Patents

Literature

93results about How to "Improve shift comfort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

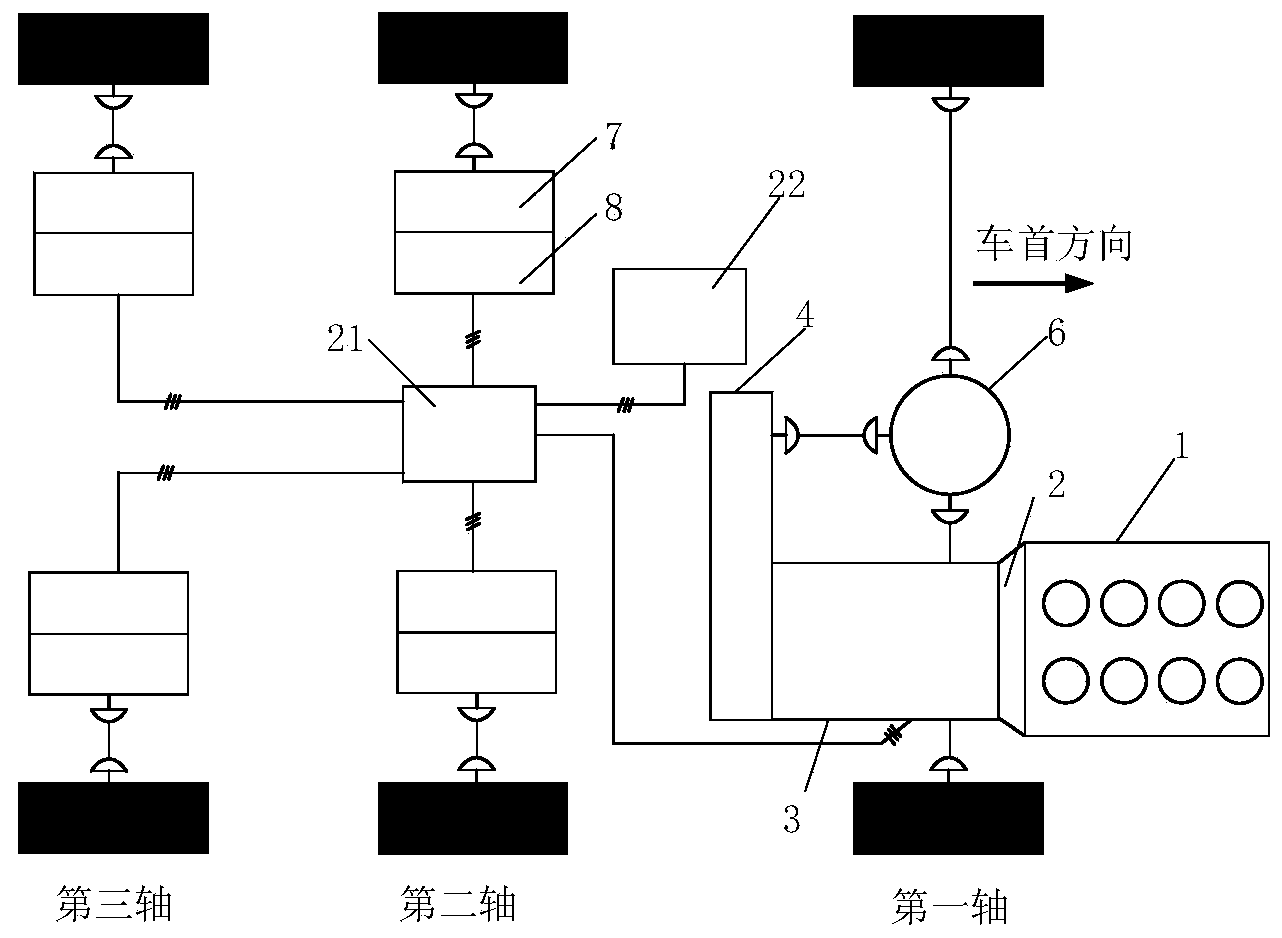

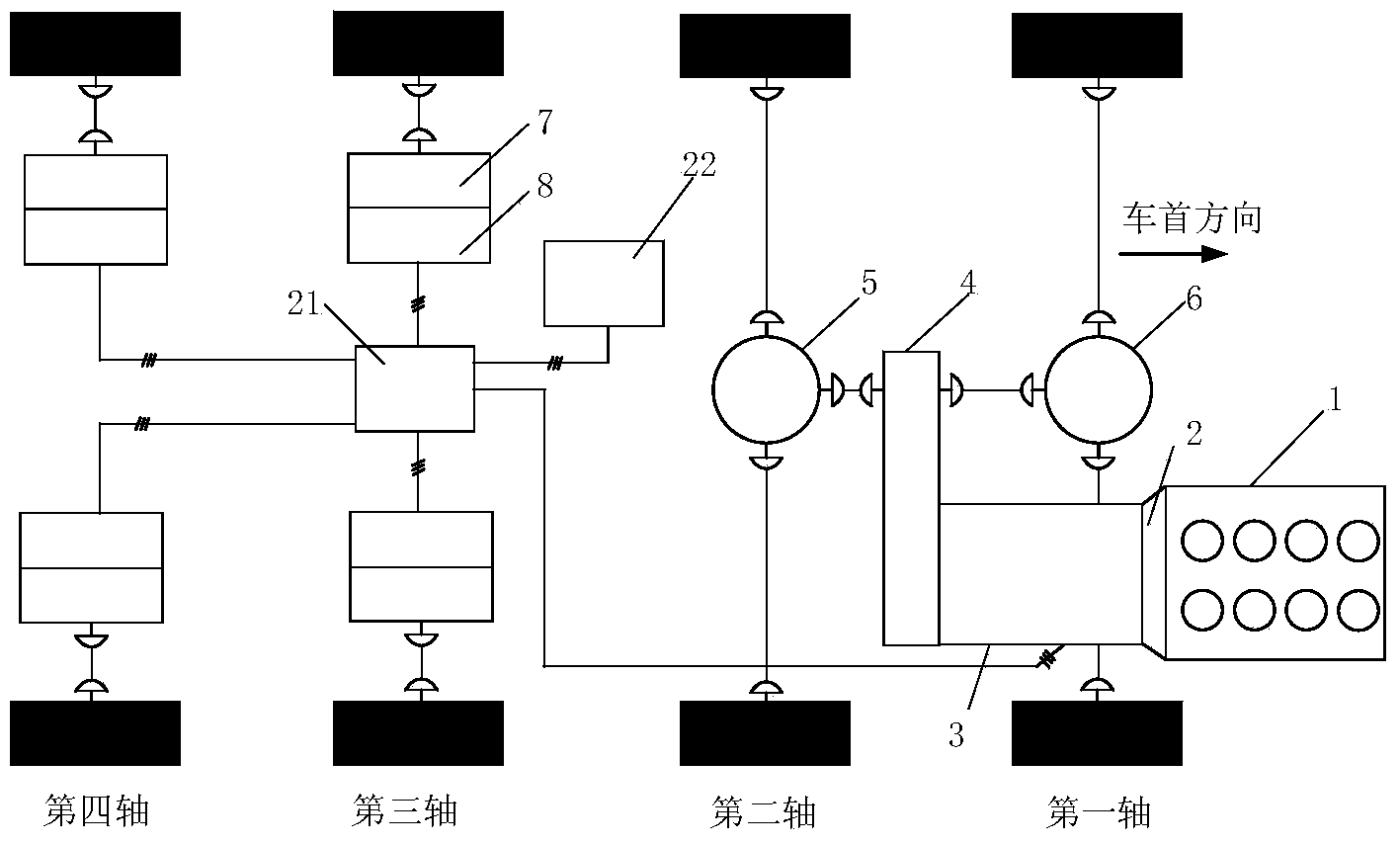

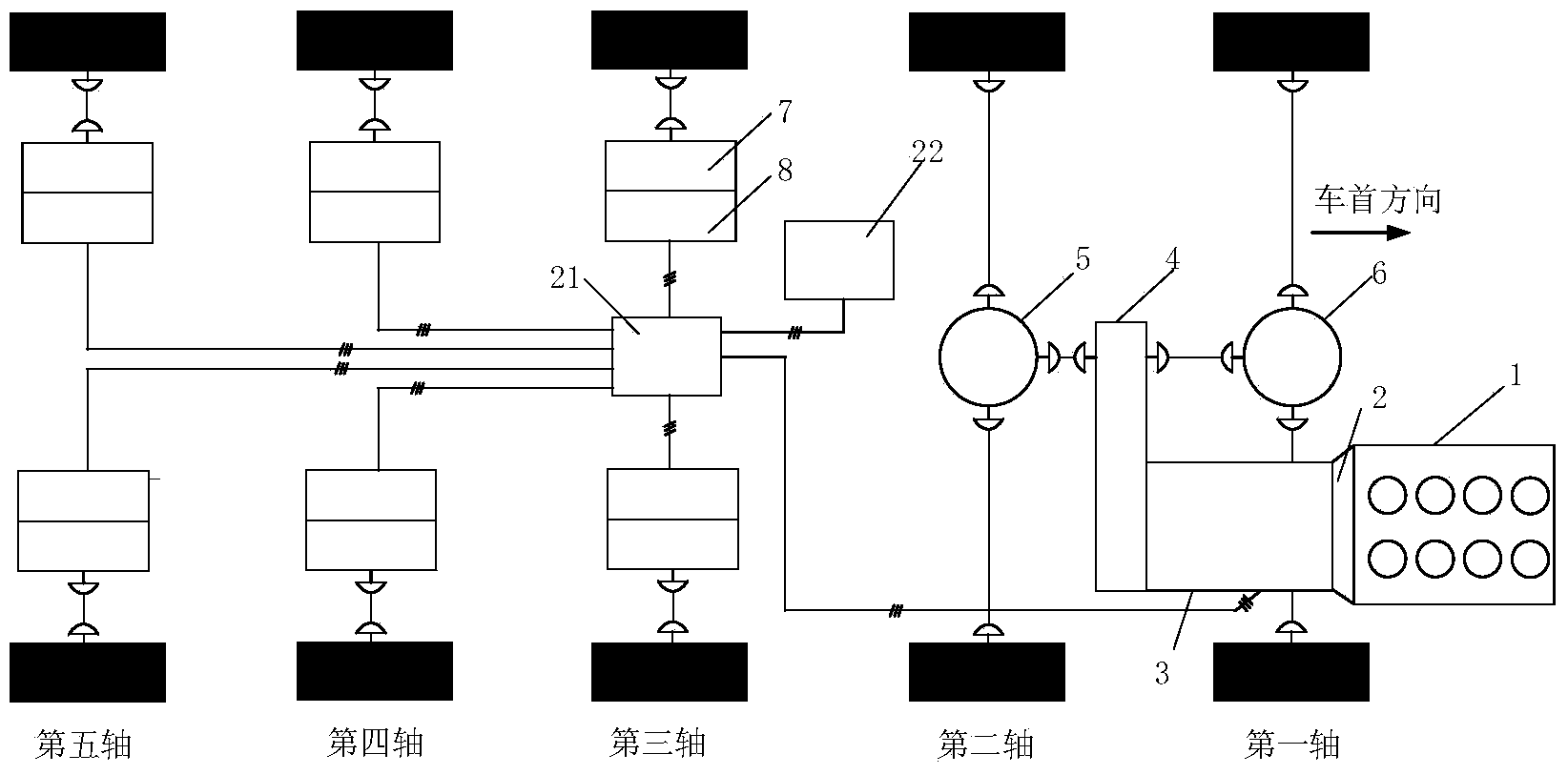

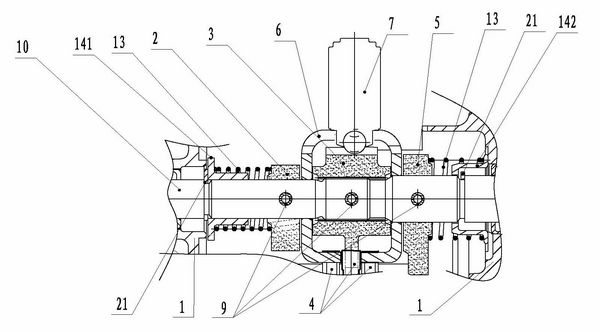

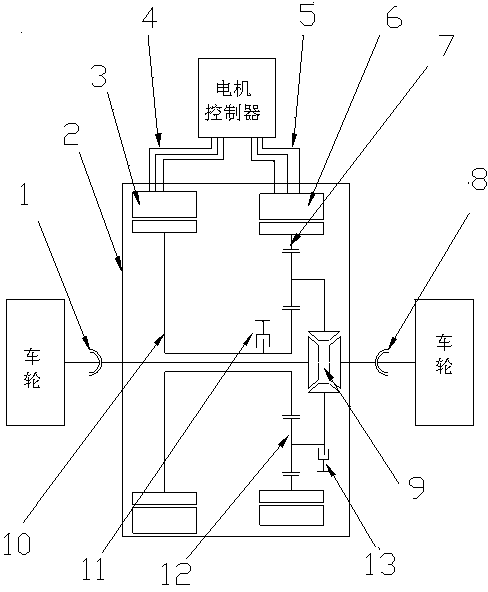

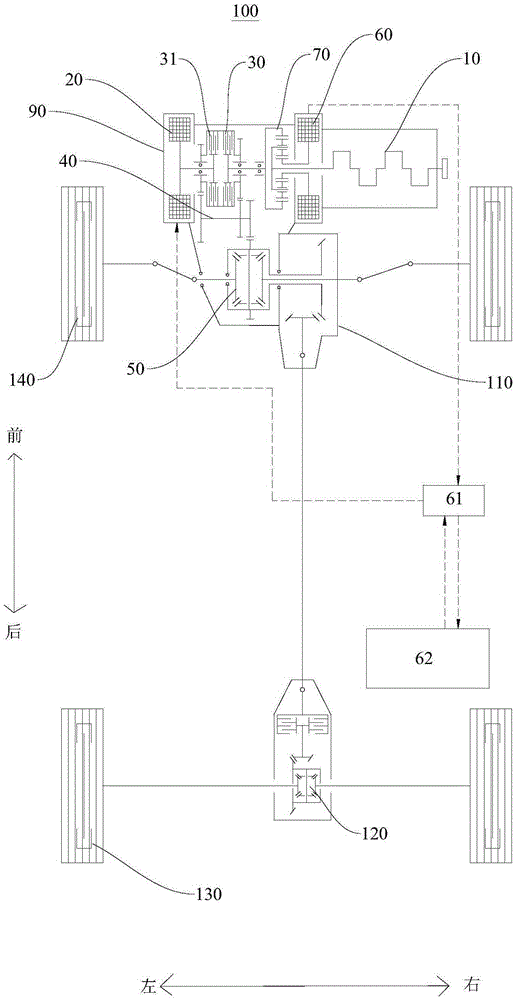

Multi-axle multi-wheel vehicle hybrid electric driving system

ActiveCN103587403ASimple structureDrive chain shortHybrid vehiclesGas pressure propulsion mountingElectric driveDrive motor

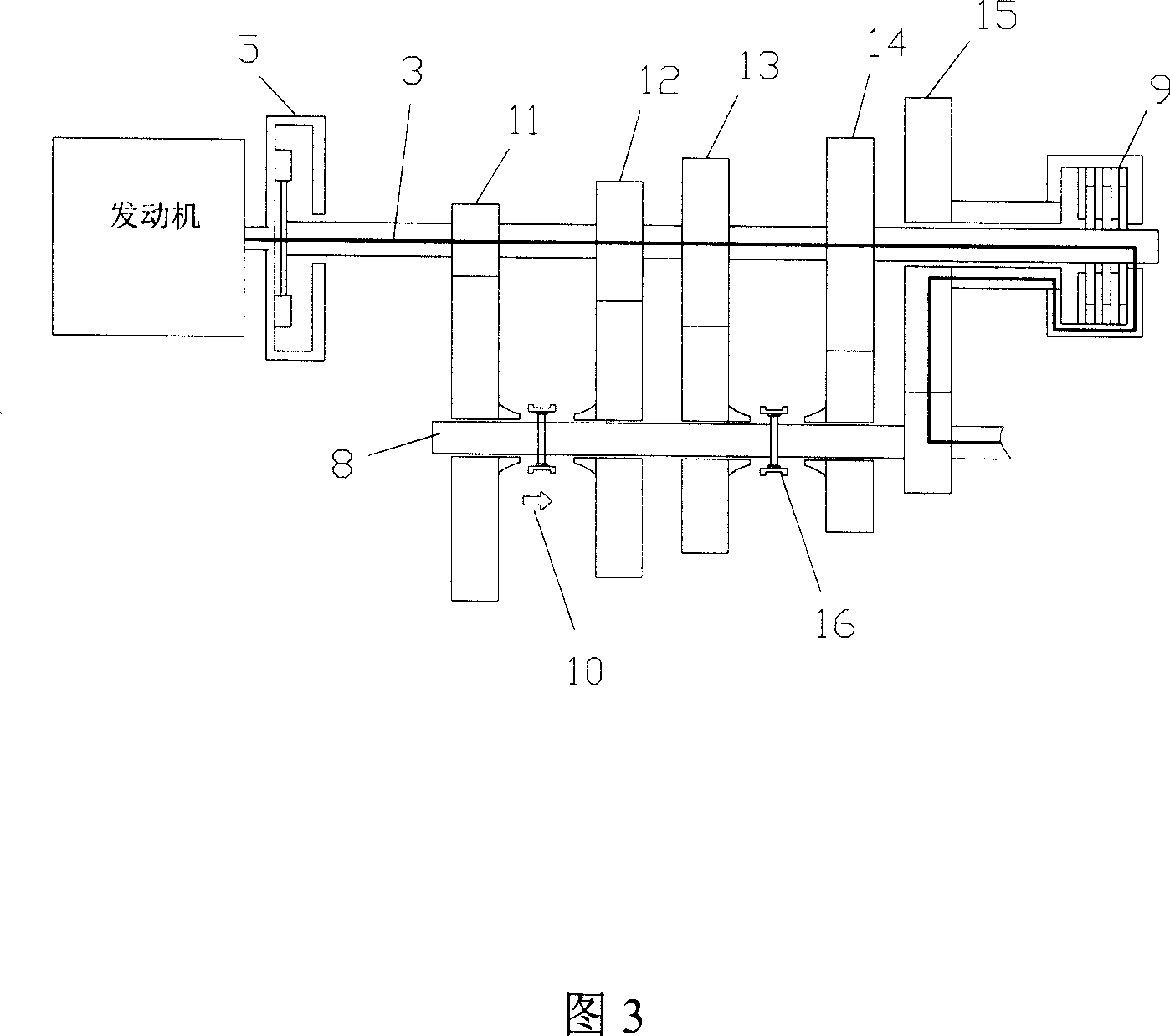

The invention belongs to the technical field of power transmission, and particularly relates to a vehicle hybrid power driving system. According to the technical scheme of the multi-axle multi-wheel vehicle hybrid electric driving system, in a mechanical drive section, an engine (1) and a gearbox (3) are longitudinally arranged, an elastic coupler (2) is arranged between the engine and the gearbox, a transfer case (4) is connected to the rear side of the gearbox (3), and the transfer case (4) conducts power distribution and distributes the power into axles through a drive axle; in a dynamic drive section, a wheel edge drive motor (8) and a double-gear gearbox (7) are combined to drive the axles, the wheel edge drive motor (8) is connected to a power management system (21), and the power management system (21) is connected with a battery pack (22) and the gearbox (3). According to the multi-axle multi-wheel vehicle hybrid electric driving system, an inter-axle differential mechanism and an inter-wheel differential mechanism are omitted, the structure of the driving system is simplified, a transmission chain is shortened, and power distribution is flexible.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

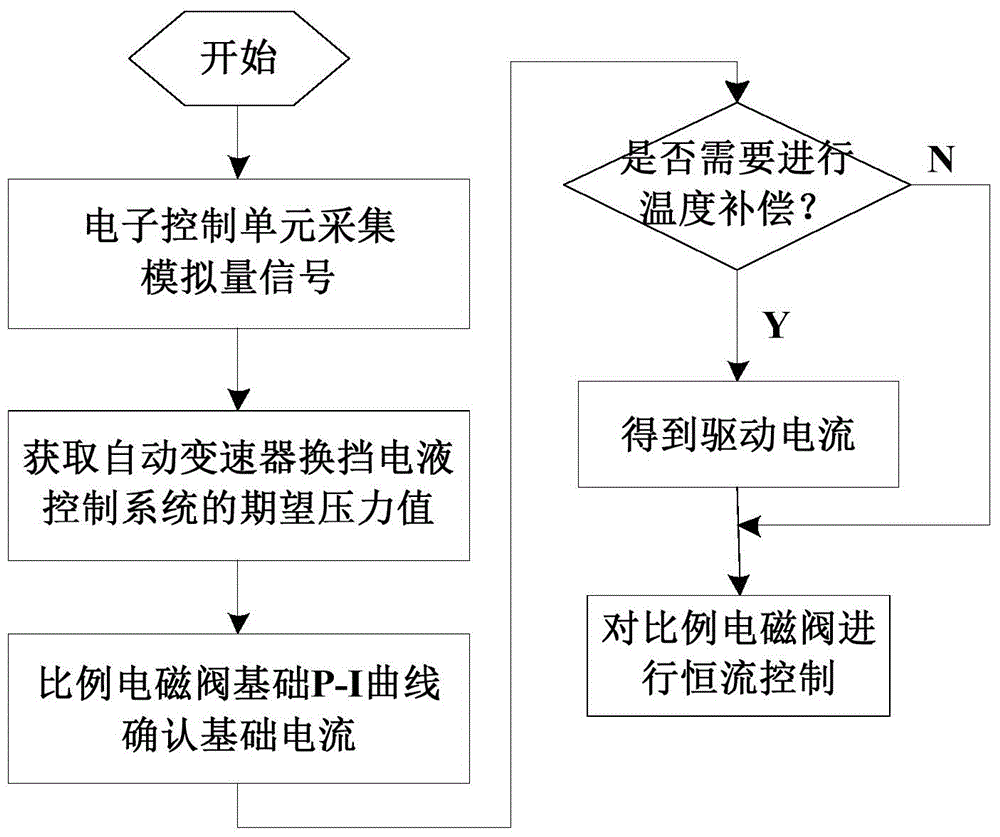

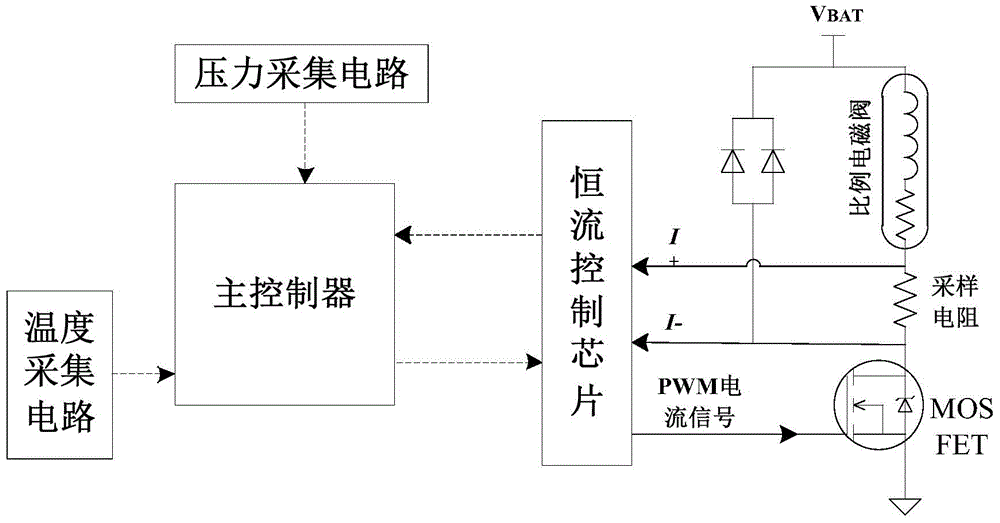

Method for achieving temperature compensation of proportional electromagnetic valve based on constant-current control

InactiveCN105179671AImprove shift comfortGearing controlElectronic control unitElectromagnetic valve

The invention provides a method for achieving temperature compensation of a proportional electromagnetic valve based on constant-current control. The method comprises the following steps that an analog quantity signal is acquired through an electronic control unit; temperature compensation is conducted on the proportional electromagnetic valve; and constant-current control is conducted on the proportional electromagnetic valve. According to the method, the influence of the change of the characteristic of hydraulic oil caused by the temperature change on the gear shifting process is distinguished from the influence of the change of the physical characteristic of the proportional electromagnetic valve on the gear shifting process, the changes of the current characteristic of the proportional electromagnetic valve caused by the two factors are controlled independently, the current value of the electromagnetic valve is set through oil temperature compensation, constant-current control over the proportional electromagnetic valve is achieved through a constant-current control circuit, and thus gear shifting comfort is improved.

