Interweaved fabric with dreamlike color-change function and preparation technology of interweaved fabric

A production process and functional technology, applied in the field of textile printing and dyeing, can solve the problems of color fading, dull color, poor color fastness, etc., and achieve the effect of smooth and bright cloth surface, not easy to stain, and prevent color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

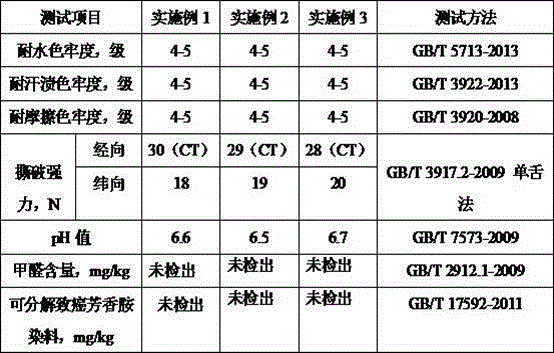

Embodiment 1

[0046] The manufacturing process of the interwoven fabric with dreamy color-changing function includes the following steps:

[0047] Step 1, distributing cloth: rolling and coiling, using "A" car to work, tearing the cloth head of each cloth to ensure that the cloth surface is flat, and the cloth is an interwoven fabric of nylon and polyester;

[0048] Step 2, flat tank desizing:

[0049] ① After entering the water in the cylinder, the temperature is raised to 80°C, and then the cloth is fed;

[0050] ②Connect each 30y guide cloth at both ends;

[0051] ③According to the water meter in the tank, add liquid caustic soda (sodium hydroxide) 25ɡ / L, refining agent (fatty alcohol ether phosphate) 15ɡ / L, degreasing agent (dodecyl alcohol) 7.5ɡ / L, and stir evenly ;

[0052] ④Raise the temperature to 95°C, and dip dye once with a dyeing jigger at a speed of 90m / min for 25 minutes;

[0053] ⑤Continue to raise the temperature to 110°C, and use the jigger for six times at a speed of 9...

Embodiment 2

[0073] The manufacturing process of the interwoven fabric with dreamy color-changing function includes the following steps:

[0074] Step 1, distributing cloth: rolling and coiling, using "A" car to work, tearing the cloth head of each cloth to ensure that the cloth surface is flat, and the cloth is an interwoven fabric of nylon and polyester;

[0075] Step 2, flat tank desizing:

[0076] ①After entering the water in the cylinder, the temperature rises to 75°C, and then the cloth is fed;

[0077] ②Connect each 30y guide cloth at both ends;

[0078] ③ According to the water meter in the tank, add liquid caustic soda (sodium hydroxide) 24 g / L, refining agent (fatty alcohol ether phosphate) 14 g / L, degreasing agent (dodecyl alcohol) 7 g / L, and stir evenly;

[0079] ④Raise the temperature to 94°C and dip dye once with a dyeing jigger at a speed of 90m / min for 27 minutes;

[0080] ⑤Continue to raise the temperature to 108°C, and use the jigger for six times at a speed of 90m / min...

Embodiment 3

[0100] The manufacturing process of the interwoven fabric with dreamy color-changing function includes the following steps:

[0101] Step 1, distributing cloth: rolling and coiling, using "A" car to work, tearing the cloth head of each cloth to ensure that the cloth surface is flat, and the cloth is an interwoven fabric of nylon and polyester;

[0102] Step 2, flat tank desizing:

[0103] ①After entering the water in the cylinder, the temperature rises to 78°C, and then the cloth is fed;

[0104] ②Connect each 30y guide cloth at both ends;

[0105] ③ According to the water meter in the tank, add liquid caustic soda (sodium hydroxide) 26 g / L, refining agent (fatty alcohol ether phosphate) 16 g / L, degreasing agent (dodecyl alcohol) 8 g / L, and stir evenly;

[0106] ④Raise the temperature to 96°C, and dip dye once with a dyeing jigger at a speed of 90m / min for 24 minutes;

[0107] ⑤Continue to raise the temperature to 112°C, and use the jigger for six times at a speed of 90m / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com