Patents

Literature

154 results about "Single cone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

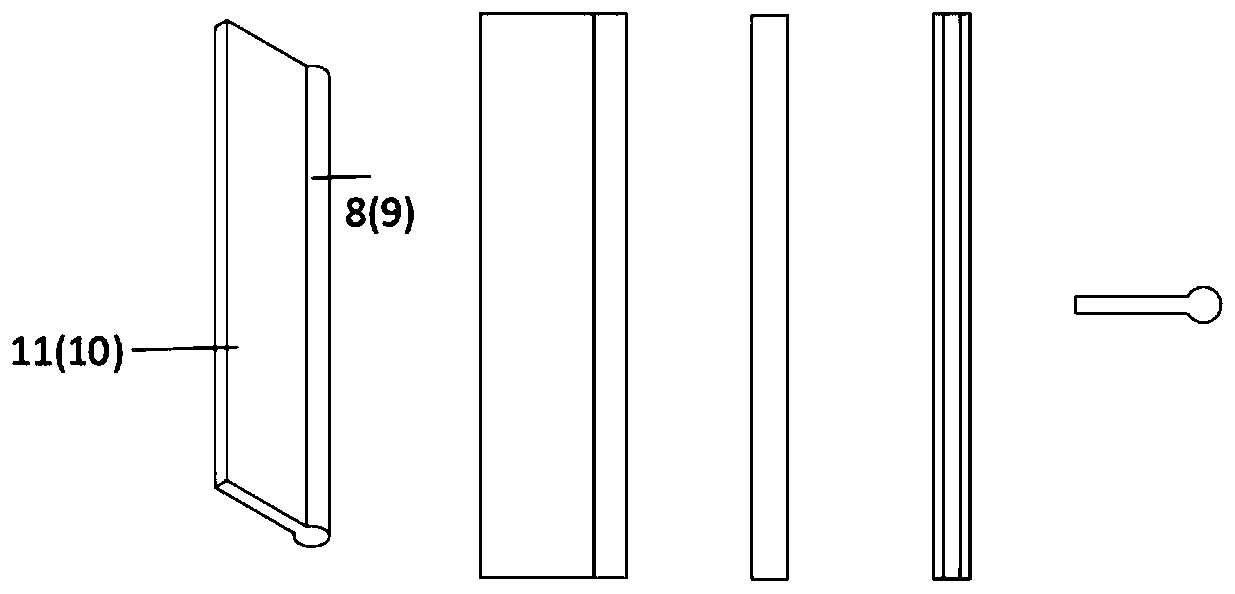

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

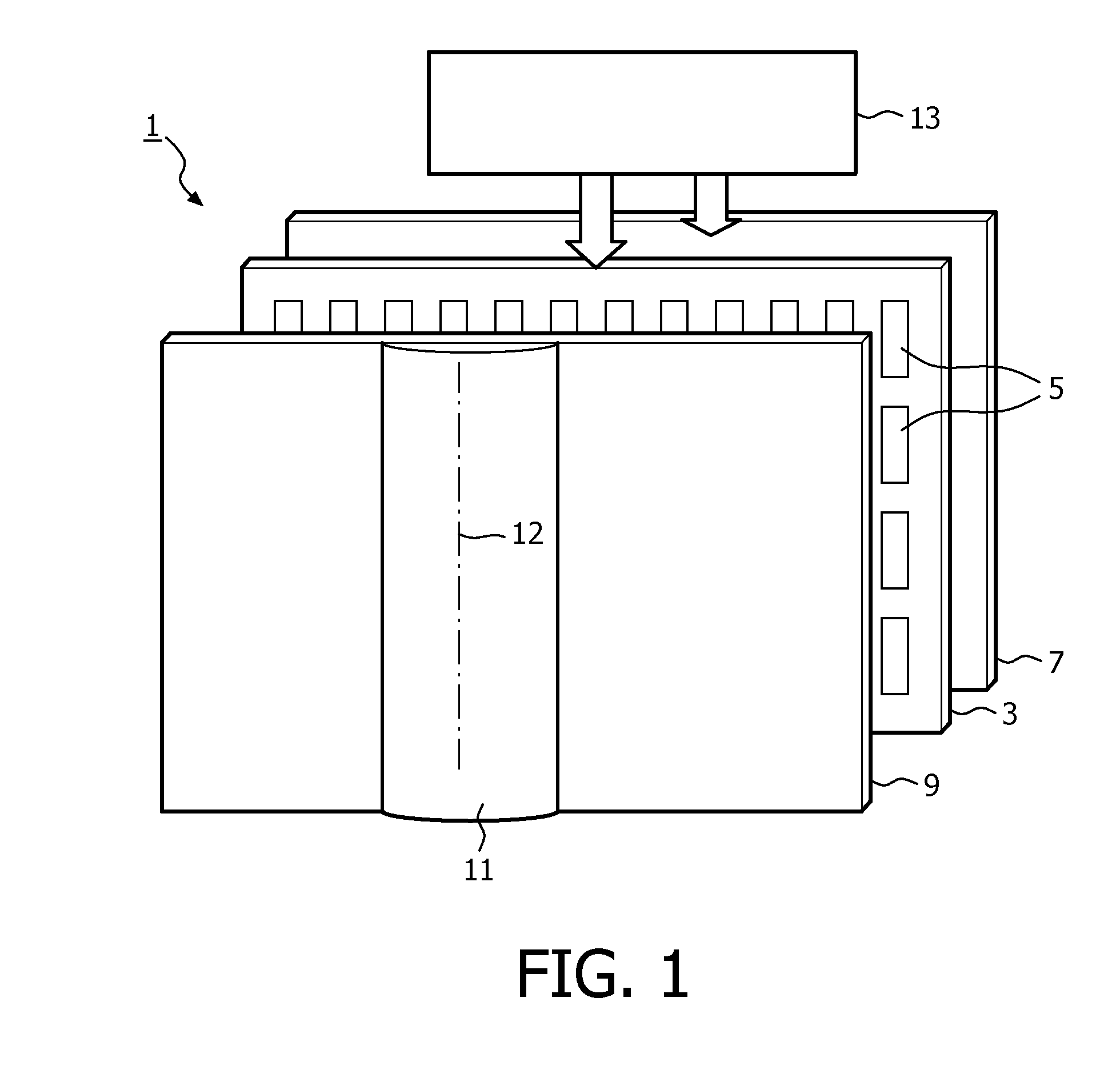

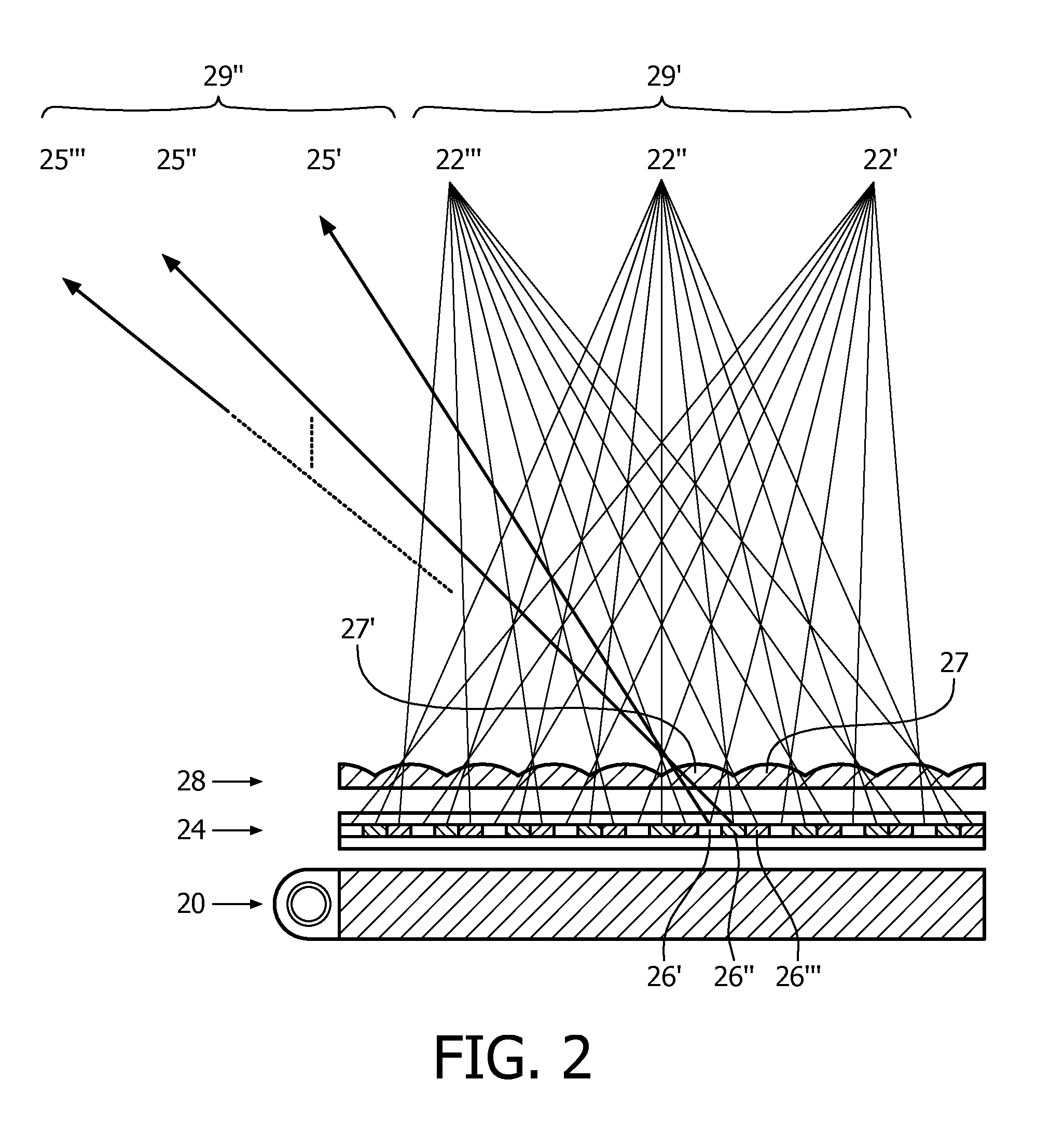

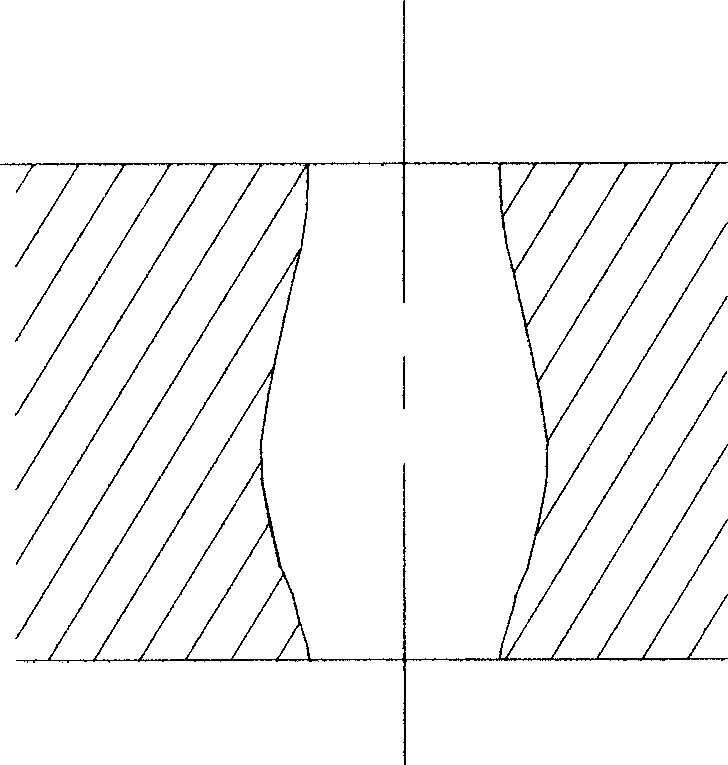

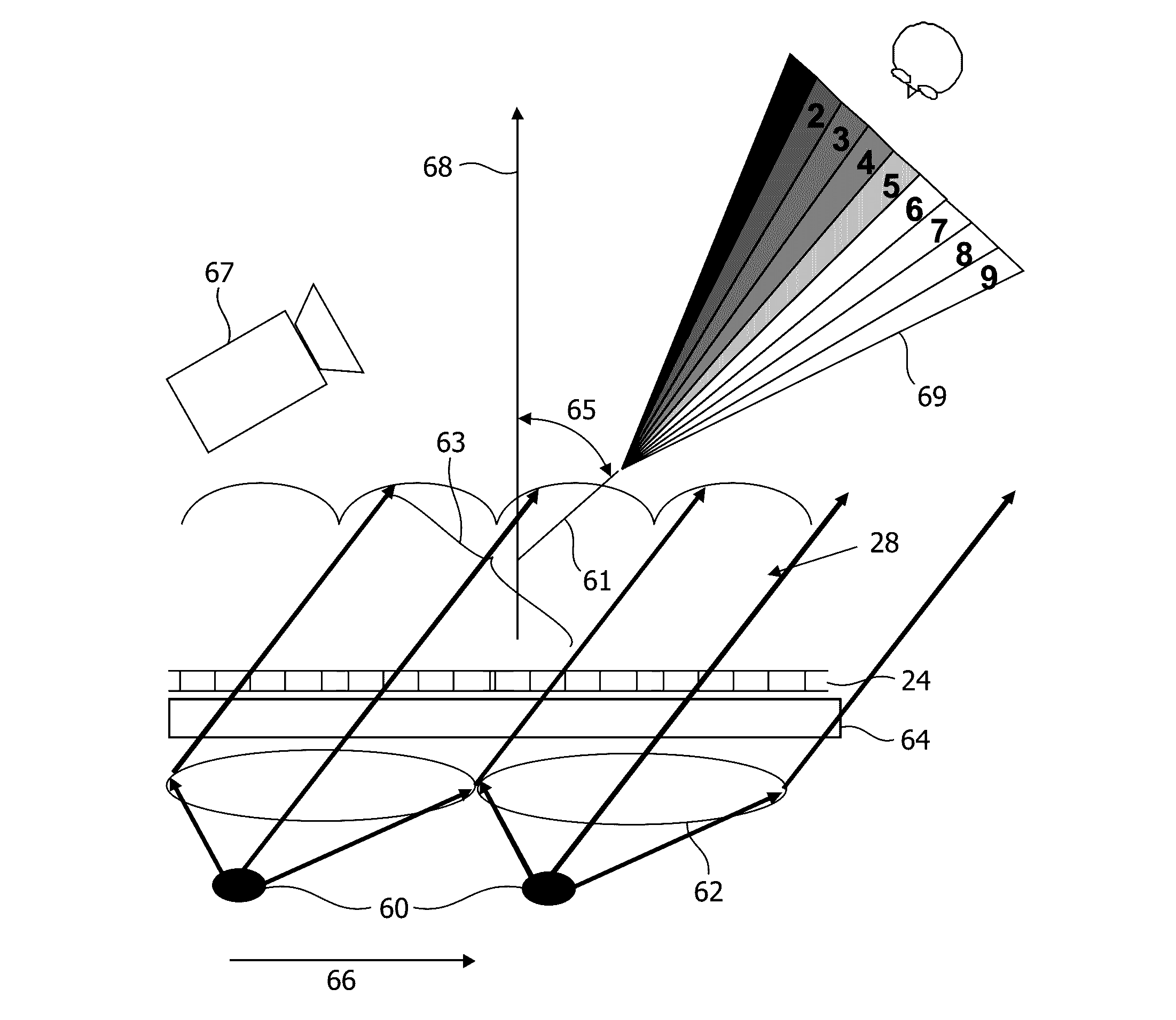

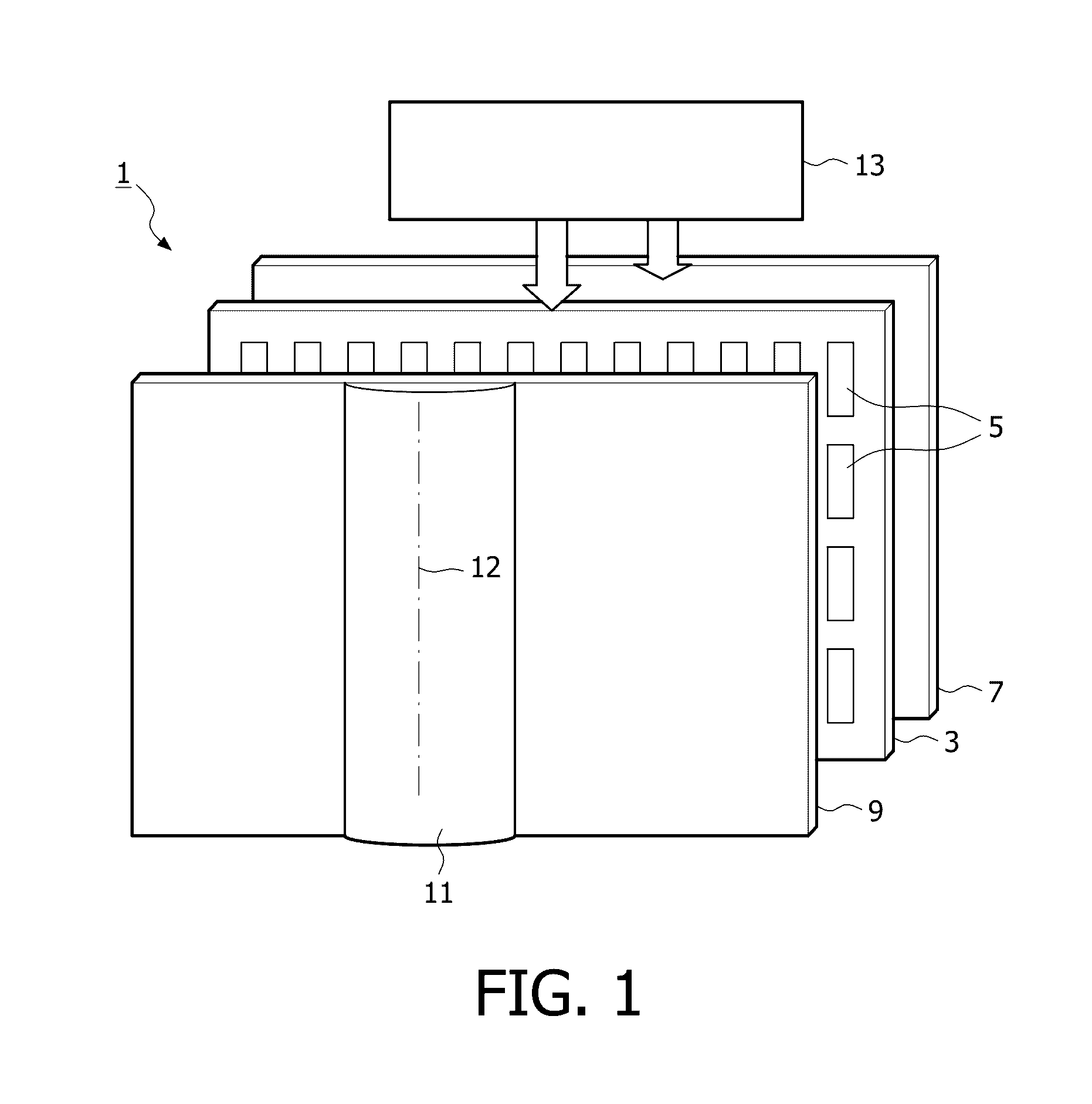

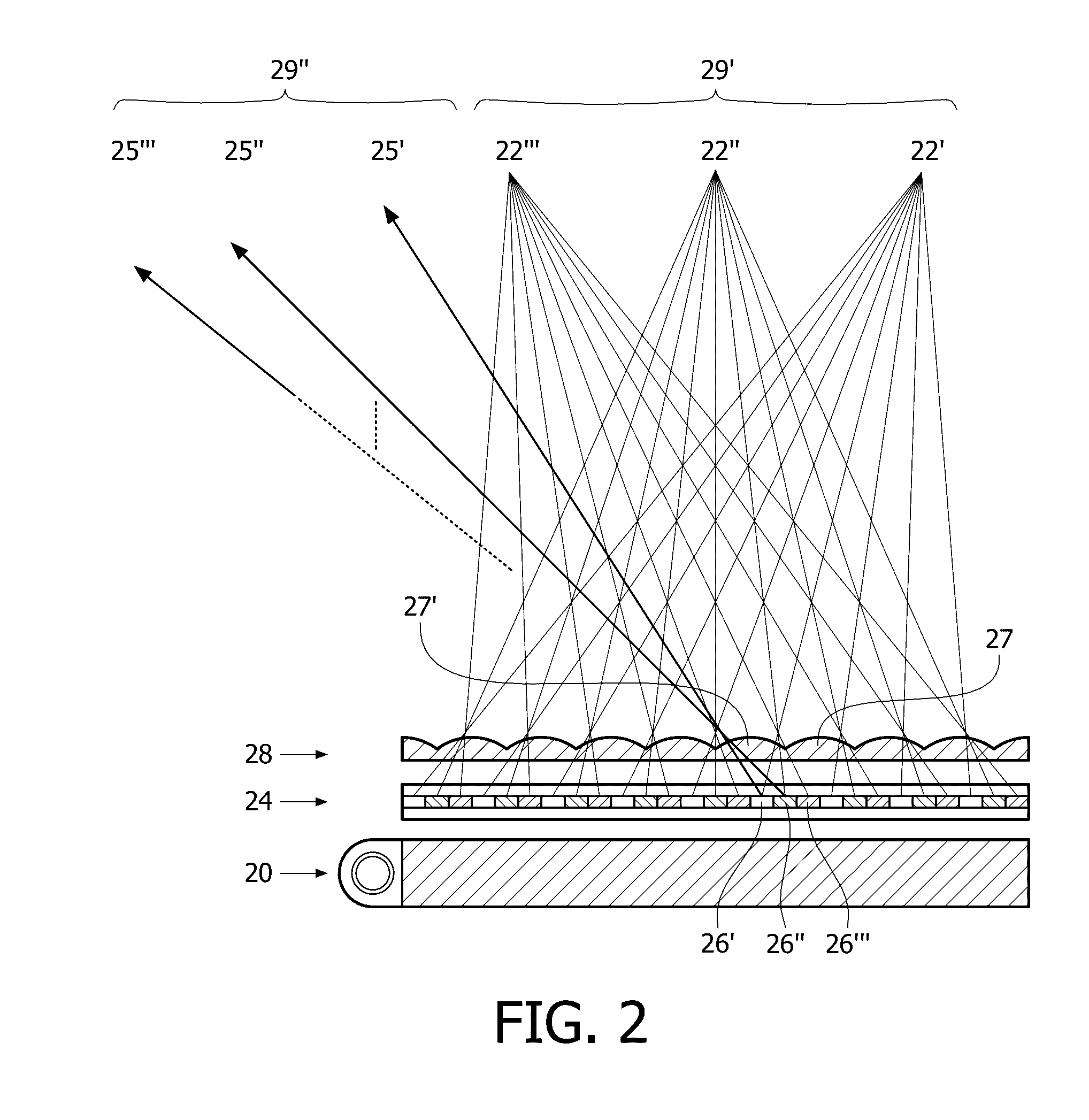

Multi-view display device

InactiveUS20130057159A1Reduce weightImprove matchElectric light circuit arrangementSteroscopic systemsComputer graphics (images)Display device

A multi-view display device comprises a pixellated display panel and a backlight comprising an arrangement of light sources (30), wherein each light source, when turned on, illuminates an associated region of pixels of the display panel. A display controller is adapted to control the pixellated display panel and the arrangement of light sources such that a partial display output is provided comprising simultaneously a set of at least three 2D views with no repetition of individual 2D views. This arrangement provides an output with controlled illumination direction of the pixels so that view repetitions are avoided. The output can be a single cone of views, and the location from which the cone of views can be viewed depends on the relationship between the light sources of the backlight which are activated and the display panel.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

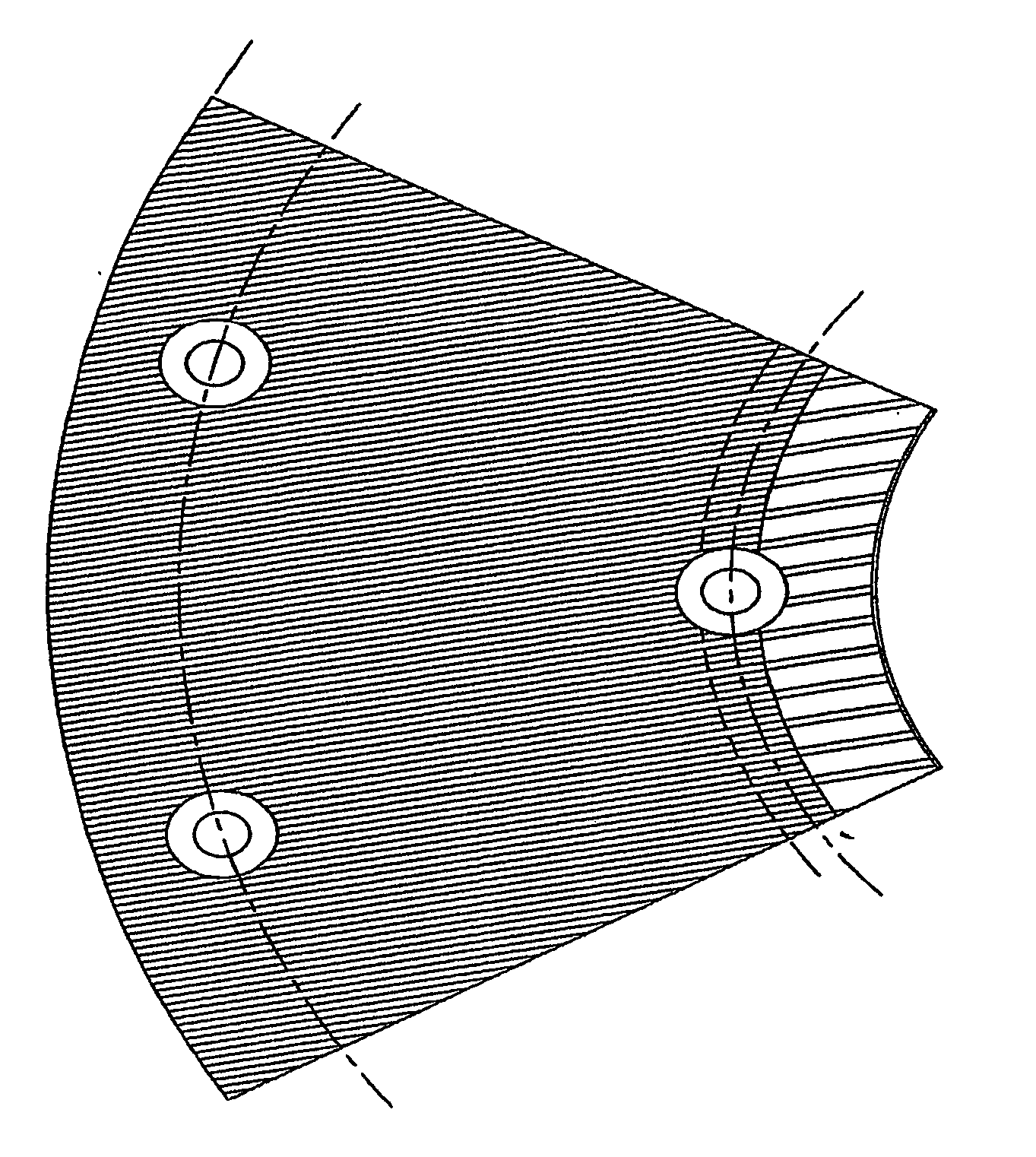

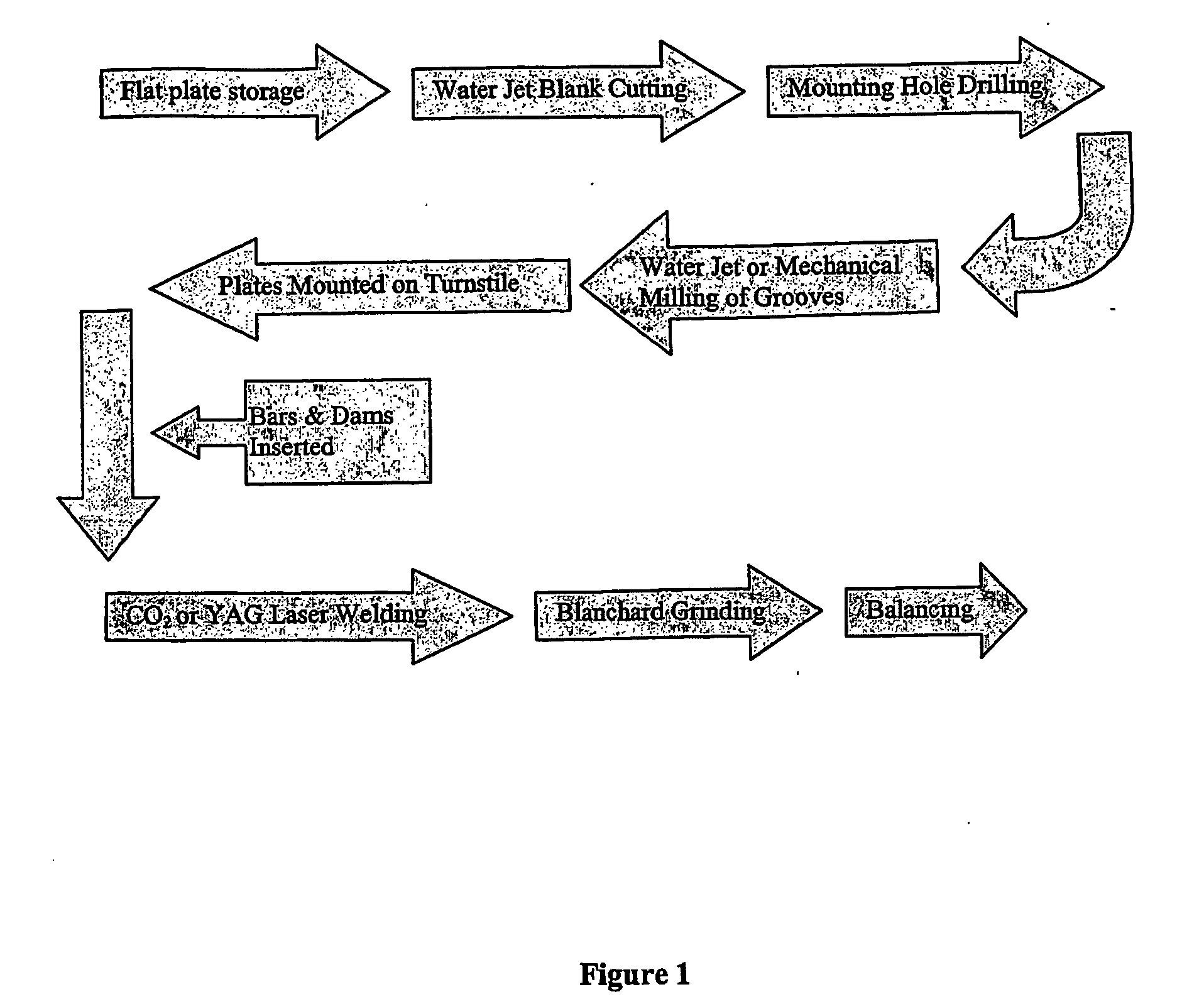

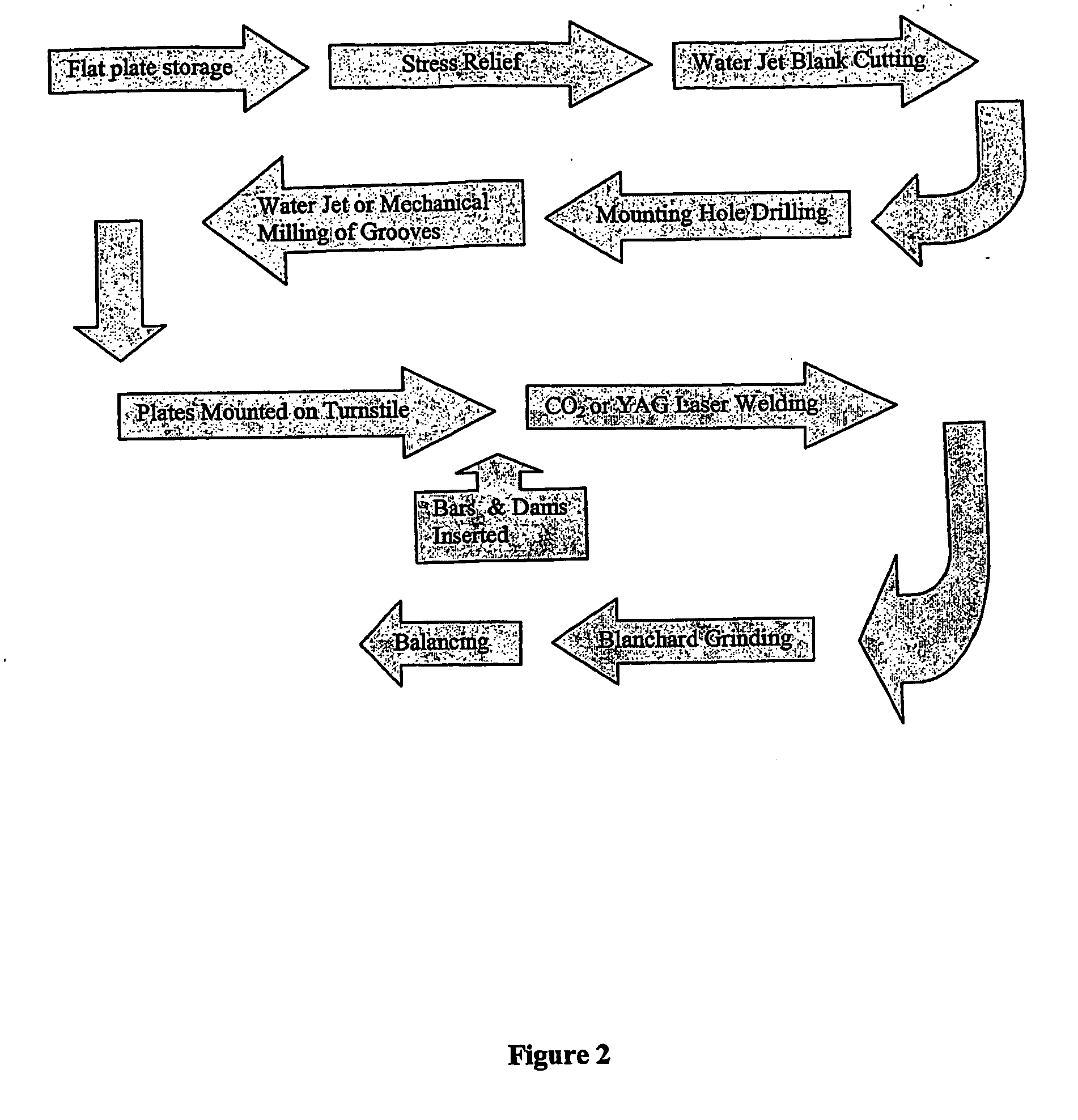

Method of manufacturing refiner elements

InactiveUS20050161542A1Life of element can be lengthenedMaximizes developmentCocoaWelding/soldering/cutting articlesEngineeringCryogenic treatment

An improved method for the manufacture of a solid disc rotor and / or rotor segment for a single disk refiner, double disk refiner, multi-disk refiner, single cone refiner, or a double cone refiner. The invention comprises a plurality of blades spaced apart by recessed locations of a base plate. Either a water jet milling machine or a horizontal gang mill or both may be used. The blades comprise appropriately dimensioned cold rolled and cryogenically stabilized stainless steel or other appropriate stock of the appropriate hardness required by the application. The blades fit into respective locations in the base. The invention is further characterized by a continuous laser weld (85) along either side of each respective blade at its junction with the base, a variety of possible blade and base materials, and the use of one or more of cryogenic treatment, water cut jetting and water jet milling technologies.

