Patents

Literature

238results about How to "Simple dyeing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological dyeing method for dyeing cotton fabric with mulberry red natural dye

InactiveCN101851868AImprove protectionNo allergic reactionDyeing processVegetal fibresEngineeringNatural dye

The invention relates to an ecological dyeing method for dyeing a cotton fabric with mulberry red natural dye, comprising the following steps: preprocessing the cotton fabric and then dyeing the preprocessed cotton fabric with the mulberry red natural dye; adding metal salt for fixation; and soaping the fabric after fixation and then fixing colors to obtain the dyed fabric with even color, wherein washing fastness can reach 3-4degrees. The ecological dyeing method has simple dyeing process, high dye-uptake, good pigment stability and wide market prospect.

Owner:CHANGZHOU GOLDEN SPRING TEXTILE +1

Method for dyeing and finishing pure-cotton high-count high-density fabric

ActiveCN101532230AReduce trafficEmission reductionTextile storage in superimposed formSingeingHigh densityMoisture absorption

The invention discloses a method for dyeing and finishing pure-cotton high-count high-density fabric, which includes steps of singeing, cold dome, desizing and boiling-off, bleaching, mercerization, dyeing, moisture absorption and breath, no-iron sorting, tentering, pre-shrinking and packaging. The fabric dyed and finished by the present invention has advantages of high rebound, moisture absorption and breath, crease-resistance and soft feel.

Owner:SUNTEX

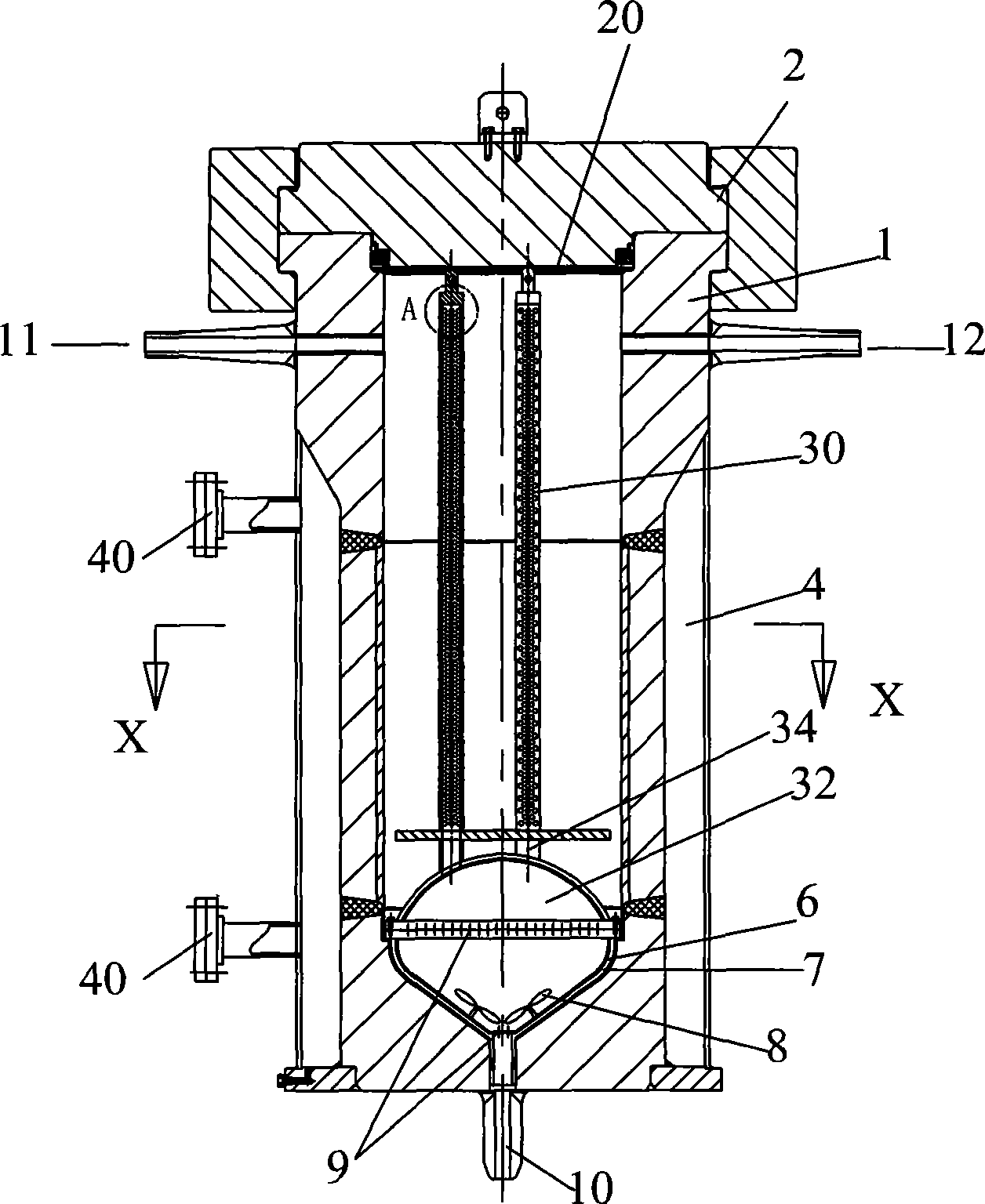

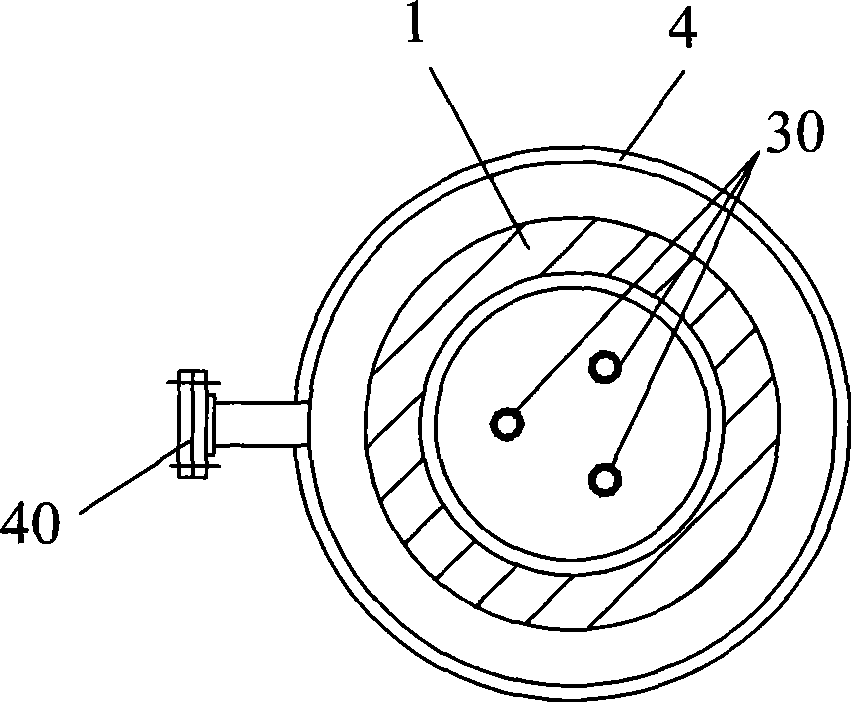

High-temperature high-pressure swelling dyeing method

InactiveCN101191306ASolving Dyeing PuzzlesIncrease profitSucessive textile treatmentsDyeing processPolymer scienceCrystallinity

The invention relates to a high temperature high pressure bulking dyeing method which comprises dyeing and after treatment. By adoption of the dyeing method of the invention, fibers or textile fabrics like aramid fibers, polysulfonamide fibers, polyphenylene sulfides, polybenzimidazole, poly-p-phenylene benzobisoxazole fibers, phenol formaldehyde resins, fibrilia and so on which have high crystallinity and high orientation degree or high glass transformation temperature can be dyed, and fibers after dyeing have the advantages of evenness, bright colors, high dyefastness, improvement of light fastness and little impact on physical properties.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Method for dyeing modified cellulose fiber fabric on rhubarb and curcuma longa dyes

InactiveCN101349020AHigh fixation rateStable color fastnessDyeing processVegetal fibresHigh rateCellulose fiber

