Patents

Literature

307results about How to "Shorten shift time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-clutch non-synchronizer AMT gear changing control method of short-distance blade electric vehicle

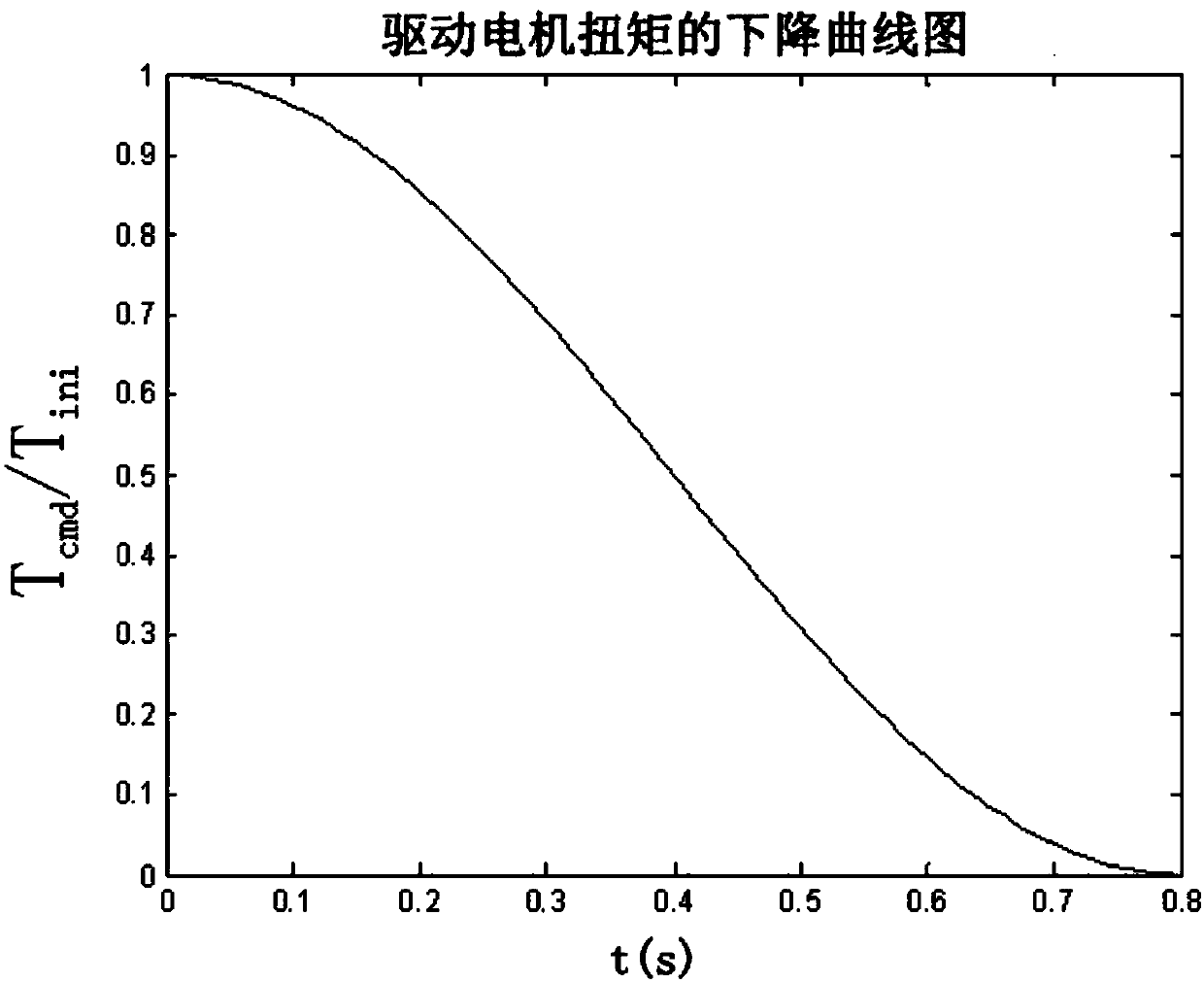

The invention discloses a non-clutch non-synchronizer AMT gear changing control method of a short-distance blade electric vehicle, and relates to a non-clutch non-synchronizer AMT gear changing control method of a blade electric vehicle. According to the control method, when the vehicle needs to change gears during traveling process, a direct-current brushless driving motor is braked by matching two forms of electric braking and PI control, the time needed in speed reduction of the driving motor is shortened, on this basis, and a gear changing motor similarly adopts electric braking, so that the motion of a gear changing execution mechanism and the speed regulation of the driving motor can be conducted simultaneously, the position control error of a shifting fork is less than 0.04mm, the fastest motion speed of the shifting fork can be guaranteed, the needed time is shortest, and the gear changing time is shortened. The gear changing time is basically the same as that in static state, smooth gear changing effect can be simultaneously guaranteed, the difference of rotating speed in gear engaging is less than 50r / min, and people basically cannot feel gear changing shock during gear changing. The gear changing speed is fast, the gear changing impact degree is low, and the dynamic performance of the electric vehicle can be improved.

Owner:HARBIN INST OF TECH AT WEIHAI

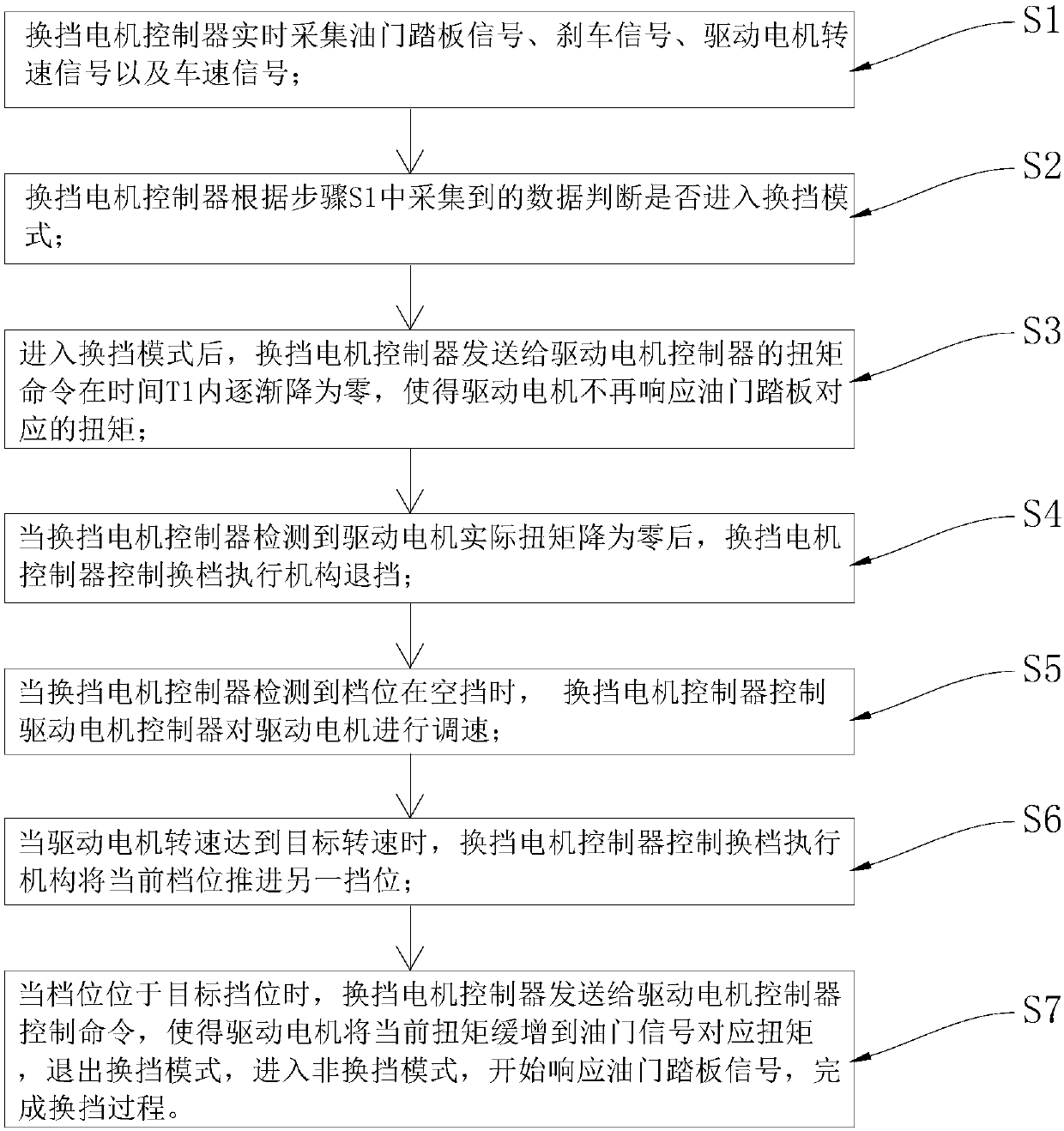

Automatic gear-shifting control method and system for two-gear transmission of electric vehicle

ActiveCN107606129AImprove climbing abilityImprove drivabilityGearing controlElectric machineControl system

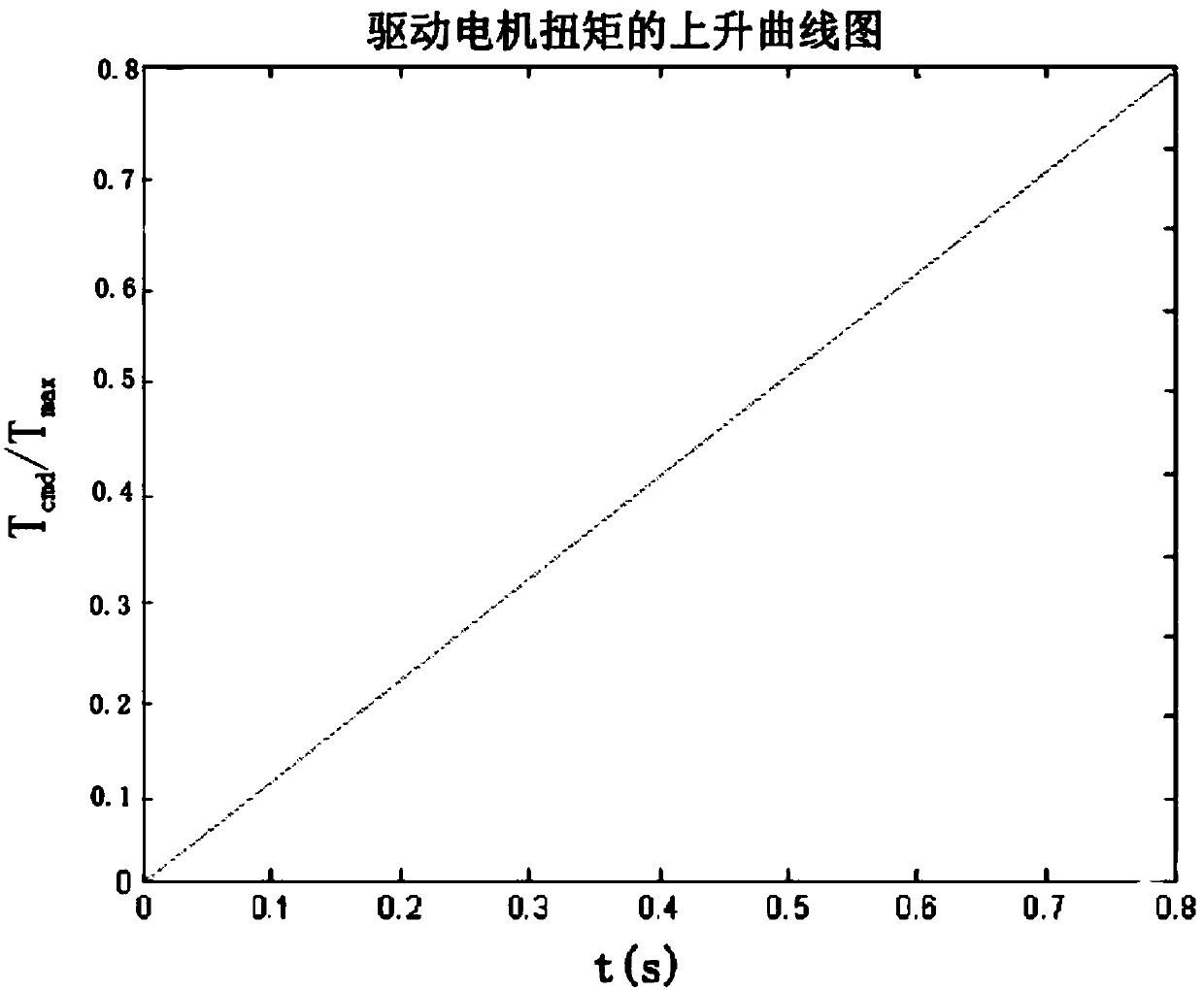

The invention discloses an automatic gear-shifting control method and system for a two-gear transmission of an electric vehicle, and belongs to the technical field of electric vehicle gear-shifting control. The automatic gear-shifting control method comprises the specific steps that whether the gear-shifting condition is met or not is judged, if the gear-shifting condition is met, the gear-shifting mode is conducted, and transmission control unit (TCU) replaces a vehicle controller to control a driving motor controller, so that torque of the driving motor is reduced to zero torque according toa certain curve; in the zero torque, the TCU controls a gear-shifting executing mechanism to shift a gear down to a neutral gear; in the neutral gear, control torque is determined through the TCU byutilizing a certain algorithm, so that the rotating speed of a driving motor is adjusted to the target speed; After the target speed is reached, the TCU controls the gear-shifting executing mechanismto shift gear; a non-gear-shifting mode is conducted, torque is slowly increased to the torque corresponding to an accelerator signal according to a certain curve; torque reducing and torque increasing are conducted according to the certain curve, and the speed is adjusted through the TCU by using a torque mode, so that the speed adjusting time is reduced, quick gear shifting is achieved, abruptness caused by power interruption during gear shifting can be effectively alleviated, and the driving feeling is improved.

Owner:济宁中科智能科技有限公司

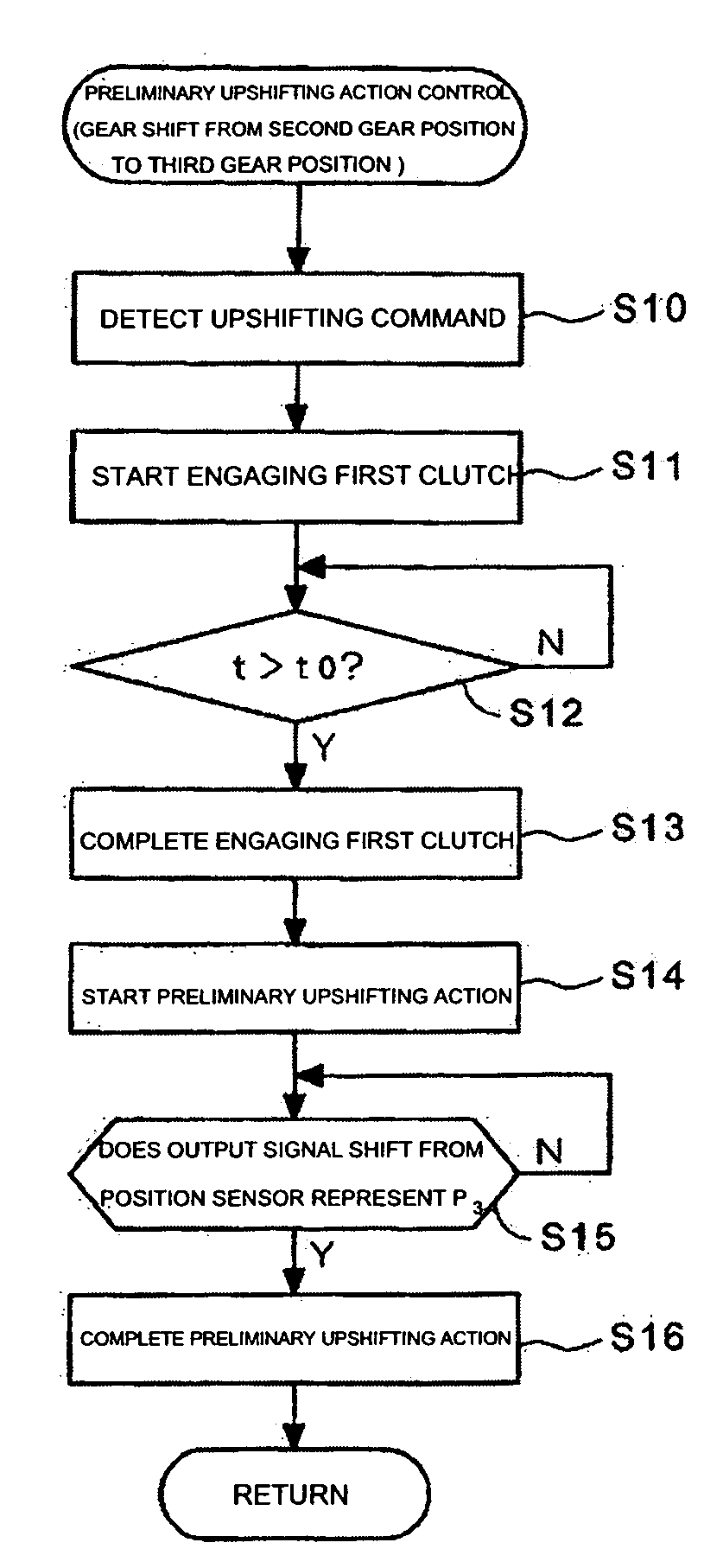

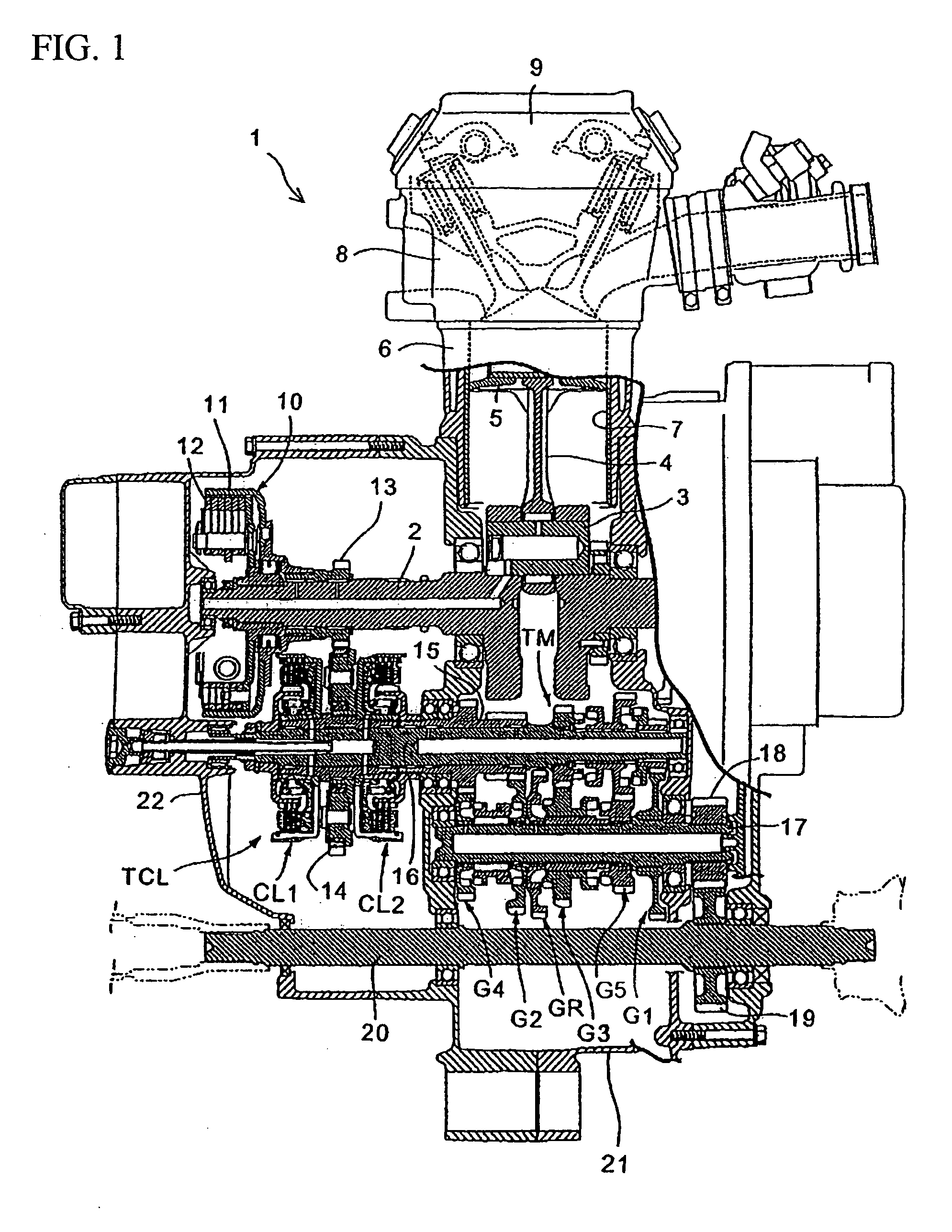

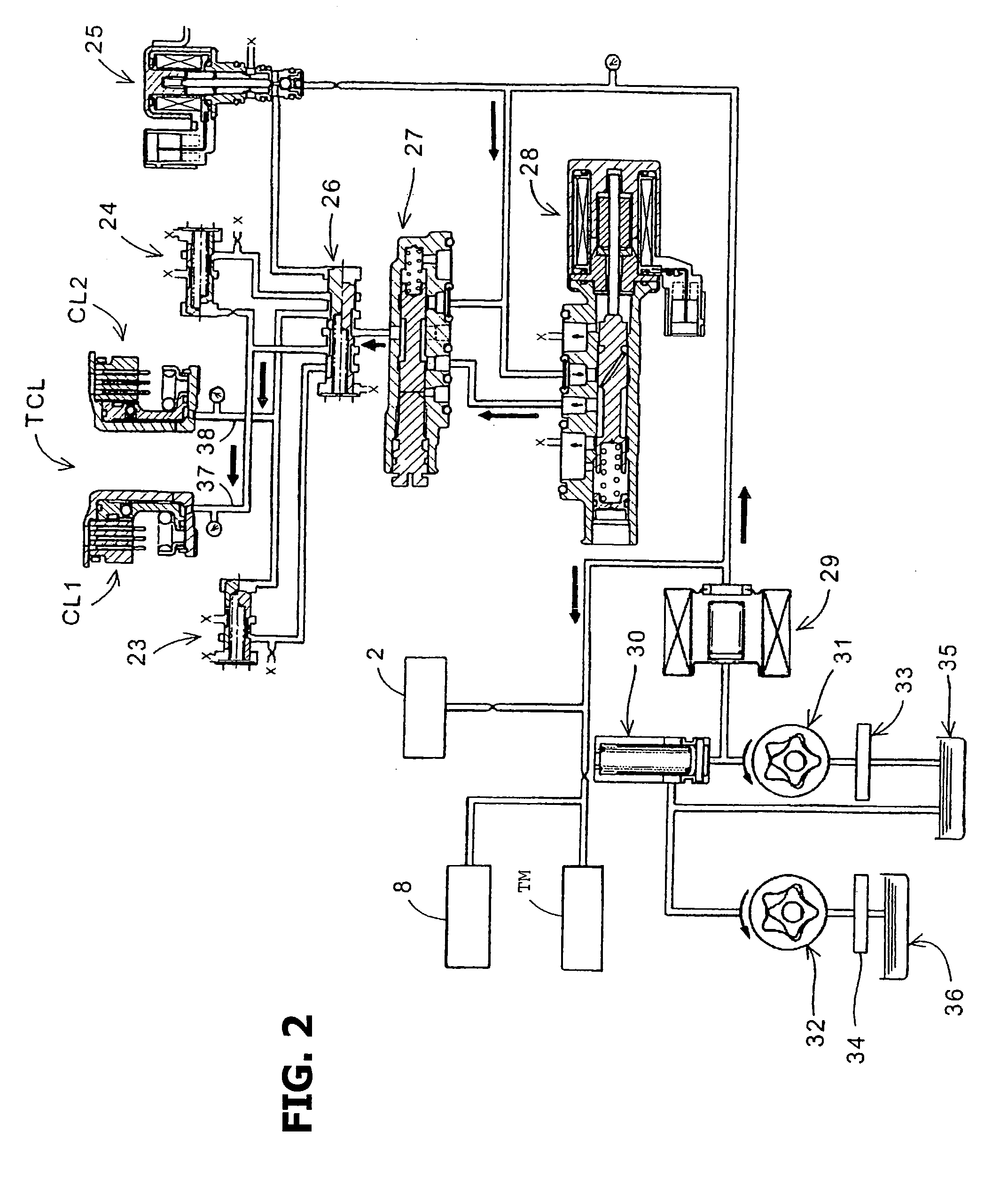

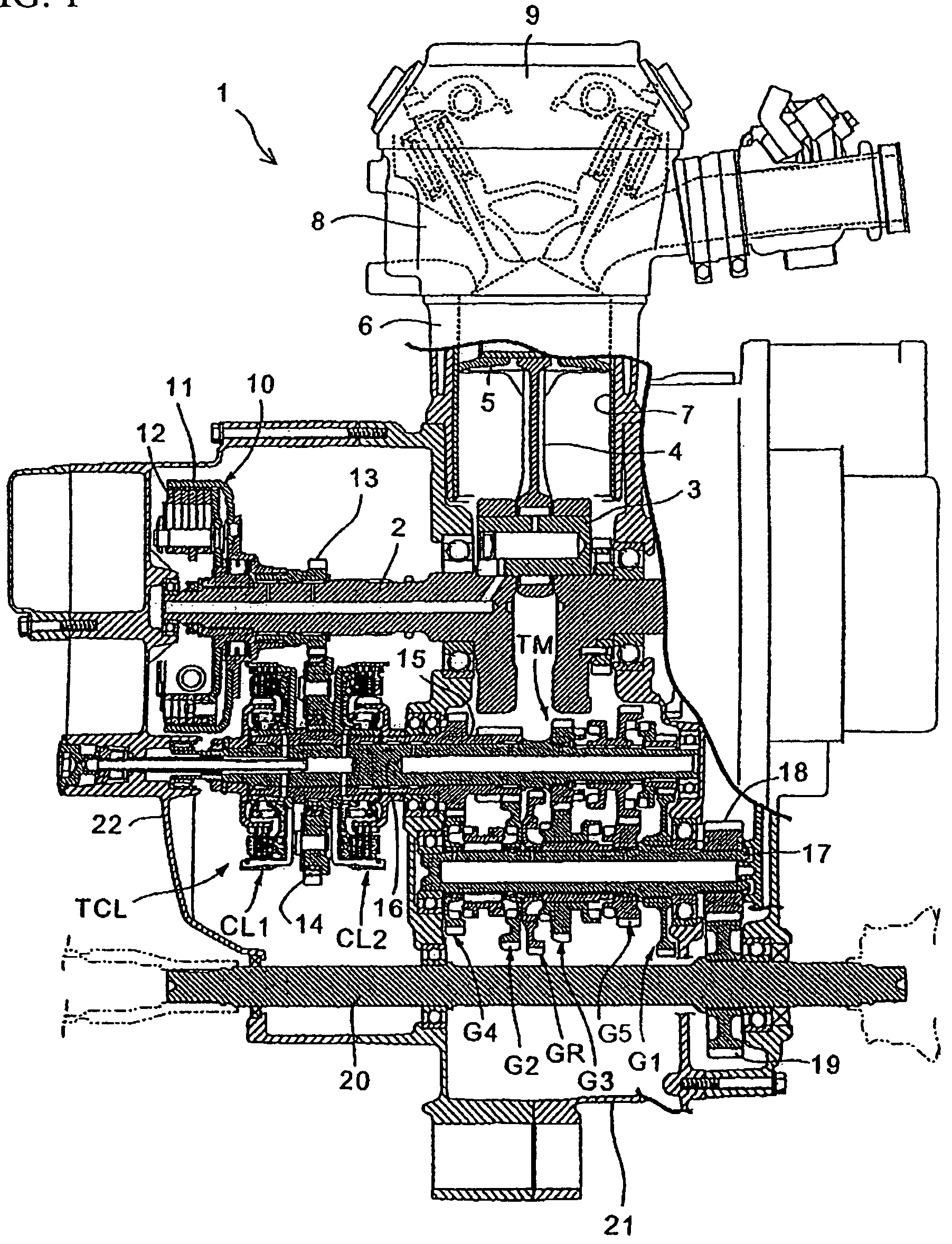

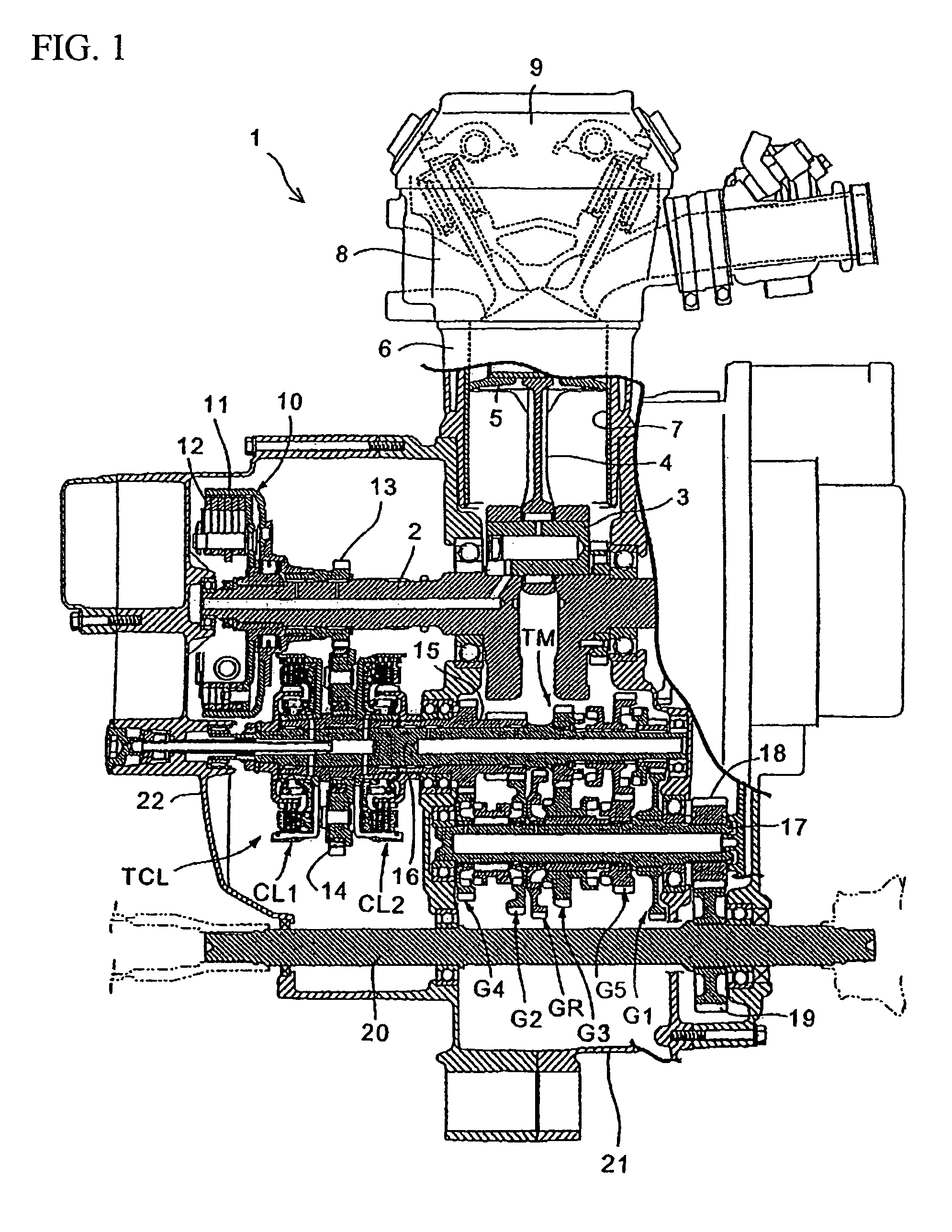

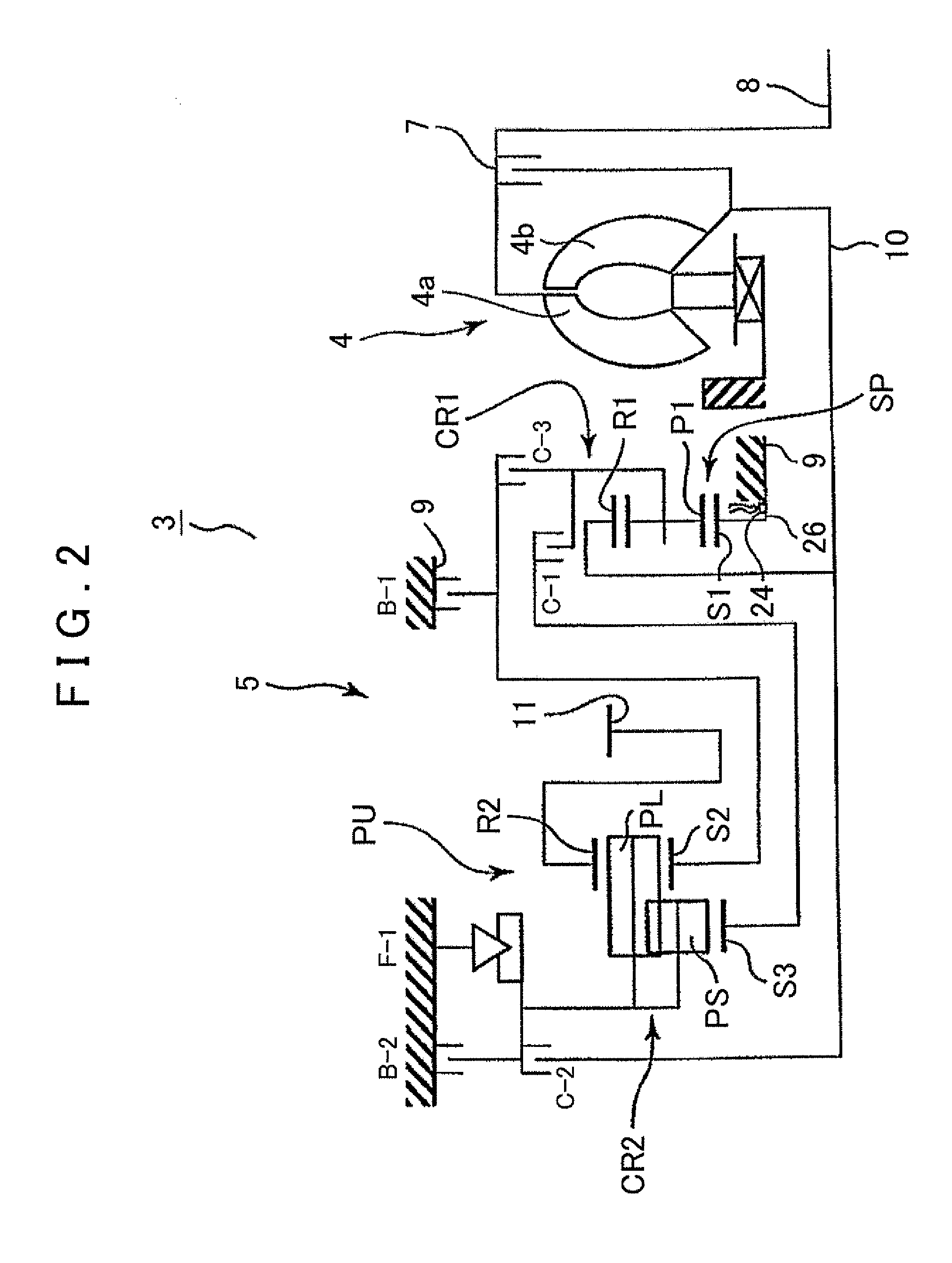

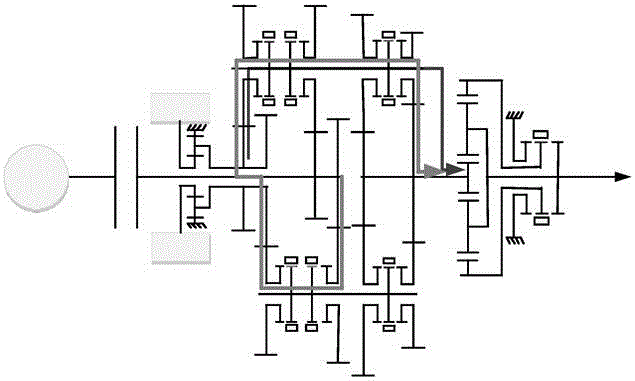

Automatic transmission assembly for a vehicle, and vehicle incorporating same

ActiveUS20080220936A1Reduce angular velocityShorten shift timeOff-road vehiclesToothed gearingsAutomatic transmissionEngineering

An automatic transmission assembly having a transmission unit including a plurality of gear pairs, a shift drum, a pair of clutches; and a controller. The controller performs a preliminary upshifting action in advance for angularly moving the shift drum depending on a next gear position in an upshifting direction while rotary drive power is being maintained at a given gear position, and when an upshifting command is output, the controller engages one of the clutches simultaneously with the command. When a downshifting command is output, the controller performs a preliminary downshifting action in advance based on the downshifting command. The partially neutral positions are provided between predetermined angular positions on the shift drum for temporarily reducing the angular speed of the shift drum when the shift drum is being angularly rotated.

