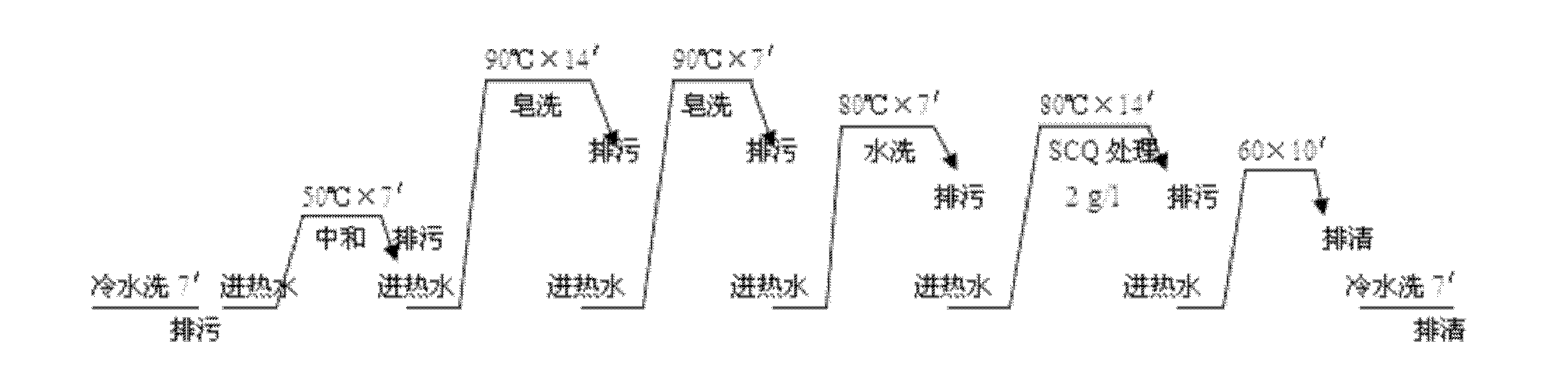

Dyeing processing technology of polylactic acid fiber shuttle looms cloth

The invention relates to a dyeing and processing technique for polylactic acid fiber woven fabric, belonging to the technical field of dyeing of textiles. Pure PLA fiber woven fabric or PLA fiber / cotton mixed woven fabric completing preprocessing and dyeing liquor are put into an overflow dyeing machine, temperature rises to 70 DEG C plus or minus 5 DEG C and then rises to 85-95 DEG C at a rate of 1-2 DEG C / min, the temperature is maintained for 5-10 minutes; if the fiber woven fabric is dyed in medium and light colors, then the temperature keeps rising to 95-105 DEG C at a rate of 1-2 DEG C / min, the temperature is maintained for 30-45min; if the fiber woven fabric is dyed in dark colors, the temperature rises to 110-120 DEG C at a rate of 1-2 DEG C / min, the temperature is maintained for 45-60min and then lowered to 60-70 DEG C for soaping; at the temperature of 40 DEG C plus or minus 5 DEG C, reactive dyes and sodium sulphate are continued to be added to PLA fiber / cotton mixed woven fabric, then the temperature is maintained, afterwards, calcined soda is added when the temperature rises to 60 DEG C at a rate of 1-2 DEG C / min, the temperature is lowered for washing after being maintained for 30 plus or minus 5min. The technique features reasonable design, simple and convenient operation and can effectively reduce dosage of addition agent and environmental pollution.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Dyeing technology for brocade-cotton blended fabric

A disclosed dyeing technology for brocade-cotton blended fabric comprises the following steps: (1) adding a dye and an auxiliary agent into water to prepare a dye solution, controlling the temperature of the dye solution at 20-30 DEG C, then adding brocade-cotton blended fabric, keeping the temperature for 5-10 min, heating to 55-65 DEG C at a speed of 1-3 DEG C / min, keeping the temperature for 20-40 min, adding an alkali to adjust pH to 9-10 for dye fixation, then keeping the temperature for 20-40 min to obtain a dyed half-finished product; and (2) adding glacial acetic acid into the dyed half-finished product to adjust pH to 4-4.5, heating to 80-90 DEG C at a speed of 1-3 DEG C / min, successively performing water washing, soaping, water washing and drying to obtain the dyed finished product. The level-dyeing property of the dyeing technology and the dye spreadability on fabric of the dye are excellent, hydrolyzed dye is less, dye fixation rate is improved, discharged wastewater is reduced, and the dyeing technology has the advantages of being substantial in energy-saving, emission-reduction and environment-friendly.

Owner:ZHEJIANG SHUNLONG CHEM

Deep color dyeing and finishing technique of poly lactic acid (PLA) fiber and gossamer fiber blending fabrics

ActiveCN102864663AGuaranteed StrengthGuaranteed feelHeating/cooling textile fabricsDry-cleaning apparatus for textilesChemistryAfter treatment

A deep color dyeing and finishing technique of poly lactic acid (PLA) fiber and gossamer fiber blending fabrics comprises the following steps of greige cloth sewing, preliminary shaping, preliminary treatment, dyeing, fixation, dehydration and an after treatment process. The deep color dyeing and finishing technique of PLA fiber and gossamer fiber blending fabrics uses a dual-bathing method to dye. A mesotherm type disperse dye is used for dyeing (enabling color to be deep) PLA fibers, and a carrier is added during dyeing. An environment-friendly mesotherm direct dye is used for dyeing (enabling color to be deep) gossamer fibers, fixation treatment is carried out after dyeing, fibers with two components can be dyed into a deep color simultaneously, and strength and feeling of the PLA fibers and the gossamer fibers are guaranteed.

Owner:ZHEJIANG DANENG TEXTILE PRINTING & DYEING

Dyeing process of regenerated polyester

The invention provides a dyeing process of regenerated polyester. The dyeing process is characterized by comprising the following steps of (1) performing high-temperature presetting: performing high-temperature presetting on regenerated polyester fabric; (2) performing pretreatment oil removal: performing oil removal treatment on the regenerated polyester fabric subjected to presetting in step (1)by utilizing an oil removal agent; (3) performing dyeing: dyeing the regenerated polyester fabric subjected to pretreatment oil removal in step (2) in dye liquor; (4) performing cleaning: introducingwater into the dye liquor subjected to dyeing in step (3), and performing cooling and cleaning the dyed regenerated polyester fabric; and (5) performing setting: setting the regenerated polyester fabric cleaned in step (4). According to the dyeing process of the regenerated polyester, the defect that the dyeing color light is unstable due to excessive knitting oil on the surface of the regenerated polyester fabric is overcome, and the problems that the regenerated polyester fabric is low in strength and poor in color fastness are solved.

Owner:PACIFIC (PANYU) TEXTILES LTD

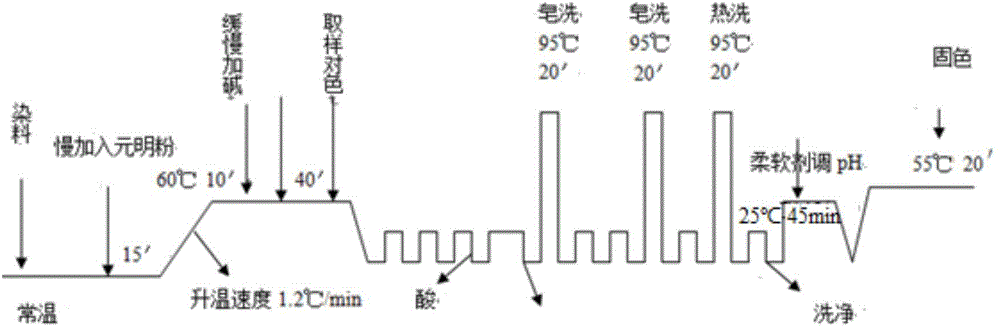

Cellulosic fiber in-situ mineralization deep water-saving and emission reduction dyeing aftertreatment method and additive

