Multi-axle multi-wheel vehicle hybrid electric driving system

A hybrid electric drive and wheel-side drive technology, applied in the field of power transmission, can solve the problems of wheel loss of power, complicated mechanical structure and control, and inability to realize flexible distribution, so as to achieve flexible power distribution, facilitate modular expansion, and improve dynamic cycle. The effect of trace ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

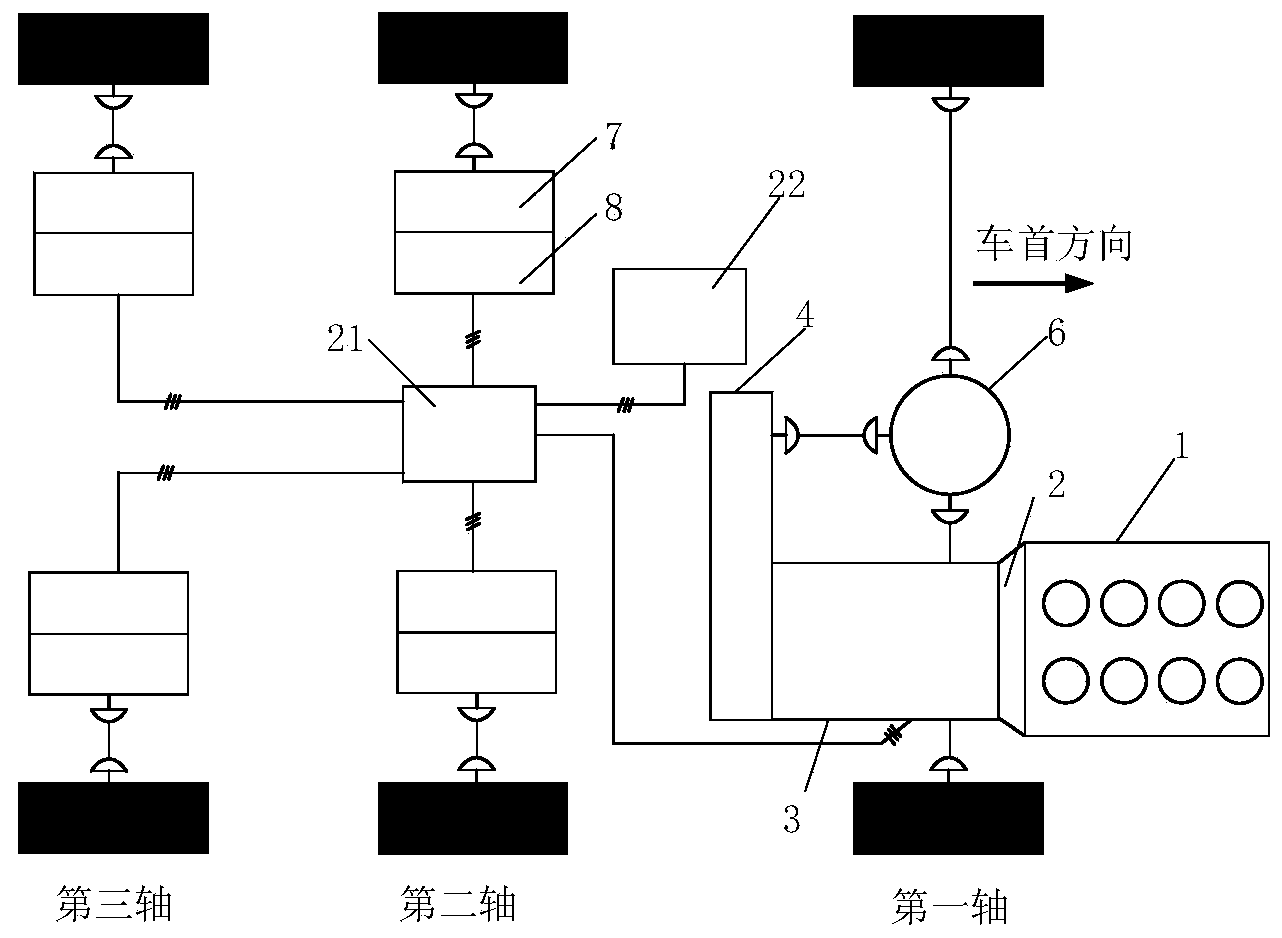

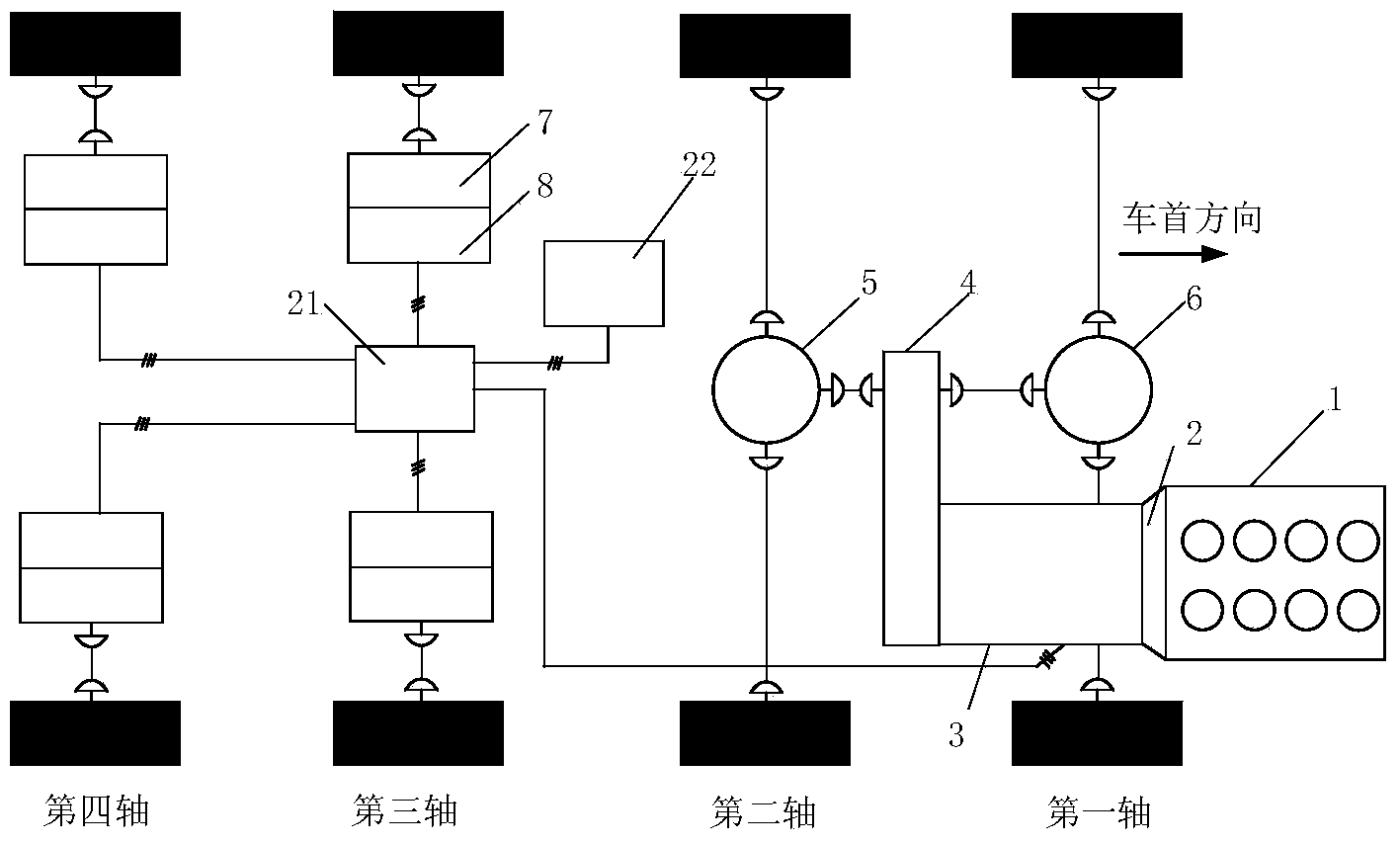

