Method for dyeing superfine terylene fabric

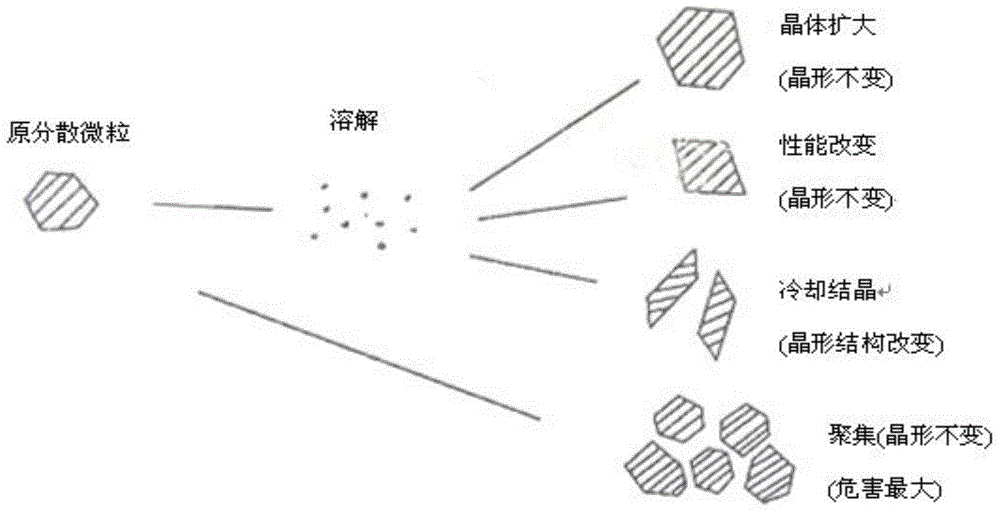

A dyeing method, ultra-fine polyester technology, applied in the field of textile printing and dyeing, can solve the problems of discoloration and poor level dyeing, achieve the effect of preventing secondary aggregation, increasing dyeing rate, and improving dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 disperses brilliant blue superfine polyester fabric (light color)

[0041] Fabric: Superfine polyester 500Kg (88% Poly+12% Lycra), specification 50D / 144F SD Poly+40D Lycra, width 160cm, weight 95g / m 2

[0042] Dyeing machine: THEN airflow dyeing machine

[0043] The dyeing formula is as follows:

[0044]

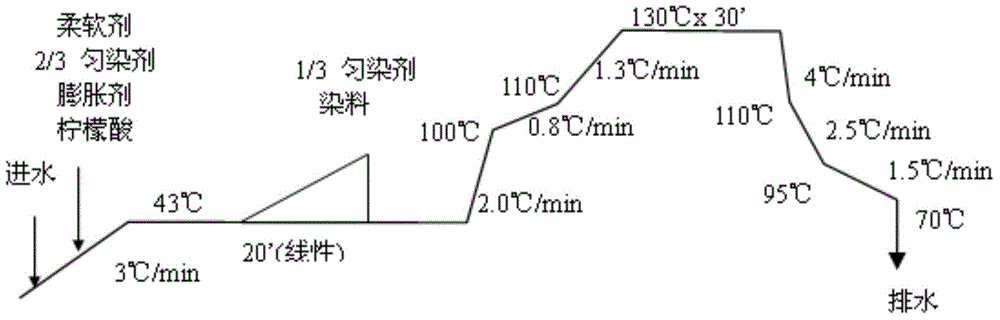

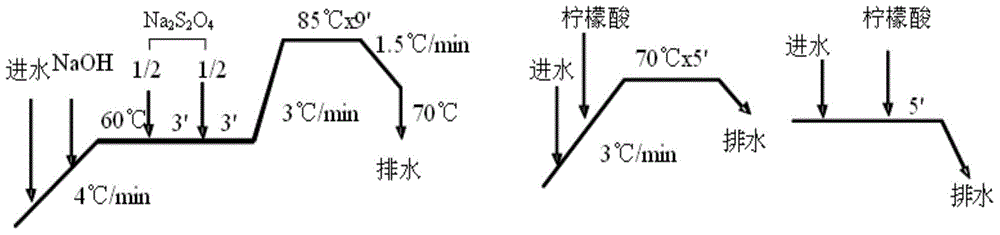

[0045] Put the ultra-fine polyester fabric in the presetting machine, pre-setting treatment at 190°C for 20s; then put the ultra-fine polyester fabric in the dyeing machine, add water to soak, add disperse brilliant blue, softener, 2 / 3 uniform according to the above formula Dyeing agent and swelling agent, add citric acid to adjust the pH to 3.92, raise the temperature to 43°C at a rate of 3°C / min, and linearly add disperse dye Foron CYANINE SWF blue and the remaining 1 / 3 leveling agent (adding time is 20min), Raise the temperature to 100°C at a rate of 2°C / min, then raise the temperature to 110°C at 0.8°C / min, then raise the temperature to 130°C at...

Embodiment 2

[0046] Embodiment 2 disperses brilliant blue superfine polyester fabric (medium color)

[0047] Fabric and dyeing machine are all identical with embodiment 1.

[0048] The dyeing formula is as follows:

[0049]

[0050] According to the above formula and liquor ratio, the same dyeing method as in Example 1 was used to prepare a blue superfine polyester fabric (neutral color), the difference being that the presetting treatment time was 30 s, and the pH was adjusted to 3.75 with citric acid.

Embodiment 3

[0051] Embodiment 3 disperses brilliant blue superfine polyester fabric (dark color)

[0052] Fabric and dyeing machine are all identical with embodiment 1.

[0054]

[0055]

[0056] According to above-mentioned prescription and bath ratio, adopt the dyeing method identical with embodiment 1 to prepare blue superfine polyester fabric (dark color), difference is to adopt citric acid to adjust pH to 3.56, the addition amount of sodium hydroxide and hydrosulfite is equal to It is 6g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com