Device and method for treating fluorine-containing, ammonia-nitrogen-containing and phosphorus-containing wastewater

A technology of treatment device and treatment method, which is applied in the directions of neutralized water/sewage treatment, reduced water/sewage treatment, oxidized water/sewage treatment, etc., which can solve the problems of unsuitable removal of fluoride, ammonium nitrogen, total phosphorus, inability to handle ammonia nitrogen, and complicated process flow and other problems, to achieve the effect of stable treatment effect, reduced sludge output, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

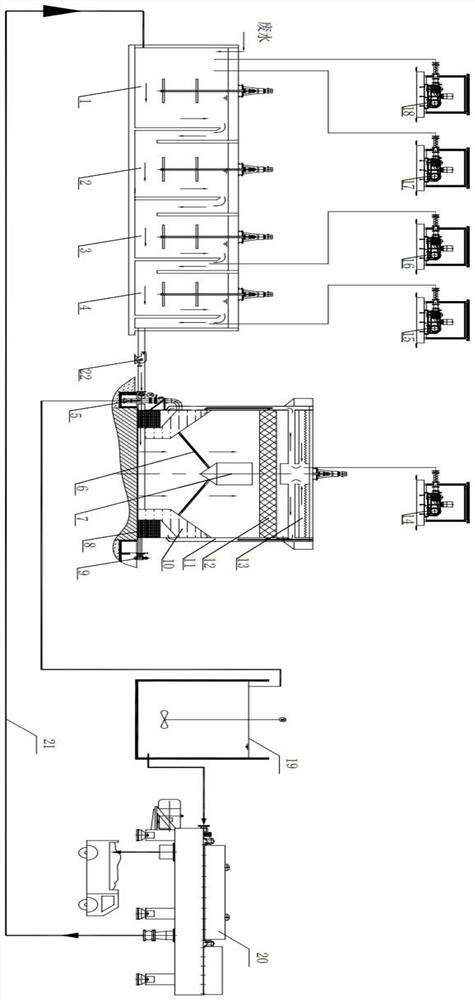

Image

Examples

experiment example 1

[0049] The concentration is fluoride = 30mg / L, ammonia nitrogen = 25mg / L, total phosphorus = 190mg / L, water inflow 250m 3 / h Wastewater containing fluorine, ammonium, nitrogen, and phosphorus is passed through the above-mentioned treatment device for wastewater containing fluorine, ammonia, nitrogen, and phosphorus, and the pH is adjusted to 10 by adding calcium hydroxide and sodium hypochlorite. After pH adjustment, the stirring reaction time is 70 minutes. After entering the reduction pool, sodium sulfite is added for reduction, while the residual chlorine content is monitored online, and polyacrylamide with a molecular formula of 1400w is added to the outlet of the reduction pool. Tangentially enters the integrated water purifier for cyclone reaction, suspension clarification, inclined tube sedimentation, acid neutralization, filtration and adsorption, and the effluent is directly discharged. The measured sludge volume is 20m 3 / h, sludge accounted for 8%, total solids 3.4%...

experiment example 2

[0051] The concentration is fluoride = 20mg / L, ammonia nitrogen = 33.6mg / L, total phosphorus = 180mg / L, water inflow 280m 3 / h wastewater containing fluorine, ammonia, nitrogen and phosphorus, through the above-mentioned treatment device for wastewater containing fluorine, ammonia, nitrogen and phosphorus, adjust the pH to 10.9 by adding calcium hydroxide and calcium hypochlorite, and the stirring reaction time after pH adjustment is 60min. After entering the reduction pool, sodium thiosulfate is added for reduction, while the residual chlorine content is monitored online, and polyacrylamide with a molecular formula of 1600w is added to the outlet of the reduction pool. Tangentially enters the integrated water purifier for cyclone reaction, suspension clarification, inclined tube sedimentation, acid neutralization, filtration and adsorption, and the effluent is directly discharged. The measured sludge volume is 31.6m 3 / h, sludge accounted for 9.2%, total solids 2.5%, effluent...

experiment example 3

[0053] The concentration is fluoride = 50mg / L, ammonia nitrogen = 40mg / L, total phosphorus = 200mg / L, water inflow 260m 3 / h Wastewater containing fluorine, ammonium, nitrogen, and phosphorus is passed through the above-mentioned treatment device for wastewater containing fluorine, ammonia, nitrogen, and phosphorus, and the pH is adjusted to 10.5 by adding calcium oxide and sodium hypochlorite. After pH adjustment, the stirring reaction time is 90 minutes. After entering the reduction pool, sodium sulfite is added for reduction, while the residual chlorine content is monitored online, and polyacrylamide with a molecular formula of 1500w is added to the outlet of the reduction pool. Tangentially enters the integrated water purifier for cyclone reaction, suspension clarification, inclined tube sedimentation, acid neutralization, filtration and adsorption, and the effluent is directly discharged. The measured sludge volume is 20m 3 / h, sludge accounted for 11%, total solids 2.8%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com