Patents

Literature

57results about How to "Short footprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

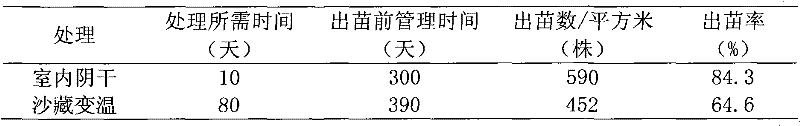

Paris polyphylla var. yunnanensis scale seedling culturing method

InactiveCN101822157AUnsleepImprove germination rateSeed and root treatmentHorticultureParis polyphylla var. yunnanensisHigh survival rate

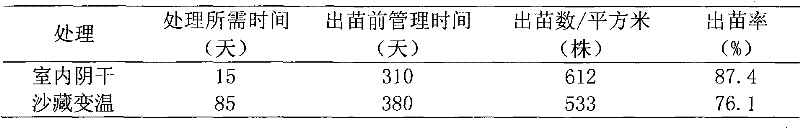

The invention relates to a Paris polyphylla var. yunnanensis scale seedling culturing method. The method comprises the following steps of: selecting Paris polyphylla var. yunnanensis plants more than 10 years old and reserving seeds for planting; collecting mature seeds; washing the collected seeds to remove episperm; spreading and drying the seeds in a shade and ventilating place within 12 hours, wherein a temperature is maintained and an accumulation thickness is less than or equal to 6 cm; spreading the seeds uniformly and drying; filling the seeds into a ventilating container; storing the container in a shade environment with a suitable temperature, wherein the storage time is no more than 2 months; clearing impurities and residues in a seedling culturing field; fertilizing decayed farm manure and calcium superphosphate; plowing and raking soil; forming a furrow; spreading humus soil on the furrow surface; flatting the furrow surface; sowing in early June next year; taking the stored seeds, and after sterilizing, broadcasting the seeds uniformly according to the thickness of sowing; earthing after broadcasting; covering mantle on the furrow surface; irrigating sufficiently and performing seedling management. A method for drying the seeds of the Paris polyphylla var. yunnanensis in shade in an environment without direct sunlight is adopted, the dormancy of the seeds of the Paris polyphylla var. yunnanensis is broken, and the scale production of Paris polyphylla var. yunnanensis seedlings is realized, so that germchit guarantee is provided for large-area popularization and cultivation of the Paris polyphylla var. yunnanensis. The method has the characteristics of simple and easily-learned operation, high survival rate of germchit, low production cost, healthy and strong germchit, stable and reliable technology, high repeatability, and capacity of effectively solving the problem of scale seedling cultivation of the Paris polyphylla var. yunnanensis.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

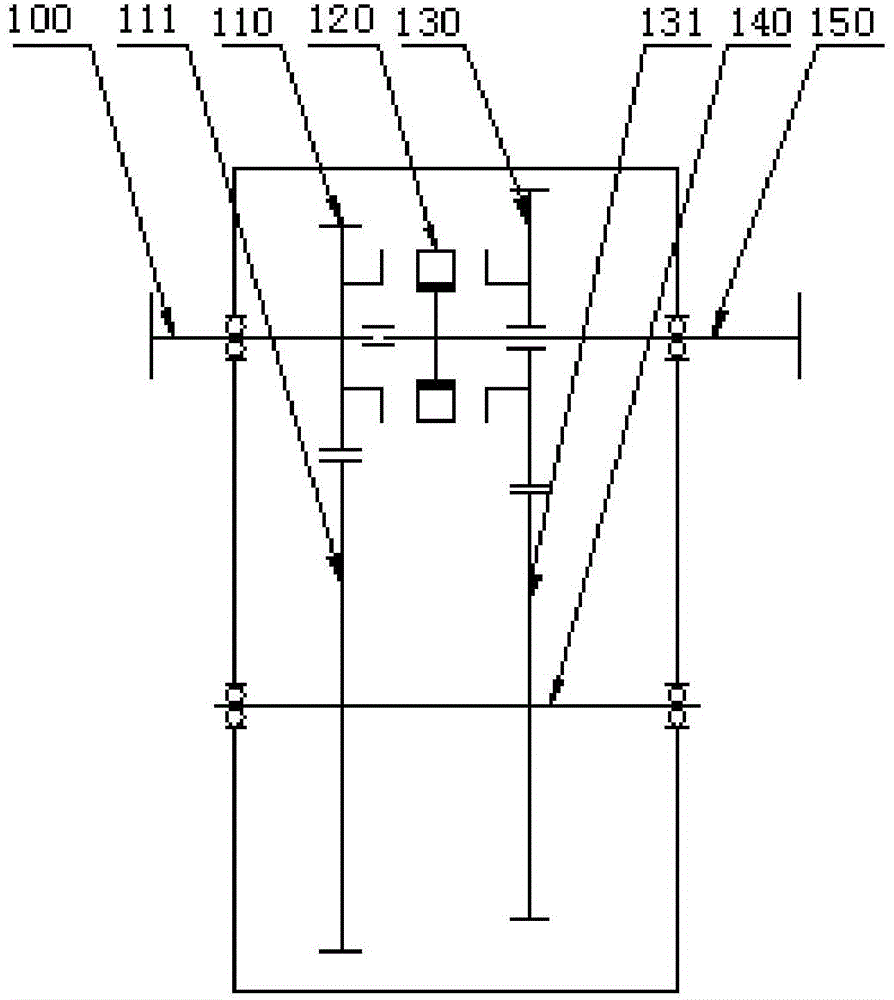

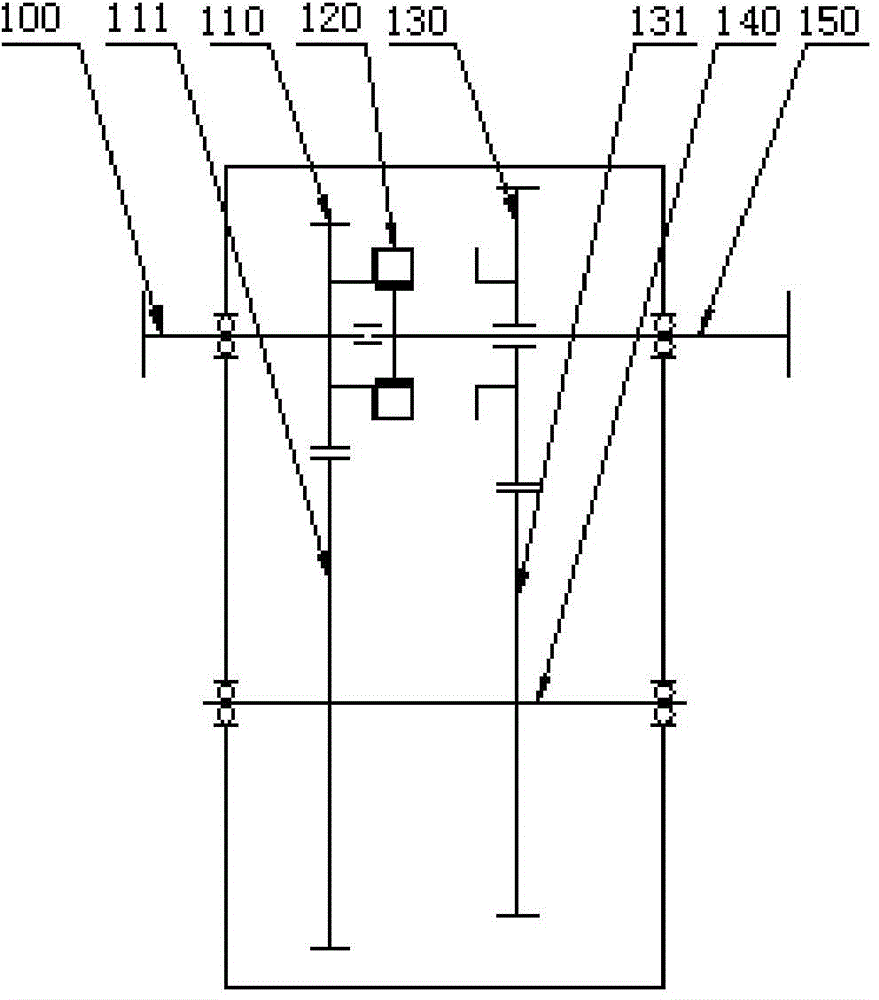

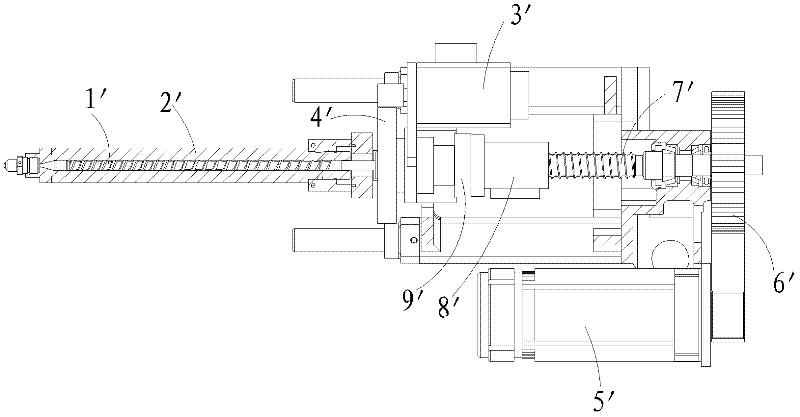

Automatic speed changer

ActiveCN104930137AOptimize layoutImprove reliabilityGearboxesToothed gearingsAutomatic transmissionEngineering

The invention discloses an automatic speed changer. The automatic speed changer comprises a double-end-face tooth combined fluted disc and a two-level speed reduction fixed shaft wheel train. A gear shifting mechanism of the speed changer is the double-end-face tooth combined fluted disc and is provided with double-end-face teeth including the left end face teeth and the right end face teeth. The double-end-face tooth combined fluted disc axially moves on an output shaft of the speed changer, the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are engaged with end face teeth of a one-level speed reduction gear and a two-level speed reduction gear respectively, the two-gear position and the one-gear position are achieved, and when the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are not combined with the end face teeth of the one-level speed reduction gear and the two-level speed reduction gear, the speed changer is at a neutral position. According to the technical scheme, compared with a traditional AMT, a synchronizer is removed, the structure is simple, reliability is high, the gear shifting time is short, the gear shifting impact is small, the production cost is low, and industrialization is easy to achieve. The gear arrangement mode of the speed changer is simple, the axial size is short, the occupied space is small, the weight is low, and the automatic speed changer conforms to the development trend of light weight and energy saving.