Owner:THEUT PATRICK J

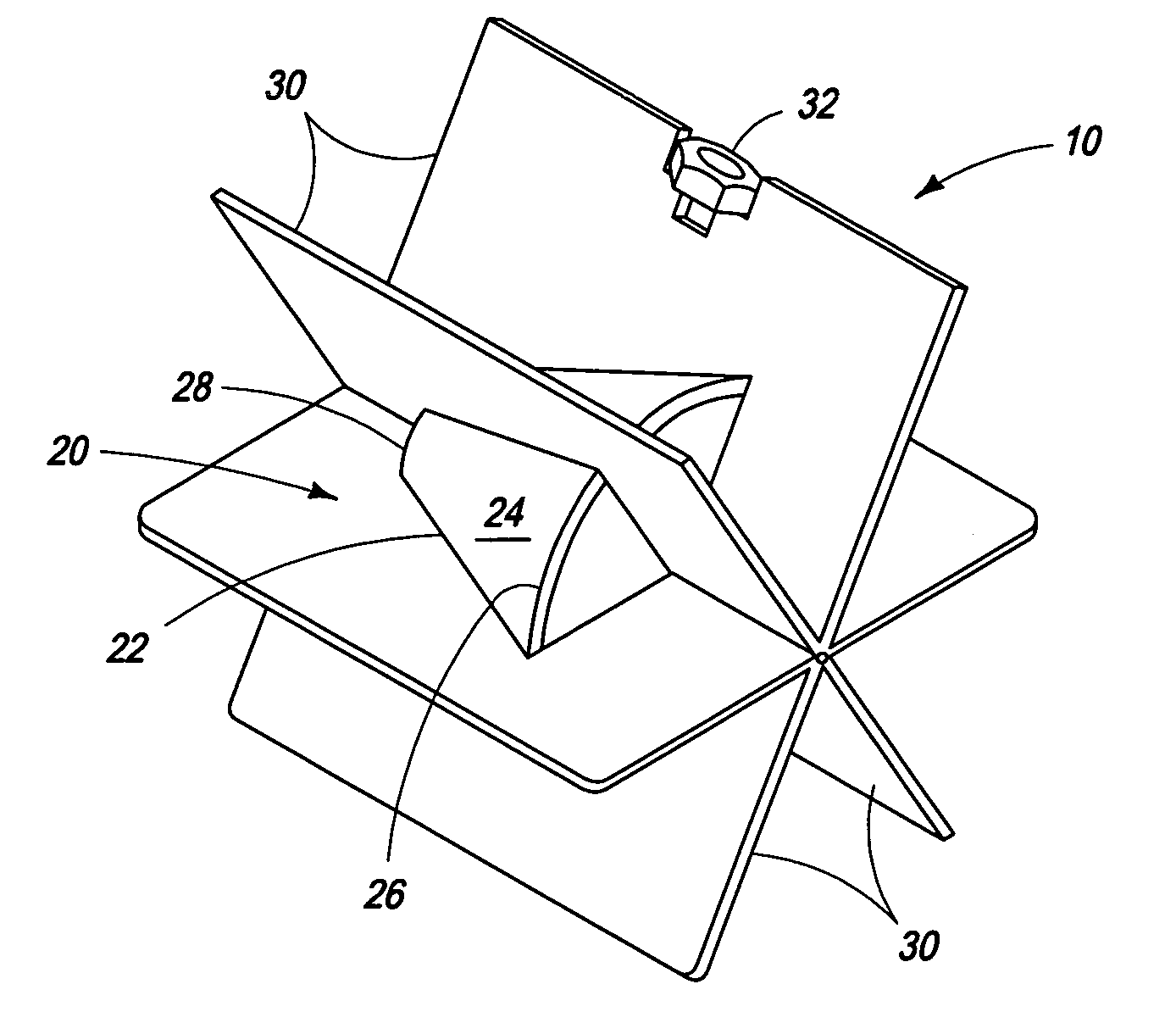

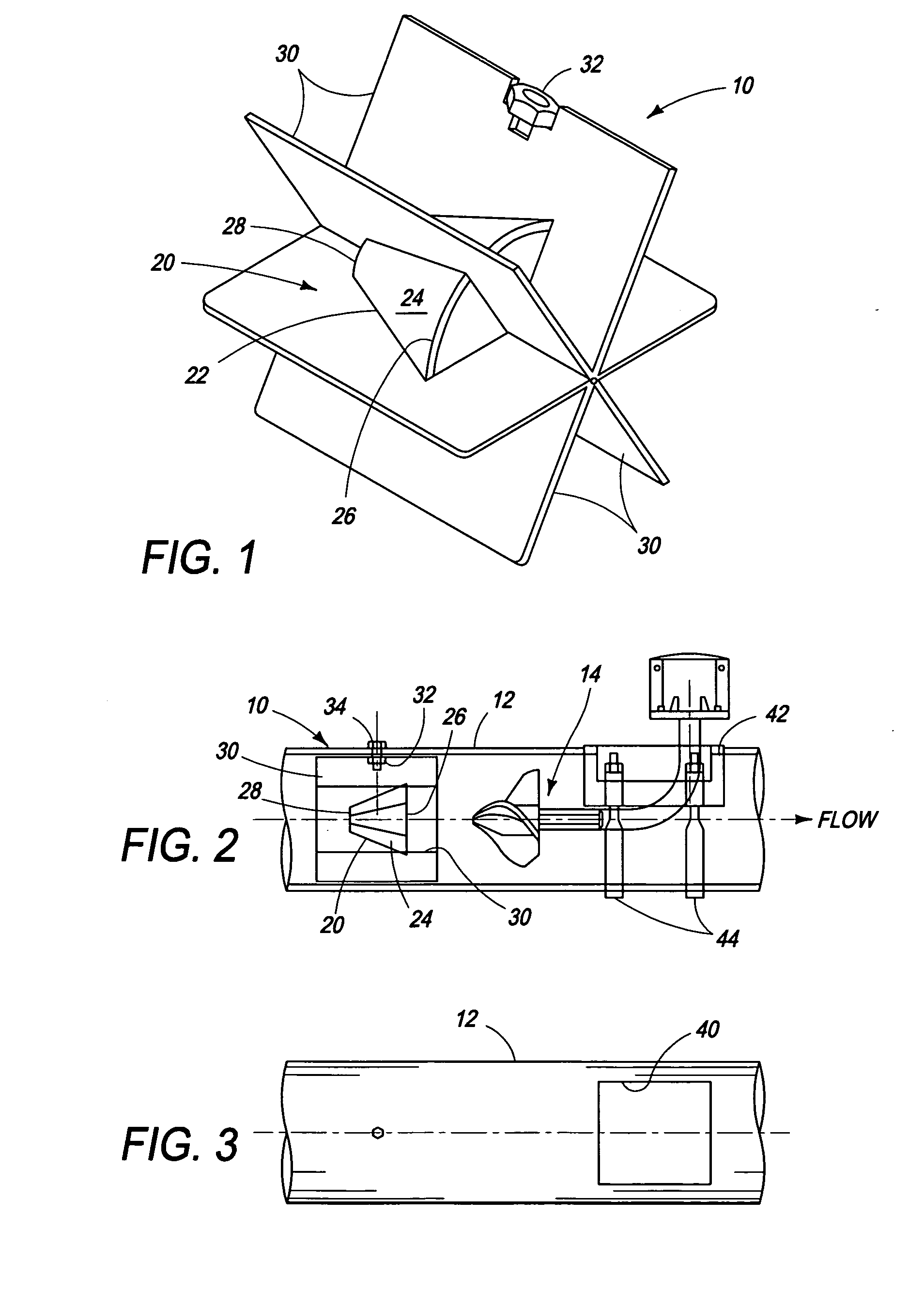

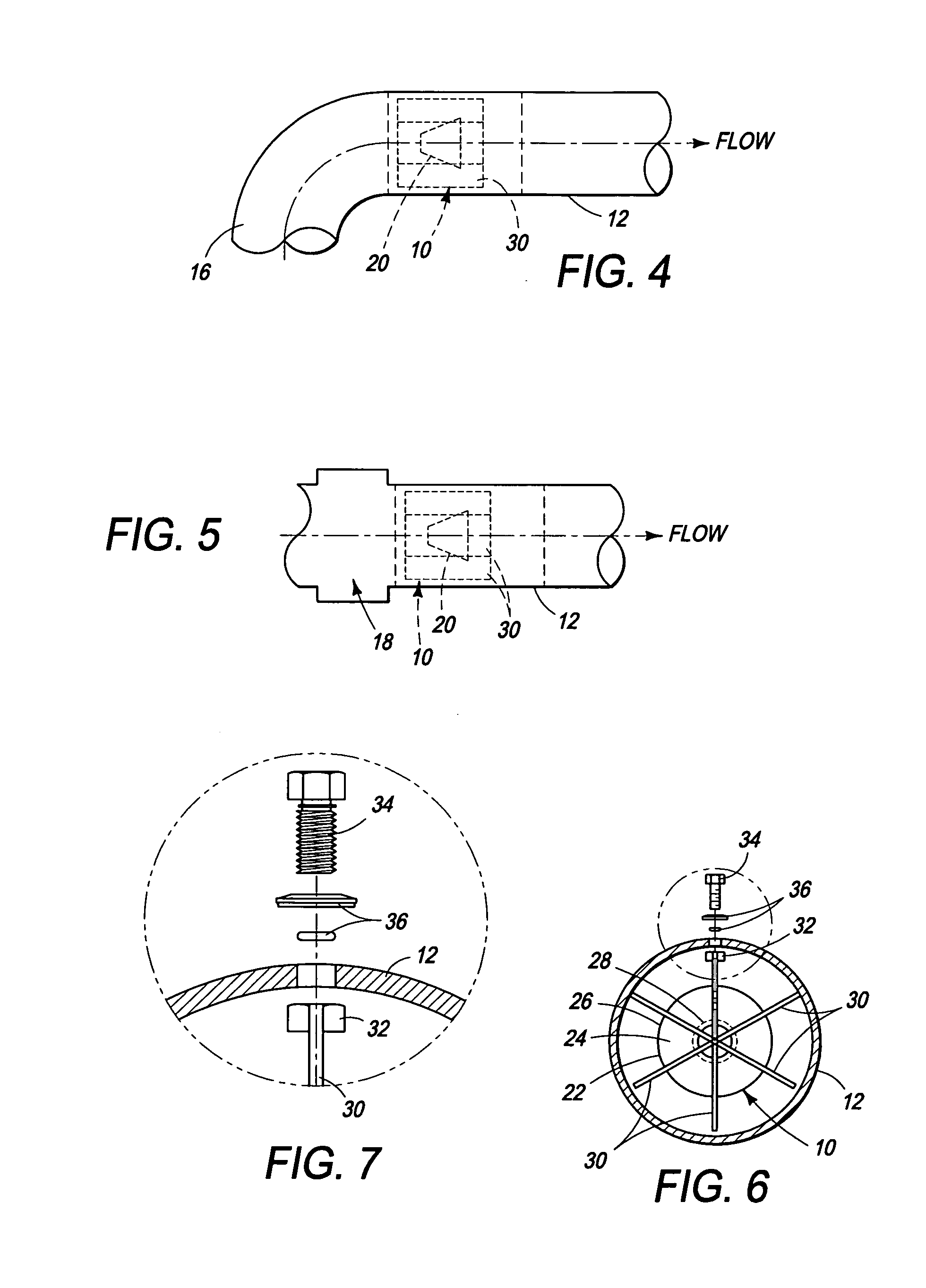

Flow straightening apparatus

ActiveUS20100224275A1Cheap constructionAccelerated settlementFlow mixersFluid dynamicsEngineeringWater irrigation

An apparatus for straightening fluid flow in a conduit or pipeline, such as an irrigation pipeline, resides in an integral assembly of a conical fluid flow displacement member effective to substantially lineralize the velocity profile of fluid flowing through the pipeline and a plurality of circumferentially spaced vanes extending longitudinally and radially of the conical member and effective to mitigate swirl and eccentric velocity profiles in the flowing fluid. The conical member consists simply of a single cone that is centered in the pipeline by the vanes. A bolt extending through the wall of the pipe and threaded into a nut on a vane secures the straightener in the line.

Owner:MCCROMETER

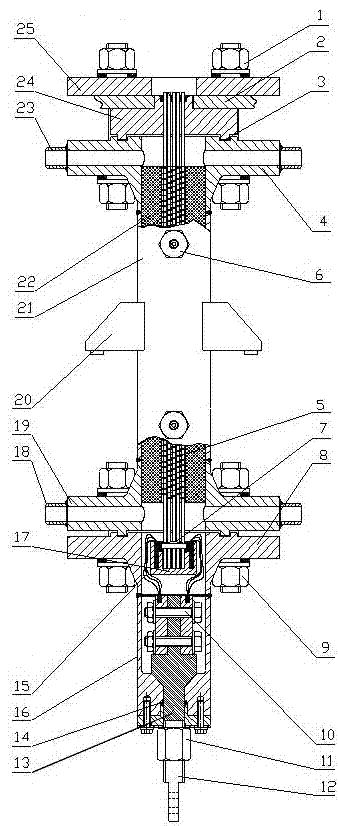

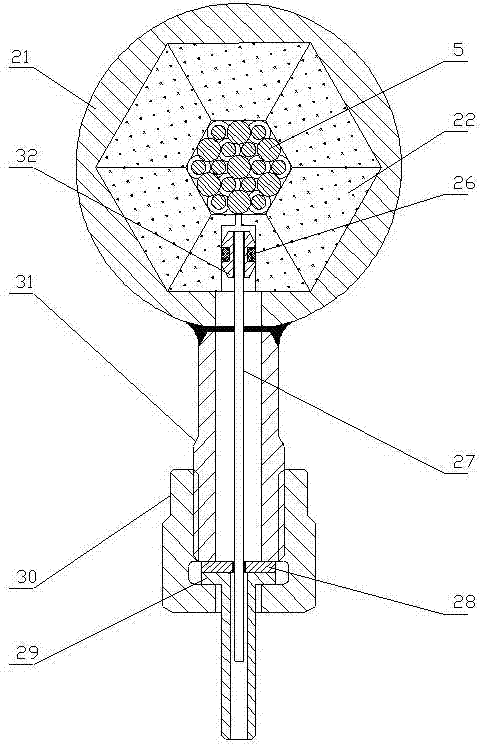

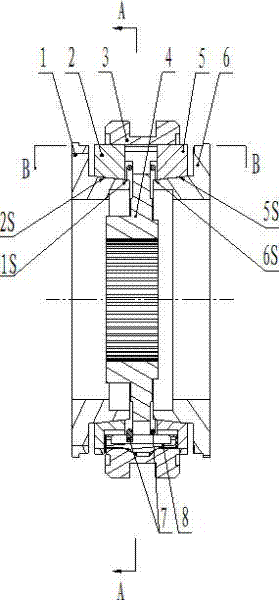

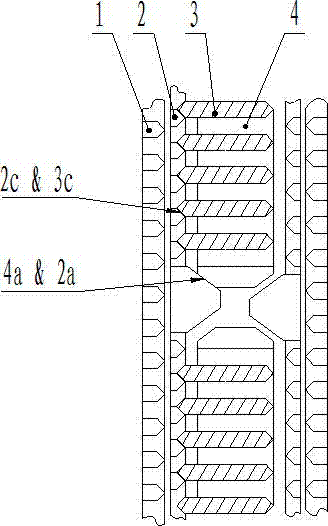

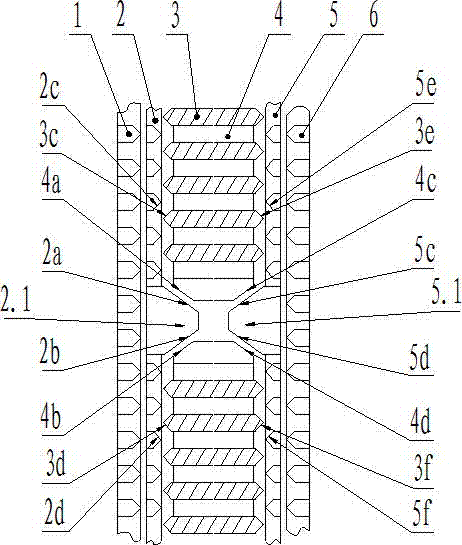

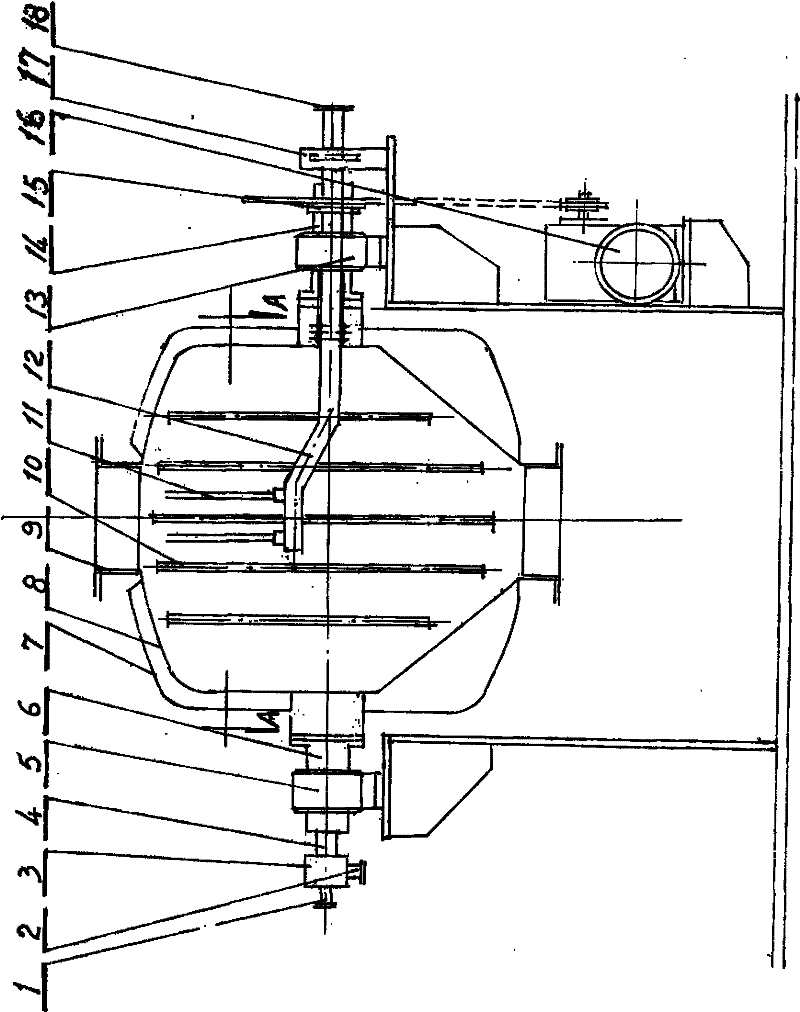

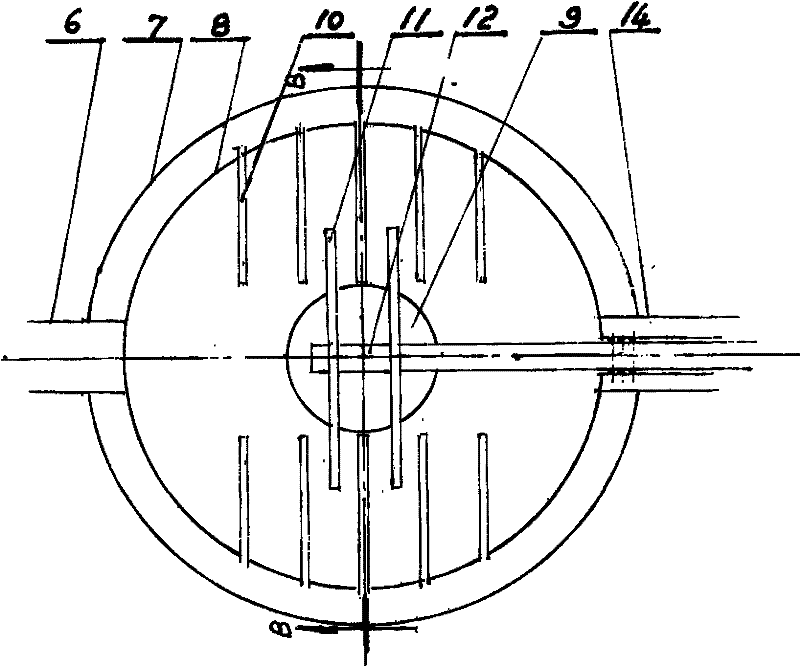

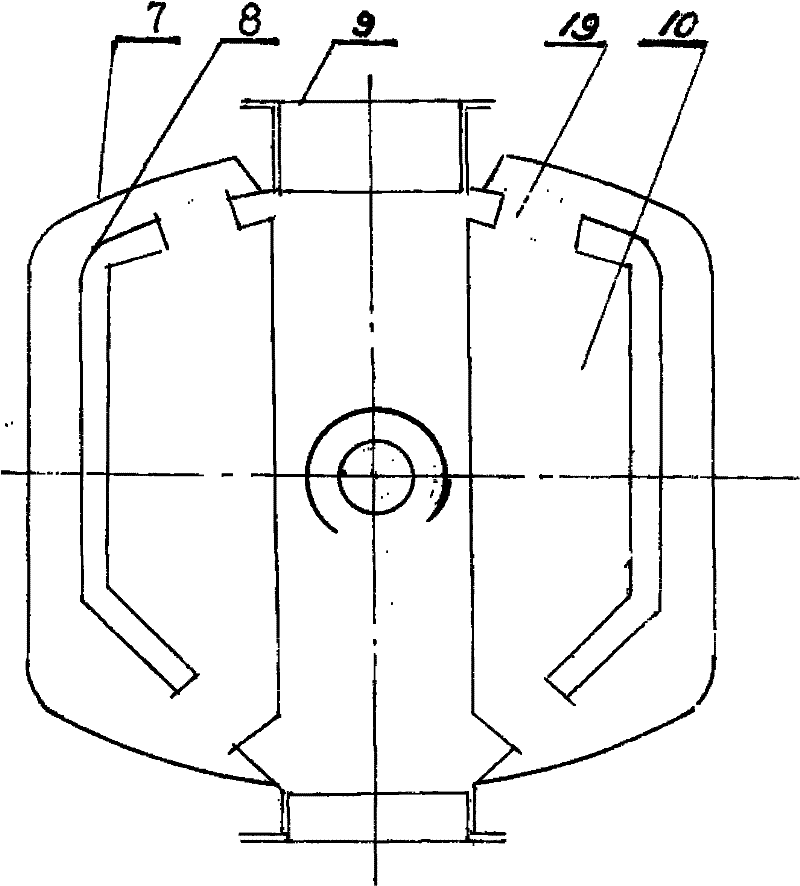

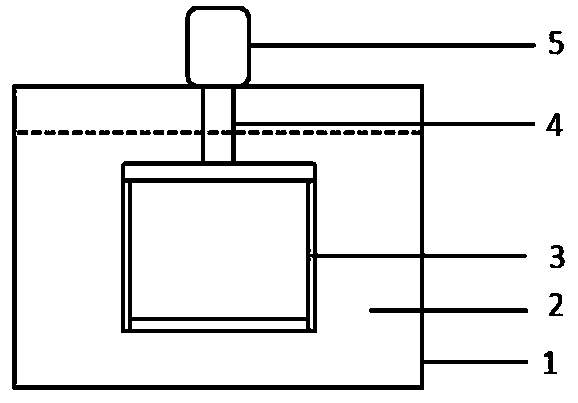

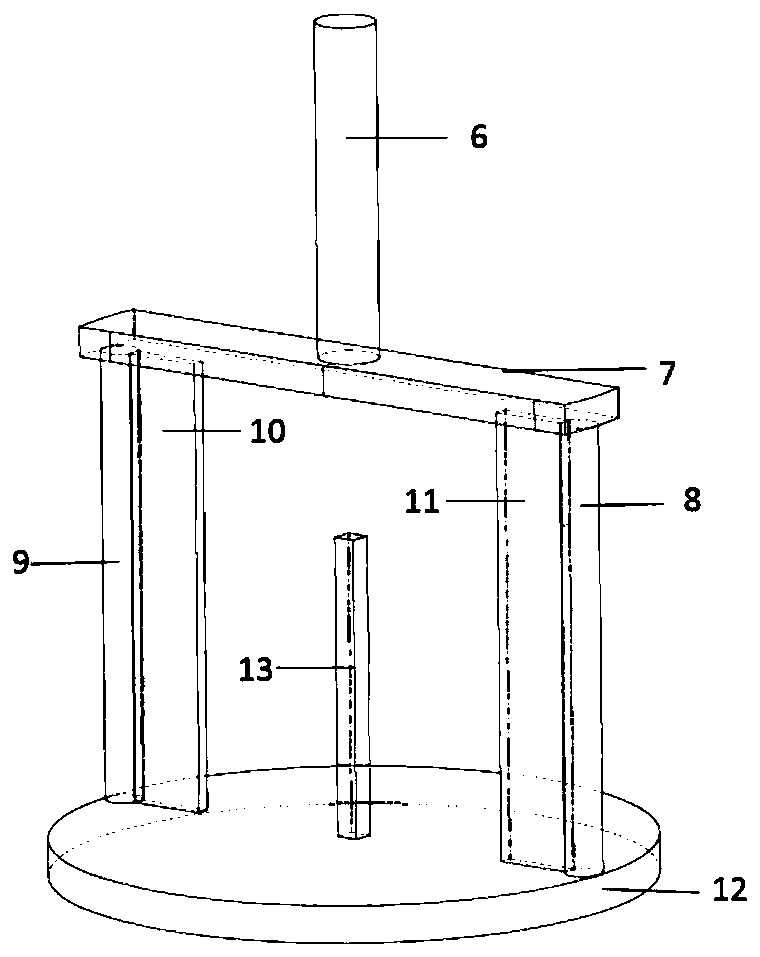

Spherical flue element equivalent model thermotechnical waterpower experimental apparatus

ActiveCN102855802AReflect thermal hydraulic characteristicsRealize electric heatingEducational modelsThermal expansionEngineering

The invention discloses a spherical flue element equivalent model thermotechnical waterpower experimental apparatus comprising a pressure-bearing component, an electric heating component, an insulation component, a seal component, a pressure measurement component and the like, and field assembly and disassembly can be realized between the components. According to the spherical flue element equivalent model thermotechnical waterpower experimental apparatus, a banded fin thin rod bundle electric element is taken as an equivalent model structure of the spherical flue element, electrical heating method is realized, single-phase water flow and heat transfer experiment can be developed, and thermal-hydraulics of the spherical flue element can be reflected. The pressure measurement component can be assembled and disassembled on spot, consumables such as an O-shaped seal ring and a lead pressure pipe are convenient to replace, thereby reducing loss and cost. A grid spacer plays a role in transverse orientation for the banded fin thin rod bundle electric element, and a single-cone structure of the grid spacer can guide a plurality of the banded fin thin rod bundles to assemble, thereby reducing the difficulty of assembling and improving the efficiency of assembling. Copper braid is adopted to connect a lower conducting element and a lower conductive contact to realize flexible connection, so that the problem caused by electric component thermal expansion is effectively solved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

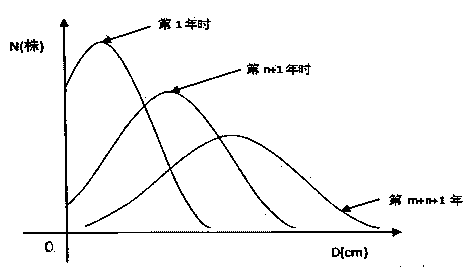

Forest stand growth modeling method based on relation model

InactiveCN104166748AEfficient and precise constructionFlexible constructionSoftware simulation/interpretation/emulationSpecial data processing applicationsRelational modelNormal density

