Patents

Literature

48results about How to "Small shift force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

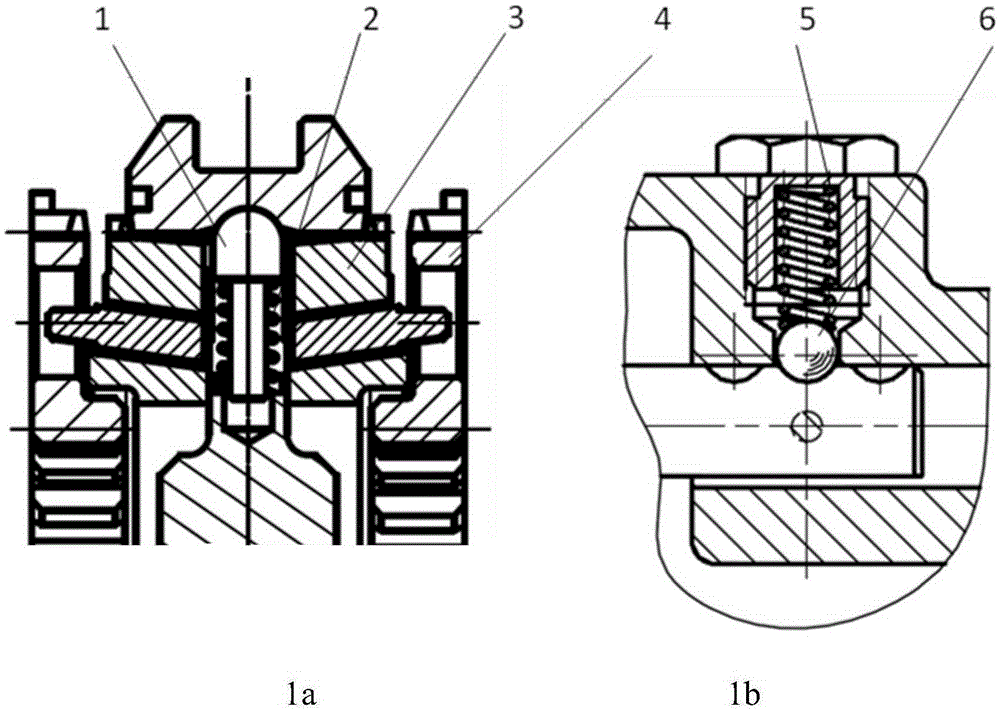

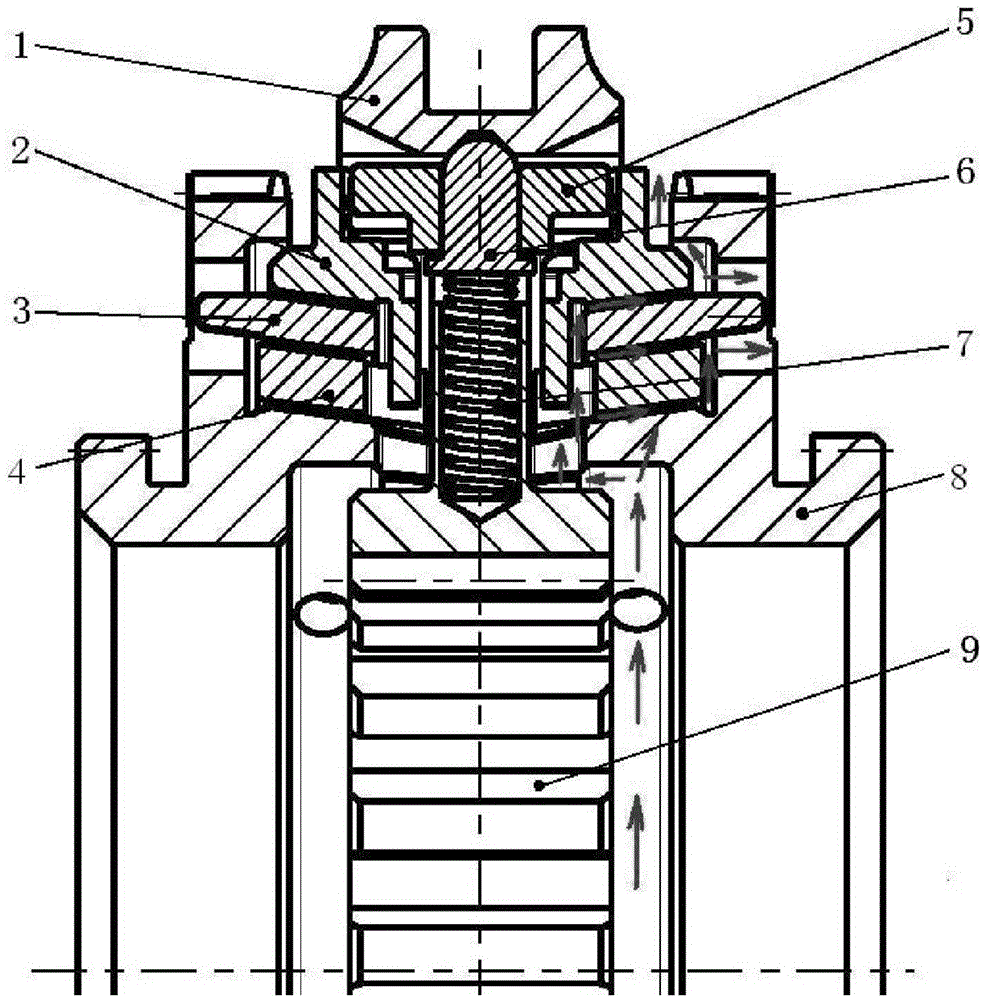

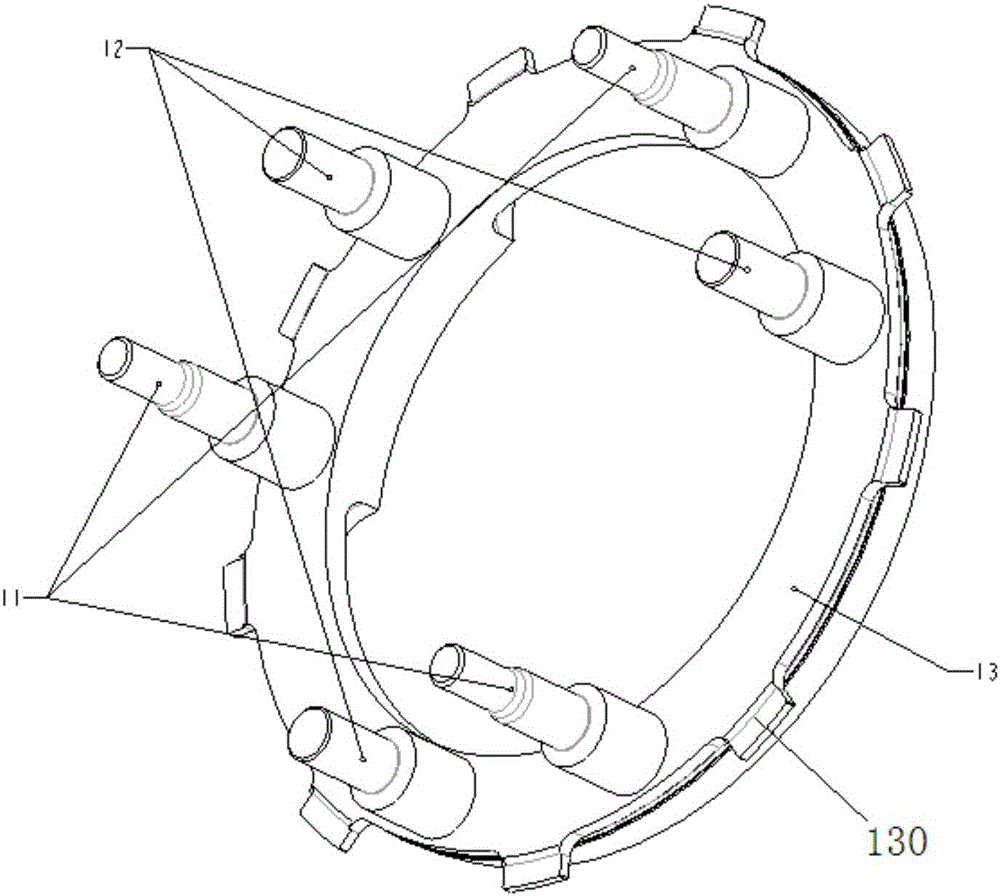

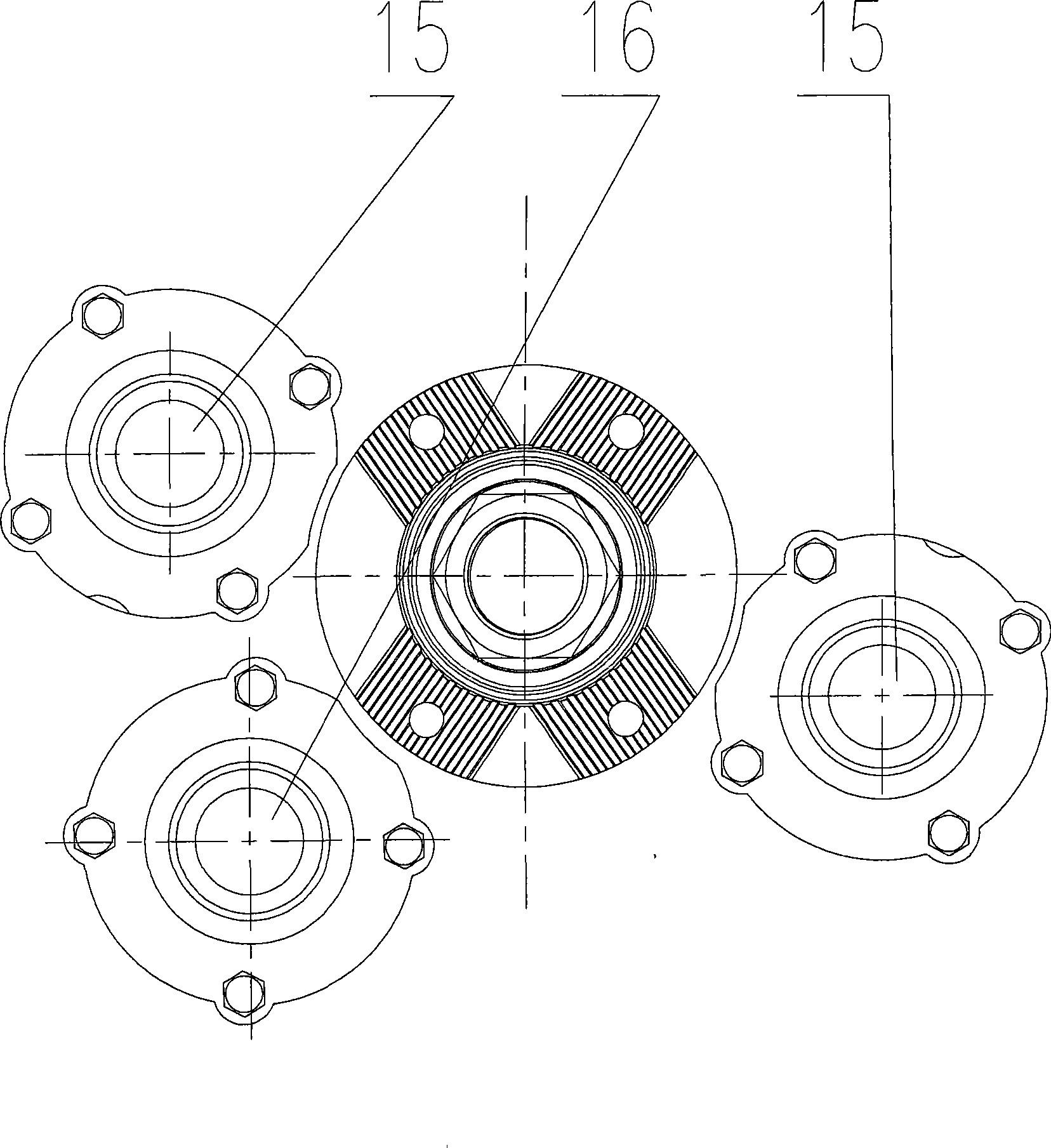

Three-conical-face synchronizer with lubricating oil way

ActiveCN103790994ASimple structureShort shift timesMechanical actuated clutchesCouplingsEngineeringShift time