Owner:JING JIN ELECTRIC TECH CO LTD +1

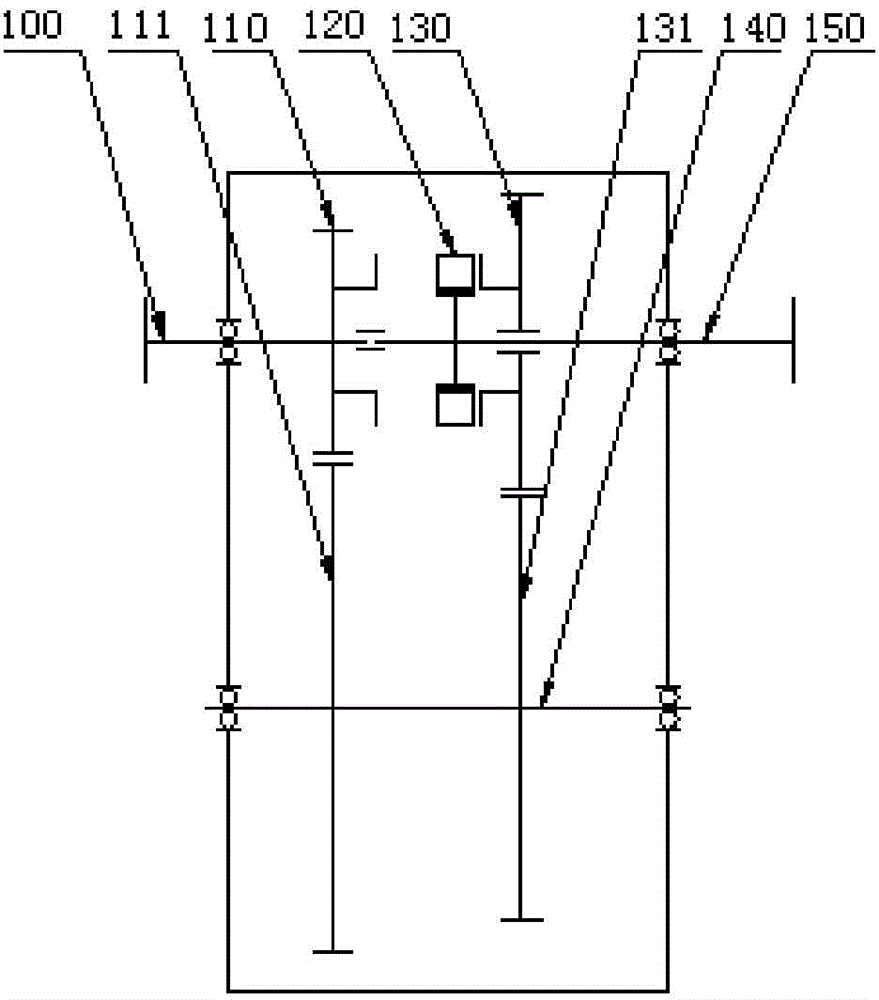

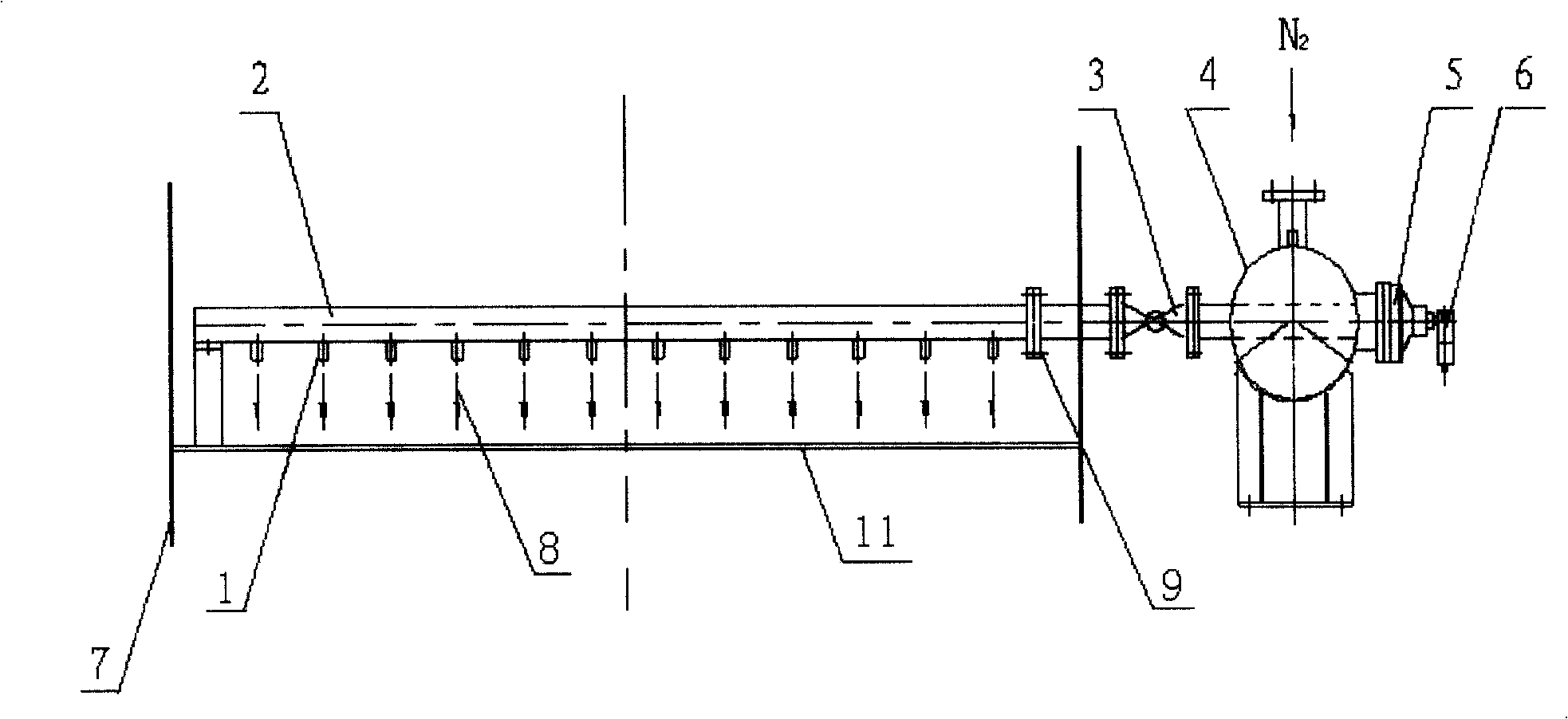

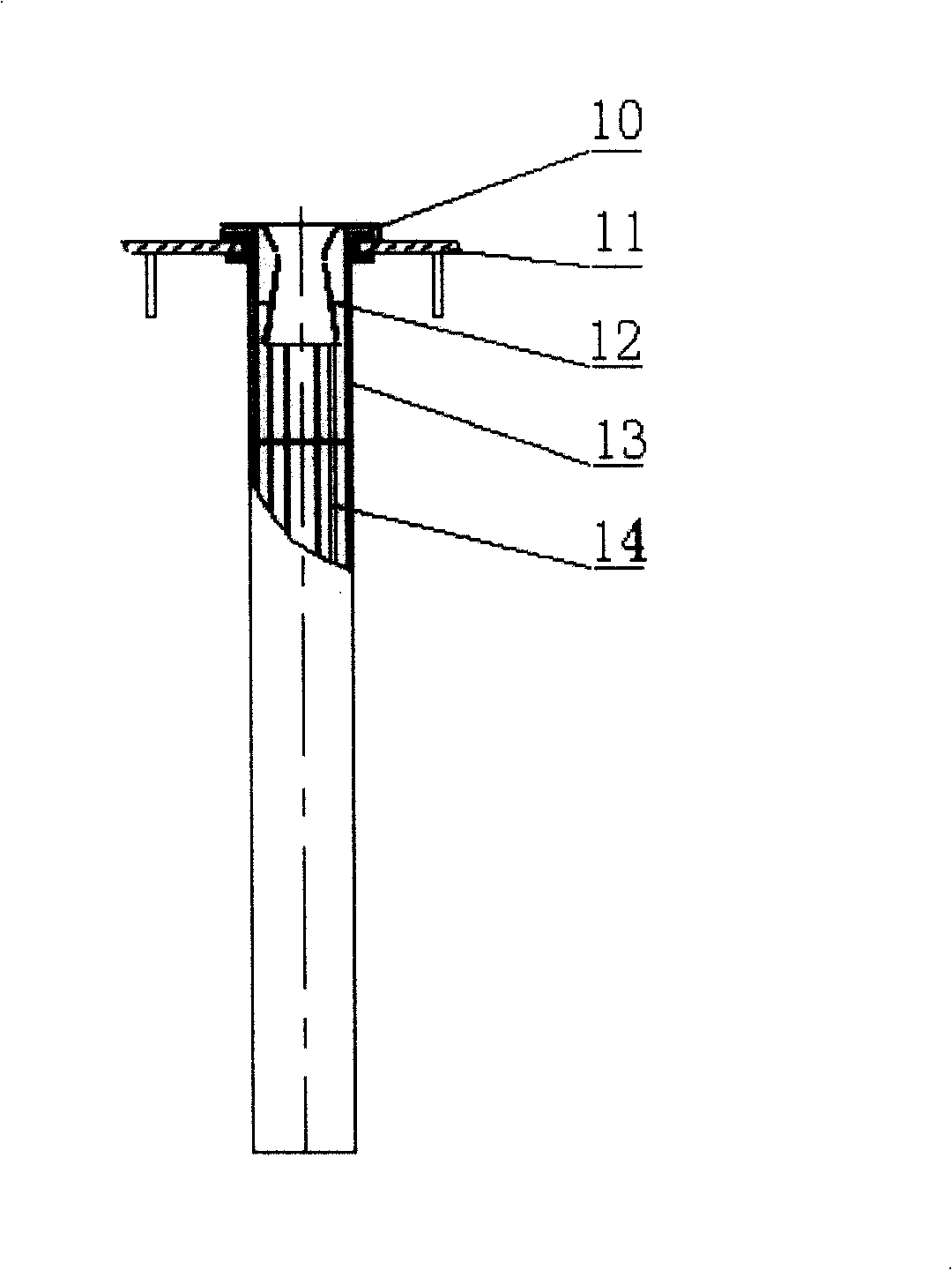

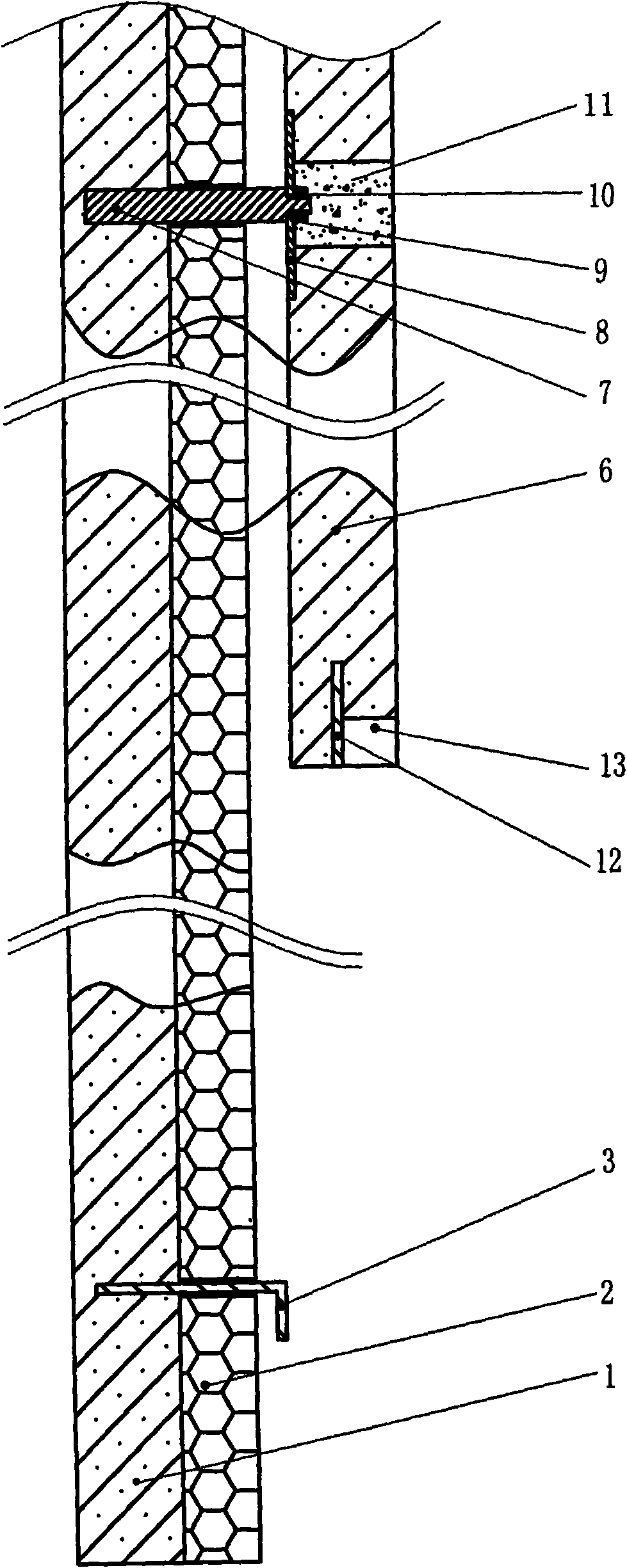

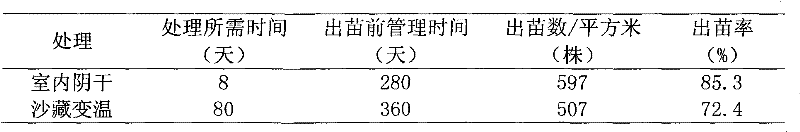

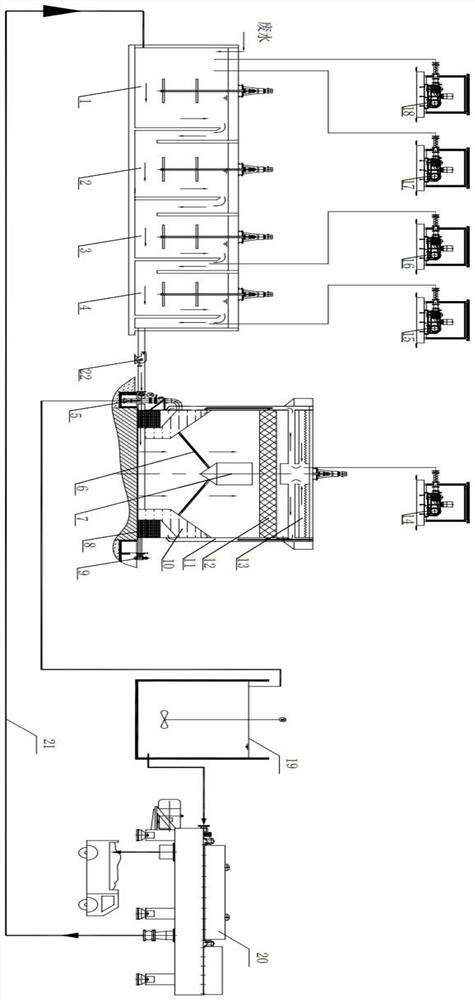

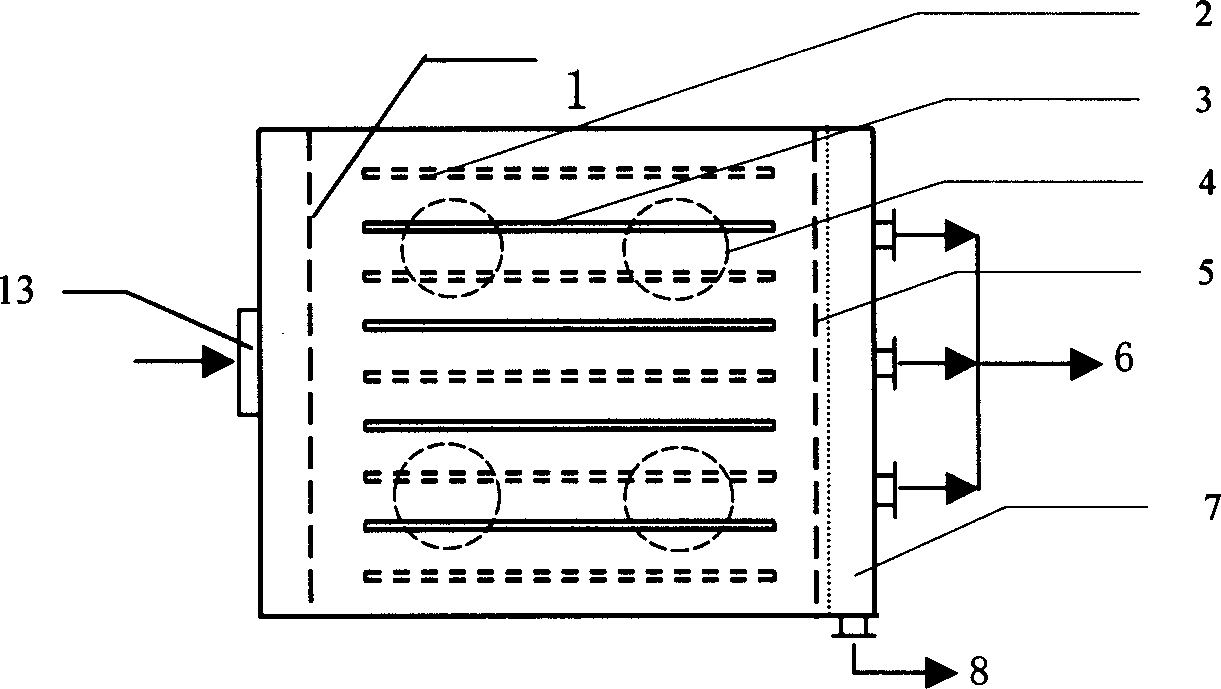

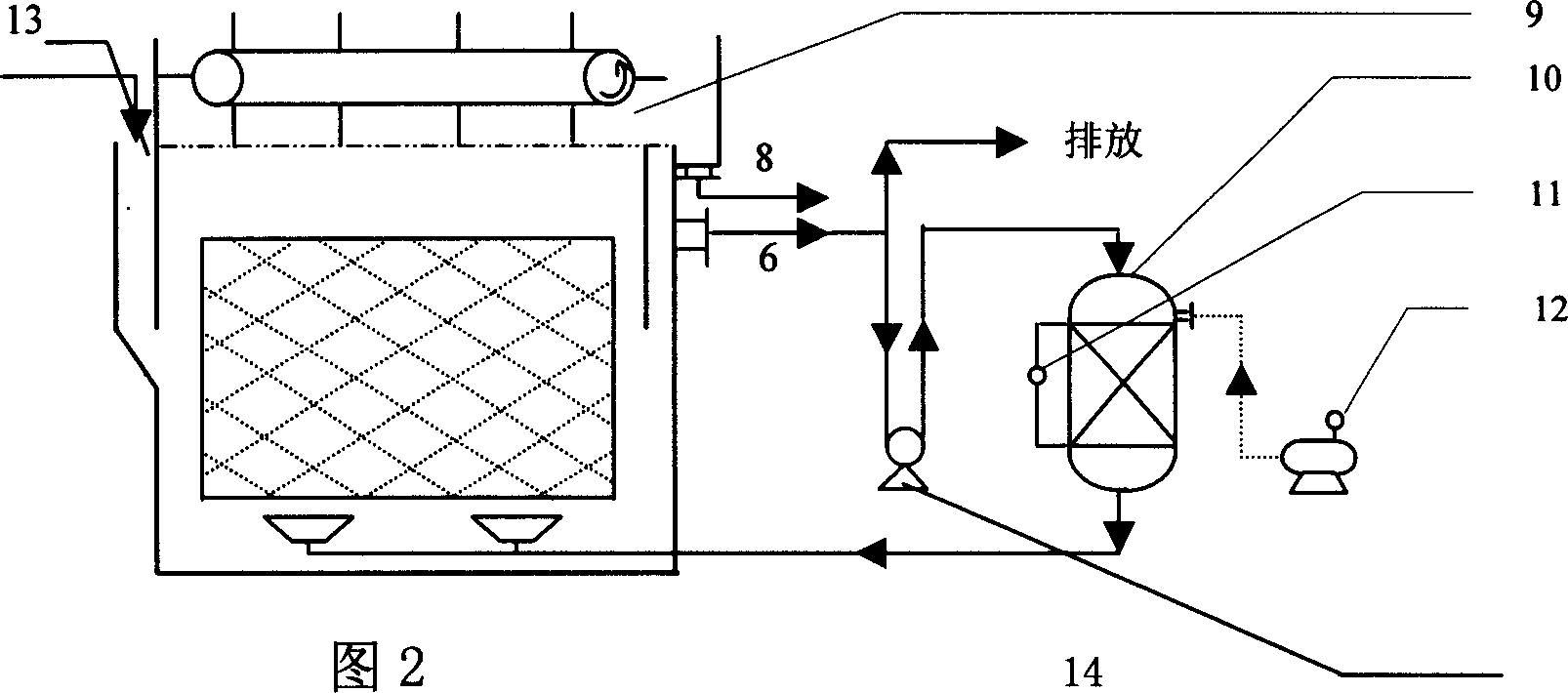

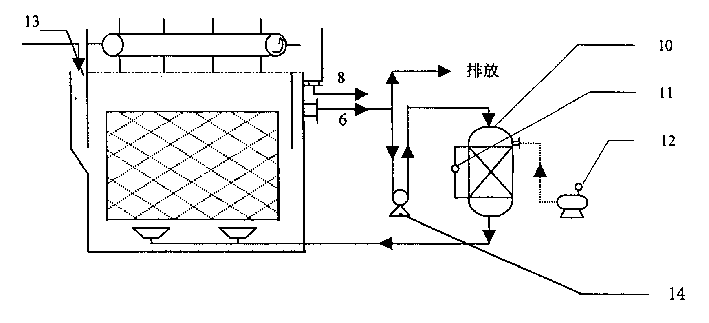

Blast furnace gas dust removing device and technique by dry method

ActiveCN101260322AEnsure safetyGet rid of dependenceChemical industryGas dust removalAutomatic controlProcess engineering

The invention relates to a blast furnace gas dry cloth-bag dust-removing device and technology, belonging to the metallurgy environmental protection dust removing technical field. The blast furnace gas dry cloth-bag dust-removing device and technology mainly comprise devices such as a dust-removing filtering device, an ash-clearing device, a dust-unloading and transporting device, an automatic control device, a gas dispersion device, and technologies such as large filtering wind speed, nitrogen or pure coal gas pulse current back-blowing and ash-clearing, pneumatic unloading and transporting ash and backup for nitrogen and pure coal gas, wherein, coal gas is filtered and purified by a filtering bag, the ash is back-blown by nitrogen or pure coal gas pulse current so as to control the resistance of the dust remover, thereby the filtering bag has the ideal dust removing effect, which is a dry dust-removing purification system having the advantages of high dust-removing efficiency, low dust content of the pure coal gas, low energy consumption of the dust-removing system, high heat efficiency of the pure coal gas and high automation degree; the filtering bag with over-long specification and a biserial pulse back-blowing system are adopted to meet the requirements of the dust-removing system upon a large filtering area and an excellent back-blowing efficiency; a crude gas bleeding valve group is increased to ensure that the coal gas with overproof temperature can not enter to a case of the dust remover, which protects the cloth-bag, controls effectively the high furnace roof pressure and operates the system more safer; the whole course waterless operation is realized so as to prevent the possibility of water containing coal gas dust to paste the filtering bag, thereby having the characteristics of less occupied area, short technology process, strong ability of clearing the ash, simple equipment and low labor intensity.

