Patents

Literature

106results about How to "Stable and efficient processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

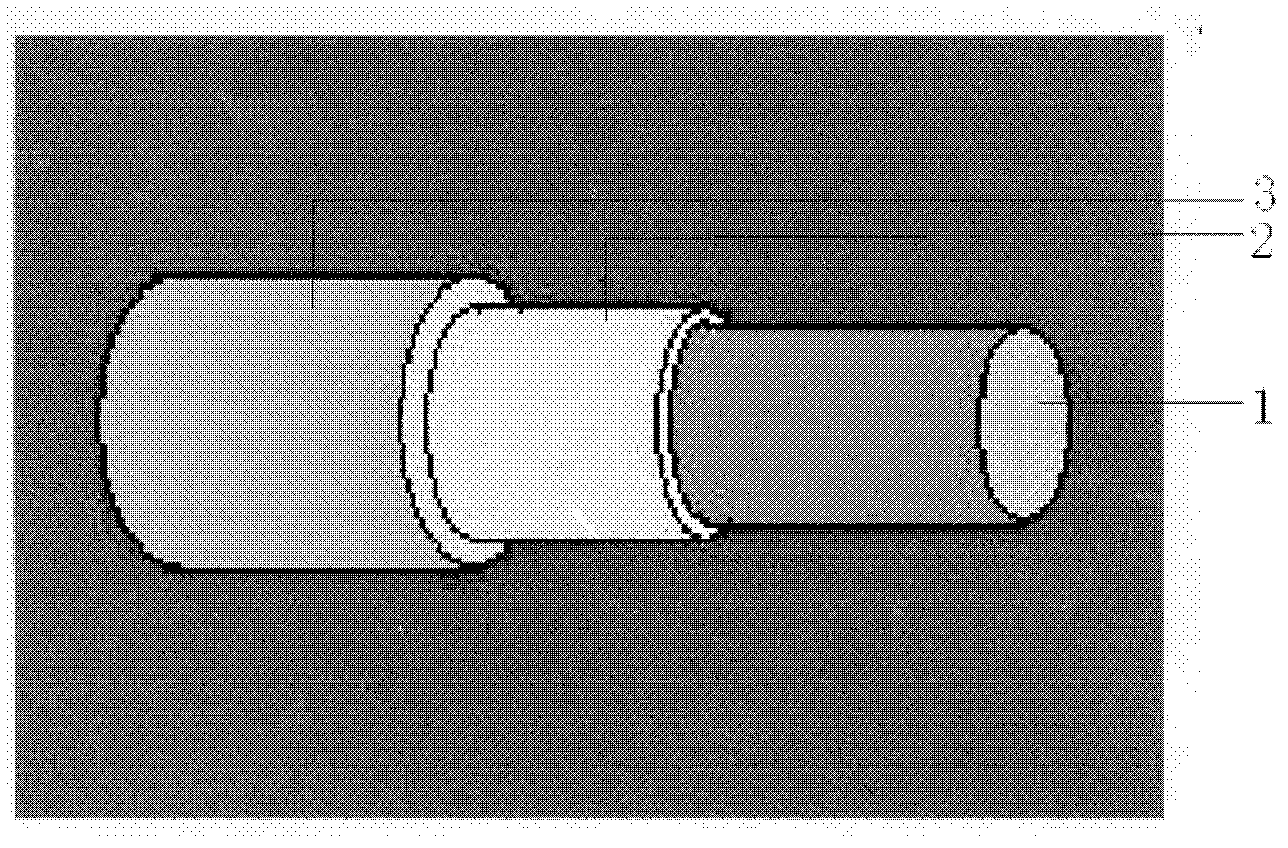

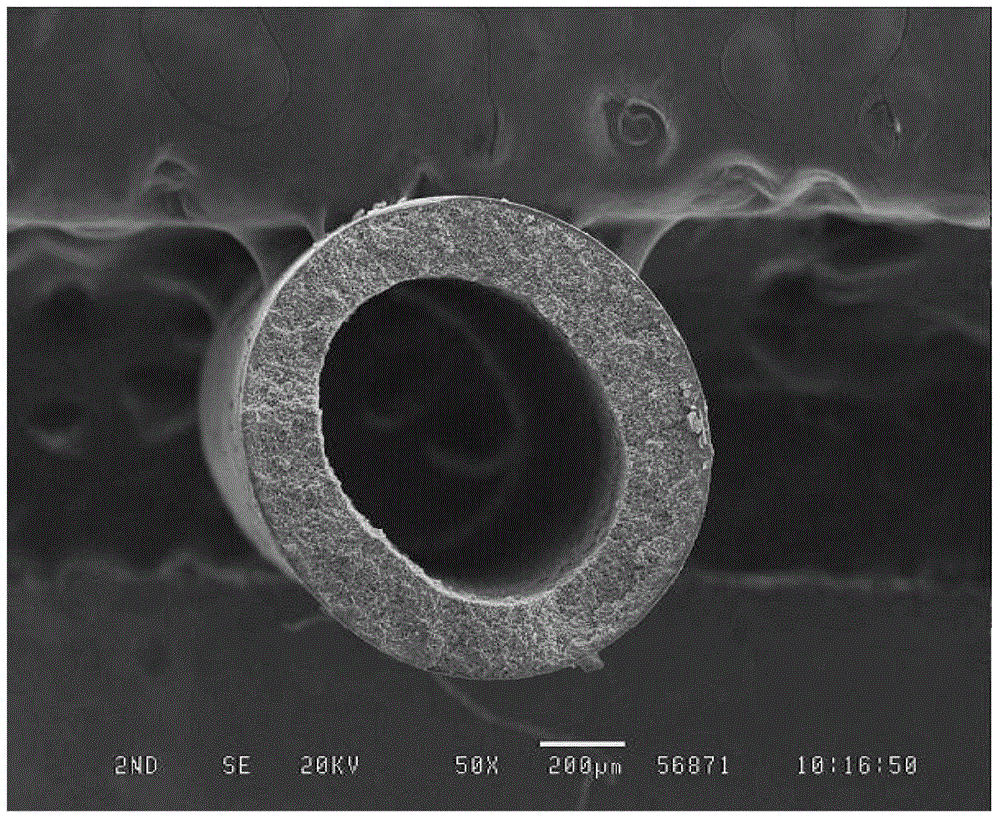

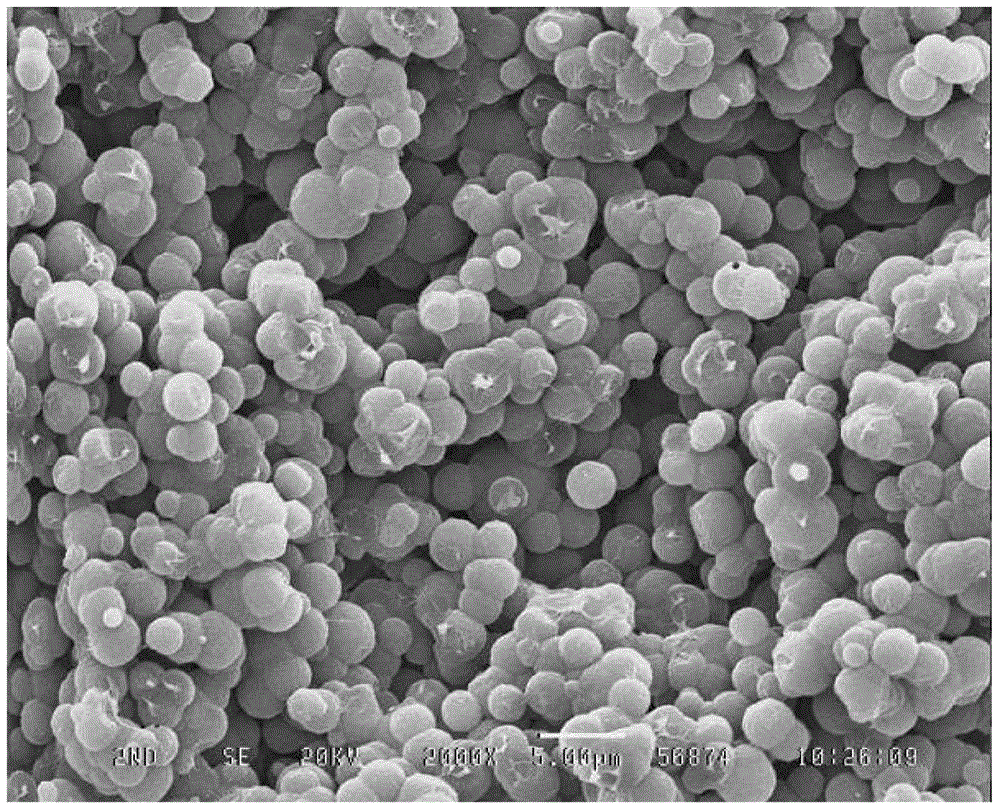

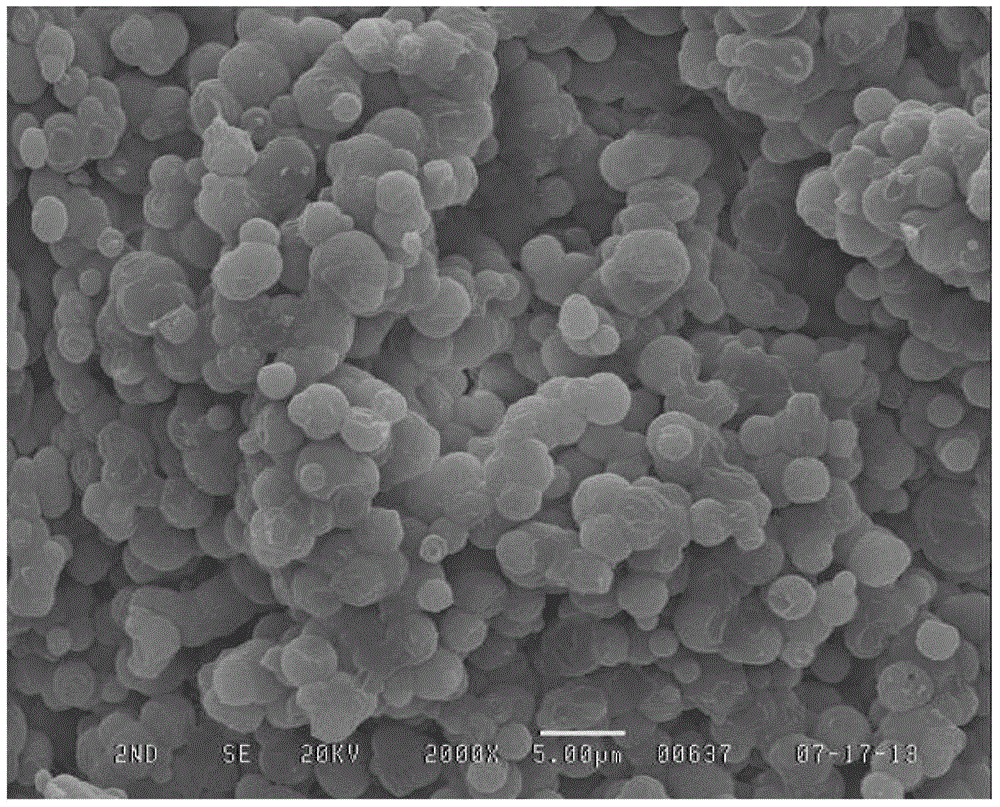

Ionic conductive membrane for chlorine-alkali industry and preparation method thereof

The invention relates to the technical field of ionic membranes, and particularly relates to an ionic conductive membrane for a chlorine-alkali industry and a preparation method thereof. The ionic conductive membrane comprises a perfluorinated ion exchange resin base membrane, a micro-porous reinforcing material and a surface layer of a perfluorinated ion exchange resin microparticle. The perfluorinated ion exchange resin microparticle is a mixture of one or two of a perfluorinated carboxylic acid resin microparticle or perfluorinated sulfonic acid-carboxylic acid copolymer resin microparticle and a perfluorinated sulfonic acid resin microparticle, wherein the perfluorinated sulfonic acid resin microparticle accounts for 95%-50% of the percentage by mass of the mixture. The surface layer of the ionic conductive membrane has good compatibility and adhesion and maintains a good degassing effect in the whole service life of the ionic conductive membrane. An alkali metal chloride solution of which the range of concentration is wide can be efficiently and stably treated by the ionic conductive membrane in the chlorine-alkali industry, and the ionic conductive membrane is applicable for running in a zero-pole electrolytic cell under a novel high current density condition and a very excellent product purity index is achieved. The invention also provides a preparation method of the ionic conductive membrane, the process is simple and reasonable and industrial production is easily achieved.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

