Automatic speed changer

A technology of automatic transmission and transmission, which is applied in the direction of vehicle gearboxes, gearboxes, transmissions, etc., and can solve the problems of reduced system reliability, increased system cost and volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

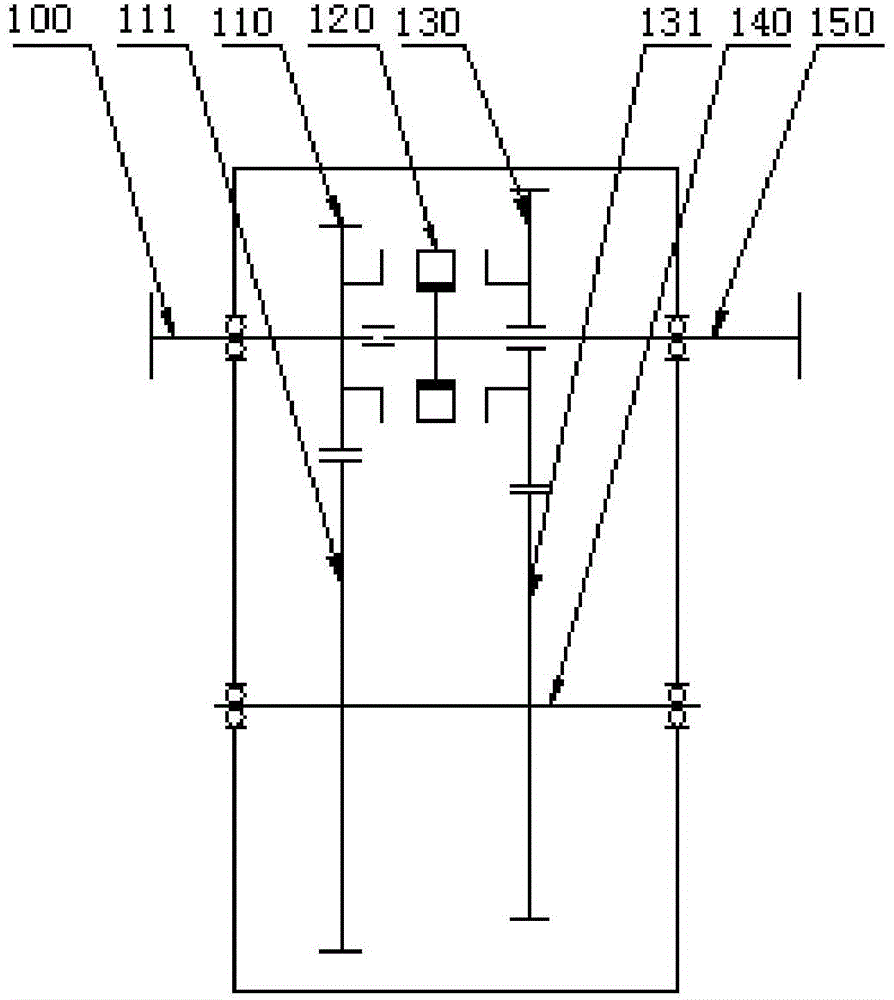

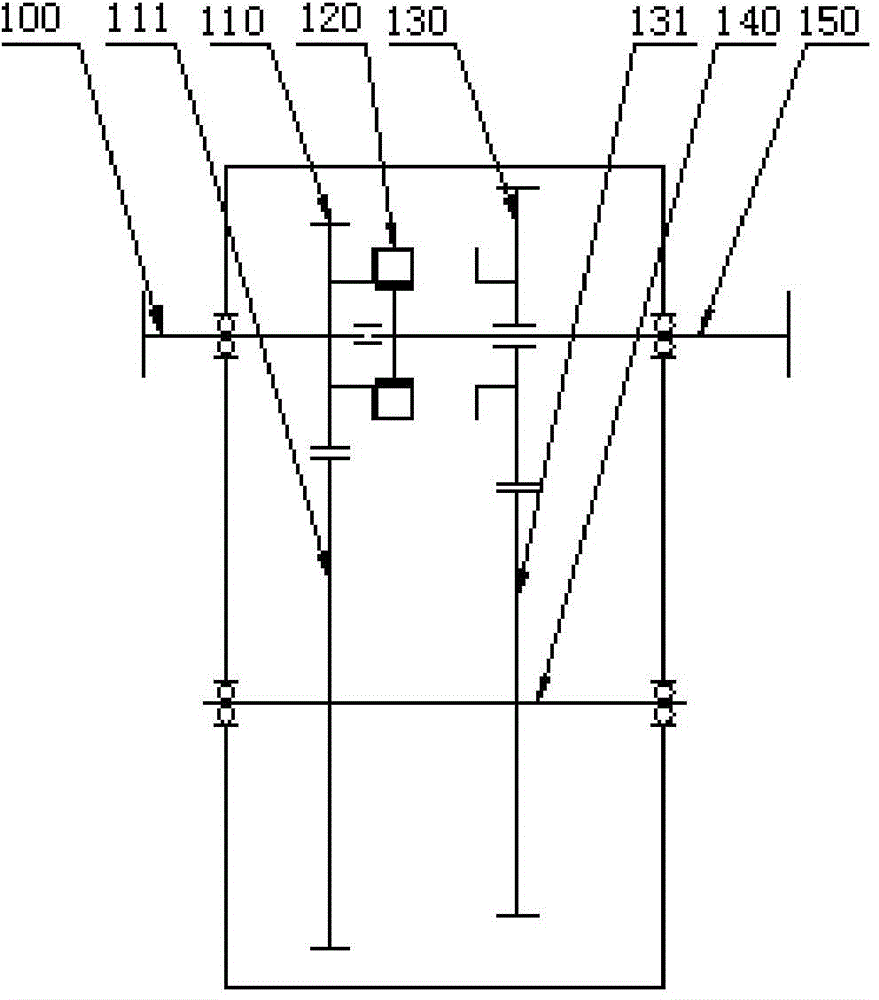

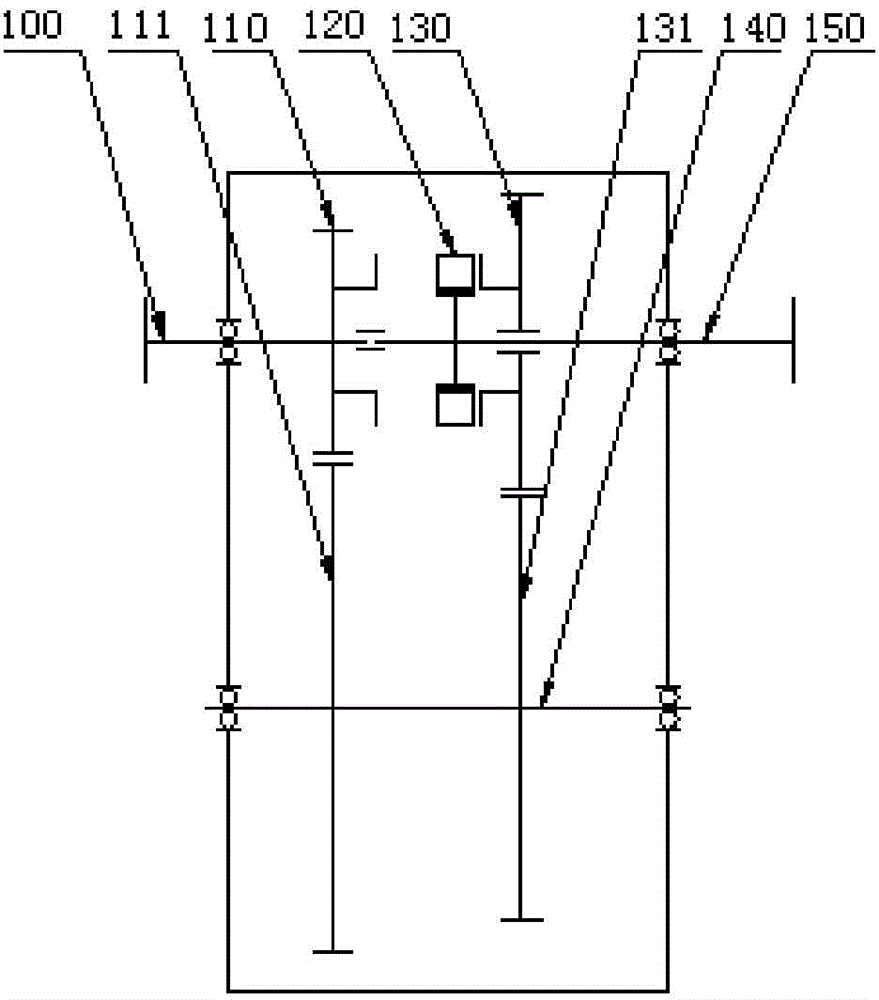

[0083] figure 1 It is a schematic structural diagram of the two-speed automatic transmission in Embodiment 1 of the present invention. figure 2 It is a transmission diagram of the second gear of the two-speed automatic transmission in Embodiment 1 of the present invention; image 3 It is a transmission diagram of the first gear of the two-speed automatic transmission in Embodiment 1 of the present invention.

[0084] see figure 1 , The automatic transmission in Embodiment 1 includes: a first double-face tooth combined chainring 120 and a fixed-axis gear train with two-stage reduction. The two-stage deceleration fixed-axis gear train includes: a transmission input shaft 100, a transmission intermediate shaft 140, a transmission output shaft 150, a combination tooth 110 on the right end face of the first external gear, a combination tooth 130 on the left end face of the first external gear, a first gear 111 and a second gear 131 .

[0085] Among them, the transmission input...

Embodiment 2

[0094] The specific structure of the double-face tooth combined toothed plate of the present invention can be easily extended to third gear, fourth gear, fifth gear, sixth gear and so on. In the second embodiment, the structure extended from the second-speed automatic transmission to the third-speed automatic transmission is given.