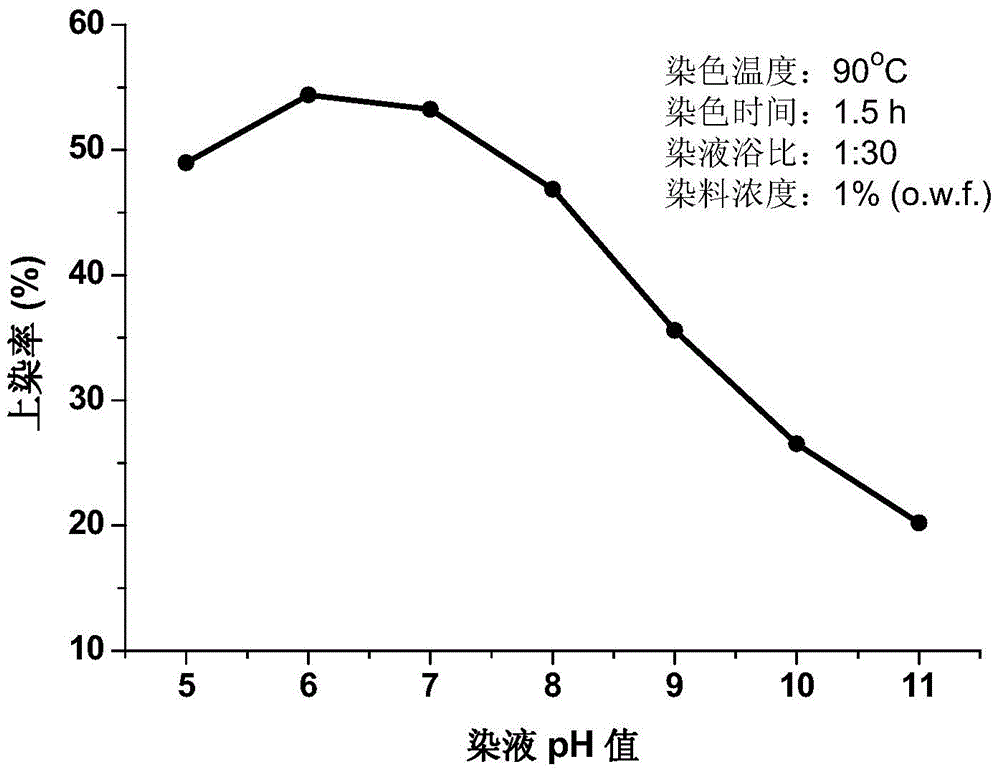

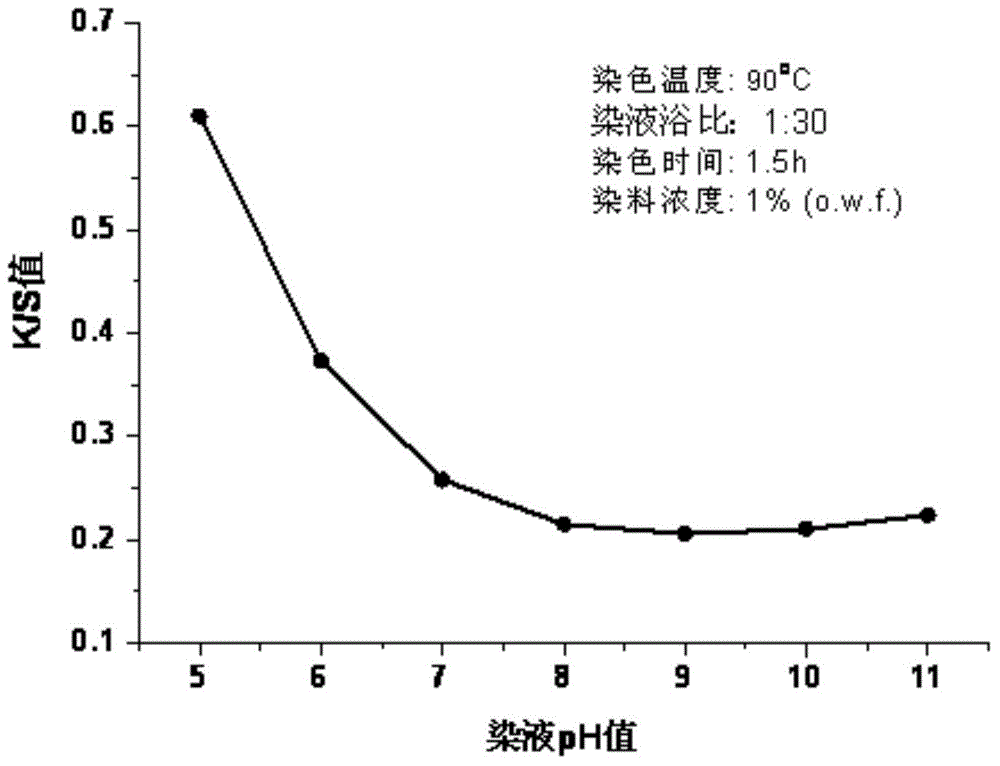

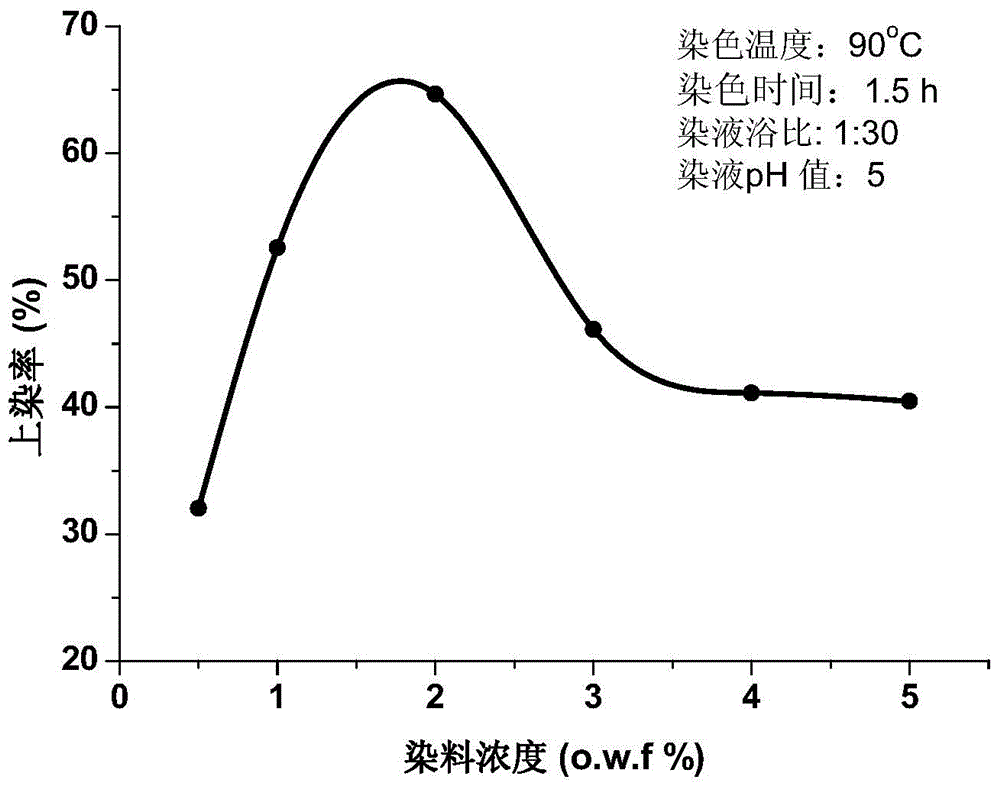

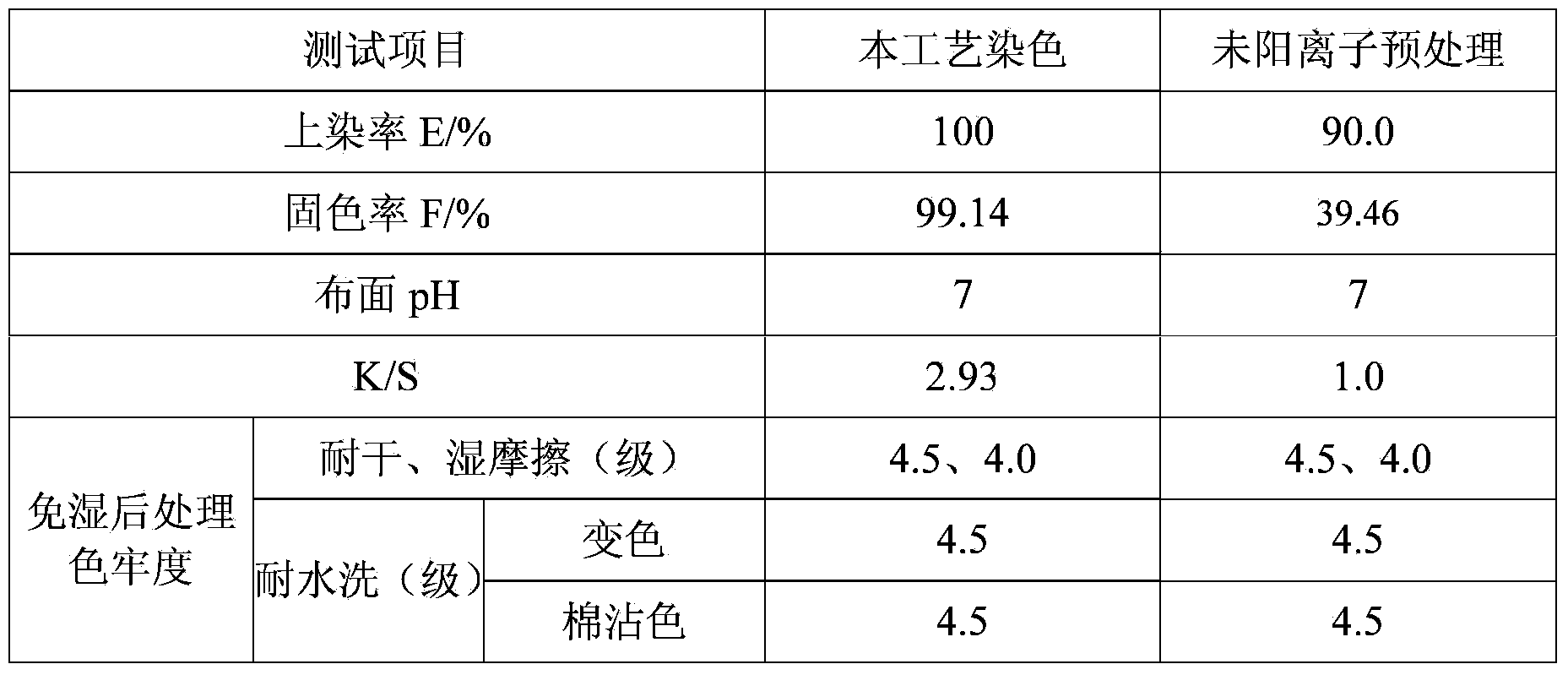

The invention provides a method for dyeing a modified cellulose fiber textile by a rhubarb and turmeric dye. The method comprises the following: 1. a step of modifying a quaternary ammonium group of the cellulose fiber textile, in which a modifying agent with a concentration of 50 to 60 g / l and sodium hydrate with a concentration of 12 to 18g / l react for 40 to 60 minutes at a temperature of between 64 and 75 DEG C, the bath ratio is 1:30; in the post treatment after the modification, the fiber textile is washed by hot water at a temperature of between 40 and 50 DEG C for 10 minutes, is washed by cold water, is prickled by HAC with a concentration of 2 to 3g / l for 2 minutes, is washed by water to be neutral and is dried; 2. a step of preparing the dye solution by the sodium hydrate extracting agent with a concentration of 15 to 45g / l; and 3. a step in which the modified cellulose fiber textile is dyed, washed by water and dried directly by the dyeing technique and is washed by soap, washed by water and dried. The technique is simple and easy to implement, does not need the mordanting and the fixation processes and the like, has high rate of dye-uptake, good dye quality and the friction resisting color fastness and the colorfastness to washing up to more than three grades, is nontoxic, does not pollute the environment, and has low cost, and remarkable economic benefits and environmental benefits.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Preparation of nano black carbon and use of nano black carbon in fabric dyeing

InactiveCN101348618ASimple preparation processLow costInorganic pigment treatmentDyeing processPigment dispersionCellulose fiber

