Treatment process for discharging metribuzin wastewater in compliance with standard in coordination with salt recycling and running method of treatment process

A treatment process and wastewater treatment technology, which is applied in natural water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of long residence time, difficult to meet discharge standards, low degradation rate, etc., and achieve resource conservation, Effect of reducing pollution and reducing biological toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

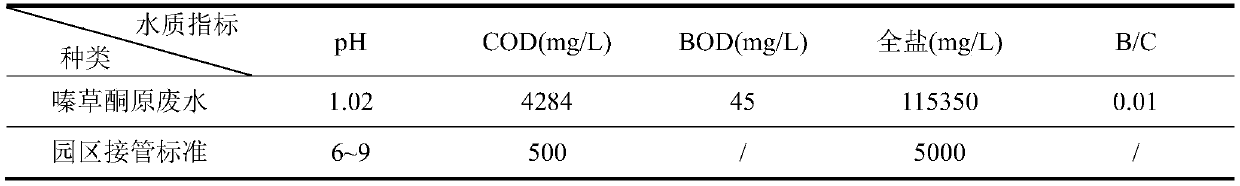

[0046] As shown in Table 1, the water quality of metrizone wastewater produced in the workshop of a pesticide enterprise in Binhai, Jiangsu Province belongs to high-salt, high-COD and refractory biodegradable wastewater.

[0047] The instruments and equipment of wastewater treatment in this embodiment include: advection grit chamber; intermediate pond; resin adsorption-desorption tower; pH neutralization pond; MVR evaporator; pH adjustment pond; Fenton oxidation tower; ; Vertical centrifuge; Single cone vacuum dryer; Distillation tower.

[0048] Table 1 Water quality of azimidone wastewater and park takeover standards

[0049]