Owner:HONDA MOTOR CO LTD

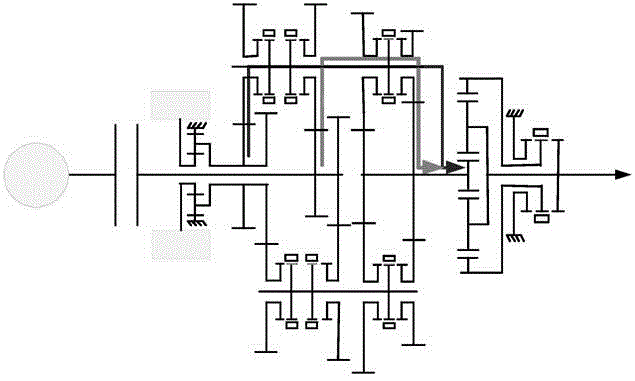

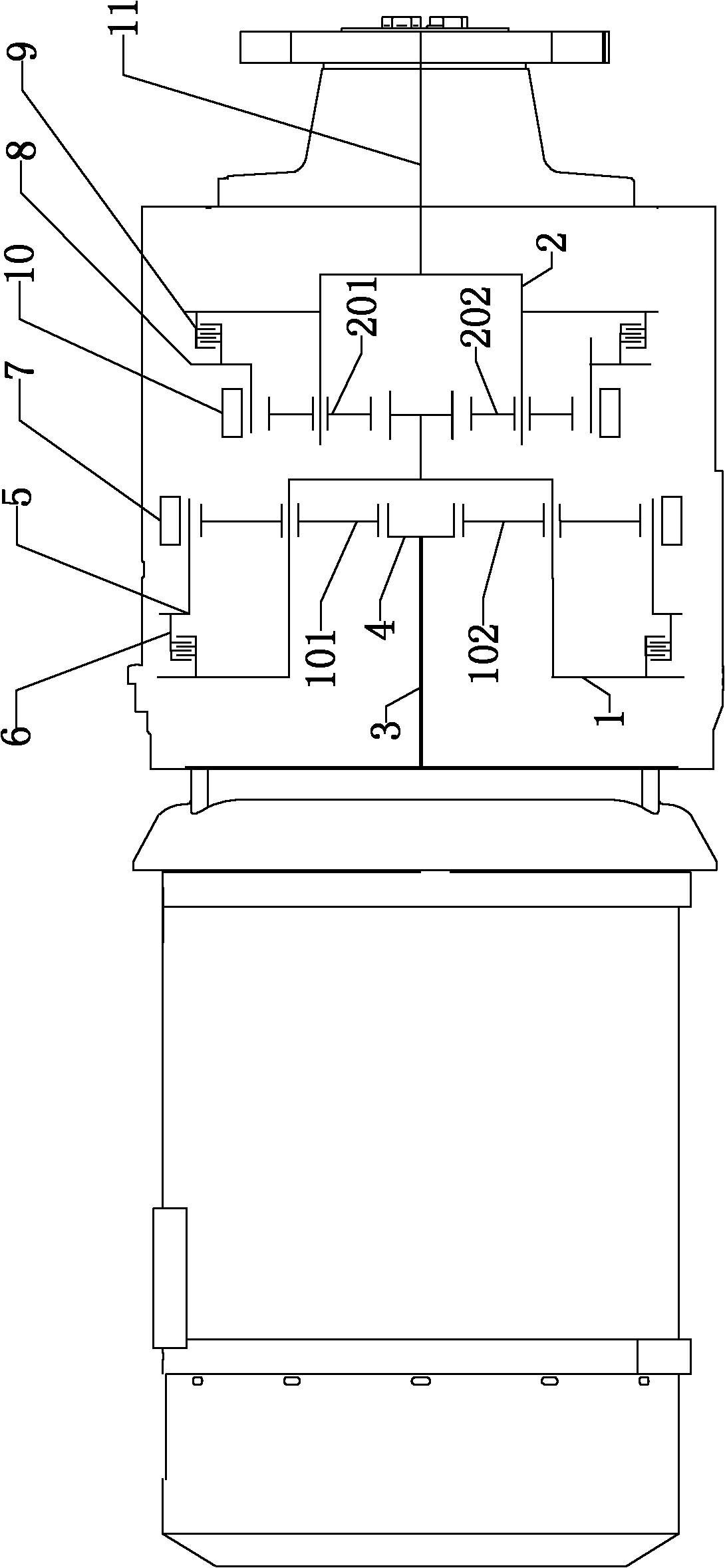

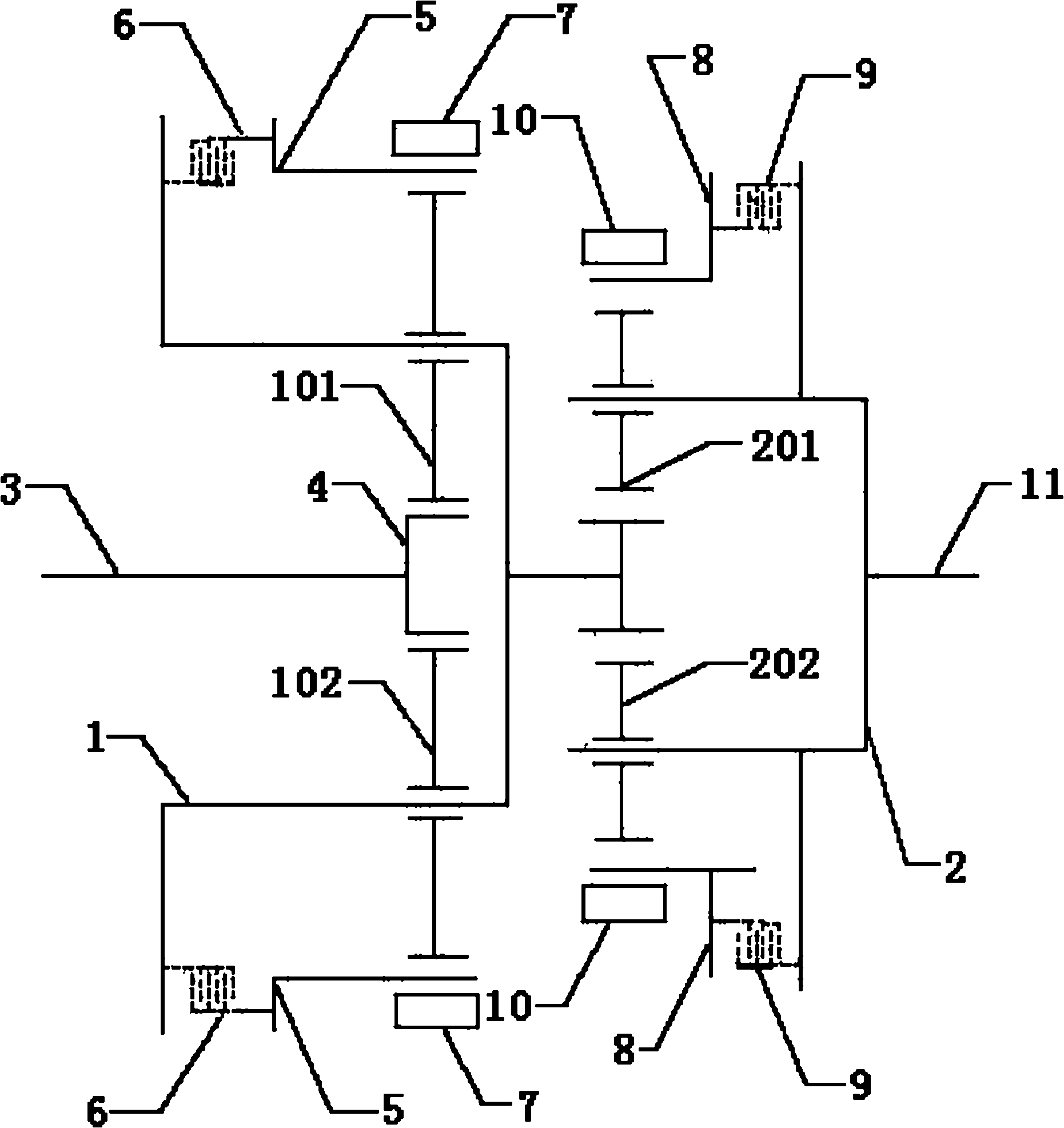

Automatic speed changer

ActiveCN104930137AOptimize layoutImprove reliabilityGearboxesToothed gearingsAutomatic transmissionEngineering

The invention discloses an automatic speed changer. The automatic speed changer comprises a double-end-face tooth combined fluted disc and a two-level speed reduction fixed shaft wheel train. A gear shifting mechanism of the speed changer is the double-end-face tooth combined fluted disc and is provided with double-end-face teeth including the left end face teeth and the right end face teeth. The double-end-face tooth combined fluted disc axially moves on an output shaft of the speed changer, the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are engaged with end face teeth of a one-level speed reduction gear and a two-level speed reduction gear respectively, the two-gear position and the one-gear position are achieved, and when the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are not combined with the end face teeth of the one-level speed reduction gear and the two-level speed reduction gear, the speed changer is at a neutral position. According to the technical scheme, compared with a traditional AMT, a synchronizer is removed, the structure is simple, reliability is high, the gear shifting time is short, the gear shifting impact is small, the production cost is low, and industrialization is easy to achieve. The gear arrangement mode of the speed changer is simple, the axial size is short, the occupied space is small, the weight is low, and the automatic speed changer conforms to the development trend of light weight and energy saving.

Owner:JING JIN ELECTRIC TECH CO LTD +1

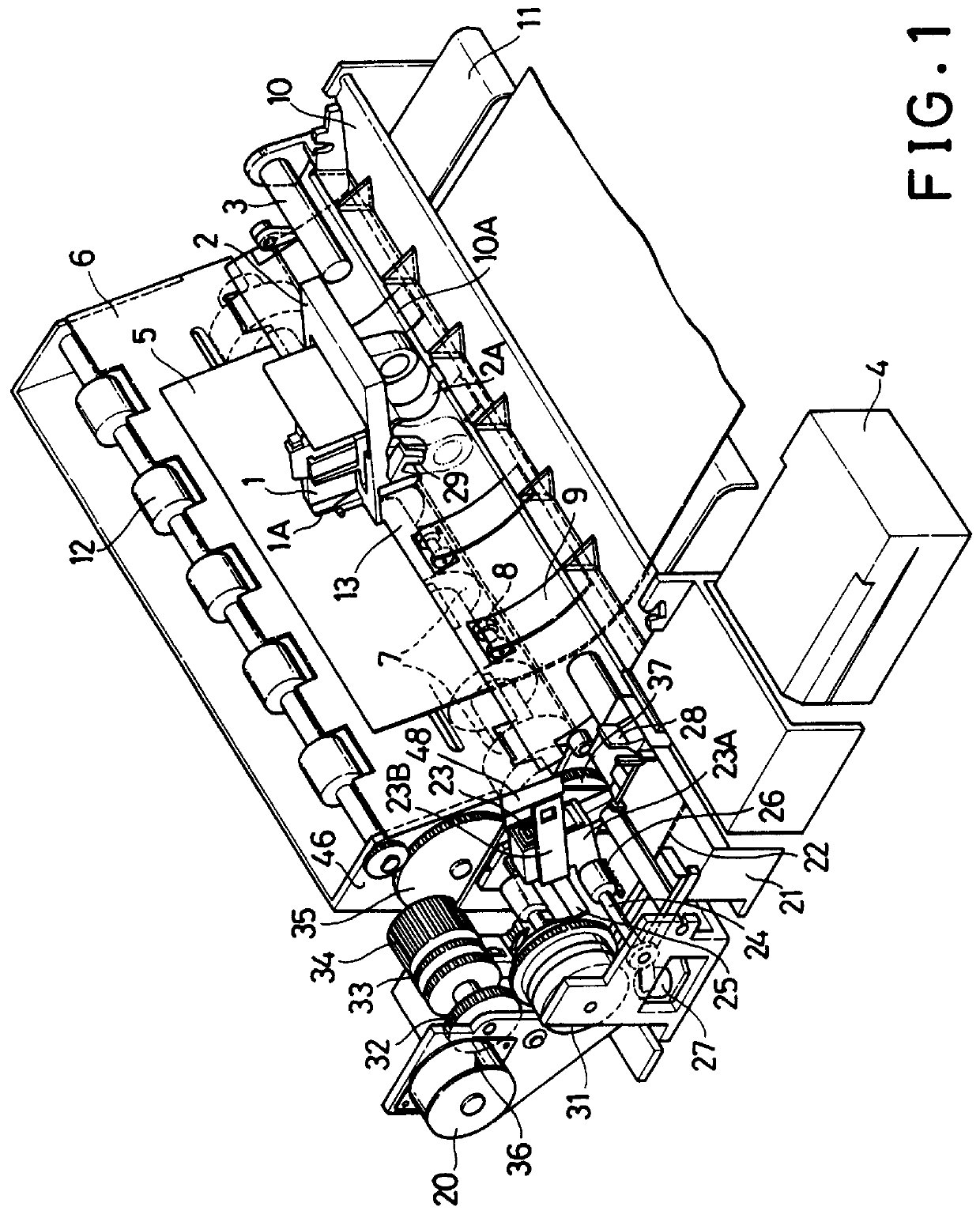

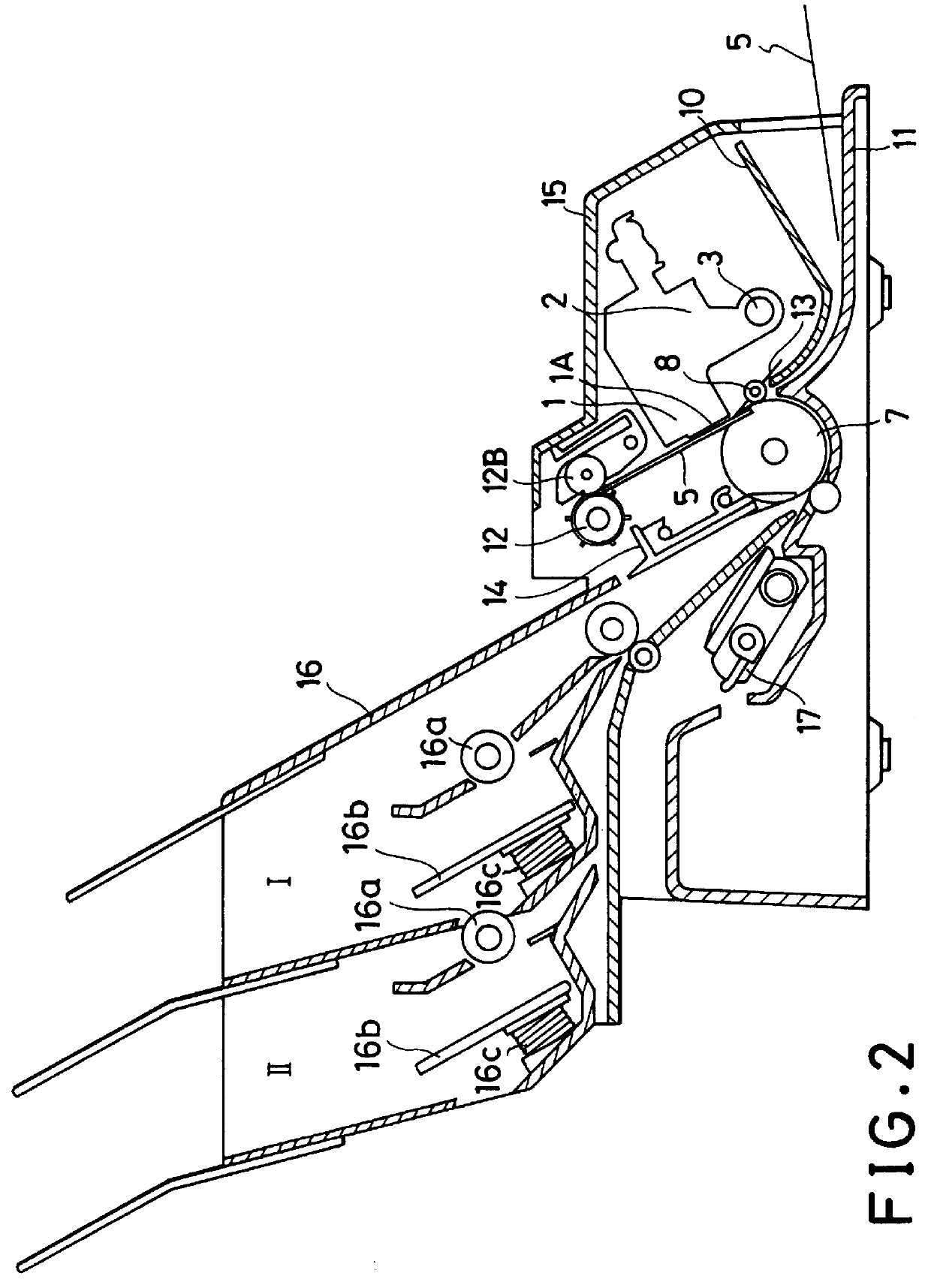

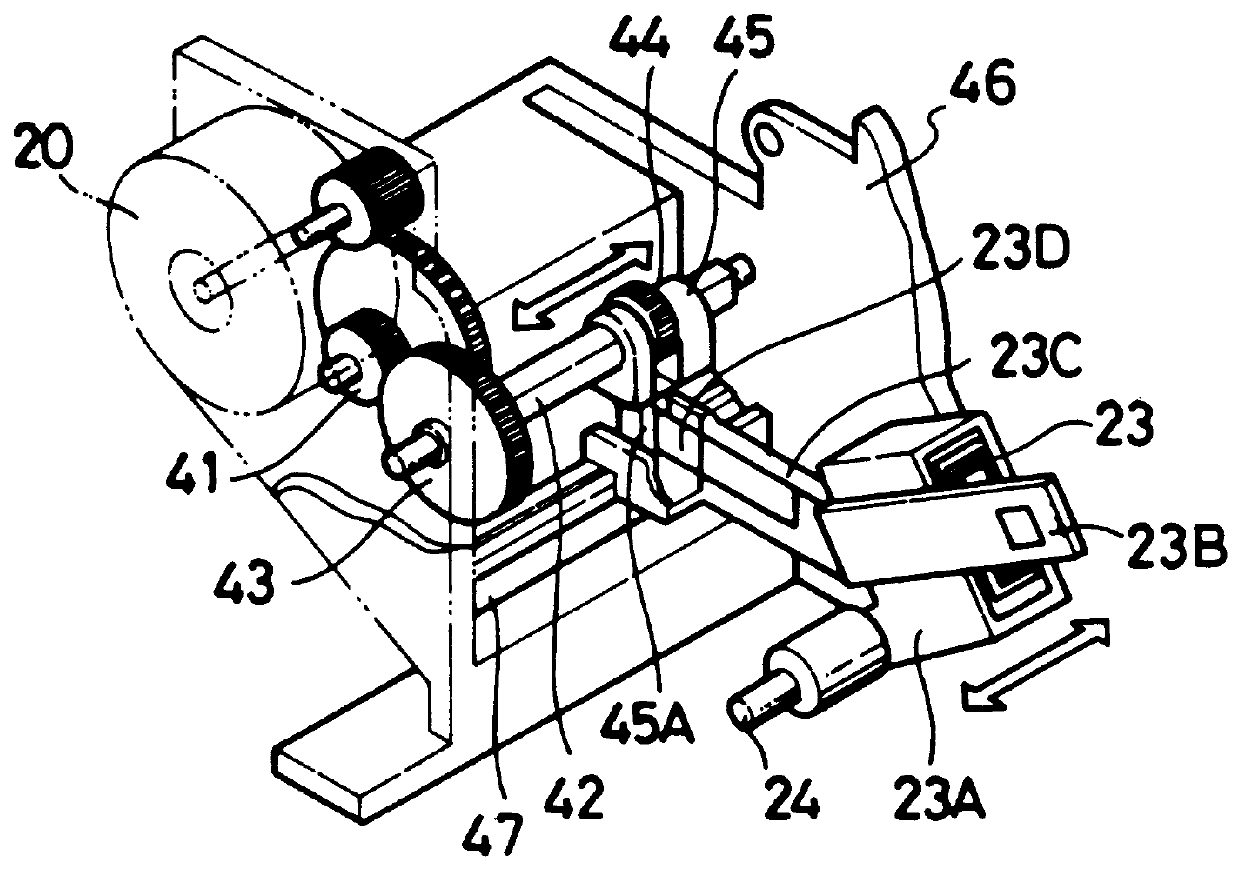

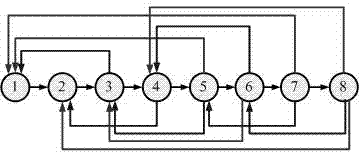

Recording apparatus

InactiveUS6015202ATime period necessary for a recording operation is reducedShorten the time periodSpacing mechanismsOther printing apparatusGear wheelInk printer

In a recording apparatus or more specifically an ink-jet printer, a plurality of gears are disposed in parallel with the direction of movement of a carriage and a slide gear is connected with the carriage outside of the recording space and is made to engage with one of a plurality of the gears corresponding the moving position of the carriage. The control sequences each for causing a gear being shifted from one gear engagement position to the adjacent position, are so combined that the gear can be shifted past the adjacent gear engagement position to a desired gear engagement position and the overlapped operations in each of the gear shift control sequence combinations can be skipped.

Owner:CANON KK

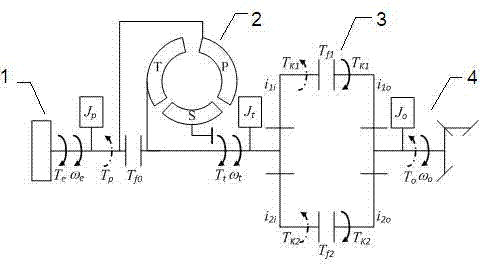

Gear-shifting control method for automatic hydraulic speed changer

ActiveCN103671898AControl torque variationCombined with softGearing controlAutomatic transmissionControl theory

The invention discloses a gear-shifting control method for an automatic hydraulic speed changer. The gear-shifting control method comprises the steps that in the one-time gear shifting process, only one clutch is started, the other clutch is combined, the torque exchanging process is carried out between the two movement clutches, oil pressure is controlled through the combination of the clutch controlling step and the separated clutch controlling step, and the flexible clutch combination is guaranteed by adjusting the K1 and K2 control pressure in the gear shifting process. The engine torque changing is controlled, and easy, efficient and smooth gear shifting controlling of the automatic hydraulic speed changer is achieved. The test carried out under the full accelerator aperture and other limiting conditions such as gear lifting and gear jumping and reducing in a low-gear gear area shows that the control method can meet the requirements for gear shifting quality of forward torque gear lifting, forward torque gear reducing, negative torque gear lifting and negative toque gear reducing.

Owner:SHENGRUI TRANSMISSION

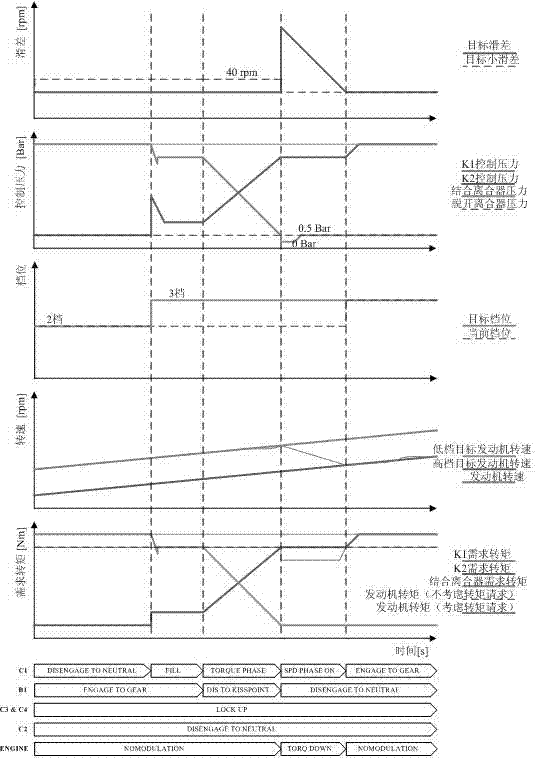

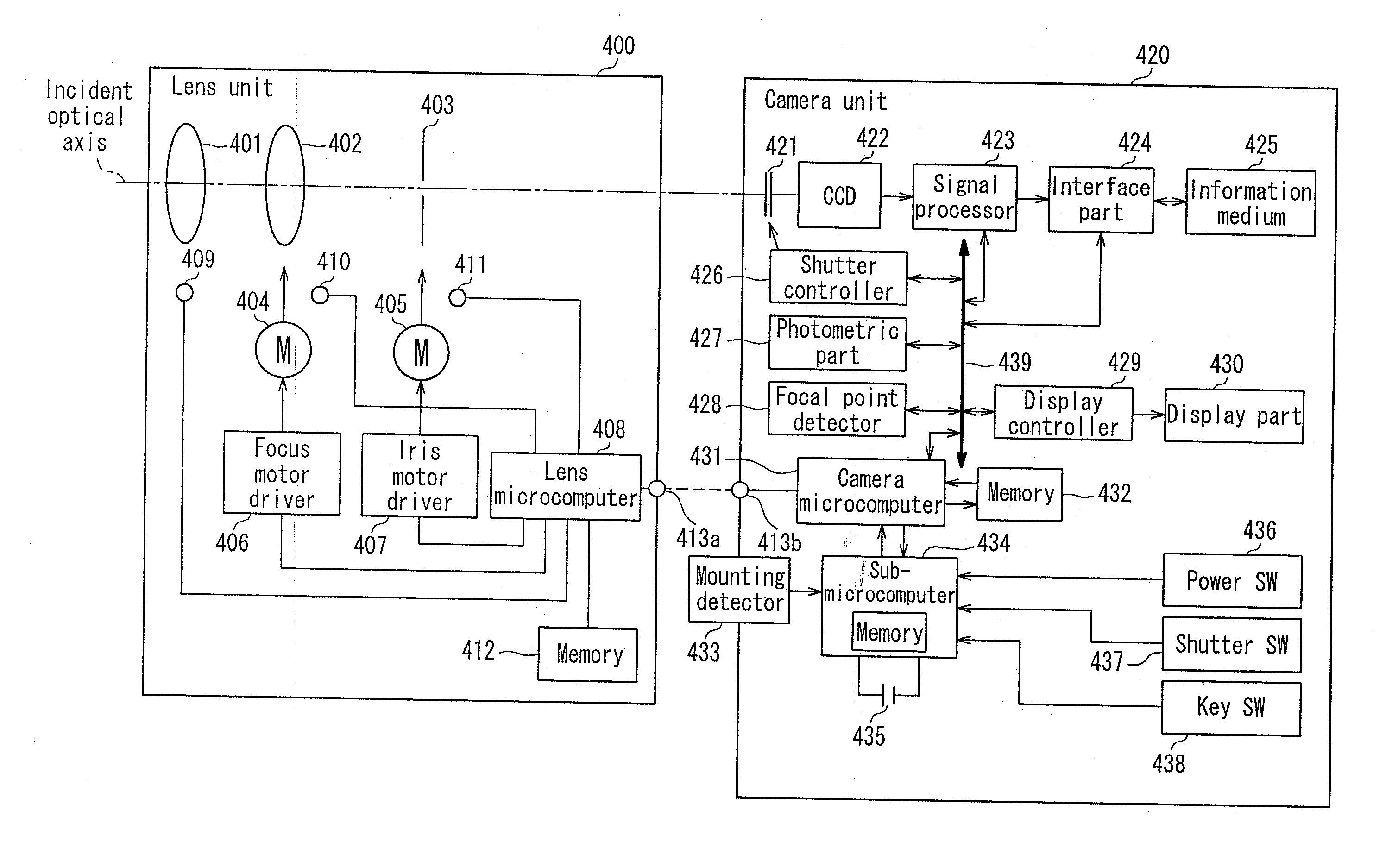

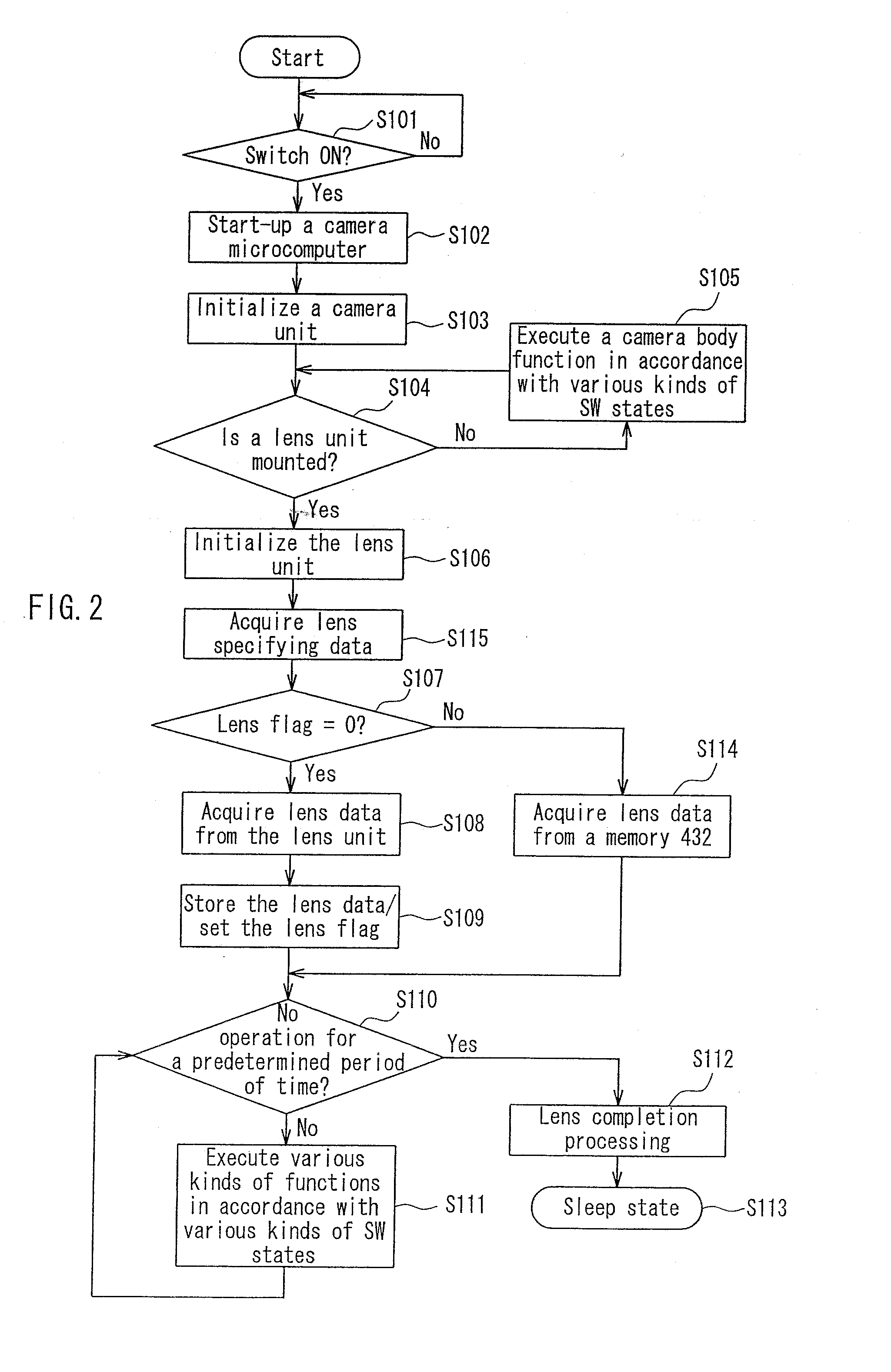

Image pickup apparatus and image pickup system

ActiveUS20070104474A1Easy to operateShorten shift timeTelevision system detailsProjector focusing arrangementMicrocontrollerMicrocomputer

A camera apparatus and a camera system of the present invention are configured so that a lens unit is attachable / detachable. The lens unit contains at least a lens and an iris, and contains a memory storing setting information required for operating the lens and the iris. When a camera microcomputer checks detection information stored in a memory in a sub-microcomputer at a time of start-up of the camera apparatus, and first detection information is stored in the memory, the setting information is acquired from the lens unit. When second detection information is stored in the memory, the setting information is acquired from another memory in the camera apparatus. Due to this configuration, the time for shifting the switch-on to a photographable state is shortened, and the ease of convenience can be enhanced.