The invention relates to a nano-carbon black preparation method and an application of nano-carbon black in fabric dyeing, belonging to the technical field of textile chemical engineering. The preparation method is characterized in that an ultrasonic technique is utilized to prepare the nano-carbon black, so as to obtain a nano-carbon black pigment dispersion system with good dispersivity and high stability; the prepared nano-carbon black pigment dispersion system can be used for dyeing natural cellulose fiber and regenerated cellulose fiber fabrics; and the dyed fabrics are pure in color, good in jet-black degree and excellent in color fastness. The preparation method has the advantages of simple process, low cost and little pollution.

Owner:JIANGNAN UNIV

Method for dyeing reactive dye by one-step method without salt

InactiveCN101532259AReduce consumptionImprove the shortcomings of dyeing batch productionDyeing processFiberSalt free

The invention relates to a method for dyeing a reactive dye by one-step method without salt. The method comprises two-dip-one-dry or three-dip-one-dry process, wherein dye solution used for dipping and drying consists of 15 to 25g / l of dye and 1g / l of an alkaline agent; pickup is between 55 and 60 percent; then, the dyeing solution is subjected to steaming, washing, hot water washing and drying. The method has a simple dyeing process, does not have special requirement on the dye, does not relate to modification of fibers and application of salt-free dye cross linker; preliminary drying and cylinder drying are saved, and consumption of heat energy is greatly reduced; compared with a cold pad-batch dyeing process, the defects of cold pad-batch clearance production is improved, efficiency is improved, and defects of water spots, stains and hard hand feel are overcome.

Owner:DONGHUA UNIV +1

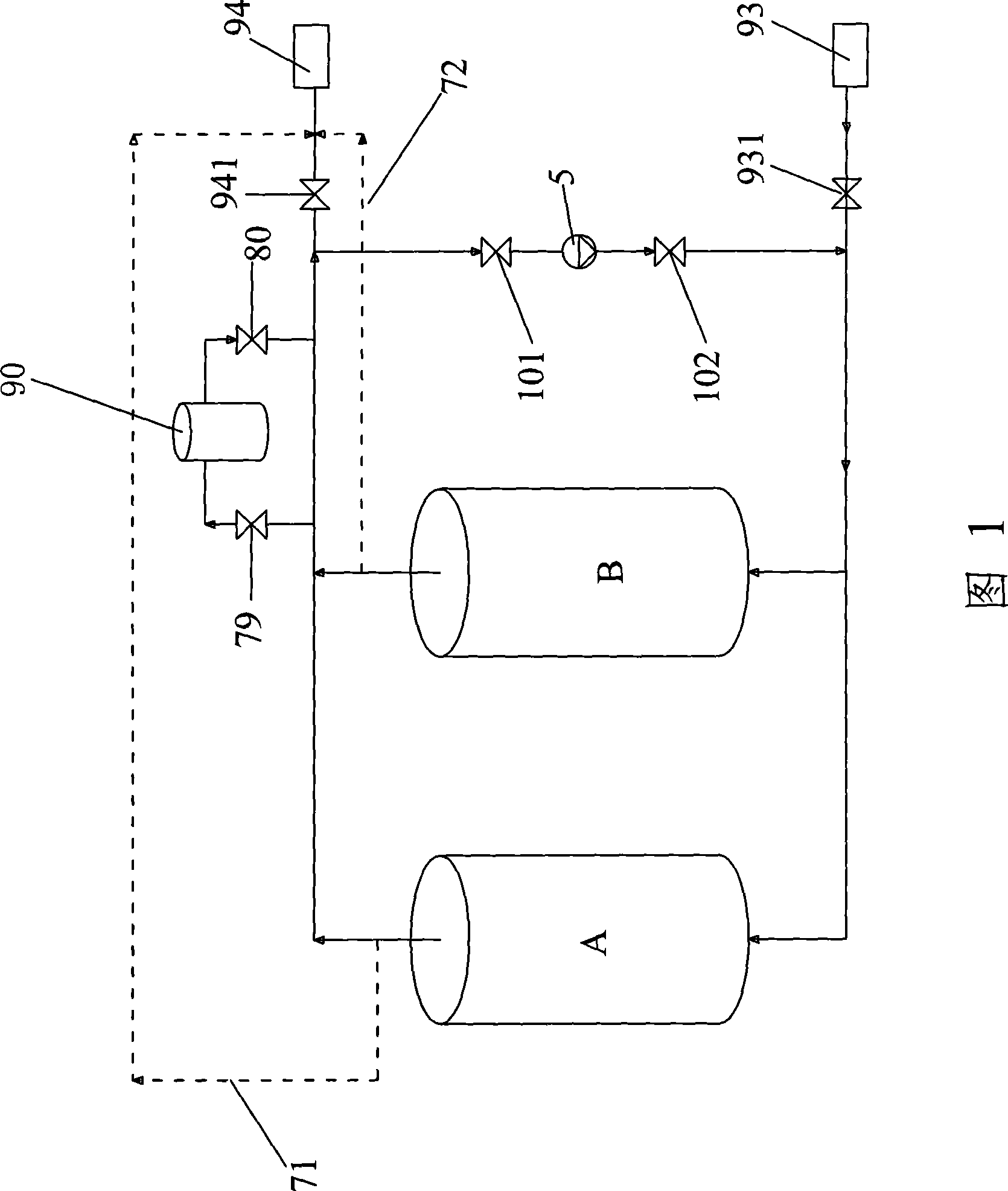

Supercritical CO2 anhydrous yarn warp dyeing system and dyeing method thereof

InactiveCN101413191ALow costIncrease capacityTextile treatment sample takingTextile treatment containersYarnProcess engineering