Owner:CHINA NORTH VEHICLE RES INST

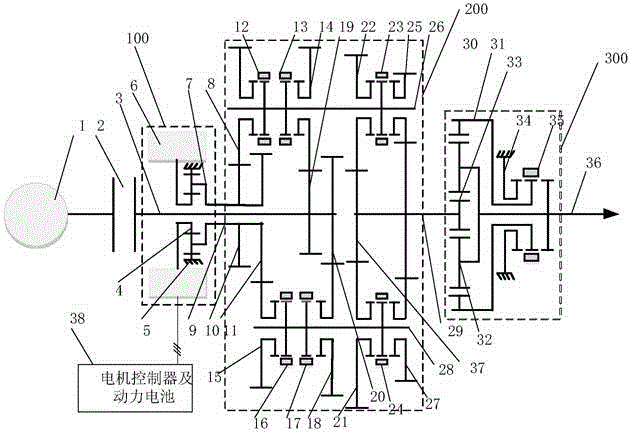

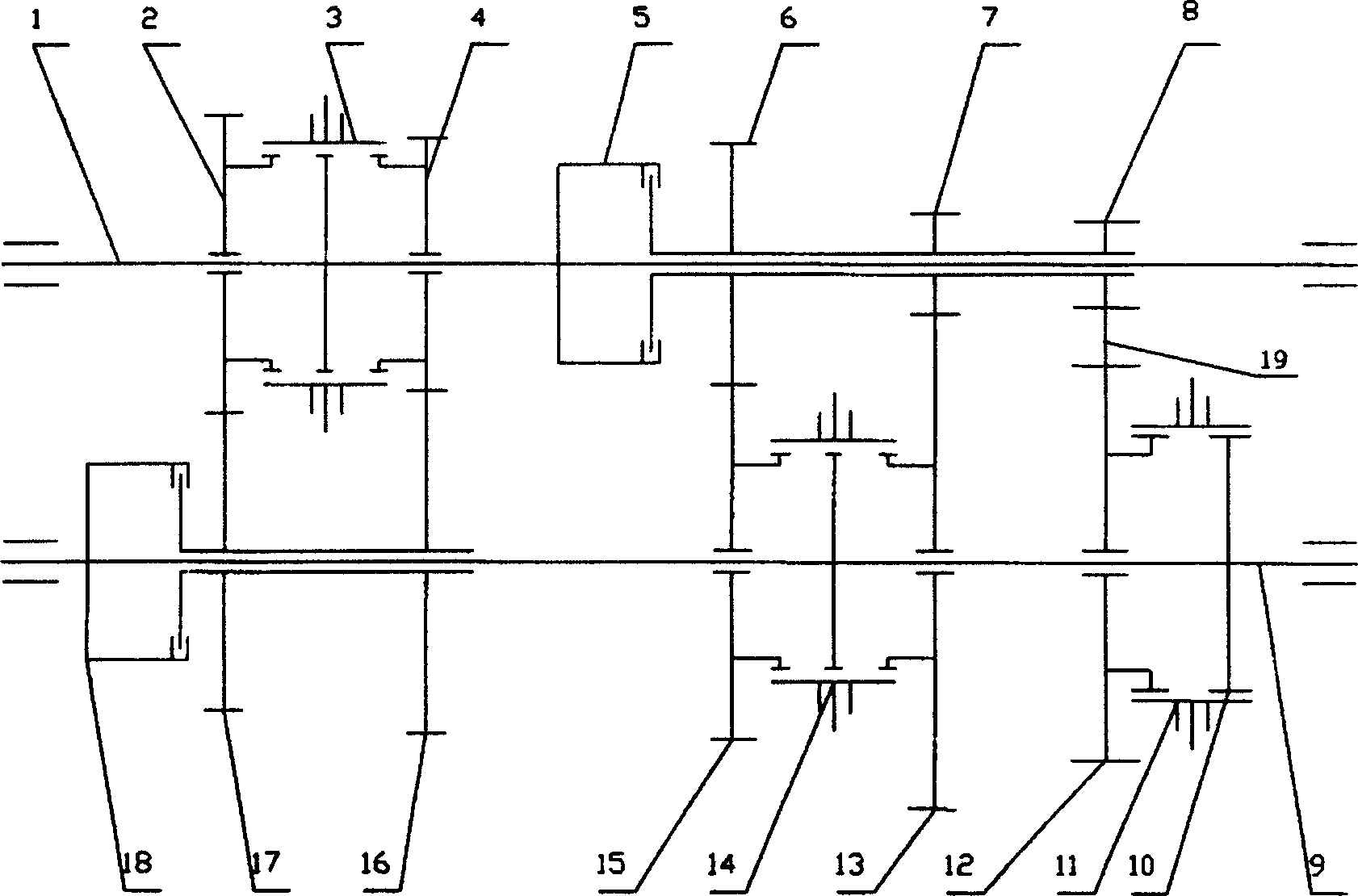

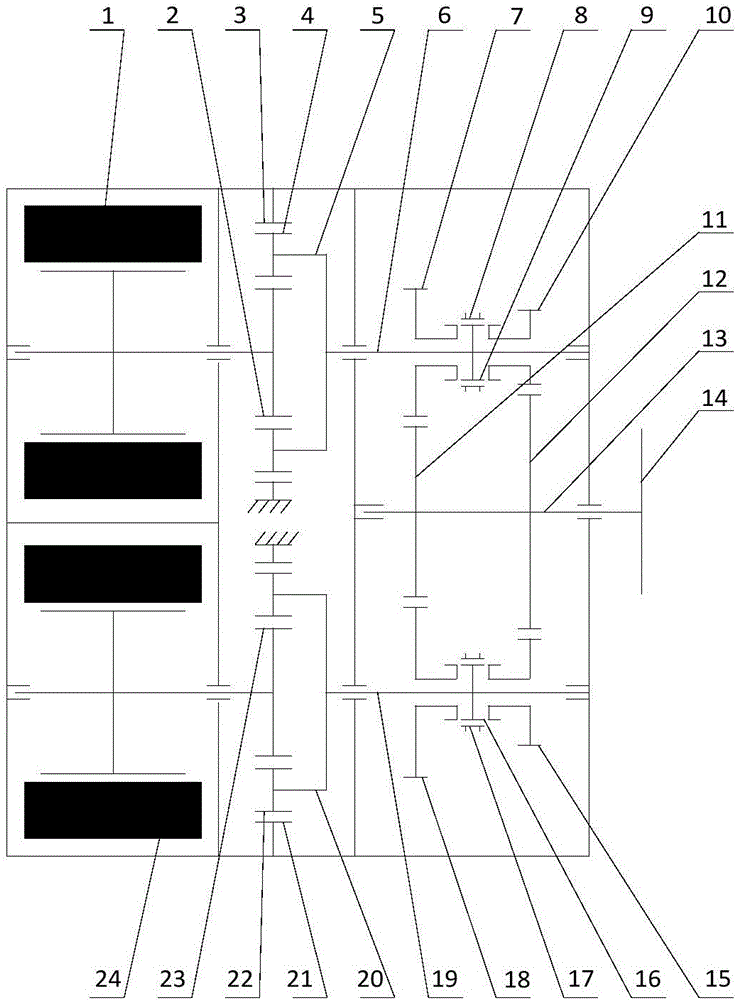

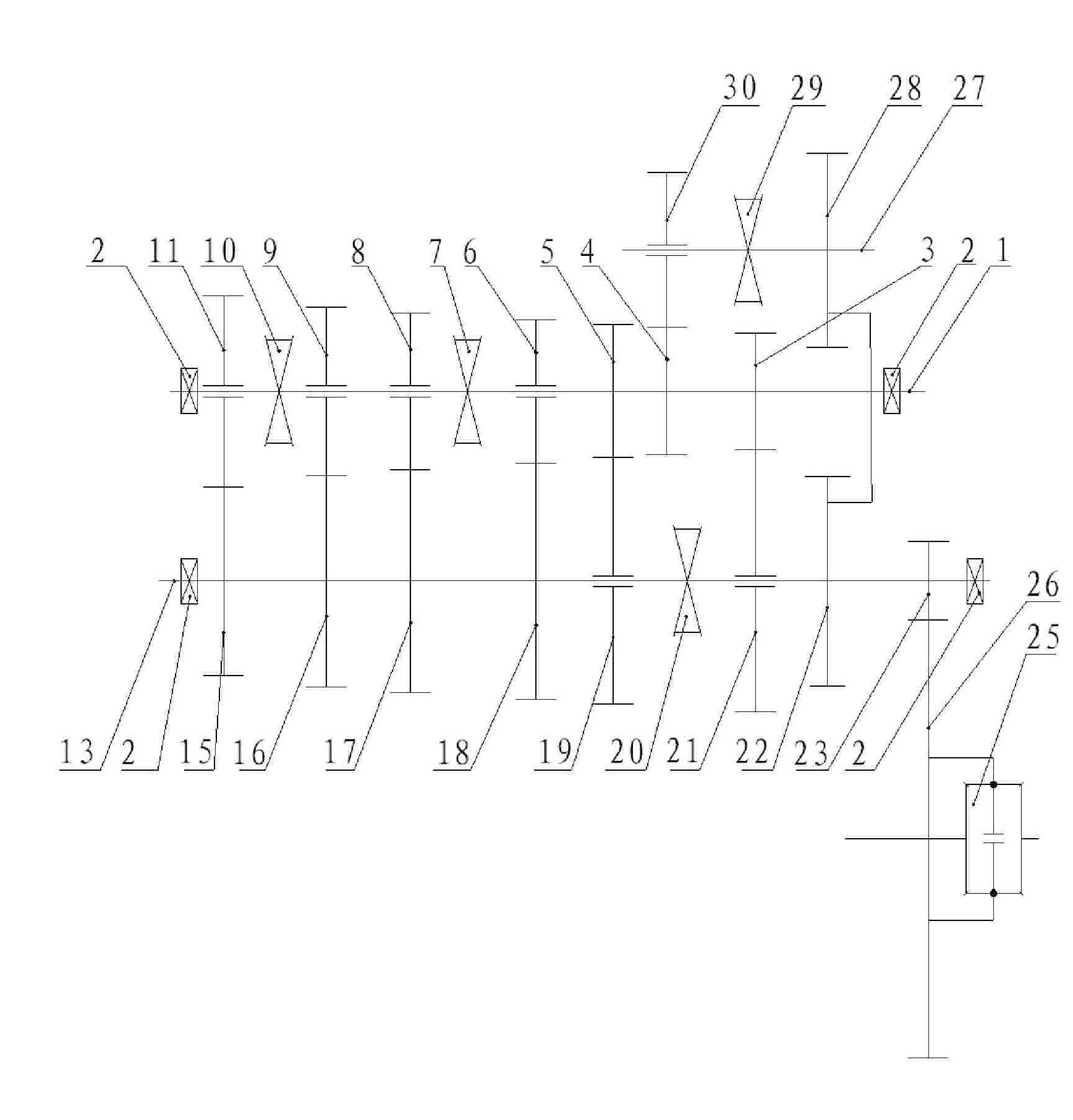

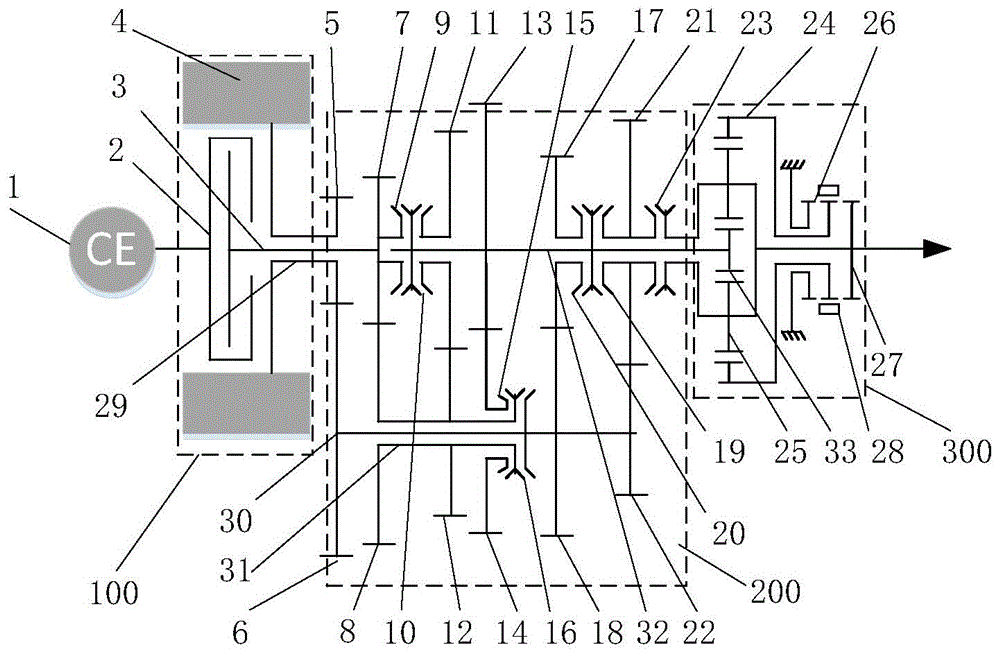

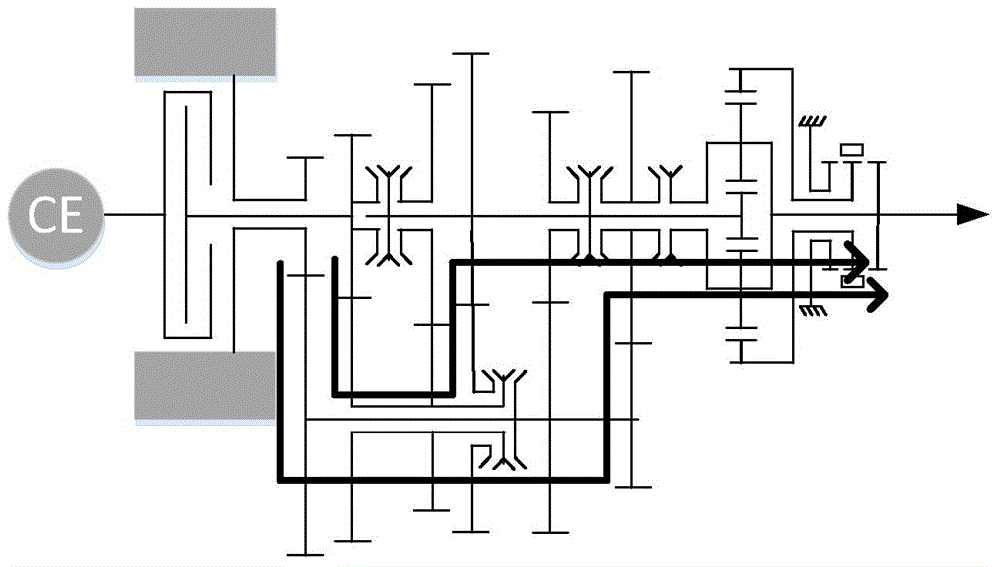

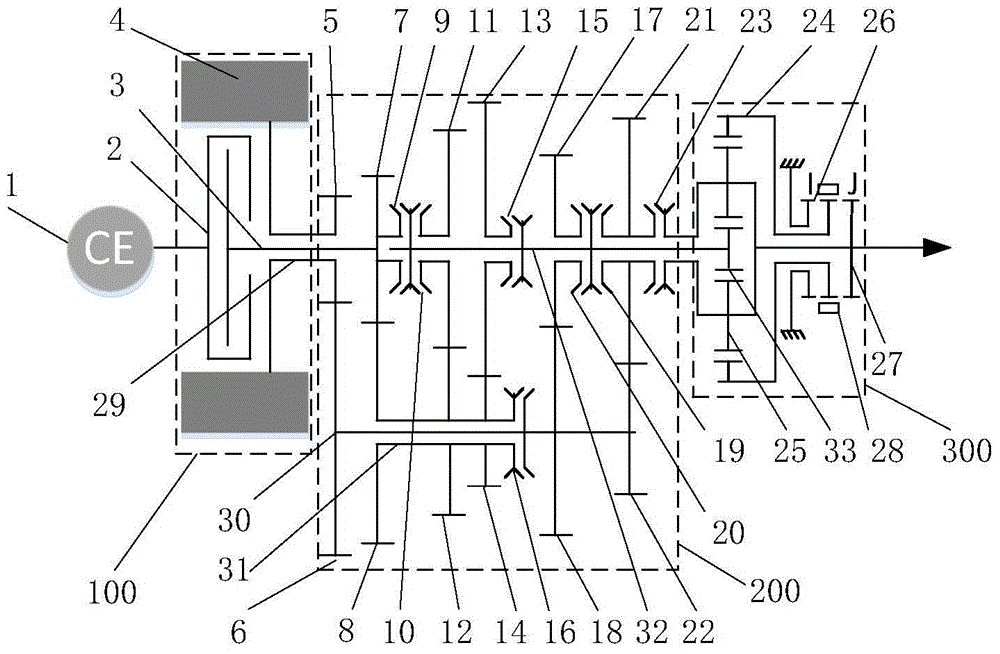

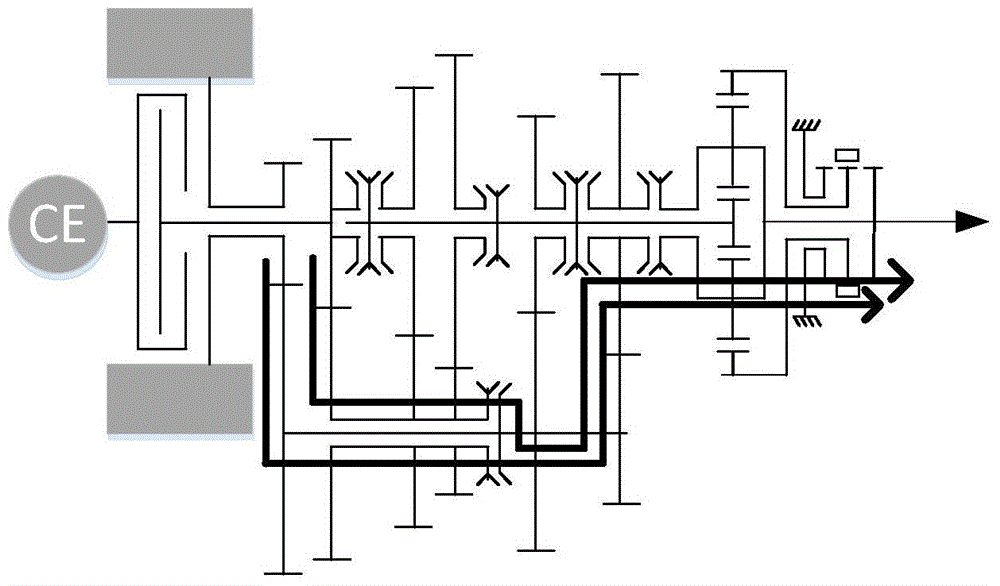

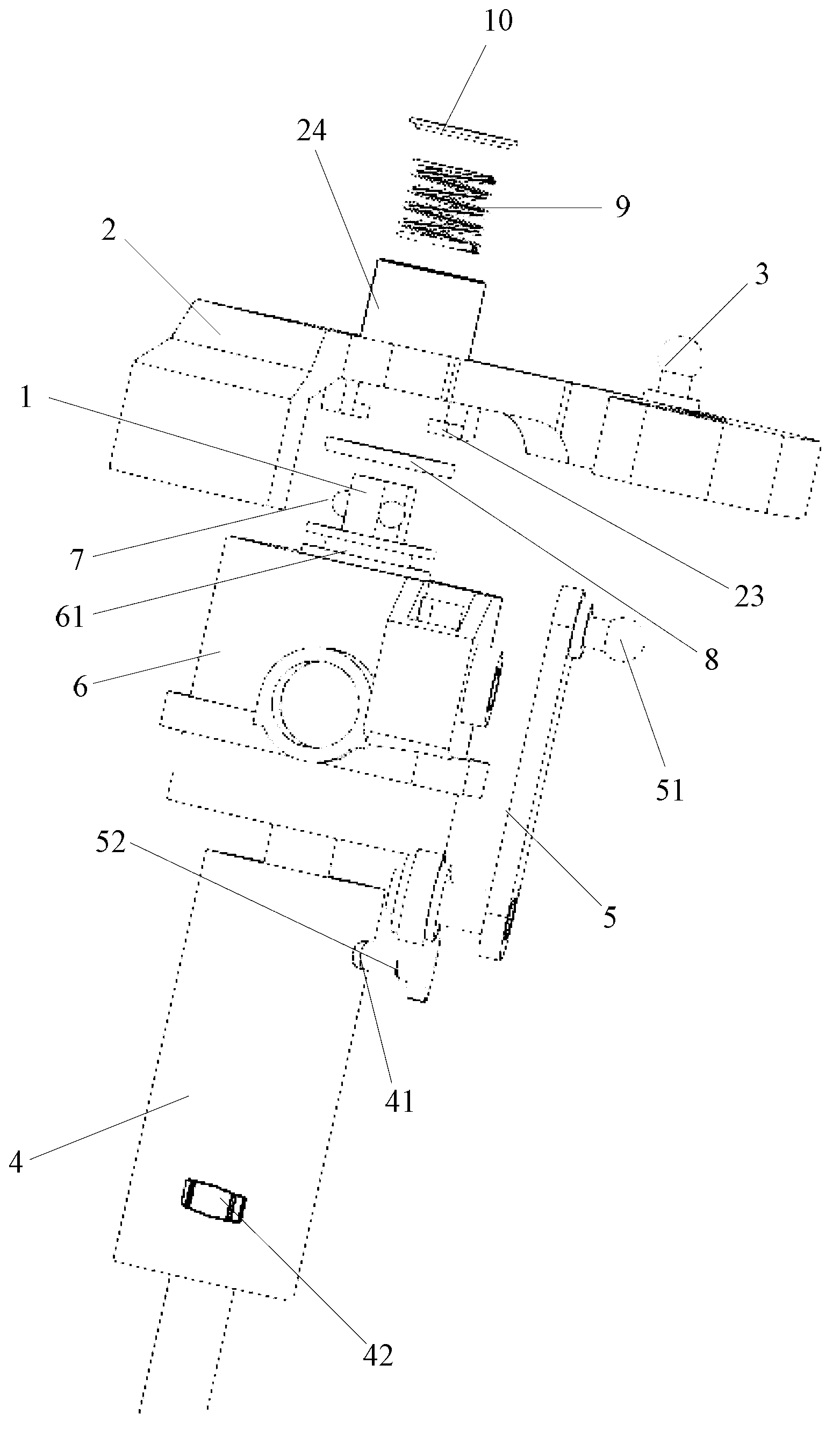

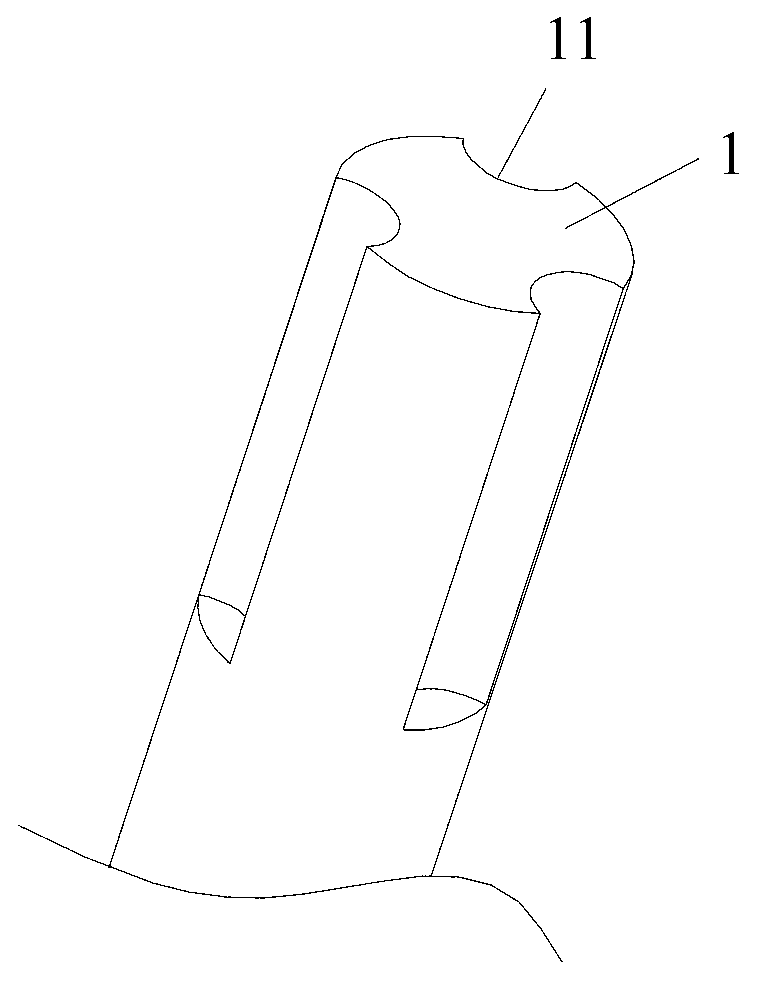

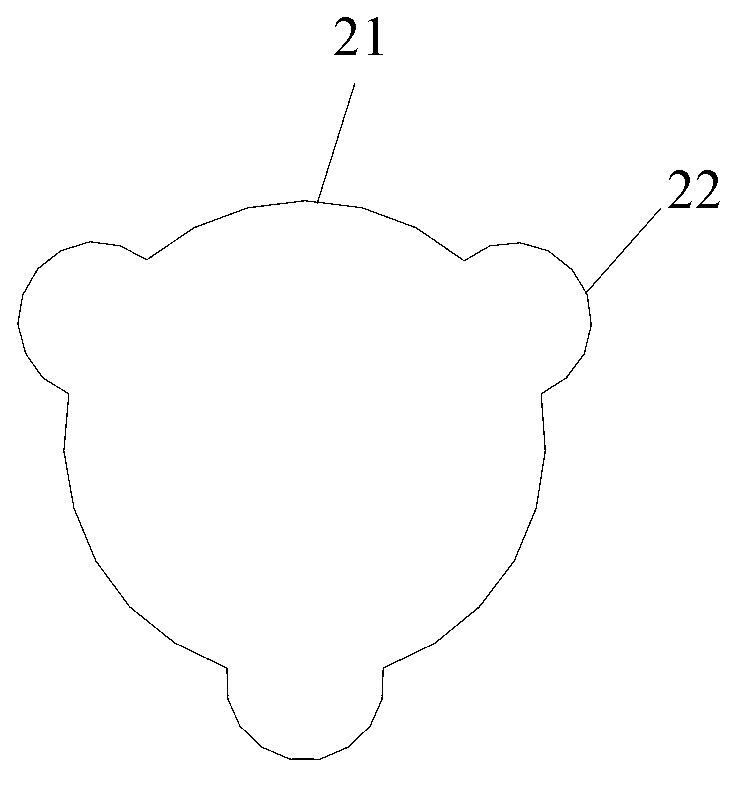

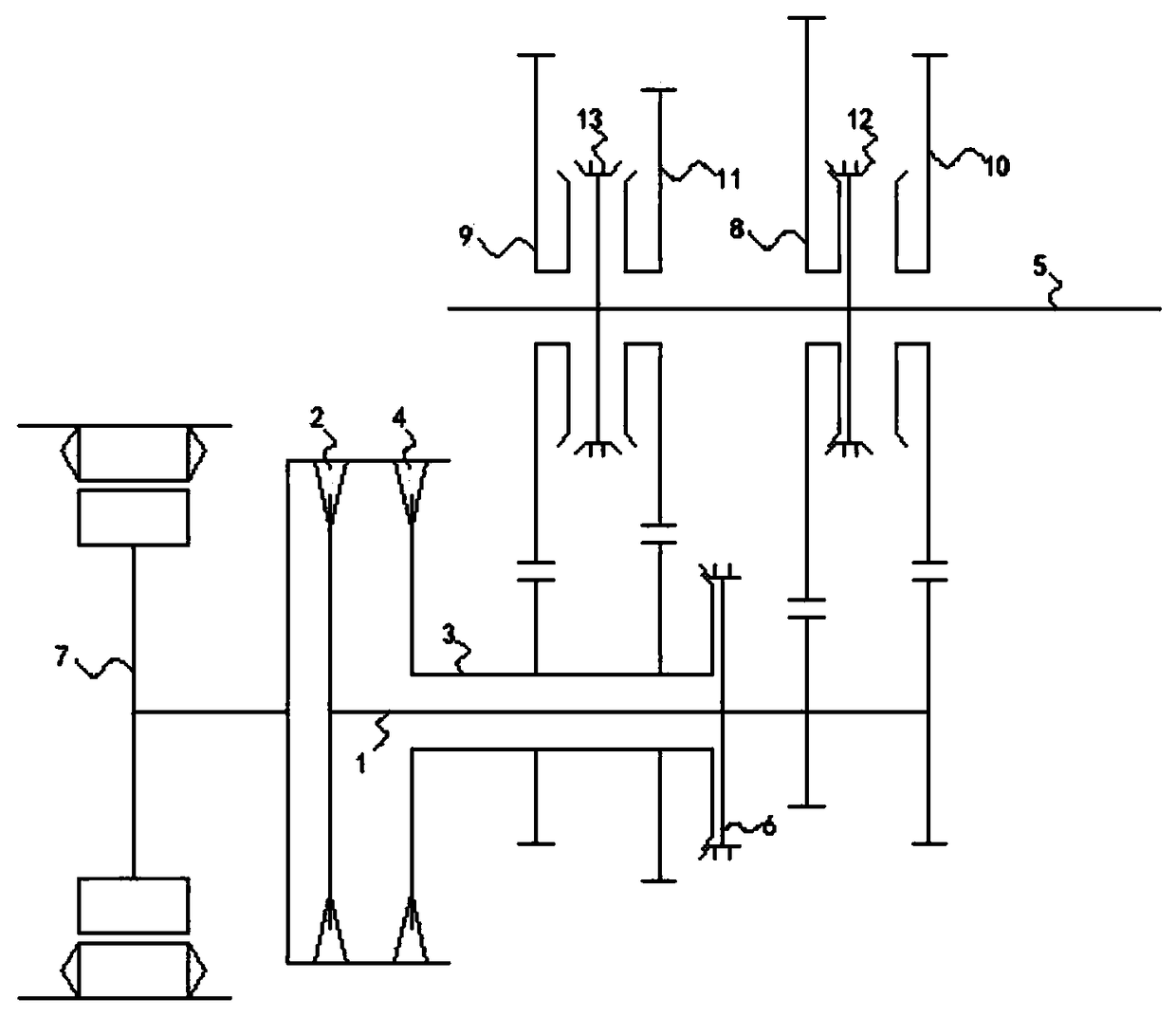

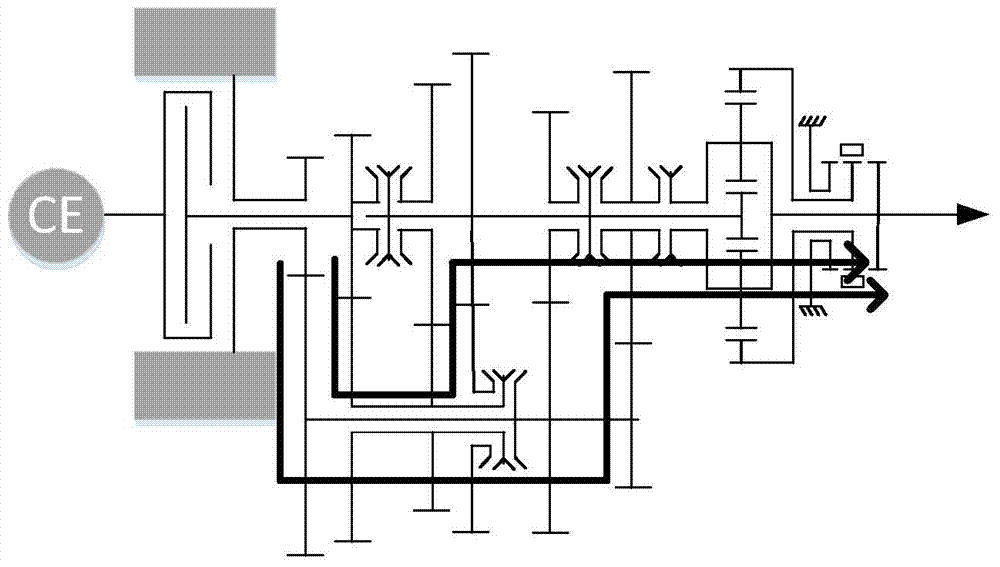

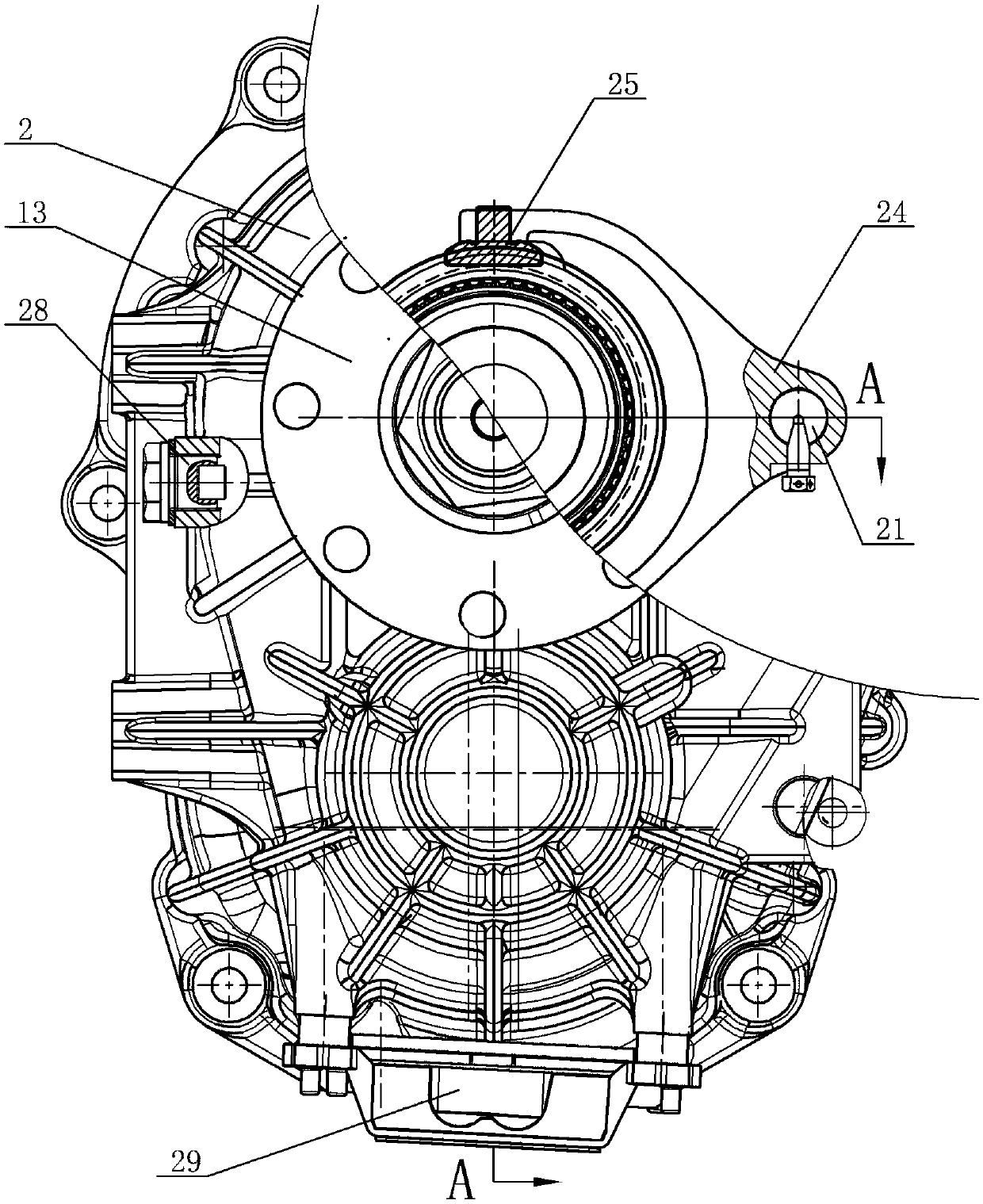

Multi-degree-of-freedom power gear-shifting parallel form hybrid power multi-gear speed changing box

