Deoiling method for cold rolling oil-rich emulsion wastewater, and device thereof

An emulsion and wastewater technology, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc. Efficient coalescence performance, reduced interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

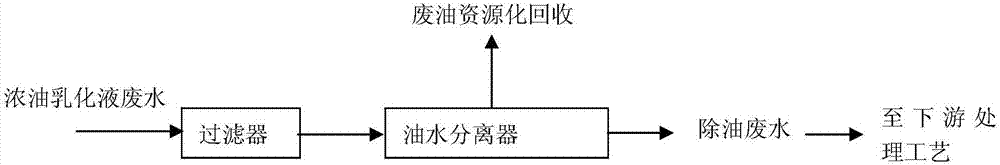

Problems solved by technology

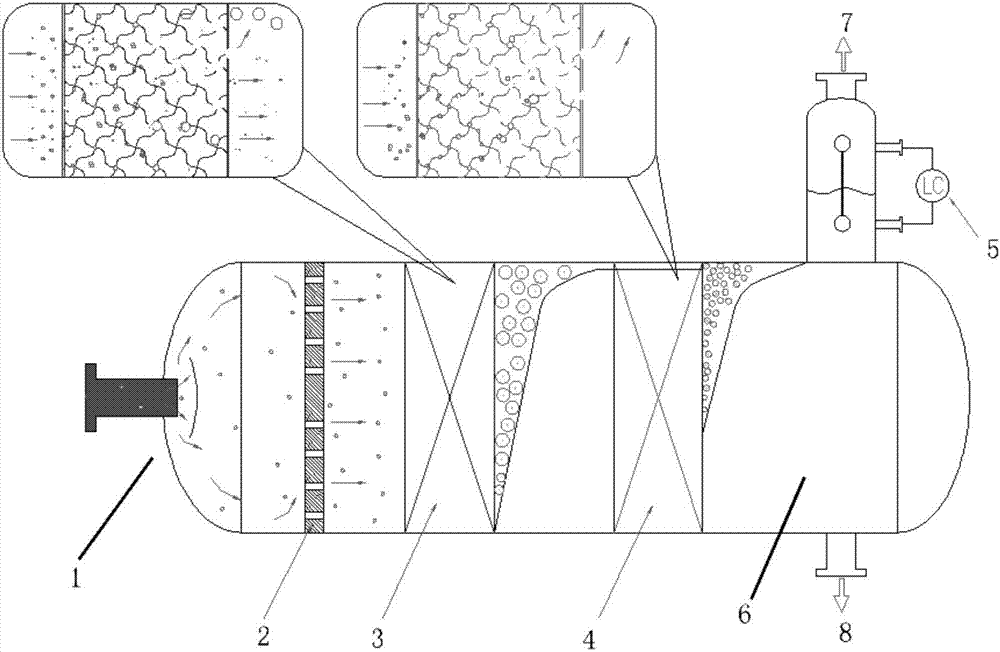

Method used

Image

Examples

Embodiment

[0086] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

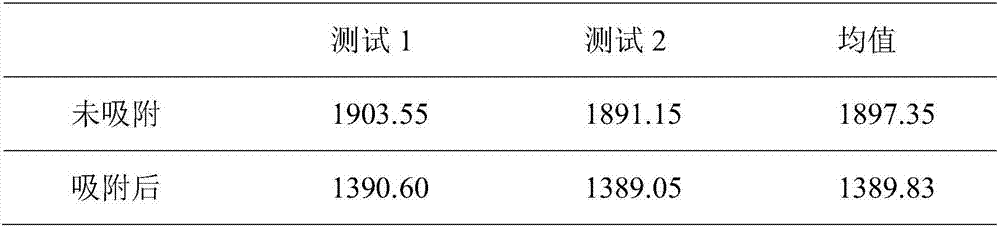

[0087] The device provided by the invention is used to perform oil removal treatment on the concentrated oily waste water produced in the 2030 cold rolling workshop. The expected effect: the solid content of treated wastewater is not higher than 200mg / L, the water content in oil is not higher than 3%, and the oil removal rate is not lower than 90%. The treatment experiment verified that the expected treatment effect was achieved.

[0088] Firstly, the waste water is filtered with a paper bag, and the pre-separation treatment is carried out to remove the suspended particles in the waste water, so as to ensure that the influent turbidity is not higher than 100NTU, and the SS is not higher than 200mg / L. Reduce the fouling probability of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com