Owner:PANASONIC CORP

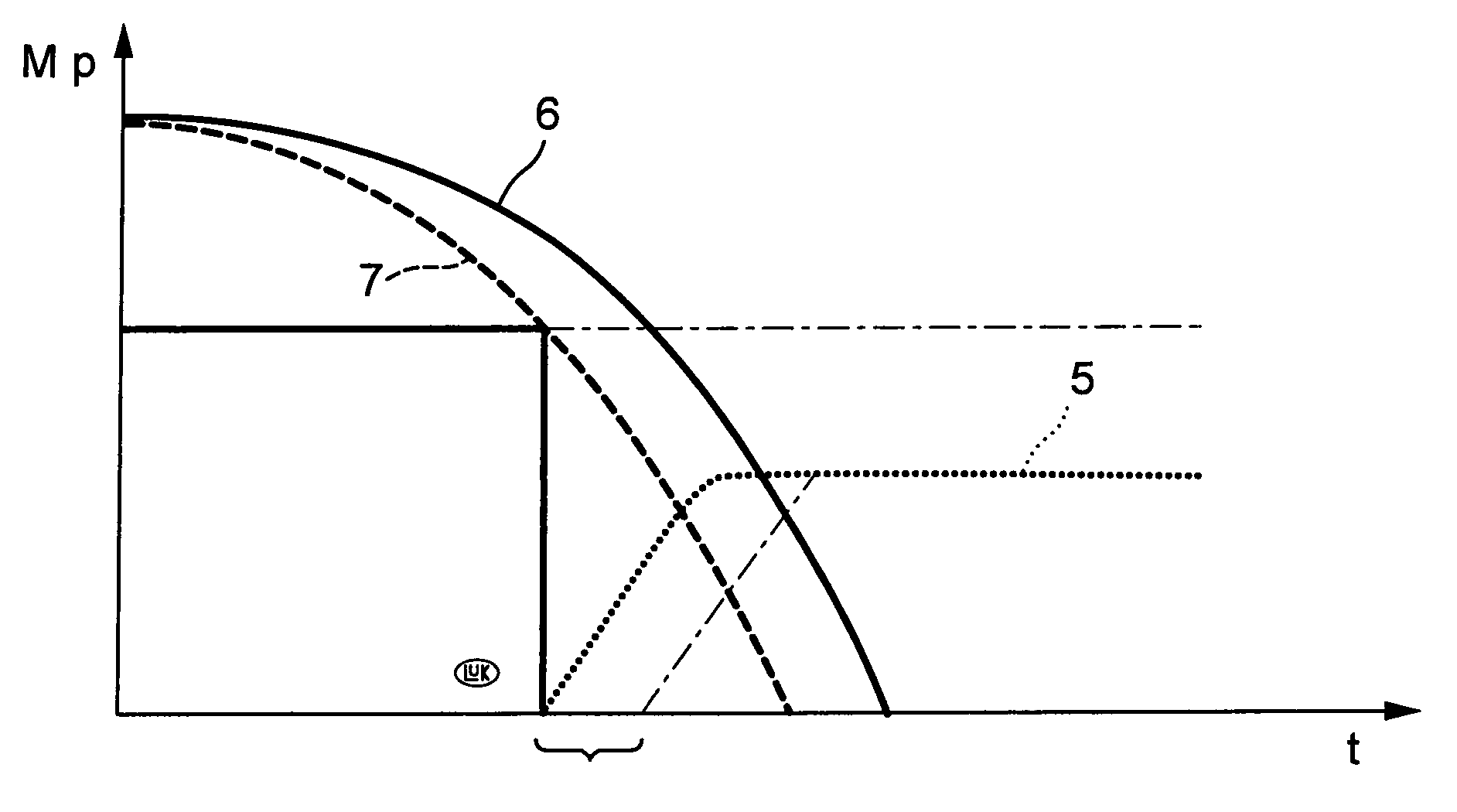

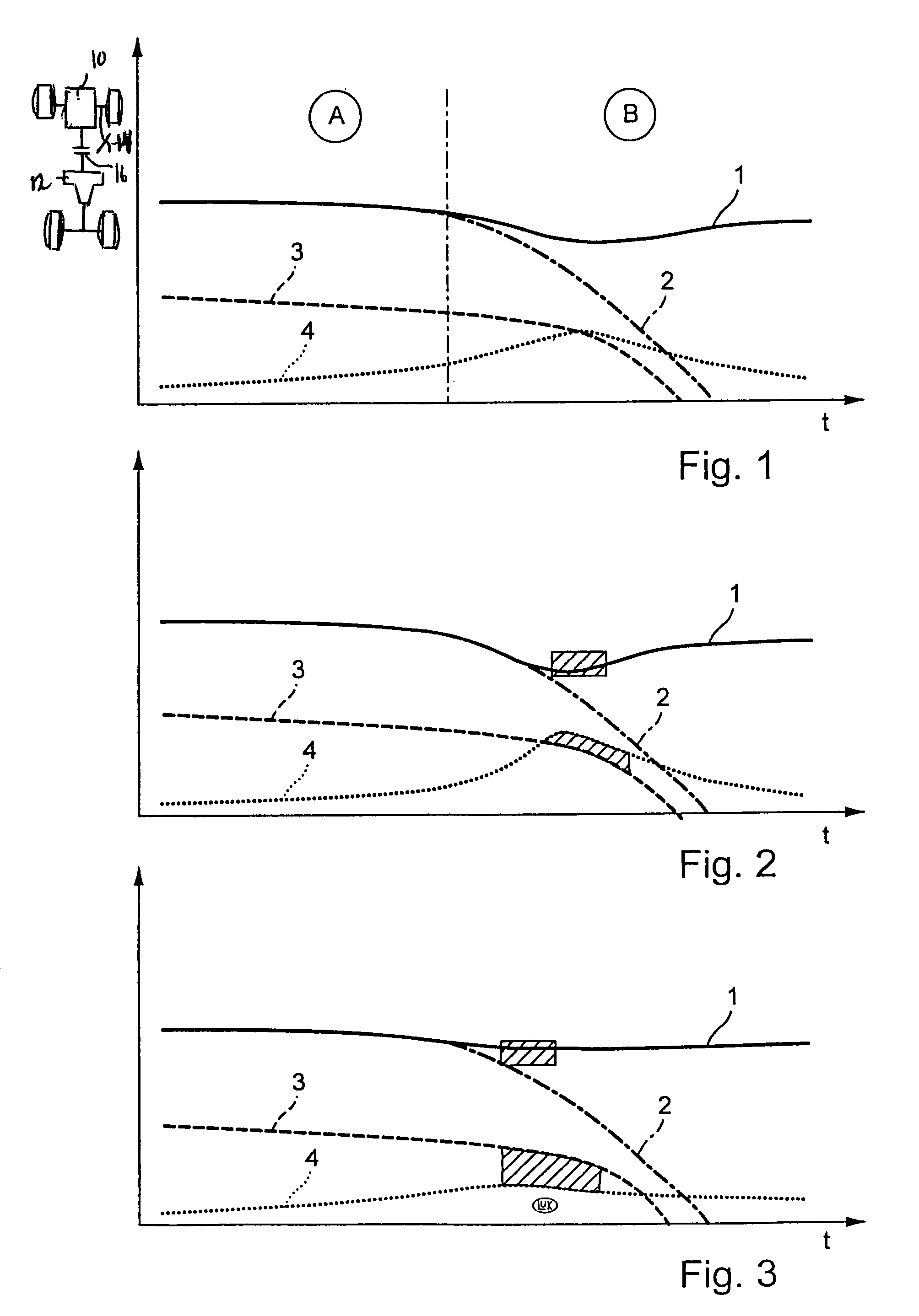

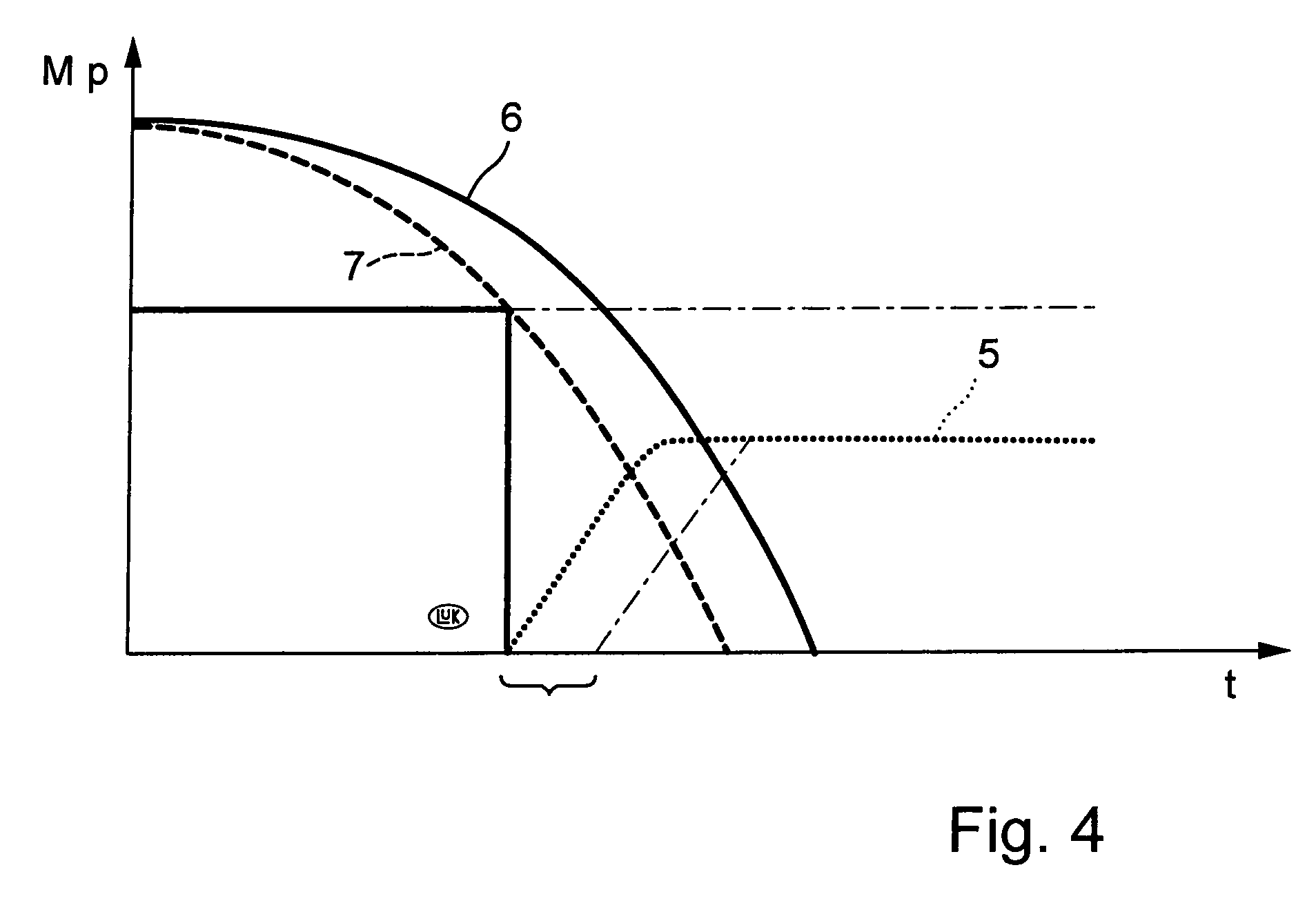

Method for changing the clutch torque in a clutch in the power train of a vehicle having an automated manual shift transmission

A method for altering the coupling torque of a coupling in the drive train of a vehicle with an automatic gearbox and / or automatic coupling in a creep drive mode of a vehicle. According to the invention, the coupling torque is altered according to at least one variable, the parameter of the vehicle describing the creep drive mode thereof.

Owner:SCHAEFFLER TECH AG & CO KG

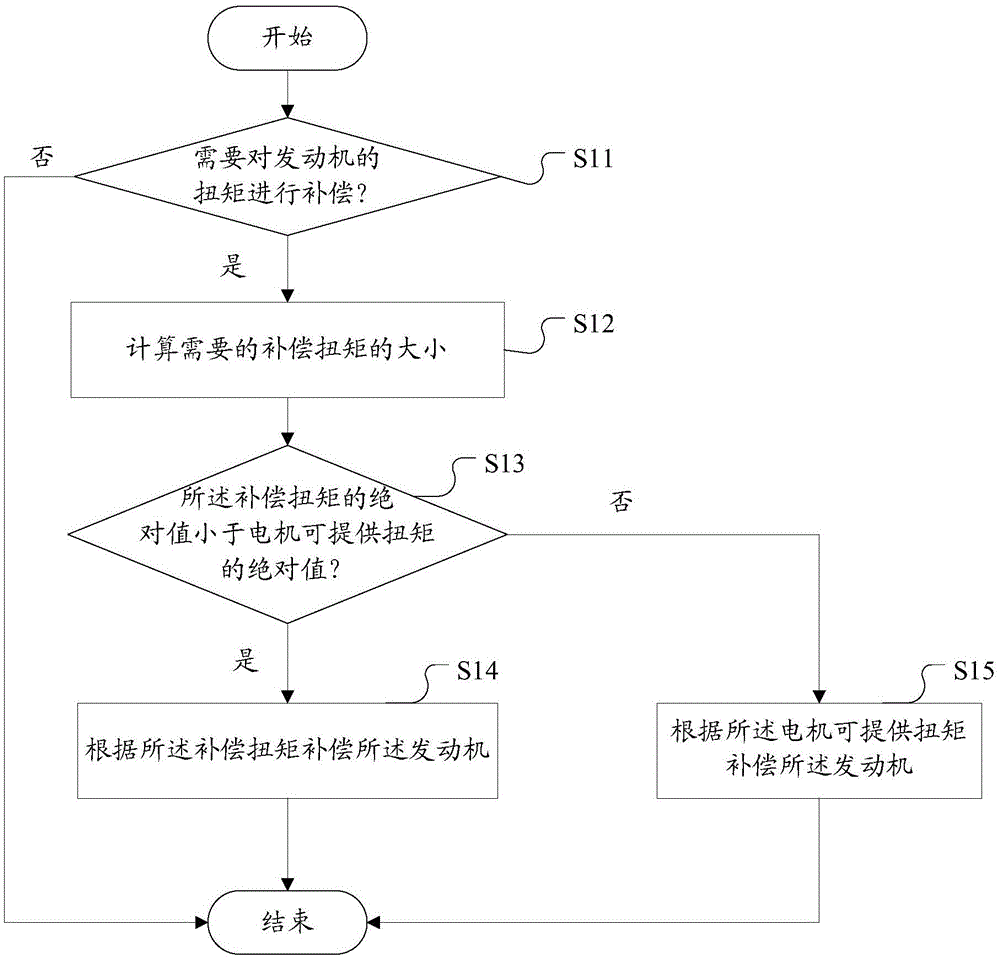

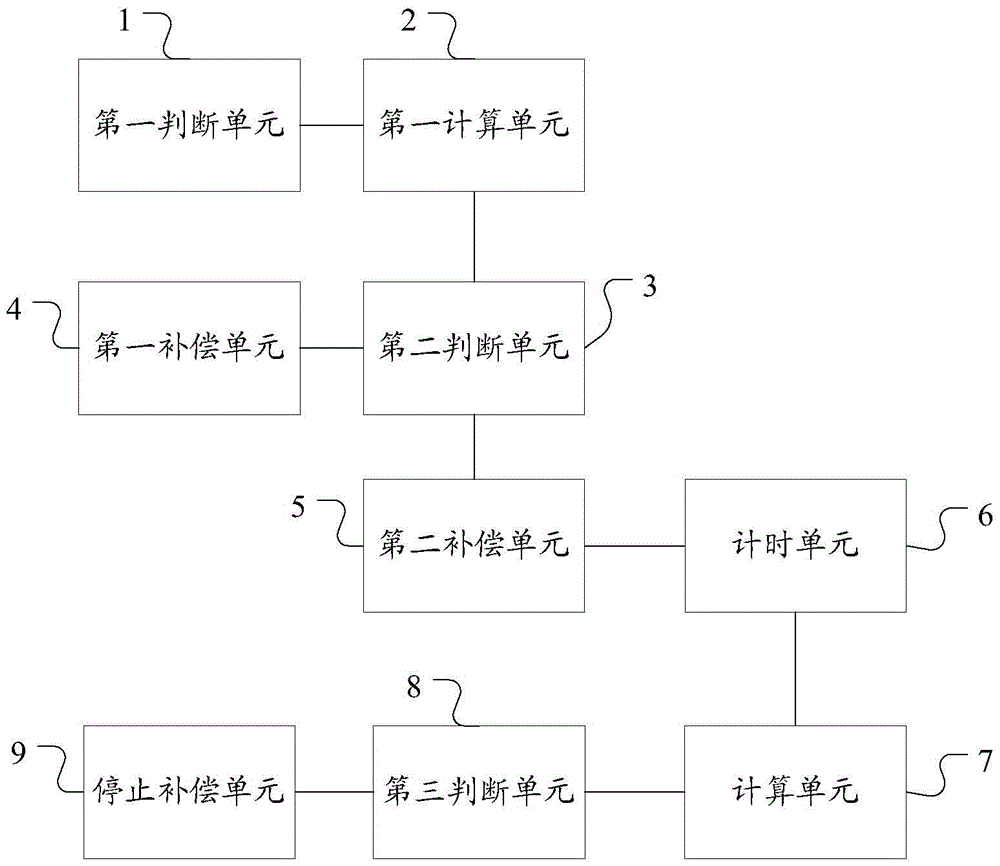

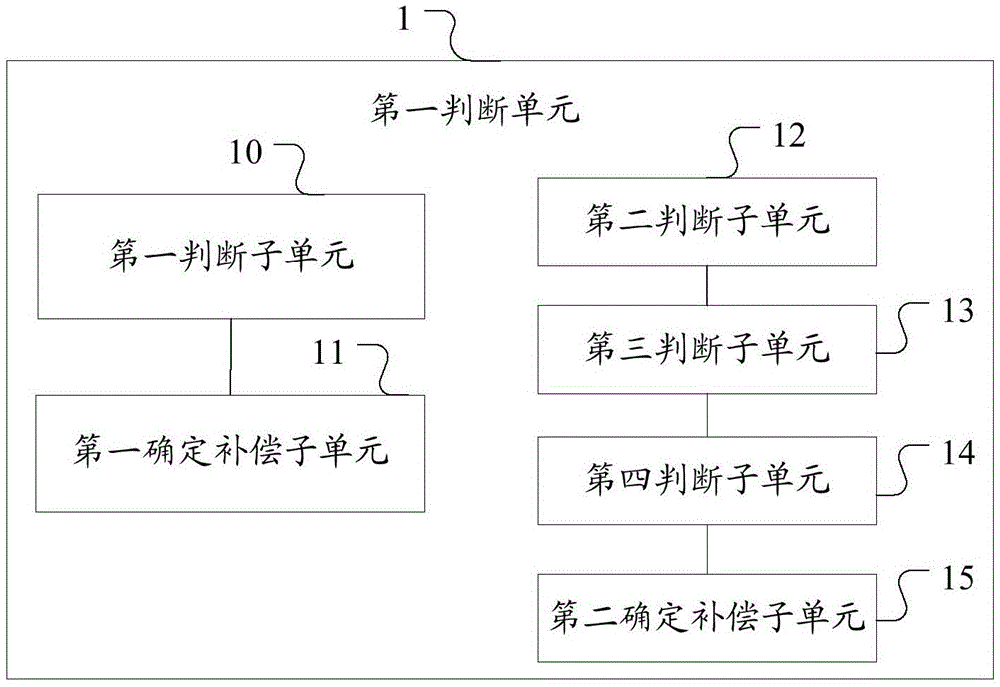

HCU (hybrid control unit) and torque compensation control method

The invention provides an HCU (hybrid control unit) and a torque compensation control method. The method comprises the following steps of judging whether the torque of an engine needs to be compensated or not; when the condition that the torque of the engine needs to be compensated is determined, calculating the dimension of the torque to be compensated; judging whether the absolute value of the compensation torque is smaller than the absolute value of the torque capable of being provided by a motor or not; if the absolute value of the compensation torque is smaller than or equal to the absolute value of the torque capable of being provided by the motor, compensating the engine according to the compensation torque. By using the technical scheme, the deviation between the required torque of the vehicle driving and the practical provided torque of the engine can be reduced, so that the driving safety can be improved; in addition, the gear shifting time can be reduced.

Owner:SAIC MOTOR

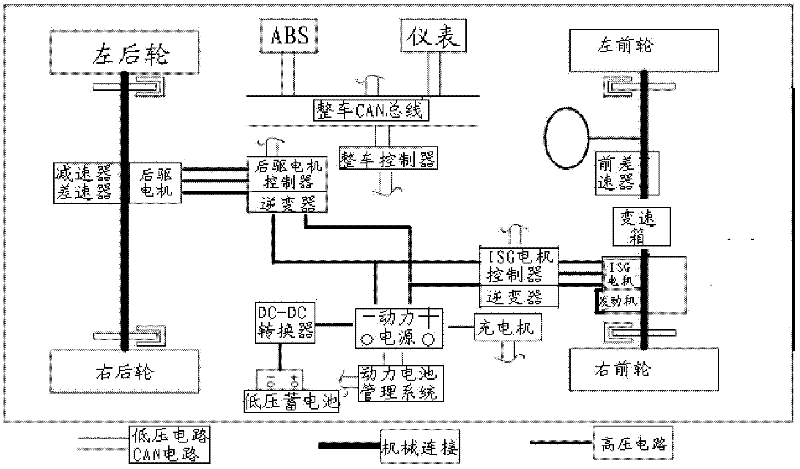

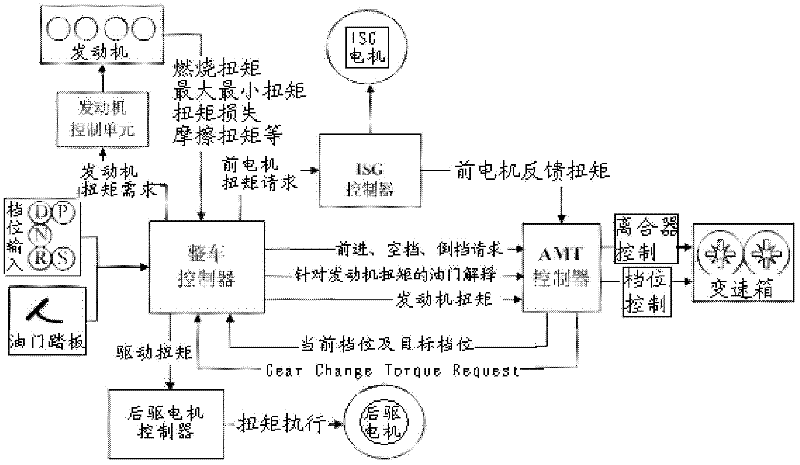

Four-driven strong-hybrid automobile AMT (automated mechanical transmission) coordinated control method and system thereof

The invention discloses a four-driven strong-hybrid automobile AMT (automated mechanical transmission) coordinated control method and a system thereof, belonging to the field of hybrid automobile control. Driving information is acquired by a whole automobile controller which is also responsible for managing and distributing the torque needed by the whole automobile. The method comprises the following steps of: determining the whole automobile driving mode, and selecting the whole automobile driving mode adaptive to the driving information; sending instruction information to an AMT controller according to the whole automobile driving mode, and executing the instruction control of the whole automobile controller by the AMT controller; and carrying out coordinated control on all driving motor controllers by the whole automobile controller according to the execution condition of the AMT controller so as to meet the requirement for smooth shifting of a driver for driving. In the AMT coordinated control method, by coordinated control of the whole automobile controller to the AMT controller, the shifting smoothness of an AMT is effectively improved, so that the shifting becomes faster and more comfortable; and simultaneously a rear-driven pure-electric driving mode is utilized for preventing an AMT system from working at the stages of starting and low speed, so that the automobile driving is more economic.

Owner:CHERY AUTOMOBILE CO LTD

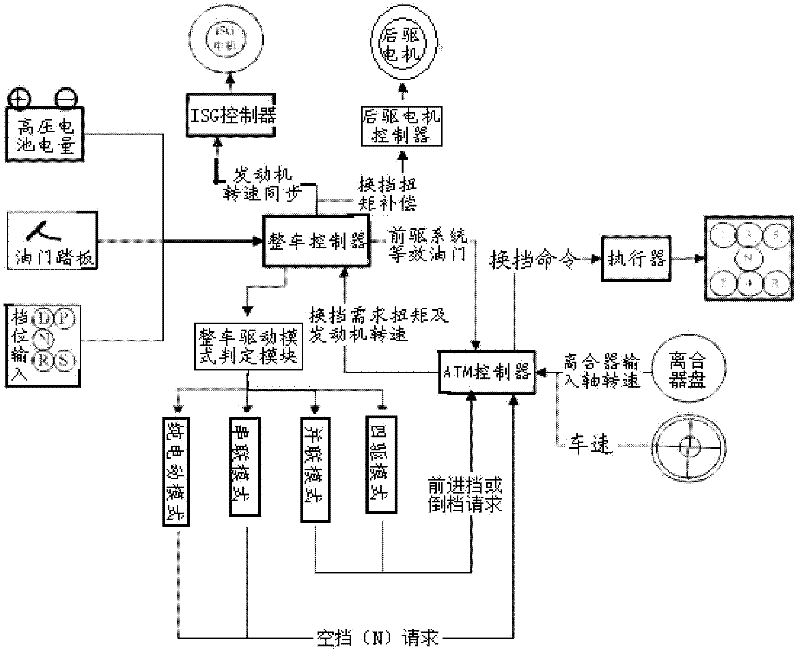

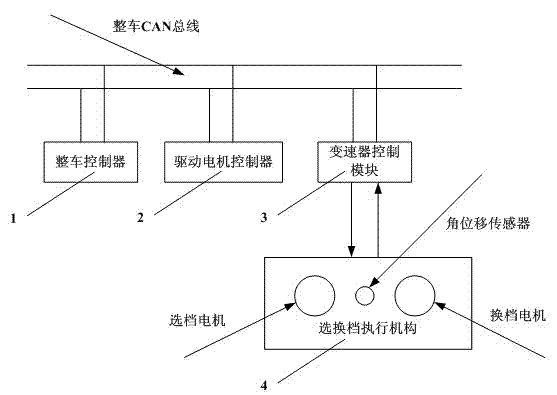

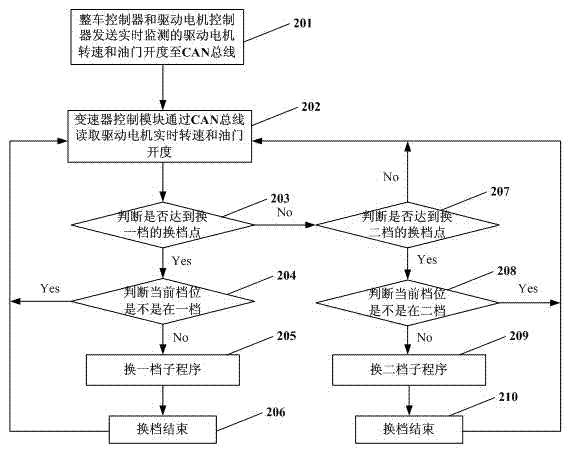

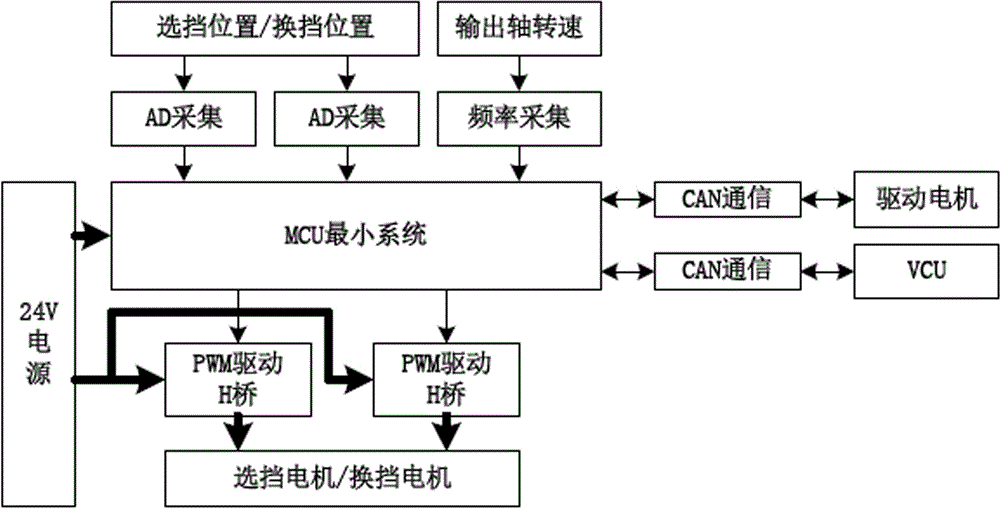

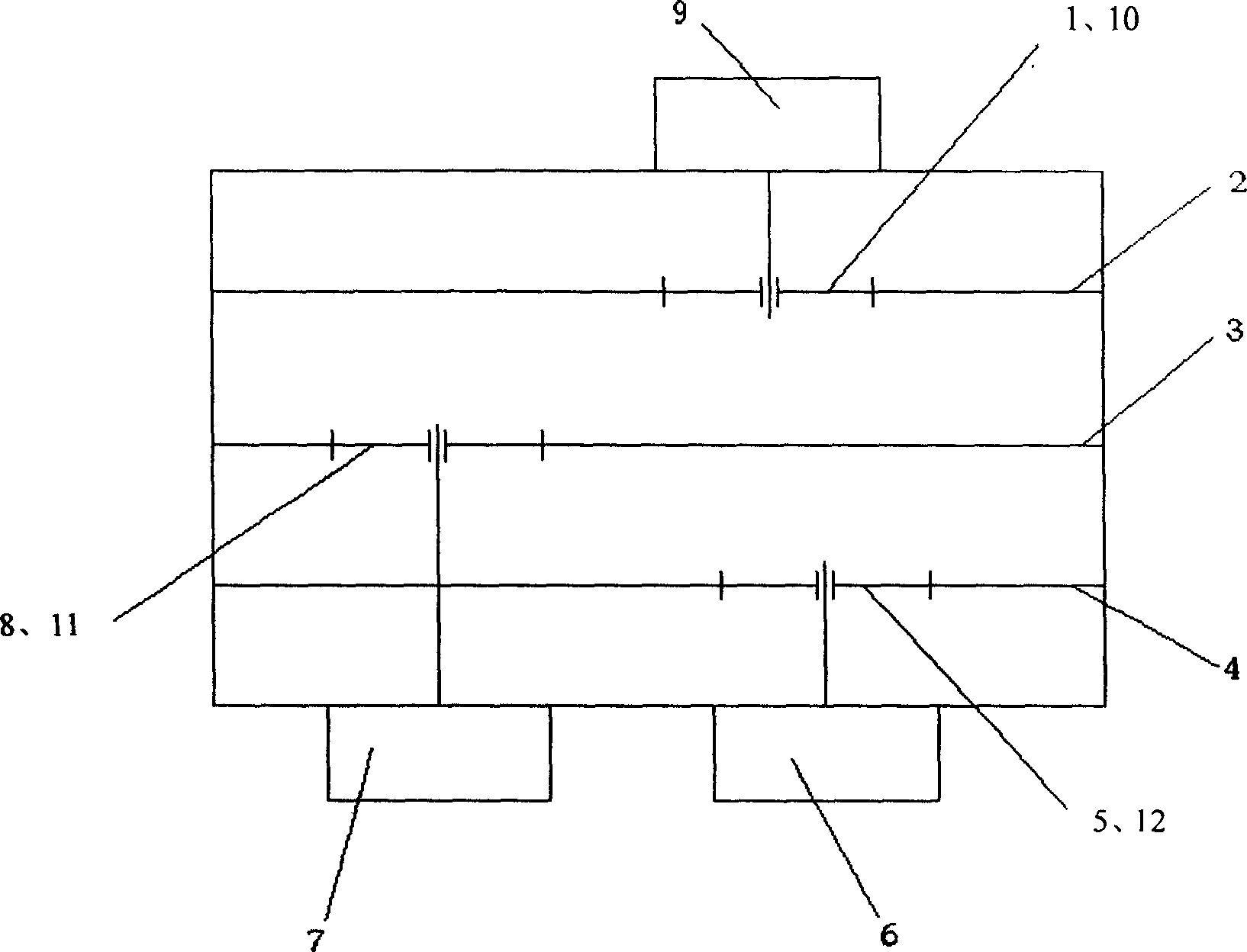

A control system and control method for a two-speed automatic transmission of a pure electric vehicle