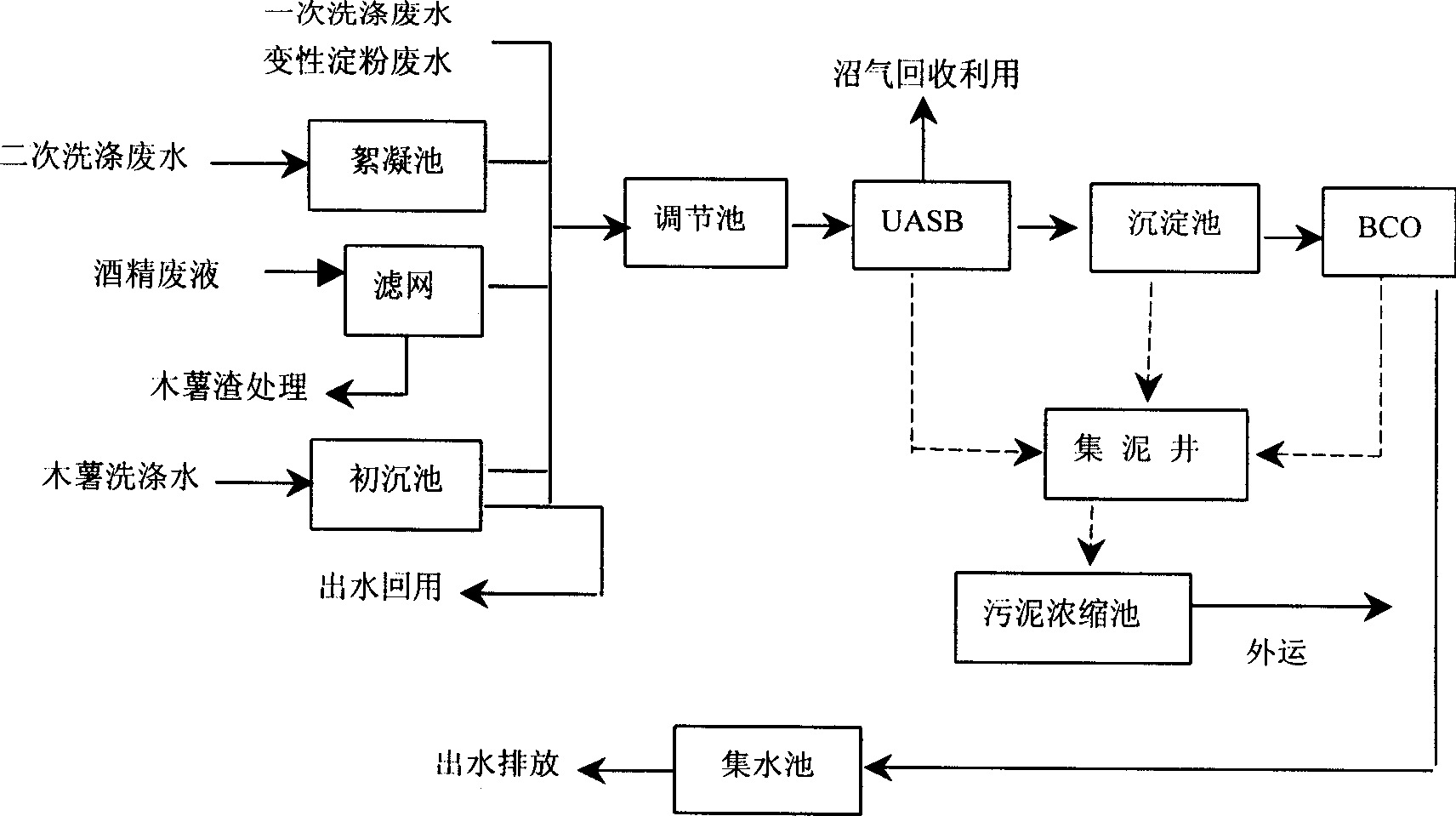

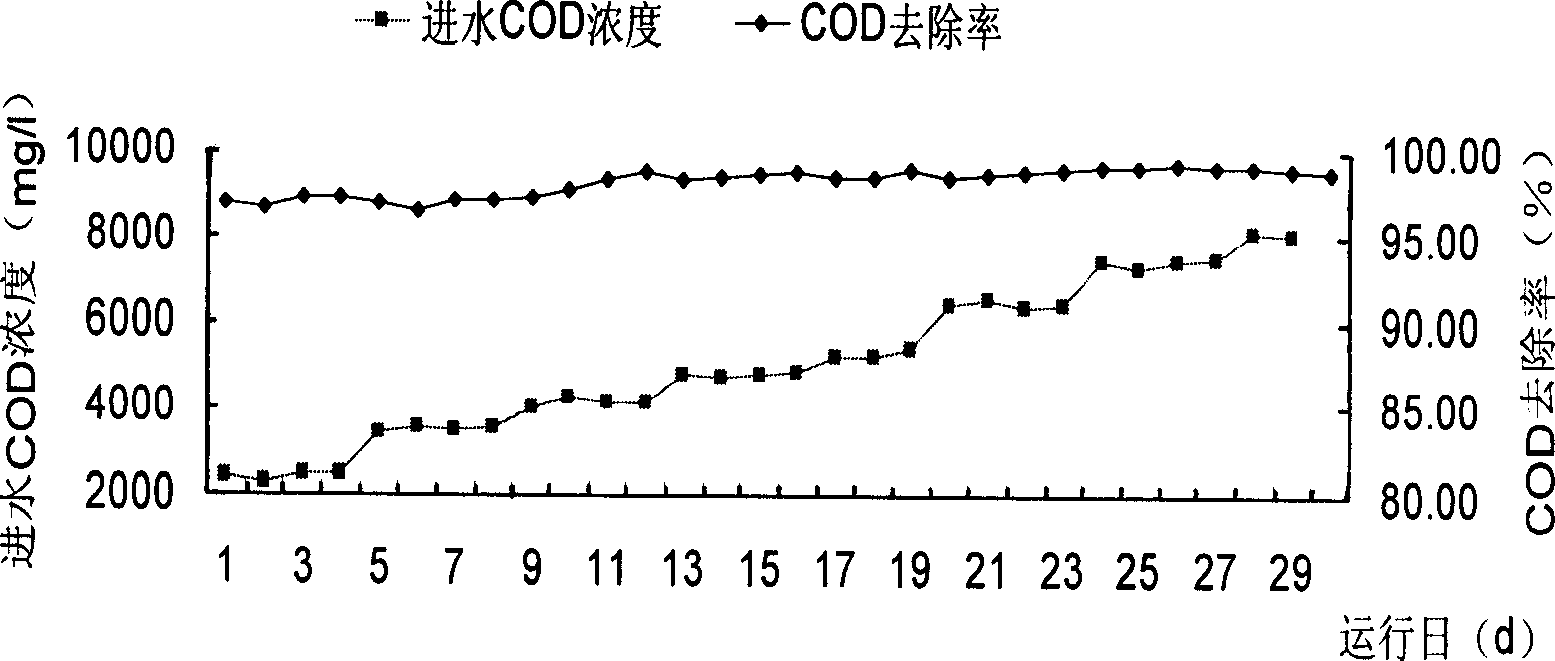

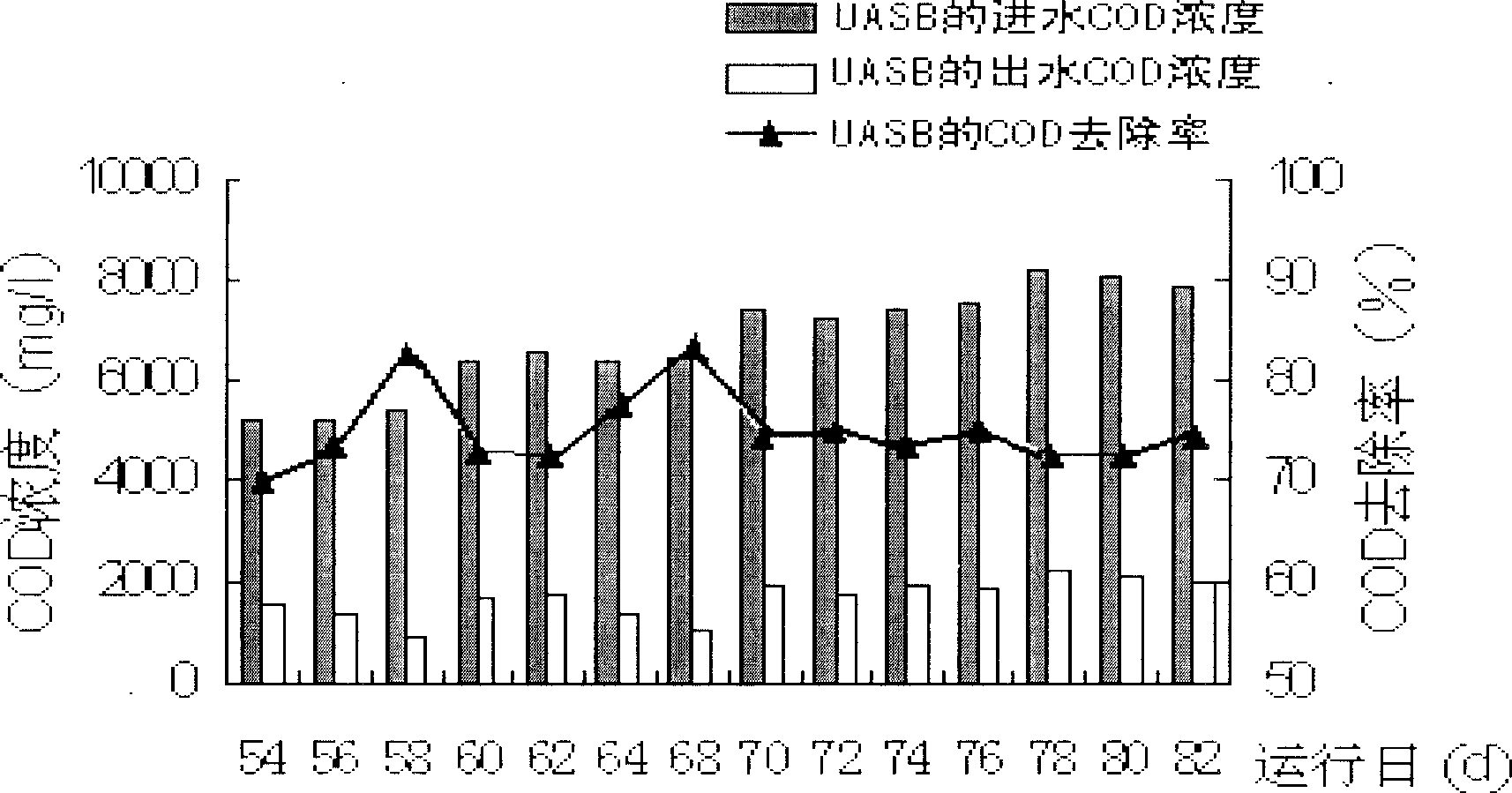

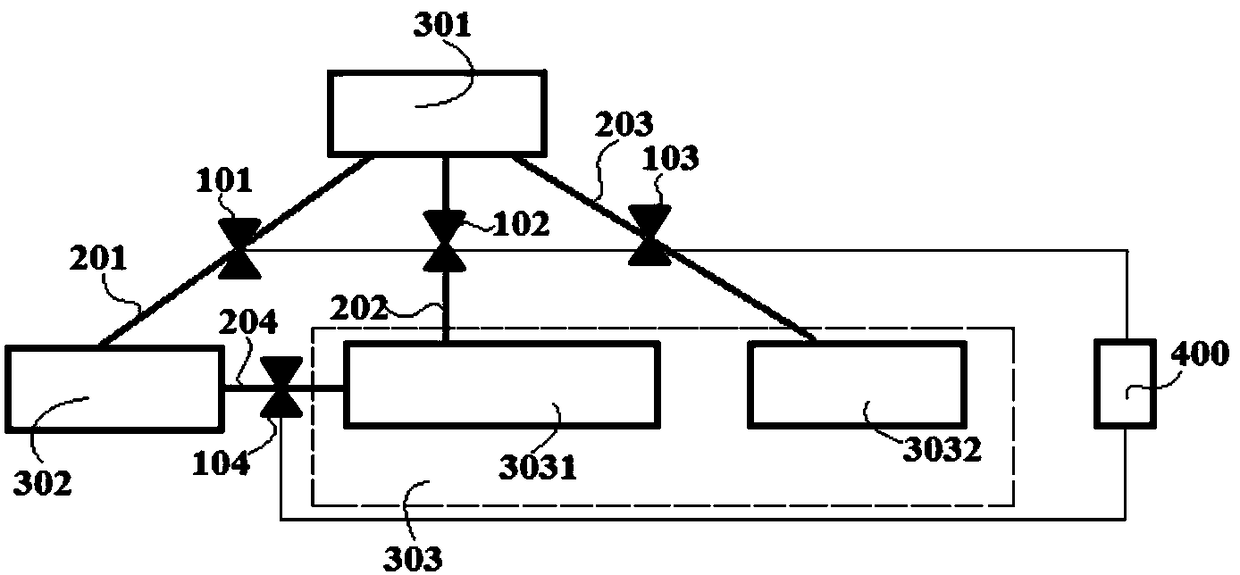

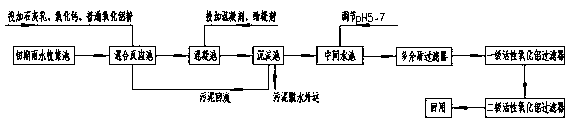

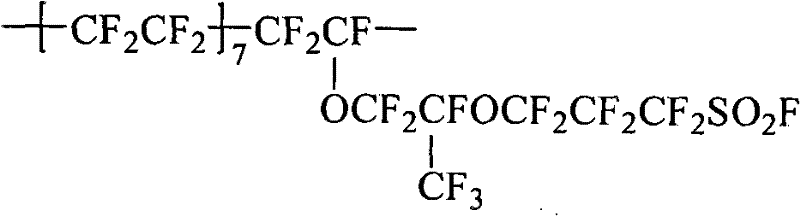

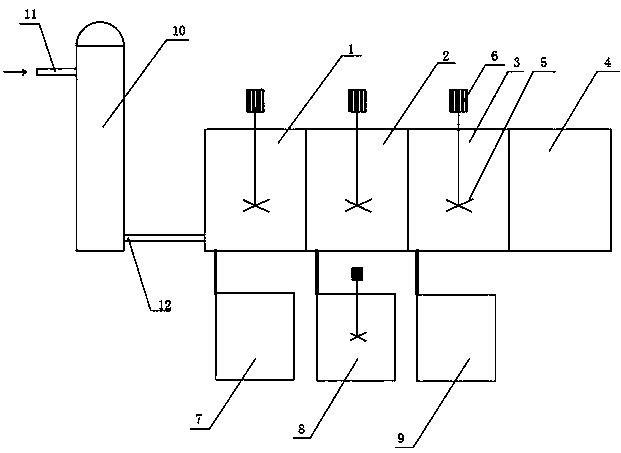

Combined treatment process for manioc producing effluent

InactiveCN1772661AGuaranteed uptimeStable and efficient processingTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAlcoholHandling system

The present invention discloses combined treatment process for manioc producing effluent. The combined treatment process includes the following steps: 1. pre-treating partial effluent, including manioc material washing water, primary starch separating washing water, secondary starch separating washing water, denatured starch effluent and manioc alcohol producing effluent, while making the rest enter to the regulating tank directly; 2. regulating pH value of homogenized effluent, treating in anaerobic biological treating system to degrade COD and recover marsh gas; 3. settling and treating in aerobic bioreaction pond; and 4. exhausting treated water with COD content below 100 mg / L. The present invention has simple technological process, high treating effect, low comprehensive cost and recovery of biomass resource.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

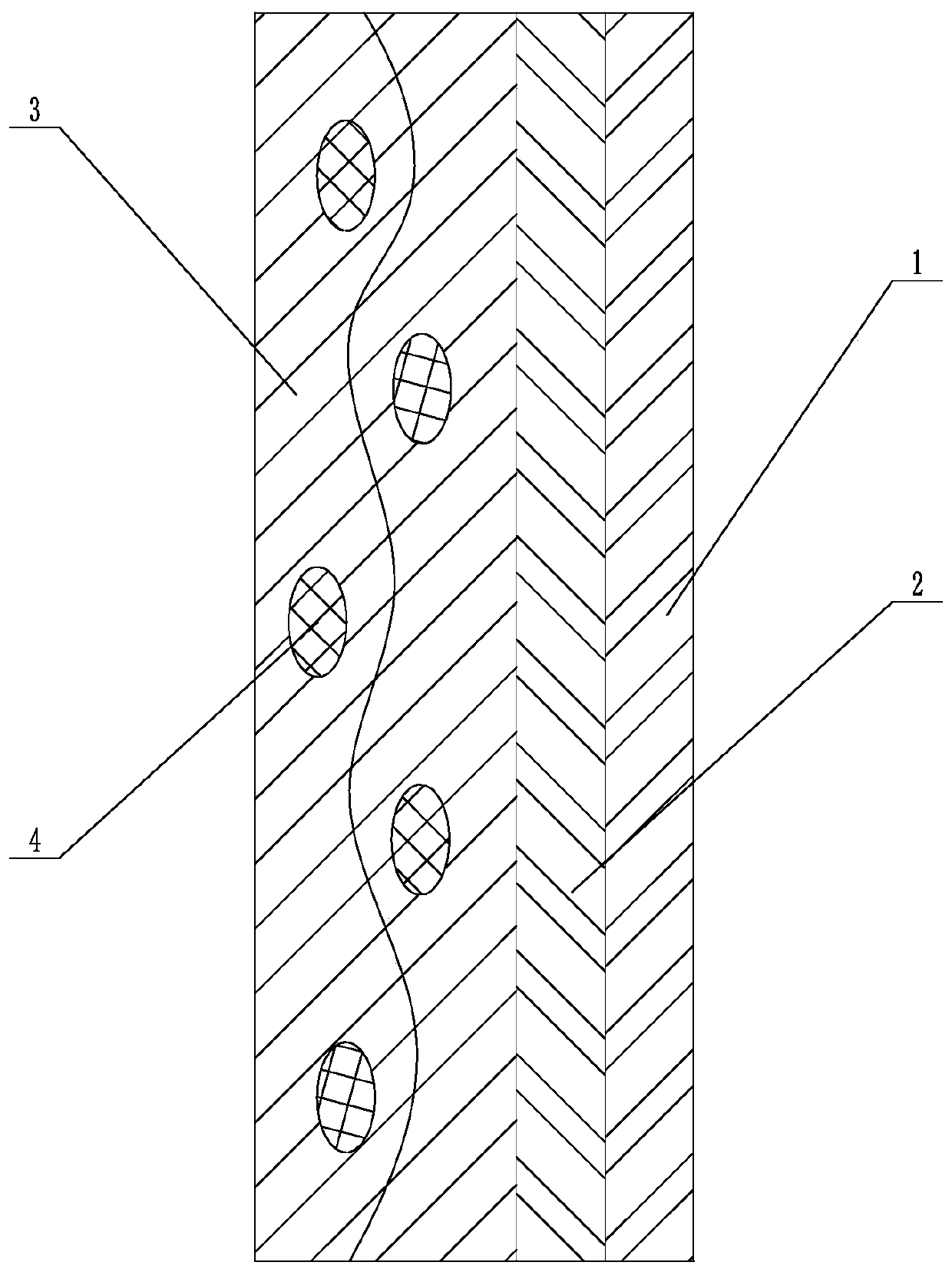

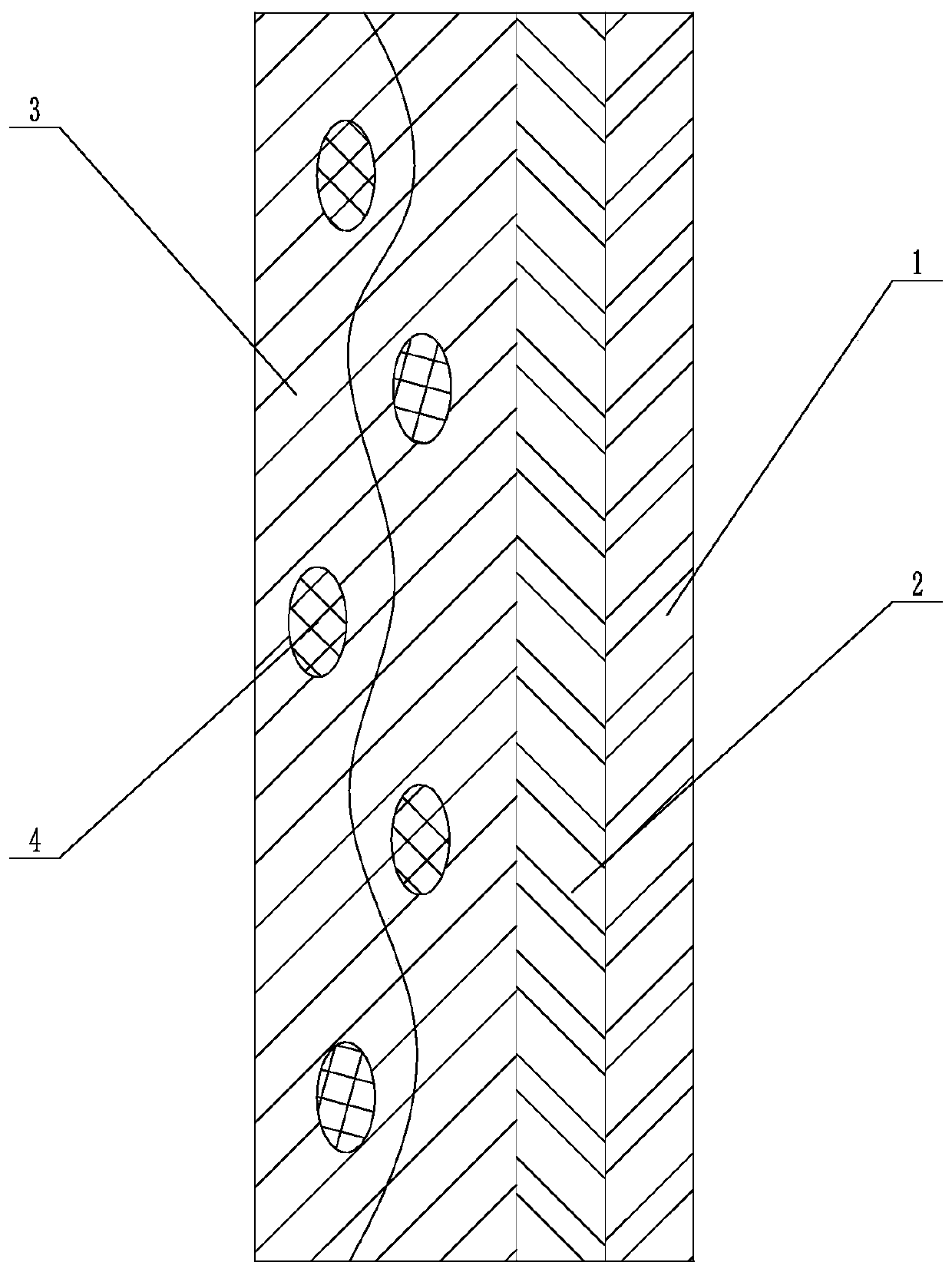

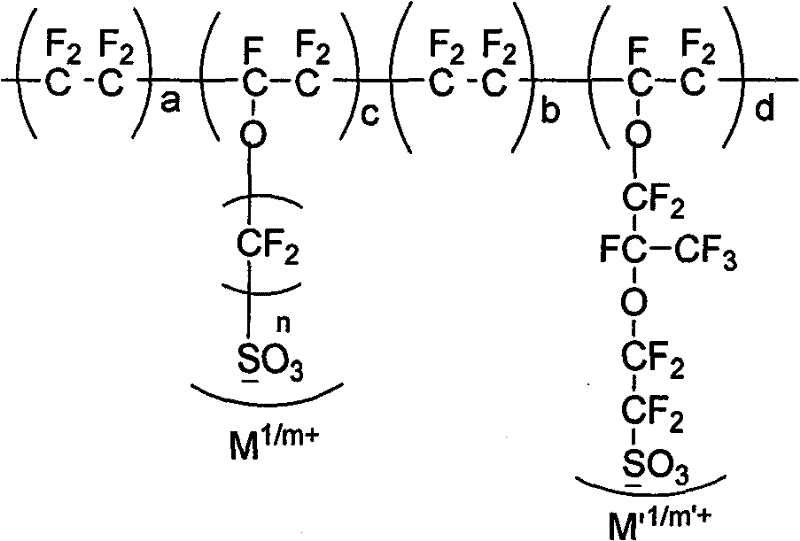

Novel ionic conduction membrane and preparation method thereof

ActiveCN104018179AGood compatibilityGood adhesionOrganic diaphragmsHigh current densityInorganic compound

The invention belongs to the technical field of ionic membranes, and particularly relates to a novel ionic conduction membrane. The novel ionic conduction membrane comprises a perfluoro ion exchange resin basal membrane, a porous reinforcing material and a surface layer made of a mixture of perfluoro ion exchange resin microparticle and inorganic compound particle, wherein the inorganic compound particle is one of or a mixture of oxides, hydroxides and nitrides of IV-A groups, IV-B groups, V-B groups, iron, cobalt, nickel, chromium, manganese or boron elements; and the perfluoro ion exchange resin microparticle is a mixture of one or two of perfluoro carboxylic acid resin microparticle or perfluoro sulfonic acid carboxylic acid copolymerization resin microparticle and perfluoro sulfonic acid resin microparticle. The novel ionic conduction membrane is used for the chlorine-alkali industry and is capable of stably and efficiently treating an alkali chloride solution wide in concentration range and suitable for operation in a novel zero-polar-distance electrolytic bath under the condition of high electric current density, and the product is high in purity. The invention also provides a preparation method of the novel ionic conduction membrane, which is simple and reasonable in process and facilitates industrial production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

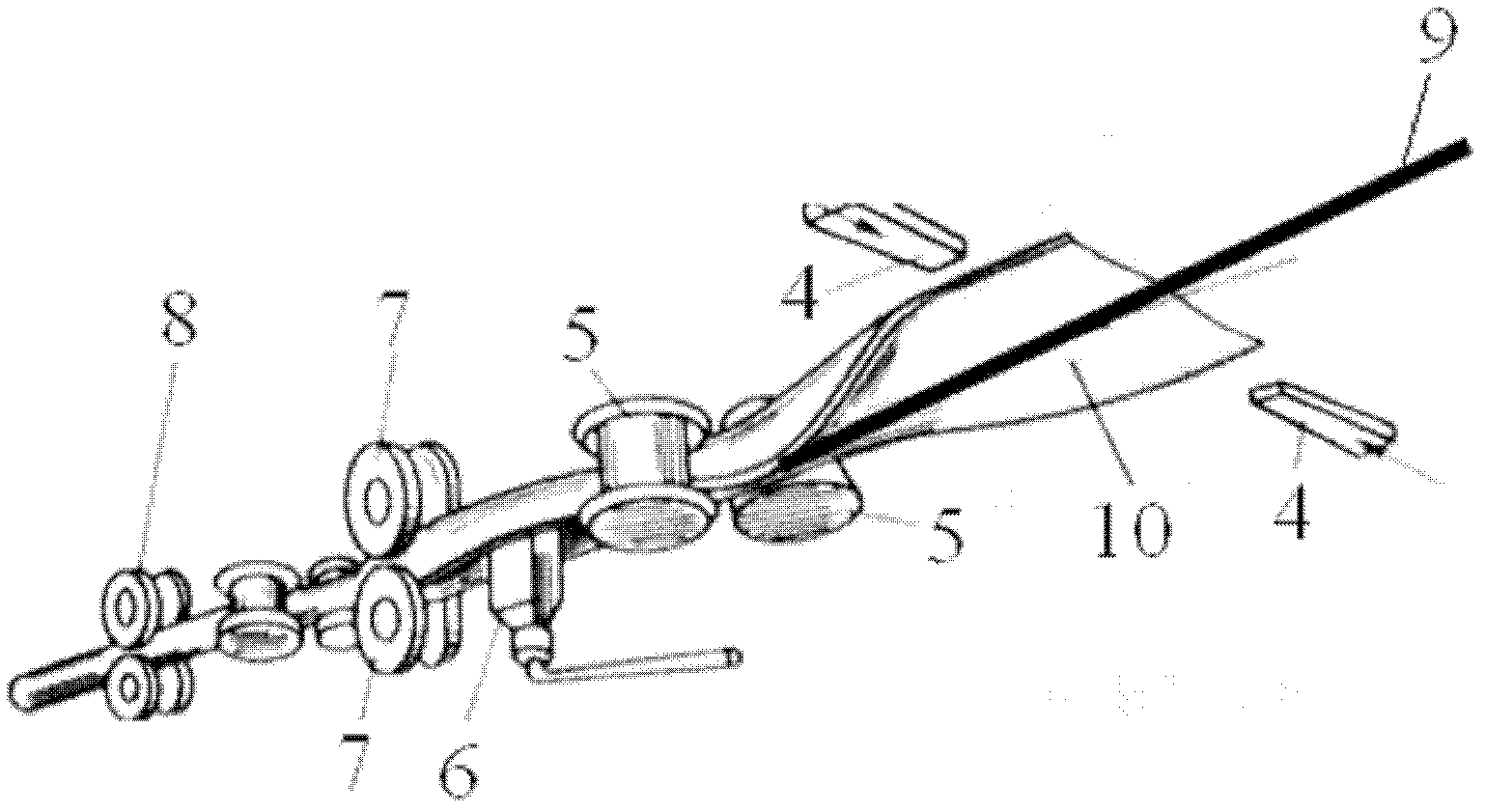

Seamless solid metal calcium cored wire for steelmaking and deoxidation and preparation method thereof

The invention discloses a seamless solid metal calcium cored wire for steelmaking and deoxidation and a preparation method thereof. The seamless solid metal calcium cored wire consists of an outer-layer steel tube, a middle coating layer and an inner core, wherein the inner core is a solid metal calcium (pure calcium) wire. The seamless solid metal calcium cored wire disclosed by the utility model has the beneficial effects that vapor pressure and the gasification rate of metal calcium can be reduced, the depth of the seamless solid metal calcium cored wire inserted in molten steel is increased, the boiling of the molten steel is reduced, the time that the metal calcium is adsorbed by metal is reduced, the boiling phenomenon of the existing seamed solid calcium cored wire inserted in the molten steel is overcome, the phenomenon that the wire feeding is affected due to hollow powder calcium cored wire and non-uniform core powder weigh is reduced, and the bring-in of harmful elements (S, P, C and Si) in the powder calcium cored wire is avoided, so that the yield and the stability of metal calcium are greatly improved.