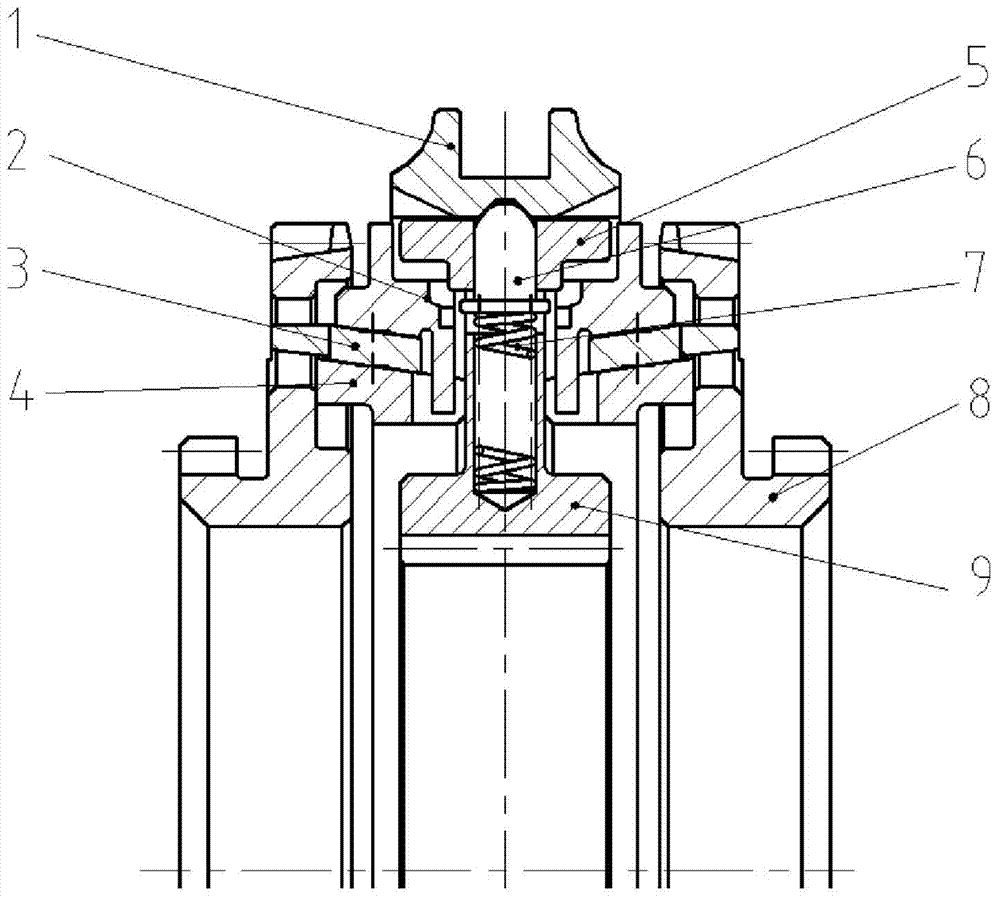

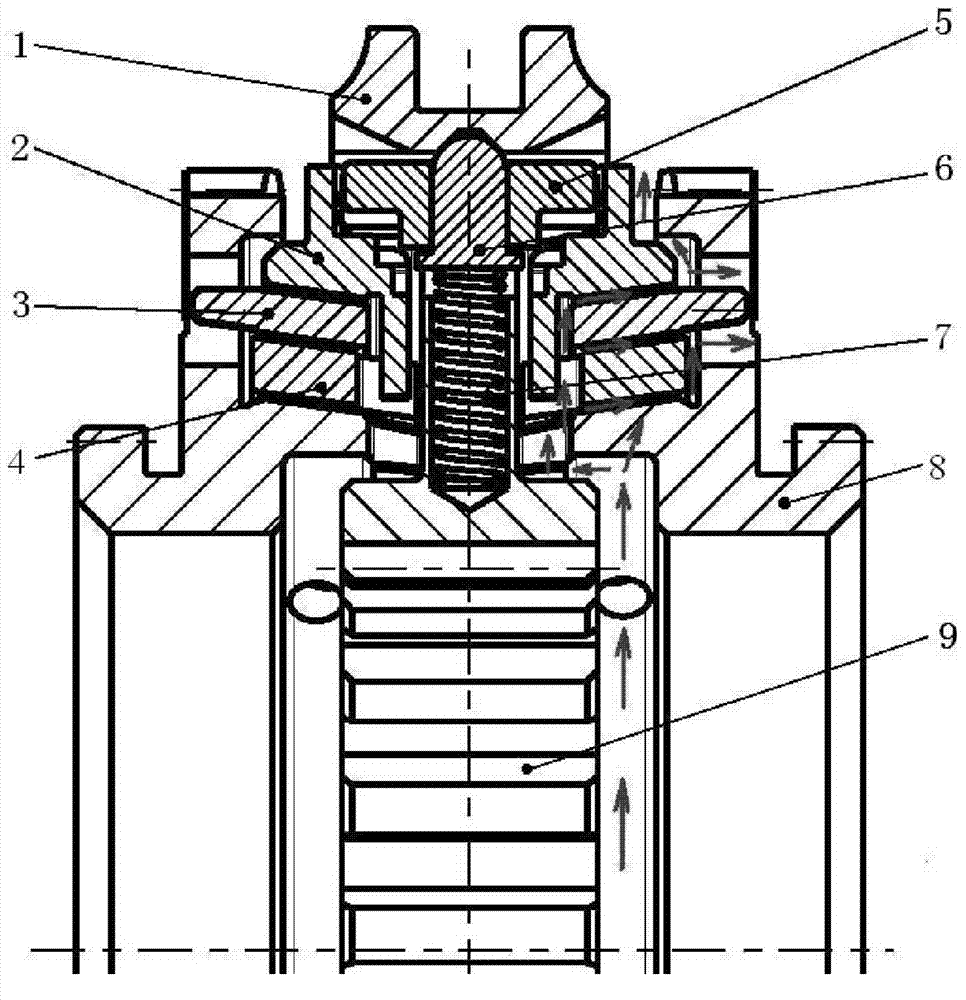

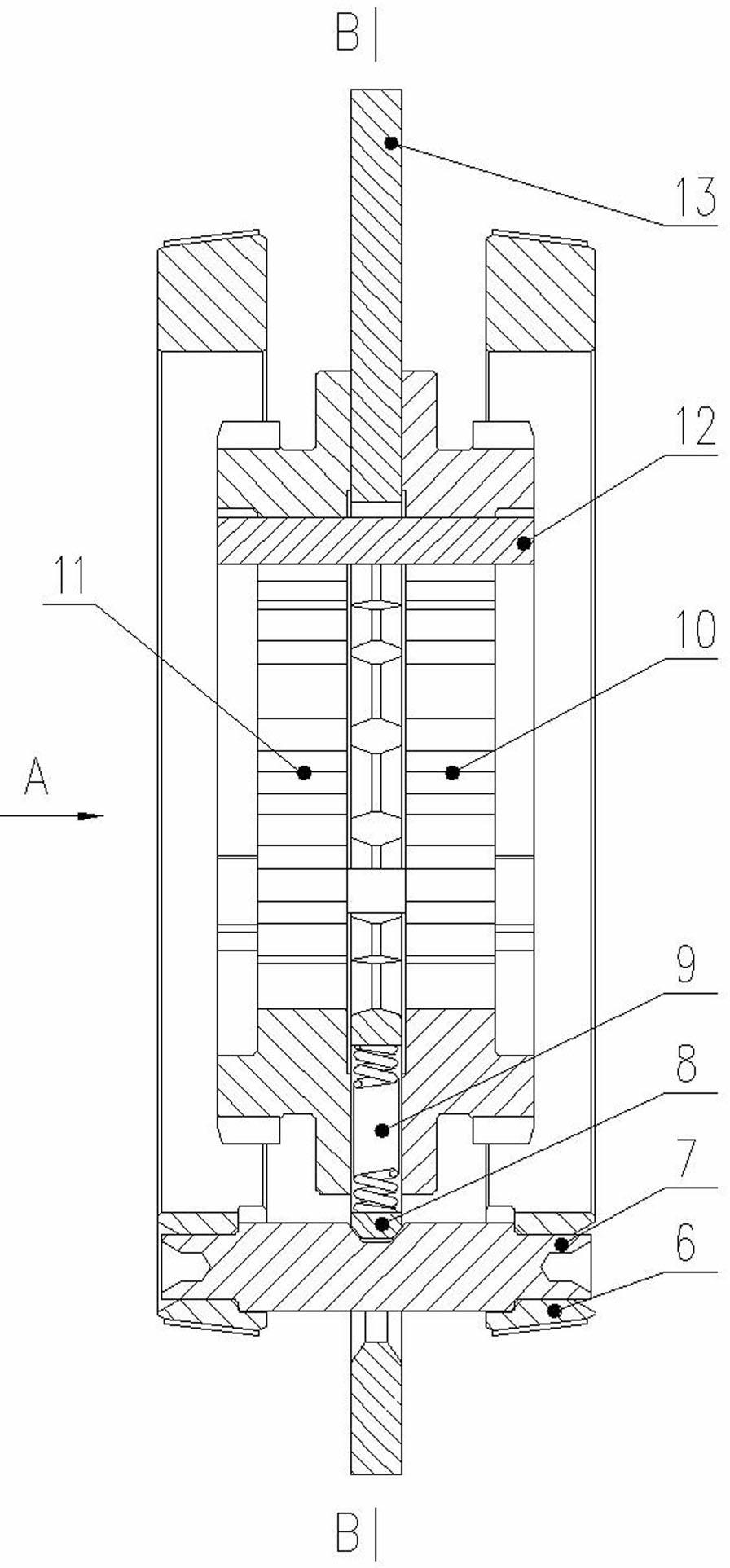

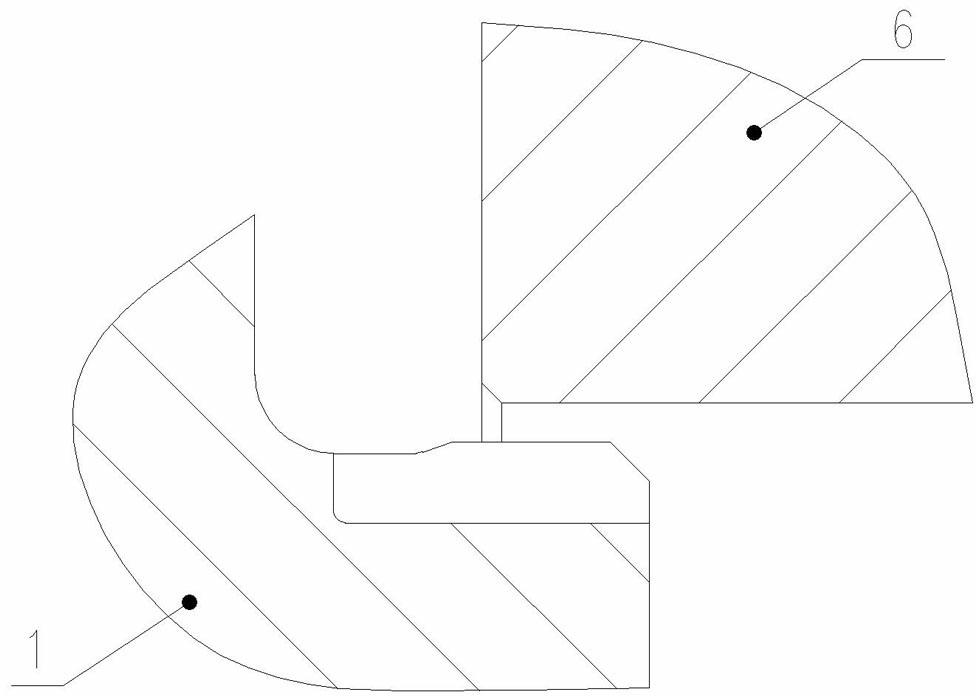

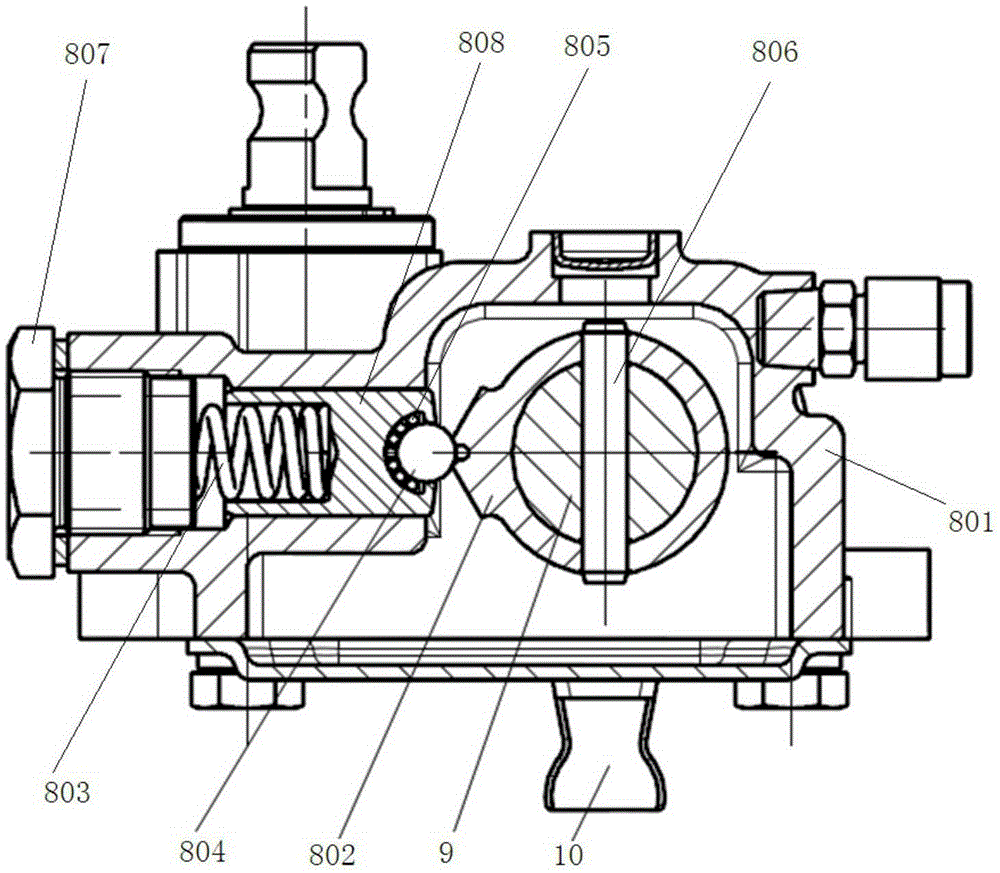

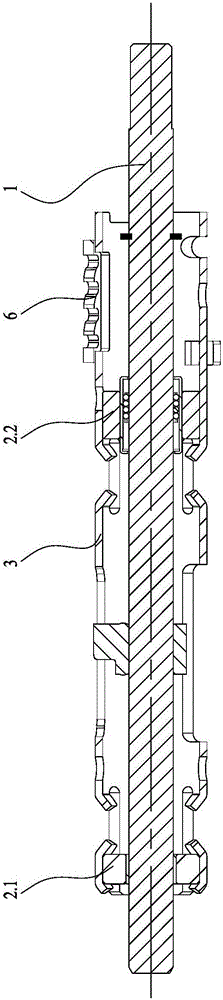

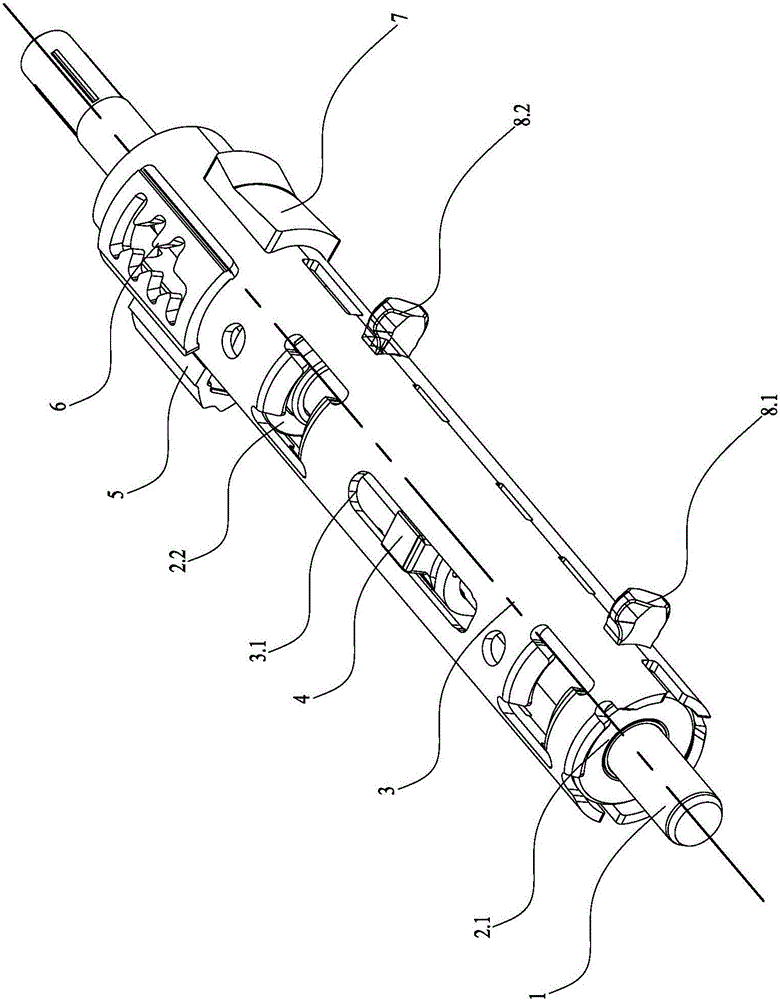

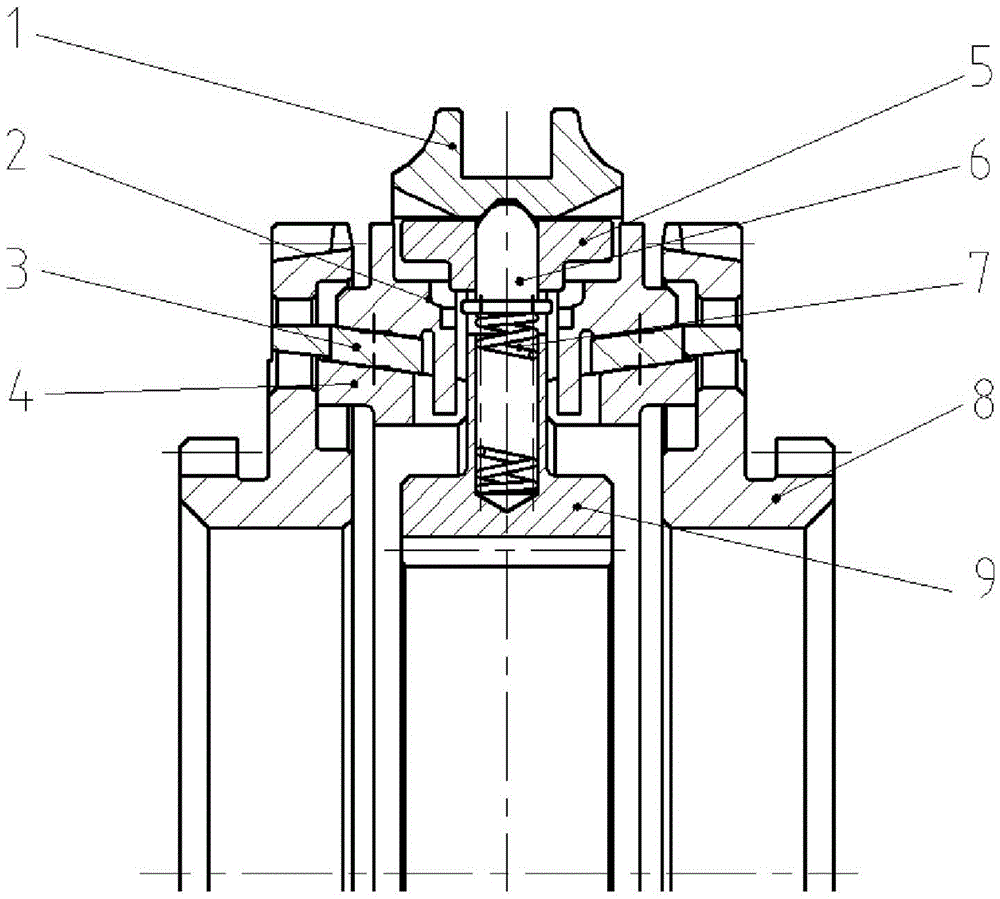

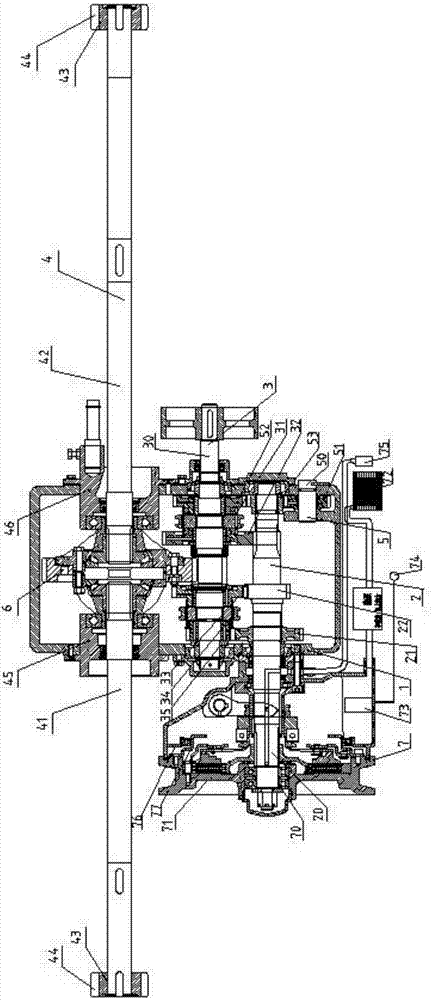

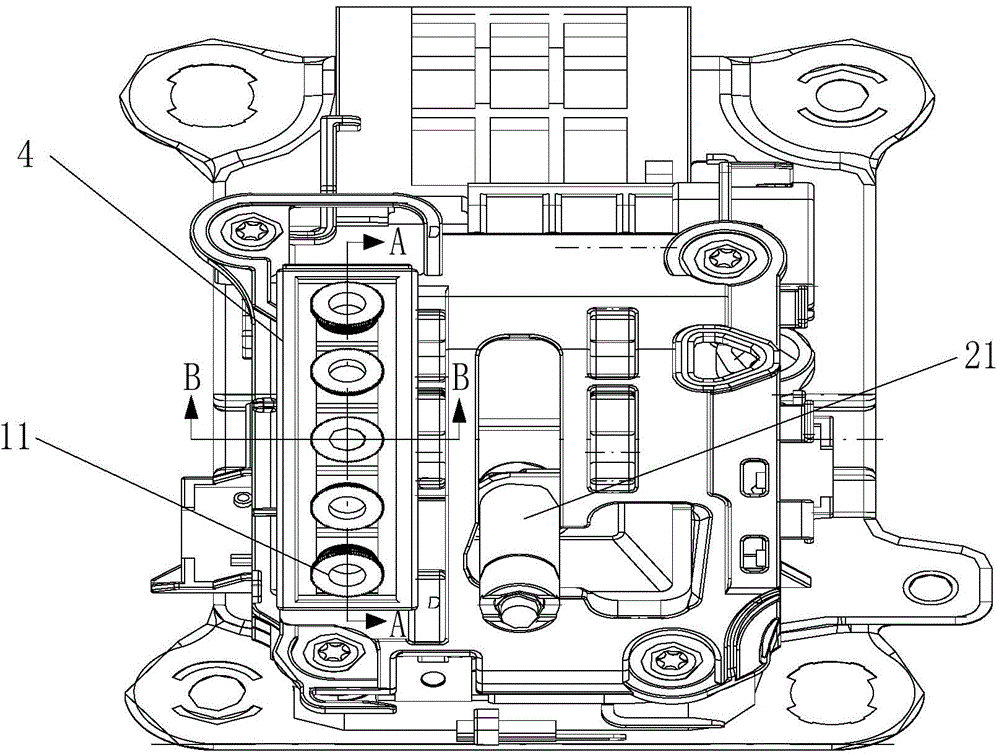

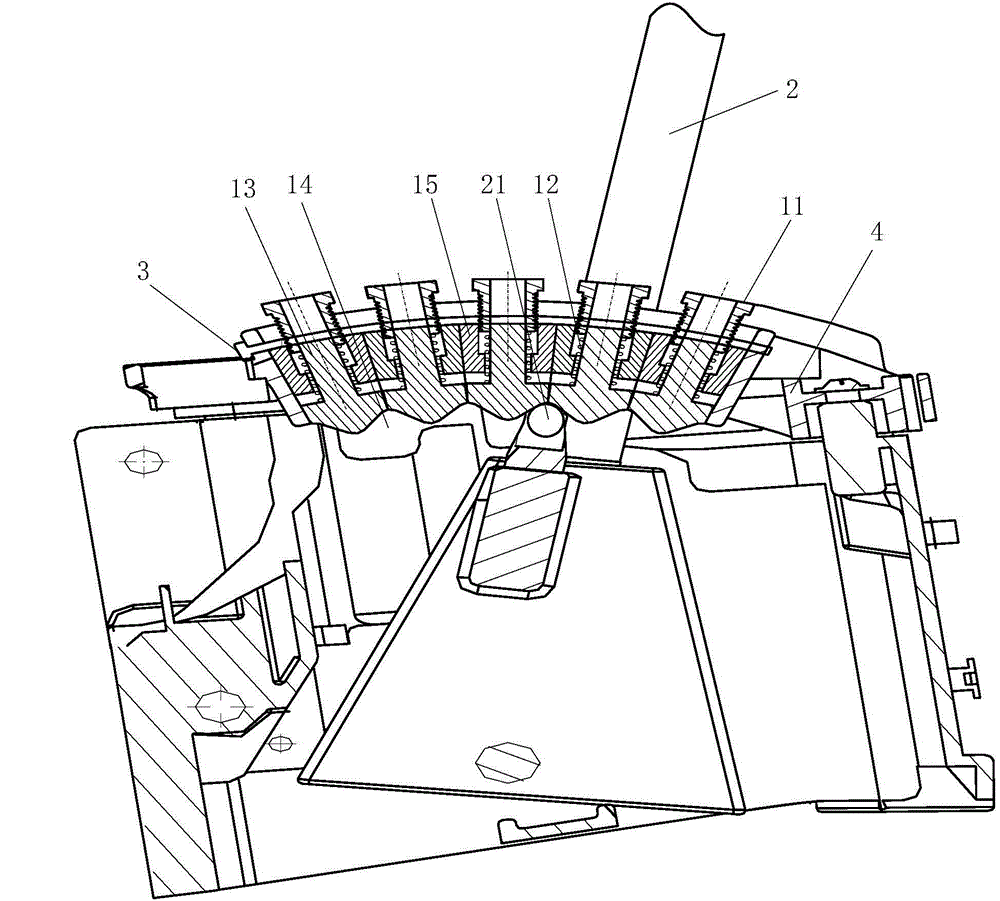

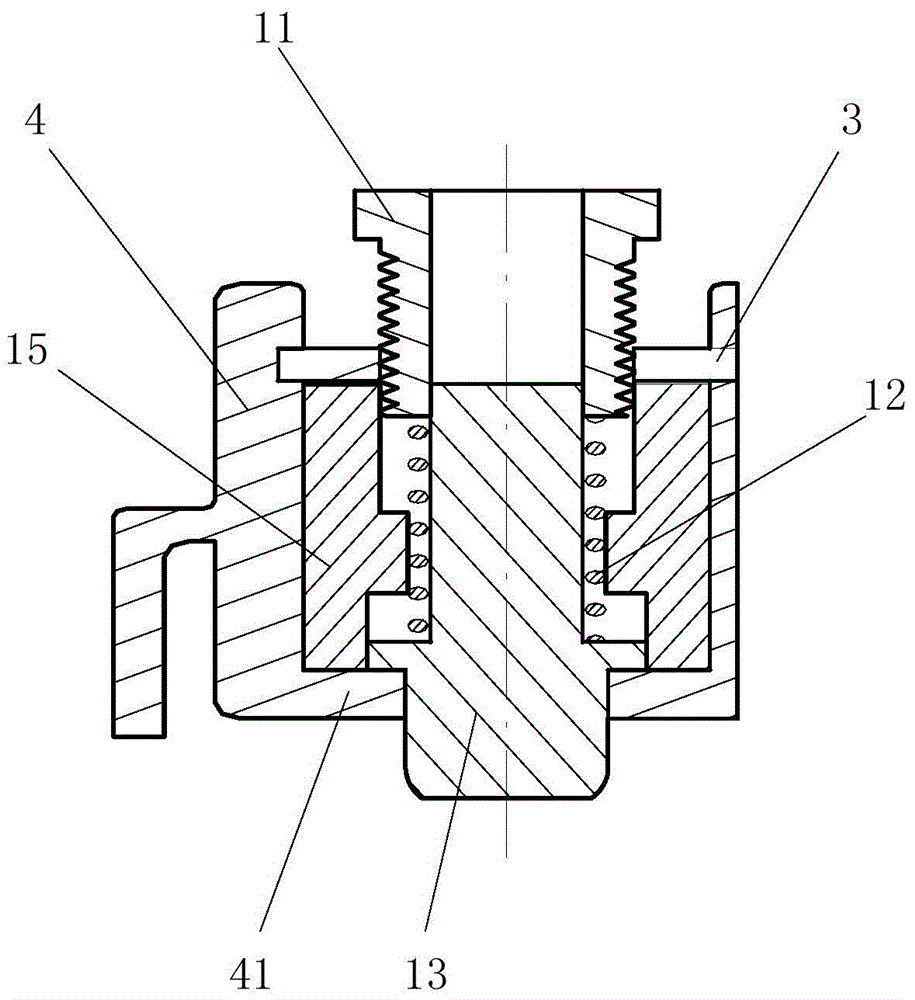

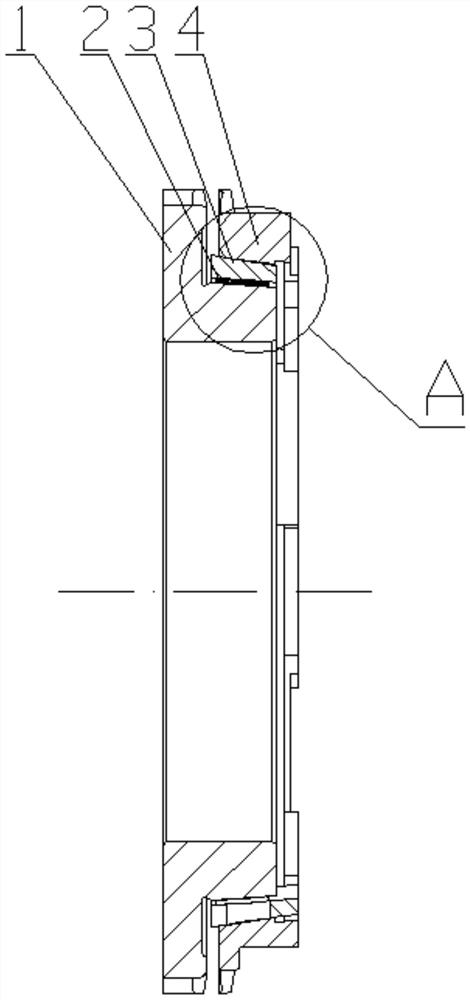

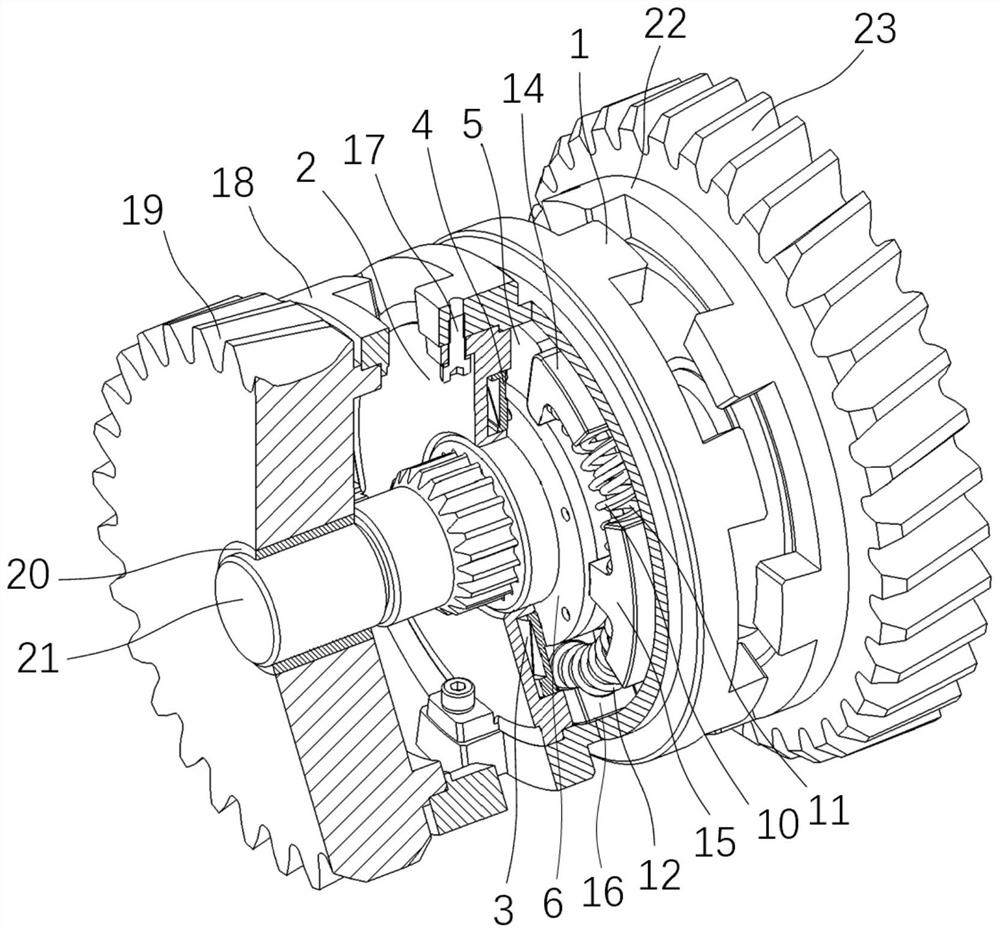

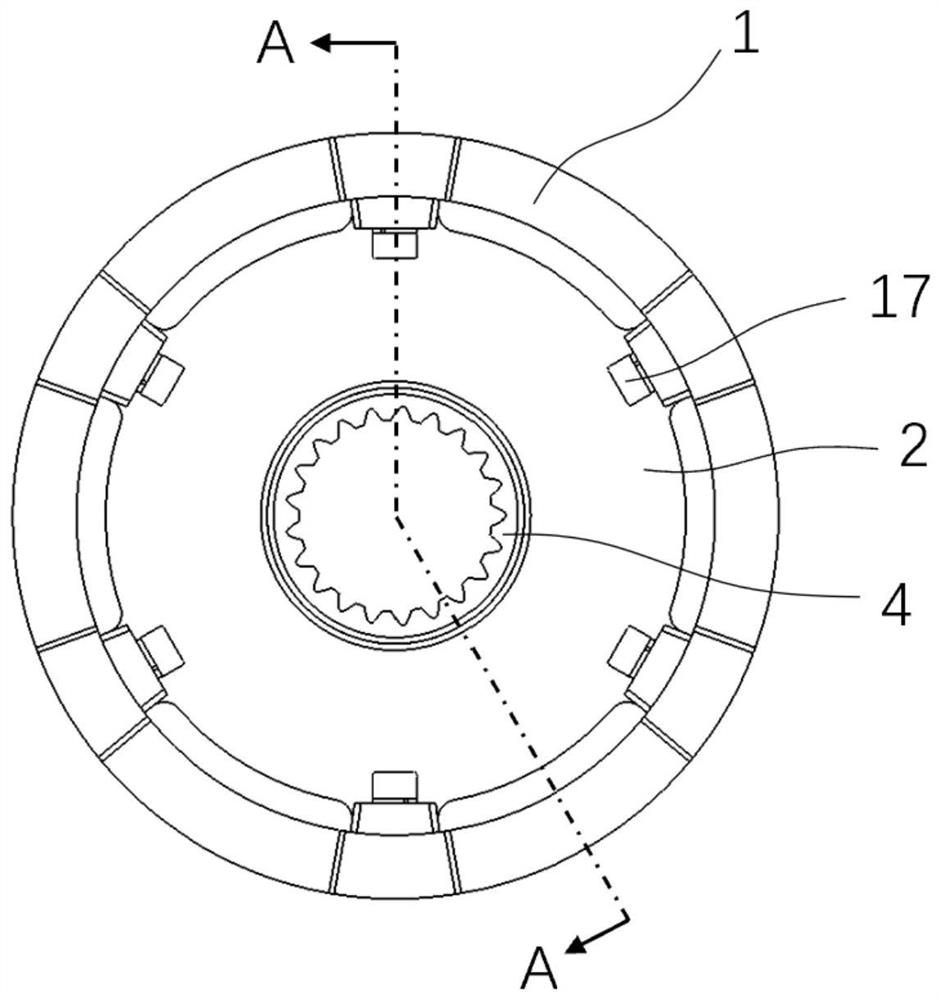

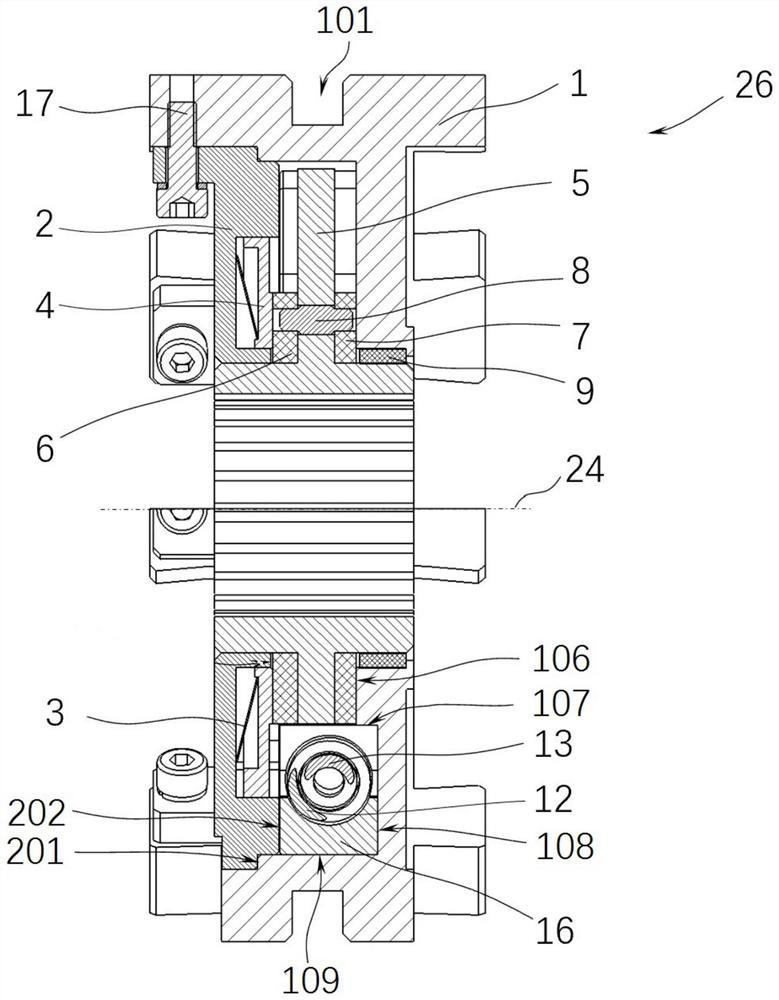

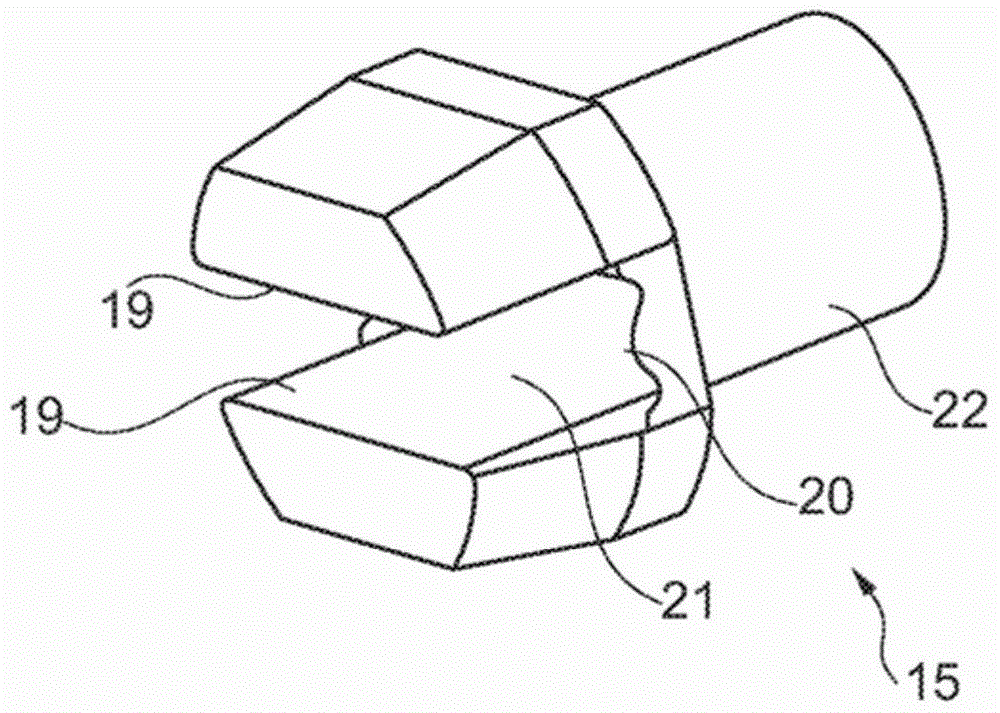

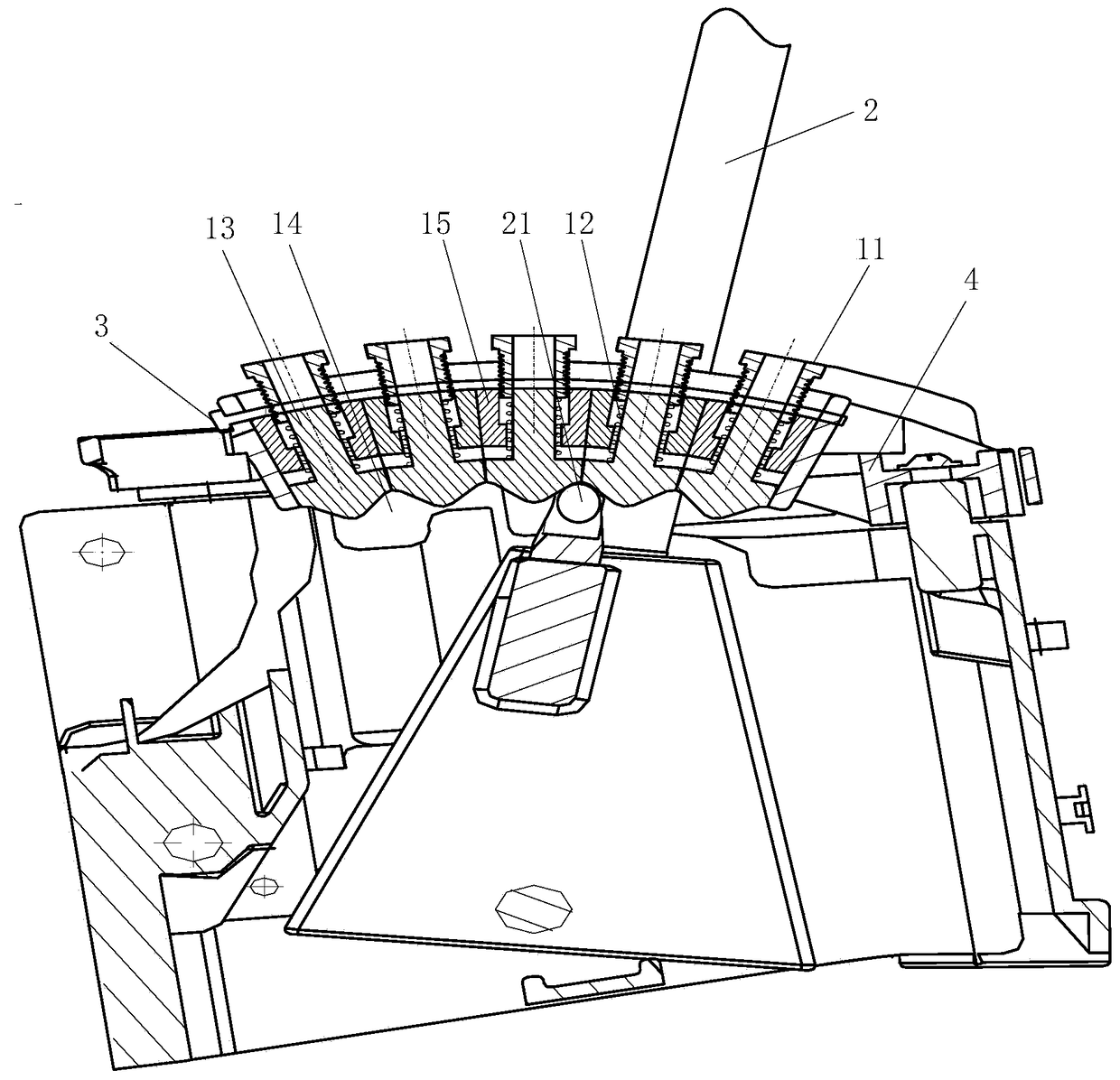

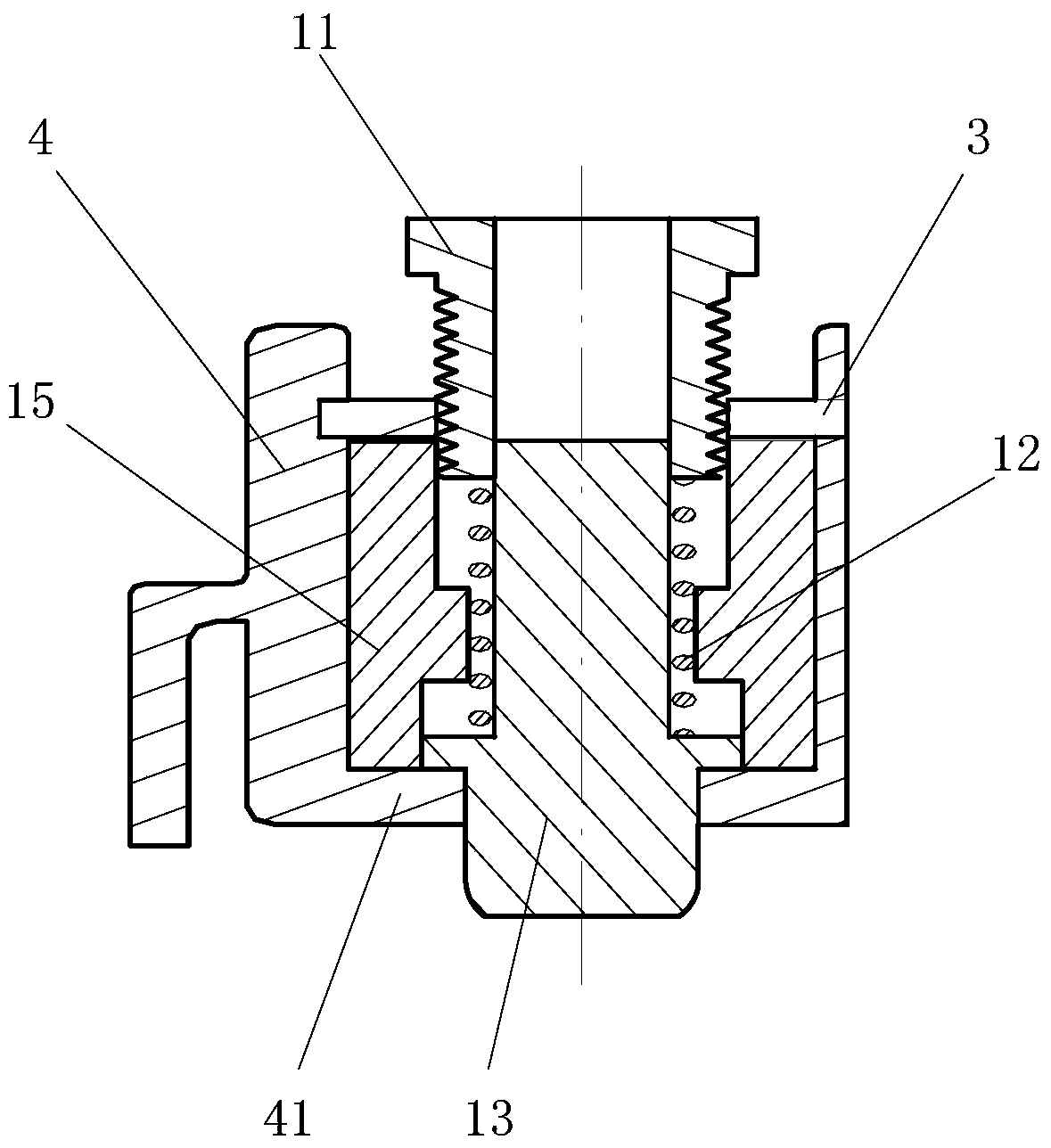

The invention discloses a three-conical-face synchronizer with a lubricating oil way. The three-conical-face synchronizer comprises a sliding gear sleeve, external friction rings, middle friction rings, internal friction rings, a sliding block, a pin, a spring, combined gear rings and a gear hub. A pair of the combined gear rings are symmetrically arranged on the two sides of the gear hub, and conical face bodies of the combined gear rings face one side of the gear hub. A pair of the internal friction rings are arranged on the combined gear rings and provided with a pair of the middle friction rings. Second claws of the middle friction rings extend into oil passing holes of the combined gear rings. A pair of the external friction rings are arranged on the middle friction rings. First claws of the external friction rings extend into oil passing grooves of the internal friction rings. The sliding gear sleeve, the sliding block, the pin and the spring are arranged between the external friction rings. One end of the pin penetrates through the sliding block and is matched with the sliding gear sleeve, and the other end of the pin makes contact with the gear hub through the spring. Compared with a double-conical-face synchronizer, the three-conical-face synchronizer is shorter in shift time, smaller in shift force, more comfortable to control and longer in service life.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

