Method for efficiently dehalogenating waste plastics

A high-efficiency technology for waste plastics, applied in the field of dehalogenation of halogen-containing waste plastics, can solve the problems of low energy consumption, achieve high reaction temperature, reduce operation difficulty, and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

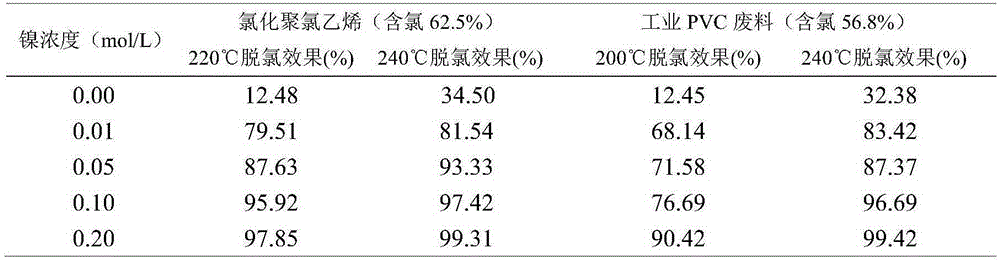

[0025] Embodiment one: chlorinated polyvinyl chloride is an example:

[0026] Step 1: Chlorinated polyvinyl chloride produced by a certain manufacturer has a chlorine content of 62.5%, does not add alkaline chemical raw materials, and does not add Ni 2+ , mix and stir PVC and deionized water in a mass ratio of 1:15;

[0027] Step 2: hydrothermally treating the mixture in step 1 at 220° C. for 45 minutes;

[0028] Step 3: Dehydrating the mixture in Step 2, the content of organic chlorine in the solid phase product is reduced to 53.75%, and the removal rate of organic chlorine is only 12.48%.

[0029] Under the same conditions, adding nickel nitrate makes the Ni in the solution 2+ The concentration is 0.01mol / L, and the removal rate of organic chlorine reaches 79.51%.

Embodiment 2

[0030] Embodiment two: Take industrial polyvinyl chloride PVC as an example

[0031] Step 1: The chlorine content of polyvinyl chloride PVC is 56.8%, add 6% CaO, add water, add a certain amount of nickel nitrate again, make the Ni in the solution 2+ The concentration is 0.01mol / L, mix and stir evenly;

[0032] Step 2: hydrothermally treating the mixture in step 1 at 200° C. for 30 minutes;

[0033] Step 3: Dehydrate the reacted mixture in Step 2, dry it, measure the chlorine content in the solid, and calculate the removal amount of chlorine to be 68.14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com