Non-clutch AMT (Automatic Manual Transmission) control system and method

A clutchless, control system technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as restricting shifting quality, optimize shifting quality, shorten shifting time, The effect of improving shifting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better understand the present invention, the present invention is described in detail below in conjunction with specific embodiment, but obviously can carry out different modification and modification to the present invention and not exceed the broader spirit and scope of the present invention that appended claims limit . Accordingly, the following examples are meant to be illustrative and not limiting.

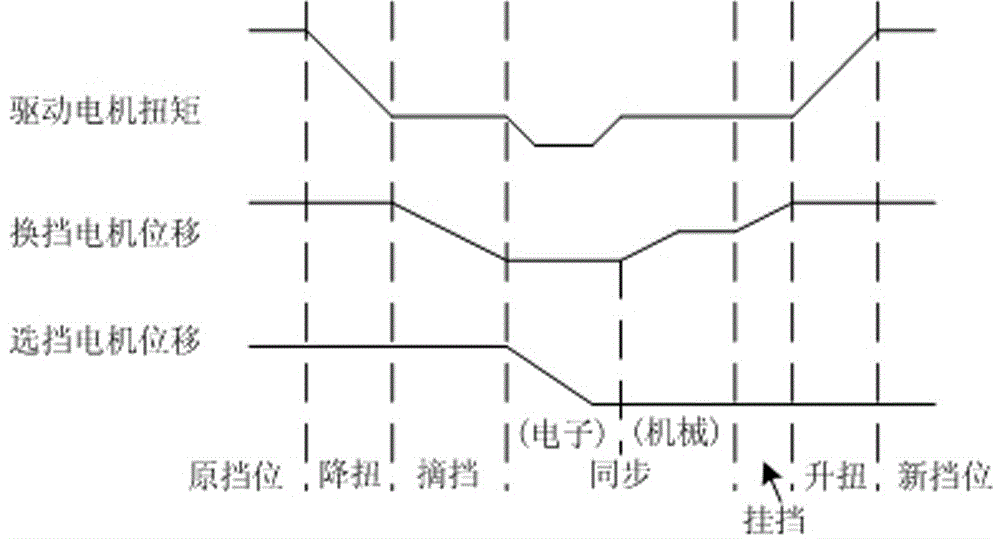

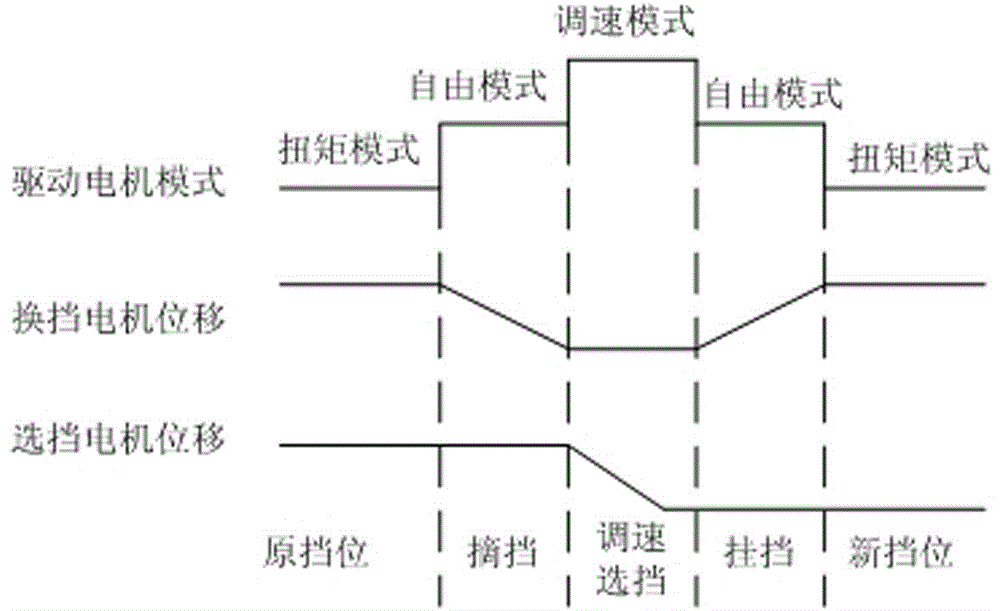

[0047] The clutchless AMT control system of the present invention adopts the AMT configuration without clutch and synchronizer. The gearbox is basically the same as the traditional MT. The reverse gear is canceled, and the shift actuator and TCU are added. The following combination figure 1 , 4 Describe the technical scheme of described control system in detail:

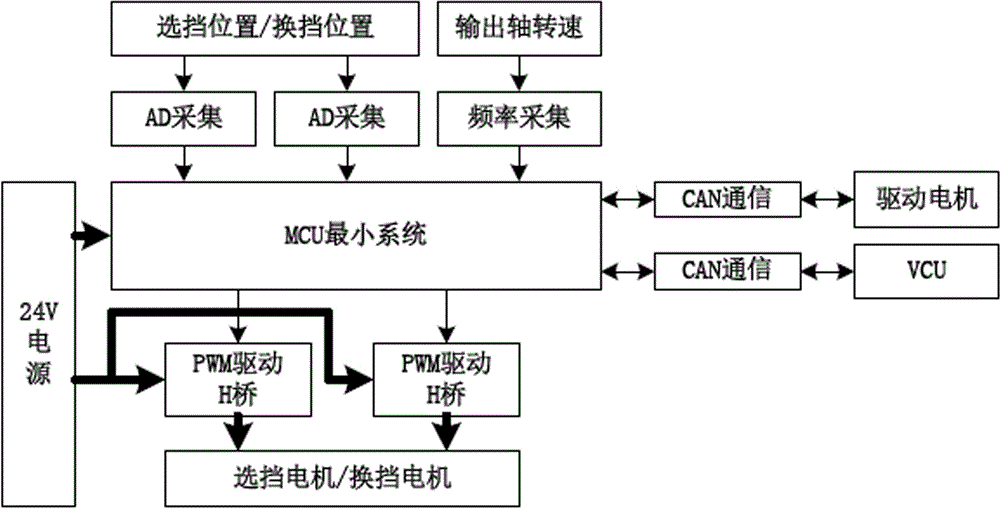

[0048] A clutchless AMT control system includes an MCU and a TCU, and the MCU is connected with the TCU. It includes a VCU and a BMS, and the VCU is connected to the MCU and the BMS respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com