Gear shifting device and automobile

A technology of shifting device and shifting lever, which is applied to control devices, vehicle parts, transportation and packaging, etc., can solve the problems of low shifting comfort of automobiles and unadjustable shifting force of shifting devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

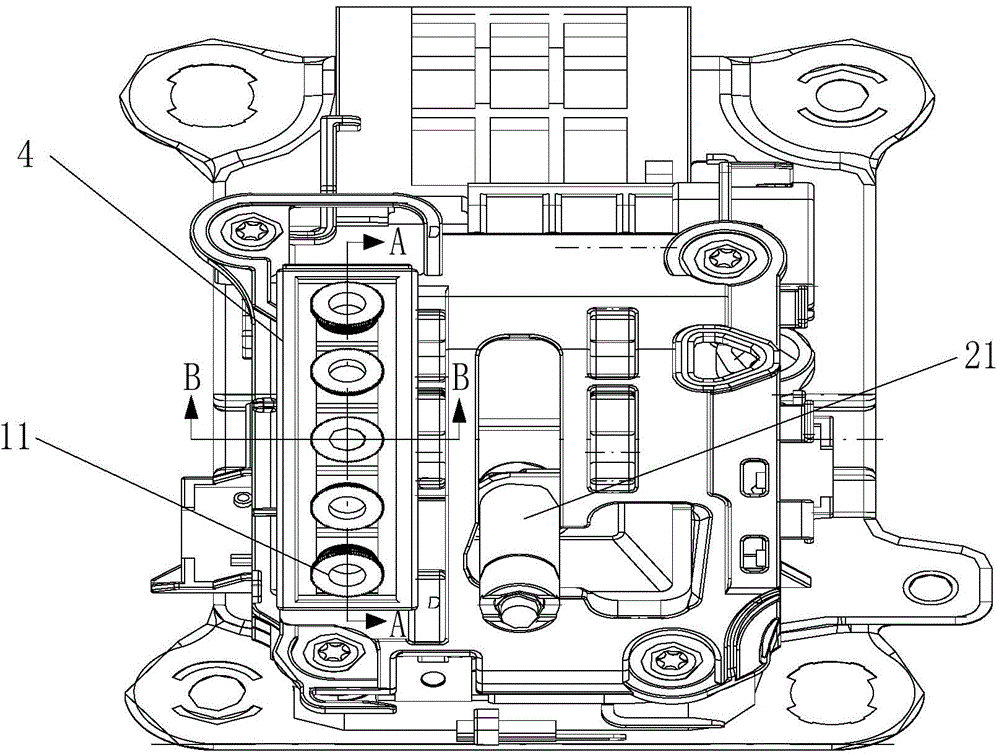

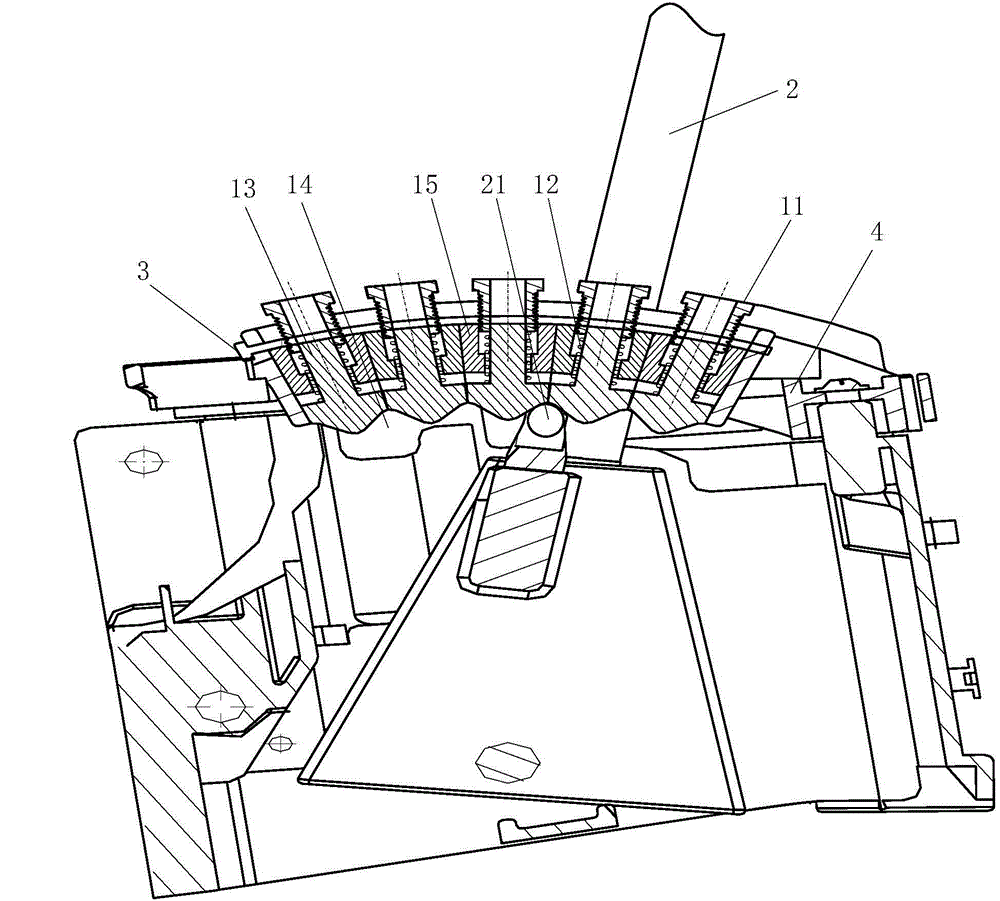

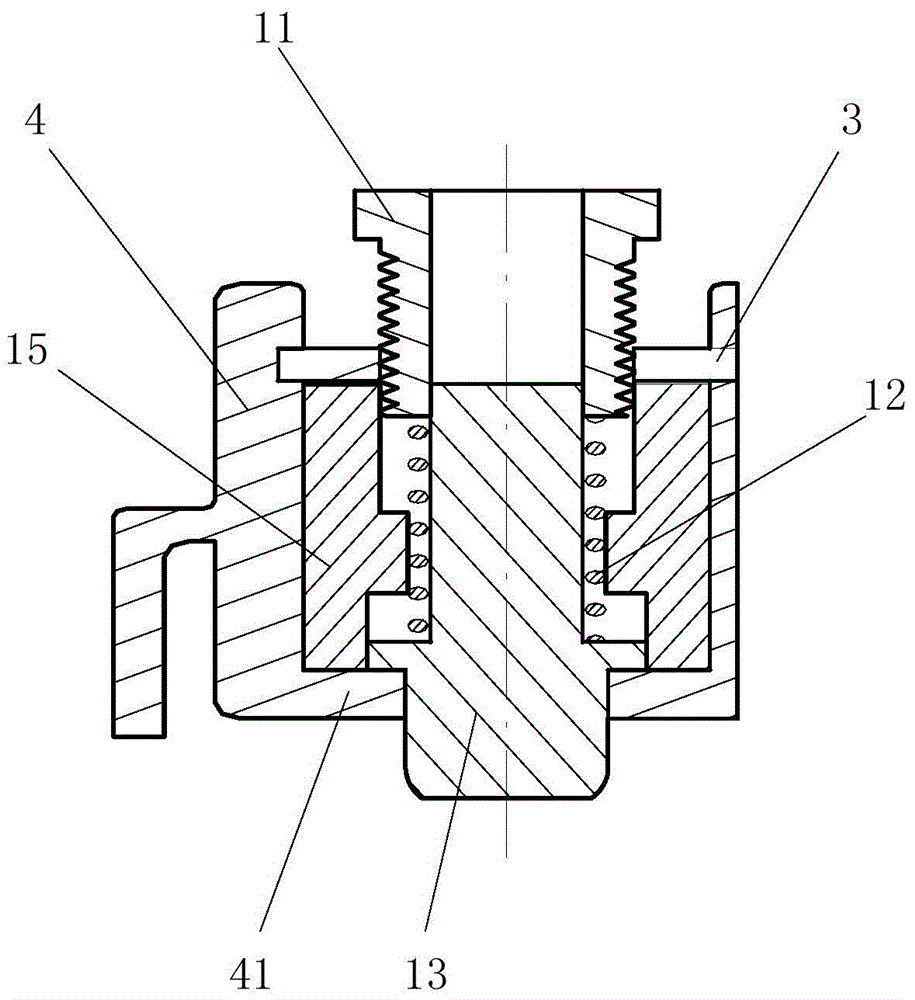

[0039] see figure 1 , the embodiment of the present invention provides a gear shifting device, including: a gear shift housing 4 having a housing chamber, and a gear shift lever 2 installed in the housing chamber of the gear shift housing 4, a fixed gear lever 21 and a gear shifter The positioning assembly, wherein the shift lever 2 protrudes from the shift housing 4, the fixed gear lever 21 is fixedly connected with the shift lever 2, the shift positioning assembly is located beside the fixed gear lever 21, and the shift positioning assembly includes a plurality of shift positioning components. Block 13, the bottom surface of each shift positioning block 13 is a protruding arc surface respectively, a shift positioning groove 14 is formed between two adjacent shift positioning blocks 13, when the shifting action is not performed, the fixed gear lever 21 The head is located in one of the shift positioning grooves 14, and an adjustment member is respectively arranged in the area...

Embodiment 2

[0051] Embodiment 2 of the present invention provides an automobile, which is provided with the shifting device provided in Embodiment 1 above. In the process of using the shifting device in the above-mentioned automobile, if a user with greater strength uses the above-mentioned shifting device, it is necessary to adjust the shifting device to increase the required shifting force to meet the requirements of the stronger user on the shifting force. Specifically, adjust the position of the adjusting member to increase the compression amount of the elastic member 12, so that the thrust force applied by the elastic member 12 to the shift positioning block 13 increases. During the shifting process, the shift lever 2 drives the fixed The force required for the shift rod 21 to push the shift positioning block 13 increases, thereby increasing the shift force; if the user with less strength uses the above shift device, the shift device needs to be adjusted to reduce the required shift f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com