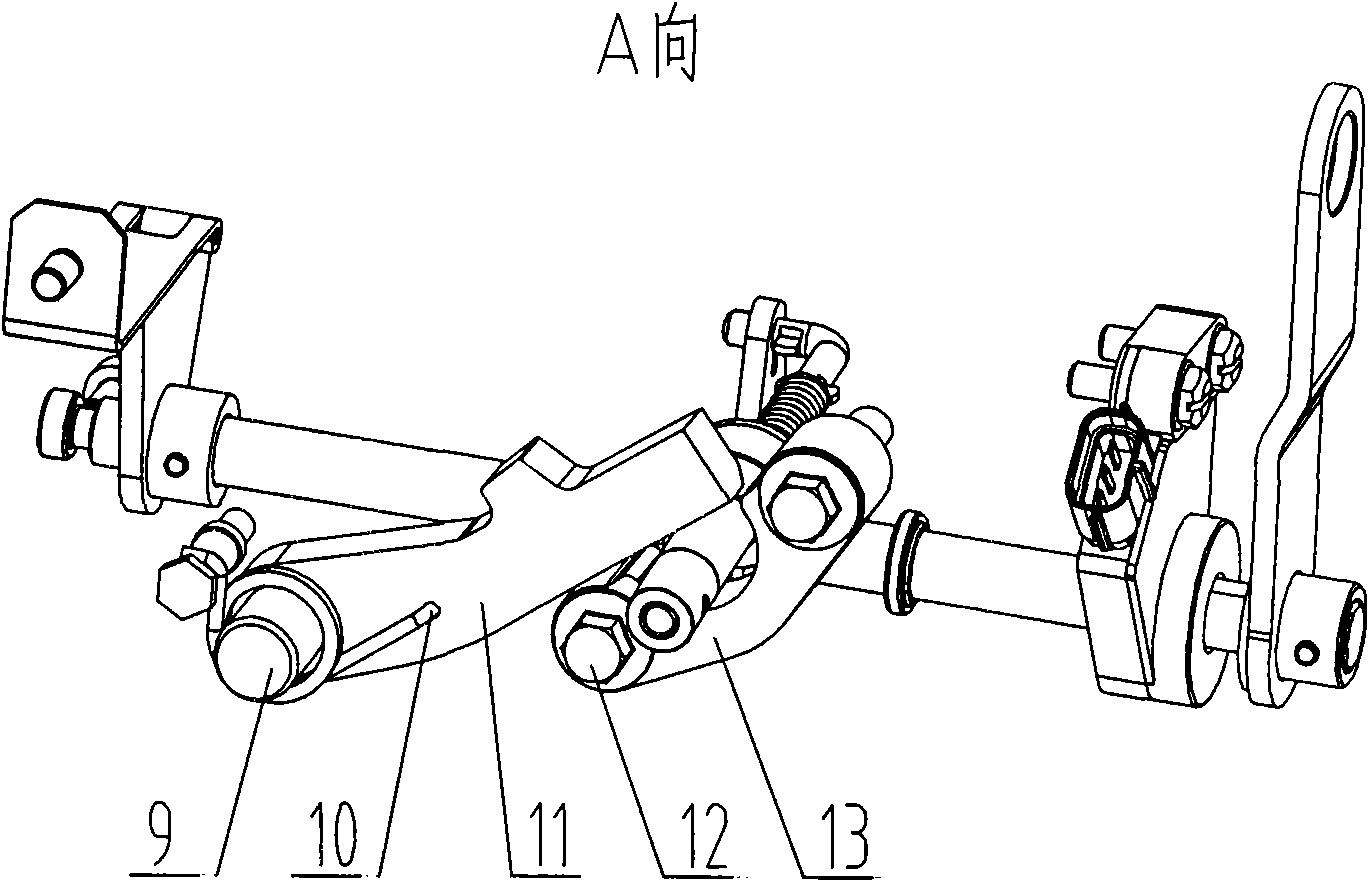

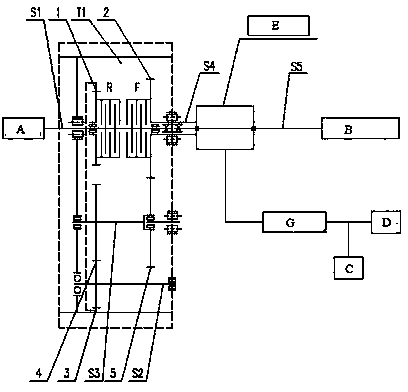

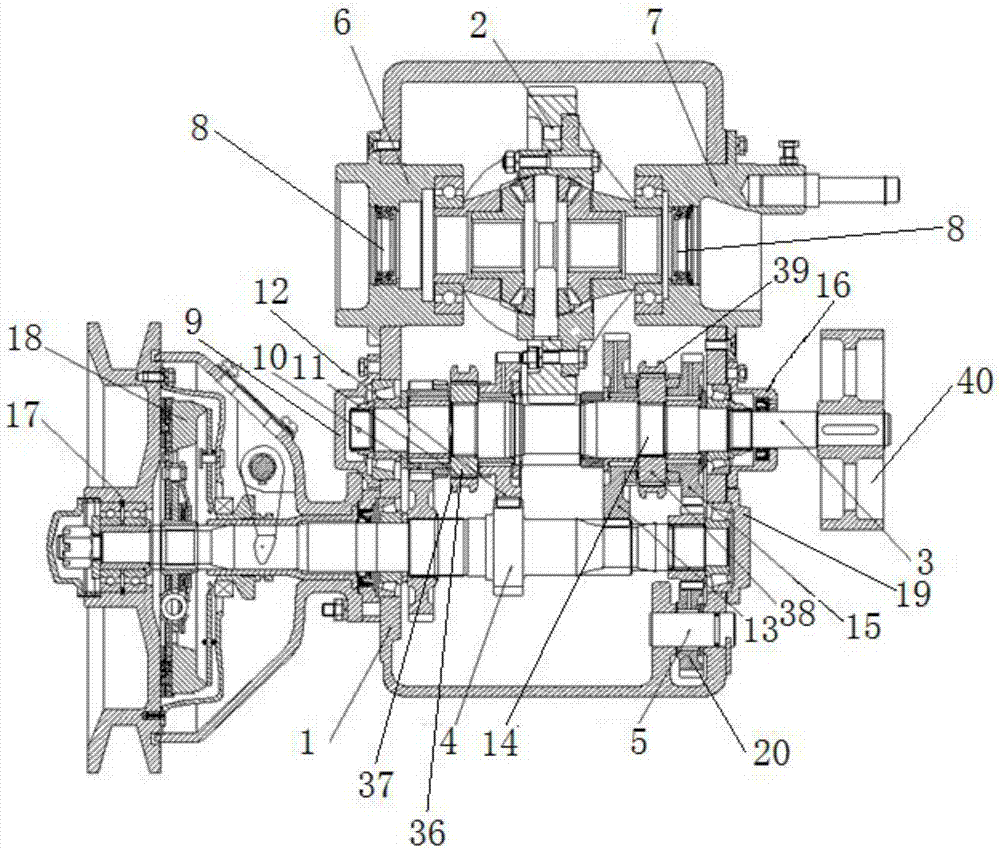

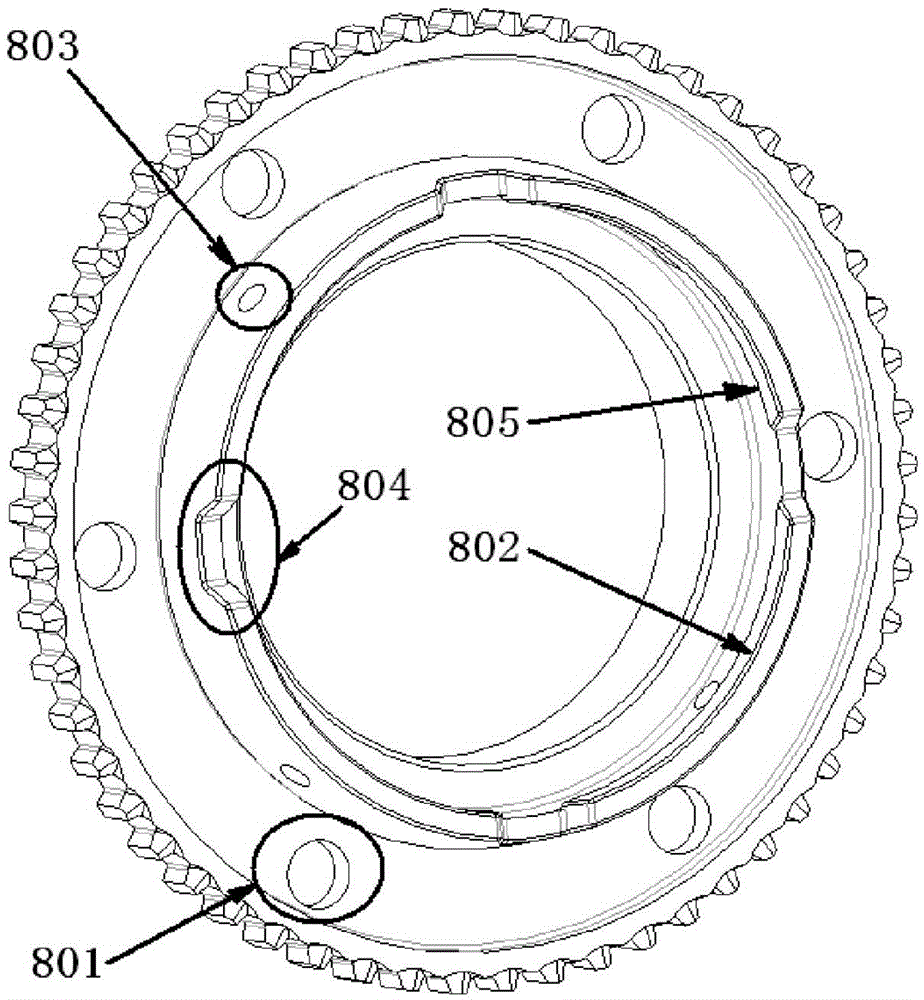

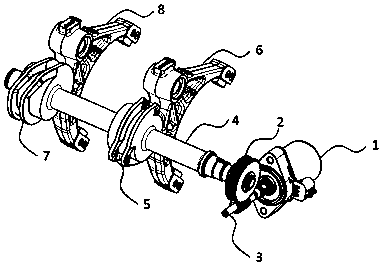

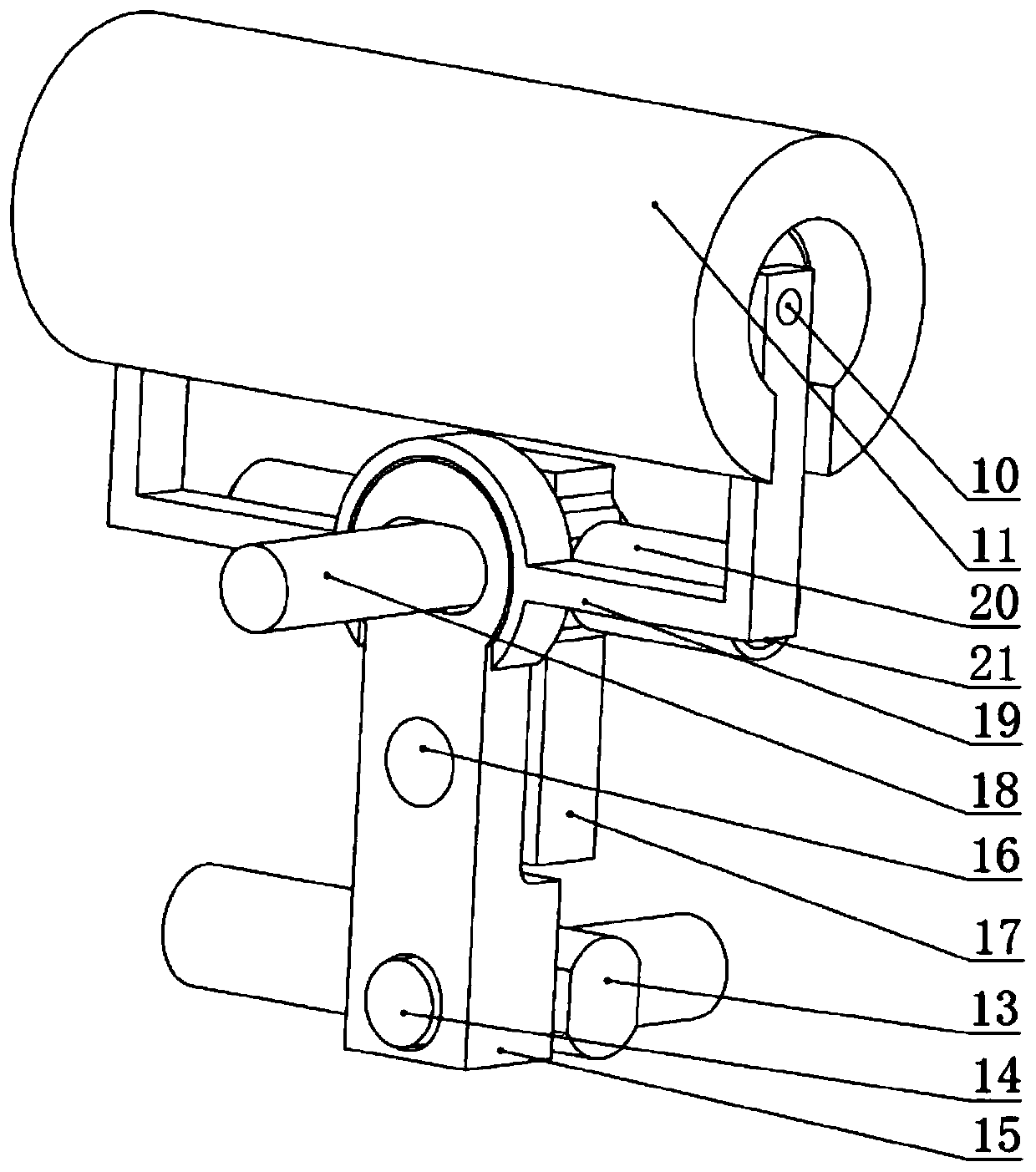

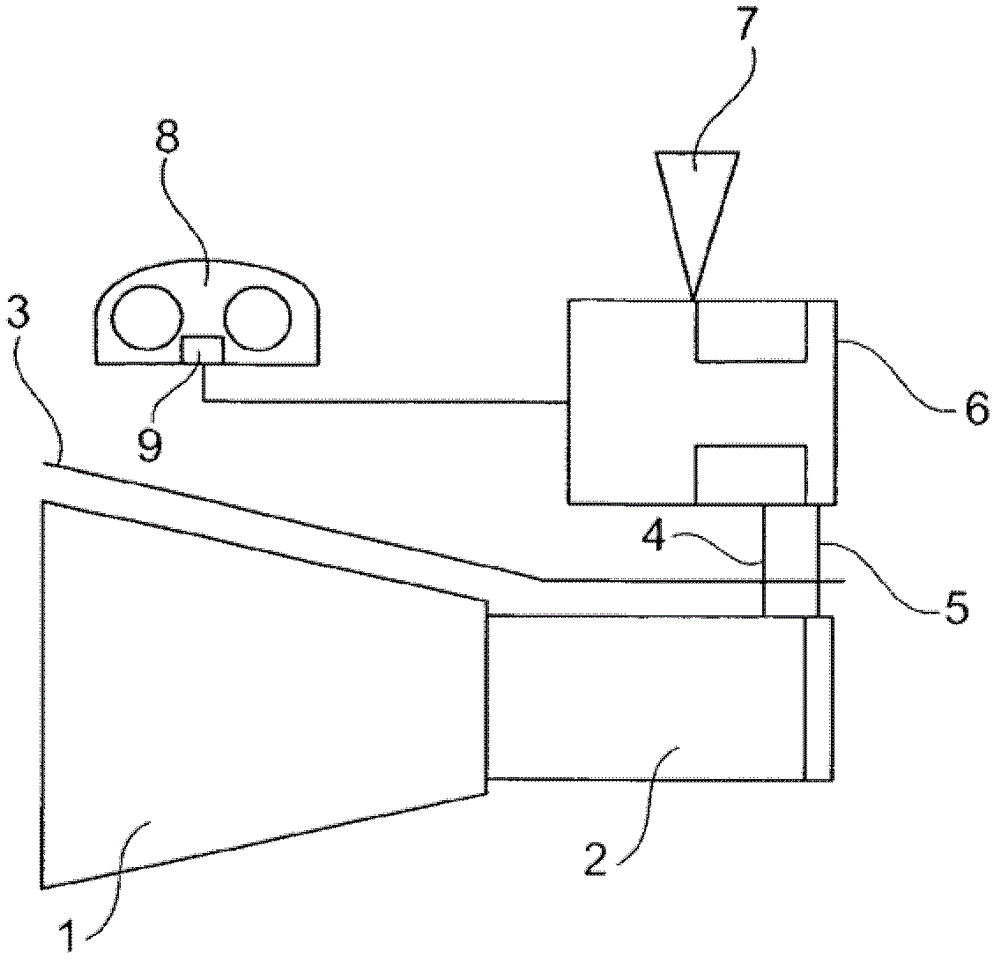

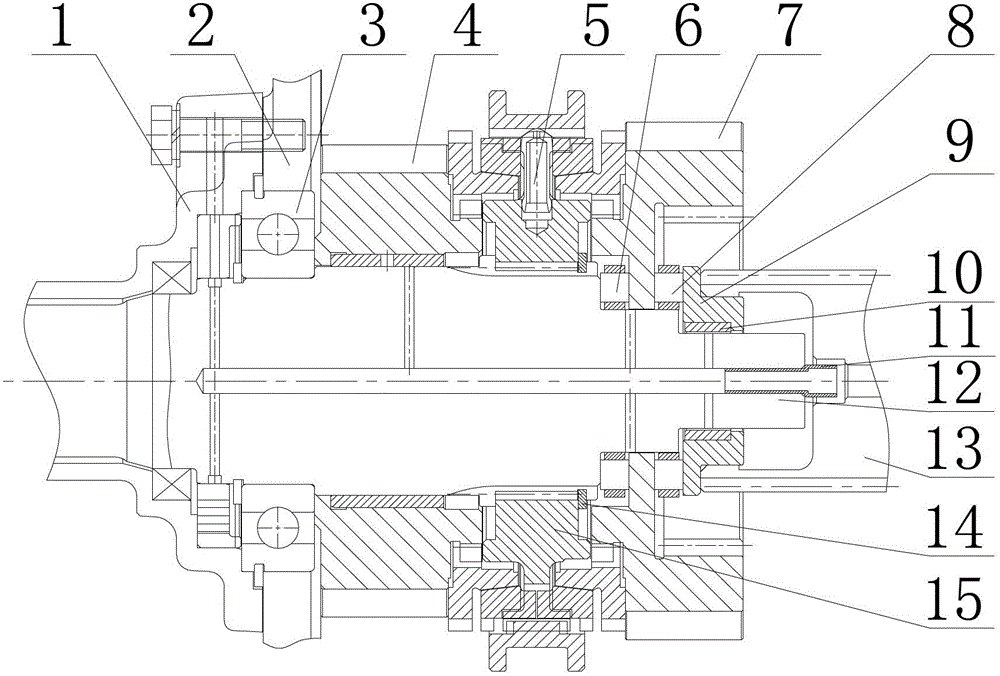

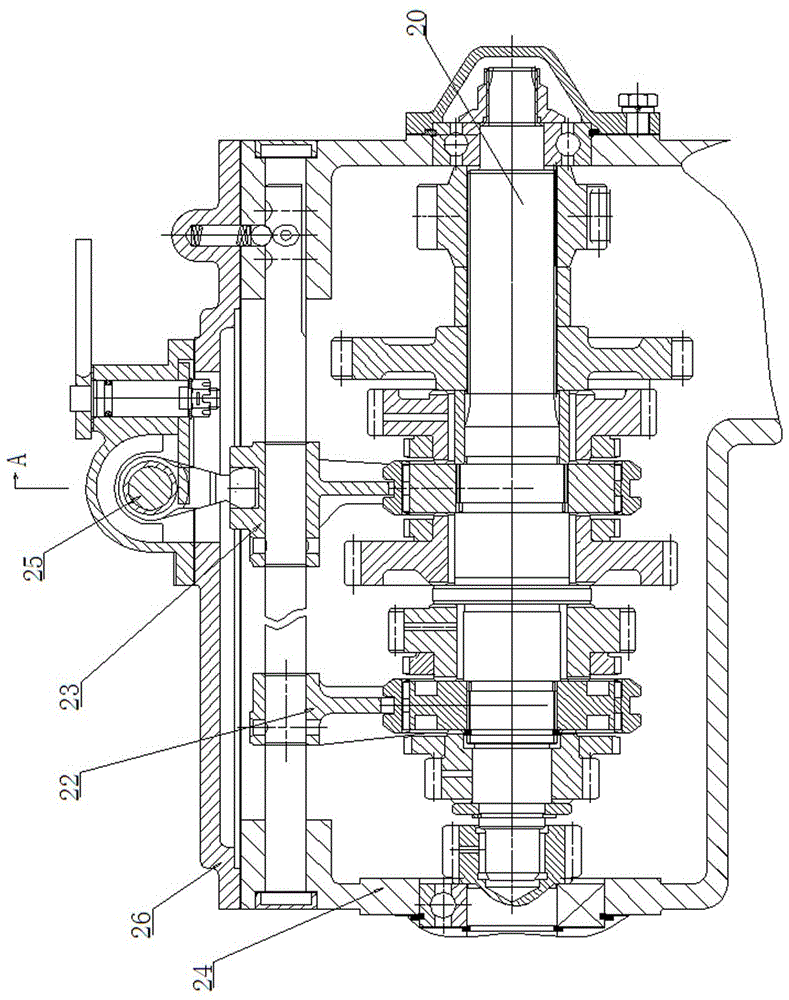

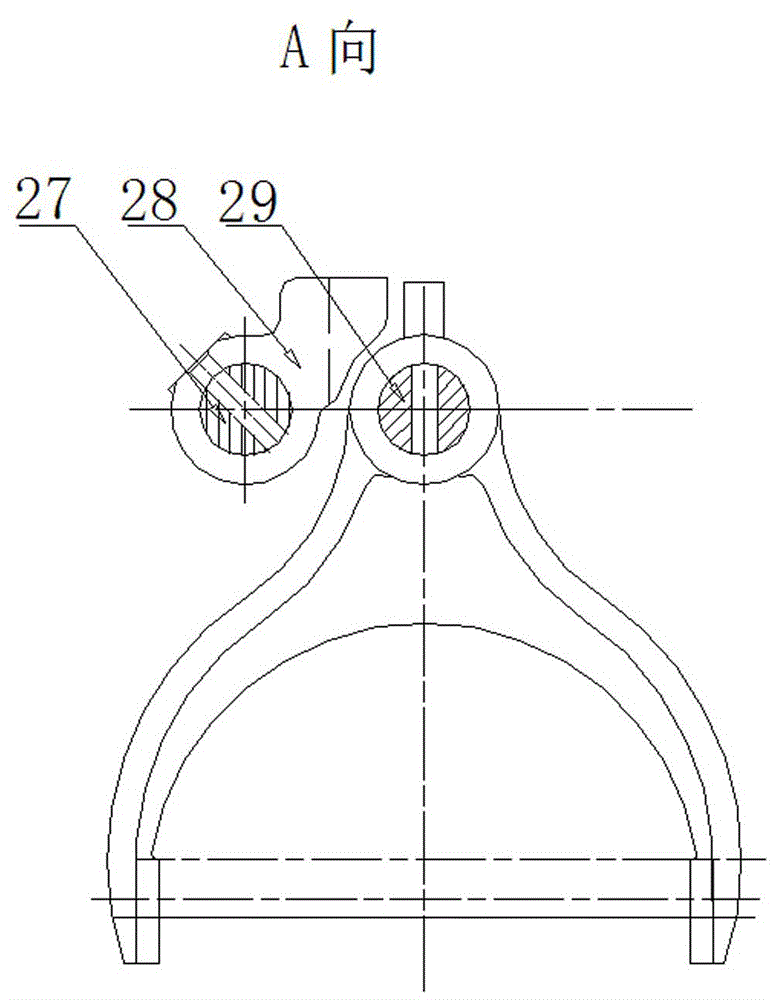

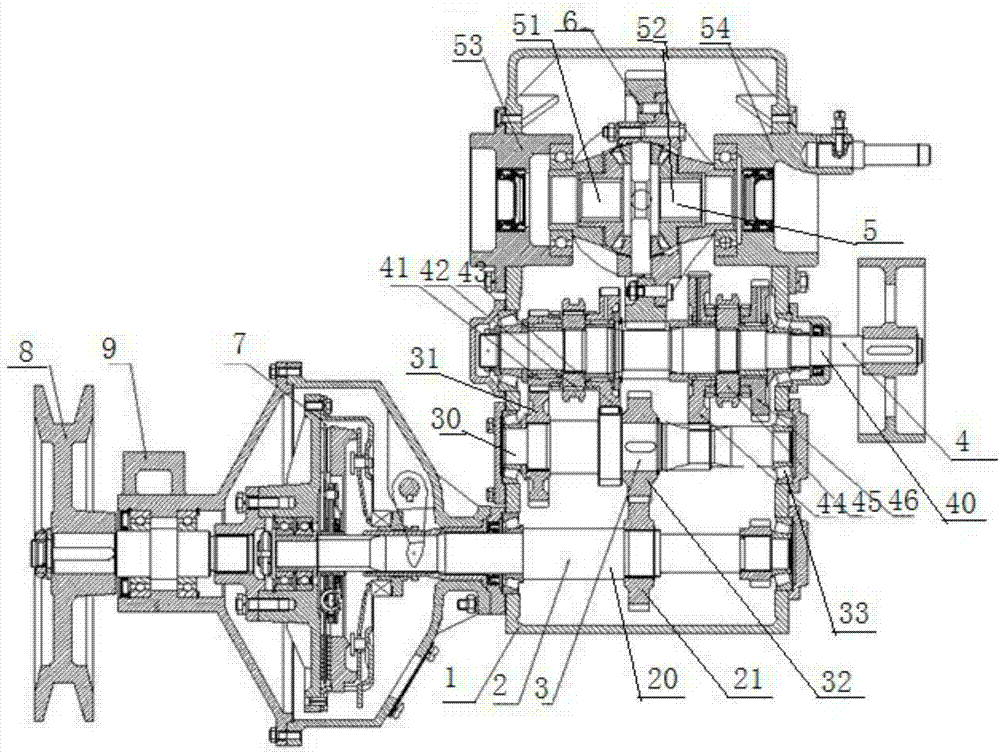

Novel parking braking mechanism of dual clutch automatic transmission (DCT)

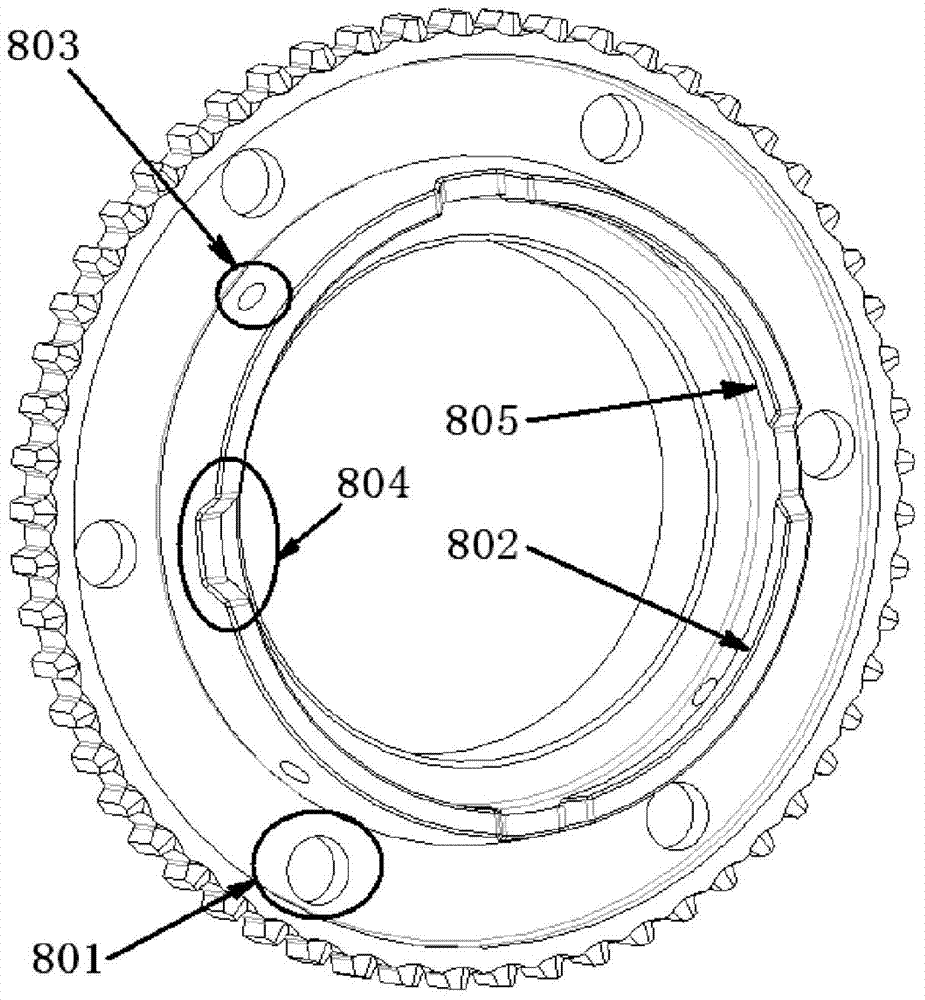

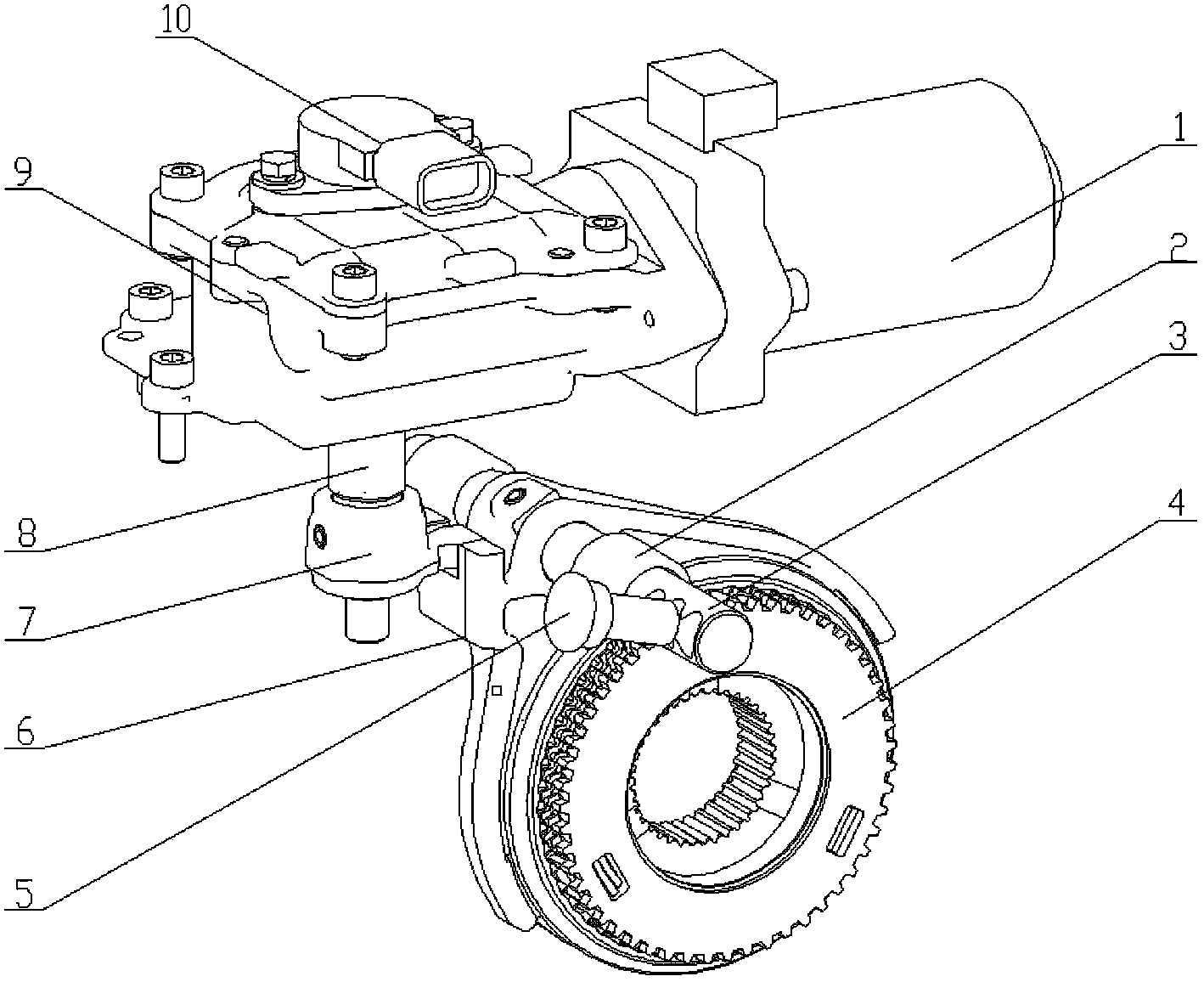

InactiveCN102338213AP gear parking is reliableCompact structureBraking element arrangementsGearing controlAutomatic transmissionParking pawl

The invention discloses a novel parking braking mechanism of a dual clutch automatic transmission (DCT). The novel parking braking mechanism is characterized in that a gear-shafting arm, a push arm, a sector plate and a gear-position sensor are arranged on a gear-shifting shaft, one end of a pull rod is arranged on the push arm, the other end of the pull rod is overlapped inside a fixator hole, a parking gear is arranged on an intermediate shaft of the transmission, and a parking pawl rotates around a parking shaft; and a plate spring is composed of a spring piece, a pin shaft and a casing pipe, and the casing pipe rolls in a groove of the sector plate on a pin shaft in a sleeved manner. The novel parking braking mechanism disclosed by the invention has the advantages of simple and compact structure, light weight, low cost, strong parking bearing capacity, accuracy in gear-shifting positioning, low gear-shifting force, and good hand feel, can be used for realizing five PRNDS (Parking, Reverse, Null, Drive, Sports) gear positions including a parking gear, a reverse gear, a null gear, a drive gear and a sport gear, and can be used for guaranteeing the reliable parking at the P gear.

Owner:FAW GROUP

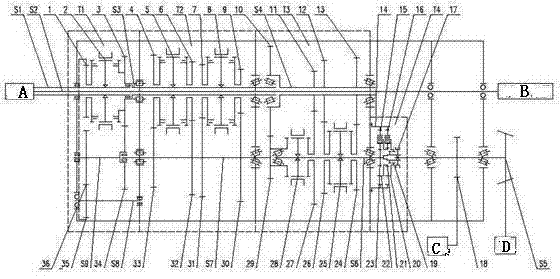

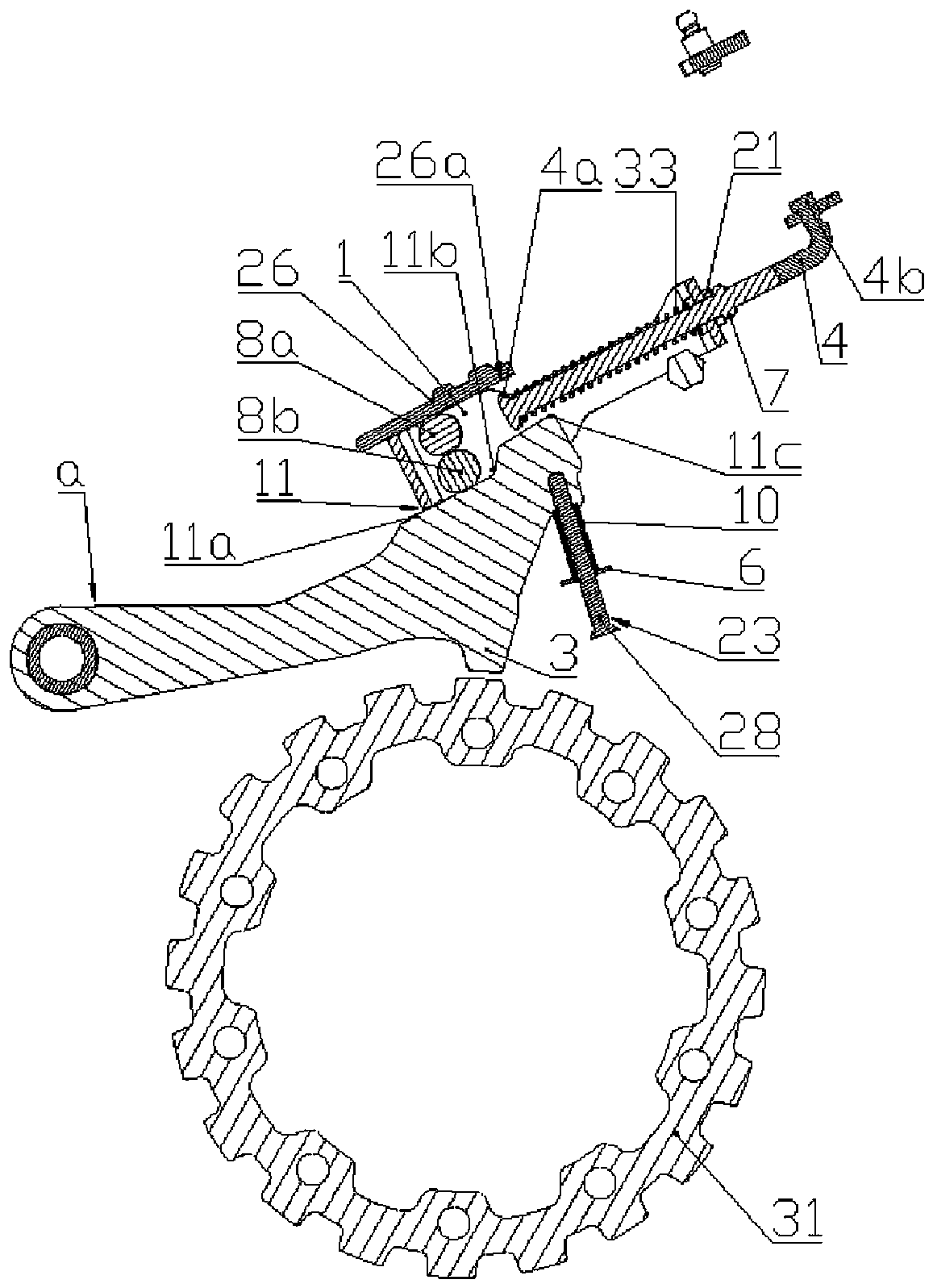

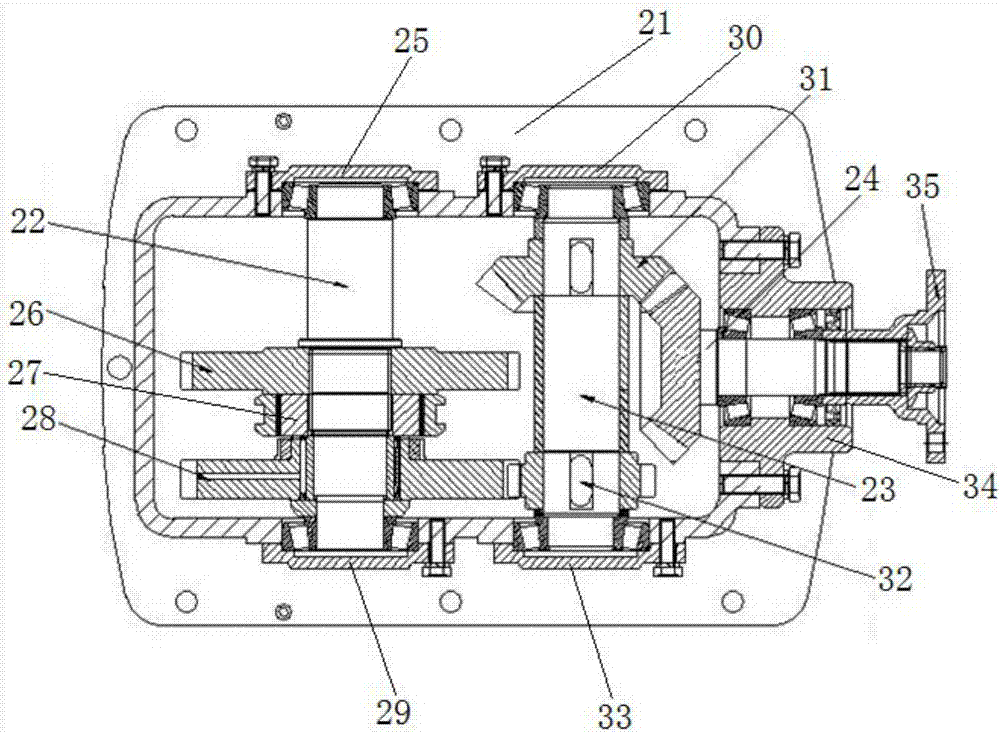

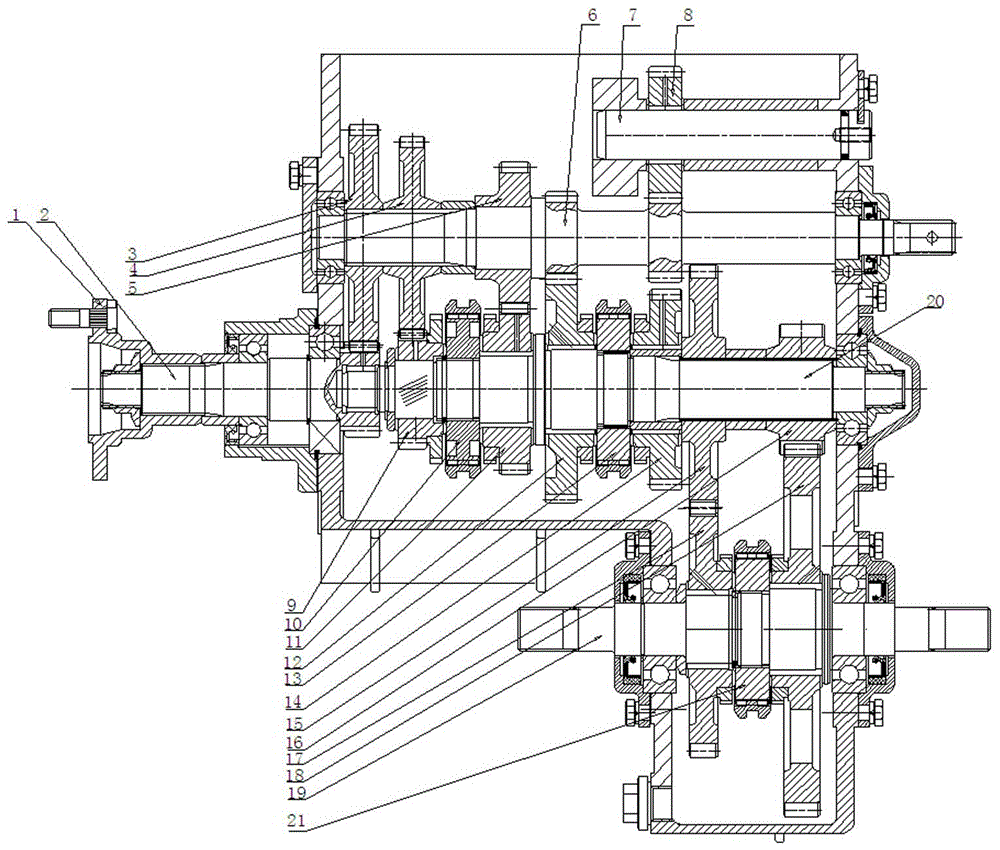

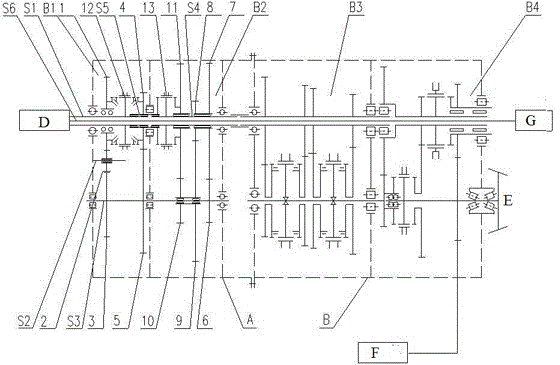

Synchronous reversing belt crawling-gear gearbox of tractor

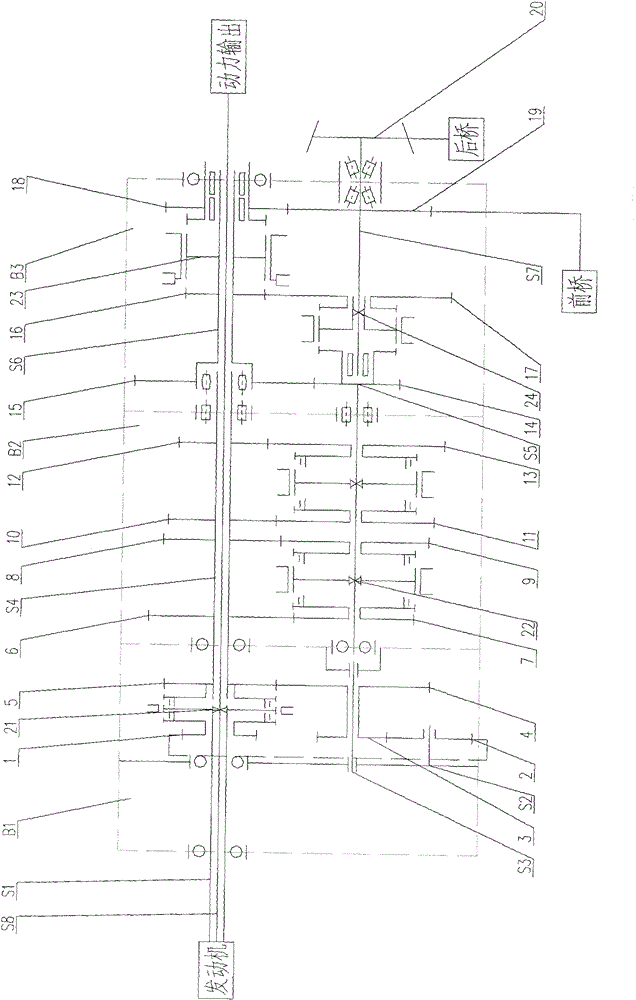

The invention discloses a synchronous reversing belt crawling-gear gearbox of a tractor. The synchronous reversing belt crawling-gear gearbox comprises a synchronizer reversing device, a main speed variator, an auxiliary speed variator and a crawling gear device which are sequentially arranged. One end of the synchronizer reversing device is connected with an engine, and one end of the crawling gear device is connected with a bevel pinion. The synchronizer reversing device and the main speed variator are double-friction-cone synchronizers. By combining the synchronizer reversing device, the main speed variator, the auxiliary speed variator and the crawling gear device, 32 forward gears and 32 reverse gears can be realized, the more the reverse gears are, the better the operation needs can be met. The synchronizer reversing device is disposed at the front end of the main speed variator, gear reversing and engaging of the double-friction-cone synchronizers are realized, parking for gear engagement is omitted when at low speed, gear shift impact and force are low, gear shift time is short, and operation efficiency is high.