ActiveCN104477023AImplement power shiftImprove powerGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelElectric machine

The invention belongs to the technical field of power transmission and particularly relates to a hybrid power multi-gear speed changing box. The multi-degree-of-freedom power gear-shifting parallel form hybrid power multi-gear speed changing box is characterized in that power of an engine is input to an engine input shaft through a rear input shaft of a clutch; a motor module comprises a motor and a speed reducing planet row; the rotary speed of the motor is accelerated by the speed reducing planet row. A main box module of the speed changing box is composed of a multi-degree-of-freedom fixed shaft gear mechanism, and can be used for coupling power of an engine and the motor and realizing five gears matched with the engine and three gears matched with the motor. A secondary box module of the speed changing box can be used for realizing high-gear and low-gear gears, and commonly work with a main box input module of the speed changing box to realize nine gears matched with the engine and five gears matched with the motor. According to the hybrid power multi-gear speed changing box, power gear shifting is realized and the power performance of vehicles is improved; the gear-shifting quality is improved, the abrasion of the clutch is reduced and the fuel oil economical efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Double clutch type automatic gearbox

InactiveCN1616853AImprove fuel economyImprove powerToothed gearingsGearing controlAutomatic transmissionGear wheel

The present invention belongs to the field of mechanical automatic speed variator for vehicle, and is especially one kind of double clutch type automatic gear box in new structure. The automatic gear box includes various setting gear pairs, synchronous shifting unit and shifting control system, and features that each of the power input shaft and the power output shaft is provided with one wet clutch, all the setting gear pairs are divided into odd number set and even number set connected separately to the driven sheet of one of the clutches, and two clutches transmit the work power alternately to realize setting switching. The shift process has no power interruption, short shifting time, greatly raised shifting comfort and excellent shifting power performance and quality of vehicle. The present invention has simple and compact parallel shaft structure, low cost but the same effect as automatic rotary shaft gear box in complicated structure.

Owner:JILIN UNIV

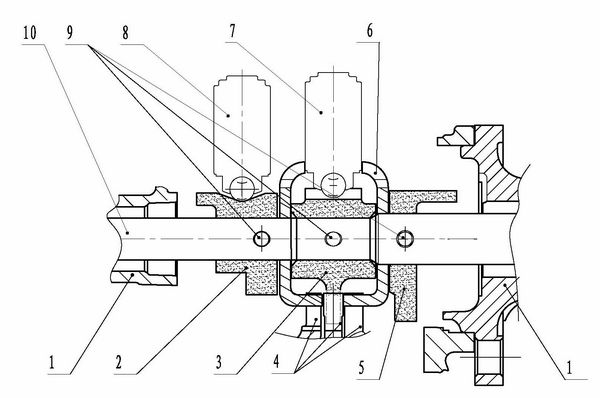

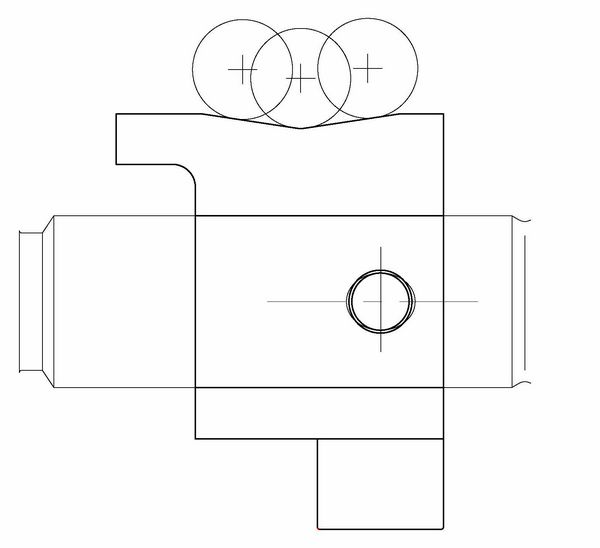

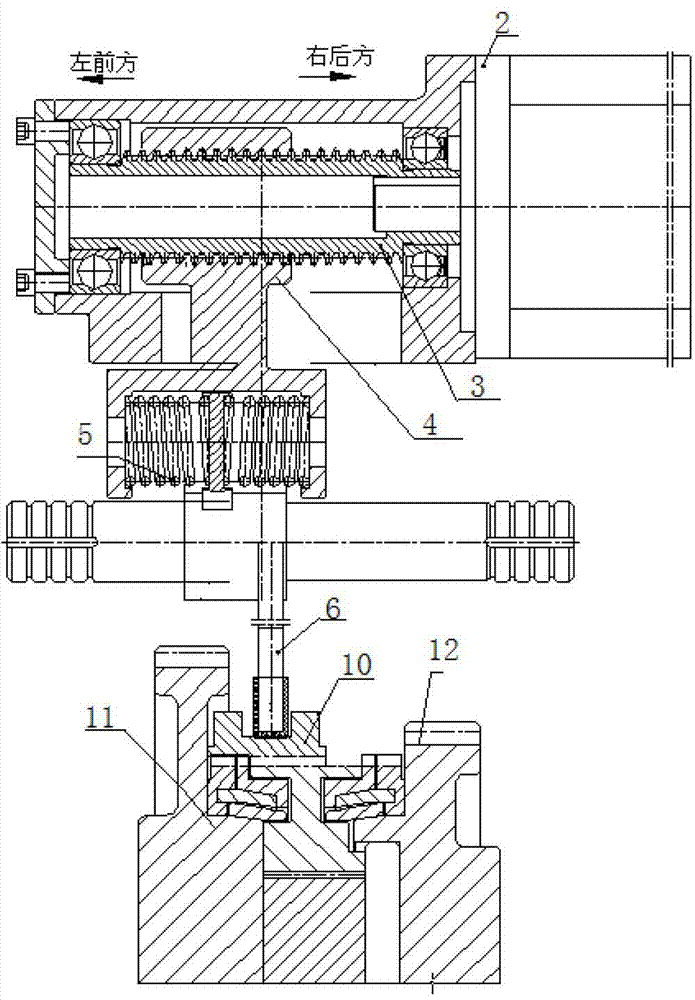

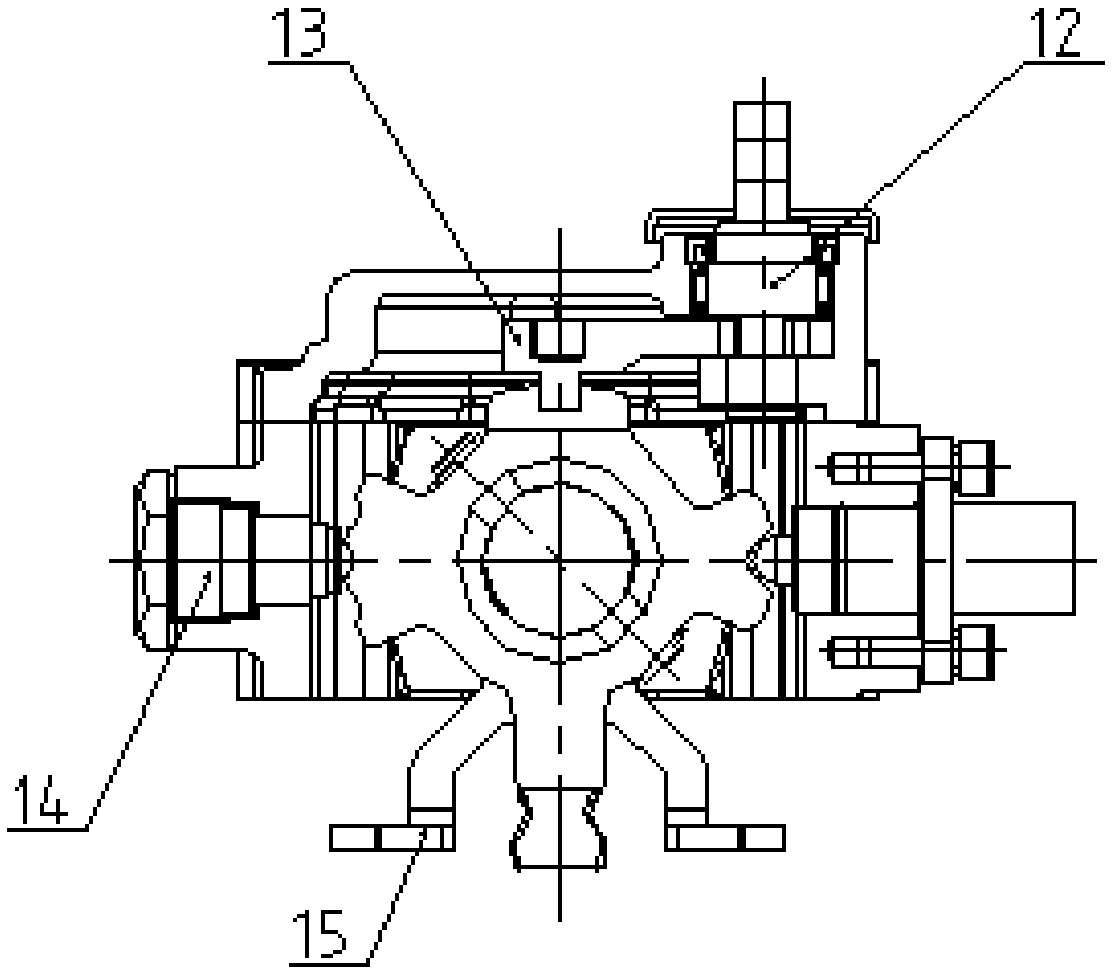

Operating mechanism for manual transmission of automobile

The invention discloses an operating mechanism for a manual transmission of an automobile. The mechanism comprises a gear-shifting shaft, a gear-selecting interlocking block, an elastic pin, a gear-shifting shifting block, a gear-shifting interlocking plate, a shell, a gear-selecting positioning seat and a gear-shifting positioning seat, wherein the gear-selecting interlocking block and the gear-shifting shifting block are fixedly connected with the gear-shifting shaft through the elastic pin respectively and are positioned on the outer side of the shell respectively; relative motion does not exist among the gear-selecting interlocking block, the gear-shifting shifting block and the gear-shifting shaft; and the gear-selecting positioning seat and the gear-shifting positioning seat are fixedly connected with the shell of the transmission respectively. A gear-selecting force-sensing block, an interlocking shifting block and a limit mechanism are integrated on the same part through a centralized design, so that the mechanism has a compact structure, a reasonable design, good gear-selecting handfeel and high comfort, is easy to assemble, reduces the processing cost of parts, saves raw materials, and realizes the functions of neutral gear positioning, gear-selecting return, gear-selecting force generation, gear-shifting force generation (for enhancing gear-shifting suction feeling) and the like. The invention is suitable to be used as an operating mechanism for the manual transmissions of various vehicles.

Owner:GREAT WALL MOTOR CO LTD

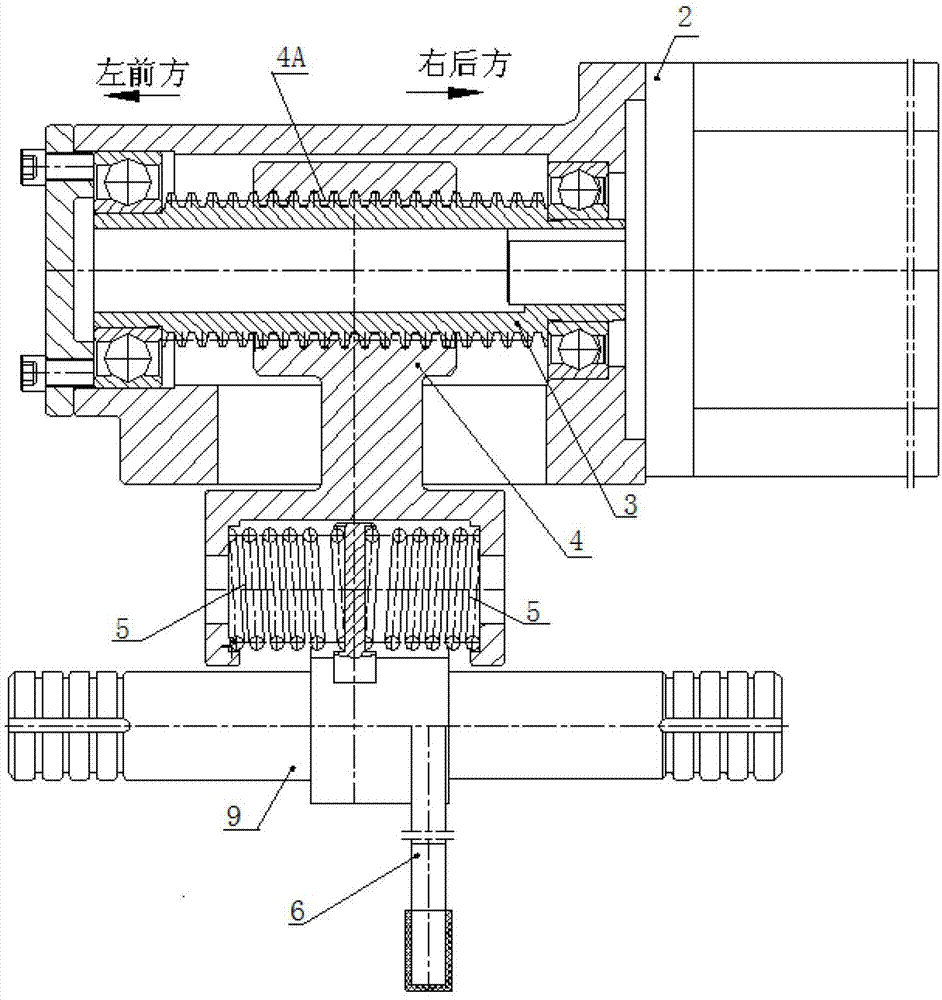

Linear movement buffering type speed change control mechanism and automatic speed change device

InactiveCN103206529ASimple designImprove shift comfortGearing controlAutomatic transmissionChange control

The invention provides an automatic speed change device and a linear movement buffering type speed change control mechanism thereof. The linear movement buffering type speed change control mechanism comprises a transmission screw rod fixed to an output shaft of a servo motor, a screw meshed to the transmission screw rod and capable of moving in the direction of the axis of the transmission screw rod, a shifting fork mounted between two buffering springs and capable of being pushed by the two buffering springs to horizontally move, a sensing element arranged on the screw and used for indicating moving distance of the shifting fork, and a gear sensor. A meshing portion and a spring mounting groove which are meshed are formed on the screw, the two buffering springs are mounted in the spring mounting groove which is arranged at the other end opposite to the meshing portion, and when the sensing element is detected, corresponding shifting end signals are given out. The scheme combining embedded computer control with mechanical fault-tolerant technology is adopted, so that shifting comfortability, reliability and practicability are all improved effectively, and the problem of gear shifting of a two-gear-type automatic speed changer is solved.

Owner:无锡金田元丰科技股份有限公司

Double-motor compact transmission without power failure

InactiveCN106382349AAvoid power interruptionImprove shift comfortToothed gearingsGearing controlEngineeringPlanet

The invention provides a double-motor compact transmission without power failure. The double-motor compact transmission without power failure comprises a motor A, a motor B, a planet row speed reduction device and a mechanical transmission module, wherein the planet row speed reduction device comprises sun gears, planet gears, planet carriers and gear rings; and the transmission module comprises an input shaft A, an input shaft B, four pairs of reduction gears and an output shaft. According to the transmission, through overall planning of the integral space of the motors and the transmission, the spatial size of the transmission is decreased, the light-weight design requirement is achieved, the economy of the transmission is improved, and three matched gears are achieved.

Owner:天津天海同步集团有限公司

Twin-shaft six-speed mechanical speed changer

InactiveCN101915287AReduce radial sizeCompact and reasonable space structureToothed gearingsGear wheelControl theory

The invention discloses a twin-shaft six-speed mechanical speed changer, and provides the twin-shaft six-speed mechanical speed changer which has the advantages of multiple gears, high transmission efficiency, compact installation space, light weight, low cost, low gear shift noise and good handfeel, and is particularly suitable for medium and small torsion. The twin-shaft six-speed mechanical speed changer solves the technical problems of low transmission efficiency, large required installation space, heavy weight, high cost, high gear shift noise, poor handfeel and the like of the speed changer in the prior art, and comprises an input shaft connected with an engine and an output shaft and a differential mechanism which are engaged with the input shaft selectively, wherein the output shaft and a reverse gear shaft are parallel to the input shaft; a driving gear for realizing a first gear, a second gear, a third gear, a fourth gear, a fifth gear and a sixth gear is arranged on the input shaft; a driven gear corresponding to the driving gear on the input shaft is arranged on the output shaft; and a synchronizer is arranged on the input shaft, the output shaft and the reverse gear shaft.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Power assembly of full electric vehicle electric drive system

The invention provides a power assembly of a full electric vehicle electric drive system. The invention has a core that the power assembly is provided with an integral integration power assembly design consisting of one set of planetary gear train mechanism and two sets of drive motors; the motors and the transmission shaft of the power assembly adopt a coaxial design; two sets of motors are respectively connected with a planetary gear sun gear and a gear ring; two motors are in coordination control to realize stepless speed regulation; for an electric vehicle which requires high performance, an original single big motor is changed into two small motors for input, and the optimal matching of the revolving speed, the torque and the high efficiency area of the motors can be realized so as to realize the low cost and the high reliability of motor miniaturization, realize the high efficiency of the electric drive system and improve an endurance mileage to the maximum limit. Meanwhile, a speed change mechanism formed by a planetary mechanism has the advantages of compact structure and the like and is favorable for arrangement.

Owner:奇瑞新能源汽车股份有限公司

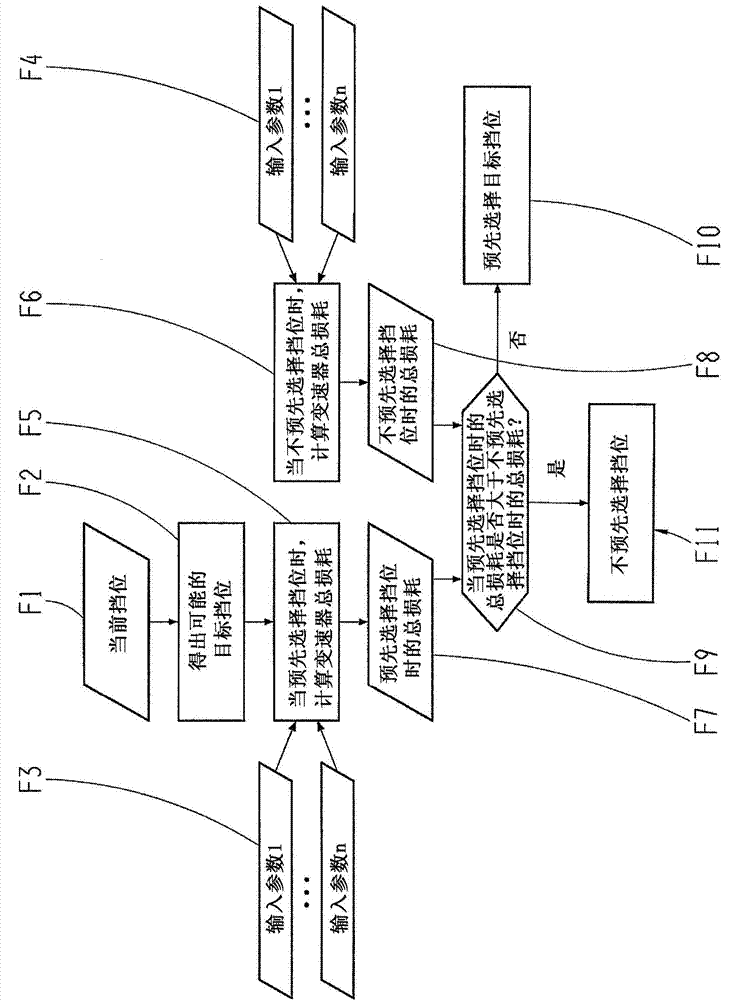

Method for controlling a dual clutch transmission

The invention relates to a method for controlling a dual clutch transmission that has two partial transmissions which are each connected to a clutch on the input side, via which a drive connection can be established to a drive motor, wherein a target gear following a currently active gear can be pre-selected in a particular load-free partial transmission of the two partial transmissions. The following steps are performed: determining a potential target gear, - measuring a total loss of the transmission with the aid of measurements and / or model calculations and / or variables derived therefrom, - in the first case in which the target gear is pre-selected and - in the second case in which no gear is selected, - ascertaining whether the total loss is greater or lesser when the target gear is pre-selected or when no gear is selected, - deciding whether or not a target gear should be pre-selected with the aid of the measured total loss as a criterion, and - implementing measures according to the decision that is made.