The invention discloses a supercritical CO2 anhydrous warp beam dyeing system and a dyeing method thereof. The system comprises a CO2 pressure supply device, a circulating pump, a separation and recovery device and two or more than two dyeing kettles which are arranged in parallel, wherein the dyeing kettles are arranged in parallel and connected in series with the circulating pump to form a closed dyeing circuit; a shutoff valve is respectively arranged on both ends of the circulating pump; the CO2 pressure supply device and the separation and recovery device are connected between the shutoff valves and the dyeing kettles respectively; and an outlet of each dyeing kettle is connected with an independent recovery bypass which is communicated with the separation and recovery device and independent of the closed dyeing circuit which is formed by the dyeing kettles and the circulating pump, so that different dyeing kettles can perform dyeing and recovery of CO2 simultaneously. The system can perform dyeing and recovery of the CO2 simultaneously and respectively, reduces consumption of the CO2 to the maximum degree, reduces the cost, can realize discontinuous operation and improve the production efficiency, and has quick dyeing speed.

Owner:HONG KONG PRODUCTIVITY COUNCIL

Dyeing method for calcium alginate fibers

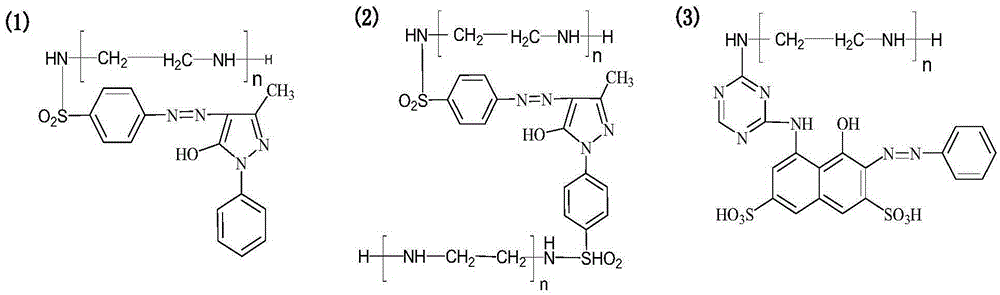

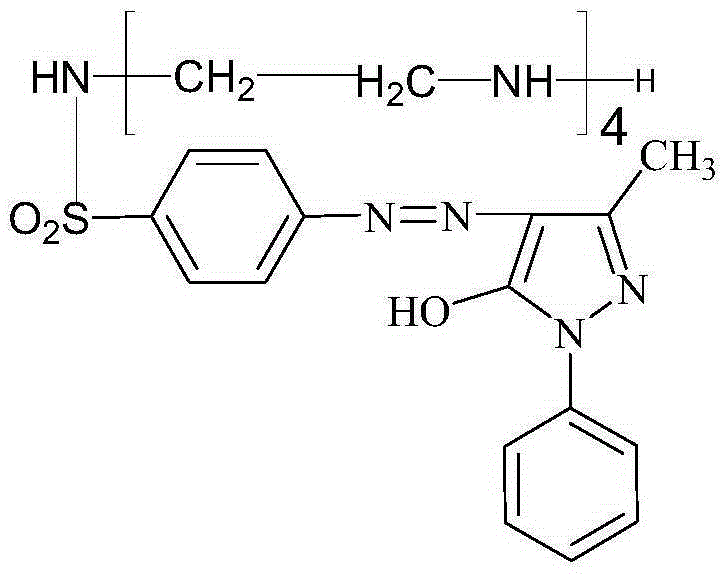

The invention belongs to the technical field of fiber dyeing, and particularly relates to a dyeing method for calcium alginate fibers. According to the dyeing method for the calcium alginate fibers, dye containing polyethylene polyamine framework structures is adopted to dye the calcium alginate fibers; the defect that the fibers are damaged due to the fact that inorganic salt needs to be added for dyeing accelerating in the dyeing process of traditional dye is fundamentally overcome, and the strength loss of the fibers after dyeing is small; meanwhile, compared with the weaker intermolecular force and hydrogen-bond interaction between general direct dye and the fibers, the acting force between molecules of the dye and the fibers is higher, and then the advantages of being higher in dye-uptake rate and soaping fastness and the like are achieved; the dyed fibers are uniform and bright in color and meet the dyeing requirements of the calcium alginate fibers, and the dyeing method is economical in energy and environmentally friendly.

Owner:SHANDONG UNIV OF TECH

Dyeing method suitable for dacron fabric and application thereof

The invention discloses a polyester fiber fabric coloring method and the fabric adopting the method and manufactured by using the method. The method is a method which combines pretreatment and coloring to carry out one bath one step coloring. The dosage of alkali is 0.3 to 30g / l, and the bath ratio is 1:3 to 1:40 under the strong alkalinity condition that the pH of a dye bath is equal to or more than 10.6 and is equal to or less than 14. An alkali resistance dispersing dye is used for carrying out the one bath one step coloring on the polyester fiber and a fabric thereof under the condition of having a pretreatment addition agent or having no pretreatment addition agent. The invention carries out the one bath one step coloring under the strong alkalinity condition. The alkalinity condition can effectively remove the slurry and oil agent on a polyester fabric, overcome the defects of generating a plurality of dye defects caused by the precipitation of other decomposing products such as polyester oligomer in an acid bath and simultaneously bring the effect of neat fabric surface and good fabric style which can meet the requirement of fastness that usually needs no reduction and cleaning. The amount reducing effect of the alkali can also lead the fabric to be smooth and the hand feeling to be better. The method simplifies the coloring technique, reduces the waste water of pretreatment, saves energy, reduces the manufacture cost and improves the labor production efficiency.

Owner:浙江昱泰染化科技有限公司

Preparation method of liquid disperse dye

A liquid-state disperse dye is prepared through reaction, press filter to obtain cake, dissolving it in acetone or alcohol, dissolving disperser in water, mixing them together while stirring, and heating for evaporating organic solvent.

Owner:ZHEJIANG YUDA CHEM IND

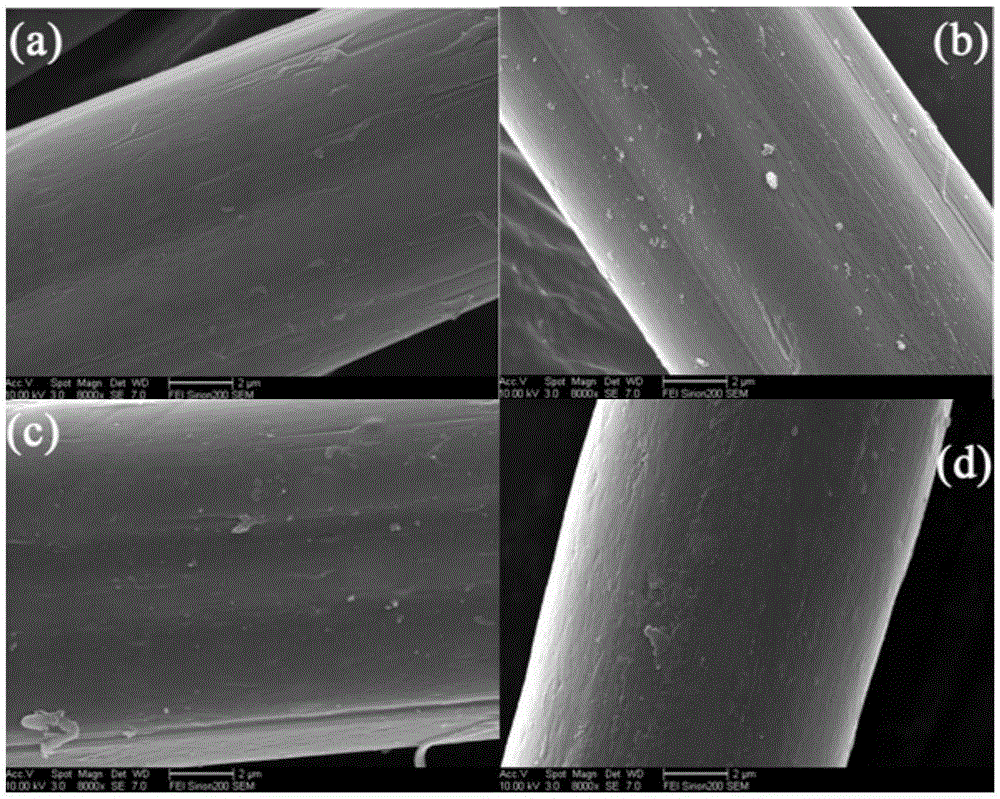

Preparation method of solvent-based dyeable wet polyurethane resin

InactiveCN102746484ASolve illsReduce manufacturing costTextiles and paperColour fastnessPolymer science

The invention provides a preparation method of a solvent-based dyeable wet polyurethane resin, comprising the following steps: introducing a group into polyurethane molecules to let the reacted polyurethane contain the group; and then establishing chemical bond between the polyurethane resin and dye molecules. The invention mainly aims at the problem that difficulty in coloring polyurethane and low color fastness after coloring in the existing dyeing process of non-figured islands-in-sea microfiber synthetic leather. The invention discloses a synthesis and preparation method of the polyurethane resin with good dyeing performance and obviously improved dyeing color fastness. According to the invention, after dyeing the non-figured islands-in-sea microfiber synthetic leather prepared by using the resin, the color fastness is raised 0.5-1.5 grade as against that of conventional polyurethane, the color is bright, the dyeing uniformity is raised, the dye application amount is reduced, the dyeing technology is simplified, and the invention has high application value and economic value.