Owner:BAOTOU IRON & STEEL GRP

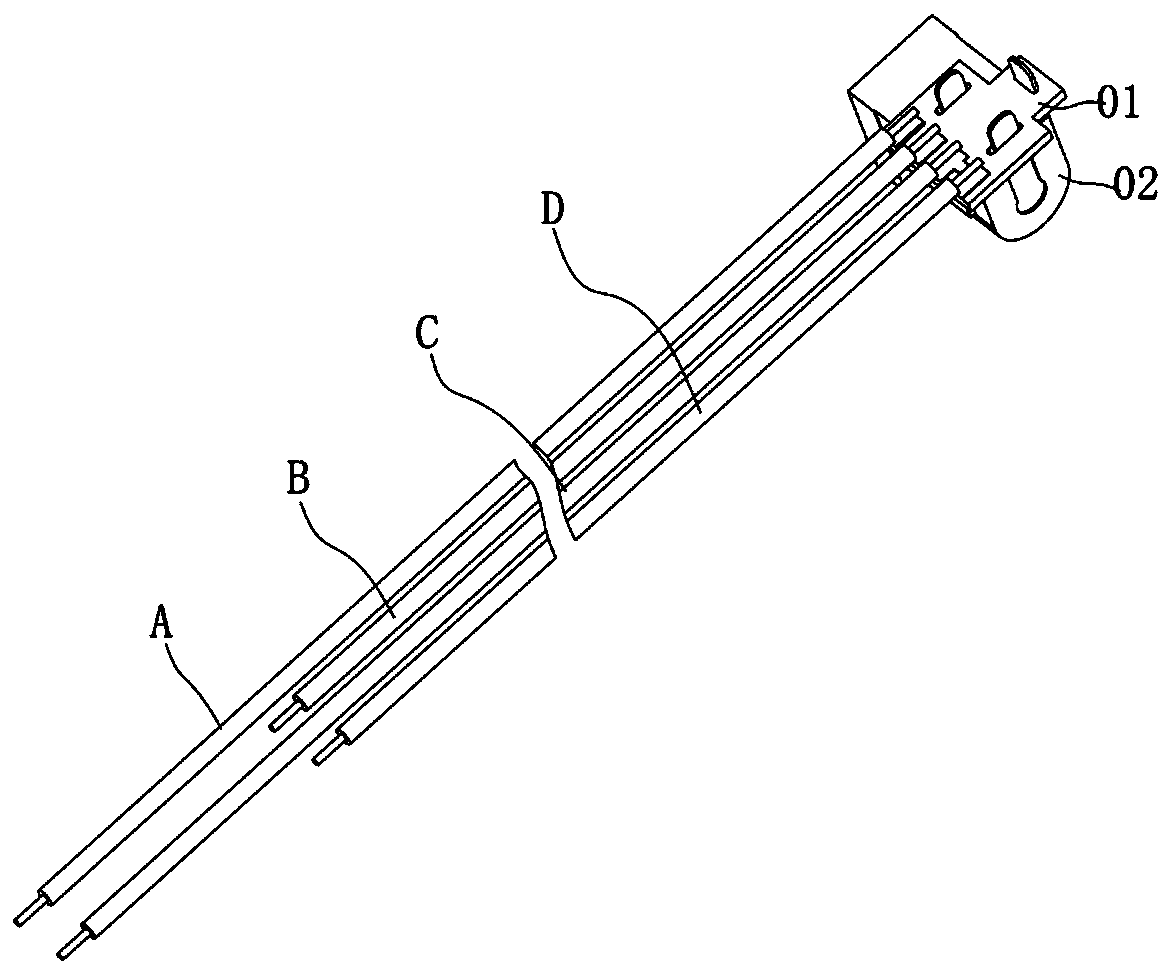

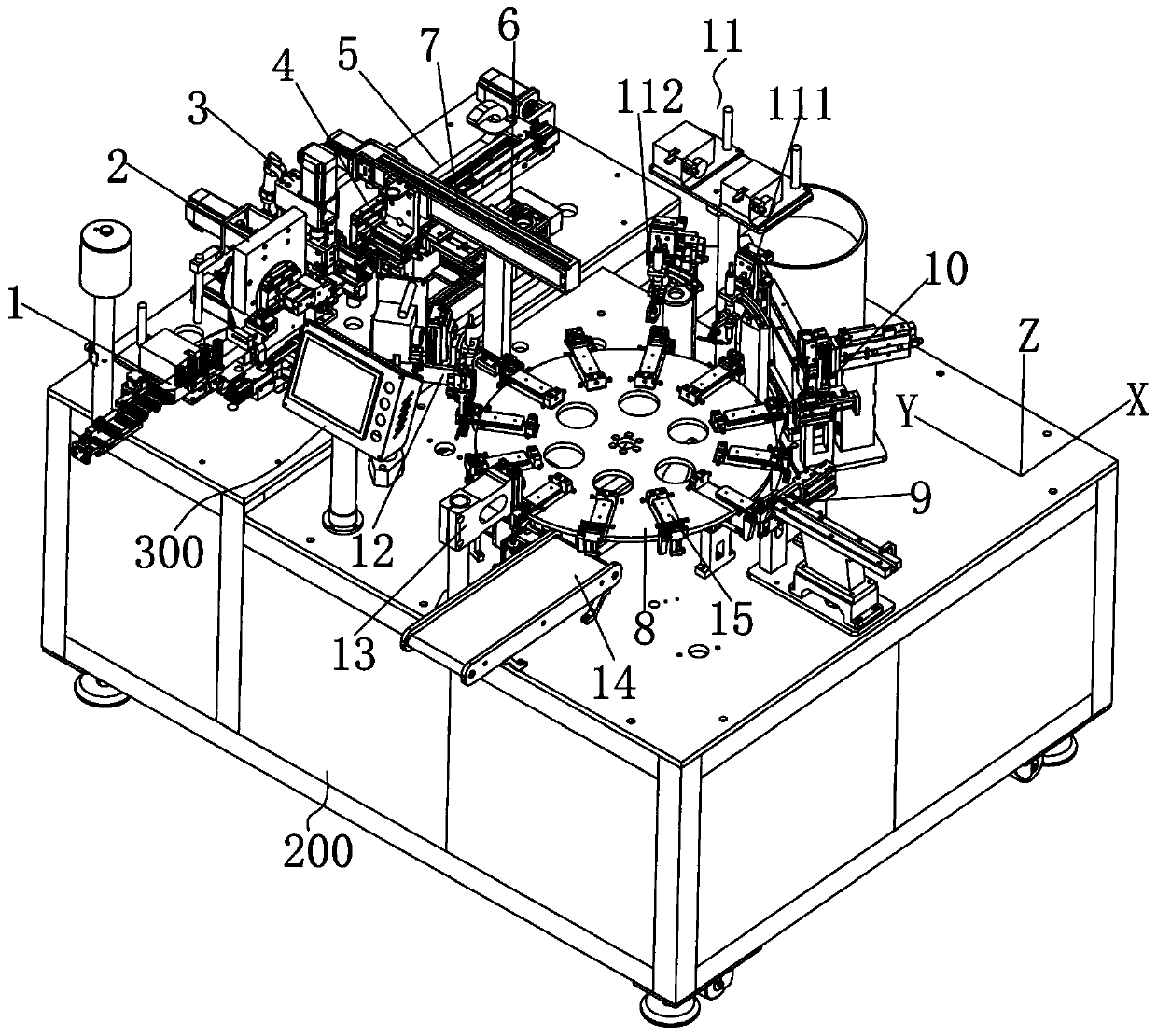

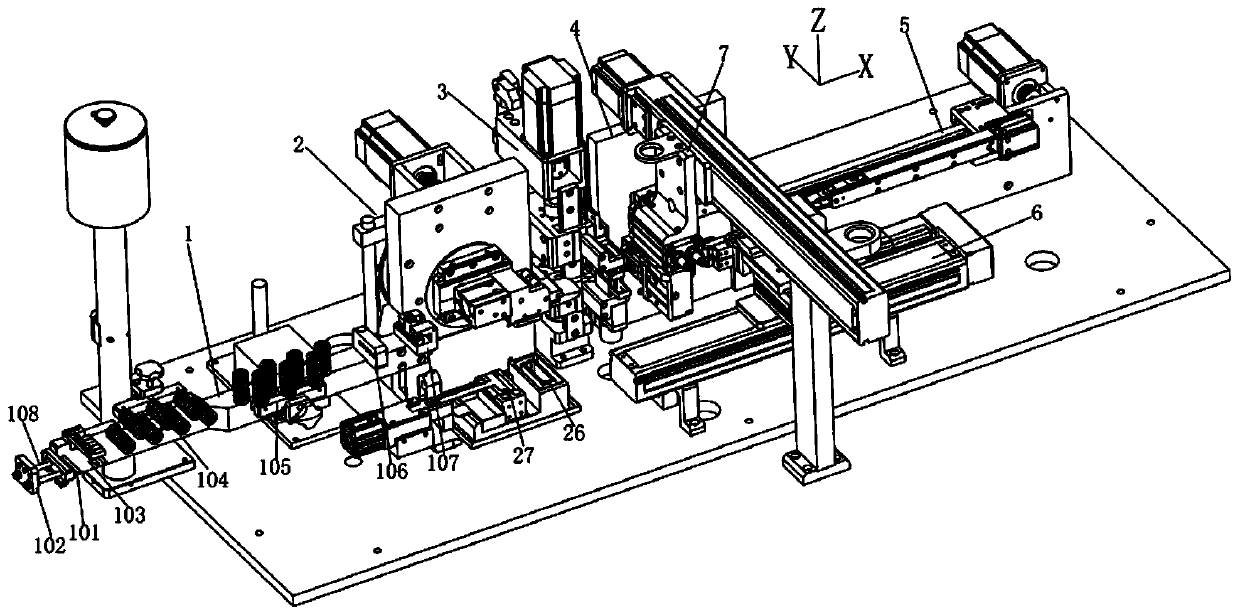

DC charging terminal automatic wire welder

PendingCN109994908AImprove work efficiencyCompact structureLine/current collector detailsTinningEngineering

The invention discloses a DC charging terminal automatic wire welder. The automatic wire welder includes a wire processing mechanism and further includes a wire frame assembly, a tinning assembly, a cutting and stripping assembly, a stripping assembly, a long cable assembly, a cable assembly and a cable feed assembly, wherein the long cable assembly is matched with the cable assembly to pull out two long wires and two short wires with matching length, the cutting and stripping assembly is used for aligning the two long wires and the two short wires with respect to electric wires for cutting and stripping rubber of opposite ends of the electric wires and the long wires / short wires, the stripping assembly is used for stripping the rubber of abutting ends of the long and short wires and the electric wires, the tinning assembly is used for tinning cores of the electric wires and of the abutting ends of the long and short wires, the wire feed assembly is used for transferring the cut two long wires and short wires to the abutting position with of a welding mechanism, and the welding mechanism includes a DC terminal feed assembly, a PCB feed assembly, a spot welding assembly, a multi-point pressure welding assembly, a finished material dispensing assembly and a blanking assembly disposed around the divider.

Owner:东莞市科锐思智能设备有限公司

Method for separating and purifying nonane diacid

ActiveCN101250101AReduce lossesGuaranteed yieldCarboxylic preparation by ozone oxidationCarboxylic compound separation/purificationPurification methodsDecomposition

The invention discloses a separation purification method of azelaic acid, belonging to the separation purification technical field of organic compound, which comprises depressurizing and distilling the oxidation solution obtained by treating ozonation-oxidation decomposition on unsaturated fatty acid to remove solvent and pelargonic acid, transferring left oxidation solution to a film evaporator to be distilled to obtain crude azelaic acid, extracting and recrystallizing the crude azelaic acid to obtain azelaic acid crystal. In the recrystallization of azelaic acid, the low-carbon dibasic acid of C<4>-C<8> in azelaic acid is dissolved in cold water, to be discharged along with crystallization mother liquor, and the left azelaic acid in the recrystallization mother liquor is recovered by the film separator. The obtained azelaic acid is transferred to a rising film evaporator to be dried and dehydrated and the dehydrated azelaic acid is evaporated by film to obtain the azelaic acid. The whole process can confirm the yield of azelaic aicd and obtain high-quality azelaic acid, while the whole system is sealed and the process has better environmental compatibility.

Owner:SICHUAN SIPO CHEMICAL CO LTD

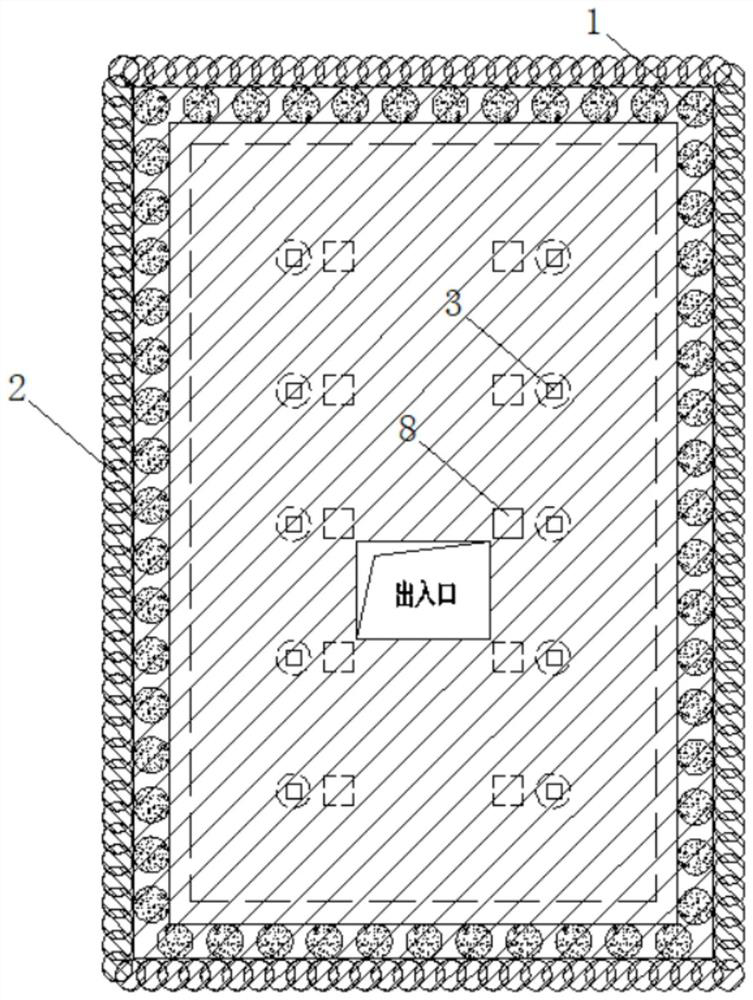

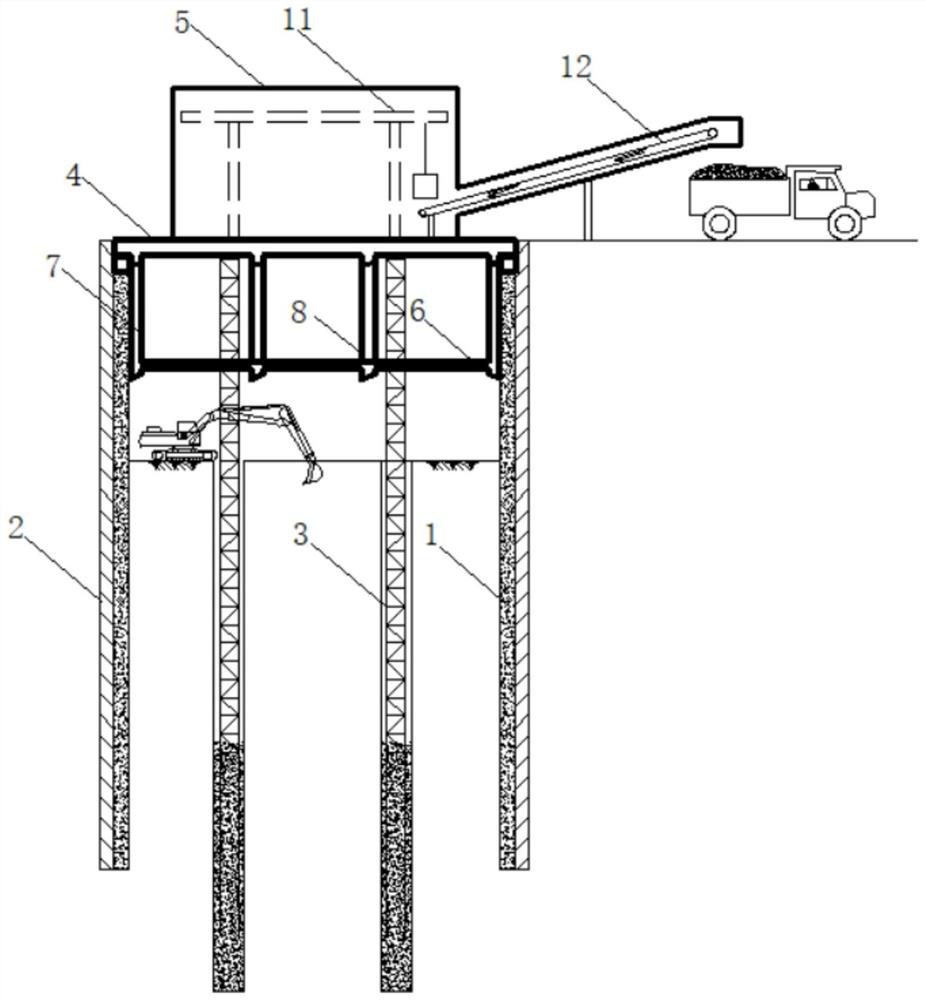

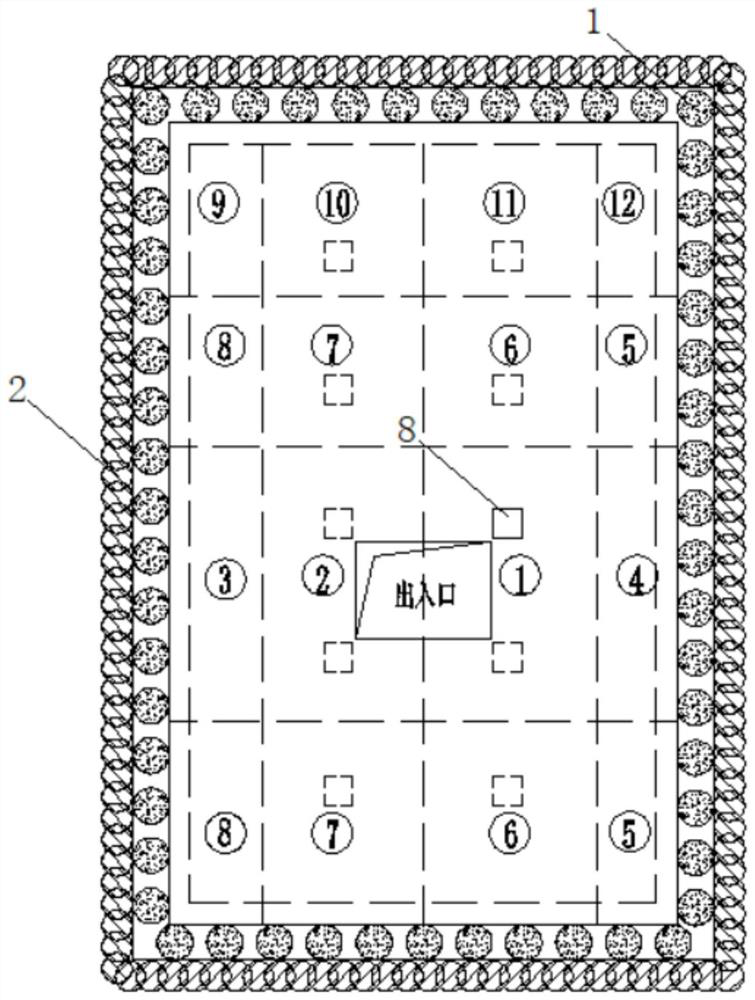

Construction method for constructing underground garage through cover-excavation reverse construction

InactiveCN111779027ASolve the problem that there is nowhere to stack and the machinery cannot be positioned for constructionReduce occupancyArtificial islandsProtective foundationArchitectural engineeringFoundation engineering

The invention discloses a construction method for constructing an underground garage through cover-excavation reverse construction, and is applied to the field of underground permanent structures andfoundation engineering in civil engineering. The construction method comprises the following steps that a temporary vertical enclosure structure, a temporary descending / stopping structure and a temporary vertical supporting structure are constructed at a ground elevation position, earthwork is excavated to a bottom elevation position of a top plate of the underground permanent structure, the top plate of the underground permanent structure is constructed, an entrance and exit for transporting the earthwork and materials are reserved in the top plate of the underground permanent structure, enclosure is sealed through a fence, other places except the entrance and exit are backfilled with surface layer covering soil, and ground or road restoration is carried out; earth excavation is carried out under the top plate through the entrance and exit, net hanging and spray protection are carried out on the surface of the temporary vertical enclosure structure, the underground permanent structureand a waterproof structure are constructed, and construction of the underground permanent structure and the waterproof structure of each layer is completed through circulation; and a parking system,a garage matching system and garage ancillary facilities are installed and debugged in the completed underground permanent structure.

Owner:北京中岩智泊科技有限公司

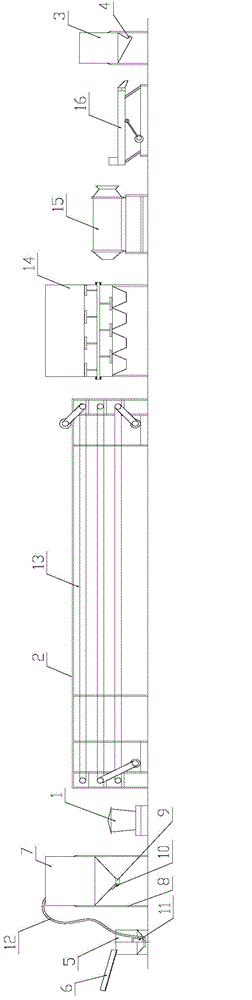

Production technology for processed rice

ActiveCN104146208AReduce labor intensityIncrease productivityFood preparationRice dishesSmall footprint

The invention discloses a production technology for processed rice. The production technology specifically comprises the following steps: A. cleaning polished glutinous rice and removing impurities; B. soaking and fermenting the polished glutinous rice which is cleaned; C. draining water out of the polished glutinous rice and cooking the polished glutinous rice; D. spreading and airing the glutinous rice which is fully cooked on a transportation type spreading and airing device; E. successively baking, cooling and screening glutinous rice blocks which are spread and aired to obtain processed rice; and F. packaging the processed rice. With the production technology for the processed rice, disclosed by the invention, the rice which is fully cooked is spread and aired on the transportation type spreading and airing device, and the transportation and the spreading and airing are combined together, so that the production efficiency can be improved, the production cost is reduced, the labor intensity of operators is low, a floor space for spreading and airing is small, the production cycle is short, the product quality is stable, the safety, the stability and the hygiene of products can be fully ensured, the standardized production technology is formed, and popularization and application are facilitated.

