Production method and production device of non-dismantling non-metal bottom plate fixed die laminated plate

A laminated board, non-metallic technology, applied to floors, manufacturing tools, structural elements, etc., can solve problems such as not easy to bend, waste, and affect reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

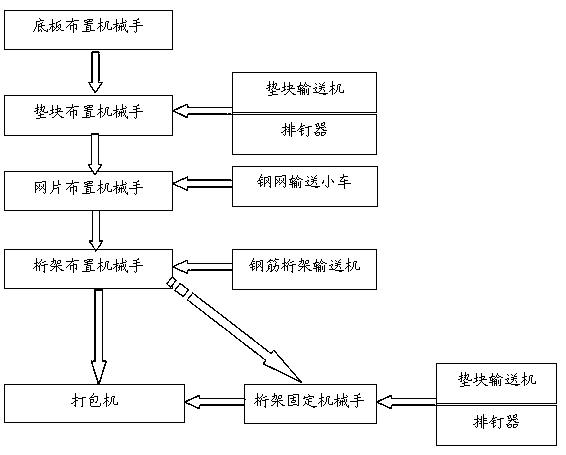

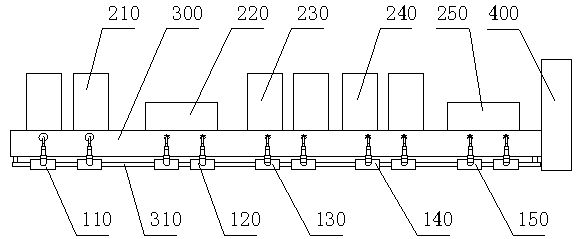

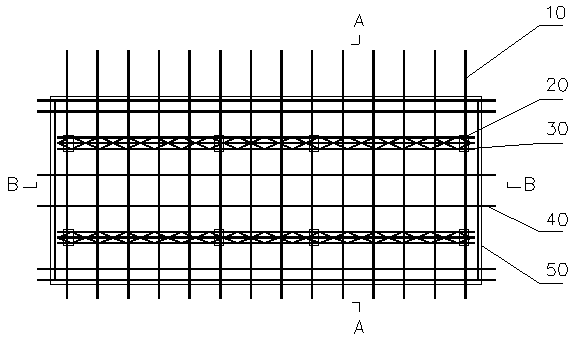

[0112] The invention is used to prepare a new type of non-metal base plate fixed form laminated board, which can be used as a fixed formwork for floors and roofs and other similar occasions, without prefabricated concrete layer, and is suitable for The machined non-metal plate is used as the bottom plate, the processing equipment and processing technology are simple, the impact on the working environment is small, the operation is convenient, the labor intensity is reduced, the working environment is improved, and there is no need to set up concrete-related equipment and facilities, and the floor area less, which greatly reduces the investment in production equipment and facilities; no need to spend concrete curing time in the preparation process, which significantly shortens the production cycle and improves production efficiency; light weight, low requirements on the load-bearing capacity of the plant, allowing the plant to be set up as multi-storey , which further reduces th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com