Owner:FUJIAN TOPSUN MICROFIBER

Liquid paraffin bath dyeing method of cotton fiber

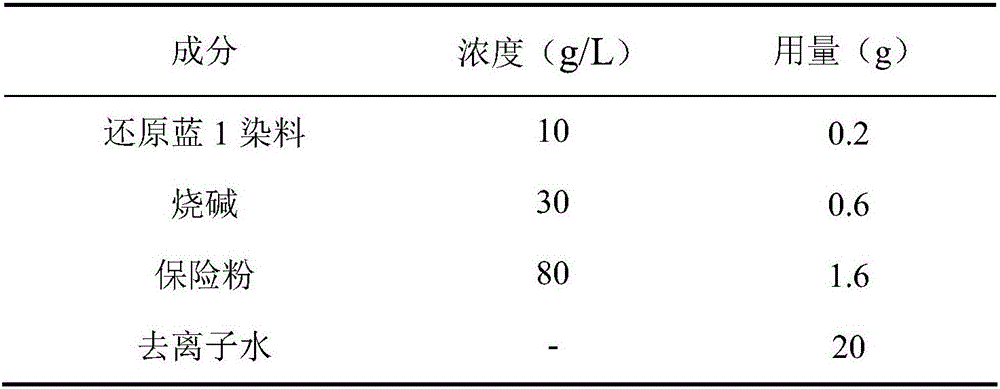

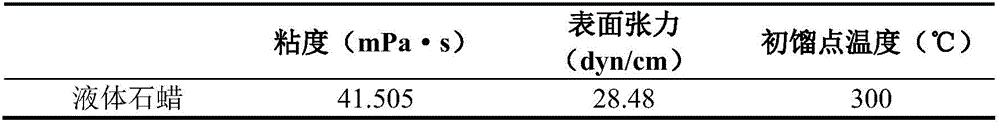

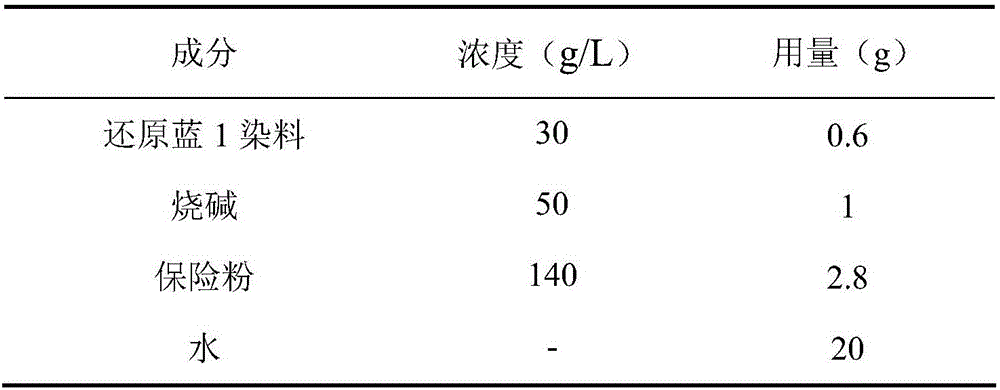

The invention discloses a liquid paraffin bath dyeing method of cotton fiber. The method is applied to a liquid paraffin bath for performing reduction dye dyeing on the cotton fiber, due to the fact that liquid paraffin and water are completely immiscible, both the cotton fiber and a reduction dye leuco body have the good compatibility with water, and leuco body droplets dispersing in the liquid paraffin have the intense tendency of being repellent to the liquid paraffin and compatible to the cotton fiber, and the reduction dye leuco body can be spontaneously transferred to the surface of the fiber from the liquid paraffin solution and then dispersed into the fiber. The adopted liquid paraffin is low in cost, safe, environmentally friendly and recyclable. According to the method, the dye-uptake rate of the reduction dye is greatly increased, the leuco body and oxidizing substances are isolated in the dyeing process, oxidation of the leuco body and losses of sodium hydrosulfite are effectively avoided, and the production cost is remarkably reduced. More importantly, the method greatly reduces water for dyeing and wastewater discharge and meets the development requirement for ecological dyeing and finishing.

Owner:ZHEJIANG SCI-TECH UNIV

Chemical structure modification-based water-soluble curcumin dye, and preparation method and application thereof

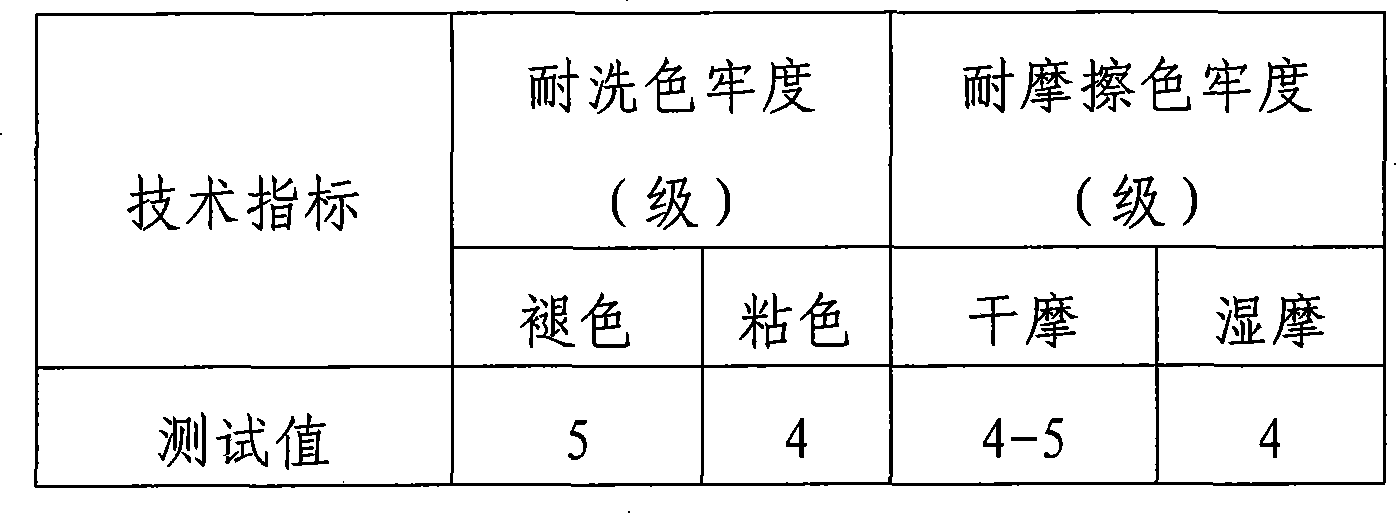

The invention discloses a chemical structure modification-based water-soluble curcumin dye. The invention also discloses a preparation method of the chemical structure modification-based water-soluble curcumin dye. The preparation method comprises the following steps: reacting curcumin with 1,2-dibromoethane, and reacting the above obtained product with triethylamine to obtain the chemical structure modification-based water-soluble curcumin dye. The invention also discloses an application method of the chemical structure modification-based water-soluble curcumin dye. The dye can be directly used for dyeing unmodified cotton fabrics without a dyeing accelerant, a dye leveler or a dye mordant, so the environmental protection property of a dyeing process and the safety of the fabric are improved. All dyeing indexes, especially the indexes comprising the washing color fastness and the like of the water-soluble dye are obviously better than that of natural curcumin for direct dyeing, wherein the washing color fastness reaches 3 level, the staining fastness reaches 5 level, and each of the dry crock fastness and the wet crock fastness reaches 5 level.