The invention discloses a two-speed automatic transmission control system and control method for pure electric vehicles. The control system includes a vehicle controller, a drive motor controller, a transmission control module, and a gear selection actuator. It includes a gear selection motor, a gear shifting motor, a gear position sensor, an angular displacement sensor and a mechanical transmission part. The invention improves the transmission system of the traditional pure electric vehicle. The transmission adopts a two-speed structure, which can improve the performance of the electric vehicle, reduce the requirements on the performance of the motor, make the motor work more in the high-efficiency area, and extend its driving range. During the shifting process, the transmission control module automatically controls the gear selection and shifting actuator to realize automatic shifting and reduce the labor intensity of the operator; during the shifting process, the transmission control module, the vehicle controller and the drive motor controller Through the set control method, the working state of the drive motor is integratedly controlled, the speed of the drive motor is precisely controlled, the impact of shifting is small, and the smoothness of shifting and ride comfort of the vehicle are improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

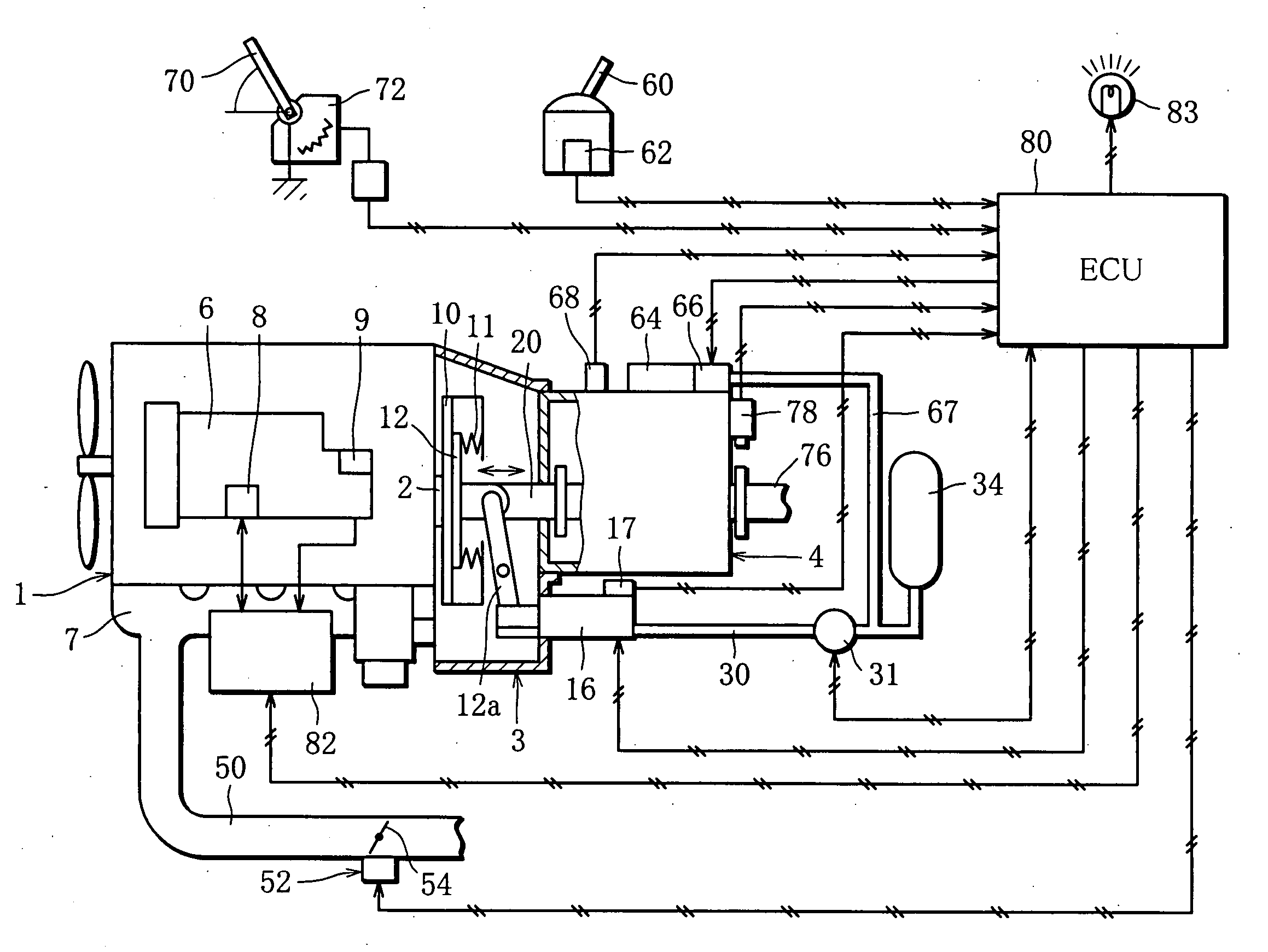

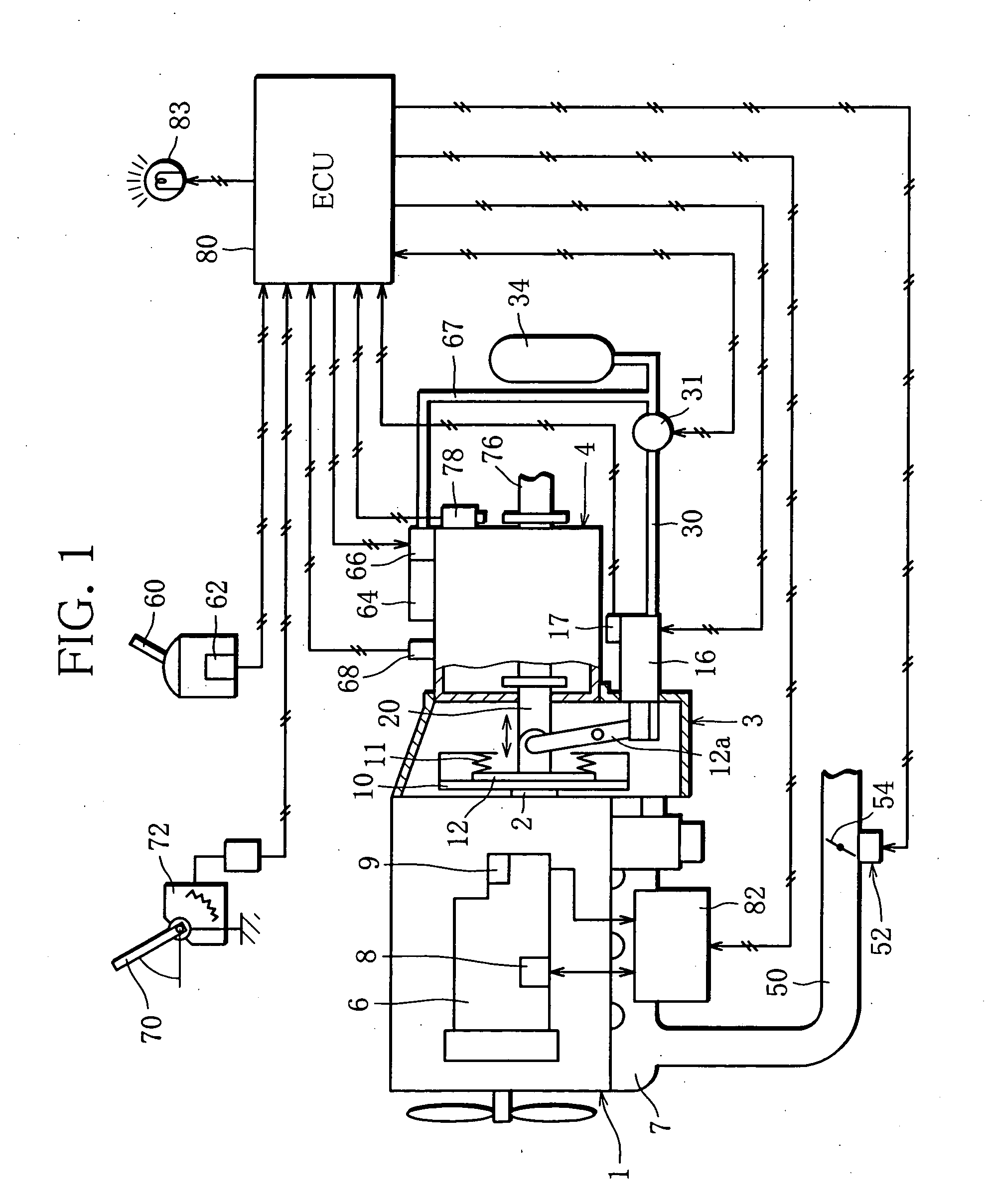

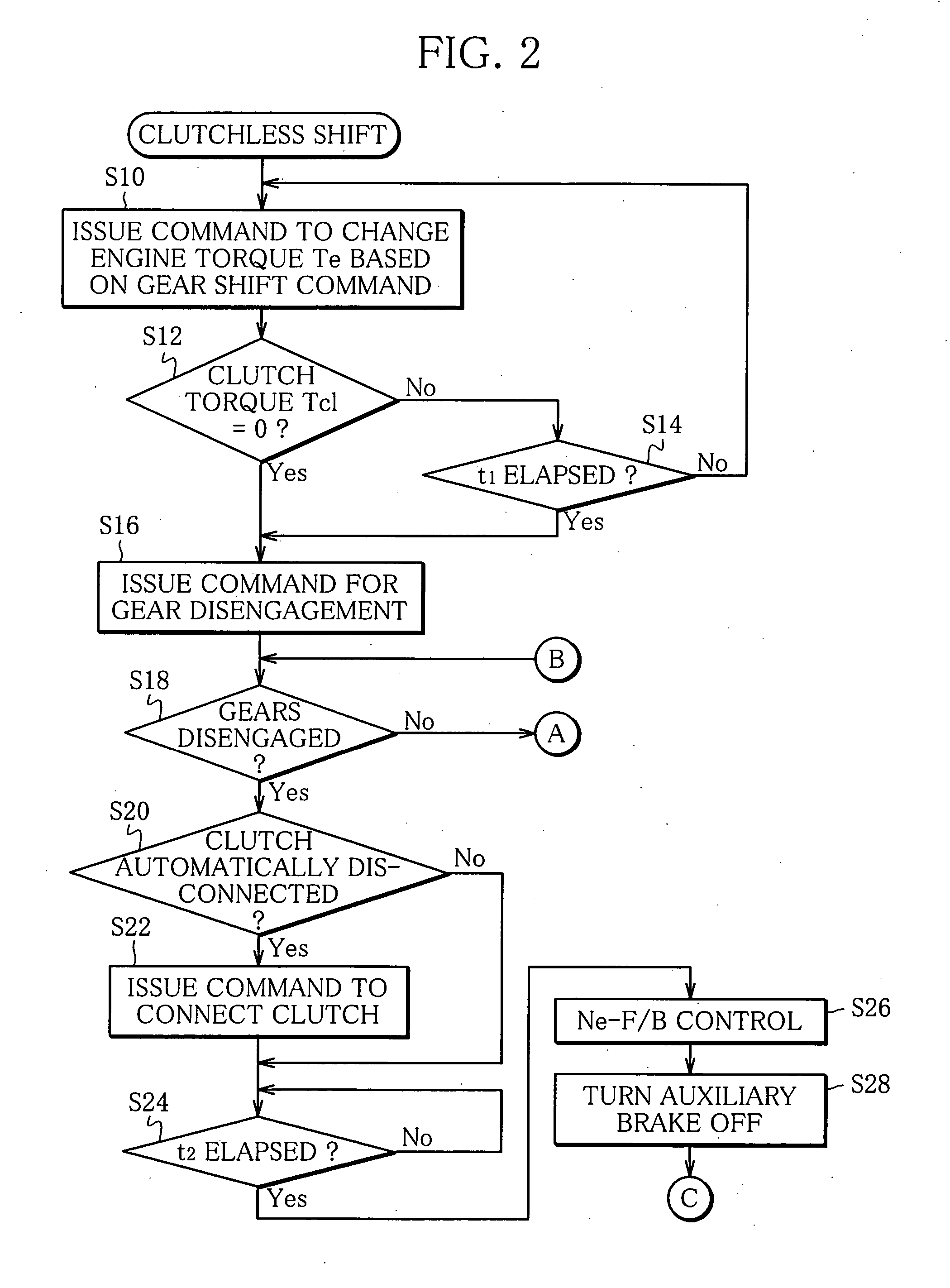

Method and device for controlling gear shift of mechanical transmission

InactiveUS20060047395A1Shorten shift timeShort timeElectrical controlDigital data processing detailsGear wheelInternal combustion engine

Provided are a transmission control method for a mechanical transmission, capable of shortening a gear shift time without undergoing a shock attributed to gear disengagement, and an apparatus therefor. The transmission control apparatus comprises engine torque control means (S10) for controlling an engine torque generated by an internal combustion engine so that the value of a transfer torque of a friction clutch is 0 or near 0 when a gear shift of the mechanical transmission is required, gear shift allowing means (S12) for aloowing the gear shift of the mechanical transmission when the engine torque is controlled by the engine torque control means so that the value of the transfer torque is 0 or near 0, and gear shift executing means (S16) for disengaging and engaging gears with the clutch kept connected when the gear shift is allowed by the gear shift allowing means.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

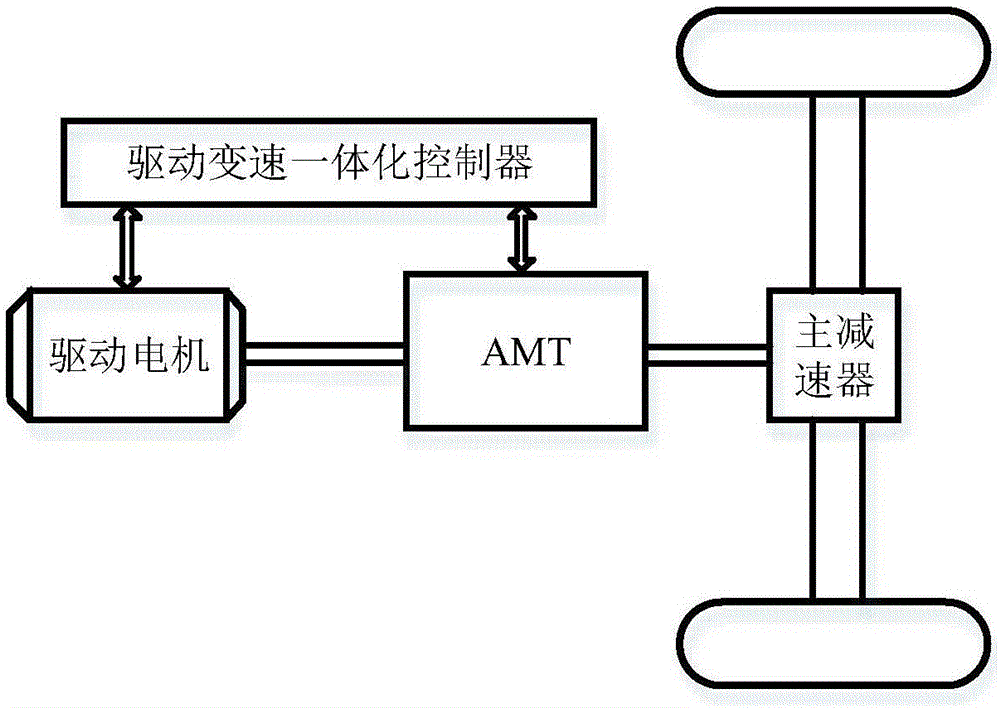

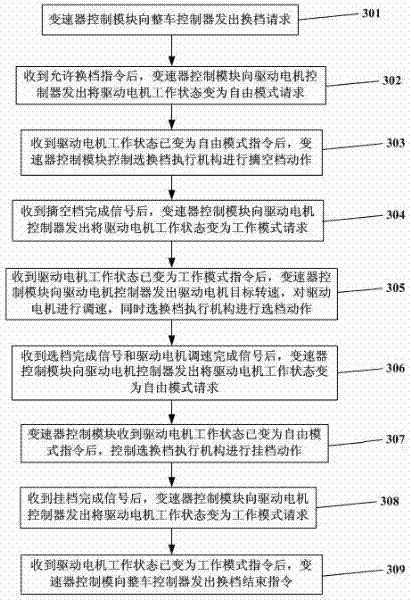

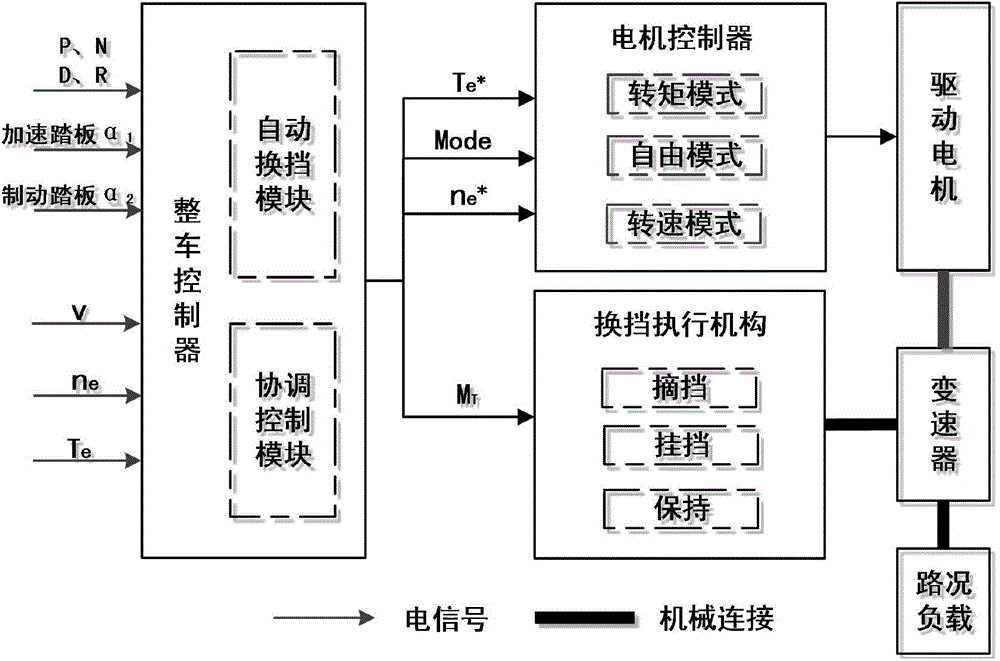

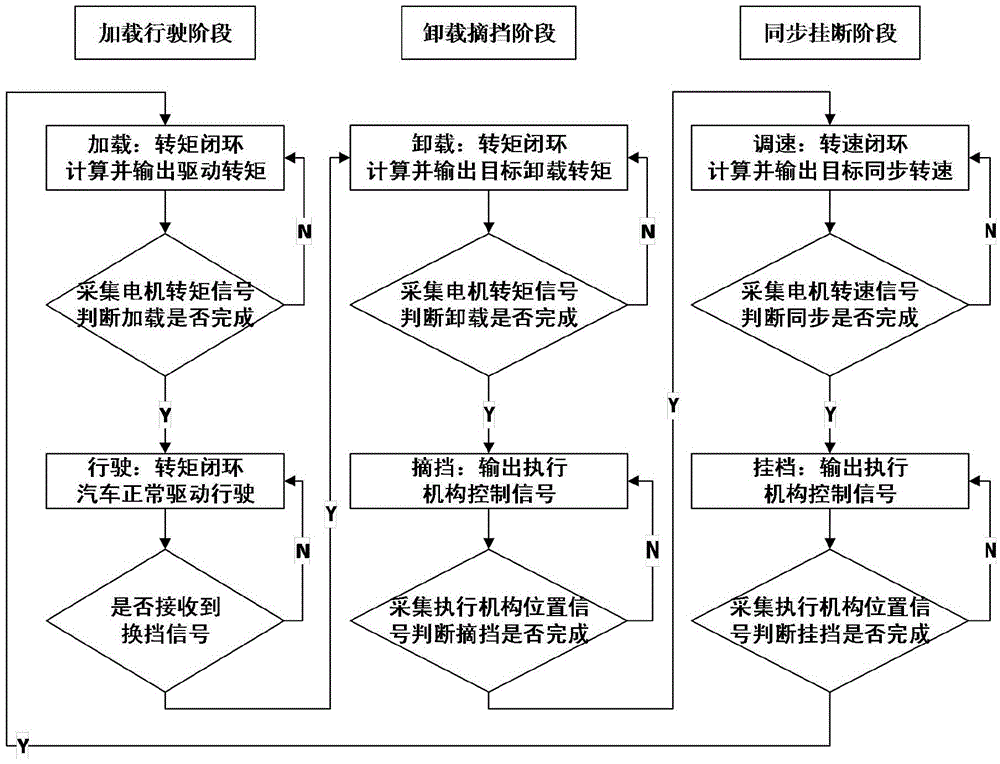

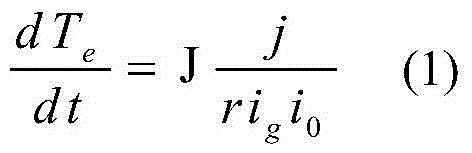

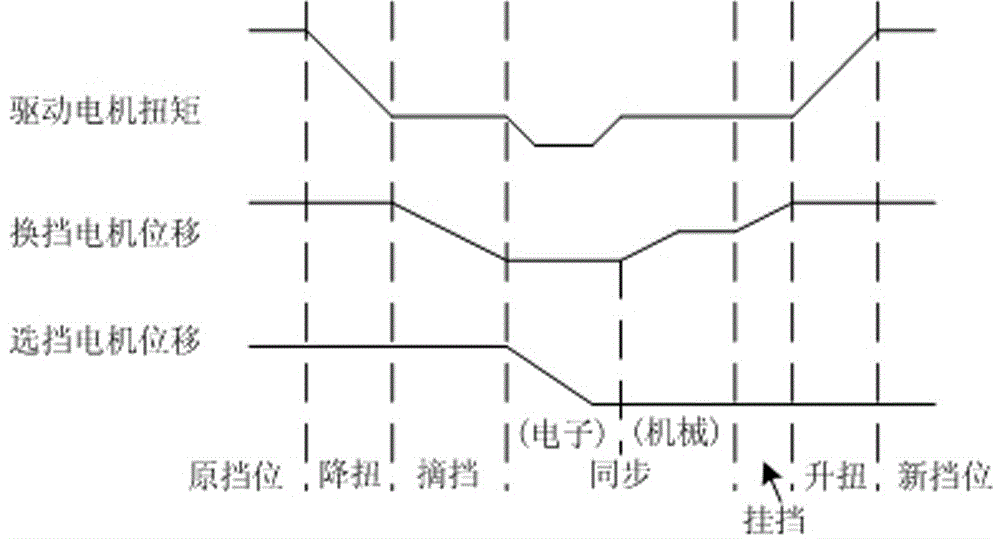

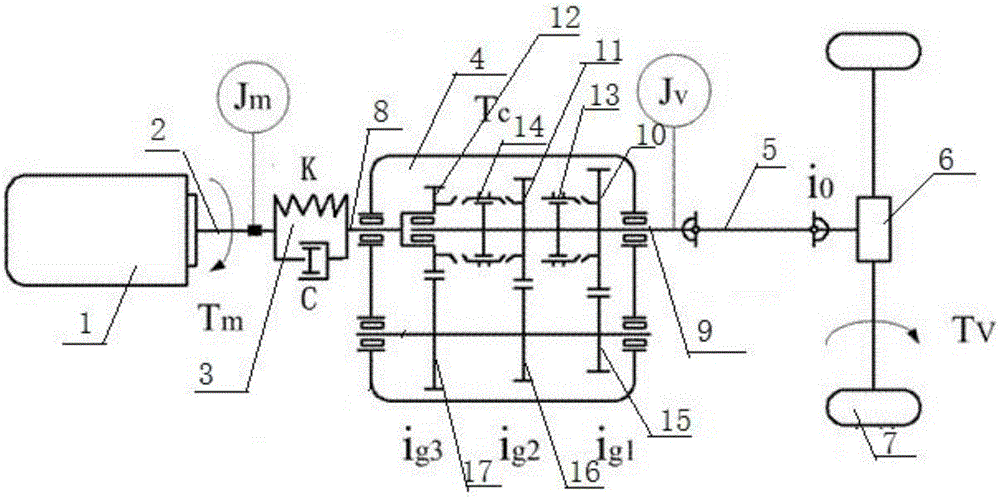

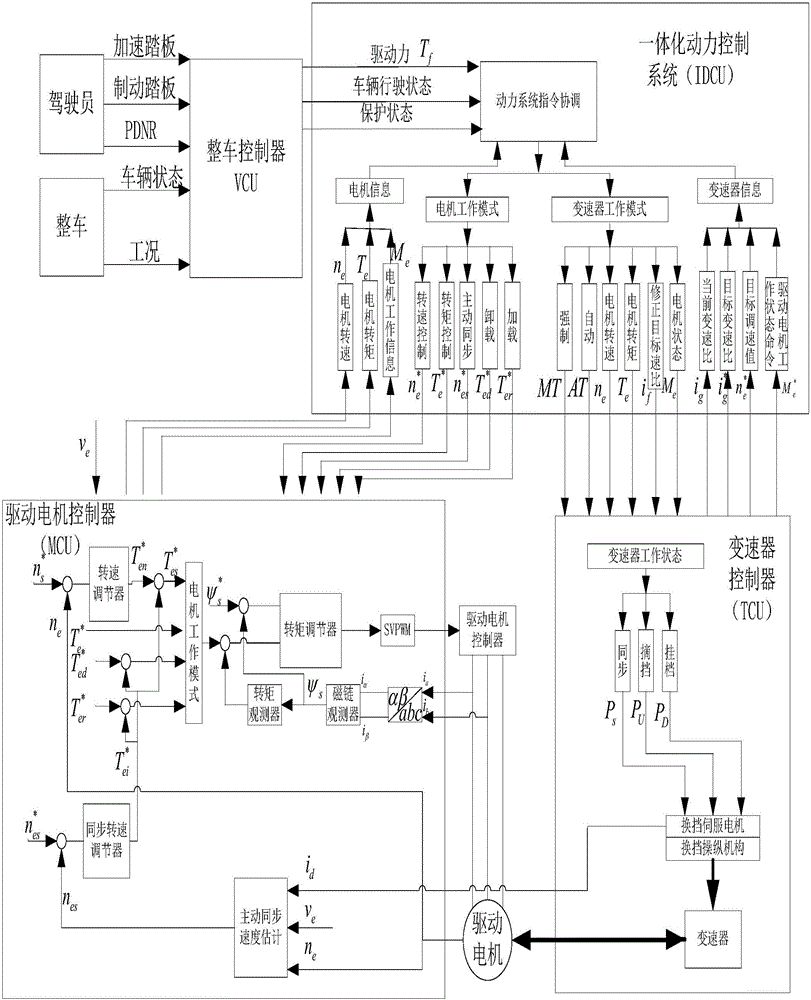

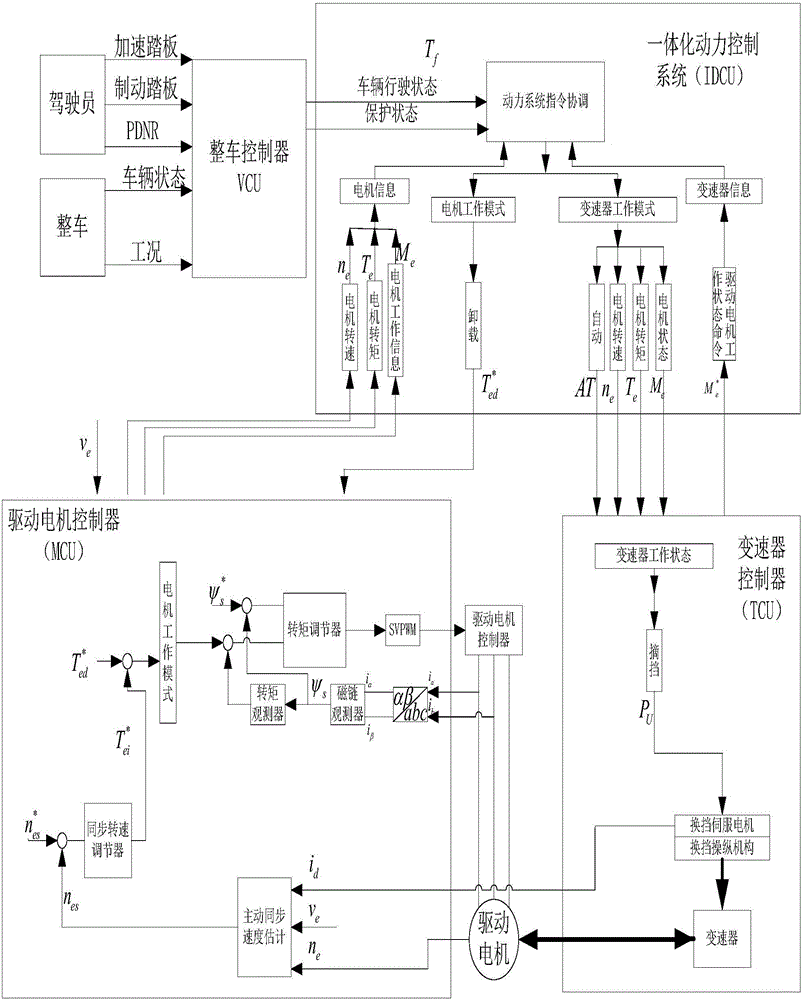

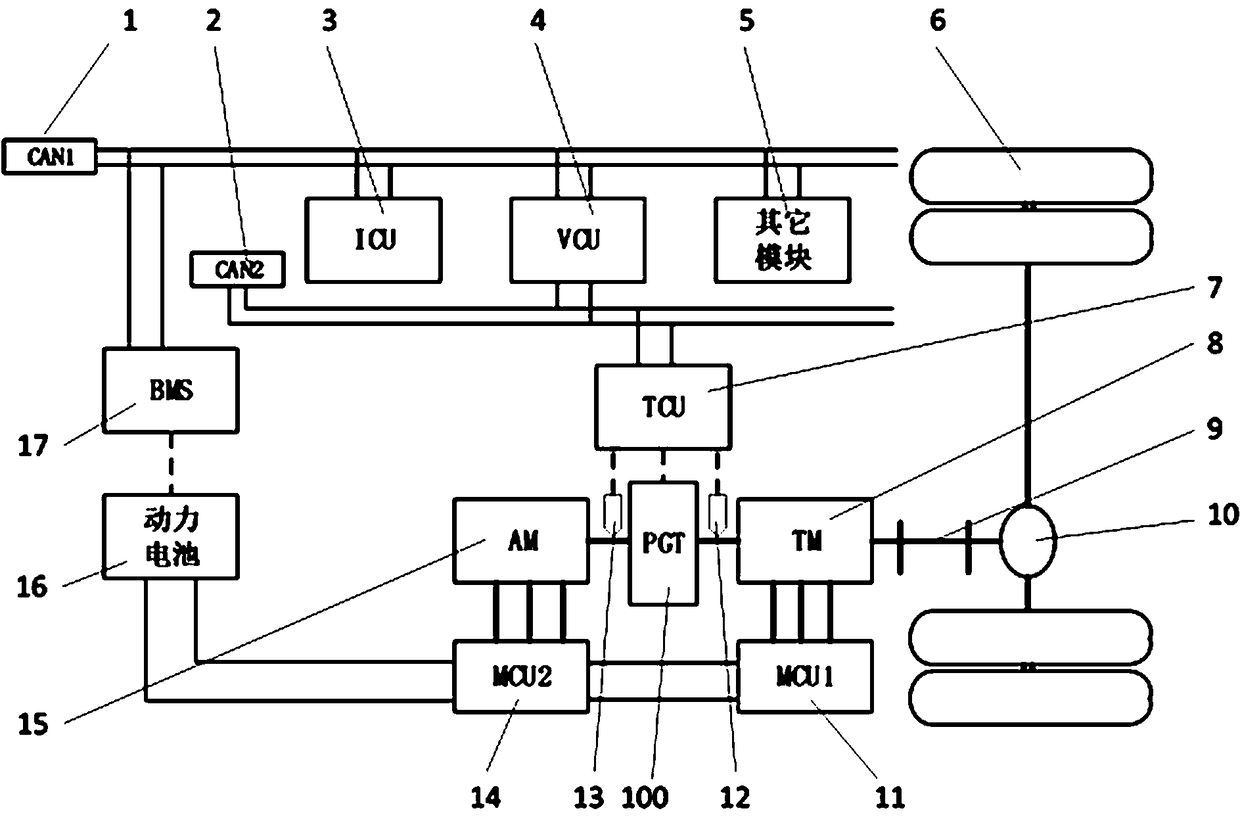

Automatic gear shift control system and method of motor-transmission integrated drive system for electrical vehicle

ActiveCN104442822AImprove shift qualityRealize automatic shift functionControl systemMotor controller

The invention discloses an automatic gear shift control system and method of a motor-transmission integrated drive system for an electrical vehicle. The motor-transmission integrated drive system comprises a drive motor, a transmission, a motor controller and a gear shift execution mechanism, wherein the drive motor is directly connected with the transmission through a spline and controlled by the motor controller to output a torque to the transmission; the gear shift execution mechanism is used for finishing the gear shift operation of the transmission; the motor-transmission integrated drive system is characterized in that a vehicle controller is arranged for coordination control on the motor controller and the gear shift execution mechanism to realize automatic gear shift function of the motor-transmission integrated drive system; the vehicle controller and the motor-transmission integrated drive system form the automatic gear shift control system. According to the automatic gear shift control system, the automatic gear shift function of the motor-transmission integrated drive system can be realized and the gear shift quality of the motor-transmission integrated drive system can be improved.