Owner:ZF FRIEDRICHSHAFEN AG

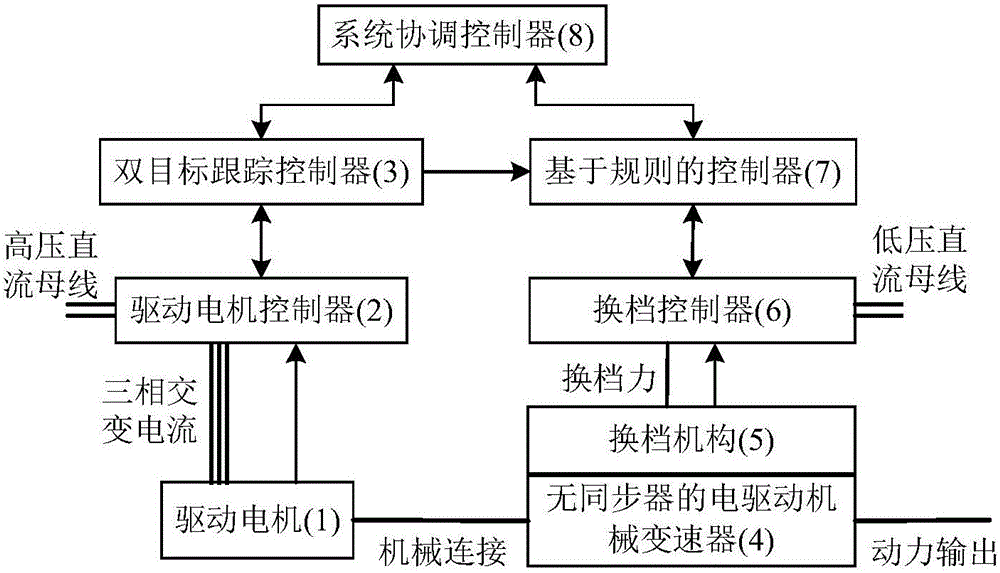

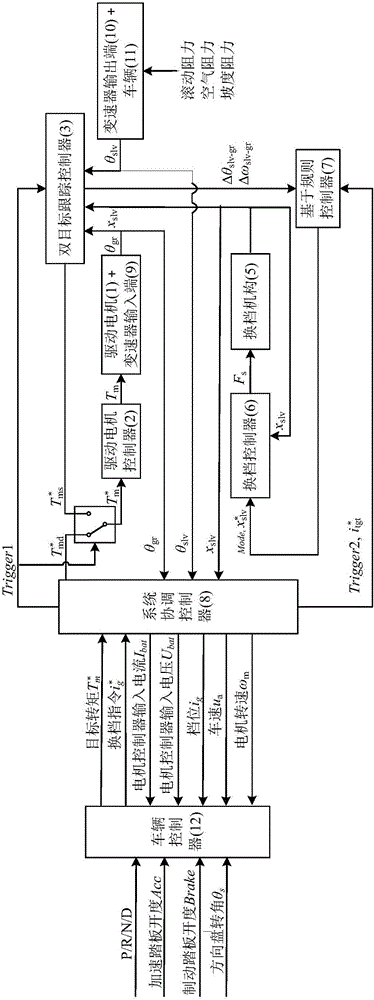

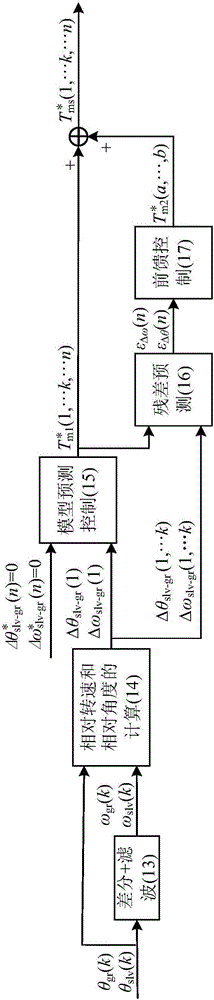

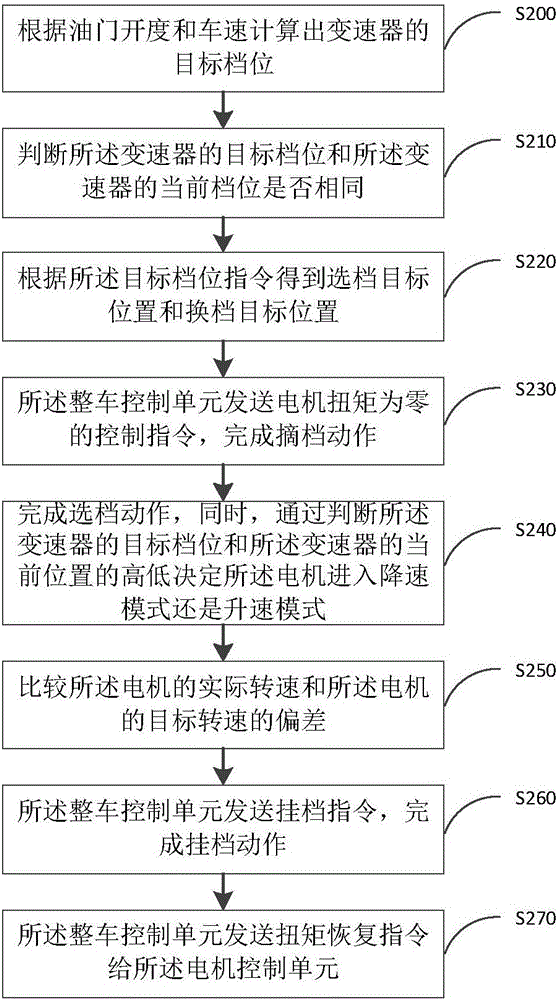

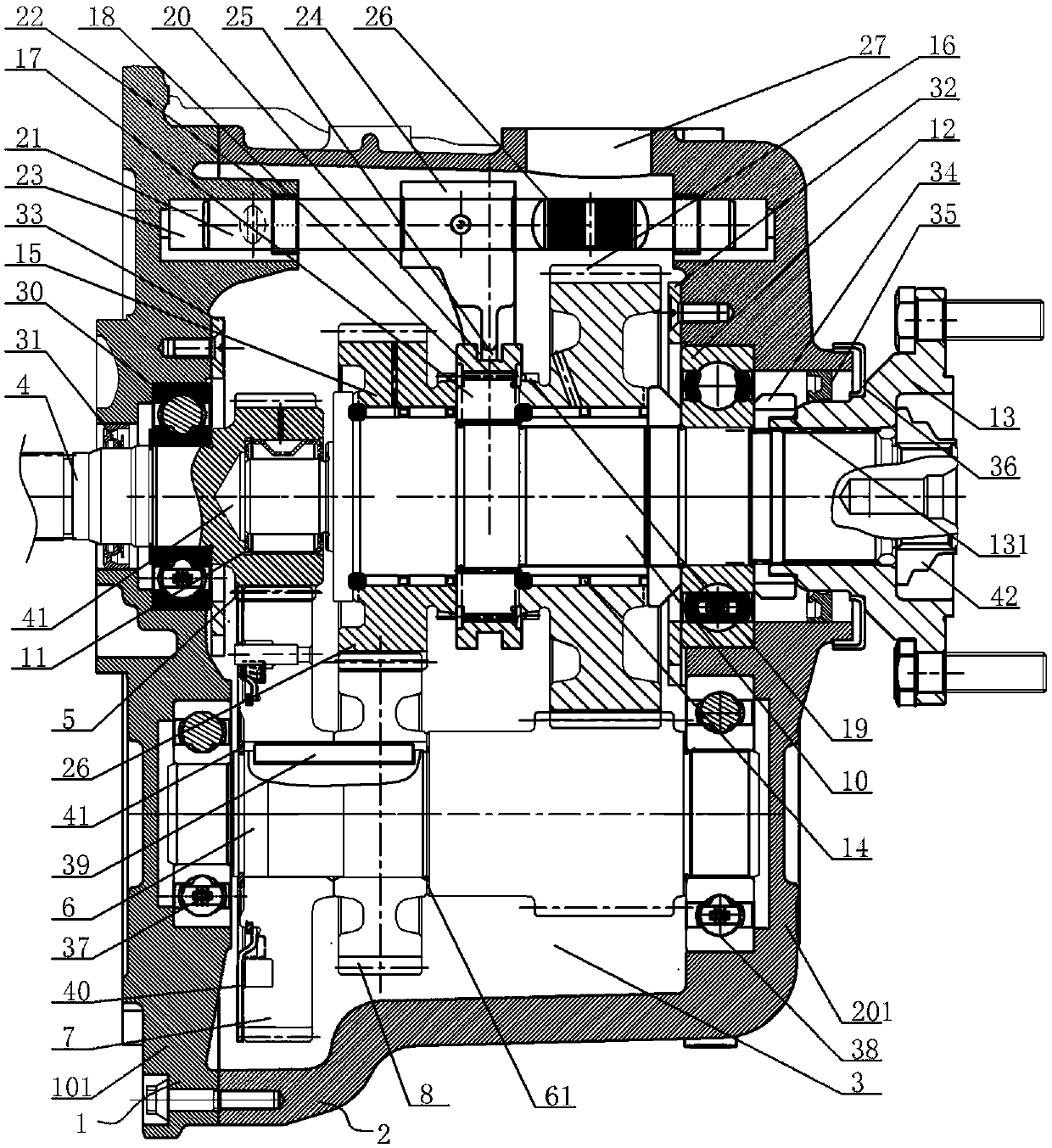

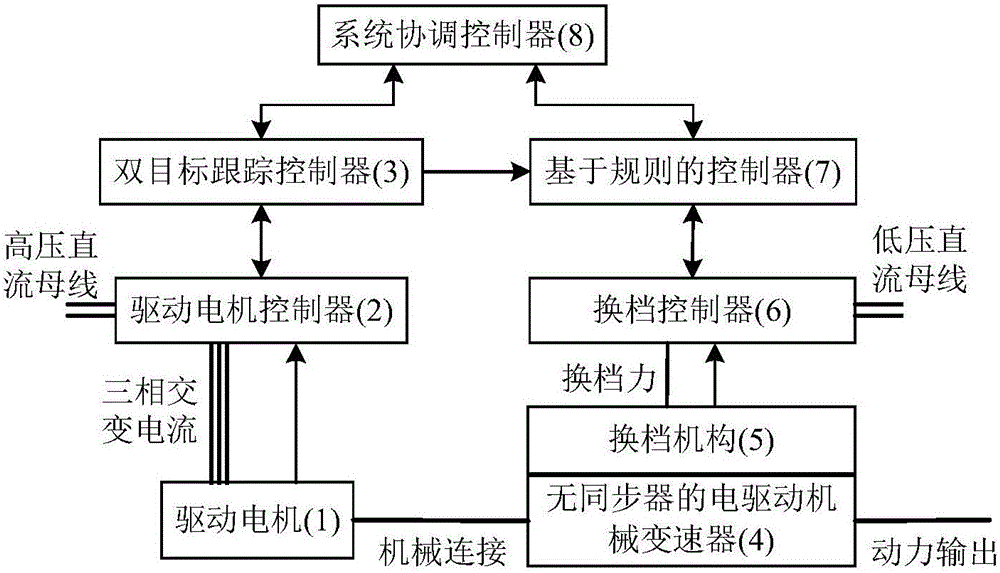

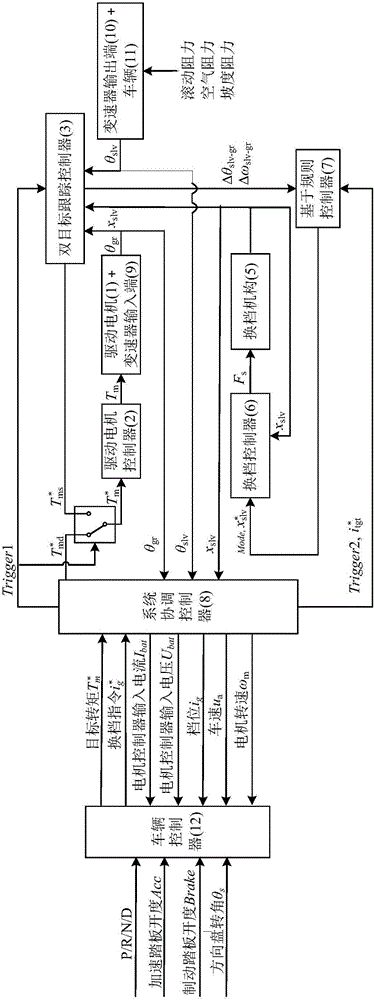

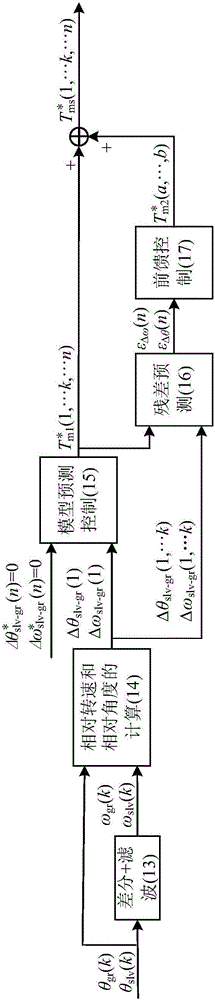

Impact-free gear shift control method and system for electrically driven mechanical transmission without synchronizer

The invention relates to an impact-free gear shift control method and system for an electrically driven mechanical transmission without a synchronizer. The electrically driven mechanical transmission is provided with no synchronizer; a drive motor and the electrically driven mechanical transmission are directly coupled, and a clutch between the drive motor and the electrically driven mechanical transmission is omitted. An automobile controller determines the target gear and sends a gear shift instruction to a system coordinating controller; the system coordinating controller coordinates the working sequence and working mode of a dual target tracking controller and a rule-based controller, so that the drive motor and the electrically driven mechanical transmission are in coordinated fit to achieve gear shift; and by accurately controlling a motor rotor, a target joint gear ring accurately tracks rotation of a joint sleeve in the joint process, the requirements for zero rotation speed difference and zero rotation corner difference are met, and impact-free gear shift control is achieved. The method and system can eliminate collision between the joint sleeve and the joint gear ring in the joint process, then gear shift impact is restrained, and the power failure duration is shortened.

Owner:TSINGHUA UNIV

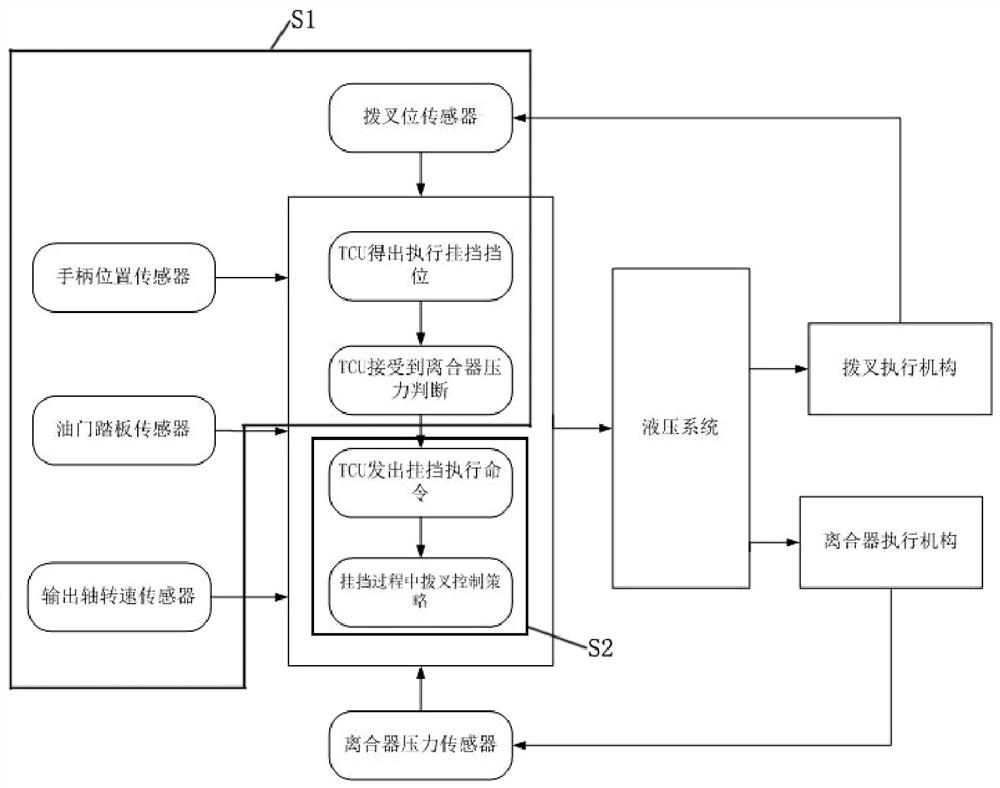

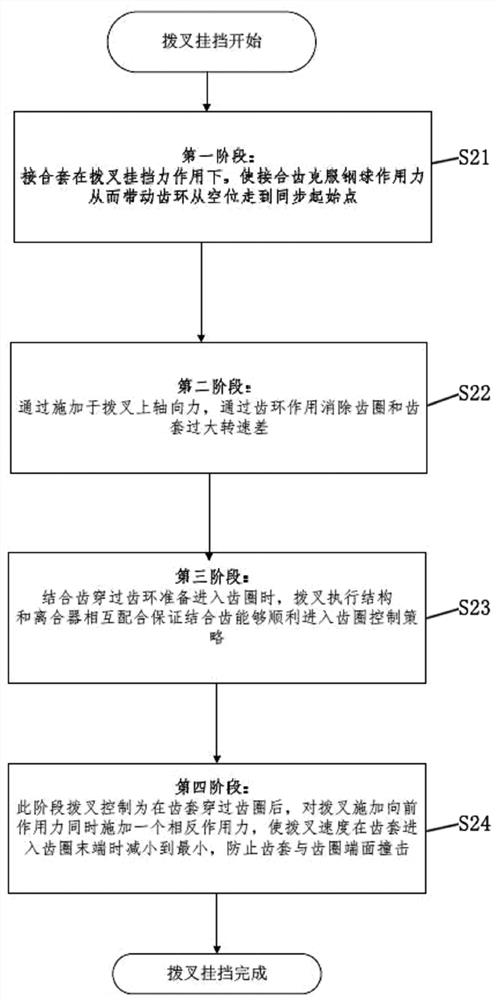

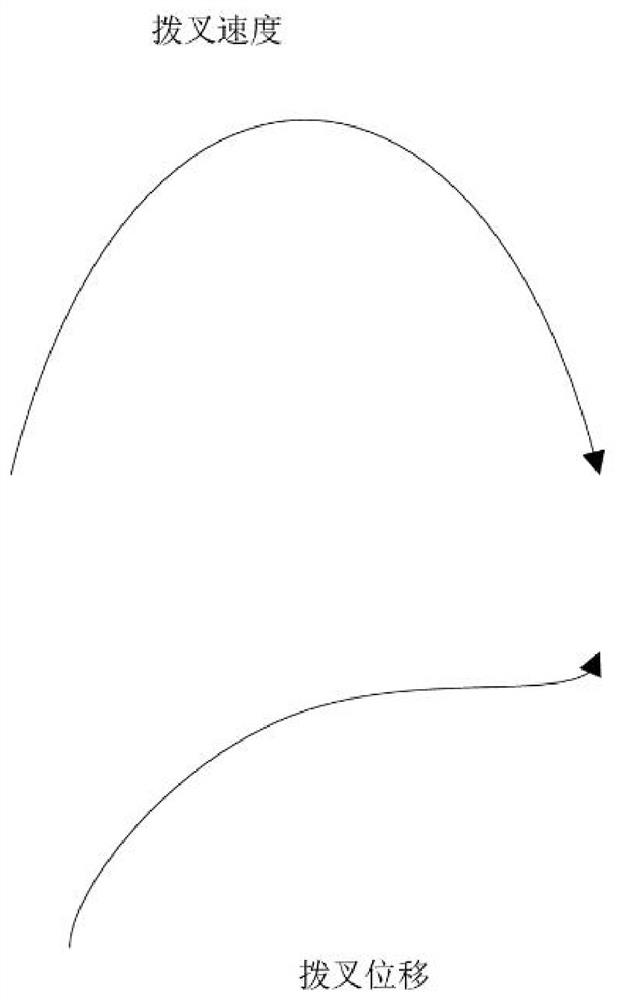

DCT speed changer shifting fork gear engaging controlling method

The invention discloses a DCT speed changer shifting fork gear engaging controlling method. The method comprises the following steps: S1: a TCU issues a gear engaging executing command; S2: the gear engaging executing command is processed by a gear engaging controlling strategy in the TCU; S21: in the first stage, under the action of shifting fork gear engaging force, a combined sleeve enables combined teeth to overcome acting force of a steel ball and therefore drives a ring gear to move from a vacant site to a synchronous starting point; S22: in the second stage, by exerting axial force on ashifting fork, and by eliminating revolving speed difference between a tooth ring and a tooth sleeve via the ring gear, the revolving speed difference is larger than a determined first threshold, andpreparation is made for the tooth sleeve to successfully push apart the ring gear and enter the tooth ring; S23: in the third stage, when the combined teeth penetrate through the ring gear and are ready to enter the tooth ring, the shifting fork and a clutch are matched with each other to ensure that the combined teeth can successfully enter the tooth ring; and S24: in the fourth stage, after thetooth sleeve penetrates through the tooth ring, when forward acting force is exerted on the shifting fork, reverse acting force is exerted at the same time, so the speed of the shifting fork is reduced to 0-0.0005m / s upon entering the tail end of the tooth ring and the tooth sleeve is prevented from striking the end surface of the tooth ring.