Owner:周海涛 +1

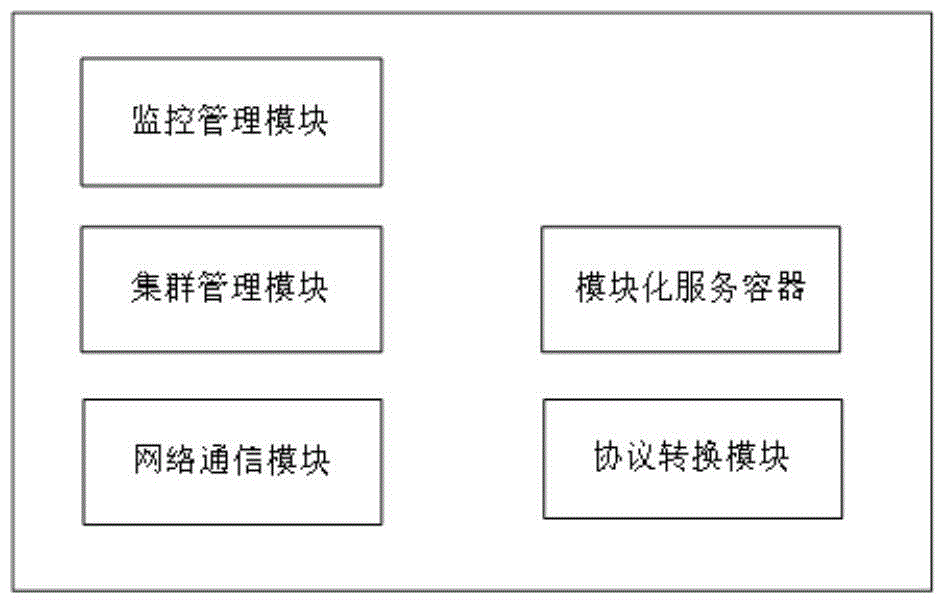

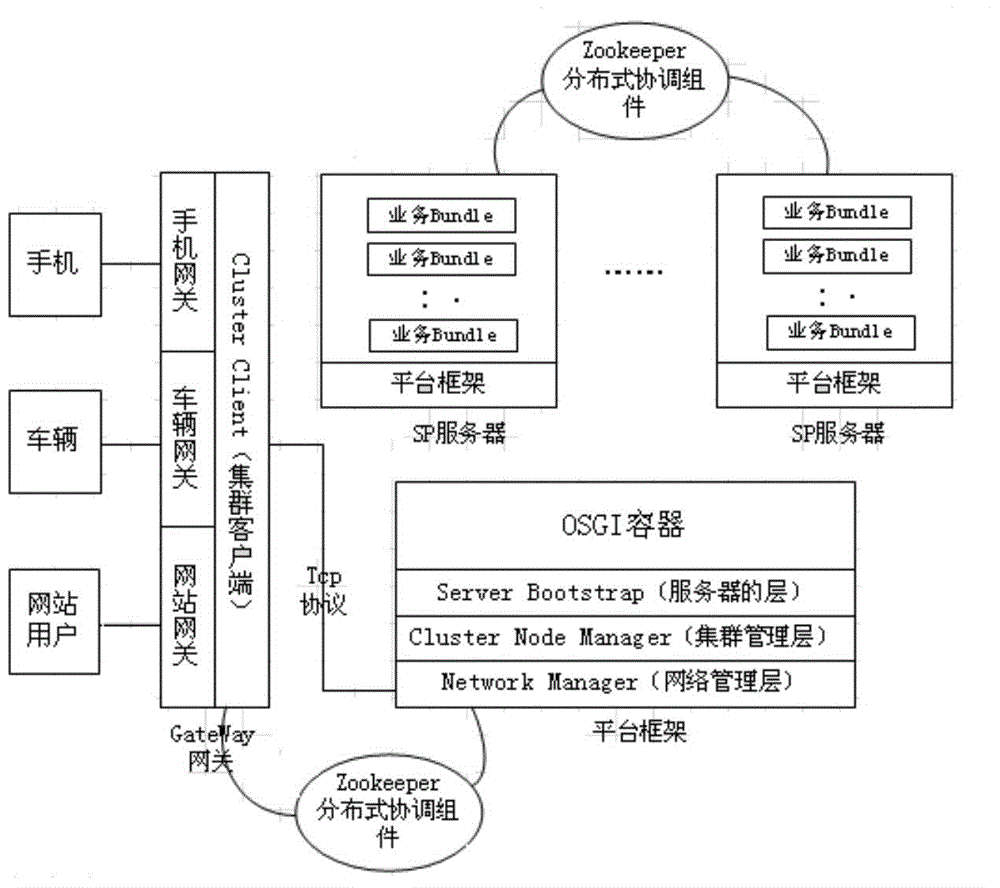

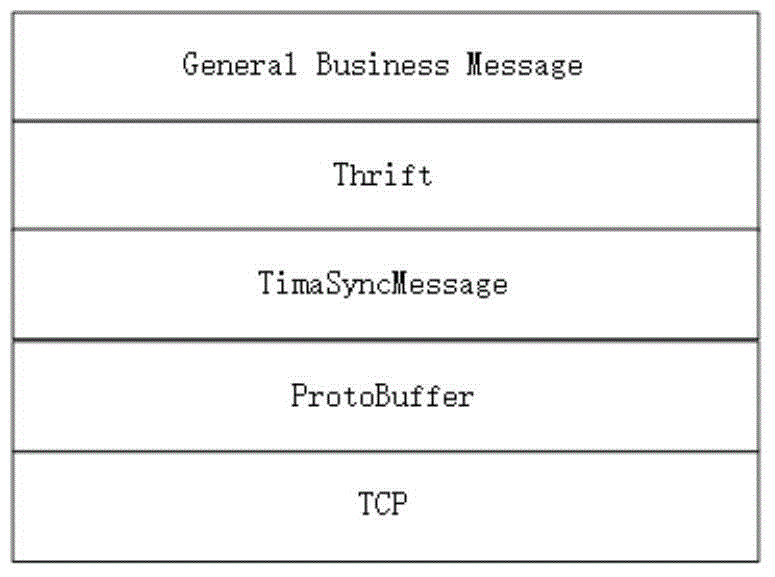

OSG-based parallel extendable application server

The invention discloses an OSG-based parallel extendable application server, which comprises a network communication module, a protocol conversion module, a cluster management module, a modularized service container and a monitoring management module. The network communication module is used for connecting the application server with terminal equipment. The protocol conversion module is used for achieving protocol conversion between a client and the server. The cluster management module is used for integrating a Zookeeper assembly into the application server so that the application server has a dynamic cluster capability. The modularized service container is used for making all network requests from the network communication module enter a thread pool, the requests will be distributed to different service processors after tasks in the thread pool are carried out, and the service processors search corresponding services in an osgi container to finish associated service processing. The monitoring management module is used for monitoring a service module. The application server can be clustered, is parallel extendable, and meets high concurrency demands of automobile data acquisition of Internet-of-Vehicles.

Owner:钛马信息网络技术有限公司

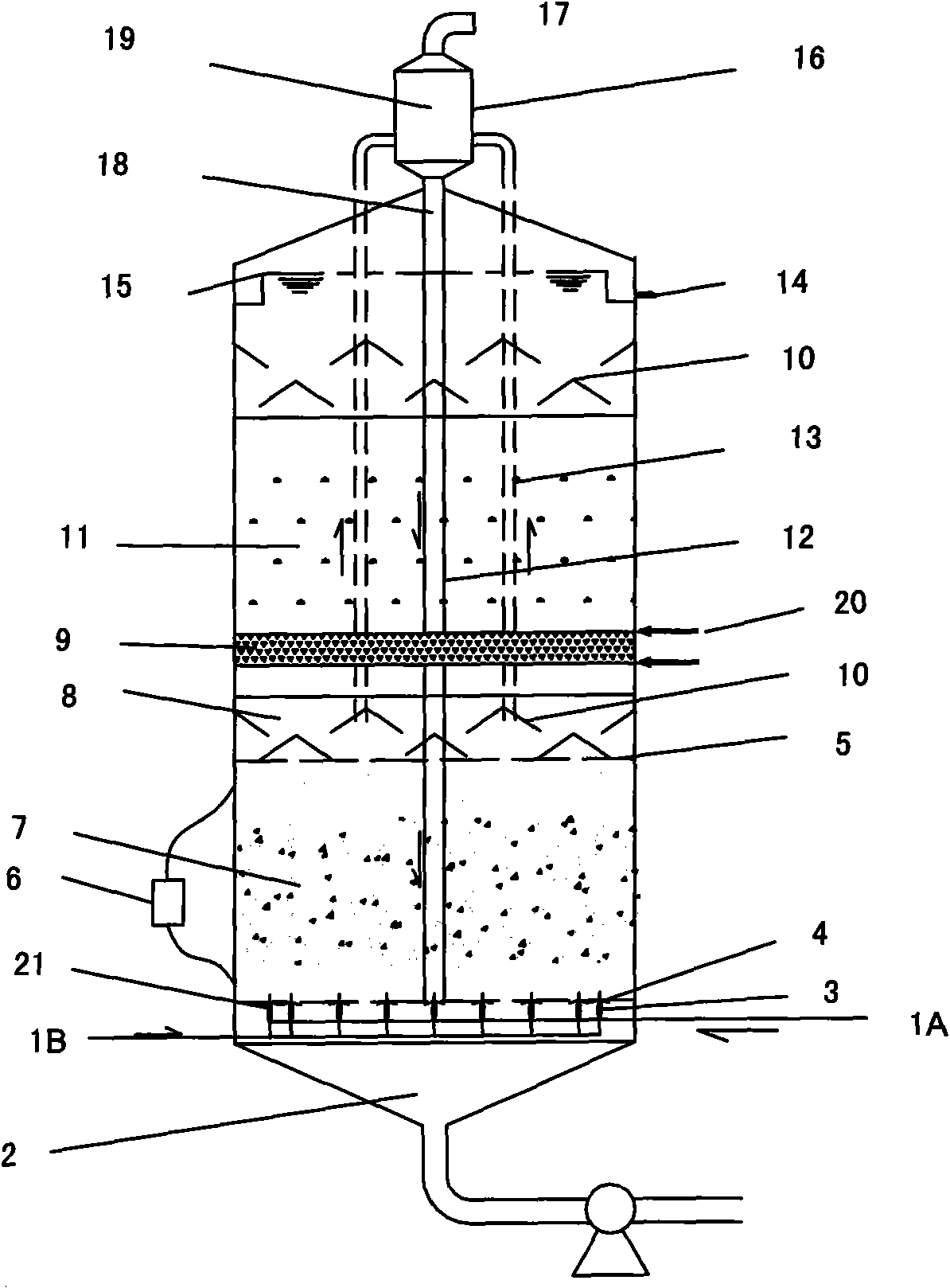

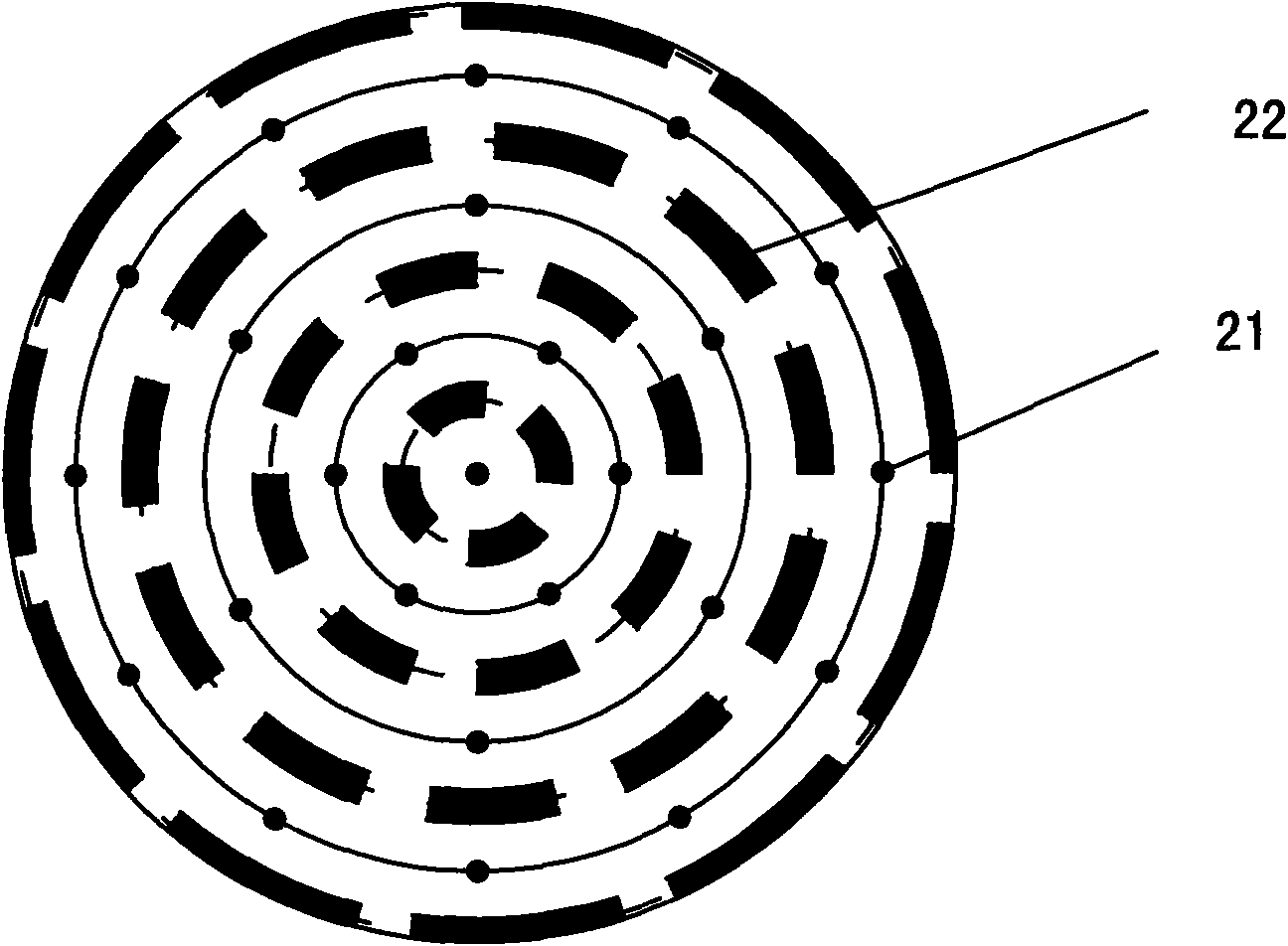

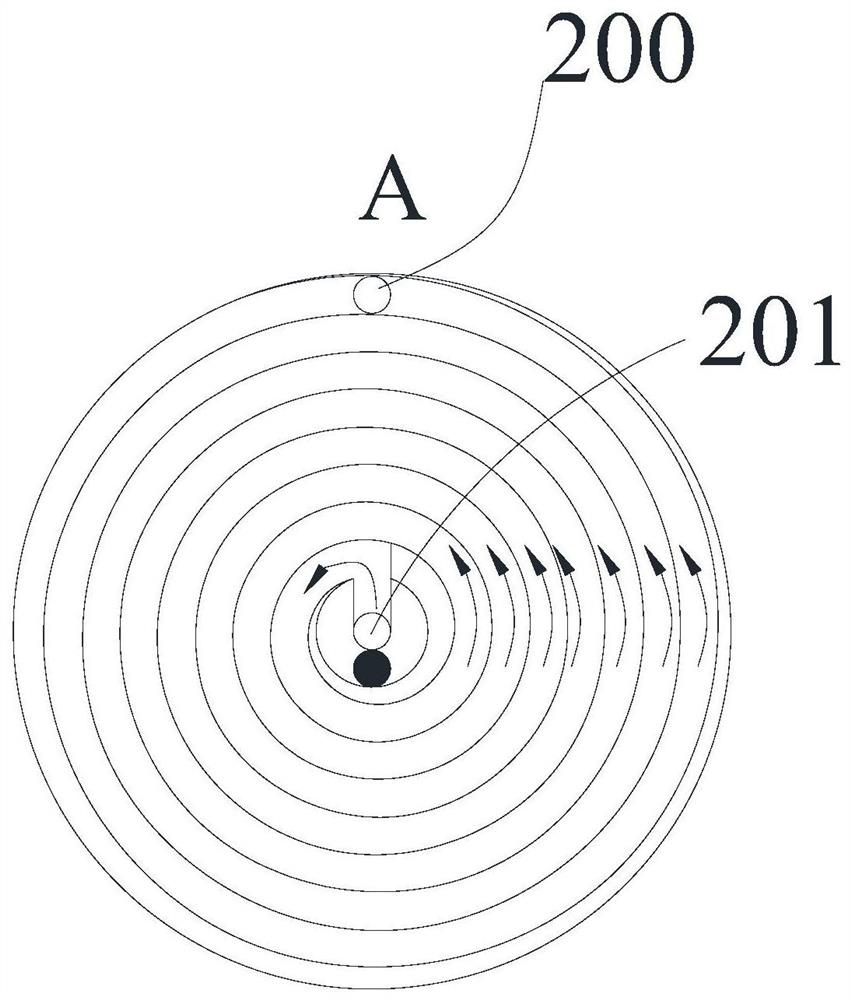

Electric field strengthening two-phase anaerobic reactor

InactiveCN101928065AOvercoming substrate competitive inhibitionReproduce fastWaste based fuelTreatment with anaerobic digestion processesHigh concentrationMethanation

The invention discloses an electric field strengthening two-phase anaerobic reactor being suitable for treating high-concentration sulfates and organic pollutant effluents. The interior of a tank body of the reactor is respectively provided with a sludge precipitation zone, an acidification reaction chamber and a methanation reaction chamber from the bottom up; the top of the tank body is provided with a gas-liquid separator; the upper side and the lower side of the acidification reaction chamber are respectively provided with a negative electrode plate and a positive electrode plate, and the negative electrode plate and the positive electrode plate are connected with a constant-current voltage source outside the tank body so as to form a constant-voltage electric field; the methanation reaction chamber and the acidification reaction chamber are separated by a sludge trapping layer; the inner edge at the top of the tank body is provided with a water outlet slot; a water outlet pipe is communicated with the water outlet slot and extends out of the tank body, and the effluent thereof can be directly discharged or recycled. The processes of the constant-voltage electric filed and the two-phase anaerobic reactor are adopted in the reactor; and the reactor adopts a sulfate reduction process which can realize that a hydrogen supply system is strengthened at constant pressure under the condition of introducing direct current. The reactor has the advantages of high volume load, high reaction speed, small occupied area, low operating cost, good treatment effect, and the like.