Owner:HEFEI UNIV OF TECH

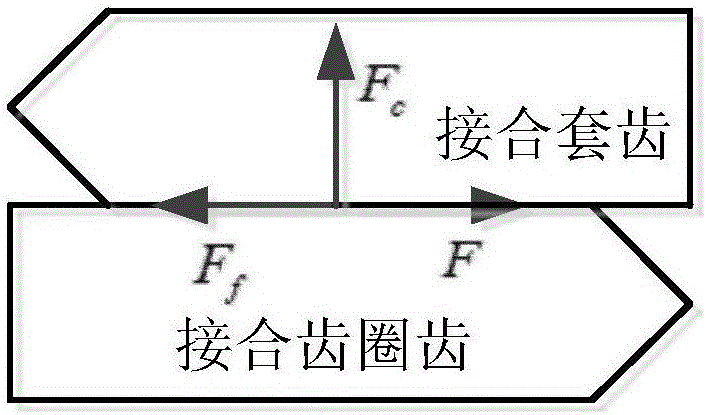

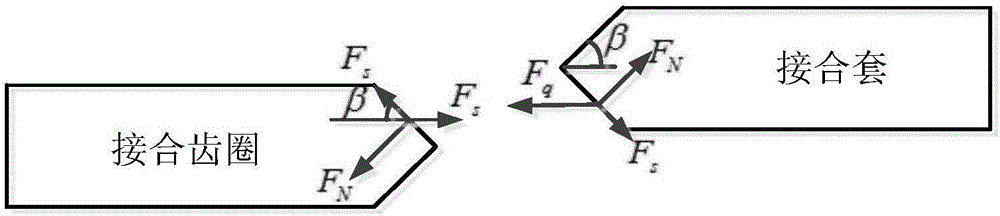

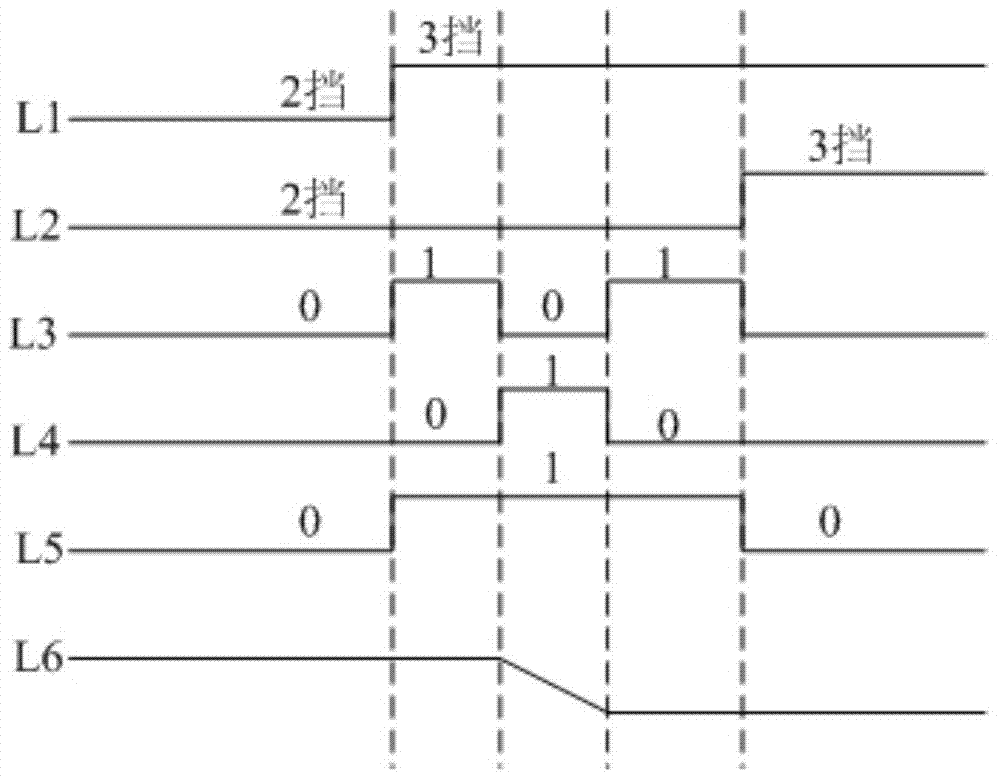

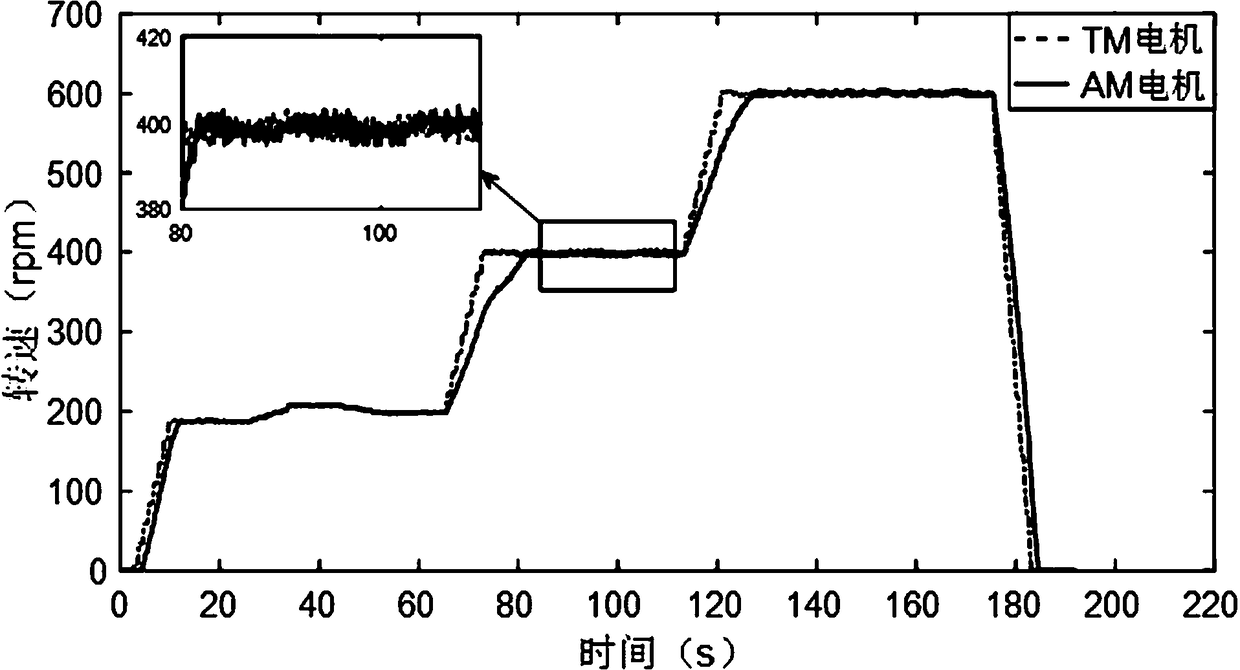

Non-clutch AMT (Automatic Manual Transmission) control system and method

ActiveCN105972199AImprove shift qualityImproved shift stabilityGearing controlControl systemElectric machine

The invention relates to a non-clutch AMT (Automatic Manual Transmission) control system. The non-clutch AMT control system comprises an MCU (Microprogrammed Control Unit) and a TCU (Transmission Control Unit) which are interconnected. Compared with the prior art, the non-clutch AMT control system has the beneficial effects that after the system enters a shifting process, the TCU can take over the control right of a driving motor, so that the technical effects of optimizing the shifting quality, reducing the shifting time and improving the shifting stability can be achieved. The invention also relates to a non-clutch AMT control method. The non-clutch AMT control method comprises a speed regulating stage; the motor in the shifting process of the method is in a torque mode; the speed regulating stage comprises a motor synchronous speed regulating stage and a mechanical synchronous speed regulating stage. Compared with the prior art, the non-clutch AMT control method has the beneficial effects that the shifting process is divided into six stages through the control method, namely, an unloading stage, an idling stage, an electronic synchronizing stage, a mechanical synchronizing stage, a gear engaging stage and a loading stage, and thus the technical effects of greatly reducing the overall shifting time, reducing the impact in gear engaging, and prolonging the service lives of mechanical parts such as a synchronizer can be achieved.

Owner:北理华创(佛山)新能源汽车科技有限公司

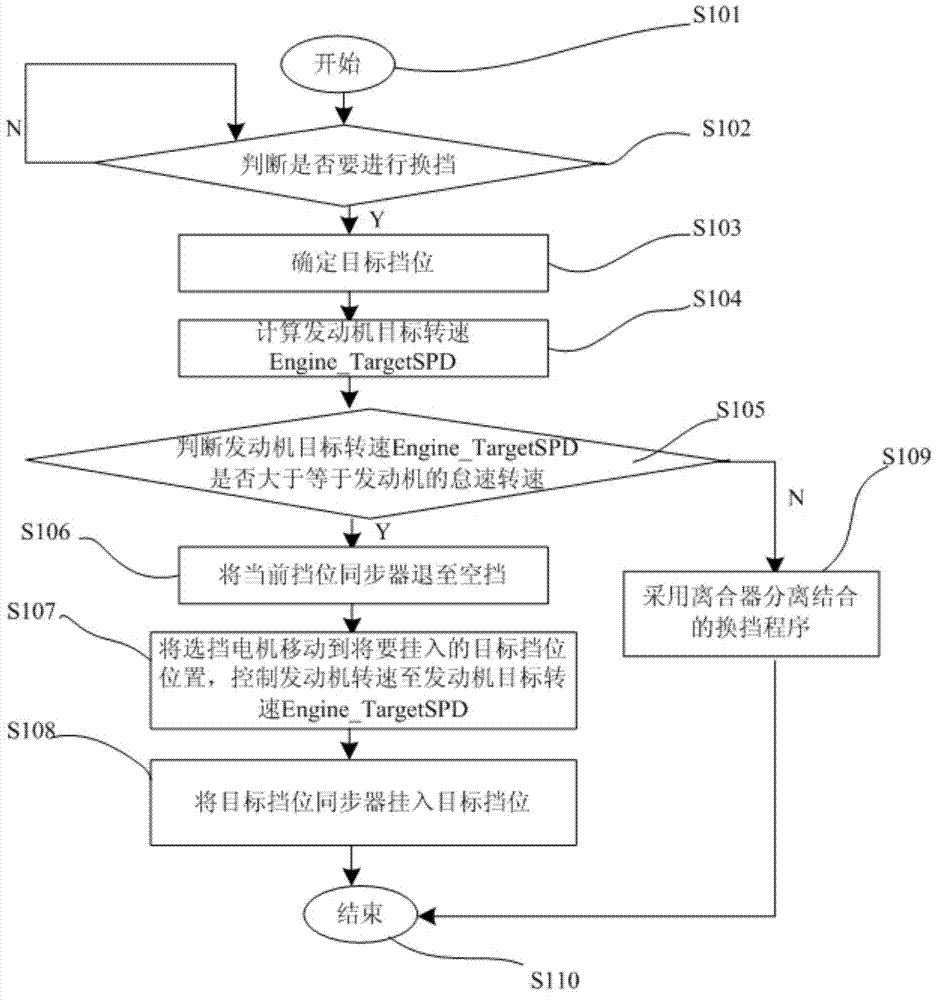

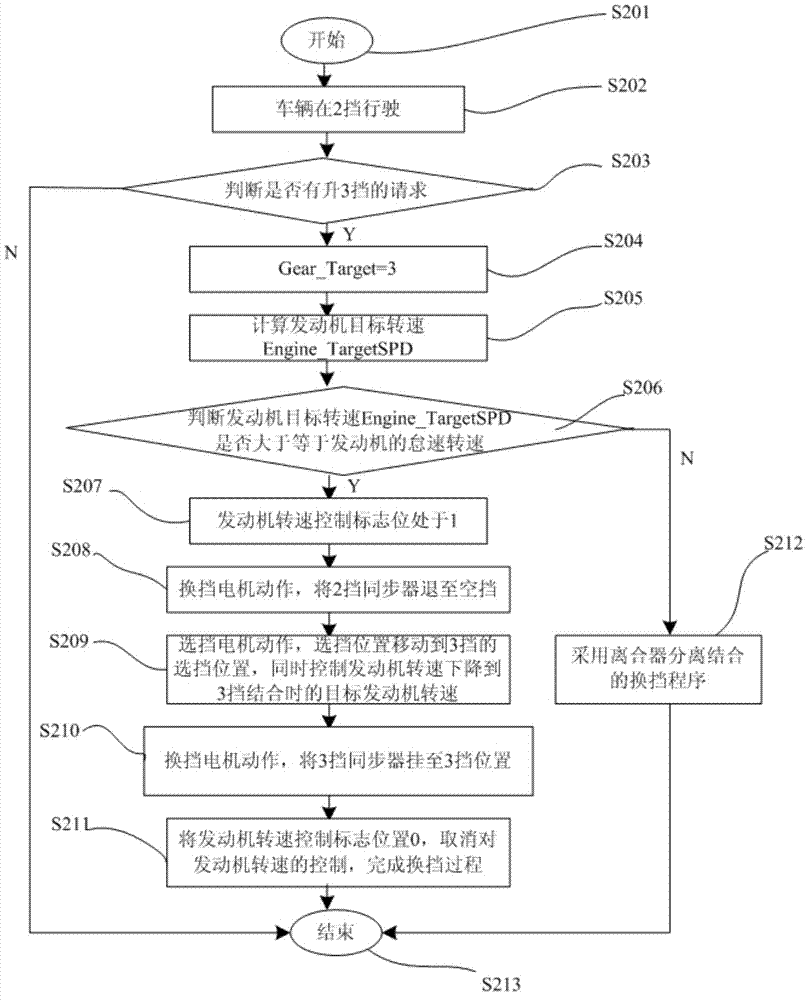

Shifting method for AMT (Automated Mechanical Transmission) automatic gearbox

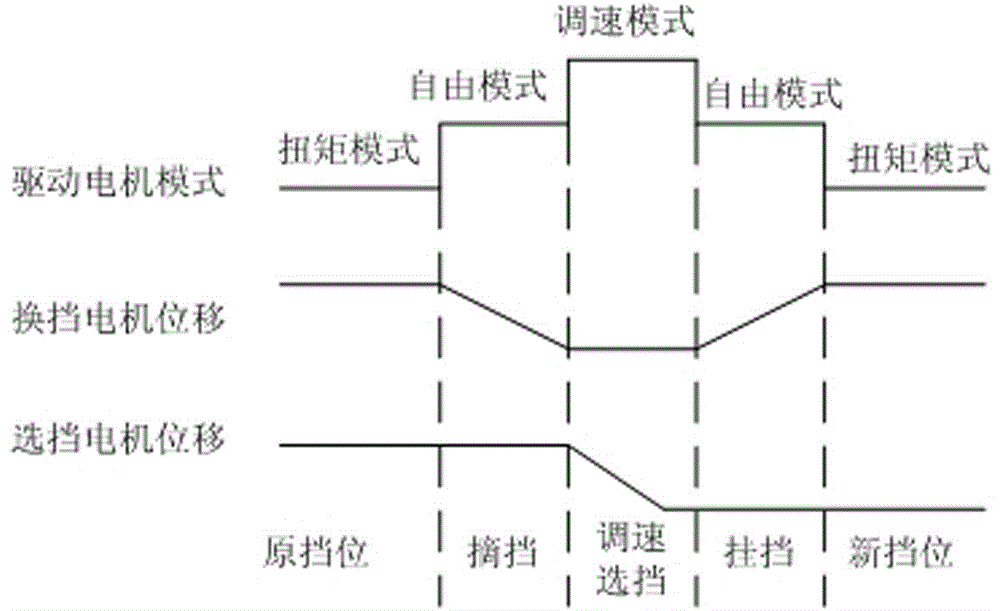

ActiveCN103697154ASmall shift shockShorten shift timeGearing controlFluid gearingsMechanical transmissionElectric machine

The invention relates to a shifting method for an AMT (Automated Mechanical Transmission) automatic gearbox. The shifting method comprises the following steps A, during a driving process of a vehicle, judging whether shifting to other advancing gears or not according to a vehicle driving state parameter and an operation signal, if yes, executing step B, and if not, repeating step A; B, determining a target gear; C, calculating a target rotating speed of an engine according to a rate of the present vehicle speed to the gear speed of the target gear; D, judging whether the target rotating speed of the engine is greater than or equal to an idle speed or not, and if yes, executing steps E-G; E, maintaining the present rotating speed and using a shifting motor for retreating a present gear synchronizer to a neutral gear; F, controlling a gear selecting motor to act, and controlling the rotating speed of the engine to the target rotating speed of the engine when the gear selecting motor moves to the target gear position; G, controlling the gear selecting motor to act, shifting a target gear synchronizer to the target gear, cancelling the control on the rotating speed of the engine and finishing the gear shifting.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Optimized integrated system with drive motor and automatic transmission and gear shifting control method

ActiveCN106080155AMitigate the cause of loud noiseAvoid damageElectric propulsion mountingControl devicesDrive motorIntegrated systems

The invention provides an optimized integrated system with a drive motor and an automatic transmission and a gear shifting control method. The optimized integrated system comprises the drive motor, an input shaft, a torsional damper, the automatic transmission, a transmission shaft, a main speed reducer and an integrated control unit. An output shaft of the drive motor is connected with one end of the torsional damper through a spline, and the other end of the torsional damper is connected with an input shaft of the automatic transmission through a spline. An output shaft of the automatic transmission is connected with one end of the transmission shaft through a universal joint, and the other end of the transmission shaft is connected with the main speed reducer through a universal joint. The drive motor is directly connected with the automatic transmission through the torsional damper, damage of impact generated in the gear shifting process to the shaft of the drive motor is reduced, and meanwhile, the gear shifting failure rate caused by gear shifting impact is reduced. According to the optimized integrated system, the gear shifting time is shortened, the phenomena of power impact and unsmooth gear shifting are eliminated, equipment abrasion is lowered, and the dynamic performance, the economic performance and the smoothness of an electric automobile are improved.

Owner:金碧波

Automatic transmission assembly for a vehicle, and vehicle incorporating same

ActiveUS7752936B2Shorten the timeShorten shift timeToothed gearingsOff-road vehiclesAutomatic transmissionEngineering

Owner:HONDA MOTOR CO LTD

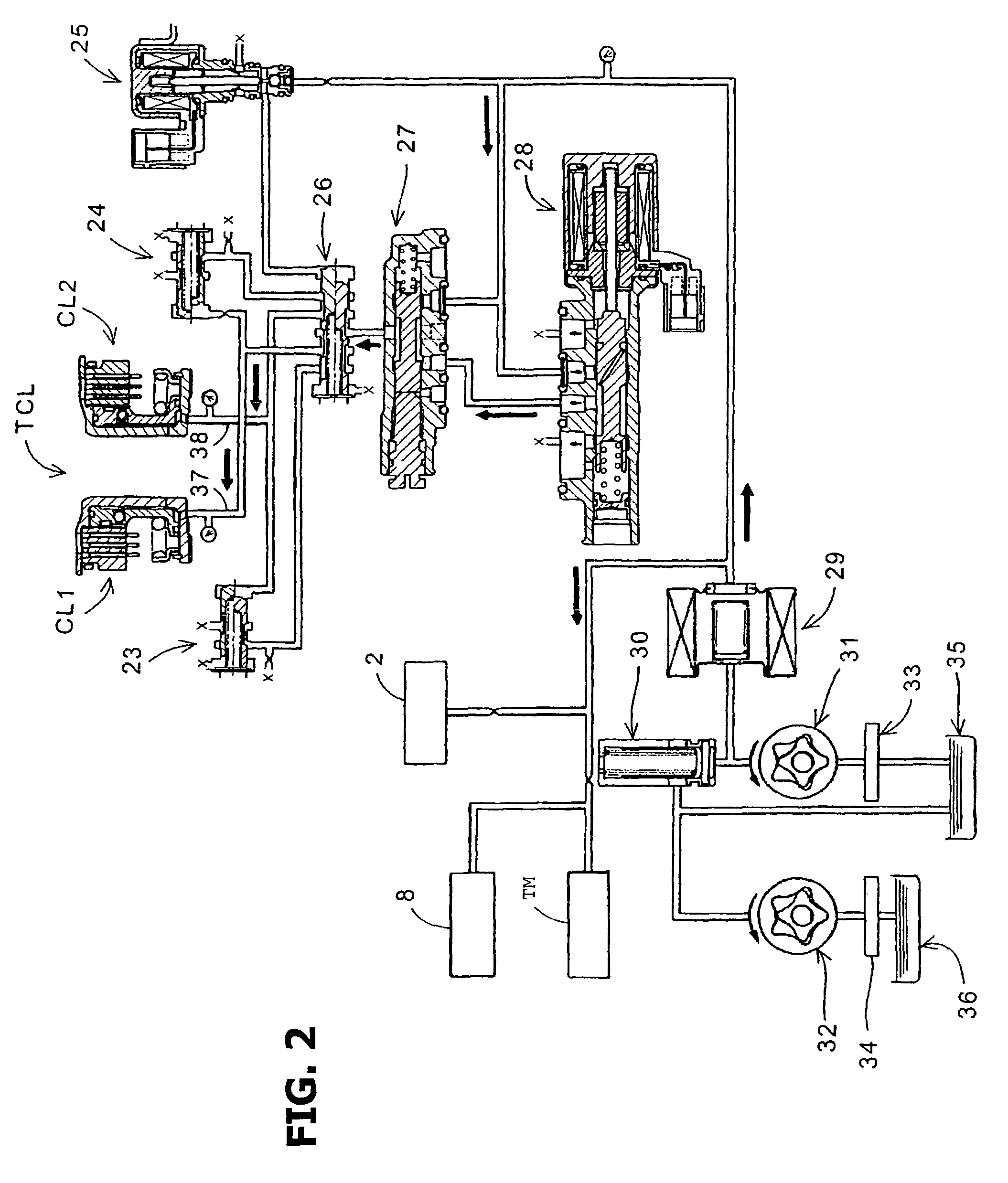

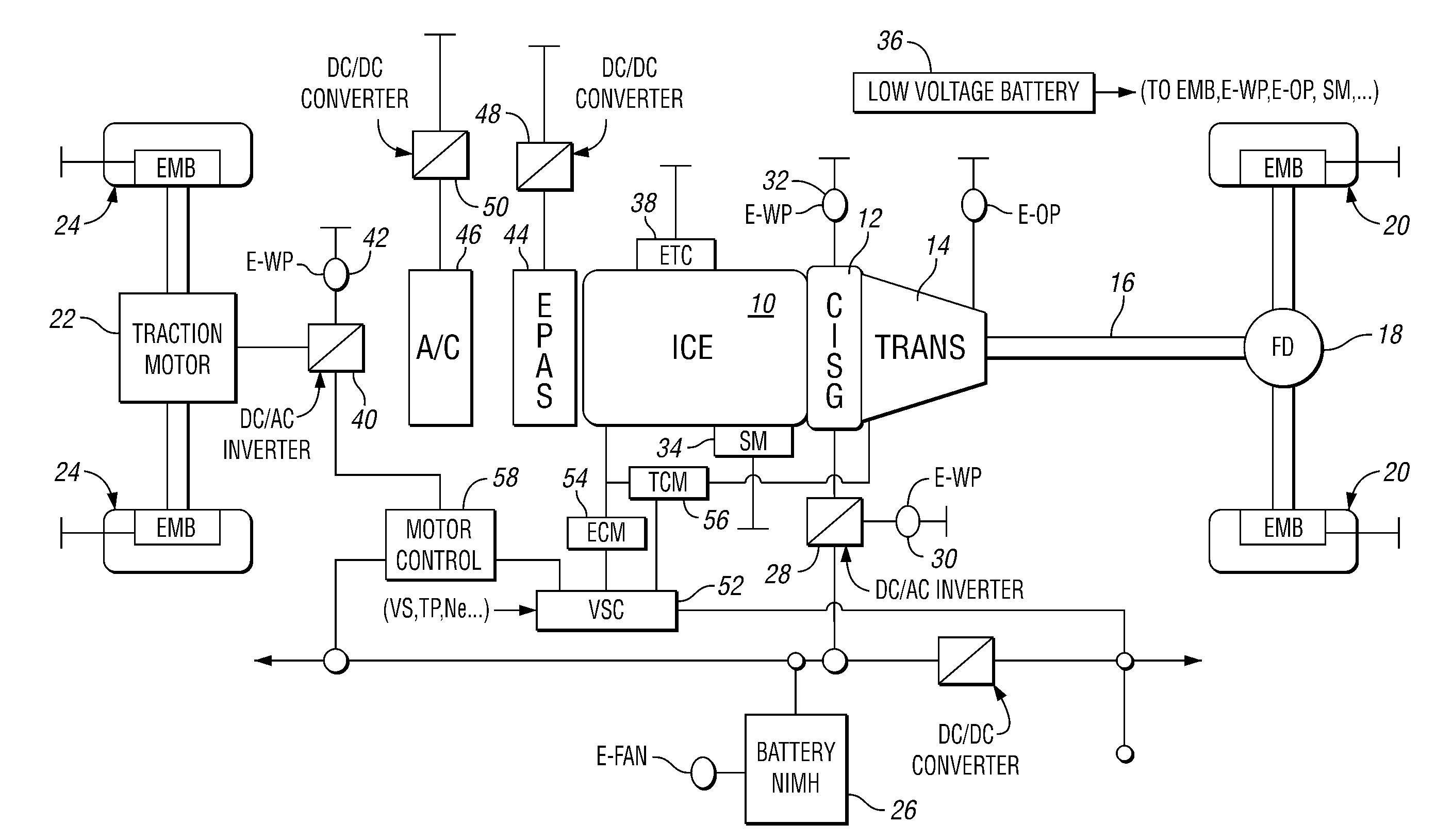

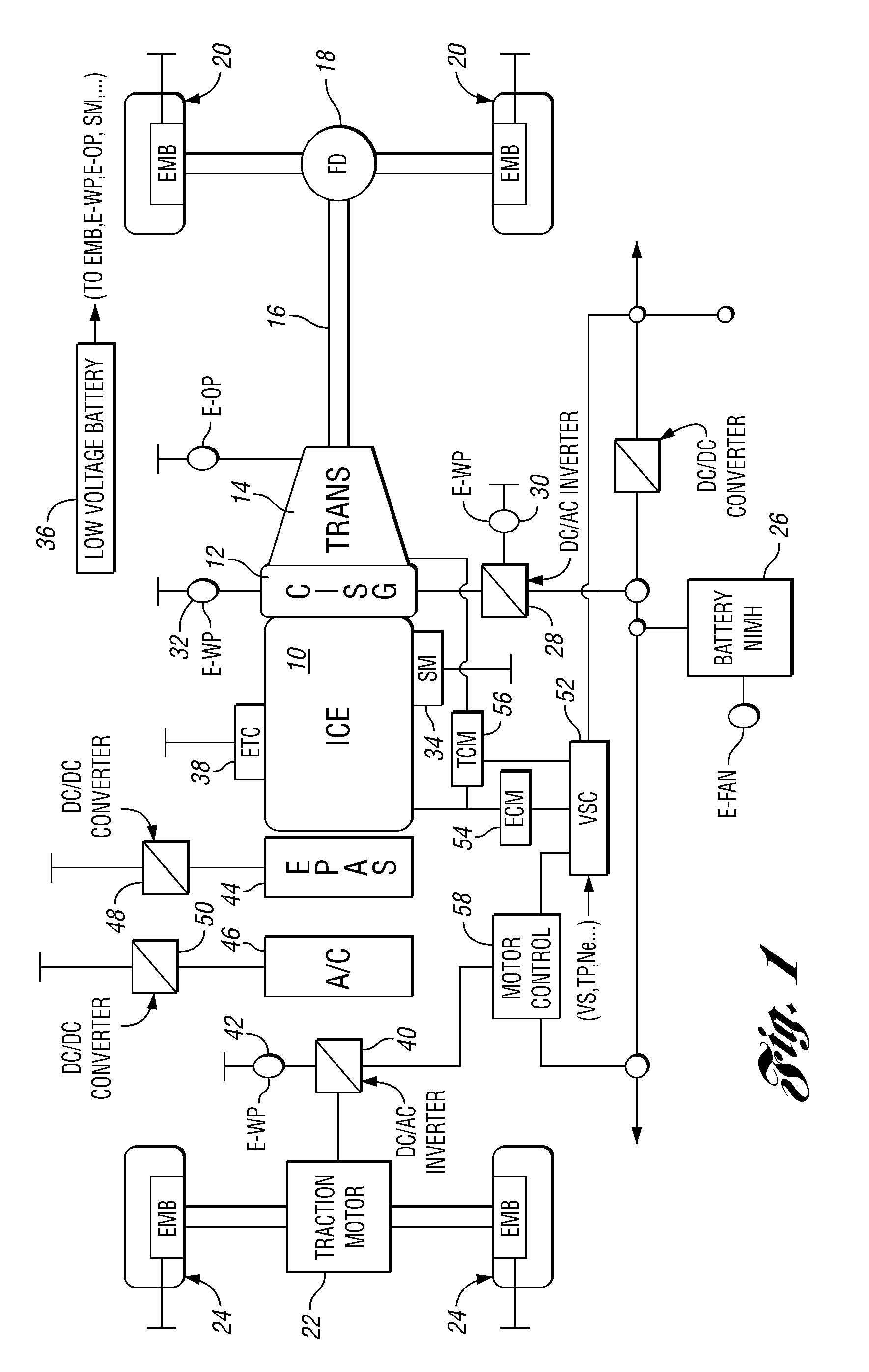

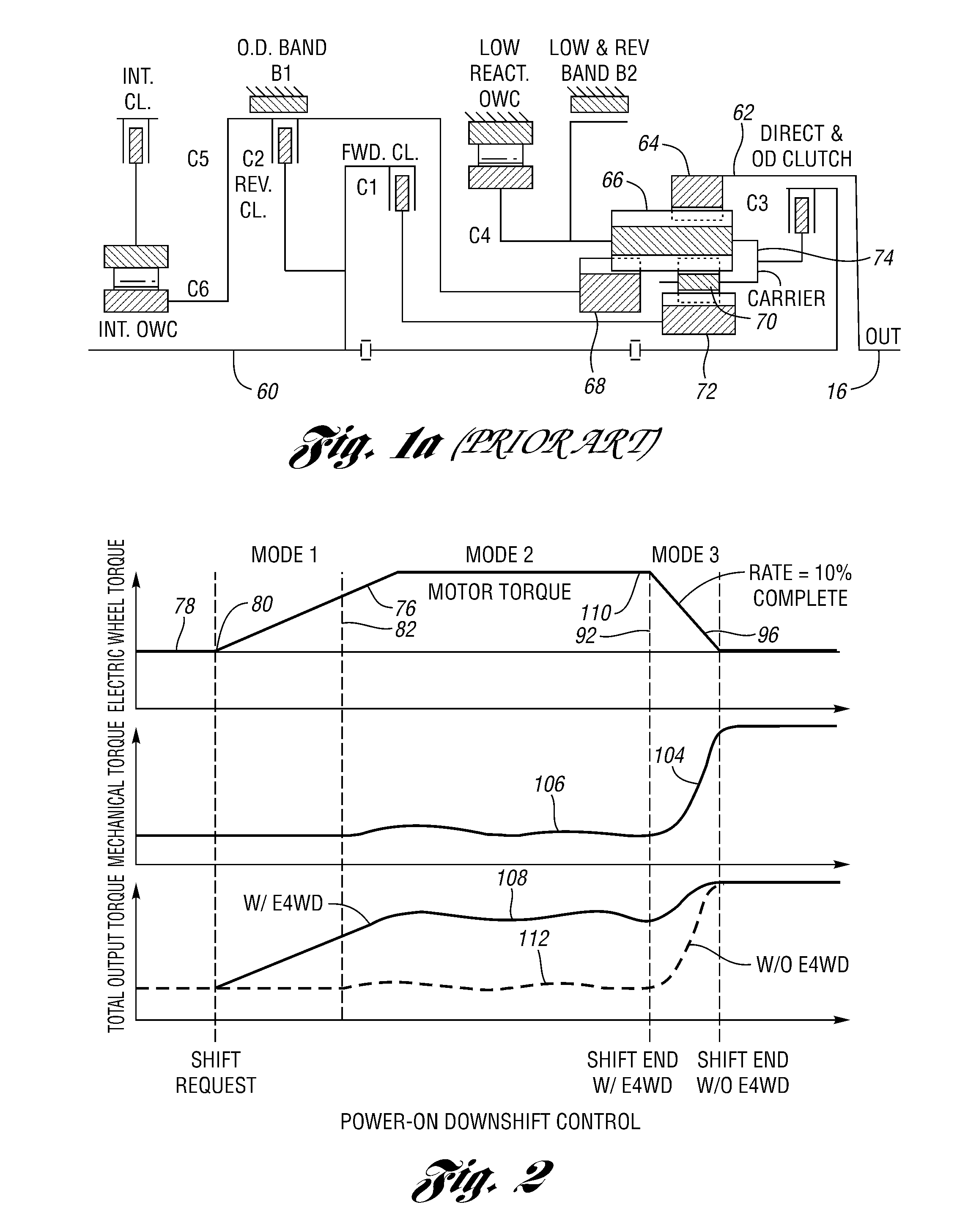

Power-on downshift control for a hybrid electric vehicle powertrain

InactiveUS20080058152A1Quality improvementImprove the level ofElectric propulsion mountingToothed gearingsElectric vehiclePowertrain

A method is disclosed for controlling a hybrid electric vehicle powertrain having a multiple-ratio transmission. On a power-on transmission downshift, electric wheel torque is used to compensate for a slow response of an engine to a request for increased traction wheel torque.