Owner:CHONGQING WENCAI AGRI PROD

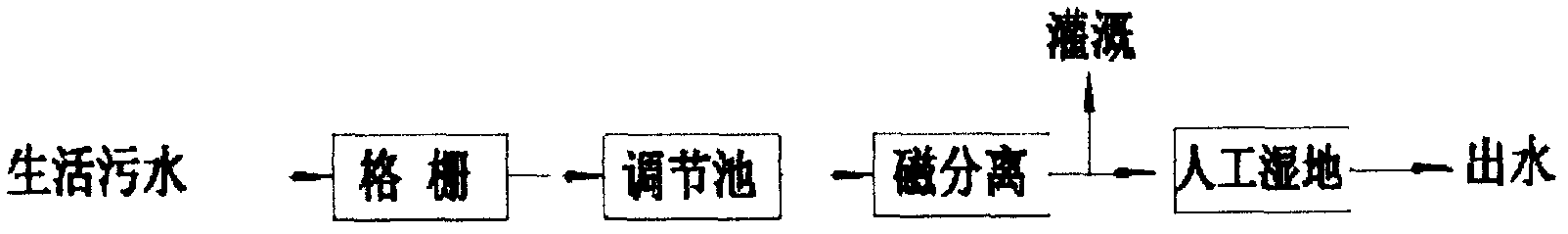

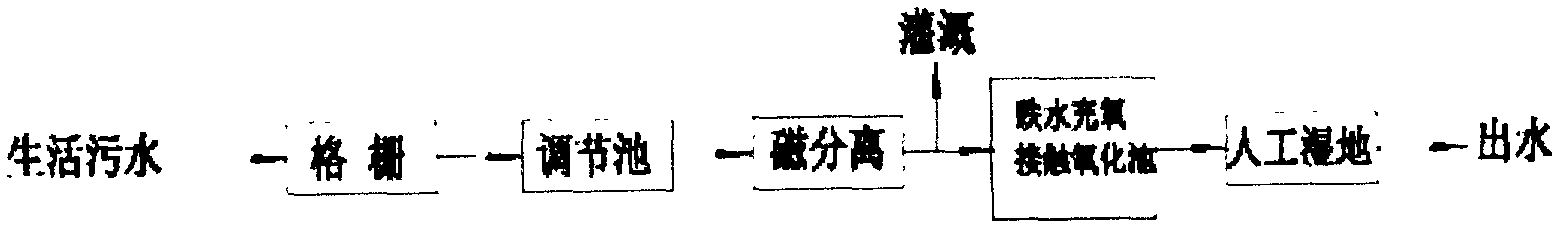

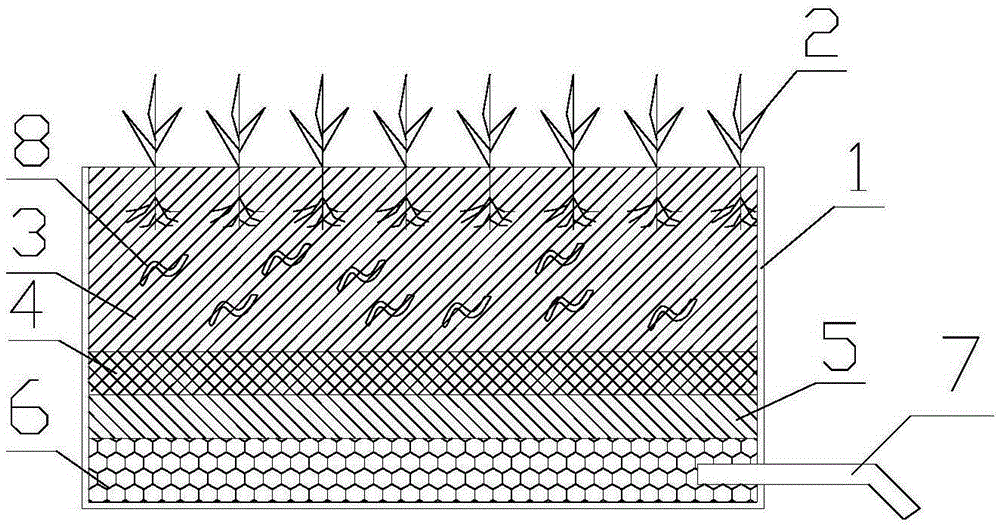

Technology for distributed treatment on domestic sewage from small rural towns

InactiveCN103011490ASmall footprintShort processWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentConstructed wetlandPollution

The invention belongs to the field of sewage treatment and relates to a technology for distributed treatment on domestic sewage from small rural towns. The technology comprises that domestic sewage is treated orderly by a grid, a regulating tank, a magnetic separation device and a constructed wetland and then forms product water. The technology has the advantages of small floor space, short flow, convenient equipment operation, low operation cost, no secondary pollution and flexible treatment on a load change, and is suitable for being popularized in small rural towns of China.

Owner:SCIMEE TECH & SCI CO LTD

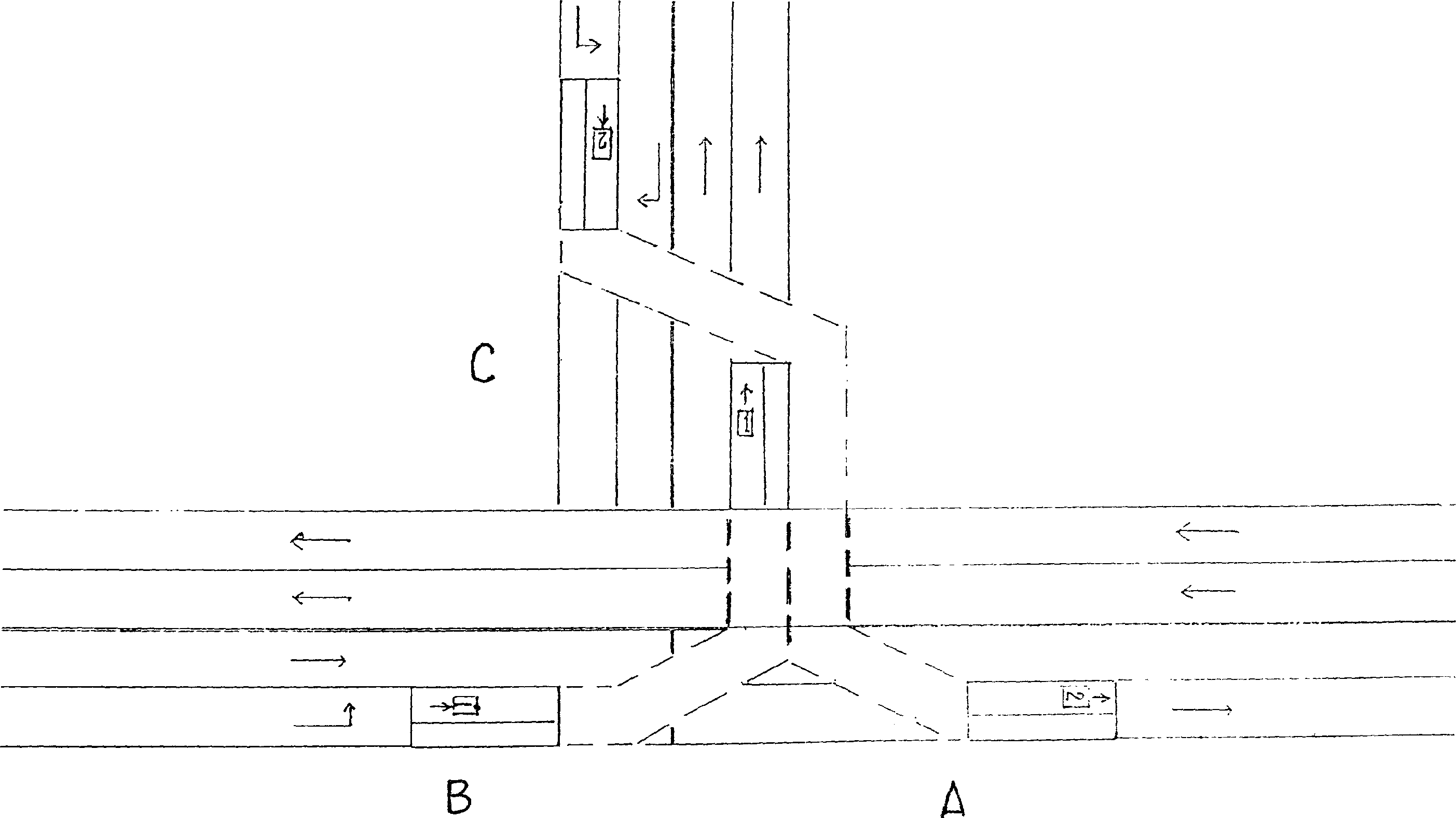

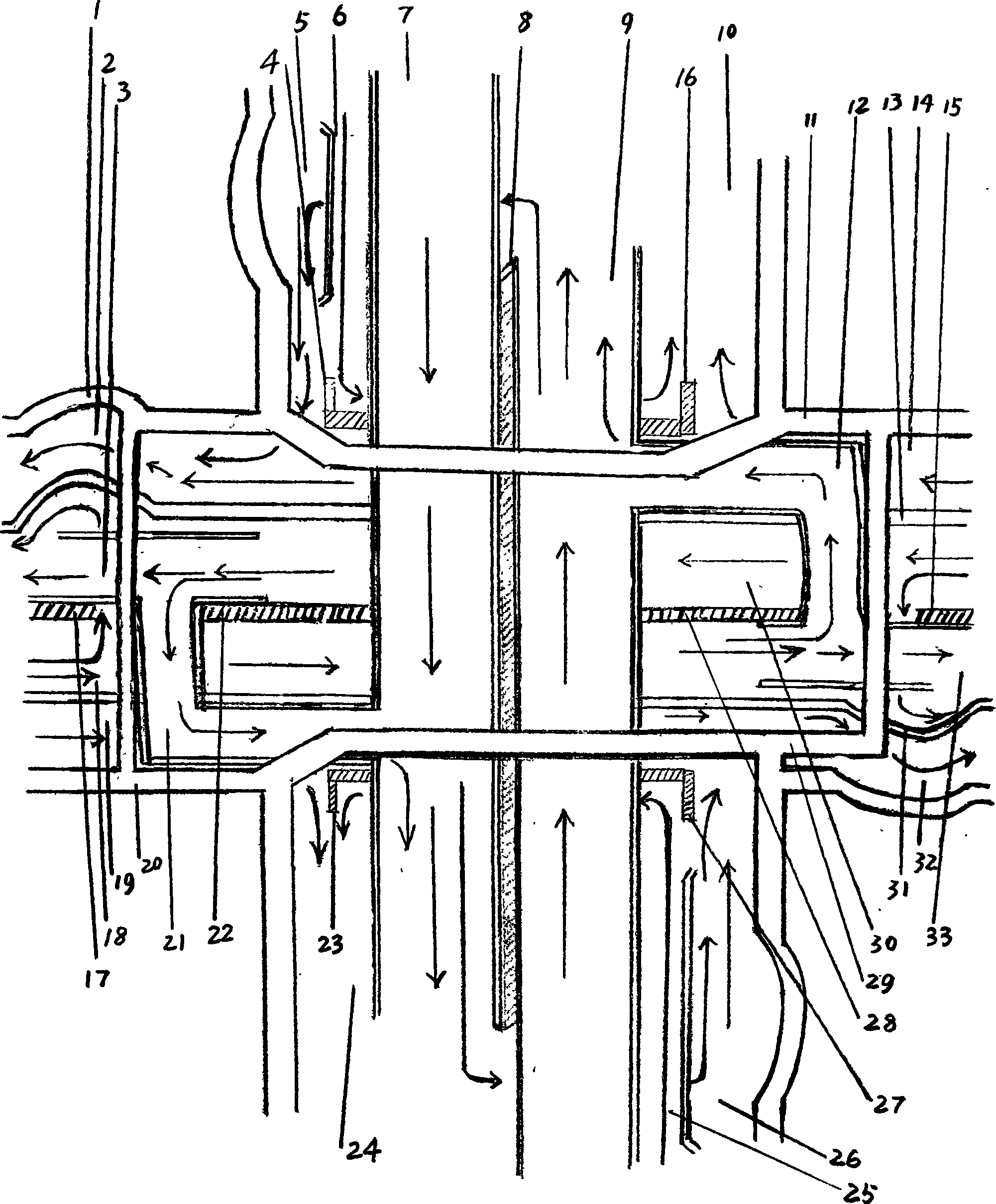

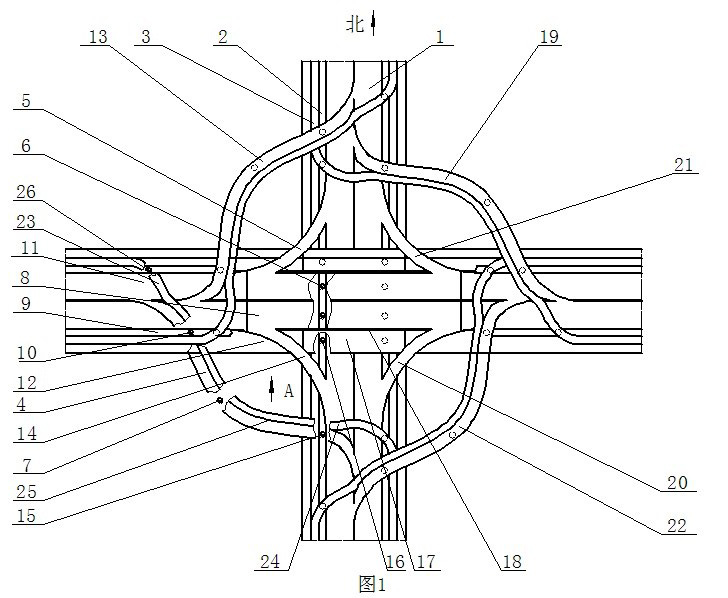

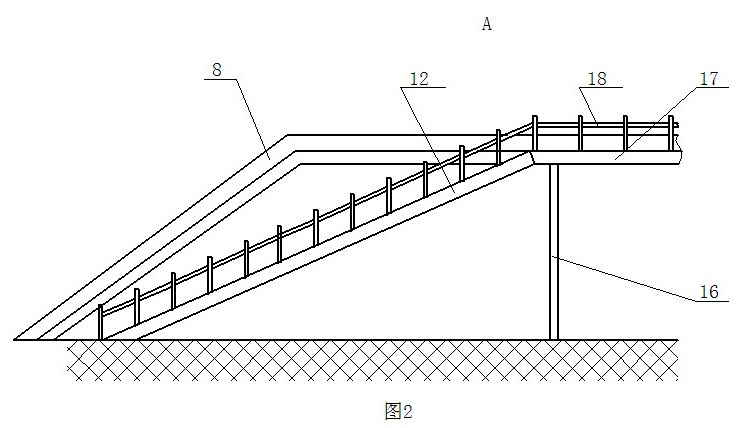

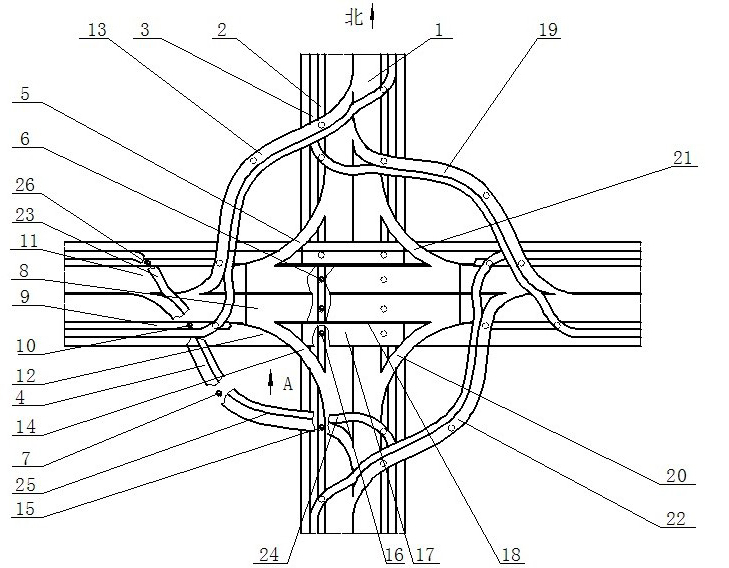

Two-underpass for turn left for man and vehicle unblocking at T-shaped crossroads

InactiveCN1598149ASolve the problem of stopping and waitingThere is no problem of stopping and waitingRoadwaysEngineeringRoad T junction

The invention belongs to road technology field. The essential of the invention is that there are two left turning underground passage on landscape orientation and on vertical orientation at the T-shaped crossing, and each passage is dual passage. On the landscape orientated passage, passerby and cars are coming from the landscape orientated passage, enter into the entrance of the left turning underground passage and go to the exit along the landscape orientated passage. On the vertical orientated passage, passerby and cars are coming from the vertical orientated passage, enter into the entrance of the left turning underground passage, pass through the left front exit along the passage, turn right front and keep going along the passage, pass the landscape orientated passage, then turn left front and go out from the exit. The dual passage means that the left side of each passage is for passerby, and the left side is for motor vehicles. The invention solves the problem of stop, run and wait of the road, saves much time of the passerby and vehicles, increases the passing speed, cancels traffic lights and traffic police, and saves cost.

