One-bath dyeing technology for protein fiber and PTT fiber

A protein fiber, same-bath dyeing technology, used in dyeing, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] [Example 1] Skein dyeing

[0047] Raw material: 70% protein fiber (cashmere) 30% PTT; Count: 52S / 2

[0048] Color number: W3330

[0049] Dyeing process:

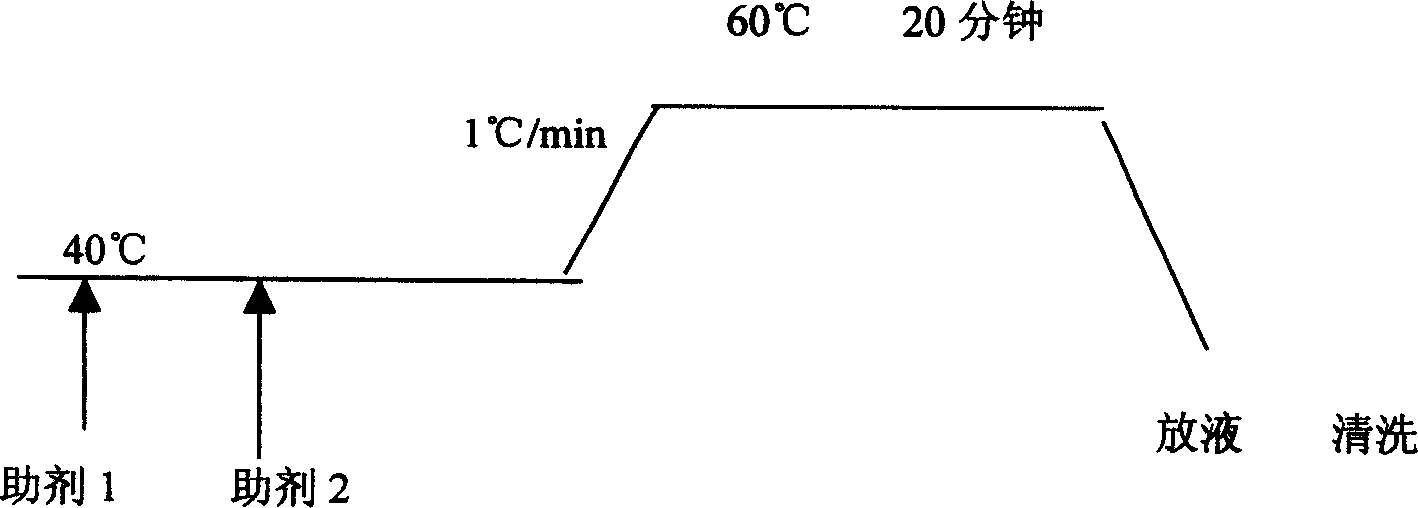

[0050] PTT dyeing prescription: Tolas disperse dye navy blue NFA 3.0% (OWF)

[0051] Process: Dyeing and post-processing adopt the aforementioned "2.1" process.