Owner:FORD GLOBAL TECH LLC

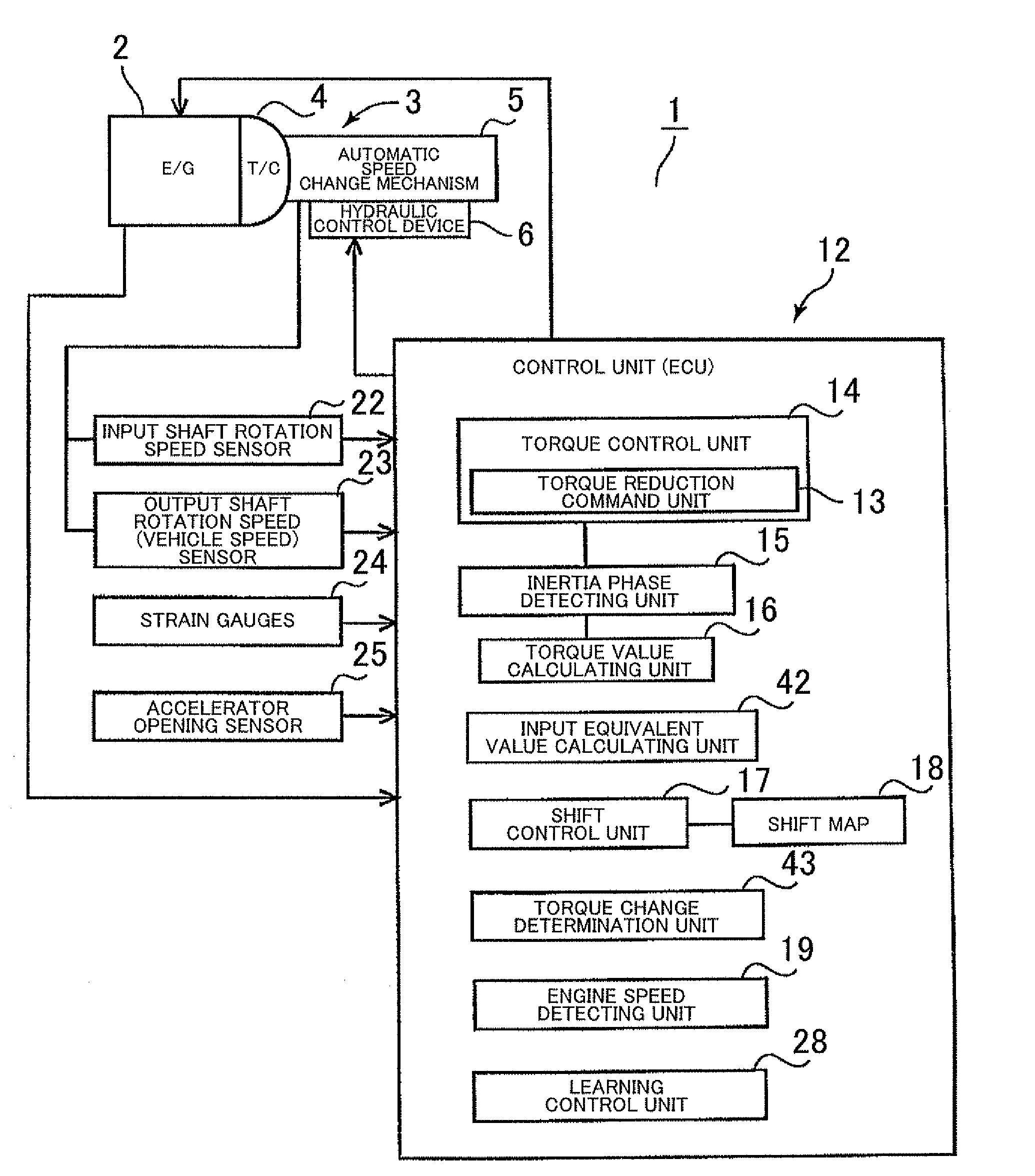

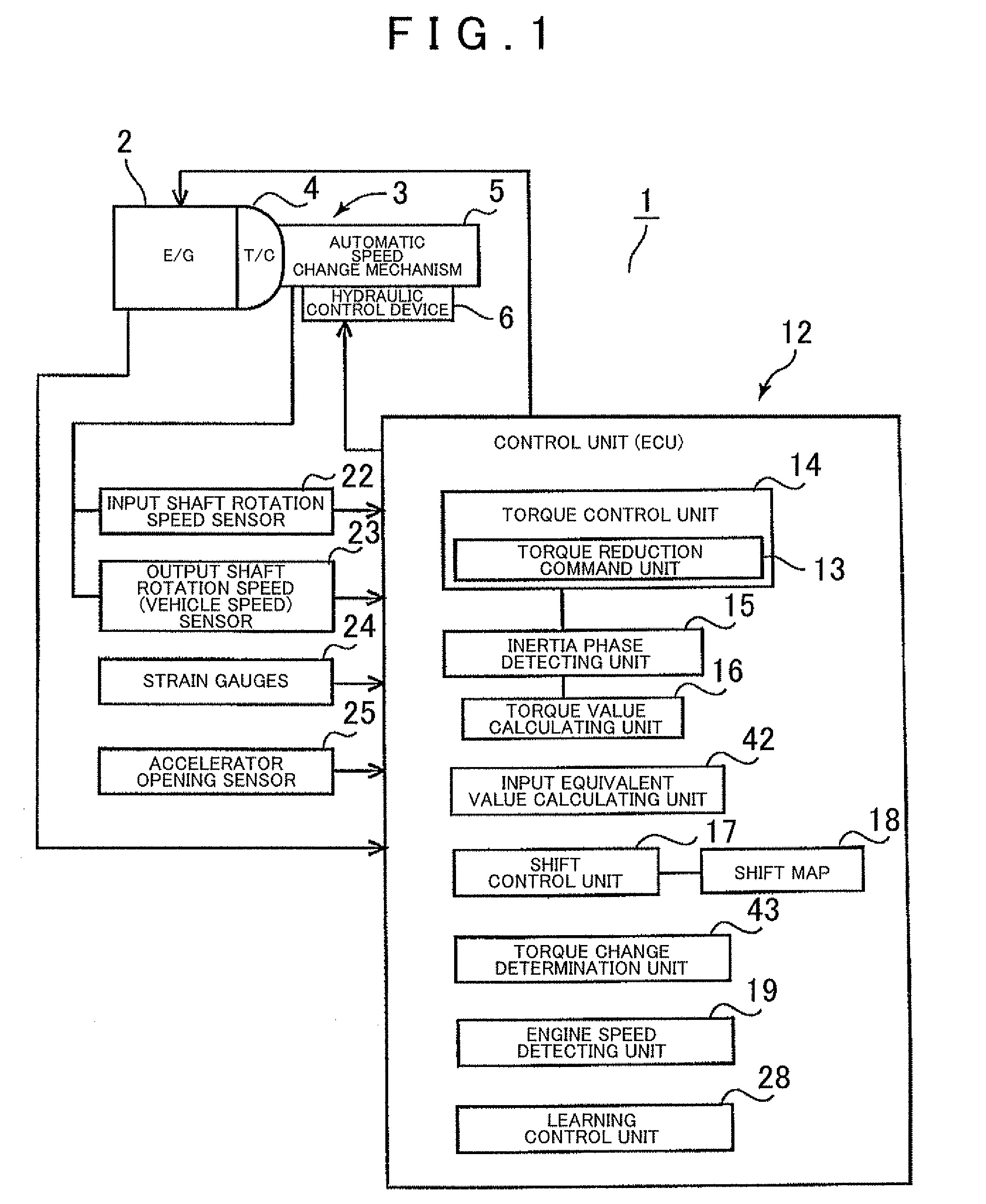

Shift control apparatus for automatic transmission

InactiveUS20090248263A1Simple structureLow costDigital data processing detailsVehicle sub-unit featuresAutomatic transmissionControl theory

Owner:AISIN AW CO LTD

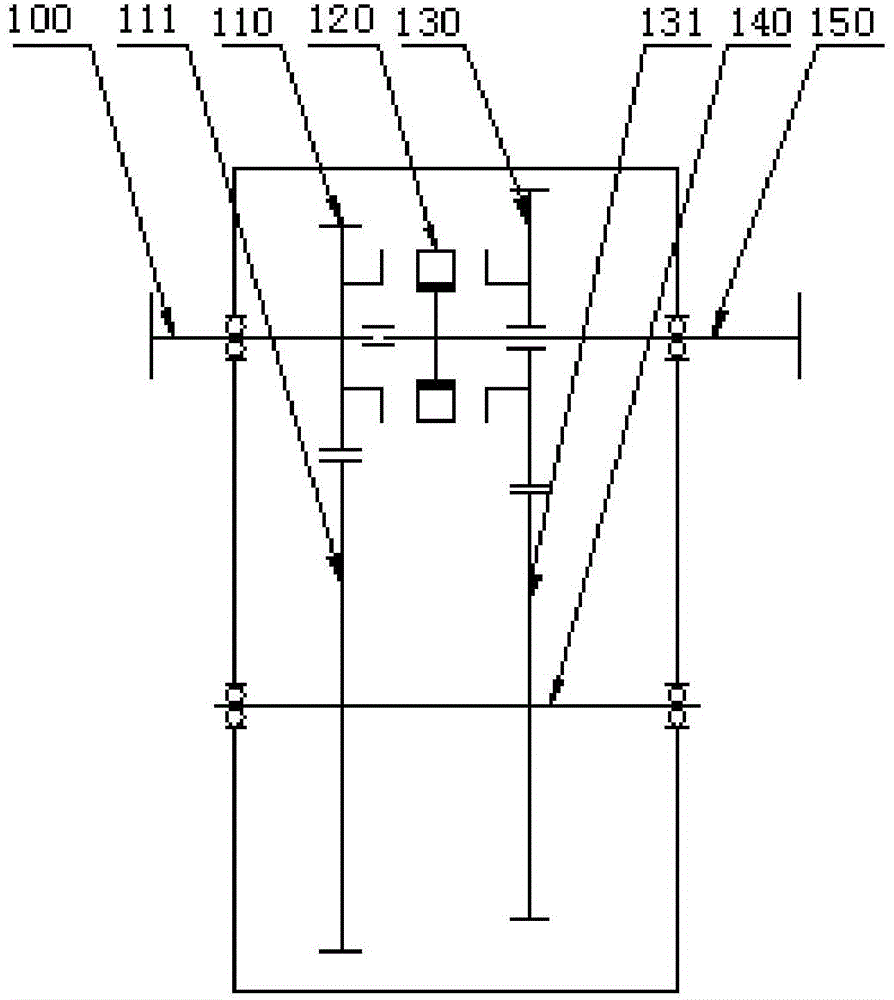

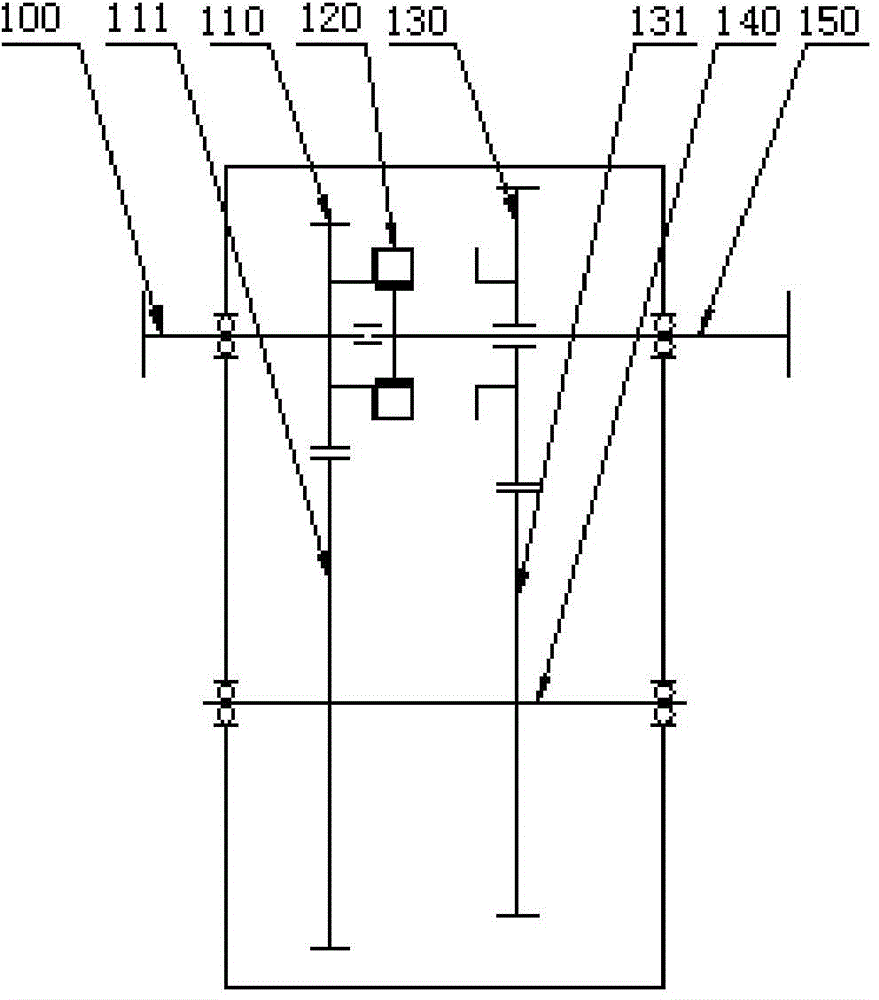

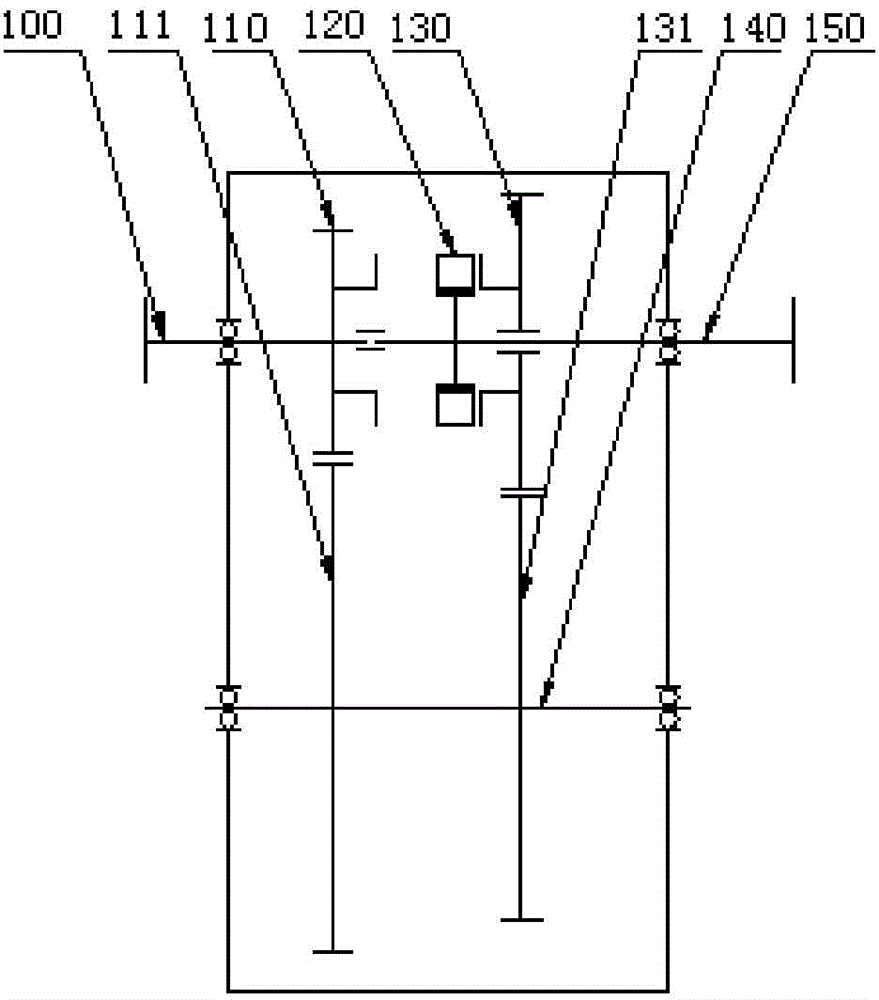

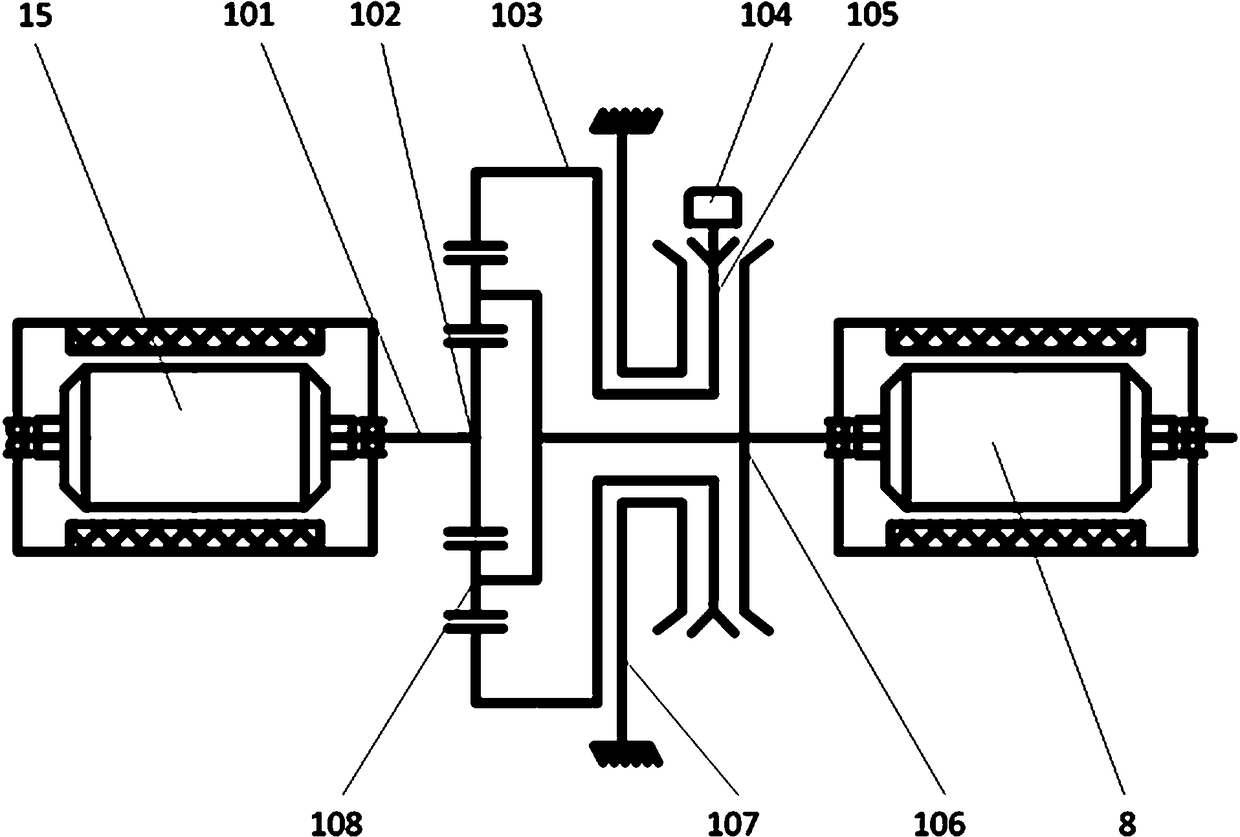

Double-motor self-adaptive speed pre-regulating multi-gear power coupling device and control method thereof

PendingCN108312896ASimplify the shifting processThere will be no phenomenon such as cyclic shiftingSpeed controllerControl devicesPower couplingDrive shaft

The invention relates to a double-motor self-adaptive speed pre-regulating multi-gear power coupling device and a control method thereof. The double-motor self-adaptive speed pre-regulating multi-gearpower coupling device comprises a main driving motor (8), a planetary line speed change device (100), an auxiliary motor (15), a vehicle transmission shaft (9) and a vehicle driving axle (10); the planetary line speed change device (100) comprises a planet gear mechanism and a double-way combining device (105); the planet gear mechanism comprises a planetary line sun gear (102), a planetary linegear ring (103), a planetary line planet carrier (108) and a planetary line shell (107); and the planetary line gear ring (103) is jointed with the planetary line shell (107) or a planet carrier output shaft (106) through the double-way combining device (105). Compared with the prior art, the double-motor self-adaptive speed pre-regulating multi-gear power coupling device has the advantages that running requirements of a pure electric bus can be satisfied, the rotation speed of the motor can be pre-regulated before the gear shifting process, self-adaptive speed regulation is realized to a certain degree, and the rotation speed relation is automatically regulated and matched according to gear shifting needs in any running state.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

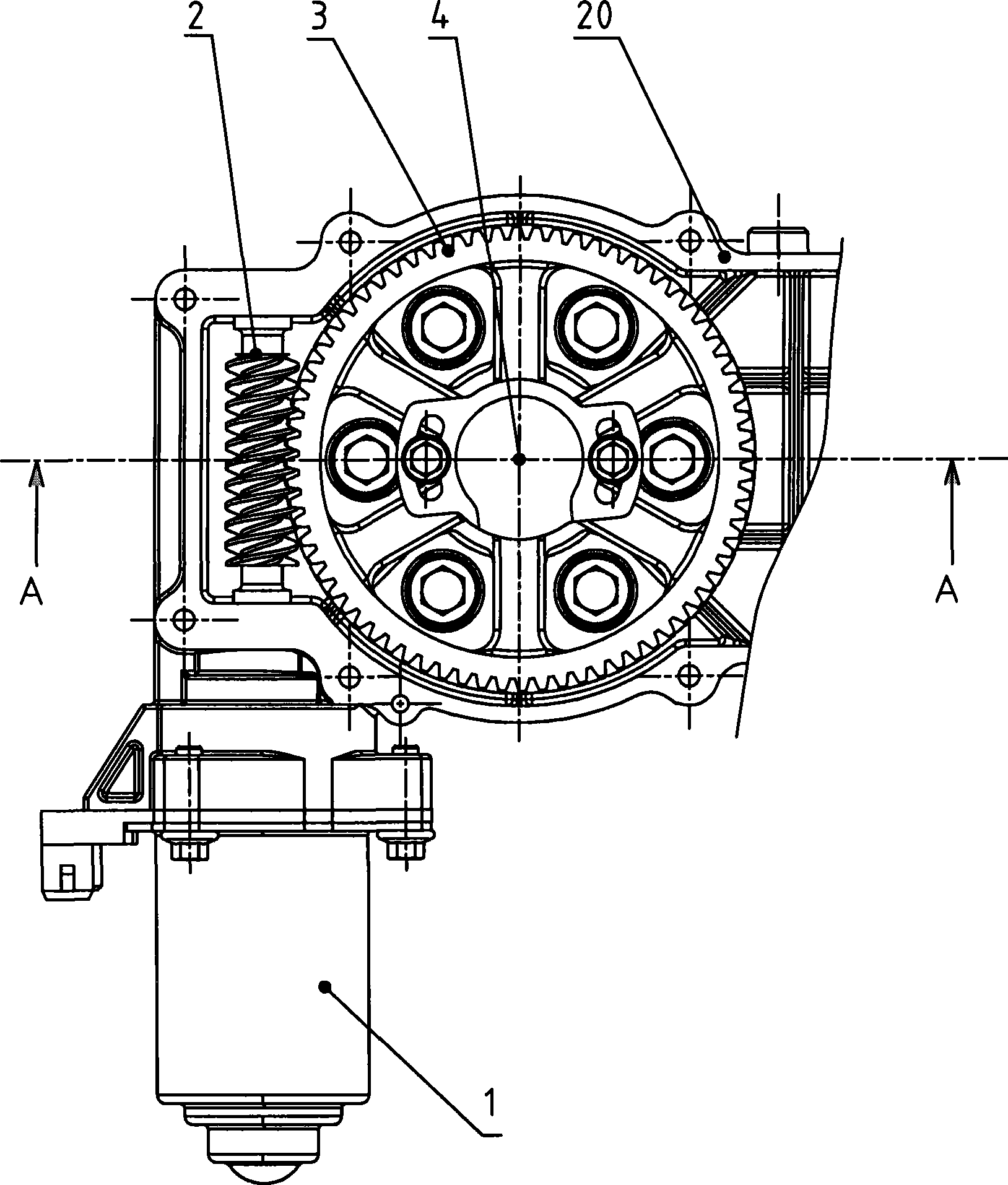

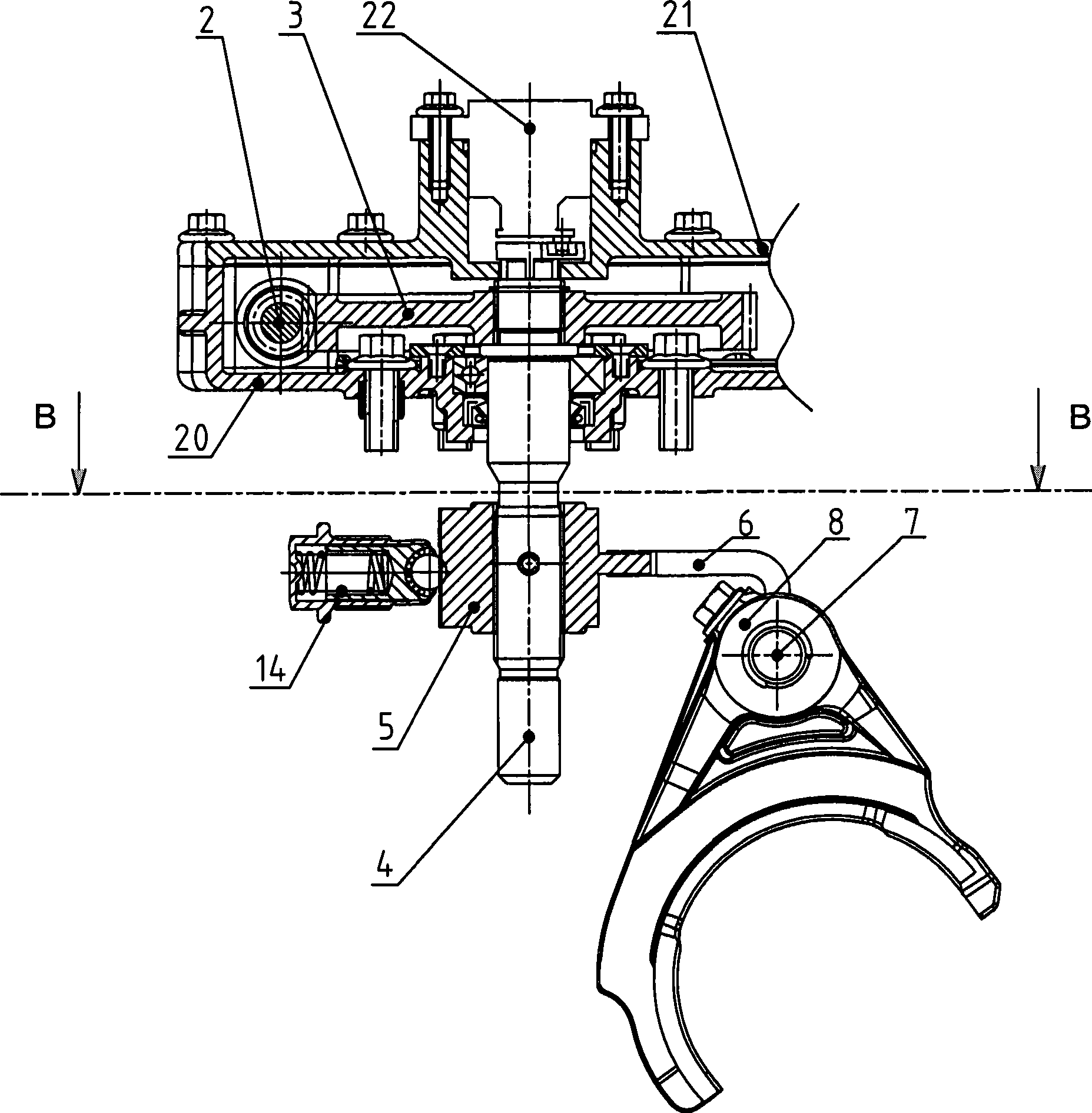

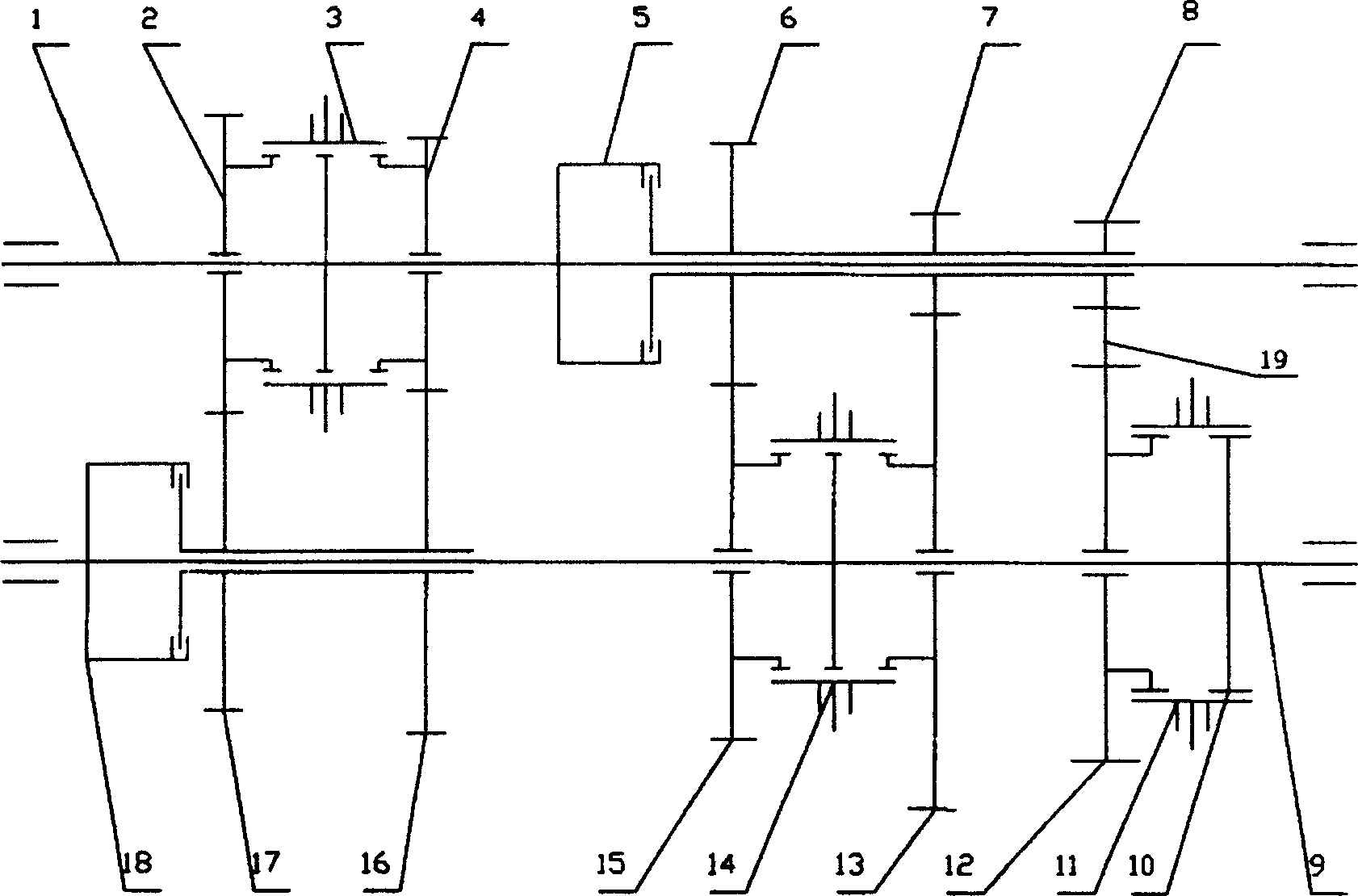

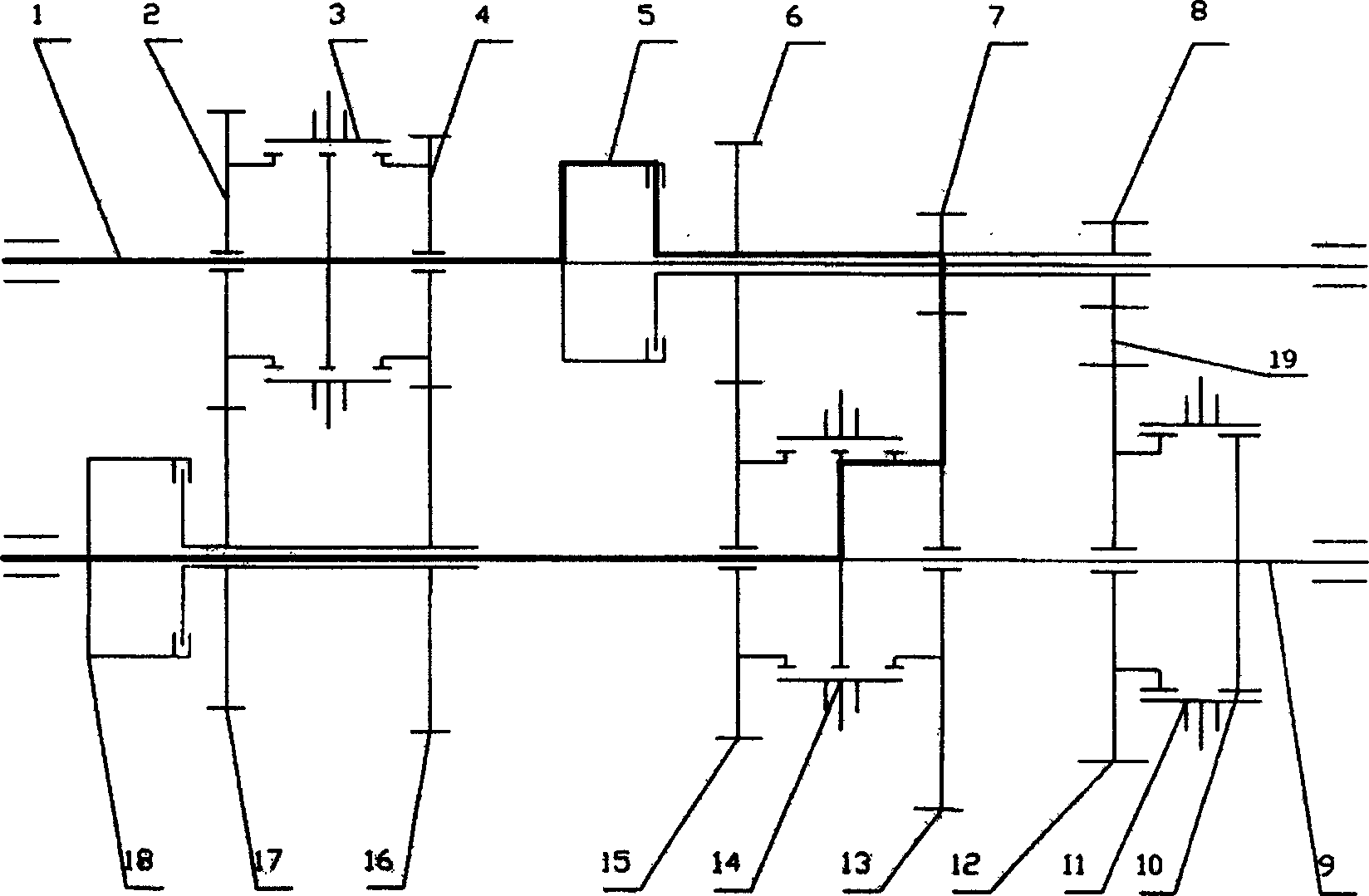

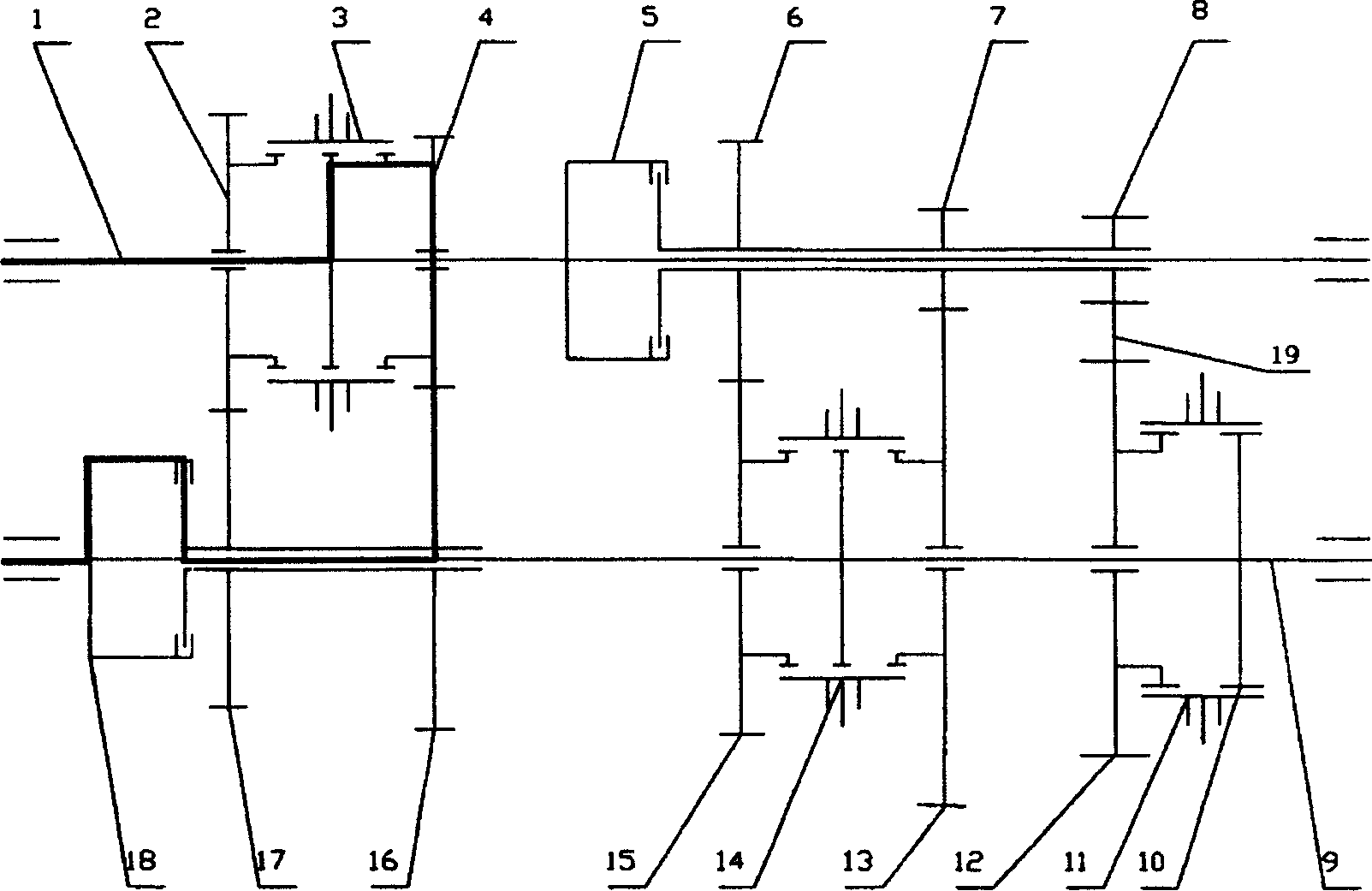

Automatic gear shift mechanism for transmission

ActiveCN101457831ASimple structureShort shift timesGearing controlMotor driveElectrical and Electronics engineering