Owner:FIRST TRACTOR

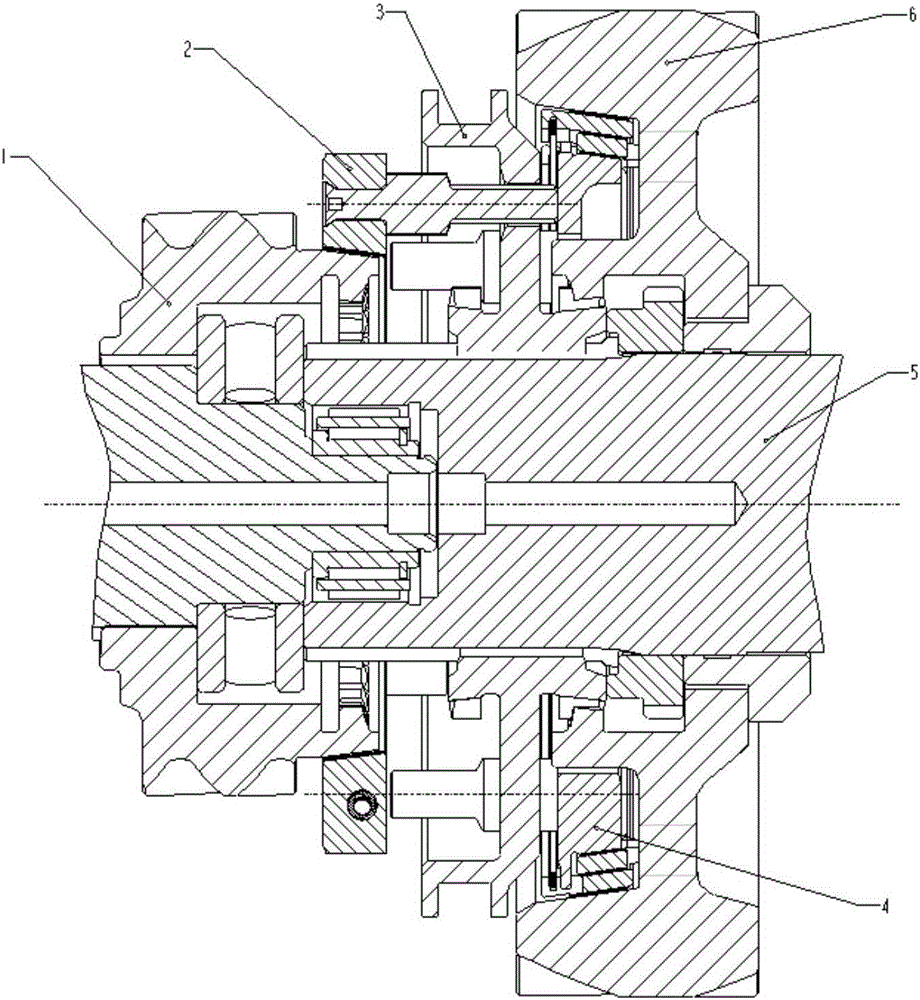

Synchronous structure for twin countershaft transmission

InactiveCN102494048AExtended service lifeSmall shift forceMechanical actuated clutchesEngineeringNeutral position

The invention discloses a synchronous structure for a twin countershaft transmission. The synchronous structure comprises a main shaft, a synchronizer and two tap-position gears, wherein the synchronizer is arranged on the main shaft; each of two tap-position gears is provided with one boss extending into the inner circle of a corresponding synchronizer taper ring; at a neutral position, the inner circle surfaces of the synchronizer taper rings contact the bosses; and when a synchronous taper surfaces on the synchronizer taper rings contact the synchronous taper surfaces on the tap-position gears, the inner circle surfaces of the synchronizer taper rings do not contact the bosses on the tap-position gears. According to the synchronous structure for a twin countershaft transmission, the eccentricity of the synchronizer taper rings and the tap-position gears is controlled; at the neutral position, the synchronous taper surfaces of the synchronizer taper rings do not contact the synchronous taper surfaces of the tap-position gears; therefore, taper surfaces cannot be worn at the neutral position; and the service life is long. Because of the special connection structure of a sliding disk and the main shaft, self energizing effort can be generated, the shifting force is lowered, and the synchronous structure can conveniently shift.

Owner:SINO TRUK JINAN POWER

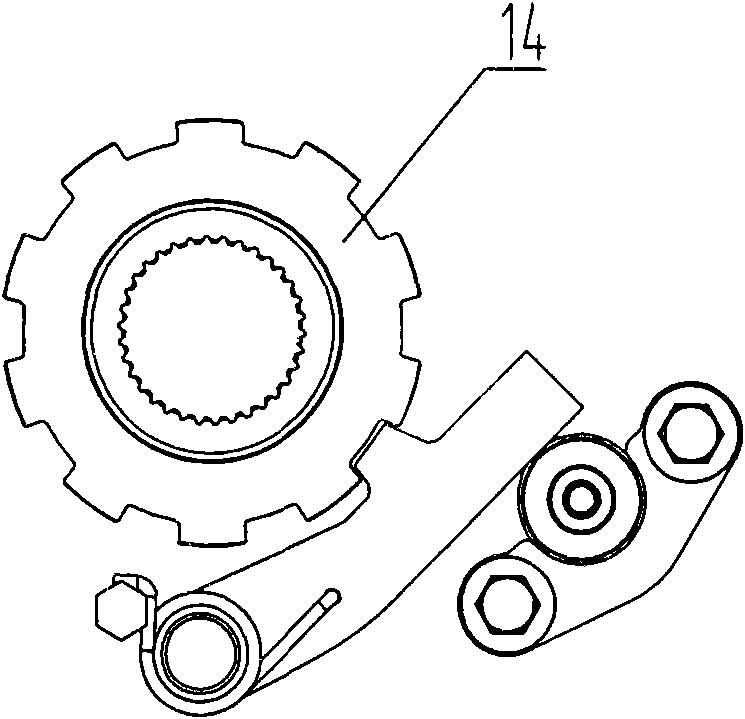

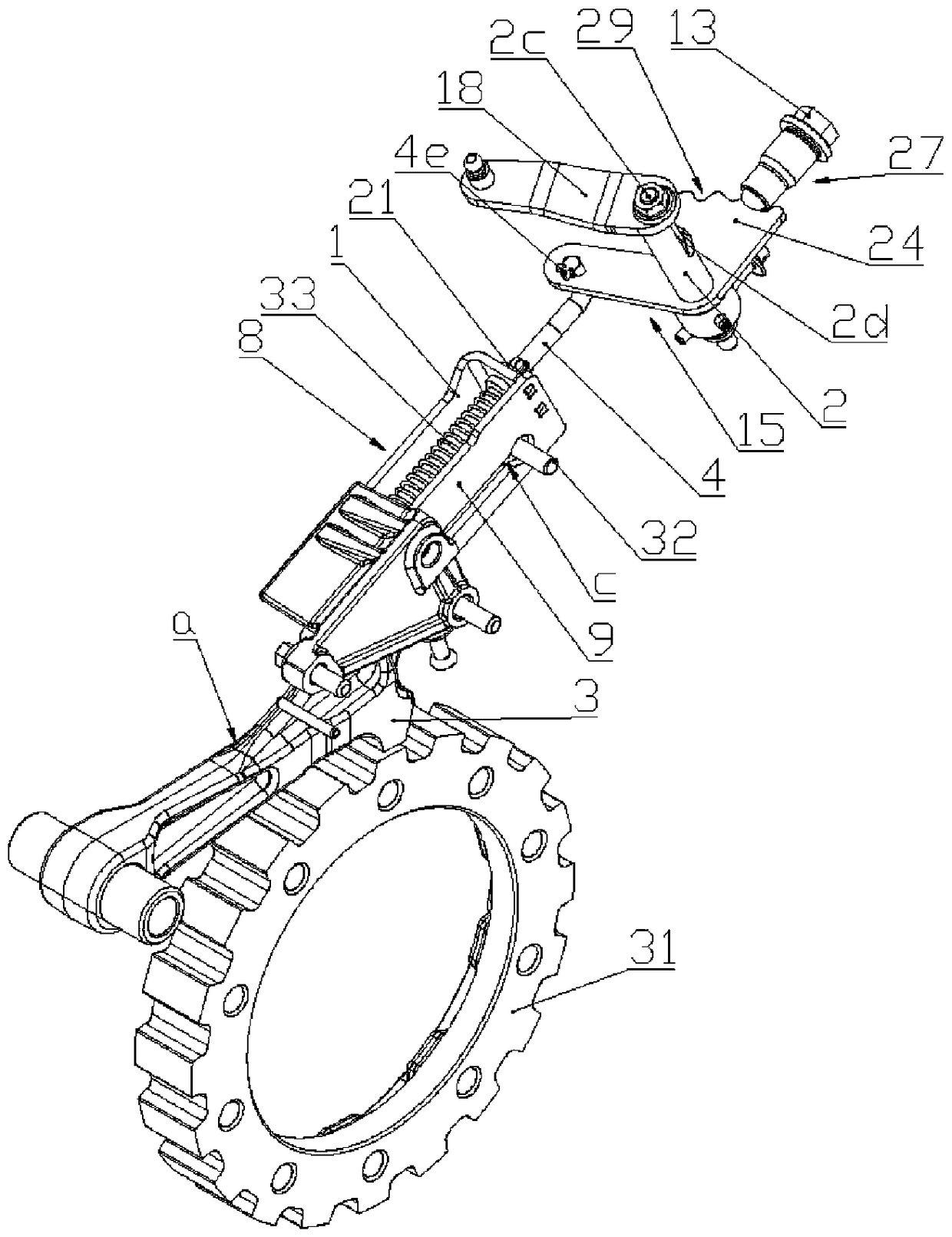

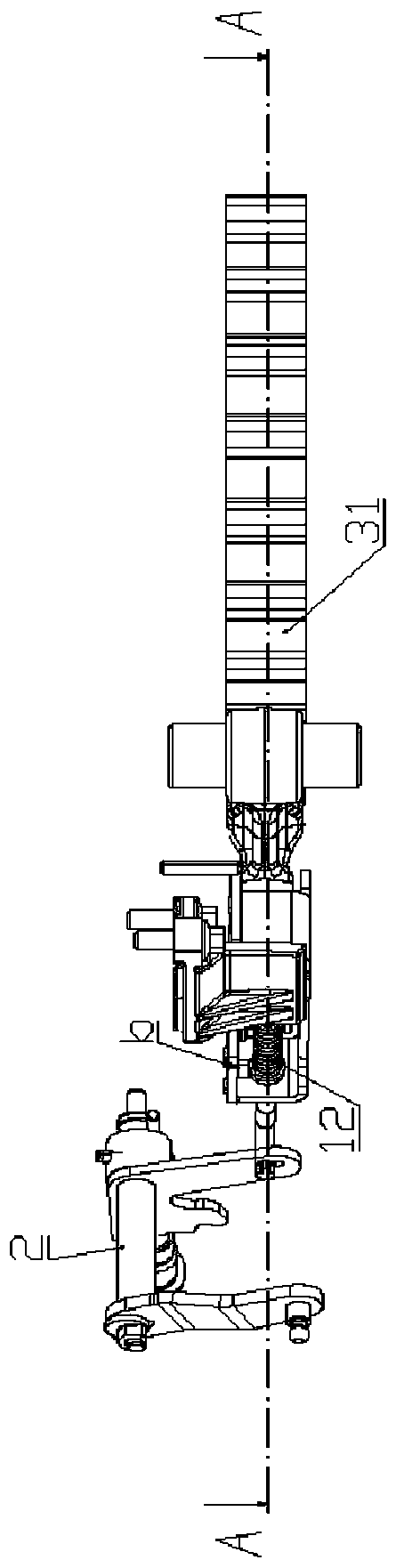

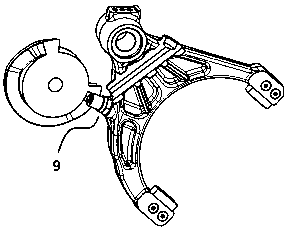

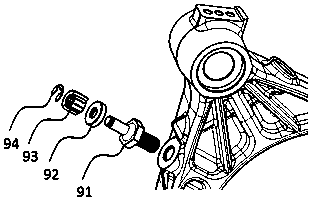

Automatic transmission mechanical parking mechanism

The invention relates to an automatic transmission mechanical parking mechanism. The automatic transmission mechanical parking mechanism comprises a parking ratchet wheel circumferentially fixed to atransmission shaft system. A gear shifting rotary shaft is arranged on a transmission box. One end of the gear shifting rotary shaft is fixedly connected with a gear shifting rotary arm, and the otherend of the gear shifting rotary shaft is fixedly connected with a parking rotary arm. The parking rotary arm is in an L shape. The short arm end of the L-shaped parking rotary arm is provided with sectored teeth. An elastic compression lock pin is arranged on the transmission box. The long arm end of the L-shaped parking rotary arm is hinged to a parking push-pull rod. The extension end of the parking push-pull rod is inserted into a parking driving frame which is in sliding fit with the transmission box. The extension end, inserted into the parking driving frame, of the parking push-pull rodis sleeved with a push rod compression spring. One end of the push rod compression spring is limited by a convex edge of the extension end of the parking push-pull rod, and the other end of the pushrod compression spring is limited by an end plate of the parking driving frame. A first roller makes rolling contact with the lower end face of a guide plate, and a second roller makes rolling contactwith the free end of a parking detent. The transmission box is provided with a reset device corresponding to the free end of the parking detent.

Owner:CHONGQING TSINGSHAN IND

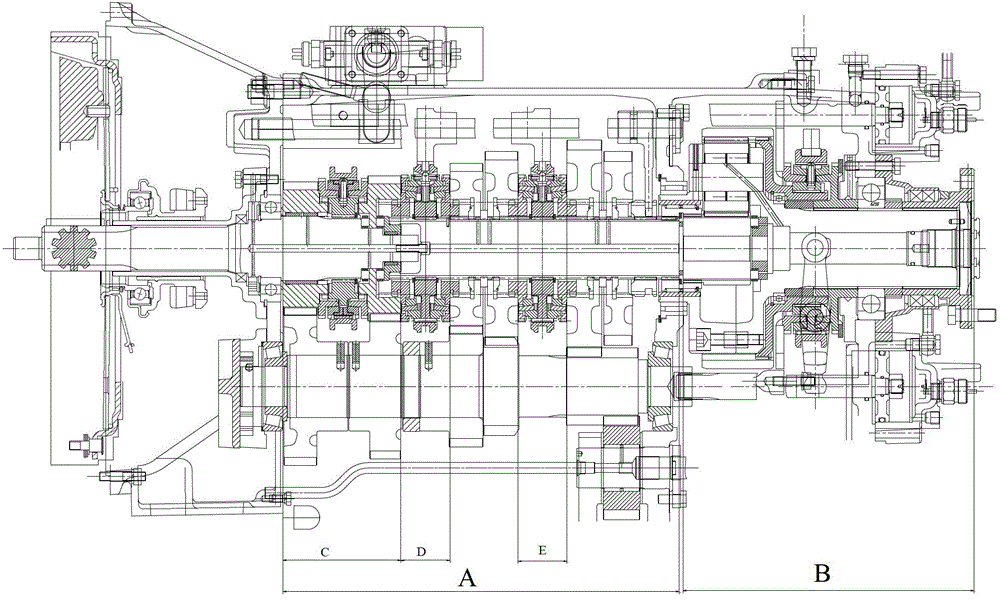

Tractor load reversing transmission device

InactiveCN103863101AIncreased operating comfortCompact structureFluid gearingsGearing detailsEngineeringIdler-wheel

The invention relates to a tractor load reversing transmission device. The tractor load reversing transmission device comprises a load reversing device, a main speed change device and an auxiliary speed change device, wherein the load reversing device, the main speed change device and the auxiliary speed change device are sequentially arranged, one end of the load reversing device is connected with an engine and the other end of the load reversing device is connected with the main speed change device. An input shaft, a reversing driven gear shaft and a reversing idler shaft are installed in the load reversing device; a main speed change driving shaft is installed in the main speed change device, the axes of the input shaft and the main speed change driving shaft are on the same line, and a power output front shaft penetrates through the internal part of the main speed change driving shaft. A reversing driving gear is sheathed on the input shaft, a forward clutch and a reverse clutch are fixedly installed on the input shaft, a reversing primary driven gear and a reversing secondary driving gear are integrated with the reversing driven gear shaft, and a reversing idler is integrated with the reversing idler shaft; the reversing idler is respectively and normally engaged with the reversing driving gear and the reversing primary driven gear, the reversing secondary driving gear is engaged with a reversing secondary driven gear and the reversing secondary driven gear is fixedly installed on the main speed change driving shaft.