The invention relates to a forest stand growth modeling method based on a relation model. The method includes the following steps that (1) tree trunks are established, and the trunks are considered as models respectively formed by a single cone frustum or multiple cone frustums; (2) bending of the trunks is controlled, the bending degree of the trunks is controlled by adjusting the relative positions of the cone frustums, the shapes of the tree trunks are fit into a parabola set, and every two adjacent cone frustums are processed in a smooth splicing mode; (3) the angles of elevation of branches are controlled, the branches are set on the trunks, the angles of elevation of the branches are set to obey the normal distribution law, and the initial angles of elevation of the branches are determined through a probability density function and a random function; (4) the azimuth angles of the branches are controlled, and the azimuth angles of the branches are controlled through a chaos function; (5) leaves are drawn, the leaves are set on the branches, and image vectorization and triangularization subdivision or leave photo transparency efficient processing are adopted; (6) a tree growth model is established; (7) a forest stand growth model is established. Compared with the prior art, the forest stand growth modeling method has the advantages that modeling is performed based on a small amount of actually measured data of trees, trees and forest stands can be vividly simulated while efficient and fast modeling is achieved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

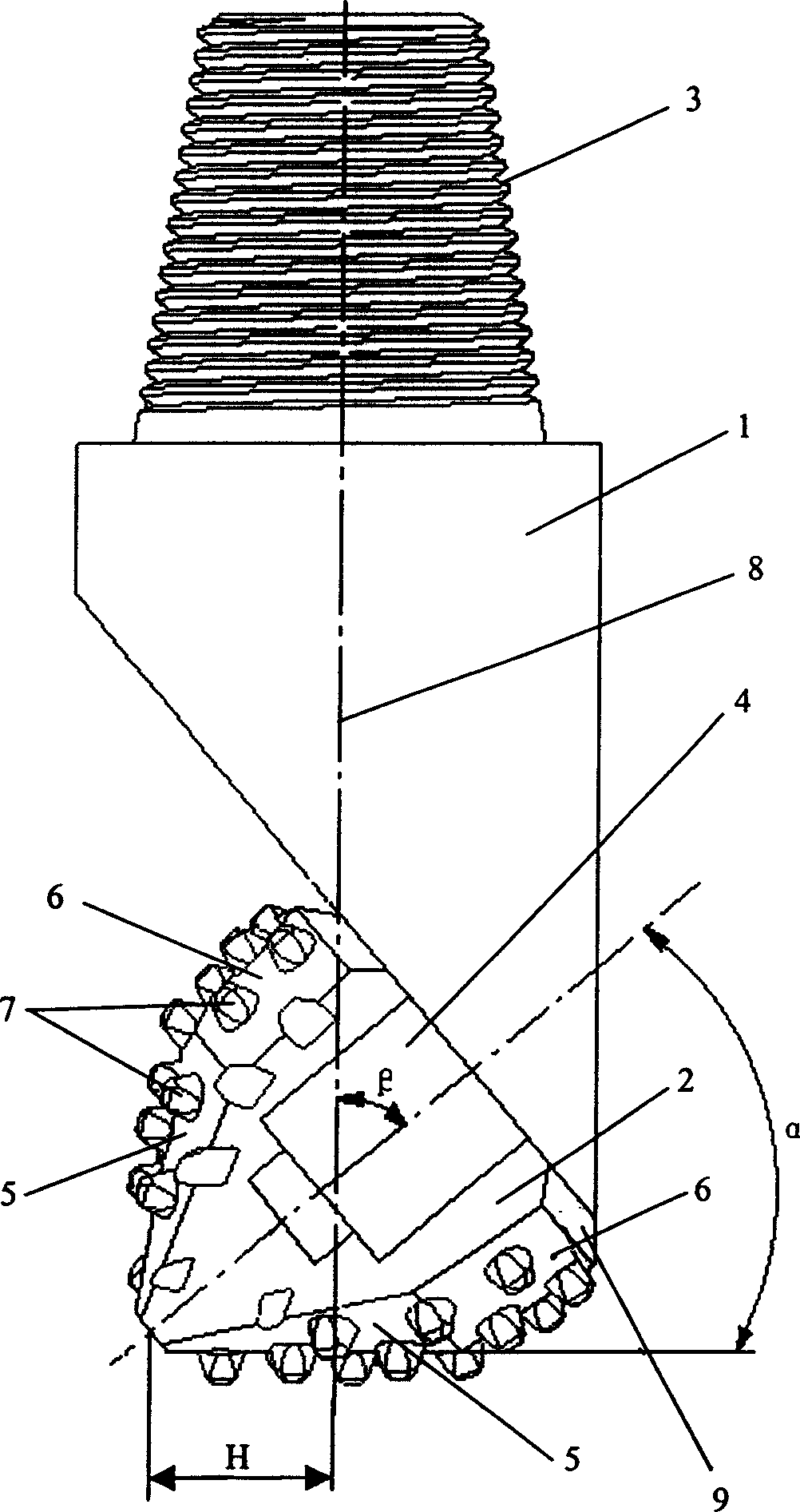

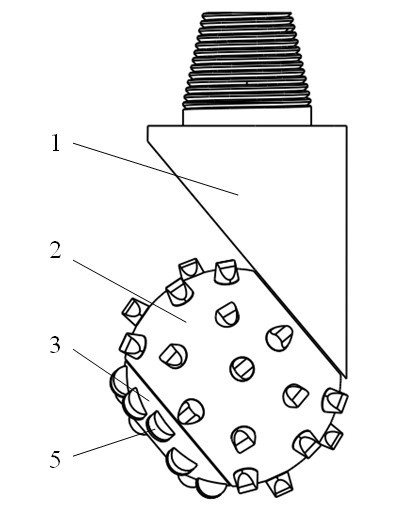

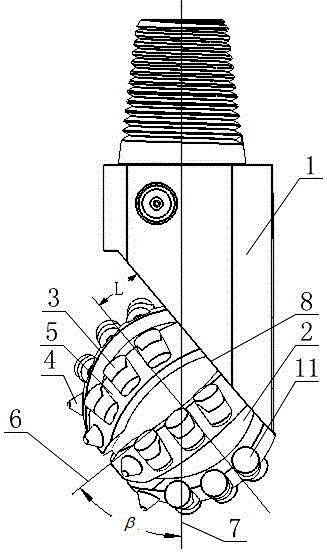

Cone single roller bit

The present invention relates to a single cone bit used for petroleum well drilling and geological prospecting field. The single cone bit includes a bit body and a cone. The bit body is connected to the cone through a bias bit leg journal at lower end. It is characterized in that the cone surface is composed of a main distribution tooth surface and at least one auxiliary distribution tooth surface; the main distribution tooth surface is cone surface or cone ball surface, the auxiliary distribution tooth surface is ball surface or truncated cone surface. The main distribution tooth surface and the auxiliary distribution tooth surface are mounted with teeth. The invention adopts a cone shape combined by main and auxiliary distribution tooth surfaces, and can reduce the tooth scrape distance, make the cutting load of each part of teeth of the cone be reasonably distributed in order to reduce the abrasion of the teeth and reinforce the impact effect of the teeth to make the bit can be adapted to break rigid ground and prolong the effective use life of the bit. The invention can increase the cone surface, dispose plurality of teeth, and can make the reverse composite force of the rock for the cone bit adjacent to the bit axes; the invention also can satisfy the requirements for drilling different ground.

Owner:SINOPEC OILFIELD EQUIP CORP

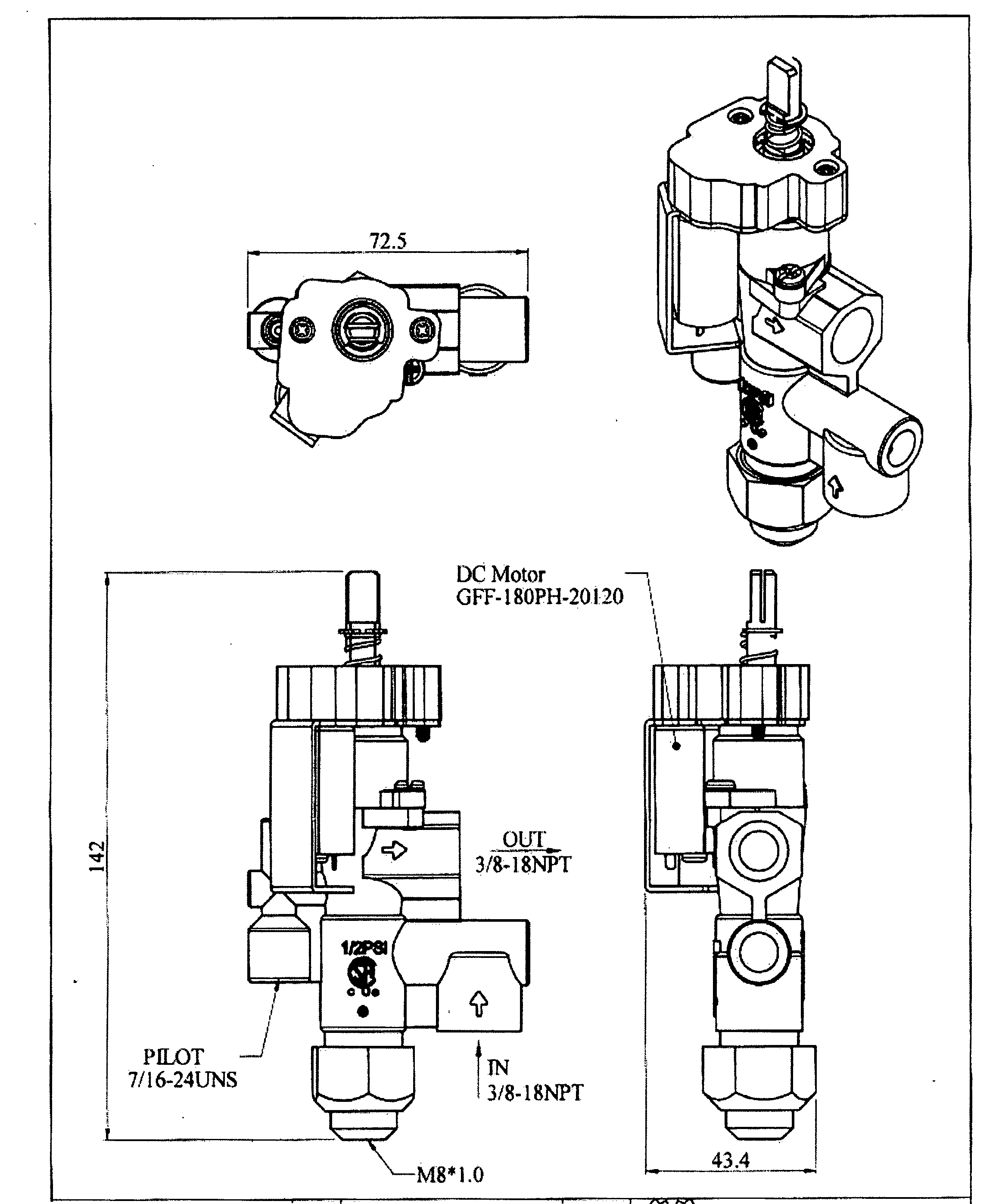

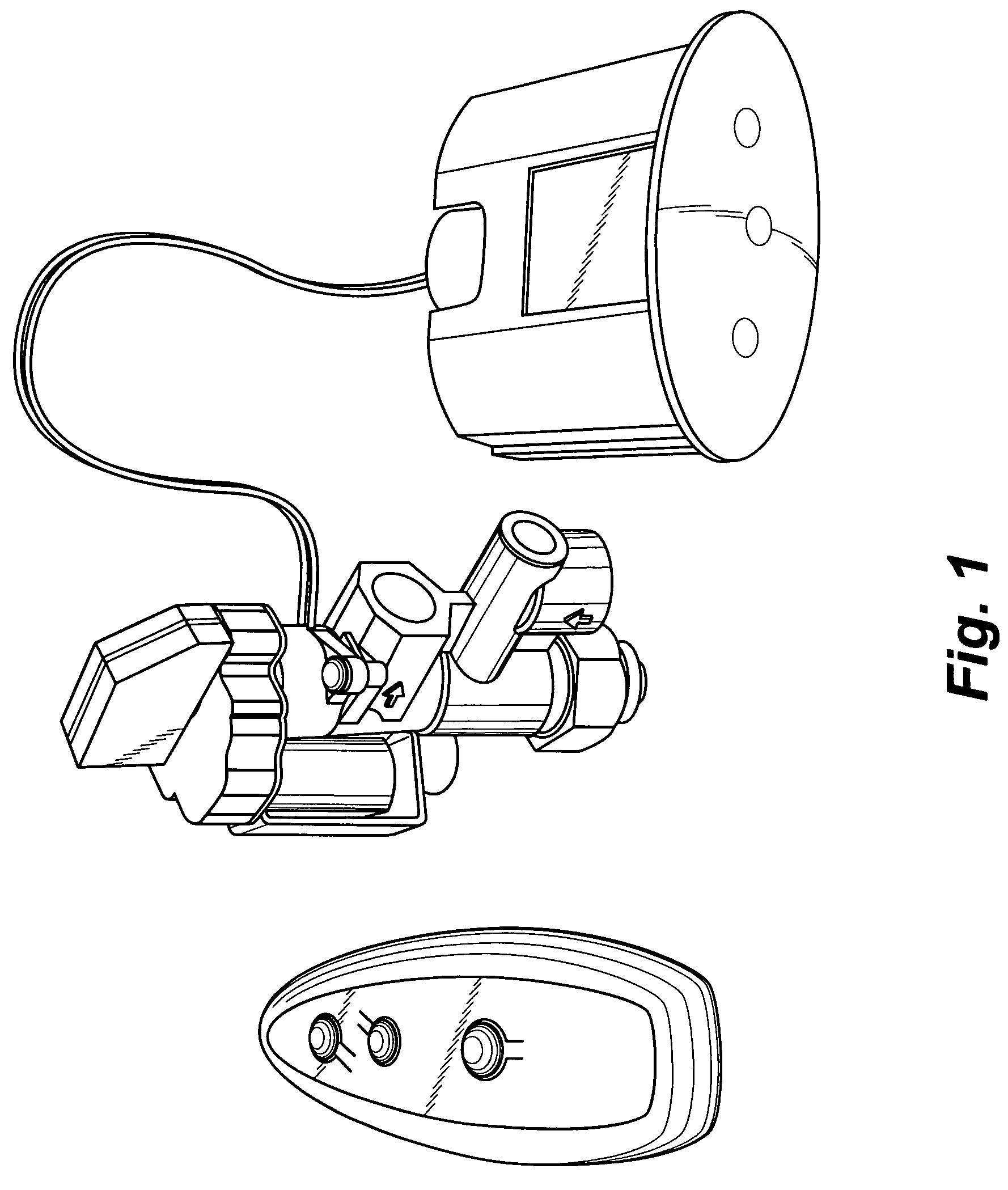

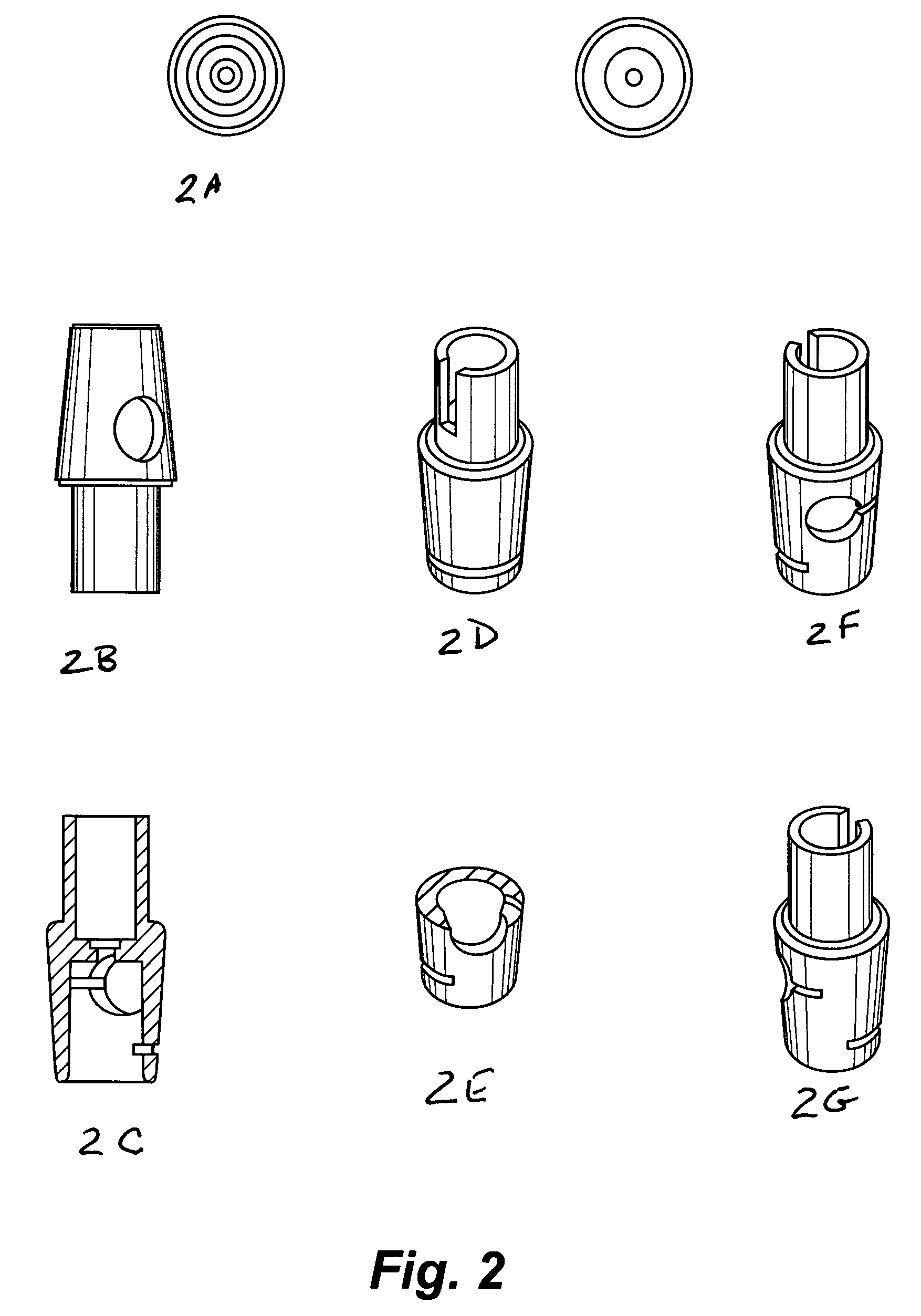

Remote control linearly regulated fuel valve

InactiveUS20090047610A1Fuel supply regulationCombustion valves/nozzle/pumpsRemote controlConical cavity

A linearly regulated fuel valve system is provided that includes a slotted conical rotatable plug component that is received in a conical cavity formed in a valve body which can be remotely controlled. The slotted plug serves to establish multiple flow paths through the valve body when rotated so as to align an opening formed in the cavity wall with an orifice formed in the side of the plug. The rotational orientation of the plug with respect to the wall and the orifice in the plug is set by a latch element permitting graduated stepwise adjustment settings such as high, medium, low and shut off of gas flow through the valve. Accordingly, the unique system may be adjusted by remote controlled to a wide range of settings by a single cone having a constant channel for fuel flow.

Owner:TENG YUSN

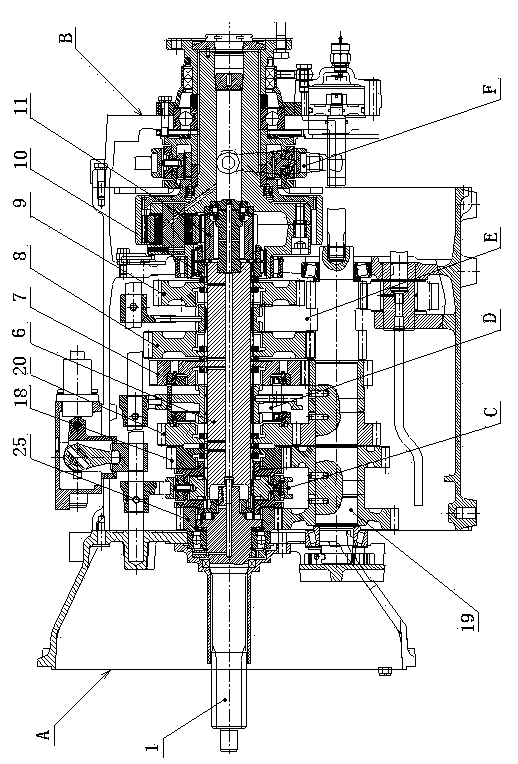

Synchronizer for dual-clutch automatic transmission of car

InactiveCN102367839ALarge synchronous torqueIncrease sync capacityMechanical actuated clutchesIsosceles trapezoidAutomatic transmission

The invention relates to a synchronizer for a dual-clutch automatic transmission of a car. The synchronizer comprises an inertia locking-ring-type synchronizer, and is characterized in that the middle part of each boost groove on a splined hub of the synchronizer is a straight groove, and two ends of the straight groove are bellmouths extending outwards; and the end part of an indexing bump on a corresponding X-gear synchronous ring is an isosceles trapezoid, wherein the waist edges at two sides of the indexing bump are correspondingly matched with two side edges of the bellmouths of the boost groove of the splined hub for the synchronizer. According to the invention, based on the existing locking-ring-type synchronizer, improvements are made to achieve the following three aims: firstly, the synchronization capacity can be increased; secondly, cost is lowered and performances are improved, a single-cone synchronizer can replace a bi-conical synchronizer, the bi-conical synchronizer can replace a tri-conical synchronizer, and the tri-conical synchronizer develops more potentiality; and additionally, the gear shift force acting on a gear sleeve of the synchronizer is reduced, and the requirements for a gear shift fork and a hydraulic system are lowered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

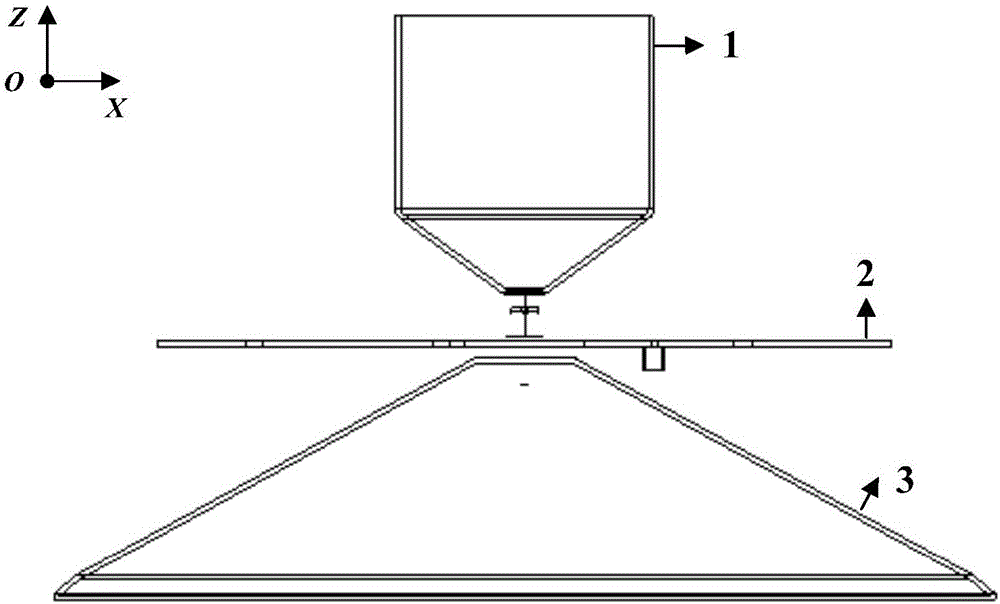

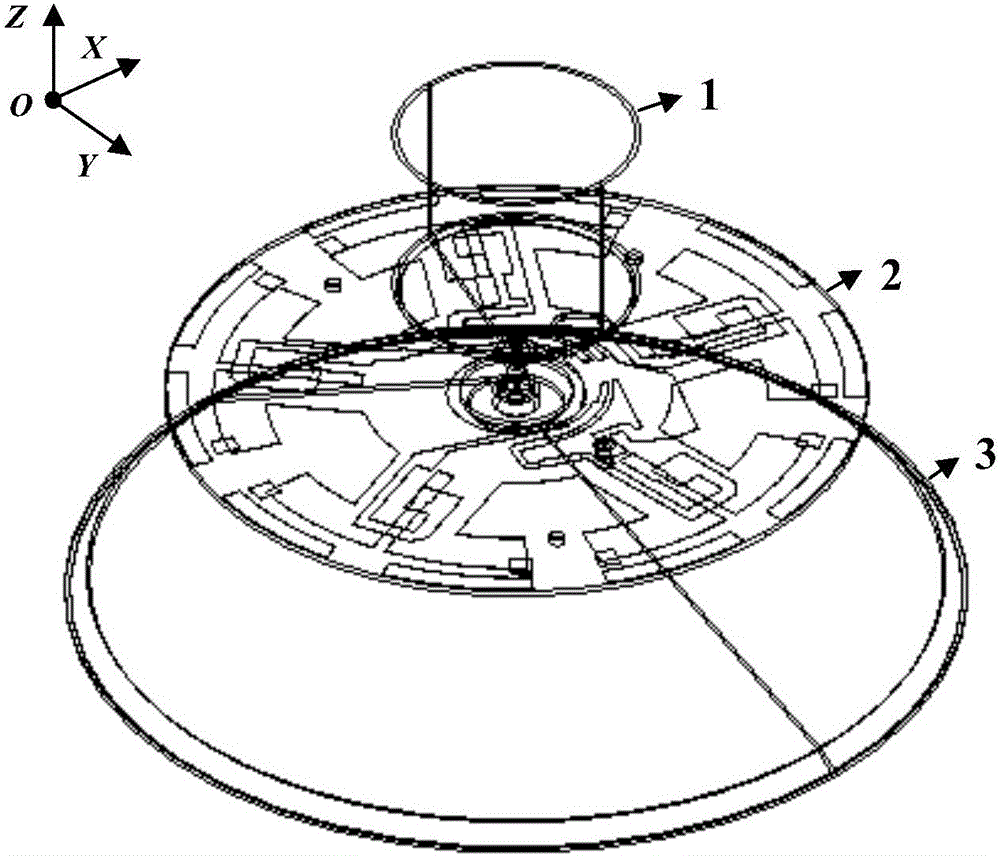

Mini enhanced dual-polarization omnidirectional ceiling antenna

ActiveCN106602230AImprove out of roundnessImprove consistencyParticular array feeding systemsRadiating elements structural formsMiniaturizationImpedance matching

The invention provides a mini enhanced dual-polarization omnidirectional ceiling antenna. The antenna comprises a single cone, a horizontal polarization unit and a step-shaped floor which are arranged in a vertically coaxial and centrally overlapped manner from top to bottom successively, the single cone comprises a first single cone radiator and a second single cone radiator which are arranged in a crossing manner, the bottom of the single cone is provided with a feed point, and a coaxial feed cable is connected to the feed point in the bottom of the single cone by penetrating the step-shaped floor and the horizontal polarization unit from bottom to top successively. Within the frequency range from 0.8GHz to 2.70GHz, the single-cone ceiling antenna realizes effective impedance match, an ideal omnidirectional radiation performance, a substantial edge coverage enhanced effect, a consistent in-band coverage range, higher efficiency, higher port isolation degree (better than -24dB), small size and low profile and is suitable for indoor coverage. The antenna is also characterized by being novel in ideas, clear in principles, universal in methods, easy to realize, low in cost and suitable for batch production, the antenna can be used to replace a routine dual-polarization omnidirectional ceiling antenna, and can be used for design and improvement of a vertical-polarization enhanced omnidirectional ceiling antenna and a planar Alford loop antenna.