Owner:BYD CO LTD

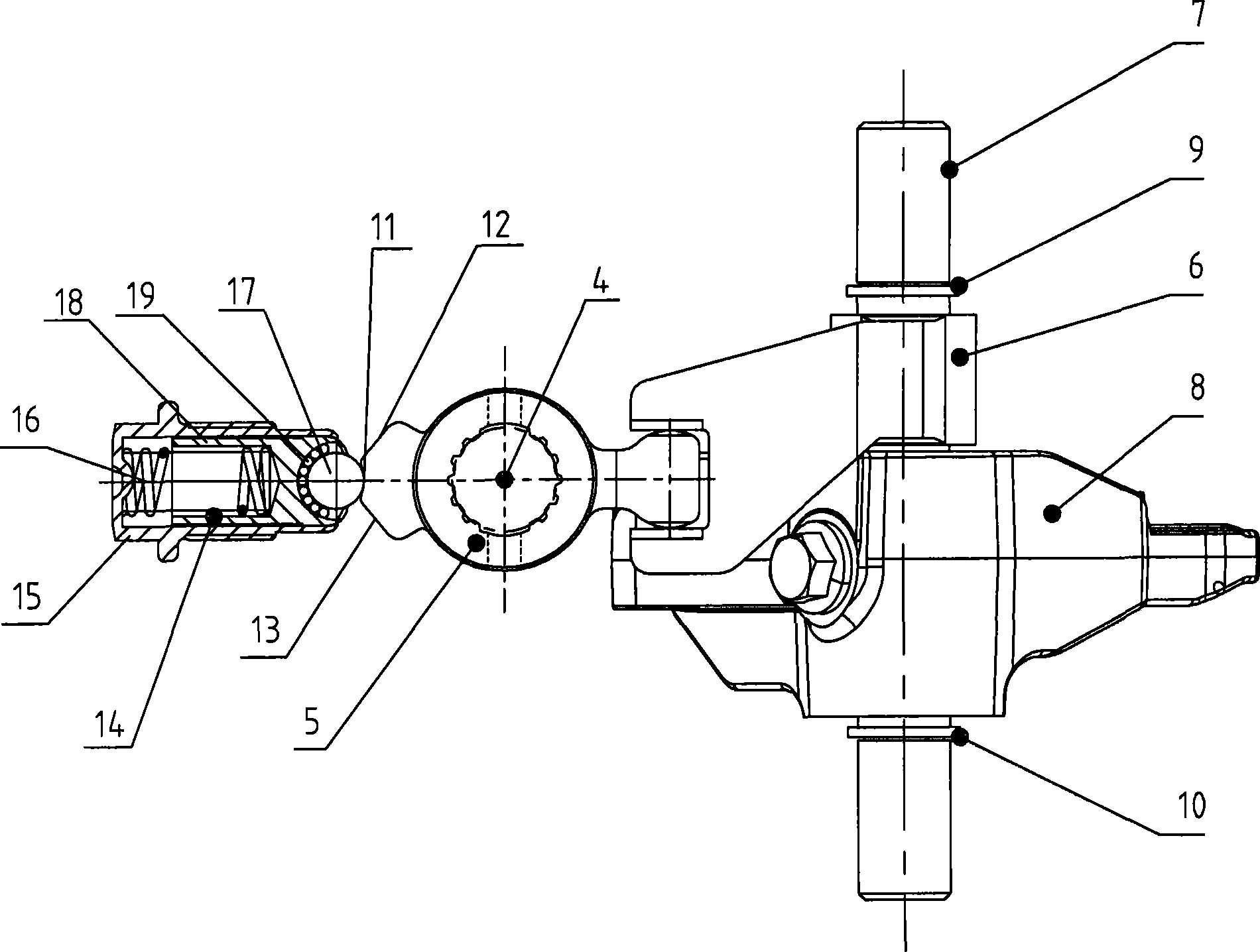

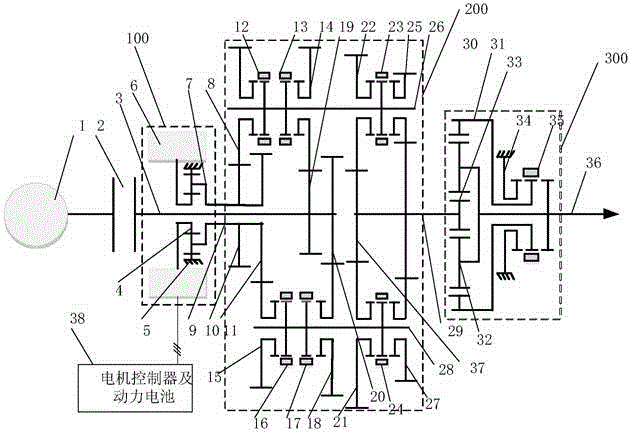

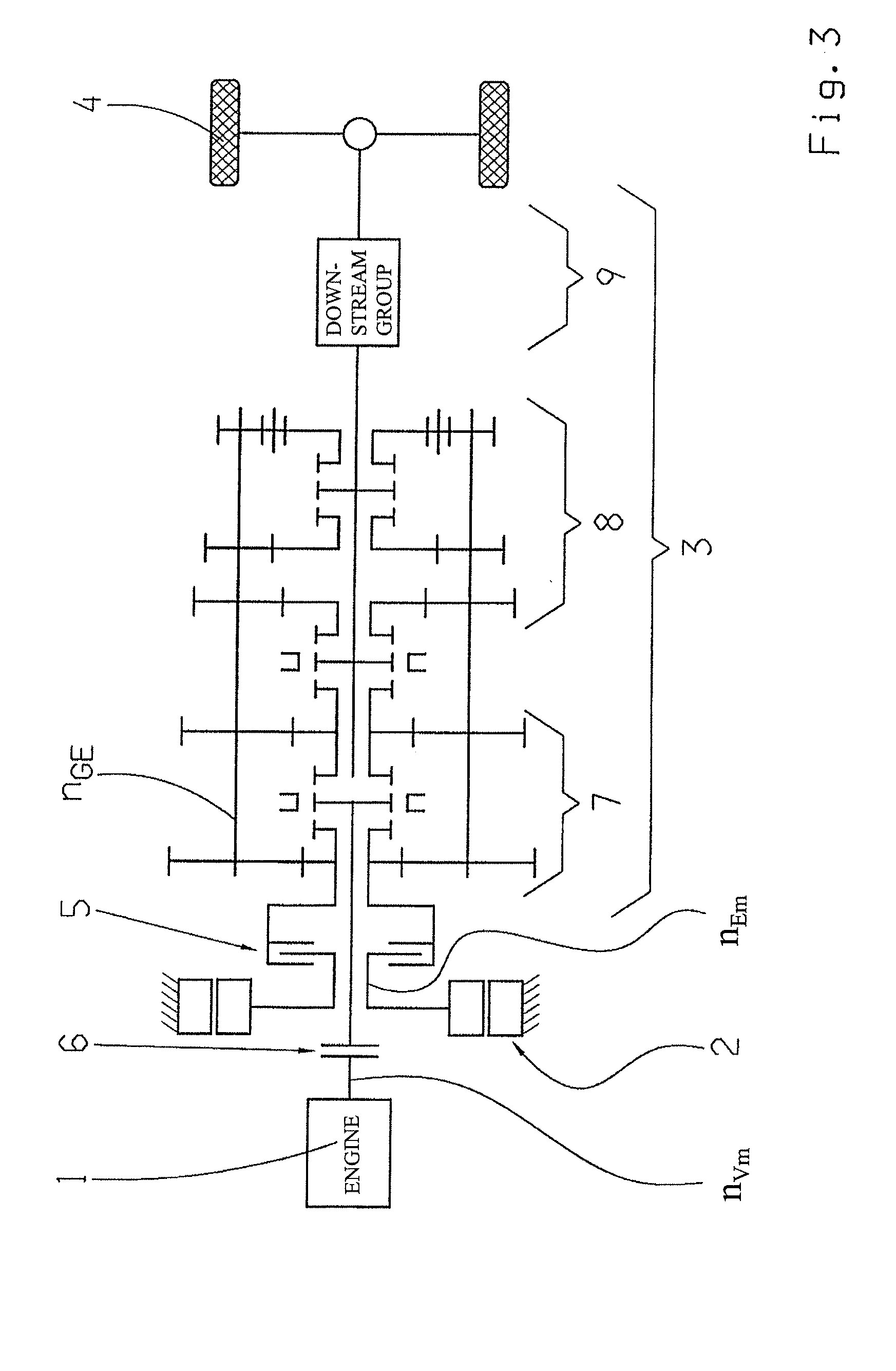

Multi-degree-of-freedom power gear-shifting parallel form hybrid power multi-gear speed changing box

ActiveCN104477023AImplement power shiftImprove powerGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelElectric machine

The invention belongs to the technical field of power transmission and particularly relates to a hybrid power multi-gear speed changing box. The multi-degree-of-freedom power gear-shifting parallel form hybrid power multi-gear speed changing box is characterized in that power of an engine is input to an engine input shaft through a rear input shaft of a clutch; a motor module comprises a motor and a speed reducing planet row; the rotary speed of the motor is accelerated by the speed reducing planet row. A main box module of the speed changing box is composed of a multi-degree-of-freedom fixed shaft gear mechanism, and can be used for coupling power of an engine and the motor and realizing five gears matched with the engine and three gears matched with the motor. A secondary box module of the speed changing box can be used for realizing high-gear and low-gear gears, and commonly work with a main box input module of the speed changing box to realize nine gears matched with the engine and five gears matched with the motor. According to the hybrid power multi-gear speed changing box, power gear shifting is realized and the power performance of vehicles is improved; the gear-shifting quality is improved, the abrasion of the clutch is reduced and the fuel oil economical efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Electronic control electromechanical gear shifting system for automatic transmission

InactiveCN1635289AShorten shift timeSimple structureGearing controlControl devicesAutomatic transmissionControl system

This invention relates to an electric controlled mechanic automatic speed variator shift system, which comprises shift execution structure and shift control system, wherein the said execution structure is composed of independent each shift fork current motor, shift gear, and shift gear bars, that is, each direct current motor is connected to one shift gear fixed on each fork axis shift gear bar and shift gear and each direct current motor is separately connected to the said shift control system.

Owner:JILIN UNIV

Double clutch type automatic gearbox

InactiveCN1616853AImprove fuel economyImprove powerToothed gearingsGearing controlAutomatic transmissionGear wheel

The present invention belongs to the field of mechanical automatic speed variator for vehicle, and is especially one kind of double clutch type automatic gear box in new structure. The automatic gear box includes various setting gear pairs, synchronous shifting unit and shifting control system, and features that each of the power input shaft and the power output shaft is provided with one wet clutch, all the setting gear pairs are divided into odd number set and even number set connected separately to the driven sheet of one of the clutches, and two clutches transmit the work power alternately to realize setting switching. The shift process has no power interruption, short shifting time, greatly raised shifting comfort and excellent shifting power performance and quality of vehicle. The present invention has simple and compact parallel shaft structure, low cost but the same effect as automatic rotary shaft gear box in complicated structure.

Owner:JILIN UNIV

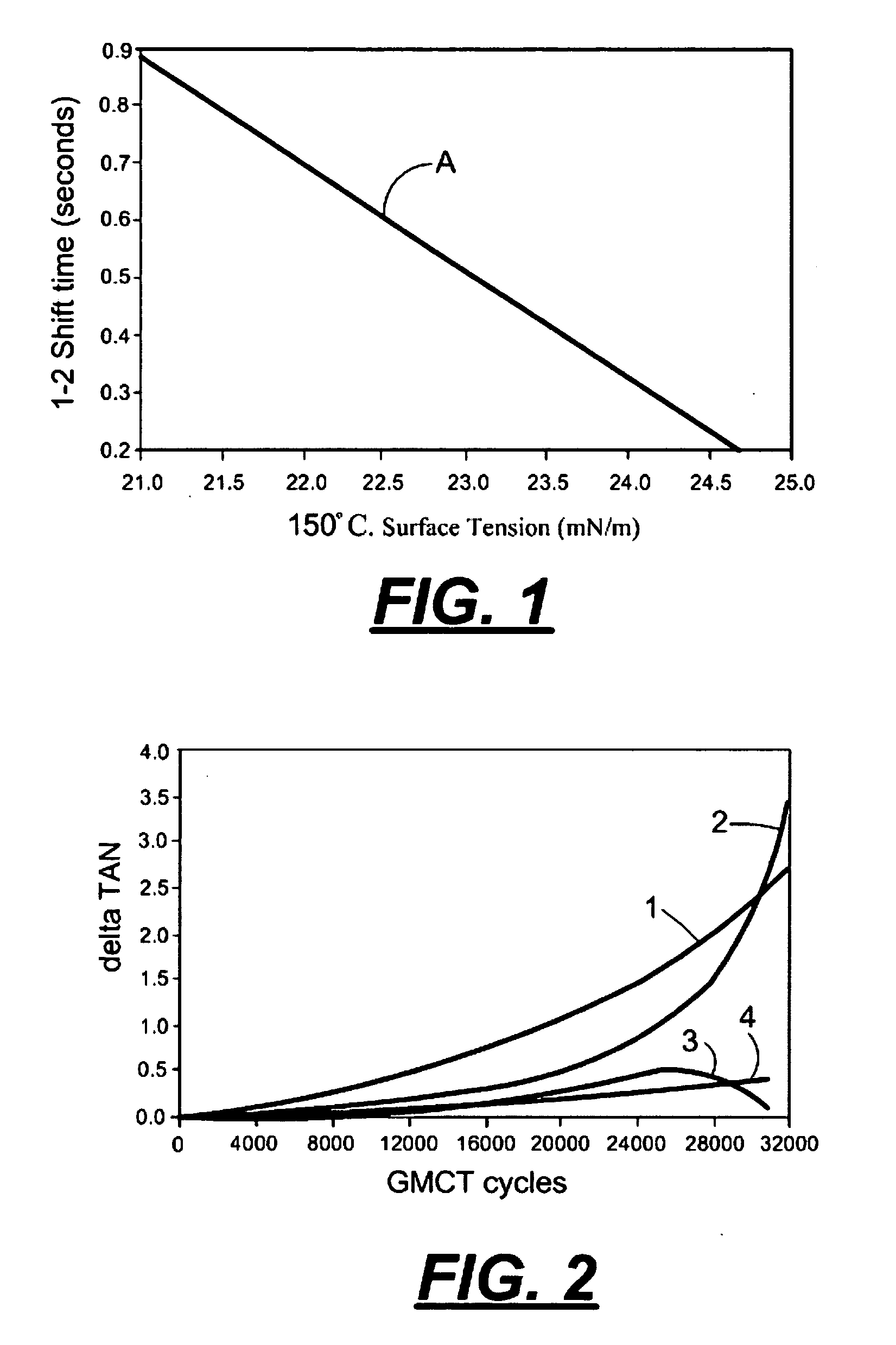

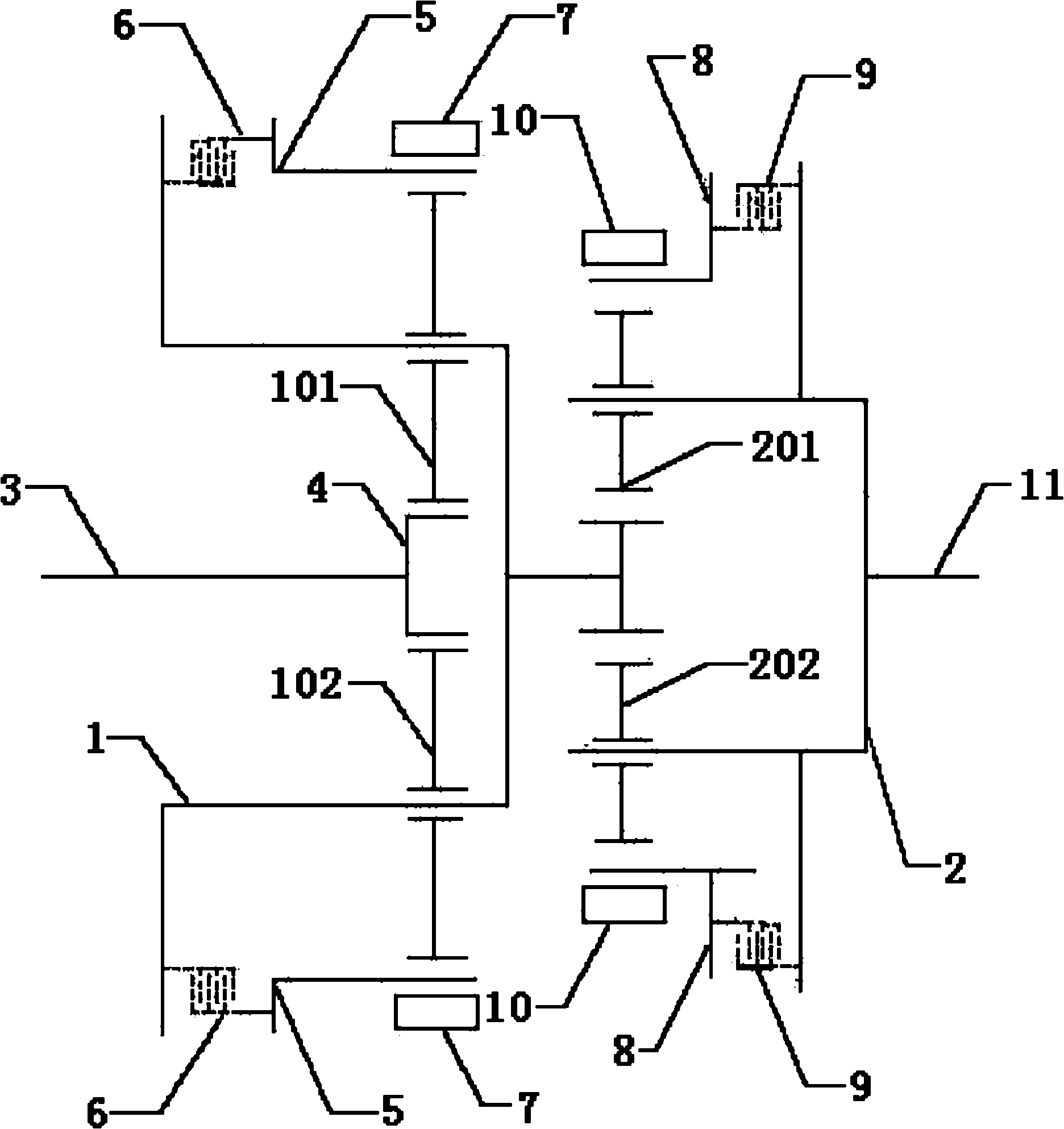

Power transmission fluids with enhanced lifetime characteristics

InactiveUS20060264339A1Reduce surface tensionDecrease foaming tendencyGear lubrication/coolingAdditivesCentistokesShift time

A power transmission fluid having improved characteristics, a method of lubricating a transmission, and a vehicle containing the transmission fluid is disclosed. The transmission fluid includes an amount of silicon-containing antifoam agent having a kinematic viscosity of greater than about 20,000 centistokes at 25° C. that is effective to provide gear shifting times of no more than about 0.75 seconds over a useful lifetime of the transmission fluid.

Owner:DEVLIN MARK T +3

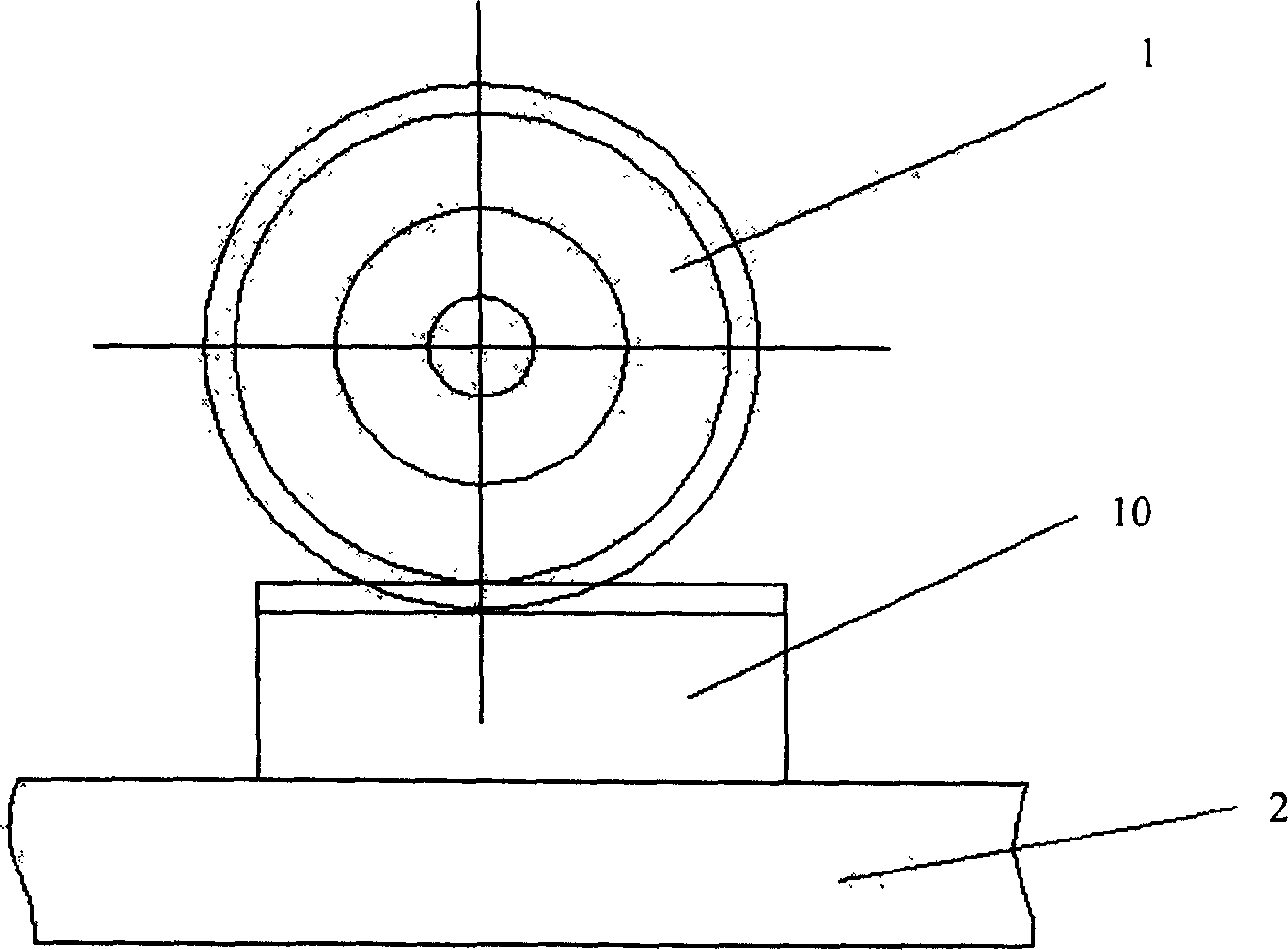

Planet gear type automatic speed change system for electric automobile

InactiveCN102162505ASave the link of speed adjustmentEasy gear shiftingToothed gearingsGear wheelEngineering

The invention relates to a planet gear type automatic speed change system for an electric automobile, which comprises a front planet row, a rear planet row and an input shaft, wherein a sun gear at the front end of the input shaft is meshed and connected with a first planet gear and a second planet gear; the first planet gear and the second planet gear are respectively meshed and connected with a first gear ring; a first clutch is arranged between a first planet carrier and the first gear ring; a first brake is arranged on the first gear ring; the first planet carrier is meshed and connected with a third planet gear and a fourth planet gear; the third planet gear and the fourth planet gear are respectively meshed and connected with a second gear ring; a second clutch is arranged between a second planet carrier and the second gear ring; a second brake is arranged on the second gear ring; and the second planet carrier is connected with an output shaft. The planet gear type automatic speed change system provided by the invention has the beneficial effects of simple and compact structure, smaller volume and weight and higher transmission efficiency, omits the link of adjusting the speed by a motor, shortens the gear shift time, improves the gear shift quality, and meets the light weight principle of an automobile.

