Multifunctional bio-based composite microporous membrane and preparation method thereof

A microporous membrane, bio-based technology, applied in the field of water treatment and purification, can solve problems such as water resources pollution, and achieve the effects of simple preparation process, convenient operation, stable and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

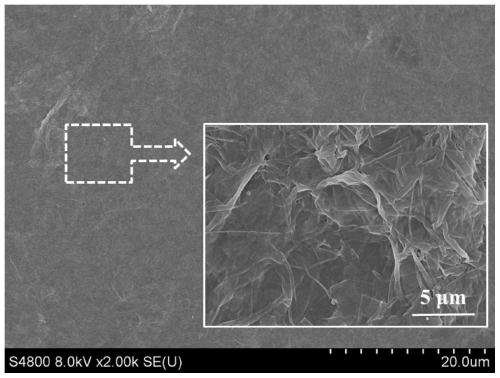

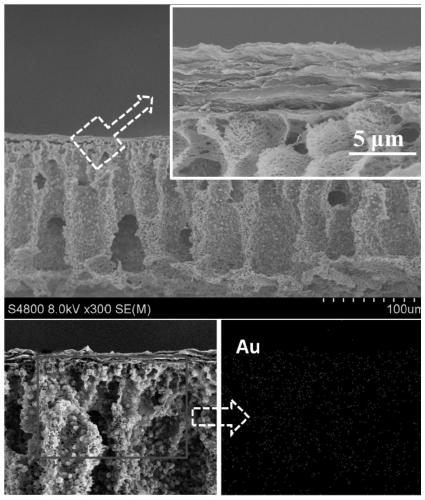

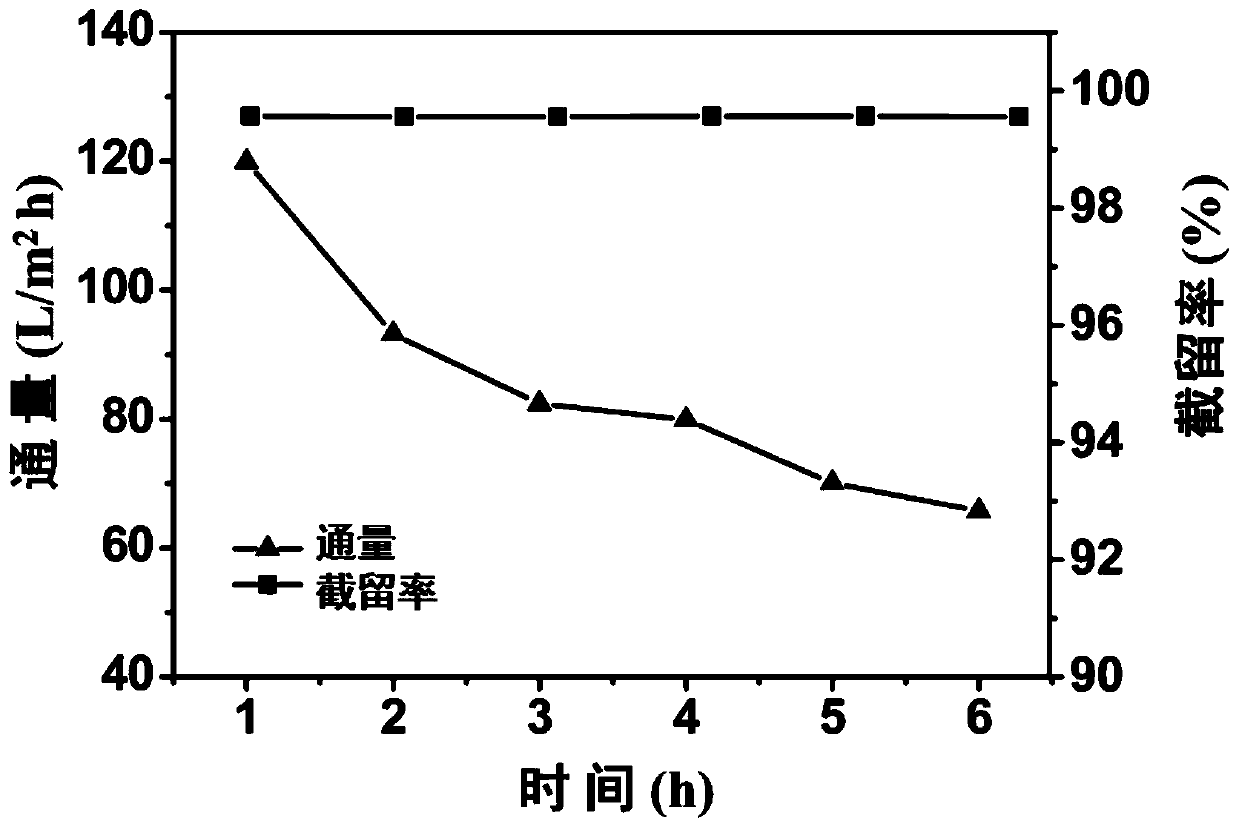

[0036] This example is an example of the preparation method of the multifunctional bio-based composite microporous membrane of the present invention. The preparation method of the multifunctional bio-based composite microporous membrane in this embodiment comprises the following steps:

[0037] (1) Under nitrogen protection, dissolve 3g D-type polylactic acid and 17g L-type polylactic acid in 80g N-methylpyrrolidone to obtain a film-forming precursor solution, wherein the dissolution temperature is 85 ° C, and the dissolution time is 5h; then In this film-forming precursor solution, add 20g active solution to carry out in-situ polymerization reaction, wherein, active solution is made of azobisisobutyronitrile, N-vinylpyrrolidone and vinyltriethoxysilane (mass ratio is nitrogen two Isobutyronitrile: N-vinylpyrrolidone: vinyltriethoxysilane = 1:80:50), the reaction time is 24h; after the reaction, the protective gas protection is stopped and the defoaming is carried out, and the f...

Embodiment 2

[0041] This example is an example of the preparation method of the multifunctional bio-based composite microporous membrane of the present invention. The preparation method of the multifunctional bio-based composite microporous membrane in this embodiment comprises the following steps:

