Synchronizer for dual-clutch automatic transmission of car

A technology of automatic transmission and double clutch, which is applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of cost increase, synchronous torque limitation, shift fork and hydraulic system requirements, and achieve cost reduction and large synchronization Moment, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

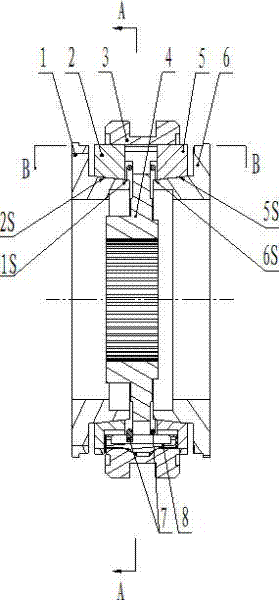

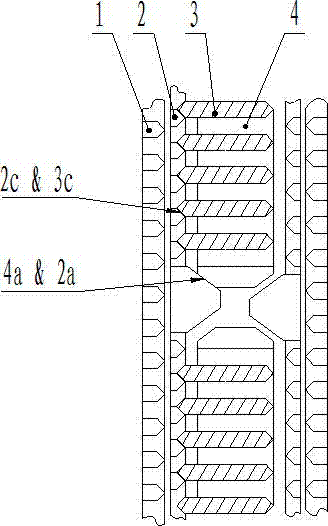

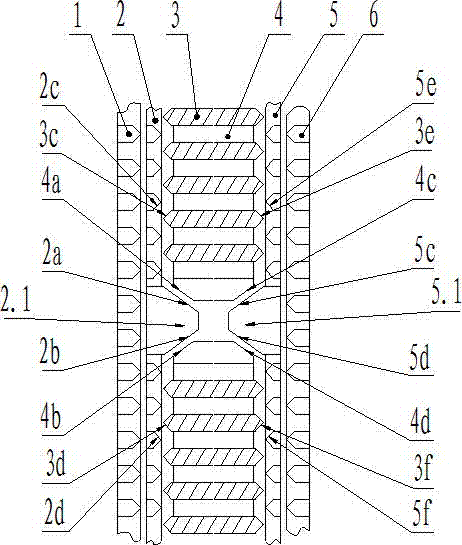

[0020] see figure 1 and figure 2 , the synchronizer used in dual-clutch automatic transmission for cars includes an inertia lock ring type synchronizer, which includes an X-gear engaging ring 1, an X-gear synchronizing ring 2, a synchronizer engaging gear sleeve 3, and a synchronizer spline hub 4 , Y gear synchronizing ring 5 and Y gear engaging gear ring 6; wherein the synchronizer engaging gear sleeve 3 is set on the X gear synchronizing ring 2 and Y gear synchronizing ring 5 at the same time; the synchronizer spline hub 4 is located on the X gear synchronizing ring 2 and In the inner circumference of the corresponding end of the Y gear synchronizing ring 5; the axial side surfaces of the synchronizer spline hub 4 are respectively equipped with synchronizer springs 7, and the circumference of the synchronizer spline hub 4 is evenly distributed with three axial slide grooves and Three axial booster slots, each slide slot is equipped with a slider 8; the circumference of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com