Owner:TONGYU COMM INC

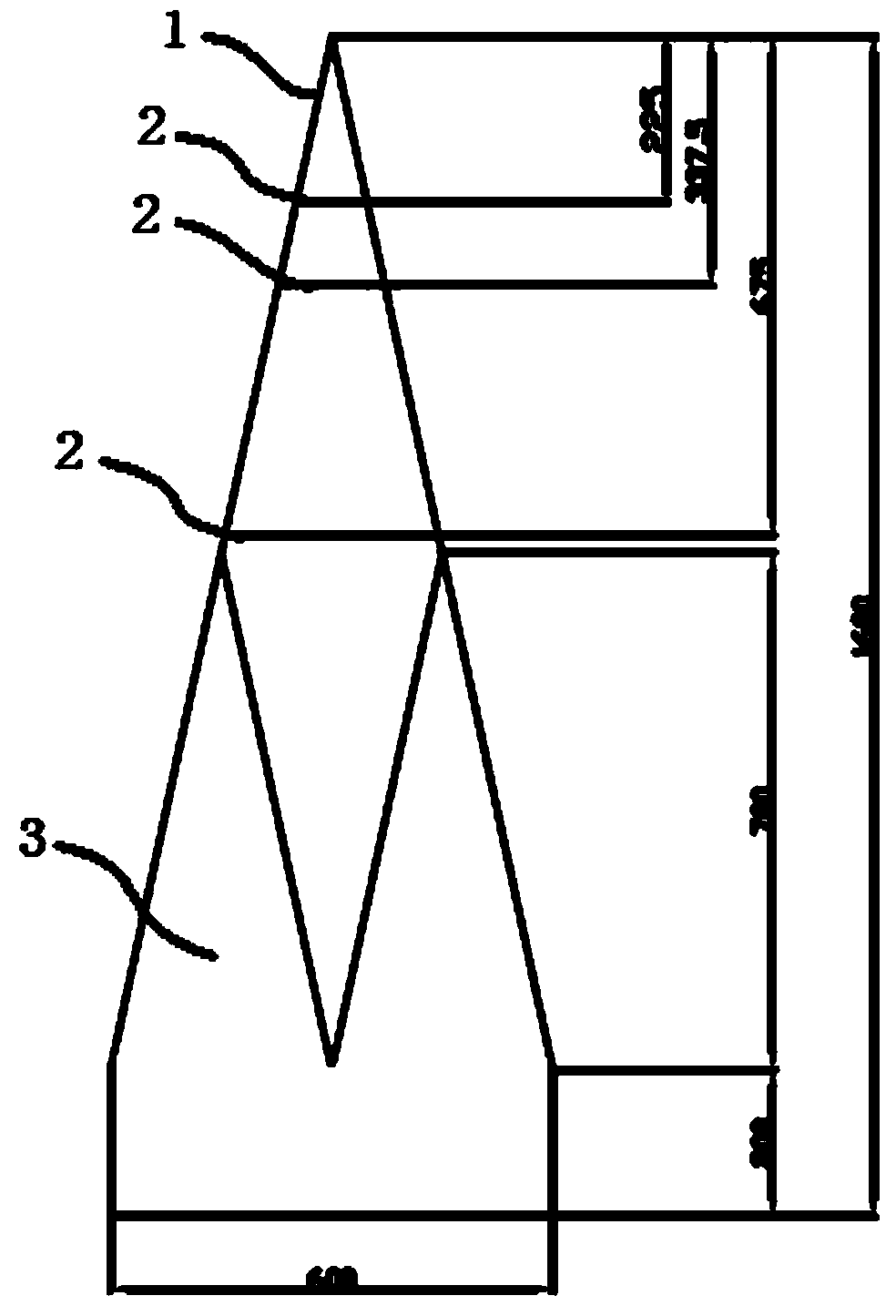

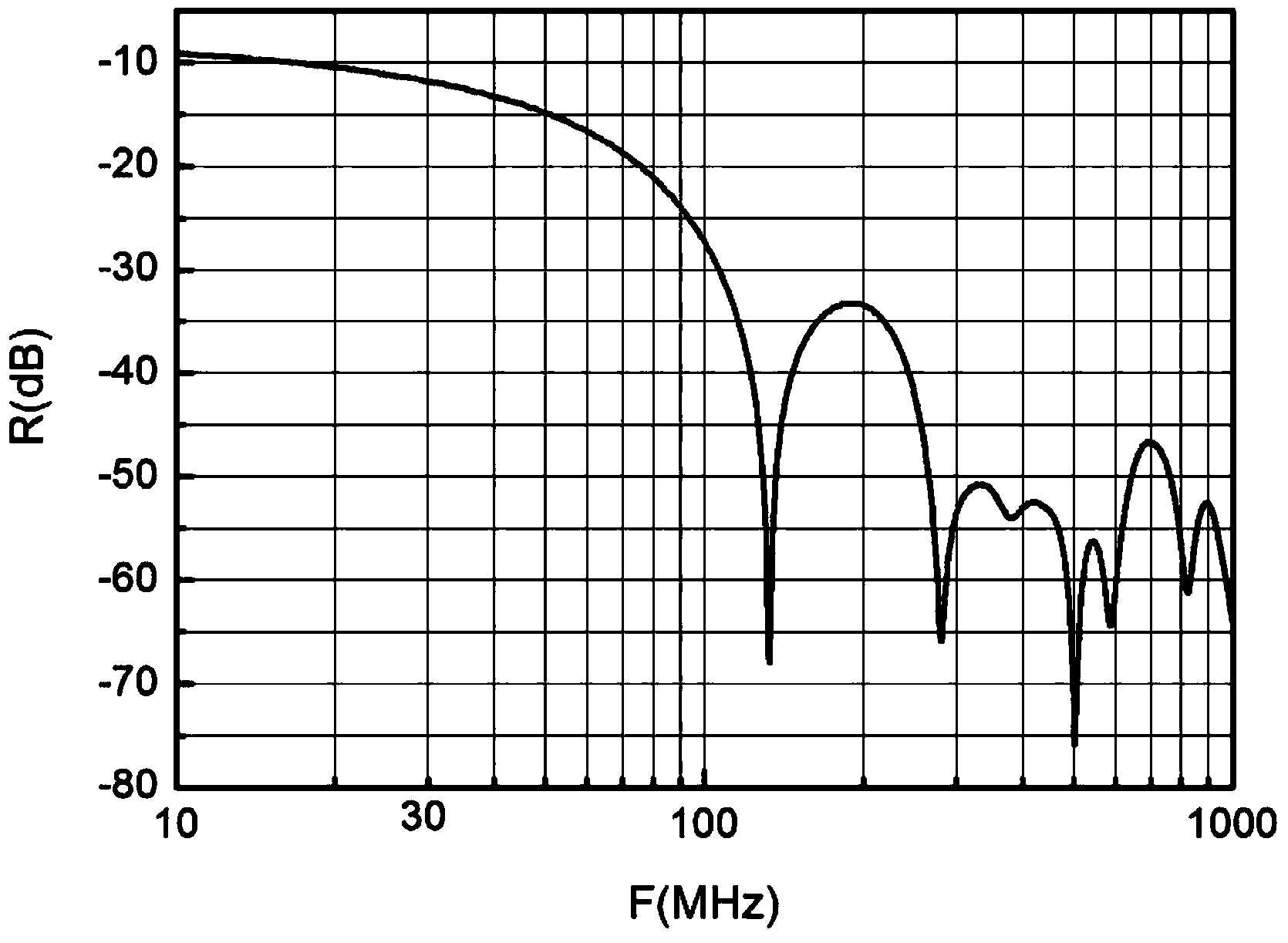

Low-frequency stage microwave absorption material

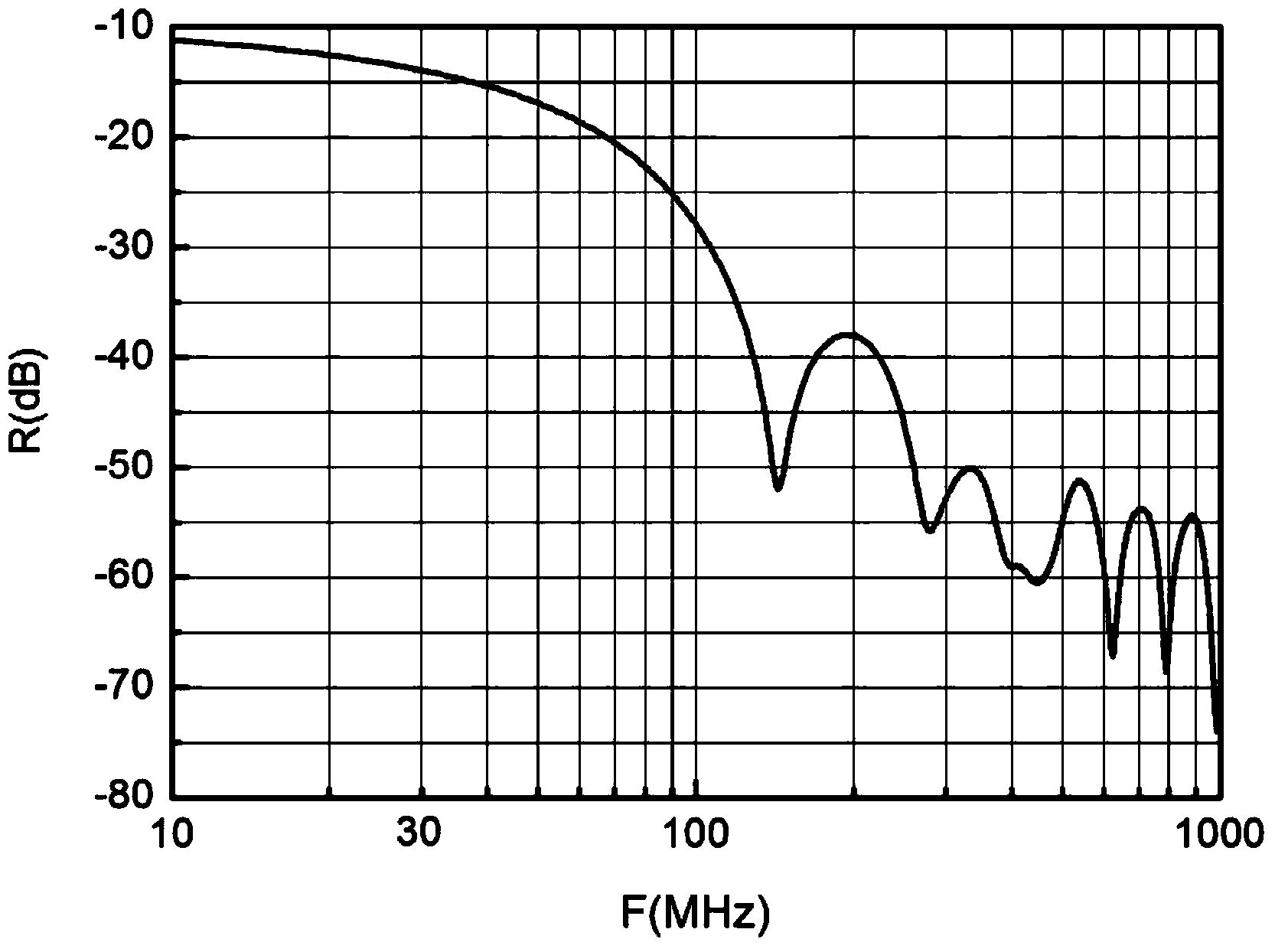

InactiveCN103436220AMeet needsImprove microwave absorption performanceOther chemical processesElectrical resistance and conductanceMicrowave

The invention relates to a low-frequency stage microwave absorption material which comprises a polyurethane pyramid and a base, wherein the polyurethane pyramid is internally provided with two same inner single cones close to the base; three-layer microwave absorption sheets with same square resistance values are arranged above the inner single cones and parallel to a cone base; the square resistance values of the microwave absorption sheets range from 350 ohm to 420 ohm, the square resistance of the polyurethane pyramid ranges from 400 ohm to 600 ohm, and the square resistances of the inner single cones range from 150 ohm to 200 ohm. According to the invention, the three-layer parallel structure approximate to an electric wave in space equivalent square resistance value (377 ohm) is arranged in a polyurethane pyramid material, so that the microwave absorption property of the polyurethane pyramid wave-absorbing material between 30 MHz and 100 MHz is improved, and the absorption value ranges from -12 dB to 20 dB. The low-frequency stage microwave absorption material disclosed by the invention meets the requirement for electromagnetic compatibility and the requirement of an antenna simulation darkroom on the material.

Owner:NANJING BOPING ELECTRONICS TECH CO LTD

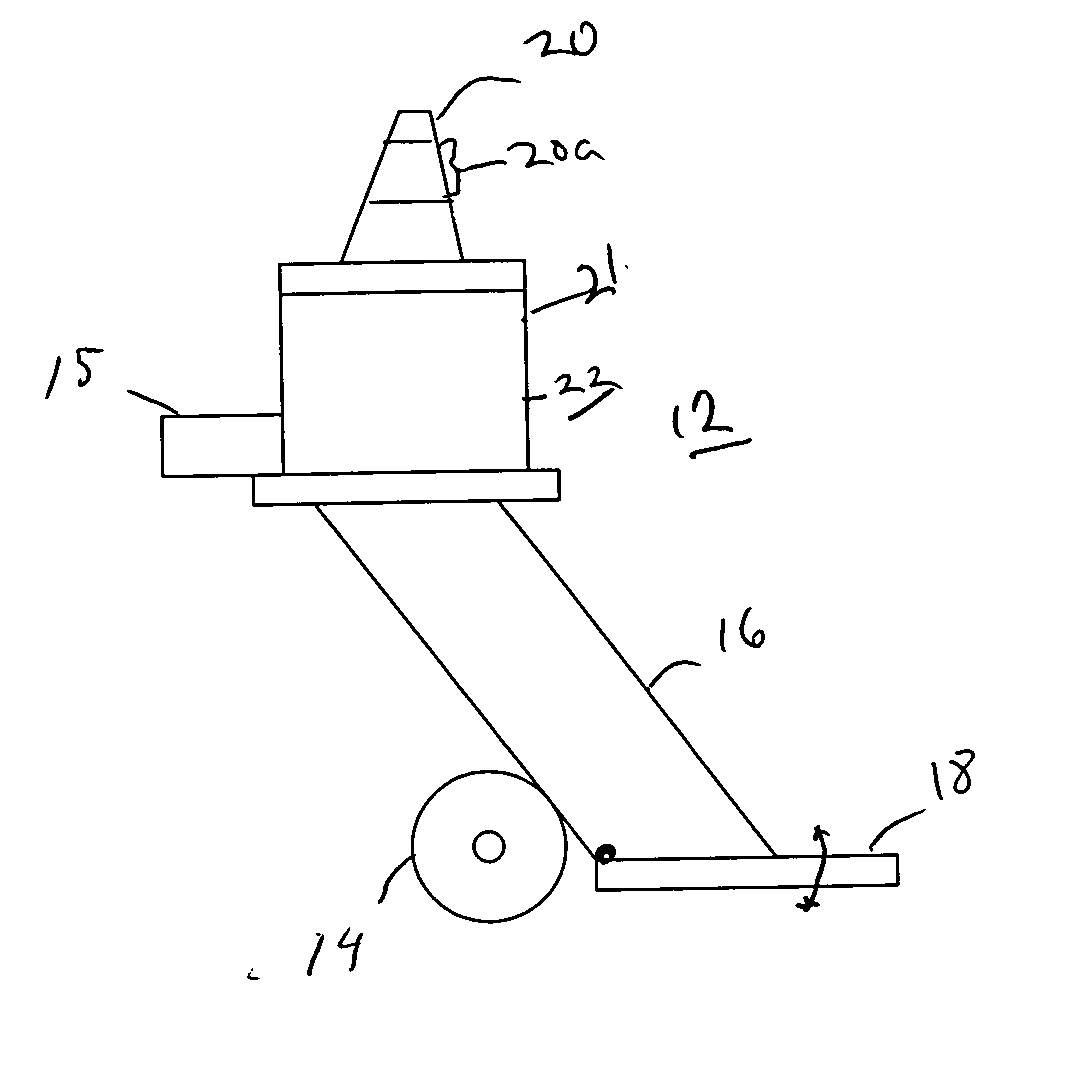

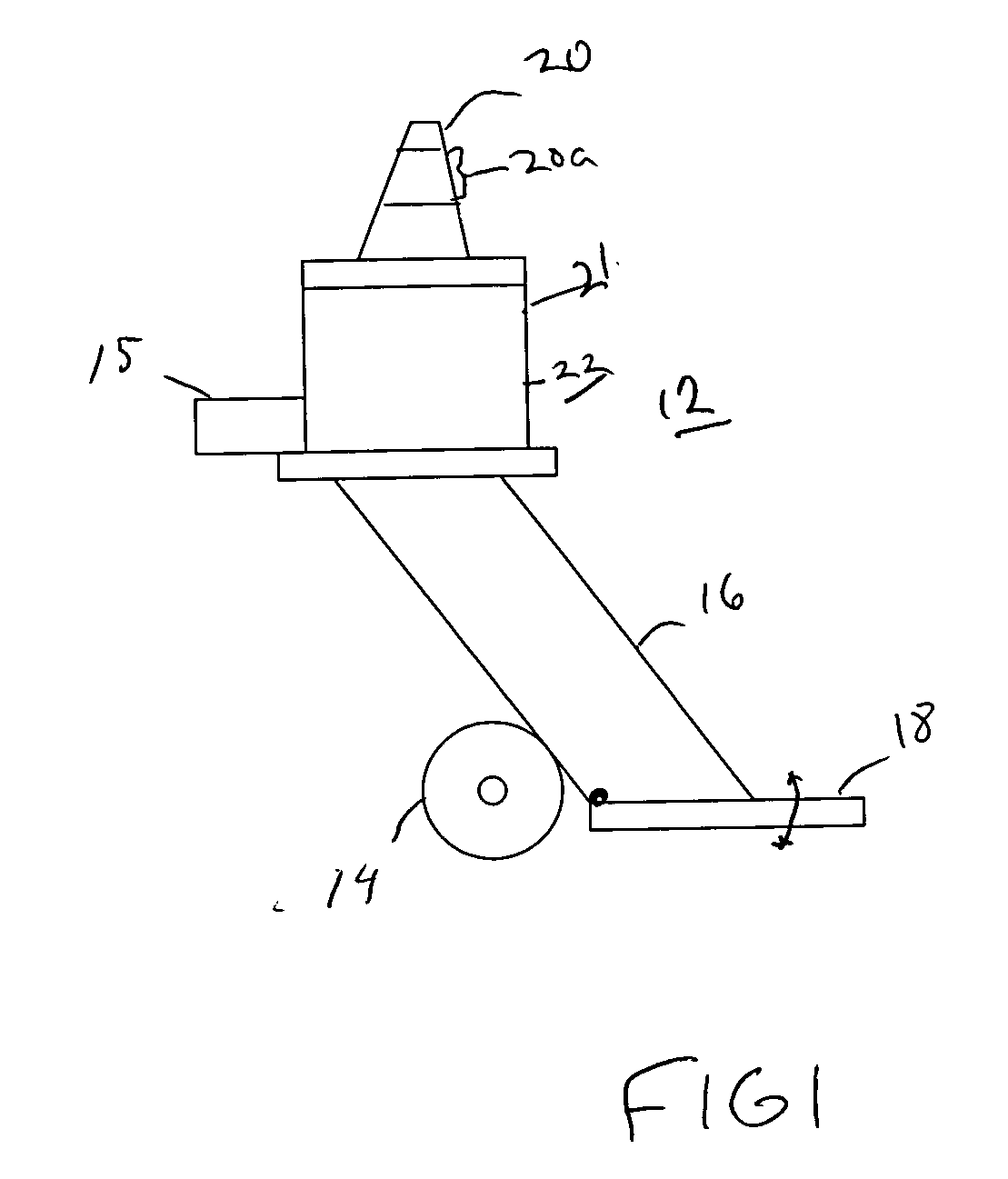

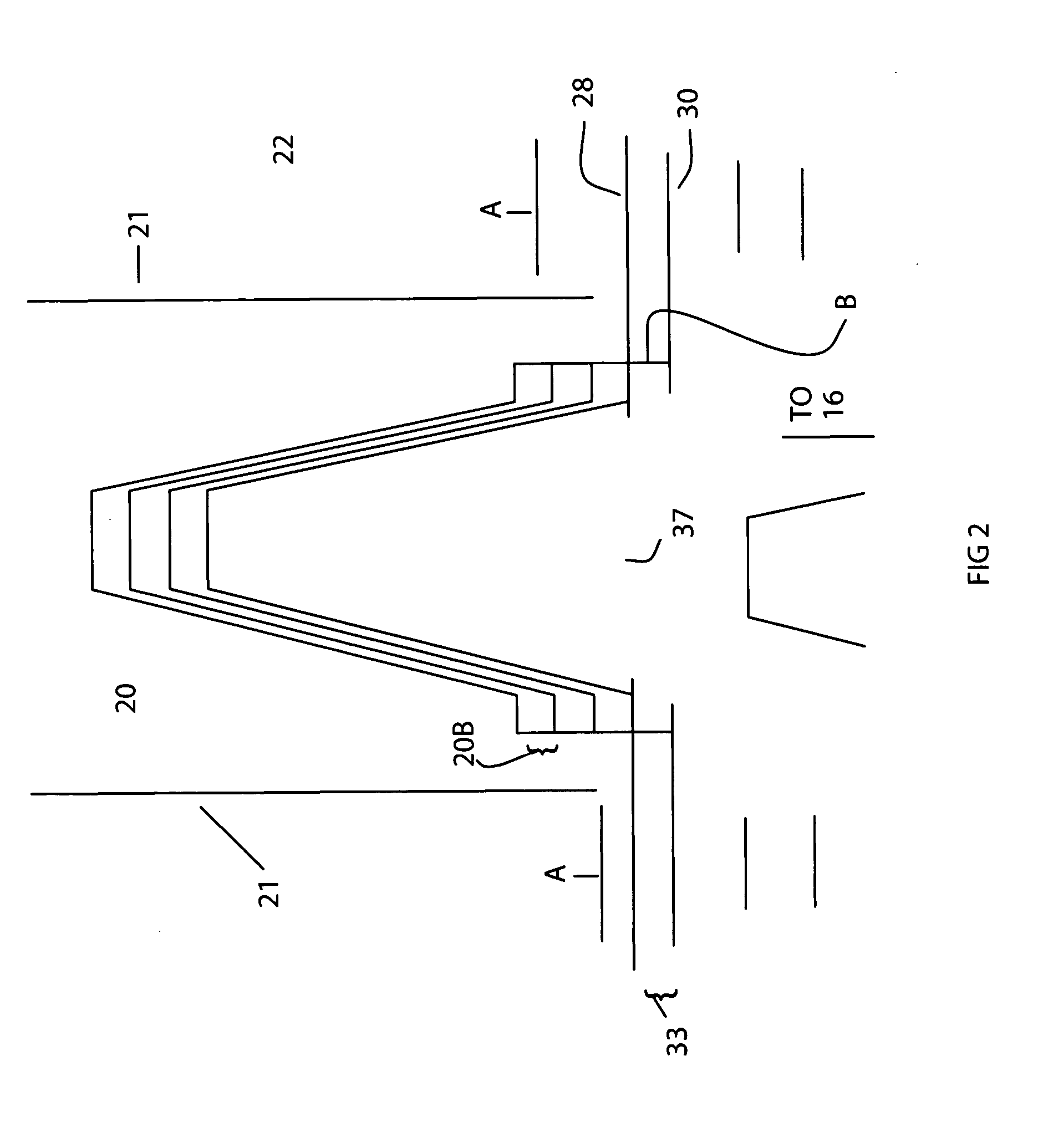

Conical warning marker placer

InactiveUS20050095105A1Facilitated releaseRefuse receptaclesLoading/unloading vehicle arrangmentSlide plateEngineering

An apparatus for releasing a single road cone at a timed interval comprising a mechanism comprising at least one reciprocating shoe which support a plurality of road cones in a first position, and which lock a single cone on a second position which is then released at a timed interval, a chute proximate to the door to permit said released cone to slide downward toward the road surface, and a vertical angle slide plate affixed to said chute to permit said cone to be released smoothly onto a road surface as the vehicle moves forward.