The invention discloses a cellulosic fiber in-situ mineralization deep water-saving and emission reduction dyeing aftertreatment method which comprises the following steps: firstly, putting a fabric to be dyed into dyeing equipment, adding dyeing water into the dyeing equipment, and keeping circulation of a dye bath; performing dyeing processing on the fabric to be dyed by using a common deying method for the cellulosic fiber, and after dyeing is completed, retaining the residual dyeing liquid; further simultaneously performing in-situ mineralization treatment on the residual dyeing liquid obtained after cellulosic fiber dyeing processing and the dyed fabric by using cellulosic fiber aftertreatment additives XAC, XBC and XYC; storing the residual dyeing liquid obtained after the mineralization treatment as later dyeing water; dehydrating and drying the dyed fabric, thereby completing dyeing and aftertreatment on the fabric. The invention further discloses the cellulosic fiber dyeing aftertreatment additives XAC, XBC and XYC. By adopting the dyeing aftertreatment method disclosed by the invention, the water consumption problem and the wastewater discharge problem in the cellulosic fiber dyeing processing can be fundamentally solved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Water-saving dyeing process of cheese

InactiveCN103806308ASoft touchThe color difference between the inner and outer layers is not obviousDyeing processYarnElectricity

The invention provides a water-saving dyeing process of cheese, and the cheese is dyed by yarn pretreatment, dyeing and dyeing postprocessing. According to the water-saving dyeing process of the cheese, a refining agent is chosen to replace caustic soda and hydrogen peroxide of a traditional process for the yarn pretreatment, and the refining agent can ensure that yarn is soft in hand feeling, is unconspicuous in inner and outer-layer color difference, and is basically free of reparation and broken end phenomenon, a woven fabric is smooth, the weight loss rate is reduced to about 3%, acid pickling is not needed, the time is short, and is shortened by 30 minutes to 1 hours compared with that of the traditional process, so that the water, electricity and time are saved, the bleaching consumption is low, the dyeing quality is good, and the comprehensive cost is low. At the same time, in the water-saving dyeing process of the cheese, a neutral electrolyte is added for accelerating the dying in a diffusion stage, the dye uptake of the cheese is ensured, and the problems of dyeing defects, deep and shallow strips, great inner and outer-layer difference and the like can be avoided.

Owner:WUHU FUCHUN DYEING & WEAVING

One-bath dyeing technology for protein fiber and PTT fiber

A codyebath process for protein fiber and PTT fiber is characteristic of that firstly the disperse dye is used to dye PTT fiber and added with protein fiber protectant to reduce the damage to protein fiber, then cleaning by additive, fully removing loose color to keep PTT fiber fastness, then added with protein fiber adoptive dye, through cleaning by ammonia and fixing by color fixatives to keep the fastness of protein fiber.

Owner:INNER MONGOLIA ERDUOSI CASHMERE PRODS

Copper electroplate liquid and preparation method thereof

The invention relates to a copper electroplate liquid and a preparation method thereof. The formula of the electroplate liquid comprises the following raw materials: 80-150g / L of copper sulfate, 50-90g / L of copper chloride, 40-70g / L of sodium sulfate, 60-120g / L of potassium sulphate, 5-30g / L of a brightener, 5-20g / L of a wetting agent, 25-55g / L of a buffer agent and deionized water added to 1,000ml. The method comprises the following steps: putting the deionized water into a container; weighing a proper amount of brightener and a proper amount of wetting agent, stirring and dissolving; weighing a proper amount of copper sulfate and a proper amount of sulfur copper chloride to a solution, stirring and dissolving at room temperature; adding sodium sulfate and potassium sulphate to the solution; and heating the solution to 55-65 DEG C, heating and stirring, and then adjusting the pH value of the solution by adopting the buffer agent. A clad layer formed by the method is good in ductility, free of brittleness, bright in surface, high in flatness, strong in throwing power and covering power, and high in current efficiency; the electroplate liquid is non-toxic; and a high-density zone of the clad layer is not scorched.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Paste for digital printing as well as preparation method and application thereof

The invention discloses a paste for digital printing as well as a preparation method and application thereof. The paste is prepared from the following components in percentage by weight: 1-5% of sodium alginate, 1-5% of modified starch, 1-5% of sodium hydrogen carbonate, 3-15% of carbamide, 0.1-1% of reserve salt and water. When the paste is used for digital printing of silks and cotton cloths, the paste has better color yield and flower type fineness while the color fastness is ensured.

Owner:浙江劲光纺织科技有限公司

Dyeing and post-finishing process of woolen bamboo polyester fabrics

InactiveCN102517754AUniform coloring effectGuaranteed color fastnessSingeingDry-cleaning apparatus for textilesPolyesterFiber

The invention discloses a dyeing and post-finishing process of woolen bamboo polyester fabrics, which includes steps: firstly joining ends of gray fabrics, namely using a splicer to joining the ends of the gray fabrics; secondly, singeing, brushing and shearing; thirdly, desizing, boiling off and using an open-width washing machine for scouring; fourthly, preshrinking for shaping; fifthly, using the high-temperature two-bath method for dyeing, namely using reactive dye of CibacronFN cotton at 60-65 DGE C for 50-60 minutes first, and then using acid dye to dye at 130-135 DEG C for 40-50 minutes; sixthly, soft finish shaping, namely performing soft finish shaping twice; seventhly, decatizing for shaping, wherein the internal pressure of a decatizing machine is 0.5-1.2bar, and the cold drawing time is 1-1.5 minutes; and eighthly, light decatizing for shaping, wherein the internal pressure of a decatizing machine is 0.4-0.5bar, and the cold drawing time is 1-1.5 minutes. By the dyeing and post-finishing process, loose colour of fabrics can be reduced, color fastness can be guaranteed, coloring is uniform, the characteristics of bamboo fiber products such as softness and moisture absorption are kept, hand touch is improved and woolen surfaces of the fabrics are flat, smooth and clear in texture.

Owner:HANGZHOU FUEN TEXTILE

Direct dyeing process for chemical fiber

InactiveCN104762828AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsColour fastness

The invention provides a direct dyeing process for a chemical fiber. The direct dyeing process for the chemical fiber comprises the steps of pretreatment, pre-shaping, modification treatment, dyeing, soaping, color fixing, after-treatment, drying, sizing, calendaring and rolling. According to the direct dyeing process for the chemical fiber, the modification treatment is added, so that performances of a chemical fabric are subjected to the modification treatment basically, the dyeing degree of the fabric is increased, and the difficulty of a subsequent dyeing step is reduced; during dyeing, the mass utilization of inorganic salt is avoided; furthermore, substitute alkali is used for replacing a conventional sodium carbonate substance, so that the consumption is reduced, a color fixation effect is also improved, and the washing fastness of the chemical fiber is further improved; soaping and color fixing processes are added, so that the dyeing fastness is good; environment-protection formaldehyde-free TCD-R is utilized in the color fixing process, and color-fixed fibers are gradually dried, so that the firmness of the fibers is greatly improved; the post-treatment process is added, so that the color fastness and the flexibility of the fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and has high resilience.