Owner:CHONGQING TSINGSHAN IND

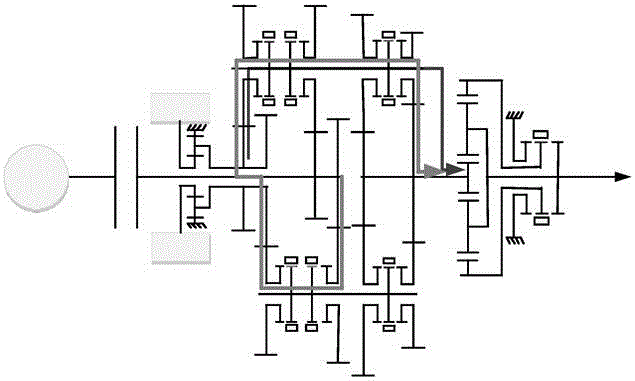

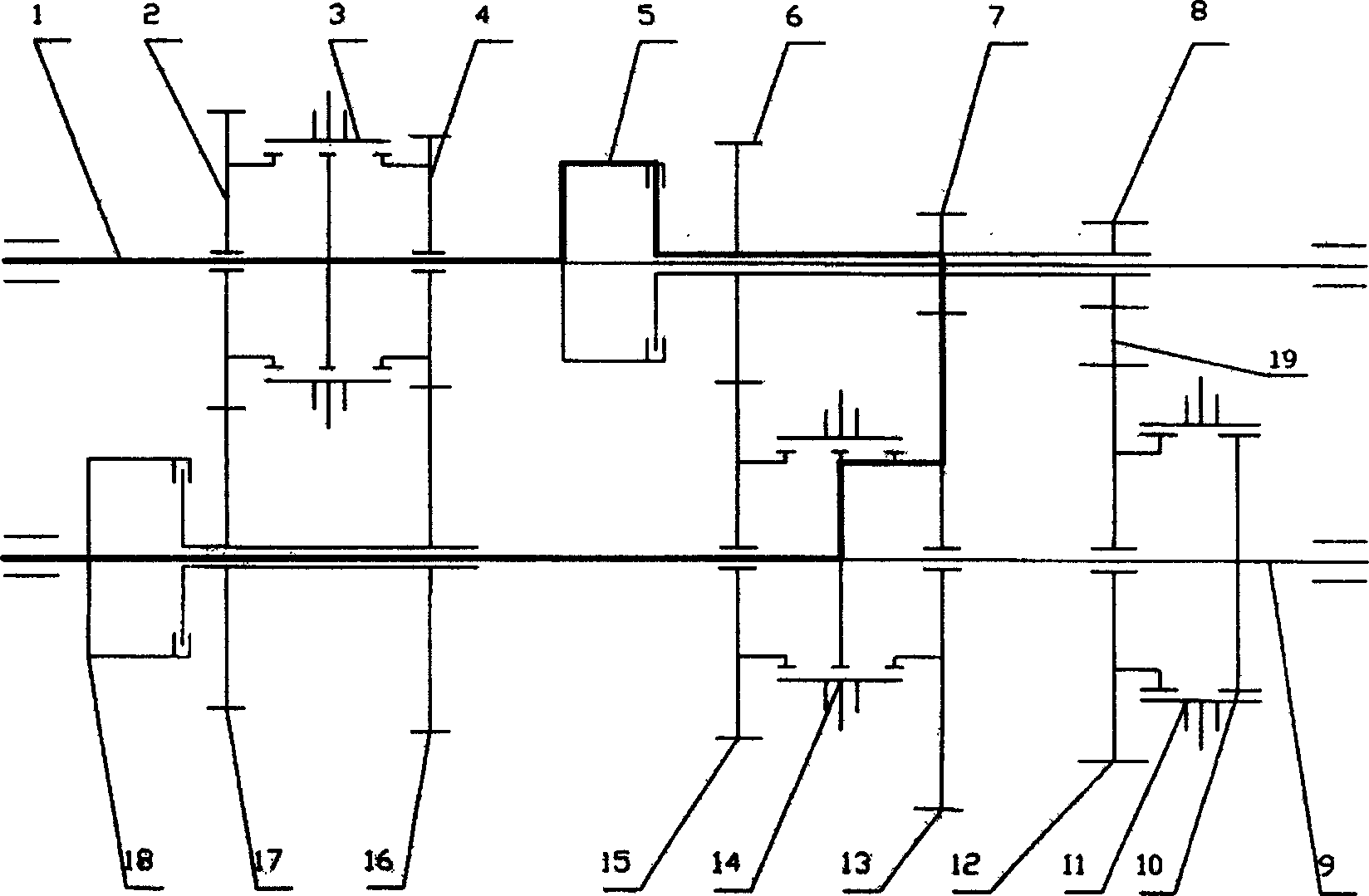

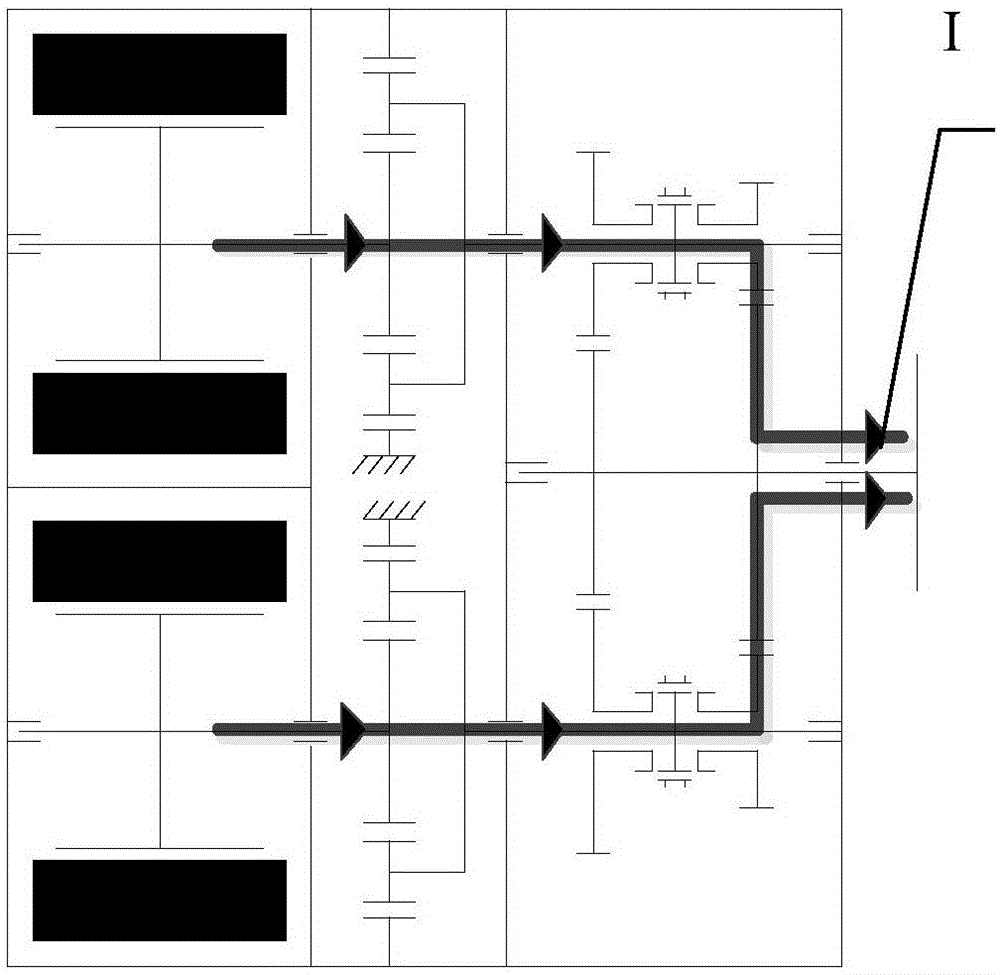

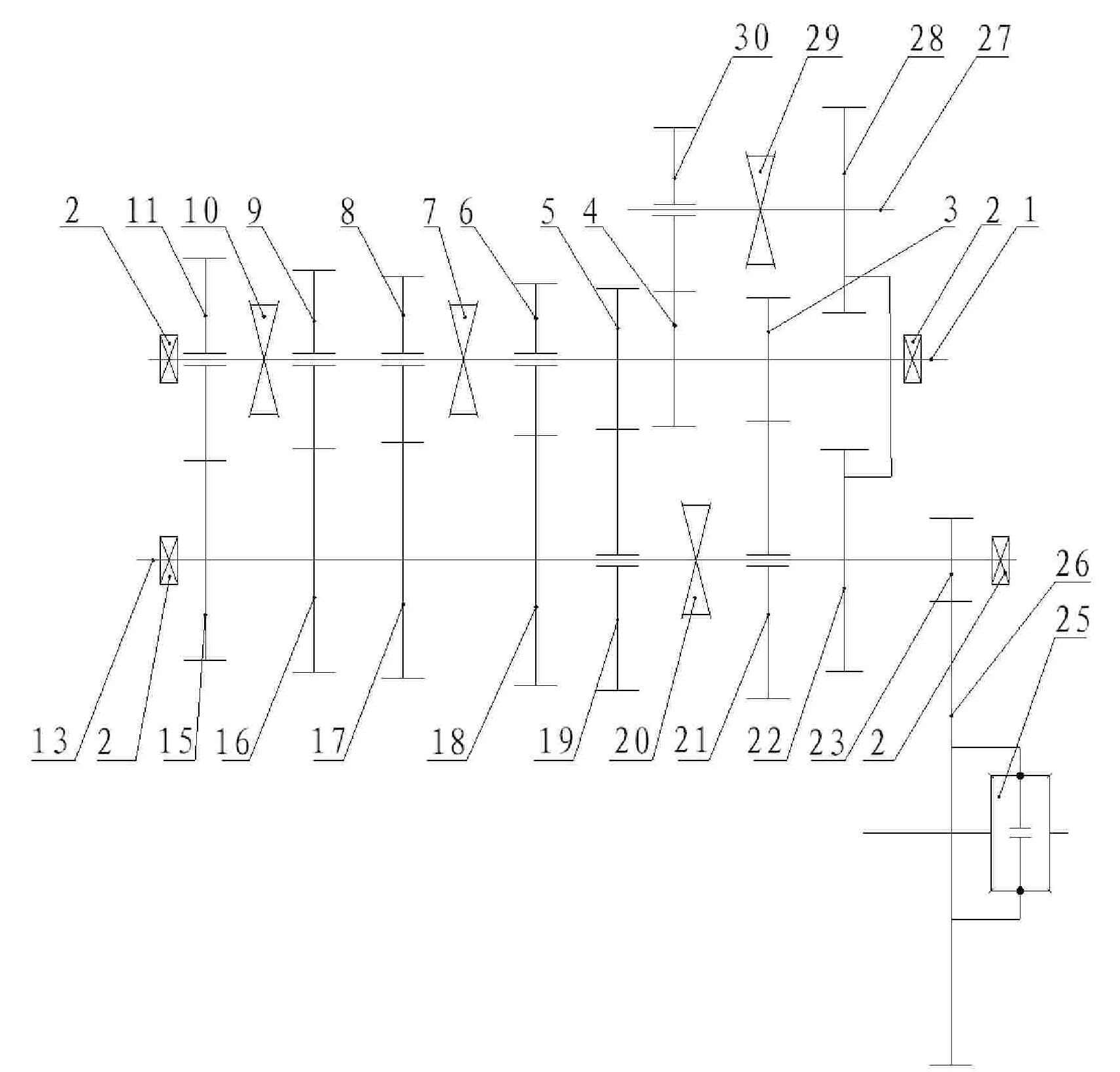

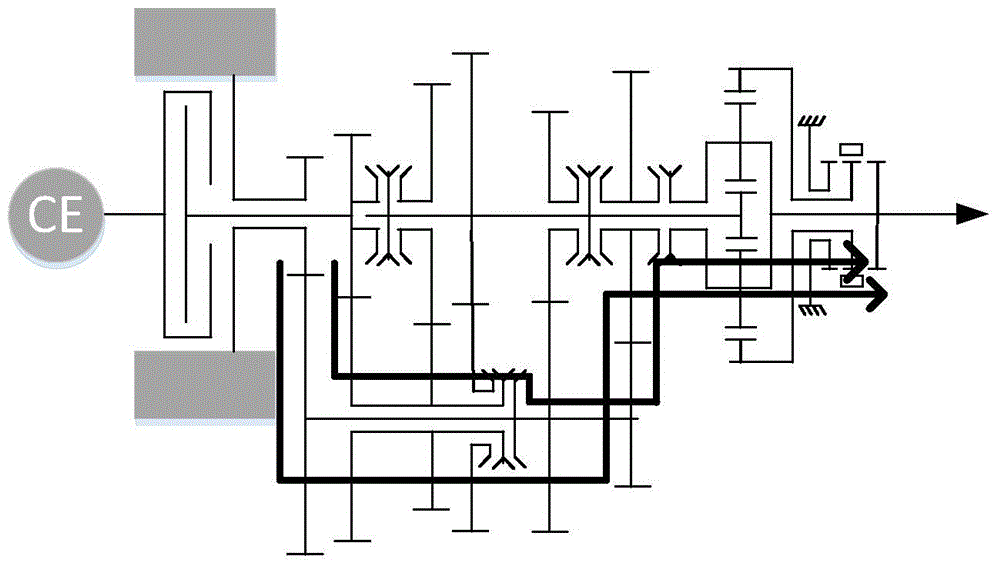

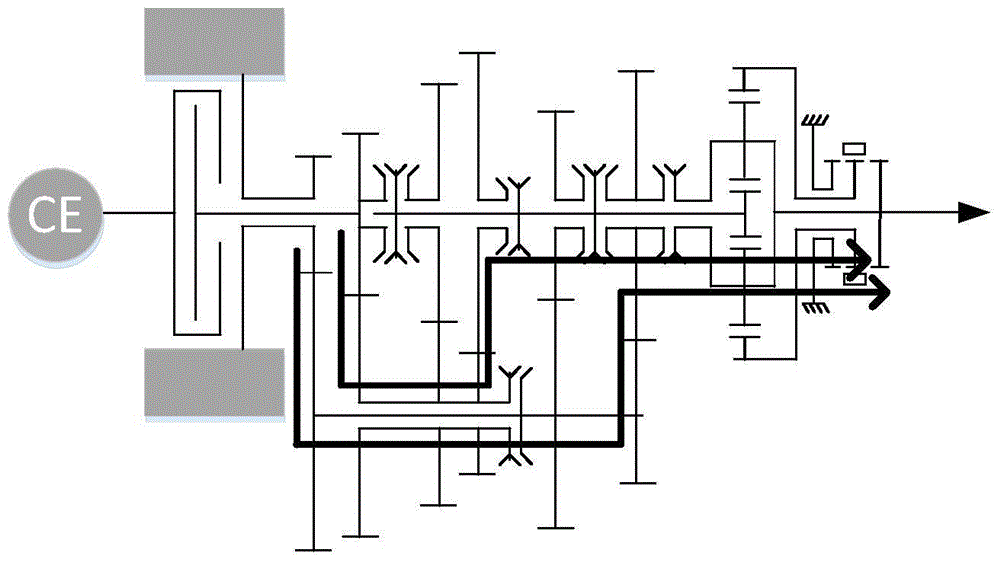

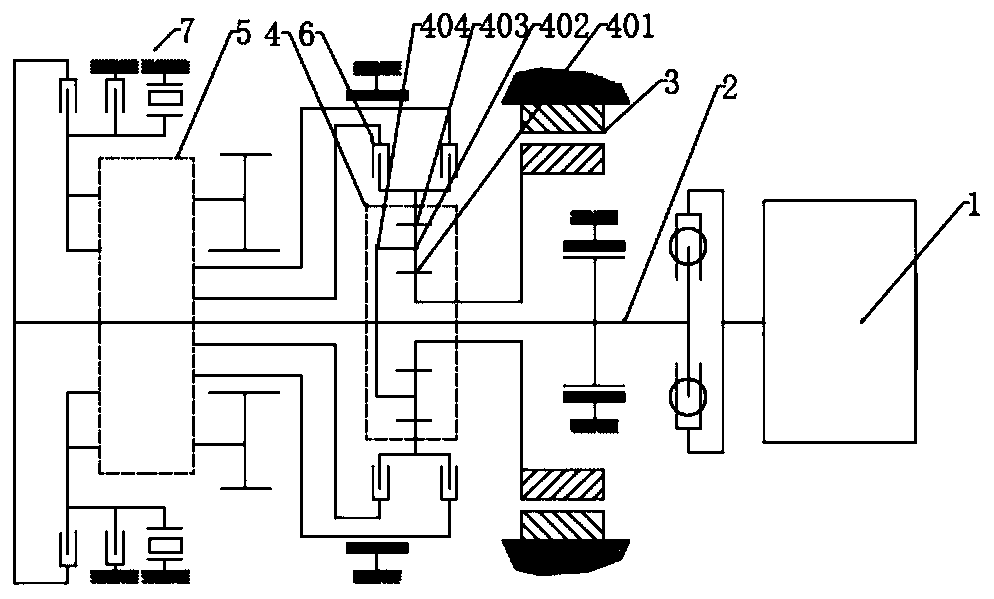

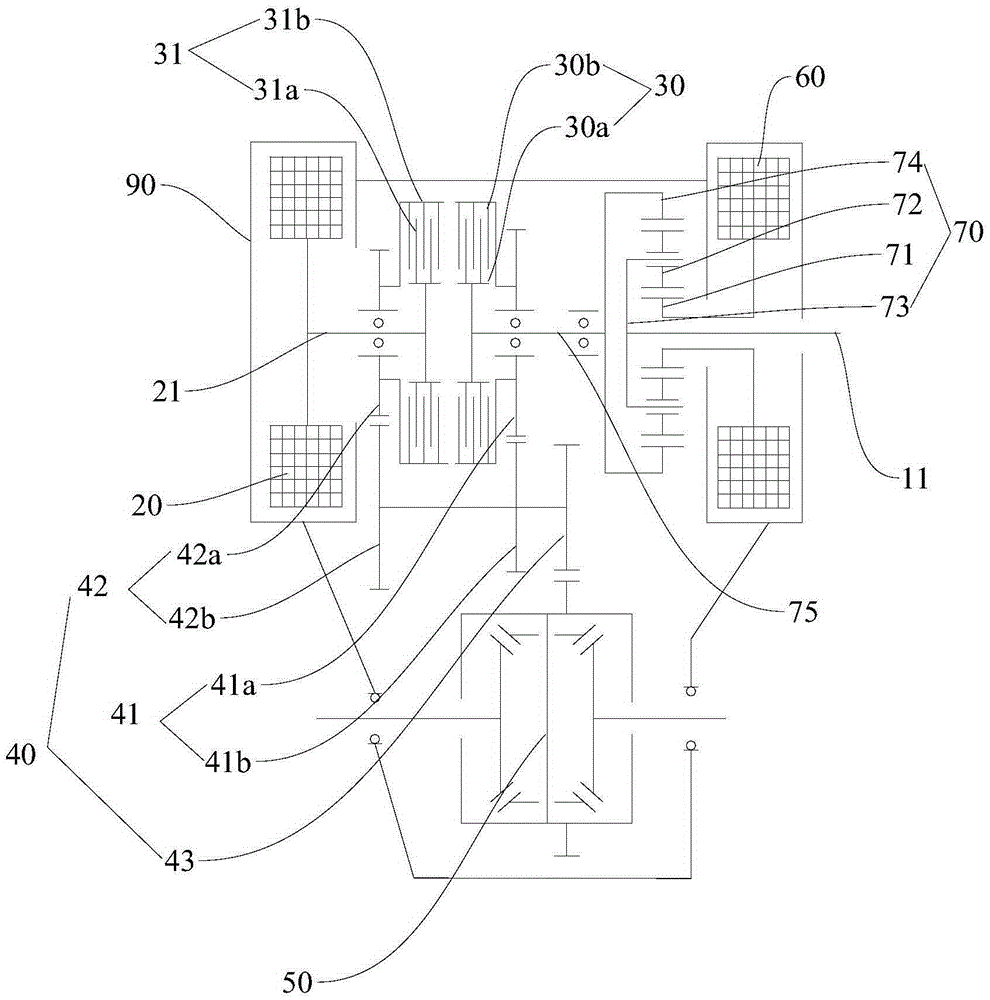

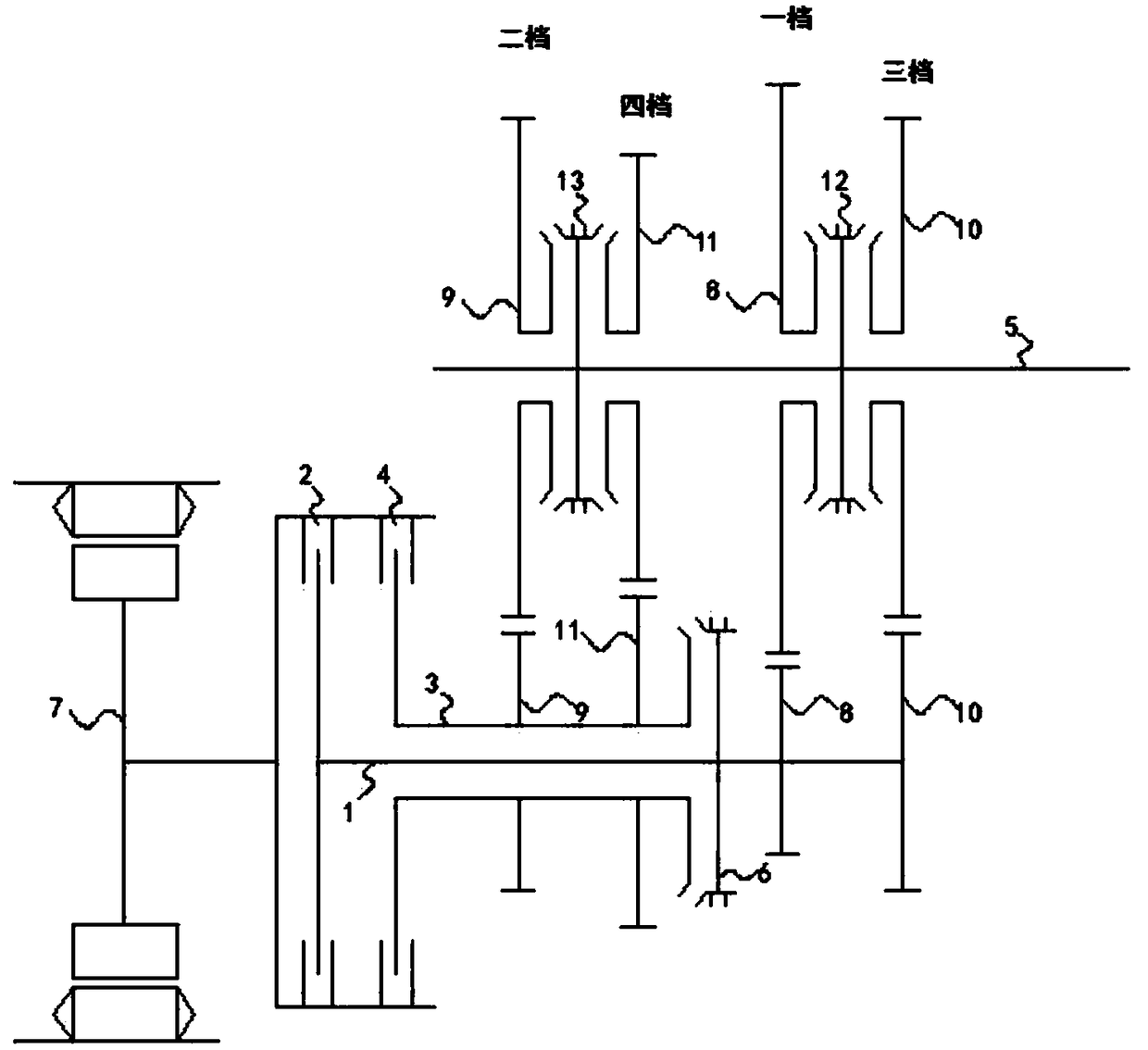

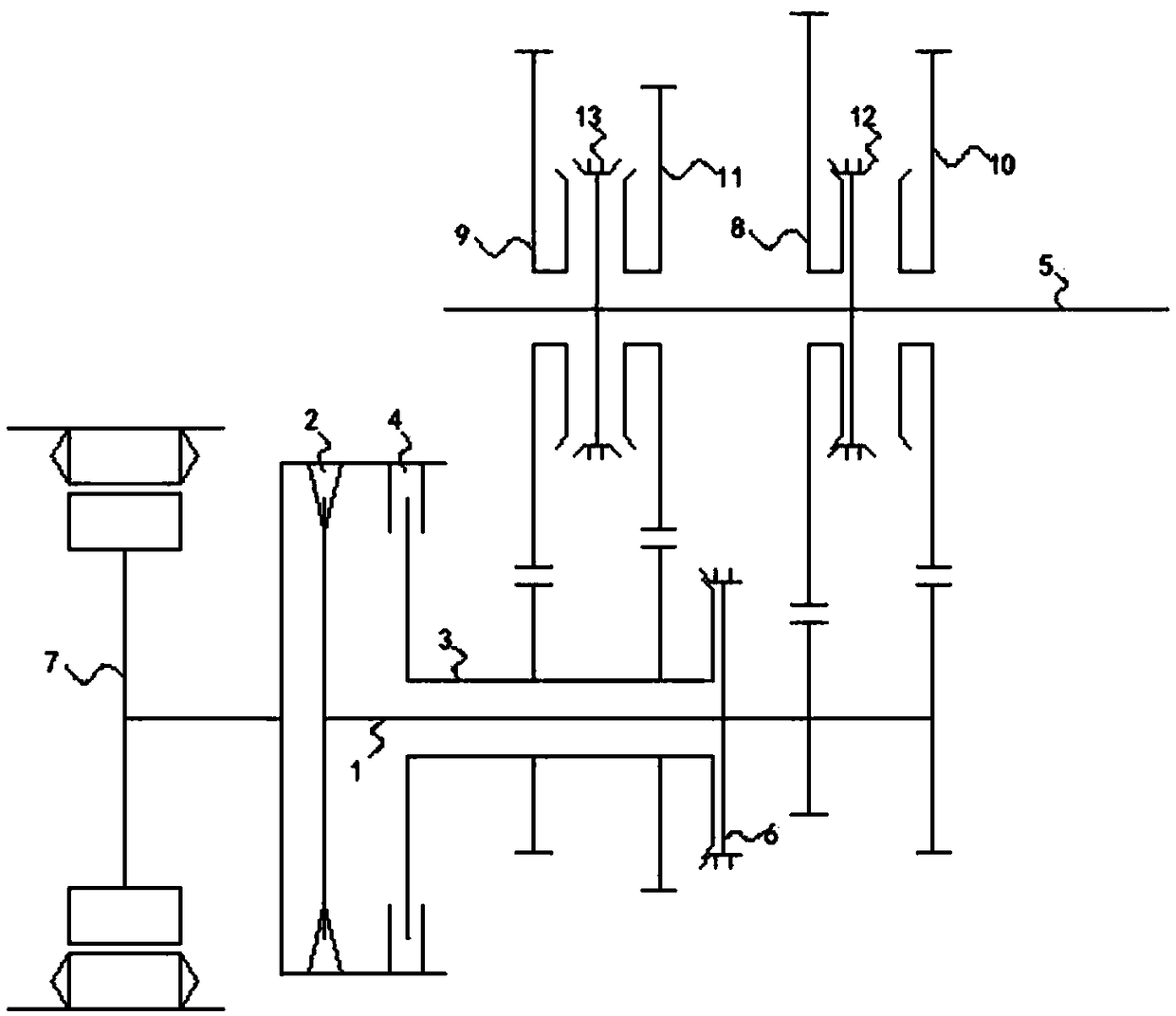

Parallel-type hybrid-power multi-gear gearbox of commercial vehicle

ActiveCN105196857AImprove power performanceImprove shift comfortHybrid vehiclesGas pressure propulsion mountingClutchCommercial vehicle

The invention belongs to the technical field of hybrid-power commercial vehicles, and particularly relates to a multi-gear gearbox. According to the technical scheme of a parallel-type hybrid-power multi-gear gearbox of a commercial vehicle, the power of an engine is input to an engine input shaft after passing through a clutch; a motor module comprises a motor and a drive gear, and the power of the motor is output through the drive gear and a motor input shaft; a gearbox primary box module consists of a multi-degree-of-freedom stationary-shaft gear mechanism, can be used for coupling the power of the engine and the motor, and can be used for realizing the gears of five matched engines and the gears of two matched motors; a gearbox auxiliary box module can be used for realizing two gears of a high gear and a lower gear, and can be used for realizing the gears of ten matched engines and the gears of four matched motors when jointly working with the gearbox primary box input module; the parallel-type hybrid-power multi-gear gearbox of the commercial vehicle is characterized in that the power of the motor and the engine is coupled by adopting the multi-degree-of-freedom gear mechanism, and the functions of hybrid power and power gear shifting are realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

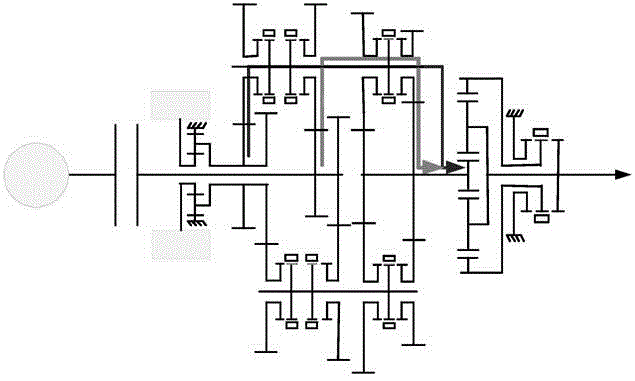

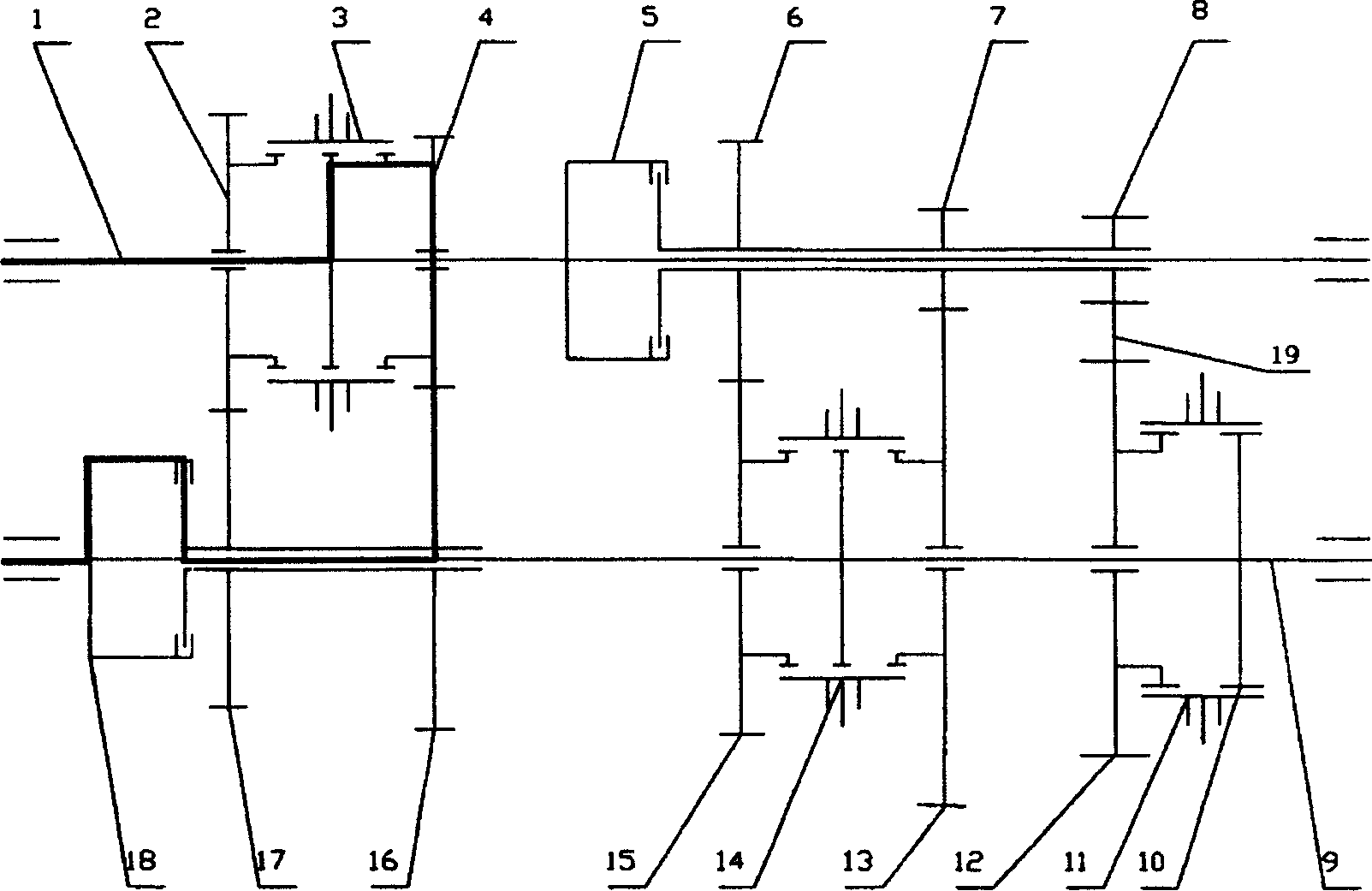

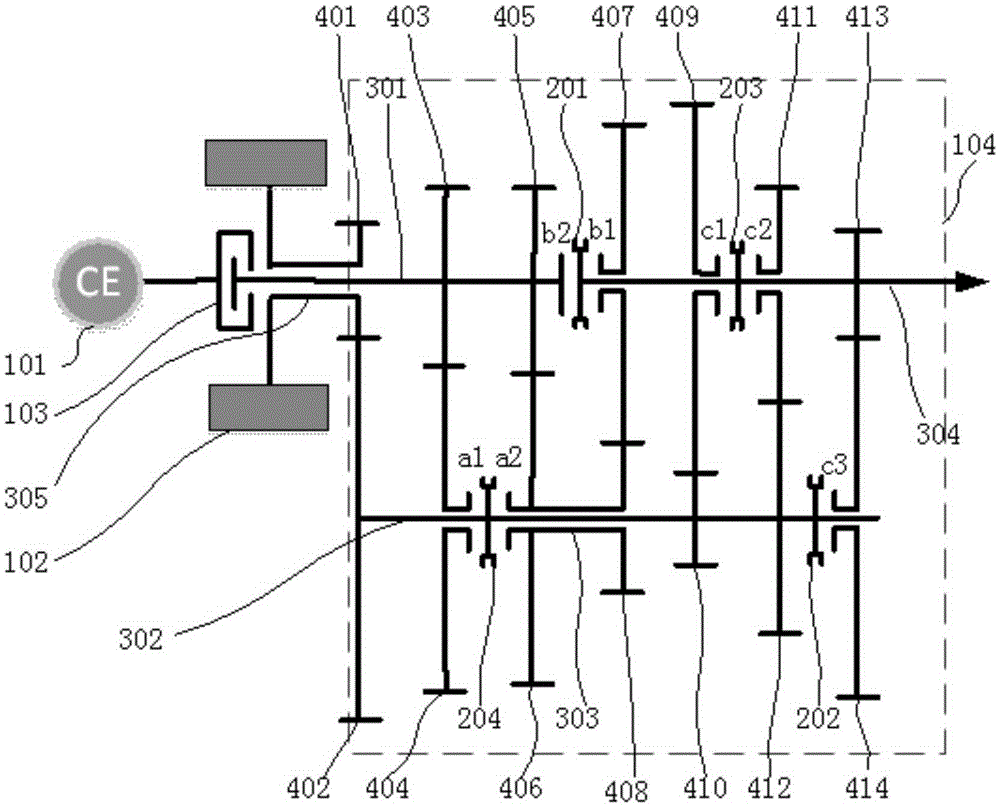

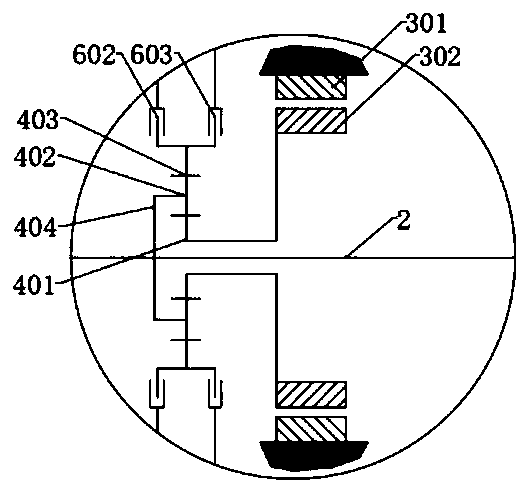

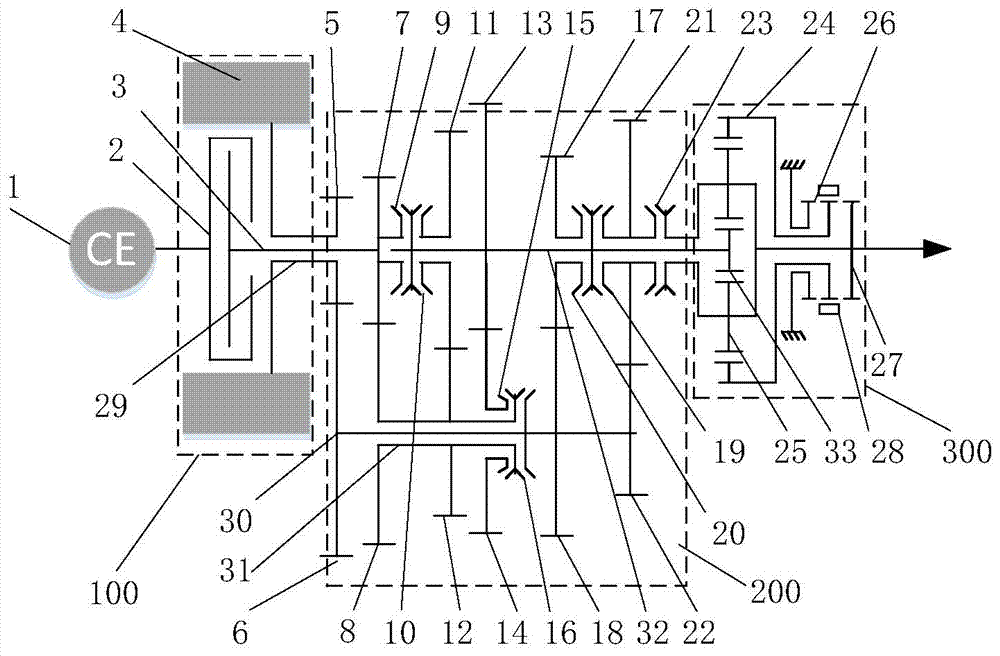

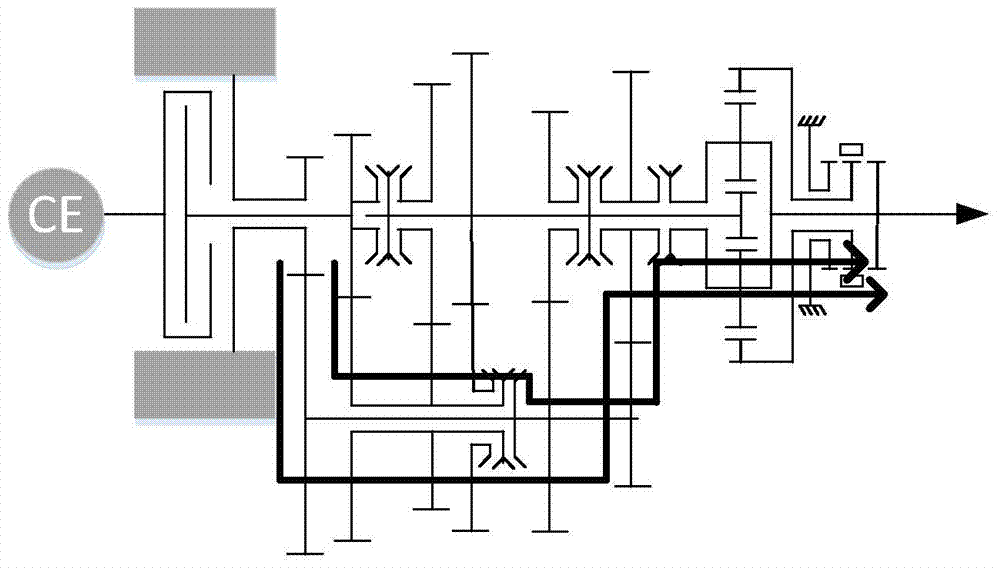

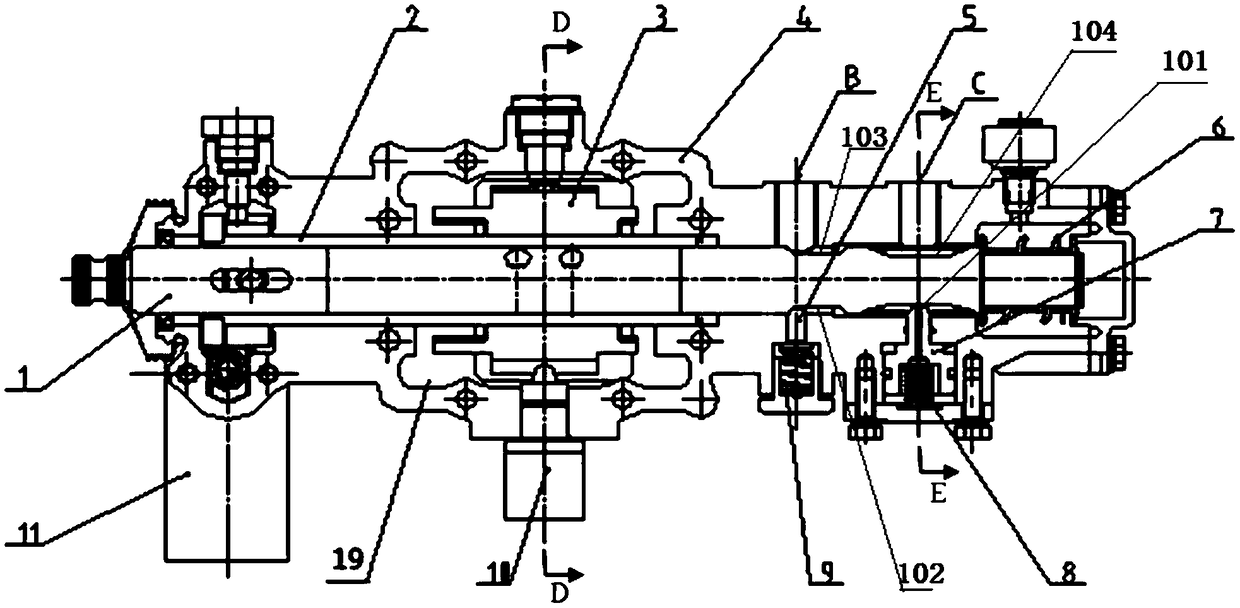

Power gear-shifting hybrid gearbox for commercial vehicle

ActiveCN105398323AOptimize space layoutImplement power shiftGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelElectric machine