Owner:FIRST TRACTOR

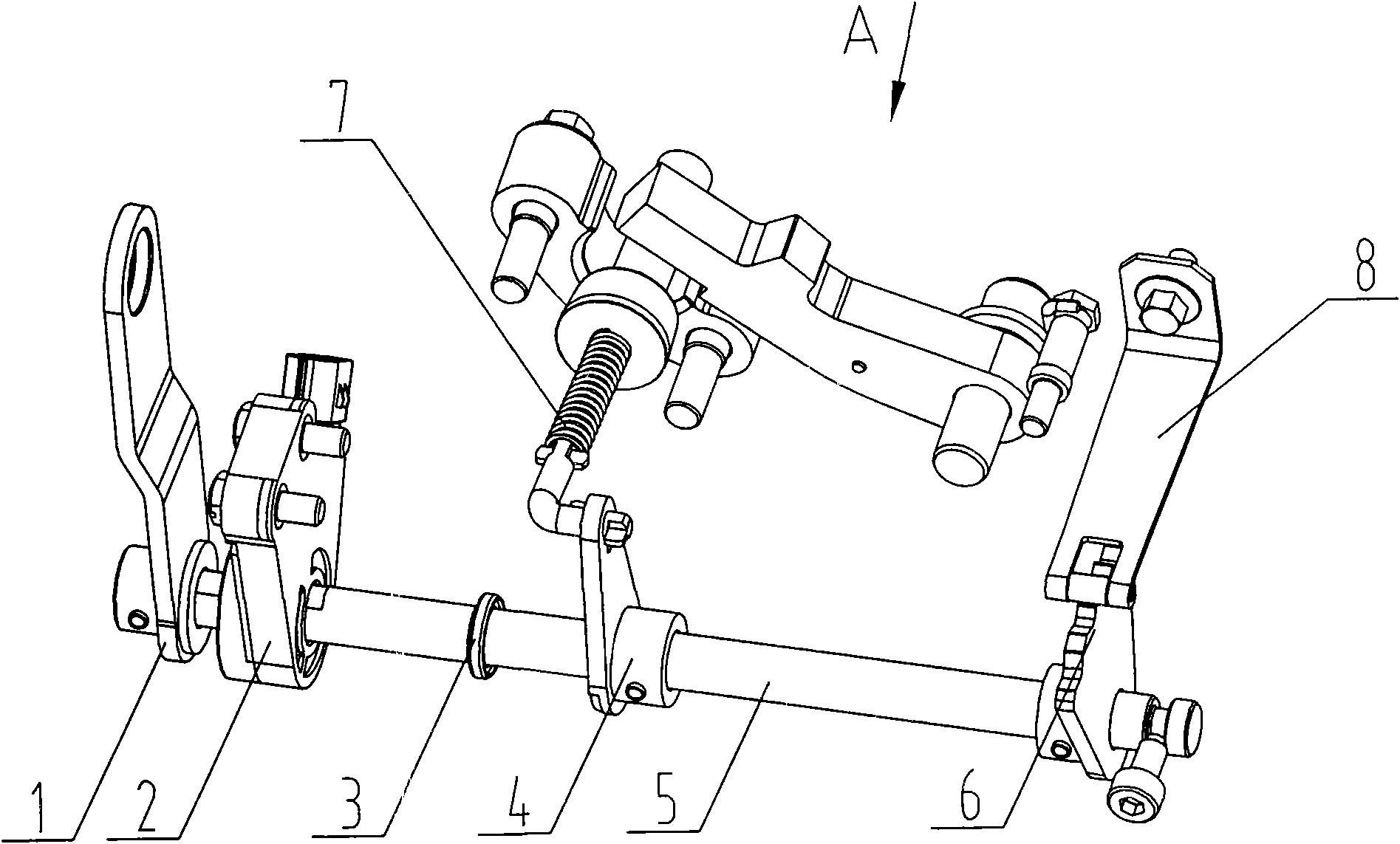

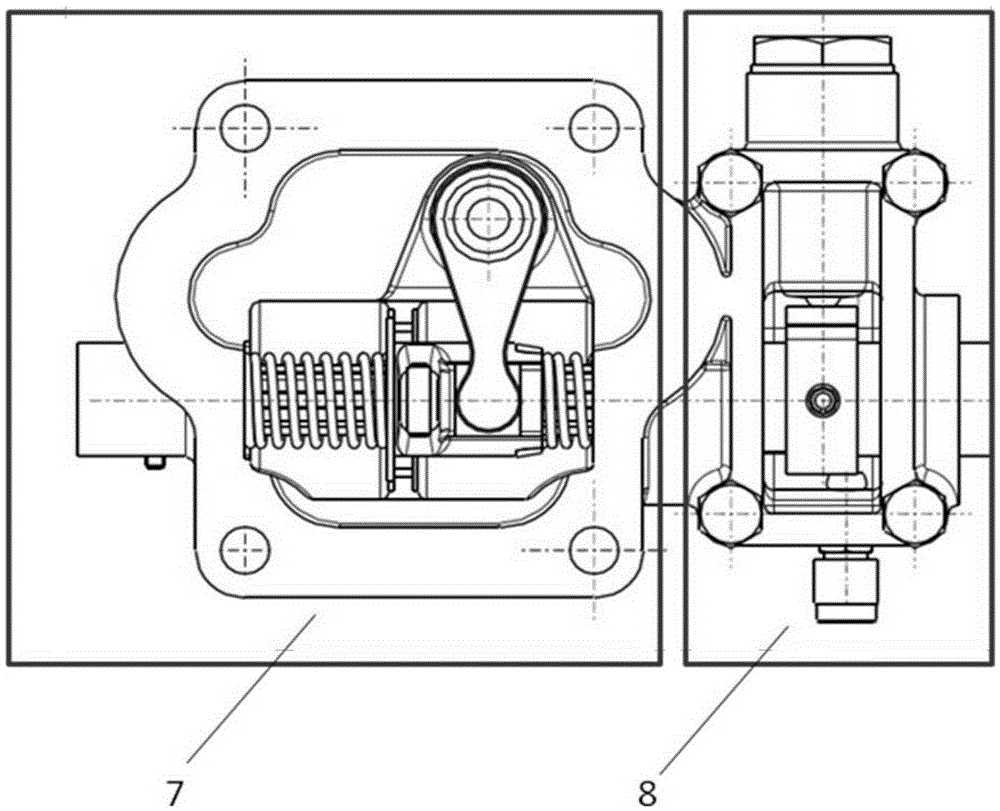

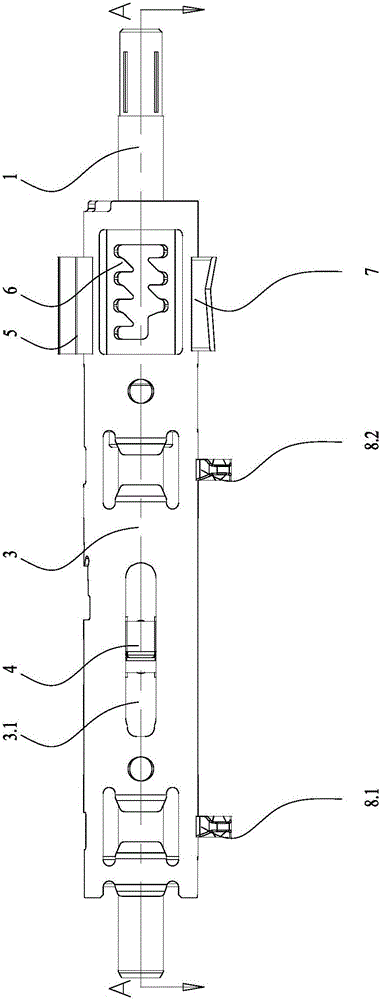

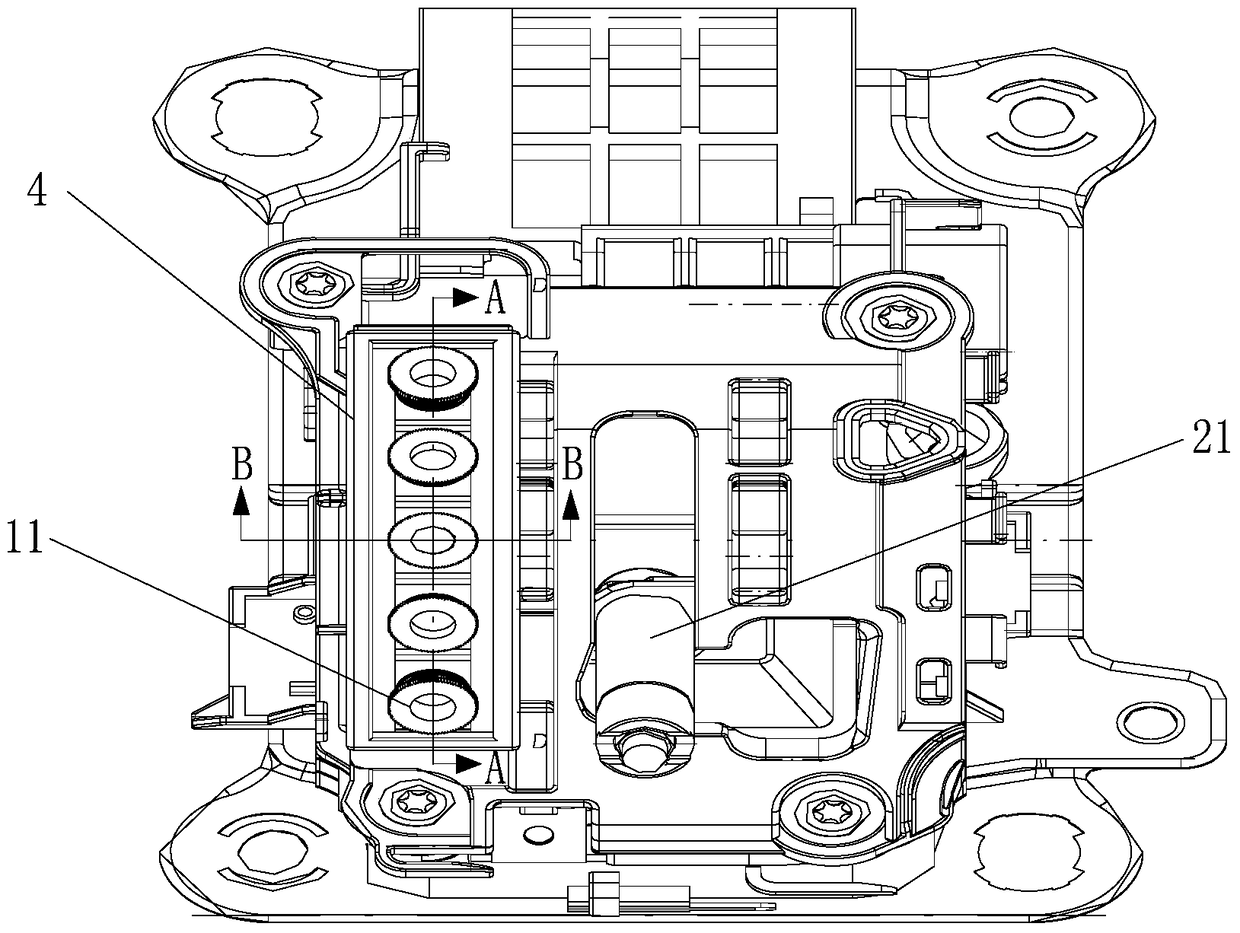

Vehicle transmission operating control device

The invention discloses a vehicle transmission operating control device. The vehicle transmission operating control device comprises a gear selecting / shifting device assembly and a neutral position locator. A vehicle transmission comprises a synchronizer assembly. A synchronizer compression spring in the synchronizer assembly is pressed on a synchronizer pin in a synchronizer sliding gear sleeve groove, and neutral gear positioning of a synchronizer is achieved. The gear selecting / shifting device assembly comprises a shift fork shaft connected with a shift fork, a gear shifting rod connected with a shift head, and a shift fork shaft locator. The shift fork shaft locator is pressed in a shift fork shaft groove through a shift fork shaft compression spring, and neutral gear positioning of the shift fork shaft is achieved. The neutral position locator comprises a shell fixed in the vehicle transmission, a self-locking compression spring arranged in the shell, a self-locking pin arranged on the shell in a sliding manner, and a positioning cam fixed to the gear shifting rod. A surface work part of the positioning cam is provided with a V-shaped protrusion, and a positioning groove is formed in the top end of the V-shaped protrusion. The self-locking compression spring is pressed on the self-locking pin in a matched manner, the self-locking pin is arranged in the positioning groove, and the neutral gear positioning of the shift head is achieved.

Owner:SHAANXI FAST GEAR CO

Four-wheel drive gearbox for agricultural equipment

InactiveCN106884950AEasy conversionEasy to shift gearsToothed gearingsGearing detailsTerrainTransfer case

The invention belongs to the technical field of transmissions, and specifically relates to a four-wheel drive transmission for agricultural equipment, which consists of an active case and a transfer case. The cut-off input power of the rear axle provided by the transfer case realizes the output of the four-wheel drive. The conversion between the two-wheel drive and the four-wheel drive is easy to operate and can be switched at any time. The column gear structure with low processing difficulty is adopted, which reduces the processing cost and improves the Transmission efficiency, gear design conforms to ergonomics, it is convenient for the operator to shift gears, effectively avoids the phenomenon of disengagement and disordered gears, and provides enough power for agricultural equipment used in complex terrain conditions; it has fewer gears and the gear shifting operation is simple , small shifting force, reasonable gear arrangement and gear speed, good safety performance, high reliability, long service life, four drive power outputs provide enough power for agricultural equipment driving on complex roads.

Owner:山东卫禾传动股份有限公司

Gear selecting and shifting control mechanism of gear selecting and shifting device in automobile gearbox

The invention relates to a gear selecting and shifting control mechanism of a gear selecting and shifting device in an automobile gearbox. The gear selecting and shifting control mechanism comprises a control shaft, a first bearing supporting seat, a second bearing supporting seat, a gear shifter casing, a gear shafting guide block, an M-shaped gear shafting groove, a gear shifting groove in the shape of a Chinese character 'wang', a V-shaped gear shifting return block, a first gear shifting finger and a second gear shifting finger, wherein the gear shifter casing, the first bearing supporting seat, the first gear shifting finger, the M-shaped gear shifting groove, the gear shifting groove in the shape like a Chinese character 'wang', the V-shaped gear shifting return block, the second gear shifting finger and the second bearing supporting seat are integrally welded; a control shaft is mounted in the second bearing supporting seat and the first bearing supporting seat; the gear shifting guide block is welded to the control shaft, and is matched with a guiding waist-shaped hole. The gear selecting and shifting control mechanism disclosed by the invention is small in gear shifting force, simple in structure, convenient to mount and replace and simple in forming process, and has favorable selecting and shifting hand feel.

Owner:WUXI ZHONGJIE VIBRATION ISOLATORS

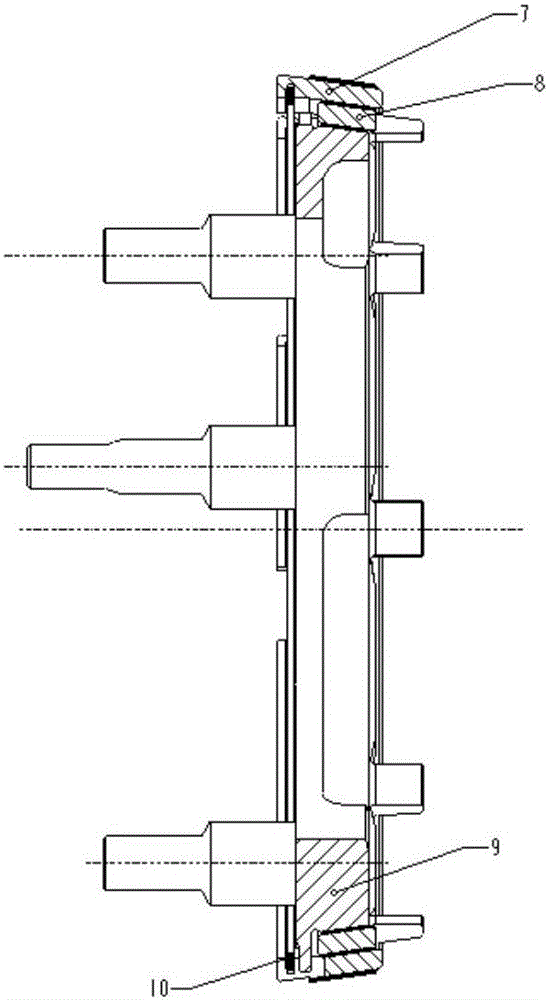

Transmission shifting mechanism for all-electric cars

The invention relates to a transmission shifting mechanism for all-electric cars. According to the technical scheme, the transmission shifting mechanism mainly comprises a shifting motor, linear bearings, a shift fork shaft, a triple-cone synchronizer, a self-locking pin, a shift fork, a shift block, a shift shaft, a buffer, an angle sensor and the like. The buffer is connected with the shifting motor. The shift shaft is mounted on the buffer in a connected manner through splines. Two ends of the shift shaft are provided with the angle sensor and the shift block respectively. An oil seal is disposed between the angle sensor and the shift block. The shift block is inserted into a shift fork hole. The shift fork is connected with the shift fork shaft through the pin. The shift fork shaft is connected to front and rear shells through the linear bearings. The shift fork is inserted into a gear ring of the triple-cone synchronizer. The transmission shifting mechanism has the advantages that shifting force is small, shifting is stable, shifting time is short, and accordingly ECT shifting is higher in quality and reliability.

Owner:姜华

Tractor speed-changing box unit with synchronizer commutation

ActiveCN101837729BCompact structureMany reverse gearsToothed gearingsControl devicesLow speedDrive shaft

The invention relates to a tractor speed-changing box unit with synchronizer commutation, comprising an inverter unit, a main speed-changing unit and an auxiliary speed-changing unit which are arranged in sequence, wherein one end of the inverter unit is connected with a tractor engine, and one end of the auxiliary speed-changing unit is connected with a tractor rear axle. By adopting the arranging manners, the tractor speed-changing box unit with synchronizer commutation can transmit motive power of the tractor engine to the tractor rear axle, a tractor front axle and a power output shaft. By the combination of the inverter unit, the main speed-changing unit and the auxiliary speed-changing unit, 12 forward gears and12 backward gears can be realized; the inverter unit is arranged at front end of the main speed-changing unit, which is convenient to realize commutation and gear engagement by adopting a synchronizer structure and unnecessary to stop the tractor to engage gears in low speed, therefore, the gear-shifting impact and the gear-shifting force are small; the main speed-changing unit adopts a synchronizer to shift gears and is unnecessary to stop the tractor to shift gears, therefore, the gear-shifting impact and the gear-shifting force are small; and an auxiliary speed-changing driven shaft and a bevel pinion in the auxiliary speed-changing unit are integrated, therefore, the structure is compact.

Owner:FIRST TRACTOR

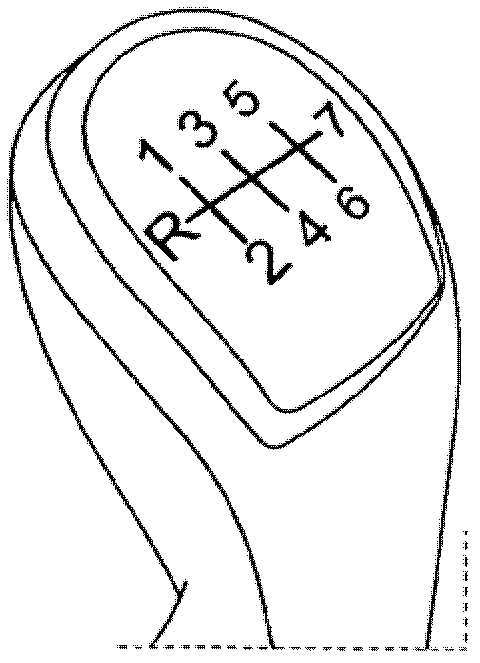

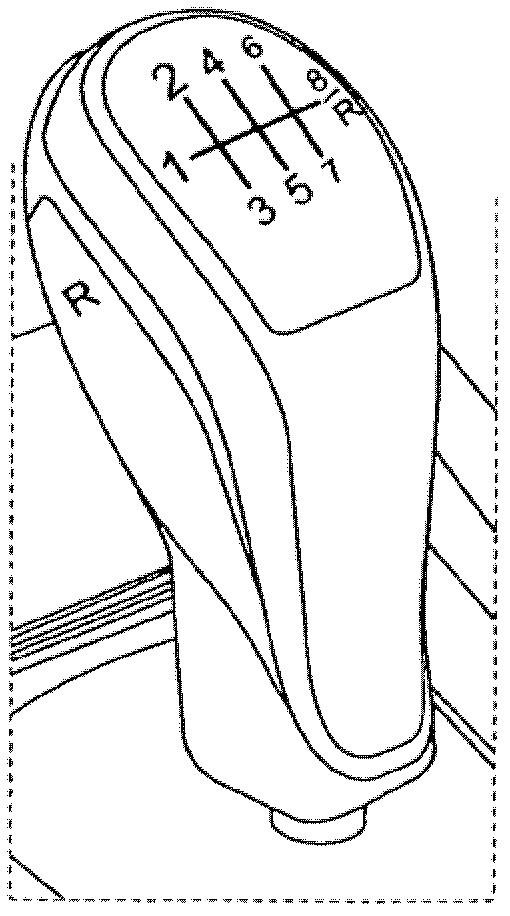

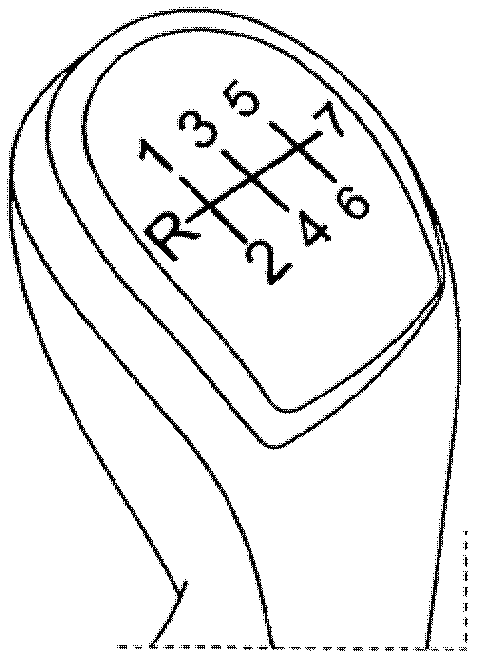

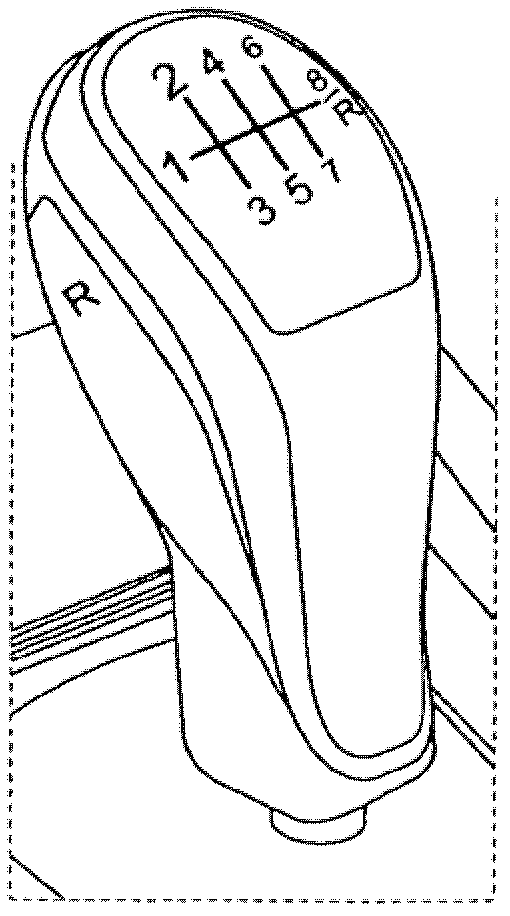

Vehicle having a transmission and a selection element for shifting gears

The invention relates to a vehicle, comprising a transmission having at least one controllable actuator, which is designed to engage and / or disengage at least one transmission gear, and a selection element to be operated manually, by means of which the actuator can be controlled, wherein in order to engage a transmission gear, the selection element must first be moved in the direction of a specified end position associated with the particular transmission gear. The selection element can be moved to the end position associated with the particular transmission gear only if the particular transmission gear is actually engaged.

Owner:BAYERISCHE MOTOREN WERKE AG

Power reversing tractor transmission system of main clutch between main speed variator and auxiliary speed variator

The invention relates to a power reversing tractor transmission system of a main clutch between a main speed variator and an auxiliary speed variator. The power reversing tractor transmission system comprises a main speed variator, a creeper gear device, an auxiliary speed variator, a transfer case, an oil pump drive device, a power output device, a normally-engaged driving gear, a normally-engaged driven gear, a power output shaft rear shaft, a power output front shaft, an oil pump drive driving gear, a torsion shock absorber and a front output shaft; the main speed variator is connected with the creeper gear device by virtue of the engagement of the normally-engaged driving gear and the normally-engaged drive gear, the creeper gear device is connected with the auxiliary speed variator, an output shaft in the auxiliary speed variator is connected with a primary driving gear of the transfer case, the primary driving gear of the transfer case is engaged with a primary driven gear of the transfer case, and the oil pump drive device is connected with the power output device by virtue of the engagement of the oil pump drive driving gear and the oil pump drive driven gear; a shaft in the main speed variator is connected with the torsion shock absorber, an auxiliary speed change output shaft in the auxiliary speed variator is connected with a rear axle of a tractor, and the transfer case is connected with a front axle of the tractor through the front output shaft.