Owner:NANJING UNIV

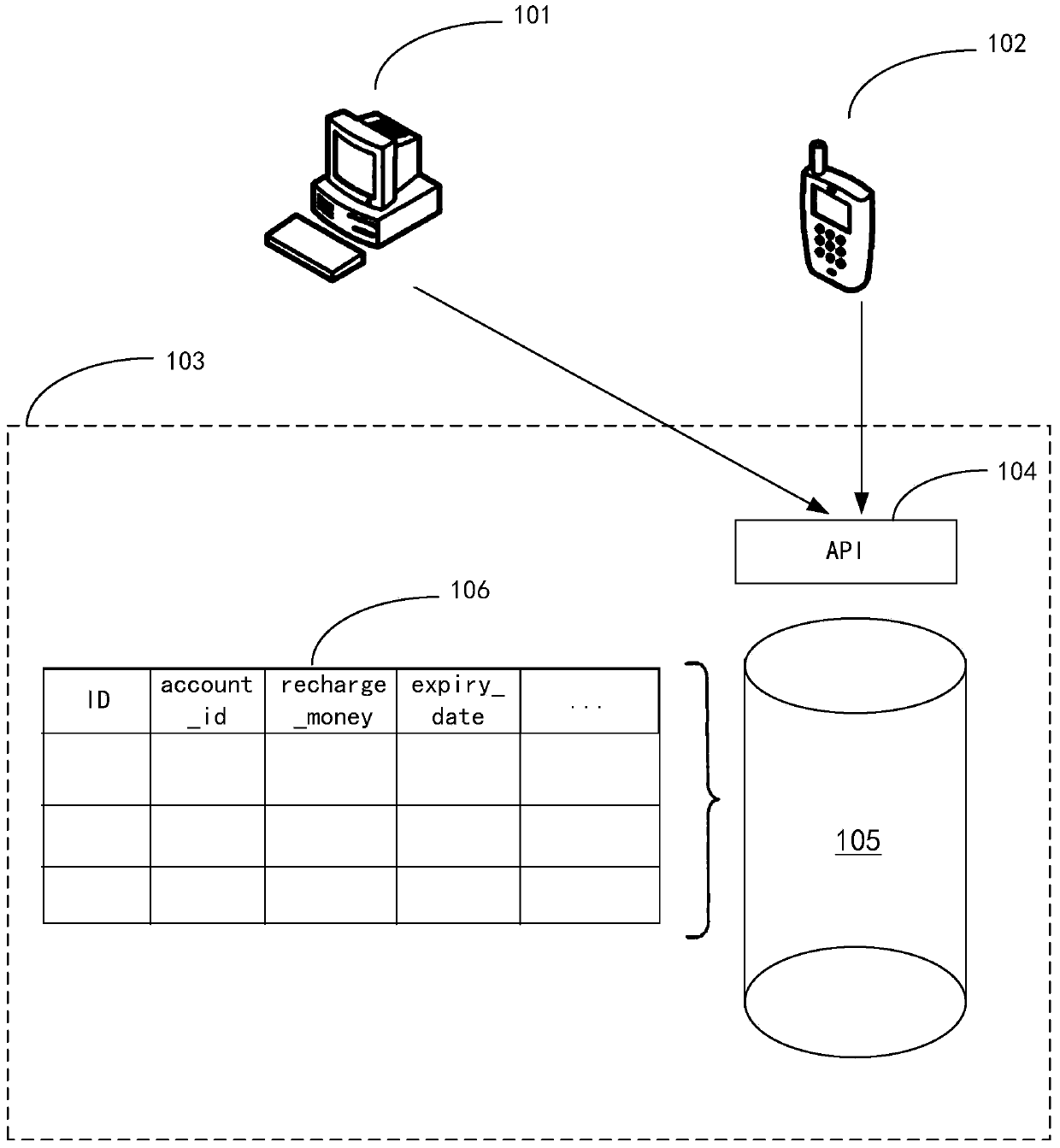

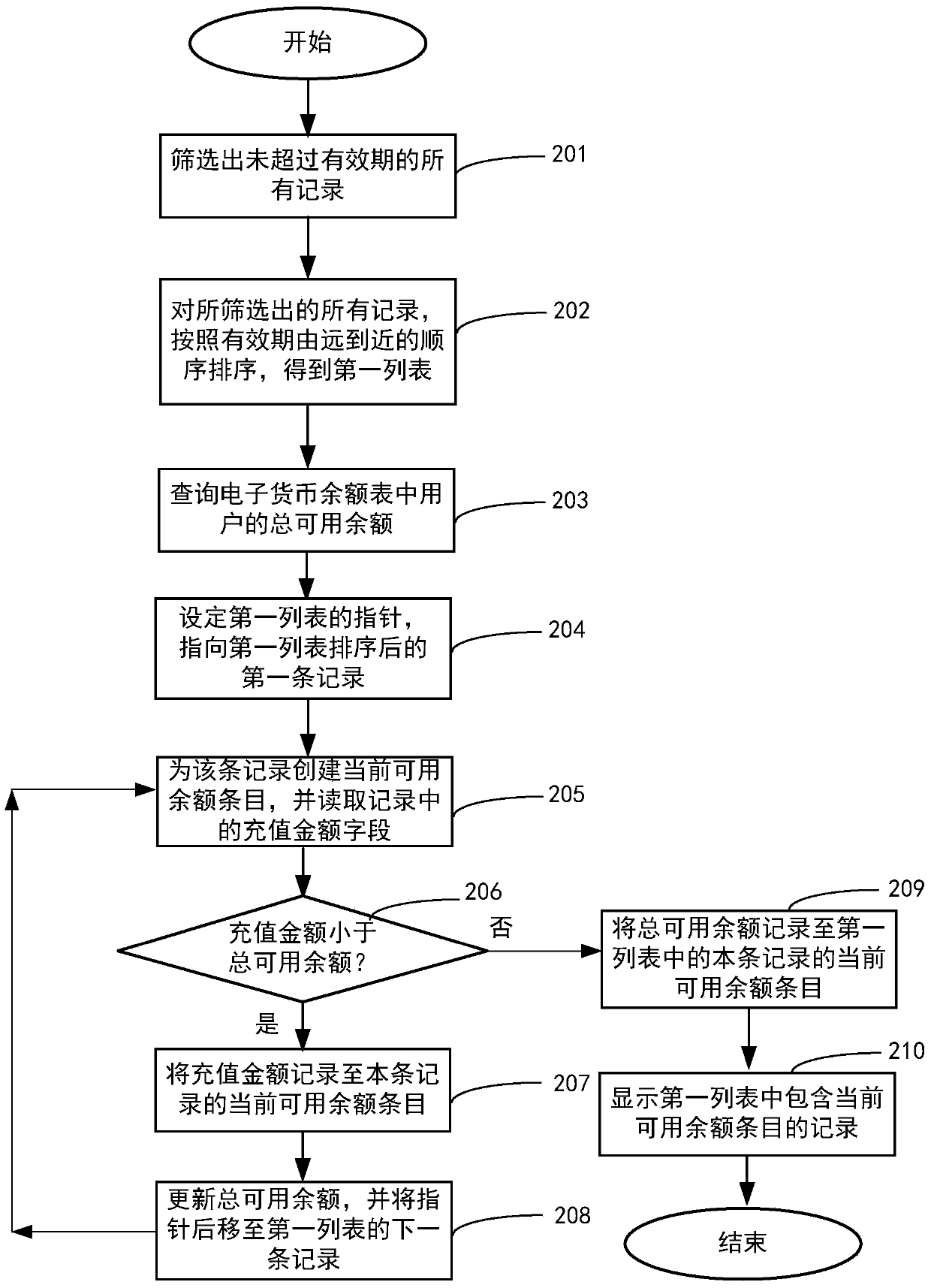

Method for managing electronic money with valid period

The invention provides a method for managing electronic money with a valid period. According to the method, a user can communicate with a server through a network so as to query or trade the electronic money, the server comprises a database and an application interface, and the database is used for storing data records of the electronic money with the valid period for the user in the form of a data sheet; data record sheets of the electronic money with the valid period comprise an electronic money valid period record sheet and an electronic money balance sheet, wherein the electronic money valid period record sheet comprises at least one record, and each record comprises the following data items: a record number, user ID (Identity), an electronic money amount and an amount valid period as well as record creation time; the electronic money balance sheet comprises at least one record, and each record comprises the following data items: user ID, total available balance and the type of the total available balance. The method has the advantages that a variety of processes, such as transfer, enquiry, transaction deduction, payment and refund, can be realized by only querying and increasing database records.

Owner:BEIJING 58 INFORMATION TECH

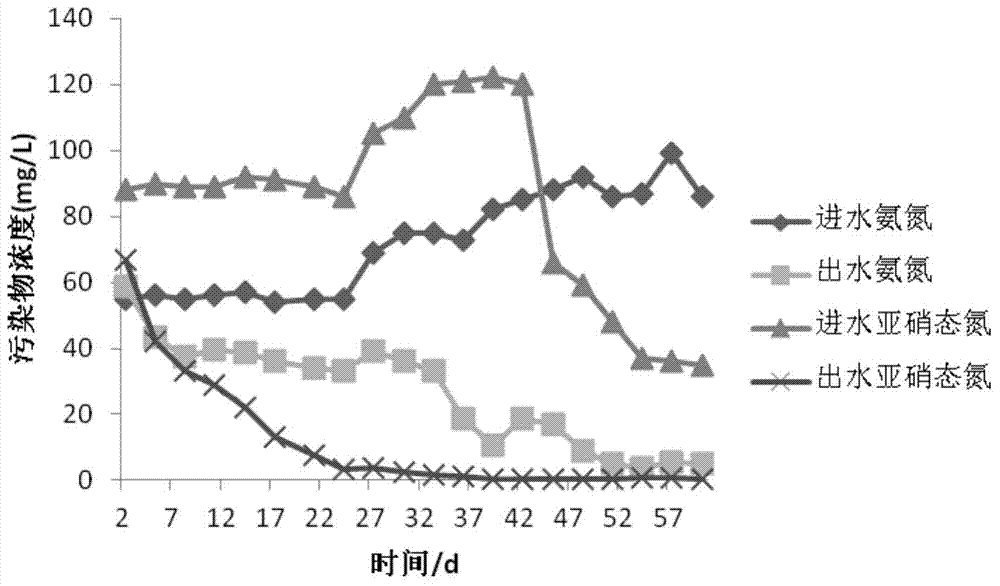

Method for rapidly starting anaerobic ammoxidation by utilizing anaerobic filter

ActiveCN104496017AGood effectSpeed up the domestication processWater contaminantsBiological treatment apparatusActivated sludgeHigh concentration

A related method for rapidly starting anaerobic ammoxidation by utilizing an anaerobic filter comprises: utilizing denitrification sludge to perform inoculation, performing an activated-sludge membrane-forming stage and reaction-starting first, second and third stages, utilizing simulated wastewater and breeding wastewater for domestication, and precisely controlling water inlet conditions, so as to realize rapid starting of anaerobic ammoxidation. By utilizing the efficient adhesion performance of a filling material and through variation of control conditions at different stages, and the method is capable of accelerating domestication process of microbes and culturing stable anaerobic ammonium oxidation bacteria flora within 2-3 months, and is large in biomass, rapid in starting process and good in processing effect. The method is capable of processing low-concentration simulated waste water, and also is capable of realizing stable efficient processing of high-concentration breeding wastewater through a period of domestication, and gives play to dual effects of reducing total nitrogen and COD.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Biological treatment method and treatment device for amine-containing waste water

ActiveCN103648989AStabilizationEfficient processingWater contaminantsWater/sewage treatment by neutralisationUltrapure waterWater composition

In biological treatment of amine-containing waste water, which is organic waste water in an ultrapure water recovery system, the treatment during fluctuating conditions is stabilized and stable treatment is carried out at the start of operation, and during fluctuating load and waste water composition. A method for introducing amine-containing waste water, which is organic waste water in an ultrapure water recovery system, to a biological treatment tank to carry out biological treatment, wherein an acid is added to the biological treatment tank on the basis of the pH value of the liquid in the biological treatment tank. When amine-containing waste water, which is organic waste water in an ultrapure water recovery system, is to be biologically treated, an increase is detected in the pH of the liquid in the biological treatment tank caused by ammonia generated by amine oxidation, and an acid is added to the biological treatment tank in accordance with the pH value, whereby the liquid in the biological treatment tank can be adjusted to an optimal pH value. Therefore, stable and efficient treatment can be carried out without a reduction in the activity of the biological treatment, even during operation startup, or during fluctuating waste water composition or waste water load.

Owner:KURITA INDUSTRIAL CO LTD

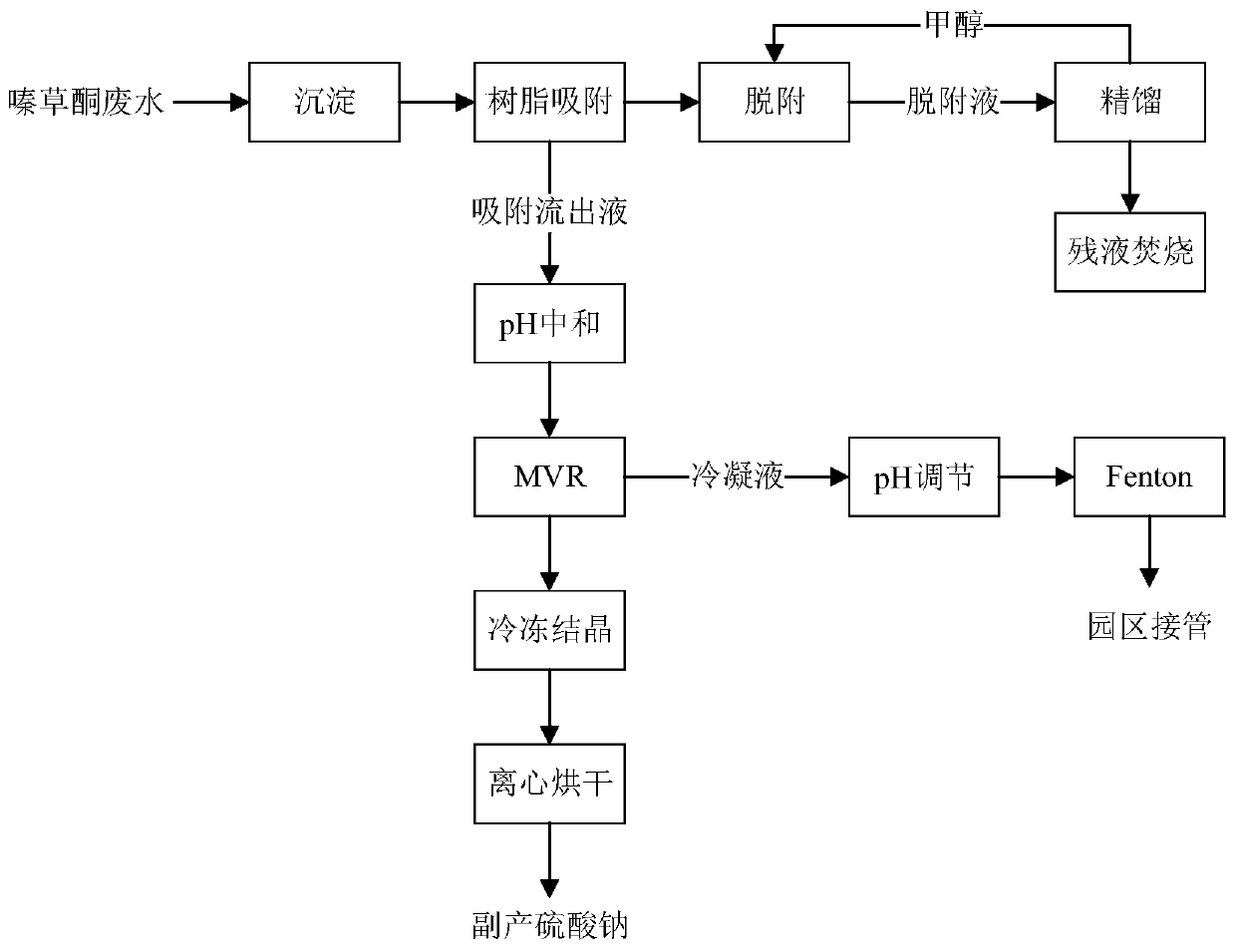

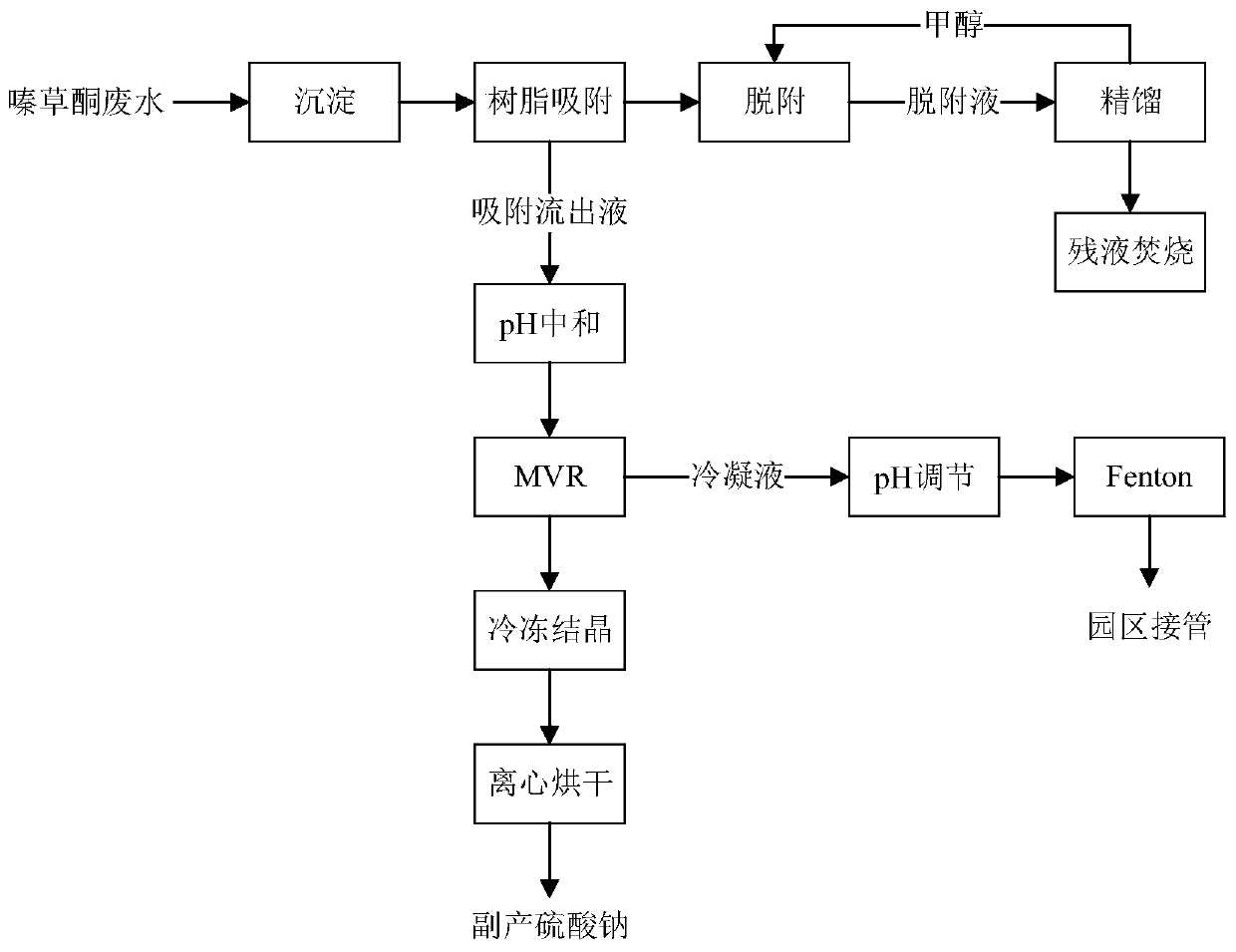

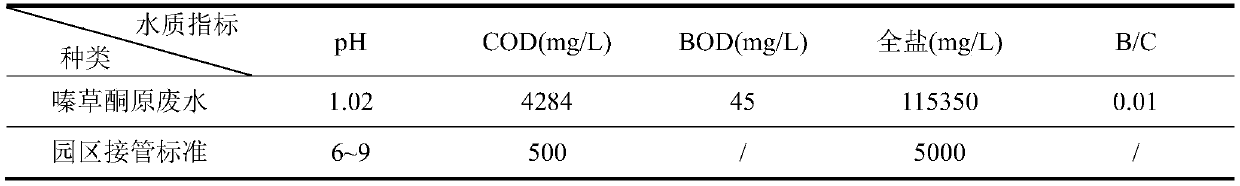

Treatment process for discharging metribuzin wastewater in compliance with standard in coordination with salt recycling and running method of treatment process

InactiveCN109912094AReduce COD concentrationSave resourcesWater contaminantsAlkali metal sulfite/sulfate purificationPh neutralizationFiltration

The invention discloses a treatment process for discharging metribuzin wastewater in compliance with standard in coordination with salt recycling and a running method of the treatment process, and belongs to the technical field of pesticide wastewater treatment. The treatment process mainly comprises the steps of precipitation filtration, resin adsorption, pH neutralization, MVR, pH adjustment andFenton advanced oxidation. Salt recycling is conducted by steps as follows: performing evaporation crystallization and centrifugal drying to obtain refined industrial sodium sulfate. The concentration of COD in the metribuzin wastewater can be greatly reduced by resin adsorption treatment, and salt in wastewater can be further removed by MVR. Finally, Fenton advanced oxidation treatment is adopted, and effluent meets the connection standard of the park pipe network. Efficient and stable treatment of the metribuzin wastewater which contains high COD and high salt and is difficult to biologically degrade is realized, so that the metribuzin wastewater is discharged continuously in compliance with standard, and recycling of sodium sulfate in the wastewater is also realized.

Owner:江苏南大华兴环保科技股份公司

Fluorine-containing ion exchange membrane for alkali chloride electrolysis

ActiveCN110699706AImprove interface compatibilityImprove interlayer adhesionOrganic diaphragmsPhysical chemistryCarboxylic acid

The invention belongs to the technical field of ion exchange membranes, and relates to a fluorine-containing ion exchange membrane for alkali chloride electrolysis. The fluorine-containing ion exchange membrane comprises a fluorine-containing polymer layer with carboxylic acid type functional groups, a fluorine-containing polymer layer with sulfonic acid type and carboxylic acid type functional groups, and a fluorine-containing polymer layer with sulfonic acid type functional groups; wherein a reinforcing material is embedded in the fluorine-containing polymer layer with the sulfonic acid typefunctional group, and the reinforcing material is parallel to the fluorine-containing polymer layer with the carboxylic acid type functional group and the fluorine-containing polymer layer with the sulfonic acid type functional group and the carboxylic acid type functional group; the surface of the fluorine-containing ion exchange membrane is provided with a surface modification coating formed byion exchange resin and inorganic ions. According to the invention, the electrolytic voltage during alkali chloride electrolysis can be reduced, the defect of interlayer stripping of the multi-layer composite membrane in the application process is inhibited, and the product is suitable for running in a zero-polar-distance electrolytic cell under novel high-current density conditions.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

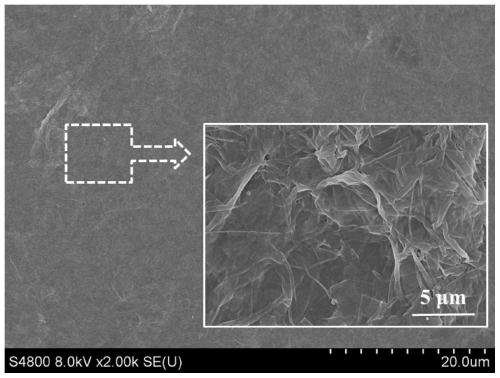

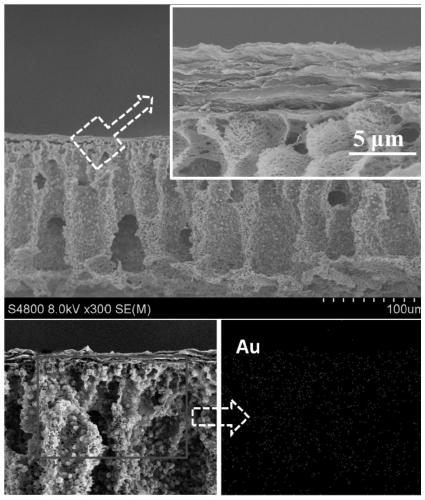

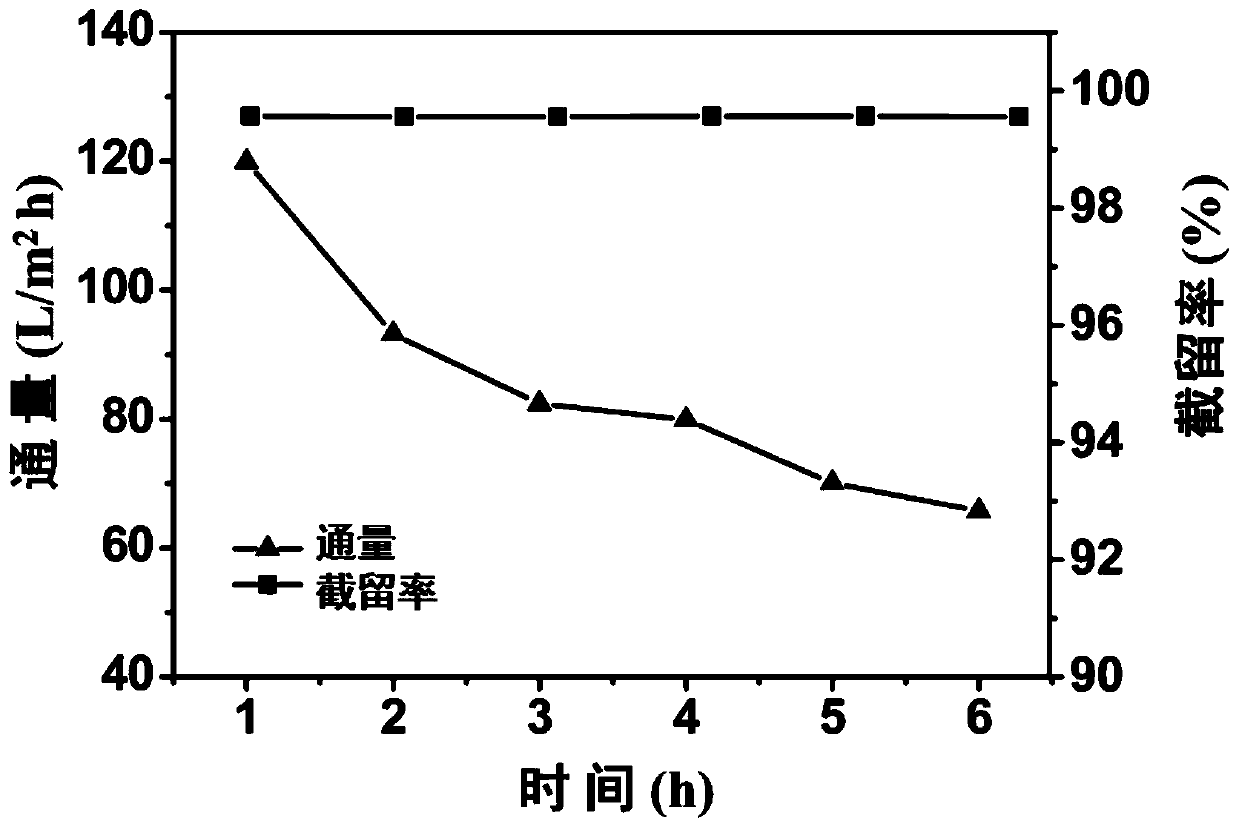

Multifunctional bio-based composite microporous membrane and preparation method thereof

ActiveCN111346523APromote degradationStable and efficient processingMembranesSemi-permeable membranesEngineeringMaterials science

The invention discloses a multifunctional bio-based composite microporous membrane and a preparation method thereof, and belongs to the field of water treatment and purification. The multifunctional bio-based composite microporous membrane is mainly composed of a separation layer and a support layer, the separation layer is mainly prepared by mixing a nano material and an additive, and has a three-dimensional structure capable of intercepting dye small molecules; the support layer comprises a stereocomplex polylactic acid microporous membrane and noble metal nanoparticles which are loaded in the stereocomplex polylactic acid microporous membrane and have catalytic performance, so that rapid degradation of aromatic compounds in a sewage system is realized. Compared with a microporous membrane in the prior art, the multifunctional bio-based composite microporous membrane disclosed by the invention can be used for more stably and efficiently treating dye molecules and aromatic compounds in sewage under the synergistic effect of the separation layer and the support layer, and meanwhile, the multifunctional bio-based composite microporous membrane is simple in preparation process and convenient to operate, and has very important scientific and application prospects.