Owner:TAICANG CHENGLE CHEM FIBER

A cyanide-free silvering electroplating solution and a preparing method thereof

The invention relates to a cyanide-free silvering electroplating solution and a preparing method thereof. The electroplating solution comprises 50-90 g / L of silver nitrate, 40-70 g / L of potassium sulfate, 60-140 g / L of sodium sulfate, 30-50 g / L of a buffering agent, 5-25 g / L of a wetting agent and 5-35 g / L of a brightener, with the balance being deionized water and the total volume being 1000 mL. The electroplating solution is prepared by weighing a proper amount of the wetting agent according to the formula, adding the deionized water, stirring until the wetting agent is dissolved, weighing proper amounts of the silver nitrate, the potassium sulfate and the sodium sulfate, adding the weighed silver nitrate, the weighed potassium sulfate and the weighed sodium sulfate into the above-mentioned solution, stirring at room temperature until the silver nitrate, the potassium sulfate and the sodium sulfate are dissolved, heating the solution to 65 DEG C by using a water bath, adding a proper amount of the brightener, adjusting the pH value of the solution by using the buffering agent, and stirring uniformly. A plating formed by the electroplating solution is wear-resistant, good in corrosion resistance, high in brightness, good in conductivity and good in stability.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

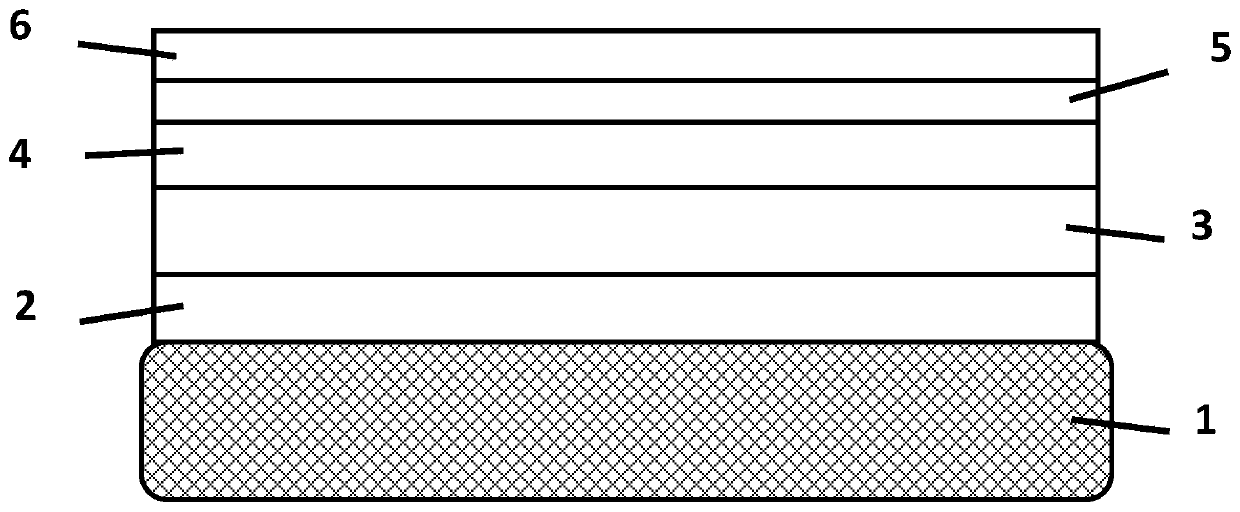

Color fiber fabric and production method thereof

InactiveCN110396670AEasy to oxidizeImprove anti-oxidation and anti-corrosion performanceVacuum evaporation coatingSputtering coatingFiberComposite film

The invention provides a production method of color fiber fabric. The production method comprises the following steps that at least one composite film is deposited on at least one surface of the fiberfabric through a vacuum deposition method, wherein the composite film sequentially comprises a cushioning layer, a reflective layer, a first protective layer, a color producing layer and a second protective layer from bottom to top; the color producing layer comprises at least one of ZnO, Fe2O3, TIO2 and CuO; and when the layers of the composite film are deposited, working gas needs to be continuously introduced, and the working gas comprises argon and / or nitrogen and / or oxygen. According to the production method, the color adjustment control of the fiber fabric is simple and practicable, theproblem that the metal film is easily oxidized is solved, and the oxidation resistance of a surface film of the fiber fabric is enhanced, so that colored film coated on the surface of the fiber fabric is more durable; and the method is suitable for industrial production. The invention further provides the color fiber fabric. The color fiber fabric is rich in color and good in color fastness and can be prepared through an industrial method.

Owner:北京斐摩科技有限公司

Trivalent chromium electroplating liquid and preparation method thereof

The invention relates to trivalent chromium electroplating liquid and a preparation method thereof. The formula of the trivalent chromium electroplating liquid is as follows: 50-150g / L of chromium chloride, 30-120g / L of chromium sulfate, 50-120g / L of sodium chloride, 40-80g / L of boric acid, 20-90g / L of a stabilizer, 5-25g / L of a complexing agent, 7-45g / L of a brightener and the balance of deionized water with the total volume of various components being 1000ml. The preparation method comprises the steps of weighting appropriate amounts of the stabilizer and the complexing agent according to the formula, adding deionized water and stirring until the stabilizer and the complexing agent are dissolved; weighting appropriate amounts of chromium chloride, chromium sulfate and sodium chloride into the solution, stirring at room temperature until chromium chloride, chromium sulfate and sodium chloride are dissolved; heating the solution to 65 DEG C by virtue of a water-bath pot, adding an appropriate amount of the brightener additive and adjusting the pH value of the solution with boric acid to obtain the trivalent chromium electroplating liquid. The formed electroplated layer has the advantages of good abrasion resistance, corrosion resistance and high brightness and the electroplating liquid has good stability in the storage and application processes.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Processing method of sun-proof and flame-retardant seat fabric

InactiveCN107299478AStrong sun protection performanceProcess OptimizationHeating/cooling textile fabricsTextile treatment machine arrangementsColour fastnessYarn

The invention discloses a processing method of sun-proof and flame-retardant seat fabric. The processing method of the sun-proof and flame-retardant seat fabric comprises the steps of preparing yarns, dyeing the yarns, performing color separation on the yarns, carrying out looming and weaving, shearing, washing with water, shaping, packaging and the like. The processing method of the sun-proof and flame-retardant seat fabric has the following advantages: sun-proof dye and an anti-UV improver are added in the yarn dyeing process, and the heating process of dyeing adopts a programmed heating mode, so that the sun-proof property of the fabric can be effectively enhanced; the raw materials in the yarn preparation process and the process are optimized, so that the color fastness of the yarns can be effectively enhanced; the shaping process is adjusted, so that the color fastness of the fabric can be guaranteed and the hand feeling of the fabric can be guaranteed.