Owner:李凤岐

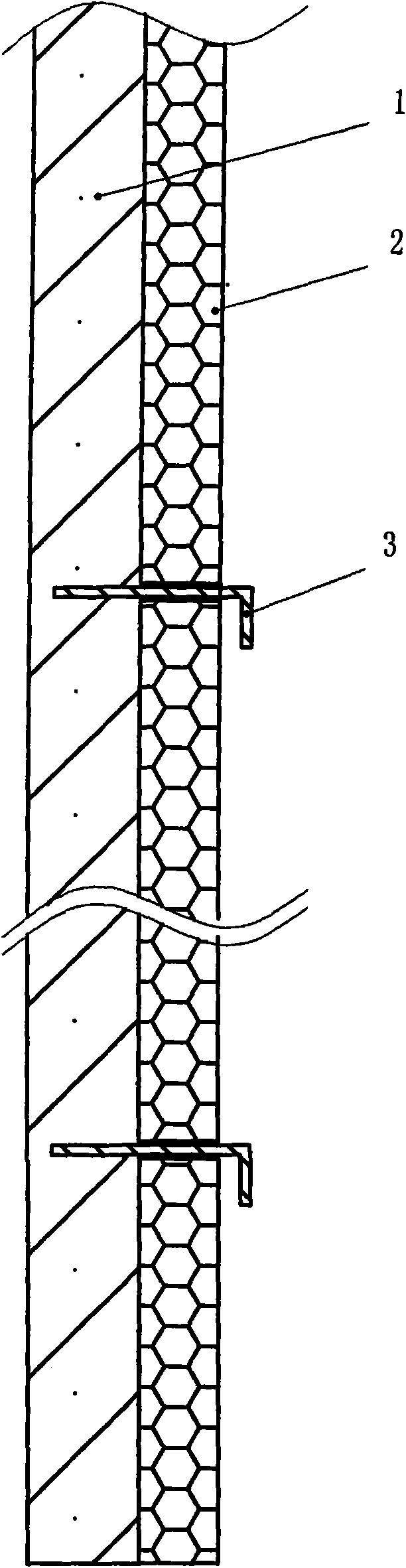

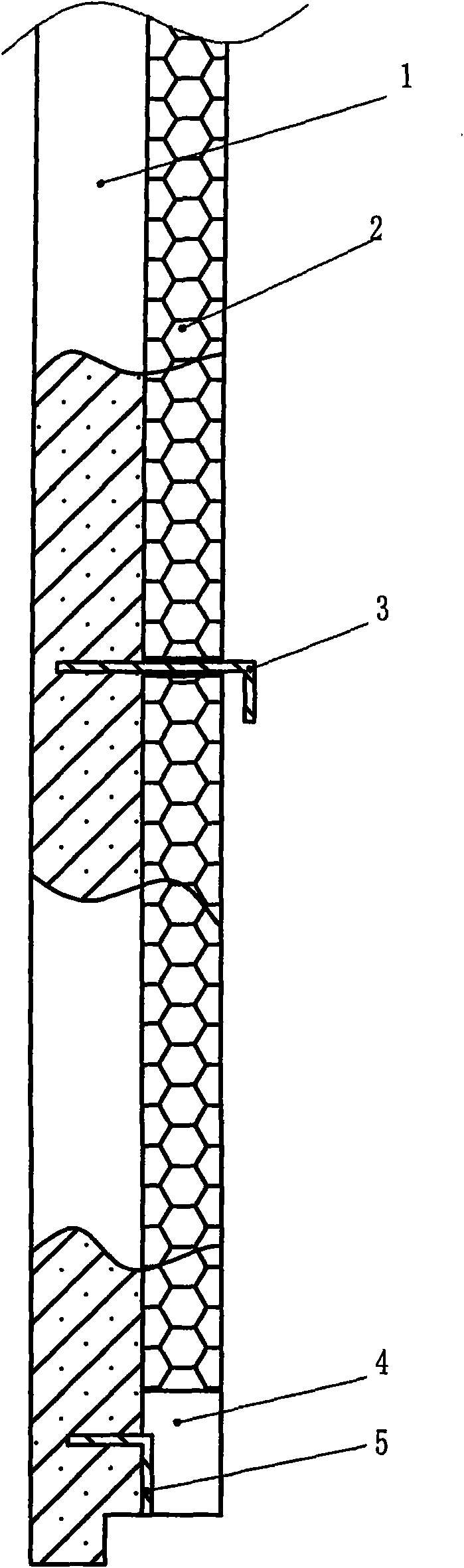

Outer wallboard

Owner:陈华照

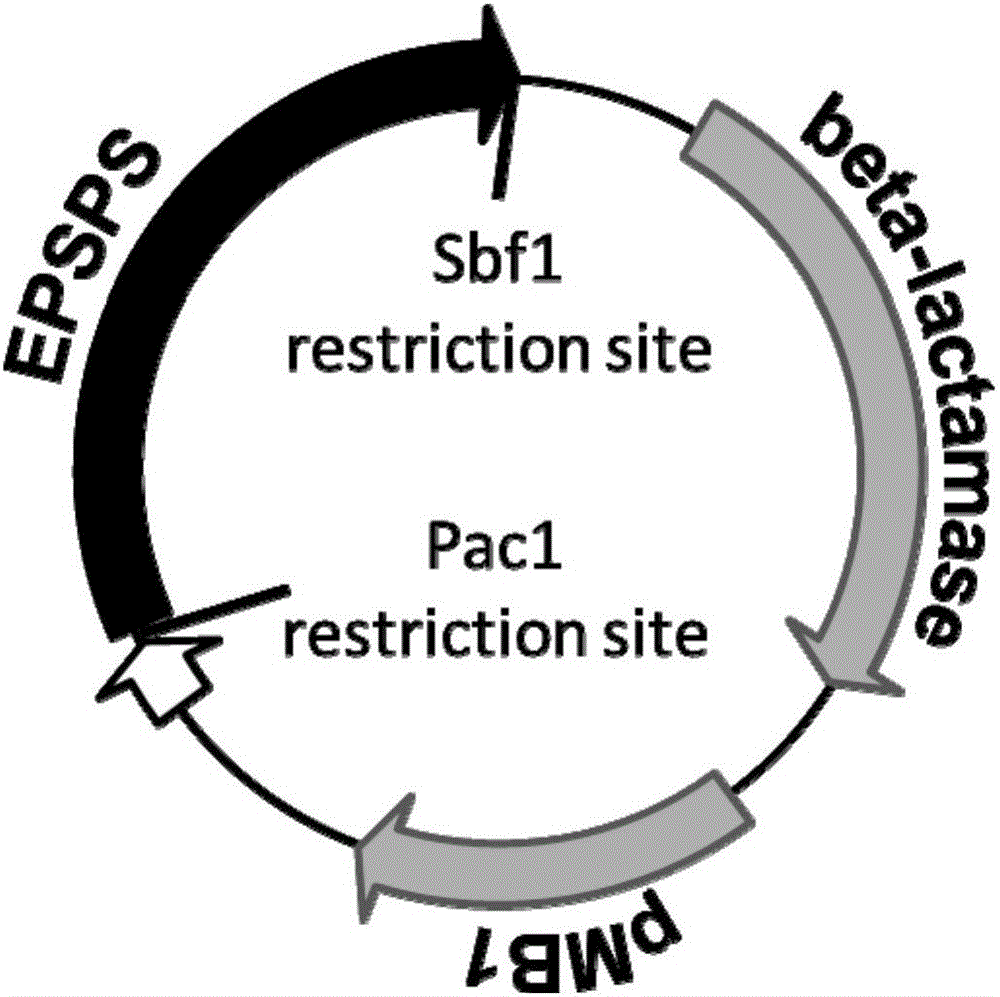

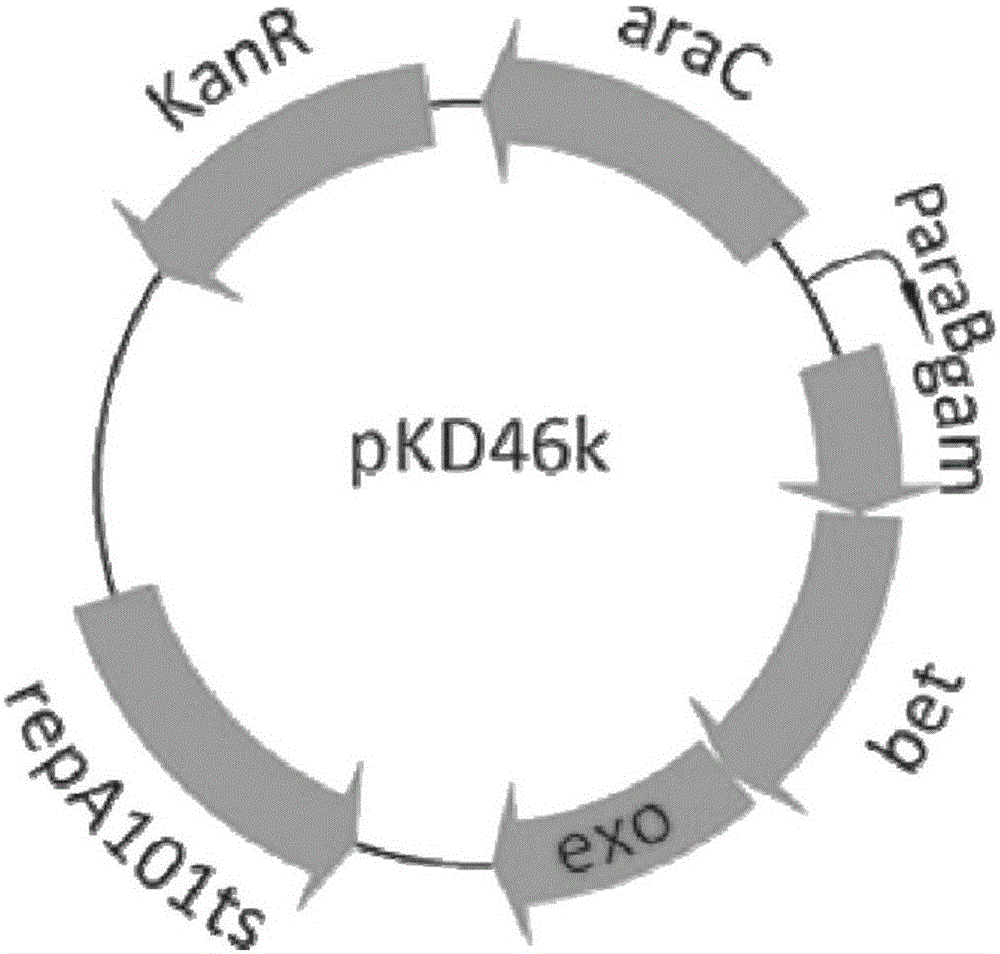

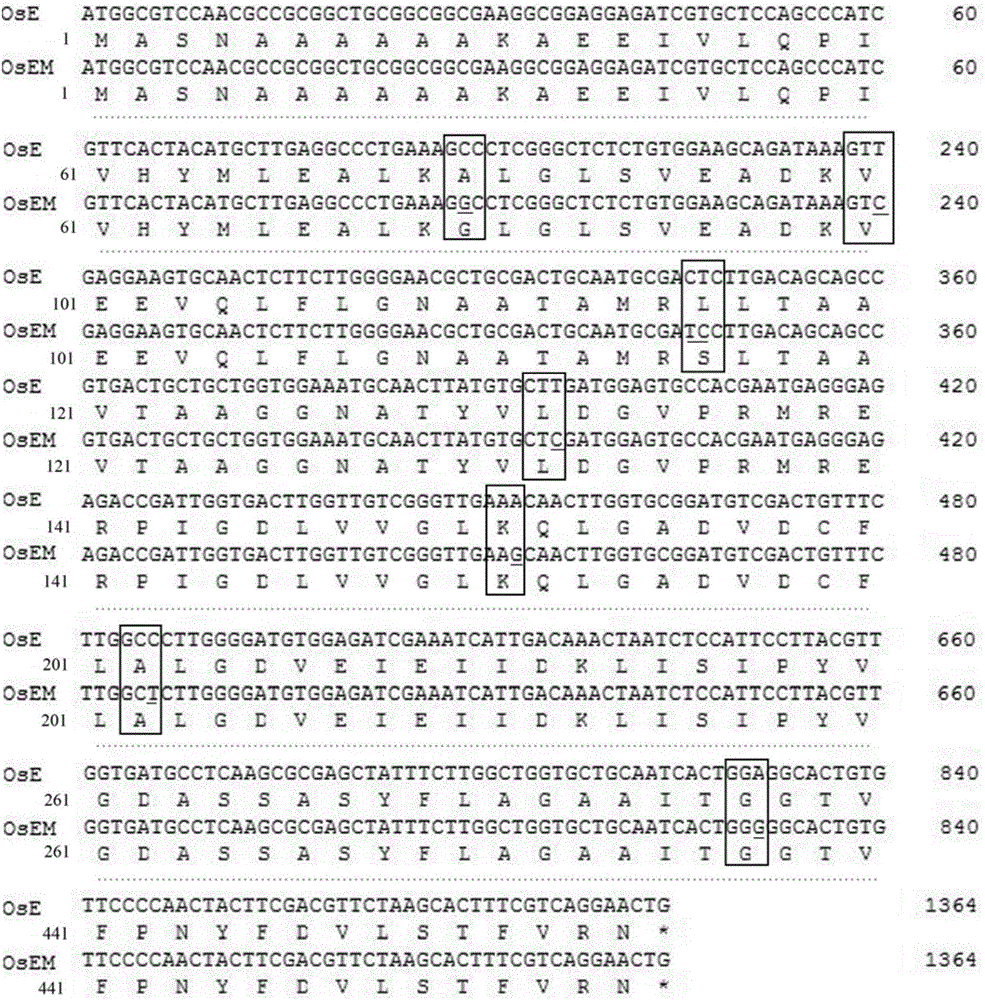

Method for screening glyphosate-resistant gene, EPSPS mutant gene, defect strain and application thereof

ActiveCN105969782AReproduce fastReduce volumeBacteriaMicrobiological testing/measurementGlyphosatePlant genes

The invention discloses a method for screening a glyphosate-resistant gene, an EPSPS mutant gene, a defect strain and application thereof. The method can be used for cloning glyphosate feeling related genes, including plant genes for multidirectional accelerated mutation and high-throughput glyphosate-resistant performance screening, so that a high glyphosate-resistant gene can be quickly evolved. By adopting the screening method, plants and other sourced genes can be quickly evolved to become mutant genes with glyphosate resistance by utilizing the characteristics of quick growth and reproduction and easy culture of bacteria.

Owner:SICHUAN GEVOTO BIOTECH CO LTD

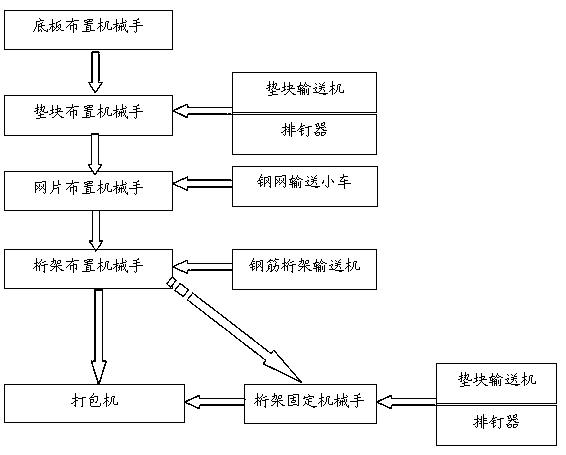

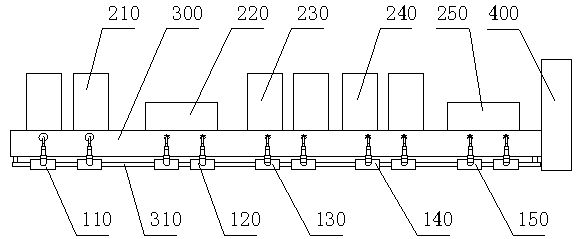

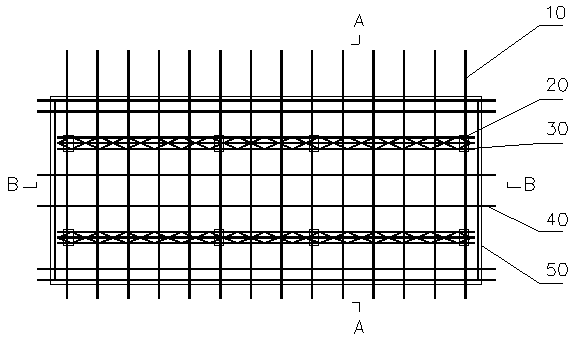

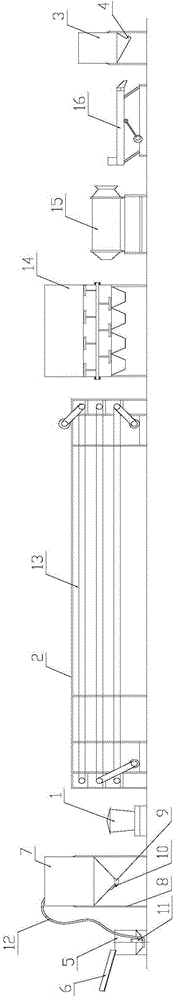

Production method and production device of non-dismantling non-metal bottom plate fixed die laminated plate

ActiveCN111075084AShort load capacity requirementsLow load capacity requirementFloorsCeramic shaping plantsAssembly lineMachine

The invention relates to a production method of a non-dismantling non-metal bottom plate fixed die laminated plate and a production device for the non-dismantling non-metal bottom plate fixed die laminated plate by adopting the method. The method comprises the steps of bottom plate arrangement, cushion block arrangement, mesh arrangement, truss arrangement, truss fixing and the like, wherein the device adopts corresponding manipulators of an assembly line or other machines capable of executing related work to carry out operation of each step. The method and the device have the beneficial effects that the process is simple and convenient, the production period is short, the cost is low, the produced non-dismantling non-metal bottom plate fixed die laminated plate can be used as a permanentformwork for a floor and a roof, the cast-in-situ concrete layer is not dismounted after being consolidated, the production cost is low, the field construction is convenient, the formed floor has quality and texture meeting the habits of people, and the decoration is convenient.

