Hydraulic leveling base and washing machine

A flat base and hydraulic technology, applied in the field of washing machines, can solve problems such as support failure, inconvenient operation for users, and the weight of washing machines, etc., and achieve the effect of strong applicability and good adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Such as Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, a hydraulic leveling base of this embodiment includes a bracket 2101 that can be connected in combination or used independently and a leveling foot 10 arranged at the lower part of the bracket 2101, and the upper part of the bracket 2101 is a supporting surface for bearing; the The inside of the leveling feet 10 is filled with hydraulic medium, and the hydraulic medium can circulate inside the leveling feet 10 and / or between the leveling feet 10 to realize automatic leveling.

[0050] The lower part of the bracket 2101 of the hydraulic leveling base of this embodiment is provided with a leveling foot 10, and the hydraulic medium can circulate inside the leveling foot 10 and / or between the leveling feet, so that the leveling foot 10 under high pressure The amount of compression is large, and the leveling foot 10 that bears a small pressure can also be extended under the action of hydraulic pressure, ther...

Embodiment 2

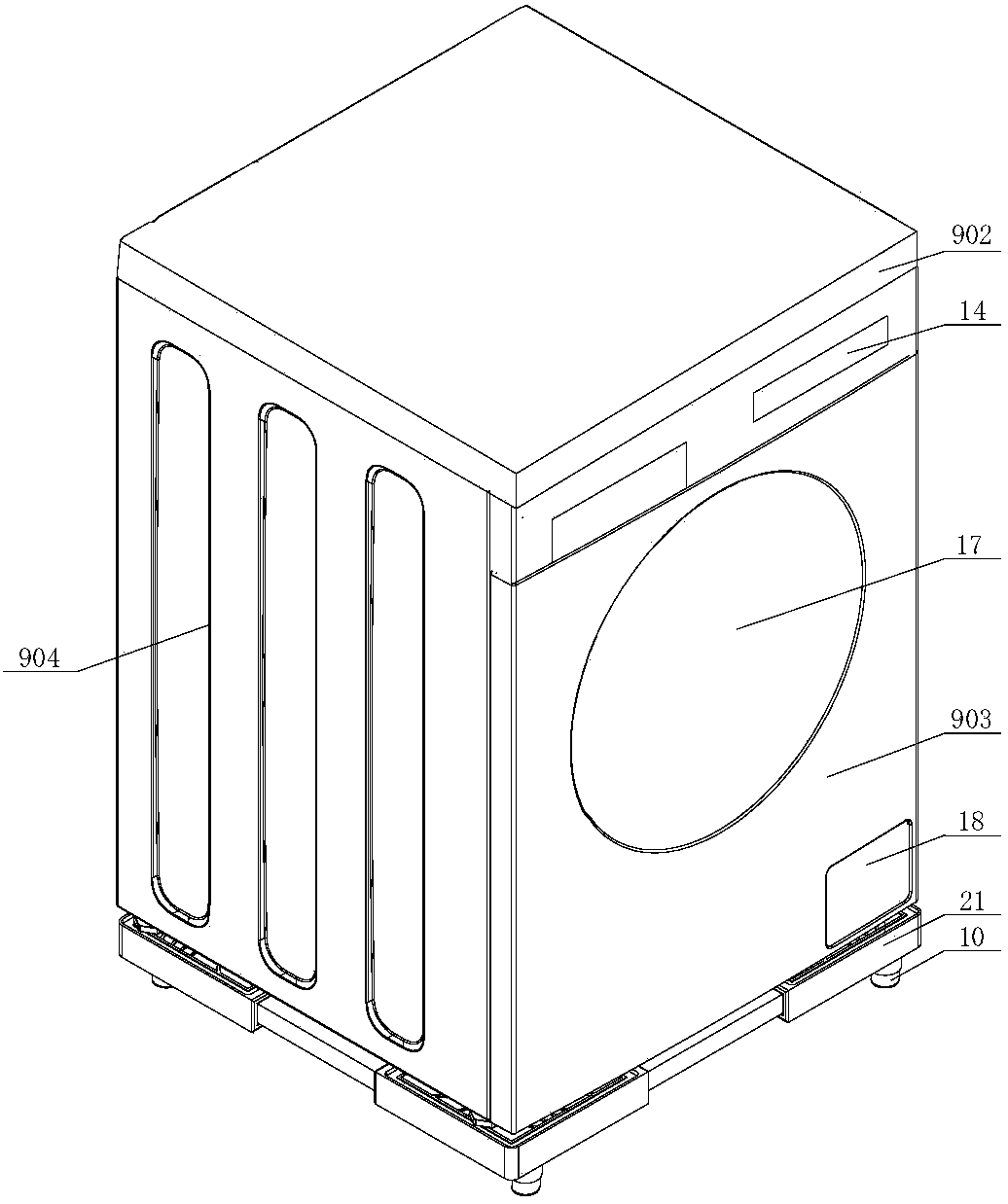

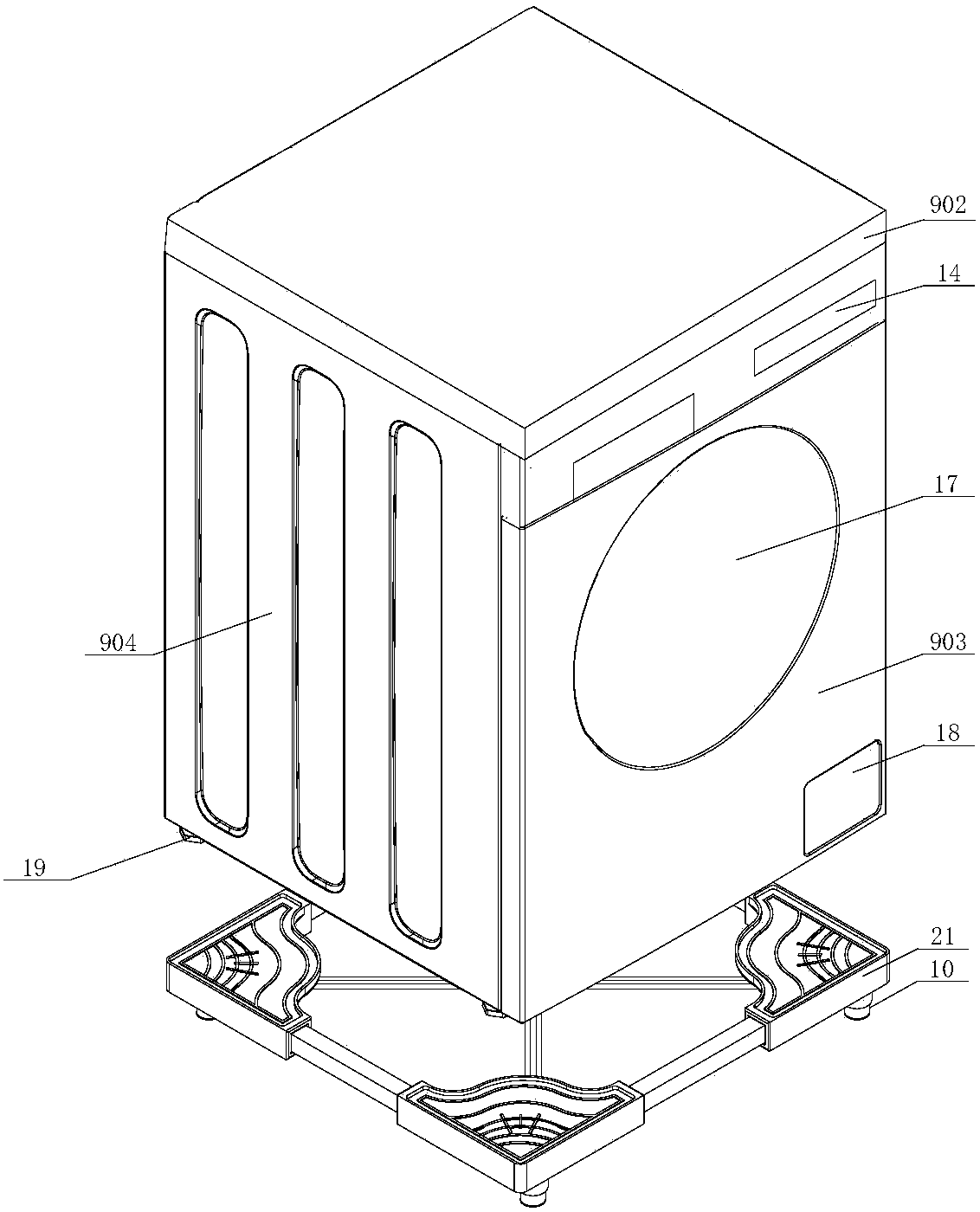

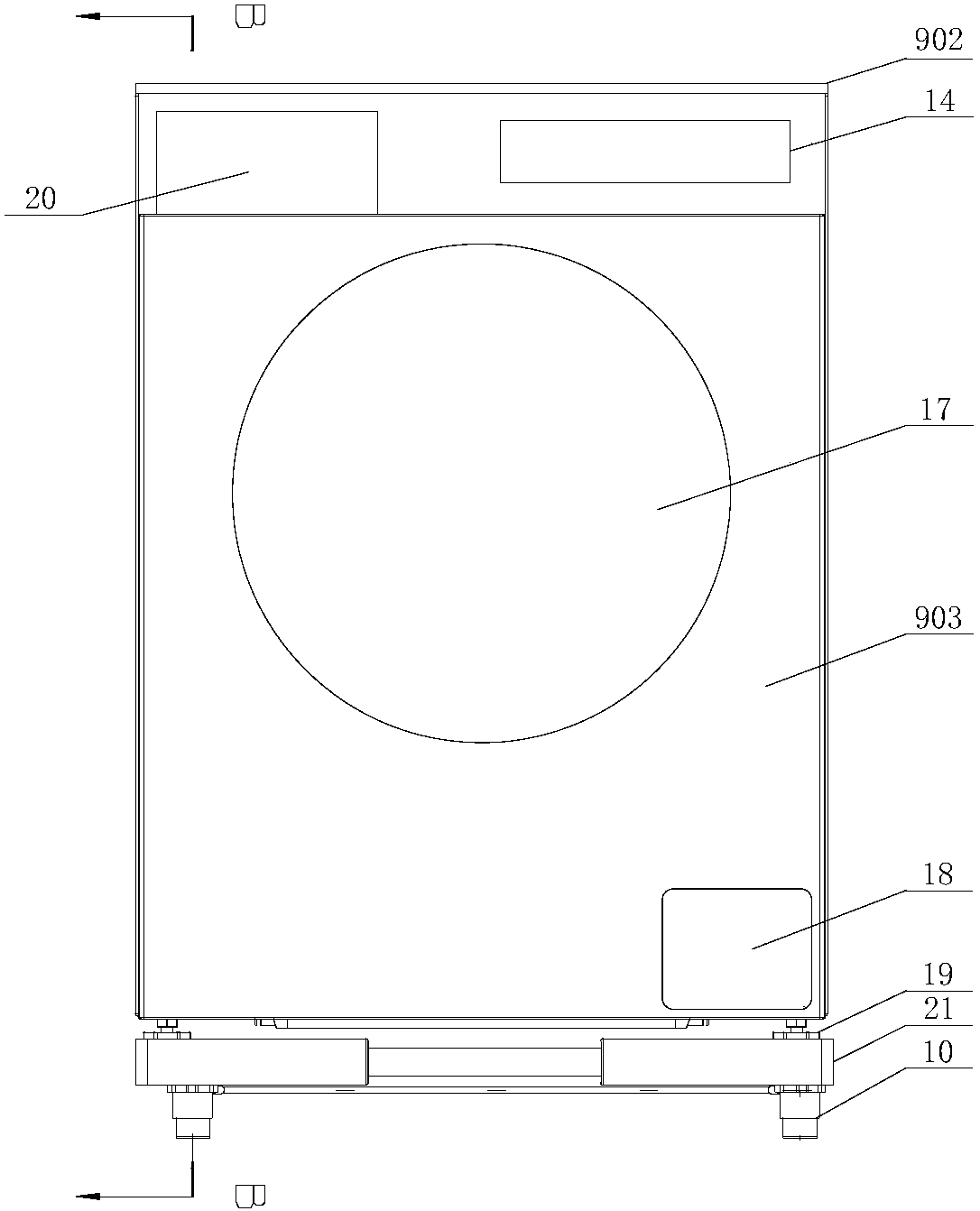

[0072] Such as Figure 1-Figure 4 As shown, a washing machine in this embodiment has the hydraulic leveling base 21 described in the embodiment, including a casing 9 and a cylinder assembly arranged in the casing 9 for washing, and the four bottom parts of the casing 9 are The two corners are respectively placed on the four brackets 2101 of the hydraulic leveling base 21.

[0073] The washing machine in this embodiment is placed on the hydraulic leveling base 21 to achieve automatic leveling, and the hydraulic leveling base can also self-level the unbalanced load during the washing and dehydration process of the washing machine, thus achieving lower vibration and higher little noise.

[0074] Specifically, the housing 9 of this embodiment includes a base plate 901, and bolt feet 19 are installed on the four corners of the bottom plate 901, and the bolt feet 19 are respectively placed on the four brackets 2101 of the hydraulic leveling base 21. superior. In this way, the str...

Embodiment 3

[0086] Such as Figure 9-Figure 19 As shown, the leveling foot 10 of this embodiment includes a foot seat, a flexible container body 6 and an adjustment foot 4; the foot seat has a hollow chamber, and the foot seats are respectively provided with joints communicating with the hollow chamber. The orifice 7 and the valve hole 8, the throttle hole 7 and the valve hole 8 are respectively connected to the high-pressure oil pipe; the flexible containing body 6 is arranged in the hollow chamber, and the flexible containing body 6 has a containing chamber inside, and the inside of the containing chamber is filled with hydraulic pressure. Medium, under pressure, the hydraulic medium in multiple feet can communicate with each other through high-pressure oil pipes; one end of the adjustment foot 4 can be relatively slidably arranged in the hollow chamber, and the flexible containing body 6 is in contact with or connected with the adjustment foot 4 .

[0087] The leveling foot 10 of this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com