Patents

Literature

65results about How to "Improve resource utilization value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

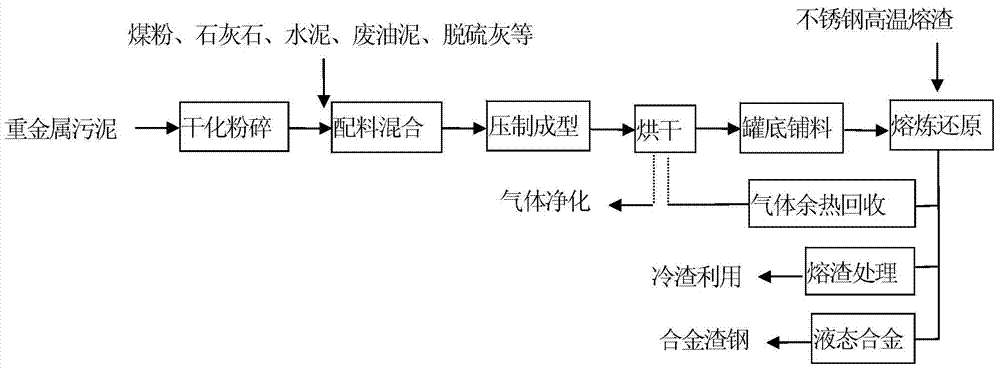

Method for treating heavy metal sludge by using stainless steel molten slag

InactiveCN104512988AIncrease productionIncrease temperatureSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeMetallurgy

The present invention discloses a method for treating heavy metal sludge by using stainless steel molten slag. The method comprises drying crushing, material matching mixing, pressing molding, drying, tank bottom material spreading, smelting reduction, gas purification, molten slag treating, metal recovery and other steps, and specifically comprises that: after heavy metal sludge is subjected to pre-treatment, a certain proportion of ingredients are matched, and the sludge agglomerate is adopted as the bottom spreading material and is placed into a stainless steel molten slag tank to carry out a harmless treatment on the sludge agglomerate. According to the present invention, the characteristics of high production amount, high temperature and rich sensible heat resource of the stainless steel molten slag are adopted, and the stainless steel molten slag is adopted to treat the heavy metal sludge, such that the harmless treatment on the hazardous components and the resource on the valuable material are achieved, the method is the new attempt crossing the industry, and the waste heat resource can be effectively utilized so as to achieve the waste treatment adopting the waste.

Owner:BAOSHAN IRON & STEEL CO LTD +1

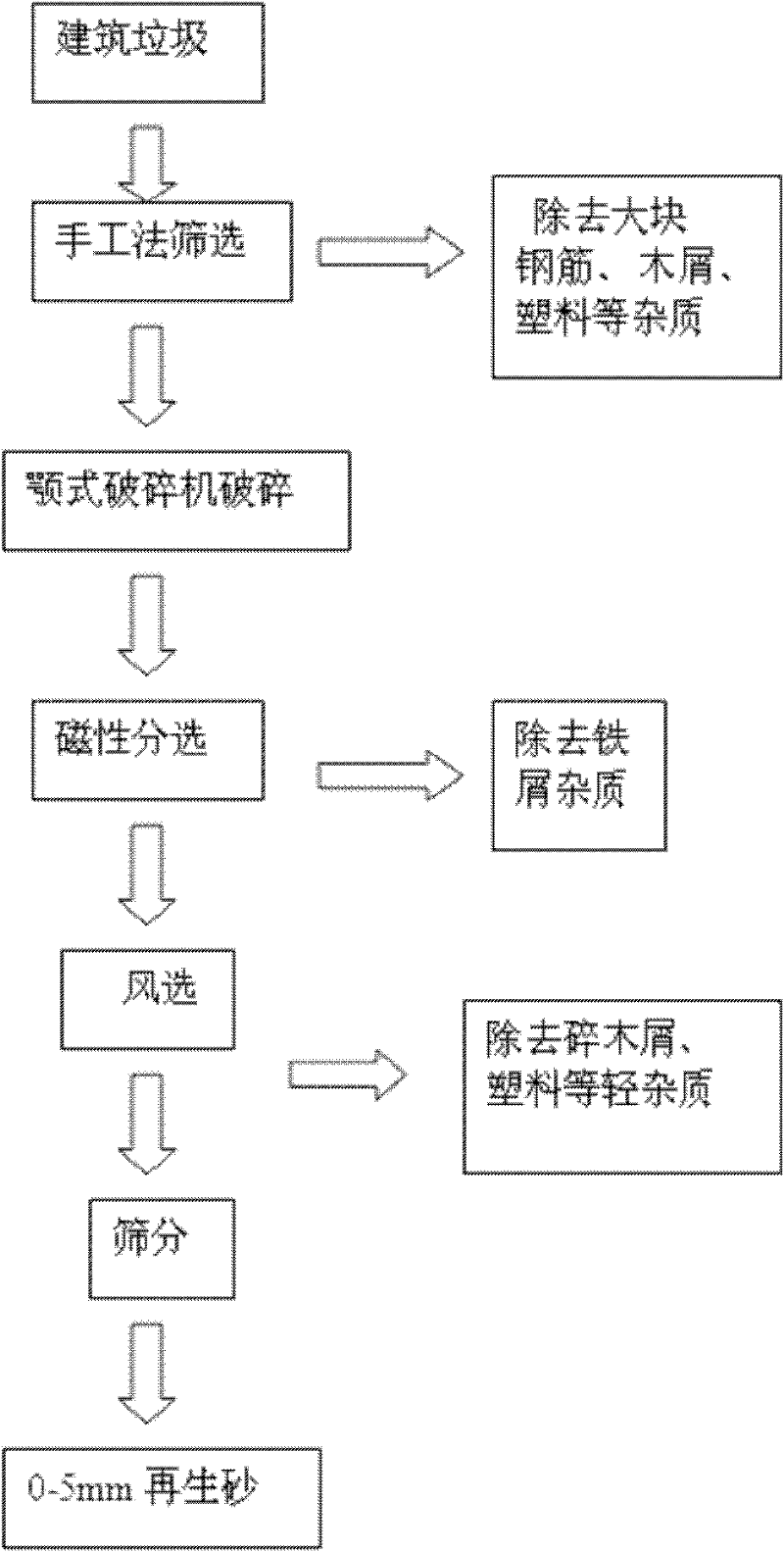

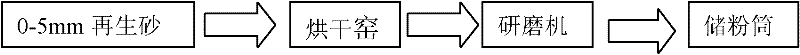

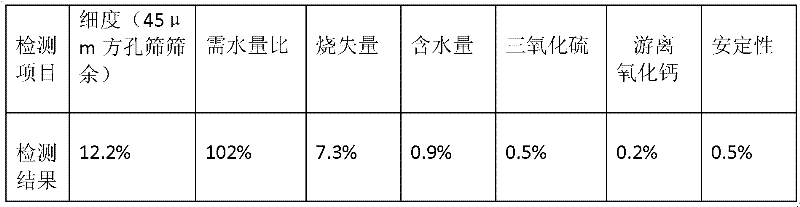

Method for resource recovery of construction wastes

InactiveCN102211889AImprove resource utilization valueHigh activitySolid waste managementResource utilizationImpurity

The invention provides a method for resource recovery of construction wastes, which comprises the following steps of: separating and removing impurities from the construction waste materials and preparing aggregates from the materials through the disposal processes of manual separation, crushing, magnetic separation, air separation, screen separation and the like, wherein the particle sizes of the aggregate meet the requirement of milling equipment, and then preparing regenerated powder from the regenerated fine aggregates with various particle sizes through the disposal processes of drying, grinding, air separation and the like. According to the method, the resource utilization value of the construction wastes is improved, and simultaneously, a resource utilization channel of the construction wastes is opened up; and the produced regenerated powder of the construction wastes can partially substitute fly ash to serve as a cement-base construction raw material such as a building mortar, a walling material, a low-end concrete and the like.

Owner:上海德滨环保科技有限公司

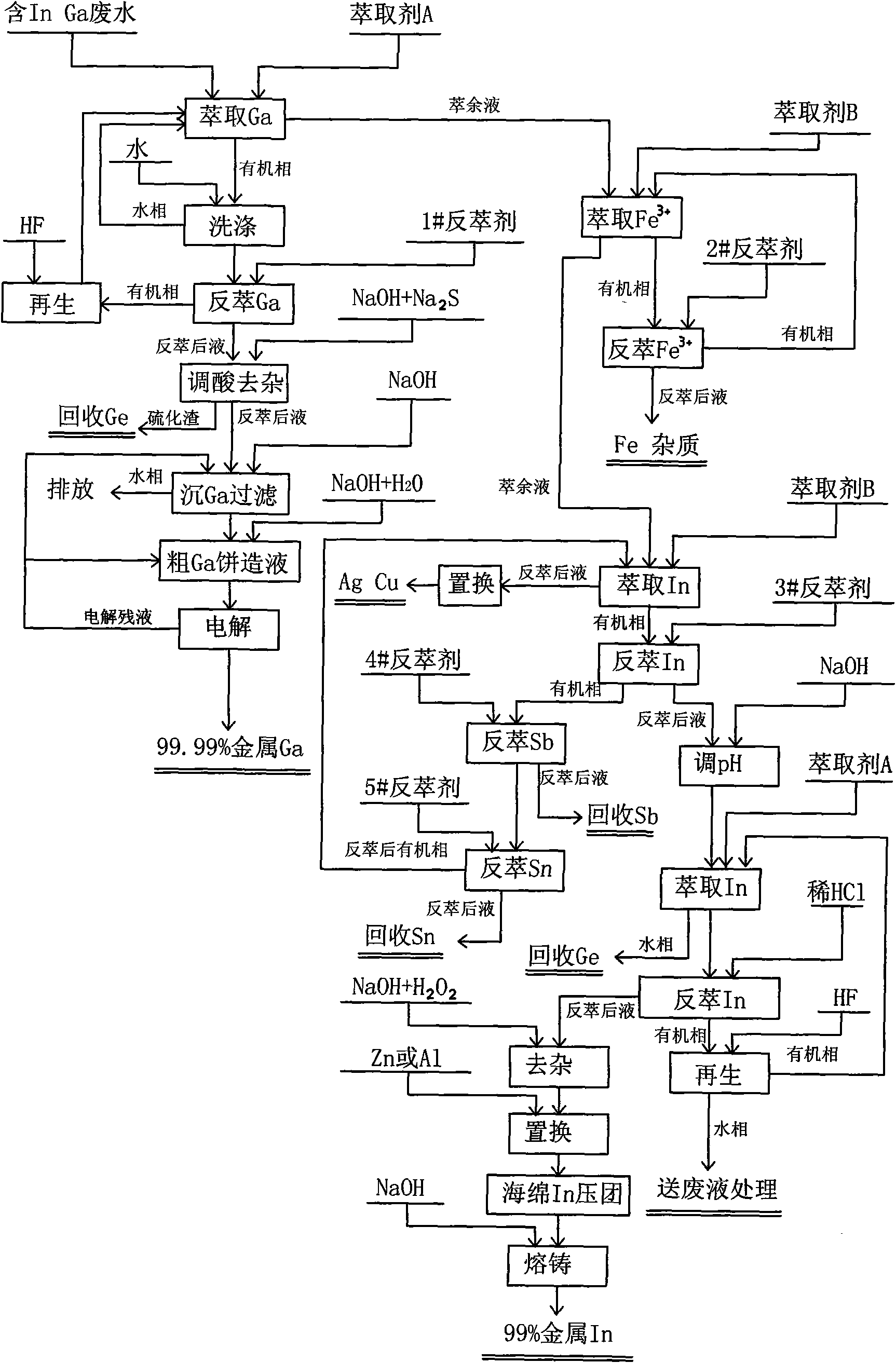

Multi-metal recovery processing technique of waste liquid generated in germanium producing process

InactiveCN101671777AReduce corrosionLow pricePhotography auxillary processesProcess efficiency improvementLiquid wasteIndium

The invention relates to a multi-metal recovery processing technique of waste liquid generated in a germanium producing process, belonging to the technical field of non-ferrous metal wet method metallurgy. The multi-metal recovery processing technique comprises the following steps: extracting germanium from the waste liquid generated in the germanium producing process by an extractant A and a kerose diluent, washing, carrying out back-extraction, removing impurities, purifying, depositing the germanium and electrolyzing to obtain the metal germanium with the purity of 99.99%; firstly extracting iron and partial impurities from the residual waste liquid after extracting the germanium by an extractant B and the kerose diluent, and extracting indium from the residual waste liquid after extracting the iron by the same organic extractant B, adjusting the pH, extracting the indium by the extractant A, carrying out the back-extraction, neutralizing, oxidizing, removing the impurities and replacing to obtain spongy indium, and then briquetting and casting to obtain 99% metal indium. The invention has the advantages of short process flow, small occupied area, few investment, fast implementation and good working conditions, solves the problems that the valuable metal in the waste acid solution can not be recovered and has higher value of the resource comprehensive utilization. Furthermore, the metal recovery rate is larger than 92%; the purity of the obtained product, metal germanium, is 99.99%, and the purity of the metal indium is 99%.