Owner:PARKS WILLIAM

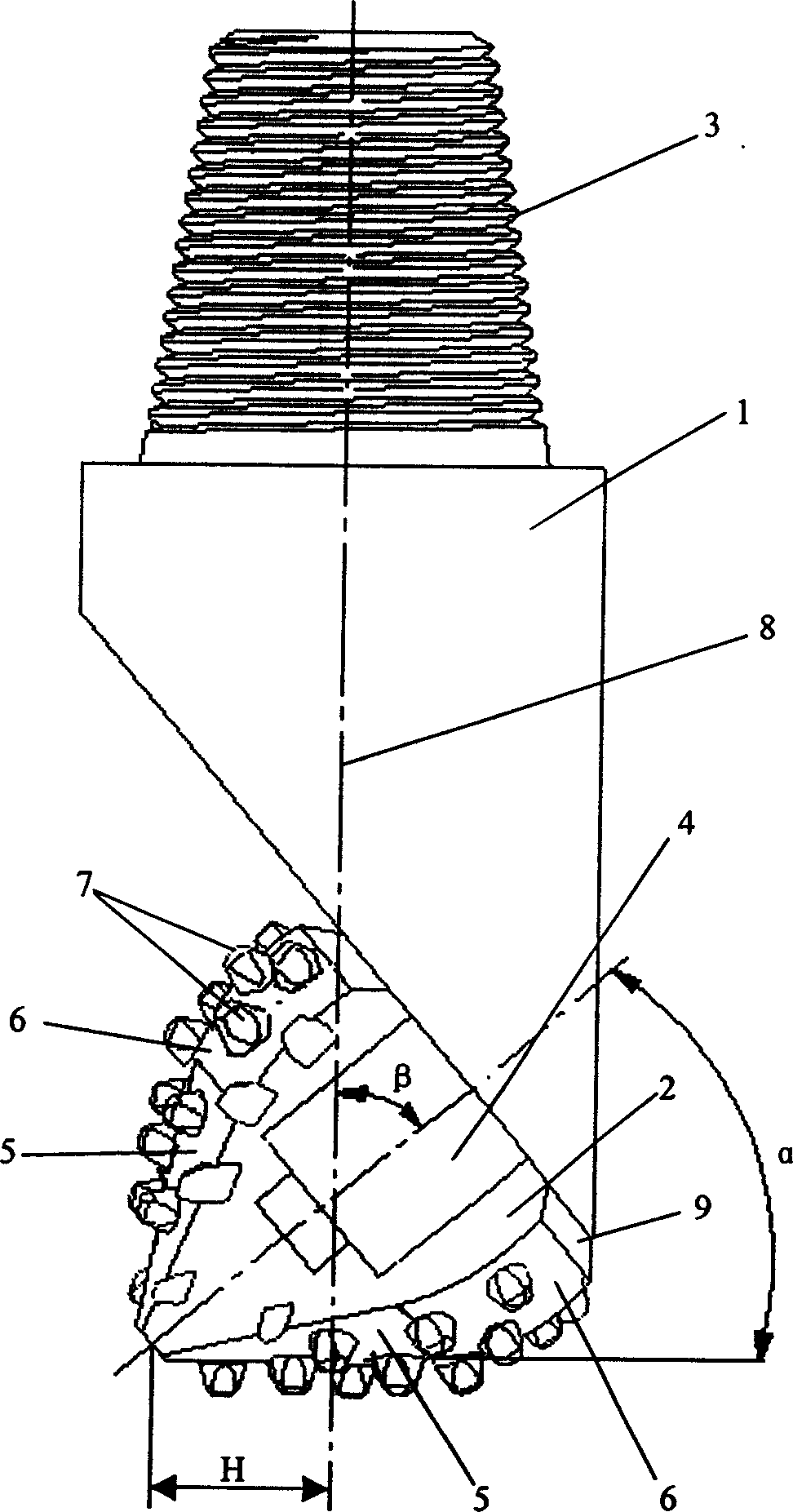

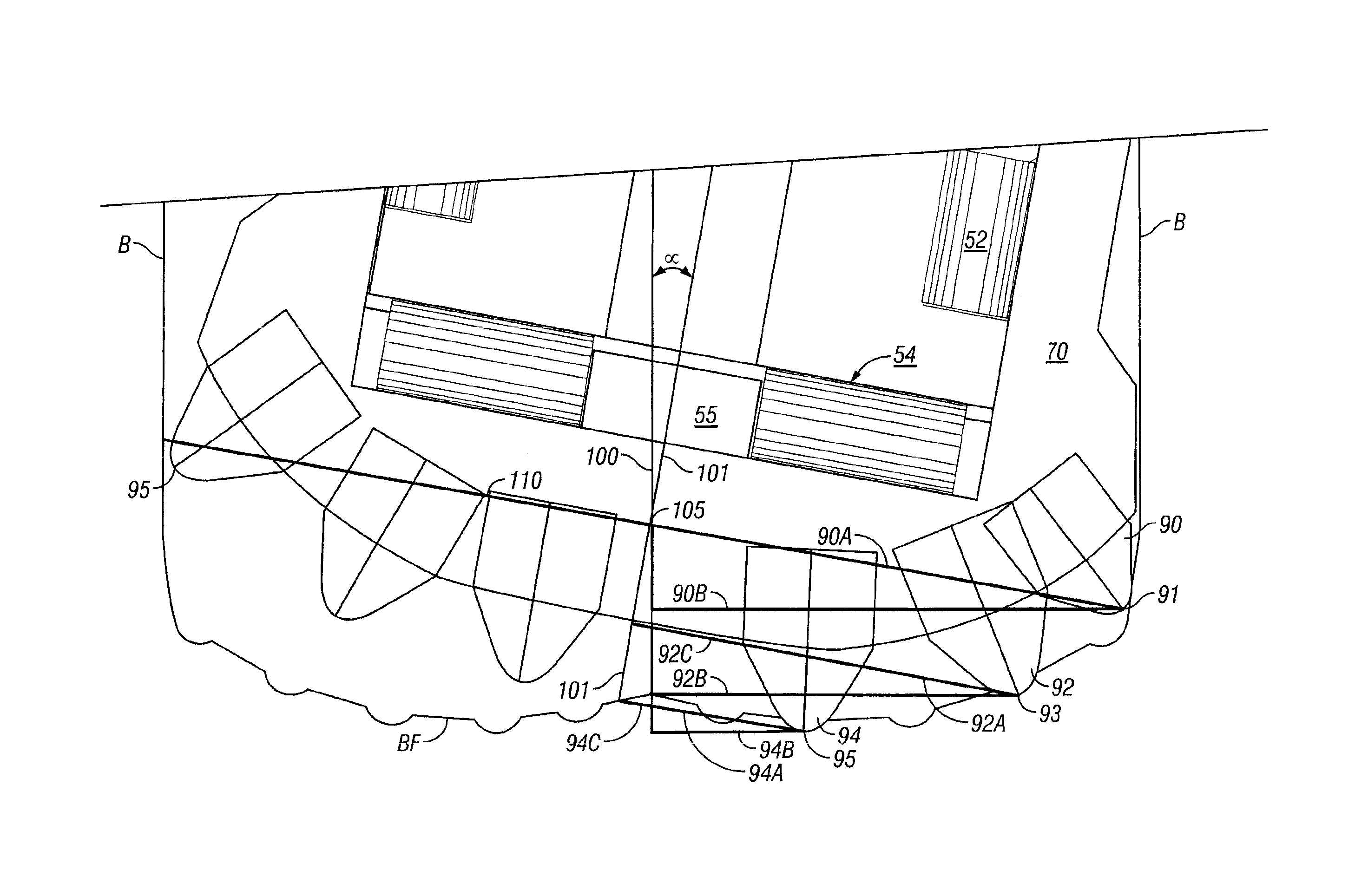

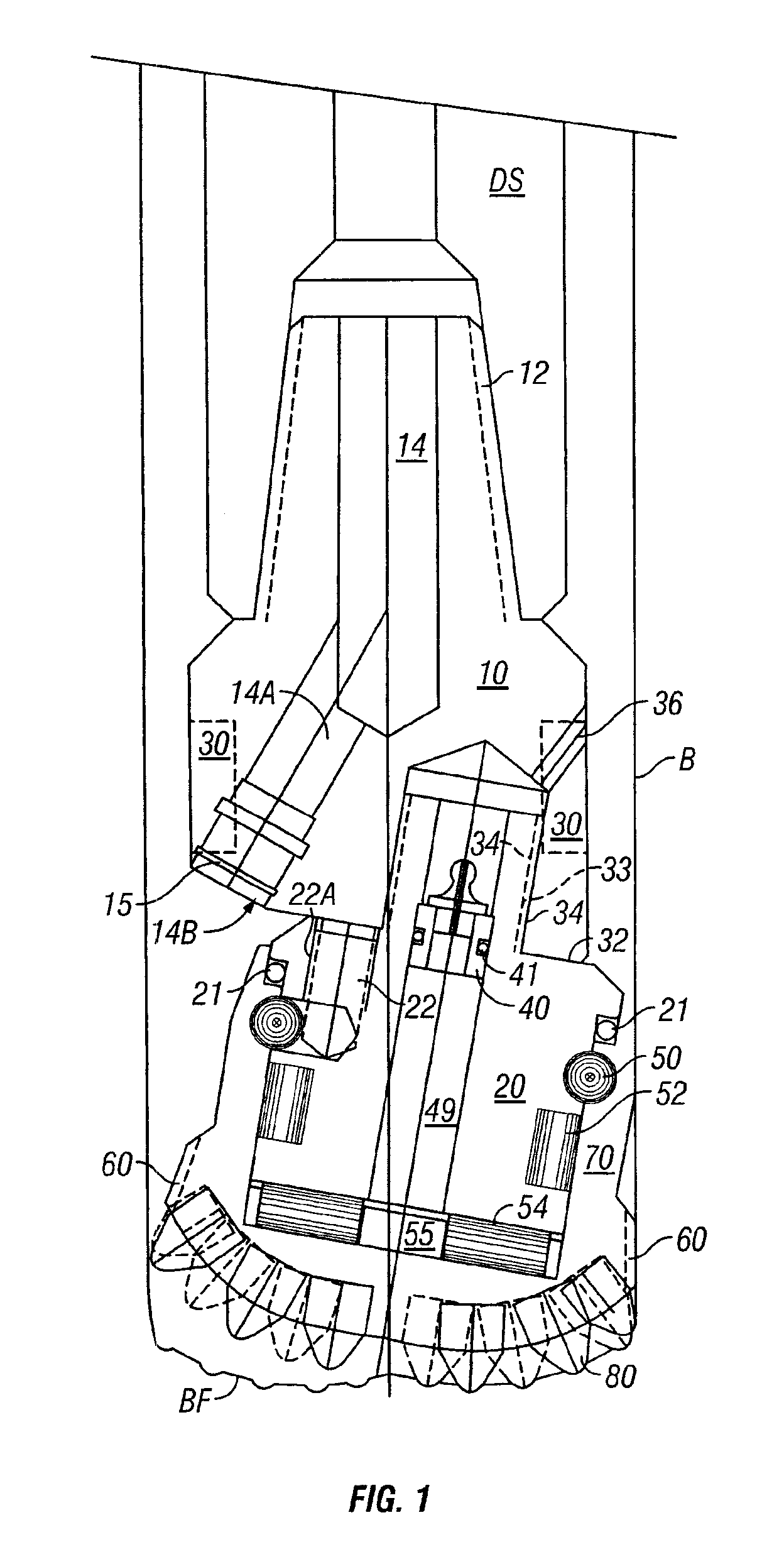

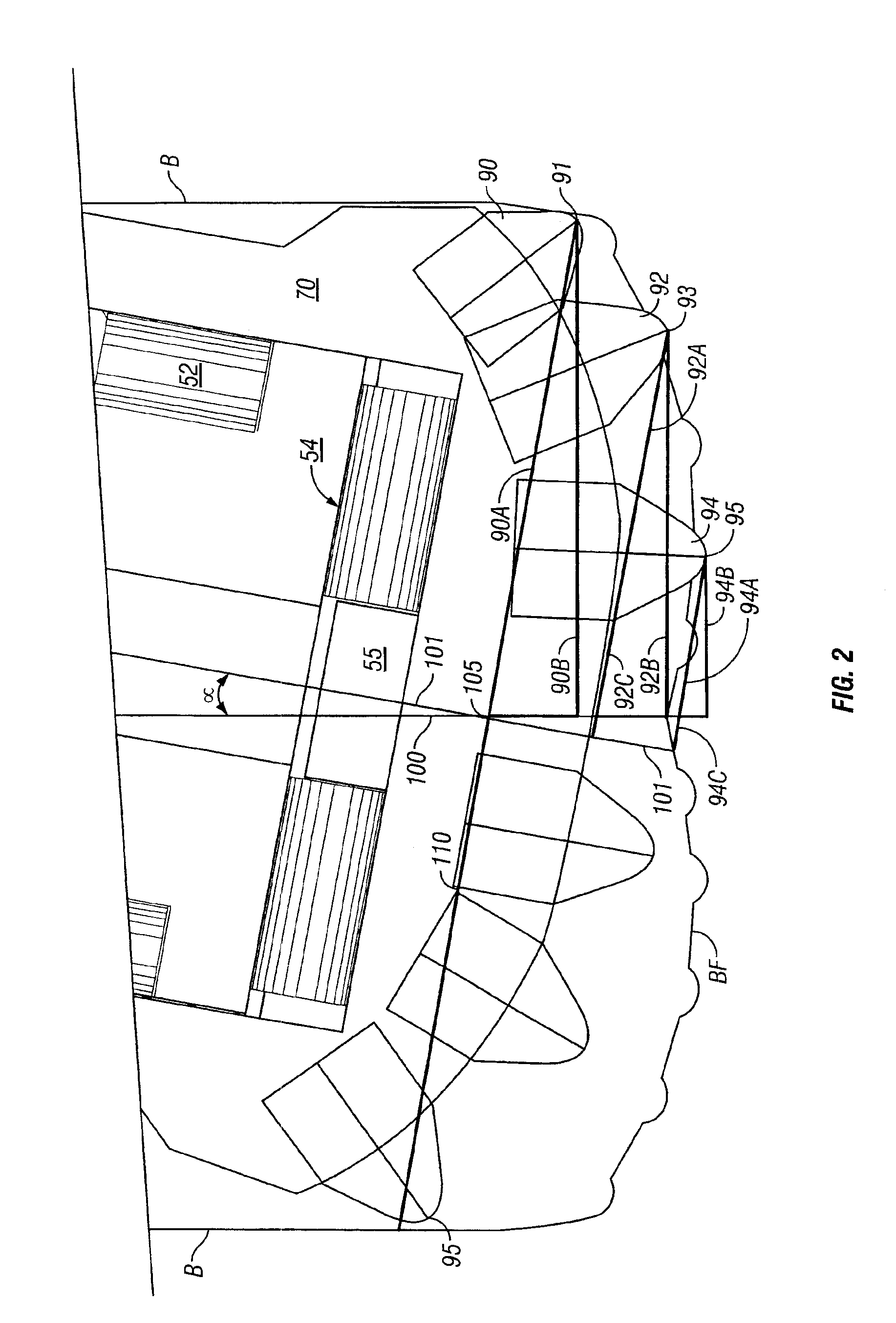

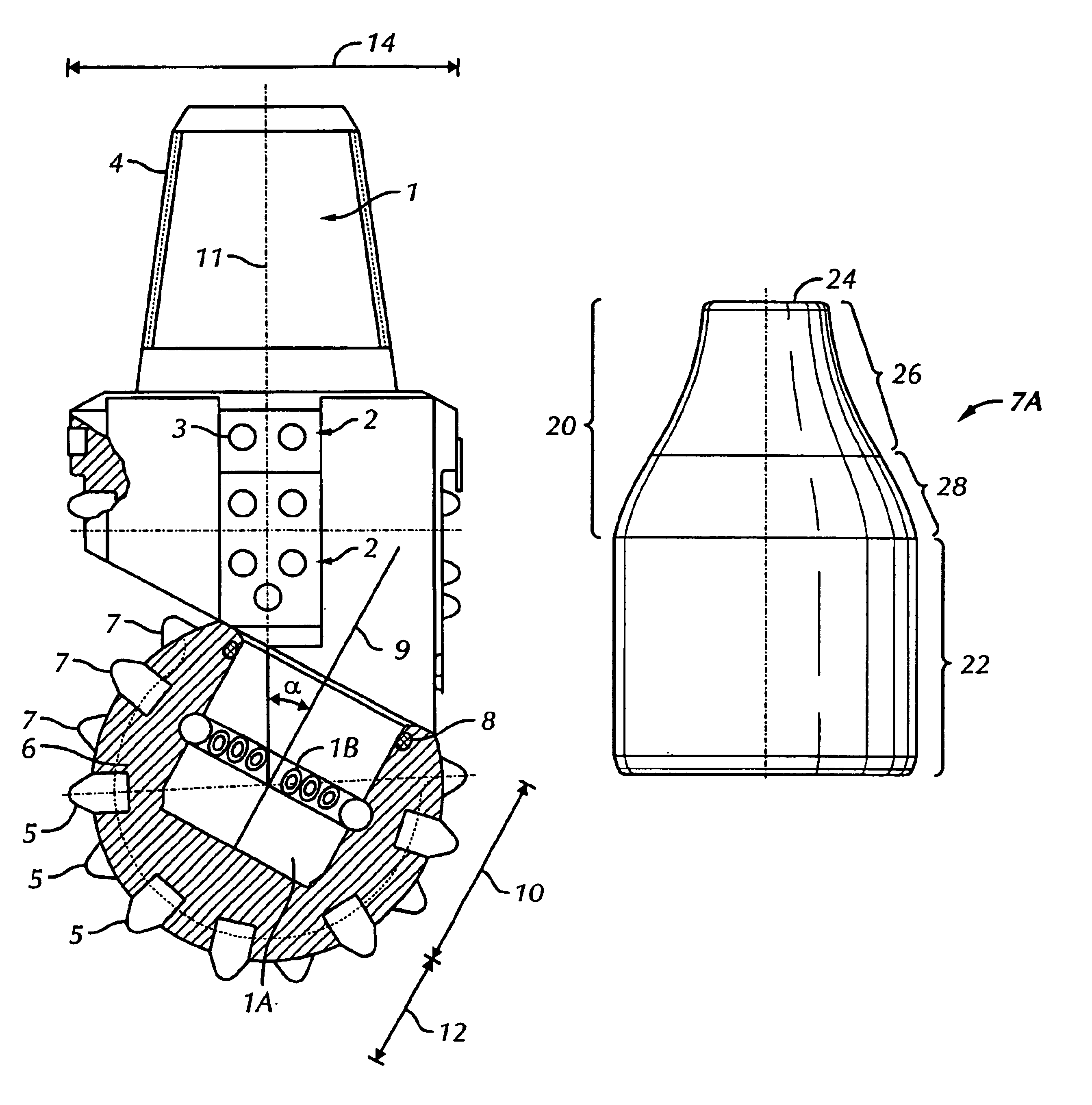

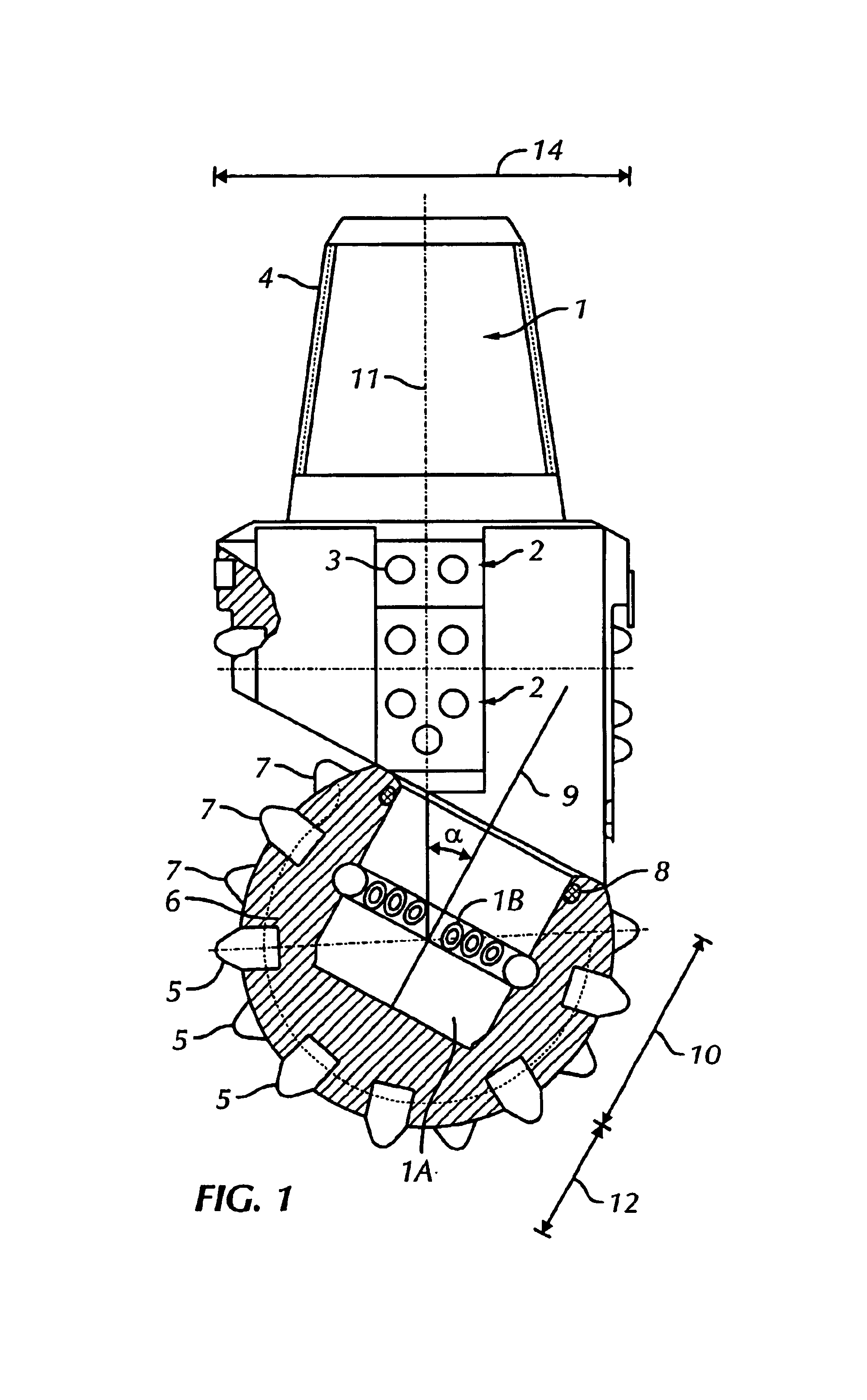

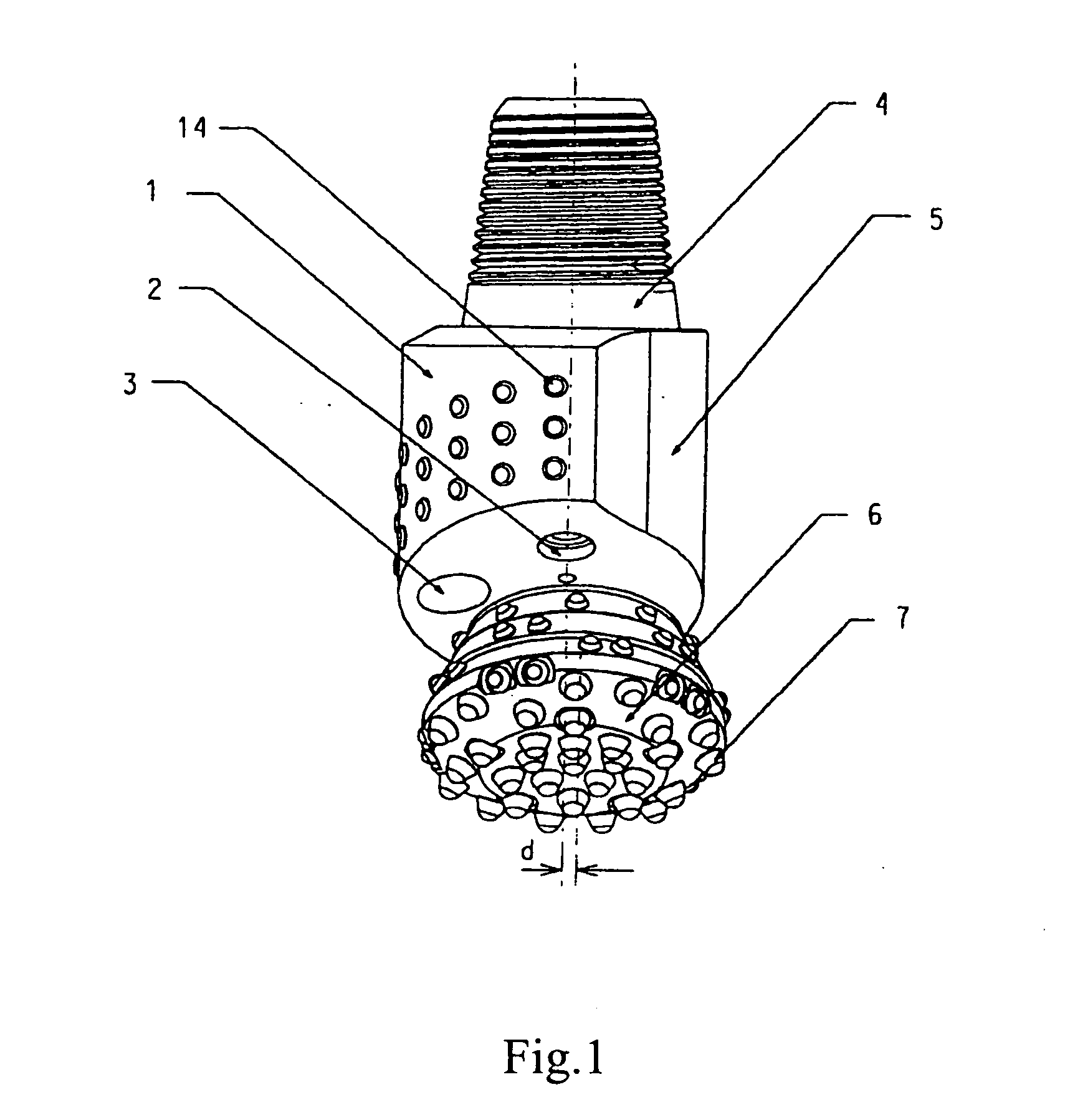

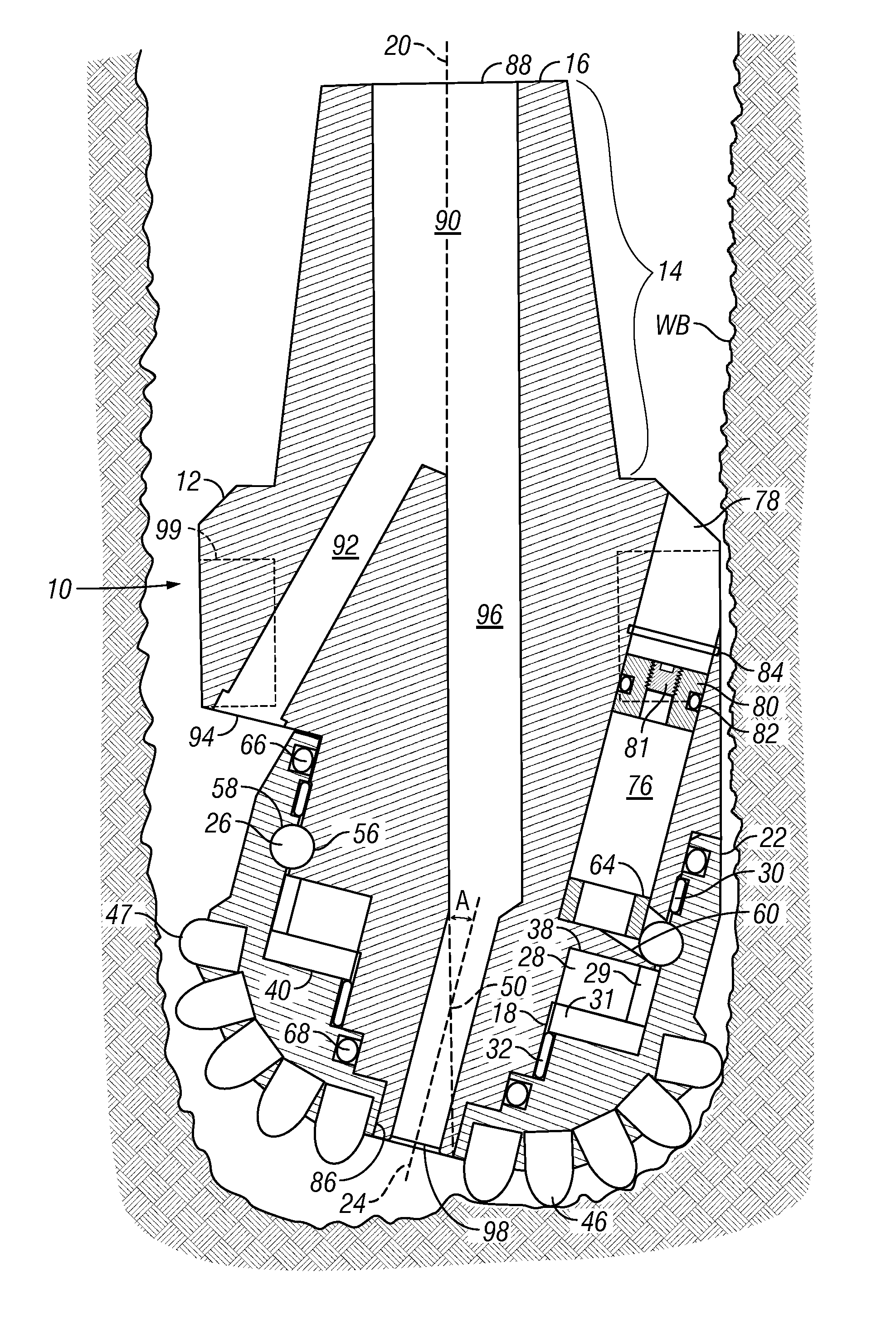

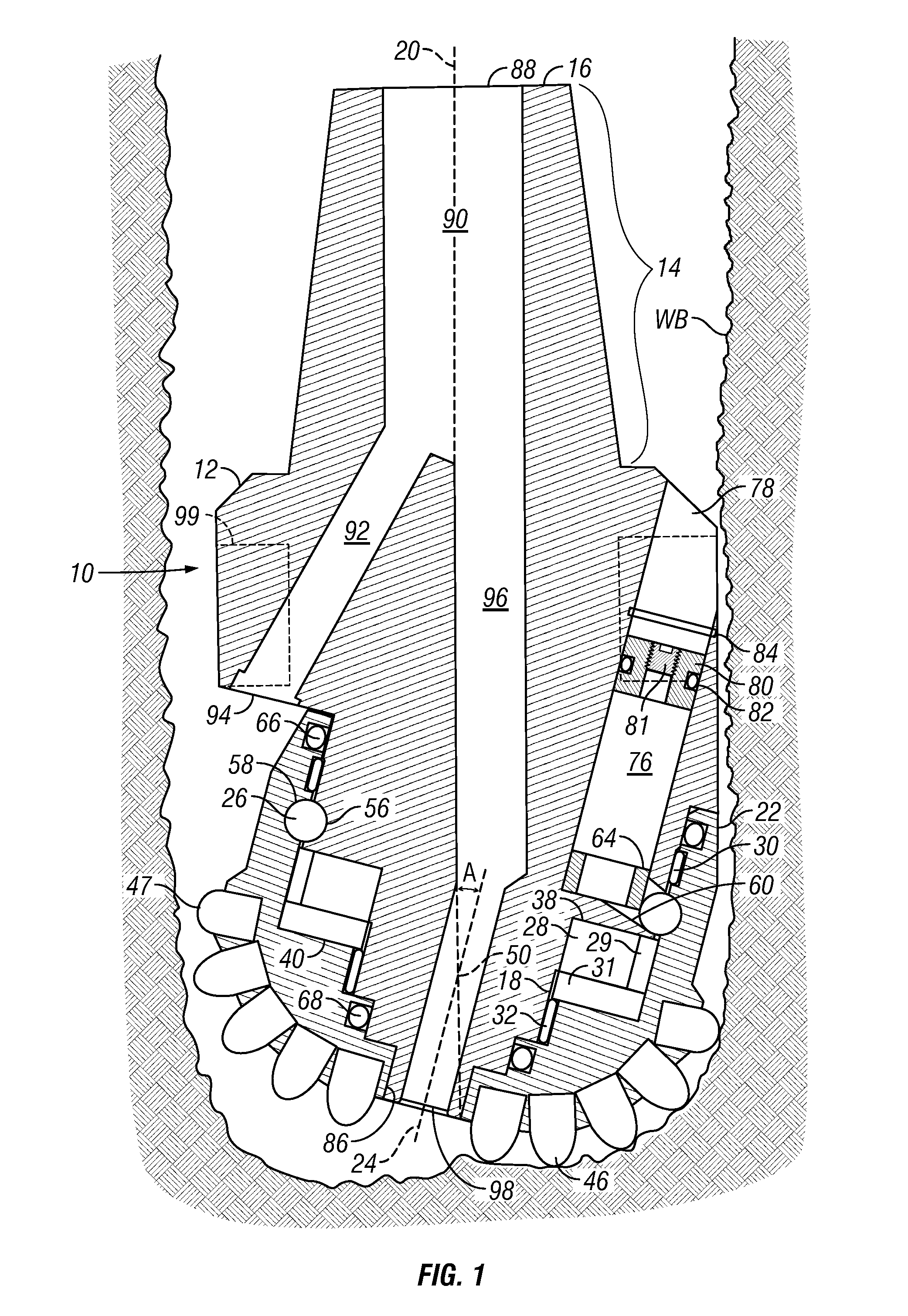

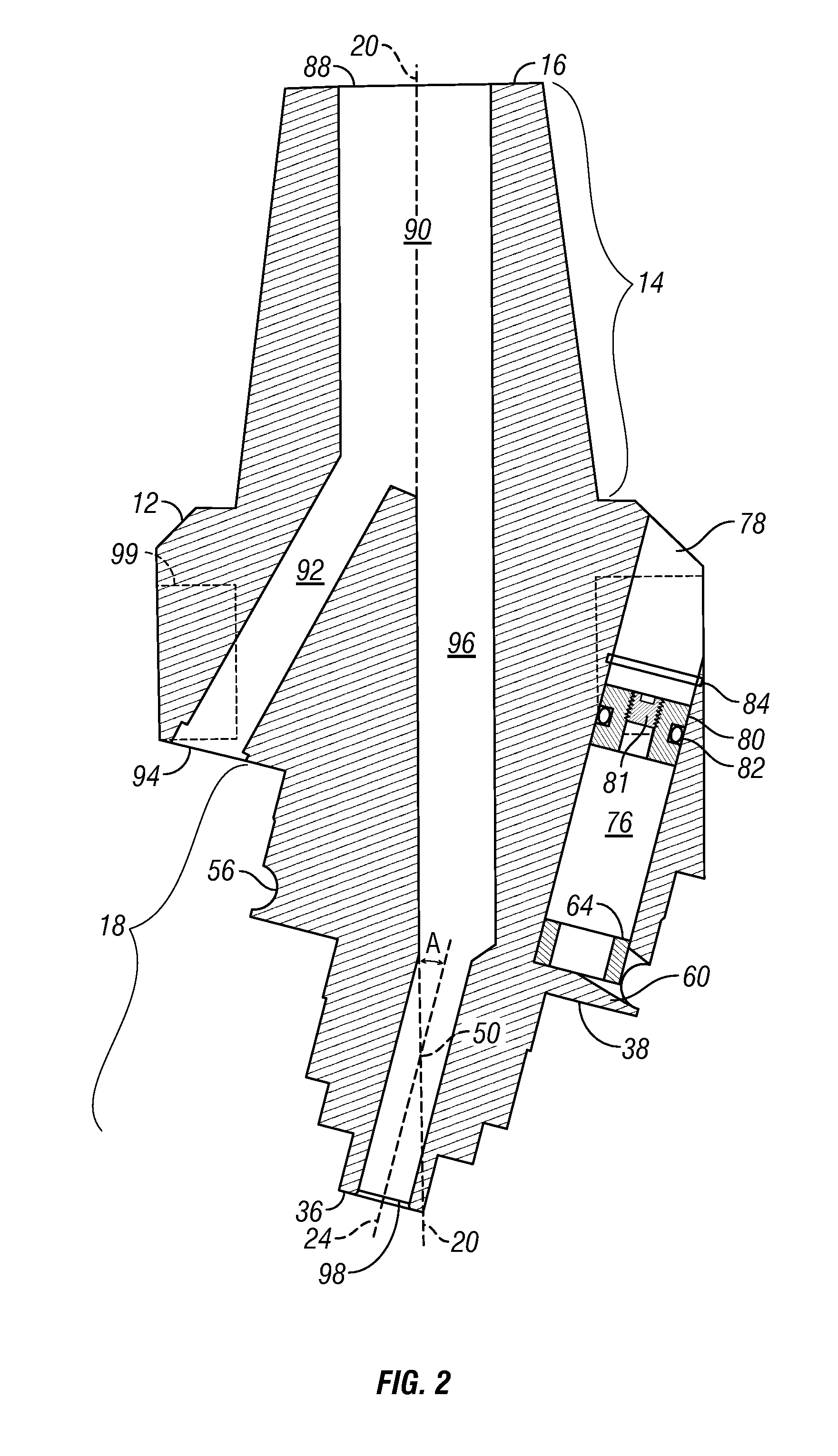

Nutating single cone drill bit

A nutating single cone drill bit includes a bit shank defining a bit axis, a journal defining a rotation axis skewed from the bit axis, and a cutter elements mounted upon a cutter body wherein the tip of each cutter elements is forward a plane defined normal to the cutter axis at an intersection of the cutter axis with the bit axis.

Owner:TIGER 19 PARTNERS

Novel nuclear pore membrane

InactiveCN101380547AIncreased etch sensitivityReduce taperSemi-permeable membranesMass numberMembrane surface

The invention relates to a novel nuclear pore membrane (or nuclear track membrane), generally the nuclear track always has conicity after etching, the millipore of the nuclear pore membrane is single-cone or double-cone, the center aperture of the millipore of the double cone is less than the aperture on both surfaces of the membrane. Particles are blocked in the millipore easily when filtering, and the membrane is blocked easily. Meanwhile, the ions with lower mass number are utilized for irradiating the electrolyte membranes, for the nuclear track etching sensitivity is lower, conicity is larger, the nuclear pore membrane with small aperture is made hard. The center aperture of the millipore of the nuclear pore membrane made by the invention is larger than the diameters of both surfaces of the membrane or is of column form capillary tube shape. The shape of the millipore causes the particles larger than the membrane surface aperture to be trapped on the membrane surface, and the nuclear pore membrane is not blocked easily. Meanwhile, a new method is provided for making nuclear pore membranes by utilizing the ions with lower mass number.

Owner:毕明光

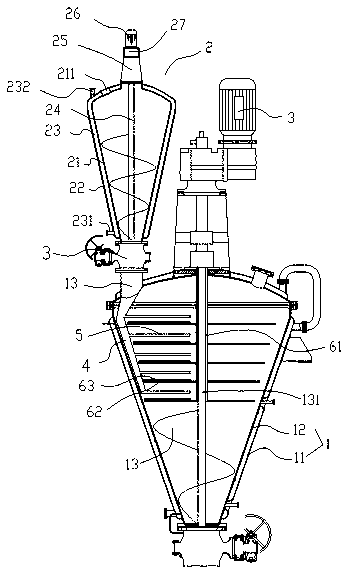

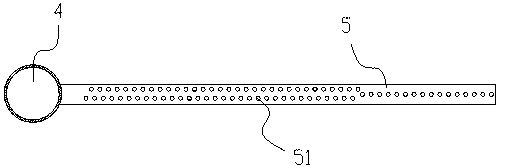

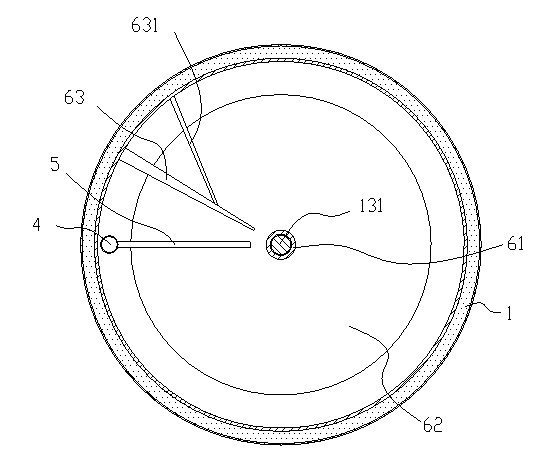

Single-cone drier for feeding liquid continuously

InactiveCN103234334ARealize continuous feedingVoid physicalEvaporationDrying machines with non-progressive movementsChemical reactionLiquid state

The invention discloses a single-cone drier for feeding liquid continuously. The single-cone drier comprises a conical drier body, wherein a stirrer is arranged inside the drier body, and is driven by a motor through a spindle; the drier is provided with a liquid-flow type predrying continuous feeding device; the continuous feeding device comprises two parts, namely a liquid-flow structure and a predrying structure; the liquid-flow structure is arranged on a feed opening of the drier body, and comprises a feeding barrel; the lower part of the feeding barrel is communicated with a liquid flow path stretching into the drier body through a valve; a plurality of branch tubes are inwardly arranged in the liquid flow path; and a plurality of small liquid-flow holes are formed in the lower side of each branch tube and corresponding to the predrying structure. By adopting the single-cone drier for feeding liquid continuously, for solid state feeding of materials, solvation of the materials due to physical, chemical reactions can be avoided, and then the material huddle into blocks can be avoided; for liquid state direct feeding of materials with poor heat penetration capacities, lumping solidification and wall-hanging coaking in the drying process can be avoided; and moreover, the application range of the single-cone drier can be greatly expanded, and emission of atmospheric pollutant can be greatly reduced.