Owner:JIANGSU TIANYUAN NEW MATERIAL CO LTD

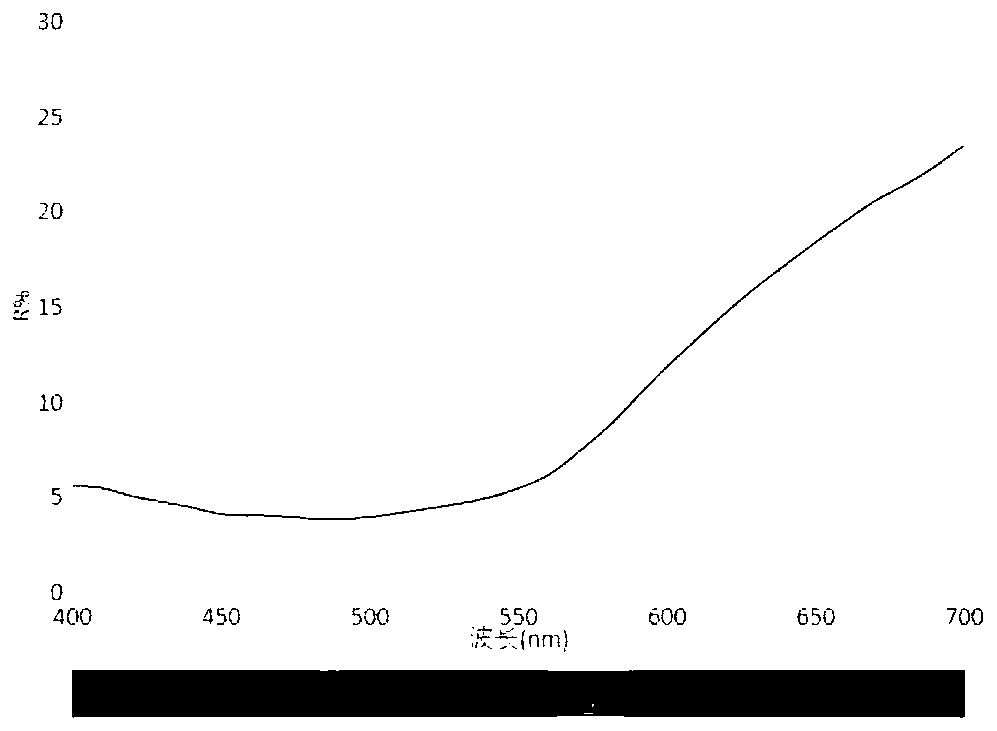

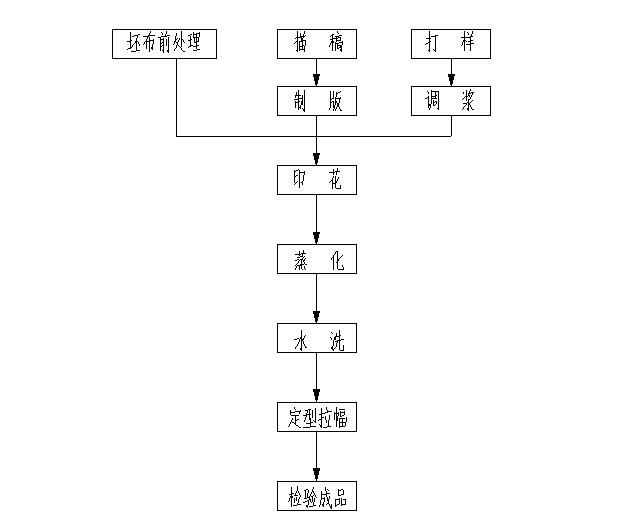

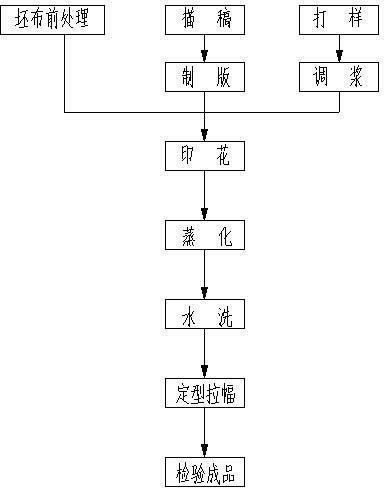

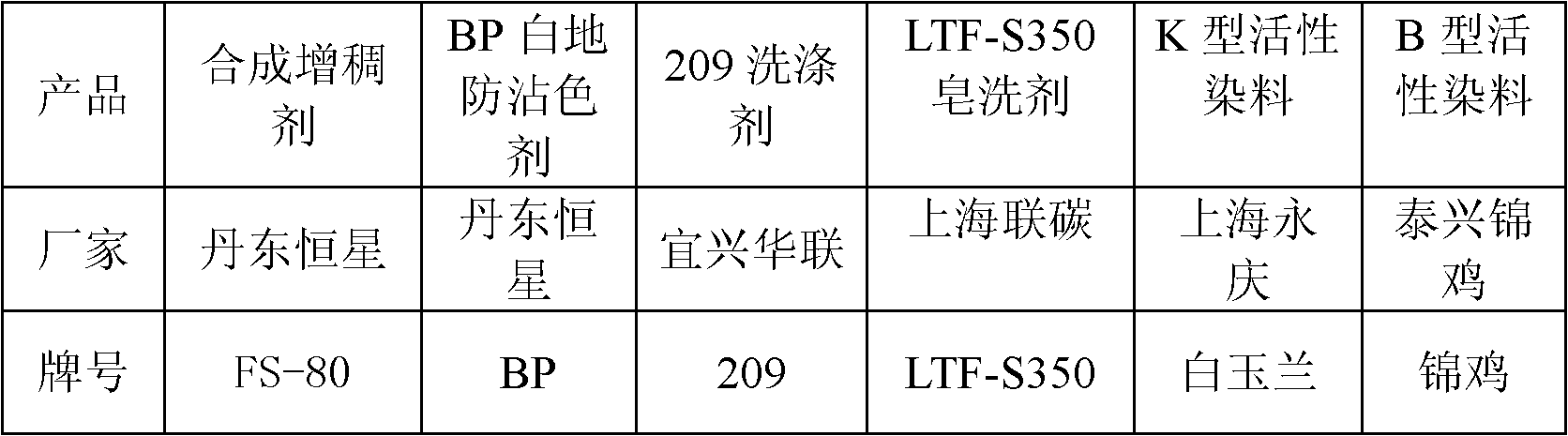

Silk floss memory satin reactive dye printing process

InactiveCN102634997AHigh printing fixation rateGuaranteed color fastnessDyeing processPre treatmentSizing

The invention relates to a silk floss memory satin reactive dye printing process, comprising the following processing steps of: firstly carrying out pre-treatment on a silk floss memory satin grey cloth which takes silk as a satin face and cotton and metal silk fiber as plain printing plates, and simultaneously completing preparation work of drawing and platemaking, proofing and size mixing; and then sequentially printing, ageing, washing, sizing and tentering as well as checking out a finished product. The silk floss memory satin reactive dye printing process is characterized in that printing paste used by printing contains dye, a paste material and a fixing agent, and the dye is K-type or B-type reactive dye. According to the invention, the reactive dye is used on the silk floss memory satin for printing, colour fastness is guaranteed, and appearance defects are reduced. According to different dyeing requirements, appropriate dyes are selected, thus printing fixation rate of a piece in deep colour can be high, and the printing colourpurity and brightness of the piece in light colour can be good; and appropriate pasting agent and auxiliaries are used by adjusting, washing time can be beneficially reduced, and colour fastness can be improved.

Owner:SHENGHONG GRP CO LTD

High-temperature environmentally-friendly chemical fiber dyeing technology

InactiveCN107164976AGuaranteed functionAvoid damageBiochemical treatment with enzymes/microorganismsDyeing processFiberCellulose

The invention relates to a high-temperature environmentally-friendly chemical dyeing technology. The technology comprises preprocessing, pre-setting, dyeing, water washing, soaping, dye fixation, softening, drying, setting and winding. A stepped heating dyeing method is adopted, and the heating and cooling rates and the dyeing time are strictly controlled, so dyeing of a fiber fabric has high fastness, the dyeing is uniform, and the dyeing has good stability; an anti-dyeing salt S is added in the dyeing process, so the destroy of potential aldehyde groups in cellulose molecules in chemical fiber filaments to a dye is greatly improved, thereby a dyed product has pure color light, the color difference of dyeing is avoided, and the reappearance and the stability of the dyeing are good. Chemical fiber filaments finally produced in the invention have the advantages of uniform dyeing, stability, strong recurrence, elasticity, softness and high dyeing fastness.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