Owner:湖南福欣锗业科技有限公司

Floatation method of pyrites

InactiveCN101658818AImprove surface propertiesHigh recovery rateFlotationFoaming agentNonferrous metal

The invention provides a floatation method of pyrites, belonging to the field of floatation technologies. The floatation method is characterized by comprising the following steps: adding ammonium saltand sulfide as activating agents under the condition of alkaline ore pulp after the floatation of nonferrous metal sulphide ore, then adding collector xanthate and foaming agent pine oil, and stirring to float the pyrites. In the floatation process, the addition amount of the activating agent is 6-120mol / t raw ore, the addition amount of the activating agent sulfide is 6-36mol / t raw ore, the addition amount of the collector xanthate is 500g / t raw ore, and the addition amount of the foaming agent pine oil is 50g / t raw ore. The method can improve the surface properties and the floatation conditions of the pyrites, accelerate the upward-floating speed of the pyrites, improve the recovery rate and the concentrate grade of the pyrites and reduce the flotation agent consumption and the production cost.

Owner:浙江巨化化工矿业有限公司 +1

Method for extracting pigment from walnut green hulls through subcritical water and using pigment for dyeing

InactiveCN105133380ACostlyImprove resource utilization valueNatural dyesDyeing processAdditive ingredientSolvent

The invention relates to a method for extracting natural pigment from walnut green hulls and using the natural pigment for dyeing and belongs to the field of natural product extraction and application. According to the method, subcritical water serves as an extraction solvent, polyphenol, flavone, anthraquinone, naphthoquinone and other natural pigment in the walnut green hulls are extracted, and a natural pigment extraction solution is directly used for dyeing cotton and wool fabric. The method has the advantages that the active ingredient extraction rate is high, no organic solvent is used in the extracting and dyeing process, the process is environmentally friendly, and products are free of pollution, safe, free of toxicity and the like. No toxic and harmful pigment ingredient is contained in dyed fabric obtained through the method, and the method is suitable for dyeing the various cotton and wool fabric and particularly suitable for dyeing infant articles for use, underwear and other articles due to the fact that the natural pigment of the walnut green hulls further has anti-bacterium activity, anti-oxidation activity and the like.

Owner:XINJIANG UNIVERSITY

Method for preparing organic liquid fertilizer by using animal carcasses

InactiveCN106083219AAvoid contactReduce pollutionAnimal corpse fertilisersClimate change adaptationOrganic acidResource utilization

The present invention discloses a method for preparing an organic liquid fertilizer by using animal carcasses. The method comprises: (1) collecting various kinds of livestock and poultry carcasses, placing into a refrigerating cabinet, and storing; (2) crushing the frozen animal carcasses into appropriate blocks; (3) conveying the crushed animal carcass blocks into an acidolysis kettle through a conveyor, adding an organic acid, and carrying out acidolysis liquefaction on the animal carcasses; (4) separating and removing the upper layer grease of the acidolysis liquid, adding an alkali to the remaining lower layer amino acid-containing liquid, and neutralizing; and (5) adding a certain amount of trace elements to the neutralized liquid, and chelating to prepare the amino acid trace element water soluble fertilizer. According to the present invention, the animal carcasses are subjected to the acidolysis with the organic acid, and the trace elements are added to prepare the trace element water-soluble fertilizer, such that the animal carcasses can be effectively and safely treated; and the treatment method has characteristics of harmlessness, economy and environmental protection, and can effectively solve the animal carcass treatment problem so as to achieve the harmless treatment and the resource utilization of the animal carcasses.

Owner:河北中恩生物科技集团有限公司

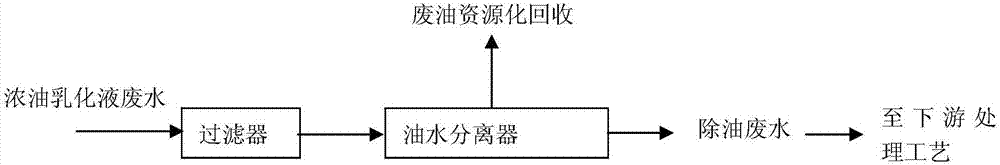

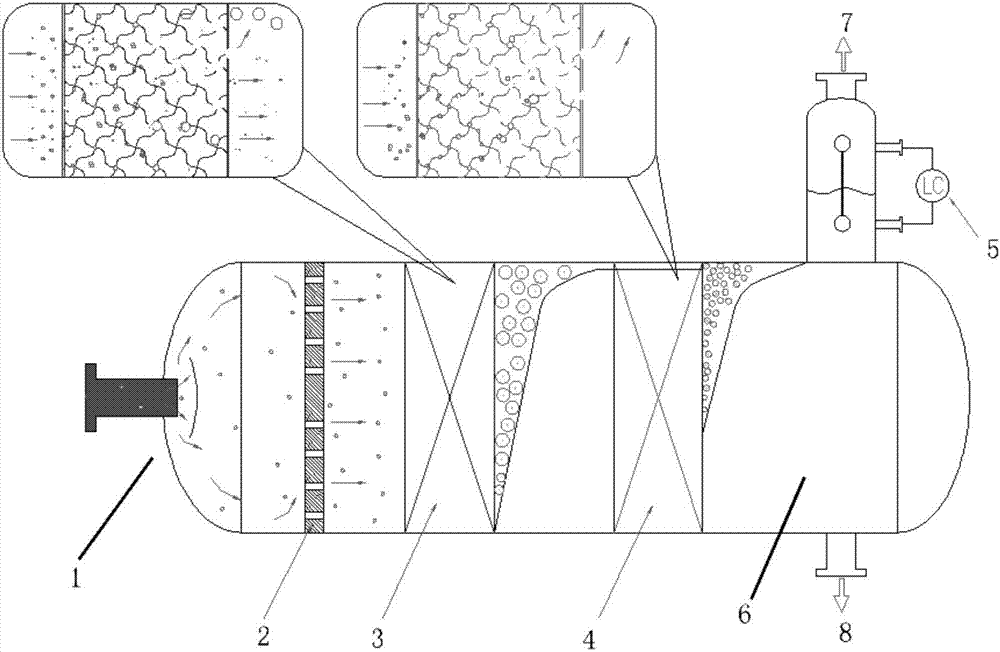

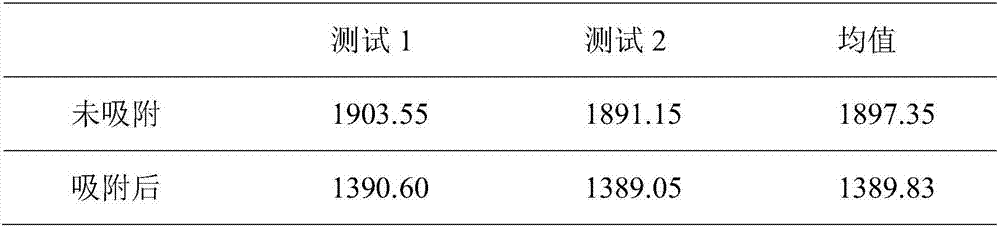

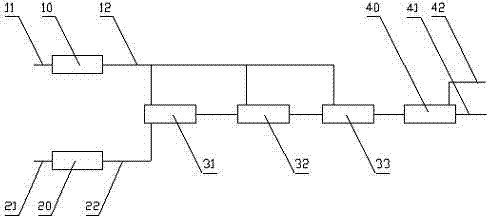

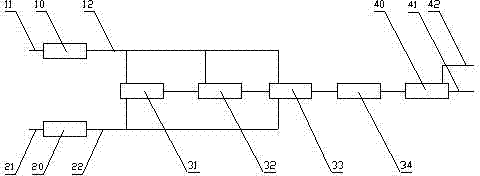

Deoiling method for cold rolling oil-rich emulsion wastewater, and device thereof

ActiveCN107540105AAchieve separationReduce distractionsWaste water treatment from metallurgical processMultistage water/sewage treatmentTherapeutic effectEngineering

The invention relates to a deoiling method for cold rolling oil-rich emulsion wastewater, and a device thereof. The method comprises the following steps: 1, filtering pretreatment; 2, oil-water separation; and 3, waste oil recycling. An oil-water separator comprises an oil-water rectifier, a porous filled area and a multilayer folded plate oil-water separation area, the porous filled area and themultilayer folded plate oil-water separation area are filled with functional nano-fiber filter cores, and every functional nano-fiber filter core is a 304 stainless steel wire fiber and modified polypropylene fiber hybrid fabric filter layer, wherein the denier (fiber diameter) of each of the 304 stainless steel wire fiber and the modified polypropylene fiber is 50-500 nm. The method and the device thereof have the advantages of good treatment effect, low running cost, no secondary pollution, and realization of waste oil recovery.

Owner:BAOSHAN IRON & STEEL CO LTD

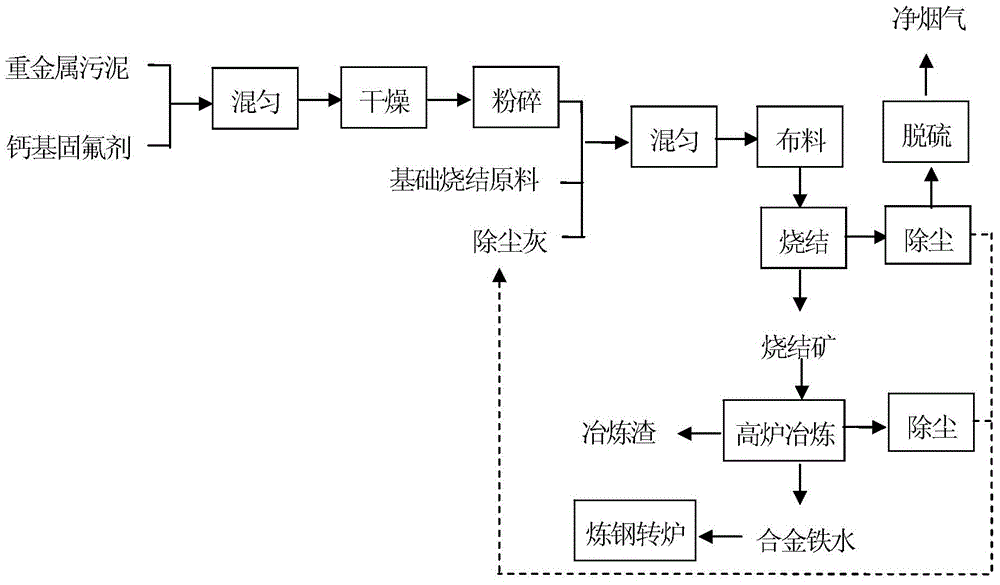

Method for synergistically treating heavy metal sludge

ActiveCN105271624AEfficient recyclingNo slag effectSludge treatmentWaste water treatment from metallurgical processSteelmakingSludge