Owner:FIRST TRACTOR

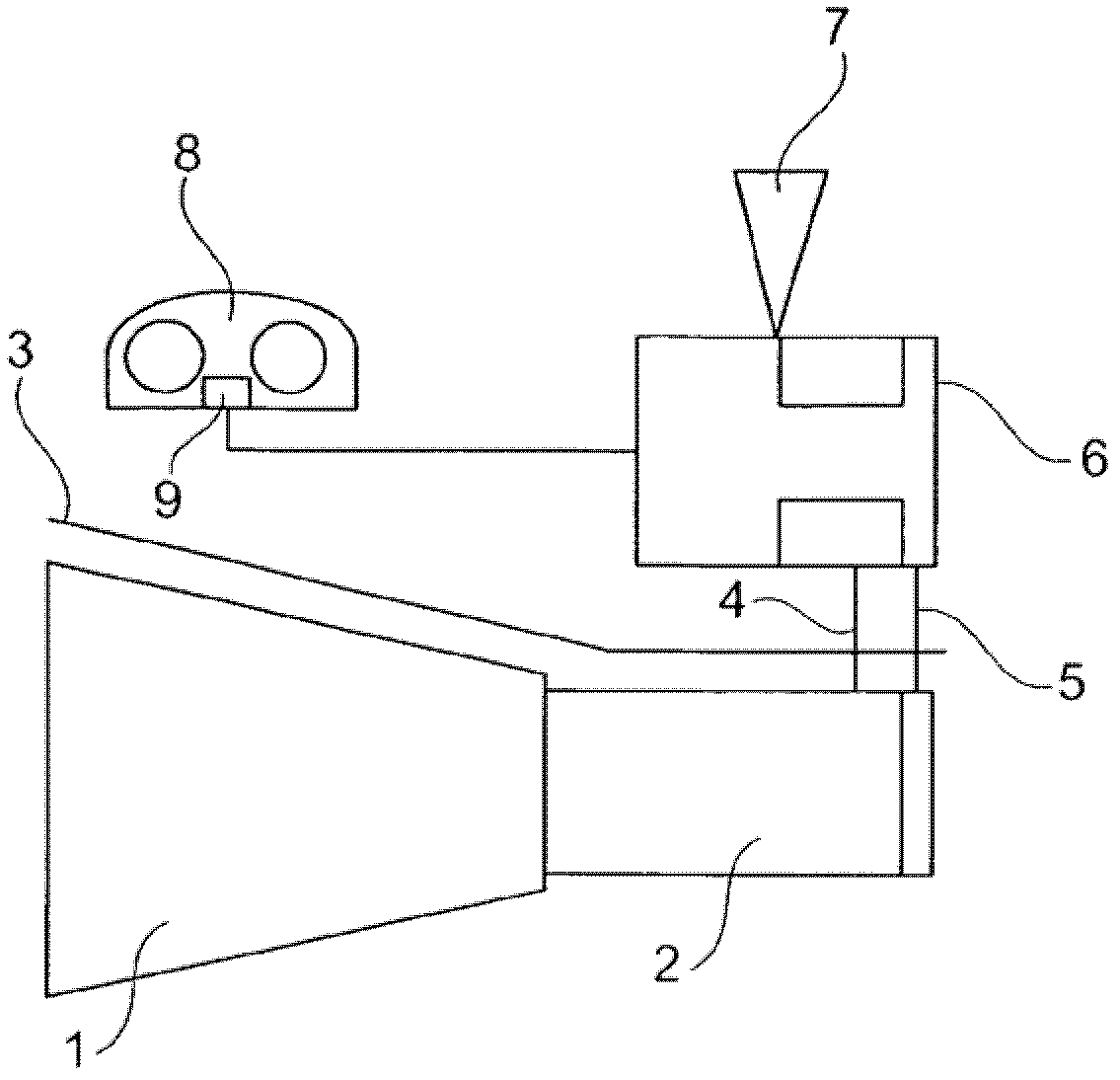

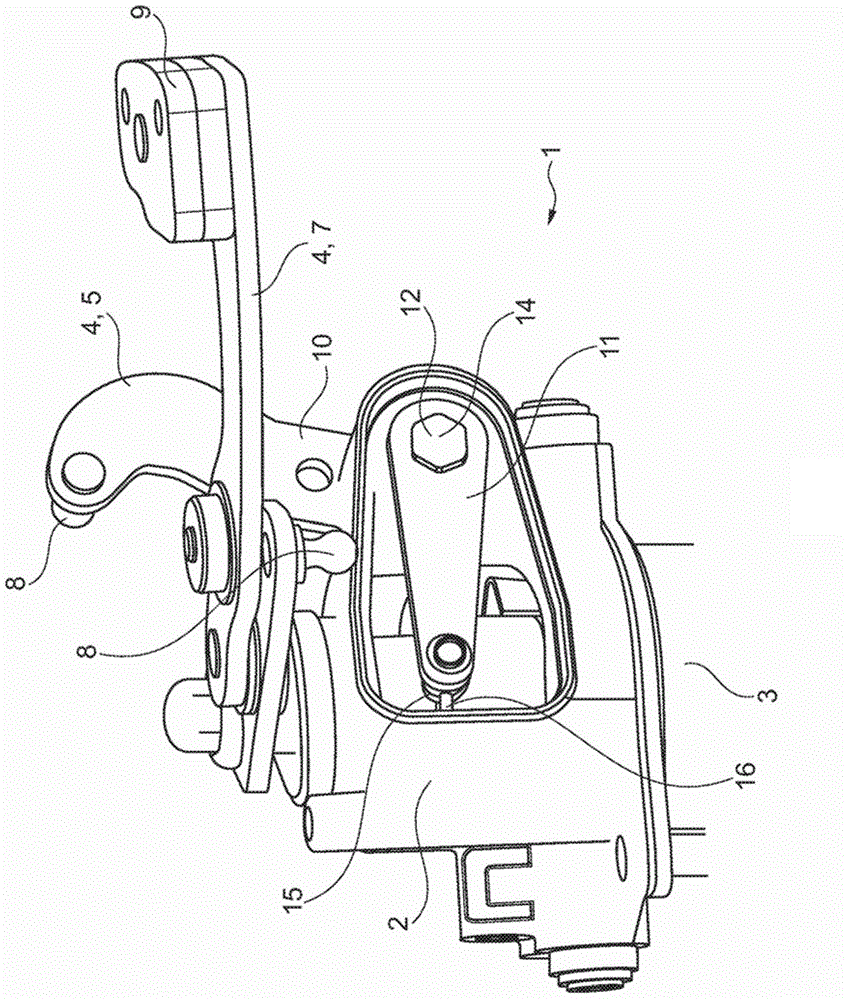

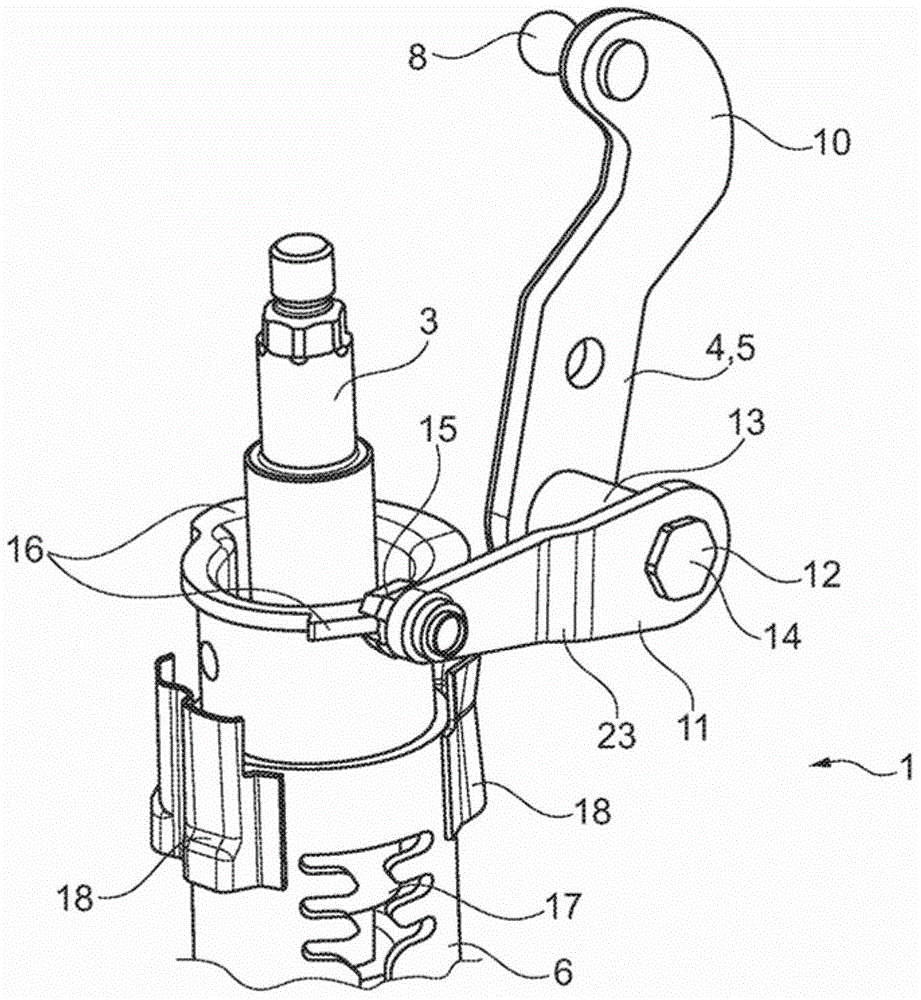

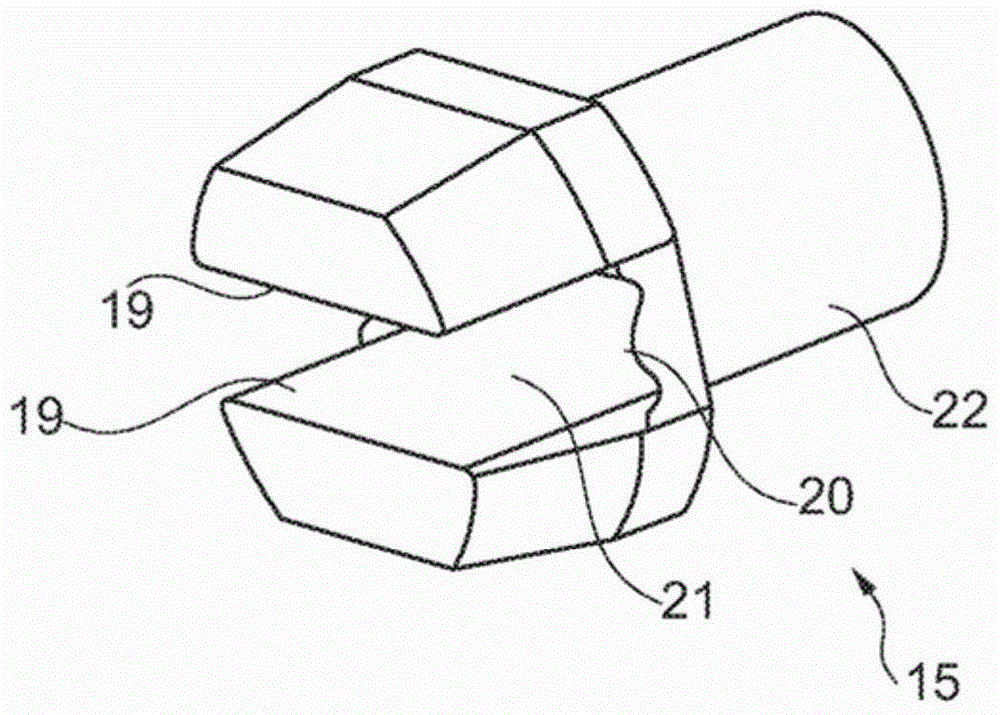

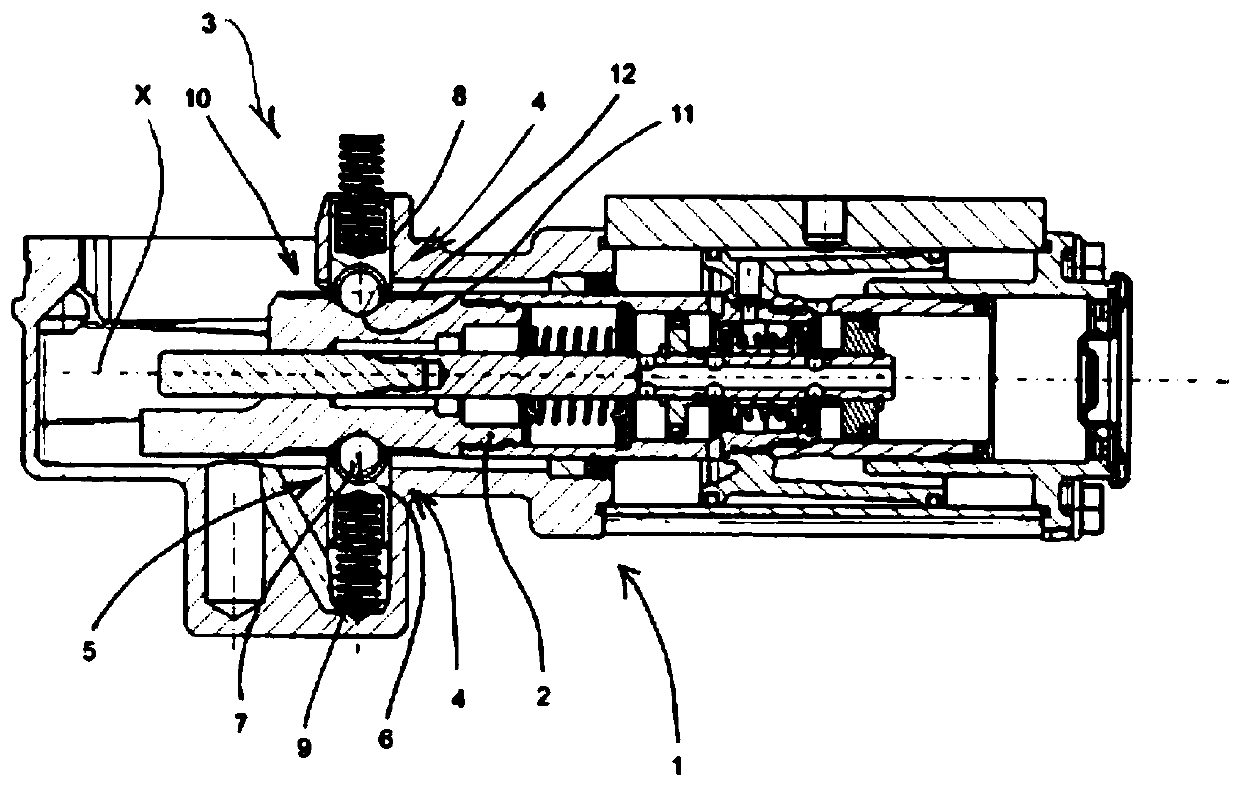

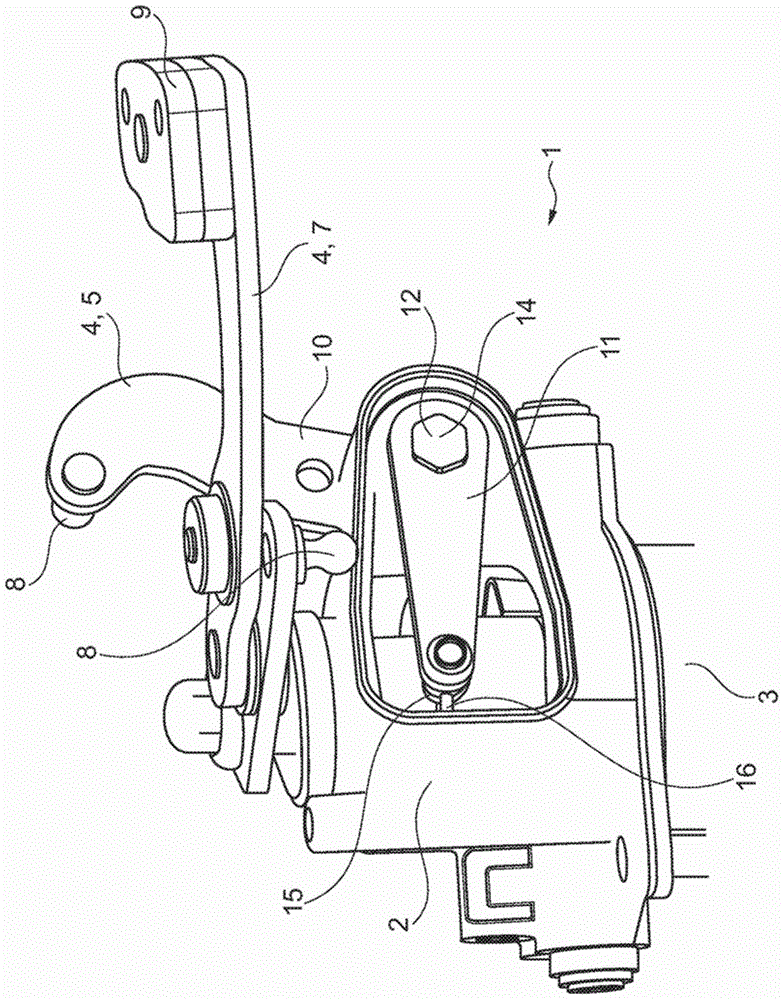

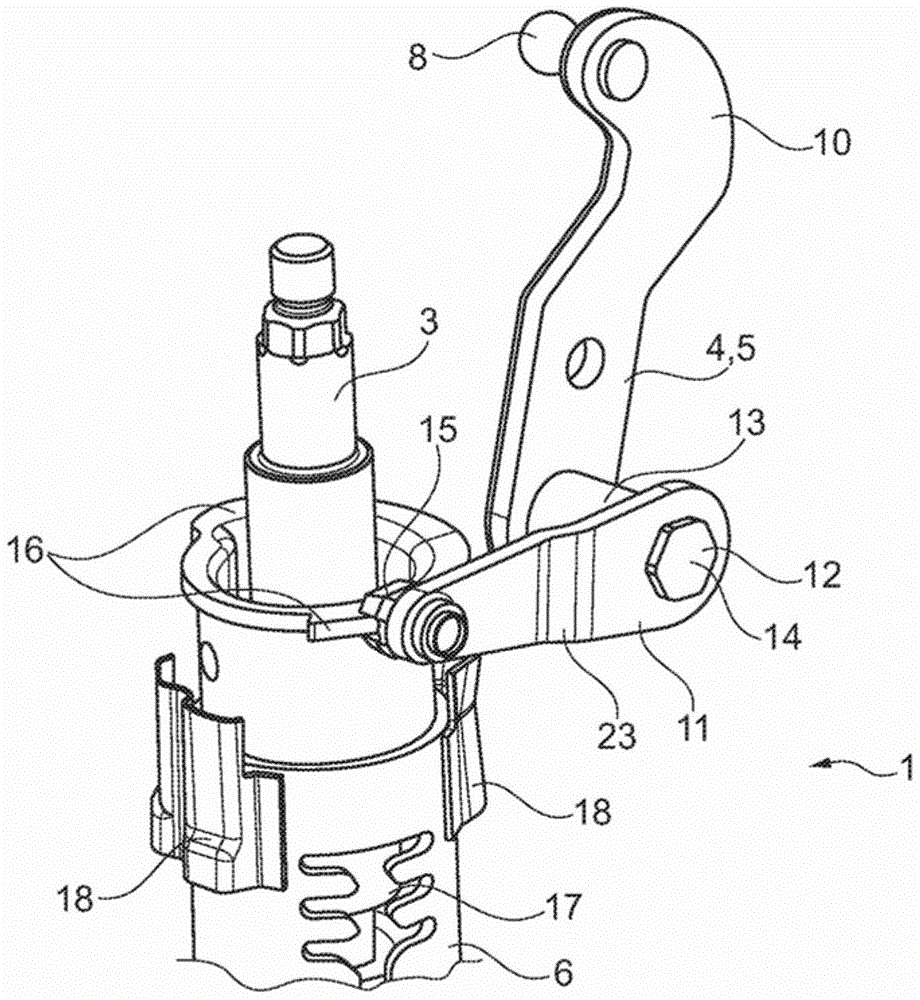

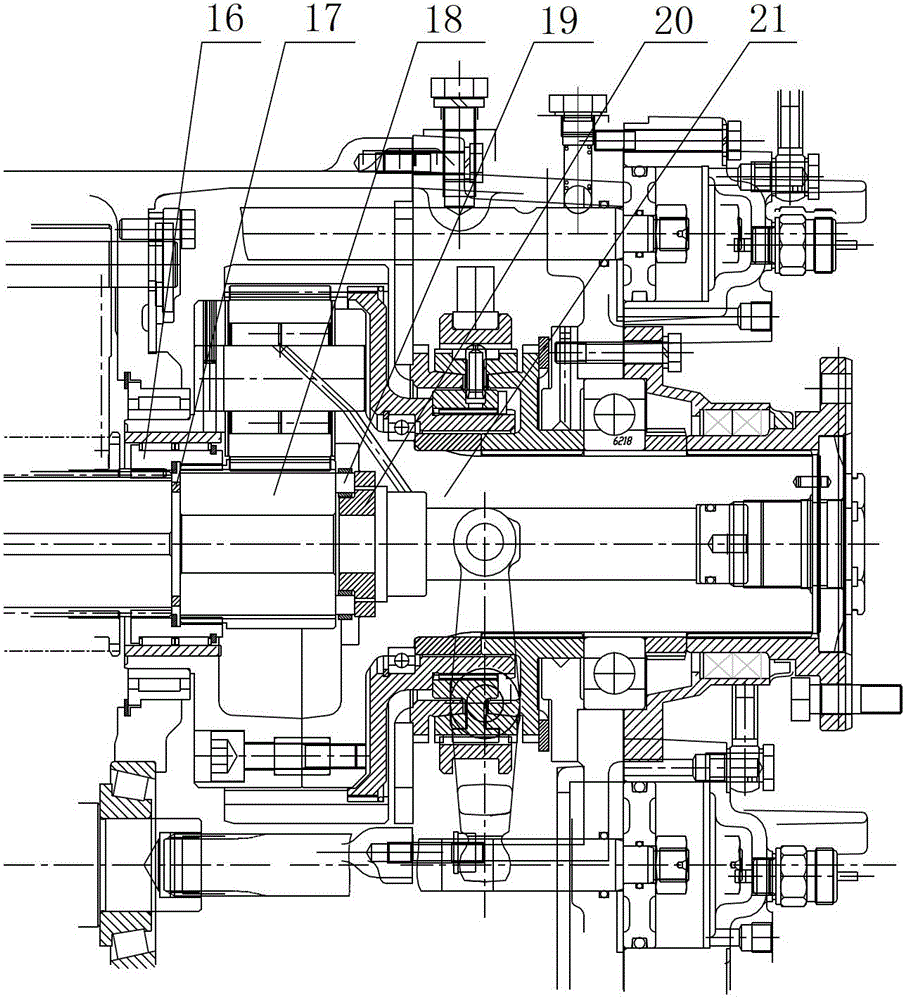

Shifting device of a motor vehicle speed-change gearbox

The invention relates to a shifting device (1) of a motor vehicle speed-change gearbox having a shift rod (3), a pivotable lever (4, 5) which has an actuating element (15) by means of which the shift rod (3) or a shifting element disposed on the shift rod is translationally movable and a coupling element (16) which is disposed on the shift rod (3) so as to not move axially and on which the actuating element (15) engages. The invention is characterized in that in at least one rest position the actuating element (15) is spaced apart from the coupling element (16) or in that in at least one rest position the actuating element (15) and the coupling element (16) have a contact surface which is minimal with regard to the possible positions of the actuating element (15).

Owner:SCHAEFFLER TECH AG & CO KG

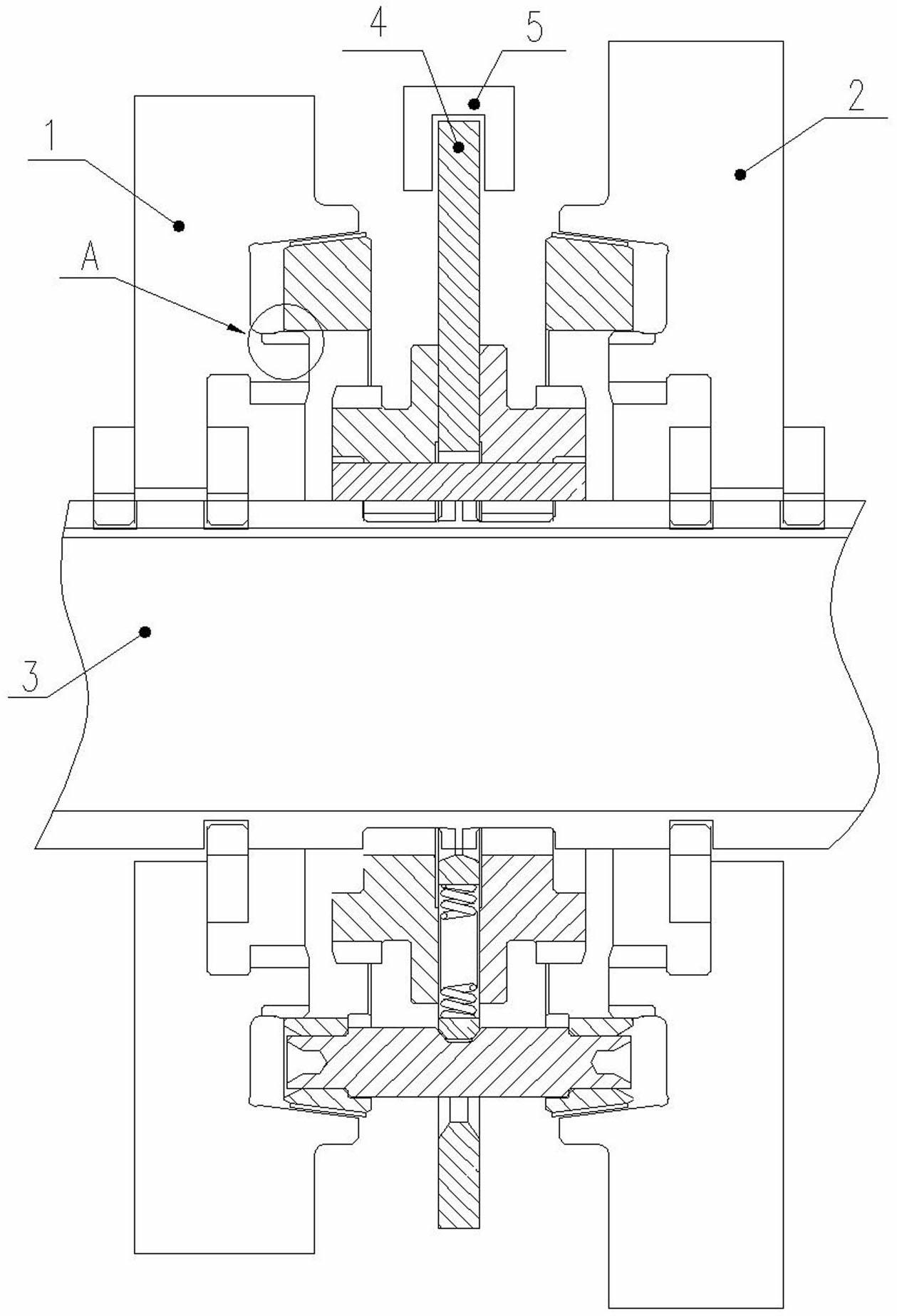

A three-cone synchronizer with lubricating oil passage

ActiveCN103790994BSimple structureShort shift timesMechanical actuated clutchesCouplingsEngineeringMechanical engineering

The invention discloses a three-cone synchronizer with a lubricating oil path, which comprises a sliding gear sleeve, an outer friction ring, a friction intermediate ring, an inner friction ring, a slider, a pin, a spring, a combined ring gear and a tooth hub; , a pair of combined ring gears are symmetrically arranged on both sides of the gear hub, and the conical body of the combined ring gear faces the side of the gear hub, a pair of inner friction rings are arranged on the pair of combined ring gears, and a pair of friction intermediate rings are arranged on it. The second claws of the pair of friction intermediate rings extend into the oil holes of the pair of combined ring gears, the pair of outer friction rings are arranged on the pair of friction intermediate rings, and the first claws of the pair of friction intermediate rings extend into the pair of inner friction rings In the oil groove, the sliding gear sleeve, slider, pin and spring are all arranged between a pair of outer friction rings, and one end of the pin passes through the slider to match the sliding gear sleeve, and the other end of the pin is connected to the gear hub through the spring. touch. Compared with the double-cone synchronizer, the three-cone synchronizer of the present invention has shorter shift time, smaller shift force, comfortable operation and long service life.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

Lock pin type three-conical-surface synchronizer

ActiveCN106763277AEnough clearanceEnough concentricityMechanical actuated clutchesEngineeringConical surface

The invention discloses a lock pin type three-conical-surface synchronizer which comprises a high-gear conical ring assembly, a synchronizer sliding gear sleeve, a low-gear conical ring assembly and three groups of conical surface friction pairs, wherein the high-gear conical ring assembly, the synchronizer sliding gear sleeve and the low-gear conical ring assembly are sequentially arranged; a high-gear lock pin of the high-gear conical ring assembly is connected with a high-gear lock hole of the synchronizer sliding gear sleeve; the three groups of conical surface friction pairs comprise a first friction pair formed by a friction internal ring assembly and a friction middle ring, a second friction pair formed by the friction middle ring and a friction external ring and a third friction pair formed by the friction external ring and a low-gear gear respectively; the friction internal ring assembly comprises a friction internal ring and a low-gear lock pin, and the low-gear lock pin of the friction internal ring assembly is connected with a low-gear lock hole in the synchronizer sliding gear sleeve; the friction external ring and the friction internal ring are both oppositely provided with snap spring slots, and are relatively positioned by snap springs arranged in the snap spring slots. According to the lock pin type three-conical-surface synchronizer, a novel mechanical structure is adopted, so that the problems of poor concentricity of the three conical surfaces and unreliable gear engagement locking of the three-conical-surface synchronizer are solved.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD +1

Gear shifting mechanism and method of transmission and vehicle

InactiveCN111173925AEnsure adequate lubricationReduce volumeControlled membersGear lubrication/coolingNeedle roller bearingNew energy

The invention discloses a gear shifting mechanism and method of a transmission and a vehicle. The gear shifting mechanism and method are particularly suitable for transmissions of new energy vehicles.The gear shifting mechanism adopts a gear shifting drum type structure. Shifting forks are connected with gear shifting drums through connection pieces. Lubricating oil channels are additionally arranged on the shifting forks, so that lubrication of needle bearings is achieved, the gear shifting force can be effectively reduced, and gear shifting smoothness is improved. Meanwhile, the torque of the motor drives the gear shifting drums through a worm and gear mechanism, the executing motor and the gear shifting drums are perpendicularly arranged, so that the occupied space is small, and the structure is compact. Besides, when the motor drives the gear shifting drums to rotate, since the path of a rotating guide groove on the outer surface of each gear shifting drum is designed in advance,the shifting forks can move according to the pre-designed path, and then sequential gear shifting is achieved.

Owner:SUZHOU KAIBO YIKONG DRIVE TECH CO LTD

Agricultural vehicle gearbox with wet type clutch

InactiveCN106870671AAvoid damageStrong transmission torqueGearingFriction clutchesAgricultural engineeringEconomic benefits

The invention belongs to the field of gearboxes, and relates to a gearbox for agricultural vehicles, especially a gearbox for agricultural vehicles with a wet clutch, which is used in the preparation of agricultural vehicles and solves the problem that friction plates are easily damaged due to improper operation by users. It adopts a wet clutch, which makes the service life of the friction plate longer and the transmission torque stronger, avoiding damage to the clutch due to improper operation, thereby improving the service life of the clutch; the housing is equipped with an intermediate shaft assembly, an output shaft assembly, and a differential assembly, first shaft assembly and reverse gear idler shaft assembly, there is a wet clutch assembly outside the housing, the wet clutch assembly is connected with the first shaft assembly through a pulley, and the other assemblies are connected by gears; the overall structure is reasonable , low processing difficulty, low preparation cost, high transmission efficiency, energy saving and environmental protection, few gears, small shifting resistance, easy and convenient operation, good economic benefits and broad market prospects.

Owner:山东卫禾传动股份有限公司

Gear shifting device and automobile

ActiveCN106314139ALarge amount of compressionSmall amount of compressionControl devicesEngineeringMechanical engineering

The invention provides a gear shifting device and an automobile, and relates to the technical field of automobiles. The problem that the gear shifting comfort of the automobile is low is solved. The gear shifting device comprises a gear shifting shell body, a gear shifting rod, a gear fixing rod and a gear shifting positioning assembly, wherein the gear shifting shell body is provided with a containing cavity; the gear shifting rod is arranged in the gear shifting shell body, and one end of the gear shifting rod stretches out of the gear shifting shell body; the gear fixing rod and the gear shifting positioning assembly are arranged in the containing cavity; the gear fixing rod is fixedly connected with the gear shifting rod; the gear shifting positioning assembly comprises a plurality of gear shifting positioning blocks arranged in the gear shifting direction; a gear shifting positioning groove is formed between every two adjacent gear shifting positioning blocks; an adjusting piece of which one end stretches out of the gear shifting shell body is arranged in the area, corresponding to each gear shifting positioning block, in the gear shifting shell body; an elastic piece is arranged between each gear shifting positioning block and the corresponding adjusting piece; the two ends of the elastic pieces make contact with the gear shifting positioning blocks and the adjusting pieces correspondingly; and the positions of the adjusting pieces are adjusted, so that the compression amount of the elastic pieces is changed, and the gear shifting force is changed. The gear shifting device is used for improving the gear shifting comfort of the automobile.

