Combined treatment process for manioc producing effluent

A technology for the production of wastewater and tapioca starch, which is applied in the fields of flocculation/sedimentation water/sewage treatment, flotation water/sewage treatment, neutralized water/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

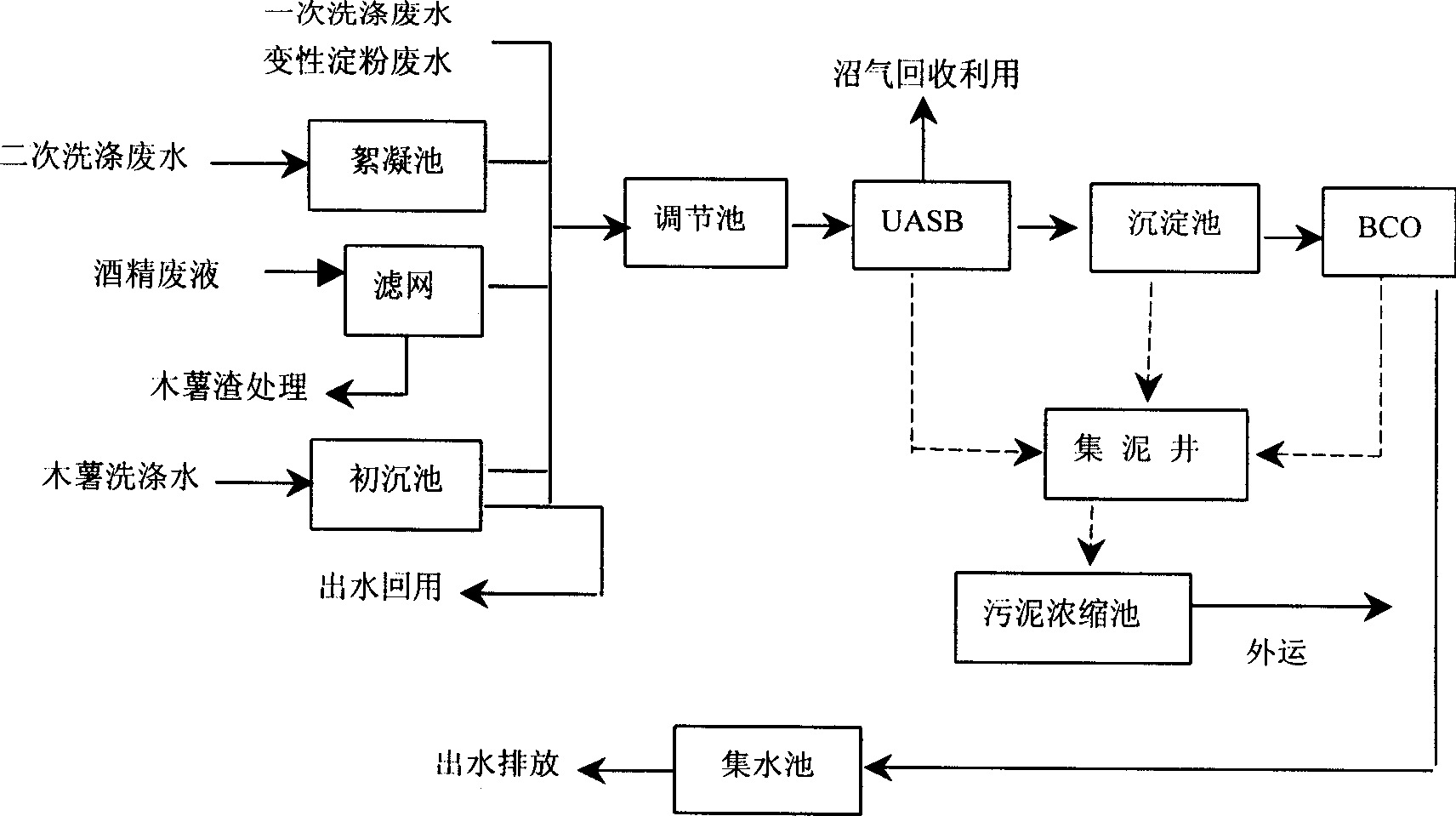

[0039] The cassava cleaning water in cassava starch production enters the primary sedimentation tank to remove most of the mud and sand, and then is recycled for cassava cleaning. When the COD concentration in the wastewater is close to 1000mg / L, it enters the homogeneous adjustment tank.

[0040] Tapioca starch primary washing separation wastewater and modified starch production wastewater directly enter the regulating tank.

[0041] Secondary washing and separation of cassava starch wastewater is firstly pretreated by an air flotation tank to separate and remove residual starch particles in the wastewater, 60% of COD in the wastewater is removed, and the effluent enters the regulating tank.

[0042] Alcohol production wastewater is sedimented to remove slag, and the supernatant in the sedimentation tank is taken for treatment, so as to make the SS value of the wastewater less than 100mg / L. According to the general practice of alcohol production workshops, the cassava residue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com