The present invention provides a method for synergistically treating heavy metal sludge. The method comprises: uniformly mixing heavy metal sludge with a water content of 20-50% and a calcium-based fluorine fixing agent, drying, crushing to obtain calcium-based sludge, uniformly mixing with a base sintering raw material and dust removing ash, granulating, and distributing the material, wherein a mass ratio of the base sintering raw material to the heavy metal sludge to the calcium-based fluorine fixing agent to the dust removing ash is 50-120:0.3-20:0.1-2:0.5-5; sintering the granulated mixing material to obtain sintered ore, wherein the flue gas produced during the sintering process passes through a dust removing and desulfurization device, and the purified flue gas is externally discharged through a chimney; and conveying the sintered ore into a blast furnace, and smelting, wherein the flue gas is externally discharged after the dust removing, the smelting residue is comprehensively utilized, and the alloy hot metal enters the steelmaking converter of the stainless steel enterprise. According to the present invention, dust, gas and wastewater can be discharged into the existing facilities so as to be treated; and with the synergetic treatment of the sintering process and the blast furnace smelting, most of the metal elements can be effectively recovered so as to achieve harmlessness and resources.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Garbage pretreatment and efficient recycling technology matched with garbage combustion system

InactiveCN105149320APromote resource utilizationImprove resource utilization valueSolid waste disposalTransportation and packagingCombustion systemDecomposition

The invention discloses a garbage pretreatment and efficient recycling technology matched with a garbage combustion system. The garbage pretreatment and efficient recycling technology comprises the following steps: a, a garbage bag is broken open by a bag breaking machine; b, most leachate of household garbage subjected to bag breakage is drained by a leachate processing technology; c, after most leachate of household garbage is drained, the household garbage is screened and separated, and oversize products and undersize products are separated; d, the oversize products and the undersize products pass through a magnetic separation apparatus to separate and recycle ferromagnetic objects; e, the oversize products pass through a gravity winnowing apparatus to separate oversize heavy objects and oversize light objects; f, the oversize light objects pass through a waste and old plastic fine separation and recycling dry separator to separate waste plastics and oversize light impurities; g, the undersize products, the oversize heavy objects and the oversize light impurities are stirred, uniformly mixed and dried, and then enter an incinerator for incineration and power generation; and h, the separated waste plastics are processed by a splitting decomposition oil refining device. According to the garbage pretreatment and efficient recycling technology matched with a garbage combustion system, the household garbage incineration disposal has the characteristics of harmlessness, recycling, industrialization and the like.

Owner:BEIJING ZHENGSHI ENVIRONMENTAL PROTECTION ENG CO LTD

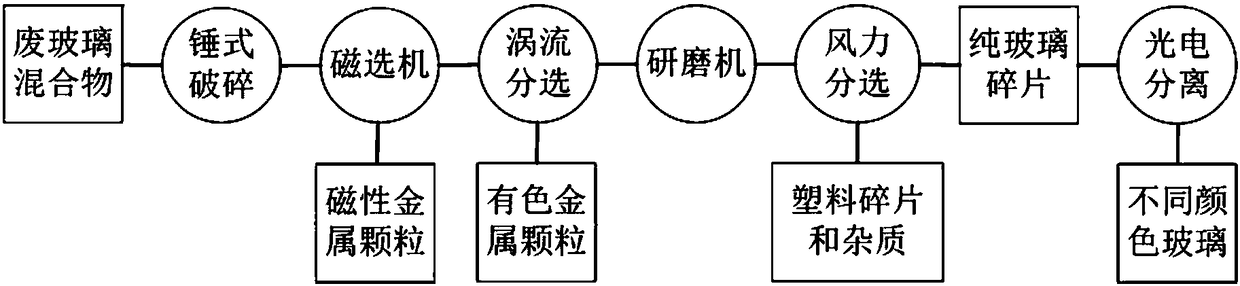

Waste glass crushing and sorting recycling system and method

InactiveCN108480358AImprove resource utilization valueAchieve separationWaste processingGlass recyclingNonferrous metalGlass fragment

The invention discloses a waste glass crushing and sorting recycling system. The waste glass crushing and sorting recycling system comprises a glass breaking device, a magnetic separation device, a vortex sorting device, a grinding device, a wind power sorting device and a photoelectric separation device. According to the waste glass crushing and sorting recycling system, the separation between the magnetic metal mixture, the nonferrous metal, the plastic and glass fragments of different colors in the waste glass and the decontamination operation of the glass can be simultaneously realized, the waste glass crushing and sorting recycling system has the advantages of being wide in application range, high in sorting efficiency, environmentally friendly and the like. The invention further discloses a waste glass crushing and sorting recycling method.

Owner:SUN YAT SEN UNIV

Method for coprocessing zinc-contained leaching residues through steel mill dezincification furnace

The invention relates to a method for coprocesisng zinc-contained leaching residues through a steel mill dezincification furnace. The method comprises the steps that 1, the zinc-contained leaching residues and a reducing agent are added into steel mill dust in a prepared manner; 2, roller press briquetting or disc balling machine balling molding is adopted; 3, waste hot gas is adopted for drying; 4, dried materials are fed into a steel mill dust smelting furnace to be smelted, the smelting temperature is 1150-1250 DEG C, and the standing time inside the furnace is 25-120 min; 5, enriched zinc-contained and lead-contained ash inside cloth bag fly ash is recycled; and 6, metallized pellets obtained from the steel mill dezincification furnace are cooled. The zinc-contained leaching residues are co-processed by means of the steel mill dust processing equipment, and the problem of secondary pollution caused by zinc-contained leaching residues or zinc-contained electroplating sludge generated in the colored, chemical and other industries is solved.

Owner:CHINA IRON & STEEL RES INST GRP

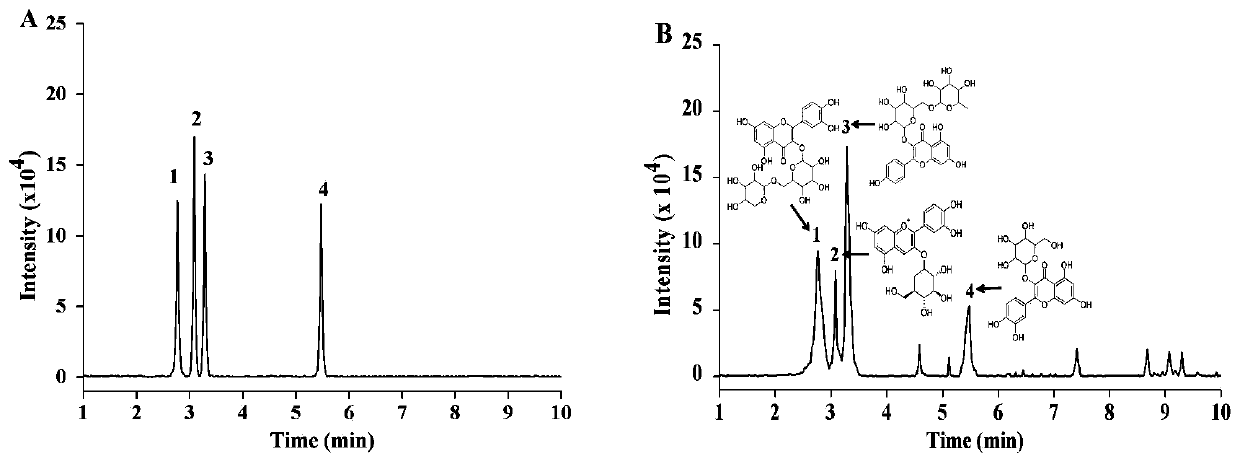

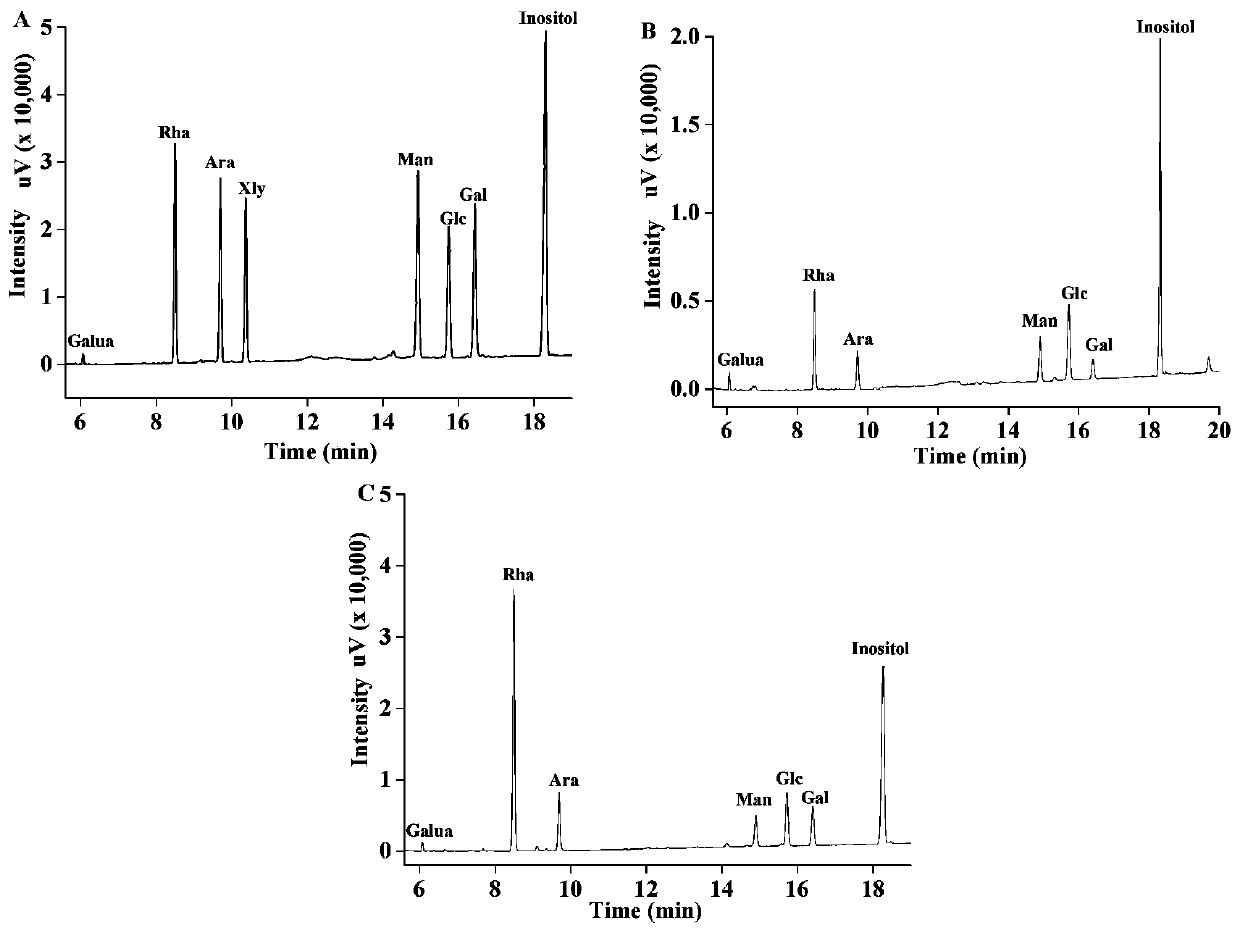

Method for simultaneously preparing polyphenols and polysaccharides from black currants

ActiveCN111249321AEasy extractionEasy to operateFood ingredient functionsPolysaccharide/gum food ingredientsInorganic saltsAlcohol ethyl

The invention relates to a method for simultaneously preparing polyphenols and polysaccharides from black currants. The method comprises the following steps: black currant fruit dry powder is extracted by microwave-assisted ethanol-ammonium sulfate dual aqueous phase system in one step, then separated to obtain two phases. The upper phase is an ethanol phase containing a large amount of polyphenols and a small amount of polysaccharides, and the lower phase is an inorganic salt phase rich in another polysaccharide. In the upper phase, the polyphenols are separated from the polysaccharides by anAB-8 macroporous resin column, and then the polysaccharides and the polyphenols are eluted sequentially with acidic water and ethanol aqueous solution. The two eluents are collected, concentrated, and lyophilized to obtain polysaccharides and polyphenols in the upper phase. The polysaccharides in the lower phase is obtained by dialysis, alcohol precipitation, and lyophilization. The microwave-assisted dual aqueous system constructed by the invention improves the extraction efficiency and separation effect of polyphenols and polysaccharides from the black currants, and simultaneously preparesthree active ingredients, thereby greatly improving the utilization rate of raw materials. The method of the present invention has mild conditions, low cost, and simple process operation without causing inactivation or denaturation of polyphenols and polysaccharides from black currants, and is easy to use in industrial production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for direct extraction of indium from fluosilicic acid slurry

InactiveCN1865462AHigh recovery rateReduce manufacturing costProcess efficiency improvementIndiumHexafluorosilicic acid

The invention discloses an indium extraction method from fluosilicic acid ore solution, which comprises the following steps: matching P204 and diluent into organic extraction liquid; extracting indium in the fluosilicic acid solution with tin, lead, iron and indium; adopting alcaine as back extraction liquid with indium to proceed back extraction; neutralizing to strip impurity; replacing to obtain sponge indium; casting to produce metal indium. The invention is easy to operate with little erosion and pollution, which can recycle metal indium effectively.