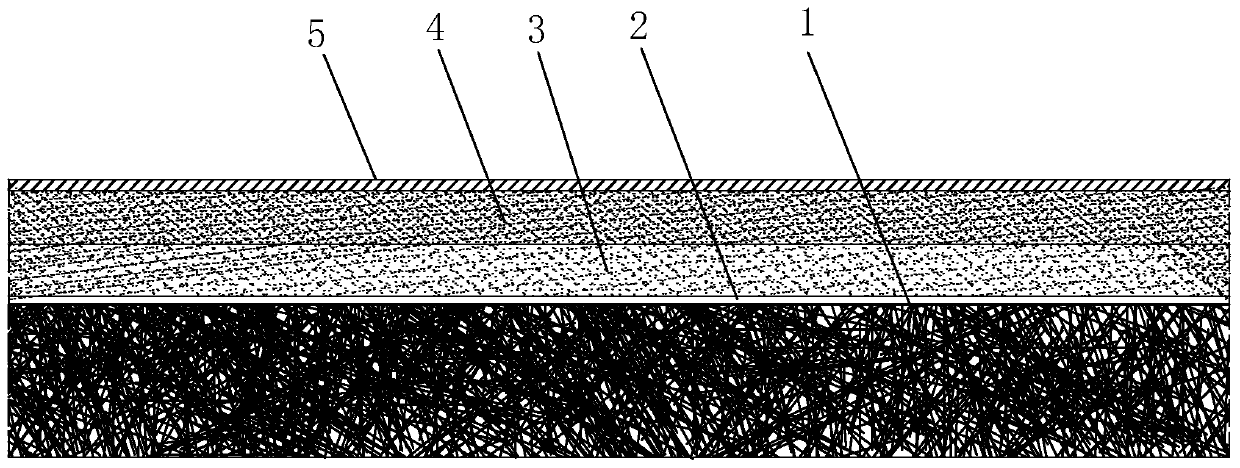

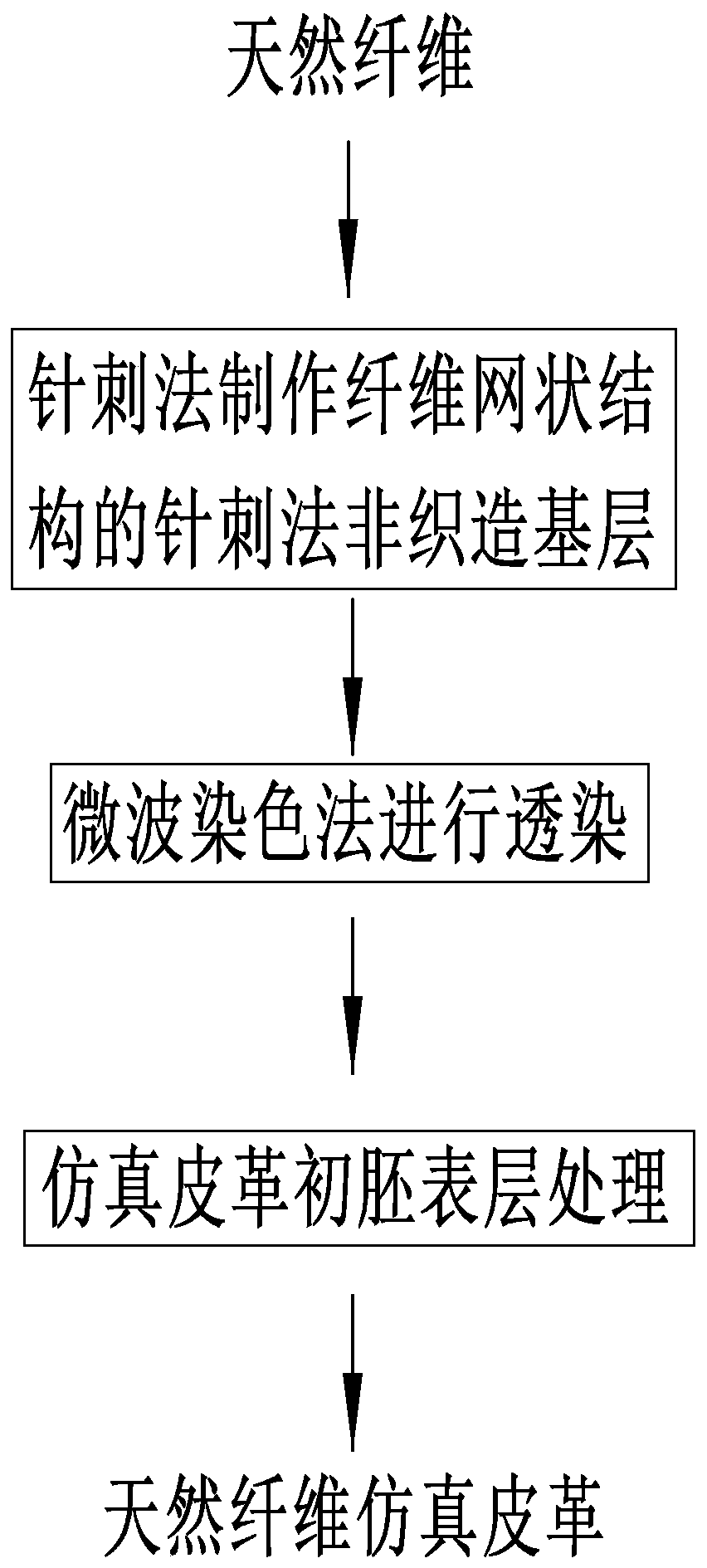

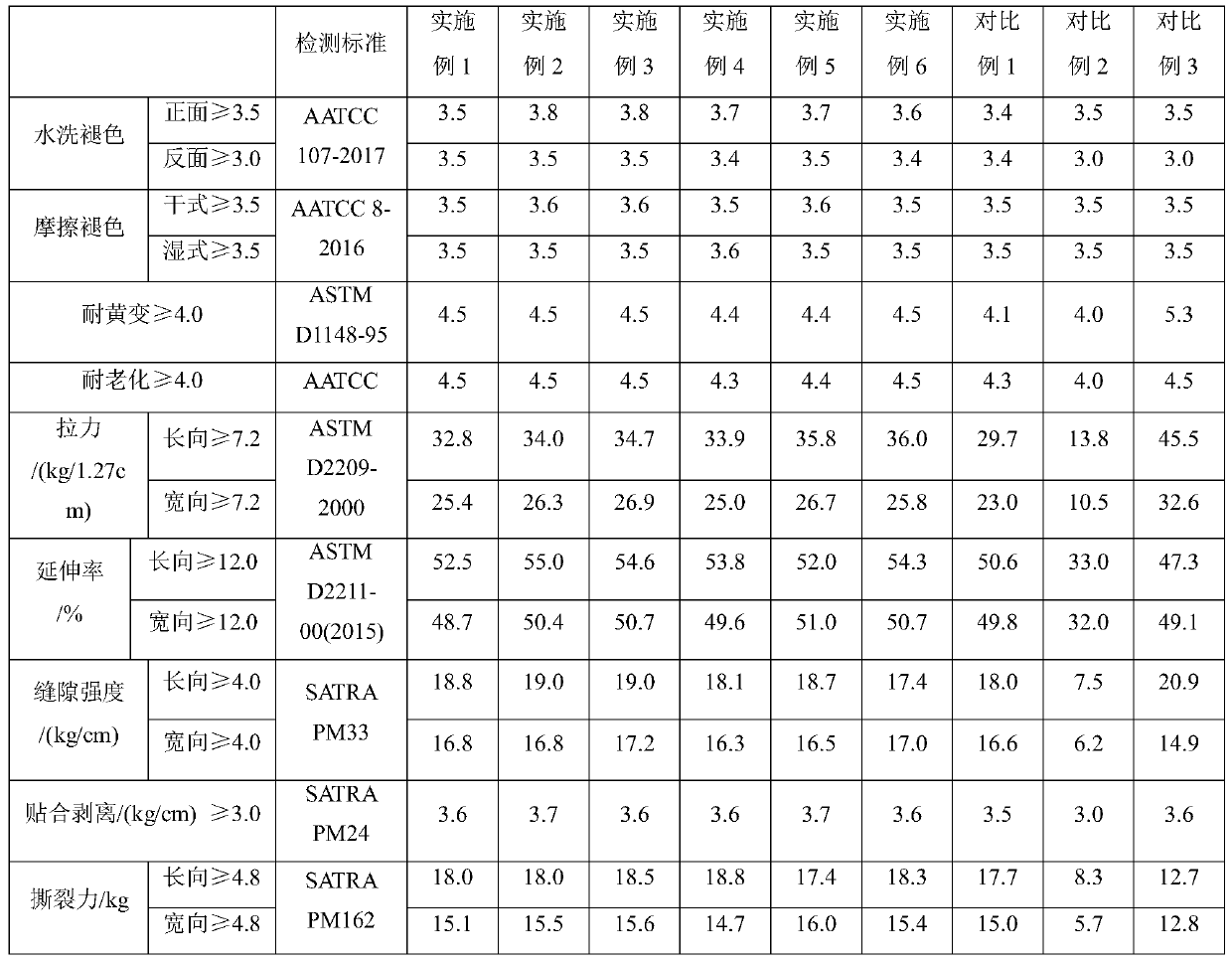

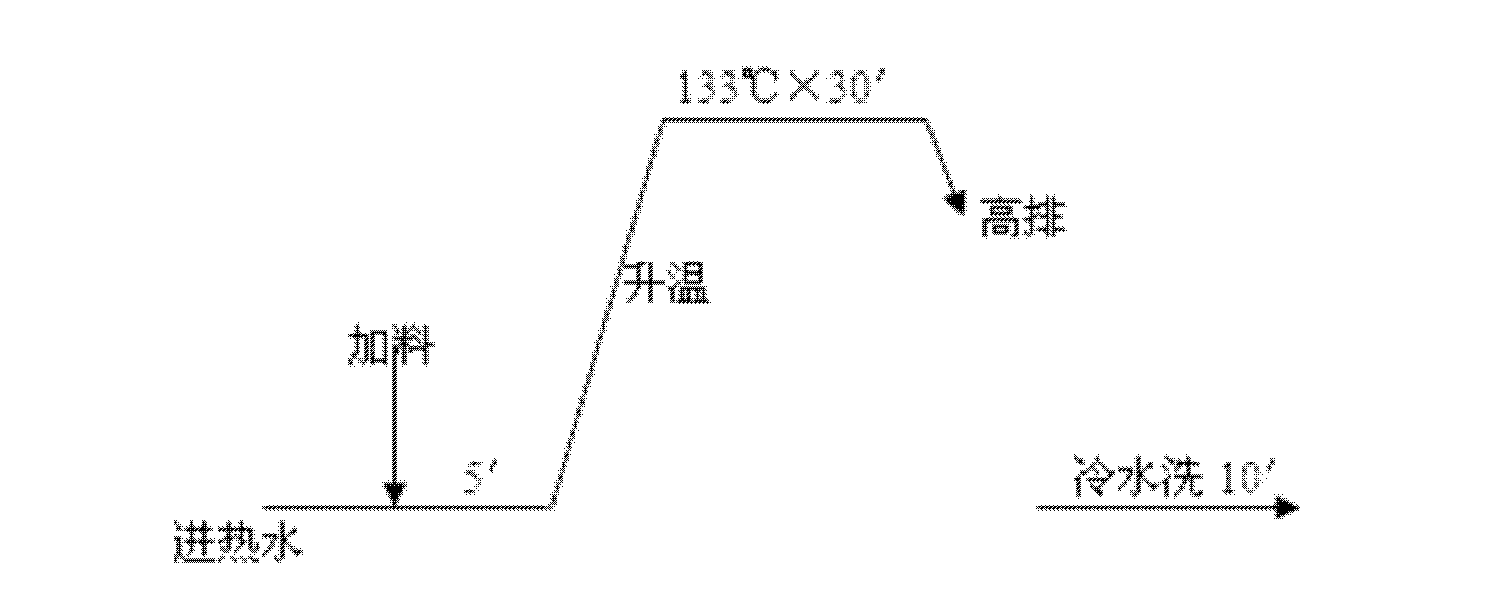

Natural-fiber artificial leather and manufacturing method thereof

ActiveCN110592968AReduce energy consumptionSolve the problem of high water consumptionTextiles and paperWaxMicrowave

The invention relates to the technical field of leather processing, in particular to natural-fiber artificial leather and a manufacturing method thereof. The natural-fiber artificial leather is obtained through the following processing steps: opening, carding and dry-process needling treatment is sequentially conducted on natural fibers to obtain a needled non-woven base layer with a fiber net structure inside; by adopting a microwave dyeing method, the needled non-woven base layer is dyed with a chemical dye in a permeating way to obtain gray artificial leather; the upper surface layer of thegray artificial leather is sequentially coated with a bottom sealing layer, a first resin layer, a second resin layer and an oil wax layer in a rolling way, and polishing is carried out to obtain thenatural fiber artificial leather. By adopting the processing technology, energy is saved, emission is reduced, the method is friendly to the environment, the processed artificial leather has excellent washing fading performance and frictional fading performance and good dyeing firmness, the yellowing resistance and aging resistance reach the standard, and various mechanical properties such as tensile strength, tearing strength and elongation are all higher than the index requirements.

Owner:辛集市宝隆科技有限公司

A kind of preparation method of printing synthetic leather

ActiveCN102296470AIncrease productivitySame natureHeating/cooling textile fabricsDyeing processState of artPrinting ink

