Multi-metal recovery processing technique of waste liquid generated in germanium producing process

A recycling and multi-metal technology, which is applied in the field of recycling multi-metal, can solve the problems of high production cost and difficulty in separating multi-element impurities, and achieve the effects of less equipment corrosion, short process flow and unusable solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

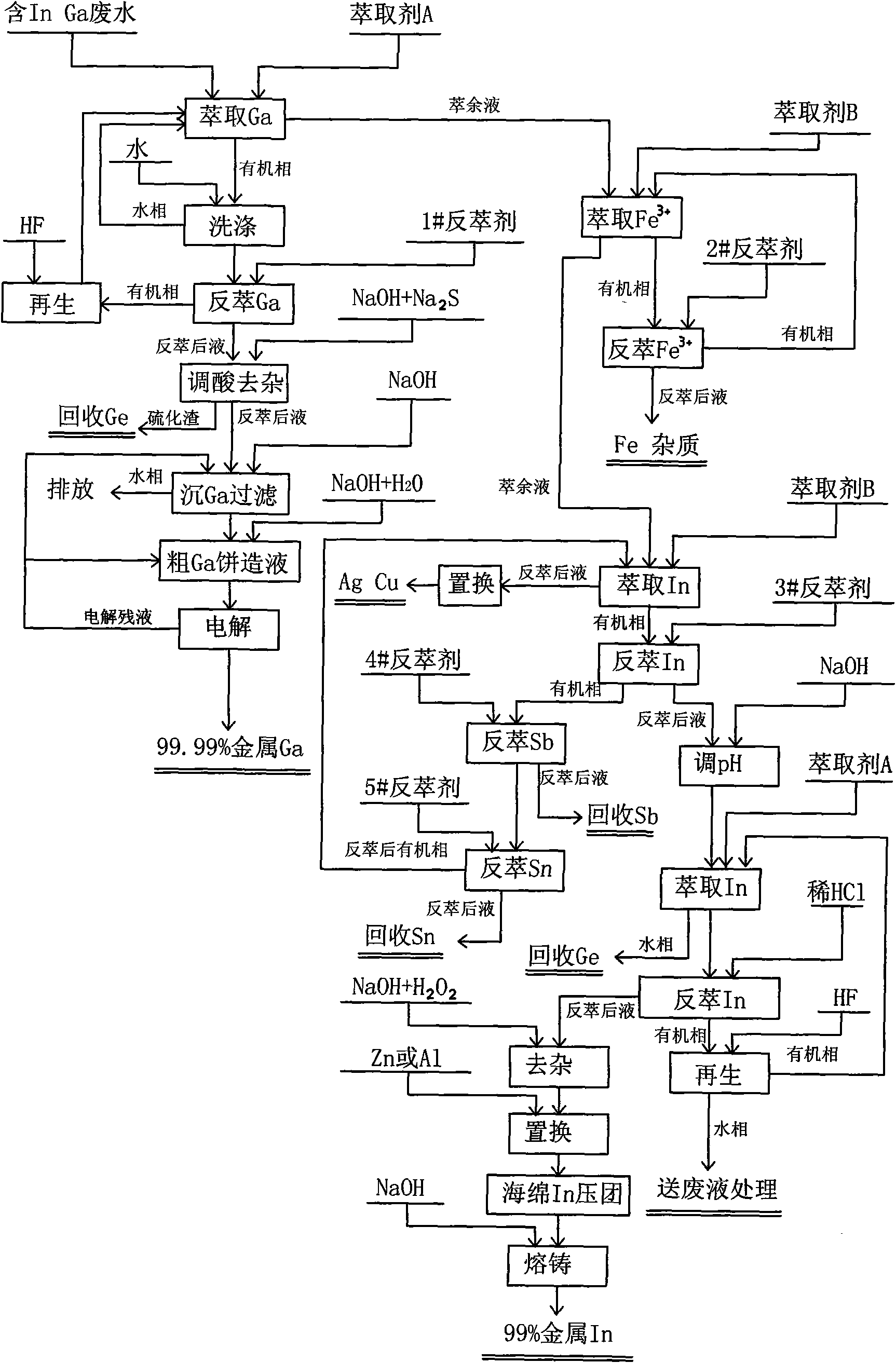

[0030] Describe the present invention in detail below in conjunction with accompanying drawing and embodiment:

[0031] A kind of multi-metal recovery and treatment process of germanium production waste liquid, the specific technical scheme is:

[0032] A extraction of gallium, by the way recovery of germanium process section

[0033] (a1) use kerosene as the diluent of extractant A, make it into the extraction organic phase containing extractant A30%, directly extract gallium from the germanium production waste liquid containing complex multiple metal ions, the organic phase is compared with the extraction phase of the aqueous phase Ratio = 1:4~6, extraction and mixing time is 5 minutes to 6 minutes, settling time is 10 minutes to 15 minutes, extraction temperature is 35°C to 40°C, and the number of extraction stages is four-stage countercurrent extraction;

[0034] (a2) The gallium-rich organic phase is washed with tap water, and the washing water is returned to the germani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com