Owner:ZHONGQINGDA TECH HLDG CO LTD +1

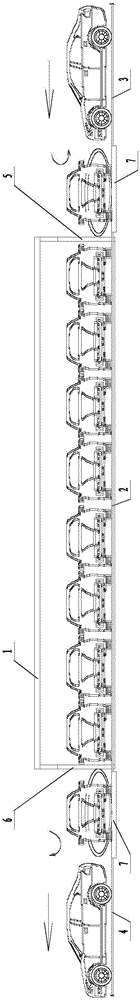

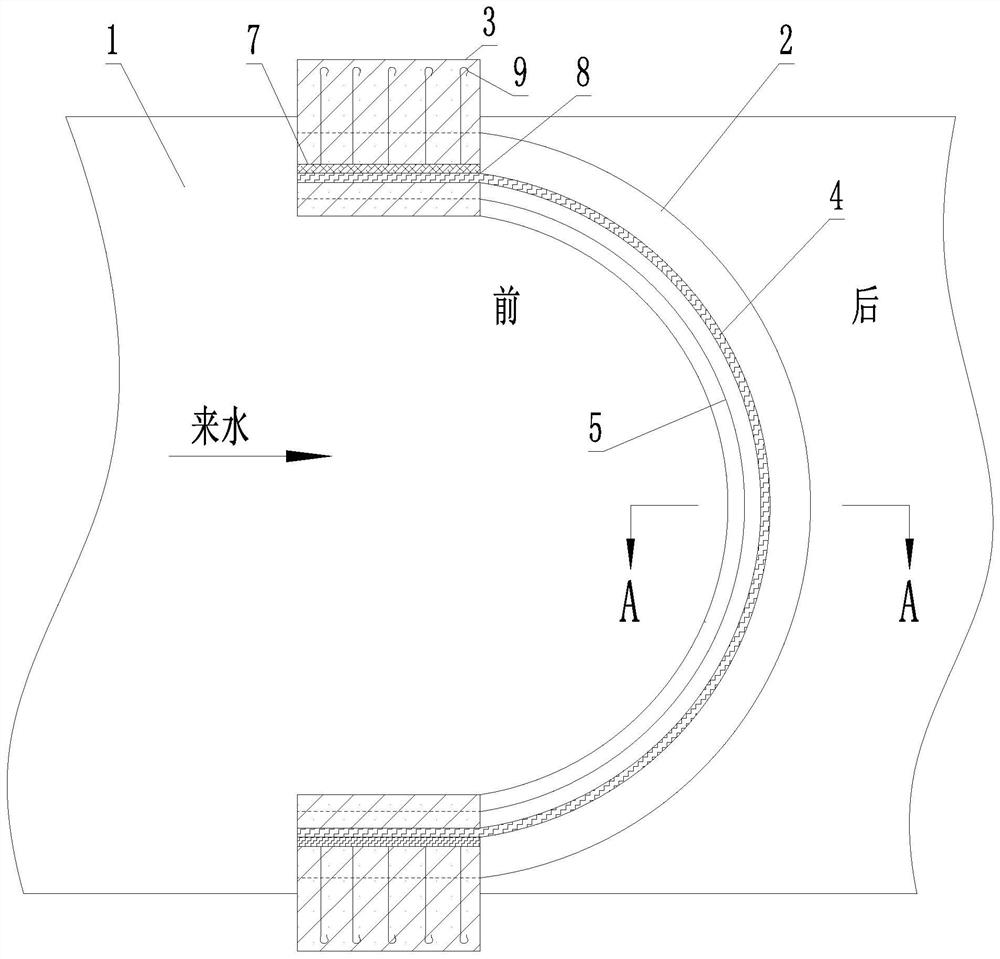

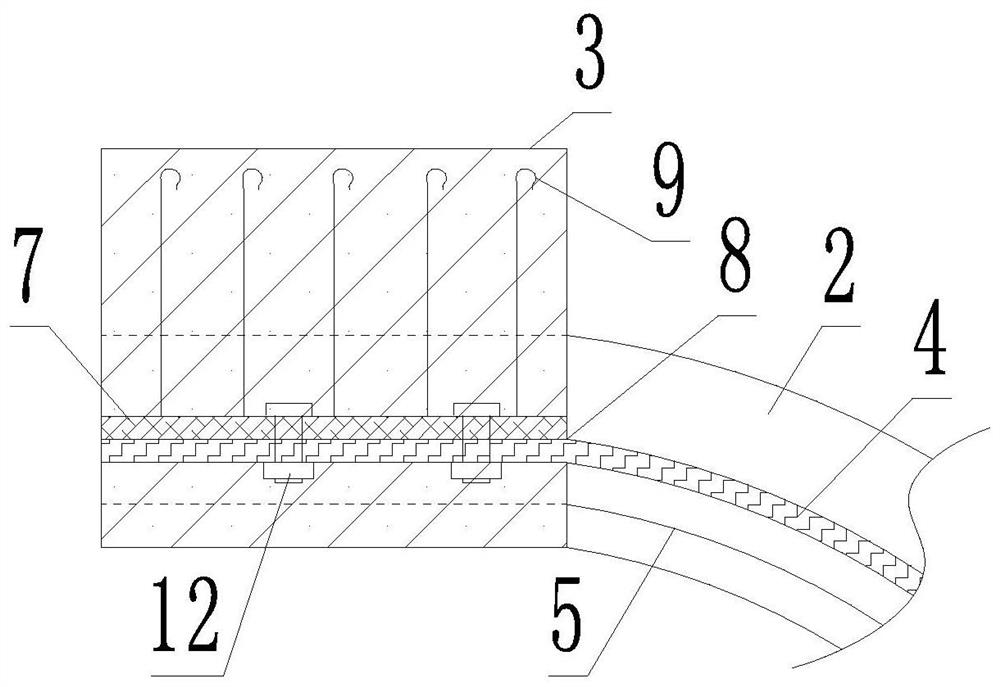

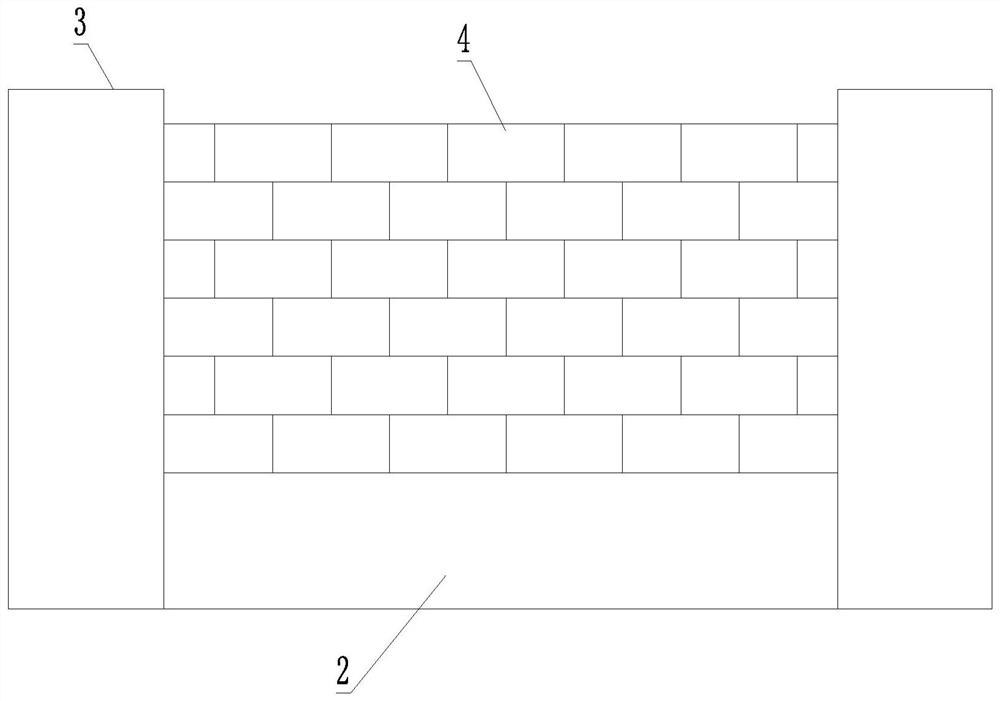

Intensive vehicle body drying system and drying method

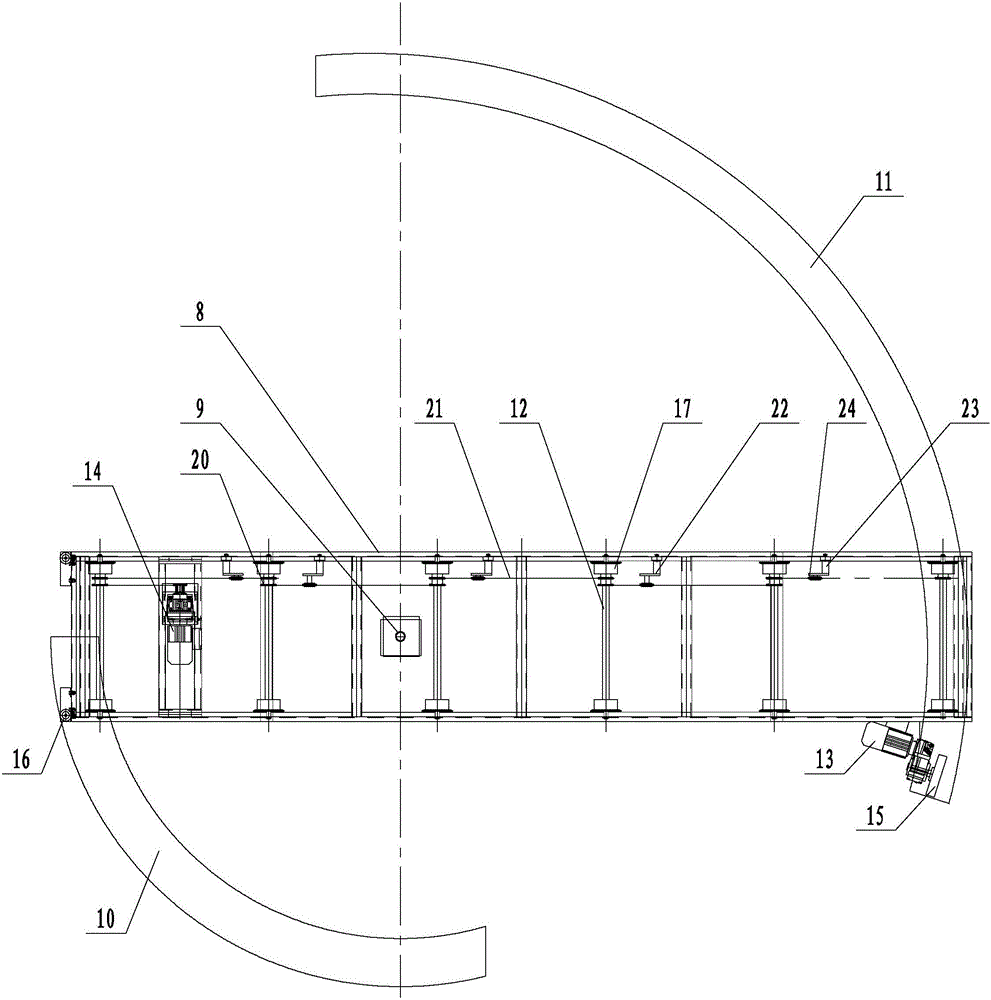

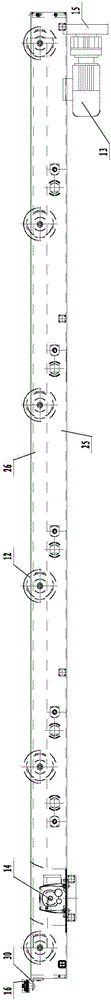

InactiveCN106583200AImprove production taktImprove compactnessConveyorsPretreated surfacesThermal energyDrive wheel

The invention discloses an intensive vehicle body drying system and drying method, and aims at overcoming the defects that a vehicle body drying room is poor in length, large in occupied area, low in heat energy utilization rate, large in power consumption and low in working efficiency. The intensive vehicle body drying system comprises a drying room, a conveying ground chain, an input conveying mechanism and an output conveying mechanism, the drying room is provided with an input port and an output port, and type shifting mechanisms are installed on the portion between the input port and the input conveying mechanism and on the portion between the output port and the output conveying mechanism outside the drying room respectively; and each type shifting mechanism comprises a type shifting frame, a steering supporting column, a front-end sliding rail and a rear-end sliding rail, wherein the steering supporting column is rotatably connected to the lower end of the type shifting frame, multiple wheel rollers which are arranged in parallel are rotatably connected to the type shifting frame, a vehicle body conveying motor and a driving motor are installed on each type shifting frame, the front-end sliding rail and the rear-end sliding rail are each of an arc-shaped structure, the driving motor is in drive connection with a driving wheel which is connected to the rear-end sliding rail in an abutted mode, a guide wheel is installed at the front end of the type shifting frame, and the guide wheel is connected in the front-end sliding rail in a matched mode.

Owner:浙江福林国润汽车零部件有限公司 +1

Rapid propagation method of nothapodytes pittosporoides

InactiveCN102948370AA large amountGuaranteed genetic stabilityHorticulture methodsPlant tissue cultureN-butyl acrylateButyric acid

The invention relates to a rapid propagation method of nothapodytes pittosporoides, and the method is characterized in that tissues such as tender shoot sections are cultivated on a murashige and skoog (MS) culture medium, a tender shoot stem section with one to two sprouts is cut as explants, the explants are grafted in MS+6-butyl acrylate (BA) 1.2mg / L+ indole butyric acid (IBA)0.2mg / L culture medium after being sterilized, the bud is germinated in 10 to 15 days after the grafting, seedlings with leaves are formed in 30 days, the seedlings are cut off and transferred onto the MS+6-BA1.2mg / L+IBA0.4mg / L culture medium to keep the high-speed increase, and the propagation coefficient is more than 5. The MS+6-BA0.5mg / L+ naphthyl acetic acid (NAA)1.5mg / L is selected as rooting culture medium, the rooting rate reaches more than 95 percent, and a complete plant can be formed in 30 days. Test-tube plantlets are transplanted in sandy soil, attention is paid on the moisture preservation, the transplanting survival rate can reach up to 93 percent after the test-tube plantlets are transplanted for 45 days, and a high-frequency stable renewable system is established. The method has the advantages of good stability, simplicity and convenience in operation, fast propagation speed, low production cost, industrialization and the like.

Owner:向华

Paris polyphylla var. yunnanensis scale seedling culturing method

InactiveCN101822157BUnsleepThe operation method is simple and easy to learnSeed and root treatmentHorticultureHigh survival rateBroadcasting

The invention relates to a Paris polyphylla var. yunnanensis scale seedling culturing method. The method comprises the following steps of: selecting Paris polyphylla var. yunnanensis plants more than 10 years old and reserving seeds for planting; collecting mature seeds; washing the collected seeds to remove episperm; spreading and drying the seeds in a shade and ventilating place within 12 hours, wherein a temperature is maintained and an accumulation thickness is less than or equal to 6 cm; spreading the seeds uniformly and drying; filling the seeds into a ventilating container; storing thecontainer in a shade environment with a suitable temperature, wherein the storage time is no more than 2 months; clearing impurities and residues in a seedling culturing field; fertilizing decayed farm manure and calcium superphosphate; plowing and raking soil; forming a furrow; spreading humus soil on the furrow surface; flatting the furrow surface; sowing in early June next year; taking the stored seeds, and after sterilizing, broadcasting the seeds uniformly according to the thickness of sowing; earthing after broadcasting; covering mantle on the furrow surface; irrigating sufficiently andperforming seedling management. A method for drying the seeds of the Paris polyphylla var. yunnanensis in shade in an environment without direct sunlight is adopted, the dormancy of the seeds of the Paris polyphylla var. yunnanensis is broken, and the scale production of Paris polyphylla var. yunnanensis seedlings is realized, so that germchit guarantee is provided for large-area popularization and cultivation of the Paris polyphylla var. yunnanensis. The method has the characteristics of simple and easily-learned operation, high survival rate of germchit, low production cost, healthy and strong germchit, stable and reliable technology, high repeatability, and capacity of effectively solving the problem of scale seedling cultivation of the Paris polyphylla var. yunnanensis.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

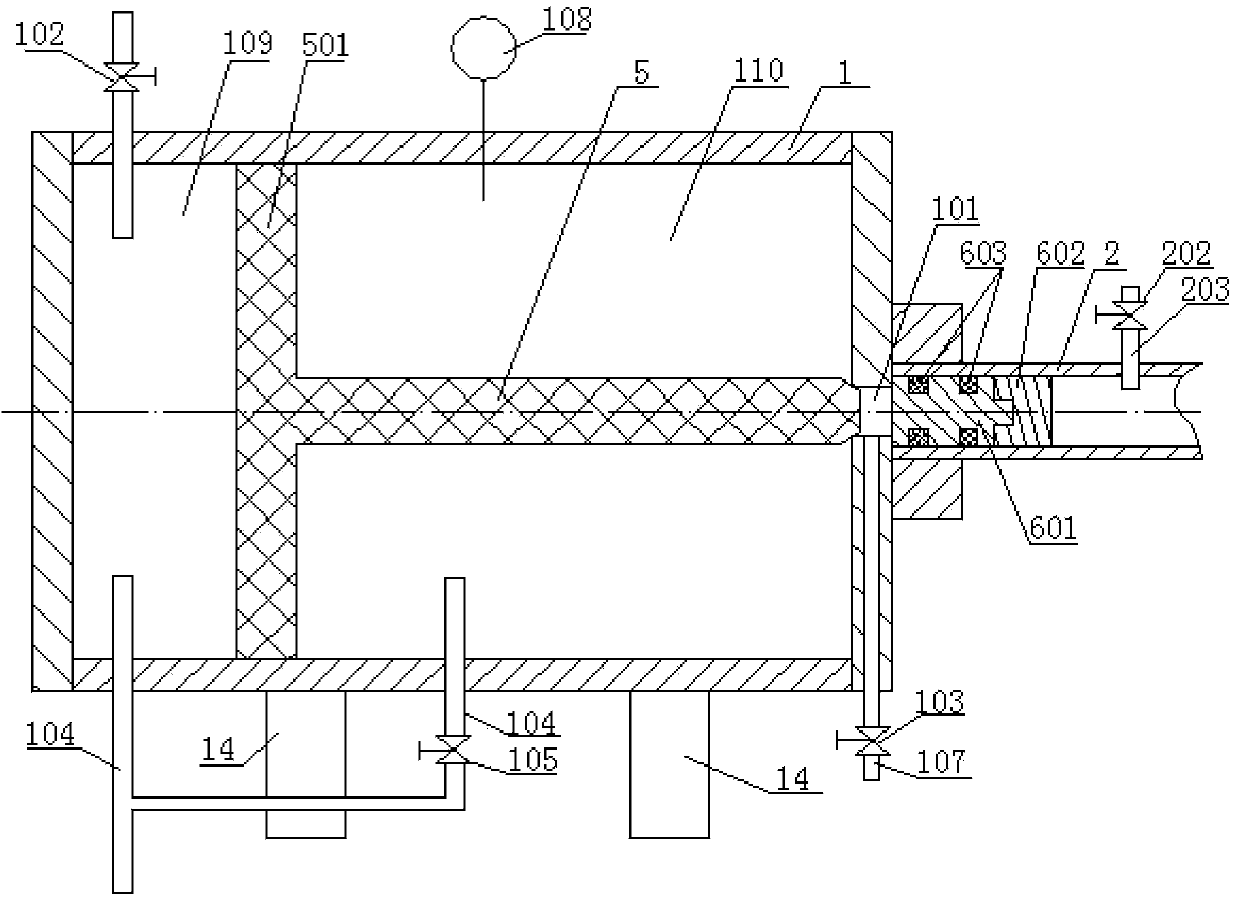

Barrier and explosion-proof skid-mounted device for petrol station

InactiveCN107352499AAvoid heavy pollutionPrevent volatilizationLiquid transferring devicesElectrical conductorPower station

The invention relates to a petrol station device, in particular to a barrier and explosion-proof skid-mounted device for a petrol station. The barrier and explosion-proof skid-mounted device comprises a barrier and explosion-proof petrol storage tank (2), split-type petrol filling machines (10) and control chambers (9) beside the petrol storage tank (2); the petrol storage tank (2) is a double-wall tank, and the petrol storage tank (2) is internally provided with a support (17) which is welded to a skid body (16); a cavity of the double-wall tank is internally provided with petrol-leakage-prevention units (14) and gas detecting alerters (18), and the petrol storage tank (2) is internally provided with a barrier and explosion-proof material (15) which is a column or a sphere of a honeycomb net structure and is made of a metal material; and the barrier and explosion-proof material (15) and the petrol storage tank (2) form a conductor. According to the barrier and explosion-proof skid-mounted device, the petrol storage tank is internally provided with a plurality of cabins, and petrol products of various types can be provided to meet different demands; and the device is of a skid-mounted structure and can be relocated and moved at any moment, the occupied area is small, the station building time is short, the cost is low, use and maintenance are easy and convenient, and the applicable places are wide.