The invention discloses a preparation method of printed synthetic leather. The printed synthetic leather is prepared by a non-woven fabric warp direction directional elongation and high-temperature sizing step, a wet process warp direction directional elongation and high-temperature sizing step, a dry method face making step and a plate printing step using at least two colors of printing ink. Compared with the prior art, the defects such as the poor printing color fastness, low production efficiency, high cost and the like of the synthetic leather can be overcome; and the prepared printed synthetic leather has rich apparent flower color and patterns, and can be produced in a large scale.

Owner:QUANZHOU WANHUA SEWANG MICRO FIBER CO LTD

Dyeing pretreatment process for pineapple leaves-cotton blended knitted fabric

InactiveCN101608398AImprove dyeing performanceEnsure level dyeingBiochemical fibre treatmentSingeingChemistryDyeing

The invention provides a dyeing pretreatment process for pineapple leaves-cotton blended knitted fabric. The process is characterized by comprising the following steps: 1, soaking the pineapple leaves-cotton blended knitted fabric in oxygen bleaching solution at a temperature between 90 and 100 DEG C for 60 minutes; 2, soaking the blended knitted fabric in acetate solution at 50 DEG C for 10 minutes; 3, soaking the blended knitted fabric in soda solution at 80 DEG C for 30 minutes; and 4, feeding the blended knitted fabric into a KMM-260 singeing machine and performing gas singeing treatment,wherein the vehicle speed is 100 meters per minute, and the amount of oil is between 25 and 30. The process has the advantages of significantly promoting the dyeing properties of the pineapple leaves-cotton blended knitted fabric subjected to the pretreatment and guaranteeing color vividness, color fastness and level dyeing property thereof; in addition, the knitted fabric integrates the excellent performances of pineapple leaves and cotton and has a unique style.