Owner:GUANGZHOU UNIVERSITY

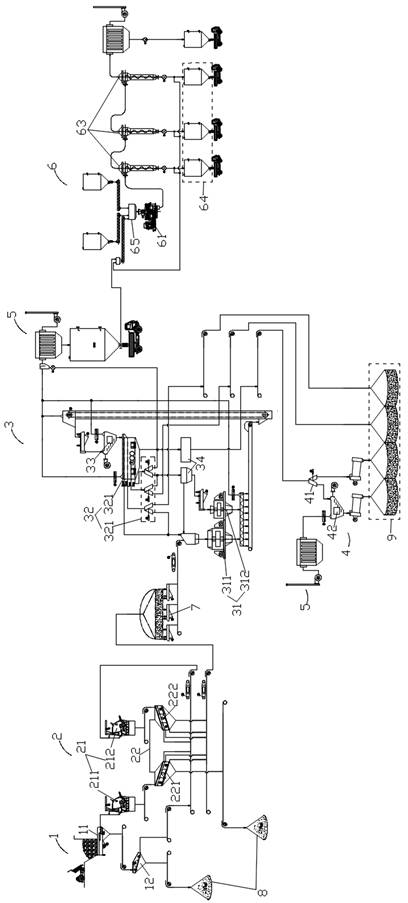

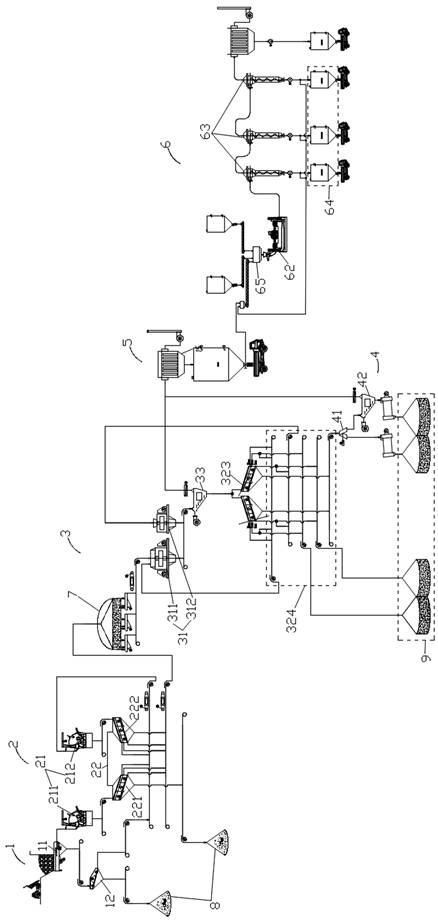

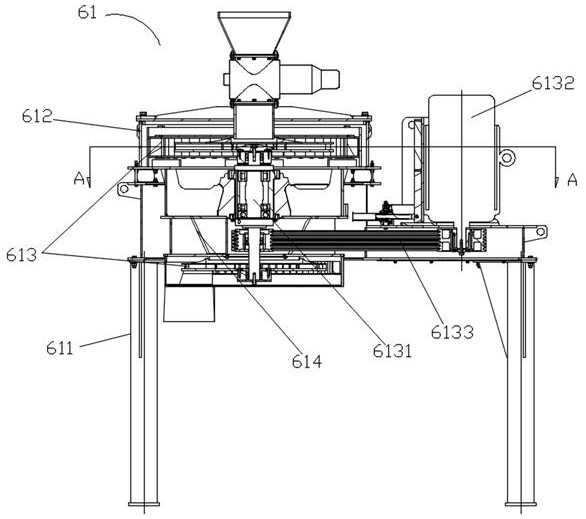

Thick-thin micro aggregate 6S processing process for concrete and production line

The invention discloses a thick-thin micro aggregate 6S processing process for concrete and a production line. The thick-thin micro aggregate 6S processing process comprises the following steps: pretreating materials; performing circulatory multi-stage rough crushing and multi-stage desliming; performing circulatory multi-stage fine crushing and multi-stage powder concentrating, and preparing finesand and aggregates of different specifications and different limestone powder contents in proportion; and performing crushing and processing, and multistage winnowing, sorting and collecting on recycled dust materials. The whole sand-making production line is perfected, so that the system yield can be effectively increased, and finished product gravel aggregate quality can be effectively improved, and therefore, various grading and optimal grading of finished product gravel aggregates are realized; moreover, recycled powder waste is effectively recycled, treatment ability is strong, mountainflour grading can be precisely controlled, and mountain flour of various specifications is prepared; and the thick-thin micro aggregate 6S processing process is used for effectively improving durability and mechanical property of concrete, is low in production cost, and is efficient and energy-saving.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

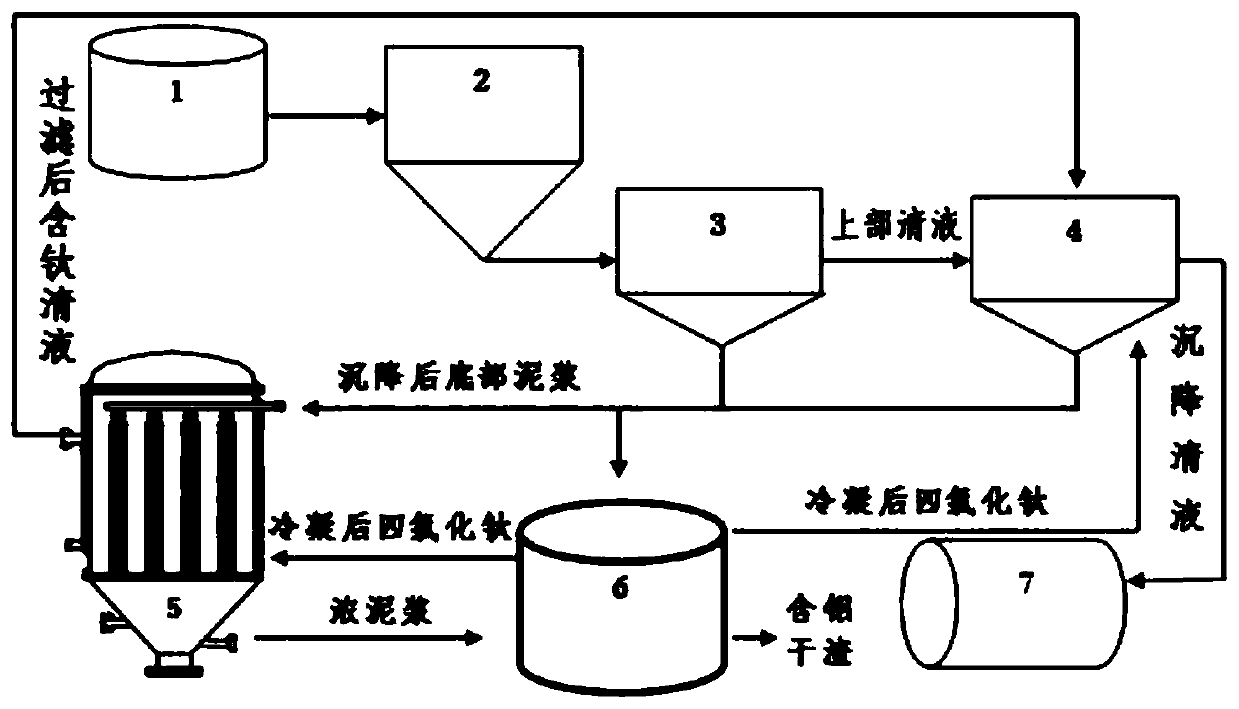

Method for removing aluminum of aluminum powder vanadium-removing crude titanium tetrachloride mud

InactiveCN110217816AStable and efficient processingStable and efficient separationTitanium tetrachlorideProcess efficiency improvementHigh energyFiltration

The invention discloses a method for removing aluminum of aluminum powder vanadium-removing crude titanium tetrachloride mud, and belongs to the technical field of metallurgy. In order to solve the the technical problems of a high content of aluminum impurities, a low separation efficiency of the aluminum impurities, high energy consumption, large environmental pollution and the like of existing aluminum powder vanadium-removing crude titanium tetrachloride mud, the invention provides a method for removing aluminum. The method comprises the steps: adding water to the aluminum powder vanadium-removing crude titanium tetrachloride mud for hydrolysis, performing first sedimentation after the hydrolysis, performing stratification so as to obtain a supernatant liquid and bottom concentrated mud, performing second sedimentation on the supernatant liquid obtained from the first sedimentation, performing stratification so as to obtain low-aluminum TiCl4 and bottom concentrated mud, and performing tubular filtration or slurry evaporation treatment on the bottom concentrated mud according to different solid content. A combined process including hydrolysis, first sedimentation, second sedimentation, tubular filtration and slurry evaporation is performed on the aluminum powder vanadium-removing mud, the aluminum impurities in the mud maximally are separated maximally, and titanium tetrachloride in the mud is recovered.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

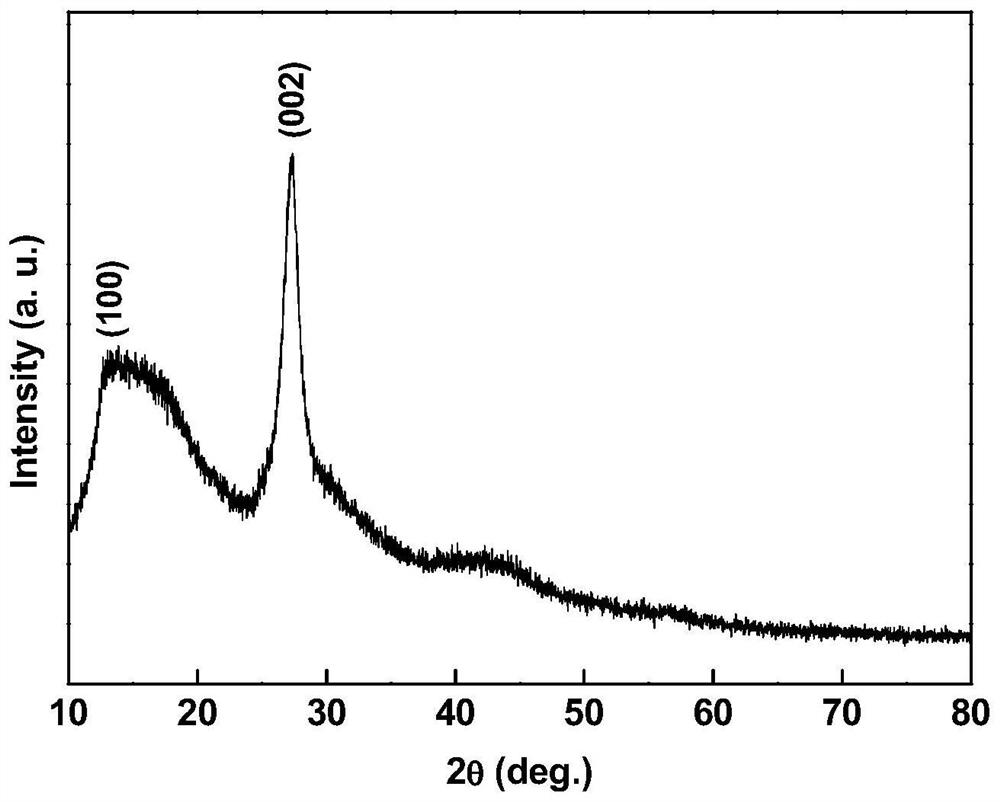

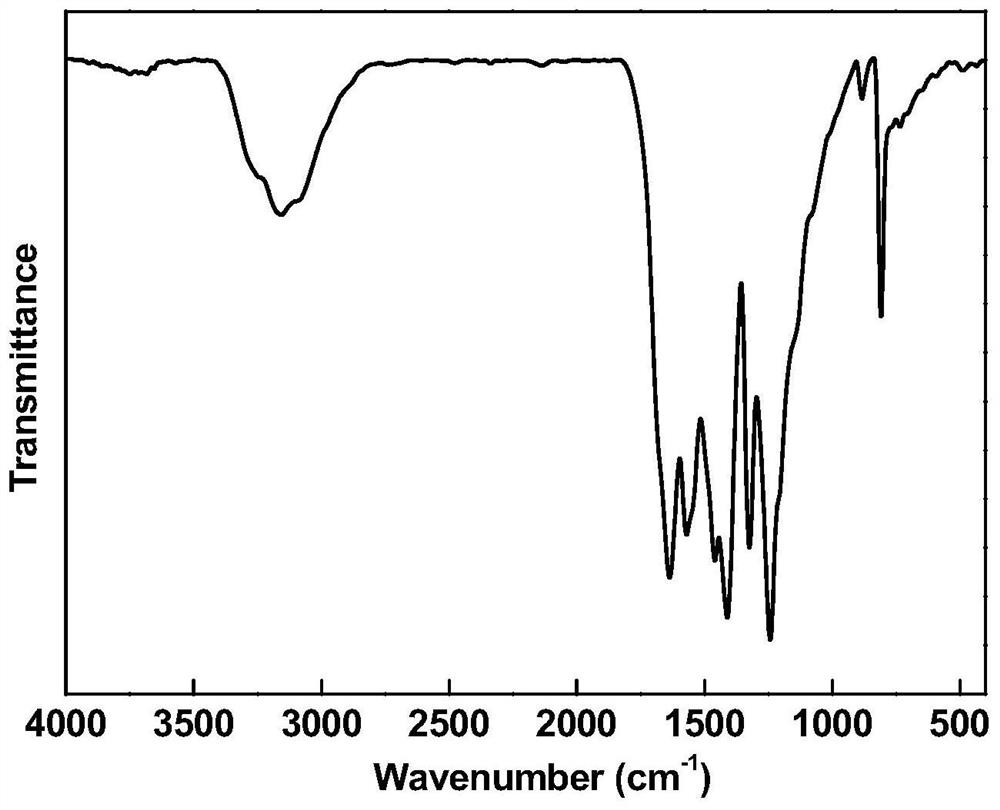

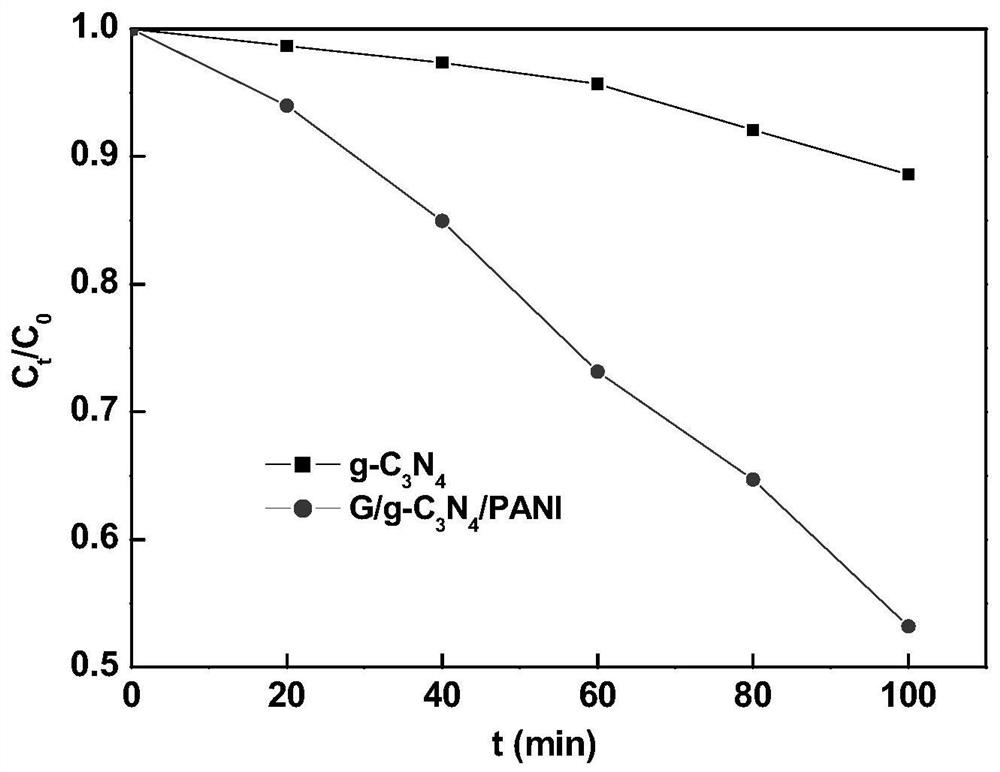

Novel ternary composite visible-light-induced photocatalyst for efficiently and stably treating hexavalent chromium wastewater and synthesis method thereof

ActiveCN111905809AStable and efficient processingAbundant and easy to get raw materialsWater/sewage treatment by irradiationWater treatment compoundsPtru catalystEngineering

The invention discloses a ternary composite visible-light-induced photocatalyst and a synthesis method thereof. The synthesis method comprises the following steps: firstly, preparing g-C3N4 by adopting a melamine calcining method; then mixing the g-C3N4 with an N,N-dimethylformamide solution of polyaniline, and carrying out ultrasonic treatment, stirring and solvent evaporation to prepare a polyaniline / g-C3N4 binary compound; and mixing the polyaniline / g-C3N4 binary compound, single-layer graphene oxide and ascorbic acid in deionized water, and carrying out hydrothermal treatment on the mixture to obtain the graphene / g-C3N4 / polyaniline ternary compound. The method is simple and easy to implement, the raw materials are rich and easy to obtain, metal and metal compounds are not used, the cost is low, and the obtained graphene / g-C3N4 / polyaniline ternary compound not only has high visible light catalytic activity on reduction of hexavalent chromium in a decorative chromium plating solution, but also has good photocatalytic stability and reusability, and can be used as a novel visible-light-induced photocatalyst to be applied to efficient and stable treatment of hexavalent chromium wastewater.

Owner:YANGZHOU UNIV

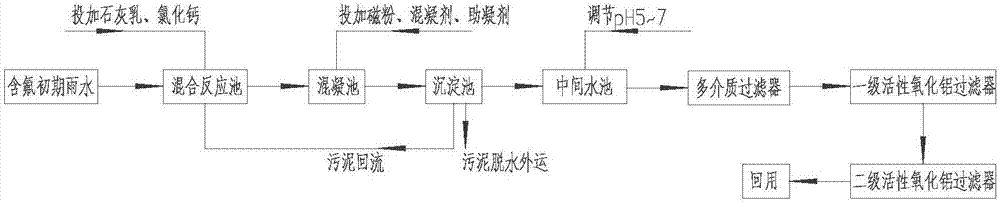

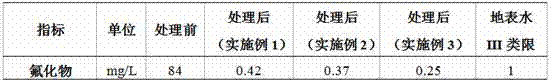

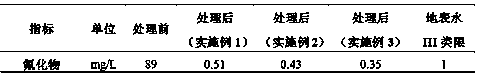

Method for treating initial fluorine-containing rainwater by adopting magnetic flocculation-adsorption

InactiveCN107879541AStable and efficient processingWater contaminantsTreatment involving filtrationPrecipitationSedimentation

The invention discloses a coagulating sedimentation-adsorption method for treating initial fluorine-containing rainwater. The method comprises the steps that lime milk is added to adjust the pH to alkaline, aluminum salt coagulant and coagulant aid are added after calcium chloride and magnetic powder are added to mixed with the lime milk, and the fluorine-containing rainwater filtered by a multi-medium filter and a second-level activated alumina filter can be reused or discharged after reactive precipitation. According to the method, a stable and high-efficient method for treating the initialfluorine-containing rainwater is provided to aim at the present situation that fluoride content in the initial rain water produced by enterprises using villiaumite exceeds a standard, which can not meet the demand of environmental protection. The method is suitable for occasions where the concentration of fluoride in the initial fluoride-containing water does not exceed 200 mg / L, and the fluorideconcentration in effluent can be controlled at 1 mg / L.