Owner:BIT HUACHUANG ELECTRIC VEHICLE TECH

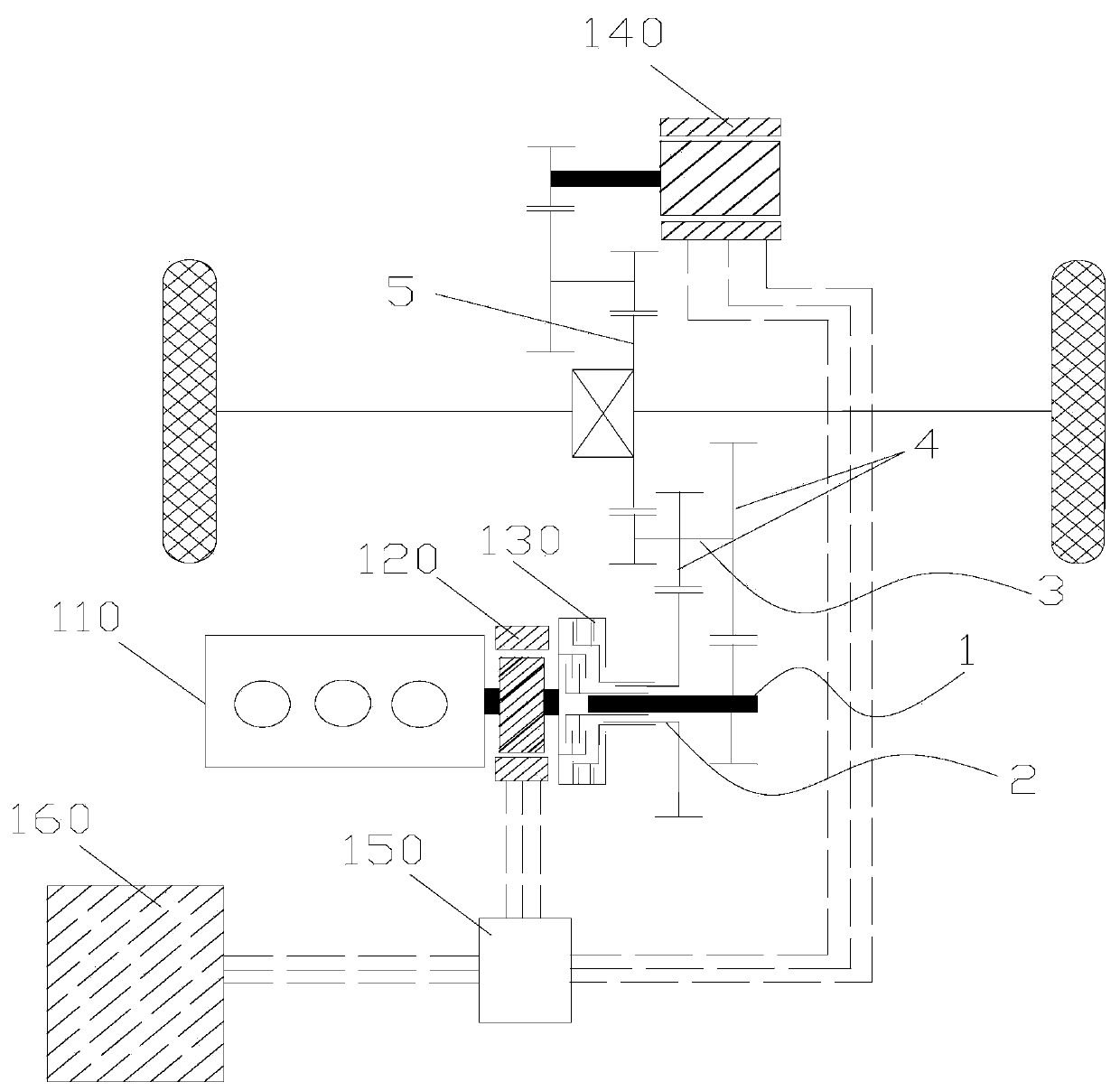

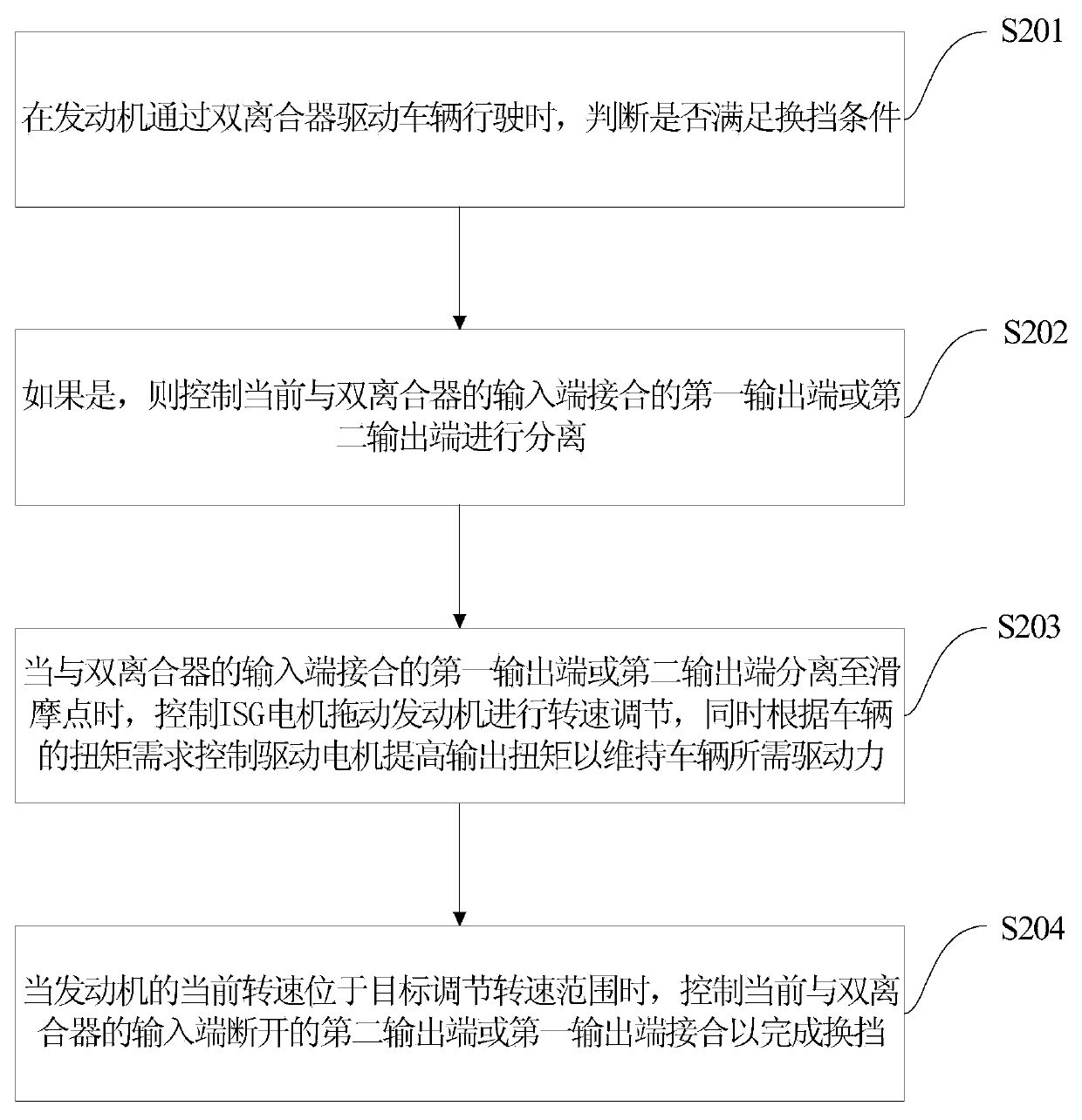

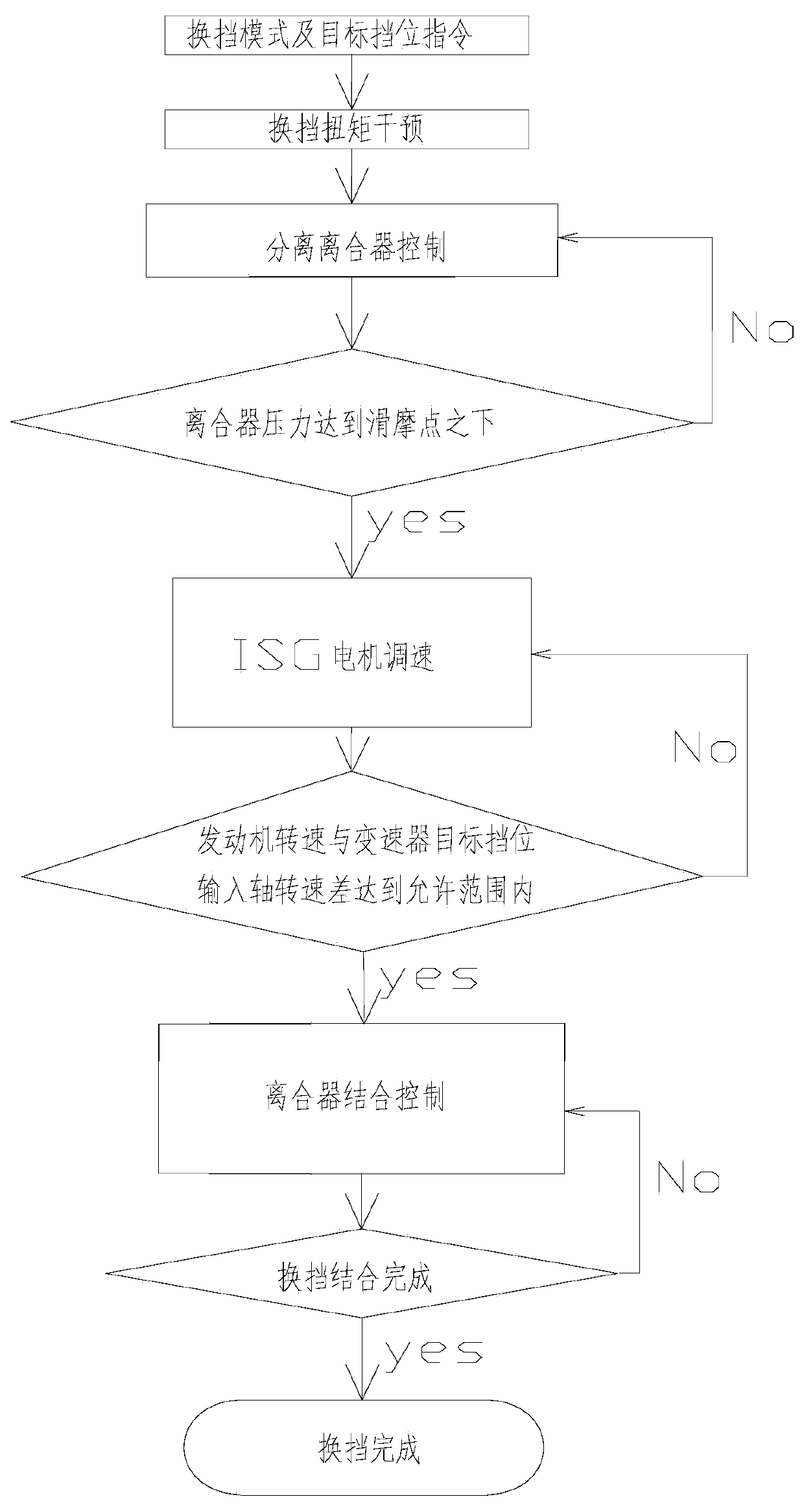

Vehicle control method, control system and vehicle comprising control system

ActiveCN104192147AGuaranteed powerImprove ride comfort performanceInternal combustion piston enginesElectric machineControl system

The invention provides a vehicle control method. The vehicle control method comprises the steps that when an engine drives a vehicle to run through two clutches, whether gear shifting conditions are met is judged, and if yes, the current first output ends or second output ends connected with the input ends of the two clutches are controlled to be separated; when the first output ends or the second output ends connected with the input ends of the two clutches are separated until reaching sliding friction points, an ISG motor is controlled to drag the engine to carry out rotation speed adjustment, and a drive motor is controlled to improve output torque to maintain the drive force needed by the vehicle according to the torque requirement of the vehicle; when the current rotation speed of the engine is within the target rotation speed adjustment range, the current second output ends or the first output ends separated from the input ends of the two clutches are controlled to be connected with the input ends of the two clutches to achieve gear shifting. The vehicle control method has the advantages that gear shifting time is short, gear shifting smoothness is high, and the two clutches are long in service life. The invention further provides a vehicle control system and a vehicle.

Owner:HYCET TRANSMISSION TECH HEBEI CO LTD

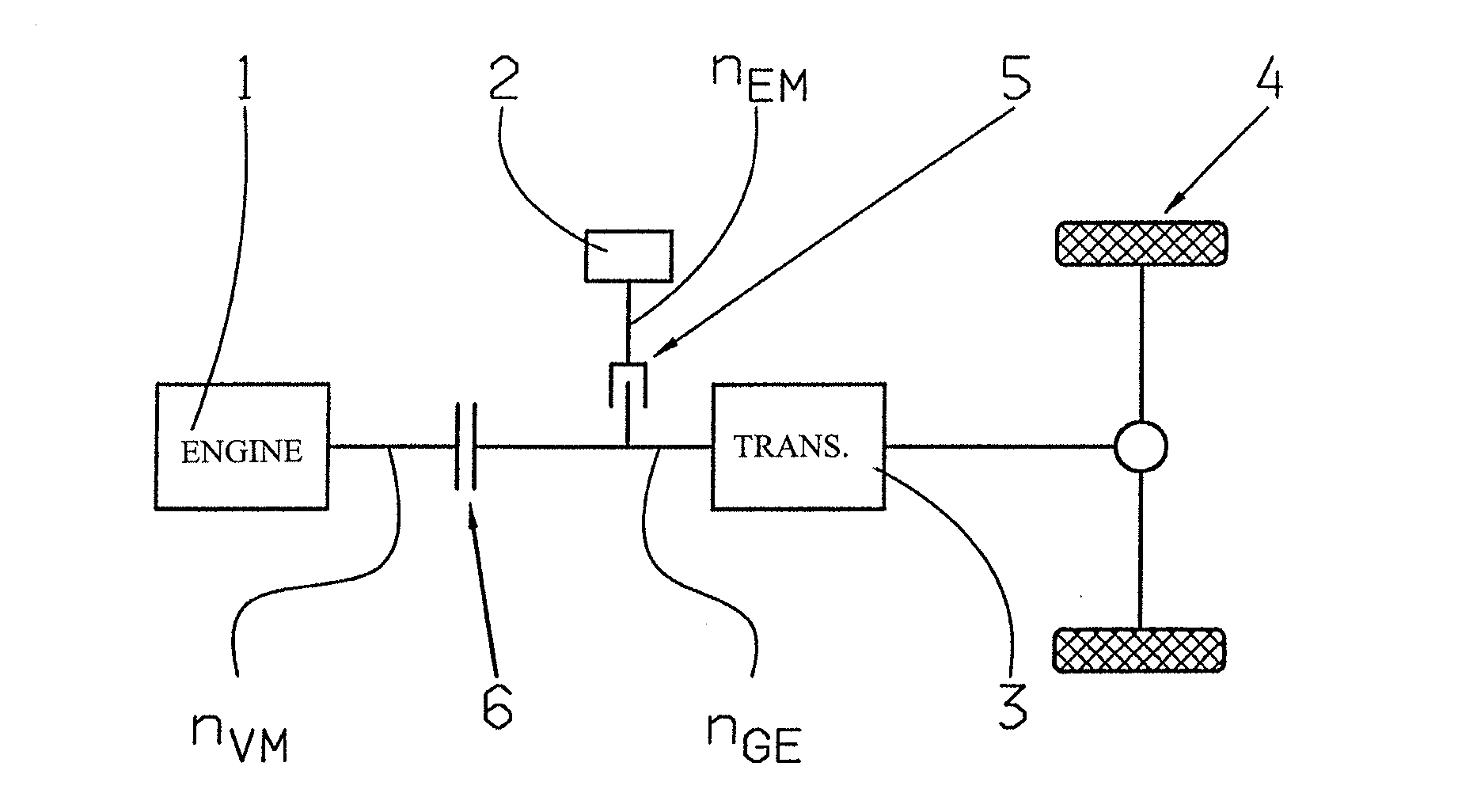

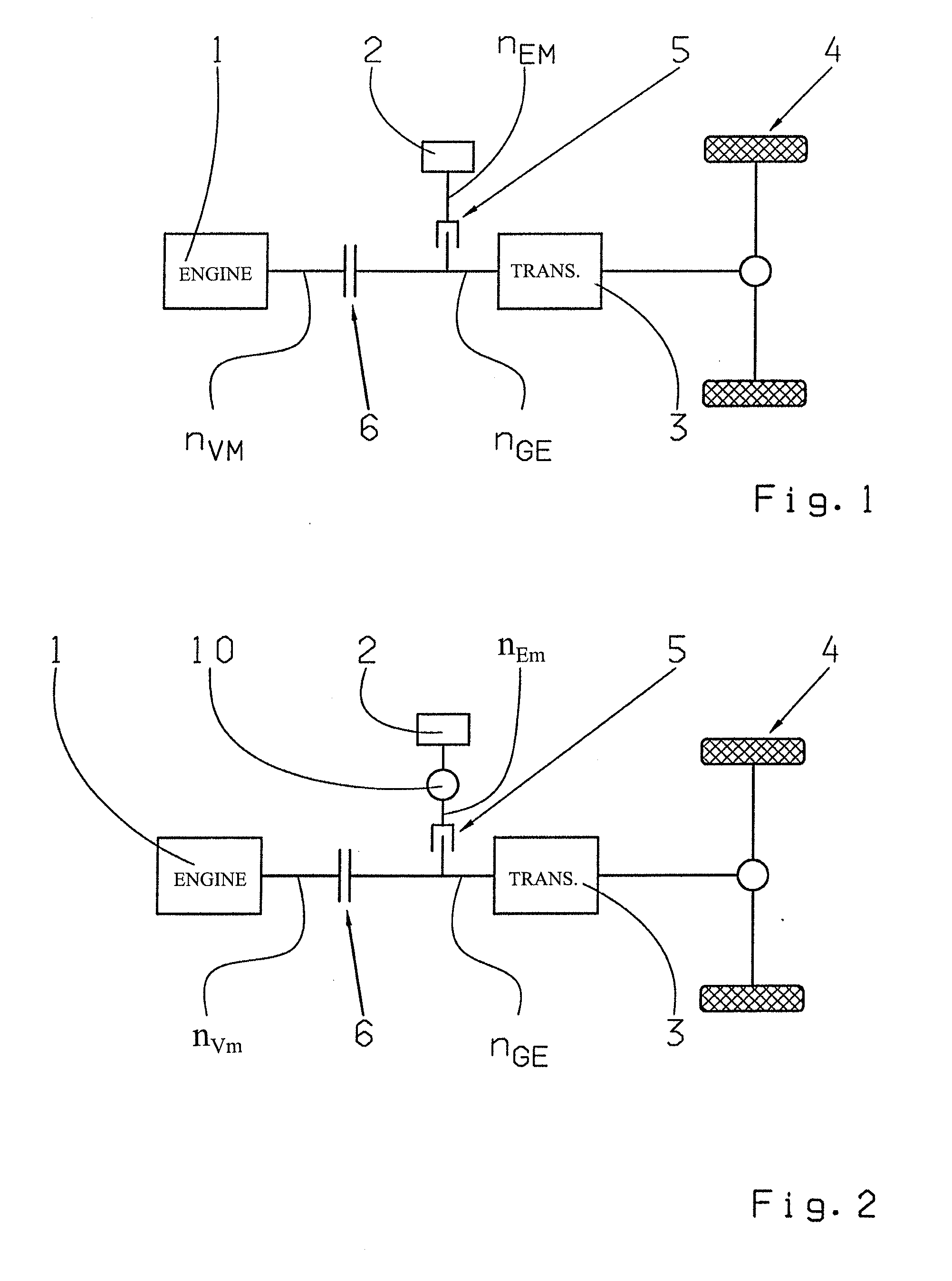

Method for operating a drive train

InactiveUS20130060411A1Simplify structureShorten shift timeHybrid vehiclesDigital data processing detailsClutchVariator

A method of operating a drive-train having a drive aggregate comprising an electric machine and internal combustion engine. An automated variable-speed transmission is connected between the engine and a drive output. The electric machine couples, via a friction clutch, a shaft of the transmission. Gearshifts are carried out in the transmission with an interruption of the drive torque provided by the drive aggregate in such manner that first the drive torque, provided at the output, is reduced to zero, then the actual gearshift is carried out, and then the drive torque, at the output, is again built up. To accomplish the gearshift, after disengaging a current gear and before engaging a target gear, the shaft of the transmission, which couples the electric machine via the friction clutch, is synchronized utilizing the inertial mass of the electric machine.

Owner:ZF FRIEDRICHSHAFEN AG

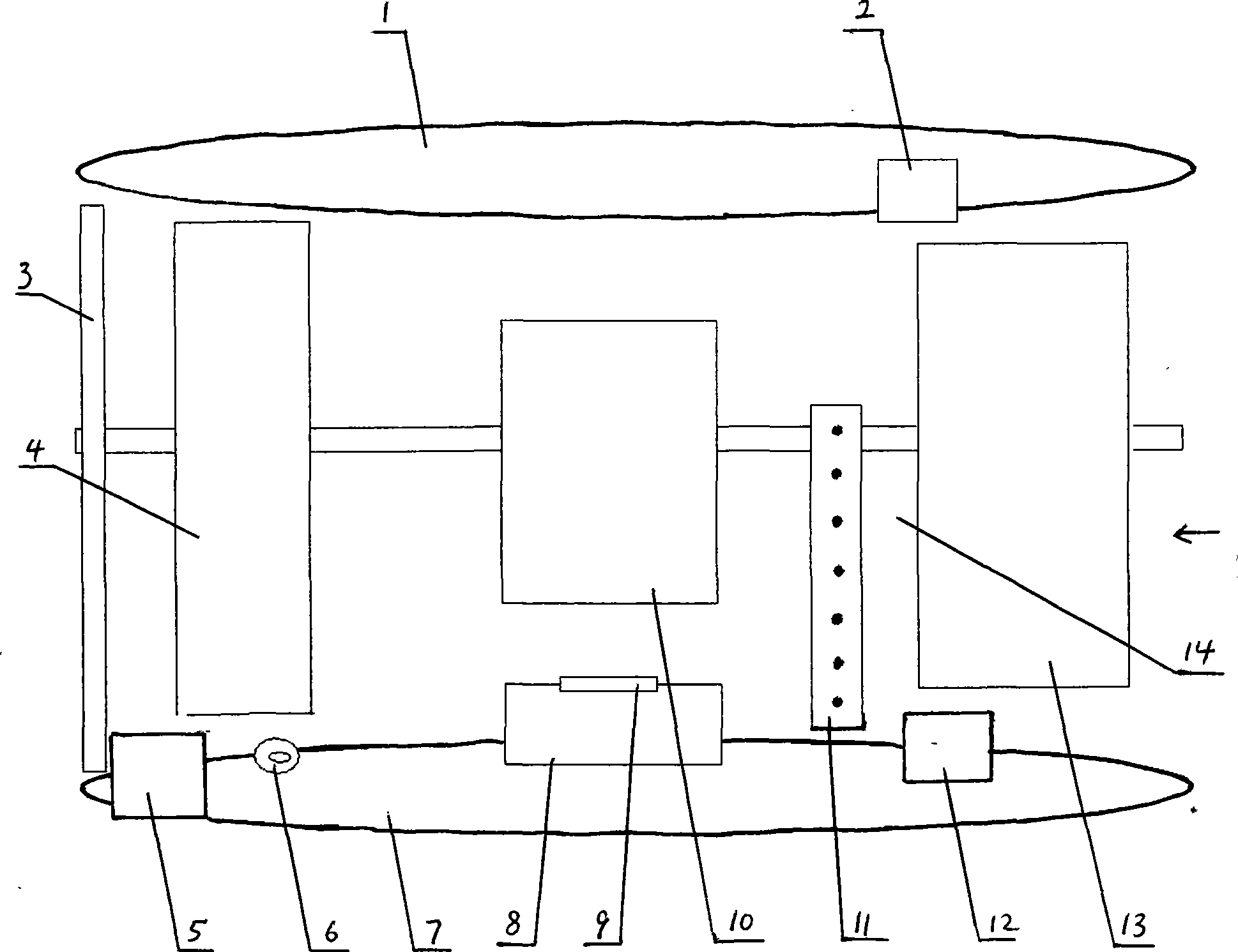

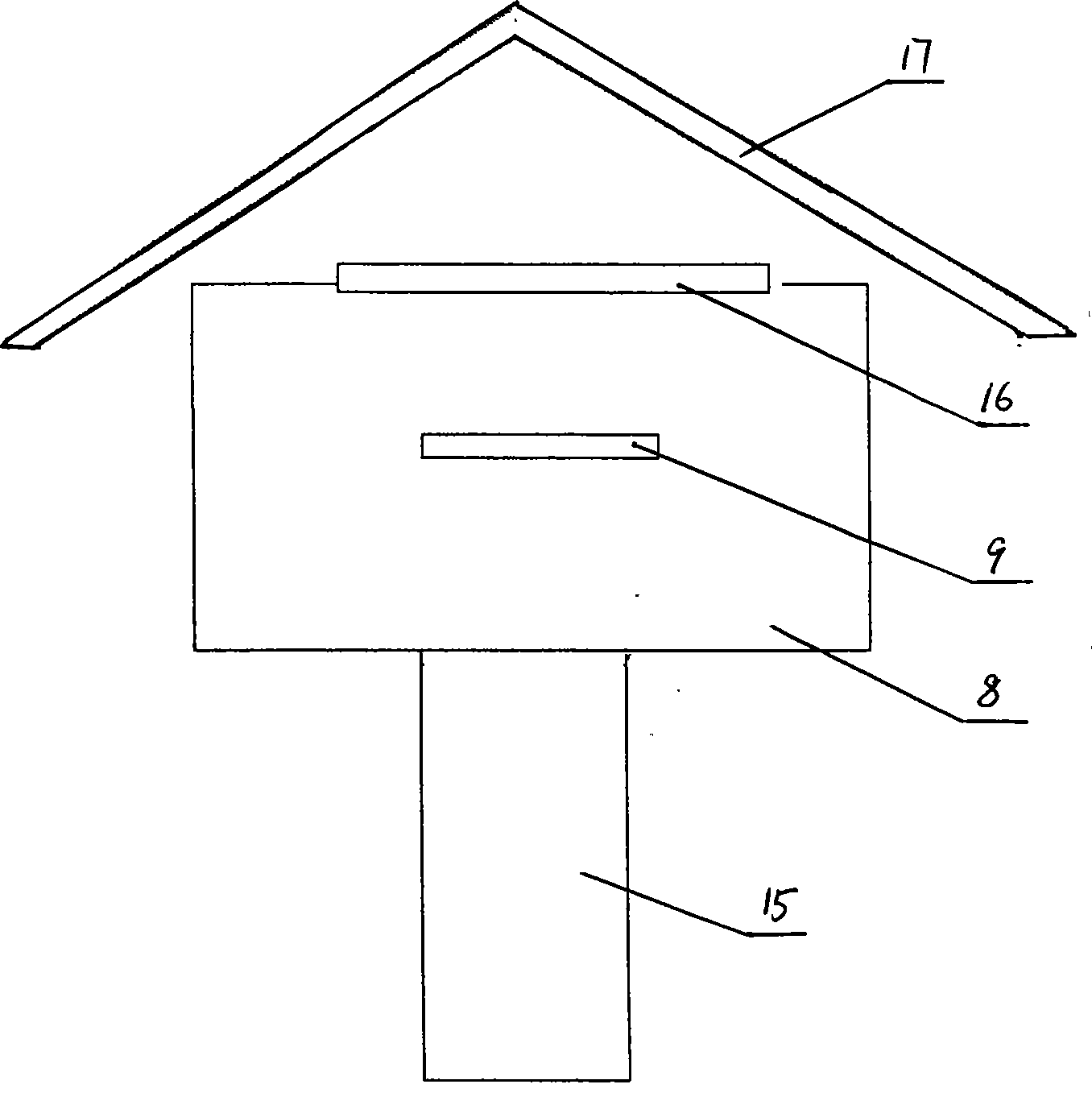

Automatic card-issuing device of highway toll-gate pass cards

InactiveCN101520906AImprove traffic capacityReduce inventory and handover workTicket-issuing apparatusCash registersInfraredCarriageway

The invention discloses an automatic card-issuing device of highway toll-gate pass cards, comprising a computer and a car stopping rod controller. The automatic card-issuing device is characterized in that a left carriageway surface induction coil, a middle carriageway surface induction coil and a right carriageway surface induction coil which are all used for inducing access vehicles and connected with a computer through cables are installed on the ground of a card issuing carriageway at intervals; a group of infrared transmitting heads and infrared receivers are installed at the back of a safety strip, and a camera for snapping vehicle license plates is installed in the front of the safety strip; an axle number recognizer is installed on the ground of the card issuing carriageway; and a strut of an automatic card-issuing pavilion is provided with an automatic card-issuing case consisting of a card storage box, a card ejector, a card outlet and a card reader. The invention has the advantages of high degree of automation, more thorough and accurate vehicle access information, great improvement of working efficiency, traffic capacity acceleration, working intensity reduction for charging working staff, error reduction of manual operation, manual dissension avoidance, low cost, labor and money saving and easy maintenance.

Owner:JIANGXI GANYUE EXPRESSWAY

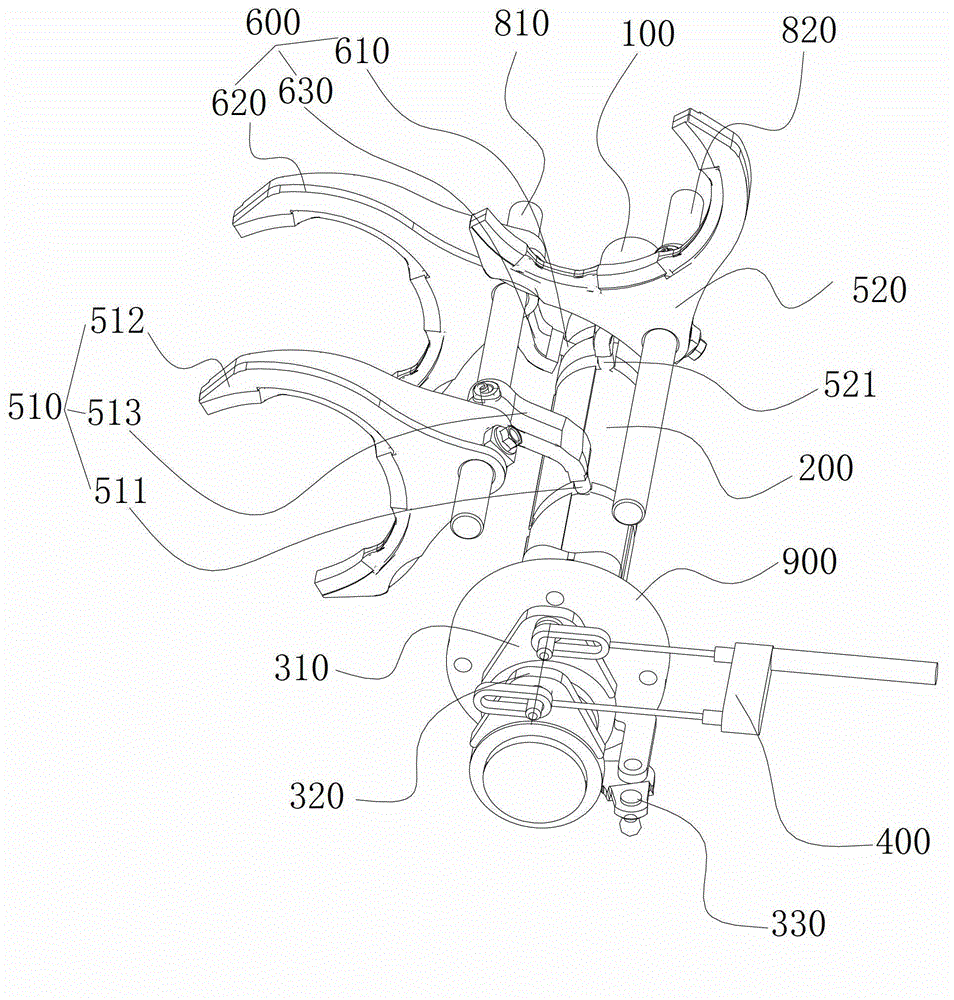

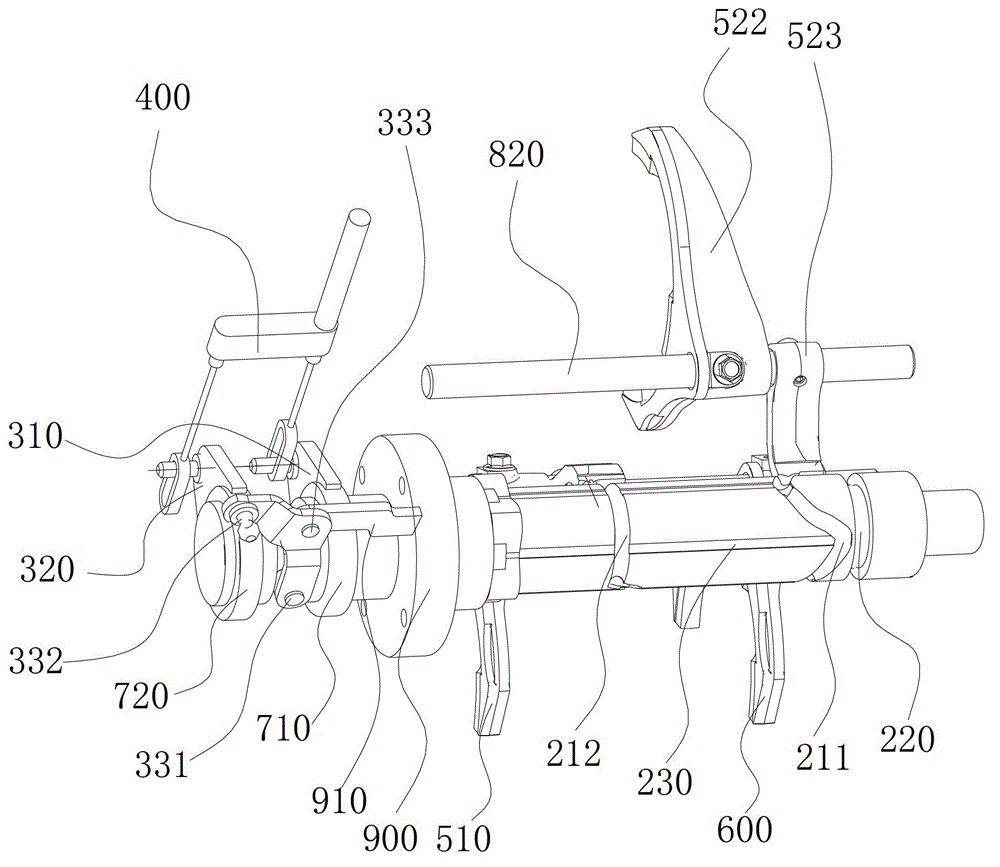

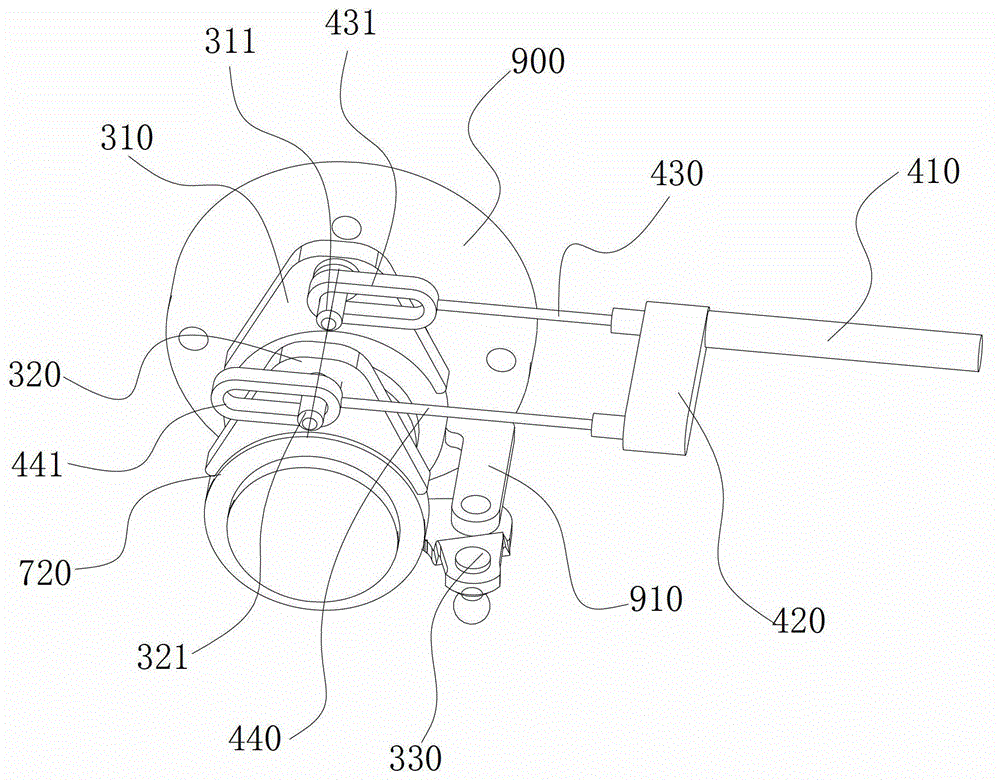

Vehicle and gearshift operating mechanism thereof

InactiveCN103148214ASimple structureSmall footprintControlled membersGearing controlGear driveDriver/operator

The invention provides a vehicle and a gearshift operating mechanism thereof. The gearshift operating mechanism comprises a gearshift shaft, a shift up rocking arm, a shift down rocking arm, a gearshift drive part, a reverse gear rocking arm, a reverse gear drive part, a shifting fork component and a reverse gear shifting component, wherein gearshift hubs of a gearshift slideway, a reverse gear slideway and a neutral gear slideway are arranged on the gearshift shaft; the shift up rocking arm drives the gearshift shaft to rotate for a preset angle in a first direction; the shift down rocking arm drives the gearshift shaft to rotate for a preset angle in a second direction; the gearshift drive part is connected with the shift up rocking arm and the shift down rocking arm and is movable among a first position, a second position and an initial position; the reverse gear drive part drives the reverse gear rocking arm to push the gearshift shaft to move in an axial direction; the gearshift slideway drives the shifting fork component to move in an axial direction so that upshift and downshift are performed; and the reverse gear slideway drives the reverse gear fork component to move in an axial direction. Therefore, the gearshift operating mechanism not only can shorten the gearshift time, improve the vehicle transmission efficiency, but also can avoid the risk of mistaken gearshift by a driver.

Owner:GREAT WALL MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com