Owner:DONGHUA UNIV +2

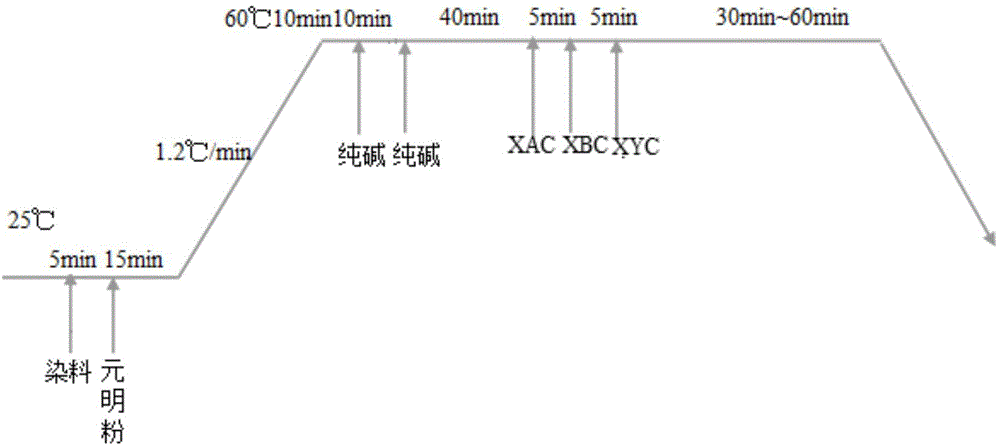

Method for dyeing polyester cotton on cone without reduction cleaning process

InactiveCN102517931AAvoid harmGuaranteed color fastnessDry-cleaning apparatus for textilesDyeing processColour fastnessDisperse dye

The present invention aims at overcoming the defects of the prior art and provides a method for dyeing polyester cotton on cone without a reduction cleaning process. The method of the invention comprises a polyester dyeing process, a cotton dyeing process and an after-washing process. Compared with the prior art, the method of the invention is characterized in that a process of reduction cleaning is avoided through a dyeing technology of a disperse dye and an auxiliary agent, the color fastness can be ensured and the damage of the used sodium hydrate and sodium hydrosulfite on the environment during the process of reduction cleaning can be simultaneously avoided, the water, electricity and steam can be saved by about 15% and the productivity of the equipments can be enhanced by 10%.

Owner:宁波侨泰兴纺织有限公司

Multi-fiber jean fabric and production method therefor

InactiveCN109023657AImprove insulation effectWarmthWoven fabricsFullingTextile technologyColour fastness

The invention relates to a multi-fiber jean fabric and a production method therefor, and belongs to the technical field of textiles. The multi-fiber jean fabric is prepared through the blending of five kinds of raw materials of tencel fiber, volcanic rock fiber, acrylic fiber, cotton fiber and spandex fiber. The mass percentages of the five raw materials is 25 to 35% of volcanic rock, 10 to 15% oftencel fiber, 6 to 9% of acrylic fiber, 40 to 60% of cotton fiber, and 0.5 to 1.5% of spandex fiber. The process sequence includes: feeding, blowing, carding, roving, spinning, dyeing, weaving, pre-shrinking, and raising. The invention has the beneficial effects that the new volcanic rock fiber is added to improve the warmth of the fabric, and the denim fabric obtained by blending the five raw materials realizes the complementary advantages of different fibers, and has the functions of keeping warm and feeling comfortable, breathable and bacteriostatic; the method adopts a reasonable processto improve the blending uniformity; the process is optimized to obtain better gloss and color fastness; the heat retention rate is 25 to 35%, the heat storage rate is greater than 40%, and the physical index of the fabric is stable; a better taking effect is obtained.

Owner:淄博海天纺织有限公司

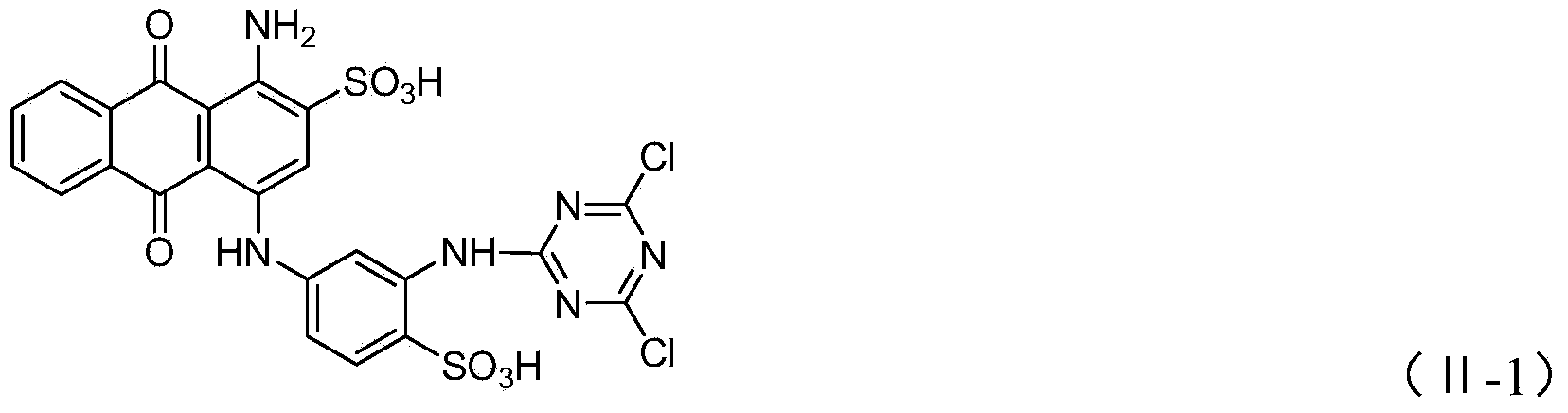

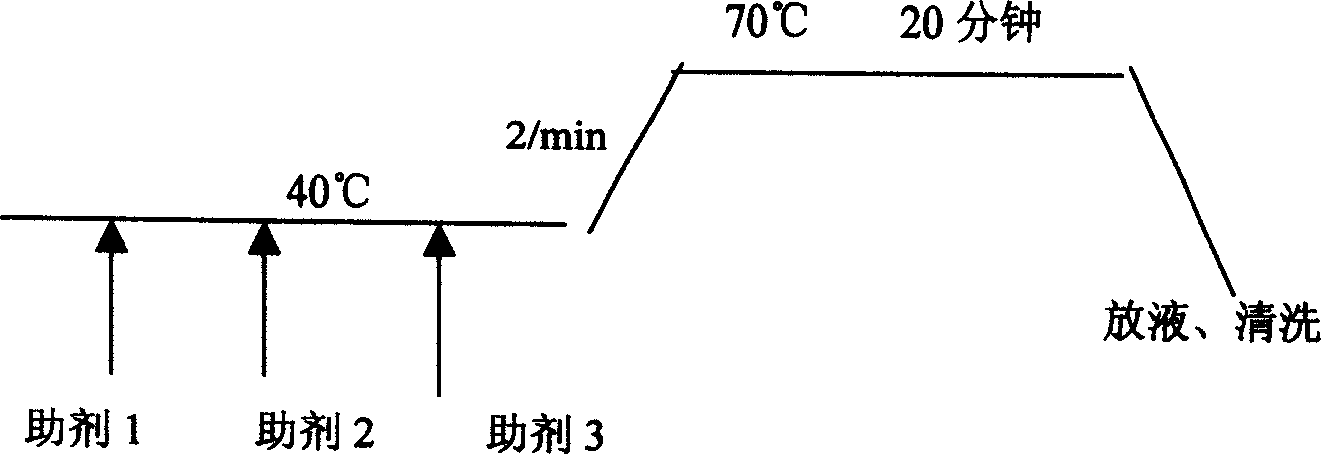

Staining method of diacetate fiber deep colors

The invention relates to a staining method of diacetate fiber deep colors. The staining method comprises the following staining steps of entering a cylinder of diacetate fiber or fabric, adding water to adjust a bath ratio, heating (1), adding staining assistants and dyes, heating (2), insulating (1), overflowing and cooling, cleaning, adding water to adjust the bath ratio, heating (1), adding post-processing assistants, heating (3), insulating (2), overflowing and cooling, cleaning, emptying the water and letting out of the cylinder. Two dyes of disperse dyes and cationic dyes with different properties are adopted to stain, and the staining method of simultaneous staining in the same cylinder by using a one-bath process is adopted, so that the technical problems of non-deep colors by adopting the disperse dyes or only light colors by adopting the cationic dyes are solved, the diacetate fiber can be stained to deep colors such as navy blue, black and the like, and additionally, the production quality requirements of color fastness, spinning and the like are satisfied.