Owner:马锡林

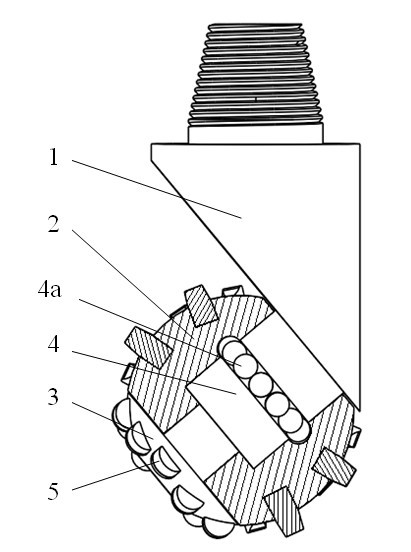

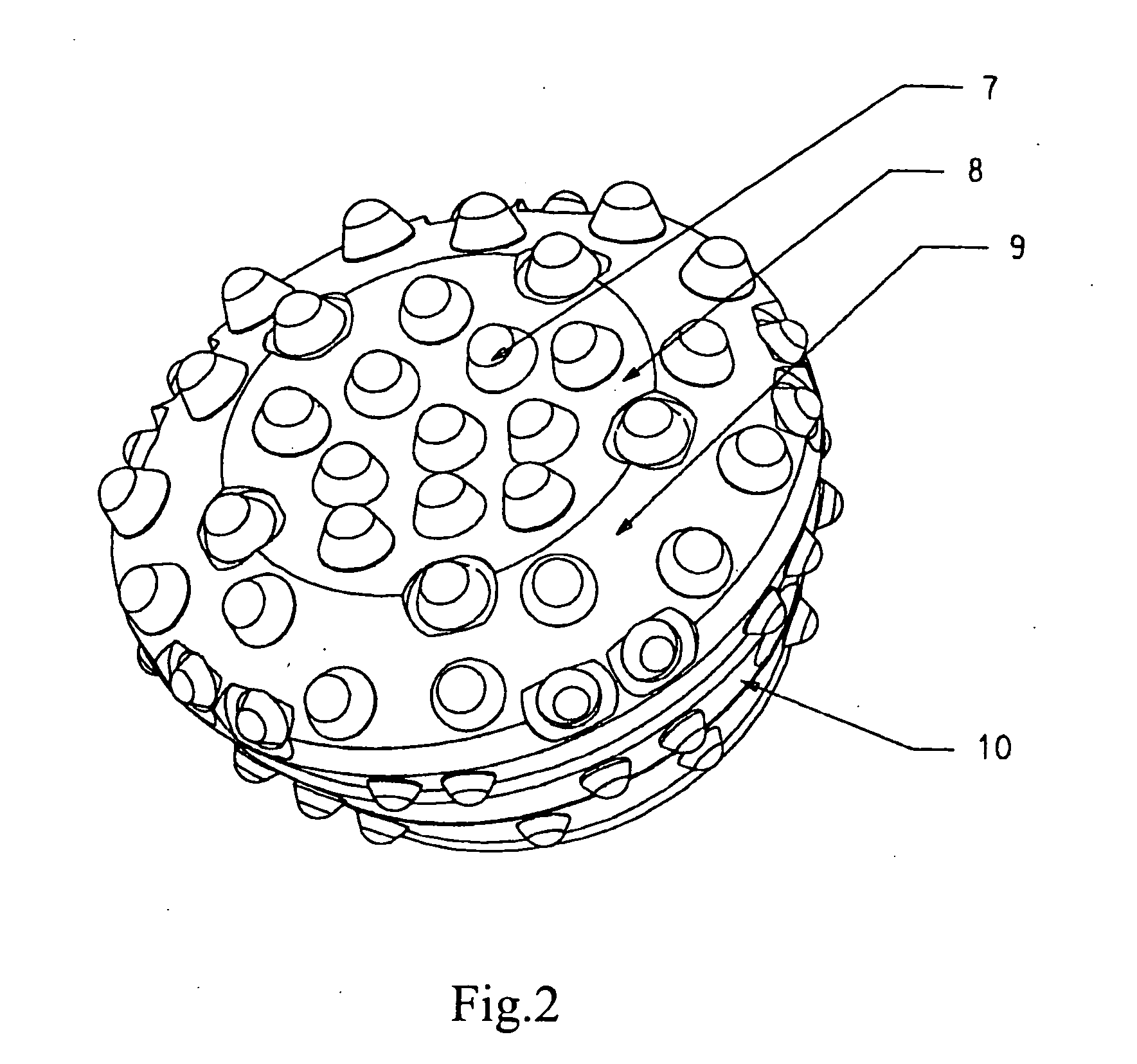

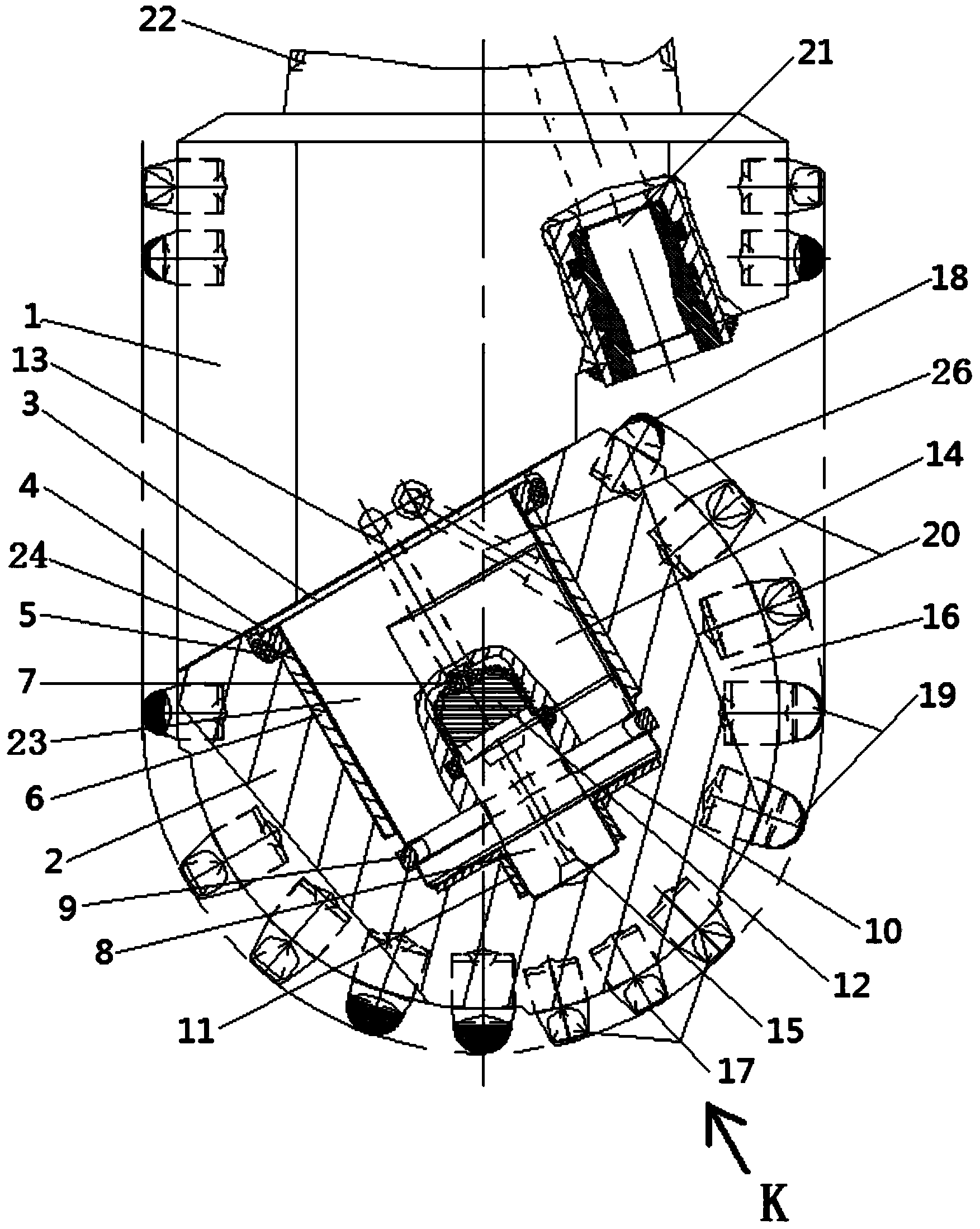

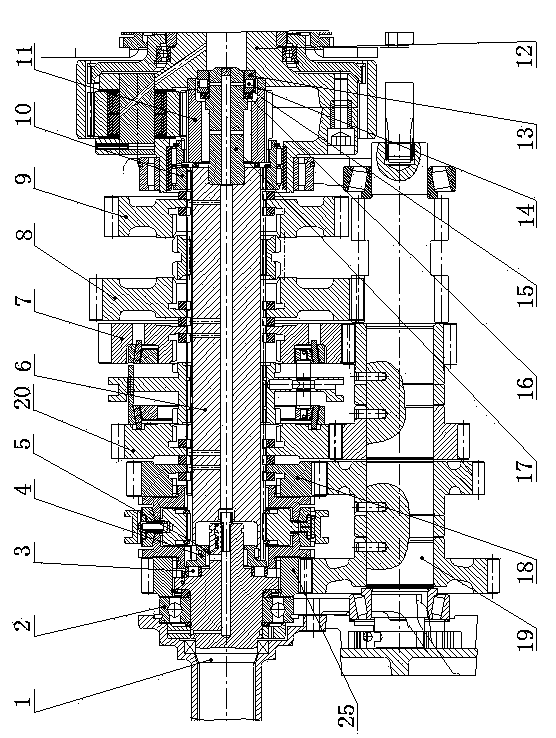

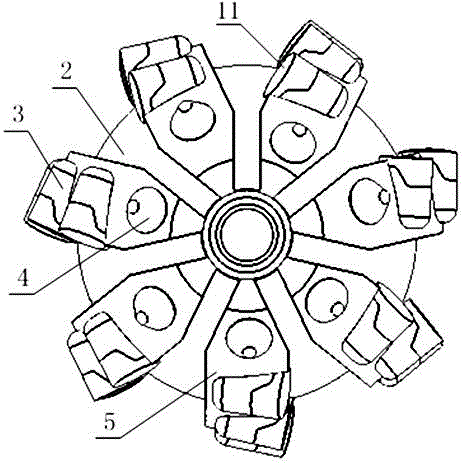

Compound single cone bit

ActiveCN102022084AImprove wear resistanceImprove rock breaking efficiencyDrill bitsEngineeringStructural engineering

The invention discloses a compound single cone bit comprising a bit body (1), a cone (2) and a cone point (3). Cutting teeth (5) are arranged on the cone (2) and the cone point (3); a shaft neck (4) is arranged on the bit body (1); the cone (2) and the shaft neck (4) are rotatably connected; and the cone point (3) is fixedly connected with the front end of the shaft neck (4). In the invention, the single cone bit is formed by compounding a fixed cutting structure and a non-fixed cutting structure so as to improve the rock removal rate of the bit and prolong the service life of the cutting teeth.

Owner:SOUTHWEST PETROLEUM UNIV

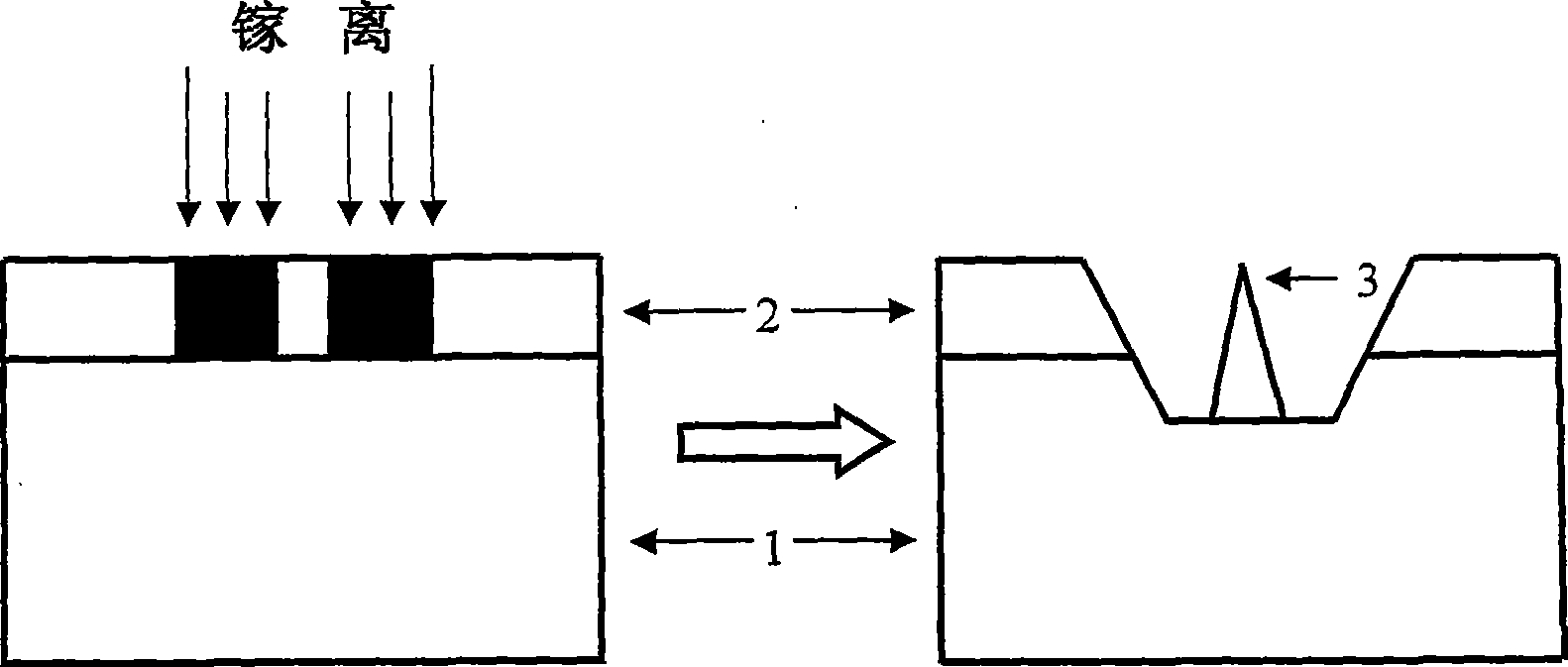

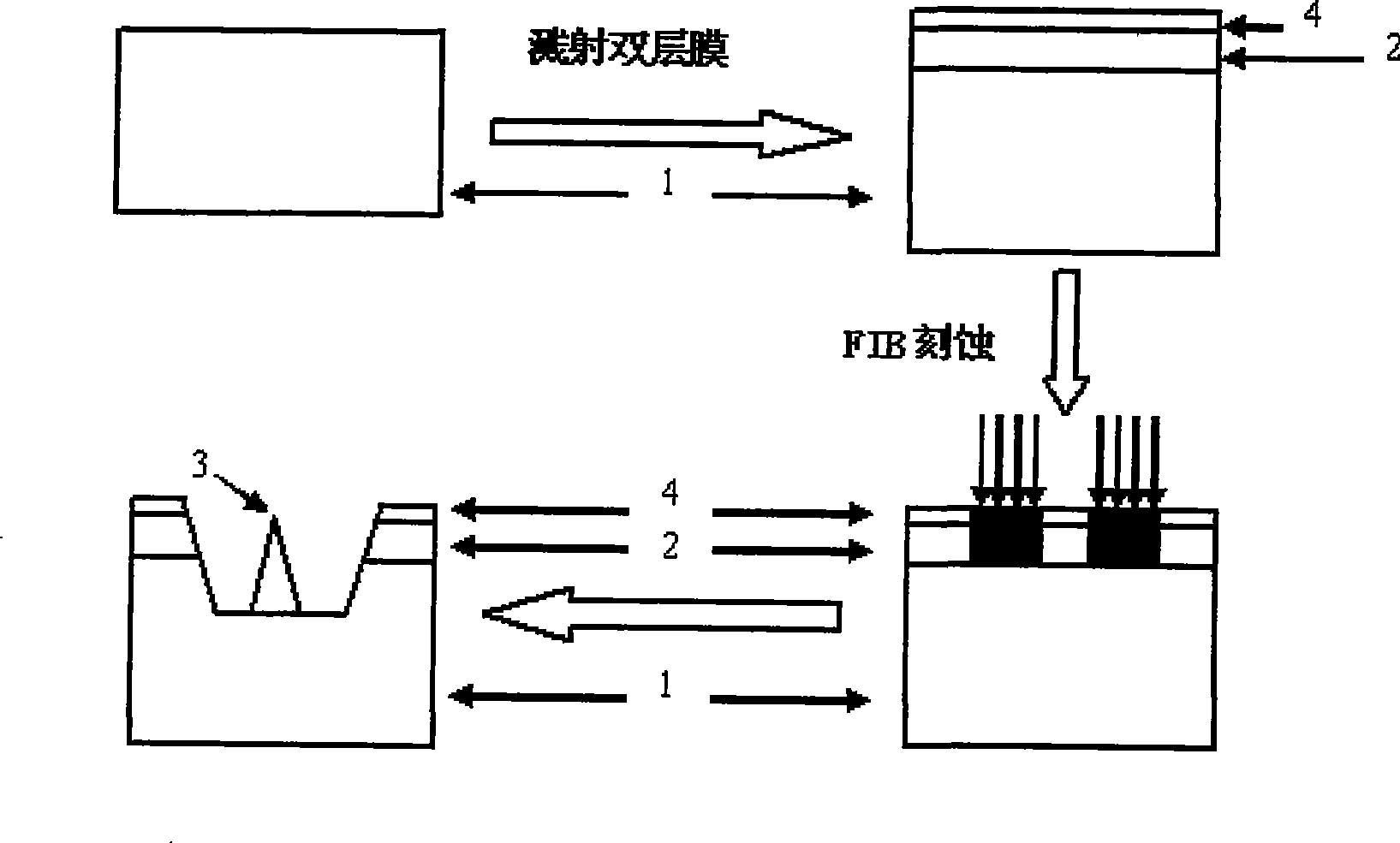

Method for manufacturing aluminum nitride silicon tip and grids structure

ActiveCN101497991APrecise control of cone densityOvercome consistencyVacuum evaporation coatingSputtering coatingEtchingRadio frequency magnetron sputtering

The invention relates to a preparation method of an aluminum nitride conical tip and a grid conical tip structure thereof. The method comprises the following steps: a layer of aluminum nitride film grows on a clean silicon substrate or a layer of gold film is then deposited on the clean silicon substrate by a radio-frequency magnetic control sputtering method; the silicon substrate is then put in a focused ion beam etching system; when the vacuum degree reaches 5.5 multiplied by 5-10mbar, a 5kV electron beam high voltage is applied to observe and position the appearance of a sample; an ion beam source is applied, and a beam current is arranged; finally, an etching pattern is arranged finally, and the focused ion beam etching is implemented to the aluminum nitride film sample according to the etching pattern to obtain the aluminum nitride conical tip 3 structure or the grid conical tip structure. The length-diameter ratio of a single cone of the aluminum nitride conical tip 3 structure is between (3-30):1, the minimum curvature radius of the tip part is less than 20 nanometer, and the diameter at the bottom is 100 nanometer to few microns. The invention can prepare the aluminum nitride conical tip and the grid conical tip structure thereof with controllable length-diameter ratio, omits a plurality of working procedures of depositing an insulating layer, photoetching, and the like which are necessary in the traditional process and has simple process and low cost.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

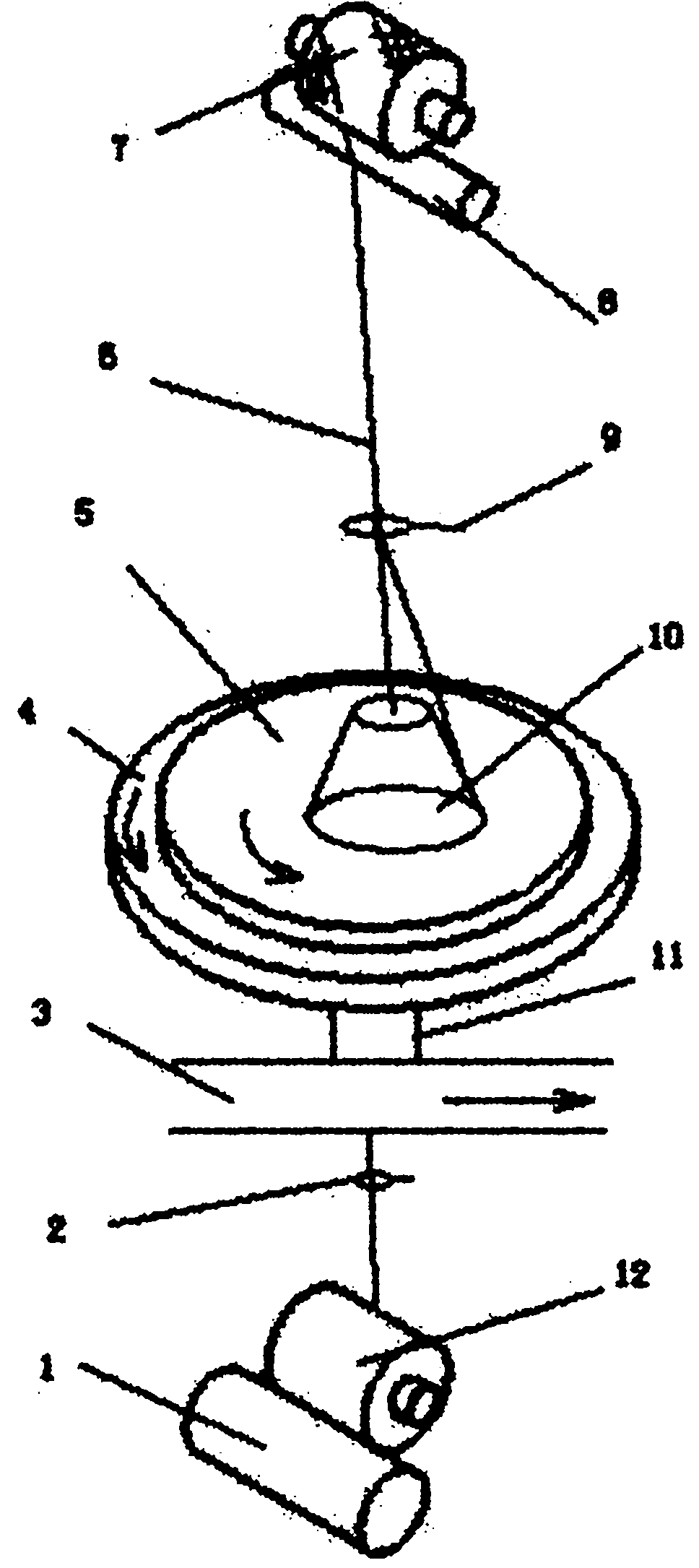

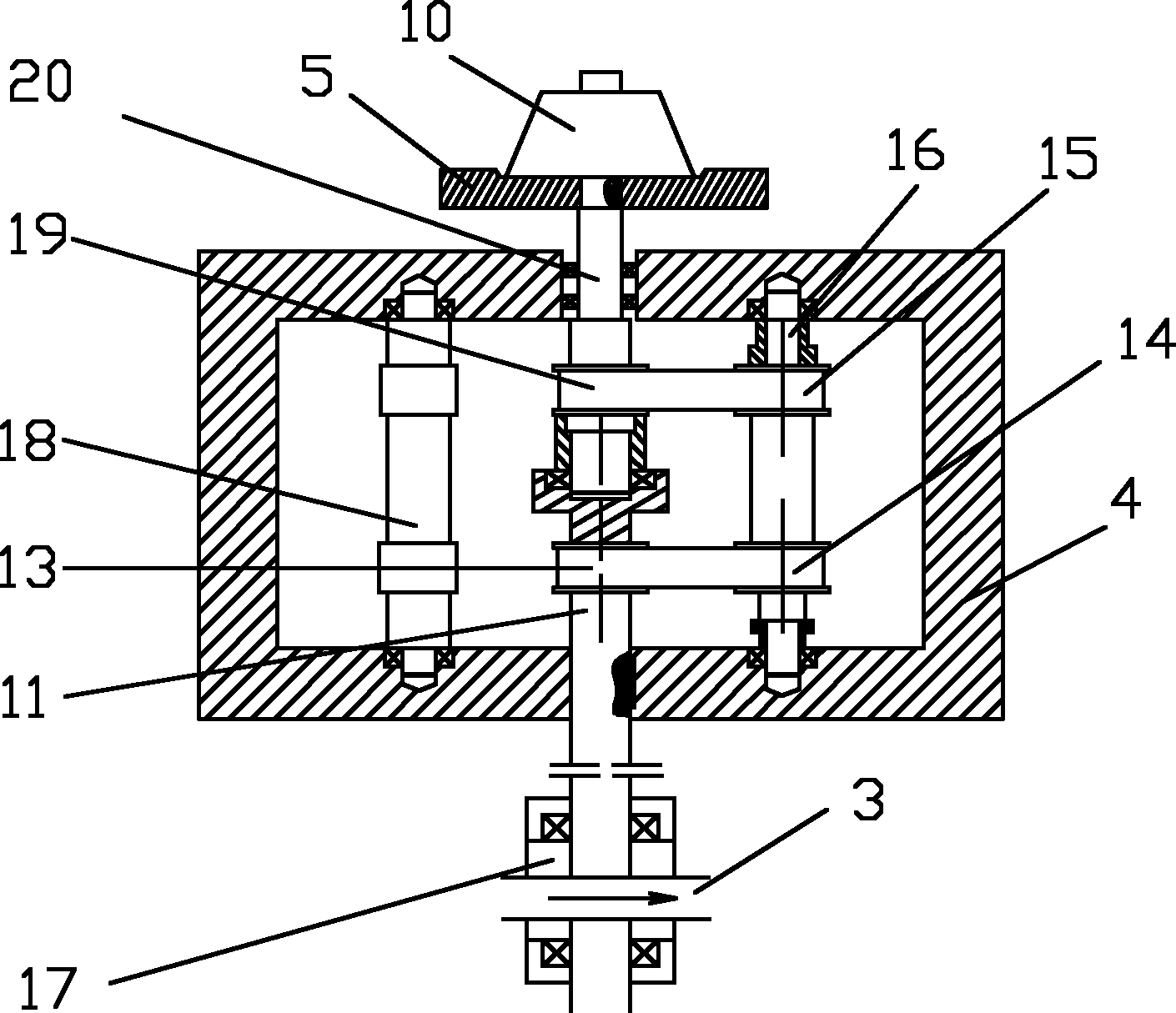

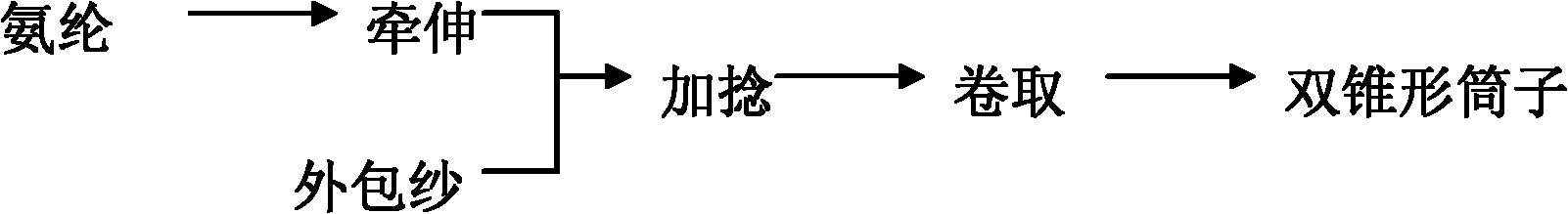

Device and method for covering yarn

The invention relates to a device for covering yarn, which comprises an unwinding device, a twisting device, a drafting device and a winding device, at least one number-one rotary plate is arranged below a number-two rotary plate, the number-two rotary plate is arranged above an axis line in the number-one rotary plate by a driven shaft, a driving shaft is arranged below the axis line in the number-one rotary plate, the number-one rotary plate is internally provided with an intermediate shaft and a balancing shaft which are parallel to the driving shaft respectively at the two sides of a shaft driving the number-two rotary plate, a tangential belt drives the driving shaft which is provided with a driving belt wheel, the driving belt wheel transmits a first intermediate belt wheel below the intermediate shaft by the belt wheel, a second intermediate belt wheel above the intermediate shaft drives the driven shaft, the driven shaft drives the number-two rotary plate to rotate, and the driving shaft drives the number-one rotary plate to rotate. The device utilizes the transmission ratio of the belt wheel to enhance the shaft rotational speed, has simple structure, is improved based on the original mechanical yarn covering machine, enhances the production efficiency, adopts the shape of a single cone in packaging outer yarn, reduces the original winding procedure and reduces the production cost.