The invention specifically relates to a hybrid multi-gear gearbox, which belongs to the technical field of vehicle transmission. A power gear-shifting hybrid gearbox for a commercial vehicle comprises an engine (101), a clutch (103), a motor (102) and a gearbox (104). The technical scheme of the power gear-shifting hybrid gearbox for the commercial vehicle is that the power of the engine (101) is input into an engine output shaft (301) after passing through the clutch (103); and the power of the motor (102) is input into a motor input shaft (305). The gearbox (104) comprises a plurality of free fixed-axle gear mechanisms, which can couple powers of the engine (101) and the motor (102) and can realize 8 gears matched with the engine, and 3 gears matched with the motor. According to the invention, power gear shifting and hybrid power working condition can be realized; vehicle power performance can be improved; gear shifting quality can be improved; clutch abrasion can be reduced; and fuel efficiency can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Power motor auxiliary gear-shifting control system and control method thereof

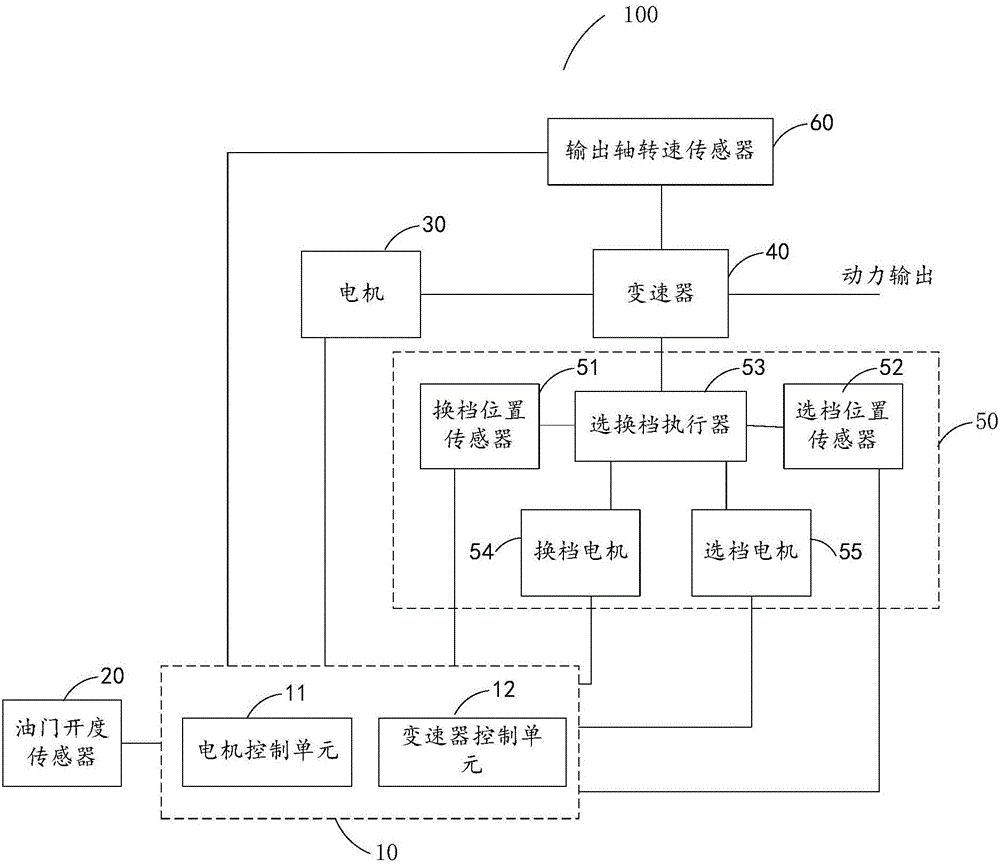

PendingCN106740856AExtended service lifeSmall shift shockDriver input parametersControl systemElectric machine

The invention discloses a power motor auxiliary gear-shifting control system and a control method thereof. The power motor auxiliary gear-shifting control system comprises a vehicle control unit, a throttle opening sensor, a motor, a transmission, a gear-selecting and gear-shifting execution device and an output shaft speed sensor, wherein the throttle opening sensor is connected with the vehicle control unit to transmit throttle opening information to the vehicle control unit, the motor is connected with the vehicle control unit and reaches a target speed according to the instruction action of the vehicle control unit after the vehicle control unit receives the throttle opening information, the gear-selecting and gear-shifting execution device is respectively connected with the vehicle control unit and the transmission and indicates gear-selecting and gear-shifting action of the transmission according to the instruction of the vehicle control unit, and the output shaft speed sensor is connected with the vehicle control unit to feed back acquired transmission output shaft speed information to the vehicle control unit. According to the power motor auxiliary gear-shifting control system and the control method thereof, gear-shifting quality can be improved, and the service life of the transmission is prolonged.

Owner:洁蓝德新能源科技有限公司

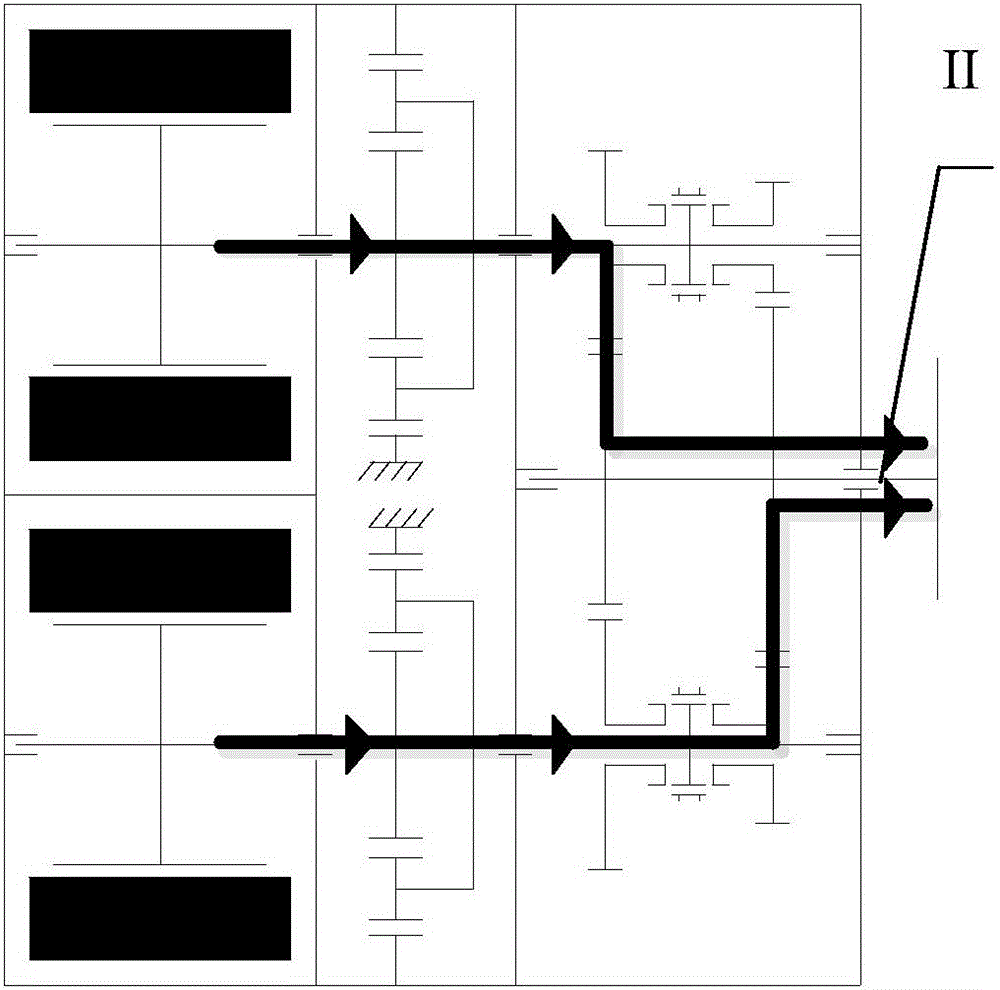

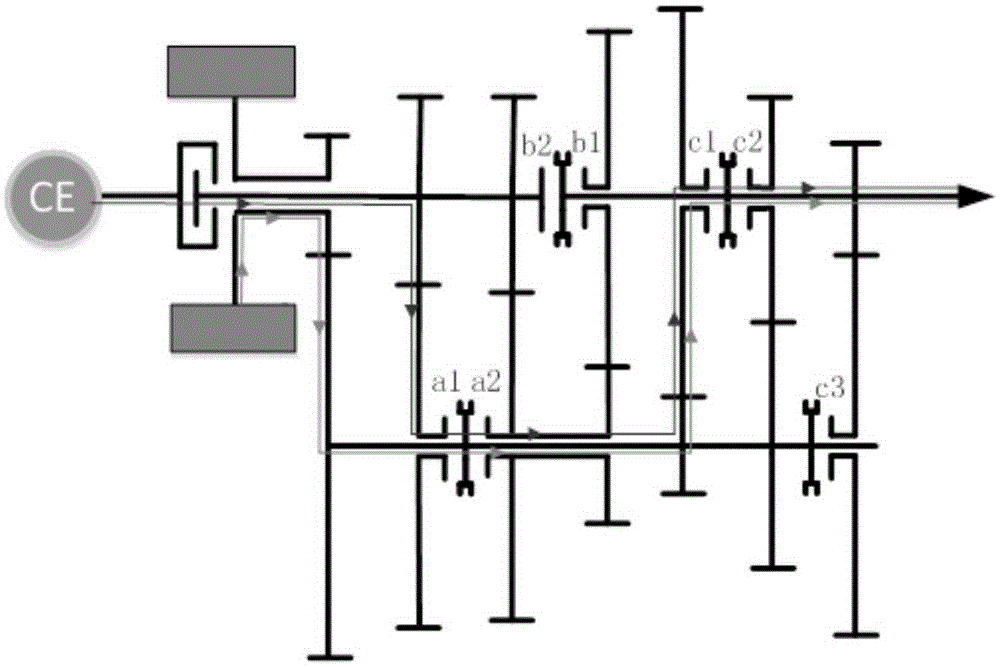

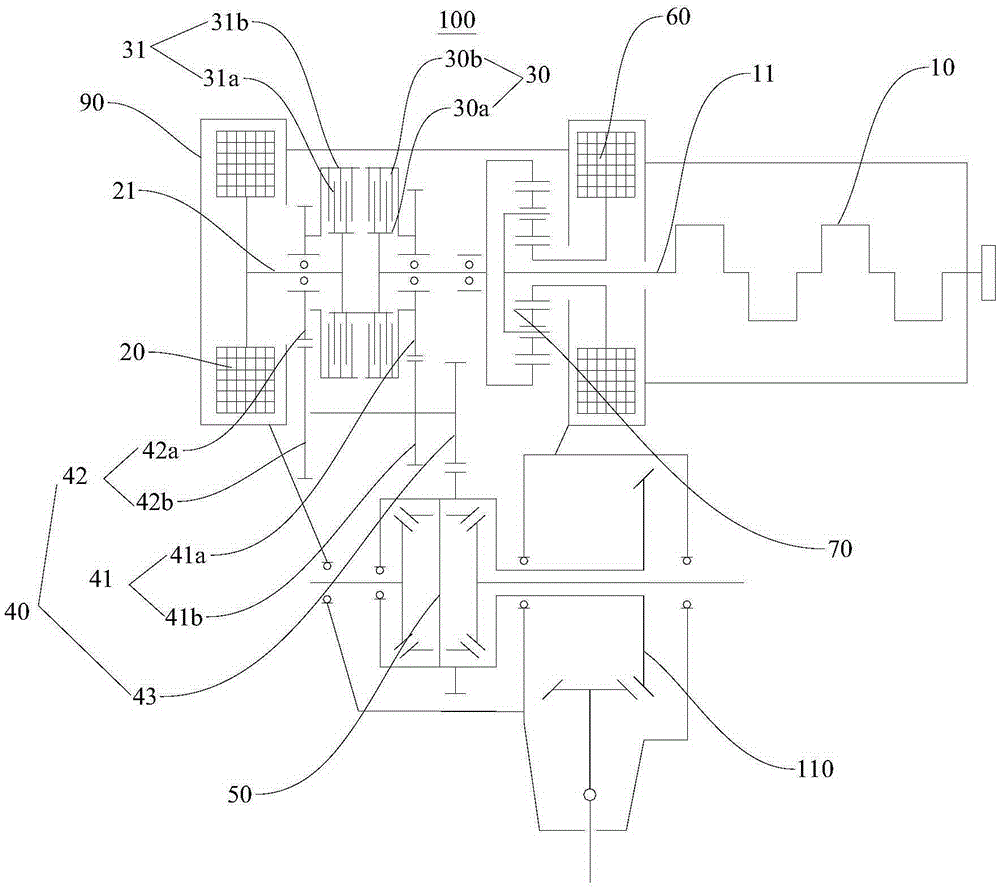

Parallel type hybrid power multi-gear transmission case for power gear-shifting of commercial vehicle

ActiveCN105172569AAchieve hybridRealize functionHybrid vehiclesGas pressure propulsion mountingElectric machineMulti degree of freedom

The invention belongs to the technical field of commercial hybrid power vehicles and relates to a multi-gear transmission case, in particular to a parallel type hybrid power multi-gear transmission case for power gear-shifting of a commercial vehicle. According to the technical scheme, the power of an engine is input to an engine input shaft after passing through a clutch; a motor module comprises an electromotor and a transmission gear, and the motor power is output through the transmission gear and an electromotor input shaft; a main box module of the transmission case is composed of a multi-degree of freedom fixed-axle gear mechanism, can be coupled with the power of the engine and a motor, and can realize the gears of five matched engines and the gears of two matched motors; an auxiliary box module of the transmission case can realize a high gear and a low gear; the auxiliary box module of the transmission case collaborates with the main box input module of the transmission case, so that the gears of ten matched engines and the gears of four matched motors can be realized. The parallel type hybrid power multi-gear transmission case has the characteristics that the multi-degree of freedom gear mechanism is adopted to couple the power of the engine and the motor and realizes the hybrid power and power gear-shifting functions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Automobile planetary gear transmission

InactiveCN110281759AAchieve power transmissionAchieve variable speedGas pressure propulsion mountingToothed gearingsEngineeringMechanical engineering

The invention discloses an automobile planetary gear transmission. The automobile planetary gear transmission comprises a split planetary gear set and a compound planetary gear set which are arranged on the same axis. The split planetary gear set comprises a split planetary sun gear, a split planetary ring gear, a split planetary carrier and a plurality of split planetary pinions; the split planetary sun gear is connected to a motor rotor; one end of the split planetary ring gear meshes with the plurality of split planetary pinions and the other end of the split planetary ring gear is separately connected to a second clutch and a third clutch; the plurality of split planetary pinions are supported on the split planetary carrier by bearings; the middle part of the split planetary carrier is connected to a first clutch and a third brake to be a whole through an engine output shaft; and through the engagement or disengagement of a plurality of engagement components and a plurality of braking components, the split planetary gear set and the compound planetary gear set output the rotation of a motor and an engine by speed changing. The automobile planetary gear transmission can reduce the impact of the transmission during gear shifting and improve the comfort of gear shifting.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

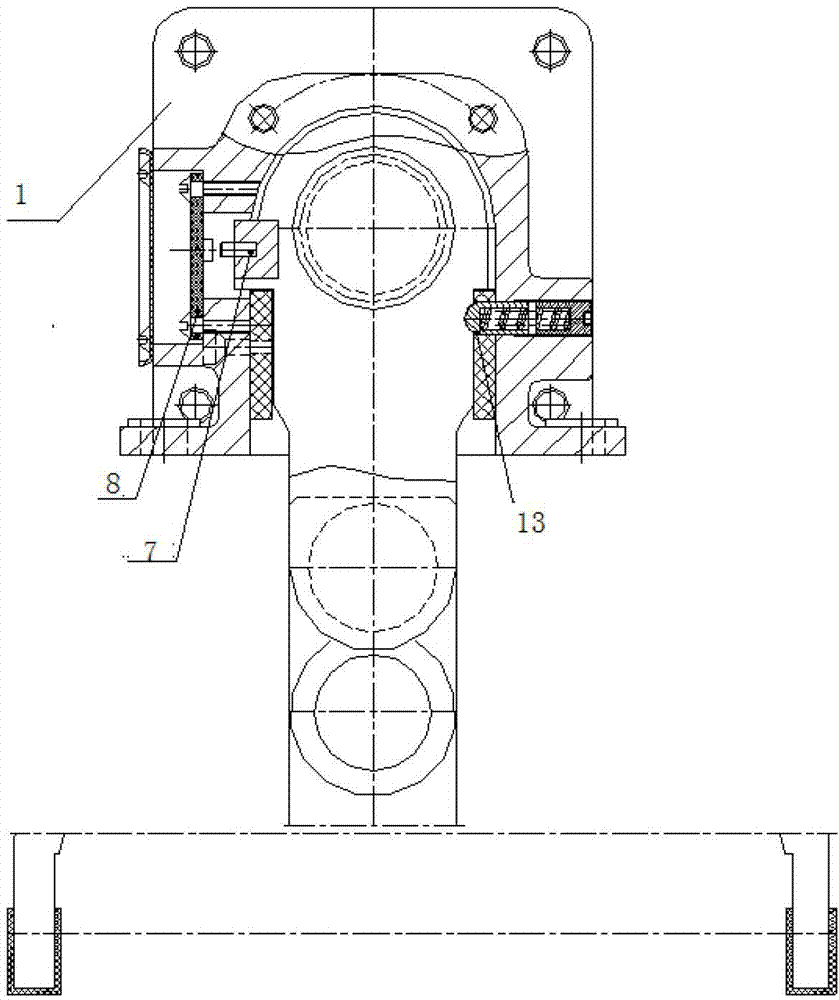

Control mechanism of manual transmission

The invention discloses a control mechanism of a manual transmission, relates to the transmission technology, and is used for solving the problems of heavier gear choosing and larger occupied space in the existing transmissions. The control mechanism comprises a gear shifting shaft which is capable of freely rotating and arranged on a control cover through axially moving, a balancing weight in axially movable connection and peripherally synchronous rotation with the gear shifting shaft, and a gear shifting rotating arm fixed on the balancing weight. The mechanism is used for achieving the gear choosing and the gear shifting of the manual transmission.

Owner:GREAT WALL MOTOR CO LTD

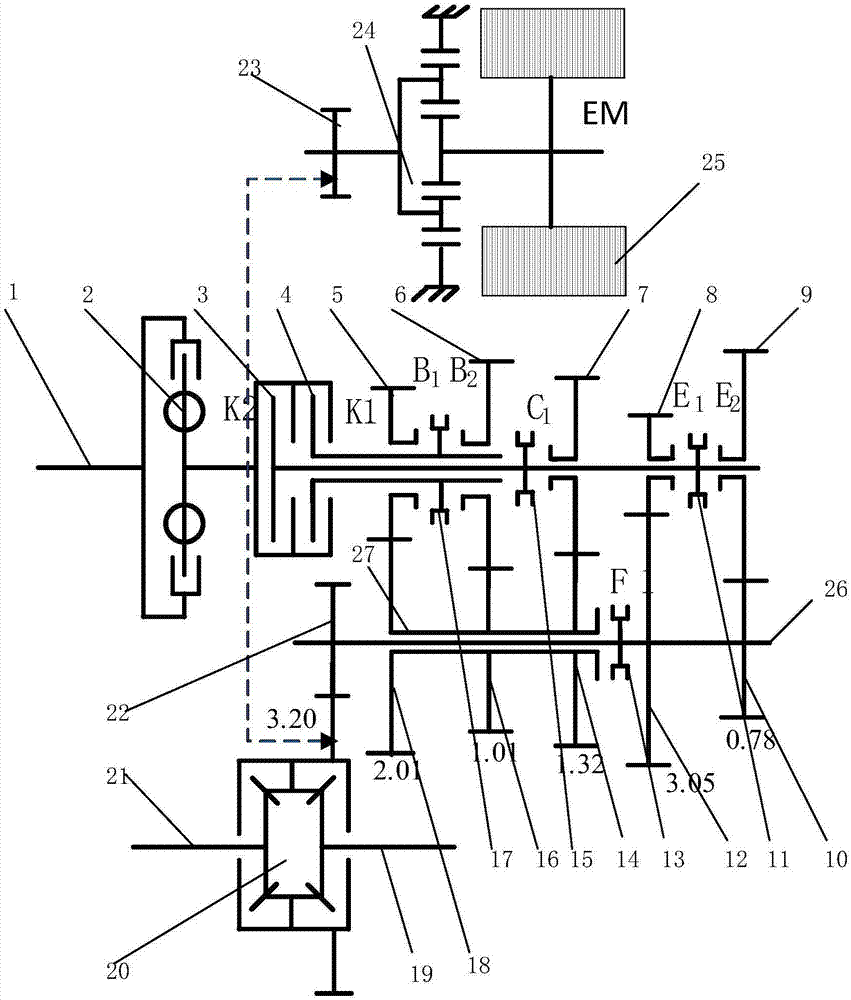

Seven-speed double-clutch hybrid power transmission device

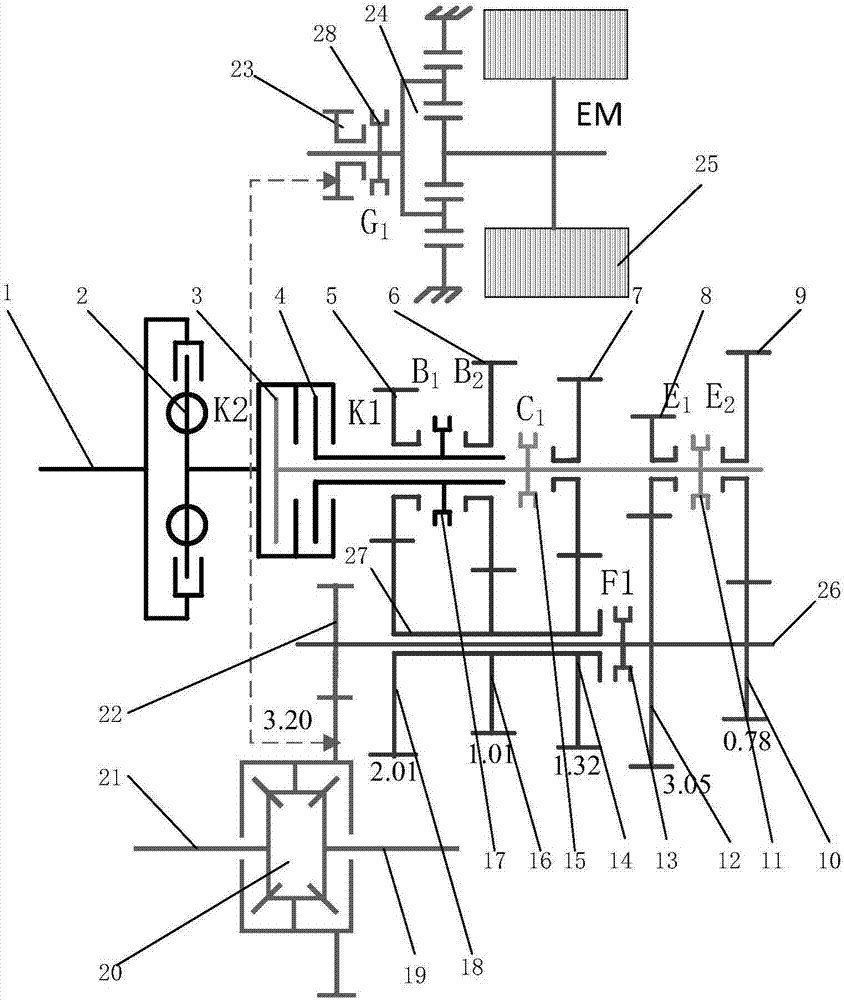

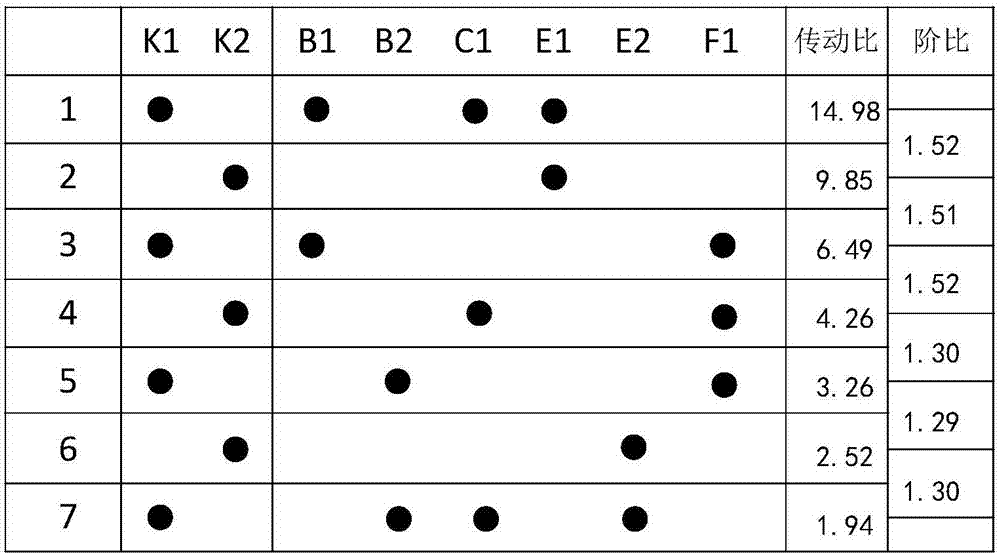

ActiveCN106864243AReduce difficultyReduce complexityGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingFuel oilGear train

The invention belongs to the technical field of hybrid power automobiles, particularly relates to transmission devices and provides a seven-speed double-clutch hybrid power transmission device. The seven-speed double-clutch hybrid power transmission device comprises an engine input shaft (1), a damper (2), a K2 clutch (3), a K1 clutch (4), a first gear (5), a second gear (6), a twelfth gear (7), a third gear (8), a fourth gear (9), a fifth gear (10), an E synchronizer (11), a sixth gear (12), an F synchronizer (13), a seventh gear (14), a C synchronizer (15), an eighth gear (16), a B synchronizer (17), a ninth gear (18), a differential mechanism (20), a tenth gear (22), an eleventh gear (23), a decelerating planetary gear train (24), a motor (25), a first shaft (26) and a second shaft (27). According to the seven-speed double-clutch hybrid power transmission device, the complexity of a mechanism is reduced, transmission efficiency is improved, and economical efficiency of vehicle fuel oil is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