Owner:云南锡业集团有限责任公司

Decomposing agent and decomposing application thereof to manure of laying hen

InactiveCN109704840AReduce dosageImprove resource utilization valueFertilizer mixturesBacteroidesBacillus licheniformis

The invention provides a decomposing agent and a decomposing application thereof to manure of a laying hen. The decomposing agent comprises the following components by weight: 2 to 4% of a composite microbial agent, 40 to 60% of an organic material and 40 to 60% of a mineral substance, wherein the composite microbial agent comprises bacteria and fungi; the content of active bacteria in the composite microbial agent is no less than 200 million CFU / g of the compound microbial agent; the content of active fungi in the composite microbial agent is no less than 25 million CFU / g of the composite microbial agent; the bacteria are one or a mixture of more selected from the group consisting of Bacillus subtilis, Bacillus thermophilus, Bacillus licheniformis, Bacillus megaterium and Lactobacillus plantarum; and the fungi are one or a mixture of more selected from the group consisting of Trichoderma reesei, Trichoderma viride, Aspergillus oryzae, Aspergillus niger, saccharomycetes, white rot fungi, Geotrichum candidum, Mucor racemosus, Trichoderma koningii and Thermophilic sporotrichum. The decomposing agent provided by the invention can quickly decompose the manure of the laying hen and reduces the loss of nutrients in the process of decomposing.

Owner:北京世纪阿姆斯生物工程有限公司

Method for recycling paraffin from polytetrafluoroethylene resin kettle-cleaning material

ActiveCN108239299AGuaranteed washing qualityEasy to controlPetroleum wax refiningPlastic recyclingParaffin waxParaffin oils

The invention provides a method for recycling paraffin from a polytetrafluoroethylene resin kettle-cleaning material. The method comprises the following steps: (1) adding the polytetrafluoroethylene resin kettle-cleaning material and water into a reaction kettle, heating until the polytetrafluoroethylene resin kettle-cleaning material is melted, and stirring, so as to finish washing; (2) standingthe washed material in the kettle for layering, adding a rough paraffin mixture on an upper layer into a dryer, and drying for dehydration; and (3) filtering: filtering the material dried and dehydrated in the step (2), so as to obtain paraffin. Separated polytetrafluoroethylene resin can be used as a common industrial product and can be widely applied to various fields and emerging industries innational economy, and the separated paraffin can be used as a civilian product. The method is applied to the recycling of paraffin from the kettle-cleaning material in the production process of the polytetrafluoroethylene resin and has the characteristics that the process is simple, the control is easy, and the purity of the paraffin product is high, and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Non-shrinkage cementing material made of phosphogypsum and preparation method of non-shrinkage cementing material and concrete

The invention relates to the technical field of comprehensive utilization of phosphogypsum, in particular to a non-shrinkage cementing material made of the phosphogypsum and a preparation method of the non-shrinkage cementing material and concrete. The phosphogypsum, coal ash or phosphorous slag, water quenching slag and steel slag are compounded to form a mixed material, the non-shrinkage cementing material is prepared by adding ordinary Portland cement, high-value comprehensive utilization of the phosphogypsum is achieved, sulfate in the phosphogypsum is used as an activator to activate theactivity of the coal ash, the phosphorous slag, the water quenching slag, the steel slag and the like, and reacts with the coal ash, the phosphorous slag, the water quenching slag, the steel slag, Al2O3 in the cement and hydrated product of the cement Ca(OH)2 to form ettringite Aft, capillary pore in the concrete is filled and blocked, the quality percentage control of raw materials is combined, the performance of the cementing material is improved, thus when the cementing material is applied to the concrete, the compactness of the concrete is improved, volume expansion is generated, the non-shrinkage high-performance concrete is obtained, at the same time, the hydration heat of the cement is lowered, cement consumption is saved, and the production cost of the concrete is lowered.

Owner:赵源 +2

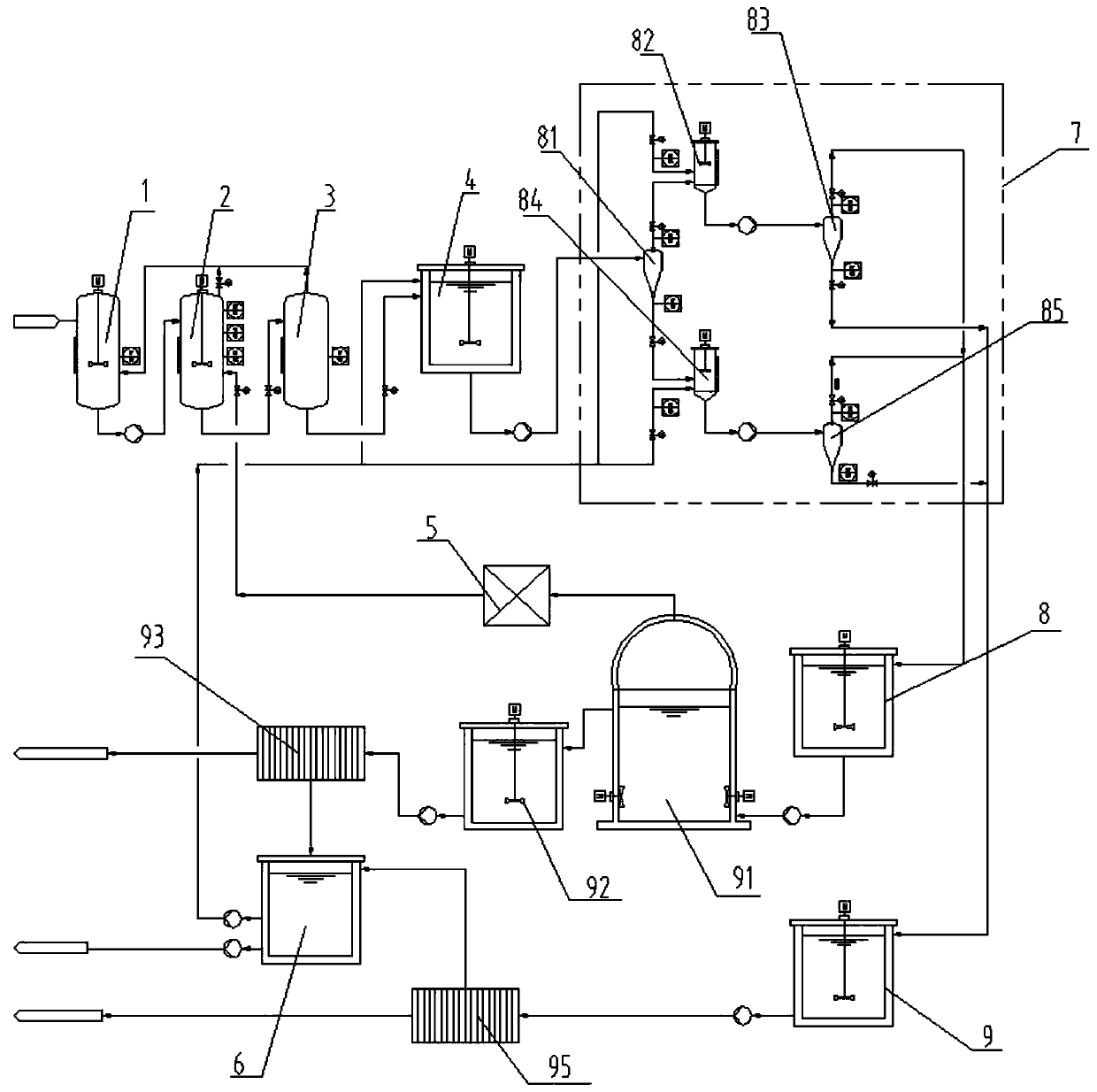

Biomass quality-based utilization system and method based on hydrothermal technology

InactiveCN111423097AIncrease solid contentEasy to dehydrateSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludge cakeBiogas production

The invention discloses a biomass quality-divided utilization system based on a hydrothermal technology. The biomass quality-divided utilization system comprises a pretreatment tank, a hydrothermal reactor, a flash evaporation reactor, a hydrothermal sludge buffer pool and a multi-stage cyclone separation system, wherein the pretreatment tank, the hydrothermal reactor, the flash evaporation reactor, the hydrothermal sludge buffer pool and the multi-stage cyclone separation system are communicated with one another through pumps; according to the invention, after organic matters and inorganic matters in the sludge are effectively separated by the system and the method, the resource utilization value of the sludge can be improved. Organic sludge is easier to perform anaerobic biogas production; inorganic sludge is excellent in dehydration performance, and a sludge cake with high solid content can be obtained, so that subsequent building materials can be conveniently utilized, or the sludge cake can be used as landfill covering soil; and the scheme is combined with an anaerobic digestion process. Due to the fact that inorganic components in the sludge are separated, sand in the sludgecan be prevented from being deposited and caked in the digestion tank, and the problems that the effective tank capacity of the digestion tank is reduced, and a pipeline is blocked can be solved.