Owner:辽宁易通智能装备制造有限公司

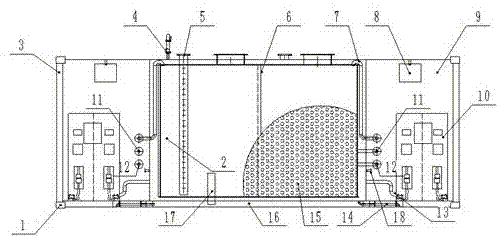

Night parking space arranged above short lawn area

The invention relates to a night parking space arranged above a short lawn area. The night parking space is a garage composed of a ground surface, a ceiling support and a ceiling. The night parking space is characterized in that the ground surface of the garage is replaced by a rectangular vehicle-carrying platform (3) positioned above the short lawn area (T); the ceiling support of the garbage is replaced by a motor wall pier (H); the ceiling of the garbage is cancelled; a large torque motor (1) arranged in the width direction of one end of the rectangular vehicle-carrying platform (3) is used for driving the rectangular vehicle-carrying platform (3) to carry out rotary displacement between a vertical state and a horizontal state through a rotating shaft (2); the rectangular vehicle-carrying platform (3) is set to be in the state of being vertically arranged in the daytime so as not to allow parking and in the state of being horizontally arranged at night so as to allow parking, and the settings are controlled by a time relay (G) and are realized through automatic control implemented according to the time period of daytime or night; the length (L) of the arranged parking space is equal to or greater than the sum of the lengths of the large torque motor (1) and an inclined slop structure (5) inside.

Owner:周巽

Device and method for treating fluorine-containing, ammonia-nitrogen-containing and phosphorus-containing wastewater

PendingCN111960582AImprove reaction efficiencyThe treatment effect is stableWater contaminantsTreatment involving filtrationTotal phosphorusEnvironmental chemistry

The invention belongs to the technical field of wastewater treatment, and particularly relates to a device and a method for treating fluorine-containing, ammonia-nitrogen-containing and phosphorus-containing wastewater. The device for treating fluorine-containing, ammonia-nitrogen-containing and phosphorus-containing wastewater comprises a reaction tank, a reduction tank and an integrated water purifier which are connected in sequence, and a matched sludge treatment system and a dosing device; all the devices are connected in sequence through pipelines; the reaction tank is provided with threegrids, and baffling connection is adopted; and an alkali regulating agent and an oxidizing agent are adopted in the reaction tank to achieve a synergistic effect, so that the reaction speed and the reaction degree are increased, the consumption of chemicals is reduced, and the sludge yield is reduced. The device is mainly used for treating fluorine ammonia nitrogen total phosphorus wastewater with medium or low concentration, ensures efficient and stable effluent, reduces the dosage of chemicals, and shortens the reaction time.

Owner:贵州中车绿色环保有限公司

A kind of flexible steel dam construction method

The invention proposes a flexible steel dam construction method, which belongs to the technical field of hydraulic engineering. The flexible steel dam includes a dam body, a concrete base, a concrete dam abutment, and channel steel. The bottom is connected in the slot of the channel steel; the dam body includes several dam body layers that are stacked and connected to each other from bottom to top, and each dam body layer includes a plurality of mutually welded steel plate units; The concrete abutments are connected, and the bottom of the concrete abutment is connected with the concrete base to form the flexible steel dam. The invention has the characteristics of high strength and good flexibility, and the dam body has good tensile properties; at the same time, it has the advantages of environmental protection and economy, short construction period and convenient dismantling and construction.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

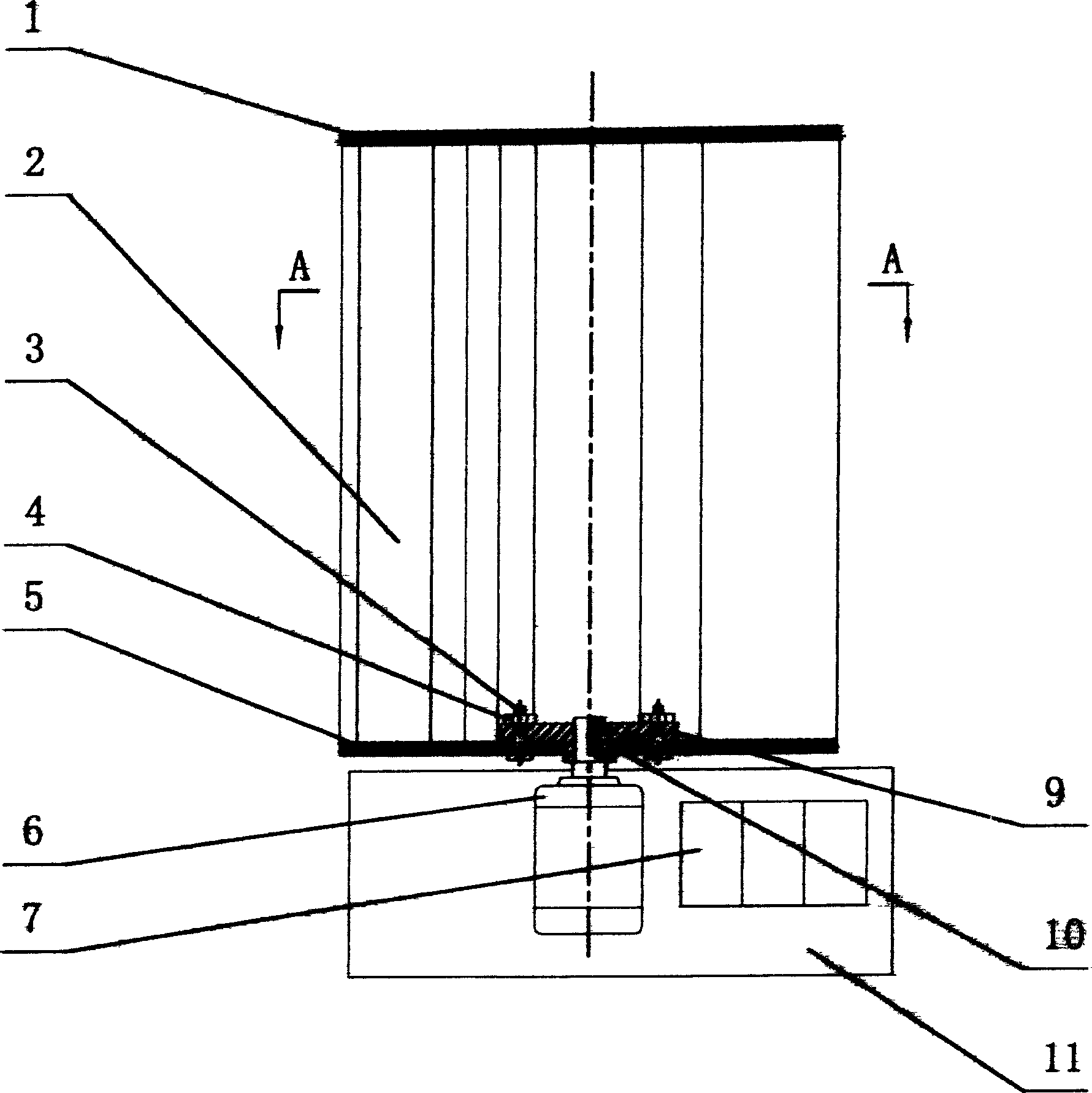

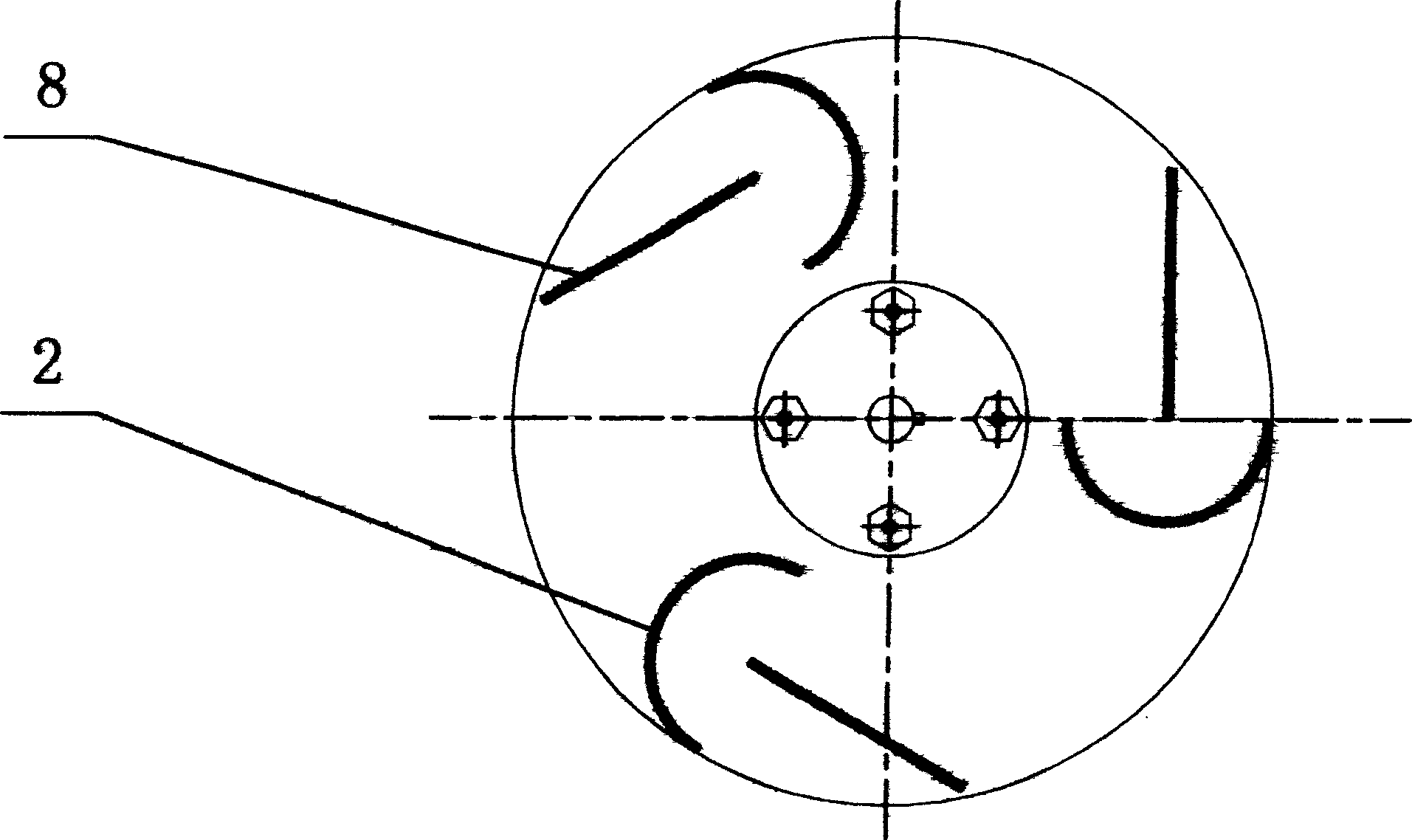

Disturbance wind speed wind generator system and vertical axis micro wind mill thereof

InactiveCN1594874ASimple structureHigh reservesWind energy with electric storageEnergy storageElectricitySEMI-CIRCLE

The present invention relates to a disturbance wind speed wind generator system which can generate electricity by using disturbance wind speed and a wind mill thereof. It is characterized in that the wind generator system includes a mobile disturbance wind source and the track of the mobile wind source, the side surface of the track of the wind source is mounted with a wind mill and a generator with a certain space, the electricity energy generated by the generator will be transmitted to corresponding electric appliances after the energy storage transformation. The wind mill is composed of an upper end plate 1, a lower end plate 5, plural vanes 2 disposed uniformly between the upper end plate and the lower end plate 5, an output shaft 10 fixed at the center of the lower end plate 5 and a base 11, wherein the section of the vane 2 is semi-circle shape, one end of the vane 2 is fixed to the inner side of the upper end plate 1, the another end of the vane 2 is fixed to the inner side of the lower end plate 5, the output shaft 10 passes through the base 11 and is connected to the corresponding rotation device on the base 11, the central axis of each semi-circle shaped vane 2 is disposed with a wind guiding board 8.

Owner:MIANYANG ZHONGTIAN SCI & TECH

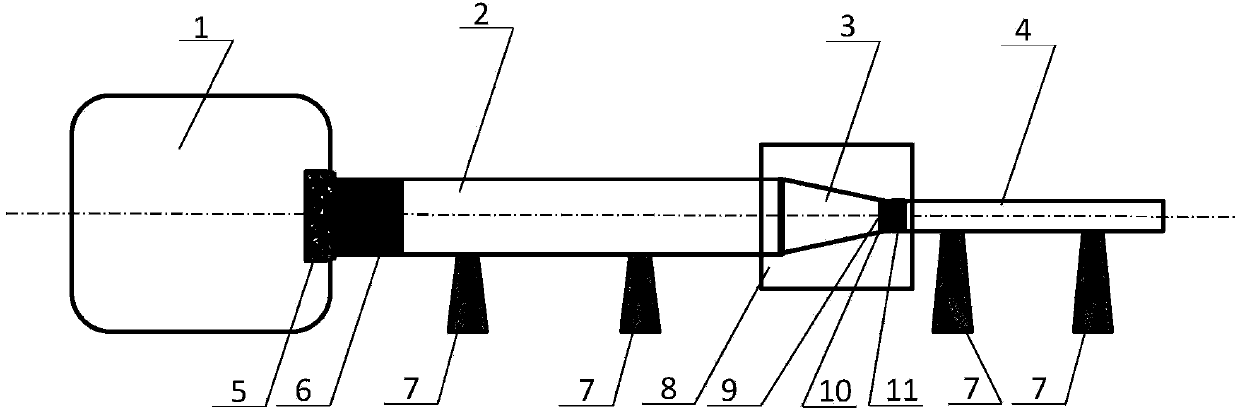

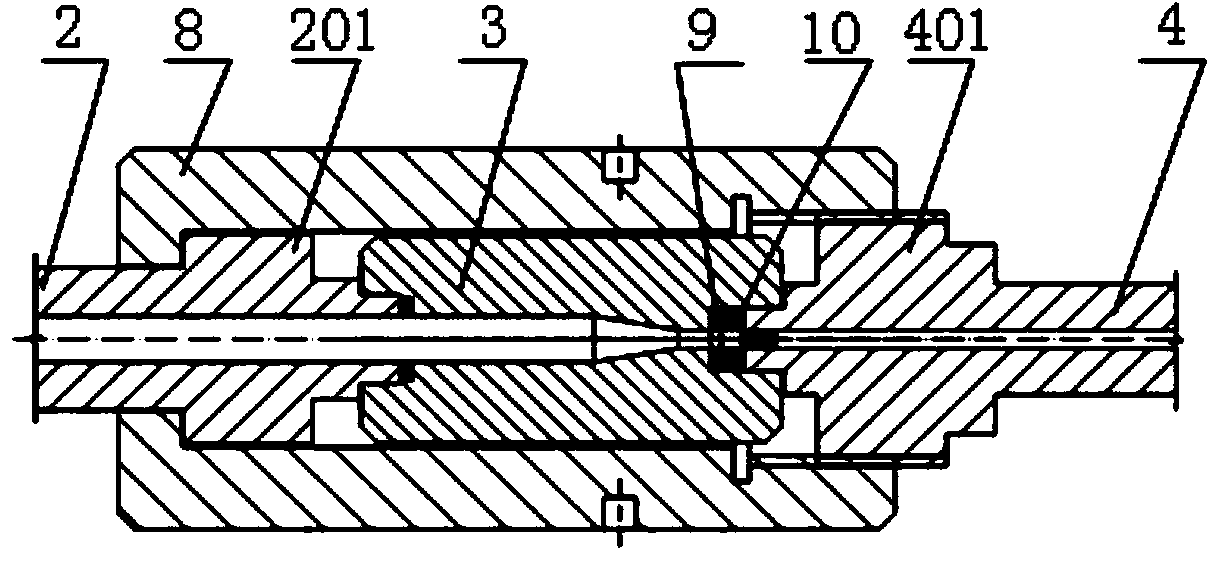

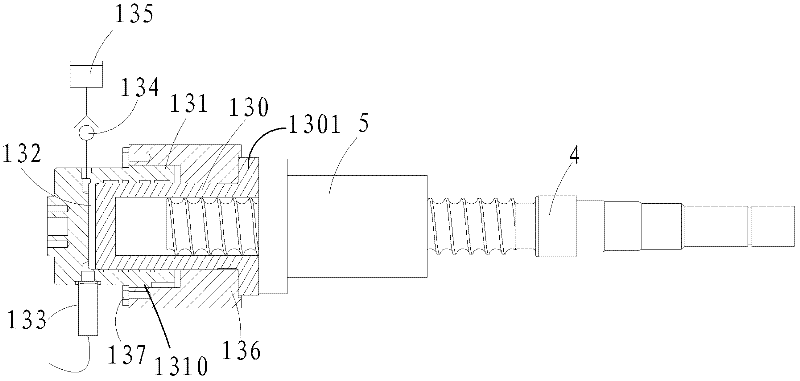

Small two-stage light-gas gun

The invention discloses a small two-stage light-gas gun and relates to a light-gas gun. The small two-stage light-gas gun comprises a cylinder barrel, a pressure transmitting tube, a pressing column, a launching tube, a piston handle, a pressure transmitting body, a membrane, a membrane rupturing device, a first sealing ring, a metal sealing ring, a support and a plurality of supporting seats; a piston on the piston handle is in sliding contact with the inner circumferential surface of a gas chamber; one end of the pressure transmitting tube is connected with a gas port in a threaded manner, and the pressure transmitting tube is hermetically connected with the pressing column; the pressure transmitting body is mounted in the pressure transmitting tube; the first sealing ring and the metal sealing ring are mounted in a mounting groove from the inside to the outside, the membrane is hermetically connected with the membrane rupturing device, and the membrane rupturing device is hermetically connected with the launching tube; the cylinder barrel is mounted on the support, and the pressure transmitting tube and the launching tube are respectively detachably connected onto the supporting seats. The small two-stage light-gas gun has the advantages that problems that an existing light-gas gun is driven by gunpowder at a primary stage, accordingly, environments are polluted, occupied space is large, sealing cannot be carried out in a membrane rupturing procedure implemented by the aid of high-pressure gas and the bullet launching speed cannot be increased are solved, and the small two-stage light-gas gun is used in fields of spacecrafts or research on material performance and the like.