Owner:KUNMING ENG & RES INST OF NONFERROUS METALLURGY +2

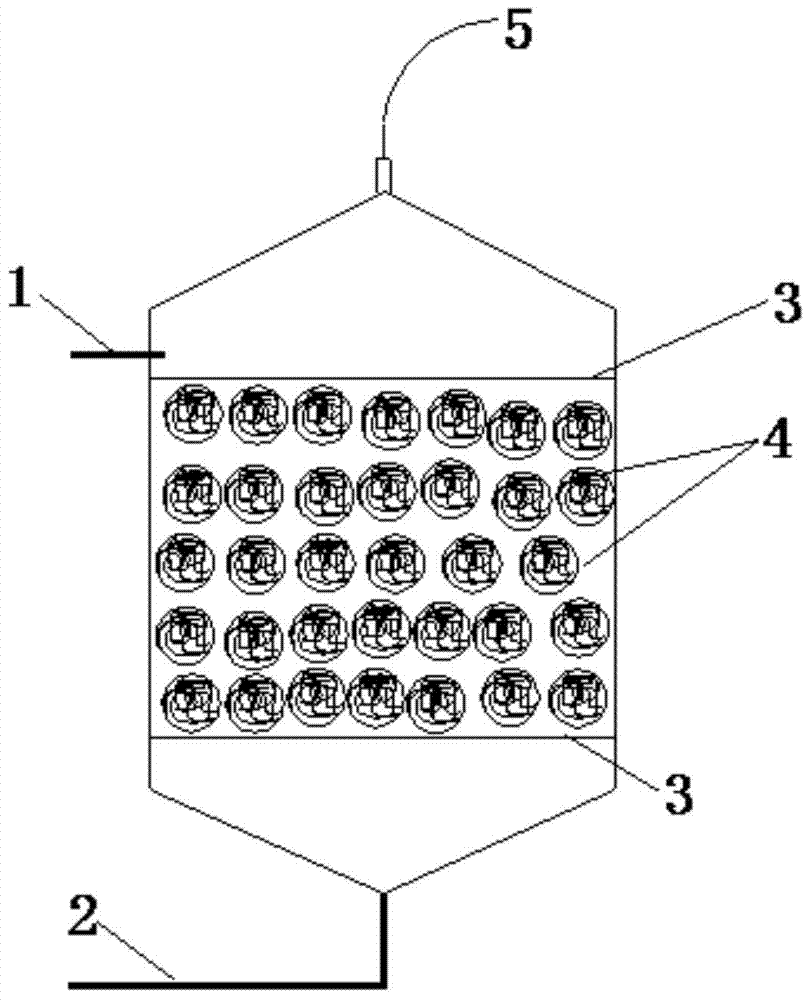

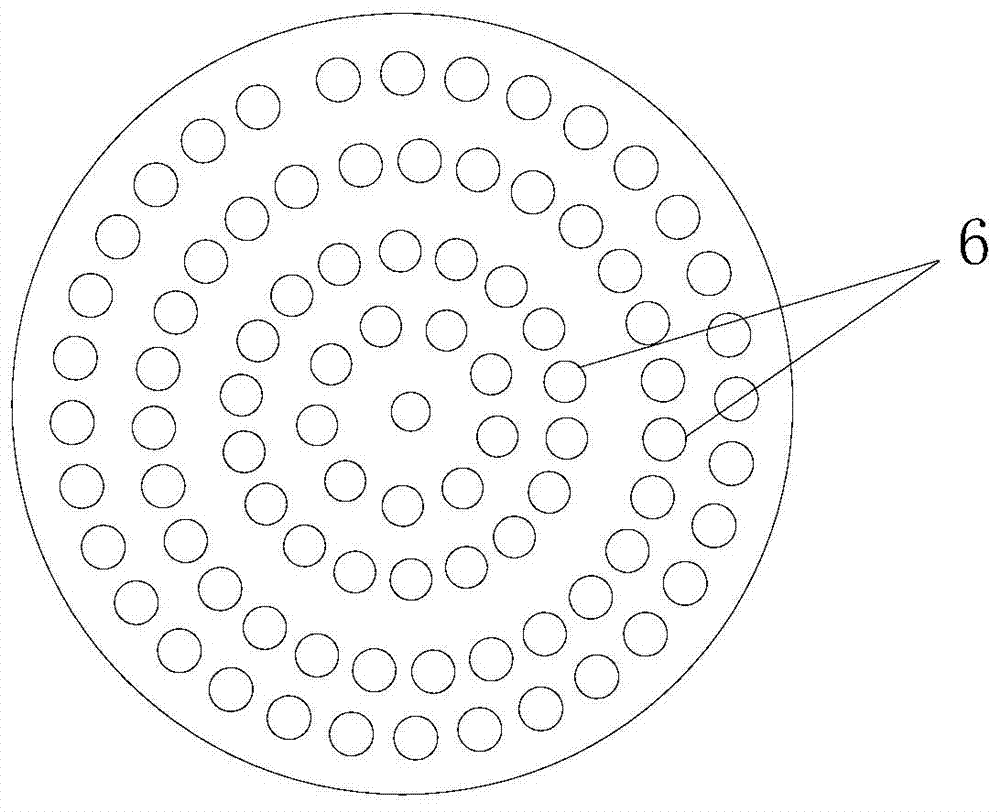

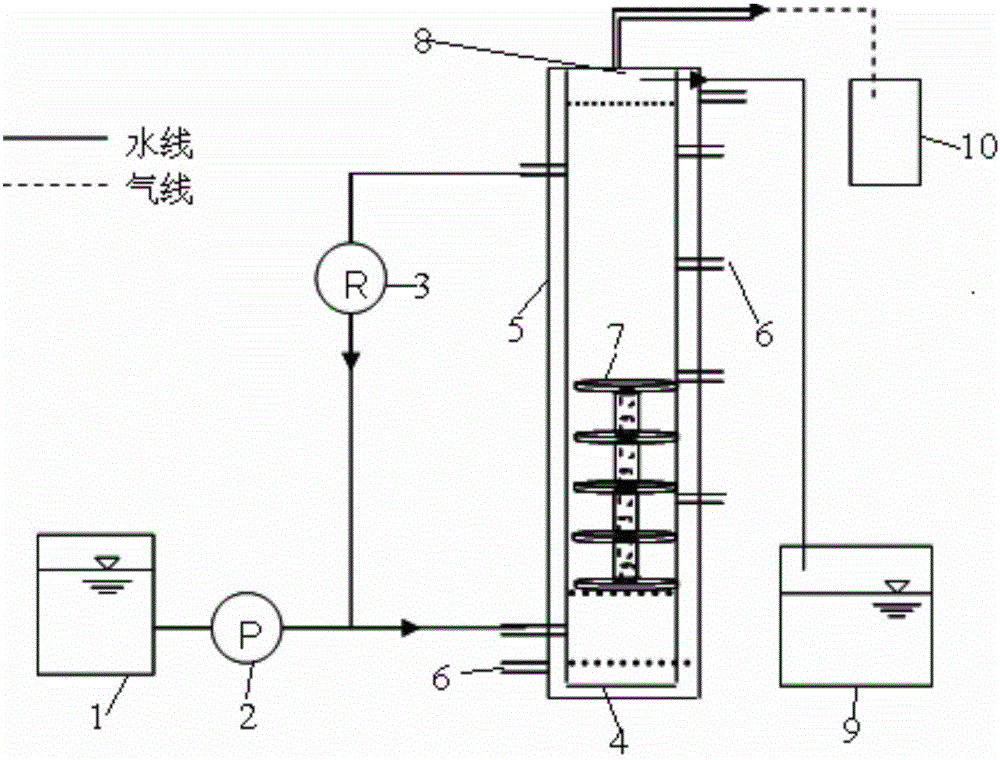

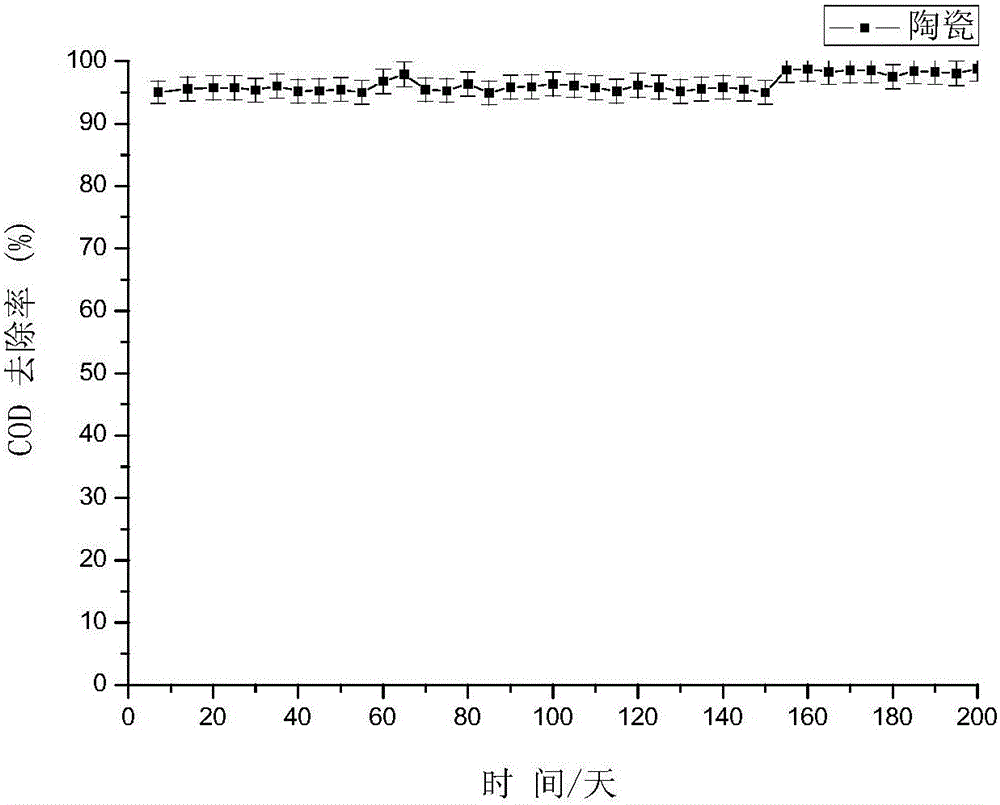

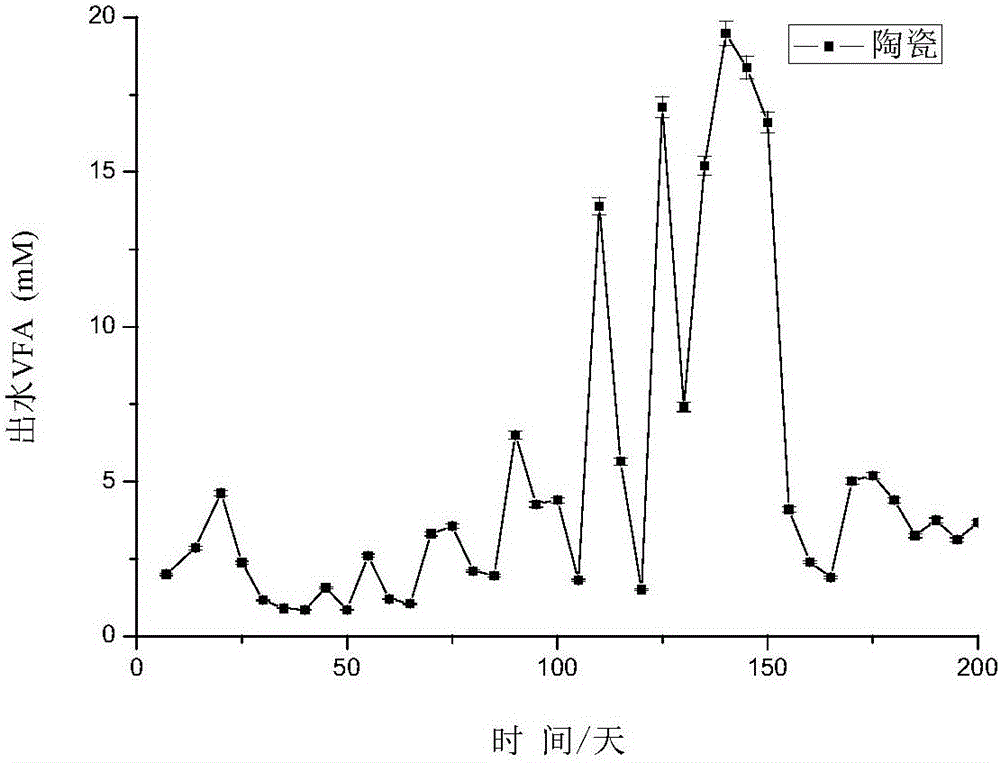

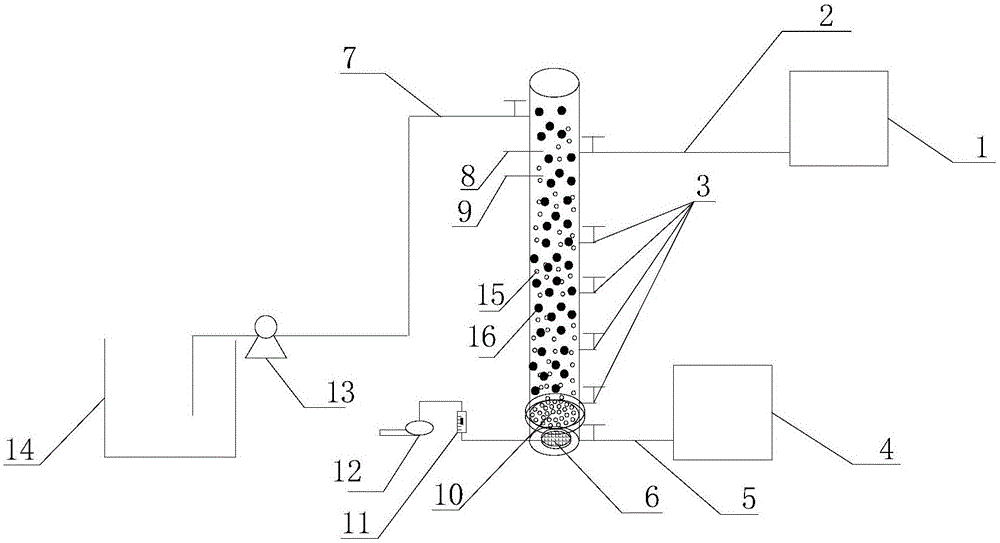

Method for treating cassava alcohol wastewater through anaerobic reactor filled with ceramic material

InactiveCN105967327AStable and efficient processingImprove processing efficiencyWaste based fuelTreatment with anaerobic digestion processesMethane yieldManihot esculenta

The invention discloses a method for treating cassava alcohol wastewater through an anaerobic reactor filled with a ceramic material. The method includes the steps that the anaerobic reactor is filled with the ceramic material serving as a sludge carrier, wherein the volume of the ceramic material is 30%-45% the working volume of the reactor; anaerobic sludge is inoculated to the ceramic carrier, and standing culture is carried out to make the anaerobic sludge adsorbed to the ceramic carrier; the anaerobic sludge is subjected to habituated culture, cassava alcohol wastewater which is diluted step by step is introduced into the reactor for reflux to make the immobilized sludge make full contact with the cassava alcohol wastewater, and habituated culture is ended when the COD removal rate and the methane yield are stable; the cassava alcohol wastewater to be treated enters the anaerobic reactor for treatment, wherein the hydraulic retention time is 0.3-0.5 h. According to the method, the COD removal rate can reach 98% or above after stable operation.

Owner:NANJING UNIV OF TECH

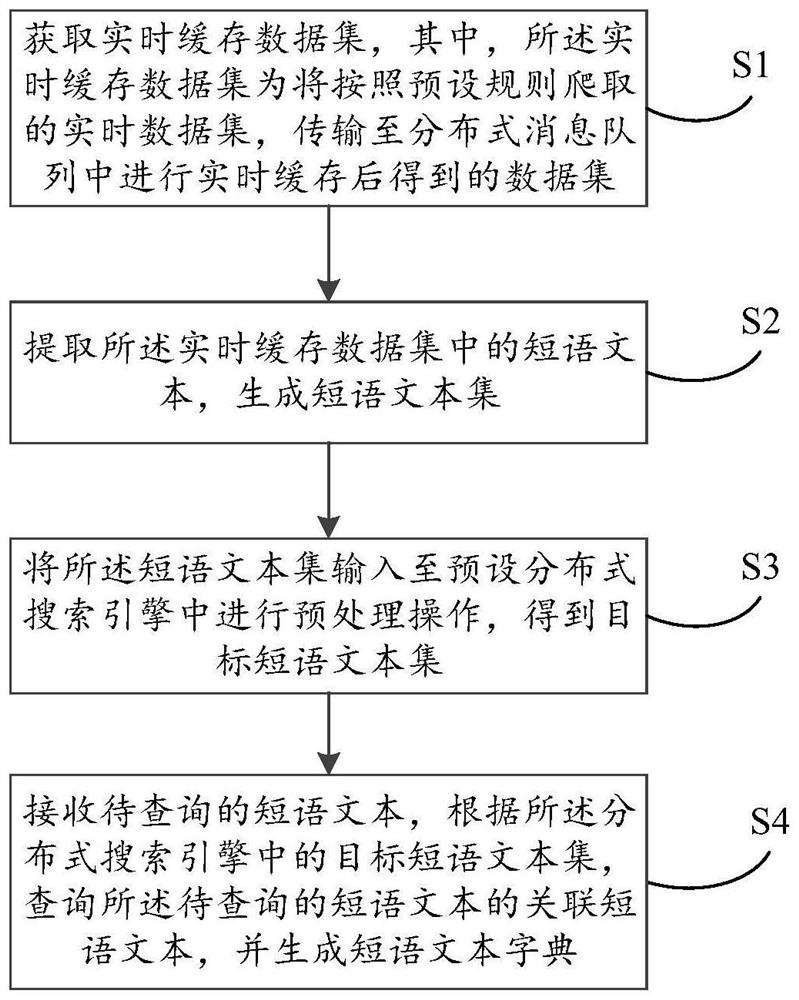

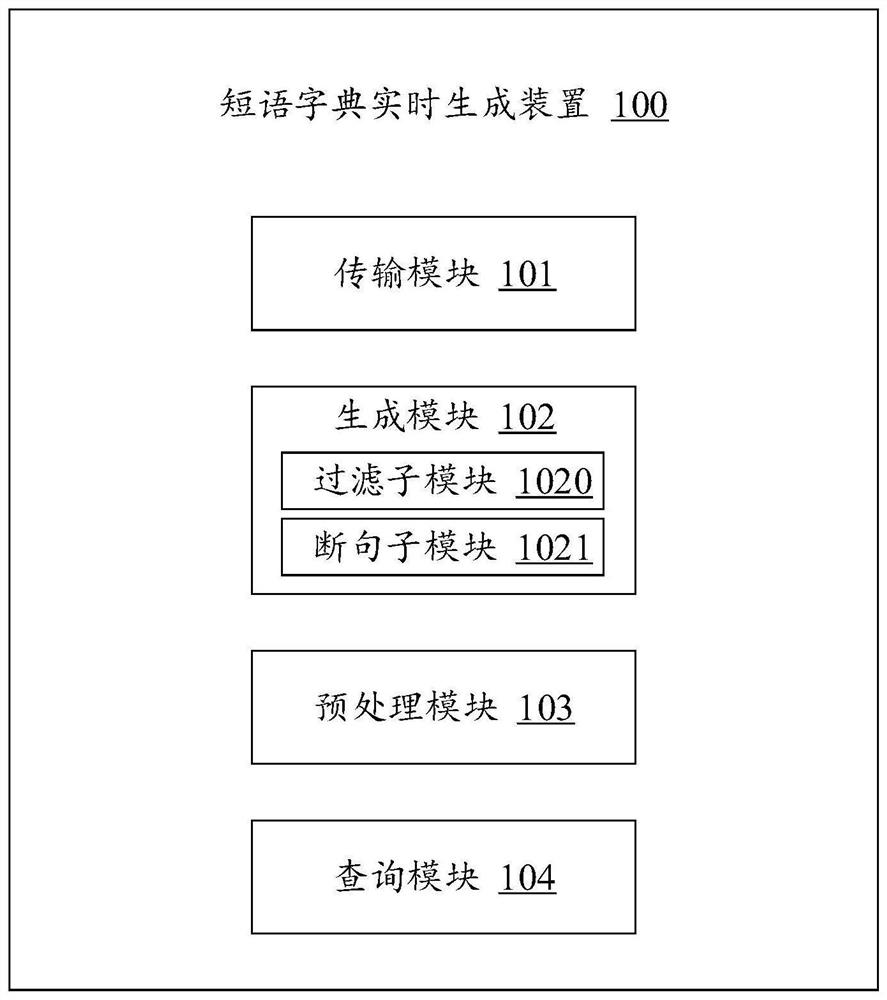

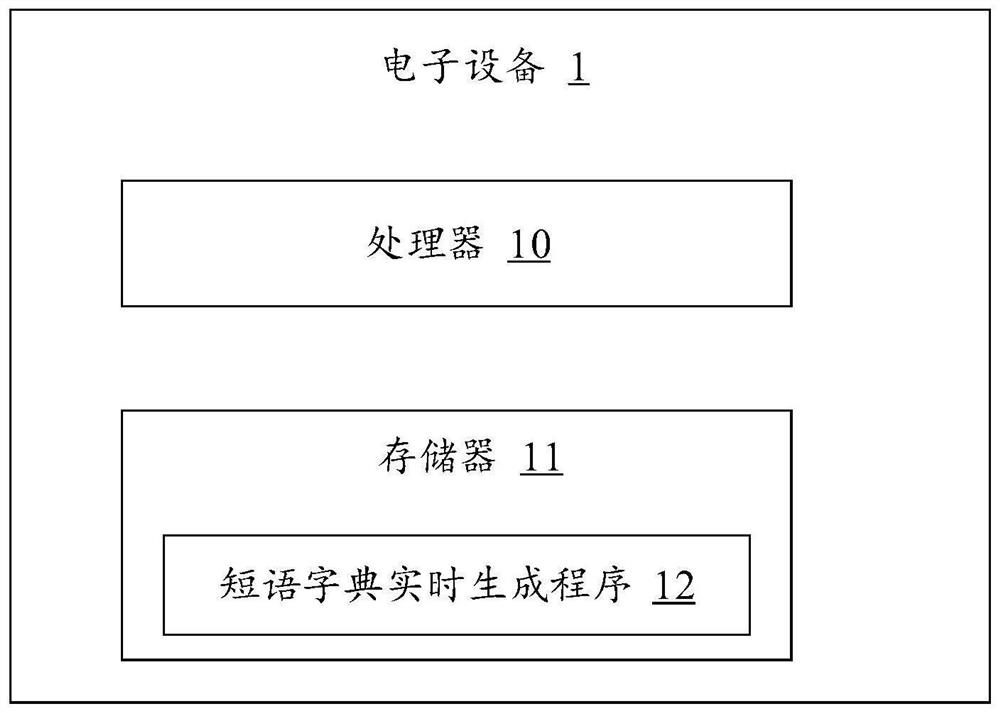

Phrase dictionary real-time generation method and device, electronic equipment and storage medium