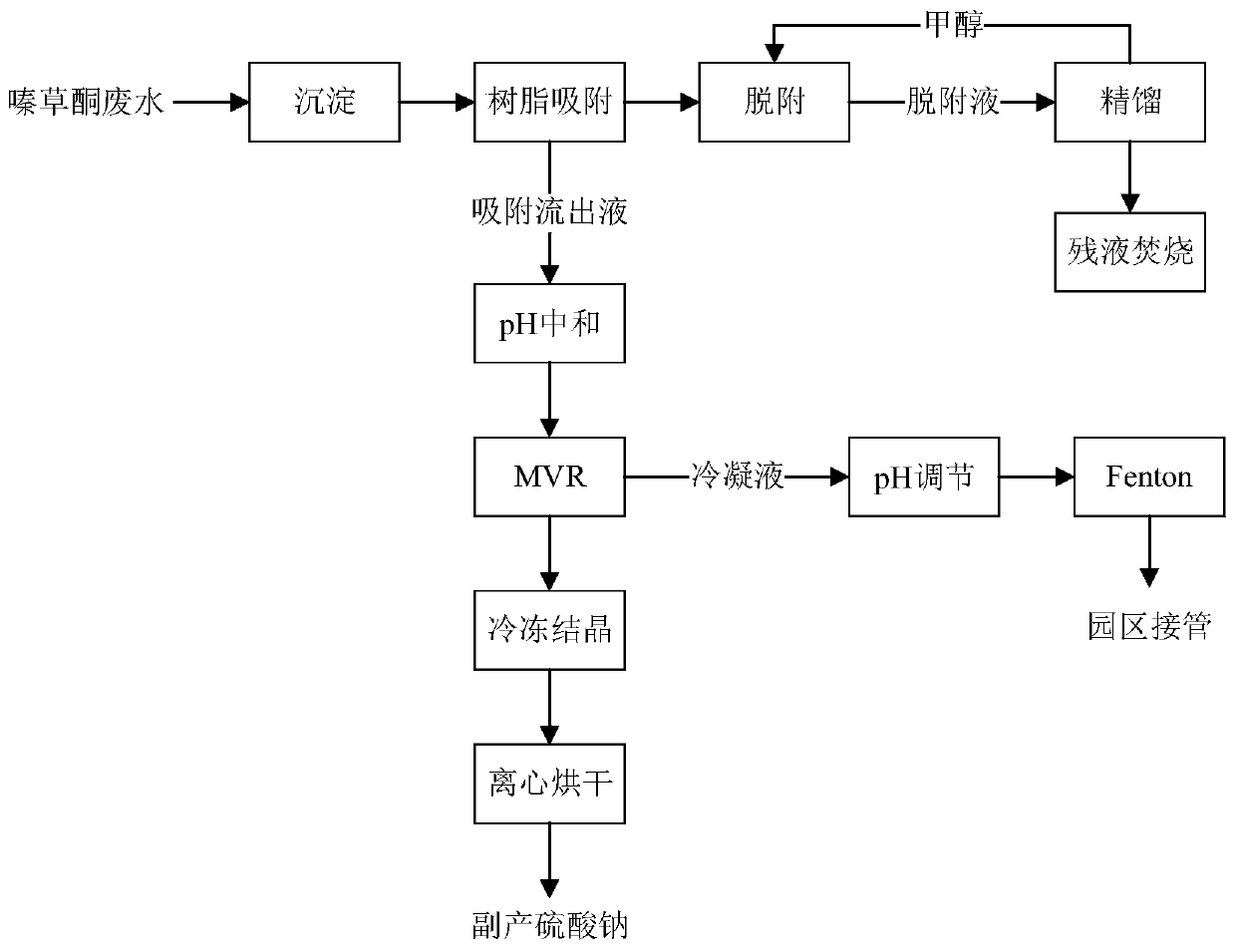

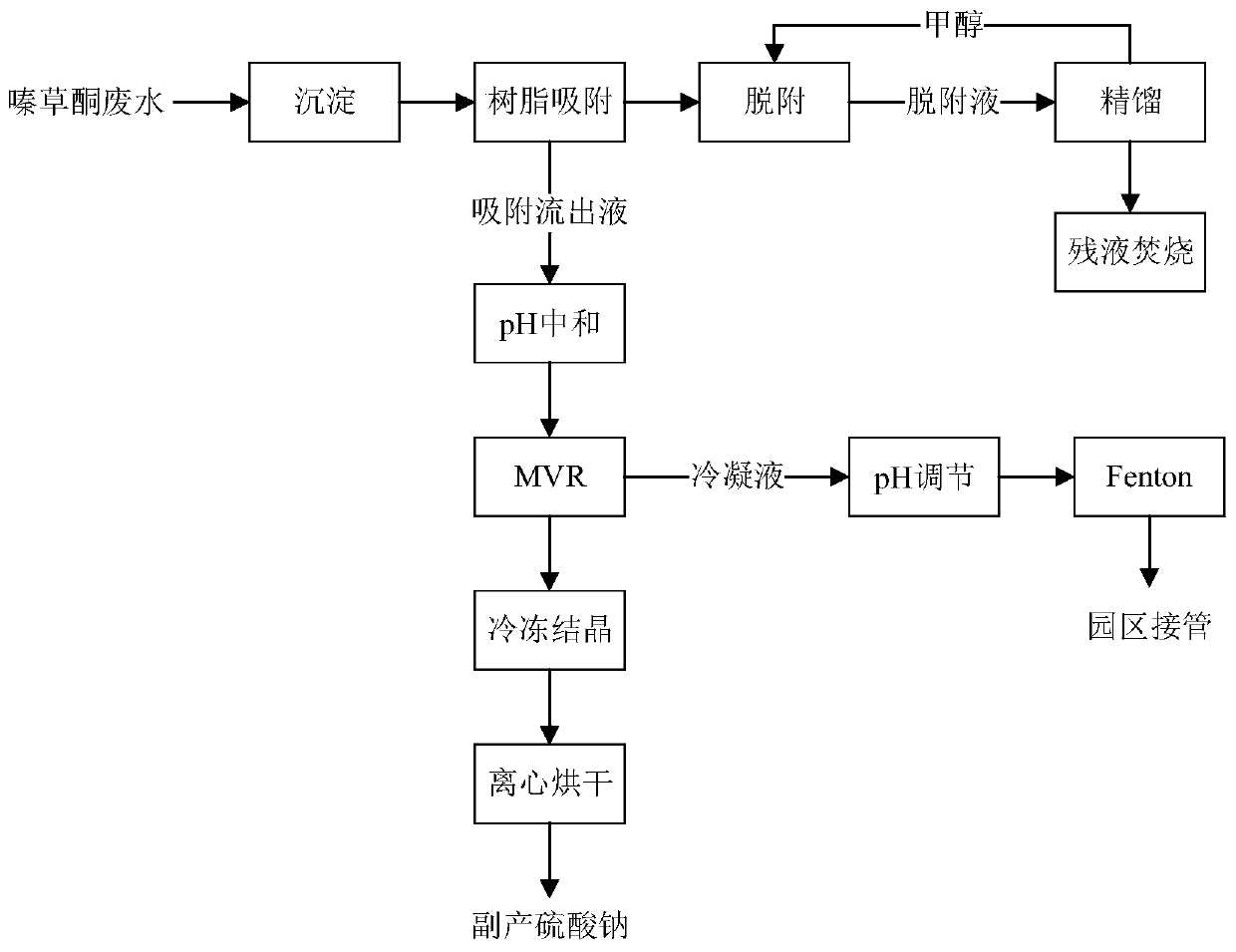

[0050] Such as figure 1 As shown, the concrete technological process of the wastewater treatment of the present embodiment is as follows:

[0051] The high-salt, high-COD, and biodegradable azimidone wastewater is passed through the advection grit chamber to remove particulate solid impurities in the wastewater and then flows into the intermediate...

Embodiment 2

[0065] Basically the same as in Example 1, the metrizone wastewater produced in the workshop of a certain pesticide enterprise in Binhai, Jiangsu was also selected as the mezone wastewater in this example, and its water quality indicators are shown in Table 1. The difference is that the process parameters have changed.

[0066] Specifically, the concrete technological process of the wastewater treatment of the present embodiment is as follows:

[0067] High-salt, high-COD, and refractory-biodegradable azimidone wastewater passes through the advection grit chamber to remove particulate solid impurities in the wastewater and then flows into the intermediate pond. Gravity sand discharge is started once every 2 days for sludge discharge; the effluent from the middle pool is pumped into the resin adsorption-desorption tower, wherein the resin particle size filled in the resin adsorption-desorption tower is 0.1mm-0.2mm, and the resin filling volume is 1 / 3 of the effective volume of...

Embodiment 3

[0081] Basically the same as in Example 1, the metrizone wastewater produced in the workshop of a certain pesticide enterprise in Binhai, Jiangsu was also selected as the mezone wastewater in this example, and its water quality indicators are shown in Table 1. The difference is that the process parameters have changed.

[0082] Specifically, the concrete technological process of the wastewater treatment of the present embodiment is as follows:

[0083] High-salt, high-COD, and refractory-biodegradable azimidone wastewater passes through the advection grit chamber to remove particulate solid impurities in the wastewater and then flows into the intermediate pond. The flow rate of the advection grit chamber is controlled at 0.2m / s, and the residence time is 1.5min. Gravity sand discharge is started once a day for sludge discharge; the effluent from the middle pool is pumped into the resin adsorption-desorption tower, wherein the resin particle size filled in the resin adsorption-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com