Owner:HARBIN INST OF TECH

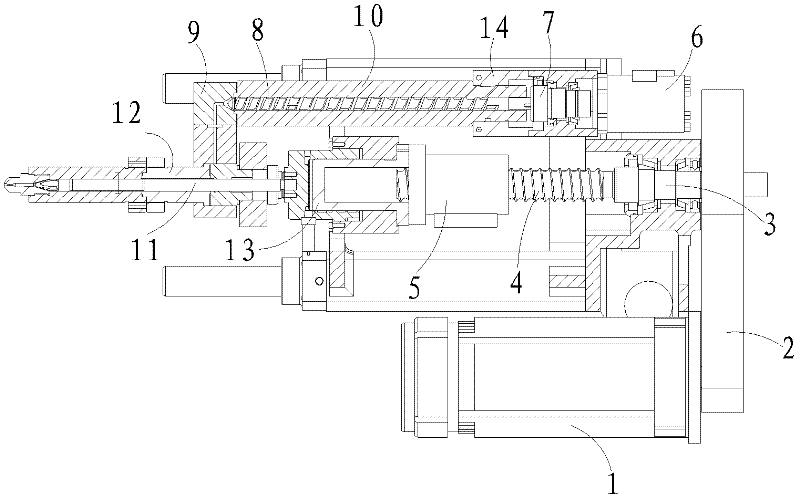

Plunger type injection molding device

The invention provides a plunger type injection molding device, comprising an actuating motor, a gearing, a transmission part, a ball screw, a ball nut, an oil hydraulic motor, a transmission shaft, a plastic screw, a guide plate, a sleeve which is sleeved on the plastic screw, a plunger rod, a discharging barrel which is sleeved on the plunger rod, and a pressure testing structure, wherein, the actuating motor is connected with the transmission part through the gearing, the transmission part is connected with the ball screw, the ball screw is connected with the ball nut, the oil hydraulic motor is connected with one end of the transmission shaft, the other end of the transmission shaft is connected with the plastic screw, the transmission shaft is fixed with the sleeve together through a base, the sleeve is connected with the discharging barrel through the guide plate, and the ball nut is connected with the tail end of the plunger rod through the pressure testing structure. According to the invention, the plastic structure can be separated from the ejection structure of the injection molding device, and the problems of short service life of traditional screw and nonuniform temperature of the plastic raw material are overcome.

Owner:SHANGHAI JIJIAN PRECISION MACHINERY

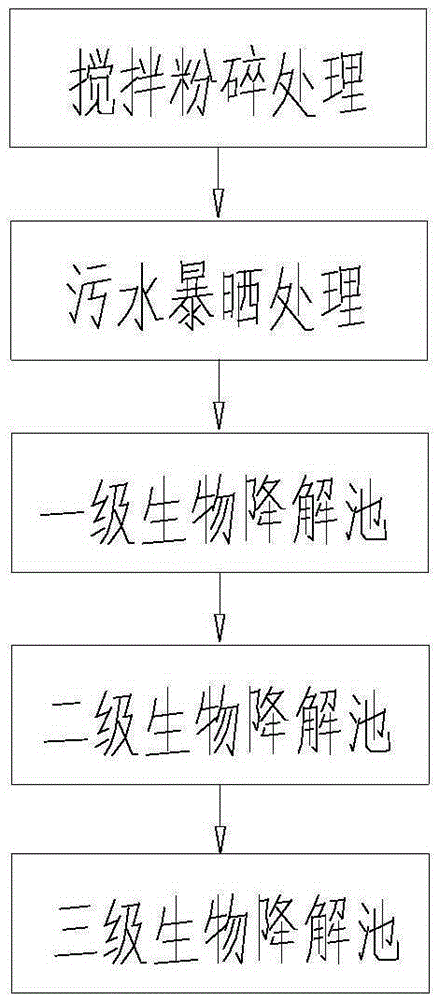

Kitchen sewage treatment method

InactiveCN105236673AScientific and reasonable process designReduce processing costsGeneral water supply conservationMultistage water/sewage treatmentConstructed wetlandMedicine

The invention relates to a kitchen sewage treatment method. The kitchen sewage treatment method comprises stirring crushing treatment, sewage exposure under sun, first-order biodegradation treatment, second-order biodegradation treatment and third-order biodegradation treatment, and the above five processes are circulated. The kitchen sewage treatment method has a scientific and reasonable process design, a low treatment cost, a short period, simple equipment processes and good operationality, is very suitable for centralized treatment on small-scale kitchen waste produced by newly built residential districts and high-grade restaurants and hotels, utilizes constructed wetland characteristics, and realizes effective treatment on sewage. The device used by the method is prepared from easily available materials, can be assembled simply, has short whole cycle time, has a small land occupation area, is convenient for treatment, can be operated easily and has a good ornamental value.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

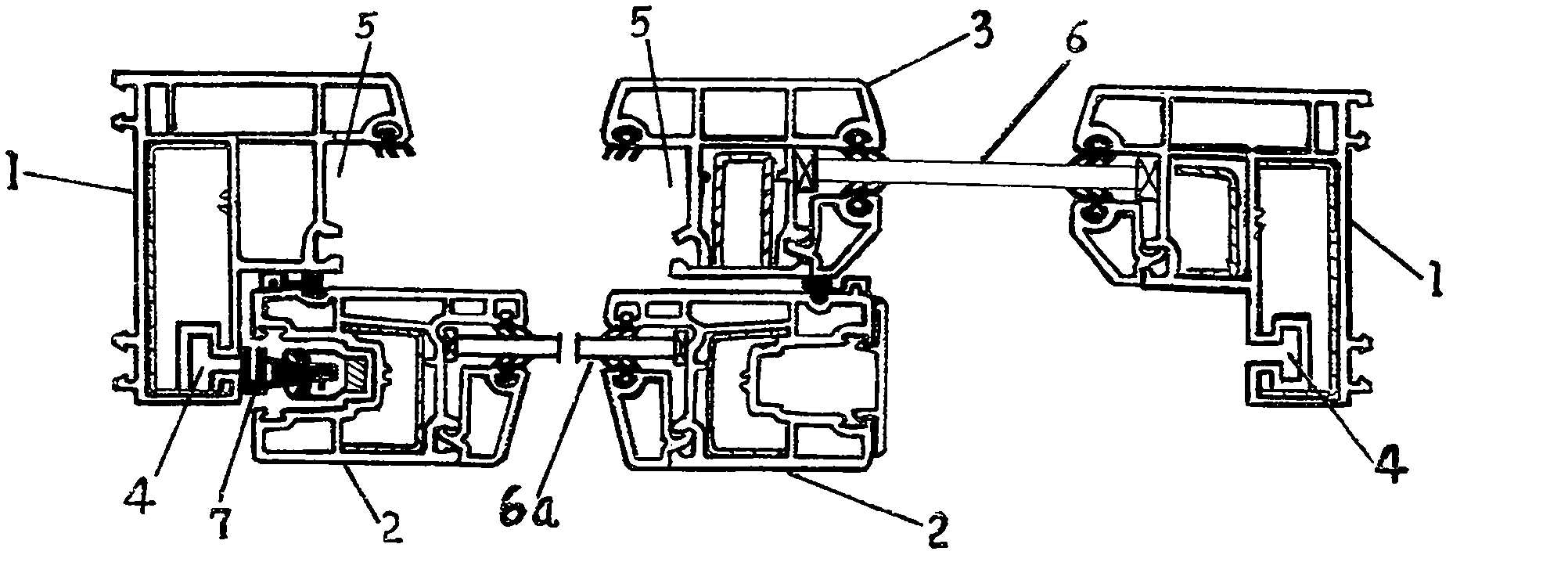

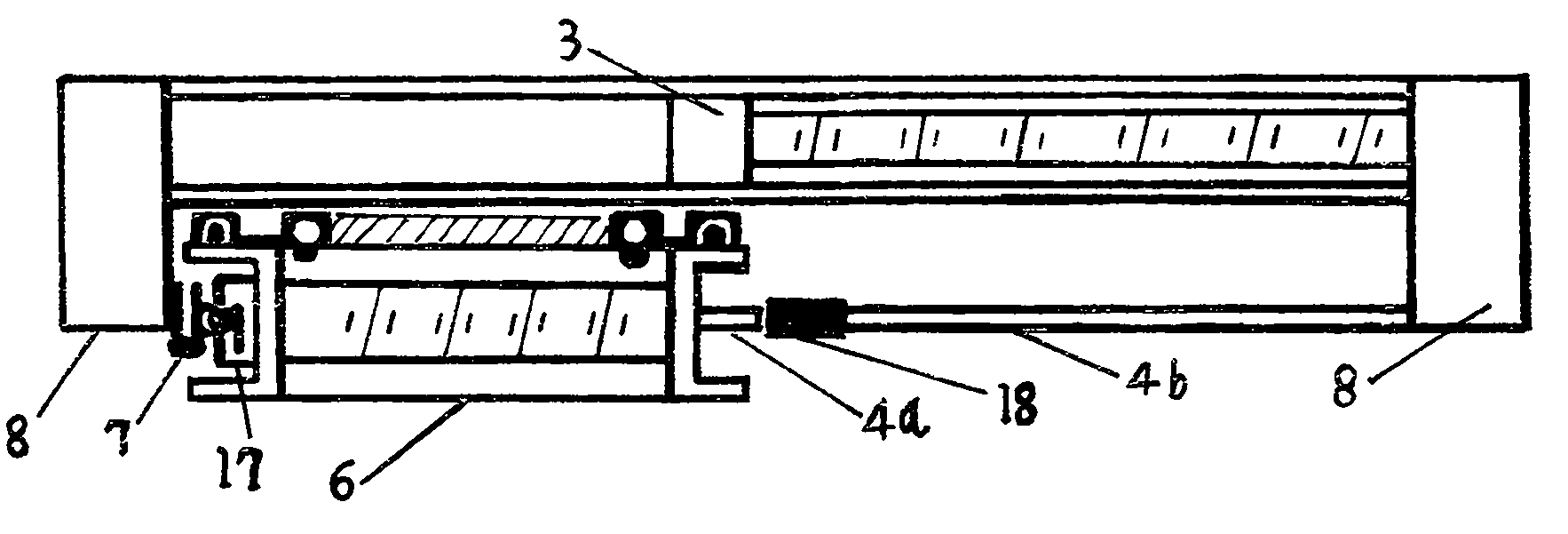

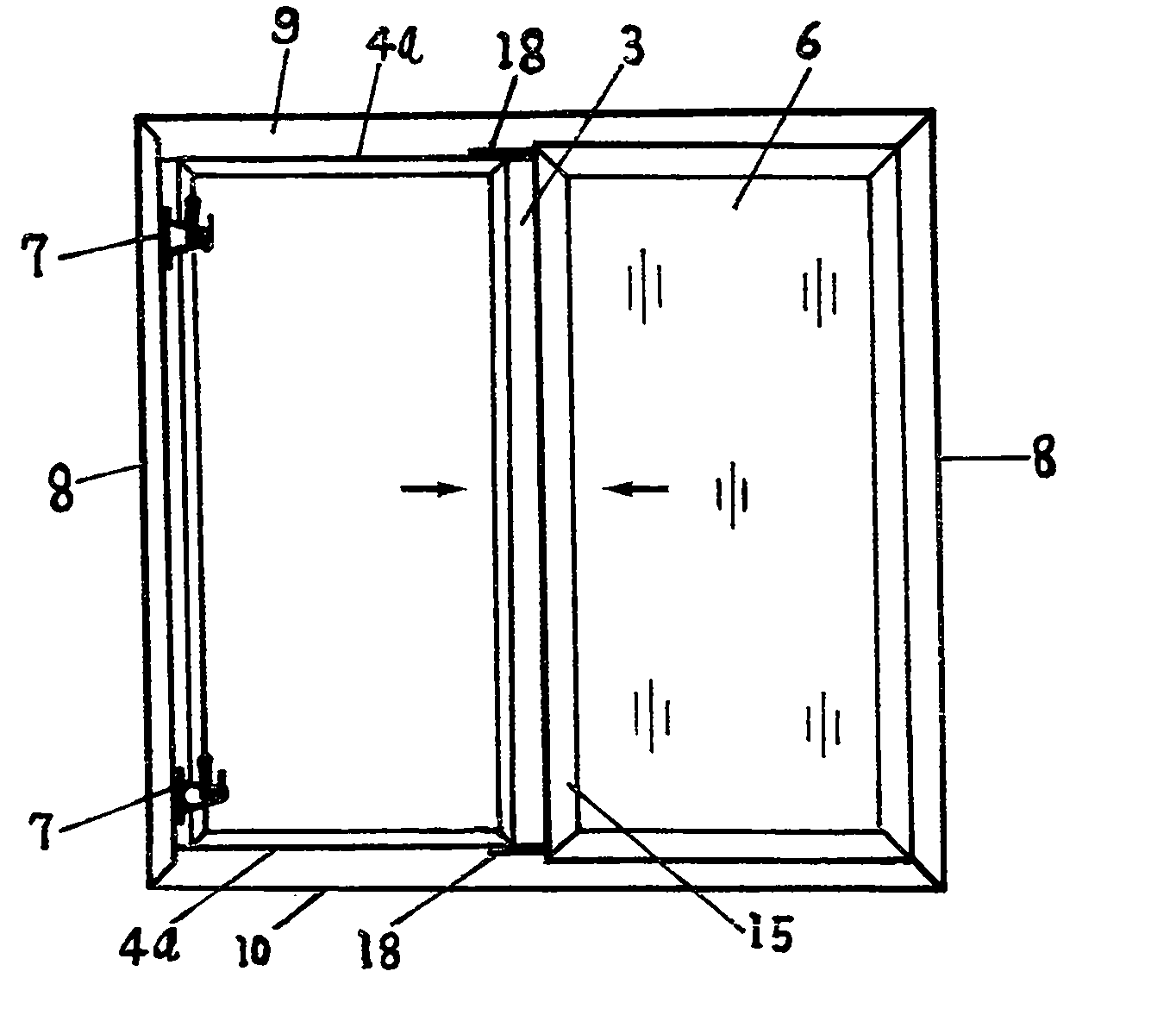

Push-pull casement window

InactiveCN102852430ASmall footprintEasy to useSealing arrangementsWing arrangementsPush and pullSlide window

A push-pull casement window is composed of a push-pull frame, a sash frame, a sash stile and a mullion. Sliding rails at the upper end and the lower end of push-pull sashes in a closed state are directly fixed on edge seals through hinges or fixed on a movable sash frame capable of being opened flatly, and the aims of push and pull and flat opening of the push-pull sashes are achieved finally. Accordingly, the push-pull casement window fundamentally solves the problems historically, performance singleness that sliding windows can only be pushed and pulled in a left-and-right mode and casement windows can only be opened flatly inwards and outwards occurs so that the sliding windows are poor in air tightness and water tightness and cannot save energy or protect the environment, and the casement windows are inconvenient to use, large in occupied space, high in cost, complex to install, unattractive and short in service lives and lead to difficulty in window screen installation. The push-pull casement window has better practicality.

Owner:彭兴勇

Treatment method of spent water from cleaning machinery parts

InactiveCN1171812CLow costReduce processing timeMultistage water/sewage treatmentFlocculationElectrolysis

A process for treating the sewage generated by washing mechanical parts features that electrolysis, flocculating and air-floating are performed in a single equipment, and includes such steps as regulating pH value to 5-9, COD concentration to 200-15000 mg / L and electric conductivity to 10 to the power (-2- -4) S / cm, stirring, loading in an electrolytic equipment, and performing electrolyzing, redox, flocculation and air floating. Its advantage is high effect on removing COD, emulsified oil, dissolved oil and surfactant.

Owner:CHINA PETROLEUM & CHEM CORP +1

Yinmi production process

The invention discloses a production technology for processed rice. The production technology specifically comprises the following steps: A. cleaning polished glutinous rice and removing impurities; B. soaking and fermenting the polished glutinous rice which is cleaned; C. draining water out of the polished glutinous rice and cooking the polished glutinous rice; D. spreading and airing the glutinous rice which is fully cooked on a transportation type spreading and airing device; E. successively baking, cooling and screening glutinous rice blocks which are spread and aired to obtain processed rice; and F. packaging the processed rice. With the production technology for the processed rice, disclosed by the invention, the rice which is fully cooked is spread and aired on the transportation type spreading and airing device, and the transportation and the spreading and airing are combined together, so that the production efficiency can be improved, the production cost is reduced, the labor intensity of operators is low, a floor space for spreading and airing is small, the production cycle is short, the product quality is stable, the safety, the stability and the hygiene of products can be fully ensured, the standardized production technology is formed, and popularization and application are facilitated.

Owner:CHONGQING WENCAI AGRI PROD

Method for separating and purifying nonane diacid

ActiveCN101250101BReduce lossesGuaranteed yieldCarboxylic preparation by ozone oxidationCarboxylic compound separation/purificationPurification methodsDecomposition

The invention discloses a separation purification method of azelaic acid, belonging to the separation purification technical field of organic compound, which comprises depressurizing and distilling the oxidation solution obtained by treating ozonation-oxidation decomposition on unsaturated fatty acid to remove solvent and pelargonic acid, transferring left oxidation solution to a film evaporator to be distilled to obtain crude azelaic acid, extracting and recrystallizing the crude azelaic acid to obtain azelaic acid crystal. In the recrystallization of azelaic acid, the low-carbon dibasic acid of C<4>-C<8> in azelaic acid is dissolved in cold water, to be discharged along with crystallization mother liquor, and the left azelaic acid in the recrystallization mother liquor is recovered by the film separator. The obtained azelaic acid is transferred to a rising film evaporator to be dried and dehydrated and the dehydrated azelaic acid is evaporated by film to obtain the azelaic acid. Thewhole process can confirm the yield of azelaic aicd and obtain high-quality azelaic acid, while the whole system is sealed and the process has better environmental compatibility.

Owner:SICHUAN SIPO CHEMICAL CO LTD

Treatment method for comprehensive sewage of smelting

InactiveCN110981041ALarge specific surface areaIncrease reaction rateSludge treatmentWater contaminantsSocial benefitsSludge

The invention discloses a treatment method for comprehensive sewage of smelting. The method comprises the following steps: introducing the comprehensive sewage of smelting into a wastewater regulatingtank to regulate a pH value of the sewage; then lifting the comprehensive sewage to a reduction reaction tank, adding a reducing agent, and carrying out a reduction reaction; after the reaction, introducing the comprehensive sewage into a coagulation reaction tank, adjusting the pH value of the comprehensive sewage to 7, then adding a heavy metal remover, and carrying out treatment; introducing the treated sewage into an inclined-tube sedimentation tank for flocculating settling, enabling the obtained supernatant to enter a clean water tank, and treating the obtained sludge for refining of heavy metals or other treatment; introducing the obtained supernatant into an LEC electro-catalytic oxidation device for degradation of organic pollutants, and discharging the sewage after the sewage reaches the standard. When the method is used for treating the comprehensive sewage, high efficiency and low cost are achieved, environmental protection is facilitated, and certain social benefits and economic benefits are achieved.

Owner:河南菲迪泰环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com