Acoustic resonance mixing equipment with labyrinth-shaped mixing channel and explosive mixing process

A technology of mixing channels and mixing equipment, which is applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problems of poor mixing effect of high polymer bonded explosives, achieve excellent mixing effect, low processing cost, and small channel weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

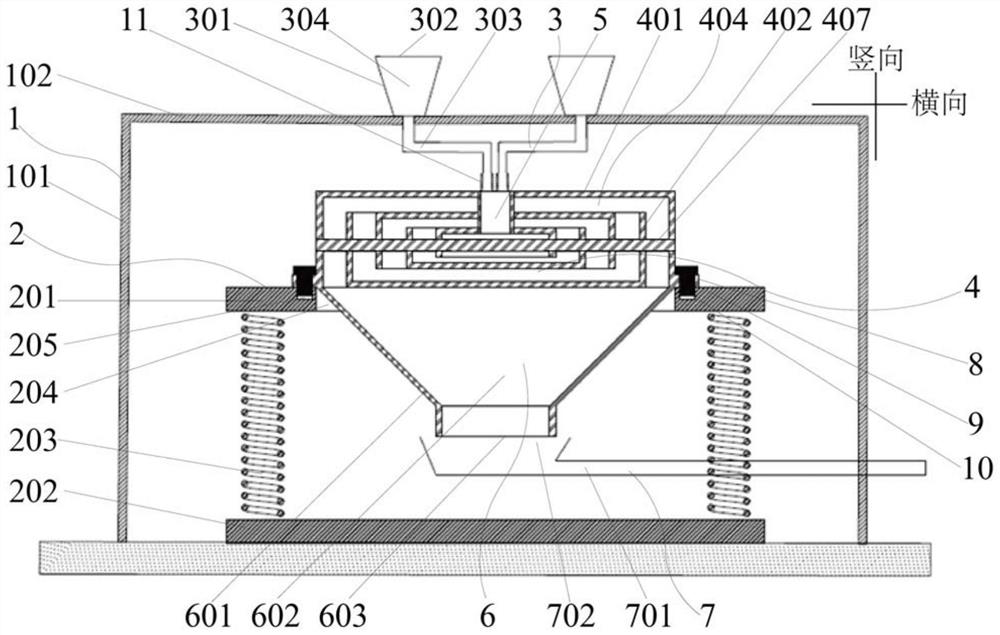

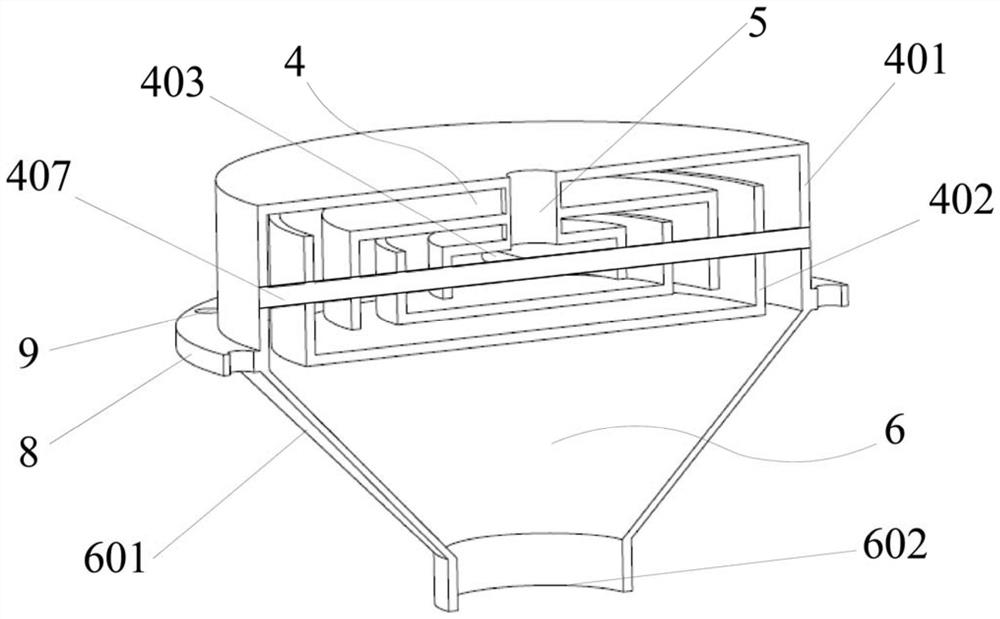

[0080] This embodiment provides a labyrinthine mixing channel, such as Figure 1 to Figure 7 As shown, it includes at least two downward-facing disks 401 with different inner diameters. The downward-facing disks 401 are coaxially nested sequentially from small to large inner diameters, and an upward-facing disk is nested between adjacent downward-facing disks 401. Body 402;