Owner:四川深蓝环保科技有限公司

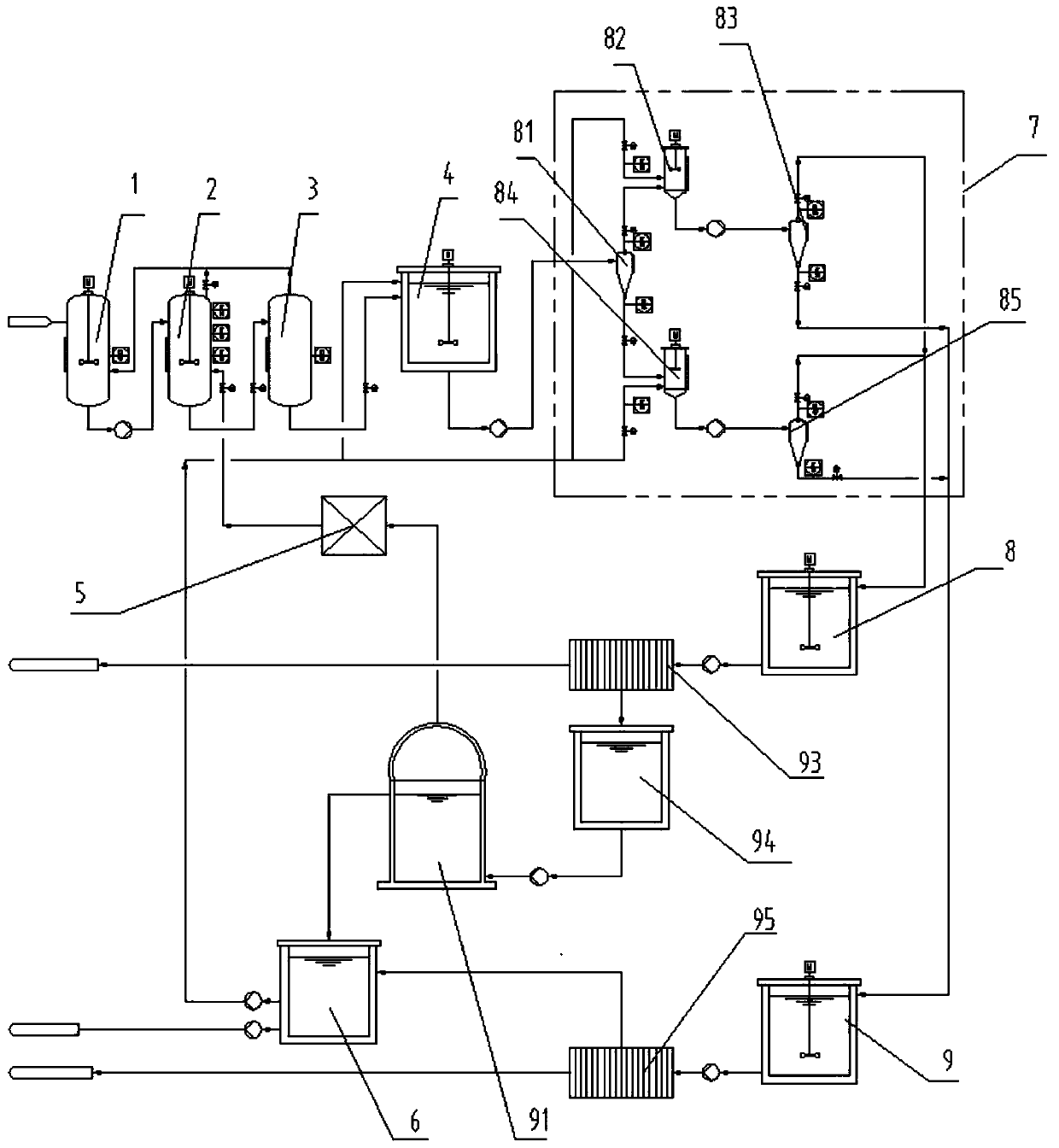

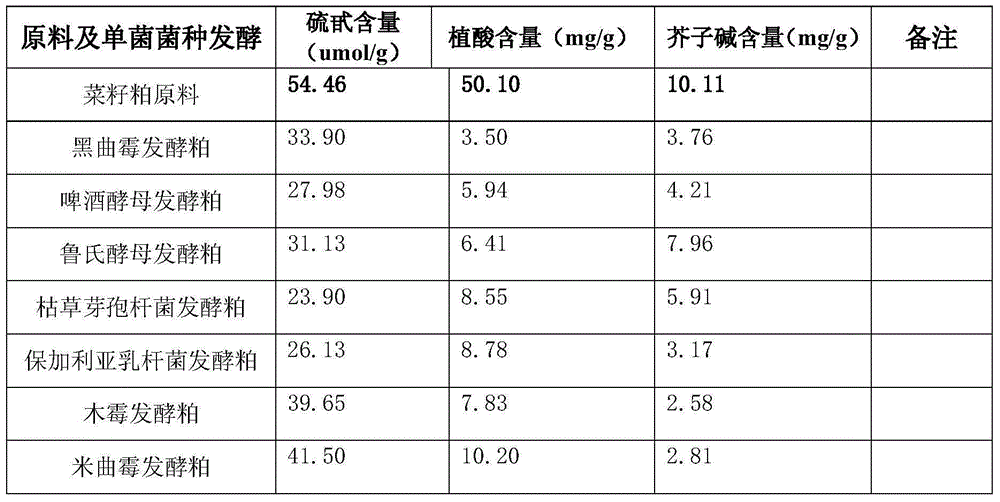

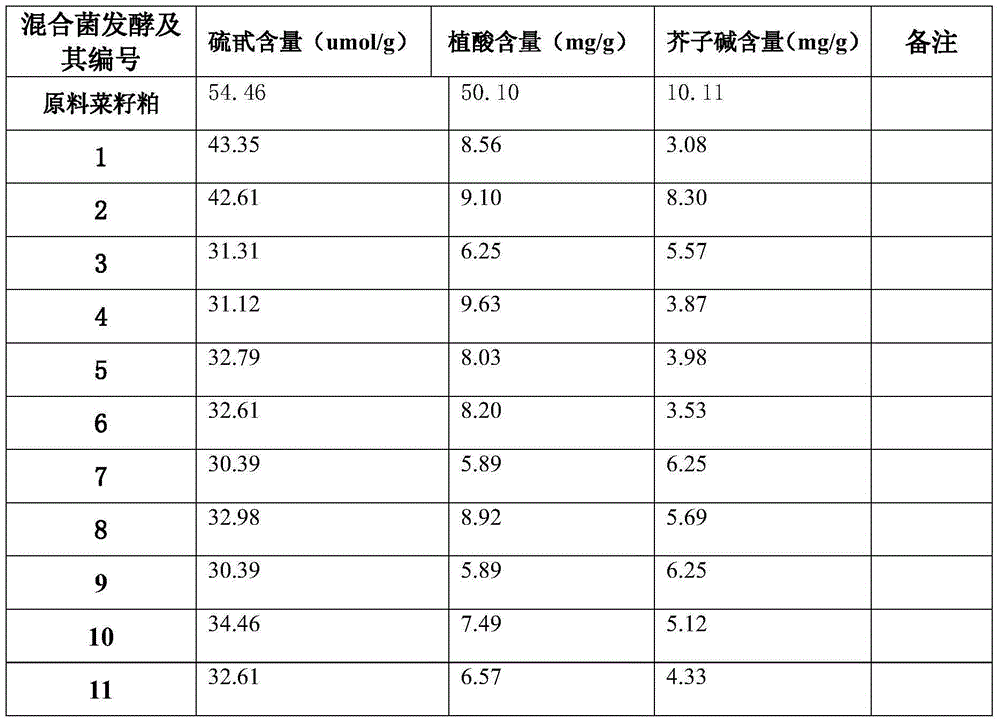

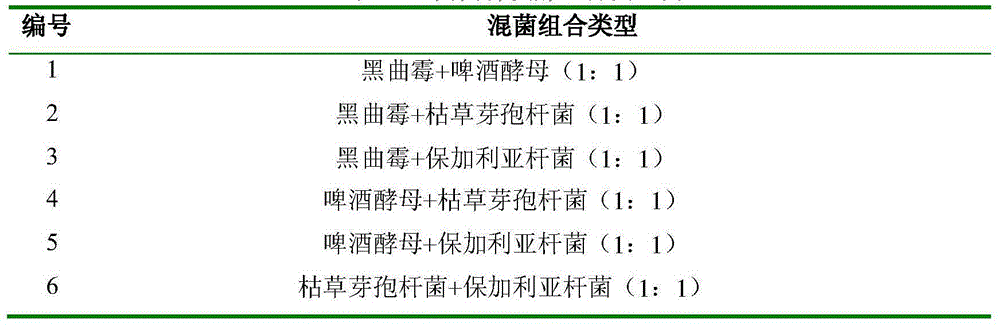

Rapeseed meal detoxifying treatment method

InactiveCN105076689AGood removal effectEasily absorbed by animalsAnimal feeding stuffProtein contentYeast

The present invention discloses a rapeseed meal detoxifying treatment method comprising the following steps: raw materials are crushed, the crushed raw materials are subjected to first-step fermentation with aspergillus niger and beer yeast and second-step fermentation with bacillus subtilis and lactobacillus bulgaricus, and the fermented rapeseed meal is subjected to alcohol washing and separation, and the obtained dry material is non-toxic rapeseed meal. The rapeseed meal detoxifying treatment method utilizes a step-by-step method to conduct detoxification, combines with ethanol elution, and finally obtains the non-toxic rapeseed meal which has a minimum content of anti-nutritional factors, is high in crude protein content and rich in prebiotics, and can be used in food and feed.

Owner:ANHUI AGRICULTURAL UNIVERSITY

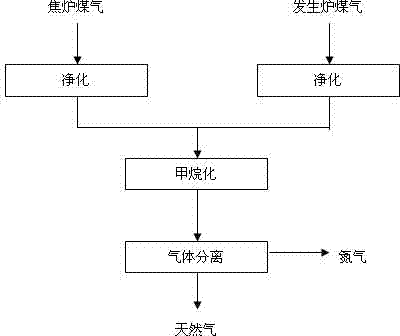

Method of producing natural gas by coupling coke oven gas and producer gas and production device

InactiveCN104194850AImprove resource utilization valueAvoid pollutionGaseous fuelsMethanationNitrogen gas

The invention relates to a method of producing natural gas by coupling coke oven gas and producer gas and a production device adopting the method for production of the natural gas. According to the method, the coke oven gas and the producer gas are adopted as raw materials; the ratio of the coke oven gas to the producer gas is calculated based on requirements on the ratio of H2, CO, and CO2 for methanation and according to the contents of the H2, the CO and the CO2 in the coke oven gas and the producer gas which are adopted as the raw materials; the coke oven gas and the producer gas which are adopted as the raw materials are fed into a methanation device according to the ratio and subjected to methanation; and nitrogen in the gas after the methanation is removed to form the natural gas formed by methane. The production device comprises the methanation device and a nitrogen separation device which are connected to each other. The method and the production device effectively utilize the component difference of the two raw material gases, achieve component complementation of the two kinds of coal gas and allow the gas after the methanation to meet requirements on the natural gas, thus simplifying the production process, reducing the production cost, avoiding environment pollution and increasing economic benefit.

Owner:顾君尧

Online tempering device and method for slag tapping and cooling process of molten steel slag

PendingCN111850193AImprove activity indexImprove resource utilization valueRecycling and recovery technologiesTemperingSlag

The invention relates to an online tempering device and method for a slag tapping and cooling process of molten steel slag. The online tempering method comprises the following steps of: uniformly pouring modifiers in a reducing agent cabin, a calcium agent cabin and a silicon agent cabin into a steel slag tank in the steel slag tapping process; then pouring the modifiers into a material mixing bedby adopting a crown block; stirring, crushing and uniformly mixing high-temperature steel slag by utilizing a material mixing machine, so as to provide good dynamic conditions for modification of thehigh-temperature steel slag; then cooling the modified steel slag subjected to reaction to certain temperature by adding water; and finally, carrying out hot sealing treatment. According to the online tempering device and method provided by the invention, the modifiers are added in the slag tapping process of the molten steel slag and the steel slag is tempered and modified under the condition that an external heat source is not provided, so that residual heat resources of the molten steel slag are sufficiently utilized. Steel slag components are regulated and controlled from the source, so that the recycling rate of metal iron in the steel slag can be improved, the content of the metal iron in tailings is reduced, the recycling rate of the steel slag iron is greatly improved, the grindability of the steel slag is improved and the activity index of the steel slag is remarkably improved; and resource utilization of all the steel slag is easy to realize and the online tempering device and method have great economic and social benefits.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