Owner:DONGHUA UNIV

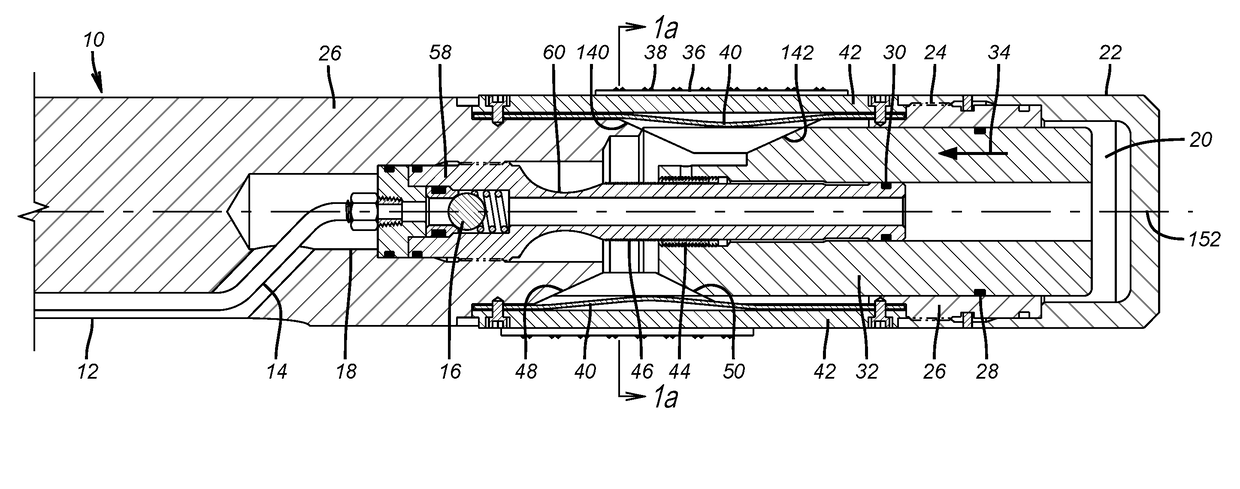

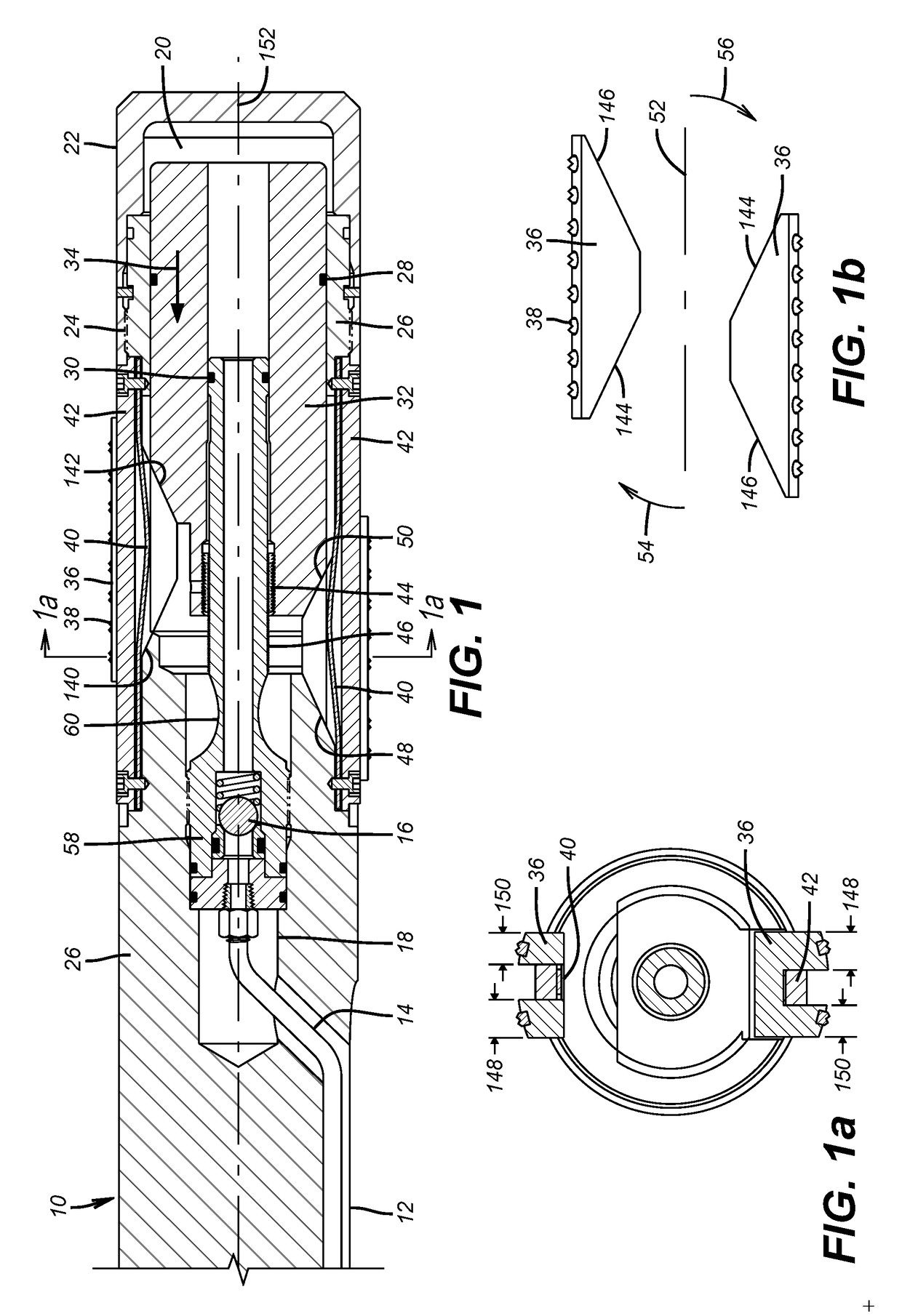

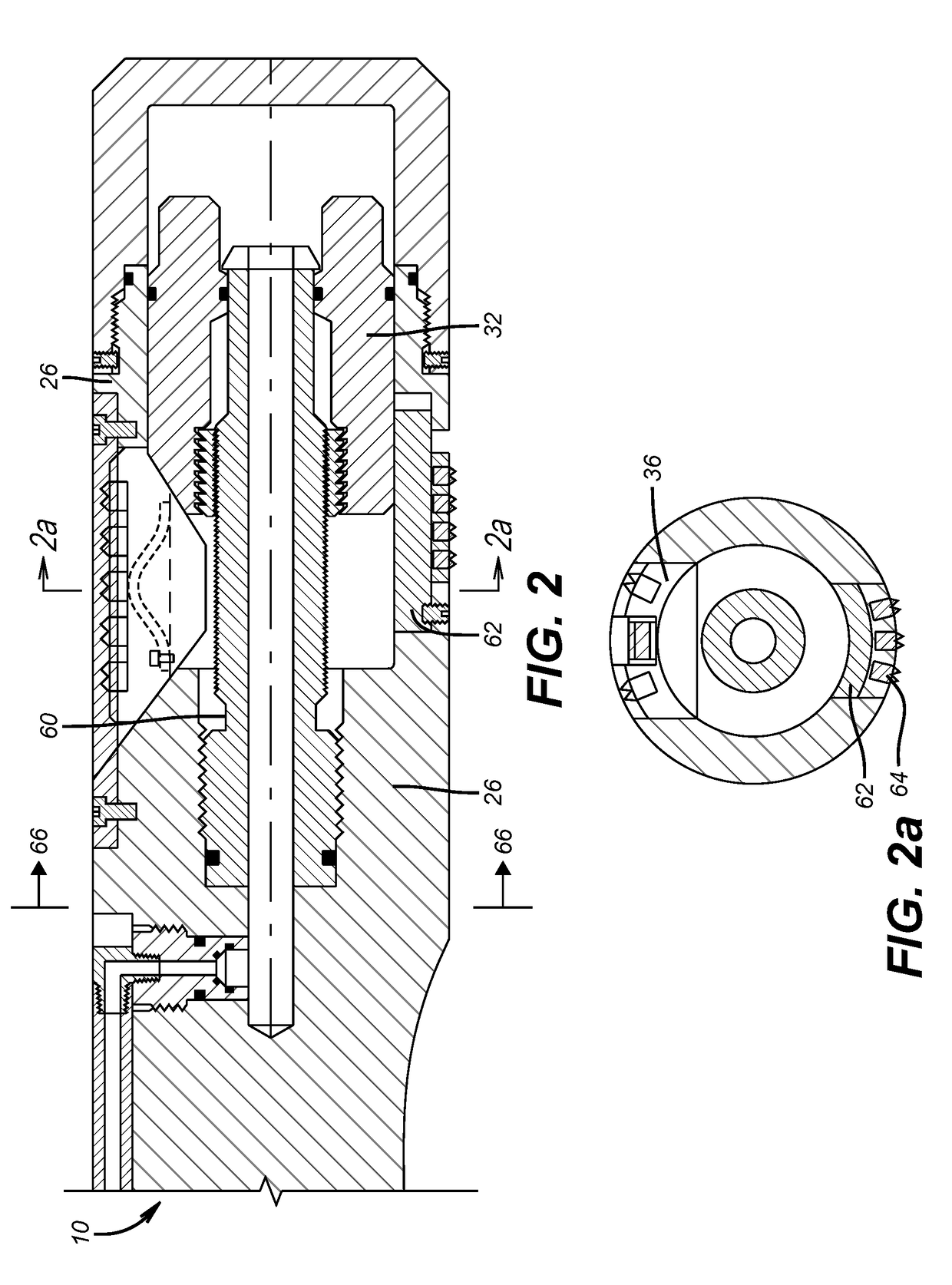

Hydraulic Whipstock Anchor

A whipstock anchor is hydraulically set and locked in the set position. Release occurs with a pull induced component failure that relieves hydraulic pressure that allows the slips to retract. Release can occur with a remotely actuated circuit that burns a retainer for a piston whose movement opens a vent or initiates a chemical reaction to undermine a lock ring. Movement of a single cone or opposed cones extends the slips. The cone angles being different (cone angles do not have to be different, it is preferred to have the slip angles different) adds a skew to the slips and positions the top of the whipstock against the tubular top in a horizontal run. A bottom cap is removable to convert to setting by set down weight or to attach a hydraulically operated packer below the slips. Slips can be extended with radial movement of pistons.

Owner:BAKER HUGHES INC

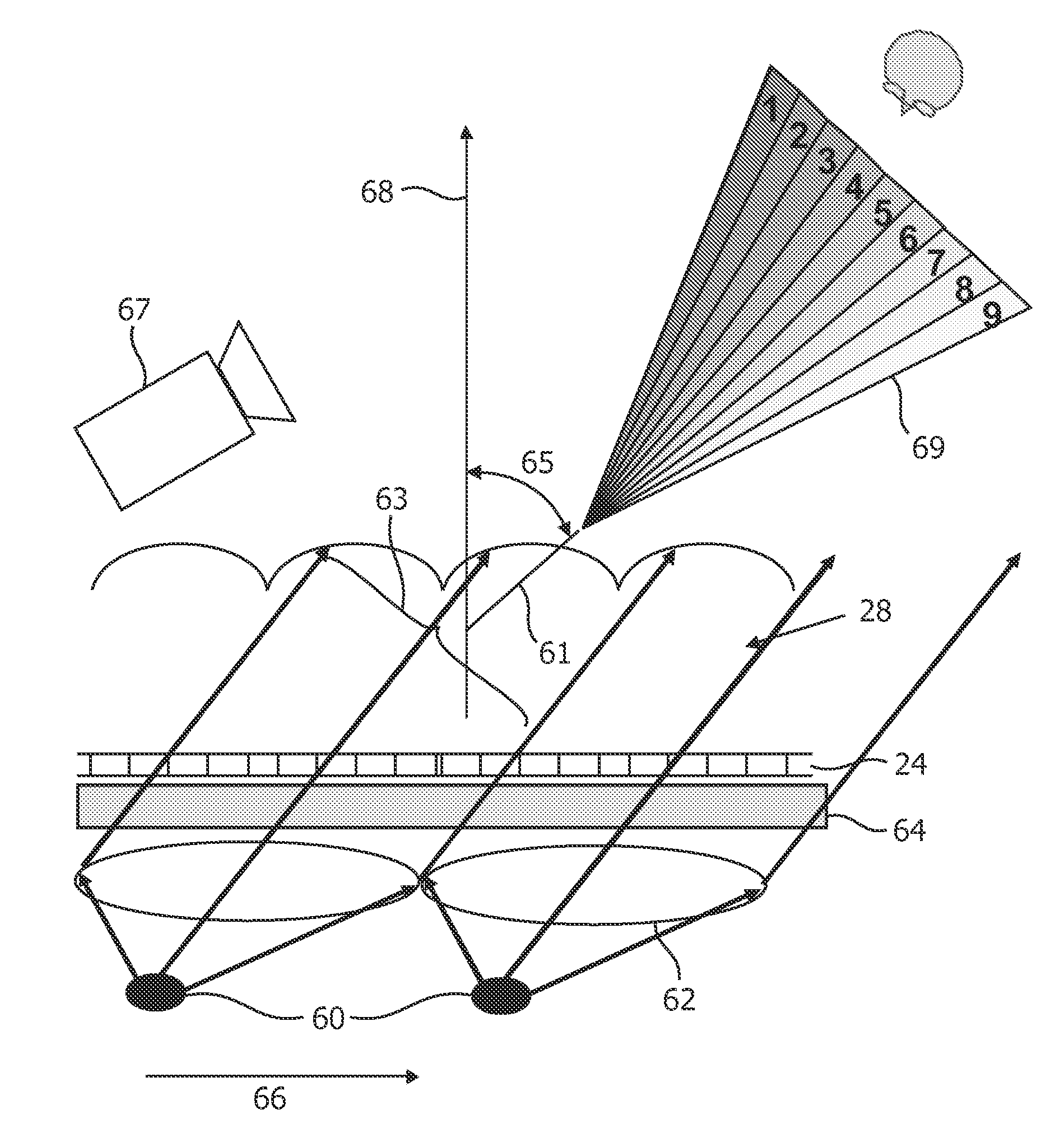

Multi-view display device

InactiveUS20160349524A1Reduce weightImprove matchSteroscopic systemsOptical elementsComputer graphics (images)Display device

A multi-view display device comprises a pixelated display panel and a backlight comprising an arrangement of light sources (30), wherein each light source, when turned on, illuminates an associated region of pixels of the display panel. A display controller is adapted to control the pixelated display panel and the arrangement of light sources such that a partial display output is provided comprising simultaneously a set of at least three 2D views with no repetition of individual 2D views.This arrangement provides an output with controlled illumination direction of the pixels so that view repetitions are avoided. The output can be a single cone of views, and the location from which the cone of views can be viewed depends on the relationship between the light sources of the backlight which are activated and the display panel.

Owner:KONINKLJIJKE PHILIPS NV

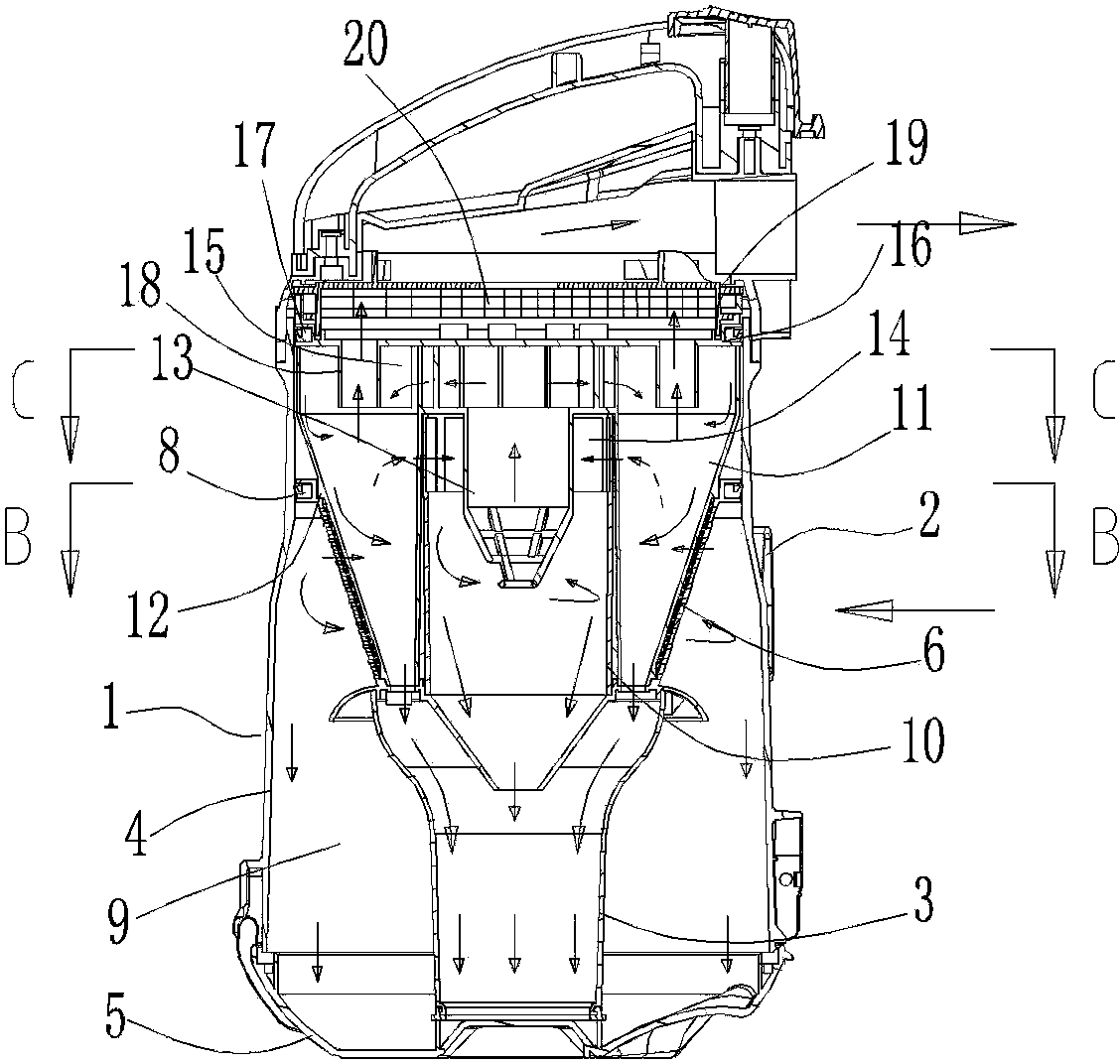

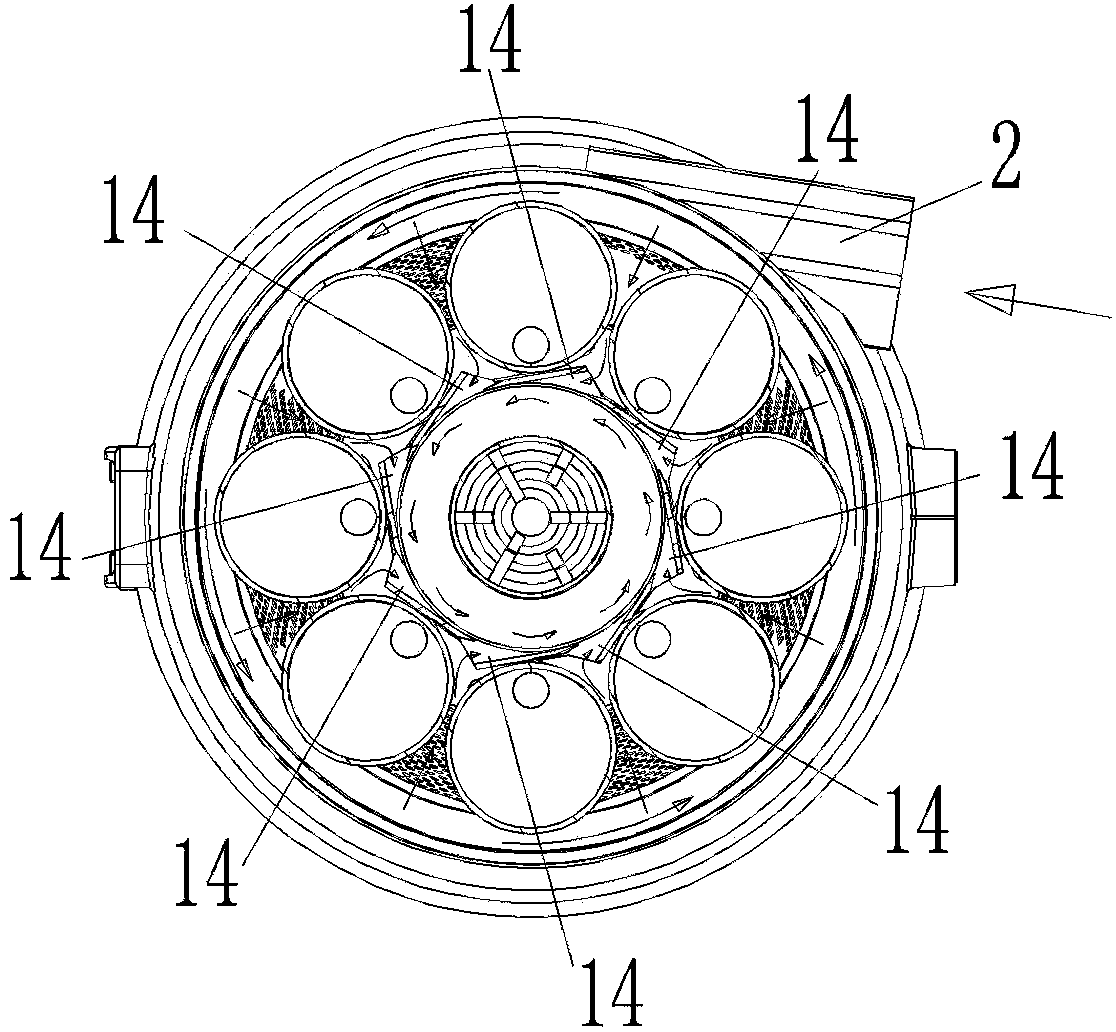

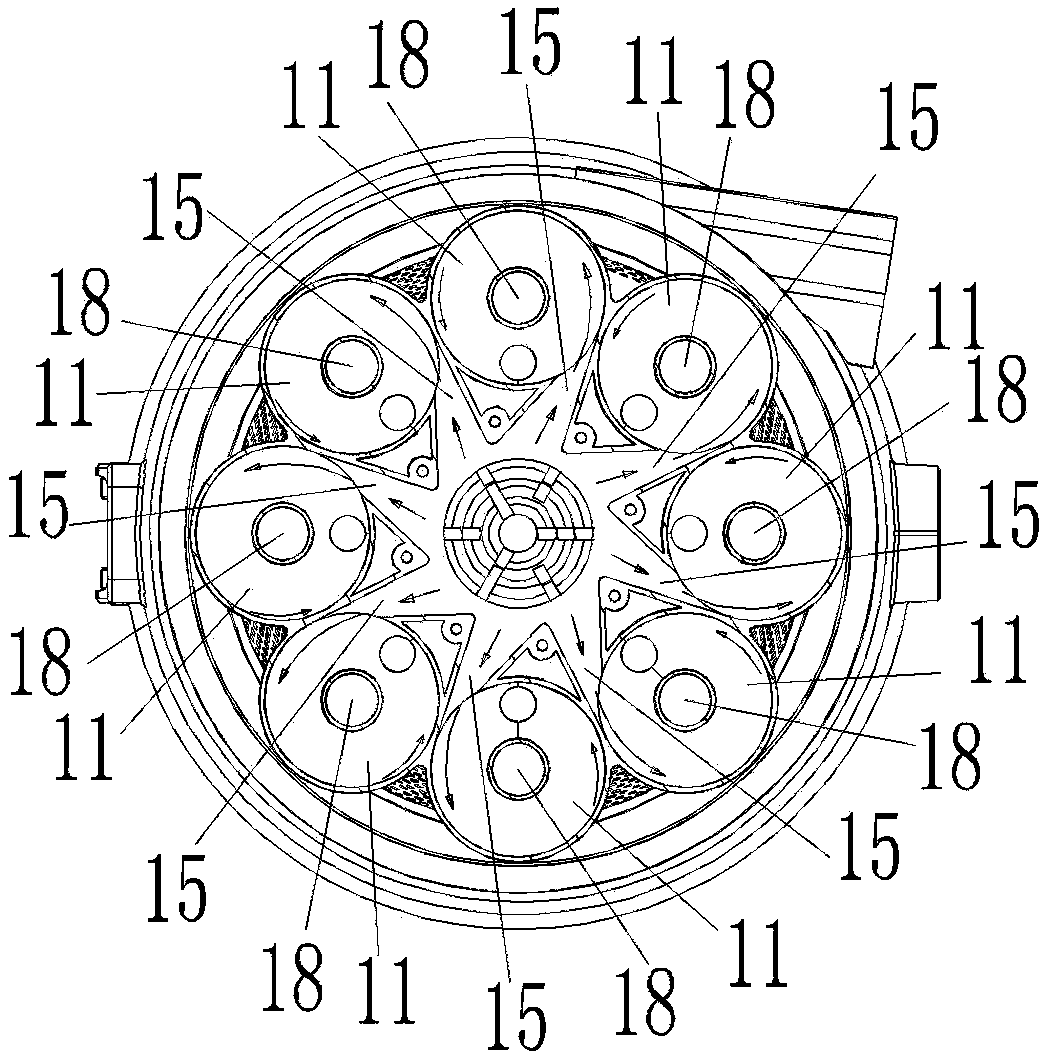

Three-stage cyclone separation dust collector

The invention discloses a three-stage cyclone separation dust collector, which comprises an outer dust bucket, wherein the outer dust bucket is provided with an outer tangential air inlet; an inner dust bucket is arranged in the outer dust bucket; a screen barrel which corresponds to the outer tangential air inlet is arranged above the inner dust bucket; the inner dust bucket, the screen barrel and the outer dust bucket are enclosed into a first-stage cyclone cavity; a rotary barrel and a group of rotary conical barrels are sleeved in the screen barrel; an air inducing barrel is further arranged in a circle enclosed by the rotary conical barrels; the air inducting barrel is inserted into the rotary barrel; the upper end of the rotary barrel is provided with a second-stage tangential air inlet; the upper end of the rotary conical barrel is provided with a third-stage tangential air inlet; an air outlet cover covers the rotary conical barrel; the back face of the air outlet cover is provided with air outlet barrels which correspond to the rotary conical barrels; the air outlet barrels extend into the rotary conical barrels; a screen cover plate further covers the air outlet cover; the screen cover plate is filled with filter cotton. According to the three-stage cyclone separation dust collector, three-stage cyclone separation is adopted, so that dust is separated more completely, and separation and coarse dust and fine dust is realized; the first stage of a cyclone system adopts the screen barrel while the second stage adopts a single cone structure, so that the structure is simple, the cost is low, and a good effect is achieved.

Owner:CUORI ELECTRICAL APPLIANCES GRP

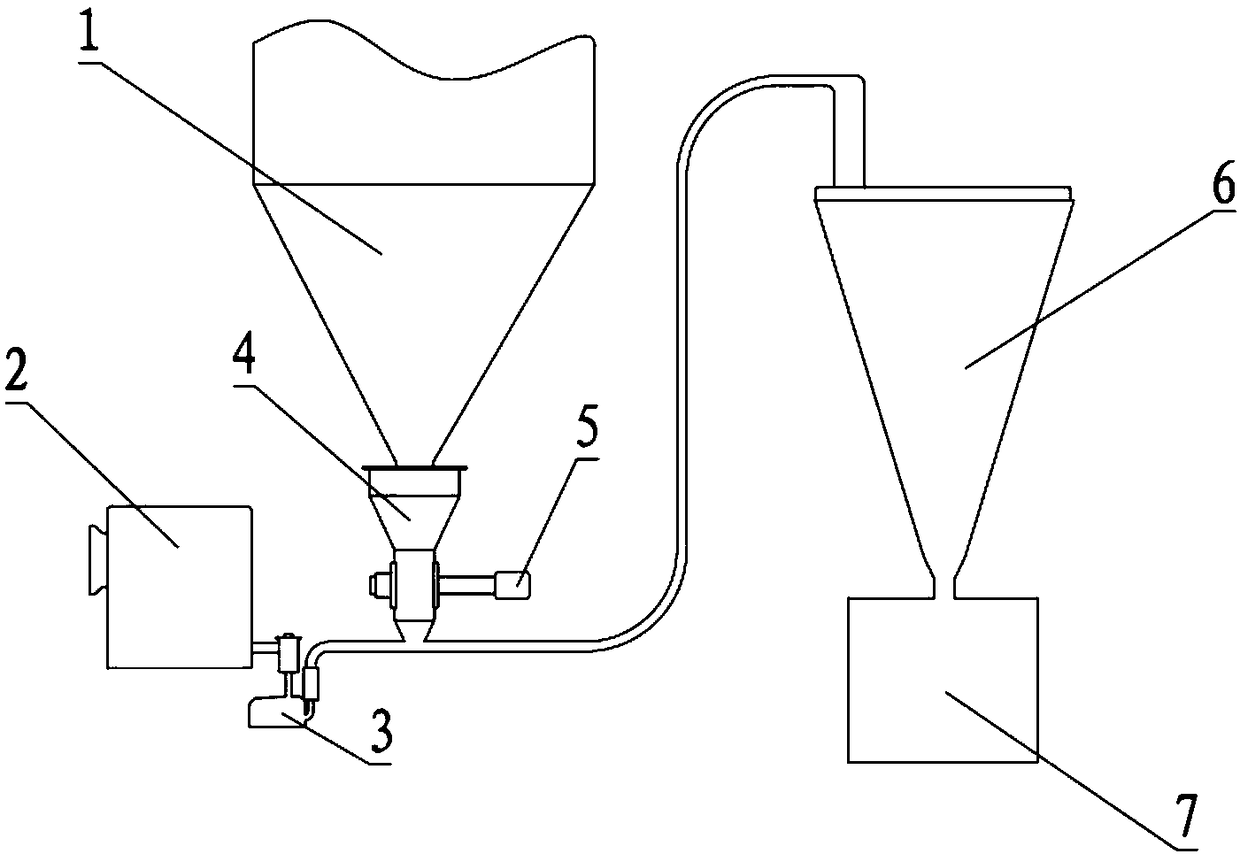

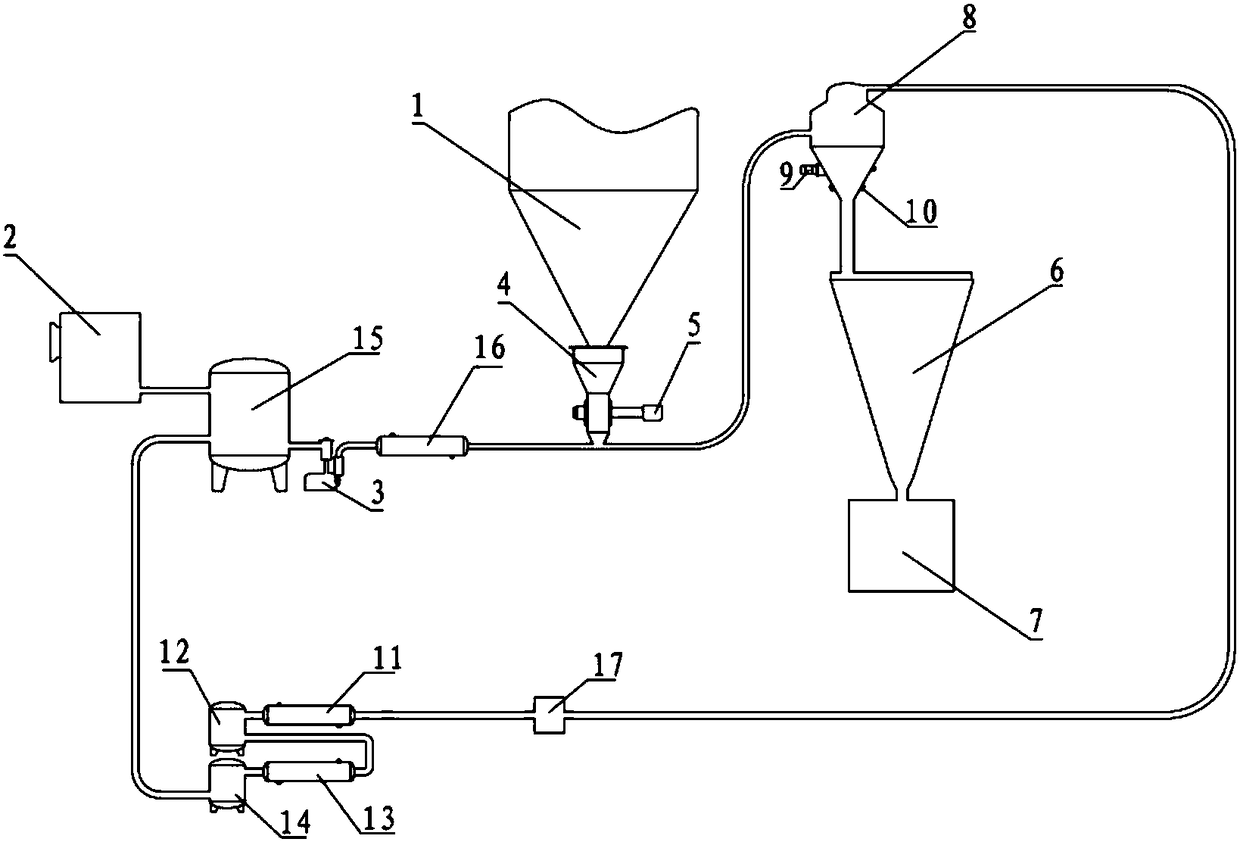

Automatic conveying system

ActiveCN108163581ARealize automatic deliveryQuality assuranceMixer accessoriesBulk conveyorsEngineeringAbsorption of water

The invention provides an automatic conveying system. The automatic conveying system comprises a feeding bin, a dehumidifying and cooling mechanism, a fan, an air locking valve and a single-cone mixer, wherein the feeding bin is used for storing output materials, and the air locking valve is arranged on an outlet pipeline of the feeding bin; an outlet of the dehumidifying and cooling mechanism communicates with an air inlet of the fan; an air outlet pipeline of the fan is connected with an inlet of the single-cone mixer, and an opening communicating with an outlet of the air locking valve is arranged in the air outlet pipeline; and an outlet of the single-cone mixer communicates with a packaging mechanism. The automatic conveying system provided by the invention has the advantages that theautomatic transporting of materials can be realized, and the conveying efficiency is increased; by adopting air which is dehumidified and cooled to transport the materials, the quality of the materials is ensured, and the problem that the quality reduction of the materials is caused by the absorption of water in the air as the materials are in contact with the air in the transporting process is avoided; and at the same time, the materials are transported in a closed environment, so that the influence of dust on the environment in the transporting process of the materials is reduced.