PendingCN111639159AStable and efficient processingGuaranteed real-time comprehensivenessWeb data indexingNatural language data processingMessage queueData set

The invention relates to the technical field of big data in artificial intelligence, and discloses a phrase dictionary real-time generation method comprising the steps that a real-time cache data setis acquired, and the real-time cache data set is a data set obtained after a real-time data set crawled according to a preset rule is transmitted to a distributed message queue to be cached in real time; extracting phrase texts in the real-time cache data set to generate a phrase text set; inputting the phrase text set into a preset distributed search engine for preprocessing operation to obtain atarget phrase text set; and receiving a to-be-queried phrase text, querying an associated phrase text of the to-be-queried phrase text according to a target phrase text set in the distributed searchengine, and generating a phrase dictionary. The invention further provides a phrase dictionary real-time generation device, electronic equipment and a computer readable storage medium. According to the invention, the phrase dictionary can be generated in real time.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

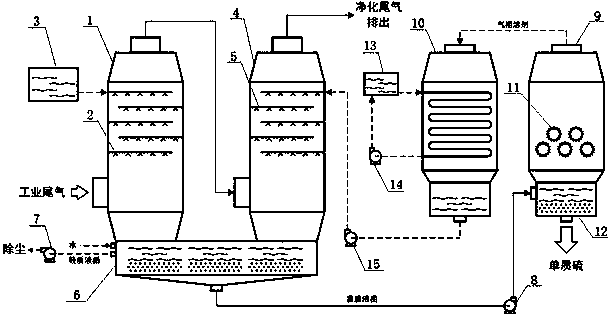

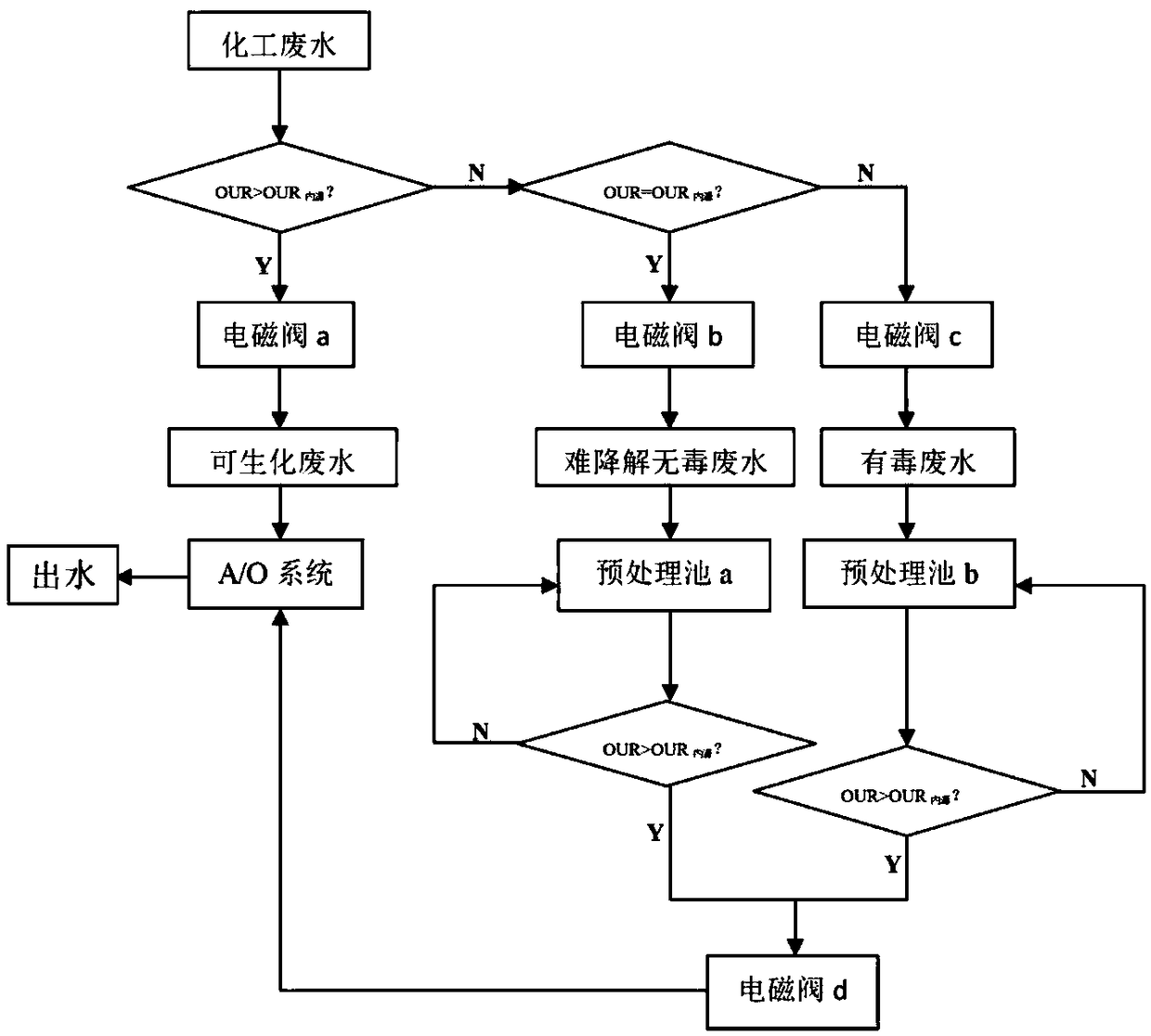

Gas-solid separating method and system for simple substance sulphur in sulphur-containing exhaust

ActiveCN109911862AAvoid pollution accidentsReduce desulfurization costGas treatmentUsing liquid separation agentSulfurGas phase

The invention discloses a gas-solid separating method and a gas-solid separating system for simple substance sulphur in sulphur-containing exhaust. The gas-solid separating method for simple substancesulphur in sulphur-containing exhaust comprises the following steps: first, cooling sulphur-containing exhaust at an extremely high speed; then, separating dust; finally, recycling a heavy liquid phase solvent and simple substance sulphur; according to the method disclosed by the invention, the separating efficiency of the simple substance sulphur is up to 90 percent or above; moreover, the exhaust is further purified, and an environment pollution accident is avoided; in a separating process of the simple substance sulphur, the heavy liquid phase solvent of the simple substance sulphur evaporates to form a gas phase solvent which can be recycled as the liquid phase solvent for reusing through cooling, so that the sulphur removing cost is reduced. The system comprises a quick cooling system, a low-temperature washing purifying system, a light liquid phase and heavy liquid phase separating system, a washing liquid recycling system and a simple substance sulphur recycling system. The system disclosed by the invention has the advantages of stability and high efficiency in high sulphur-containing exhaust treatment, high simple substance sulphur separating efficiency, energy conservation and environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

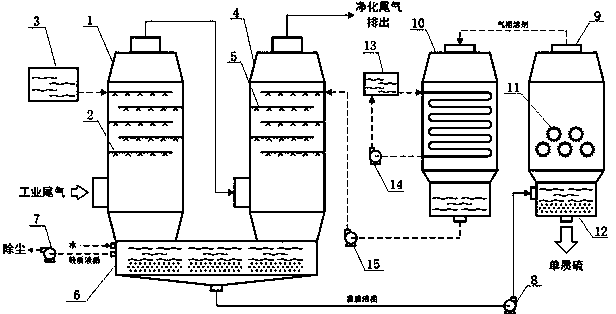

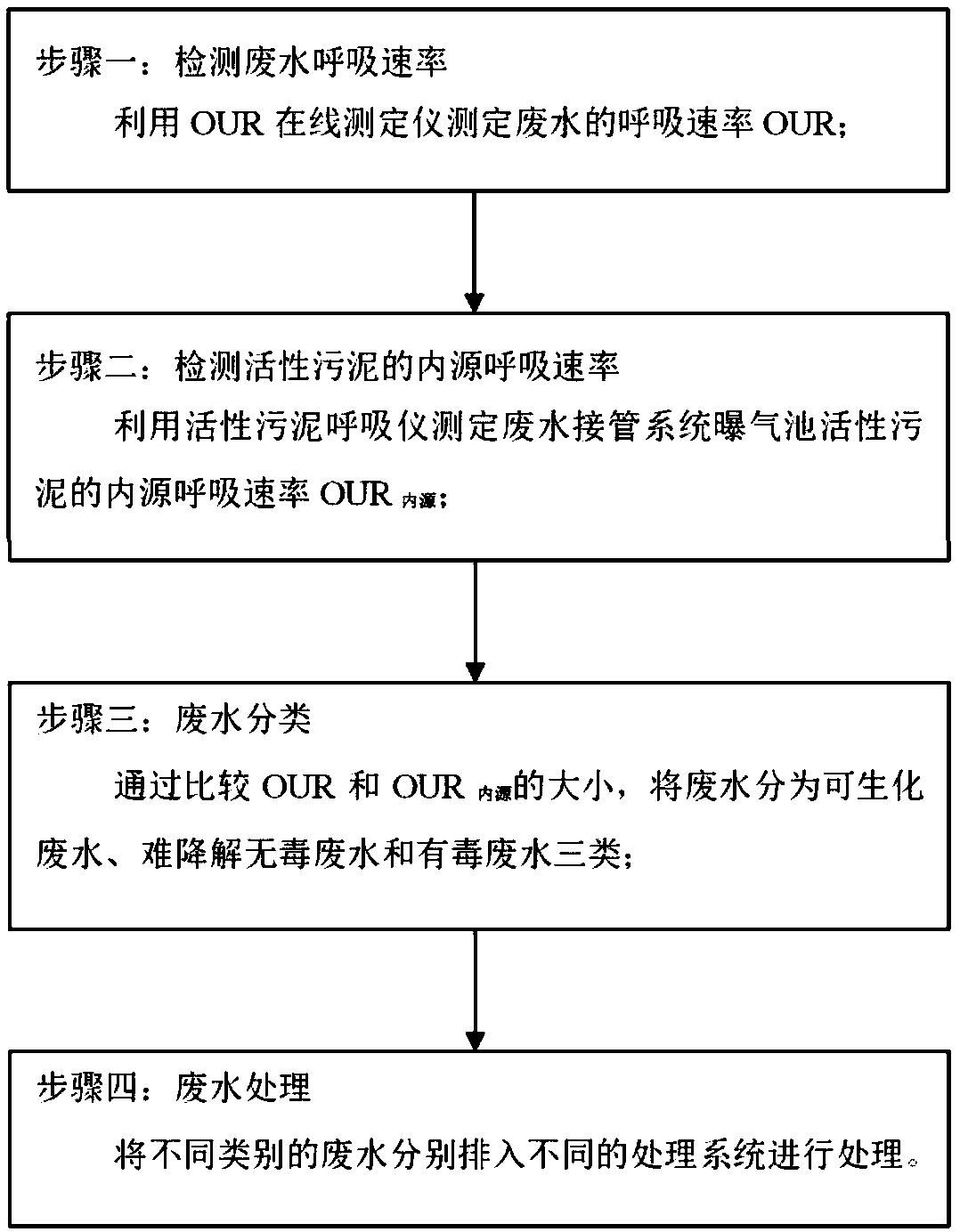

Method for quality classification and pipe connection of chemical wastewater

InactiveCN109354160AAccurate assessment of toxicityEasy to handleSustainable biological treatmentWater/sewage treatment by reductionActivated sludgeMeasuring instrument

The invention discloses a method for quality classification and pipe connection of chemical wastewater, and belongs to the technical field of wastewater treatment. The method for quality classification and pipe connection of the chemical wastewater specifically comprises the steps that 1, an OUR online measuring instrument is utilized for measuring a breathing rate OUR of the wastewater; 2, an activated sludge breathing instrument is utilized for measuring the breathing rate OUR of an endogenesis of activated sludge of an aeration tank of a wastewater pipe connection system; 3, by comparing the sizes of OUR and OUR endogenesis, the wastewater is divided into three categories including the biodegradable wastewater, the degradation-resistant non-toxic wastewater and the toxic wastewater; 4,different categories of wasterwater are discharged into different treatment systems for treatment respectively. The method solves the problems that in the prior art, non-differential treatment methodsfor chemical wastewater have high cost and unstable treatment effects. The method for quality classification and pipe connection of the chemical wastewater can effectively improve the wastewater treatment effect and achieve the wastewater treatment purpose of substantial reduction of toxic pollutants with economic stability.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

Mycelium pellet biosorption and regeneration method

InactiveCN106552593AHave mechanical strengthImprove adsorption capacityFungiTreatment using aerobic processesSporeDesorption

The invention discloses a mycelium pellet biosorption and regeneration method. The method includes the steps of preparation of mycelium pellets, specifically, spores are cultured into the mycelium pellets; biosorption, specifically, the mycelium pellets are used for conducting biosorption on anion azo dye waste water; and regeneration of the mycelium pellets, specifically, the mycelium pellets with dye adsorbed is desorbed in alkaline desorption liquid, the alkaline desorption liquid with the dye dissolved is recovered, and the desorbed regenerated mycelium pellets continue to be used for the step of biosorption. According to the mycelium pellet biosorption and regeneration method, biosorption and regeneration are conducted under the open non-sterilized condition by taking the advantages of extreme environment (such as high salinity and low pH) resistance, high adsorptive property, easy settlement and certain mechanical strength of the mycelium pellets, and a reactor is operated continuously with the biosorption technology as the core.

Owner:HUATIAN ENG & TECH CORP MCC +1

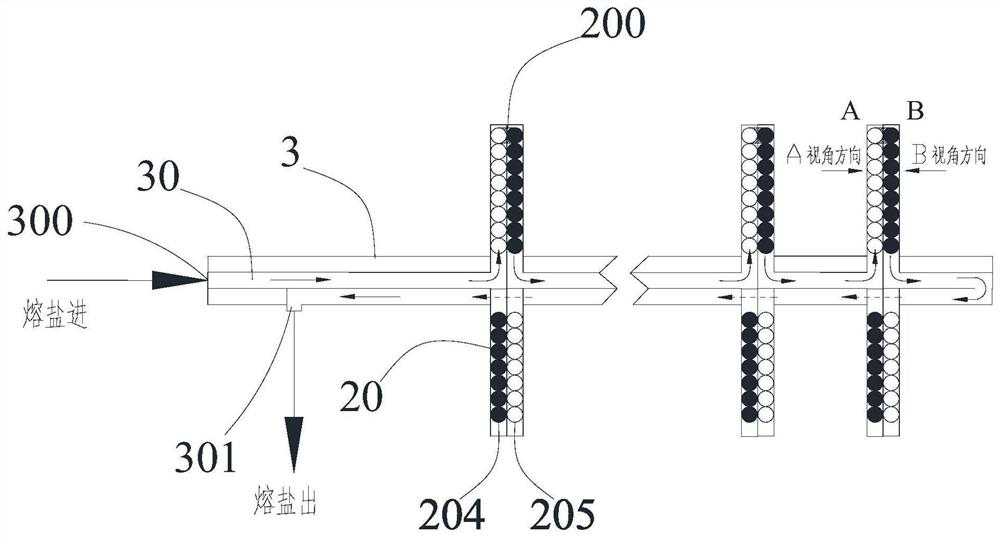

Heating furnace, heating system and method for treating oily sludge by using heating furnace and heating system

PendingCN112679068AAvoid cokingAvoid heatingWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningSludgeMolten salt

The invention provides a heating furnace, a heating system and a method for treating oily sludge by using the heating furnace and the heating system. The heating furnace comprises a furnace body, a heating turntable and a rotating shaft; wherein the heating turntable is arranged in the furnace body, and the rotating shaft penetrates through the furnace body; the rotating shaft is connected with the heating turntable and is used for driving the heating turntable to rotate; a medium channel for inputting and outputting a heating medium is arranged in the heating turntable; and a hollow pipeline is arranged in the rotating shaft, and is communicated with the feed port and the discharge port of the medium channel. Te heating system comprises the heating furnace and a molten salt heating device. The method for treating the oily sludge by using the heating system comprises the following steps: inputting the oily sludge into the furnace body, and heating the oily sludge by using the heating medium in the heating turntable. The heating furnace provided by the invention is uniform in heating.

Owner:CHENGDU SEPMEM SCI & TECH

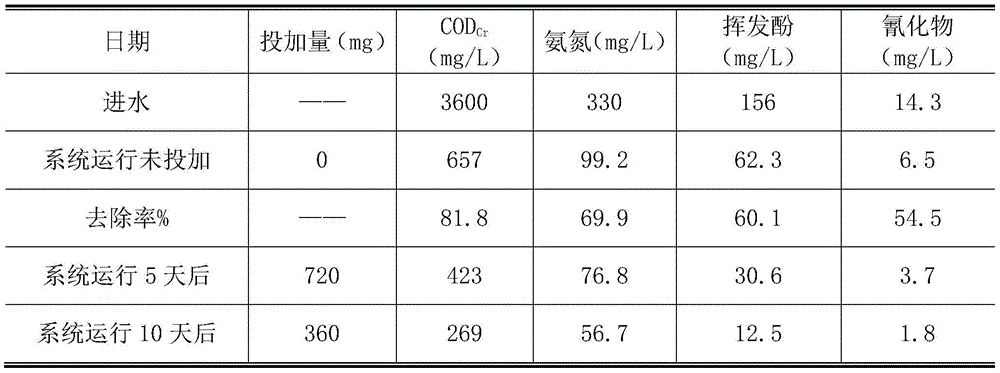

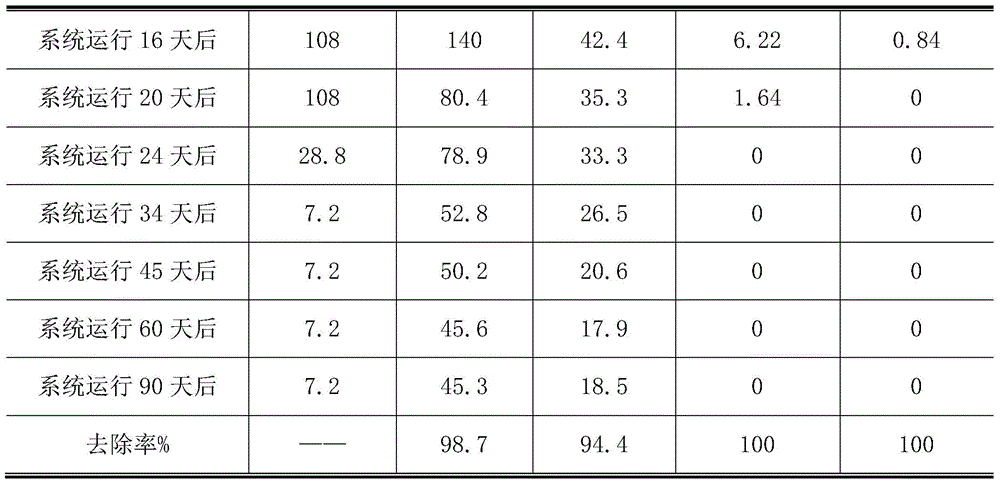

A biological treatment accelerator for coking wastewater

ActiveCN104925934BStable and efficient processingImprove bioavailabilityBiological water/sewage treatmentVitamin b6Zinc Acetate Dihydrate

The invention discloses a coking wastewater biological treatment promoter and belongs to the field of wastewater treatment. According to the method, glucose, zinc acetate, potassium acetate, ammonium dihydrogen phosphate, magnesium chloride, ferric sulfate and vitamin B6 are smashed, mixed and made into the coking wastewater biological treatment promoter. The promoter overcomes the defects that microorganisms are inhibited or poisoned easily, and the efficiency is low when coking wastewater is treated through a common biological treatment method, the co-metabolism effect of the microorganisms is initiated, the poison tolerance and the treatment efficiency of a biological treatment system on the coking wastewater are improved, and therefore the coking wastewater can be treated stably and efficiently.