Owner:嘉兴君宏光学有限公司

Method for extracting pigment from walnut green hulls through subcritical water and using pigment for dyeing

InactiveCN105133380ACostlyImprove resource utilization valueNatural dyesDyeing processAdditive ingredientSolvent

The invention relates to a method for extracting natural pigment from walnut green hulls and using the natural pigment for dyeing and belongs to the field of natural product extraction and application. According to the method, subcritical water serves as an extraction solvent, polyphenol, flavone, anthraquinone, naphthoquinone and other natural pigment in the walnut green hulls are extracted, and a natural pigment extraction solution is directly used for dyeing cotton and wool fabric. The method has the advantages that the active ingredient extraction rate is high, no organic solvent is used in the extracting and dyeing process, the process is environmentally friendly, and products are free of pollution, safe, free of toxicity and the like. No toxic and harmful pigment ingredient is contained in dyed fabric obtained through the method, and the method is suitable for dyeing the various cotton and wool fabric and particularly suitable for dyeing infant articles for use, underwear and other articles due to the fact that the natural pigment of the walnut green hulls further has anti-bacterium activity, anti-oxidation activity and the like.

Owner:XINJIANG UNIVERSITY

Non-aqueous solvent cold pad batch dyeing method of reactive dye

The invention provides a non-aqueous solvent cold pad batch dyeing method of reactive dye. The method comprises the steps of curing and drying the pad batch alkali liquor of the textile; pad dyeing the textile; yarding the pad dyed textile products in the saturated vapor atmosphere of reactive dye poor solvent; curing and drying the yarded textile products, and finishing the non-aqueous solvent cold pad batch dyeing of the reactive dye; or, conducting cationicm odification to the textile; curing and drying the pad batch alkali liquor of the textile; pad dyeing the textile; yarding the pad dyed textile products; curing and drying the yarded textile products; and finishing the non-aqueous solvent cold pad batch dyeing of the reactive dye. The method can achieve the salt free shade dyeing for the reactive dye, the dyeing fixation rate is high, the use amount of the organic solvent and water is low, the energy consumption is low, and the amount of discharged waste water is less.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Active dye non-aqueous solvent dyeing method without wet post-treatment

The invention provides an active dye non-aqueous solvent dyeing method without wet post-treatment. The method comprises the following steps: carrying out cation modification on a cotton textile; mixing the modified cotton textile with an active dye and a good solvent of the active dye; heating to a dyeing temperature at a speed of 1 DEG C / min and dyeing; adding a poor solvent of the active dye in the heating process and preserving heat for a period of time, wherein the volume ratio of the good solvent of the active dye to the poor solvent of the active dye is 1 to (3-20) and the mass ratio of the good solvent of the active dye to the cotton textile is (2-50) to 1; and drying the cotton textile to finish dyeing, wherein the good solvent of the active dye is a non-aqueous solvent which can be used for dissolving the active dye but is not subjected to a chemical reaction with the active dye, and the poor solvent of the active dye is a non-aqueous solvent which cannot be used for dissolving the active dye and is not subjected to a chemical reaction with the active dye. The active dye non-aqueous solvent dyeing method provided by the invention has a high fixation rate and does not need a wet post-treatment step.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Method for dyeing CDP/nylon/PU knitted fabrics

InactiveCN103628329ASolve the problem of color fastness declineSolve the problem of sediment generationDyeing processAcid dyeSodium sulfate

The invention discloses a method for dyeing CDP / nylon / PU knitted fabrics. The method is characterized by comprising the following steps: 1, putting fabrics and cold water into a dye vat, and sequentially adding an anti-settling agent, dyeing acid, anhydrous sodium sulfate, an anti-set-off agent, cationic dyes and acid dyes; 2, raising the temperature to 70 DEG C at a speed of 2 DEG C per minute, and keeping the temperature for 5-10 minutes; 3, raising the temperature to 110-120 DEG C at a speed of 1 DEG C per minute, and keeping the temperature for 30-60 minutes; and 4, reducing the temperature to be 60 DEG C, and sequentially draining, soaping, color fixing and discharging the fabrics out of the vat. According to the dyeing scheme, a bath dyeing process can be performed on the CDP / nylon / PU knitted fabrics by using the cationic dyes and acid dyes, the dyeing process is simplified, the production cost is reduced, and the CDP / nylon / PU knitted fabrics with different styles and diversified colors can be produced by utilizing dyeing difference of the two dyes.

Owner:上海缀菱纺织品有限公司

Method for dyeing modified cellulose fabrics by green walnut epicarp pigment

InactiveCN102644204ASimple dyeing processImprove dye uptakeDry-cleaning apparatus for textilesNatural dyesColour fastnessModified cellulose

A method for dyeing modified cellulose fabrics by green walnut epicarp pigment includes following steps of dyeing green walnut epicarp pigment dyeing extract liquor on the modified cellulose fabrics; and soaping, washing and drying after dyeing, washing and drying the modified cellulose fabrics by a direct dyeing process. The method is simple and easy in process, does not need mordant dyeing fixation and the like, is high in dyeing efficiency, fine in dyeing quality, free of toxin and pollution, low in cost and remarkable in economic and environment benefits, and has high friction resisting color fastness and washing resisting color fastness which are higher than four levels.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Superfine dispersion method for dispersed dye

Disclosed is a superfine dispersion method for dispersed dye, wherein dispersion dyes are subject to mechanical dispersion and ultrasonic wave dispersion simultaneously in an aqueous environment, the dispersion dyes are the end product of filter-pressed filter cake or sanded filter cake or dried grout of the original dyes during dispersion dyes manufacturing process, and dispersing agent is charged into the filter cake during the process of mechanical dispersion and supersonic wave dispersion.

Owner:章浩龙

Dyeing technology of bright blue-containing reactive dye

InactiveCN104313900AColor flower problem improvedSimple dyeing processBleaching apparatusDyeing processSodium sulfateWrinkle

The invention discloses a dyeing technology of bright blue-containing reactive dye. The technology includes the following steps: 1, scouring and bleaching: sequentially adding 1g / L of a stabilizer, 3.5g / L of soda ash, 0.35g / L of a non-foam detergent agent, 2.0g / L of a wrinkle resistant agent CD and 6g / L of hydrogen peroxide at 40DEG C, and heating to 90DEG C, wherein the time is 60min, and a bath ratio is 1:10; and 2, dyeing: dyeing by using 3g / L of active bright blue B-BGFN, 1.43g / L of active bright yellow B-4GLN, 0.95g / L of active golden yellow B-4RNF, 80g / L of sodium sulfate, 25g / L of soda ash, 2g / L of a leveling agent RG-133 and 1g / L of a dispersant EXL-106, wherein a bath ratio is 1:10. The dyeing technology has the advantages of simplicity, practicality, difficult fading, improvement of the dyeing defect problem of grey cloth, and obvious fastness improvement.

Owner:ANHUI ZHONGCAI PRINTING

Easily-dyed waterborne polyurethane resin as well as preparation method and application of waterborne polyurethane resin

The invention provides an easily-dyed waterborne polyurethane resin. The polyurethane resin comprises the following components in percentage by weight: 40%-80% of a monohydroxy or polyhydroxy compound, 0.5%-20% of an ionic or potential hydrophilic compound, 10%-45% of an aliphatic isocyanate compound, 0.5%-10% of low molecular weight compound, 0%-10% of auxiliaries and additives and the balance of water, wherein the monohydric or polyhydric compound comprises 20 wt%-60 wt% of the polyester polyol, 15 wt%-50 wt% of polyether polyol and 0 wt%-30 wt% of monohydroxy polyether. The invention also provides a preparation method and an application of the polyurethane resin. The waterborne polyurethane resin prepared by the invention is easily dyed, simple in dyeing process and has good high temperature resistance and color fastness, excellent resistance to light as well as a certain waterproof property and moisture penetrability.

Owner:XUCHUAN CHEM SUZHOU

Technology using vaccinium bracteatum plant dye for dyeing of black blue real silk

InactiveCN105369654AWidely distributedAchieve plantingNatural dyesDyeing processVaccinium bracteatumWater baths

The present invention relates to a technology using a vaccinium bracteatum plant dye for dyeing of real silk, the technology includes 60 DEG C water bath extraction of the vaccinium bracteatum plant dye and low temperature environmental-friendly dyeing, the dyeing is as follows: wetting real silk, squeezing to dry, putting the real silk into the plant dye with the bath ratio of 1:20 to 1: 30, adding a mordant or not, heating the water bath to 50-75 DEG C at a heating rate of 1.5 DEG C / min for thermal insulation dyeing for 1-2h; taking a dyeing cup out, standing at room temperature for 7-8h; after the dyeing, steaming the real silk at the temperature of 100-103 DEG C for 10-15min, after washing with water, boiling with soap at 90-100 DEG C for 5-10min, and finally drying at 50-60 DEG C. The obtained real silk has a rare black blue color and special natural flower and plant fresh scent.