[0095] Figure 4 It is a schematic structural diagram of the three-speed automatic transmission in Embodiment 2 of the present invention. Such as Figure 4 As shown, the realization of the three-speed automatic transmission is based on the two-speed automatic transmission in the first embodiment above, adding a one-stage deceleration fixed-axis gear train and a combined tooth plate 250 with end teeth. That is to say, the three-speed automatic transmission in the second embodiment includes a transmission input shaft 100, a transmission intermediate shaft 140, a transmission output shaft 150, a combination tooth 110 for the right end face of the f...

Embodiment 3

[0109] The specific structure of the double-face tooth combination chainring of the present invention can be easily extended to third gear, fourth gear, fifth gear, sixth gear and so on. This embodiment describes in detail how to extend from a two-speed automatic transmission to a four-speed automatic transmission.

[0110] Figure 5 It is a schematic structural diagram of the four-speed automatic transmission in Embodiment 3 of the present invention. Such as Figure 5 As shown, the four-speed automatic transmission is realized on the basis of the two-speed automatic transmission in the first embodiment above by adding another two-stage reduction and a second double-end face tooth combined chainring 350 .

[0111] Such as Figure 5 As shown, the four-speed automatic transmission in the third embodiment includes a transmission input shaft 100, a transmission intermediate shaft 140, a transmission output shaft 150, a combination tooth 110 on the right end face of the first ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com