Owner:深圳市华美绿生态环境集团有限公司

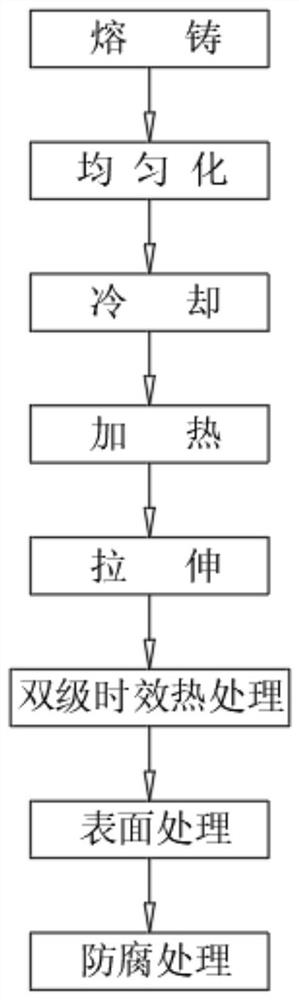

Processing technology for aluminum alloy battery tray of passenger car

PendingCN112952253AUniform temperatureBright surfaceCell component detailsEngineeringProcess engineering

The invention belongs to the technical field of battery tray processing, and particularly relates to a processing technology for an aluminum alloy battery tray of a passenger car. The processing technology comprises the following steps of casting, namely adding the prepared raw materials into a smelting furnace for melting according to technological requirements, and effectively removing miscellaneous slag and gas in a melt by degassing and deslagging refining means; combining an extrusion process for realizing isothermal extrusion by adopting variable-speed regulation and control with a gradient heating process, reducing the temperature of an aluminum bar which is heated before extrusion gradually from front to back along the axis direction of the aluminum bar to form a temperature gradient and realizing isothermal extrusion, so that aheated and processed product is uniform in core surface temperature, bright in surface color and small in mechanical property deviation; and metal elastic deformation generated when a die bears high-temperature and high-pressure heat friction is reduced and avoided, the current situation that the size deviation of the head and the tail of an extruded long material product is larger is effectively improved, and meanwhile, it can be guaranteed that the surface temperature is basically consistent when a profile is discharged, and the product quality is greatly improved.

Owner:GUANGXI UNIV

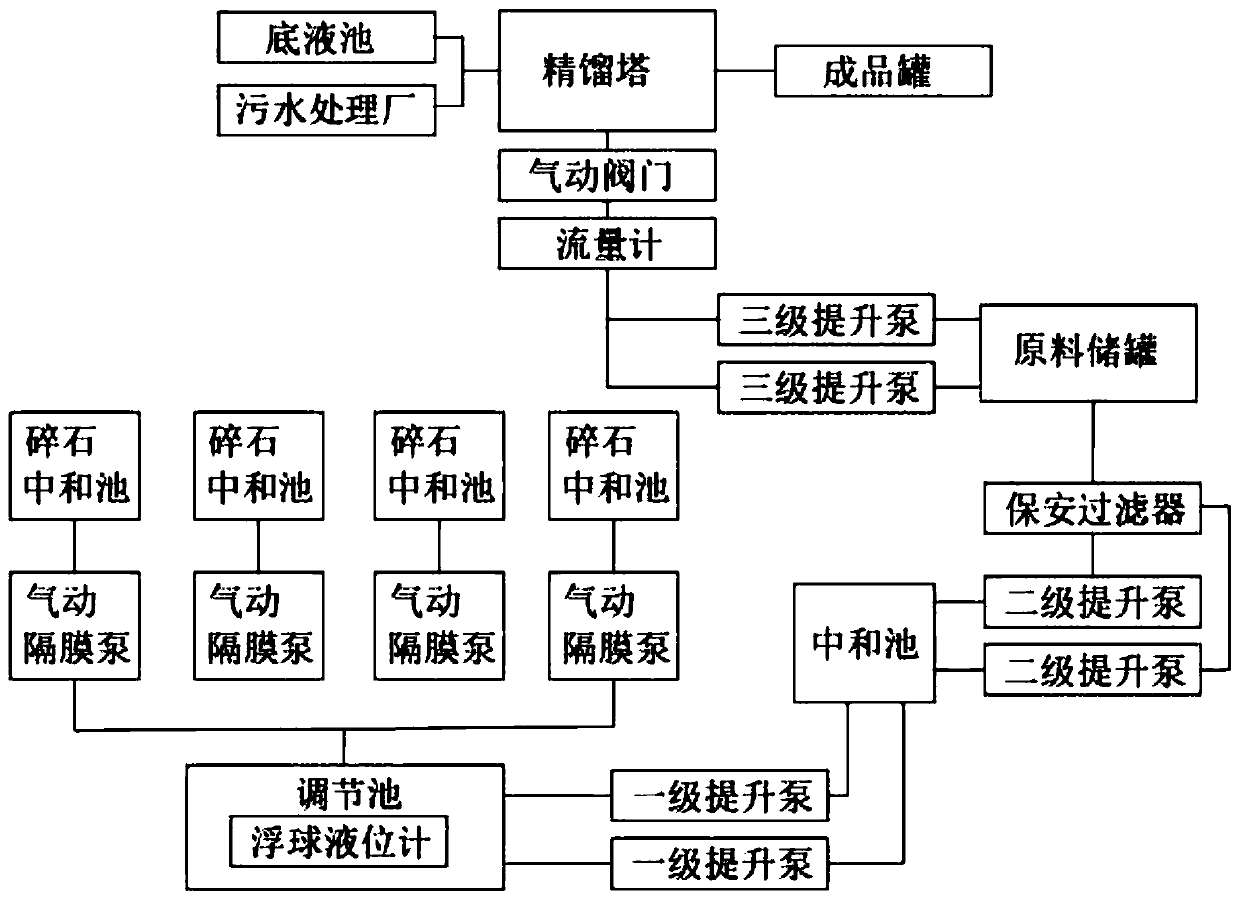

Process for neutralizing and rectifying high-hydrochloric-acid n-butyl alcohol wastewater

InactiveCN111252977AStable and efficient processingThe processing effect is stable and efficientTreatment involving filtrationMultistage water/sewage treatmentCalcium stoneWastewater

The invention relates to a process for neutralizing and rectifying high-hydrochloric-acid n-butyl alcohol wastewater. The method comprises the following steps: (1) adding high-purity calcium stone into a stone neutralizing tank, wherein the hydrochloric acid in wastewater can be neutralized by calcium carbonate in the calcium stone; (2) arranging a first-stage lift pump in a regulating tank, and controlling high start and low stop by a floating ball liquid level meter to supply water to the neutralizing tank; (3) adding a small amount of calcium carbonate powder into the neutralizing tank to neutralize the wastewater to be neutral, then conveying the wastewater to a security filter through a second-stage lifting pump, and filtering; (4) enabling the wastewater filtered by the security filter to enter a raw material storage tank under the pressure of a pump; (5) arranging a third-stage lift pump in the raw material storage tank, arranging a flow meter and a pneumatic valve, and controlling the flow of the wastewater entering a rectifying tower through the pneumatic valve so as to achieve the separation of n-butyl alcohol from water; and (6) arranging a finished product tank beside the rectifying tower, wherein the finished product tank is used for receiving the separated n-butyl alcohol. The method can be used for efficiently and stably treating the high-hydrochloric-acid n-butyl alcohol wastewater.

Owner:国合恒新环保江苏有限公司

Method for treating fluorine-containing initial rainwater through coagulating sedimentation-adsorption

InactiveCN107673518AStable and efficient processingWater contaminantsTreatment involving filtrationChlorideFluoride

The invention discloses a method for treating fluorine-containing initial rainwater through coagulating sedimentation-adsorption. Lime milk is added to adjust the pH to be alkaline, calcium chloride and aluminum oxide powder are added and mixed, an aluminum salt coagulant and a coagulant aid are added, and reaction precipitates can be reused or discharged after being filtered by a multi-media filter and a secondary activated aluminum oxide filter. The invention provides the stable and efficient method for treating the fluorine-containing initial rainwater to eliminate the current situation that the content of a large quantity of initial rainwater fluorides produced in initial rainwater produced by fluorine salt using enterprises exceeds the standard and the environmental protection requirement cannot be met. The method is applied to occasions with the fluorine-containing initial rainwater fluoride concentration not exceeding 200 mg / L, and the effluent fluoride concentration can be controlled at 1 mg / L.

Owner:KUNMING ENG & RES INST OF NONFERROUS METALLURGY +2

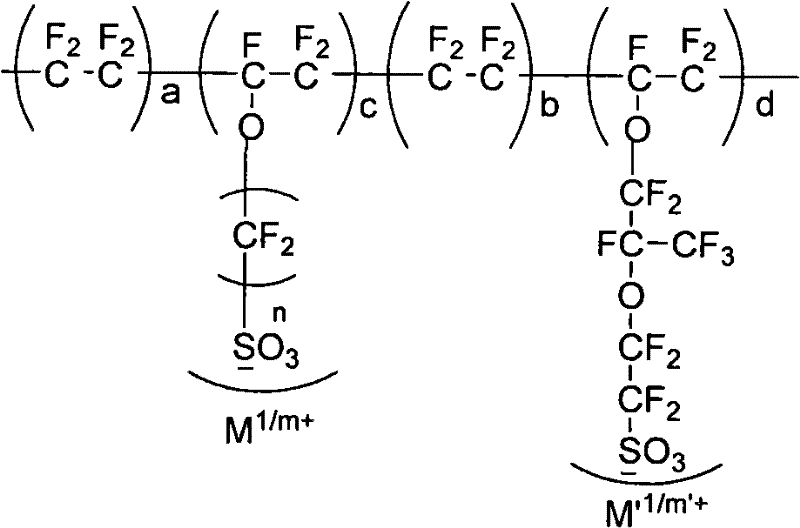

Ion exchange membrane with high impurity tolerance

InactiveCN101773791BStable and efficient processingHigh impurity toleranceSemi-permeable membranesDiaphragmsInorganic particleProduct gas

The invention relates to an ion exchange membrane with high impurity tolerance, which comprises a layer of fluorine-containing polymer film, wherein at least one layer of the fluorine-containing polymer film is adhered with a no-polarized porous gas releasing layer, and the gas releasing layer is formed by drying the surface of the polymer film which is adhered with dispersion liquid, wherein thedispersion liquid is formed by dispersing organic or inorganic grains in metal ion-containing sulfoacid resin hydroalcoholic solution. The ion exchange membrane is used for chlor-alkali industry to be stably and effectively process alkali metal chloride solution which contains high content of impurity.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Rubbish penetrating fluid and urban sewage treatment device

PendingCN107720990AMeet emission standardsStable and efficient processingWater contaminantsMultistage water/sewage treatmentAmmoniacal nitrogenFiltration

The invention discloses rubbish penetrating fluid and an urban sewage treatment device. The device comprises a disinfection and sterilization tank, a heavy metal separation tank, a secondary reactiontank and a precipitation tank, wherein the disinfection and sterilization tank, the heavy metal separation tank and the secondary reaction tank are all internally provided with stirring paddles whichare driven by a motor arranged above, the outer sides of the disinfection and sterilization tank, the heavy metal separation tank and the secondary reaction tank are respectively provided with a firstliquid storage bucket, a second liquid storage bucket and a third liquid storage bucket, in the second liquid storage bucket, a stirring paddle is arranged, a stirring motor is arranged above the second liquid storage bucket, the front end of the disinfection and sterilization tank is connected with an ammonia nitrogen air stripping tower, a water inlet is arranged above the ammonia nitrogen airstripping tower, a water outlet is arranged below the ammonia nitrogen air stripping tower, and the water outlet is connected to the disinfection and sterilization tank through a pipeline. The urban sewage treatment device can be used for achieving efficient and stable treatment of the filtration and decomposition of organic matter, nitrogen, phosphorus and heavy metal, and the discharge standardis met.

Owner:莱州洁宇机械设备有限公司

Polymer resin composition for preparing hollow fiber membrane, preparation method of hollow fiber membrane, and hollow fiber membrane

InactiveCN104645837AWith pure water permeate fluxStabilizationSemi-permeable membranesMembranesAlkanePolymer science

Owner:LOTTE CHEM CORP

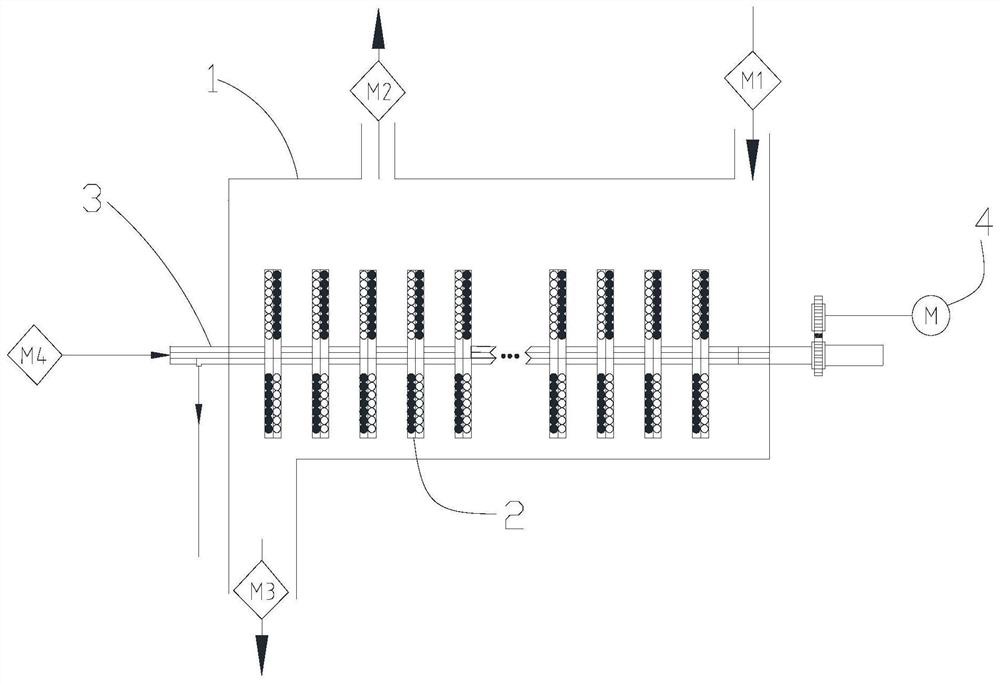

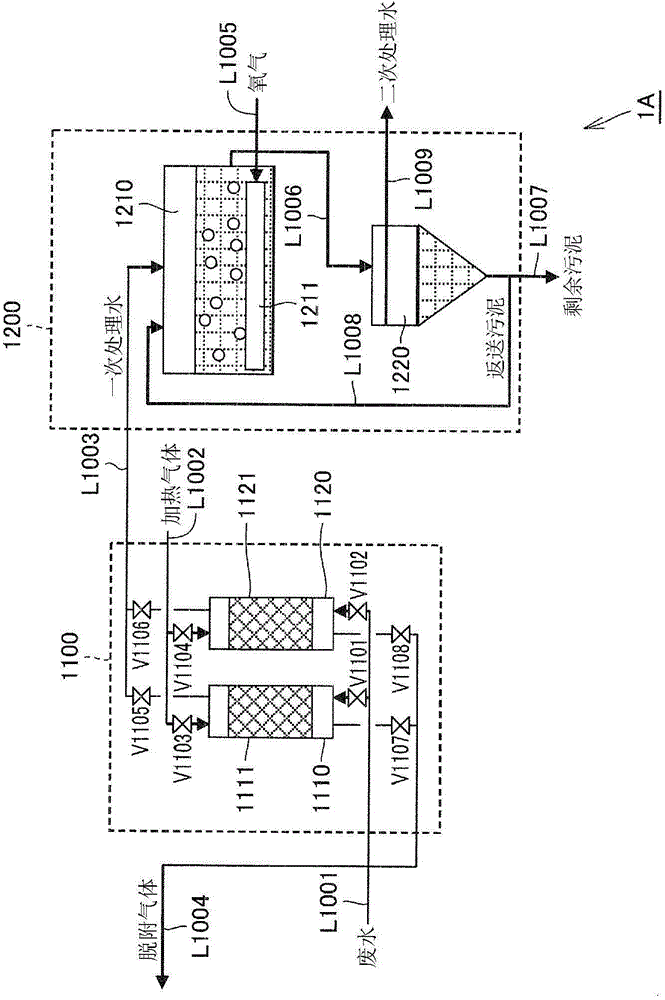

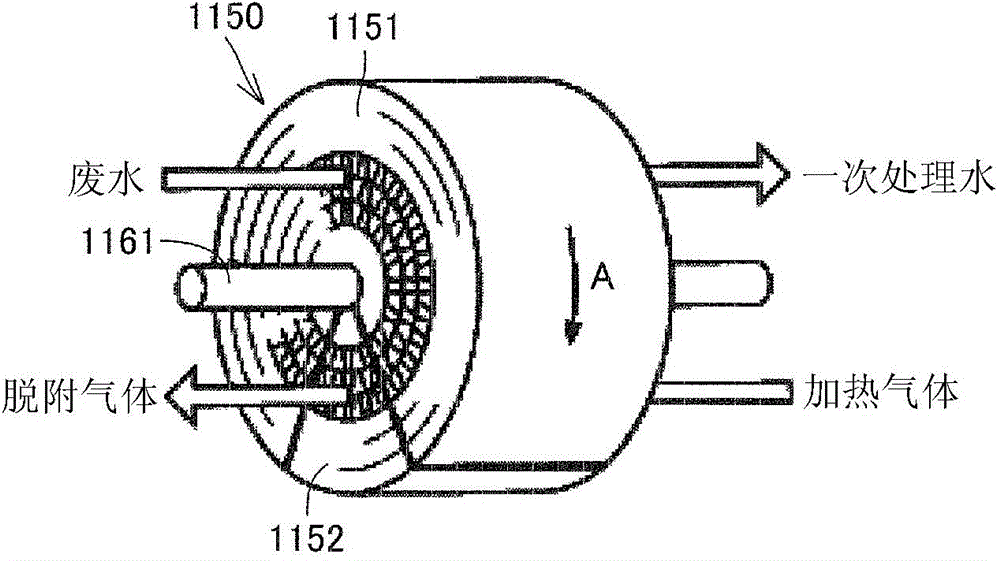

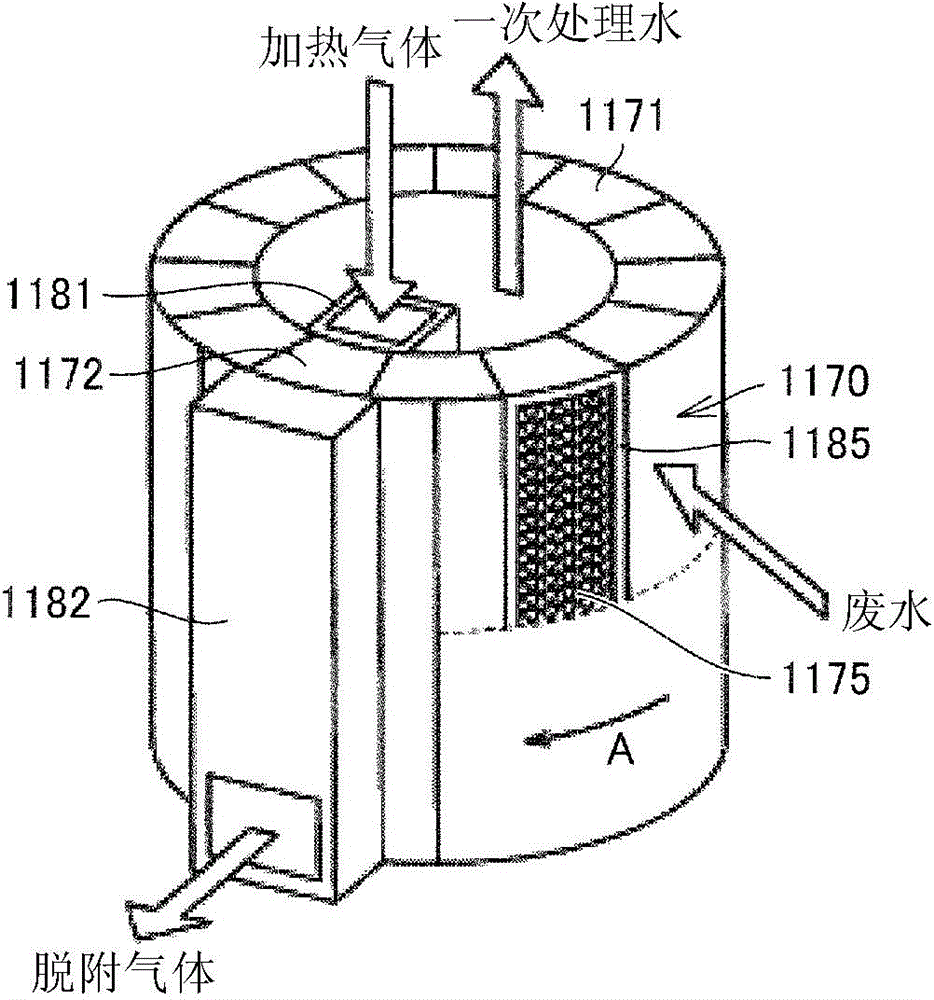

Waste water treatment system

InactiveCN104649448AEfficient and continuous removalStable removalSpecific water treatment objectivesWater contaminantsWater treatment systemCombustion

A waste water treatment system is provided with an aeration tank (2100) that vaporizes and removes organic material in waste water by aerating the waste water containing organic material and that discharges the aeration gas containing the organic material; a waste water treatment device (2200) that is connected to the aeration tank (2100)and has adsorption elements (2211, 2221) that adsorb organic material by coming into contact with the waste water containing the organic material, and desorb the adsorbed organic material by bringing the same into contact with hot gas; and a combustion device (2300) that is connected to the aeration tank (2100) and the waste water treatment device (2200) and that discharges a decomposed gas resulting from burning and oxidatively decomposing a mixed gas comprising the aeration gas and the desorbed gas containing organic material that are discharged from the aeration tank (2100) and the waste water treatment device (2200) respectively.

Owner:TOYOBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com