Owner:JINGMEN GEM NEW MATERIAL

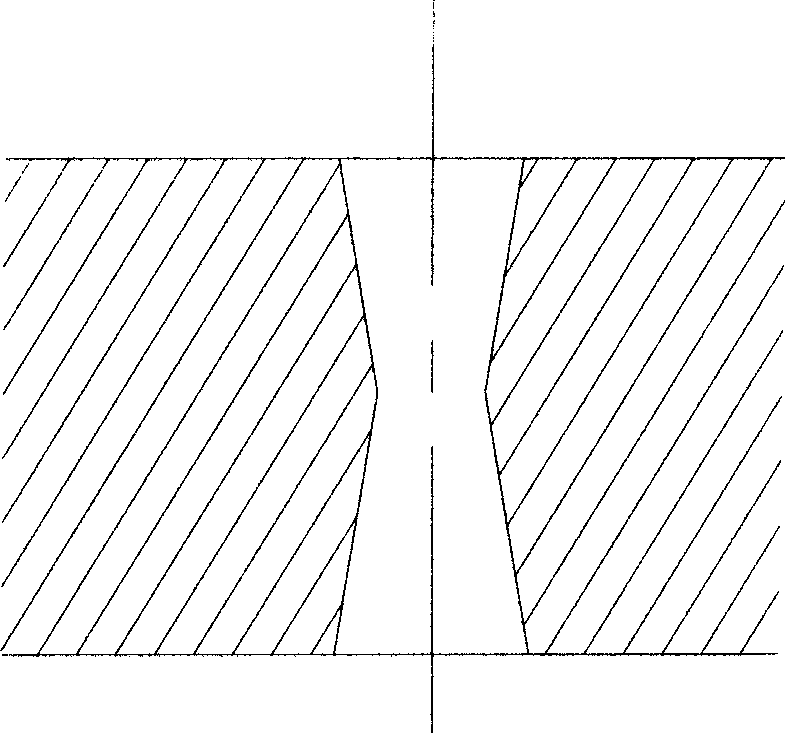

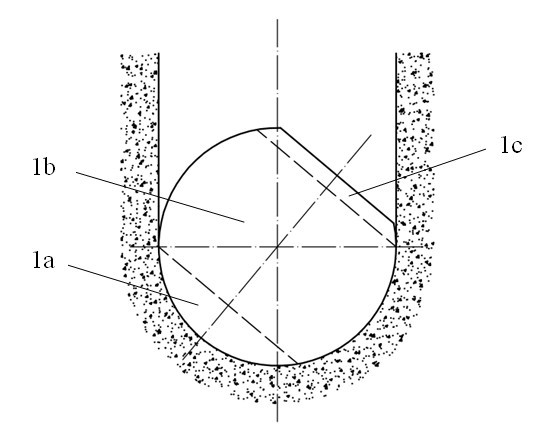

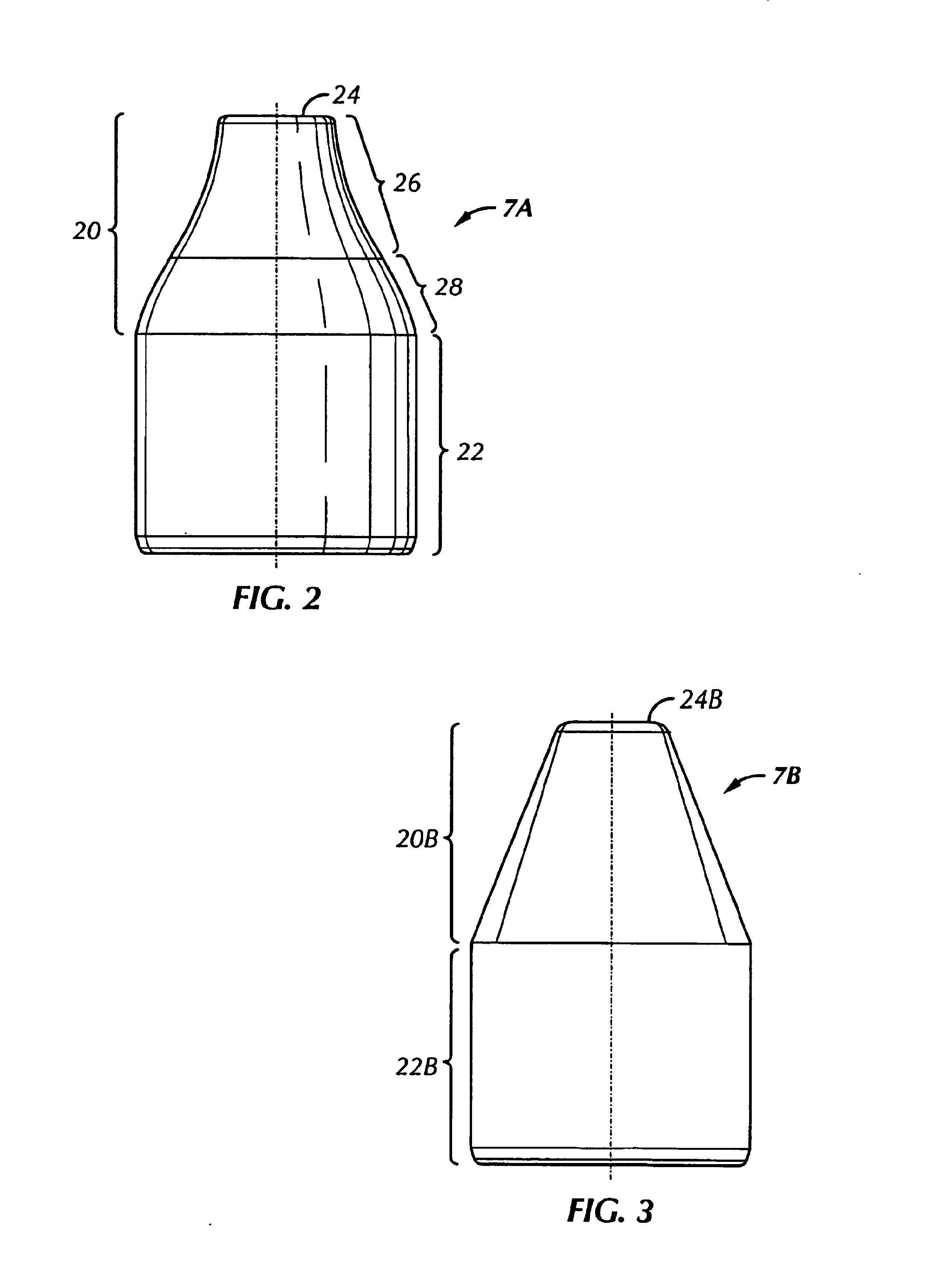

Single cone rock bit having inserts adapted to maintain hole gage during drilling

A roller cone drill bit is disclosed which includes a bit body adapted to be coupled to a drill string. A bearing journal depends from the bit body. A single roller cone is rotatably attached to the bearing journal. The roller cone has a plurality of inserts disposed at selected positions about the cone. The journal defines a rotation angle with respect to an axis of rotation of the bit such that the roller cone includes a wall contact zone and a bottom contact zone. At least one of the inserts disposed in the wall contact zone has an extension portion terminating in a substantially planar upper surface.

Owner:SMITH INT INC

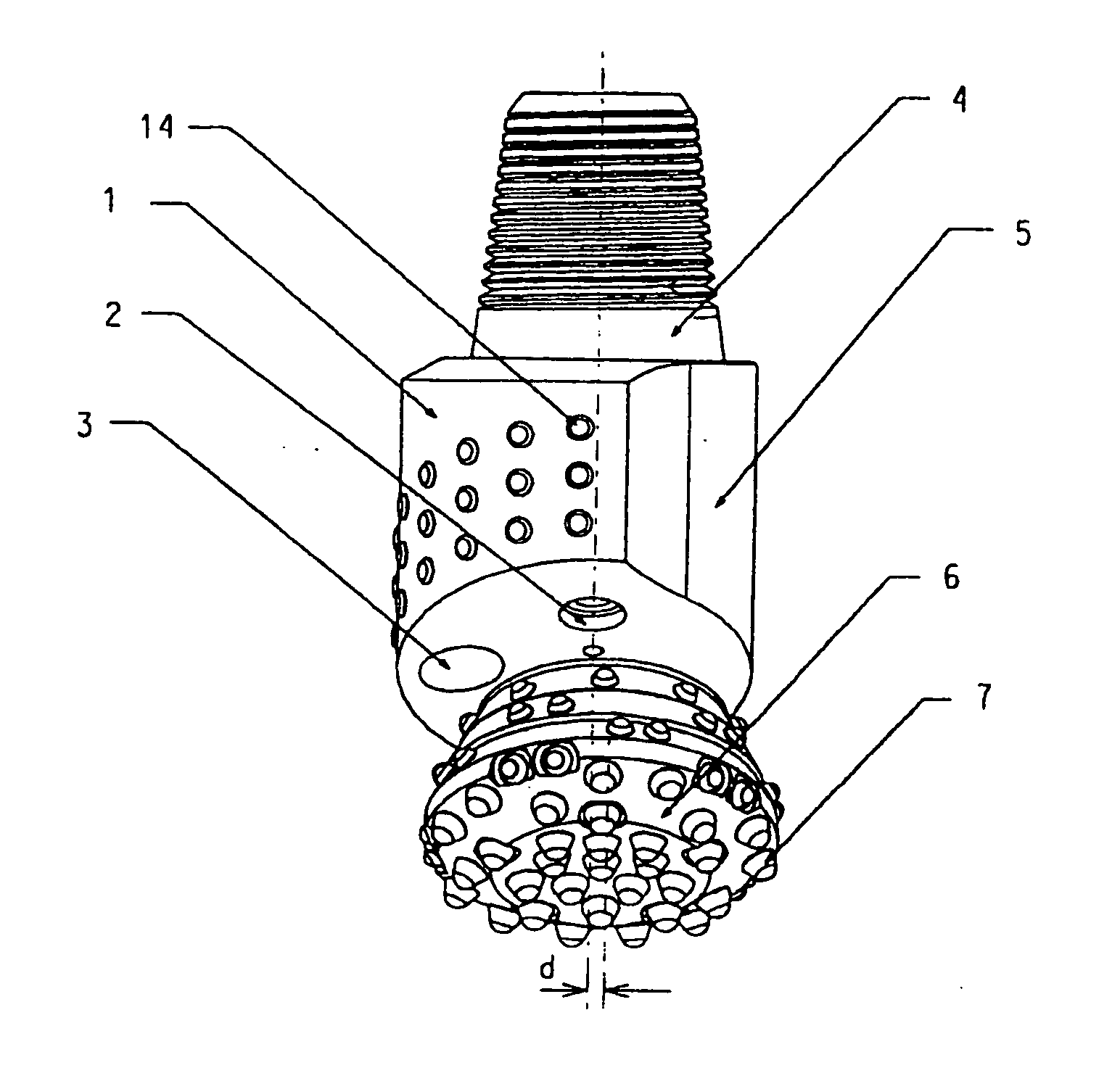

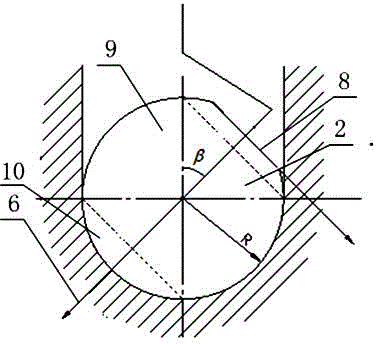

Roller bit with a journal pin offset from the central axis thereof

ActiveUS20050252692A1Impact abilityReduce distanceDrill bitsCutting machinesWear resistantWell drilling

This invention relates to a single cone bit with offset axis and composite cones for oil and gas drilling, mining and other subterranean drilling operations. The bit consists of a head body and a cone. The cone section has a shape of composite cones. The outer circumference of the cone is composed of from back face of the cone to top of the cone an extended gage surface, an outer cone surface and a main cone surface. A plurality of cutting elements is mounted onto each cone surface. A head journal at lower end of the head body is for rotatablely connection with the cone. Between the axis of head journal and the axis of the bit, there is an offset value d along rotating direction of the cone. A gage pad is arranged on head body at a location opposite to the offset direction of the head journal. The gage pad is fitted with inserts or hardfaced with wear resistant alloy to prevent bit from whirling and prevent head body from being worn out and to ensure gage protection. Junk slots are machined along the side of head body and jet ports are arranged at lower bevel of the head body to guarantee cuttings removal and effective cleaning results. This invention improves the bit's ability to break rocks through impact for specific use in hard formations. The bit performance is obviously improved and overall drilling cost reduced.

Owner:KINGDREAM PLC CO

Single cone vacuum drier

InactiveCN102331159AIncrease volumeIncrease the areaDrying using combination processesDrying solid materials with heatOrganic solventEngineering

The invention relates to a single cone vacuum drier, which belongs to the technical field of heat exchange. The single cone vacuum drier is used for vacuum drying thermally sensitive medicines and organic solvent chemical products and recovering the organic solvent and comprises an inner cylinder body, a steam heating jacket, a left rotating shaft, a right rotating shaft, a left bearing block, a right bearing block, an inner heating plate, a driving chain wheel, a driver and the like, wherein one end of the inner cylinder body adopts a standard elliptical end socket; the other end of the inner cylinder body adopts a conical body; for efficiency of a product in drying and the increase of the number of inner heating plates, the standard elliptical end sockets are respectively arranged at two ends of the steam heating jacket; the system is heated by using 40-100 low-temperature saturated water steam instead of traditional hot water; the inner heating plates are arranged, so that the total heating area of the drier is increased by 2-4 times compared with that of a traditional dual cone vacuum dryer; the thickness of stainless steel of each inner heating plate is only 1 / 4-1 / 2 of the thickness of the cone; and one single cone vacuum drier can be equivalent to a traditional dual cone vacuum dryer, thus the drying efficiency can be multiply improved and the consumption of the stainless steel and power consumption can be greatly saved.

Owner:沈善明

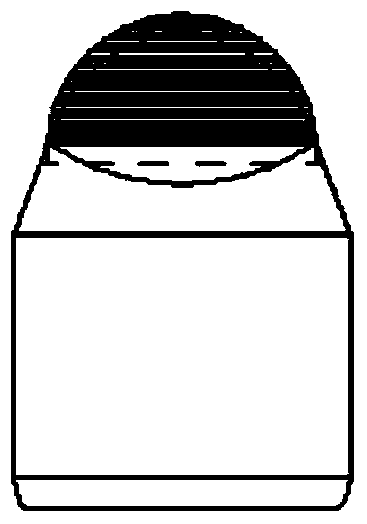

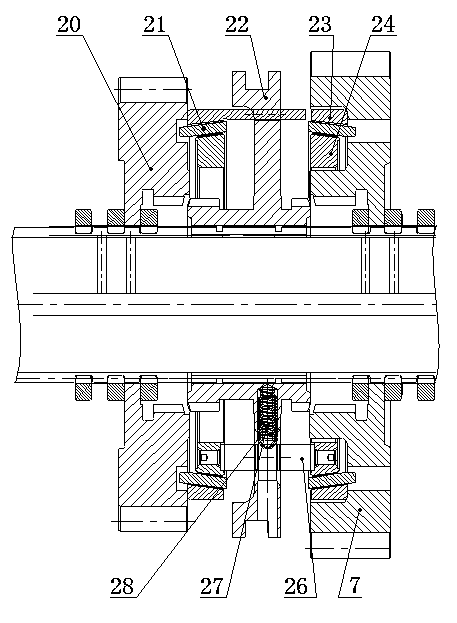

O-shaped loop and metal ring two-way combined sealed oil storage single-cone bit

ActiveCN103410448ASolve the sealing problemSolve the axial problemDrill bitsConstructionsUltra high speedAlloy

The invention discloses an O-shaped loop and metal ring two-way combined sealed oil storage single-cone bit. By means of the bit, two-way combined sealing of axial sealing of the end face of a cone metal ring (4) and radial sealing of a cone O-shaped loop (5) under the condition of ultra high speed rotation is achieved, a floating sleeve bearing communicated with an oil storage sac (7) is used, and PDC teeth and hard alloy teeth are inserted in a cone (2) and a body (1) directed at action zone differences, so that the comprehensive well bottom rock breakage efficiency is improved, the bit gauge protection effect is enhanced, the bit operation stability is improved, the drilling period is shortened, and the drilling cost is reduced.

Owner:陕西金刚石油机械有限公司

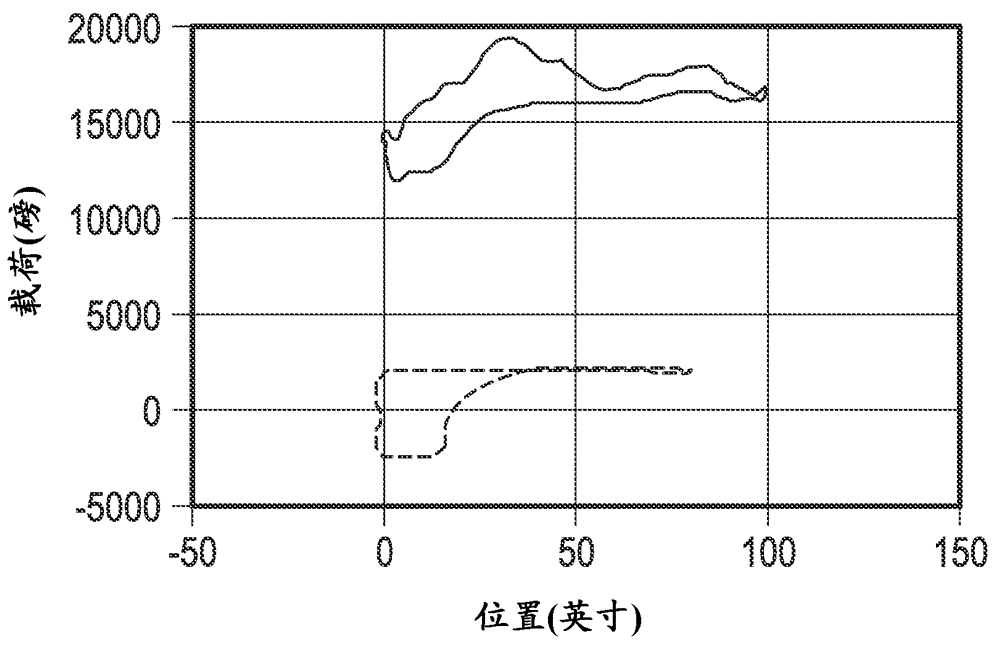

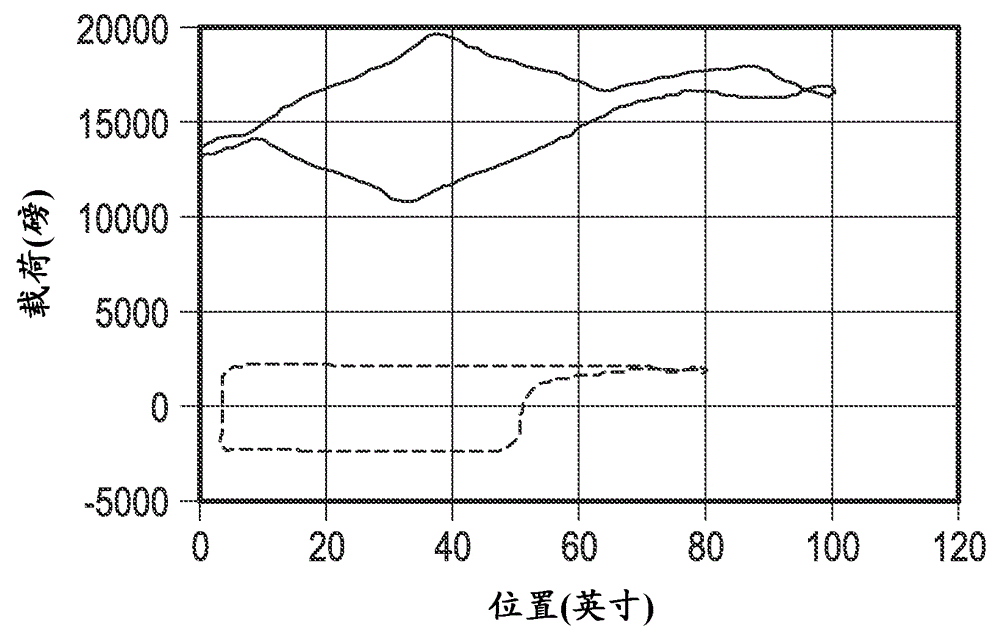

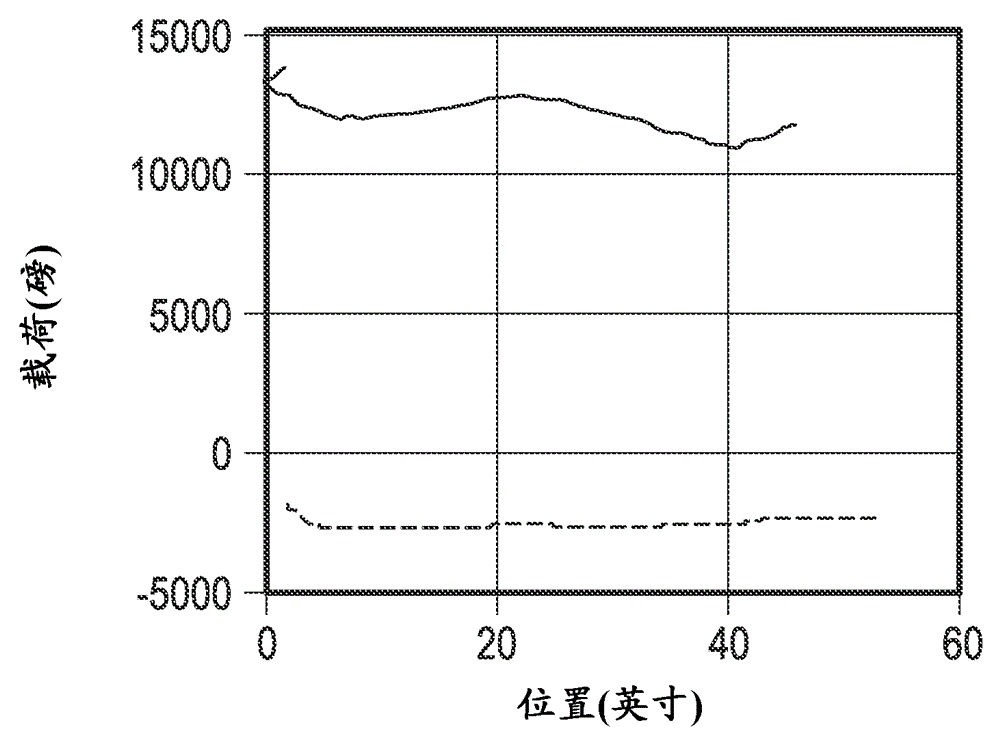

Real-time pump diagnostic algorithms and application thereof

Owner:LUFKIN INDUSTRIES

Enhanced drill bit lubrication apparatus and method

Owner:TIGER 19 PARTNERS

KDP crystalloid long-seed crystal single-cone growth method

ActiveCN110055579AImprove optical qualityImprove Optical UniformityPolycrystalline material growthFrom normal temperature solutionsPropellerTriple frequency

The invention discloses a KDP crystalloid long-seed crystal single-cone growth method. According to the growth method, the lower end of a long-seed crystal is limited by a lower tray, the upper end ofthe long-seed crystal freely and conically grows, four cylindrical surfaces in the two directions of (100) and (010) can grow, the problem of growth stress is omitted in the growth process of the crystal, all cut out optical elements have high optical quality, four cylindrical surfaces with highly similar growing environments simultaneously grow in the growth process, mixing is implemented by a leaf-shaped mixing propellers in the growth process of the crystal, so that the cut out optical elements have high optical homogeneity, a cutting angle of a KDP crystal triple frequency element is unique, the grown crystal has high cutting efficiency when cutting the triple frequency element, and the area of the cut maximum triple frequency element can be known according to the horizontal size of the grown crystal in advance.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

9-gear twin-countershaft helical gear lock pin synchronizer transmission

ActiveCN103388658AExtended service lifeHigh working reliabilityMechanical actuated clutchesToothed gearingsLow noiseGear wheel

The invention discloses a 9-gear twin-countershaft helical gear lock pin synchronizer transmission. Double countershafts and a large center distance are adopted by a main transmission part; all first, second, third and fourth speed gears, a climbing gear and a reverse gear take the shape of a helical gear; the front and rear ends of a main shaft are provided with a main shaft front positioning mechanism and a main shaft rear positioning mechanism respectively; a double cone lock pin synchronizer is arranged between the first and second speed gears; a single cone lock ring synchronizer is arranged between the third and fourth speed gears; the reverse gear and the climbing gear are connected with a sliding gear sleeve; a secondary transmission part is provided with a planetary gear train and a widened double cone lock ring synchronizer; and the main shaft is connected with a sun gear in the secondary transmission part through a spline transition sleeve. According to the 9-gear twin countershaft helical gear lock pin synchronizer transmission, full synchronizer gear shift is realized from the first to fourth speed gears, and meanwhile, the widths of the reverse gear, the climbing gear and the first gear are correspondingly increased, so that the service life at a low-gear zone during heavy load is prolonged, the gear shift performance of a high-gear zone is improved, and the working reliability of the transmission is also improved; and the 9-gear twin countershaft helical gear lock pin synchronizer transmission has the advantages of labor saving in operation, stable gear shift transmission, low noise and long service life.

Owner:SINO TRUK JINAN POWER

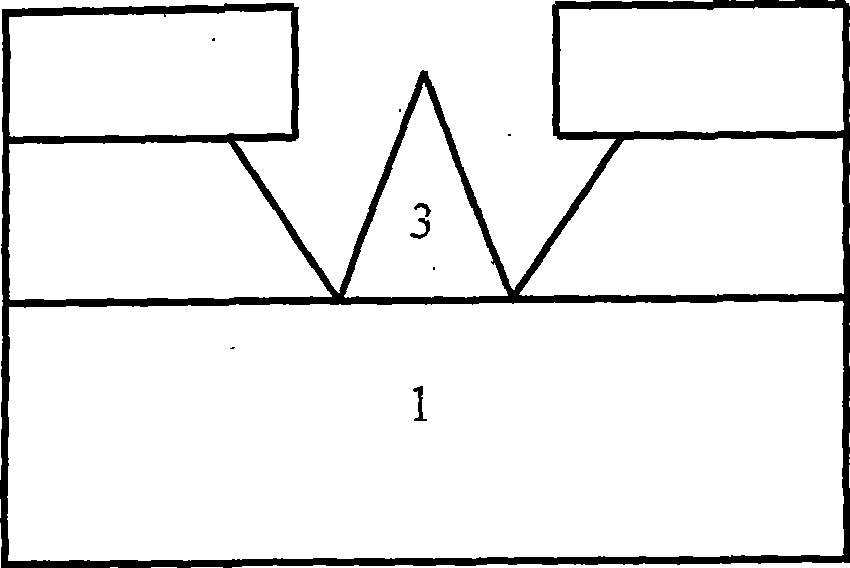

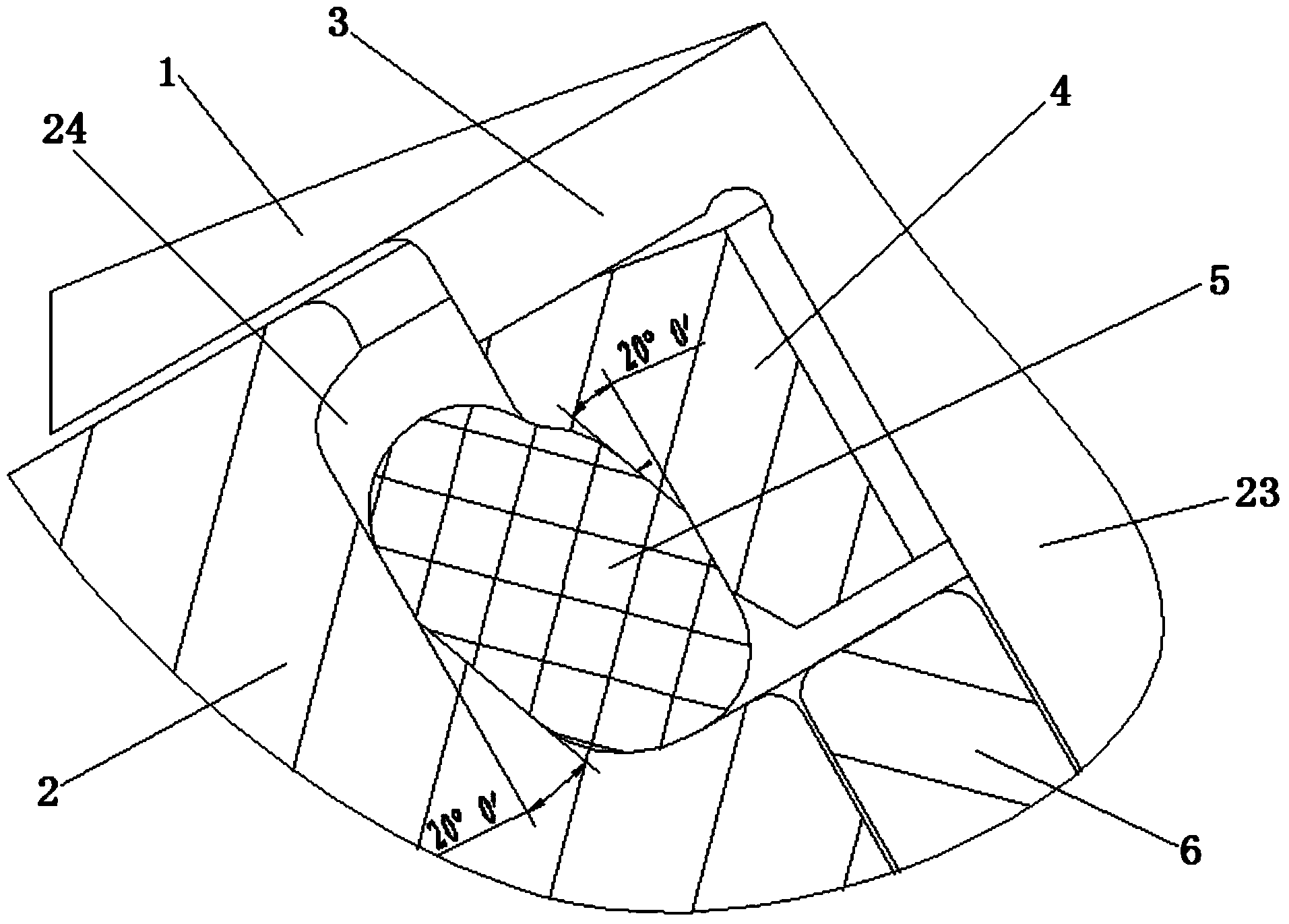

Single cone bit based on non-planar combination PDC strengthened teeth

ActiveCN104612589AImprove rock breaking efficiencyImprove wear resistanceDrill bitsConstructionsGonial angleStructural engineering

The invention discloses a single cone bit based on non-planar combination PDC strengthened teeth. The single cone bit based on the non-planar combination PDC strengthened teeth comprises a bit body (1) and a cone (2), a tooth distributing belt (5) is distributed on the cone (2), tooth holes are formed in the tooth distributing belt (5), the tooth distributing face of the cone (2) comprises a main cutting area (9) and an auxiliary cutting area (10), the non-planar combination PDC strengthened teeth (3) are welded in the tooth holes, located in the main cutting area (9), on the tooth belt (5), and cemented carbide conisphere teeth (4) are arranged in tooth holes, located in the auxiliary cutting area (10), on the tooth distributing belt (5). The single cone bit based on the non-planar combination PDC strengthened teeth has the advantages that the adopted teeth are combined the cemented carbide conisphere teeth with the non-planar combination PDC strengthened teeth, the structure angle of the teeth on the cone teeth distributing belt is reasonably arranged, so that the wear resistance of the teeth in the main cutting area is stronger, the single cone bit can be applied to harder and abrasive stratums, staggered circular tooth distributing is adopted on the cone, so that dead cutting points can be eliminated, the rock-breaking efficiency of the bit is improved and the service life of the bit is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com