Owner:JIANGYIN POLYTECHNIC COLLEGE

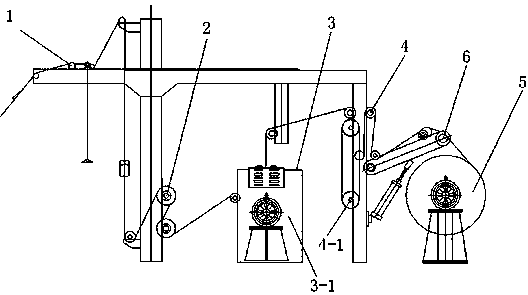

Ultrasonic-assisted cold pad-batch dyeing machine

InactiveCN103938389AReduce consumptionReduce water consumptionLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsUltrasonic assistedEngineering

The invention relates to an ultrasonic-assisted cold pad-batch dyeing machine which comprises a machine frame. The machine frame is provided with a cloth feeding device, a cooling device, a tension control device and an active winding device. An evenness padder is arranged between the cooling device and the tension control device, the tension control device is connected with the active winding device through a bearing arm, a roller is arranged between the evenness padder and the tension control device, the evenness padder comprises an ultrasonic penetration groove, and the active winding device is a constant low tension active winding system. Compared with an existing dyeing process, dyeing is achieved through ultrasonic waves, far infrared drying is not needed, steam does not need to be consumed, water consumption is small, pollution is little, consumption of dye and auxiliaries is little, the process is simple and reliable, preparation cycles are short, labor cost is reduced, equipment investment is little, the occupied area is small, and maintenance cost is low.

Owner:扬州市江都区东盛印染机械厂

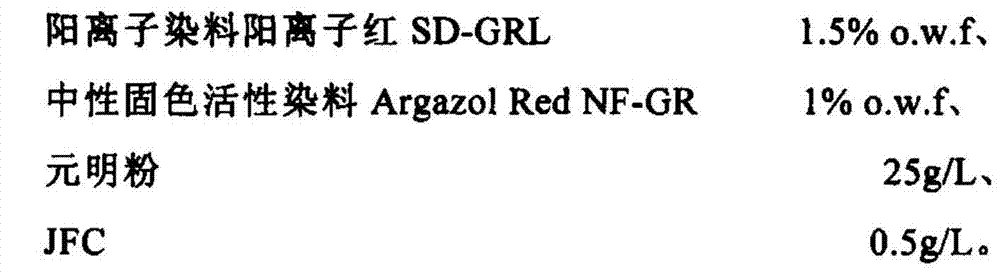

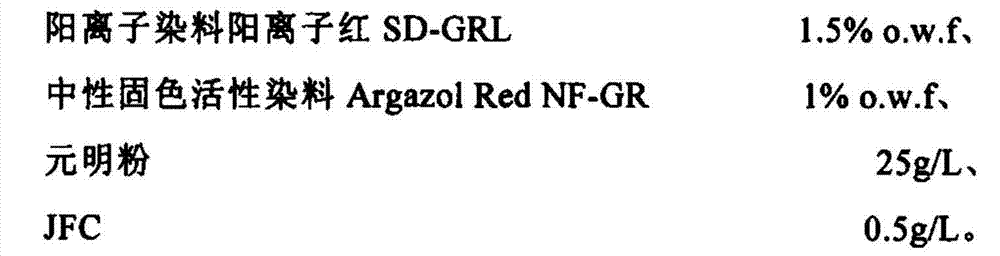

One-bath one-step dyeing method for dralon/cotton blended fabric

InactiveCN104499311AAddress reactivitySolve the problem of not being able to bathe togetherBleaching apparatusDyeing processWarm waterBleach

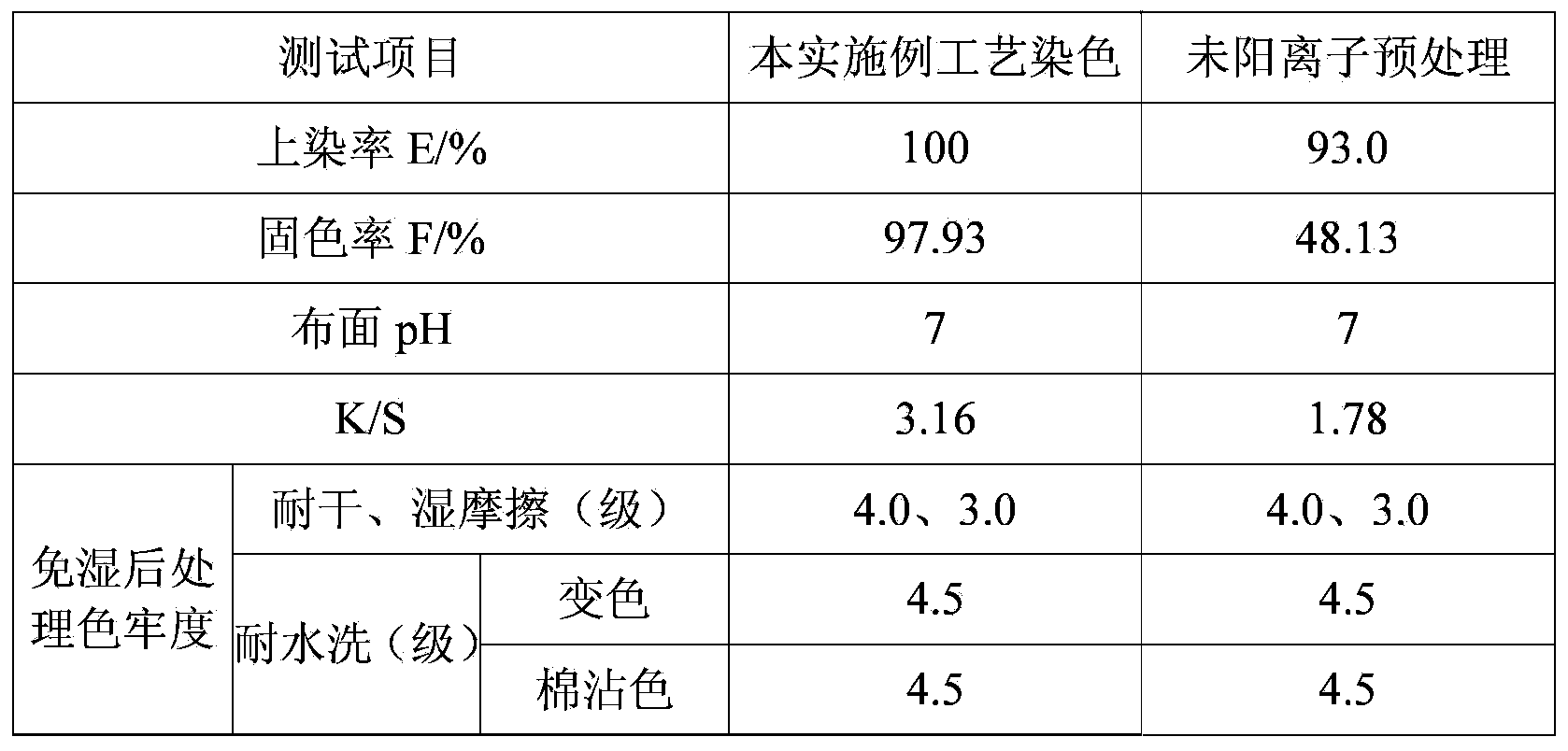

The invention relates to a one-bath one-step dyeing method for a dralon / cotton blended fabric. The method comprises the following steps: impregnating and dyeing the dralon / cotton blended fabric by adopting a neutral bath fixation reactive dye and a disperse type cationic dye; putting the dralon / cotton blended fabric into a solution with a surfactant for pre-treatment; then, soaking in a bleaching agent solution for bleaching treatment; then, dissolving the reactive dye and the cationic dye with warm water at 40 DEG C to prepare a dye liquid; fully stirring, adjusting the pH value to 4-8.5 by using a buffer liquid; putting the fabric into the dye liquid; controlling the dye bath ratio at 1: 10 to 1: 100; then, controlling temperature rise and insulation for 10-90 minutes; and then washing, soaping and drying. Compared with the prior art, the method can be used for solving the problem that the reactive dye and the cationic dye cannot be in a same bath as negative and positive charges of the reactive dye and the cationic dye react and also solving the problem of dyeing condition difference between the reactive dye and the cationic dye.