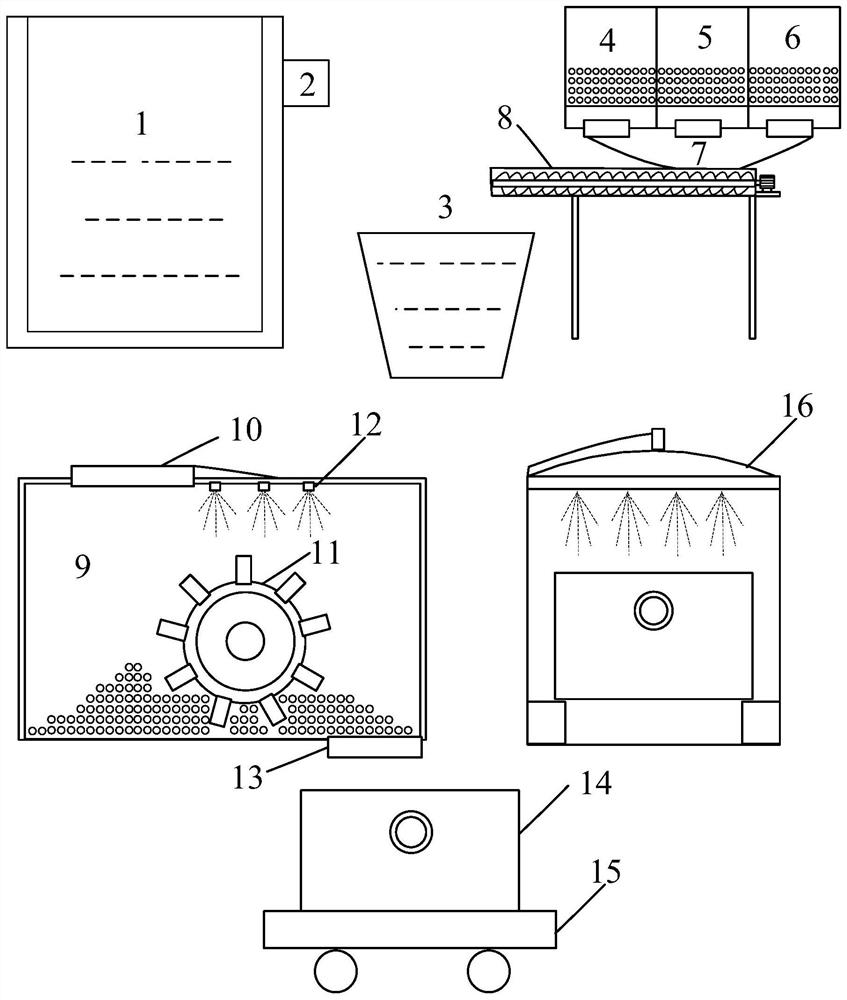

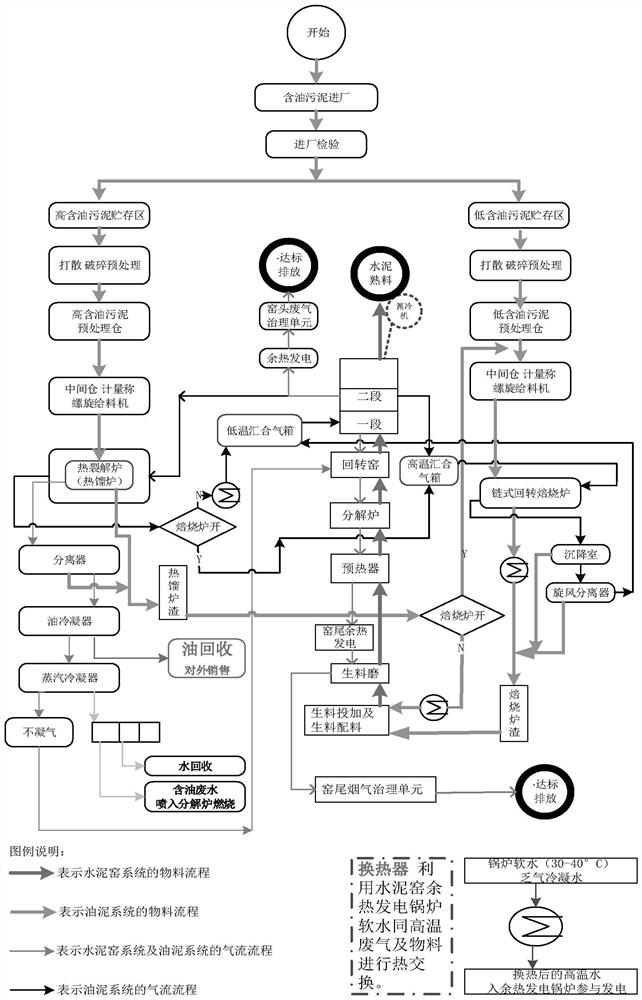

Device and method for resource utilization and harmless treatment of oily sludge

PendingCN113121082ASafe and efficient to useReduce heat consumption costsSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermodynamicsSludge

The invention discloses a device and method for resource utilization and harmless treatment of oily sludge. The method comprises the following steps: carrying out scattering and crushing pretreatment on high-oil-content sludge with an oil content of more than or equal to 5%, then carrying out thermal cracking to recover oil, and burning generated non-condensable gas in a cement kiln, subjecting generated thermal cracking furnace slag with an organic matter content of less than 0.5% to heat exchange, and then putting the thermal cracking furnace slag into a raw material system the cement kiln; carrying out scattering and crushing pretreatment on low-oil-content sludge with an oil content of less than 5%, performing roasting treatment on the low-oil-content sludge and thermal cracking furnace slag with an organic matter content of more than or equal to 0.5%, carrying out heat exchange on the generated roasting furnace slag, putting the generated roasting furnace slag into a cement raw material system, and treating the generated roasting furnace waste gas in the cement kiln. According to the invention, the traditional resource utilization and cement kiln co-processing mode of the oily sludge is innovatively changed through a system integration process, oil recovery is realized, large-scale co-processing of the oily sludge in the cement kiln is realized through raw material addition, and the method has the characteristics of wide application range, full resource utilization, thorough and harmless treatment and the like.

Owner:四川海沛环保科技有限公司

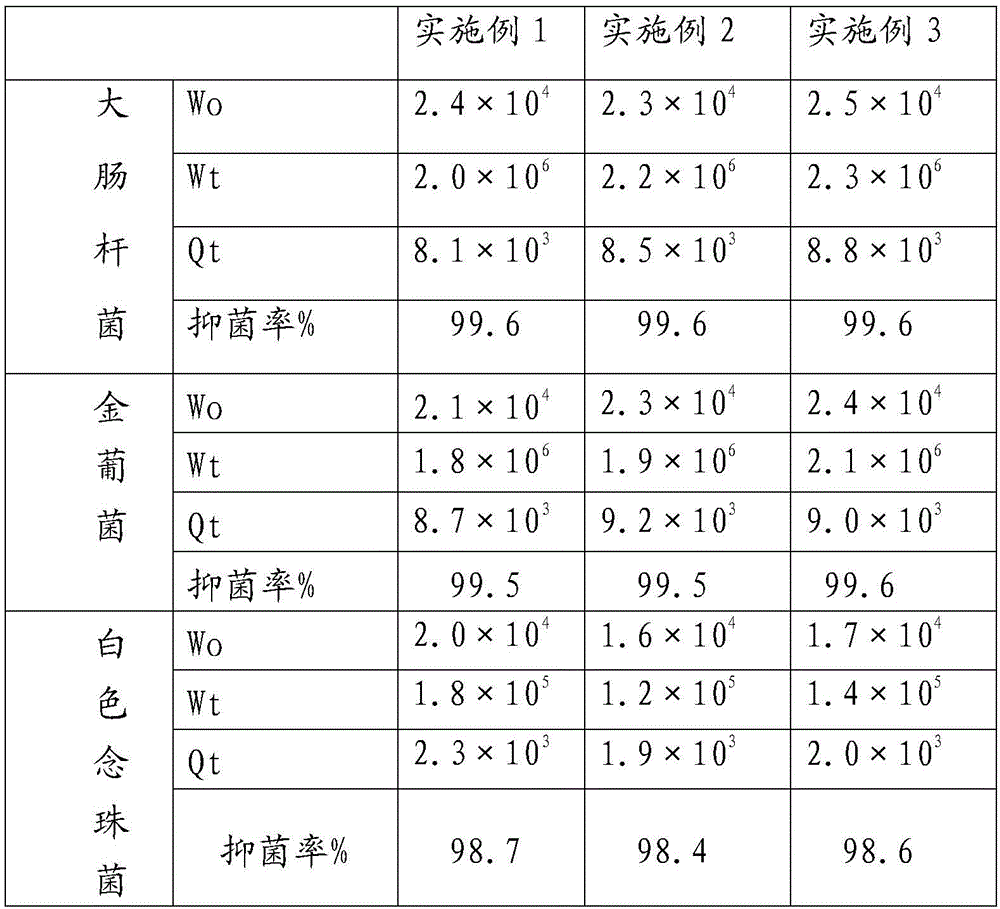

Clean preparation method of high-quality and high-purity natural-color bamboo fluff pulp

ActiveCN106192542AKeep it pureKeep naturalWashing/displacing pulp-treating liquorsMachine wet endBursting strengthFluff pulp

The invention belongs to the pulping field, and particularly relates to a clean preparation method of high-quality and high-purity natural-color bamboo fluff pulp. The method comprises the following steps that natural-color KP bamboo pulp is fully and uniformly defiberized; the defiberized pulp is diluted and then fed into a heat disperser, and sodium hydroxide is added for alkali extraction; the pulp subjected to heat dispersion is diluted with water and enters a flotation machine for flotation, and meanwhile a trapping agent oxirane-epoxypropane copolymer is added; the pulp obtained after flotation is washed and shrunk through a vacuum pulp washer, and generated washing waste liquid is drained; the pulp enters a pulp board papermaking workshop after being washed. The natural-color bamboo fluff pulp prepared through the technology has the advantages that the technological process is simple, the production efficiency, the production capacity, the finished pulp yield rate and the raw material utilization rate are high, investment is low, adopted chemicals are clean and environmentally friendly, a fluff pulp board has the low bursting strength, flexibility, comfort and elasticity are achieved, the liquid absorbing property is good, raising and dissociating are easily achieved, dust is little, and the hygienic indexes such as the good bacterium inhibiting property, antibacterial property and antianaphylaxis meet the requirement.