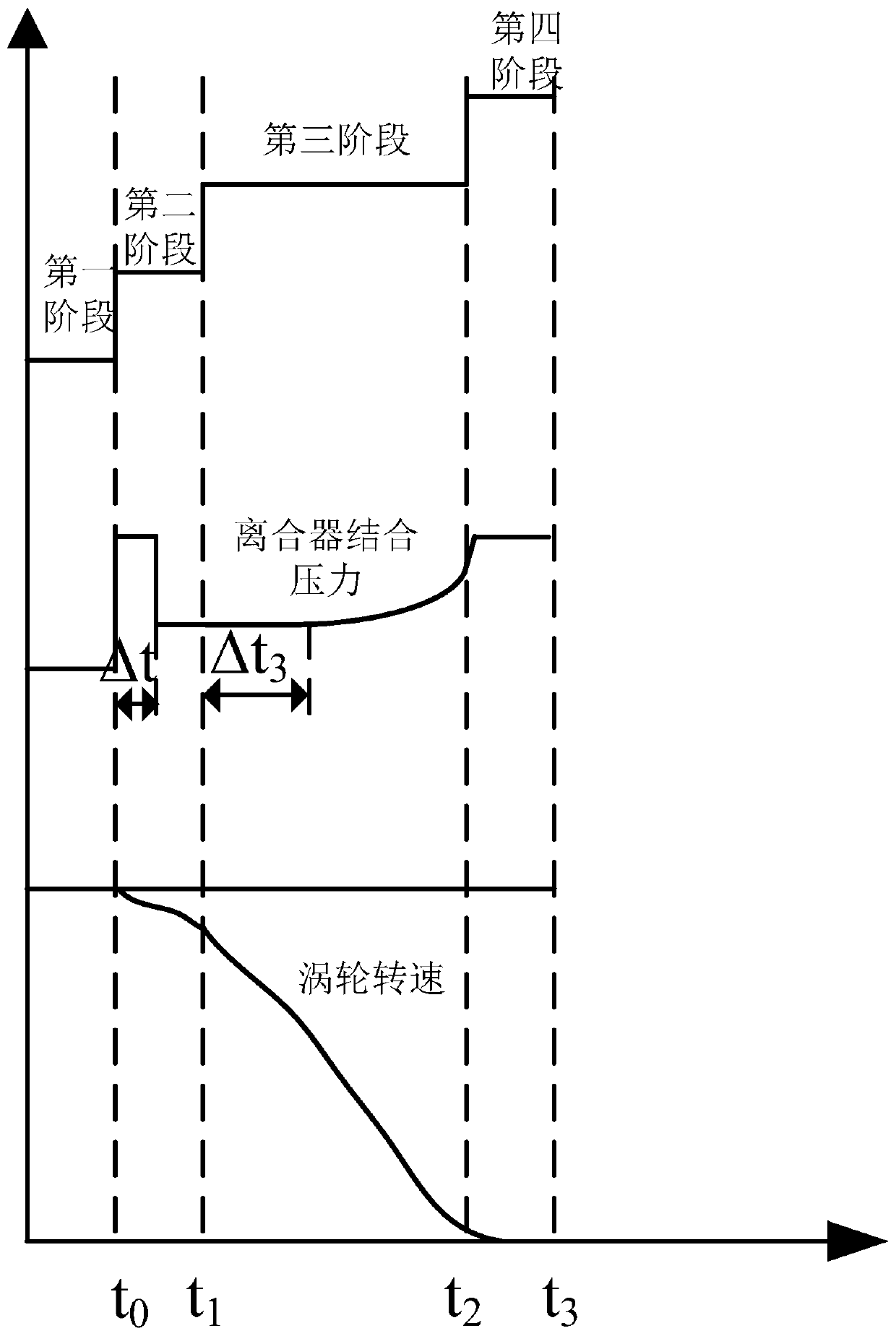

Self-adaptive learning control method during clutch engagement process

ActiveCN111365452AImprove shift comfortCombining pressure and timely correctionClutchesGearing controlThree stageControl engineering

The invention discloses a self-adaptive learning control method during a clutch engagement process. Self-adaptive control is performed in a second stage and a third stage of four stages in the clutchengagement process, with the consideration of the influence of oil temperature, the self-adaptive learning control of the time length [delta]t is performed in the second stage, and thus a first self-learning value that meets the conditions is obtained; the self-adaptive learning control of the given sliding friction target pressure is performed in the third stage, and a second self-learning valuethat meets the conditions is obtained; and by applying the first self-learning value and the second self-learning value in a next cycle, the clutch engagement pressure is corrected in time and self-learning is performed. According to the self-adaptive learning control method, the clutch engagement state can be monitored in real time, and the state of each stage is used as feedback, so that a clutch meets the requirements of the engagement time and shifting impact degree during the engagement process.

Owner:泸州容大智能变速器有限公司

Hybrid dynamic system

ActiveCN106627094AImprove acceleration performanceLow costHybrid vehiclesGas pressure propulsion mountingClutchHybrid power

The invention provides a hybrid dynamic system, which includes an engine, a first motor, a first driving disc which drives with the engine, a first clutch of a first driven disc, a second driving disc which drives with the first motor, a second clutch of a second driven disc and deceleration assemblies which includes a high retaining gear pair, a low retaining gear pair and a deceleration output gear. The high retaining gear pair includes a high retaining driving gear and a high retaining driven gear which are mutually meshed. The high driving gear is connected with a first driven plate. The low retaining gear pair includes a lowretaining driving gear and a low retaining driven gear which are mutually meshed. The low retaining driving gear is connected with asecond driven plate. The deceleration output gear respectively and synchronously rotates with the high retaining driven gear and the low retaining driven gear.The hybrid dynamic system also includes a differential mechanism which drives with the deceleration output gear. Through setting the first clutch and the second clutch, the vehicle can meet torque and speed requirements.

Owner:GREAT WALL MOTOR CO LTD

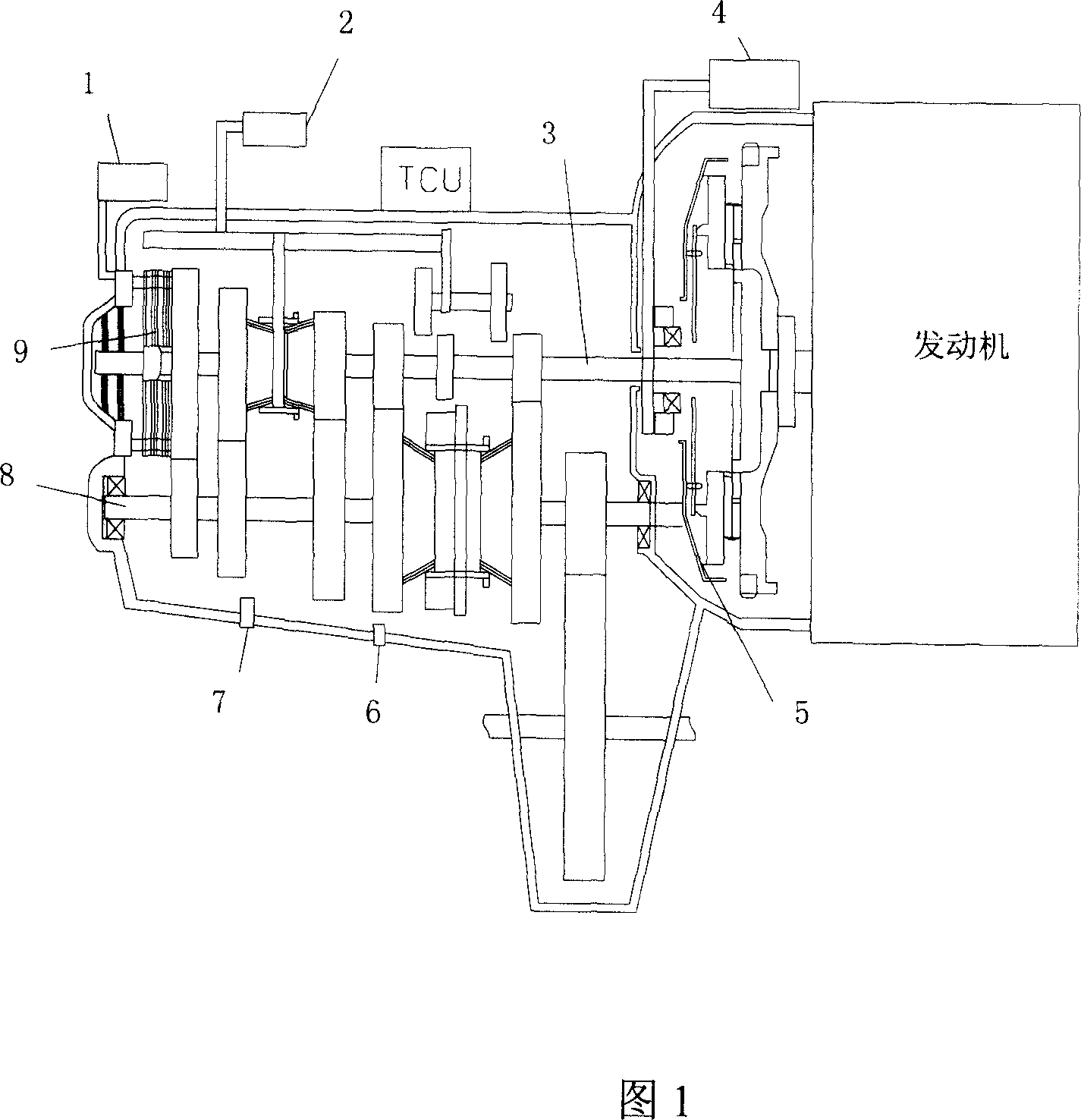

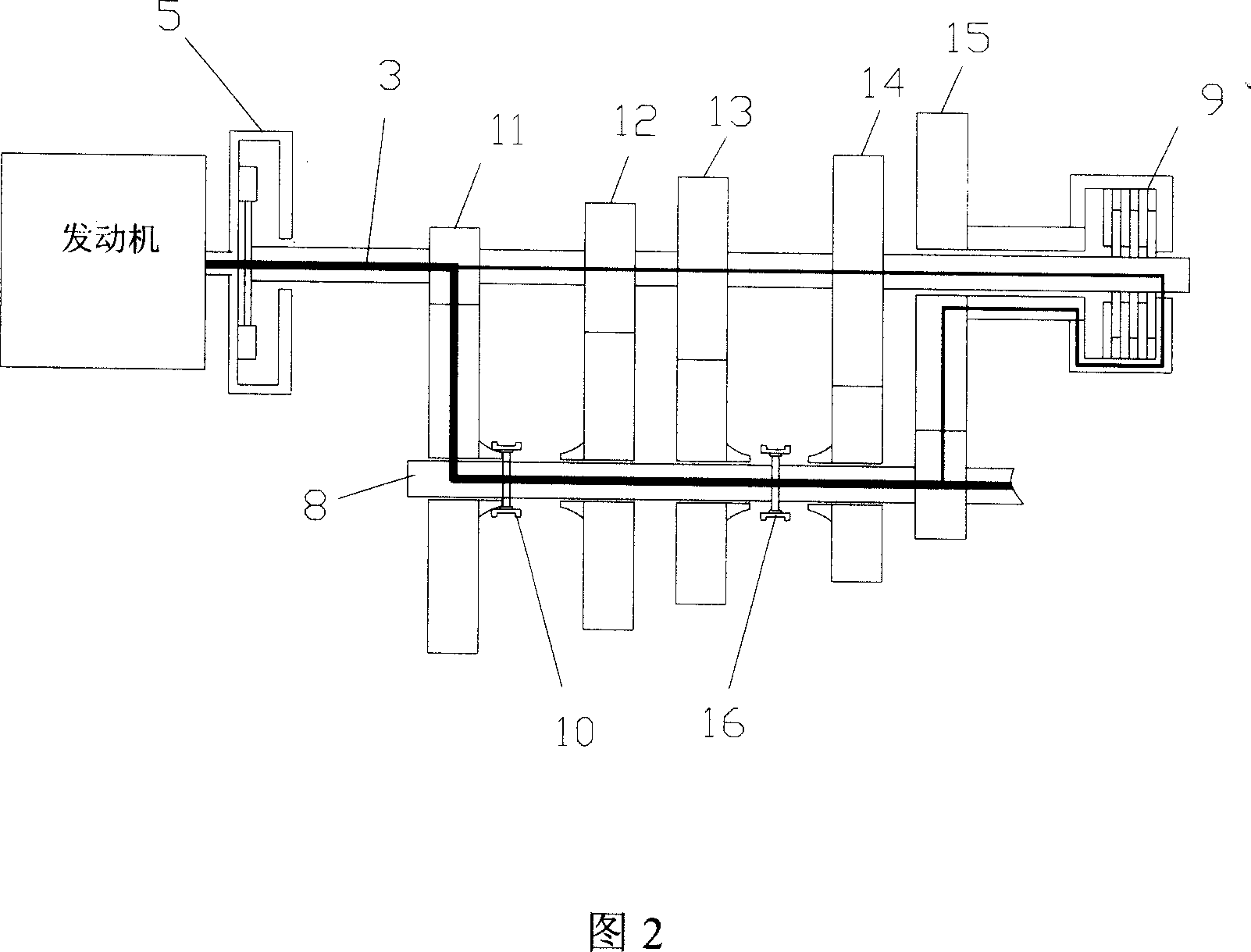

Mechanical type automatic transmission

InactiveCN101078436AImprove powerImprove stabilityGearing controlClutch controlAutomatic transmission

The invention relates to an AMT transmission with assisted clutch, comprising manual gearbox, shift control mechanism, starting clutch and the control mechanism, speed sensor of inputting shaft, speed sensor of outputting shaft, shifting position sensor and control cell TCU. It is characterized in that assisted clutch and the control mechanism are set on the inputting shaft and the assisted clutch combines with high-shift gear. By the invention the problem that in shifting process the power of engine can not be transferred to wheels so that power is off is solved. There is no distinct deceleration in shifting and shifting comfort is improved. Good power property and shifting stability of vehicles are guaranteed while oil economy is improved and oil consumption in shifting is decreased.

Owner:BYD CO LTD

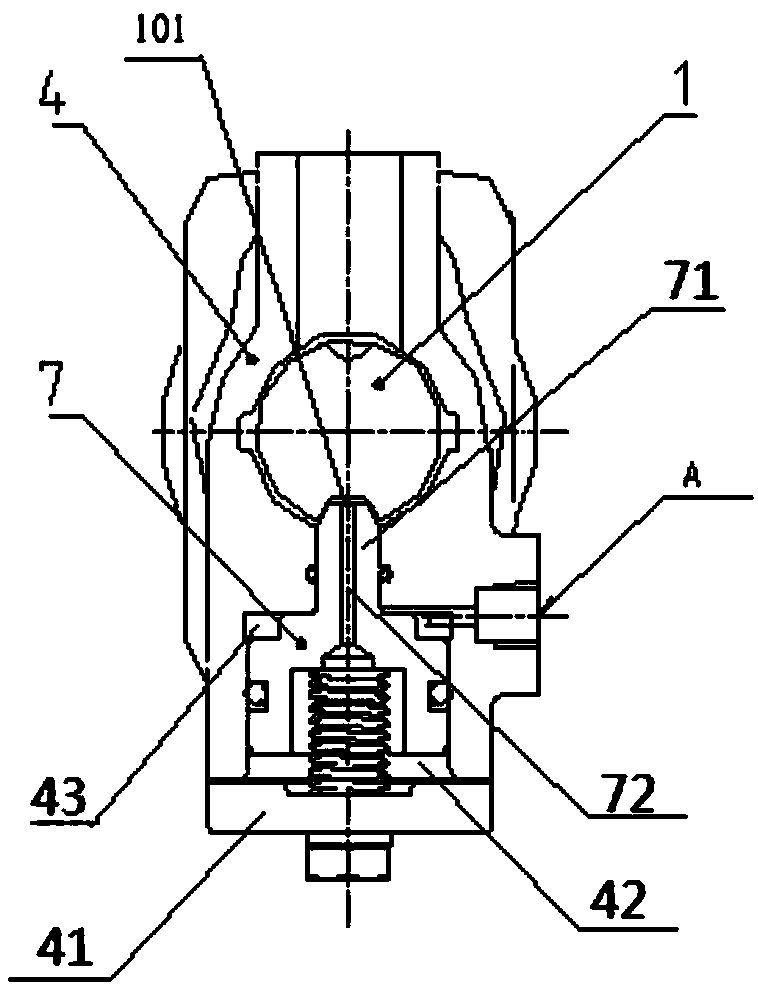

Servo-assisted device for motor vehicle switching gearbox

ActiveCN101896742AReduce release forceThe stop function is realizedGearing controlJoystickControl theory

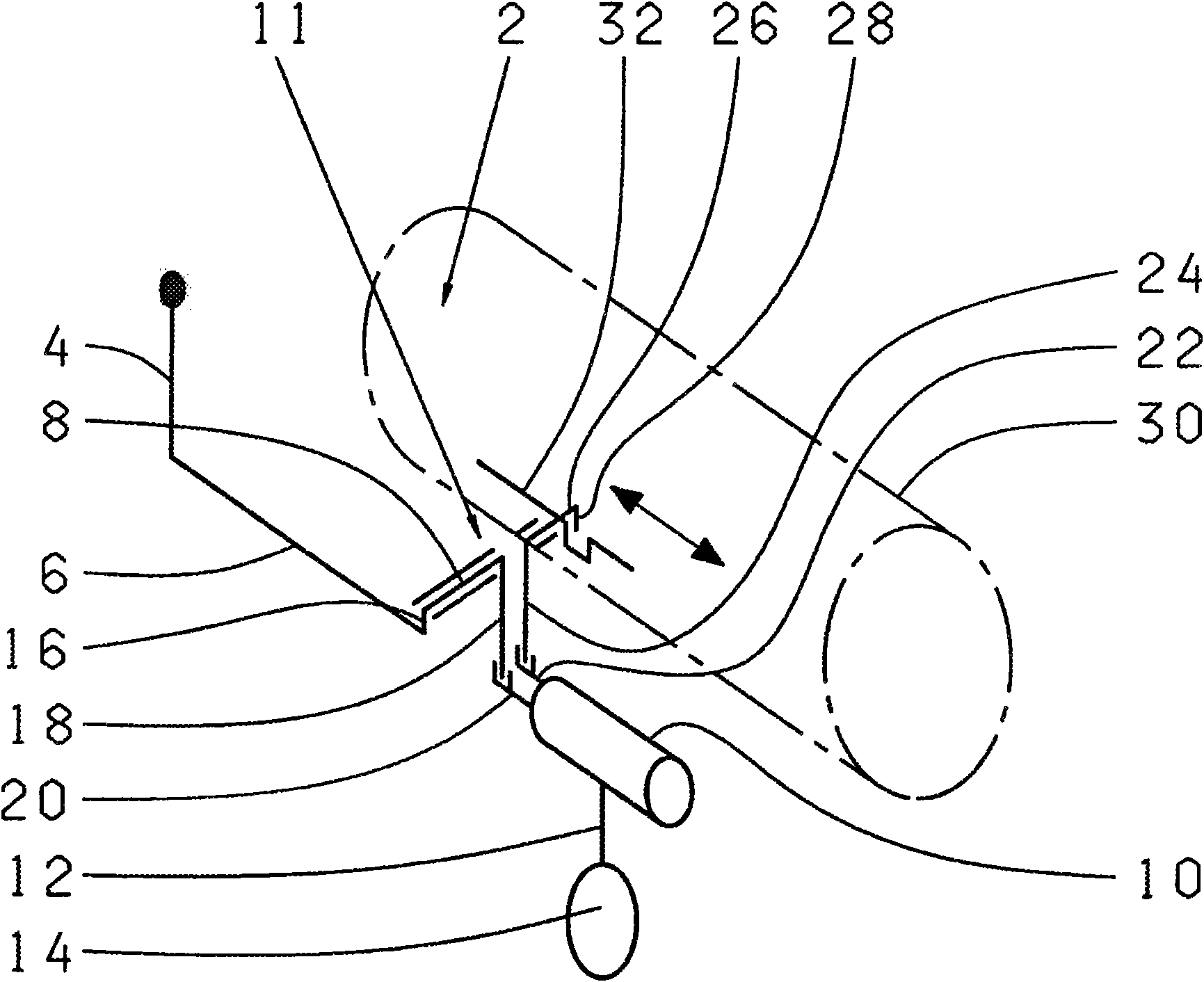

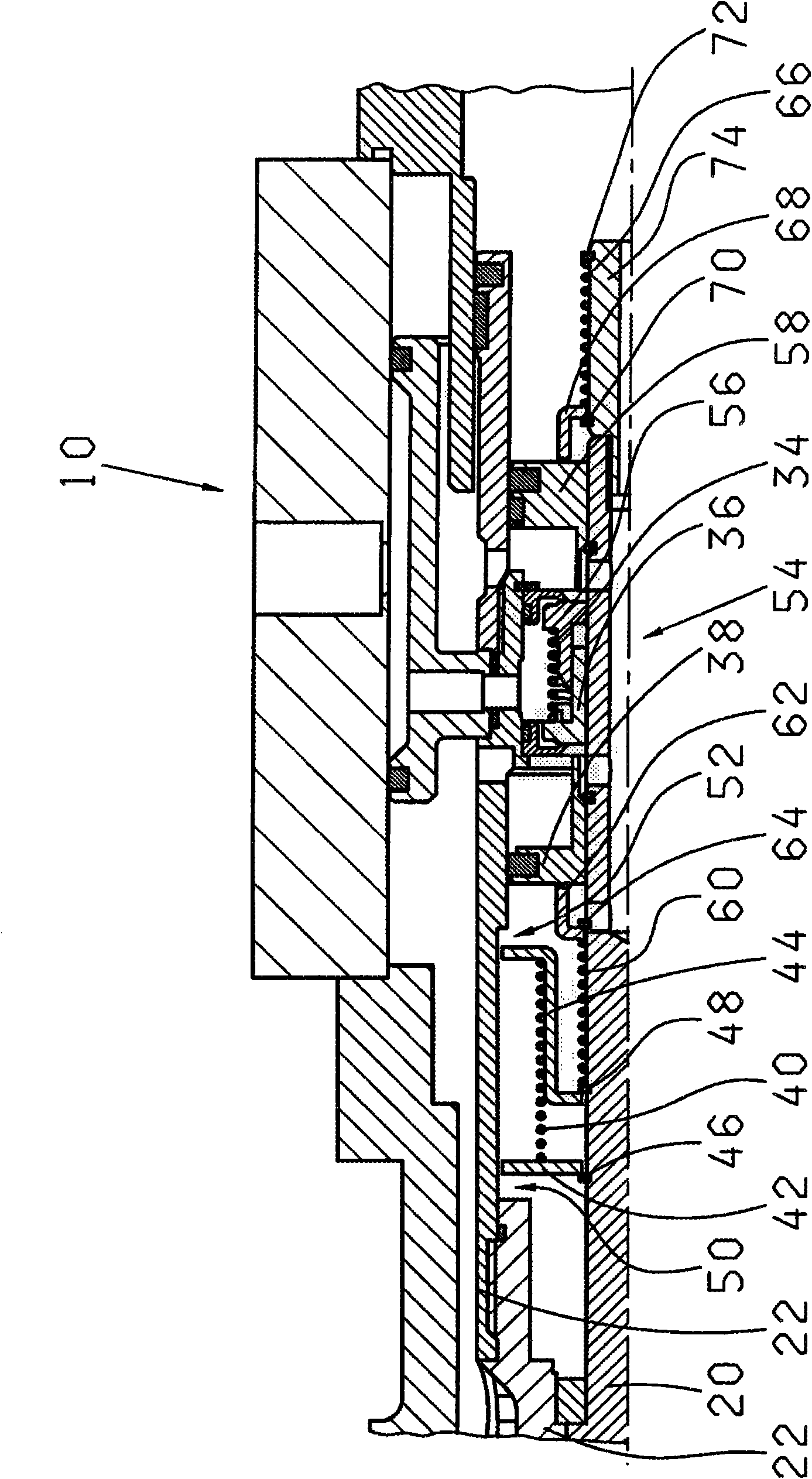

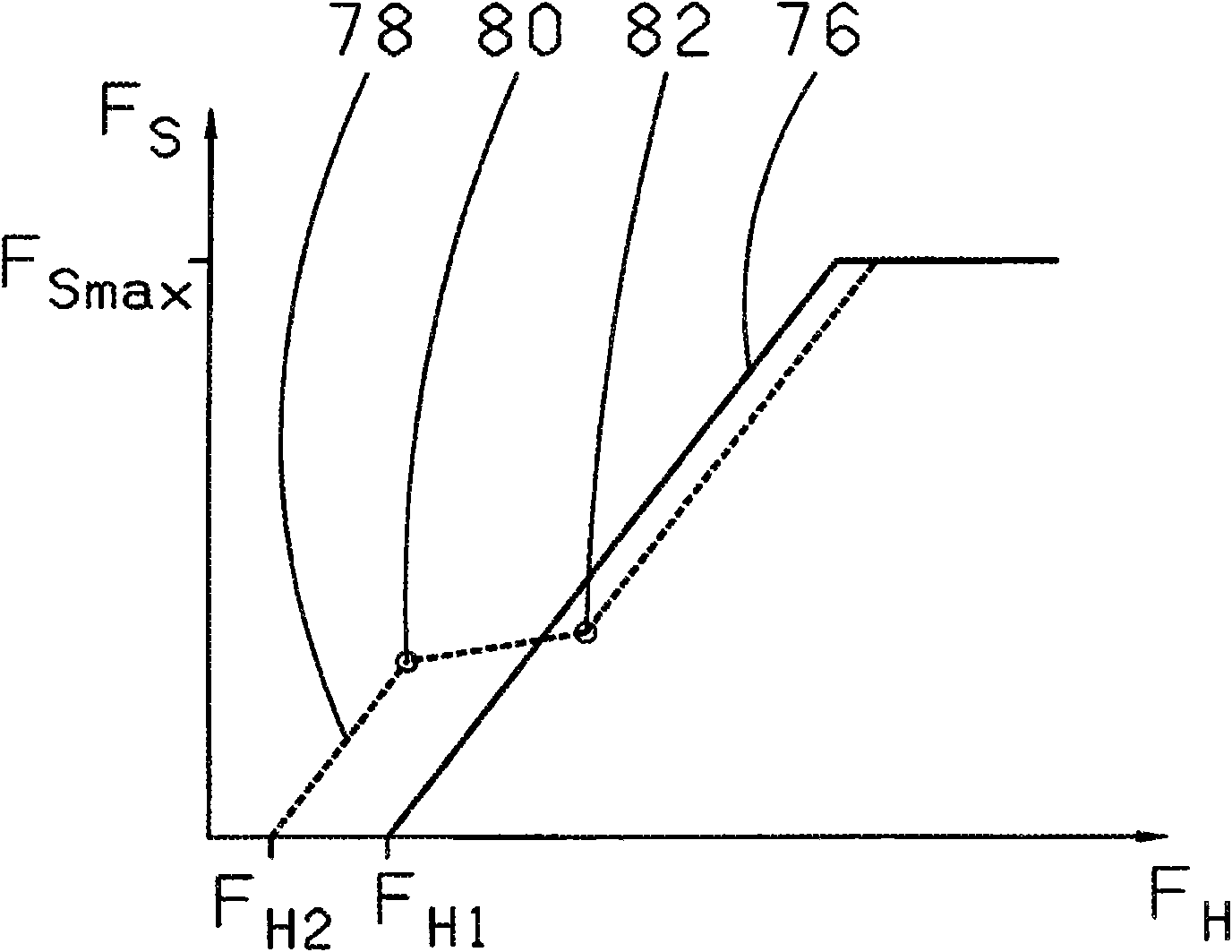

The invention relates to a servo-assisted device (10) for a switching arrangement (11) on a motor vehicle gearbox, comprising a control rod (20), on which a manual switching force for assistance acts, a piston rod (22) and at least one spring element (40), arranged on the control rod (20) and radially within the piston rod (22). According to the invention, the spring element (40) is arranged on the control rod (20) such that in one or both operating directions of the control rod (20) a play (50, 52) is provided between the spring element (40) and the piston rod (22).