Owner:SHANGHAI UNIV OF ENG SCI

Method for dyeing cotton fiber fabric by multiple auxiliaries

A method for dyeing cotton fiber fabric by multiple auxiliaries comprises steps as follows: dye, positive ions T, a dispersant CNF, nonionic alicyclic amine polyoxyethylene ether and an acid-base buffering agent are placed into a mixed liquid of an alcohol organic solvent and water and uniformly stirred to prepare a dye liquid; the dye liquid and the cotton fiber fabric are placed in a dyeing machine, the fabric is dyed at the temperature of 40 DEG C, heated at the speed of 1.5 DEG C per minute and subjected to thermal insulation dyeing; flaked soap and sodium carbonate are placed into the mixed liquid of the alcohol organic solvent and the water and stirred uniformly to prepare a washing solution; the dyed cotton fiber fabric is placed into the washing solution for washing; the cotton fiber fabric is dried and subjected to aftertreatment, stentering, preshrinking, cloth inspection and rolling. According to the method disclosed by the invention, three types of auxiliaries are matched for use, the staining property is not influenced while the dye-uptake rate and the fixation rate of dye to cotton fiber are remarkably increased; and the dyeing process is simple, environment protection is realized, the cost is lower, and the method is suitable for large-scale production.

Owner:TAICANG SULUN TEXTILE CHEM FIBER

Method for dyeing blended fabric of polysulfonamide and viscose glue

ActiveCN103643547ASimple dyeing processShort dyeing timeBleaching apparatusDyeing processDisperse dyeWater discharge

The invention relates to a method for dyeing a blended fabric of polysulfonamide and viscose glue, comprising selecting neutral bath dye fixation active / disperse dyes for one bath dyeing, adding the blended fabric of polysulfonamide and viscose glue into a solution with a surfactant, controlling the temperature at 90-100 DEG C, water-washing and drying after 30min-1h of treatment, then immersing the blended fabric of polysulfonamide and viscose glue into a bleaching agent solution for bleaching treatment, water-washing and drying, again immersing the blended fabric of polysulfonamide and viscose glue into a dye liquid containing a neutral salt, a carrier, a leveling agent, a high temperature dispersant, a reactive dye and a disperse dye, regulating a pH value at 4-9, and a bath ratio of 1:(10-100), controlling the temperature at 80-130 DEG C, carrying out dyeing treatment for the blended fabric of polysulfonamide and viscose glue for 30-90min, and water-washing, drying and soaping to complete dyeing. Compared with the prior art, the method provided by the invention has advantages of simple technology, short dyeing time, high efficiency, low energy consumption, and few amount of waste water discharge.

Owner:SHANGHAI UNIV OF ENG SCI

Method for making superfine disperse dye

Said invention discloses a method for preparing ultrafine disperse dyes. The disperse unfinished products is made by reaction to obtain filter cake through filter-press, then added with organic solvent A to solve, then added with solution of organic solvent an of dispersant, through stirring to obtain mixer containing dirperse dyes, dispersant and organic solvent A. Adding organic solvent B to replace, removing organic solvent B to obtain paste of disperse dyes, then drying to obtain solid disperse dyes. The above mentioned organic solvent an is alcahol or acetone, organic solvent B is benzene, toluene or xylene, dispersant is dispersant MF or lignosulfonate. The dyes particle cab be dispersed into size of 10-100 nm by said method which can reduce cost, simplify dyeing process and raise dyeing quality.

Owner:章浩龙

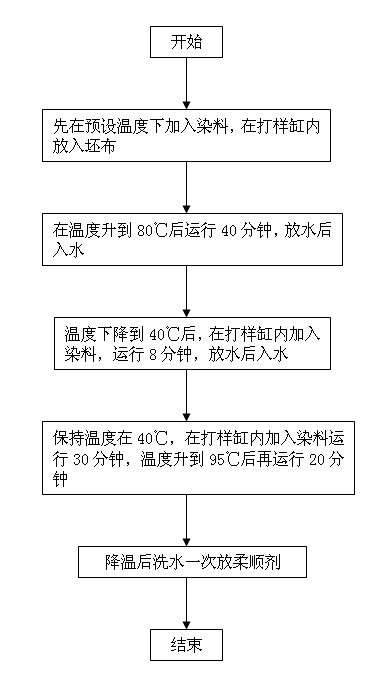

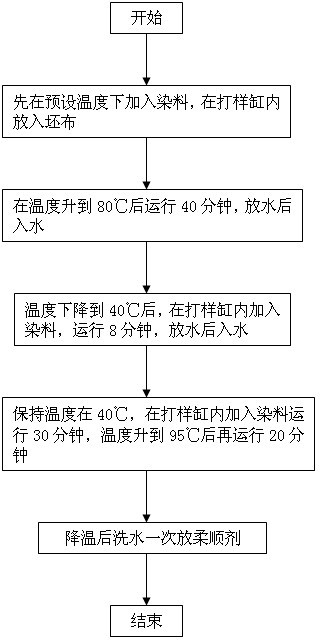

Blending flower gray and blending flower gray two-phase dyeing process

The invention discloses a blending flower gray and a blending flower gray two-phase dyeing process. The blending flower gray is formed by blending polyester yarns and full-cotton yarns. The blending flower gray two-phase dyeing process comprises the following steps of: 1, adding dye at a preset temperature, placing gray fabric in a striking off cylinder; 2, operating for 40min after raising the temperature to reach 80 DEG C, entering water after draining; 3, adding the dye in the striking-off cylinder after reducing the temperature to 40 DEG C, operating for 8min, entering water after draining; 4, keeping the temperature to 40 DEG C, adding the dye in the striking-off cylinder and operating for 30min, operating for 20min after the temperature rises to 95 DEG C; and 5, washing with water once after reducing temperature and placing a softening agent. The invention has the advantages of simplifying the traditional dyeing process, being easily understood by an operator, reducing the cost at a certain degree, and increasing the benefit of enterprises.

Owner:JIANGSU JINCHENZHEN TEXTILE

Preparation method and application of natural plant dye solution of Phytolacca acinosa berries

InactiveCN102127309AIncrease the variety of dyeingRaise the gradeNatural dyesDyeing processChemistryWool

The invention provides a preparation method and application of a natural plant dye solution of Phytolacca acinosa berries. The preparation method comprises the following steps: cleaning Phytolacca acinosa berries, draining, and grinding to obtain Phytolacca acinosa berry pulp; adding water to the Phytolacca acinosa berry pulp (the weight ratio of the Phytolacca acinosa berry pulp to the water is 1:(3-6), immersing at normal temperature under sealed conditions for 1-2 hours, and leaching once or twice; and merging the leaching solutions, and filtering to obtain the natural plant dye solution of Phytolacca acinosa berries. The application method comprises the following steps: dyeing fabric by a chrome-free dyeing, pre-chrome dyeing, metachrome dyeing or after-chrome dyeing process, taking out the fabric, flushing with water and drying in the shade. The natural dye is extracted from the waste Phytolacca acinosa berries and used for dyeing the fabric, thereby recycling the waste Phytolacca acinosa berries, increasing the dyeing types of textiles and enhancing the grade of the textiles, and is especially suitable for dyeing silk fabric and wool fabric. The preparation method and dyeing technique of the natural plant dye solution are simple, and have very broad market prospects.

Owner:YANCHENG INST OF IND TECH +2

Dyeing method for soybean fibres and blended fabric of soybean fibres

InactiveCN102767077ATroubleshoot bleachingSolve the problem of low whiteness of bleached fabricsSynthetic fibresVegetal fibresFiberAcetic acid

The invention discloses a dyeing method for soybean fibres and a blended fabric of soybean fibres. Dyeing is performed on the soybean fibres or the blended fabric of the soybean fibres through using an after-mordant method by using a mordant; and the dyeing process using the after-mordant method comprises the following steps of: pouring the soybean fibres and the blended fabric thereof in a mordant solution at 30-50 DEG C, adjusting the pH to be 4-7 by acetic acid, and adjusting a bath ratio to be 1: (10 to 100), then heating to be at 40-100 DEG C with a heating speed of 0.5-2 DEG C / min, carrying out heat preservation for 10-90 minutes, and after the dyeing is finished, washing with water, and airing. According to the dyeing method for the soybean fibres and the blended fabric of the soybean fibres, tannin or a metal slat or a mixture of the tannin and the metal slat is used as the dyeing mordant, a coordination compound is formed by intrinsic isoflavone pigments of the soybean fibres and the tannin or the metal slat or the mixture of the tannin and the metal slat, so that the fabric presents different colours; the soybean fibres do not need to be subjected to bleaching processing additionally; and dyes are not required to be added during the dyeing process.

Owner:HENAN INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com