Owner:李文俊

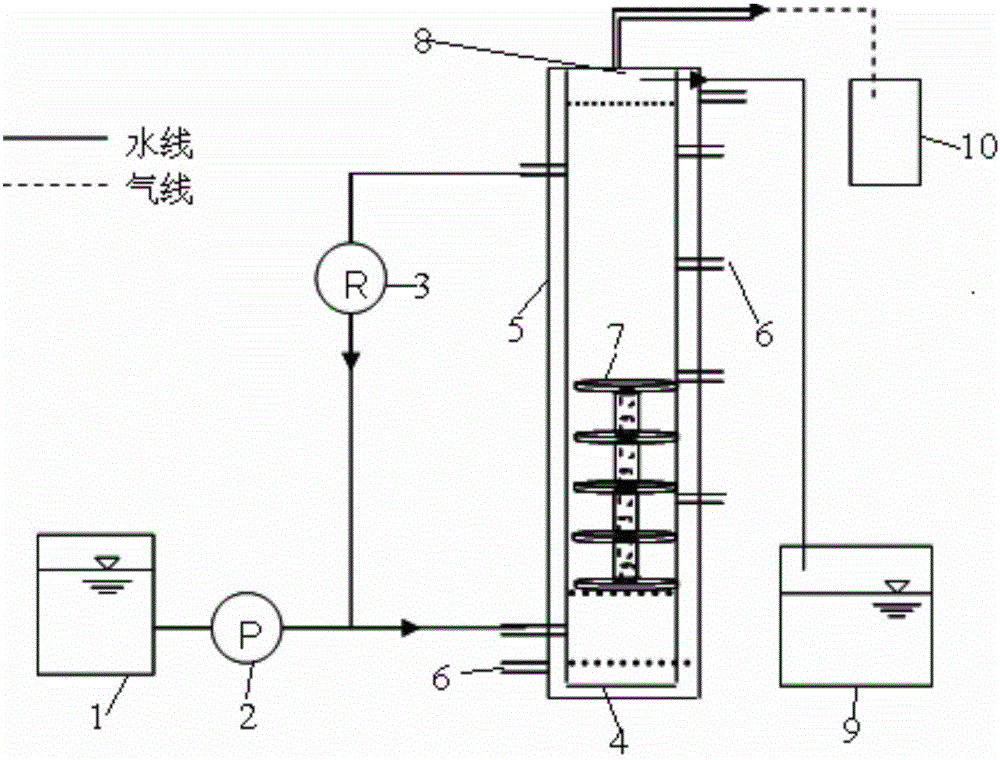

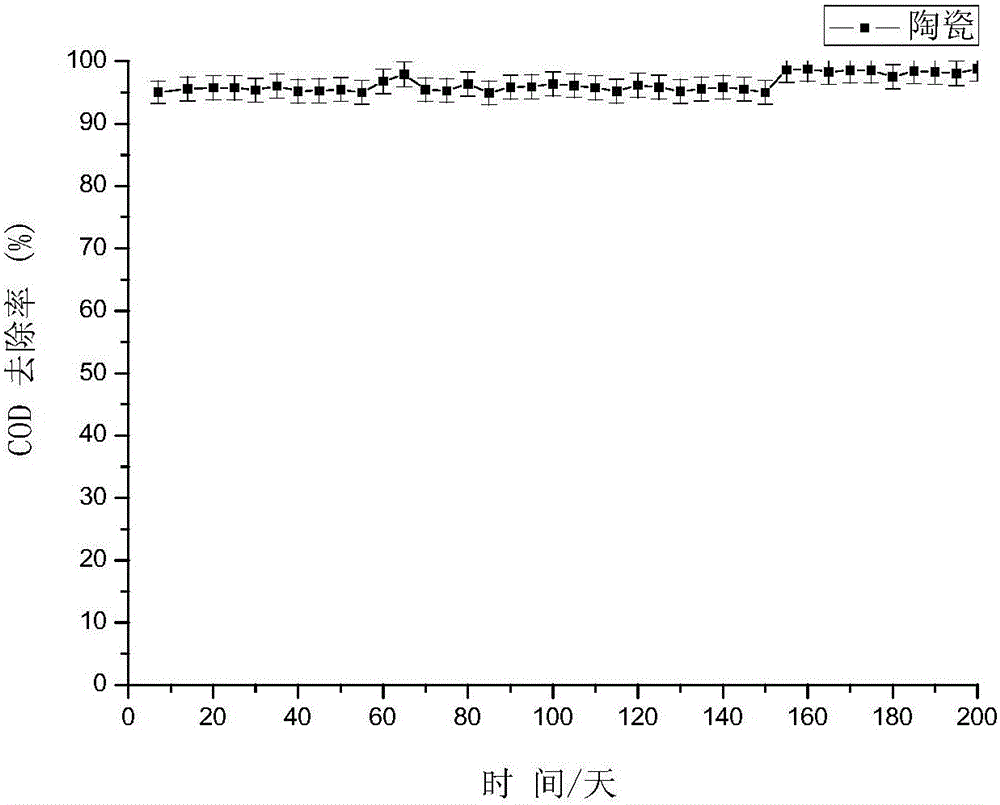

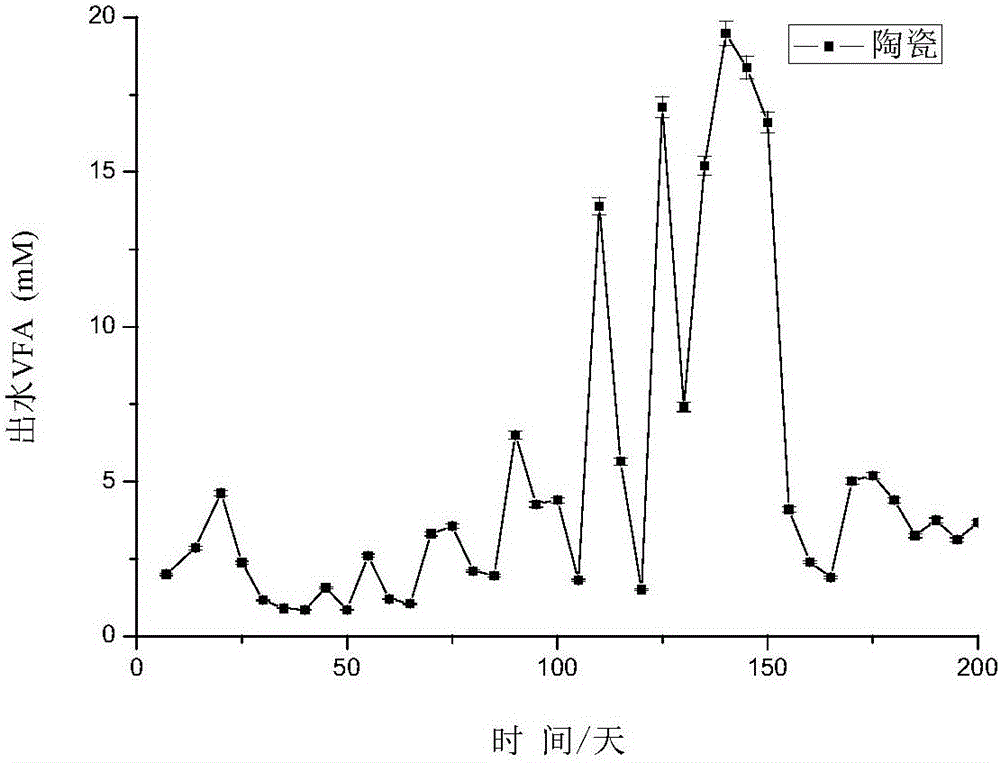

Method for treating cassava alcohol wastewater through anaerobic reactor filled with ceramic material

InactiveCN105967327AStable and efficient processingImprove processing efficiencyWaste based fuelTreatment with anaerobic digestion processesMethane yieldManihot esculenta

The invention discloses a method for treating cassava alcohol wastewater through an anaerobic reactor filled with a ceramic material. The method includes the steps that the anaerobic reactor is filled with the ceramic material serving as a sludge carrier, wherein the volume of the ceramic material is 30%-45% the working volume of the reactor; anaerobic sludge is inoculated to the ceramic carrier, and standing culture is carried out to make the anaerobic sludge adsorbed to the ceramic carrier; the anaerobic sludge is subjected to habituated culture, cassava alcohol wastewater which is diluted step by step is introduced into the reactor for reflux to make the immobilized sludge make full contact with the cassava alcohol wastewater, and habituated culture is ended when the COD removal rate and the methane yield are stable; the cassava alcohol wastewater to be treated enters the anaerobic reactor for treatment, wherein the hydraulic retention time is 0.3-0.5 h. According to the method, the COD removal rate can reach 98% or above after stable operation.

Owner:NANJING UNIV OF TECH

Filter bag for bag-type dust collector, bag-type dust collector and flue gas mercury removal method

InactiveCN105617776AWill not affect comprehensive utilizationNo secondary pollutionDispersed particle filtrationFiltration separationFiberSorbent

The invention provides a filter bag for a bag-type dust collector. The filter bag comprises a base cloth and a filter material. The filter bag is characterized in that a mercury adsorbent is arranged between the base cloth and the filter material, the mercury adsorbent comprises metal-modified active carbon fibers and the metal and mercury can form an amalgam. The filter bag is used in flue gas mercury removal. Flue gas to be treated goes through a bag-type dust collector with the filter bag so that dust is removed and flue gas mercury is removed. The method has full contact reaction time of mercury in flue gas and the mercury adsorbent in the filter bag. The mercury adsorbent has a high mercury adsorption saturation capacity. The metal in the mercury adsorbent and mercury form a stable amalgam so that adsorption efficiency and capacity are greatly improved. The filter bag maximally reduces flue gas dust-caused influence on mercury removal. The method has high mercury removal efficiency.

Owner:FUJIAN LONGKING +1

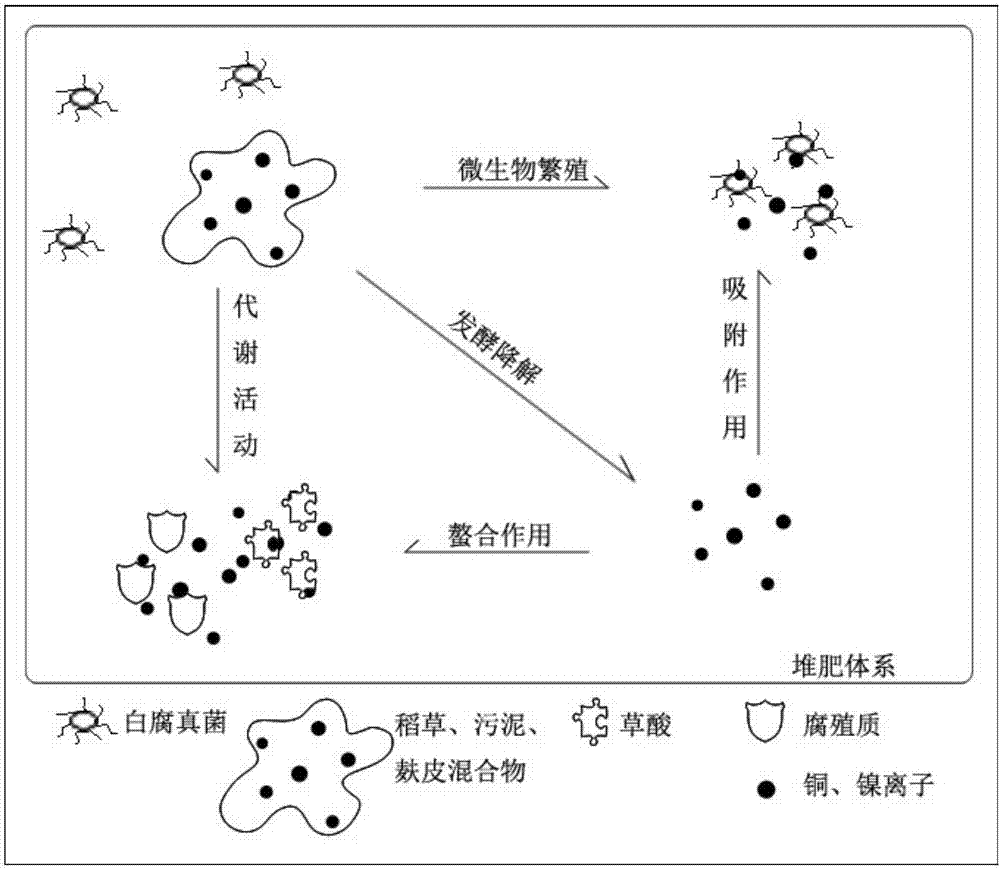

Method for passivating available copper and nickel in municipal sludge by white-rot fungi and compost

InactiveCN107032573AReduce pollutionReduce toxic and harmful organic matterSludge treatment by de-watering/drying/thickeningClimate change adaptationResource utilizationDecomposition

The invention discloses a method for passivating available copper and nickel in municipal sludge by white-rot fungi and compost, and belongs to the field of the environment. The white-rot fungi and compost treatment method synergistically acts on passivation treatment of the available copper and nickel in the municipal sludge, the available copper and nickel are fixed and chelated by a rice straw and bran compost fermented product, and meanwhile, growth nutritional substances are provided for the white-rot fungi; and the white-rot fungi promotes decomposition of substances which are difficult to decompose in a compost system, the sludge is promoted to become thoroughly decomposed, the chelating and passivating effect of a decomposed product to copper and nickel is promoted, meanwhile, by the adsorption and chelating effect of the white-rot fungi to the copper and nickel, the passivation rate of the available copper and nickel in the municipal sludge is further increased effectively, resource utilization of wastes of crops is realized, agricultural risks of the municipal sludge are reduced, and the resource utilization value of the municipal sludge is increased. The method has the advantages of zero secondary pollution, simple treatment process, simplicity and convenience in operation, low investment and running costs and the like. The practical application value is quite high.

Owner:GUANGZHOU UNIVERSITY

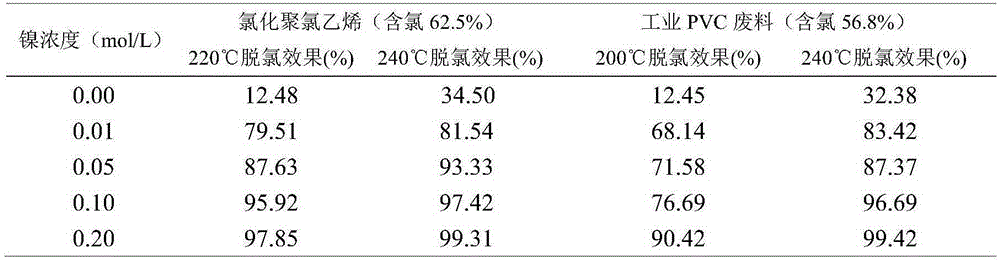

Method for efficiently dehalogenating waste plastics

ActiveCN105295088APromote conversionIncrease the number ofPlastic recyclingReaction temperatureEthyl Chloride

The invention discloses a method for efficiently dehalogenating waste plastics. The method comprises the following three steps: 1. quenching and tempering: adding an alkaline chemical raw material to the waste plastics, then adding a solution of a Ni<2+> chemical raw material / waste material and stirring and uniformly mixing the materials; 2. hydrothermal treatment: carrying out hydrothermal treatment on the prepared waste plastics at 200-240 DEG C for 10-60 minutes; 3. dehydration: carrying out solid-liquid separation on a mixture obtained after hydrothermal treatment, thus obtaining coke. The method has the beneficial effects that the function of Ni<2+> in plastic dehalogenation is confirmed for the first time; the method has the characteristics that the adding proportion of the alkaline chemical raw material is extremely small; the cost is low; the process is simple; the halogen removal efficiency is high; the reaction temperature is low; the time is short; the halogen containing rate of the waste plastics is reduced to about 0 from 56.8-74%; secondary pollution can not be caused; the plastics excluding halogen and some chemical raw materials after separation can be recycled, thus avoiding the problems of chlorine corrosion and dioxin pollution during halogen-containing plastic burning and providing beneficial conditions for harmless treatment and recycling of the halogen-containing plastics.