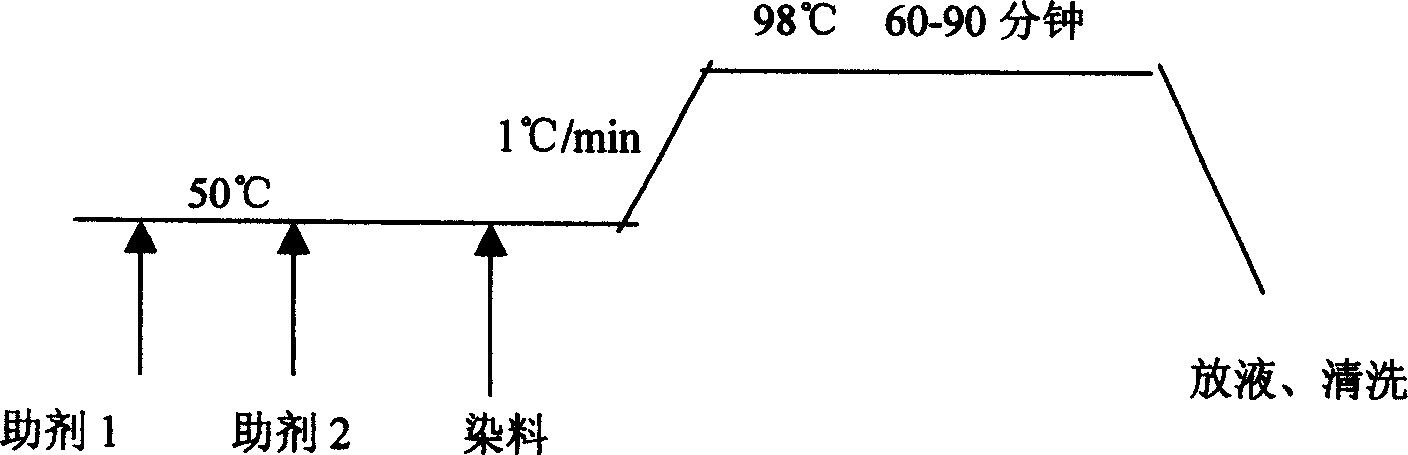

[0052] Cashmere Dyeing Prescription:

[0053] Acid Dyes Black PBB 1.5% (OWF)

[0054] Violet RC 0.45% (OWF)

[0055] Blue BXS 0.65% (OWF)

[0056] Process: Dyeing and post-processing adopt the aforementioned "2.2" process.

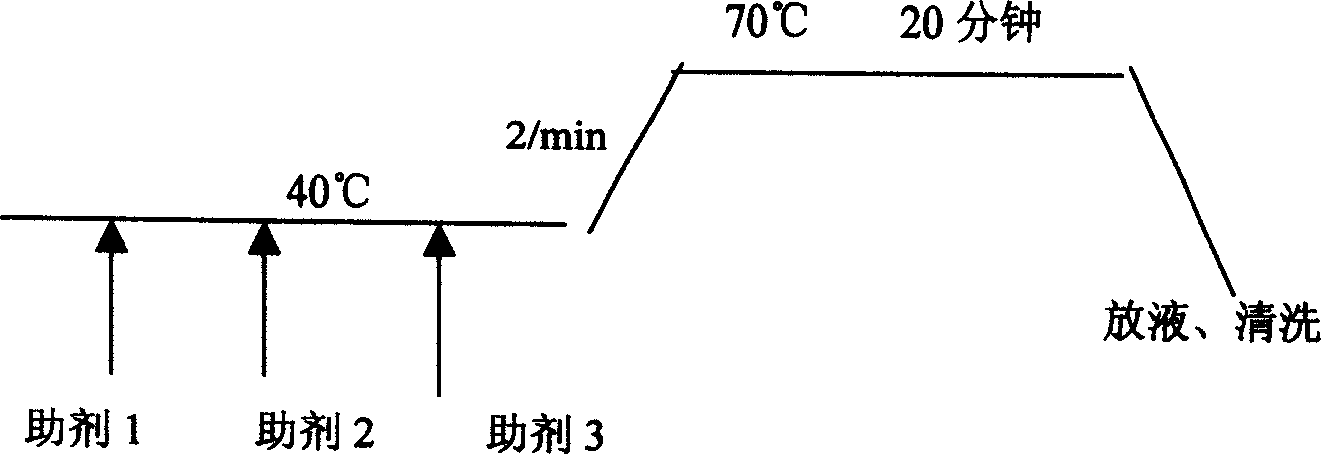

[0057] The pre- and post-treatment processes adopt the aforementioned "1" and "3" processes.

[0058] Quality Index:

[0059] Color

Embodiment 2

[0060] [Example 2] Skein dyeing

[0061] Material: 70% Wool 30% PTT

[0062] Count: 52S / 2

[0063] Color number: C3330

[0064] Dyeing process:

[0065] PTT staining prescription:

[0066] Tolas disperse dye red FBN 0.13% (OWF)

[0067] Torras Disperse Dye Blue 3RL 0.48% (OWF)

[0068] Process: Dyeing and post-processing adopt the above "2.1" process.

[0070] Lanersol Reactive Dye Red 6G 0.09% (OWF)

[0071] Lanersol Reactive Dye Blue 3R 0.35% (OWF)

[0072] Process: Dyeing and post-treatment adopt the aforementioned "2.2" process; pre- and post-treatment processes adopt the aforementioned "1" and "3" processes.

[0073] Quality Index:

[0074] Color

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com