[0042] (1) Under nitrogen protection, dissolve 6g D-type polylactic acid and 14g L-type polylactic acid in 80g N-methylpyrrolidone to obtain a film-forming precursor solution, wherein the dissolution temperature is 80°C and the dissolution time is 7h; then In this film-forming precursor solution, add 20g active solution to carry out in-situ polymerization reaction, wherein, active solution is made of azobisisobutyronitrile, N-vinylpyrrolidone and vinyltriethoxysilane (mass ratio is nitrogen two Isobutyronitrile: N-vinylpyrrolidone: vinyltriethoxysilane = 1:70:30), the reaction time is 24h; after the reaction, the protective gas protection is stopped and the defoaming is carried out, and the fl...

Embodiment 3

[0048] This example is an example of the preparation method of the multifunctional bio-based composite microporous membrane of the present invention. The preparation method of the multifunctional bio-based composite microporous membrane in this embodiment comprises the following steps:

[0049] (1) Under nitrogen protection, 4g D-type polylactic acid and 13g L-type polylactic acid were dissolved in 83g dimethyl sulfoxide to obtain a film-forming precursor solution, wherein the dissolution temperature was 90°C and the dissolution time was 9h; Add 20g active solution in this film-forming precursor solution to carry out in-situ polymerization reaction, wherein, active solution is made of azobisisobutyronitrile, N-vinylpyrrolidone and vinyltriethoxysilane (mass ratio is nitrogen diisobutyronitrile Nitrile: N-vinylpyrrolidone: vinyltriethoxysilane = 1:70:30), the reaction time is 28h; after the reaction, the protective gas protection is stopped and the defoaming is carried out, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com