Owner:GREAT WALL MOTOR CO LTD

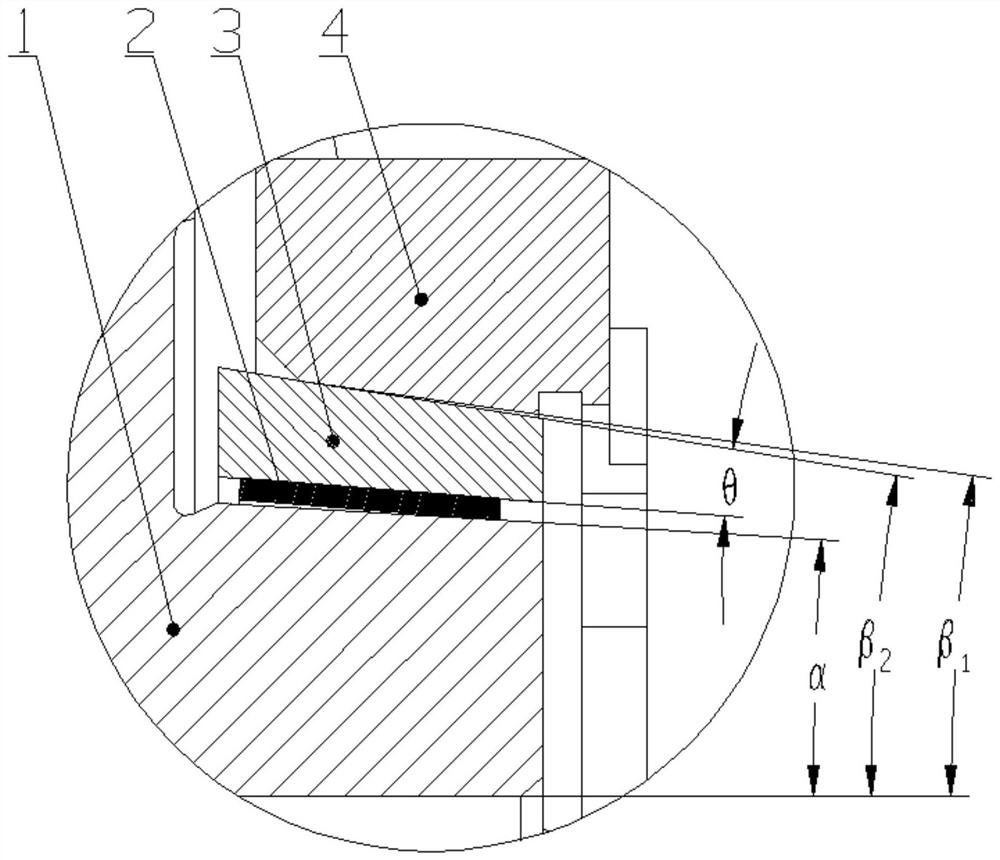

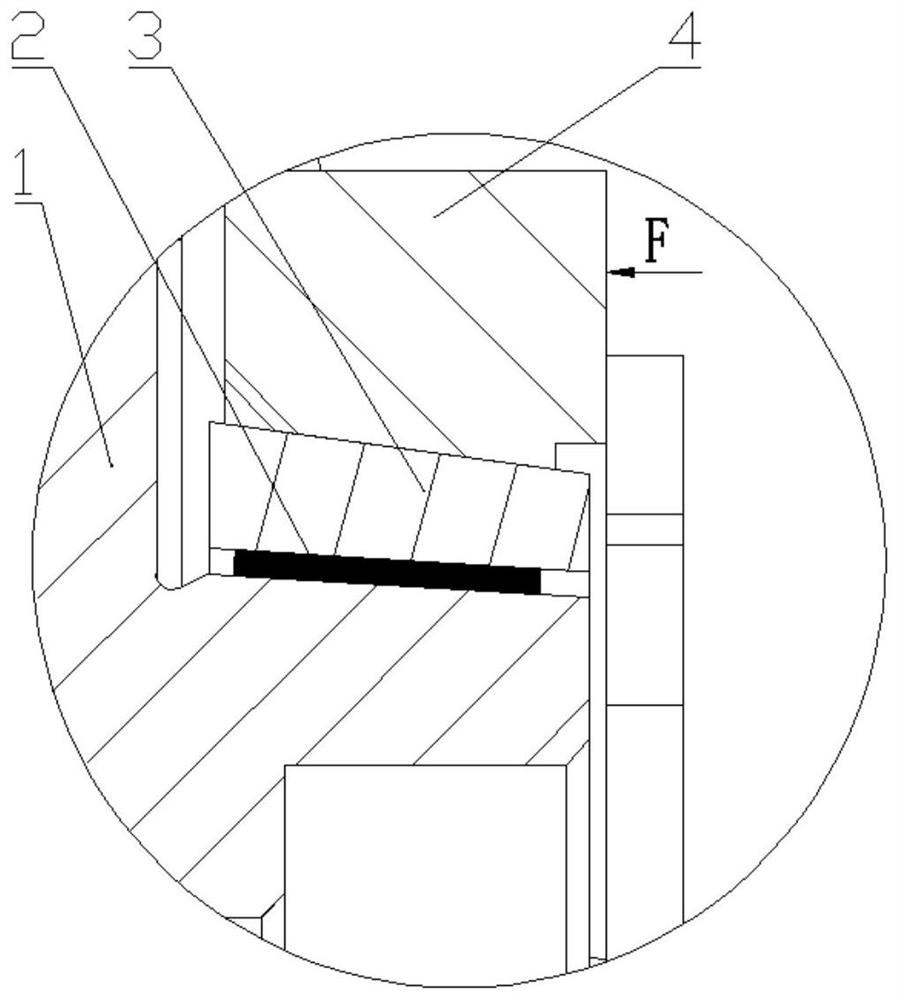

Synchronizer ring mechanism

The invention discloses a synchronizer ring mechanism. The synchronizer ring mechanism comprises a combined gear, a synchronizer locking ring, a conical ring and a plurality of friction plates, a shaft hole of the synchronizer locking ring is a conical hole, a conical boss is arranged on the combined gear, the conical ring is located on the conical boss and located between the outer conical surface of the conical boss of the combined gear and the inner conical surface of the synchronizer locking ring, and the friction plates are fixedly connected to the inner conical surface of the conical ring; the included angle beta 2 between the outer conical surface of the conical ring and the central axis is larger than the included angle beta 1 between the inner conical surface of the synchronizer locking ring and the central axis, the large end of the inner conical surface of the synchronizer locking ring makes contact with the large end of the outer conical surface of the conical ring, the included angle between the inner conical surface of the conical ring and the central axis is larger than the included angle alpha between the outer conical surface of the combined gear and the central axis, and the small end of the inner conical surface of the conical ring makes contact with the small end of the outer conical surface of the combined gear; and a plurality of open grooves are formed in the large-diameter end of the conical ring, a plurality of limiting bosses extending along a gen are arranged at the small end of the conical ring, a plurality of limiting blocks extending in the radial direction are arranged at the small end of the synchronizer locking ring, and a limiting groove is formed between every two adjacent limiting blocks and used for allowing the corresponding limiting boss to be inserted therein.

Owner:CHONGQING TSINGSHAN IND

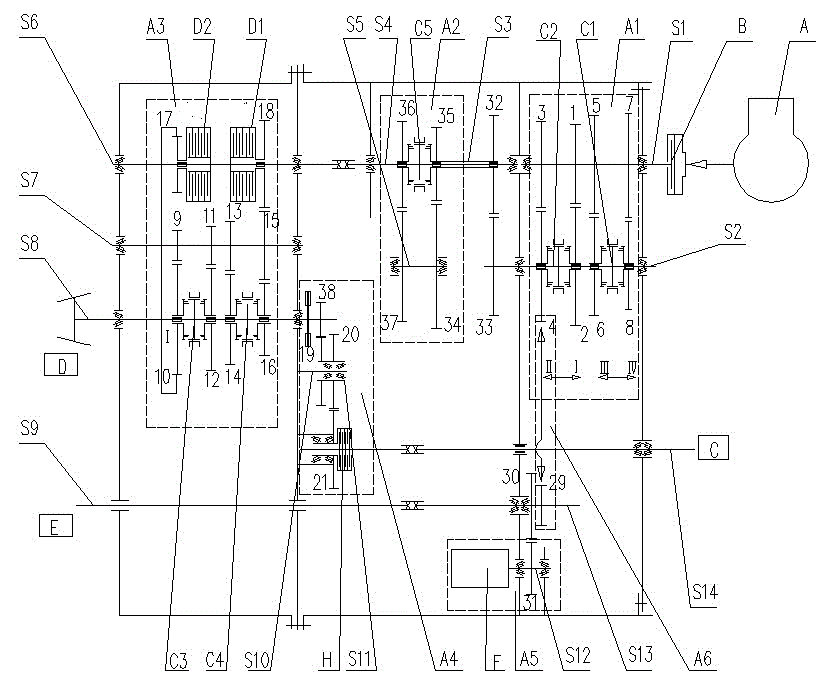

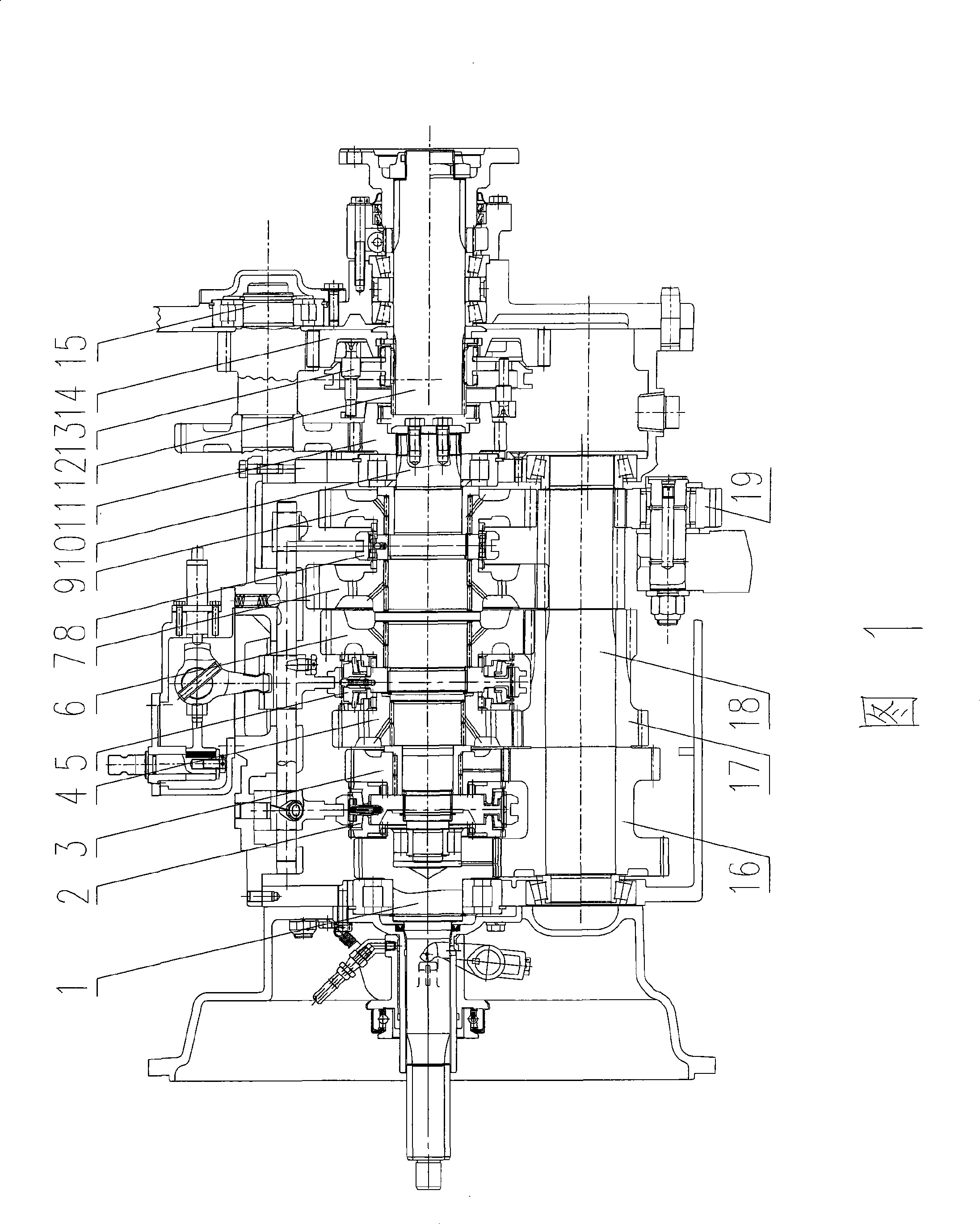

Automobile speed variator with main-sub case sub shaft of antisymmetric arrangement

InactiveCN101435490AGuaranteed performance life indexThe performance life index meetsGearboxesToothed gearingsDriver/operatorGear wheel

The invention belongs to automobile transmission, in particular to an automobile transmission of which countershafts of a main box and a minor box are in asymmetric arrangement. The automobile transmission consists of the main box and the minor box, and is characterized in that a main-box countershaft is arranged in the main box; two minor-box countershafts are arranged in the minor box; and the main-box countershaft and the minor-box countershafts are in asymmetric arrangement. A gear is arranged on a shaft I on the main box; a plurality of gears, synchronizers and toothed sleeves are arranged on a shaft II of the main box; the synchronizers and the toothed sleeves arranged on the shaft II rotate together with the shaft II; a plurality of gears are arranged on the main-box countershaft; the gears on the shaft II and the gears on the countershaft are relatively engaged and rotated with each other; an input gear, a synchronizer, a main reduction gear, two minor-box countershafts and a minor-box main shaft are arranged in the minor box; and the gear in the minor box engages mutually with the gears on the two countershafts by use of the main reduction gear respectively. The automobile transmission has the characteristics of small gear shifting force, long life span and the like, reduces the driving strength of drivers, increases driving comfort, and guarantees driving safety at the same time.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

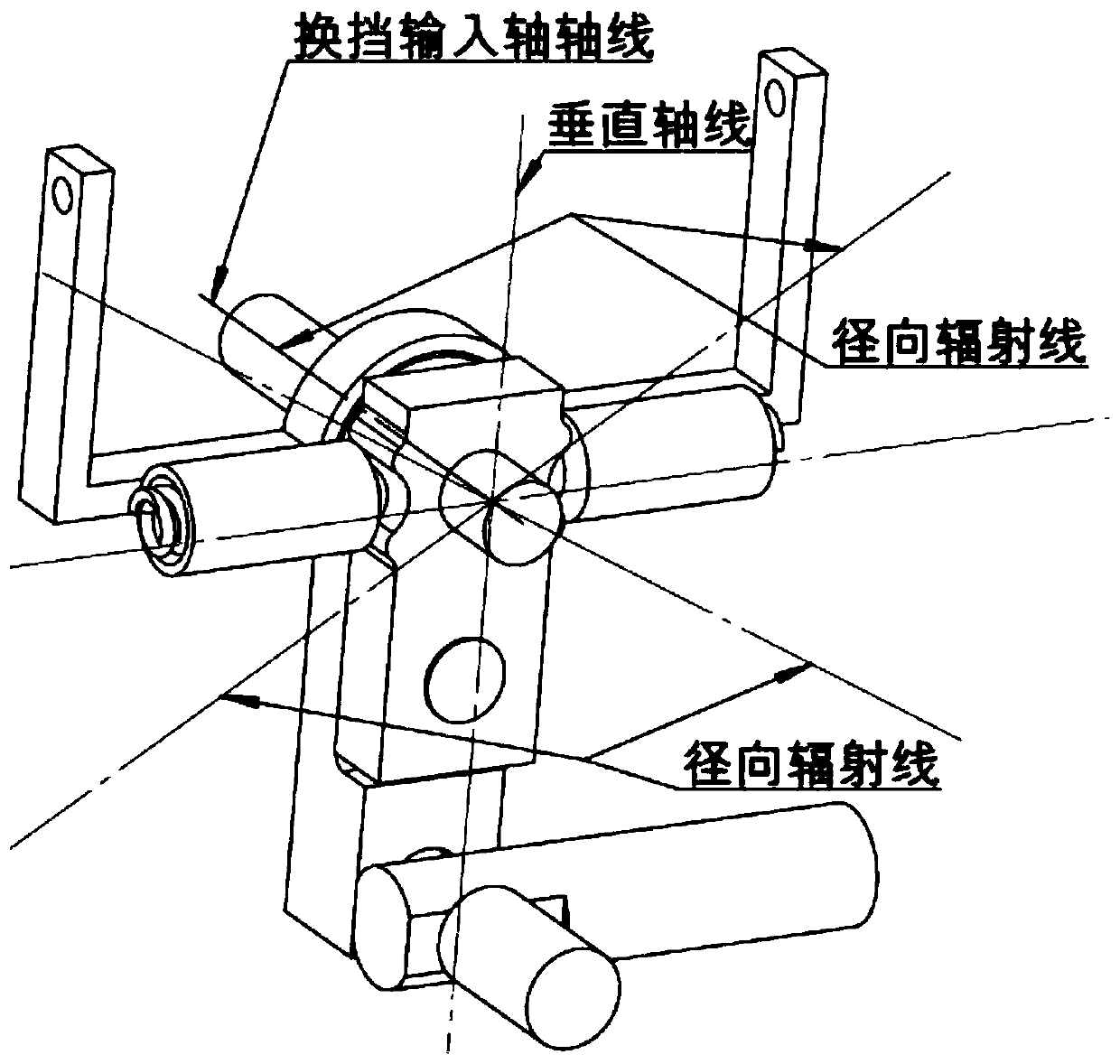

Gear shifting servo system

PendingCN110219978AImproved shifting experienceImprove fuel economyGearing controlLinear motionCentre of rotation

The invention relates to a gear shifting servo system. The system comprises a gear shifting input shaft, a transmission mechanism, a deflection mechanism, a servo valve structure, a gear shifting executing mechanism and a positioning mechanism, wherein the gear shifting input shaft drives a driven element to rotate synchronously; when the driven element rotates, a deflection element connected withthe driven element through a pin roll can be synchronously driven; and an output shaft is in a fixed state at a gear box end at the beginning of starting, the deflection element swings leftwards or rightwards by taking the output shaft as a rotating center, a deflection executing element transversely moves under the deflection of the deflection element, and an air valve in a servo valve structureis opened, so that the assisting effect is achieved. Through the conversion of the deflection mechanism, linear motion is transferred to an inhaul cable or a rod through the transmission mechanism bya shift rod of a shifter, then rotary motion generated by the linear motion on the gear shifting input shaft can be converted into the linear motion of the gear shifting output shaft which is almostin the same longitudinal position as the transmission mechanism. With the system, gear shifting force can be remarkably reduced, the gear shifting comfort is improved, the occupied space is small, theinstallation is convenient, and the cost is reduced.

Owner:赫伯力汽车技术(上海)有限公司

Joint device with torsional vibration damping function

PendingCN114658839ASmall shift forceReduce active speed adjustment timeGear vibration/noise dampingGearing controlMotor speedGear wheel

The invention relates to the technical field of automobile transmission systems, and discloses a joint device with a torsional vibration damping function, the joint device comprises a first shell and a second shell, the first shell and the second shell are both sleeved on a rotating shaft, the first shell and the second shell are oppositely arranged and fixedly connected, the outer side end face of the first shell can be connected with a gear, and the outer side end face of the second shell can be connected with a gear; an accommodating cavity is formed between the first shell and the second shell; the vibration reduction mechanism is arranged in the containing cavity, and the vibration reduction mechanism comprises a vibration reduction piece arranged around the peripheral face of the rotating shaft; and the rotating disc is fixedly connected to the rotating shaft in the circumferential direction and located in the containing cavity, and at least one end face of the rotating disc abuts against the vibration reduction piece. Vibration caused by torque impact is counteracted by the vibration reduction piece, the joint device can be jointed under the working condition of large rotating speed difference, the driving motor active speed regulation time of an electric vehicle or a hybrid electric vehicle in the gear shifting stage is shortened, and therefore the gear shifting time is shortened, and the requirement for rotating speed control of the driving motor is lowered.

Owner:莫文威

Vehicle comprising a transmission and a selection element for switching transmission gears

A vehicle includes a transmission having at least one controllable actuator provided for engaging and / or disengaging at least one transmission gear, and a selection element to be operated manually, by which the actuator can be controlled, wherein. In order to engage a transmission gear, the selection element must first be moved in the direction of a specified end position assigned to the corresponding transmission gear. The selection element can be moved into the end position assigned to the corresponding transmission gear only when the corresponding transmission gear is actually engaged.

Owner:BAYERISCHE MOTOREN WERKE AG

Gear shifting devices for motor vehicle transmissions

The invention relates to a shifting device (1) of a motor vehicle speed-change gearbox having a shift rod (3), a pivotable lever (4, 5) which has an actuating element (15) by means of which the shift rod (3) or a shifting element disposed on the shift rod is translationally movable and a coupling element (16) which is disposed on the shift rod (3) so as to not move axially and on which the actuating element (15) engages. The invention is characterized in that in at least one rest position the actuating element (15) is spaced apart from the coupling element (16) or in that in at least one rest position the actuating element (15) and the coupling element (16) have a contact surface which is minimal with regard to the possible positions of the actuating element (15).

Owner:SCHAEFFLER TECH AG & CO KG

Novel 16-gear speed changing box with oblique gears, double middle shafts and lock ring type synchronizers

ActiveCN102734421BEliminate axial forceImprove carrying capacityGearingGearing controlLine shaftMedial axis

The invention discloses a novel 16-gear speed changing box with oblique gears, double middle shafts and lock ring type synchronizers. The speed changing box comprises a main box part and an auxiliary box part, wherein an input shaft and a main shaft connected with the input shaft are arranged in the main box part; the main shaft is connected with a sun wheel in the auxiliary box part through a spline transition sleeve; front and rear ends of the main shaft are respectively provided with a main shaft front positioning mechanism and a main shaft rear positioning mechanism; a plurality of oblique gears are arranged on the main shaft; an input differential mechanism is arranged on the input shaft in the main box part; two double-cone lock ring type synchronizers are respectively arranged between the first gear and the second gear as well as between the third gear and the fourth gear which are arranged on the main shaft in the main box part; and a planetary gear train mechanism is arranged in the auxiliary box part. The speed changing box is operated in a labor-saving mode, the gears can be shifted stably, stable transmission is performed, the noise is low, and the actual service life of the speed changing box can be prolonged.

Owner:SINO TRUK JINAN POWER

A transmission for plant protection machinery

ActiveCN104343939BLess gearEasy to shiftToothed gearingsTransmission elementsNeedle roller bearingDrive shaft

The invention discloses a transmission for plant protection machinery. The transmission comprises a transmission casing provided with an upper cover at the top as well as a shaft I, a shaft II, a shaft III, a reverse gear idler shaft and an output shaft which are mounted in the transmission casing, wherein the shaft I is a gear shaft, an input flange is connected with the outer end of the shaft I and connected with an engine clutch assembly through a transmission shaft, the other end of the shaft I is connected with the shaft III through a needle roller bearing, the shaft II is mounted right below the shaft III, the reverse gear idler shaft is mounted right above the shaft III, the output shaft is arranged under the shaft III, and a first reverse gear shift shaft, a second-gear and third-gear fork shaft and a gear shift mechanism assembly are arranged above the shaft III; and a high-low gear fork shaft is arranged left above the output shaft. Compared with the prior art, the transmission for the plant protection machinery has the characteristics of a few gears, high operation efficiency, small gear shifting force and the like, the processing difficulty is effectively reduced, the transmission efficiency is improved, further, the gear distribution is reasonable, and gear separation and disorder are effectively avoided.

Owner:山东卫禾传动股份有限公司

A kind of shifting device and automobile

ActiveCN106314139BLarge amount of compressionSmall amount of compressionControl devicesMechanical engineeringEngineering

The invention provides a gear shifting device and an automobile, and relates to the technical field of automobiles. The problem that the gear shifting comfort of the automobile is low is solved. The gear shifting device comprises a gear shifting shell body, a gear shifting rod, a gear fixing rod and a gear shifting positioning assembly, wherein the gear shifting shell body is provided with a containing cavity; the gear shifting rod is arranged in the gear shifting shell body, and one end of the gear shifting rod stretches out of the gear shifting shell body; the gear fixing rod and the gear shifting positioning assembly are arranged in the containing cavity; the gear fixing rod is fixedly connected with the gear shifting rod; the gear shifting positioning assembly comprises a plurality of gear shifting positioning blocks arranged in the gear shifting direction; a gear shifting positioning groove is formed between every two adjacent gear shifting positioning blocks; an adjusting piece of which one end stretches out of the gear shifting shell body is arranged in the area, corresponding to each gear shifting positioning block, in the gear shifting shell body; an elastic piece is arranged between each gear shifting positioning block and the corresponding adjusting piece; the two ends of the elastic pieces make contact with the gear shifting positioning blocks and the adjusting pieces correspondingly; and the positions of the adjusting pieces are adjusted, so that the compression amount of the elastic pieces is changed, and the gear shifting force is changed. The gear shifting device is used for improving the gear shifting comfort of the automobile.

Owner:GREAT WALL MOTOR CO LTD

Agricultural vehicle gearbox with gap bridge bearing

InactiveCN106931095AExtended service lifeReduce vibrationToothed gearingsTransmission elementsTransmission beltAgricultural engineering

The invention belongs to the field of gearboxes, and relates to a gearbox for agricultural vehicles with bridge bearings, which is used in the preparation of agricultural vehicles, and solves the problem that the eccentricity of the whole vehicle occurs in the gearbox with a single pulley, which causes excessive vibration of the pulley transmission, and the belt and the gearbox are easily damaged. The problem of damage, the use of bridge bearings can effectively reduce the vibration of the gearbox and improve the service life of the transmission belt and gearbox. The main structure includes the gearbox housing and the first shaft assembly and the second shaft assembly installed in the gearbox housing. , intermediate shaft assembly, output shaft assembly, differential assembly, clutch, pulley and bridge bearing, the front end of one shaft assembly is equipped with a clutch, the clutch is connected with the pulley through the bridge bearing, and the whole is a four-axis transmission. It can realize the reverse design of the whole machine; its overall structure is simple, the gears are arranged reasonably, the production cost is low, the gears are few, the shifting resistance is small, the processing difficulty is small, the transmission efficiency is high, the operation is easy and convenient, energy saving and environmental protection, and has good performance Economic benefits and broad market value.

Owner:山东卫禾传动股份有限公司

Gearboxes with crawler gears and reverse gears for tractors

ActiveCN103912638BSmall reduction ratioLarge reduction ratioGearboxesToothed gearingsThree stageDrive shaft

The invention provides a gearbox with a crawling block and a retrograde device for a tractor. The gearbox with the crawling block and the retrograde device for the tractor comprises a retrograde device, a crawling block device, a main speed change device and an auxiliary speed change device; the retrograde device, the crawling block device, the main speed change device and the auxiliary speed change device are arranged in sequence, one end of the retrograde device is connected with a motor, and one end of the auxiliary speed change device is connected with a rear axle of the tractor; the retrograde device and the crawling block are arranged in a front transmission box, and the main speed change device and the auxiliary speed change device are arranged in a rear transmission box. According to the gearbox with the crawling block and the retrograde device for the tractor, a synchronizer structure is adopted to achieve convenient reverse gear, gear shifting impinge and gear shifting force are small, gear shifting time is less, and work efficiency is high; the crawling block can obtain a larger reduction ratio due to speed reducing realized through a three-stage gear, and the maximum speed of the crawling block can be lower; a synchronizer is adopted in the main speed change device to shift gear, the gear shifting can be conducted without stopping the tractor, gear shifting impinge and gear shifting force are small, and work efficiency is high; an auxiliary speed change driven shaft in the auxiliary speed change device is integrated with a small bevel gear, and the structure is compact and nimble.

Owner:FIRST TRACTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com