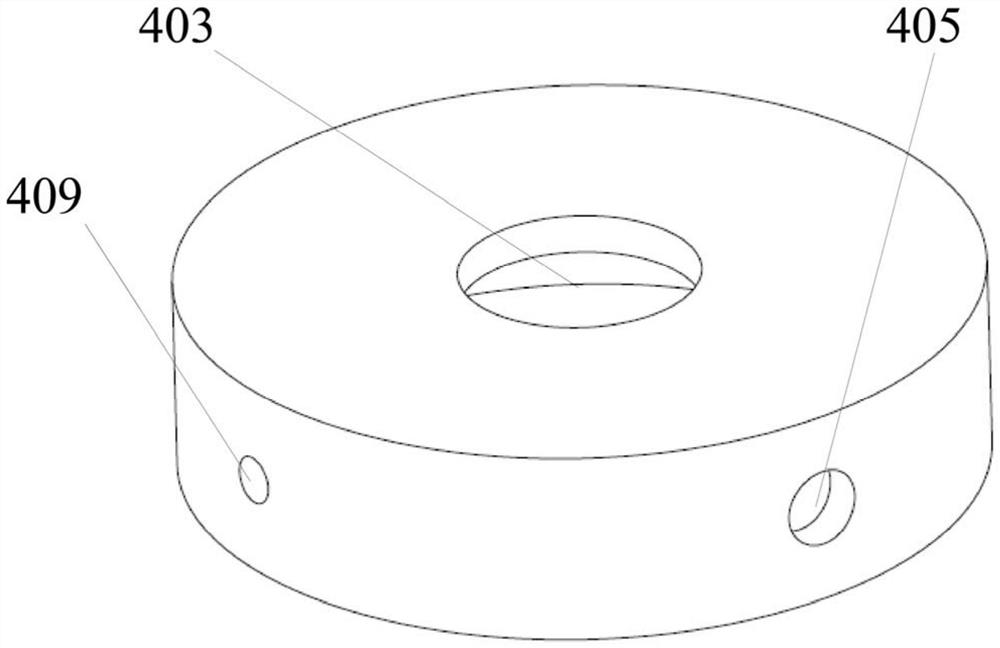

[0081] The bottom of the lower tray 401 is open towards the bottom of the lower tray 401, and the center of the top surface of the lower tray 401 is provided with a feed channel installation hole 403; the upper tray 402 is formed by the bottom and The side wall is formed and is open towards the top of the upper disc body 402; the space in the upper disc body 402 and the lower disc body 401 is an explosive mixing flow chamber 404;

[0082] On the side wall of the downward disc body 401, there is a pair of coarse positioning rod through holes 405 facing downward, and on the side wall of the upward disc bod...

Embodiment 2

[0087] This embodiment provides an acoustic resonance mixing device with a labyrinth mixing channel, which adopts the labyrinth mixing channel in Embodiment 1; as Figure 1 to Figure 7 As shown, the equipment support 1 is included, and it is characterized in that an acoustic resonance platform 2 is arranged on the ground inside the equipment support 1, and a labyrinth mixing channel 4 is installed on the acoustic resonance platform 2;

[0088] The center of the labyrinth-shaped mixing channel 4 is detachably provided with a feed channel 5, the top and bottom ends of the feed channel 5 are open, and the labyrinth-shaped mixing channel 4 communicates with a plurality of solid-liquid feeding devices 3 through the feed channel 5, The solid-liquid feeding device 3 is installed on the equipment support 1; the bottom end of the labyrinth-shaped mixing channel 4 is adjacent to the discharge device 6, which is installed on the acoustic resonance platform 2, and the bottom end of the dis...

Embodiment 3

[0109] This embodiment provides a kind of explosive mixing process, this process adopts the acoustic resonance mixing equipment with labyrinth mixing channel of embodiment 2; This process specifically comprises the following steps:

[0110] Step 1, adding materials;

[0111] After the equipment is assembled, weigh 10Kg of Class 2 RDX (RDX) and 4Kg of aluminum powder with a particle diameter of 13um, configure 2Kg of hydroxyl-terminated polybutadiene and DOA according to the ratio of 11:16, and the above-mentioned explosive material 13 Including solid explosive materials and liquid explosive materials, the mass fraction of solid explosive materials in explosive materials 13 accounts for 82% to 92%, the hydroxyl-terminated polybutadiene (HTPB) is a binder, and the DOA It is a premix of plasticizer;

[0112] Add the above-mentioned explosive material 13 into the solid-liquid feeding hopper 301 and cover the end cover 302 of the feeding hopper, and adjust the feeding speed for feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com