Owner:CHINA UNIV OF MINING & TECH

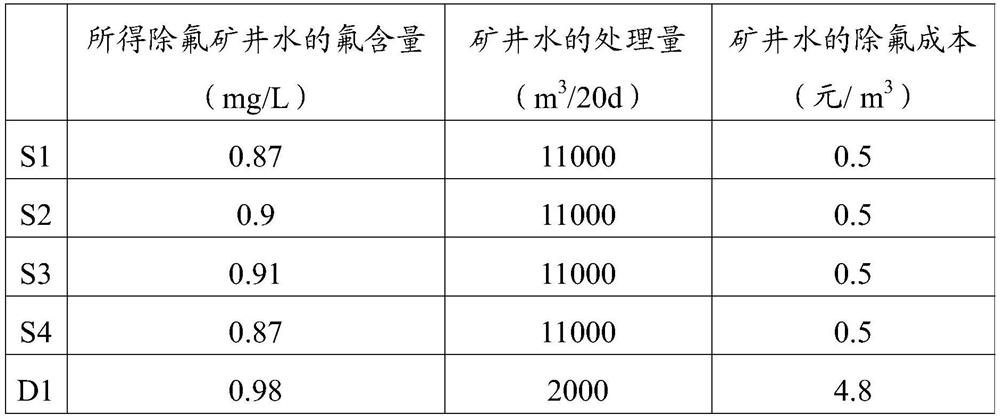

Method and system for defluorinating mine water

PendingCN113072125AImprove resource utilization valueImprove adsorption capacityWater contaminantsWater/sewage treatment by ion-exchangeWater dischargeEnvironmental engineering

A method for defluorinating mine water removes fluorine in the mine water through a fluorine removal agent, the fluorine removal agent comprises a main fluorine removal agent, and the main fluorine removal agent is fly ash. The invention also provides a system for defluorinating the mine water by using the method. The system comprises a first underground reservoir, a mine water injection pipeline, a fly ash adding device and a mine water discharge pipeline; the fly ash adding device comprises a stirring pool and a grouting pump; the stirring pool is used for stirring the added fluorine removal agent and water to obtain a mixture; the feeding end of the grouting pump is connected to the discharging port of the stirring pool, and the discharging end of the grouting pump is connected to the mine water injection pipeline and used for pumping the mixture to the mine water injection pipeline; the mine water injection pipeline is connected to the water injection port of the first underground reservoir and is used for injecting mine water and the mixture into the first underground reservoir; and the mine water discharge pipeline is connected to the water intake of the first underground reservoir and is used for discharging the fluorine-removed mine water. According to the method and the system, the treatment capacity of the mine water is large, the fluorine removal cost is low, and fluorine can be effectively removed, so that the fluorine content of the mine water is reduced to 1 mg / L or below.

Owner:SHENHUA SHENDONG COAL GRP

Method for planting Yunran mountain ginseng

InactiveCN1826858AImprove resource utilization valueMaster economyHorticulture methodsPlant protectionGene conversionSoil horizon

A method for cultivating mountain ginseng, which is characterized in that the main technique operation rules comprises: field choosing and cleaning-restoring original soil layer and manuring- choosing plantation and making shed-property and cover-management and observation-harvest; the operational rule is to replenish the two defects of sunlight shortage for wild ginseng and ginseng under trees, and saponine gene conversion rate and fertilizer can not be supplied separately, and domesticate a ginseng variety which is characterized by the high content of saponine, nice taste, good color and shortened growth time.

Owner:张庆基

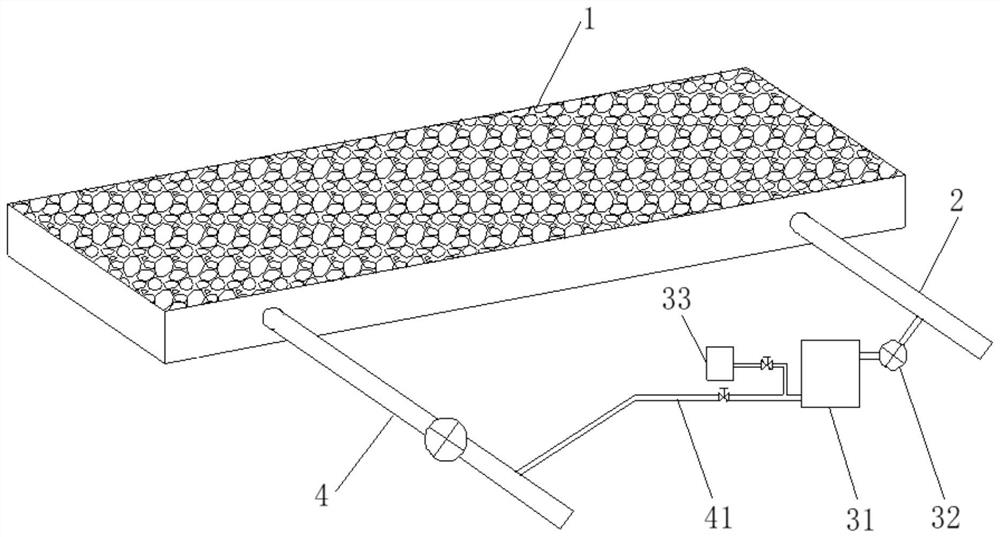

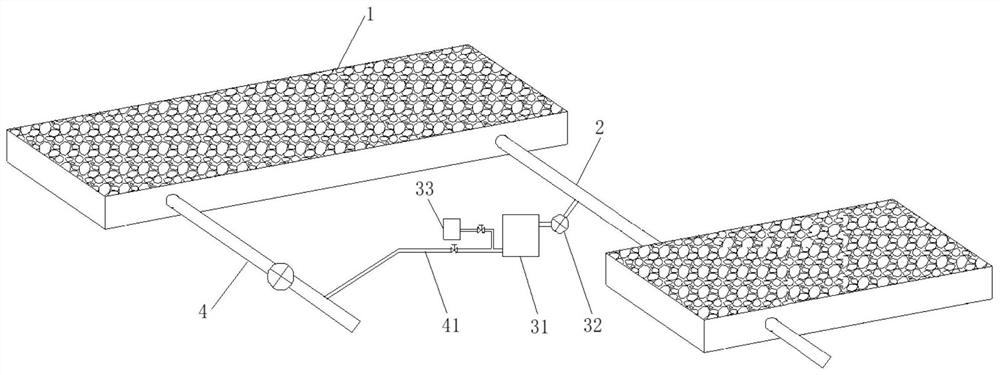

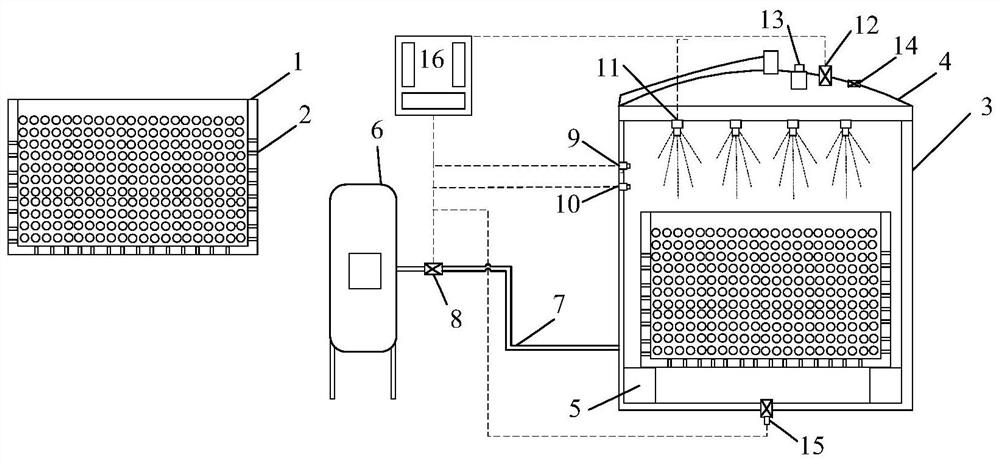

High-temperature steel slag carbonation deep stabilization treatment device and method

PendingCN111763786AImprove stability indexImprove resource utilization valueRecycling and recovery technologiesCarbonationSlag

The invention relates to a high-temperature steel slag carbonation deep stabilization treatment device and method. The device includes a steel slag tank (1), an air hole (2), a stabilizing tank (3), atank door (4), a tank seat (5), a gas tank (6), an air pipe (7), a water spraying port (11), an exhaust valve (12), a safety valve (13), an explosion-proof valve (14) and a water discharge valve (15), wherein high-temperature steel slag is deeply stabilized with CO2, and free CaO in the high-temperature steel slag is digested with water and other acid gases. The process flow is short, the degreeof automation of the device is high, the production efficiency in the treatment process is high, the treated steel slag has good stability and can replace sand stone material in large quantities, andthus recycling of the steel slag is facilitated.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

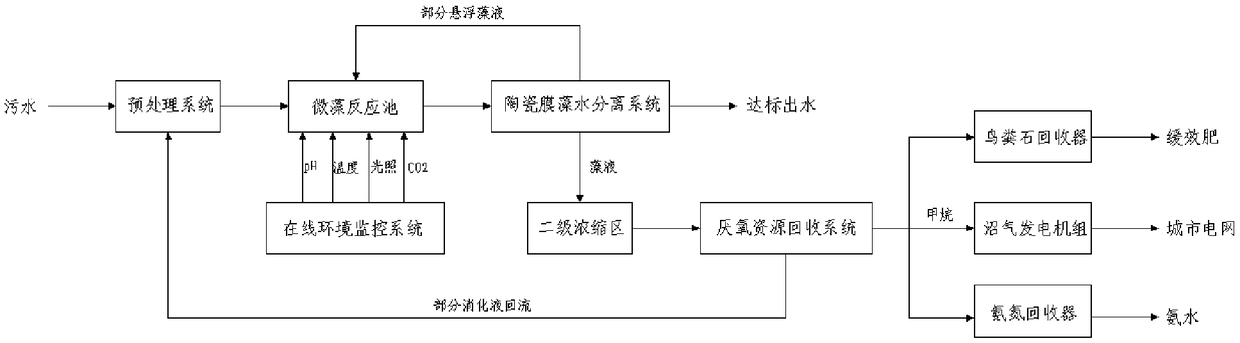

Resource and energy recovery-based sewage treatment method

InactiveCN109160686AEasy to handleImprove separation efficiencyTreatment using aerobic processesWaste based fuelEnergy balancingEnergy recovery

The invention relates to a resource and energy recovery-based sewage treatment method, and provides a sewage treatment system. The sewage treatment system comprises a pre-treatment system, a microalgae reaction tank, an online environment monitoring system, a ceramic membrane and algae separation system and an anaerobic resource recovery system. The method for carrying out sewage treatment by utilizing the sewage treatment system comprises the following steps of: enabling pre-treated sewage to enter the microalgae reaction tank, and reducing the concentrations of nitrogen, phosphorus and organic matters in the sewage through biochemical reaction of microalgae under a controlled environment condition; and carrying out separation on algae-water mixed solution through the ceramic membrane andalgae separation system, discharging qualified effluent, enabling a little suspension algae solution to flow back, carrying out secondary concentration on most of the algae solution to enter the anaerobic resource recovery system so as to carry out anaerobic digestion reaction, and respectively generating electric energy, fertilizer and ammonium hydroxide from generated methane and residual digestion solution through a marsh gas generating set, a struvite recovery device and an ammonia nitrogen recovery device. The system is good in sewage treatment effect and high in nitrogen and phosphorusrecycle rate, and is capable of realizing resource and energy balance of sewage treatment.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com