Owner:JIANGSU DANMAO TEXTILE

Interweaved fabric with dreamlike color-change function and preparation technology of interweaved fabric

ActiveCN105274879AWith two-color dream effectImprove breathabilityFibre typesDry-cleaning apparatus for textilesColor effectPolymer science

The invention relates to interweaved fabric with a dreamlike color-change function and a preparation technology of the interweaved fabric, and belongs to the technical field of textile dyeing. The preparation technology comprises the following steps: preparing cloth; carrying out flat cylinder desizing; dyeing; carrying out color fixation; drying; sizing and carrying out finish inspection and packaging. The fabric prepared by the technology has a dual-color effect, and has the dreamlike color-change effect after being prepared into clothing; the fabric prepared according to the technology has excellent air permeability, comfortableness, abrasive resistance and color fastness; and the fabric surface is smooth and bright, is not easily stained, and is relatively good in stain resistance. In addition, the preparation technology disclosed by the invention is convenient to control, high in operability and suitable for large-scale popularization and application.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

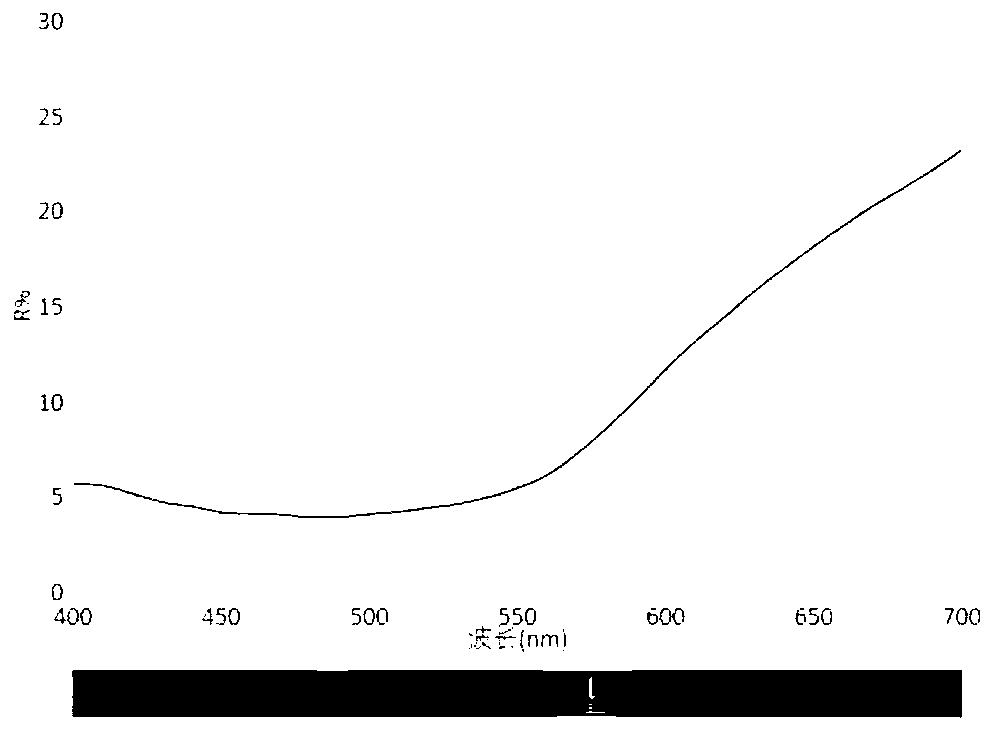

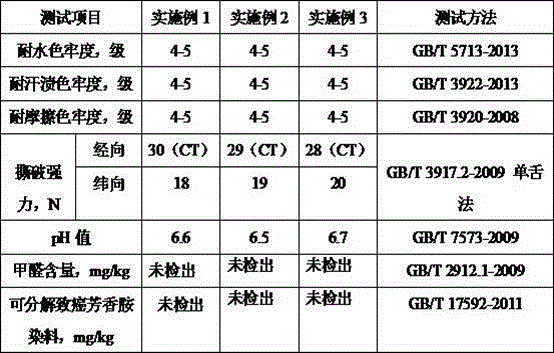

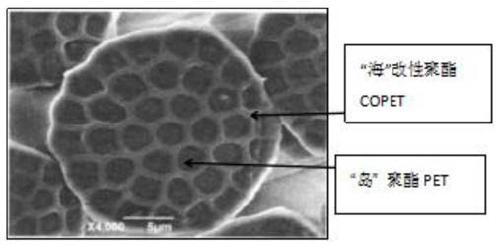

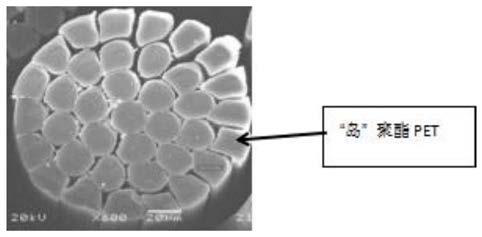

High-color-fastness polyester microfiber dyeing method

PendingCN111041859AHigh color fastnessHigh color fastness to migrationFibre typesDyeing processMicrofiberWoven fabric

The invention discloses a high-color-fastness polyester microfiber dyeing method. The high-color-fastness polyester microfiber dyeing method is characterized by comprising the following steps of: 1, preparing an ultrafine fiber non-woven fabric with a gram weight of 20 to 1,500g / m<2>; 2, carrying out pre-impregnation treatment on the ultrafine fiber non-woven fabric in the step S1, i.e., using modified PVA and CMC, regulating viscosity to 300 to 5,000 cp.s, regulating solid content to 5% to 40%, regulating impregnation pick-up to 30 to 300%, and drying at a temperature of 110 to 150 DEG C; 3,carrying out polyurethane impregnation treatment on a semi-finished product in the step S2, i.e., using impregnation; regulating viscosity to 300 to 30,000 cp.s, regulating solid content to 5% to 40%,regulating impregnation pick-up to 30 to 300%, and drying at a temperature of 90 to 160 DEG C; 4, carrying out dyeing finishing on the semi-finished product in the step S3, i.e., carrying out directdyeing on fibrils which are not opened by adopting a disperse dye, wherein a molecular particle size of the disperse dye is 0.3 to 10 mum; and 5, carrying out alkali decrement opening treatment on thesemi-finished product in the step S4. Polyester microfibers prepared by the high-color-fastness polyester microfiber dyeing method disclosed by the invention are high in color fastness and excellentin comprehensive performance.

Owner:明新梅诺卡(江苏)新材料有限公司

Dyeing process of black matt lattice tower fleece fabric

InactiveCN103382657ASimple dyeing processMaintain glossDry-cleaning apparatus for textilesDyeing processColour fastnessProduct inspection

The invention discloses a dyeing process of a black matt lattice tower fleece fabric. The process comprises the following procedures in order: matching of gray fabric with a cylinder, pretreatment desizing, gray fabric cleaning by hot water, heating dyeing, cooling cleaning, fabric discharge and waterproof shaping, finished product inspection and finished product rolling-up. The desizing additives adopted by the pretreatment desizing step are 40kg / l liquid alkali, 10kg / l pure alkali, a 1kg / l desizing agent, and 1kg / l Lamepon. In the heating dyeing step, 12.88g of a 172 element dye, 2.772g of an RXL yellow dye, and 0.508g of a B peach dye are added into per kilogram of the fabric. After dye proportioning, dyeing additives, i.e. a 0.6g / l acid homogenizing agent, 2g / l acetic acid, and a 3g / l nylon color-fixing agent. The dyeing process provided in the invention is simple, uses fewer additives to achieve optimal dyeing effects of uniformity and transparency, and ensures dyeing glossiness and excellent color fastness after dyeing, reduces the production cost, and improves the economic benefits.

Owner:苏州市富达化纤印染有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com