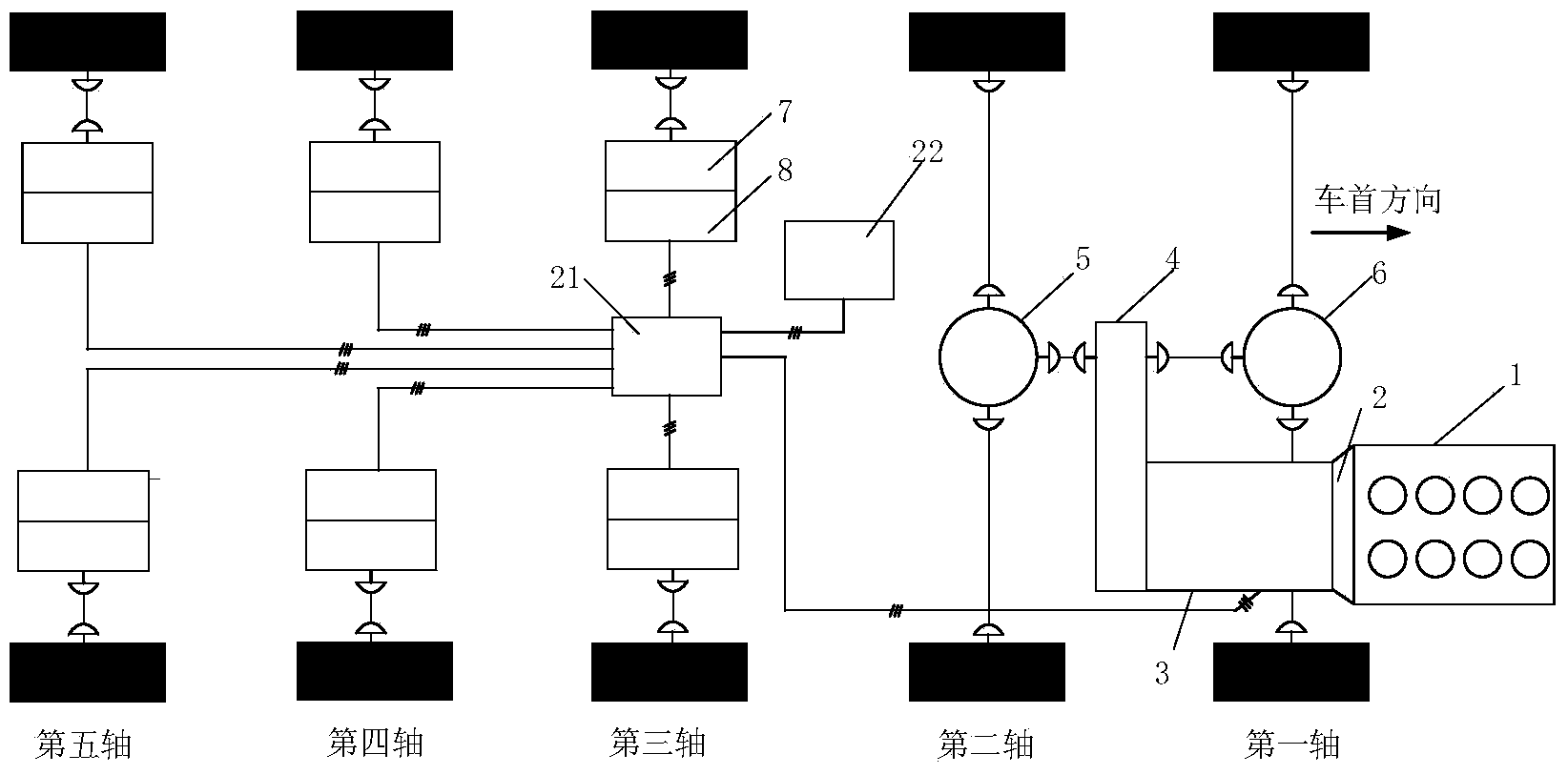

[0024] Hybrid electric drive system for multi-axle wheeled vehicles, which includes a mechanical drive section and an electric drive section;

[0025] In the mechanical drive section: the engine 1 and the gearbox 3 are in front, located on the right side of the front of the car, the engine 1 and the gearbox 3 are arranged longitudinally, and there is an elastic coupling 2 between them; the gearbox 3 is connected to the transfer case 4, and the transfer is Box 4 splits the power and distributes the power to the shaft through the drive axle;

[0026] In the electric drive section: the wheel drive motor 8 is combined with the second gear transmission 7 to drive the shaft, the wheel drive motor 8 is connected to the power management system 21, and the power management system 21 is connected to the power battery pack 22 and the transmission 3 respectively , The gearbox 3 provides power to the power management system 21. The power management system 21 transmits and controls the power of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com