Owner:ZF FRIEDRICHSHAFEN AG

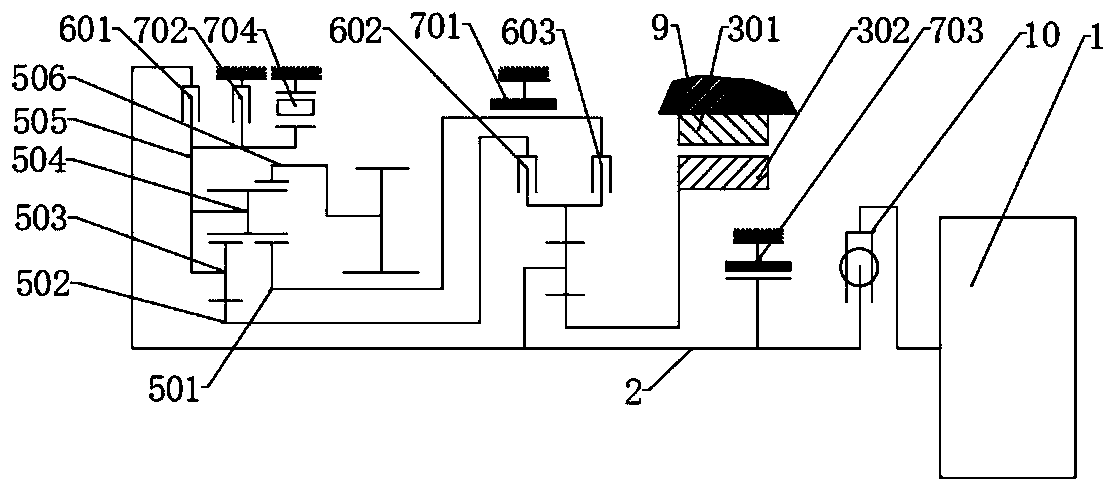

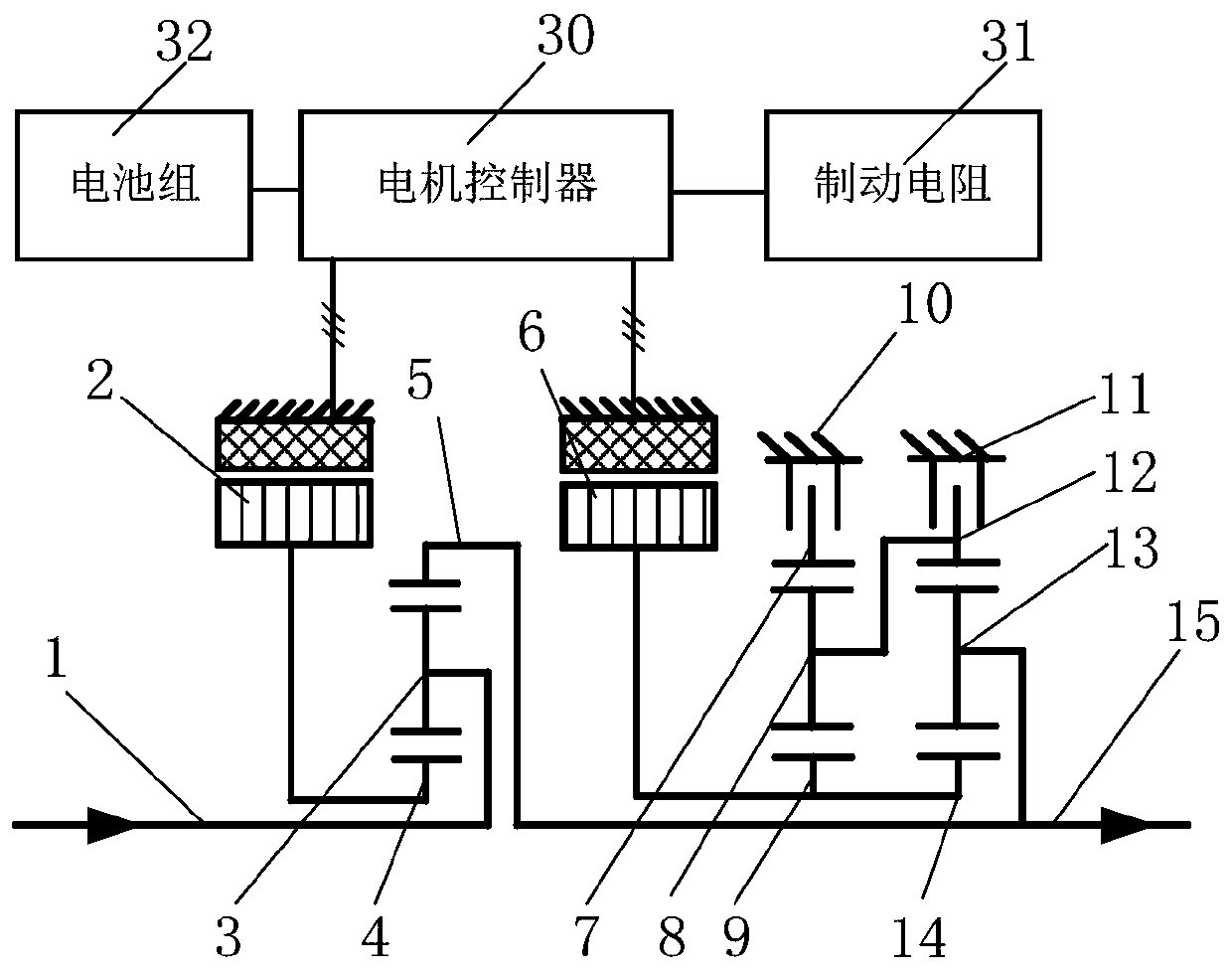

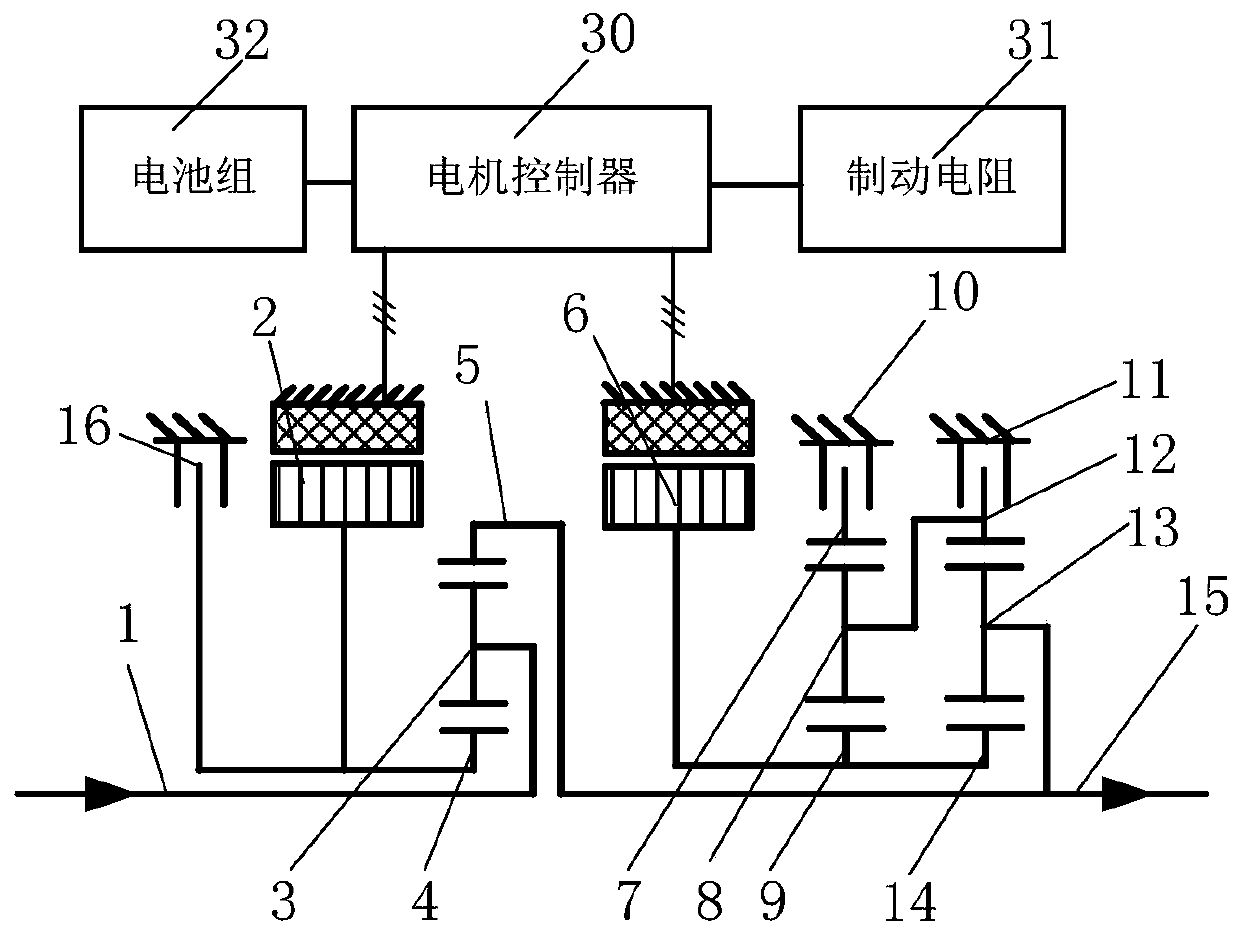

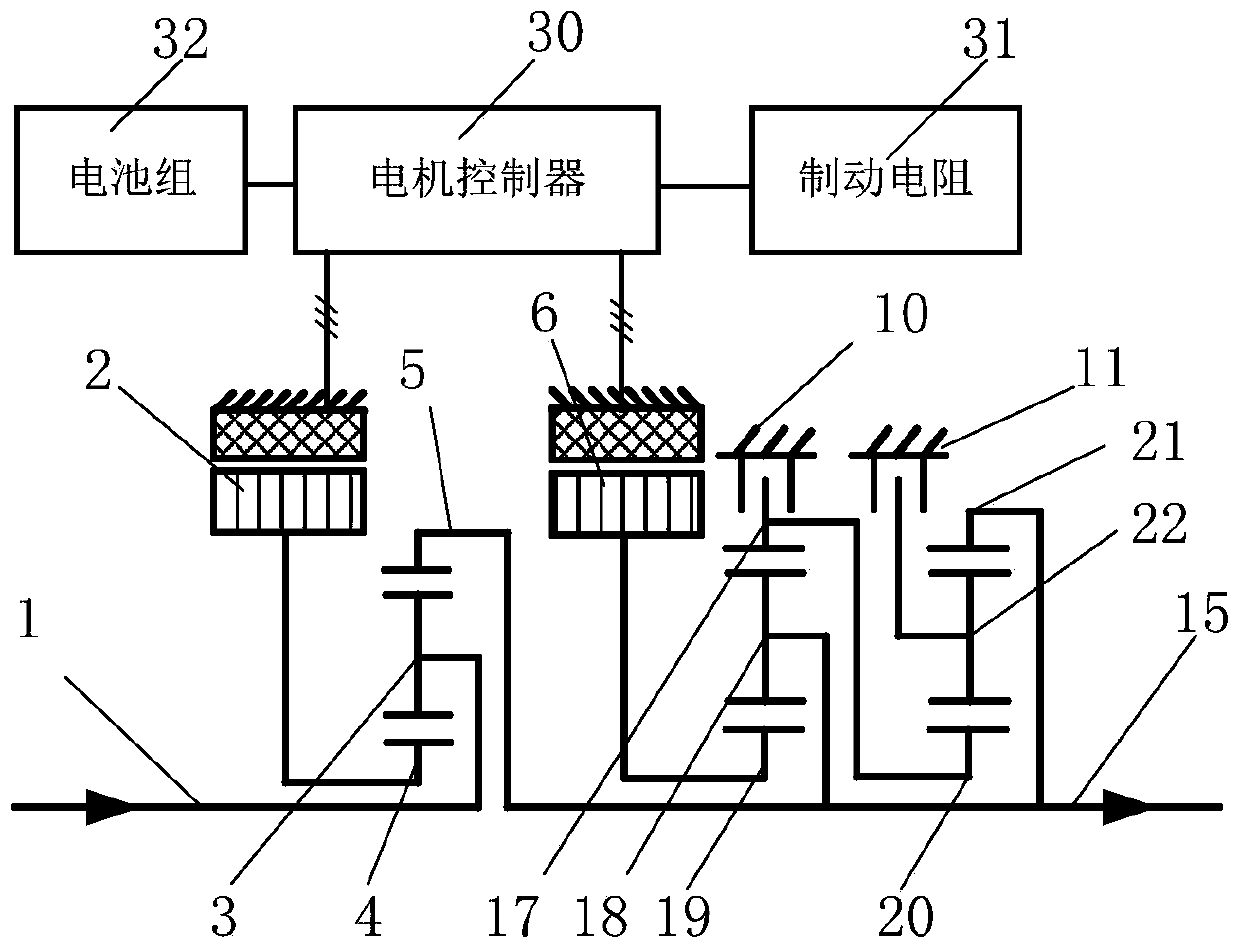

Commercial vehicle hybrid power transmission device with retarding function

ActiveCN110039989AEnsure safetyUninterrupted powerElectrodynamic brake systemsGas pressure propulsion mountingElectrical resistance and conductanceEnergy recovery

The invention belongs to the technical field of hybrid electric vehicles, and particularly relates to a hybrid power transmission device. A commercial vehicle hybrid power transmission device with a retarding function comprises a battery pack, a motor controller, a brake resistor, a first motor, a second motor, brakes and a planetary sub-confluence mechanism, wherein the first motor, the second motor, the brakes and the planetary sub-confluence mechanism are coaxially arranged. The planetary sub-confluence mechanism includes a power dividing planetary row, a first deceleration planetary row and a second deceleration planetary row. The brakes comprise a first brake and a second brake. The power dividing planetary row is connected with an input shaft, a rotor of the first motor and an outputshaft, and the first deceleration planetary row and the second deceleration planetary row are both connected to a rotor of the second motor and the output shaft. The first brake and the second brakeand the first deceleration planetary row and the second deceleration planetary row constitute a two-speed retarding mechanism. The commercial vehicle hybrid power transmission device utilizes the motors to realize braking energy recovery, the brake resistor is arranged to ensure that the braking power of the motors is consumed when the battery SOC is high, and the retarding brake function is stillachieved during long-time brake.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Automobile transmission and control method thereof

PendingCN108343714AReduce loadReduce volumeControlled membersMechanical actuated clutchesDrive shaftEngineering

The invention discloses a multi-gear double-clutch transmission system. The multi-gear double-clutch transmission system comprises double clutches and a transmission; two output ends of the double clutches are correspondingly used for inputting power to an odd-number-gear transmission chain and an even-number-gear transmission chain of the transmission; the odd-number-gear transmission chain and the even-number-gear transmission chain can be locked at a suitable time so as to be integrated as a whole; the transmission comprises driving shafts and driven shafts; and gear speed-change transmission structures are correspondingly formed between the driving shafts and between the driven shafts both. The power system disclosed by the invention is relatively high in compactness and relatively shot in longitudinal length and has a relatively large number of gears.

Owner:才亚民 +1

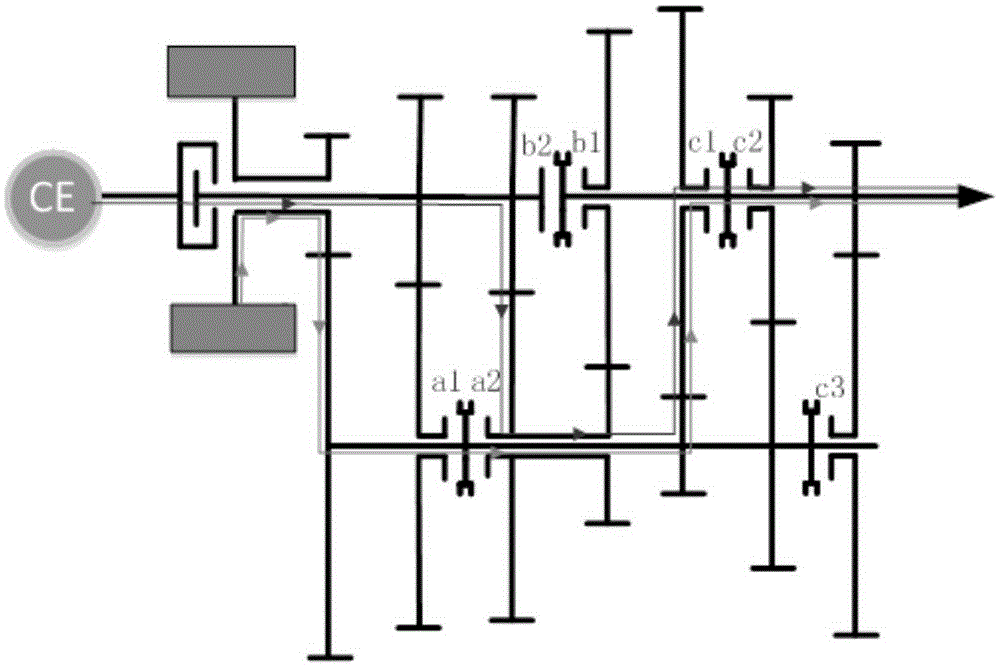

Commercial Vehicle Parallel Hybrid Multi-speed Transmission

ActiveCN105196857BRealize functionImplement power shiftHybrid vehiclesGas pressure propulsion mountingGear wheelElectric machine

The invention belongs to the technical field of hybrid-power commercial vehicles, and particularly relates to a multi-gear gearbox. According to the technical scheme of a parallel-type hybrid-power multi-gear gearbox of a commercial vehicle, the power of an engine is input to an engine input shaft after passing through a clutch; a motor module comprises a motor and a drive gear, and the power of the motor is output through the drive gear and a motor input shaft; a gearbox primary box module consists of a multi-degree-of-freedom stationary-shaft gear mechanism, can be used for coupling the power of the engine and the motor, and can be used for realizing the gears of five matched engines and the gears of two matched motors; a gearbox auxiliary box module can be used for realizing two gears of a high gear and a lower gear, and can be used for realizing the gears of ten matched engines and the gears of four matched motors when jointly working with the gearbox primary box input module; the parallel-type hybrid-power multi-gear gearbox of the commercial vehicle is characterized in that the power of the motor and the engine is coupled by adopting the multi-degree-of-freedom gear mechanism, and the functions of hybrid power and power gear shifting are realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

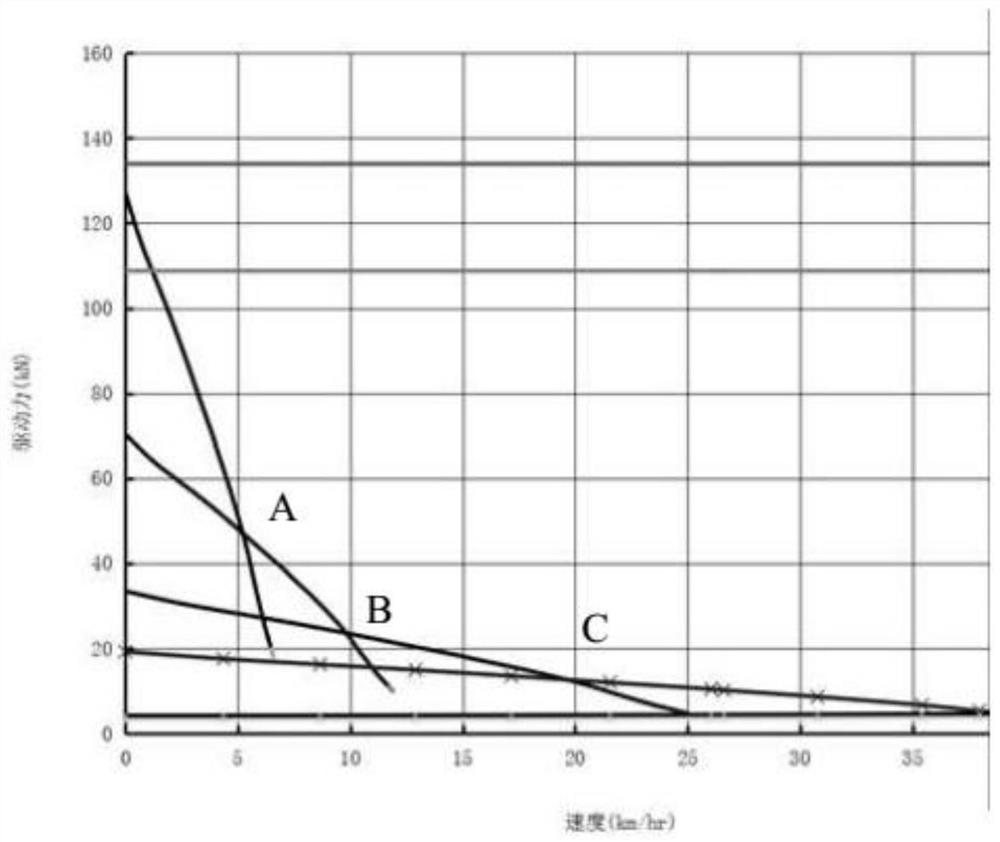

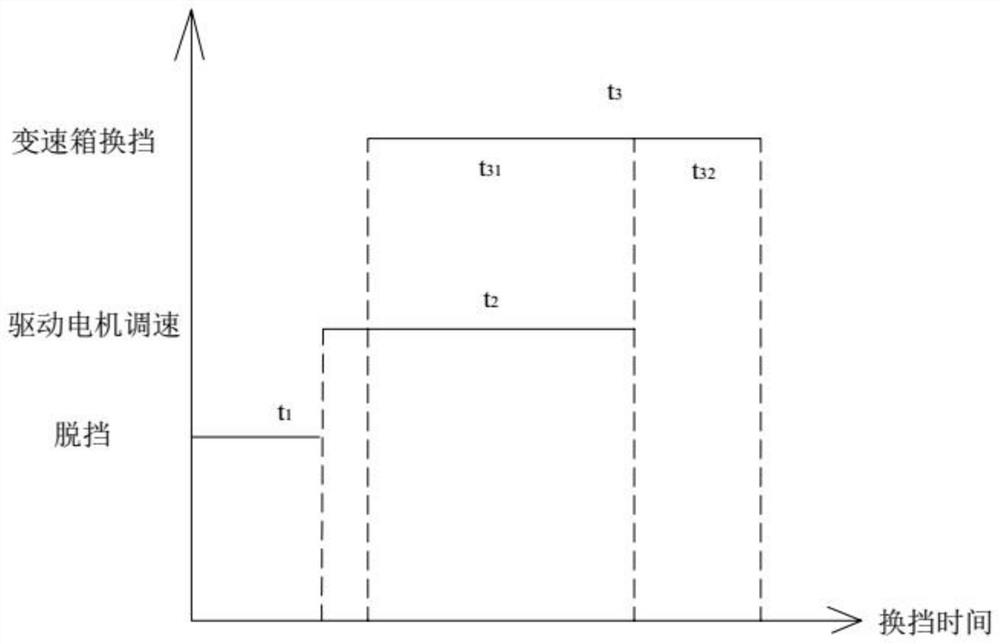

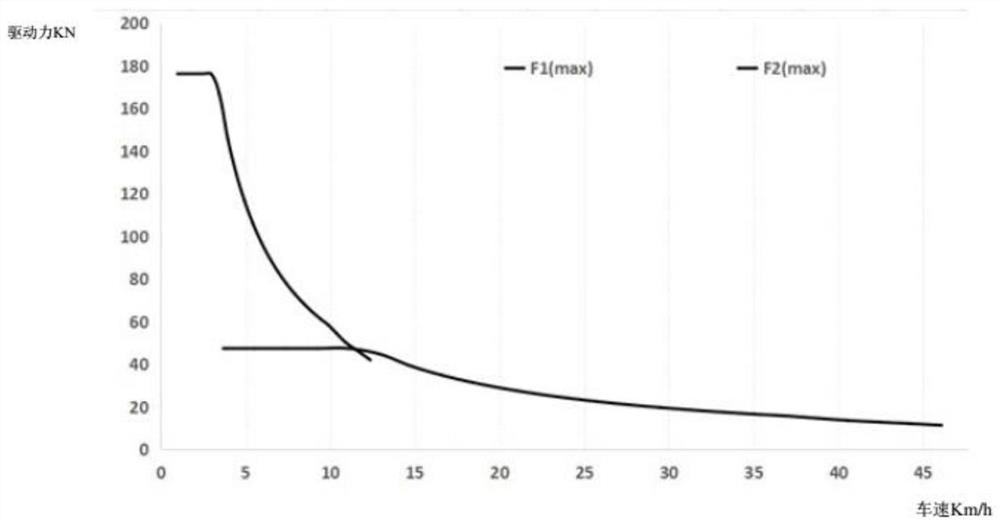

Gear shifting control method, gear shifting control system and loading machine

ActiveCN113898732ANo shift shockReduce energy conversionGearing controlElectric energy managementControl systemElectric machinery

The invention belongs to the technical field of engineering mechanisms, and discloses a gear shifting control method, a gear shifting control system and a loading machine. The gear shifting control method is used for controlling the gear shifting control system and comprises the following steps that a current gear of a gearbox is obtained, and whether gear shifting needs to be conducted on the gearbox or not is judged; and if the gearbox needs to be subjected to gear shifting, a gear shifting instruction is executed, the gearbox is controlled to be disengaged from the current gear, then the current vehicle speed of a whole vehicle is obtained, the input rotating speed of a driving motor is controlled to be adjusted to the target gear rotating speed corresponding to the current vehicle speed of the whole vehicle for speed regulation of the driving motor, and when the driving motor conducts speed regulation, gear combination of a clutch is controlled. According to the gear shifting control method, according to the principle that the current vehicle speed of the whole vehicle is kept unchanged, gear combination is carried out on the gearbox, gear combination is carried out under the condition that the vehicle speed of the whole vehicle is kept unchanged, and therefore no gear shifting impact exists in the walking shovel loading operation process of the gearbox.

Owner:柳工柳州传动件有限公司 +1

Two-gear mechanical vehicle transmission

The invention provides a two-gear mechanical vehicle transmission. A gearbox input shaft is coaxially connected with a motor; the effect of a direct driving large motor achieved through matching witha small motor is achieved by using the speed adjusting and torque increasing characteristics of the transmission; and meanwhile, two gears can be selected, so that the motor works in an efficient areamore time, and the comprehensive electric consumption is lower. The two-gear mechanical vehicle transmission comprises a first shell and a second shell; the second shell is covered at the back end ofthe first shell; the first shell and the second shell are combined to form a mounting cavity; a first shaft projected outwards is arranged on the front end wall of the first shell; an inner end of the first shaft is inserted in a front end area of the mounting cavity; an outward projection end of the first shaft is externally connected with a driving motor; a one-shaft normally engaged gear sleeves the outer ring surface of the inner end of the first shaft; an intermediate shaft is arranged between the front end wall and the back end wall of the mounting cavity; the intermediate shaft is arranged right under the first shaft in parallel; and an intermediate shaft normally engaged gear, an intermediate second gear and an intermediate first gear sleeve the outer ring surface of the intermediate shaft in from front to back.

Owner:SUZHOU LVKON TRANSMISSION TECH CO LTD

Control method and system for shockless shifting of electric drive mechanical transmission without synchronizer

The invention relates to an impact-free gear shift control method and system for an electrically driven mechanical transmission without a synchronizer. The electrically driven mechanical transmission is provided with no synchronizer; a drive motor and the electrically driven mechanical transmission are directly coupled, and a clutch between the drive motor and the electrically driven mechanical transmission is omitted. An automobile controller determines the target gear and sends a gear shift instruction to a system coordinating controller; the system coordinating controller coordinates the working sequence and working mode of a dual target tracking controller and a rule-based controller, so that the drive motor and the electrically driven mechanical transmission are in coordinated fit to achieve gear shift; and by accurately controlling a motor rotor, a target joint gear ring accurately tracks rotation of a joint sleeve in the joint process, the requirements for zero rotation speed difference and zero rotation corner difference are met, and impact-free gear shift control is achieved. The method and system can eliminate collision between the joint sleeve and the joint gear ring in the joint process, then gear shift impact is restrained, and the power failure duration is shortened.

Owner:TSINGHUA UNIV

Integrated manual transmission control assembly

PendingCN109372980AQuick unlockImprove reliabilityGearing controlLocking mechanismManual transmission

The invention belongs to the technical field of gearboxes, in particular relates to an integrated manual transmission control assembly. The invention provides the integrated manual transmission control assembly which is used for transmission operation to solve the problems that a gear shifting booster is long in distance from a gear shifting head with an existing transmission control assembly, theoverall rigidity of the operation and the gear shifting performance consistency of the transmission are influenced, and after the gear shifting booster is added, the gear shifting force is light, theclutch is not trampled out, the synchronizer is damaged can be caused. The integrated manual transmission control assembly comprises a control shell, an inner shaft, an outer shaft and a gear shifting booster, wherein the control shell is provided with a control window. The inner shaft is arranged in the control shell in a penetrating mode. The outer shaft is arranged between the inner shaft andthe control shell in a sleeved mode. The control window is arranged close to one end of the gear shifting booster. An interlocking groove is arranged in one end, far away from the gear shifting booster, of the inner shaft. A locking mechanism is arranged at the position, corresponding to the interlocking groove, of the control shell.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com